Nissan Sunny 1973, Cherry 1973, Bluebird 1973, 200 SX 1973 User Manual

J

J

l

Otl

P

r

l

J

X

4

h

t

t

3

f

f

510

1200

610

710

810

8210

f10

1973

2005

510

1973

1974

1977

1974

1977

197778

1978

76

77

78

78

78

R4

speCltlC

ourselt

lt

oo

J

tlAalote

r

J

spARK

PLUli

ENGINE

7

J

rAR8

J

J

CHILTON

S

Repair

and

Tune

Up

Guide

Datsun

1973

o

W

l

e

a

I

en

l

J

J

J

78

Prepared

Automotive

Chilton

Chilton

Radnor

215687

CHILTON

Way

Pa

by

Book

8200

the

Editorial

19089

BOOK

Company

COMPANY

Department

president

executIve

and

general

KERRY

RIVELE

and

vice

A

editor

chief

president

manager

FREEMAN

ROBERT

executIve

JOHNPKUSHNERICK

RICHARD

S

A

E

KING

F

officer

H

senior

RADNOR

WILLIAM

GROVES

managing

editor

PENNSYLVANIA

BARBOUR

A

vice

RICHARD

president

editor

J

r

f

ht

C

CopHlp

All

Rlg

Pubh

and

b

Thoma

Manufactured

1978

ltl

Re

erud

hedInRadnor

Imlllt

meoll

Ne

In

4567890 765432109

ChIlton

s

Repau

ISBI0

LIbrary

ChIlton

USA

of

tIon

Although

source

tlon

changes

total

billt

comp

SAFETY

Proper

operatIOn

performmg

rep31nng

contain

followed

80196694

of

Congress

Book

Compan

Gardena

thIS

book

the

1Oformahon

IS

as

and

the

po

blhty

whIch

could

accuracy

for

ChIlton

an

errors

lahonofthISdata

NOTICE

service

and

of

all

motor

repaIrs

vehIcles

NOTES

many

along

Wlth

poSSlbllttyofpersonal

the

vehicle

or

It

IS

and

parts

of

the

antIcipate

be

may

that

may

Rlent

shouldlbe

goggles

chlsehng

or

projectiles

Some

speCllic

must

be

performance

compromise

for

to

servlcmg

performmg

Important

mdlVldual

alloftheconceivable

5elVlced

result

or

Standard and

used

or

other

protechon

or

prytng

procedures

purpose

completely

of

the

BefOre

h

on

the

ChIlton

hy

In

Untted

Tune

9

pbk

Catalog

P

l

OntdTlO

Son

Up

Book

Chilton

I

Ltd

States

GUIde

Card

tharok

Cahfomla

complete

repair

90247

10

eXISt

not

be 10cluded

Book

change50

procedures

thIS

as

pO

that

Company

or

omlSSlon

vehIclesaswellasthe

TIus

book

outlmes

nfe

usmg

effechve

CAUTIONS

standard

Injury

note

motor

to

proVIde

safety

or

Improper

Its

safety

that

repaIr

vehIclesaswellasthe

the

work

ways

cauhons as to

accepted

when

any

reqlllre

handltng

other

tOXIC

shouldbeused

pnxess

the

use

subshtutmg

sahslied

that

neither

vehIcle

WlII

be

endangered

Companv

Book

Canad

t

of

Amenca

Dat

un

No7790862

NIS

an

Motor

for

a

tance

IS

gUIde

Slbleatthe

the manufacturer

here

cannot

that

are

VItaltothe

personal

prreedures

methods

and

WARNINGS

procedures

serVIce

procedures

vary

Wldely

orconmhons

allofthe

safety

precauhons

or

flammable

dunng

that

can

cause

of

tools

specIally

another

tool

your

personal

Compan

1973

Corporahon

ba ed

hme

While

assume

may

for

to

whICh

and

techmques

skill

It

under

cuthng

matenal

or

78

10

the

on

of

made

stnvlOg

responSl

occur

safe

safety

servIcmg

The

procedures

wh

ch

should

eltm10ate

could

and

expenence

IS not

poSSIble

which

poSSIble

and

flUIds and

deSIgned

procedure

safety

prepara

10dustry

pubhca

later

In

the

rellable

of

those

and

damage

tools

vehicles

hazards

equlp

safety

gnndlOg

removal

for

you

nor

10

for

I

be

the

to

a

the

Contents

Chapter

J

How

Tools

History

Senal

Routme

Au

PosItive

Evaporal1ve

Belts 5

Au

Chapter

Tune

Spark

Tune

Spark

Breaker

Dwell

Chapter

Engme

Dlstnbutor

Fmng

Alternator

Regulator

Starter

Battery

Engme

Design

Engme

General

Crankshaft

catIons

Piston

Valve

Torque

Engme

gmes

General

1

To

Use

This

and

EqUipment

2

Number

Mamtenance

Cleaner 3

Crankcase

EmissIOns

CondltIonmg

2

Tune

Procedures

Up

Up

17

Plugs

SpeCificatIons

Heat

Plug

Pomts

Angle

3

Engine

Electncal

53

Order

54

56

58

and

Starter

Mechamcal

61

1

D

Table

Engme

and

64

and

Rmg

SpeCificatIons

SpeCificatIons

Removal

except

Book

IdentificatIOn

Venblal10n

6

Up

Range

and

Condenser

27

53

54

SpeCifications

61

62

SpeCifications

Connectmg

SpeCifications

and

FIO

66

Information

1

2

3

System

and

17

18

21

and

Engine

Rod

65

66

and

Maintenance

2

4

Valve

5

Troubleshooting

23

Rebuilding

60

63

Speclfi

65

en

Installatlon

all

FlUid

Level

CapacIties

Tues

11

Fuel

Filter

LubncatIon

011

and

Fuel

011

Changes

Pushmg

Jackmg

Datsun

IgmtIon

Valve

Carburetor

Electromc

Towmg

16

Electromc

Tlmmg

Lash

Fuel

TroubleshootIng

Pan

Mam

Pump

Pump

Removal

Head

Mamfold

Mamfold

Cham

Cham

Cham

77

and

Lubncatlon

79

79

Cooling

80

RebUlldmg

Engme

Cylmder

Intake

Exhaust

Timmg

Tlmmg

Tlmmg

Camshaft

Pistons

Engme

011

Rear

all

Engme

Radiator

Water

Thermostat

Engme

Checks

11

12

13

RecommendatIOns

8

13

and

IgmtIon

32

33

35

38

and

68

72

73

Cover

and

Camshaft

and

TenslOner 76

Connectmg

79

81

Seal

79

80

83

011

82

Jump

InjectIon

BlO

Installatlon

73

Rods

Startmg

28

37

75

78

1

13

15

17

53

FI0

67

Chapter

EmisSion

Crankcase

Evaporative

108

Spark

Dlstnbutor

Early

Boost

Automatic

Cleaner

Exhaust

4

Emission

Controls

EmissIOn

EmissIOn

TlmmgControl

