Nissei NA9420AEG Owner's Manual

Win Equipment B.V.

De Kronkels 31

3752 LM Bunschoten

The Netherlands

Operator Manual

NA 9420

Tel.: +31 (0)33 299 22 66

E-mail: service@nissei.nl

‘translation of the original instructions’

Version date: March 26

th

2018

Operator Manual

NA 9420

Version date: March 26th 2018

3

C

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Manufacturer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Machine identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Symbols used in this manual.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Safety symbols on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Operation and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6 Hygiene . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.7 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.3 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Machine description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Machine overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Operating panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Start up (start of working day) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Switching off (end of working day). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Switching off & standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Switching off & pasteurising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Switching on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Adjusting the viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Messages on display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Faults table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Version date: March 26th 2018

4

Operator Manual

NA 9420

C

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.2 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Cleaning and disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Decalcify . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cleaning air filter (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.3 (Dis)assembling, cleaning and disinfecting the machine. . . . . . . . . . . . . . . . 28

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Defrosting and draining the machine. . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning the mix tank and cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Decalcify the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Removing the ice cream head and cylinder beater . . . . . . . . . . . . . . . . . 32

Disassembling ice cream head, cylinder beater and mix feed pipe. . . . . . . 33

Cleaning and disinfecting components . . . . . . . . . . . . . . . . . . . . . . . . . 33

Fitting the ice cream head, cylinder beater and mix feed pipe . . . . . . . . . 34

disinfecting the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Starting up the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8 Transportation and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.1 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

8.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9 Discarding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 Environmental factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Annex 1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Annex 2 Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Annex 3 EC Declaration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Version date: March 26th 2018

5

1

Operator Manual

NA 9420

1 Introduction

1.1 Purpose

The purpose of this Operator Manual is to provide the operator with information

relating to the use and maintenance of the NA 9420.

Read this Operator Manual carefully before using the machine.

1.2 Manufacturer

Win Equipment B.V.

