Nissan Bluebird Datsun 411 User Manual

Or

1

XJ

r

A

1

o

t

I

V

l

C

Z

u

i

r

I

r

t

1

1

1

0

t

A

1

j

1

t

k

t

r

MODEL

411

SERIES

DATSUN

MODEL

411

SERVICE

MANUAL

INISSANI

SERIES

NISSAN

OTEMACHI

CABLE ADDRESS

MOTOR

BLDG

TOKYO

PHONES

CO

OTEMACHI

JAPAN

llNISMOll TOKYO

216

2311

LTD

CHIYODA

KU

INTR

ODUCTION

This

manual

DATSUN

maintenance

major

distributors

components

comprehensive

assembling

ing

It

is

emphasised

should

be

used

of

instructions

as

the

and

been

has

and

dealers

Model

is

described

inspection

that

only

replacements

complies

411

P

L

are

given

of

genuine

for

these

for

in

for

purpose

effective

Each

detaiL

complete

assemblies

DATSUN

of

service

assembly

In

dismantl

Spare

assisting

of

addition

Parts

and

the

DATSUN

MODEL

411

1

U

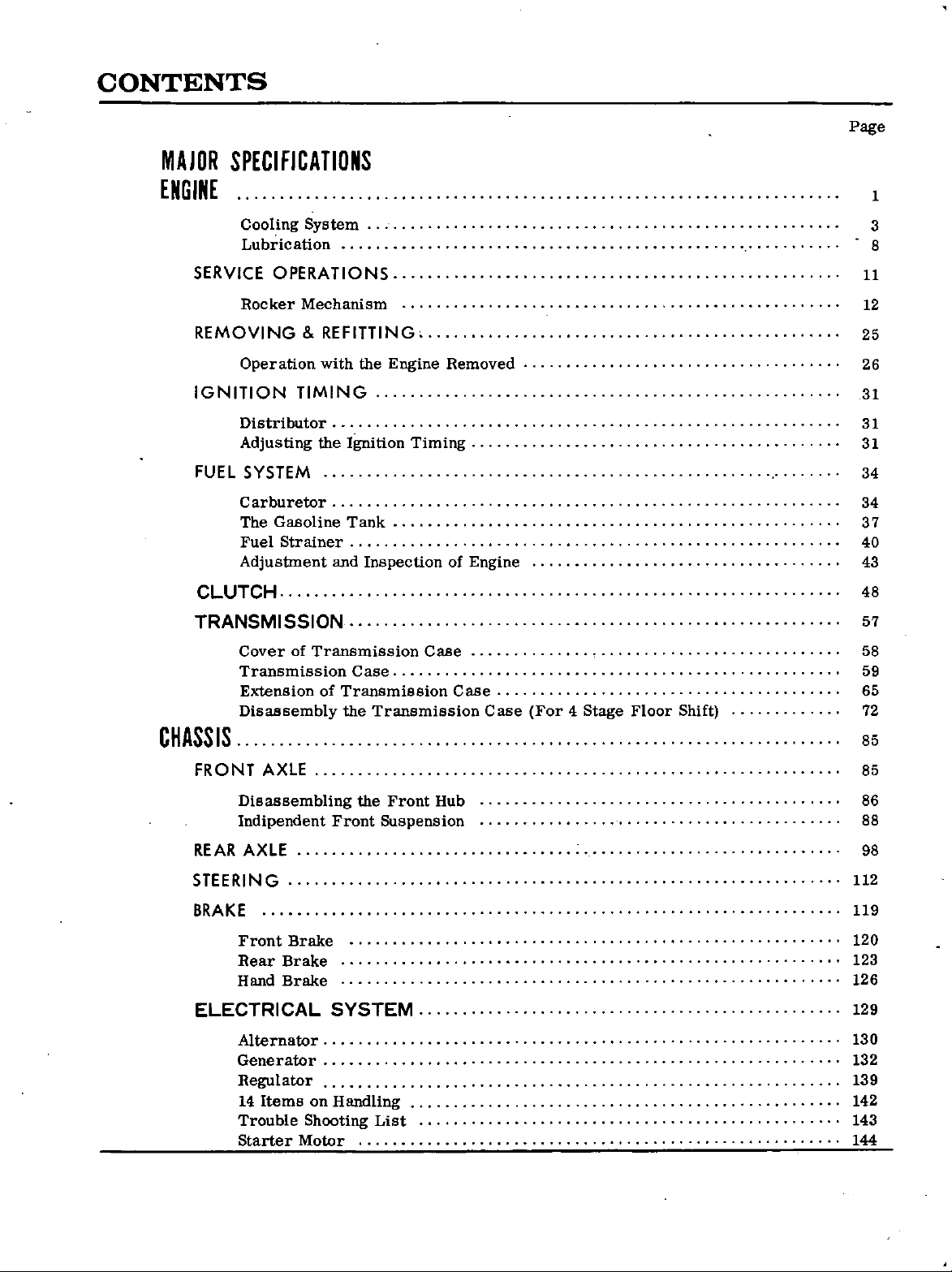

CONTENTS

Page

MAJOR

ENGINE

SERVICE

REMOVING

IGNITION

FUEL

CLUTCH

TRANSMISSION

SPECIFICATIONS

Cooling

Lubrication

Rocker

Operation

Distributor

Adjusting

SYSTEM

Carburetor

The

Fuel

Adjustment

System

OPERATIONS

Mechanism

REFITTING

with

TIMING

the

Gasoline

Strainer

and

the

Ignition

Tank

Inspection

Engine

Timing

Removed

of

Engine

1

3

8

11

12

25

26

31

31

31

34

34

37

40

43

48

57

CHASSIS

FRONT

REAR

STEERING

BRAKE

ELECTRICAL

of

Cover

Transmission

Extension

Transmission

DiBaBSembly

AXLE

DiBaBSembling

Indipendent

AXLE

Front

Rear

Hand

Alternator

Generator

Regulator

Trouble

Starter

Brake

Brake

Brake

14

ItemB

on

Shooting

Motor

TransmiBBion

of

the

Front

SYSTEM

Handling

Case

Transmission

the

List

Case

Front

Suspension

Hub

Case

Case

For

4

Stage

Floor

Shift

58

59

65

72

85

85

86

88

98

112

119

120

123

126

129

130

132

139

142

143

144

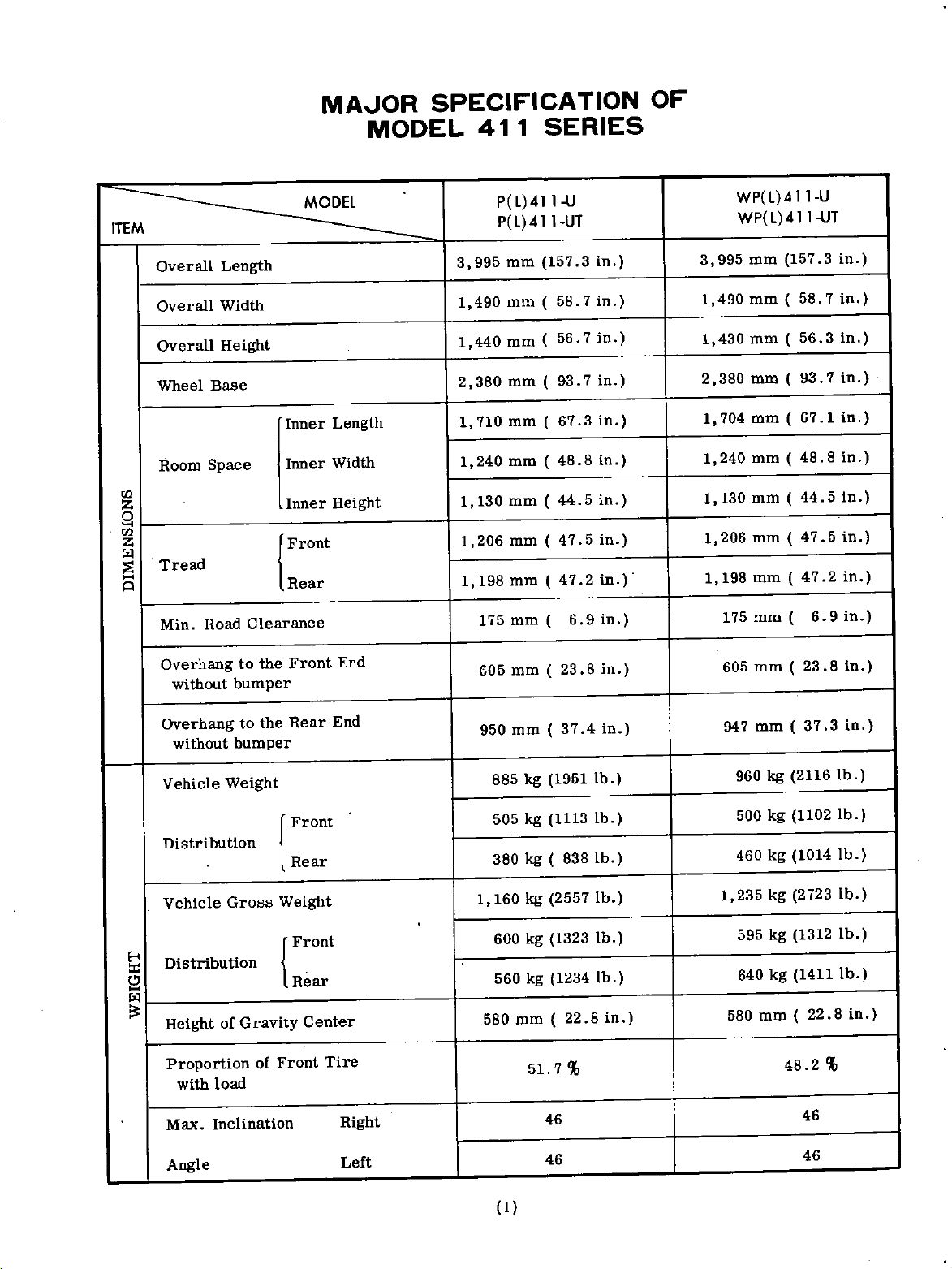

MA

JOR

MODEL

SPECIFICATION

41

1

SERIES

OF

ITEM

A

Overall

Overall

Overall

Wheel

Room

Tread

Min

Road

Overhang

without

Length

Width

Height

Base

Space

bumper

Inner

Inner

Rear

rront

Clearance

the

Front

to

MODEL

L

Width

Height

End

P L

411

U

PL4

1 1

oUT

3

995

mm

1573in

1

490

mm

1

440

mm

2

380

mm

710

1

mm

1

240

mm

130

1

mm

1

206

mm

1

198

mm

175

mm

605

mm

587in

56 7

937in

673in

488in

44

5

47

5

472in

6

9

238in

in

in

in

in

3

1

1

2

1

1

1

1

206

1

605

WPL411

WPL411

995

mm

490

mm

430

mm

380

mm

704

mm

240

mm

130

mm

mm

198

mm

175

mm

mm

U

UT

1573in

587in

56

3

7

93

671in

488in

445in

475in

47

2

6 9

23

8

in

in

in

in

in

I

9

Overhang

without

Vehicle

Distribution

Vehicle

Distribution

Height

Proportion

with

Max

Angle

to

bumper

Weight

Gross

of

Gravity

load

Inclination

of

the

Rear

Front

Rear

Weight

Front

Rear

Front

Center

Tire

End

Right

Left

1

950

580

885

505

380

160

600

560

mm

mm

kg

kg

kg

kg

51

kg

kg

2557

1323

1234

7

46

46

37 4

1951

1113

838

228in

in

Ib

lb

lb

lb

lb

lb

1

947

580

960

500

460

235

595

640

mm

mm

kg

kg

kg

kg

kg

kg

48

373in

2116

1102

1014

2723

1312

1411

22

2

lb

Ib

lb

lb

Ib

lb

8

in

46

46

I

r

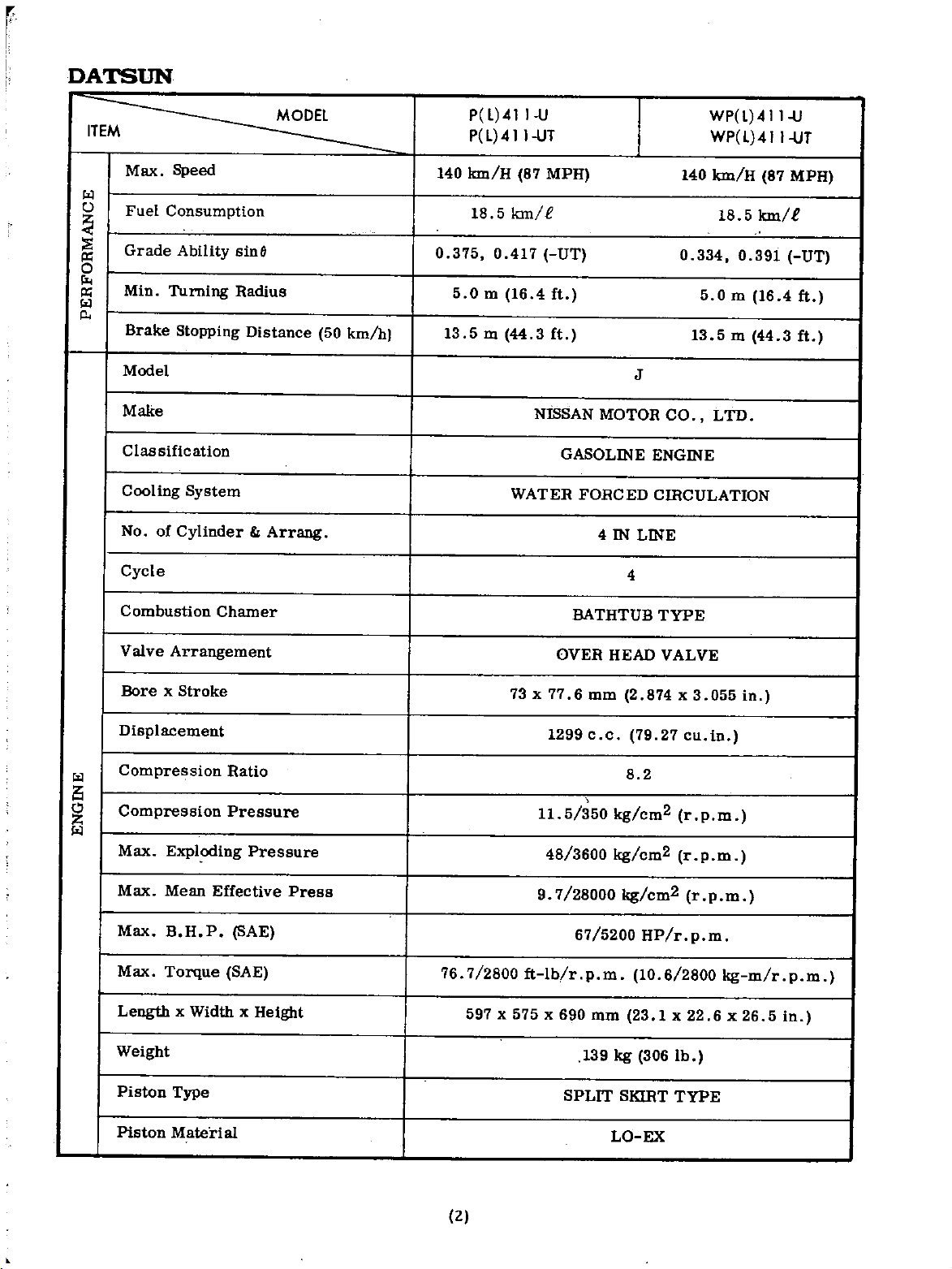

DATSUN

ITEM

l

p

0

r

p

l

Po

Max

Speed

Fuel

Consumption

Grade

Min

Turning

Brake

Model

Make

Classification

Cooling

No

of

Cycle

Ability

Stopping

System

Cylinder

sinO

Radius

Distance

MODEl

Arrang

Pl411

P

l

140

km

18

0

375

5

0

m

50

km

h

135m

U

411

UT

H 87

MPH

5

km

P

0

417

164ft

44

3

NISSAN MOTOR

WATER

UT

ft

GASOLINE

FORCED

4 IN

J

ENGINE

CIRCULATION

LINE

4

CO

140

o

334

5 0

135m

WP

WP

km

LTD

l

411

U

l

411

UT

H

87

MPH

18

5

km

t

o

391

UT

m

164ft

443ft

l

as

lE

l

Combustion

Valve

Bore

Arrangement

x

Stroke

DiBplacement

Compression

Compression

Max

Exploding

Max

Mean

Max

B H

Max

Torque

Length

x

Weight

Width

Chamer

Ratio

PreBsure

Effective

P

PresBure

SAE

SAE

x

Height

PreBB

76

7

597x575

2800

73

x

ft

BATHTUB

OVER HEAD

77

6

mm

1299

c c

11

5

350

48

3600

7

28000

9

67

Ib

rpm

x

690

mm

139

kg

kg

5200

kg

2

8 2

kg

23

TYPE

874

7927cu

cm2

cm2

cm2

HP

10

306

VALVE

x

r

rpm

rpm

6 2800

1

x

Ib

055

3

r

22

in

in

m

p

p

m

kg

m

rpm

5

6x26

in

PiBton

PiBton

Type

Mate

rial

SPLIT

2

SKIRT

LO

TYPE

EX

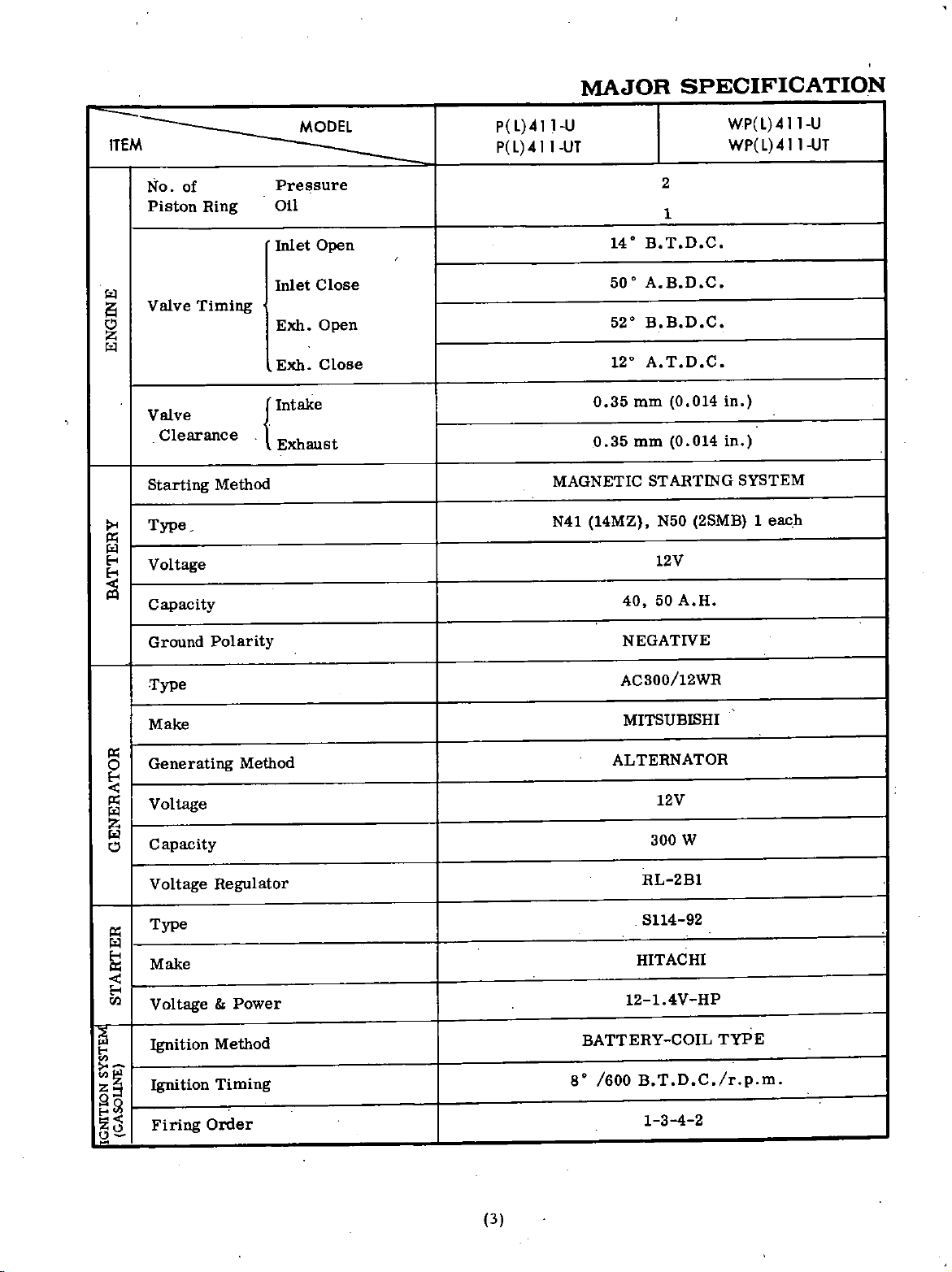

ITEM

MODEL

P

P L

MAJOR

L

411

U

411

UT

SPECIFICATION

L

411

WP

411

WP

L

U

UT

riI

iI

f

@

riI

p

riI

Eo

No

of

PiBton

Valve

Valve

Clearance

Starting

Type

Voltage

Capacity

Ground

Ring

Timing

Method

Polarity

PreBsure

011

Inlet

Inlet

Exh

Exh

Intake

ExhauBt

Open

Close

Open

CloBe

0

0

MAGNETIC

N41

14MZ

2

1

14 BTD C

ABD C

50

52 B B D

ATD

12

0

35

mm

35

mm

014