108

Fuel

Evaporation

Control

Decelerahon

Temperature

112

Gas

Recuculatlon

105

Controls

Control

System

Controls

Dual

System

Device

Controlled

113

105

System

111

Pomt

III

Au

and

Fuel

Hi

System

Transmission

115

Au

InjectIon

Electnc

Catalytic

Fuel

System

Fuel

Fuel

Pump

Carburetor

Electromc

Choke

Converter

Pump

all

Fuel

Controlled

Reactor

119

FlO

121

117

118

except

119

Injection

Spark

System

810

115

119

System

105

System

126

IV

CONTENTS

Chapter

Understandmg

Electncal

Heater

Heater

Heater

RadIo

Chapter

Manual

Clutch

Clutch

Clutch

Chapter

Dnvehne

Dnveshaft

Rear Axle

Chapter

Front

Strut

Ball

Hub

Front

Wheel

Rear

5

Chassis

130

Assembly

Core

135

6

Clutch

TransmIssIOn

149

SpecIficatIons

Master

7

Drive

157

and

161

8

Suspension

SuspensIOn

165

168

Jomt

Assembly

End

Ahgnment

Ahgnment

SuspensIOn

and

Systems

135

Cyhnder

UnIversal

169

Electrical

Troubleshootmg

128

130

and

Transmission

145

151

153

Train

Jomts

and

165

171

SpecIficatIons

175

157

Steering

172

Wmdshleld

139

Instrument

Headhghts

Fuse

LocatIons

Clutch

Slave

B1eedmg

155

AutomatIc

Axle

Shaft

Axle

Dnveshafts

Sprmgs

Shock

Absorber

Steenng

Steenng

Turn

SIgnal

Steermg

Steermg

WIper

Cluster

144

Cylmder

the

TransmIssIOn

161

179

182

Wheel

SWItch

Lock

Gear

144

Clutch

182

183

183

162

181

Motor

140

153

Hydrauhc

183

155

and

128

Lmkage

145

System

157

165

Chapter

Brake

Adjustment

HydraulIc

Master

System

Front

DISC

Chapter

Doors

Door

Appendix

9

System

Cylmder

B1eedmg

DISC

Brake

10

201

Panels

Brakes

187

187

System

Brakes

Pads

Body

202

187

191

190

187

191

Cahpers

Wheel

Rear

Brake

Parkmg

Brake

Hood

Fuel

Tank

and

Brake

Brake

Adjustment

Brakes

195

198

Beanng

Drum

Shoes

SpecIficatIons

Trunk

and

202

DISCS

195

200

TaIlgate

187

193

195

201

202

211

Ite

How

ChIlton

the

for

more

about

automobile

upkeep

most

used

nance

cedures

concern

plex

systems

systems

covered

average

volved

rebUIlding

reason

ple

and

the

task

thiS

how

to

shoes

many

money

and

help

Before

read

through

speCific

To

s

Repatr

Datsun IS

the

and

The

first

since

and

tune

The

themselves

from

to

the

dO

It

ChIlton

the

that

mvestment

uneconomICal

change

replace

more

give

you

loosemng

procedure

General

Use

and

Intended

Inner

save

two

chapters

they

information

up

follOWing

With

of

the

engine

extent

yourselfer

Datsun

s

transmiSSIOn

the

In

own

your

pOints

that

jobs

you

personal

aVOId

problems

the

entire

ThiS

and

This

Tune

workings

you

contain

seven

the

Datsun

through

that

should

2

expertIse

special

We

brake

and

Will

any

section

wIll

Information

Maintenance

Book

GUIde

Up

to

teach

you

of

your

In

be

the

mainte

and

pro

chapters

are

feel

the

in

get

t

explain

the

Sim

reqUIred

make

tell

you

and

and

you

please

and

the

the

you

itS

1

money

Will

more com

Operating

brakes

we

won

for

tools

Will

pads

plugs

save

satisfaction

bolts

give

overall

far

nothing

walk

view

tools

as

more

the

to

because

during

read

sIOn

The

your

ahead

sections

the

of

Adjustments

then

discussed

mstallatlon

overhaul

Sible

When

of

your

league

move

the

new

or

rebUIlt

at

least

you

repair

tor

mentioned

Sideofthe

specify

versely

the

most

turning

by

most

are

Two

passenger

turning

Important

of

just

screws

baSIC

the

the

counterclockwise

what

of

supplies

frustrating

bus

stop

were

you

Sunday

and

plan

begm

system

and

followed

procedures

procedures

repaIr

and

part

replacement

save

the

such

components

not

practical

mechamc

here

car

IS

dnversSide

nght

s

and

clockWIse

rule

Will

and

on

Monday

short

afternoon

ahead

Withabrief

and

what

mamtenance

or

and

where

conSidered

IS

tell

we

then

how

labor

s

One

whenever

referred

slde

of

Sideofthe

are

bolts

SafetyISalways

Constantly

be

you

than

one

by

then

you

costs

as

rules

to

ItISmeant

of

the

the

and

reqUIred

There

haVing

mornmg

metric

repair

It

Involves

removal

repair

they

tobeout

how

to

Install

In

thiS

Backyard

the

should

the

car

car

car

Second

removed

tightened

be

bolt

diSCUS

are

to

way

alterna

left

Con

means

aware

as

IS

to

So

are

and

or

fea

re

the

be

to

by

the

2

of

the

automobIle

tions

under

allow

battery

Always

recdy

fingers

eqUIpment

have

patience

nence

your

hobby

Tools

The

ment

deSCrIbed

fastened

bolts

metric

wrenches

a

fit

on

1

plug

length

break

rIC

sockets

the

ratchet

may

already

2

open

and

3

4

and

valve

5

drIvers

6

hook

tery

7

8

proper

and

aVOids

tight

9

10

moval

Never

11

handy

12

blocks

are

ports

GENERAL

dangers

Use

a

raised

an

exposed

or

any

use

bruised

aren

and

car

Will

followmg

to

perform

m

together

If

you

wrenches

are

metric

MetriC

socket

socket

m

thiS

available

Set

of

one

Spark

Flat

feeler

lash

Slot

and

TImmg

up

Dwell

Torque

tightening

or

leaks

011

can

011

filter

of

a

to

use

Pair

of

to

have

Two

brIcks

Just

INFORMATION

m

the

and