De Kronkels 31

3752 LM Bunschoten

The Netherlands

Dealer mark

1

Version date: March 26th 2018

6

Operator Manual

NA 9420

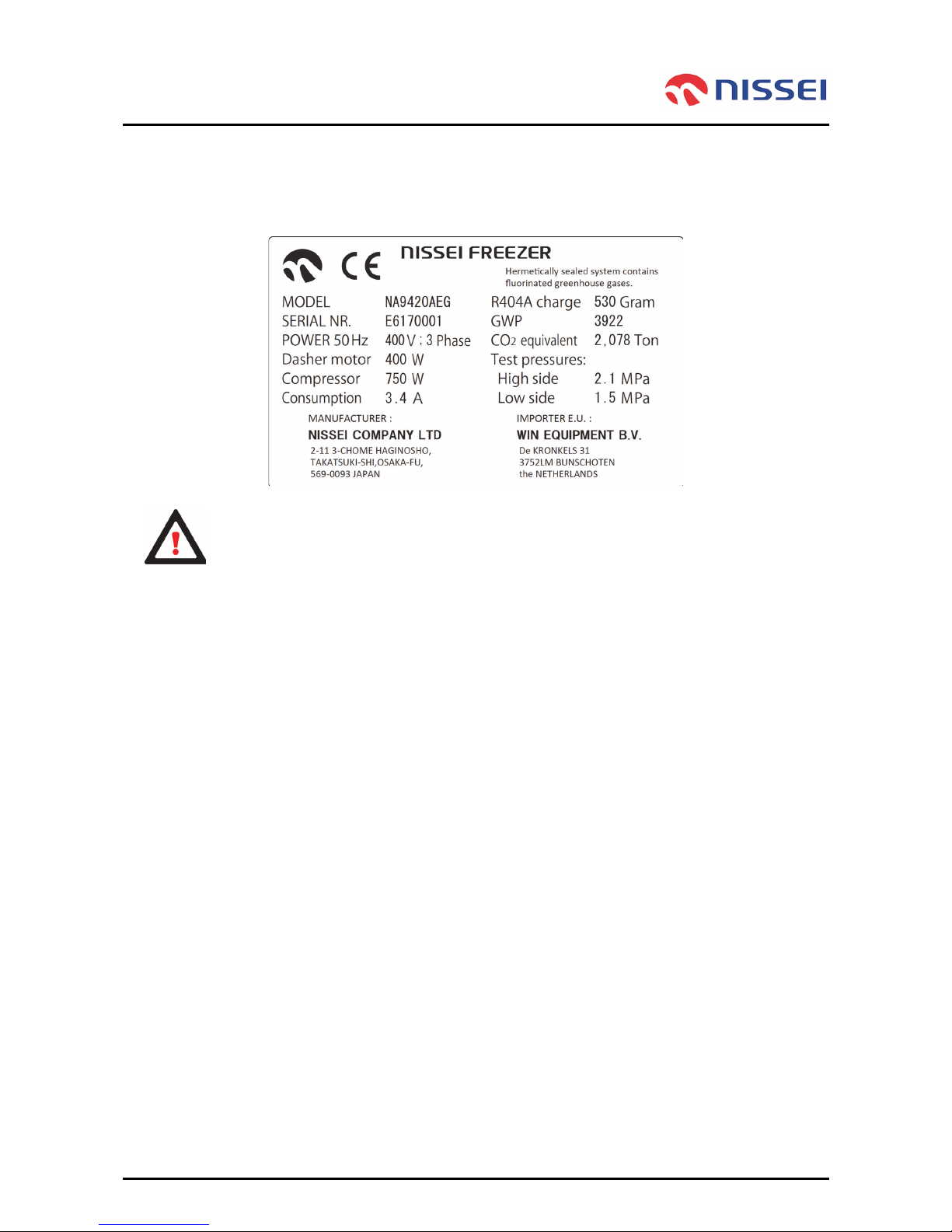

1.3 Machine identification

The machine plate is affixed to the rear of the machine. This plate carries the CE

mark. This means that the machine meets the basic health and safety

requirements of the European Union.

This machine contains fluorinated greenhouse gases in a

hermetically sealed system with the values as specified in the

label.

1.4 Warranty

The dealer offers on new machines a 5-year warranty on expensive parts and a

12-month warranty on non-wearing parts and repair costs. This is in accordance

with the conditions specified in the order confirmation.

1.5 Accessories

The following items are supplied with the machine:

• Operator manual

• O ring remover

• Cleaning brush, narrow and wide

• Tube of lubricant (Petrogel)

• O ring replacement set

•Set of fuses

Version date: March 26th 2018

7

1

Operator Manual

NA 9420

1.6 Liability

The dealer is not liable for any unsafe situations, accidents and/or damage

resulting from any of the following points:

• Failure to observe warnings or instructions as displayed on the machine or in

this Operator Manual.

• Use of the machine for applications or under conditions other than those

specified in this Operator Manual.

• Changes of kind made to the machine. This also includes the use of different

replacement parts.

• Inadequate maintenance.

Win Equipment B.V. is not liable for any consequential damage due to machine

faults, such as damage to products, business interruptions, production loss etc.

1.7 Copyright

Copyright © 2018 Win Equipment B.V.

All rights reserved.

No part of this publication may be copied, stored in an automated data file or

made public, in any form or in any way, be it electronically, mechanically, by

photocopy, recording or in any other way, without the prior written consent of

the manufacturer.

2

Version date: March 26th 2018

8

Operator Manual

NA 9420

2 Safety

2.1 Symbols used in this manual.

Below you will find an explanation of the symbols that may be used in this manual

to draw the attention of the reader to particular situations.

Caution needed:

- an accident may occur or

- damage may occur to the machine

Do not do this!!!

Suggestion to make tasks or actions easier to carry out.

It is important to read the information provided.

Wait before continuing with the next action.