014

0

STARTING

N50

2SMB

12V

40

50 A H

NEGATIVE

C

C

in

in

SYSTEM

1

each

AC300

MITSUBISHI

ALTERNATOR

p

0

Eo

p

riI

Z

riI

Type

Make

Generating

Voltage

Method

Capacity

Voltage

Type

p

riI

Make

Eo

on

Voltage

I

t

9

Zl

l

Ignition

Ignition

z

l

Firing

Regulator

Power

Method

Timing

Order

BATTERY

8

12

600

12V

300

RL

S114

HITACHI

1

BTD

1

12WR

2Bl

4V

COIL

34

W

92

HP

TYPE

C

rpm

2

3

r

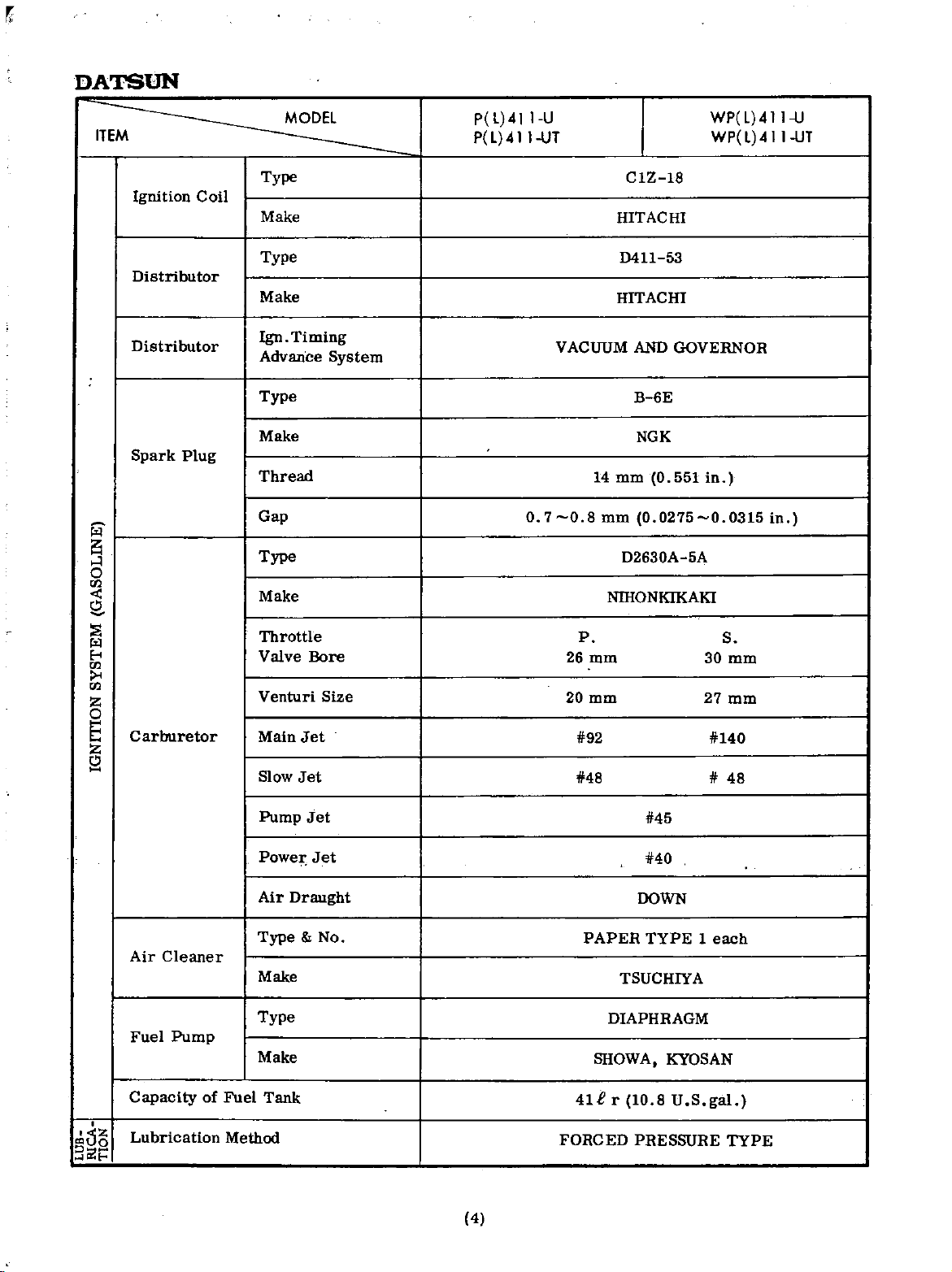

DATSUN

ITEM

l

0

Q

I

iI

Eo

Ignition

Distributor

Distributor

Spark

Plug

Coil

MODEL

l

P

P

l

411

411

UT

U

Type

Make

Type

Make

Ign

Timing

Advance

System

VACUUM

Type

Make

Thread 14

0 7

Gap

08

Type

Make

Throttle

Valve

Bore

P

26

C1Z

HITACHI

0411

HITACHI

AND GOVERNOR

B

NGK

mm

mm

D2630A

NllIONKIKAKI

mm

6E

0

00275

WP

l

411

U

WP

l

411

UT

18

53

551

in

0

5A

0315

in

S

30mm

Z

0

E

Z

0

9t2E

z

0

Carburetor

Air

Cleaner

Fuel

Pump

Capacity

Lubrication

of

Fuel Tank

Method

Venturi

Main

Slow

Pump

Power

Air

Type

Make

Type

Make

Size

Jet

Jet

Jet

Jet

Draught

No

20mm

192

148

PAPER

41f

FORCED

TSUCHIYA

DIAPHRAGM

SHOWA

r

10

PRESSURE

145

140

DOWN

TYPE

8US

1

KYOSAN

27

1140

I

gal

mm

48

each

TYPE

4

ITE

a

MODEL p

P L

MAJOR

L

411

U

411

UT

SPECIFICATION

WPL411

411

WP

L

U

UT

C

E

0

f

l

p

I

Q

H

l

riI

E

tl

as

H

0

0

U

U

E

H

U

Oil

Pump

Oil

Filter

Oil

Pan

Type

Radiator

Cooling

Water

Thermostat

Type

No

of

Out

dia

Total

dia

In

Capacity

Water

Pump

Plate

Friction

of

Type

x

In

Operating

Type

Capacity

diaxThickness

Area

Cylinder

SINGLE

200

TROCHOID

FULL

FLOW

2

9

WATER CUULING

CORRUGATED

5

4

CENTRIFUGAL

DRY

130

181x2

3 5

x

x

f

r

f

r

PELLET

DISC

1

mm

cm2

19 05

TYPE

0

76

1

43

HYDRAULIC

FACING

mm

TYPE

CARTRIDGE

U

FIN

U

TYPE

7

87x5

28

S

gal

CLOSED

AND

S

gal

TYPE

2

06

x

34in

2

TUBE

12

sq

TYPE

TYPE

TYPE

OPERATION

0

138

x

in

in

15 87

mm

5 8

3RD

FLOOR

2 2 0

8

TYPE

in

1

REVERSE

ON

4TH

SHIFT

58 U

S

gal

3

945

2

402

1

490

1

000

5

159

mm

In

Type

Gear

Z

9

Oil

f

l

l

p

E

Gear

of

dia

Shift

Capacity

Ratio

Master

Method

1st

2nd

3rd

Cylinder

3

FORWARD

ALL

SYNCHROMESHED

ON

FORWARD

REMOTE

1 7

fO45

3

1

1

1

REVERSE

GEARS

CONTROL

U

197

725

000

4

FOREARD

SYNCHROMESHED

2ND

S

gal

4th

4

Reverse

0

I

1st

Length

0

0

0

5

o

Type

Gear

of

Type

Universal

x

Out

dia

Joint

In

dia

x

125

1222x71x67

SPICER

HYPOID

5

r

DATSUN

MODEL

ITEM

0

Gear

Housing

Type

Oil

Capacity

Ratio

Type

No

of

Gear

i

1

1

r

J

is

4

Type

Gear

Eo

Ratio 15

Steering

ES

I

Eo

Angle

Steering

Oil

Capacity

Wheel

r

Out

Dia

375

L

P

P L

PL41l

WP

411

U

411

UT

U P

L

41l

U

4

111

BANJO

STRAIGHT

1fO

BEVEL

26 U

RECIRCULATING

360

280

405

mm

0

33f0

087

OP

PINION

S

BALL

0

36

15

UoS

WPL411

WP

3889

gal

95

in

gal

L

2

TYPE

WP

each

U

411

UT

L

41l

UT

L

411

UT

ES

D

p

Eo

f

j

p

l

Wheel

Front

Toe

Camber

Caster

Inclination

Rear

p

l

U

p

Arrangement

Axle

in

Axle

Type

Type

Lining

Width

x

Total

In

dia

Drum

Type

Angle

Length

Braking

of

Dimension

Thickness

x

of

Brake

King

Area

Pin

2

FRONT

WISHBONE

SEMI

FRONT

F

R

2

LEADING

40x4

40x4 5x215

q

5x215

REAR

mm

mm

351

351

228

228

FLOATING

1

1

cm2

cm2

6

6

BALL

3

mm

1

45

0

6

LEADING

575x0

575x0

54

54

mm

mm

15

2

JOINT

9

9 o

REAR

TYPE

177x8

177x8

4

in2

4

in2

0

in

in

TYPE

AND

TRAILING

465

465

in

in

6

ITEM

MODEL

P L

P L

411

411

U

UT

MAJOR

SPECIFICATION

411

WP

L

411

WP

L

U

UT

rI

n

rI rI

II II

I

Q

Z

9

Z

rI

Po

P

rI

II

I

Q

rI

0

II

rI

I

Q

t

II

Po

Front

Coil

Free

Rear

Spring

Thickness

ShOck

j

II

I

Q

H

0

Type

Lining

Total

In

dla

Suspension

Wire

dia

Length

Suspension

Size

Absorber

In

In

Max

Dimension

Braking

x

Length

No

dla

Cylinder

dla

Cylinder

Oil

Drum

of

Type

Coil

of

No

Type

x

of

of

Area

dla

Coils

Width

Master

Wheel

PreSBure

x

x

22 22

115

25

kg

F

R 23 81

MECHANICAL

40x4

INDEPENDENT

14

LONGITUDINAL

F

R H

2x94

1200x60

TELESCOPIC

5x215mm

CAR

336 R

x

325

351

SUSPENTION

x

0

8748

mm

mm

mm

cm2

1

0

1636

40

FOR

1

575xO

cm2

54

228

6

mm

8 5

L

SEMI

6 2 6 3

5 2

DOUBLE

in

000

In

In

9374

Ib

REAR

4

sq

9 0

WITH

14

ELLIPTING

1200

ln2

WHEEL

177x8

in

In

COIL

L

H

2

x

94x325

ACTION

SPRING

x

60

CAR

465

SPRING

x

5 2

In

8 5

TYPE

4P

4P

50Wx2

x2

x2

2

x

xl

ACTION

Shock

Absorber

Stabilizer

Tire

Size

e

Head

Lamp

Width

Tail

Lamps

LlcenBe

Po

Stop

H

Lamps

Reverse

Room

Indicators

Plate

LampB

Lamps

Sealed

LampB

beam

R

F

F

R

7

TELESCOPIC