mvolved

take

jackstands

vehicle

flame

to

of

the

tool

the

part

proper

knuckles

t

a

mechanic

once

confidence

take

you

have

Always

gam

become

And

Equipment

lIstISthe

most

of

thiS

gUIde

metrIc

With

don

t

already

them

buy

either

too

loose

fasteners

sockets

If

pOSSible

drIve

also

extensIOns

departJnent

m

the

handles

and

have and

metnc

plug

box

combmatlon

wrenches

WIre

gauge

gauge

for

checkmg

phillips

lIght

preferably

type

tachometer

wrench

of

Important

costly

thread

too

loose

filler

spout

wrench

strap

filter

tight

mstall

filter

channel lock

sturdy

and

not

jackstands

other

safe

working

proper

when

Don

t

come near

fuel

and

and

s

your

some

workmg

an

baSIC

the

procedures

Your

screws

have

or

13116

a

buy

IS

that

US

extensIOns

1h

breaker

heads

ThiS

strlppmg

Makes

much

plIers

makeshift

on

precau

workmg

smoke

system

useItcor

skmned

standard

time

expe

enjoyable

reqUIre

Datsun IS

and

a

set

Standard

too

tight

In

spark

various

One

the

met

all

wIll

you

m

dnve

one

end

pomts

screw

a

DC

bat

assures

fasteners

Simpler

Always

cmder

sup

the

and

too

re

an

on

fit

or

of

AND

MAINTENANCE

The

first

duced

company

last

for

nally

few

has

m

Initials

son

evolved

cars

moved

sales

ThiS

sedans

1978

Separate

240

280Z

trucks

book

1973

from

to

1977

the

new

Years

are

the

1973

1977

and

200SX

510

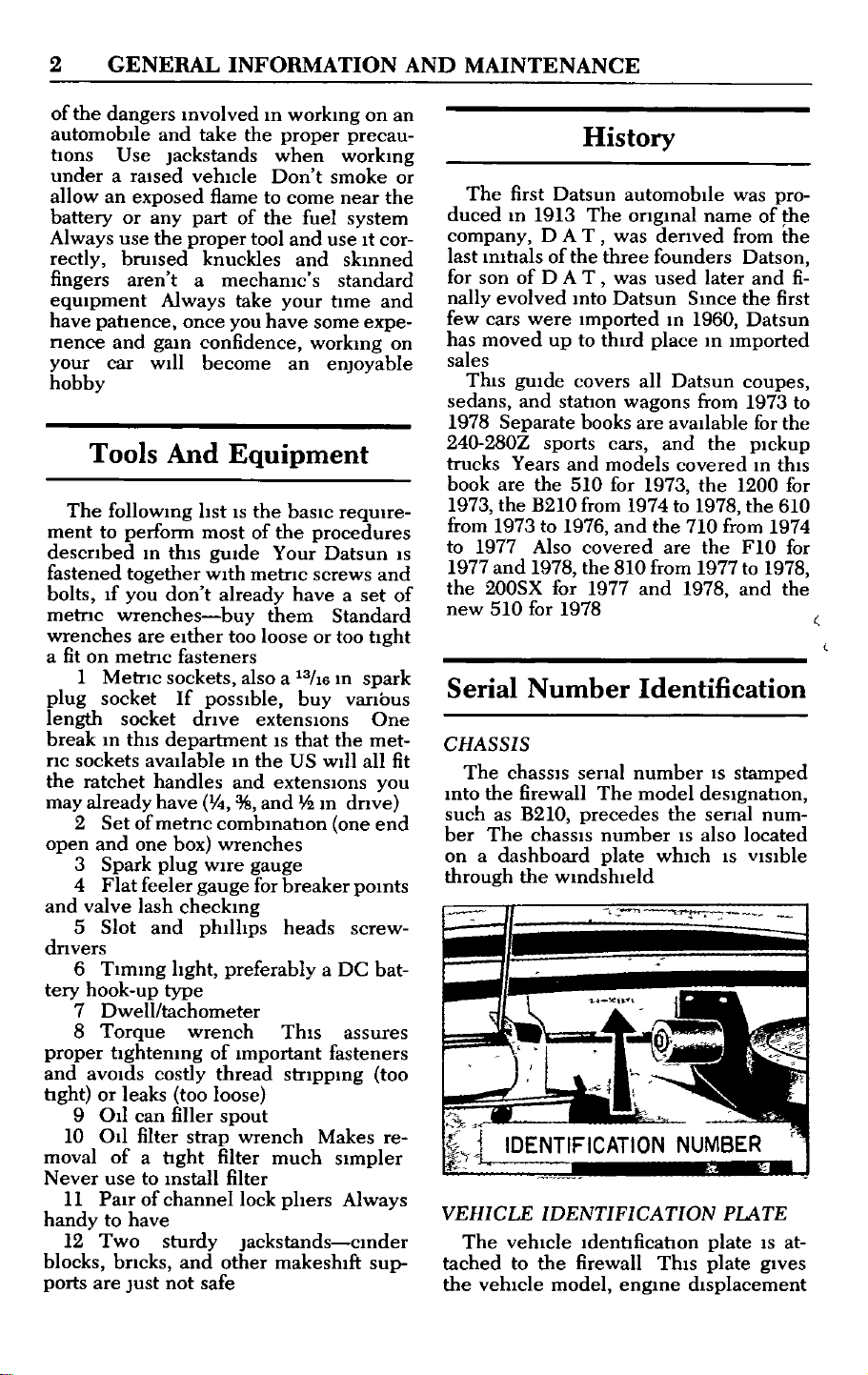

Serial

CHASSIS

The

chaSSIS

mto

the

such

as

ber

The

a

on

dashboard

through

VEHICLE

The

vehICle

tached

the

to

vehicle

Datsun

1913

DATwas

of

the three

of

D

A T

mto

were

to

up

and

covers

station

gUIde

sports

and

510

the

B210

to

1976

Also

1978

for 1977

for

1978

Number

senal

firewall

B210

chaSSIS

the

wmdshleld

IDENTIFICATION

the

firewall

model

History

automobile

The

orIgmal

was

Datsun

Imported

thIrd

all

wagons

books

are

cars

models

for

1973

from

1974

and

covered

810

the

and

Identification

number

The

model

precedes

number

plate

Identification

engIne

denved

founders

used

Smce

m

1960

place

Datsun

from

available

and

covered

the

to

1978

710

the

are

1977to1978

from

1978

the

IS

which

ThiS

displacement

was

pro

name

of

from

Datson

later

and

the

Datsun

m

Imported

coupes

1973

for

the

pickup

m

1200

the

from

1974

FlO

the

and

IS

stamped

deSignation

senal

num

also

located

IS

VISIble

PLATE

IS

plate

plate

gIVes

the

the

fi

first

to

the

thiS

for

610

for

the

at

GENERAL

INFORMATION

MAINTENANCE

number

EngIne

AND

senal

Routine Maintenance

3

VehICle

m

cc

base

ber

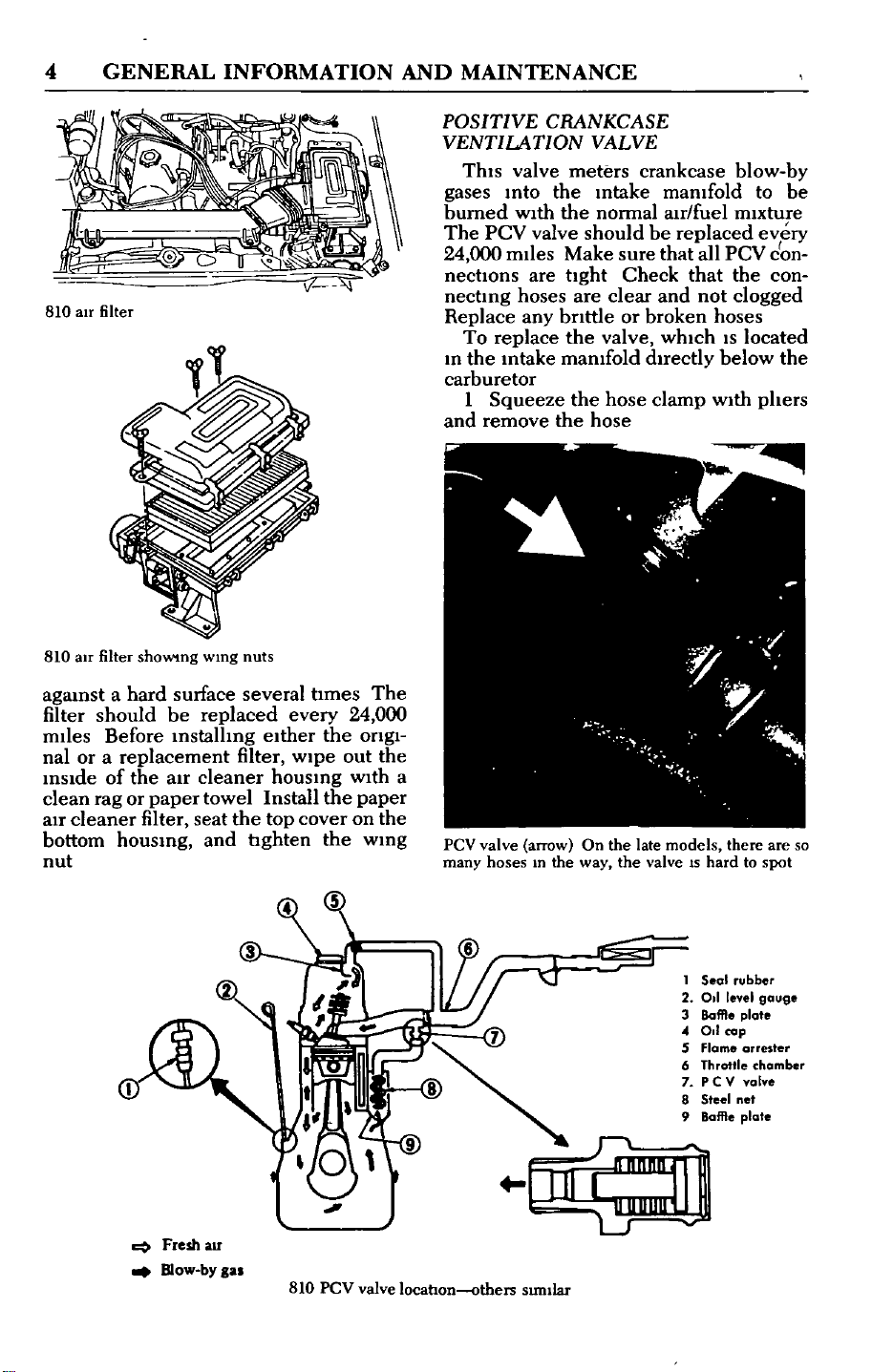

ENGINE

The

nght

The

the

engme

slde

engme

engme

IdentificatIon

SAE

engme

top

senal

model

plate

horsepower

number

number

of

edge

number

code

and

IS

the

ratmg

chassIs

stamped

cylmder

IS

preceded

wheel

num

on

block

the

by

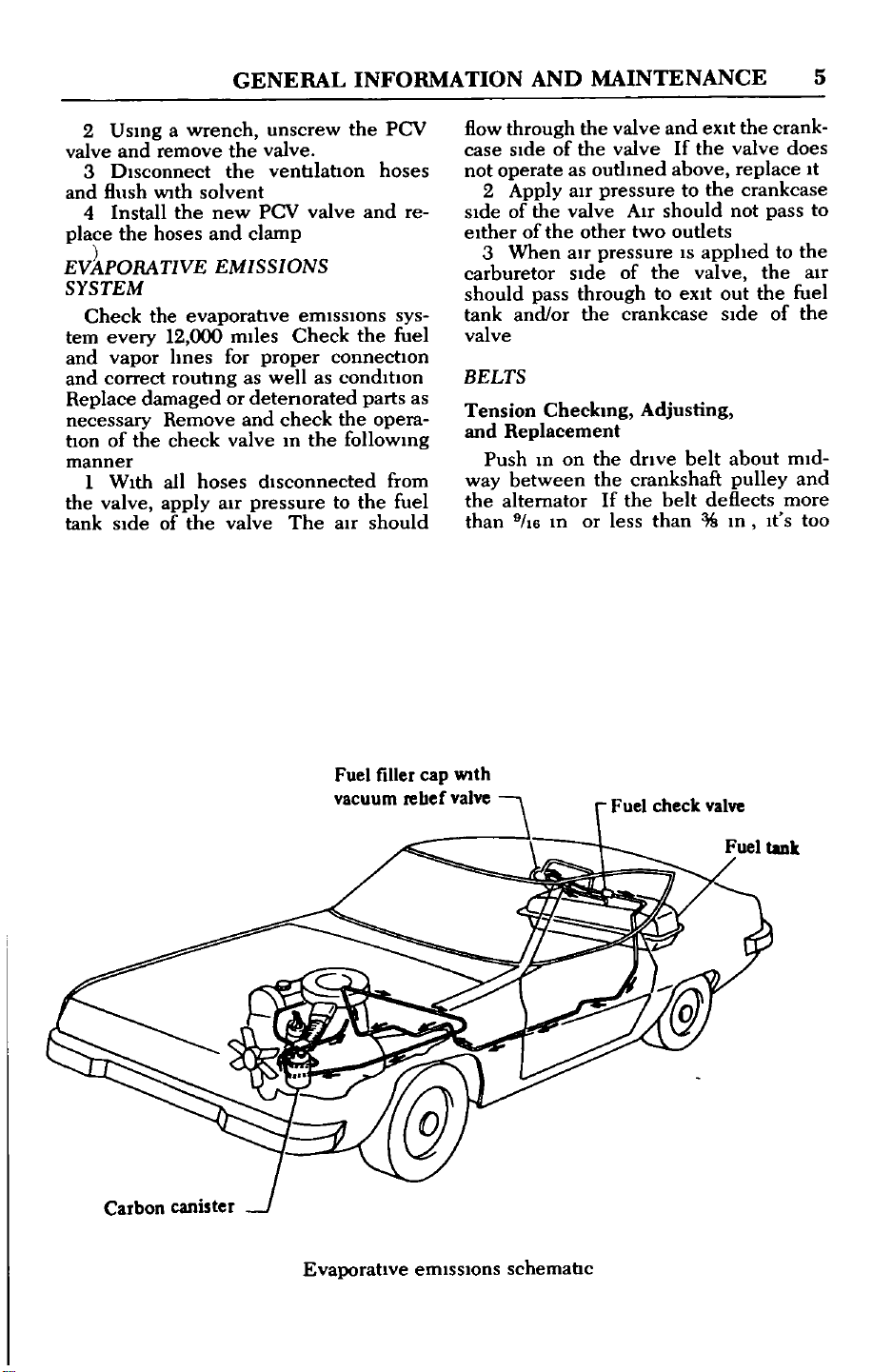

AIR

CLEANER

All

Datsuns

eqUIpped

tndge

or

up

area

dusty

housmg

Check

IS

extremely

times

au

sooner

the

be

With

cleaner

undo

top

element

removed

covered

If

and

duty

a

disposable

element

the

car

the

wmgnut

Withdraw

Replace

Loose

by

m

this

At

IS

operated

dust

stnkmg

the

the

gUIde

paper

every

remove

can

tune

element

filter

some

the

are

car

m

the

If

filter

a

It

If

the old

filter

IS

du1y

replace

It

4

GENERAL

INFORMATION

AND

MAINTENANCE

810aufilter

810

aIr

filter

shoWing

wmg

nuts

POSITIVE

VENTILATION

ThiS

valve

gases

mto

burned

PCV

The

24

000

miles

nectIons

nectmg

Replace

To

replace

m

the

mtake

carburetor

1

Squeeze

and

remove

CRANKCASE

With

valve

are

hoses

any

meters

the

the

should

Make

tIght

are

bnttle

the

mamfold

the

the

VALVE

mtake

normal

clear

valve

hose

hose

crankcase

be

sure

Check

broken

or

dIrectly

mamfold

aIr

replaced

that

and

whICh

clamp

fuel

all

that

not

blow

mixture

PCV

the

clogged

hoses

IS

below

With

to

every

don

con

located

phers

by

be

the

agamst

filter

miles

nal

or

mSlde

clean

aIr

cleaner

bottom

nut

a

hard

should

Before

a

replacement

of

the

or

paper

rag

filter

housmg

surface

be

replaced

mstallmg

cleaner

aIr

seat

Fresh

Blow

by

towel

and

air

gas

several

filter

the

tIghten

every

either

wipe

housmg

Install

cover

top

810

tImes

the

the

PCV

the

out

24

with

paper

on

valve

ongl

wmg

The

000

the

the

a

PCV

many

locabon

others

valve

arrow

hosesmthe

SffiUlar

way

On

the

late

the

models

valve1Shard

1

Seal

201

3

Baffl

4

0

5

Flame

6

Throttle

PCVvalve

7

Steel

a

9

Baffle

there

are

so

to

spot

rubber

level

gauge

plate

1

cap

arrester

chamber

net

plate

GENERAL

INFORMATION

AND

MAINTENANCE

5

2

USing

valve

Disconnect

3

and

Hush

4

place

EVApORATIVE

SYSTEM

Check

tem

every

and

vapor

and

correct

Replace

necessary

tIon

of

manner

With

1

the

valve

tank

and

Install

the

damaged

the

Side

a

remove

WIth

the

hoses

the

12

hnes

routIng

Remove

check

all

apply

of

wrench

the

the

solvent

new

and

EMISSIONS