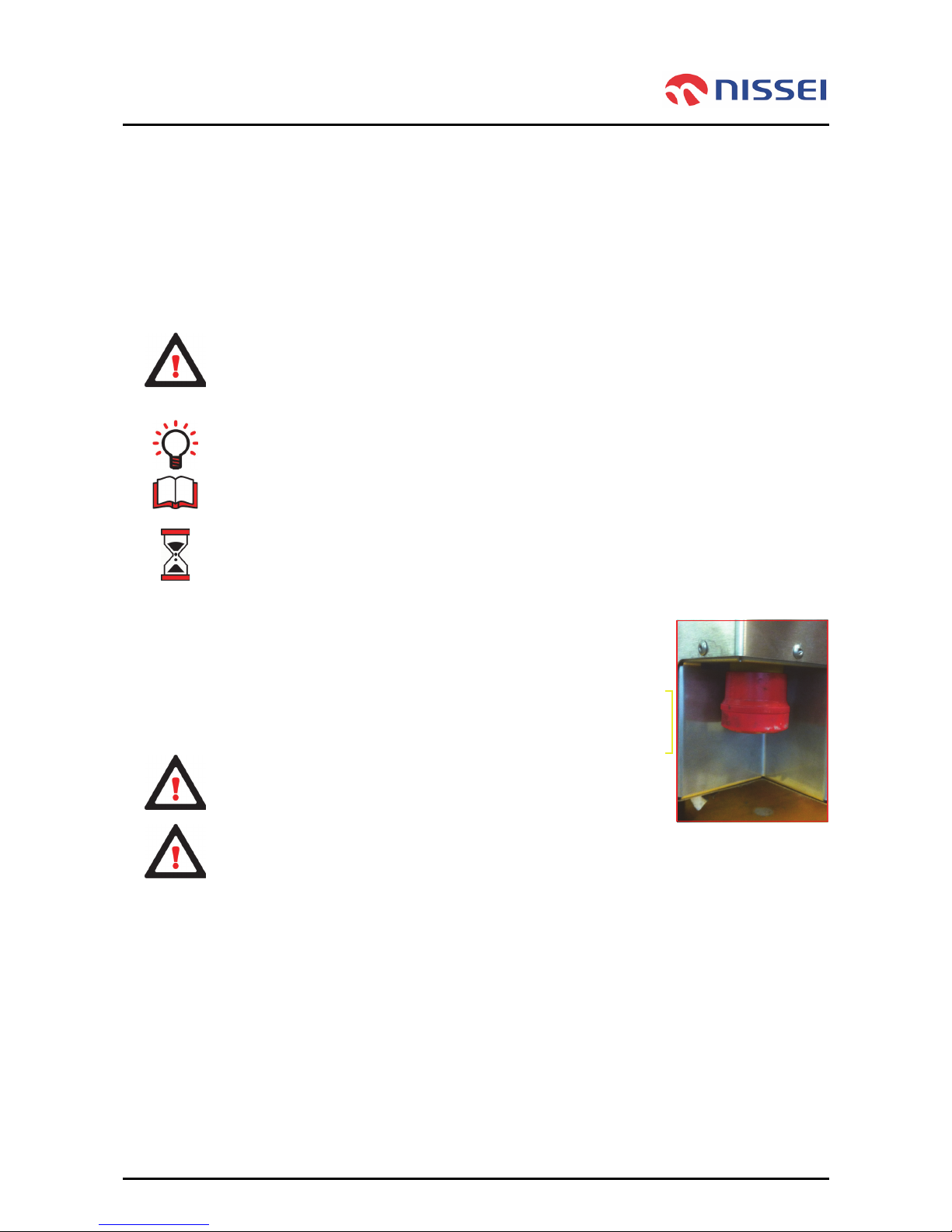

2.2 Emergency stop

The emergency stop button must be pressed immediately

if people or machinery are at risk.

The entire machine stops immediately and the power is

turned off. The emergency circuit is now in operation.

The operation of the emergency stop is described in

paragrap

h 5.3 - ’Emergency stop’.

Use the emergency stop button immediately if people

or machinery are at risk.

People who operate the machine must be informed

about the operation and location of the emergency stop button.