TORSION

12V

DOUBLE

BAR

5

60

13

5

60

13

5

37

12V

8Wx2

12V

8W

12V

8W

12V

25W

12V

25W

12V

5Wx1

r

DATSUN

L

411

U

411

UT

ITEM

p

l

Fog

Lamps

Inspection

Parking

Turn

Signal

Dash

LampB

Reflection

Warning

Lamps

Lamps

Turn

Main

Lamps

Lamps

Signal

Beam

MODEL

P L

P

411

U

l

411

UT

12V

35Wx2

12V

12V

12V

25W

12V

32

12V

15Wx2

12V

l

8Wx

8Wx4

x

3Wx4

50

x

5W

WP

WP

L

1

4

2

xl

Ignition

Oil

Pres

sure

12V

12V

5W

1

xl

l

5W

xl

8

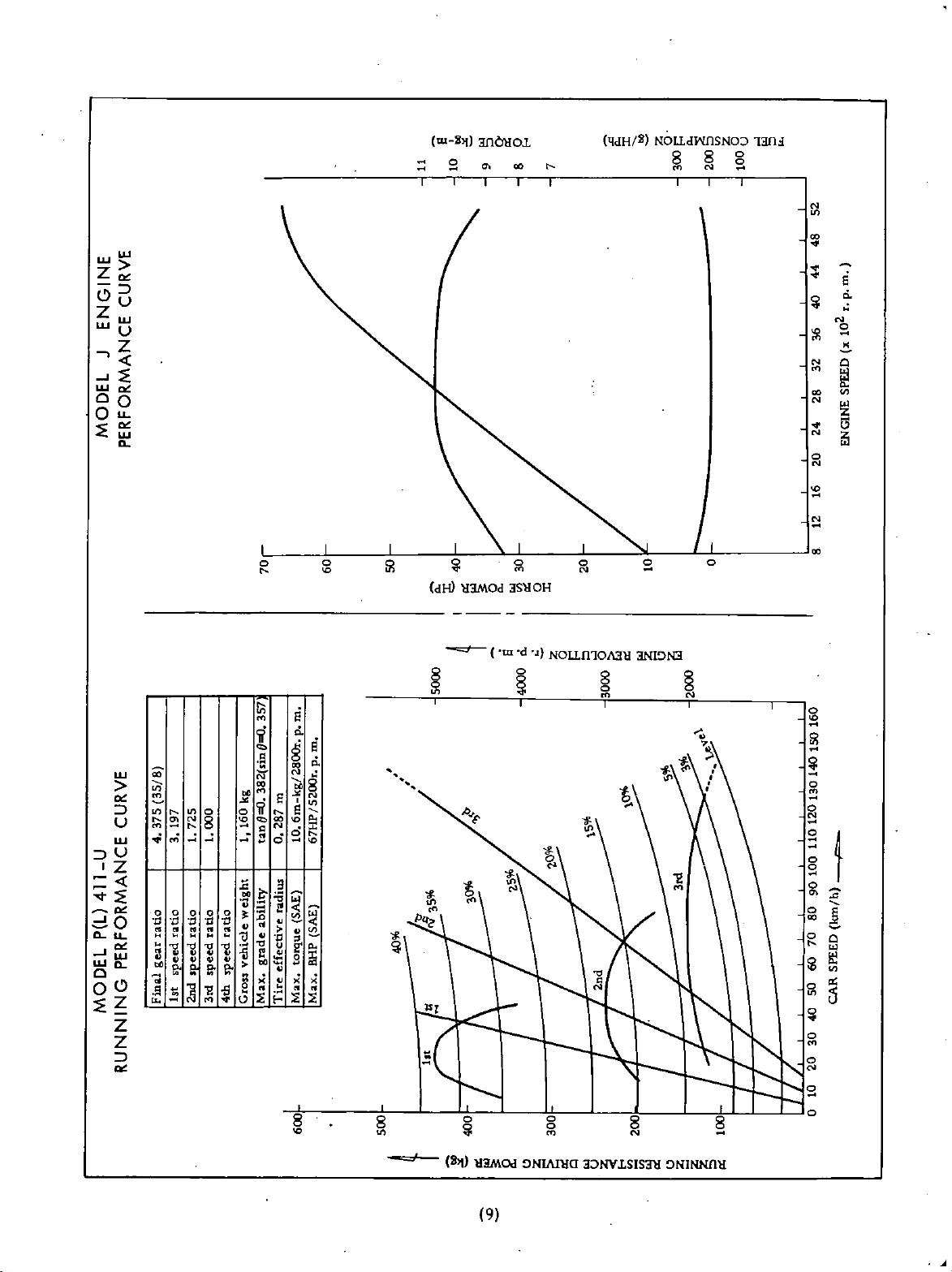

CURVE

ENGINE

J

Jo

E

c

11

10

9l8

0fo

7

l

c zo

r0E

300

z

200

8

100

g

a

m

p

40

102

x

A

SPEED

MODEL

PERFORMANCE

30

50

31

0

I

2000

le

l

70

357

sin8

O

8

35

CURVE

375

197

7251000

4

3

1

U

kg

160

1

382

lanD

O

411

L

P

MODEL

ratio

ratio

ratio

PERFORMANCE

geal

speed

speed

1st

2nd

Final

weight

ratio

speed

3td

ability

ratio

grade

vehicle

speed

4th

Gron

Max

60

rn

p

m

p

2800T

kg

m

52oor

6rn

287

10

67HP

O

radius

SAE

SAE

torque

BHP

effective

Max

Max

Tire

SO

0

O

I

I

S

d

4000

c

t

r

5

0

I

I

I

1

I

SOOO

30

40

10

I

0

3000

ENGINE

W

U

8

160

ISO

140

130

120

110

100

90

h

80

Ian

70

60

SPEEO

50

CAR

40

RUNNING

600

SOO

f

bii

400

I

2

300

200

u

V

I

100

Z

1il

I

kg

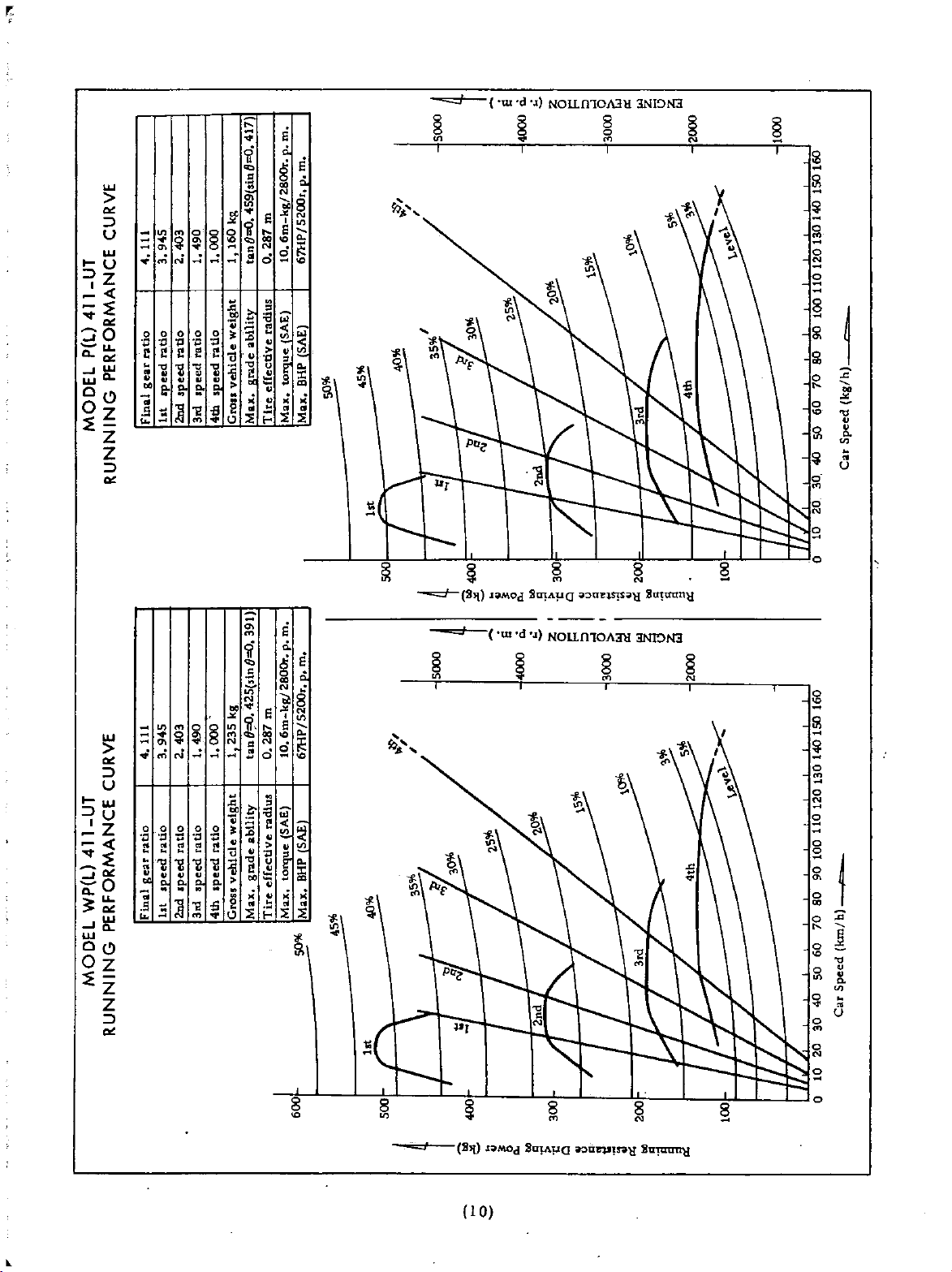

CURVE

111

945240314901000

4

UT

3

160

1

417

sinO

O

4S9

m

00

287

tan

O

m

P

m

P

2800r

kg

52oor

6m

10

67HP

t

SOOO

Ii

ci

400U

r

3000

t5

J2000

1000

foo

lSO

40

1101201301

411

radius

weight

Pill

PERFORMANCE

MODEL

ratio

ratio

ratio

eed

gear

P

speed

1st

2nd

Final

ratio

ratio

vetllc1e

speed

speed

4th

3rd

Croll

RUNNING

SAE

ability

rade

Max

SAE

p

torque

BHP

effective

Tire

Max

Max

SO

40

45

1st

soo

s

I

I

400

S

3oo

0

200

u

S

l

j

joo

90

80

h

70

kg

60

sil

Speed

Car

3040

21

10

o

391

111

9452403

4

3

g

490

1

1

000

m

p

dn8

O

2800r

425

kg

m

6m

287

10

tan8

O

m

P

52001

67HP

j

5000

Ii

0

z

OI

r

01

4000 3000 2000

160

ISO

CURVE

UT

tio

ratio

ratio

ratio

ratio

411

L

WP

PERFORMANCE

ra

gear

speed

speed

speed

1st

2nd

Final

3rd

cd

4th

DEL

MO

RUNNING

radius

weight

vehicle

spl

Gross

SAE

ability

Max

SAE

gt

llde

torque

BHP

effective

Mu

Tire

IMax

SO

600

45

lat

100

110120130140

100

90

80

h

70

km

60

50

Speed

40

Car

30

20

10

o

f

I

0

5

II

n

J

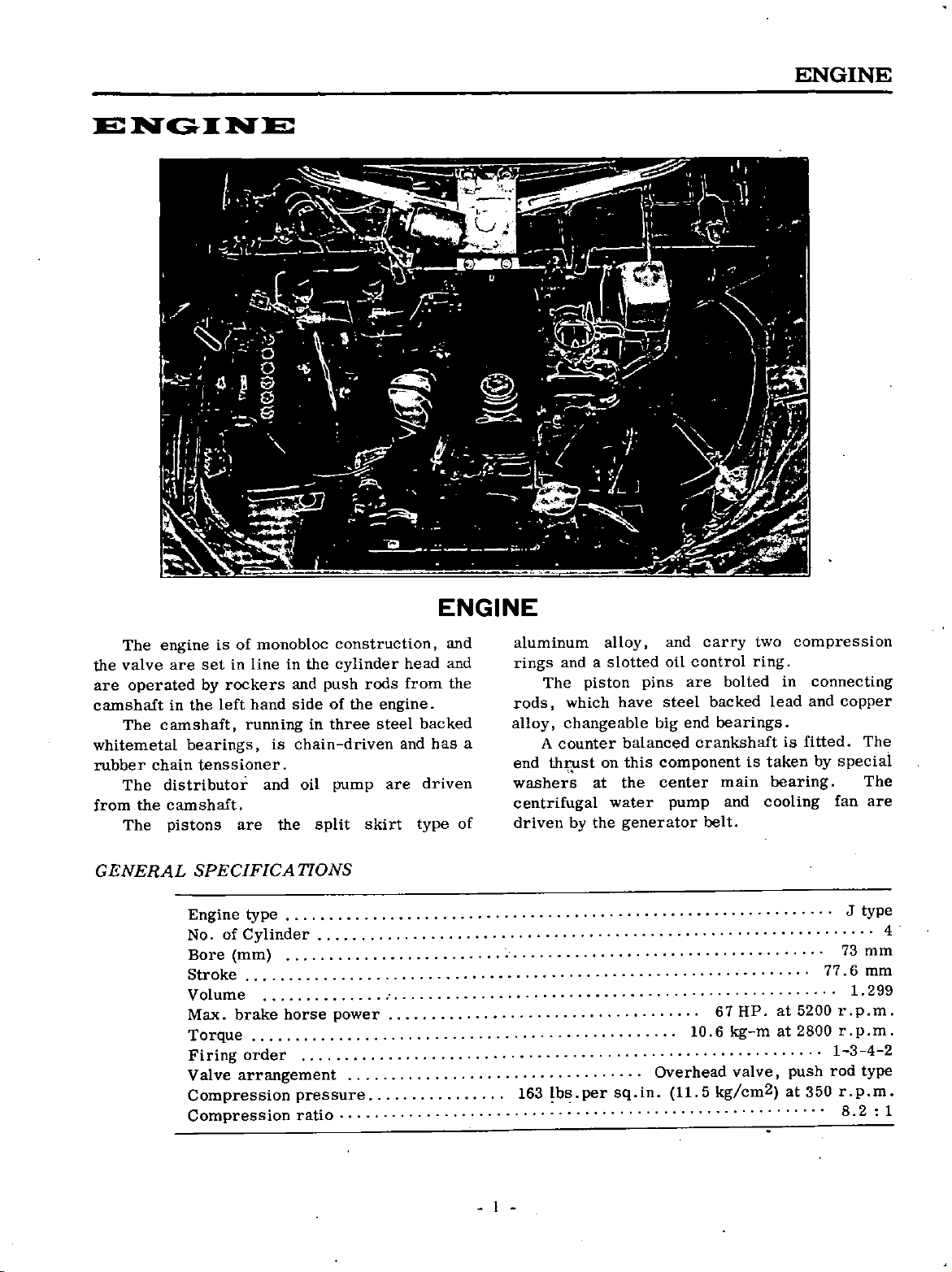

ENGINE

ENGINE

The

the

valve

are

operated

camshaft

The

whitemetal

rubber

The

the

from

The

GENERAL

engine

are

in

camshaft

chain

distributor

camshaft

pistons

is

of

in

set

rockers

by

the

left

running

bearings

tenssioner

are

SPECIFICA

Engine

No

Bore

Stroke

Volume

Max

of

Cylinder

mm

brake

type

Torque

Firing

Valve

order

arrangement

Compression

Compression

monobloc

line

hand

is

and

the

in

and

side

chain

horse

the

in

oil

split

TlONS

pressure

ratio

construction

cylinder

push

of

the

three

driven

pump

power

rods

steel

skirt

head

from

engine

and

are

ENGINE

and

and

the

backed

has

driven

type

pins

have

big

balanced

this

the

generator

and

carry

oil

control

are

steel

end

crankshaft

component

center

pump

belt

10 6

aluminum

rings

The

rods

alloy

a

A

end

washers

centrifugal

of

driven

alloy

and

a

slotted

piston

which

changeable

counter

on

thr

ust

at

water

the

by

Overhead

in

11

163

lbs

per

sq

5

bolted

backed

bearings

main

and

67

HP

kg

valve

kg

ring

is

cm2

two

lead

taken

bearing

cooling

m

compression

in

connecting

and

is

fitted

at

5200

at

2800

push

at

350

by

special

fan

77

r

r

1

rod

r

copper

J

73

6

1

p

p

3 4 2

p

821

The

The

are

type

4

mm

mm

299

m

m

type

m

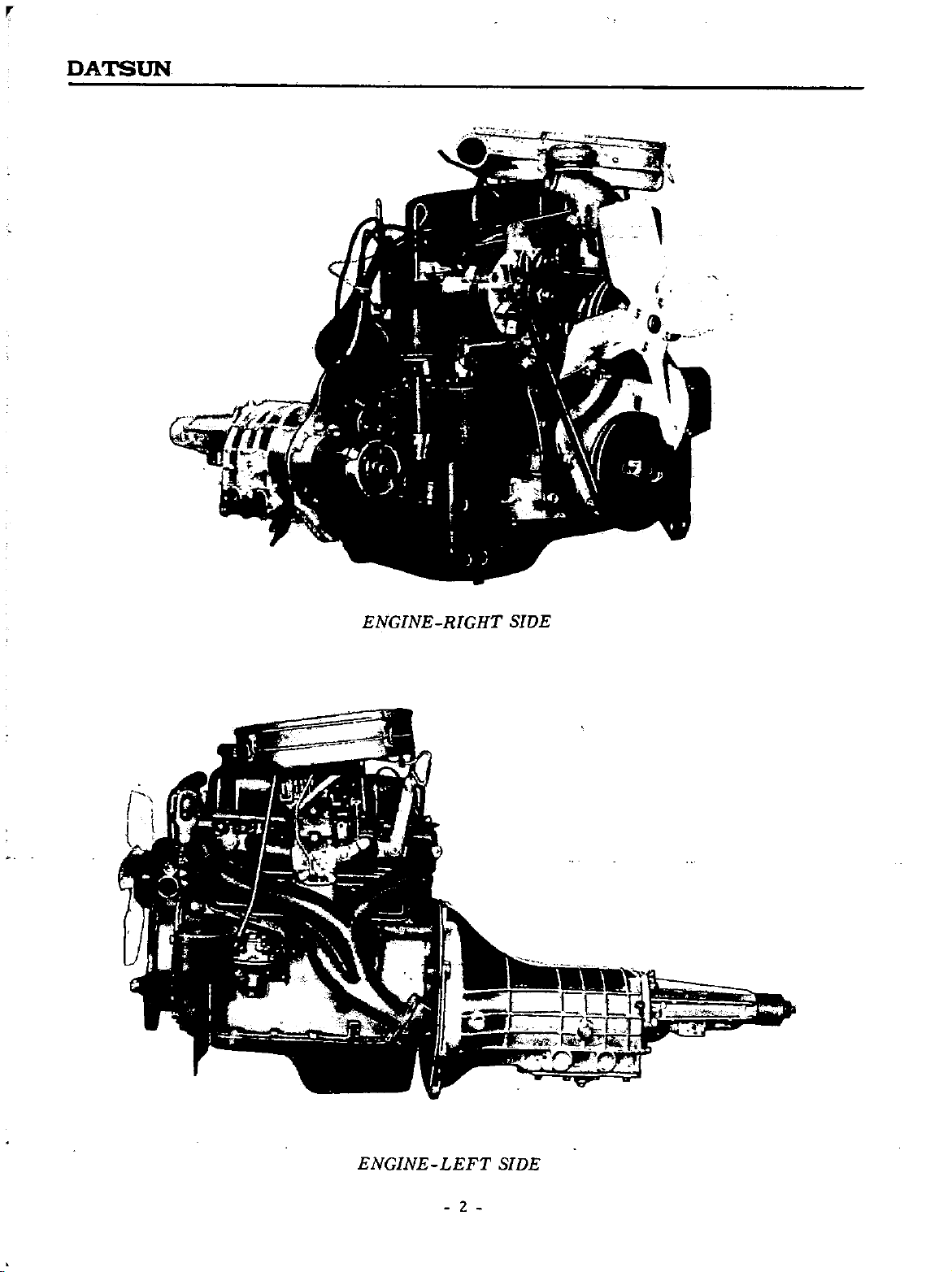

DATSUN

j

f

St

J

ENGINE

RIGHT

SIDE

ENGINE

LEFT

SIDE

2

ENGINE

COOLING

SYSTEM

f

J

I

I

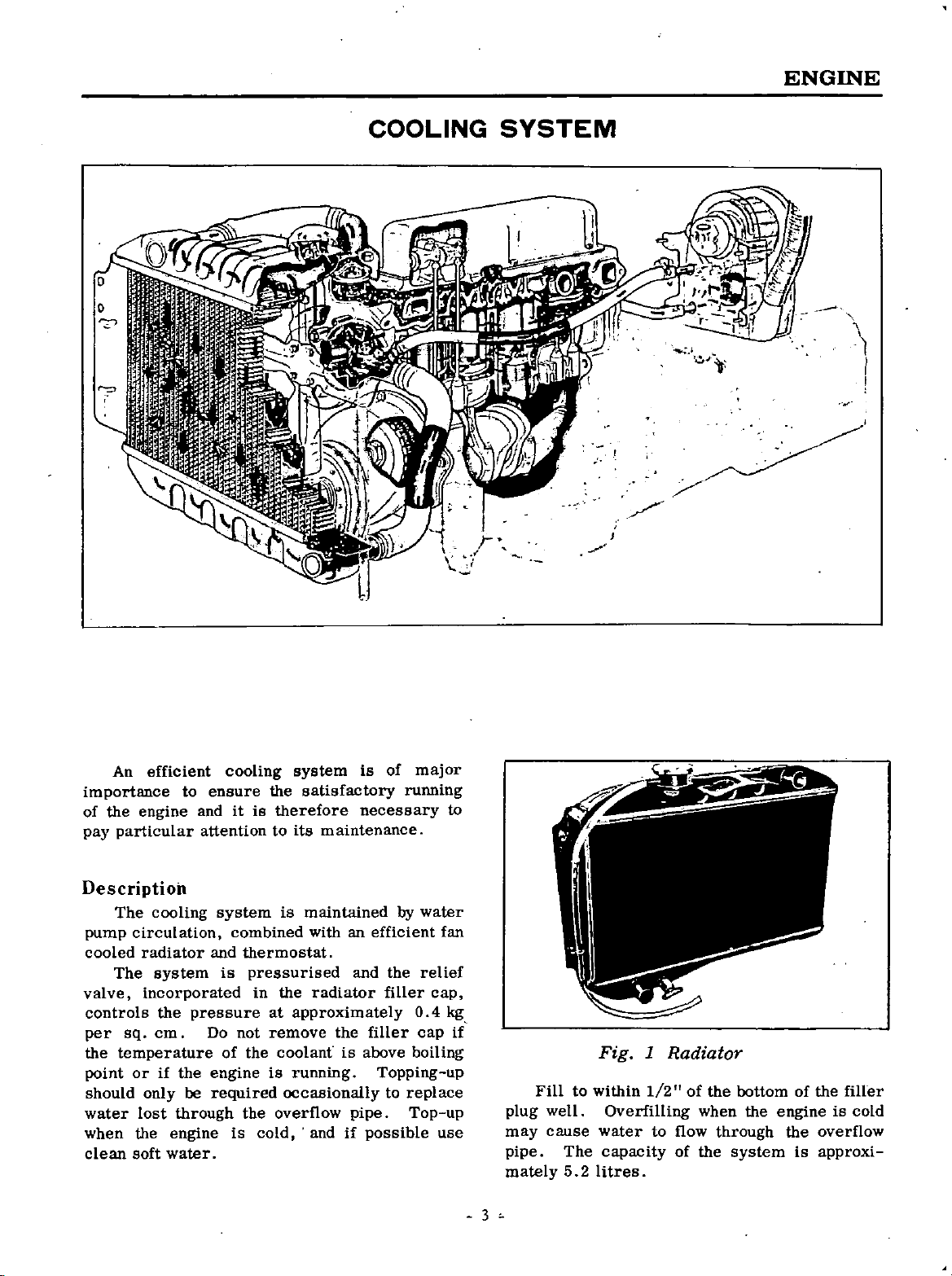

An

efficient

importance

of

the

engine

particular

pay

Description

The

circulation

pump

cooled

valve

controls

per

the

point

should

water

when

clean

radiator

The

incorporated

sq

temperature

or

only

lost

the

soft

cooling

to

enBure

and

it

attention

cooling system

combined

thermostat

and

pressure

the

be

through

is

Do

not

of

engine

required

is

the

the

system

the

cm

if

engine

water

BYBtem

the

satisfactory

iB

therefore

to

its

iB

pressurised

the

in

at

approximately

remove

coolant

iB

running

occasionally

overflow

cold

maintenance

maintained

with

radiator

the

is

and

if

is

necessary

an

efficient

and

filler

above

pipe

possible

of

running

by

the

filler

Topping

to

replace

Top

major

water

relief

cap

0 4

cap

boiling