evaporatIve

000

miles

for

as

or

and

valve

hoses

aIr

the

valve

unscrew

valve

ventIlatIon

PCV

valve

clamp

emiSSions

Check

proper

well

detenorated

check

In

the

disconnected

pressure

The

connectIOn

as

conditIon

the

follOWing

to

aIr

the

the

the

PCV

hoses

and

parts

opera

should

sys

fuel

from

fuel

How

through

case

Sideofthe

not

operate

2

Apply

re

Sideofthe

either

3

When

carburetor

should

tank

and

of

the other

pass

or

the

as

outlined

aIr

valve

aIr

pressure

Side

through

the

valve

valve

pressure

AIr

two

of

crankcase

and

should

the

to

If

the

above

to

outlets

IS

valve

eXit

eXit

the

apphed

the

valve

replace

crankcase

not

out

Side

the

the

crank

pass

to

of

does

It

to

the

aIr

fuel

the

valve

BELTS

as

Tension

and

Push

way

the

than

Checking

Replacement

In

on

between

alternator

9116

III

or

the

the

If

less

Adjusting

dnve

crankshaft

belt

the

than

belt

about

pulley

deflects

III It

mid

more

S

and

too

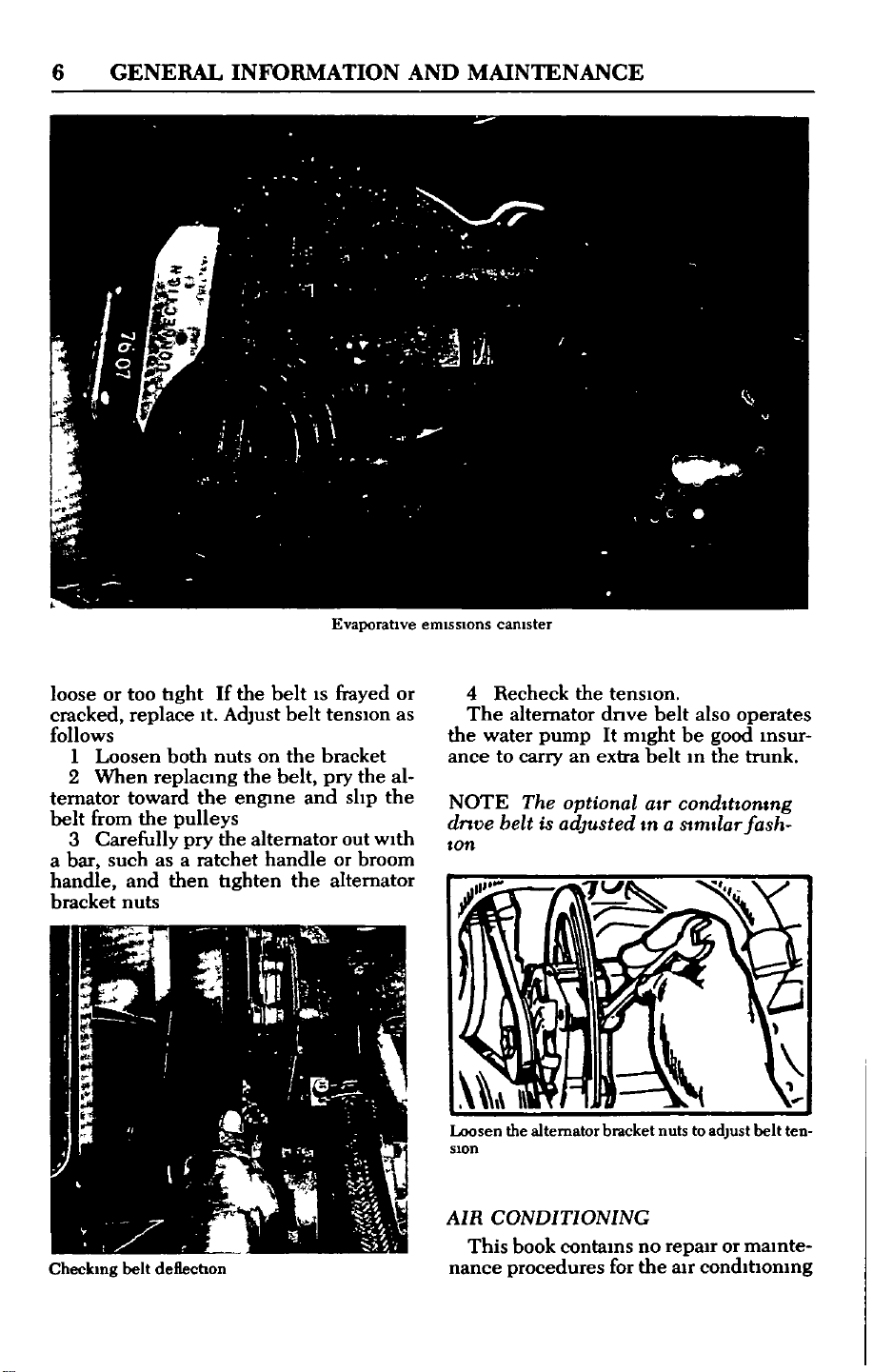

Carbon

canister

Fuel

filler

vacuum

Evaporative

rebef

emissions

cap

With

valve

schematIc

Fuel

check

valve

6

GENERAL

INFORMATION

AND

MAINTENANCE

loose

cracked

follows

1

2

ternator

belt

3

bar

a

handle

bracket

or

too

tIght

replaceItAdjust

Loosen

When

from

replacmg

toward

the

both

pulleys

Carefully

such

as

and

then

nuts

If

the

nuts

on

the

the

engine

the

pry

a

alternator

ratchet handle

tIghten

belt IS

belt

the

belt

and

the

Evaporahve

frayed

tensIOn

bracket

the

pry

shp

out

or

broom

alternator

the

With

or

as

al

emiSSiOns

the

ance

NOTE

dnve belt

IOn

Loosen

SIon

4

The

canister

Recheck

alternator

water

to

the

pump

carry

The

is

alternator

tensIOn

the

dnve

It

extra

an

optional

adjusted

bracket

belt

might

belt

aIr

In

nuts

also

operates

be

good

m

the

condItIOning

a

S1mllar

to

adjust

msur

trunk

fash

belt

ten

Checlnng

belt

deflectIon

AIR

This

nance

CONDITIONING

book

contams

procedures

for

no

the

repau

au

condlbomng

mamte

or

GENERAL

INFORMATION

AND

MAINTENANCE

PositIVe

licahng

f

lIer

CJp

With

rehef

valve

7

system

repaIrS

sonnel

who

have

CAUTION

ant

usedInthe

expands

perature

Will

eyes

refngerant

sonous

not

air

condlttOmng

Sight

You

checks

mg

system

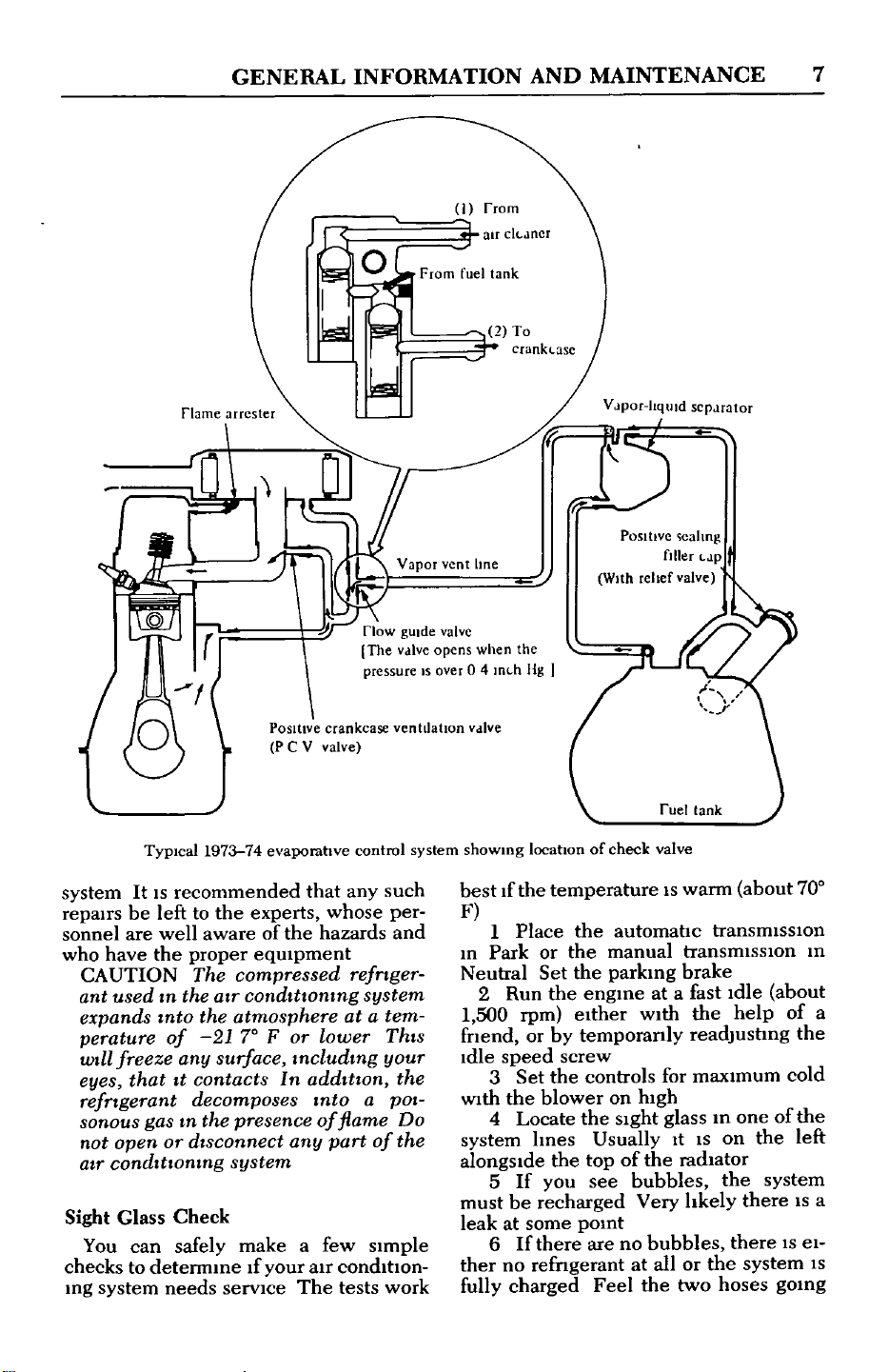

TYPIcal

It

be

are

freeze

that

gas

open

Glass

can

to

determme

1973

IS

recommended

the

left

to

well

aware

the

proper

The

aIr

Into

the

21

of

any

It

contacts

decomposes

In

the

or

dIsconnect

Check

safely

needs

PosItive

PCV

74

evaporallve

experts

of

eqUIpment

compressed

condlttOmng

atmosphere

70

F

surface

presence

system

make

If

your

service

valve

that

hazards

the

lower

or

including

In

addlttOn

Into

of

any

a

aIr

The

crankcase

control

any

whose

refnger

atatem

flame

part

few

condltlon

tests

now

The

pressure

ventIlation

such

per

and

system

ThIS

your

a

POI

of

Simple

work

gUide

vdlve

the

Do

the

IS

system

valve

when

opens

0 4

over

vdlve

showmg

bestIfthe

F

In

Neutral

1

500

fnend

Idle

With

system

alongSide

must

leak

ther

fully

lOch

1

Park

2

speed

3

4

5

6

no

the

lIg

I

location

temperature

Place

or

Set

Run

the

rpm

or

by temporanly

Set

the

the

blower

Locate

lines

the

If

you

be

recharged

at

some

If

there

refngerant

charged

the

the

the

either

screw

of check

manual

parkmg

engme

controls

on

the

Usually

top

see

pomt

are

Feel

automatic

With

high

sight

of

the

bubbles

Very

no

bubbles

at

the

valve

IS

at

for

glass

all

a

It

two

warm

transmiSSIOn

brake

radiator

or

about

transmiSSIOn

fast

Idle

the

help

readjusting

maximum

m

one

IS

on

the

there

likely

there

the

system

hoses

about

of

the

system

gomg

of

cold

IS

700

the

the

left

IS

ei

m

a

a

IS

8

GENERAL

INFORMATION

AND MAINTENANCE

45

seconds

to

disengaged

ThiS

usually

bubble

the

causes

system

poor

when

IS

the

clutch

overcharged

coohng

IS

at

low

speeds

CAUTION

system

rected

allow

very

NOTE

a

for

so

dunng

the

pOSSibilIty

drying

has

as

mOIsture

expensIVe

feu

out

If

a

soon

ExerCise

minutes

the

from

It

leak

as

rust

cold

of

IS

detenmned

It

pOSSible

to

enter

problem

the

every

months

the

lack

should

and

air

two

compressor

lubncatlOn

of

that

be

Leaks

cause

conditIOner

u

eeks

ThiS

aVOids

seals

the

cor

may

a

or

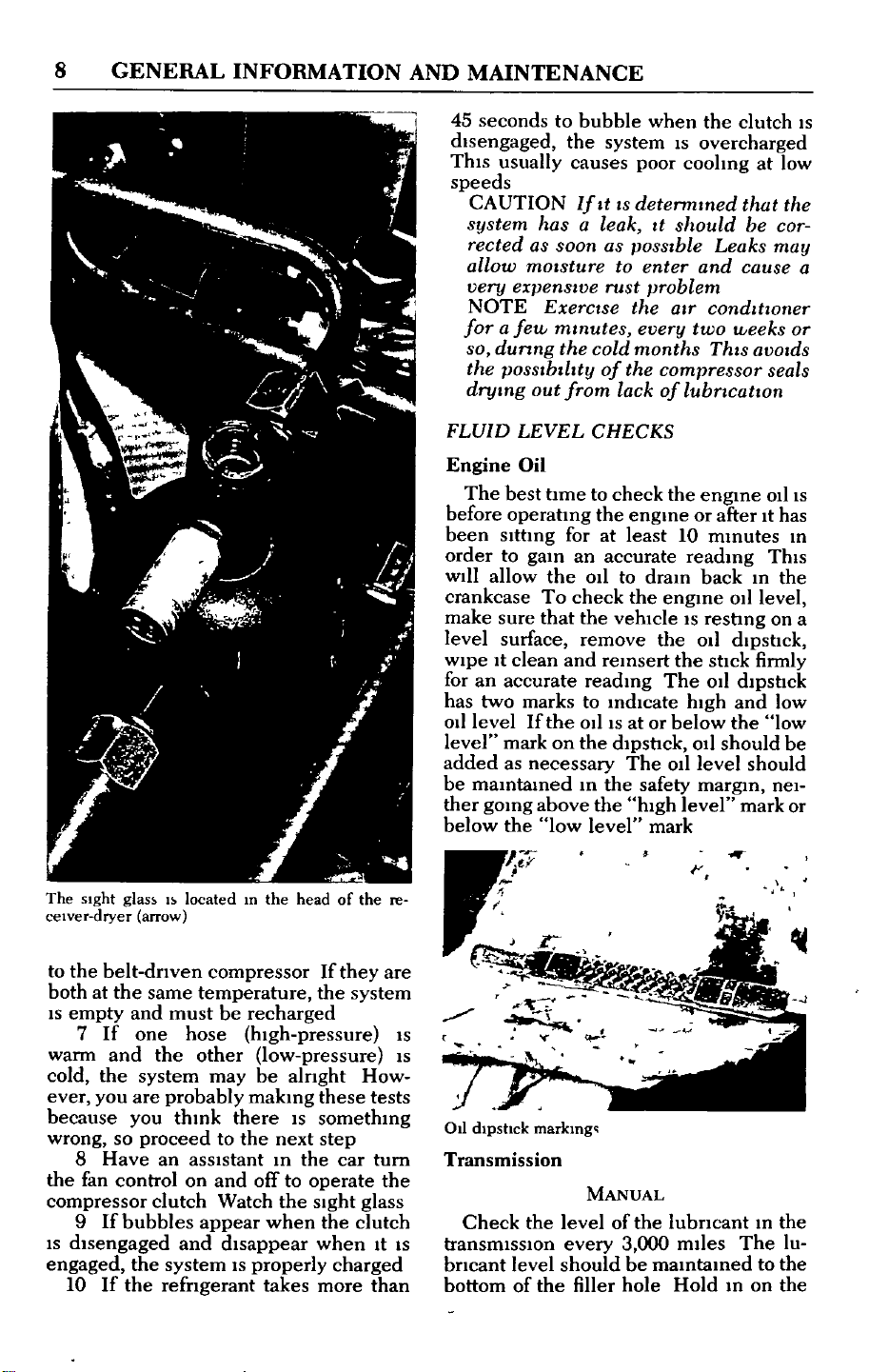

The

sIght

celver

dryer

to

the

belt

bothatthe

IS

empty

7

If one

warm

cold

ever

and

the

you

because

wrong

the

compressor

IS

so

8

Have

fan

control

9

Ifbubbles

disengaged

engaged

10

If

glas

arrow

dnven

same

and

the

system

are

you

proceed

clutch

the

the

located

compressor

temperature

must

be

hose

other

may

probably

thmk

to

an

assistant

on

and

Watch the

appear

and

disappear

system

refngerant

10

the

recharged

high

low

be

makmg

there

next

the

m

to

off

when

IS

properly

takes

headofthe

If

they

the

pressure

pressure

alnght

these

IS

somethmg

step

the

car

operate