Version date: March 26th 2018

9

2

Operator Manual

NA 9420

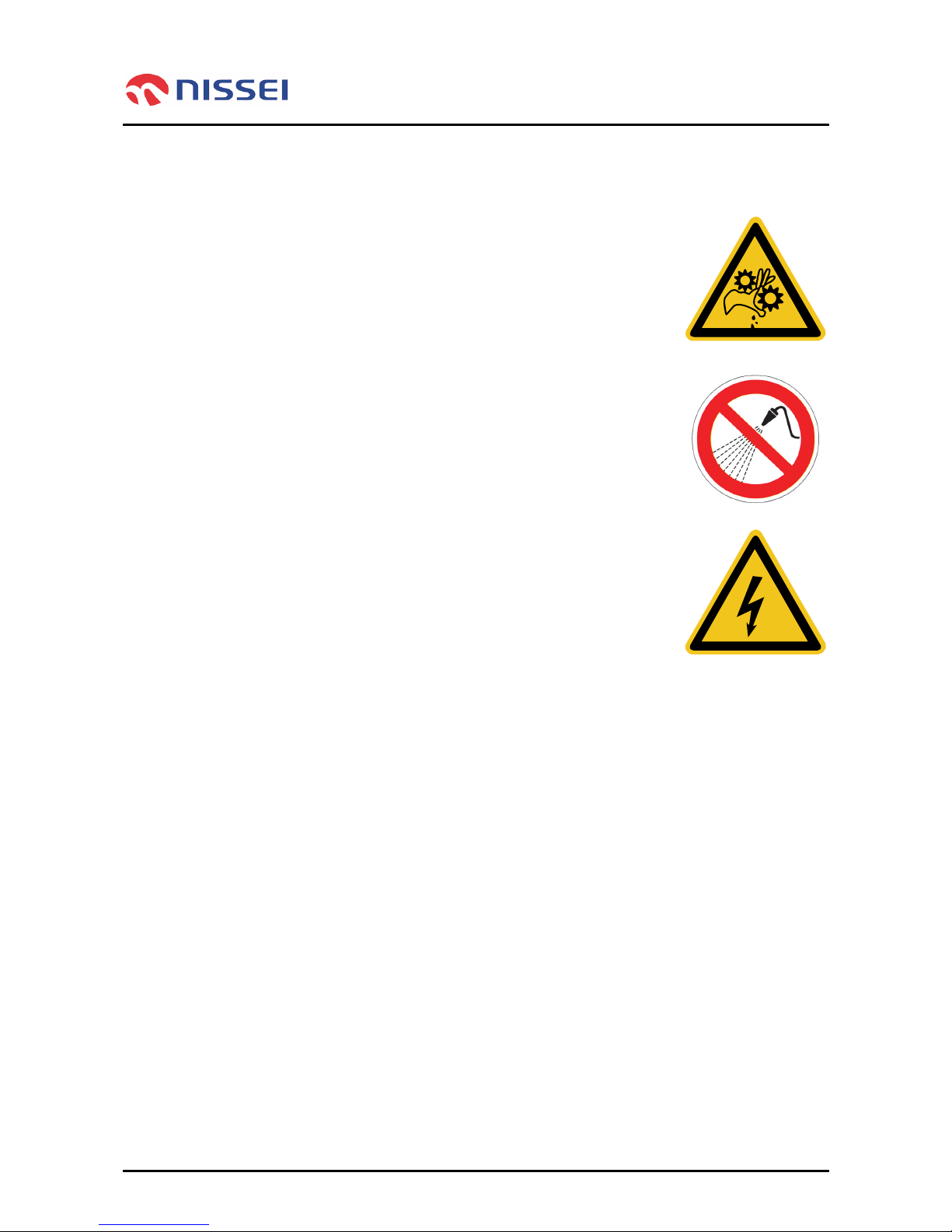

2.3 Safety symbols on the machine

The following safety symbols have been affixed to the machine:

Risk of trapping hand.

This symbol is affixed to the top of the machine next to the

mix tank.

Do not spray with water.

This symbol is affixed to the rear of the machine next to the

ventilatio

n slots.

Danger: electricity.

This symbol is affixed inside the housing.

2

Version date: March 26th 2018

10

Operator Manual

NA 9420

2.4 Safety instructions

The machine meets the basic health and safety requirements of the relevant

directives of the European Union.

Improper or careless use can lead to dangerou

s situations. Please observe the

following general safety instructions:

• Connect the machine in

accordance with the basic health and safety

requirements of the relevant European directives.