use

fan

kg

up

up

to

if

1

1

to

Radiator

2

of

flow

of

the

when

the

bottom

the

through

system

of

engine

the

is

the

is

overflow

approxi

filler

cold

3

plug

may

pipe

mately

Fill

well

cause

to

The

5 2

Fig

within

Overfilling

water

capacity

litres

DATSUN

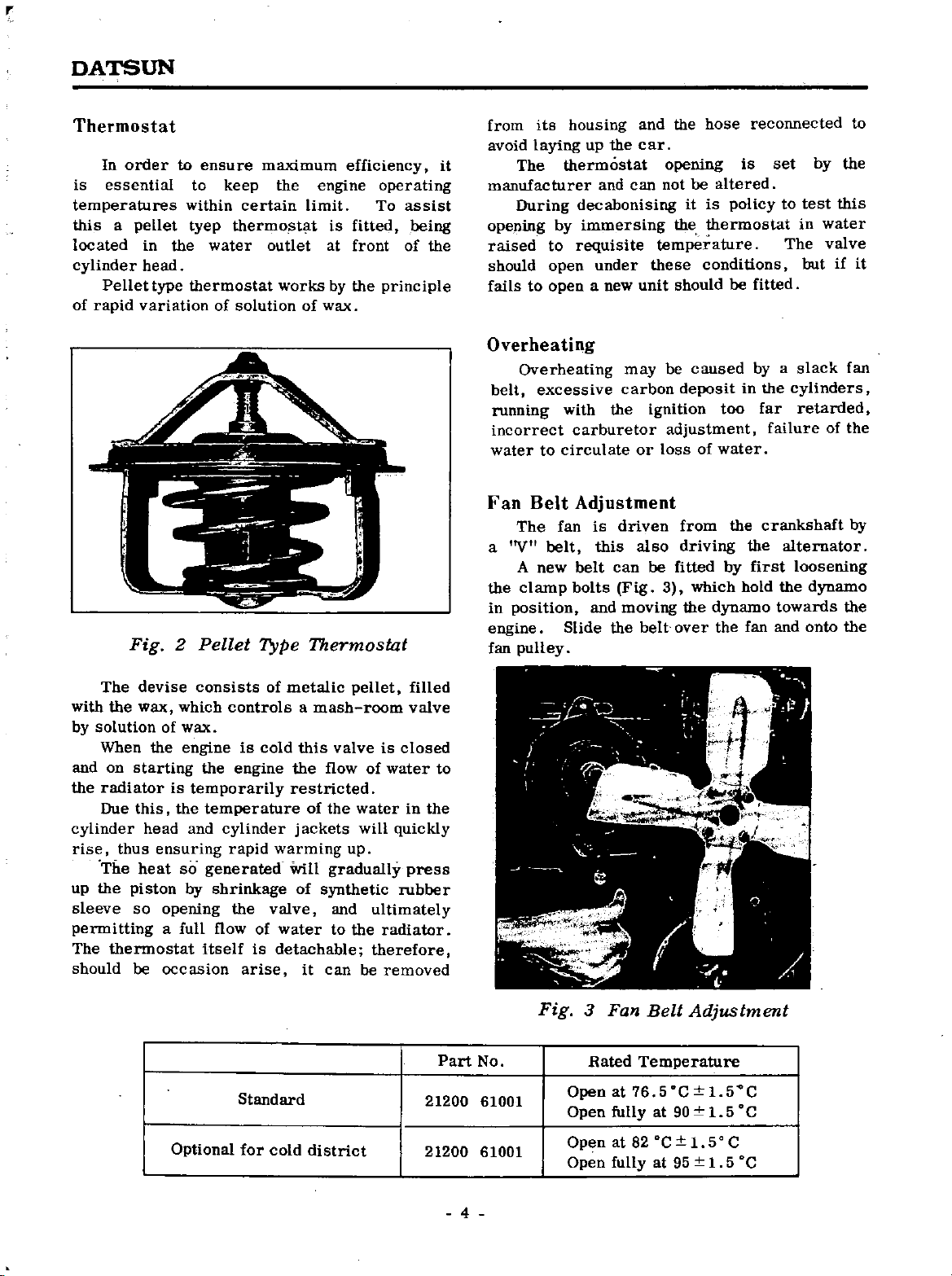

Thermostat

In

order

is

essential

temperatures

this

a

located

cylinder

Pellet

of

rapid

pellet

in

head

variation

Fig

type

to

within

the

2

ensure

to

tyep

water

thermostat

of

Pellet

keep

certain

thermostat

solution

maximum

the

outlet

works

Type

efficiency

engine

limit

is

at

by

of

wax

Thermostat

fitted

front

the

operating

To

assist

being

of

principle

the

it

its

from

avoid

laying

The

manufacturer

During

opening by

raised

should

fails

to

open

to

open

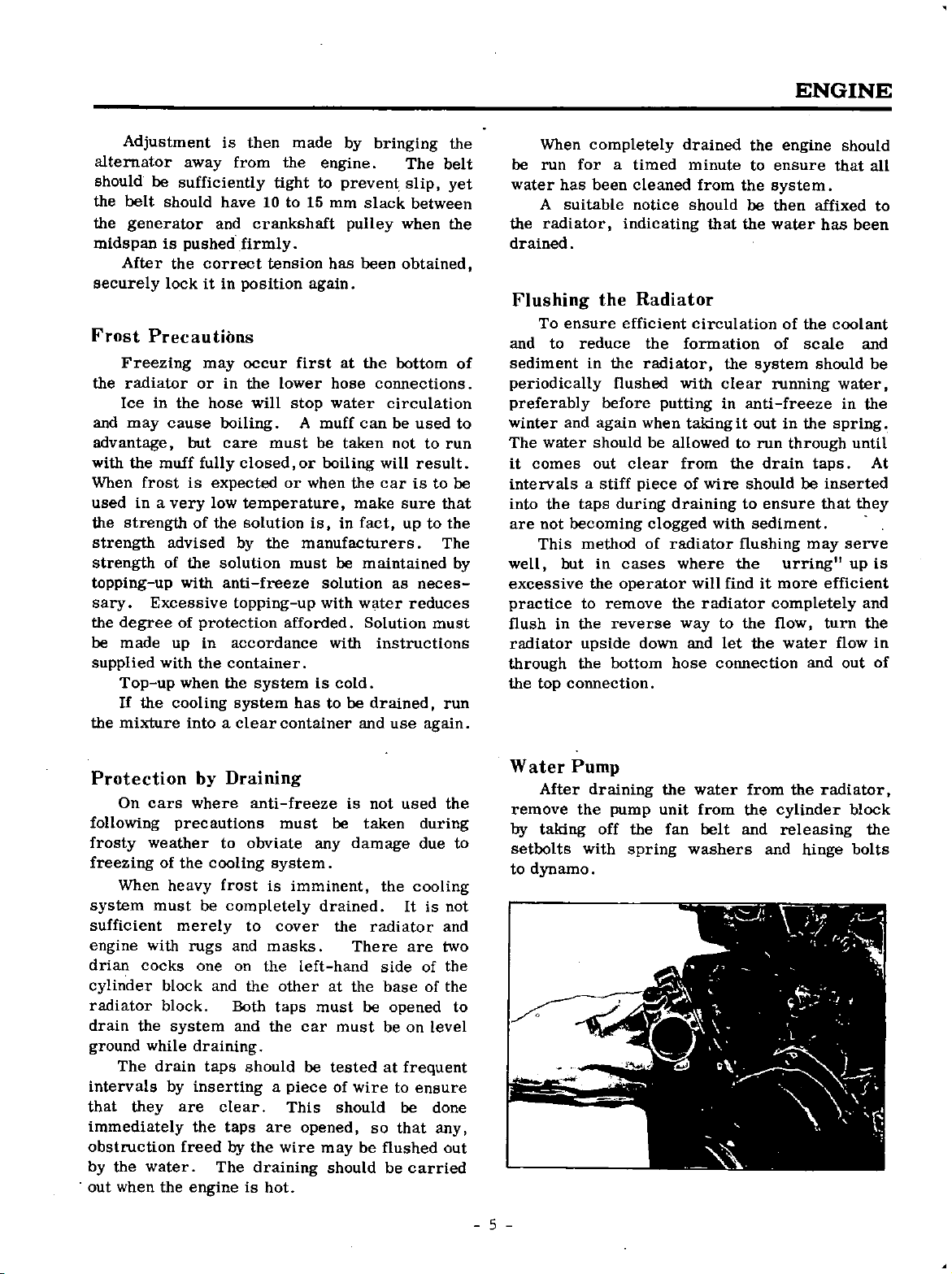

Overheating

Overheating

excessive

belt

to

Belt

The

V

A

new

clamp

pulley

with

circulate

fan

belt

running

incorrect

water

Fan

a

the

in

position

engine

fan

housing

the

up

thennostat

and

decabonising

immersing

requisite

under

a

new

carbon

the

carburetor

Adjustment

is

driven from

this

belt

can

bolts

Fig

and

moving

Slide

the

and

car

can

unit

may

ignition

or

also

be

belt

the

opening

be

not

it

the

temperature

these

should

be

caused

deposit

adjustment

of

loss

driving

fitted

which

3

the

over

hose

altered

is

policy

thennostat

conditions

be

too

water

the

by

dynamo

the

reconnected

is

set

fitted

a

by

the

in

far

failure

crankshaft

the

first

the

hold

towards

fan

and

by

test

to

in

The

but

slack

cylinders

retarded

alternator

loosening

dynamo

onto

water

valve

if

of

to

the

this

it

fan

the

by

the

the

The

with

the

solution

by

When

and

on

the

radiator

Due

cylinder

rise

The

the

up

sleeve

pennitting

The

thennostat

should

starting

thus

piston

so

be

devise

wax

the

this

head

heat

which

of

wax

engine

is

temporarily

the

and

ensuring

so

by

opening

a

full

occasion

Optional

consists

controls

the

engine

temperature

cylinder

rapid

generated

shrinkage

the

flow

itself

of

is

cold

valve

of

is

arise

Standard

for

cold

metalic

a

mash

this

the

restricted

of

jackets

warming

will

of

water

detachable

it

district

pellet

valve

flow

the

water

up

gradually

synthetic

and

to

the

can

room

is

of

water

will

quickly

ultimately

radiator

therefore

be

removed

filled

valve

closed

in

press

rubber

to

the

Part

21200

21200

No

61001

61001

Fig

3

Open

Open

Open

Open

Rated

Fall

at

fully

at

fully

76

82Ct

Belt

AdjustmeTlt

Temperature

5

C

t

at

90

t

1

t

at

95

5

1

15C

5

C

1

5

C

C

4

Adjustment

alternator

Bhould

the

belt

the

generator

midspan

After

securely

Frost

Freezing

the

radiator

Ice

and

may

advantage

with

the

When

used

the

strength

strength

topping

sary

the

be

supplied

the

frost

in

strength

degree

made

Top

the

If

mixture

away

be

sufficiently

should

is

pushed

the

correct

it in

lock

Precautions

may

or

in

the

cause

but

muff

fully

is

a

very

of

advised

of

the

with

up

Excessive

of

protection

in

up

with

the

when

up

cooling

into

is

then

from

have

and

firmly

position

occur

in

the

hose

boiling

care

closed

expected

low

temperature

the

solution

by

solution

anti

topping

accordance

container

the

system

a

clear

the

tight

10

to

crankshaft

tension

lower

will

must

or

the

must

freeze

afforded

system

container

made

engine

to

15

mm

has

again

first

hOBe

water

stop

A

muff

be

or

boiling

when

is

manufacturers

be

solution

with

up

with

is

cold

has

to

by

prevent

pulley

been

at

can

taken

the

make

in

fact

maintained

water

be

and

bringing

slack

the

connections

circulation

will

car

Solution

instructions

drained

use

The

slip

between

when

obtained

bottom

be

not

is

sure

up

as

reduces

used

to

result

to

neces

again

to

that

The

must

belt

yet

run

the

run

the

the

be

by

ENGINE

When

completely

be

water

the

run

has

A suitable

radiator

for

a

been

indicating

drained

ensure

to

and

becoming

but

in

connection

the

reduce

in

again

should

out

a

stiff

taps

method

in cases

the

to

the

upside

the

efficient

the

flushed

before

clear

during

operator

remove

reverse

bottom

Flushing

To

and

of

to

sediment

periodically

preferably

winter

The

water

it

comes

intervals

into

the

are

not

This

well

excessive

practice

flush

radiator

through

the

top

timed

cleaned

notice

Radiator

the

radiator

putting

when

be

piece

clogged

of

down

drained

minute

from

should

that

circulation

formation

with

taking

allowed

from

wire