Sight

the

when

charged

more

are

system

How

tests

turn

the

glass

clutch

It

than

re

IS

IS

IS

FLUID

Engine

The

best

before

been

slttmg

order

to

will

allow

crankcase

make

sure

level

surface

It

wipe

for

an

accurate

two

has

011

level

level

added

be

ther

below

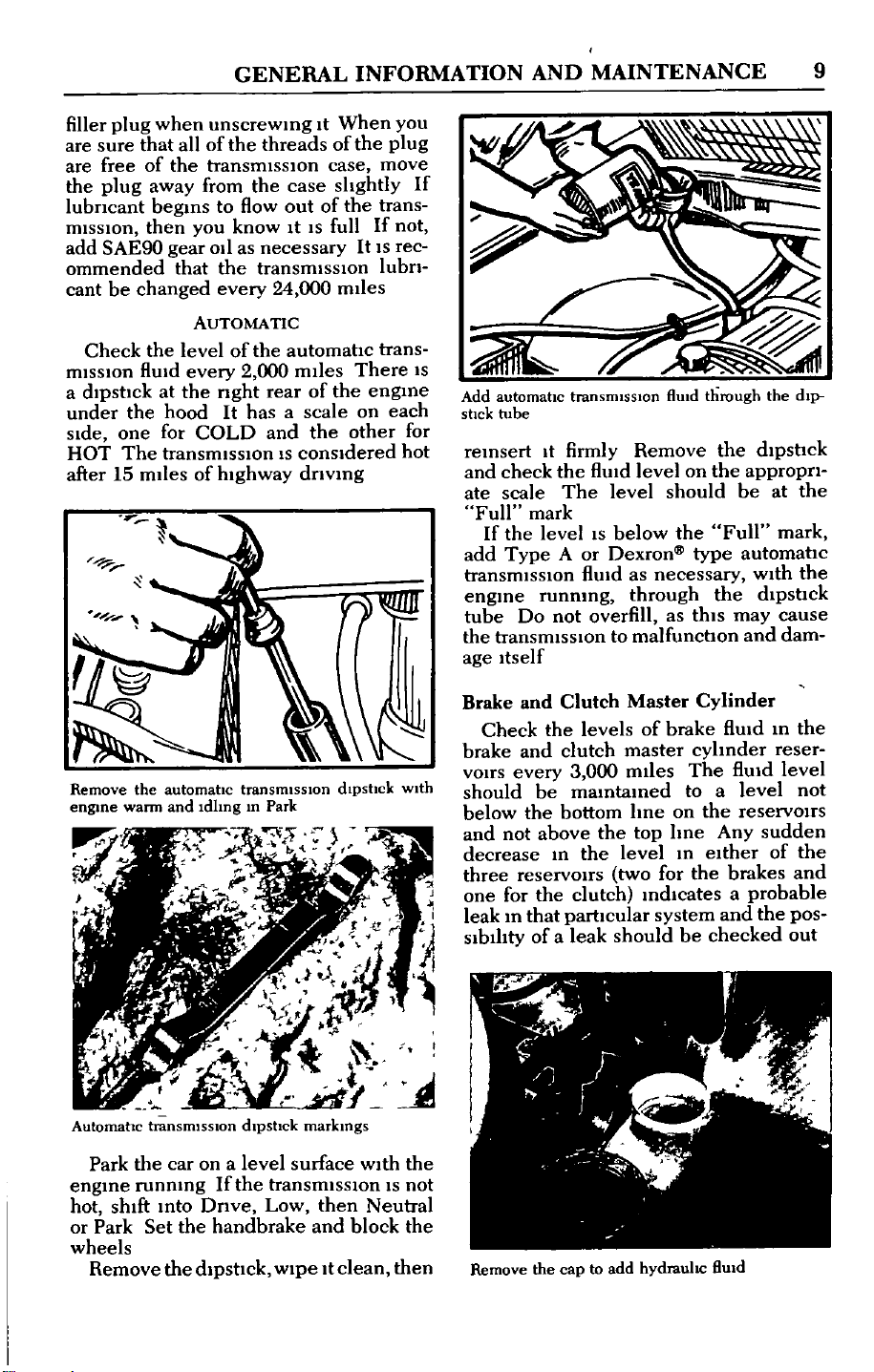

OIl

Transmission

transmiSSIOn

bncant

bottom

mark

as

mamtamed

gomg

the

dipstick

Check

LEVEL

Oil

tIme

operatIng

gam

the

To

that

clean

marks

If

the

on

necessary

above

low

mark1Og

the

level

of

the

to

for

an

011

check

the

remove

and

readmg

to

OlliS

the

m

level

MANUAL

level

every

should

filler

CHECKS

check

the

engme

at

least

accurate

to

the

vehICle

remsert

mdlcate

at

dipstick

The

the

the

of

3

be

hole

the

dram

engme

the

the

The

or

below

011

safety

high

mark

lubncant

the

000

mamtamed

Hold

engme

or

afterIthas

10

mmutes

readmg

back

IS

restIng

011

stIck

011

high

011

level

margin

level

I

miles

m

011

dipstick

dipstick

and

the

should

should

mark

The

m

on

OlliS

ThiS

the

level

on

firmly

low

low

nei

m

the

to

the

the

m

a

be

or

lu

filler

plug

are

sure

free

are

the

plug

lubncant

miSSIOn

SAE90

add

ommended

cant

be

Check

miSSIOn

a

dipstick

under

Side

HOT

after

the

one

The

15

0

when

that

allofthe

of

the

away

begins

then

gear

that

changed

the

level

flUid

every

at

the

hood

for

transmiSSIOn

miles

GENERAL

unscrewing

transmiSSIOn

from

the

to

flow

know

you

011

as

the

every

AUTOMATIC

the

of

2

nght

It

has

COLD

of

highway

threads

case

out

It

IS

necessary

transmiSSIOn

24

000

automatic

miles

000

rear

of

a

scale

and

the

IS

considered

dnvlng

INFORMATION

It

When

of

the

case

move

slightly

the

full

It

miles

There

the

engine

on

other for

trans

If

IS

lubn

trans

of

you

plug

not

rec

each

hot

If

IS

Add

automatIc

stIck

tube

reinsert

and

check

scale

ate

Full

If

the

add

Type

transmiSSIOn

engine

tube

the

transmiSSIOn

Itself

age

Do

AND

It

mark

level

runmng

MAINTENANCE

transmiSSion

firmly

the

flUid

The

level

IS

A

or

flUid

not

overfill

to

Remove

level

below

as

necessary

through

malfunction

flUid

on

should

the

Dexron

lP

type

as

thiS

through

the

the

Full

the

may

the

dipstick

appropn

be

automatic

With

dipstick

and

at

mark

cause

dam

9

dip

the

the

Remove

eng10e

AutomatIc

Park

engine

hot

or

Park

wheels

Remove

wann

shift

the

transmISSion

the

runmng

Into

Set

automatic

and

car

the

the

transmiSSIOn

Idl10g

dipstick

on a

level

If

the

Dnve

handbrake

dipstick

10

Park

transmiSSIOn

Low

wipe

markmgs

surface

then

and

It

dipstIck

With

Neutral

block

clean

IS

With

the

not

the

then

Brake

Check

brake

vous

should

below

not

and

decrease

three

one

for

In

leak

Sibility

Remove

and

and

every

be

the

above

reservOIrs

the

that

ofaleak

the

Clutch

the

levels

clutch

3

000

maintained

bottom

In

the

clutch

partICular

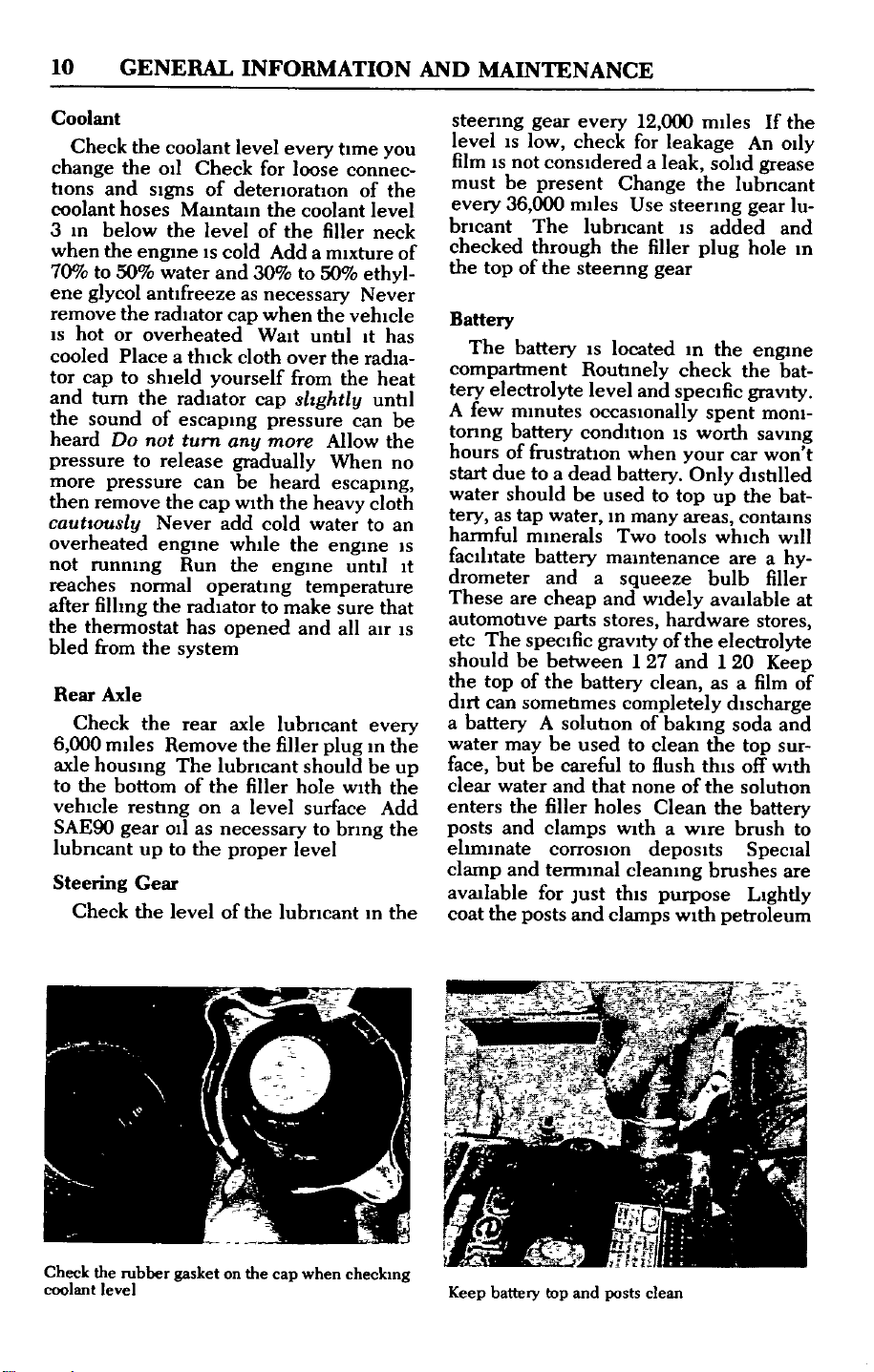

cap

to

the

add

Master

of

master

miles

line

top

level

two

indICates

should

hydraulIC

brake

to

on

line

In

for

system

be

Cylinder

flUid

cylinder

The

a

the

Any

either

the

brakes

a

and

checked

flUid

flUid

level

reservOIrS

sudden

of

probable

the

In

reser

level

the

not

the

and

POS

out

10

GENERAL

INFORMATION

AND

MAINTENANCE

Coolant

Check

change

tions

and

coolant

3

m

below

when

the

70

to

ene

glycol

remove

IS

hot

cooled

tor

cap

and

turn

the

sound

heard

pressure

more

pressure

then

remove

cautiously

overheated

not

nmmng

reaches

after

fillmg

the

thermostat

bled

from

Rear

Axle

Check

6

000

mIles

axle

housmg

to

the

vehicle

SAE90

lubncant

Steering

Check

the

the

hoses

engIne

50

the

or

overheated

Place

to

the

Do

to

normal

the

the

bottom

resting

gear

up

Gear

the

coolant

Oil

SignS

MaIntam

the

water

antifreeze

radiator

a

thick

shield

radiator

of

escapmg

not

turn

release

can

the

Never

engme

Run

the

radiator

has

system

rear

Remove

The

of

011

to

the

level

Check

of

level

IS

cold

and

cap

yourself

any

gradually

cap

add

while

the

operatmg

opened

axle

lubncant

the

on

a

as

necessary

proper

of

level

every

for

loose

detenoratlOn

the

coolant

of

the

Add

30

to

as

necessary

when

Walt

cloth

over

from

cap

slIghtly

pressure

more

be

heard

With

the

cold

the

engme

temperature

to

make

and

lubncant

the

filler

should

filler

hole

level

surface

level

the

lubncant

time

filler

a

mIXture

50

the

until

the

Allow

When

escapmg

heavy

water

engme

sure

all

plug

to

bring

connec

of

ethyl

Never

vehicle

It

radia

the

can

until

With

level

neck

heat

until

cloth

to

au

every

m

be

m

you

the

has

the

that

Add

the

the

be

no

an

the

up

the

of

IS

It

IS

steering

level

IS

film

must

every

not

IS

be

36

bncant

checked

the

top

of

Battery

The

battery

compartment

tery

electrolyte

A

tonng

hours

start

water

tery

hannful

faCIlItate

drometer

These

automotive

etc

should

the

dut

a