• Exercise caution with loose hair and clothing.

• Keep your hands away from dangerous zones.

• Never power up the machine if pe

ople are in contact with it.

• Pull the plug out of the socket before carryi

ng out maintenance work on the

machine.

• Faulty safety equipment must be replaced before the machine is used in

produ

ction.

• The machine must be maintained in accordance with the instructions found in

chapter 7 - ’Maintenance’ op pagina 24.

• Changes to the machine must not be implemented without the prior consent

of th

e manufacturer.

• The safety equipment of the machine must be checked weekly for correct

ope

ration.

• Never remove the machine's plating. There are no parts that you can replace

or adju

st yourself.

• Do not remove or cover any

labels on the machine.

The safety instructions specified in this document must be

observed. Deviating from the instructions can cause

unacceptable risks.

Version date: March 26th 2018

11

2

Operator Manual

NA 9420

2.5 Operation and maintenance

The machine may only be operated, maintained and cleaned by trained staff. The

end user determines the basis on which staff are authorised for this purpose.

2.6 Hygiene

Good hygiene is very important. Please adhere to the following rules:

• Clean and disinfect

the machine at least according the hygiene code ice

making but at least once every 6 weeks

• Decalci

fy the machine every 2nd till 4th cleaning, depending of the polution,

but at least twice a year.

• Use the recommended cleaning, disinfecting and deca

lcify agents to ensure

an optimum result.

• Use prescribed lubricants only.

Good hygiene ensures better ice cream and satisfied

customers.

The operator always remains responsible for good hygiene.

2.7 Storage

To prevent the machine being damage due to frost the machine must always be

stored by a temperature between 4°C and 50°C when it is not used.

Prevent damage by frost. Store the machine when it is not used

by a temperature between 4 °C and 50 °C .

3

Version date: March 26th 2018

12

Operator Manual

NA 9420

3 Installation

Read this chapter carefully before installing the machine. This is

the only way to ensure maximum safety.

3.1 Introduction

The manufacturer carries out the initial installation. When moving the machine

you are advised to contact the dealer.

The machine may only be installed by qualified personnel.

3.2 Installation site

• DO NOT place the machine outside.

• Place the machine on a firm, flat surface

(to prevent noise and vibration).

• Keep 10 cm free at the rear and 2 cm at the sides for ventilation.

• Do not place the machine in direct sunlight

(not even behind glass) or near to

a heat source (e.g. radiator or deep fryer).

• Place the machine in a room with a temperature between +5°C and

+35°C.

3.3 Electrical connection

• Connect the plug of the machine to a high-voltage power supply

(400 volts, 3 x 16 amps + PE).

When setting up the machine, make sure it is not positioned on

the connection cable. This can damage the insulation and lead

to a

short-circuit.

Version date: March 26th 2018

13

4

Operator Manual

NA 9420

4 Machine description

4.1 Machine overview

1

6

3

2

4

5

1.Mix tank

2.Operating

panel

3.Ice cream head with dispensing

handle

4.Drip tray

5.On/off switch

(backside of the machine)

6.Release butto

n operating panel

(behind the drip tray, optional)