of

draining

with

radiator

where the

will

the

radiator

to

way

and

hose

connection

the

clear

in

the

find

let

the

to

the

be

the

system

anti

it

out

to

run

drain

should

to

ensure

sediment

flushing

it

the

the

engine

ensure

system

then

affixed

water

has

the

of

of

scale

should

running

freeze

in

the

through

taps

be

that

may

urring

more

completely

flow

water

and

should

that

coolant

water

in

spring

inserted

serve

up

efficient

turn

flow

out

all

to

been

and

be

the

until

At

they

is

and

the

in

of

Protection

On

cars

following

frosty

weather

freezing

When

system

sufficient

engine

drian

with

cocks

cylinder

radiator

drain

the

ground

while

The

intervals

that

they

immediately

obstruction

water

the

by

out

when

precautions

of

the

heavy

must

merely

block

block

system

drain

by

are

freed

the

by

Draining

where

to

cooling

frost

be

completely

rugs

one

and

draining

taps

inserting

clear

the

taps

The

engine

and

on

Both

and

by

anti

obviate

system

is

to

cover

masks

the

the

taps

the

should

a

are

the

draining

is

hot

freeze

mUBt

any

imminent

drained

left

other at

must

car

be

piece

This

opened

wire

may

is not

be

the

hand

must

tested

of

should

should

taken

damage

the

radiator

There

side

the

base

be

be

at

wire

so

be

flushed

used

It

are

opened

on

frequent

to

be

that

be

carried

during

due

cooling

is not

of

of

level

enBure

done

any

the

and

two

the

the

out

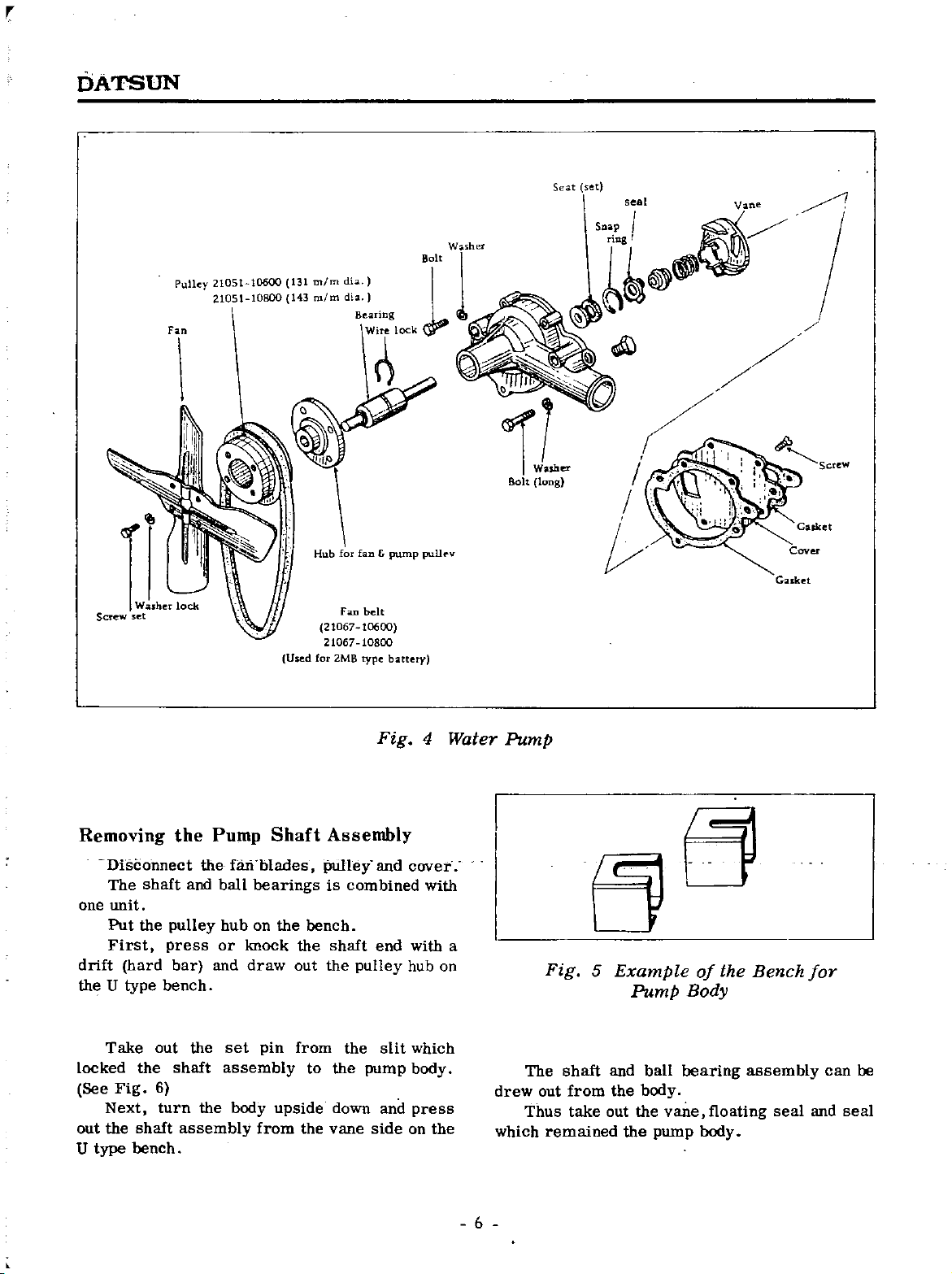

Water

remove

to

to

by

setbolts

to

5

After

taking

dynamo

Pump

draining

the

off

with

pump

the

spring

unit

the

fan

water

from

belt

washers

from

the

and

the

cylinder

releasing

and

radiator

hinge

block

the

bolts

r

DATSUN

set

Seat

n

v

Sn

r

h

Boh

m

Pulley

10600

21051

21051 10800

131

143

m

m m

db

dla

Beanng

k

t

wi

1lj

j

WA

lL

Bolt

long

L

Screw

Removing

Disconnect

The

unit

one

Put

the

First

drift

hard bar

the

U

type

shaft

the

pulley

press

bench

and

I

Pump

the

and

fan

ball

bub

or

knock the

draw

Used

Shaft

blades

bearings

on

the

out the

forfan

Hub

FOlD

21067 10600

21067 10800

for

2MB

Assembly

pulley

is

bench

shaft

belt

type

Fig

and

combined

end

pulley

pump

battery

cover

with

hub

pullf

4

with

Water

on

v

Gasket

Pump

5Jtj

a

Fig

5

Example

Pump

of

Body

the

Bench

for

locked

See

out

U

type

Take

Fig

Next

the

the

shaft

bench

out

6

turn

the

shaft

the

assembly

set

pin

assembly

body

from

from

upside

the

the

slit

which

to

the

down

vane

pump

side

and

body

press

on

the

6

drew

which

The

Thus

shaft

out

from

remained

take

out

and

the

the

ball

body

the

vane

pump

bearing

floating

body

aBsembly

seal

and

can

be

seal

ENGINE

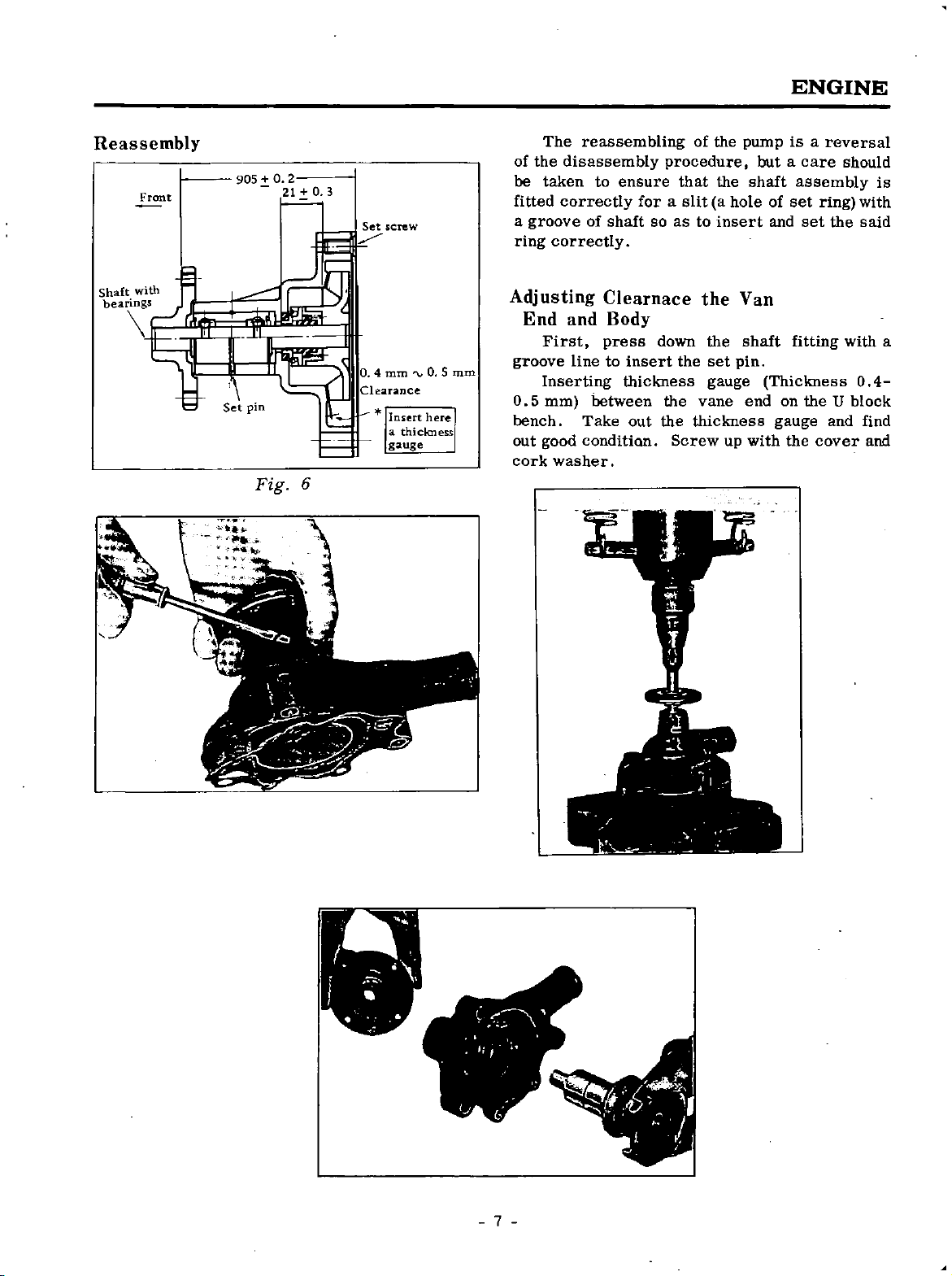

Reassembly

Front

with

Shaft

bearings

905

0 2

The

reassembling

the

of

disassembly

taken

O 3

21

screw

Set

be

fitted

a

groove

to

correctly

of

ensure

foraslit

shaft

procedure

that

so as

of

the

the

a

hole

to

insert

pump

shaft

but

of

and

is

a

a

care

assembly

set

ring

set

reversal

should

the

is

with

said

ring correctly

and

line to

between

Take

condition

Clearnace

Body

press

insert

thiclmess

out

Adjusting

End

First

mm

O

5

0 4

Clearance

Set

pin

Fig

6

Insert

a

gauge

thickness

mm

here

groove

o 5

bench

out

cork

Inserting

mm

good

washer

down

the

the

the

Screw

the

the

set

gauge

vane

thiclmess

up

Van

pin

shaft

end

with

fitting

Thiclmess

on

gauge

the

with

0 4

theUblock

and

find

cover

a

and

7

r

DATSUN

Circulatiol

Pressure

unit

and

oil

pump

hand

the

camshaft

The

is

and

relief

oil

pump

side

delivered

valve

is

oil

lubrication

provided

The

of

the

gear

is

drawn

which

by

oil

pump

crankcase

by

through

is

a

into

is

an

ecentric

is

short

the

internal

situated

used

bolted

and

vertical

pump

throughout

non

into

is

driven from

via

oilways

the

at

LUBRICA

draining

the

shaft

the

filter

to

cover

left

the

the

TION

full

of

holes

element

The

in

the

into

the

oil

cartridge

the

annular

enters

pipe

only

center

pan

the

on

drained

2000

oil

engine

miles

pan

is

escape

Oil

new

mileB

is

sealed

pipe

and

and

5000

The

hot

This

space

oil

the

the

of

into

hollow

the

can

oil

Draining

The

oil

must

be

first

after

of

is

when

every

at

3000

the

the

readilY

the

the

connect

Before

and

filling

change

and

through

and

then

3000

as

oil

oil

the

passes

space

top

and

a

from

reconditioned

filled

Lan

Lan

oil

should

the

oil

with

pan

cartridge

element

round

bottom

small

this

and

The

will