water

face

clear

enters

posts

elImmate

clamp

aVailable

coat

few

of

due

should

as

The

top

can

battery

may

but

water

and

and

the

mmutes

battery

tap

are

be

the

gear

low

considered

present

000

The

through

the

frustration

to

a

water

mmerals

battery

and

cheap

parts

speCific

between

of

the

sometImes

A

solutIon

be

be

careful

and

filler

clamps

corrosion

termmal

for

posts

every

check

for

Change

miles

dead

Use

lubricant

the

steenng

IS

located

RoutInely

level

occaSIOnally

conditIon

when

battery

be

used

m

many

Two

mamtenance

a

squeeze

and

stores

graVity

1

battery

completely

to

used

to

that

none

holes

With

cleamng

thiS

just

and

clamps

12

000

leakage

a

leak

steering

IS

filler

gear

m

check

and

speCific

IS

your

Only

to

top

areas

tools

Widely

hardware

of

the

27

and

clean

of

bakmg

clean

flush

of

Clean

a

wire

depOSits

purpose

With

miles

solId

the

lubncant

added

plug

the

spent

worth

car

distIlled

up

contams

which

are a

bulb

available

electrolyte

1

20

as

a

discharge

soda

the

thiS

the

the

brush

brushes

petroleum

If

An

Oily

grease

gear

and

hole

engIne

the bat

graVity

mom

savmg

won

the bat

Will

hy

filler

stores

Keep

film

and

sur

top

off

With

solutIon

battery

Special

are

Lightly

the

lu

In

t

at

of

to

Check

coolant

the

level

rubber

gasket

on

the

when

cap

checkmg

Keep

battery

lop

and

posts

clean

1973

510

GENERAL

INFORMATION

AND

MAINTENANCE

11

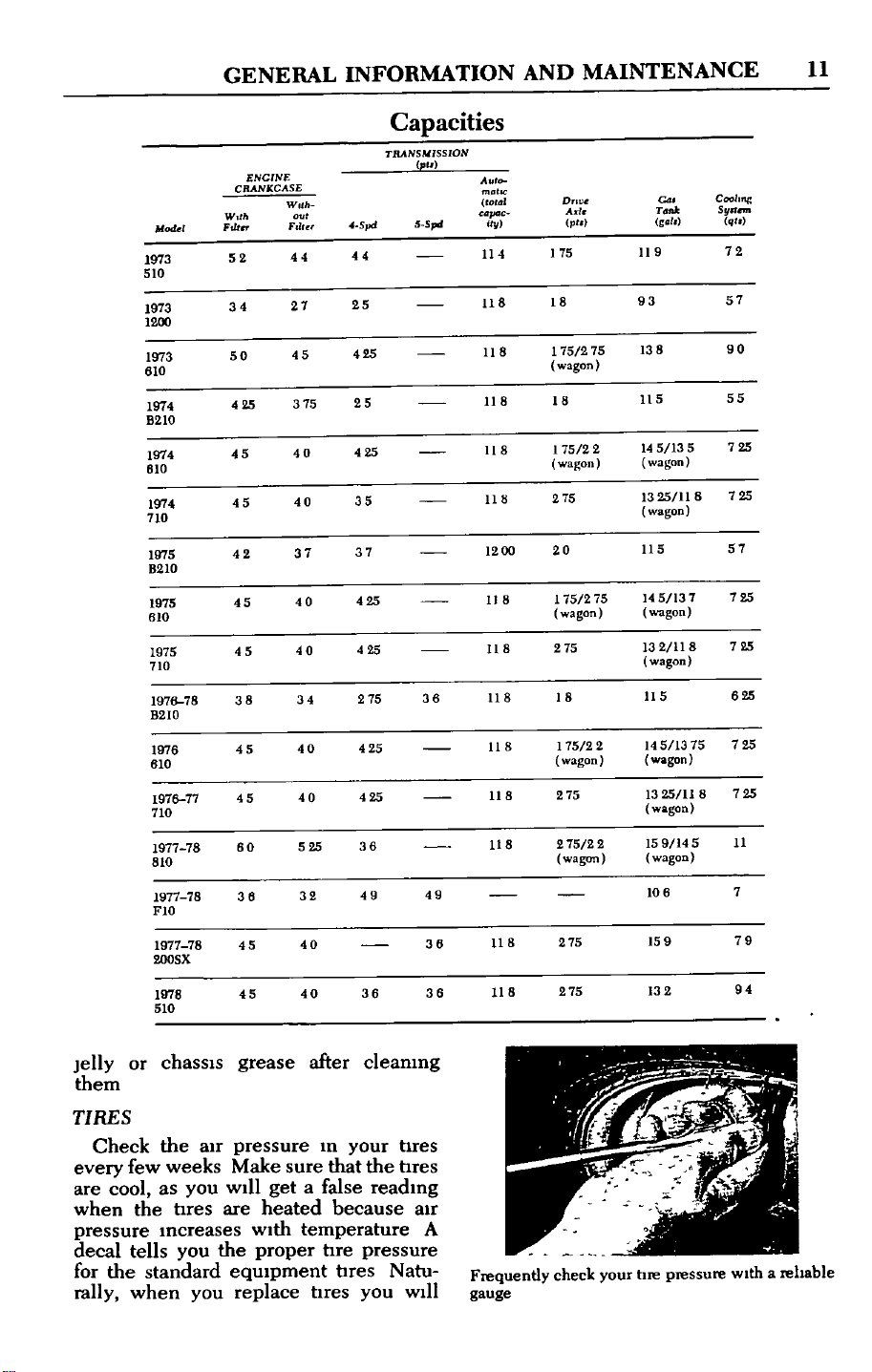

Capacities

TRANSMISSION

ENGINE

CRANKCASE

W

M

Wdh

Fdt

52

Fdtu

h

ut

4

44

44

1

S

5

Spd

Auto

mafIC

Cotal

PO

I

114 175

119

c

T

CoollJlg

nk

gall

em

S

qU

72

Dnv

A

de

pt

1973

1200

1973

610

1974

B210

1974

610

1974

710

1975

8210

1975

610

1975

710

1976

B210

1976

610

1976

710

1977

810

1977

FIO

34

SO

425

45 40

45 40 35

42 37 37

45

45

78

38 34

45

77

45 40

78

60

78

36

27 25

45

375

40

40

40

525

32 49

118

425

2S

425 118

425

425

27S

425

425

36

36

49

118

118

118

1200

118

118

118

118

118 275

118

18

I752

wagon

18

1

75

wagon wagon

275

20

I752

wagon wagon

275

18

I752

wagon wagon

2 2

2

75

wagon wagon

93

75

138

115

22

145

1325

115

75

1451137

132

wagon

115

2

145

1325

wagon

159 145

106

wagon

135

118

1375

11

57

90

55

725

11

8

725

57

725

725

625

725

8

725

II

7

jelly

them

TIRES

Check

every

are

when

pressure

decal

for

rally

cool

the

200SX

510

or

few

the

tells

standard

when

1977

78

1978

chaSSIS

the

weeks

as

you

tIres

Increases

you

you

45 40

45 40 36

grease

au

pressure

Make

wIll

get

are

heated

With

the

proper

eqUIpment

replace

after

m

sure

that

a

false

because

temperature

tIre

tIres

tIres

c1eanmg

your

the

readIng

pressure

Natu

you

tIres

tIres

will

au

36

36

A

118

118 275

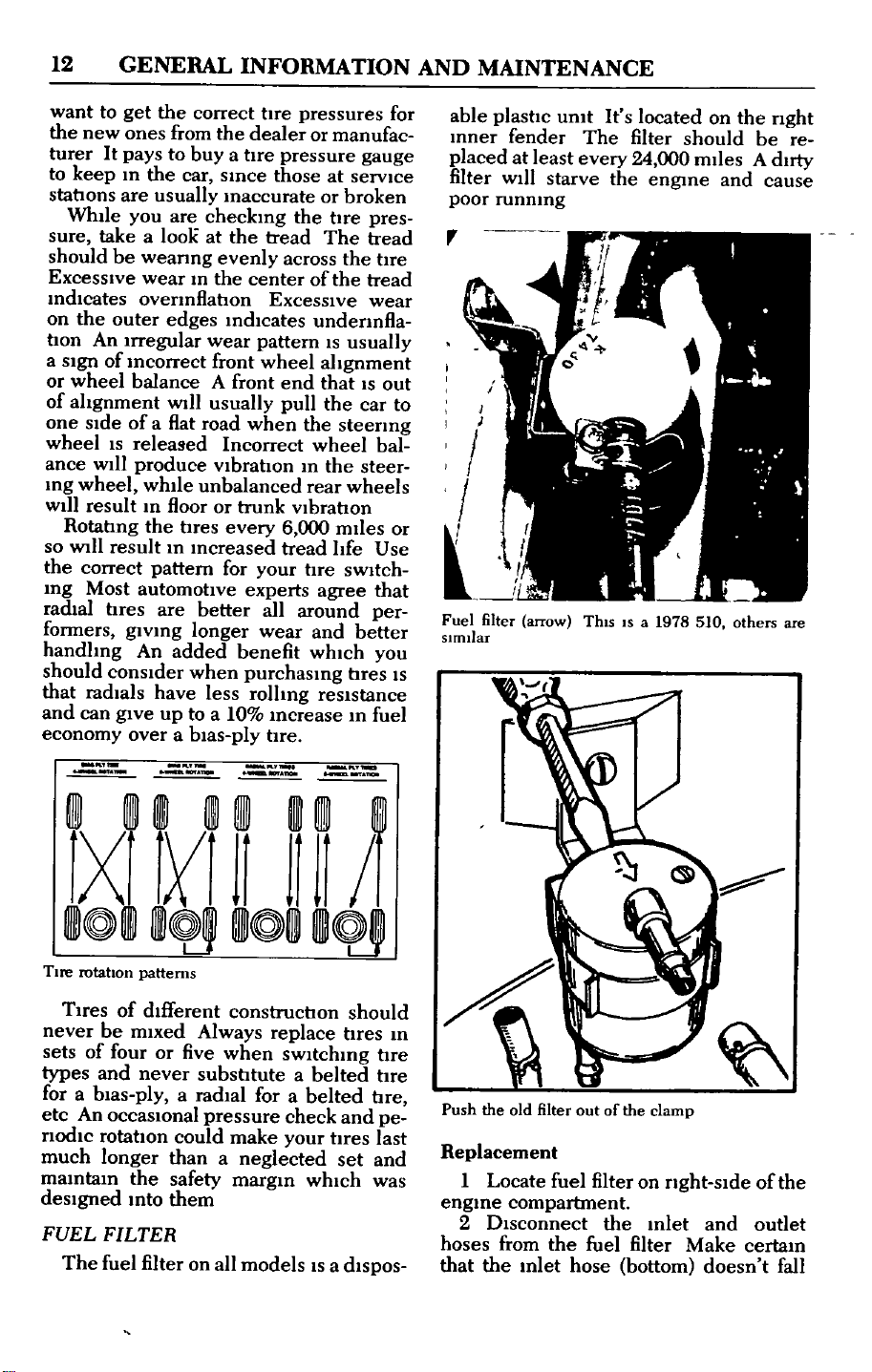

Frequently

gauge

275

check

your

159

132

lIre

pressure

79

94

Withareliable

12

want

the

turer

to

statIons

sure

should

ExceSSive

mdICates

on

tIon

a

or

of

one

wheel

ance

mg

Will

so

the

mg

radial

fonners

handhng

GENERAL

to

get

new

ones

It

pays

m

keep

While

the

are

you

takealooKatthe

be

weanng

wear

overmHatIon

outer

the

An

Irregular

of

wheel

mcorrect

balance

Sign

ahgnment

Side

ofaHat

IS

released

Will

produce

result

Most

tIres

while

m

the

result

automotIve

givmg

An

wheel

RotatIng

wIll

correct

should consider

that radials

and

can

give

economy

over

n

the

correct

from

the

to

buy

car

smce

are

maccurate

checkmg

usually

evenly

m

the

edges

wear

front

A

Will

usually

road

VibratIon

unbalanced

Hoorortrunk

tIres

mcreased

m

pattern

are

better

longer

added

when

have

less

to

a

up

a

bias

INFORMATION

tIre

pressures

a

dealer

tIre

or

pressure

those

the

tread

across

center

mdICates

of

ExceSSive

undennHa

pattern

wheel

end that

front

pull

when

the

Incorrect

wheel

m

rear

Vibration

6

every

000

tread

your

tIre

for

experts

around

all

and

wear

benefit

whICh

purchasmg

rolhng

10

mcrease

tIre

ply

y

manufac

gauge

service

at

broken

or

tIre

pres

The

tread

tIre

the

the tread

wear

IS

usually

ahgnment

IS out

the

car

steermg

bal

steer

the

wheels

miles

Use

hfe

sWltch

agree

per

better

tIres

resistance

fuel

m

for

that

you

AND

to

or

IS

MAINTENANCE

able

plastIc

mner

placed

filter

poor

Fuel

sImilar

fender

at

Will

runnmg

filter

least

arrow

umt

starve

The

every

ThiS

It

the

s

located

filter

24

IS

000

engine

a

1978

on

should

miles

510

and

the

others

A

be

nght

re

duty

cause

are

Always

five

substItute

a

radial

pressure

could

safety

them

on

iI

IOII

constructIon

when

make

a

neglected

margm

all

lXflxl

IOII

TlI

e

rotation

TIres

never

sets

types

for

a

etc

An

nodIC

much

mamtaIn

deSigned

FUEL

The

of

be

of

four

and

bias

occasional

rotatIon

longer

FILTER

fuel

patterns

different

mixed

or

never

ply

than

the

mto

filter

replace

sWltchmg

a

forabelted

check

your

whICh

models

ill

should

tIres