4

Version date: March 26th 2018

14

Operator Manual

NA 9420

4.2 Operating panel

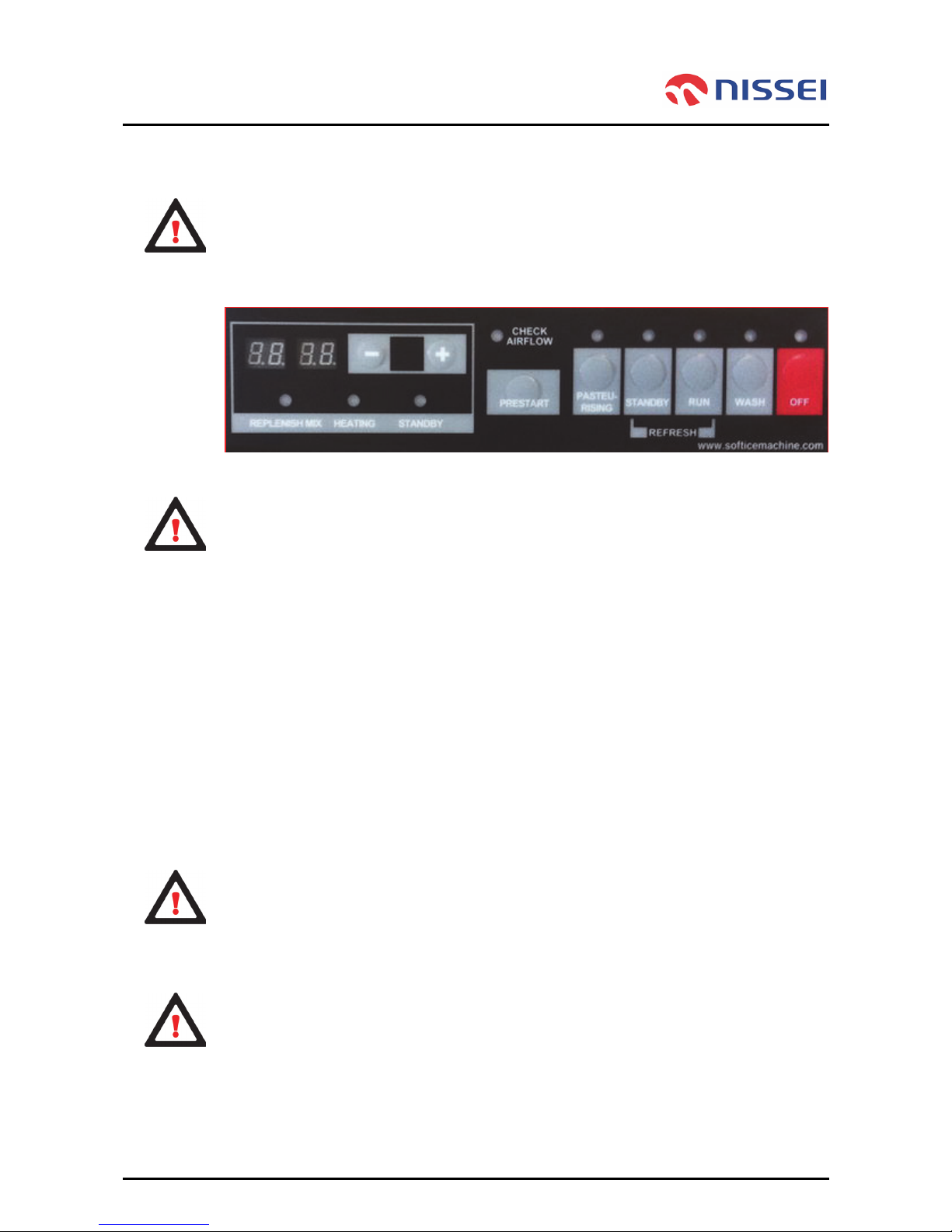

Attention! When the machine is equiped with the optional

release button the buttons on the operating panel only react

when the release

button behind the drip tray is pressed

simultaneously.

• OFF

Press to switch off the machine; only the lights remain lit.

First press 'OFF' before changing the mode.

• PAS

TEURISING

Sets the machine to pasteurising mode. The ice cream mix in the cylinder and

mix tank are heated and cooled back.

• STANDB

Y

Sets the machine to standby mode. The cylinder and mix tank are cooled to

approx. 5ºC.

• RUN

Sets the machine to operating mode.

Ice cream can be dispensed.

• WA

SH

Sets the machine to wash mode and switches on

the mixing apparatus in the

cylinder.

• REFRE

SH (press STANDBY and RUN simultaneously)

Sets the machine to refresh mode. The ice

cream mix in the cylinder is

defrosted and frozen again.

The machine can only be set in refresh mode while in run mode.

• CHECK AIR

FLOW

Control light airflow cooling, lights up RED during when the machine gets too

hot.

Check whether a free air flow to the bottomside of the machine

is possible and the air vent openings at the top side of the

machine aren’t blocked.

• - and +

Selection keys to reduce and increase viscosity.

Loading...

Loading...