through

with

at

be

new

the

hole

point

intervals

drain

flow

through

center

so

that

into

back

engines

new

plug

drained

more

oil

dis

the

oil

From

main

engine

oilways

bearings

The

block

lubricate

oil

the

from

gallery

lubricates

ings

the

front

the

camshaft

amount

during

lubric

From

hole

forms

filled

the

oil

gallery

The

to

through

connecting

and

the

via

pan

the

on

As

journal

of

case

ation

the

timing

back

to

part

with

oil

relief

the

the

rockers

the

center

the

the

the

camshaft

thrust

oil

to

revolution

for

the

of

the

under

on

flow

main

ends

rear

left

tappets

pass

the

case

oil

main

Fig

valve

the

then

drillings

are

rocker

push

camshaft

hand

register

plate

timing

the

pan

pressure

right

big

drilling

and

rod

through

rotates

into

of

the

oil

1

the

passes

end and

in

then

apertures

side

with

thus

the

camshaft

chain

oil

The

gallery

oil

hand

shaft

drains

bearing

of

individual

allowing

timing

and

returns

passes

via

the

in

the

two

a

filter

and

side

connecting

crankshaft

the

bracket

engine

grooves

small

case

to

gears

via

therefore

as

into

of

camshaft

cylinder

back

The

enters

drill

hole

a

small

twice

provide

a

drain

such

into

the

the

oil

and

Oil

Pressure

oil

The

lb

sq

road

speeds

0

7

kg

idling

considerably

should

the

following

a

That

to

a

in

in

b

c

That

pressure

ances

readily

particularly

grade

That

not

becomes

This

gauge

bearings

the

lubrication

oil

pressure

is

the

pressure

in

cm2

New

there

there

of

the

choked

the

will

as

are

pressure

2

1

whilst

should

engines

higher

beanoticeable

points

is

in

oil

strainer

with

bearings

have

excessive

from

more

cause a

compared

in

good

system

when

drops

cm2

kg

approximately

be

should

a

good

the

oil

in

sludge

the

the

the

when

fluid

with

order

starting

as

should

readings

to

sides

drop

on

shown

with

pan

the

correct

oil

the

deals

the

be

supply

which

that

from

not

the

when

new

drop

checked

oil

will

of

oil

in

The

with

oil

drop

gauge

10

the

oil

at

of

pan

oil

working

escape

the

is

preBsure

shown

relief

any

cold

becomes

at

lb

low

in

pressure

the

is

is

fed

bearings

warm

excessive

below

normal

engine

will

speeds

correct

clean

clear

on

when

valve

When

sq

under

more

more

30

in

is

give

and

and

the

the

in

hot

fluid

8

ENGINE

Check

Check

means

If

the

warning

sump

strainer

with

sludge

the

strainer

pump

rectify

Removing

A

after

first

10

000

The

the

engine

in

the

container

hand

by

sealing

The

cartridge

cylinder

system

bore

tensioner

The

If

the

starting

for

Low

the

of

the

switch

in

the

union

being

the

fault

the

new

filter

2000

km

after

forms

Take

ring

filtered

is

block

crankshaft

locker

and

oil

filter

temperature

oil

viscosity

level

dip

light

off

sump

sale

defective

Filter

miles

this

part

The

as

sent

delivered

arm

finally

Oil

of

stick

is

and

that

on

cartridge

of

element

unit

a

care

in

oil

to

journal

camshaft

is

provided

of

Pressure

oil

in

and

still

on

ascertain

is

clean

air

no

suction

the

remove

3000

the

of

it

not

the

the

oil

to

returned

lublicant

is

high

the

engine

top

upifnecessary

after

that

and

leakage

should

kIn

main

oil

filter

can

easily

to

lose

element

paasage

all

crank

journal

to

with

or

side

and

oil

the

a

oil

if

refilling

not

the

be

gallery

the

lubrication

pin

the

relief

the

sump

the

chocked

existB

of

unit

changed

then

is

removed

of

cylinder

and

oil

is

filtration

gauge

the

every

sealed

rubber

filter

in

chain

valve

low

pan

the

and

the

resistance

by

caused

opened

Removing

at

oil

of

The

and

oil

Remove

inserted

flange

the

of

engine

washers

Removing

With

remove

drawn

unto

pump

The

purpose

bell

into

the

and

its

by

with

sump

replace

from

and

housing

taking

in

the

the

the

union

unscrew

Btrainer

by

of

pressure

the

the

the

the

the

choke

Oil

capacity

the

set

the

the

lower

care

process

Strainer

snup

oil

strainer

oil

connecting

may

removing

oil

drain

underside

lowered

pump

the

filter

the

up

difference

Pan

is31

plug

screw

bolts

Lower

not

to

To

Becuring

be

dismantled

the delivery

element

relief

litres

bolts

from

the

damage

it

through

remove

the

of

the

oil

iB

oil

bolts

valve

to

the

pan

which

pick

is

bypass

Drain

which

securing

bottom

from

the

pOBsible

the

strainer

up

for

cleaning

pipe

will

flange

large

oil

edge

joint

oil

to

be

the

are

the

to

is

the

bolts

cover

Notice

which

that

must

there

be

are

positioned

the

dowel