belted

and

tIres

set

a

IS

dlspos

tIre

tIre

tIre

pe

last

and

was

m

Push

the old

Replacement

1

Locate

2

Disconnect

the

comparbnent

from

mlet

engme

hoses

that

filter

fuel

the

out

fuel

hose

of

filter

the

the

on

filter

bottom

clamp

nght

mlet

sldeofthe

and

Make

certam

doesntfall

outlet

GENERAL

INFORMATION

AND

MAINTENANCE

13

I

sure

drain

Pry

Replace

Start

AND

to

the

the

reattach

the

Be

below

will

3

replace

4

secure

5

OIL

RECOMMENDATIONS

Your

Datsun

regular

tane

fuel

low

ratings

filler

checked

gasoline

of

too

Will

must

011

States

to

be

gasoline

Umted

lar

be

mIUm

fit

octane

anticipated

penod

the

lowest

Will

suffiCient

pour

before

chart

be

Into

expected

assured

the

tank

fuel

out

fuel

the

assembly

the

hose

the

engine

Lubrication

FUEL

IS

lead

are

door

when

Should

available

Iowan

the

raise

derived

be

selected

temperatures

the

select

engine

your

lIsted

hoses

level

filter

Inlet

clamps

and

deSigned

or

lead

on

but

these

travehng

octane

octane

from

than

that

next

the

Oil

temperature

of

easy

protectIOn

Datsun

correctly

or

the

from

outlet

and

to

prevent

check

to

free

fuel

Inside

the

need

outSide

find

you

In

say

mix

enough

level

runmng

recommended

With

regard

Oil

change

VISCOSity

cold

engine

gasoline

Its

chp

for

operate

the

MeXICO

No

a

dunng

and

starting

The

hnes

leaks

leaks

The

ofthe

only

of

bene

higher

to

USing

for

Oil

should

and

regu

Pre

on

oc

be

the

the

the

the

you

and

you

to

the

have

top

tion

of

ItS

system

deSignatIOn

troleum

SE

IS

the

more

car

car

peclfic

senger

senger

a

Instance

SUitable

011

deSignated

also

be

used

claSSification

system

Oil

Viscosity

MultI

grade

Smgle

grade

OIL

CHANGES

The

mileage

owner

s

mended

changes

Datsun

your

polluted

Oil

same

and

Always

been

operating

easier

removed

drained

and

the

The

stop

tances

has

to

flow

be

were

capacity

container

adopted

Institute

highest

use

and

contains

only

Alltl

Above

May

as

Con

100

Above

Temperature

manual

Intervals

assuming

or

filter

thing

traffic

go

drain

runmng

and

drain

Under

API

The

the

second

apphcatlon

no

for

very

MS

thiS

Since

under

Selection

Klted

Range

320

be

usedaslow

F

100

tently

F

320

320Fand

figures

are

IS

being

road

off

sooner

goes

or

the

long

temperature

more

With

along

You

cold

pan

SE

marked

the

the

by

American

In

May

deSignation

S

stands

letter

SA

additIves

hght

was

ulJcraturc

helow

hetween

100

used

old

F

given

Datsun

011

duty

severe

the

API

and

dnvlng

under

motor

the

1

F

F

the

for

average

conditions

than

for

cars

for

only

after

the

Oil

enoughtobnng

Hot

contaminants

the

Oil

need

Will

whICh

you

on

claSSifica

1970

for

pas

for

pas

denotes

Oil

and

usage

may

highest

rating

Chart

Ai

lOW

20W

40

20W

5W

30

lOW

In

your

recom

filter

dusty

change

speCified

driven

short

engine

Oil

than

a

large

can

the

Pe

for

VISC

l

lOW

40

10W

30

IOW

30

lOW

40

5W

30

diS

Will

Will

If

pur

IS

ltJ

50

50

20

If

In

It

It

14

GENERAL

INFORMATION

AND

MAINTENANCE

at

chase

parts

the

used

any

Another

011

store

You Will

tles suchasthose

nc

softener

ecologically

Pne

the

used

cooperatIve

allow

you

tank

Another

around

fences

Datsun

and

011

and

the

thereafter

filter

filter at

larger

ItS

advertisements

filter

leaves

engine

m

kept

Changing

1

normal

2

It

port

3

capacity

4

out

plug

make

011

disposal

gas

to

dump

the

house

railroad

recommends

filter

dunng

filter

For

It

S

cheap

every

filter

manufacturers

one

ThiS

claim

mmd

when

Your

Run

the

operating

up

safety

the

Jack

on

ShdeadraIn

under

Loosen

hand

by

whICh

necessity

used

excellent

desuable

station

your

to

IS

keep

as

tie

borders

every

the

small

msurance

011

change

that

quart

IS

changing

Engine

engine

temperature

frontofthe

stands

pan

the

011

the

dram

By

sells

contamers

IS

find

that

for

bleach

problem

owner

used

the

a

preseIVatlve

changmg

the

first

other

pnce

to

not

of

duty

true

and

Oil

until

ofatleast

pan

plug

keepIng

automotIve

plastic

storage

soluhOl

to

IS

who

011

mto

011

etc

both

011

011

of

replace

One

pomts

changing

011

should

your

It

reaches

car

and

6

Turn

an

for

bot

or

fab

jugs

L

find

wIll

hiS

for

use

the

change

change

an

the

of

the

out

the

the

m

011

sup

quarts

the

Inward

to

a

on

011

m

be

i

wrenchwlI

A

strap

overtighten

a

new

pan

buggered

6

USing

011

filter

about

one

NOTE

510

610

7

Empty

and

Will

10

8

9

fresh

more

dispose

Usmg

adapter

that

could

Coat

when

surface

leak

Refill

of

pan

filter

sure

which

With

hand

adapter

No

It

amount

chart

D

e

1

n

1Io

l

the

or

threads

a

Keep

quart

You

and

the

the

011

or

you

the

fresh

I

Jf

make

plug

a

tnck

strap

m

mmd

of

can

remove

710

the

old filter

of

a

clean

the

on

doesntleave

rag

an

clog

rubber

Spm

the

give

ll

engme

011

r

I

y

011

filler

removal