correctly

pins

to

the

when

refitting

at

Element

Flemfilt

To

blode

Cyl

Relief

alve

I

embly

oil

filter

idge

Fig

2

Oil

Filter

9

r

DATsUN

the

the

five

are

crankcaBe

the

pump

Oil

oil

form

bolts

long

Pump

pan

With

and

securing

enough

Fig

Unscrew

its

pick

drive

to

3

illustrates

the

the

up

Becure

Bhaft

strainer

oil

long

pump

bolts

the

the

the

cover

inner

rotor

with

Refitting

Clean

care

the

before

particular

faces

joint

material

if

it

necessary

used

again

fit

a

new

grease

into

position

flange

rotor

refitting

one

and

tighting

slide

the

out

to

attention

and

Examine

if it

fit

On

with

the

remove

the

and

tilting

out

Pump

the

remove

is

Smear

them

its

sump

The

joint

insert

drive

any

oil

to

the

sound

up

the

by

washing

traces

pan

the

oil

any

joint

oil

faces

the

washer

the

evenly

body

shaft

to

pan

traces

joint

but

setscrews

upside

the

washer

it

of

and

it

of

engine

and

nf

washer

iB

the

Lift

down

the

in

paraffin

the

paraffin

crankcase

oil

jointing

and

advisable

joint

the

into

can

oil

the

outer

Pay

renew

be

to

With

pan

the

Removing

Remove

Three

bottom

pump

pump

and

of

to

in

remove

the

cover

the

explosed

Dismantling

Remove

which

secure

the

the

the

setscrews

I

j

1

o

cover

r

n

Jl

Fig

Oil

f

11

i

j

3

Pump

to

I

the

and

spring

body

and

washers

take

the

Reassembling

The

outer

rotor

of

great

important

the

base

will

way

Insert

body

off

and

the

of

result

slotted

bring

the

body

the

Oil

Pump

haB

a

chamfered

that

this

chamber

failure

in

the

end

of

rotors

cover

the

into

to

is

drive

meBh

edge

be

assemble

tightened

Bhatt

towards

in

down

into

It

is

this

the

r

Fig

l

4

Oil

Pump

10

ENGINE

SERVICE

ENGINE

Nut

the

on

and

Slacken

the

the

the

type

in

nut

pulley

Pulley

fan

starting

starting

an

the

belt

spanner

anti

Removing

Remove

attachment

1

locking

by

using

A

direction

Pull

Bend

washer

few

back

Heavy

will

off

Starting

the

bolts

the

duty

sharp

slackent

the

crankshaft

radiator

and

Unscrew

blows

remove

tab

Shock

OPERATION

dynamo

nut

dog

nut

dog

clockwise

IN

POSITION

The

the

bolt

heads

Take

cover

not

joint

to

and

damage

If

cleaning

beforehand

Removing

spring

out

its

damage

of

the

WITH

washers

the

joint

the

the

Timing

set

washer

does

faces

screw

washer

are

occur

of

Gear

immediately

bolts

Care

should

when

fit

the

joint

breaking

a

new

remove

below

be

taken

washer

surfaces

the

the

Removing

The

bolts

each

special

washer

to

the

timing

J

plain

is

timing

of

the

having

washer

elongated

cover

Fig

Timing

cover

a

flange

Fig

1

Cover

is

secured

shakeproof

Note

shape

2

and

that

washer

is

by

the

fitted

set

screw

and

special

next

3

Fig

The

timing

necessary

a

camshaft

notice

the

gears

timing

relationship

Draw

first

taken

behind

shaft

tensioner

a

chain

renew

Refitting

removing

As

not

the

gear

drive

it

the

if

off

to

crankshaft

teeth

oil

the

Replacing

is

largely

but

following

a

special

points

to

remove

to

both

the

gears

lose

and

has

the

reversal

attention

chain

together

marks

each

other

the

crankshaft

are

the

is

a

ensures

Examine

been

Timing

componentB

gears

gear

rubber

of

is

bOth

on

withdrawn

packing

silent

the

lost

be

Gear

the

dismantling

should

endless

the

Before

both

a

gear

Between

ring

felt

seepage

of

crankshaft

gears

little

retaining

care

washers

which

operation

washer

the

timing

be

paid

doing

it

and

and

their

atatime

must

from

the

cam

acts

of

gear

process

to

is

and

this

nut

be

as

the

and

the

11

DATSUN

Fit

their

respective

marks

Turn

is

at

T

in

approximately

Place

the

keys

Ensure

opposite

home

gears

The

from

replaced

been

fitted

faces

gear

feeler

be

neceBsary

wash

Fit

so

gear

front

of

is in

pOBition

the

are

the

D

are

that

to

Bame

behind

gauge

the

that

the

crankshaft

opposite

C

the

the

each

unless

and

oil

car

engine

and

gears

present

number

the

In

measuring

To

to

thrower

its

shafts

and

the

the

timing

other

new

a

this

adjust

vary

Concave

and

camshaft

and

in

line

crankshaft

camshaft

clock

one

o

into

position ensuring

in

keyways

marks

in

and

of

packing

crankshaft

crank

caBe

the

the

the

the

number

behind

face

check

that

Ensure

until

with

poBition

on

line

gear

or

alignment

alignment

alignment

it

the

the

on

the

washers

camshaft

the

towards

felt

gears

the

timing

keyway

its

keyway

the

shafts

gears

Drive

must

of

with

it

of

packing

crankshaft

waBher

into

that

taken

has

will

are