or

you

replacement

wrench

that

hot

duty

the

models

the

011

it

gasket

It

squash

See

filter

rag

engme

passage

gasket

onto

another

WIth

the

from

mto

wipe

the

touches

the

I

easIer

ll

be

buymg

plug

remove

It

S

holdmg

011

oil

filter

above

the dram

off

block

any

on

the

engine

o

Ih

4

gasket

correct

the

CapacItIes

for

the

on

the

Be

hnt

filter

by

the

turn

and

The01filteronL

the

pressure

011

can

hot

and

nght

won

remove

011

5

Allow

then

hand

t

on

escape

mstall

senes

SIdeofthe

the

plug

past

It

Without

the

011todram

engmes

block

as

the

beIng

the dram

IS

eastly

you

threads

located

unscrew

and

burned

completely

Don

plug

you

by

on

filler

before

ot

the

and

hght

then

rubber

the

start

doesn

L

It

ghtly

stal

atwn

11 Crank

tImes

Uu

t

ot

gasket

engme

It If

t

on

the

over

the

011

out

or

go

the

m

several

pressure

pres

GENERAL

INFORMATION

AND

MAINTENANCE

15

sure

gauge

and

down

12

If

are

no

lower

the

Transmission

Change

manual

your

miles

as

1

Park

the

apply

and

support

2

Remove

upper

plug

mg

can

and

one

3

Placeadram

m

4

Slowly

an

qUIckly

5

Allow

then

tighten

6

Fill

011

gear

the

CapacIties

or

squeeze

chore

and

too

7

Replace

the

car

The

transmiSSion

24

000

12

000

severe

or

dramed

has

been

chance

below

given

1

Dram

flUId

from

dram

pan

bottom

2

Thoroughly

and

posItIon

surface

mg

gasket

and

secure

tlghtenmg

3

Pour

which

shows

find

the

011

leaks

car

the

follows

the

parkmg

It

the

transmiSSion

remove

upward

pull

allofthe

replace

It

the

Refill

bulb

can

transmiSSIOn

mlles

miles

conditions

Immediately

dnven

to

cool

the

the

by

screws

pan

a

Use

to

seal

It

them

the

automatic

Dexron

ll

was

dramed

zero

out

what

pressure

shut

MANUAL

transmiSSion

transmiSSIOn

car

on

brake

on

stands

the

011

pan

pressure

It

out

the

transmiSSIOn

With

the

chart

filler

be

used

filler

the

AUTOMATIC

flUId

should

of

normal

of

dnvmg

but

Follow

automatic

transmission

removmg

clean

new

gasket

petroleum

It

Install

With

the

to

35

same

shut

the

s

wrong

OK

IS

the

engine

lubncant

every

level

surface and

a

Jack

filler

under

bottom

the dram

It

on

old

gear

Don

plug

with

quantity

suction

An

011

are

handy

for

the

plug

m

an

be

changed

dnvmg

under

The

flUId

after

the

beforeIthas

the

transmission

mto

transmiSSIOn

the

and

pan

the

bottom

on

the

jelly

the

attachmg

ft

Ibs

amount

transmiSSIOn

from

the

engine

there

and

off

and

36

000

the

up

plug

dram

the

pan

keep

plug

until

you

011todram

t

over

SAE 90

shown

gun

thiS

for

axle

rear

and

lower

automatic

every

or

every

abnormal

should

vehicle

had

procedure

a

large

gasket

mat

pan

on

bottom

screws

of

Type

flUId

Oil

pan

car

the

the

pan

the

pan

m

m

be

A

m

through

the

funnel

Item

used

sIOn

Allow

utes

apply

miSSIOn

check

the

clean

IS

4

Start

the

5

Place

the

the

level

stIck

Axle

Rear

Change

36

every

1

With

the

up

2

SlIdeadram

remove

plug

to

dram

3

Install

overtIghten

4

Refill

Oil

car

CHASSIS

tIngs

age

up

5

Datsun

or

to

Install

m

threaded

use

a

grease

With

a

the

plugs

Pushing

If

your

ual

transmiSSIOn

m

an

recognized

damaging

both

cars

both

cars

the

clutch

and

gear

the

car

10

or

the

filler

contamer

to assist

the

engine

the

parkmg

at

flUId

flUId

to

the

the

000

miles

the

car

rear

and

the

out

the dram

It

the

the

level

the

GREASING

doesntmstall

lube

pomts

suspensIOn

fittmgs

pomted

Lubncate

gun

plug

every

after

Jump

Datsun IS

extreme

that

bumpers

Make

are

pedal

SWitch

reaches

15

mph

pipe

m

engine

to

selector

brake

operating

level

FULL

gear

on

support

plug

Remove

rear

filler

as

pan

axle

of

hose

fillIng

Do

Idle

lever

add

011

follows

a

level

the

plug

Make

mark

m

It

under

and

plug

the

With

sure

or

any

transmis

the

NOT

a

few

for

m

With

the

temperatures

flUId

on

the

surface

With

the

allow

but

filler

SAE

filler

plug

and

lower

lubncatIon

on

the

all

000

can

tIp

Jomts

steenng

buy

these

end

eqUIpped

miles

to

grease

rubber

24

You

lubncatlon

Towing

and

Starting

be

the

or

the

Second

the

With

push

It

should

pOSSibilIty

fenders

bumpers

On

clutch

eqUIpped

It

may

emergency

evenly

release

IS

there

and

that

sure

matched

select

the

IgnitIon

a

speedofapproximately

other

race It

mm

Park

trans

to

bnng

the

rear

stands

dram

the

don

plug

90

metrIc

pomts

on

Replace

a

started

Depress

Third

or

When

to

that

and

dip

axle

jack

Oil

t

gear

the

fit

Imk

or

your

man

be

of

of

of

start

16

the

PUSH

SUN

Both

may

no

towed

with

or

the

Jump

starting

sure

nected

to

posItIve

aging

Keep

car

garag

engine

be

more

either

that

the

the

If

GENERAL

DO

START

manual

towed for

than

a

great

the

dnveshaCt

starting

a

car

the

negatI

or

electrical

engme

the

car

ontmual

NOT

AN

AUTOMATIC

and

short

20

mph

distance

rear

wheels

disconnected

IS

the

With

a