the

the

the

four

to

into

rocker

with

assembly

plate

and

of

the

find

the

and

It

is

necessary

slacken

the

cylinder

distonation

its

cylinders

stud

unscrew

remove

be

brackets

Dismantling

a

Assembly

first

from

rocker

If

way

Notice

nut

To

remove

the

the

head

the

the

dismantle

cylinder

cylinder

may

from

and

that

is

a

the

and

rear

shaft

pump

under

special

rocker

rocker

rockers

the

the

rocker

fixing

result

the

grob

to

head

head

cooling

the

locking

shaft

assembly

Rocker

the

bracket

nust

and

righi

rocker

screw

drain

nuts

nuts

are

allow

Bystem

plate

blacket

Shaft

and

the

because

also

hand

Complete

shaft

system

secure

not

siackened

water

rear

Completely

nuts

locking

ROCKER

Valve

nuts

Remove

washer

Rocker

Remove

securing

Removing

Drain

inuse

UBe

the

the

the

the

rocker

the

cooling

clean

MECHANISM

Cover

air

engine

Rocker

Fig

Removal

cleaner

lifting

cover

sYBtem

container

4

Unscrew

brackets

and

Assembly

If

for

the

anti

the

cork

the

freeze

fluid

cap

joint

5

Fig

is

Remove

spring

Slide

the

shaft

shaft

The

without

out

hand

by

ition

pos

Unlock

it

back

Withdraw

waBher

Sometimes

slightly

underNo

the

and

This

the

washers

rockers

Unscrew

clean

two

end

the

whole

may

until

the

as

far

and

slide

compressed

2

rocker

No

as

the

Bplit

from

out

be

tappet

it

the

Cylinder

pins

brackets

the

plug

the

oil

rockers

rocker

achived

1

push

adjuBting

will

go

Bplit pin

the

rocker

valve

by

thus

each

levering

allowing

Head

flat

end

and

from

way

may

assembly

turning

by

rod

reacher

screw

flat

spring

washers

of

Bprings

the

be

off

will

a

the

the

end

dismantled

being

the

engine

its

lowest

and

and

the

have

Bcrewdriver

end

rocker

and

shaft

from

of

the

drawn

screw

Bpring

shaft

to

be

12

ENGINE

to

slide

procedure

off

for

Reassembling

On

reassembly

bracket

3

and

4

bracket

are

all

completely

holes

reamed

shaft

nuts

so

securing

diagonally

pedestal

No

No

they

been

oil

the

bushes

on

the

from

No

on

tight

will

the

the

a

and

shaft

8

rocker

Fig

tighten

little

nut

right

returning

repeating

stripped

have

down

Rocker

6

to

the

If

to

to

easily

at

nut

nut

size

the

from

rocker

down

be

pedestal

a

left

of

the

redrilled

before

time

nut

No

the

process

assembly

and

Repeat

working

of

2

left

rebushed

assembly

bracket

No

left

nut

and

until

has

the

the

screw

split

rocker

and

Replace

pins

cover

lock

on

o

the

the

and

plate

spring

ends

gasket

flat

shaft

washers

with

Replace

the

the

and

the

of

s

0

8

Fig

The

engine

1

cap

of

of

engine

rocker

found

wise

Push

Reassembling

vent

Secure

nuts

ensuring

lifting

cover

to

be

oil

leaks

Rod

pipe

gasket

faulty

will result

Removal

should

the

plates

they

that

cover

or

the

Cylinder

at

be

are

must

the

the

by

in

the

means

rubber

position

rubber

be

renewed

front

bushed

bushes

of

Head

of

the

If

other

the

two

and

the

are

The

their

Remember

rockers

original

to

Fig

and

pOBition

replace

7

spring

on

the

the

l

Ocker

must

ends

be

shaft

replaced

of

the

shaft

locating

the

If

been

rods

hand

removed

to

be

be

taken

valve

lifted

out

rocker

all

that

out

without

assembly

remainB

They

detaching

may

has

already

iB

for

the

push

the

the

other

rocker

on

aBsembly

Remove

Slacken

their

full

the

rocker

spring

the

push

All

in

this

after

the

the

shaft

in

13

the

here

reversal

ball

onwards

slide

but

way

ends

extent

shaft

rod

removal

When

of

the

all

the

the

end

the

These

register

reassembly

the

dismantling

air

cleaner

tappet

then

as

a

fulcrum

rocker

push

of

replacing

using

will

the

in

side

rods

have

two

push

the

and

adjusting

a

screwdriver

depress

ways

can

end

rodB

tappet

is

a

straight

process

to

rocker

be

be

rockerB

cups

screws

the

and

withdrawn

withdrawn

ensure

forward

cover

lift

to

with

valve

out

from

that

From

DATSUN

Adjusting

Remove

There

0

35

mm

the

base

clearances

with

a

screw

rod

cup

result

handle

valve

in

Turn

is

of

screw

to

until

fully

Valve

the

should

between

the

it

disperse

Failure

a

wrong

the

valve

is

driver

engine

the

closed

Rocker

air

cleaner

be

the

stem

important

the

to

reading

push

a

on

film

follow

over

Clearances

clearance

face

Whilst

to

the

of

being

rod

and

of

maintain

oil

this

by

StopB

rocker

the

tappet

from

procedure

taken

hand

of0014

rocker

checking

pressure

adjusting

the

starting

falling

cover

in

and

the

push

will

the

To

the

adjusting

Then

face

lower

or

clearance

Tighten

clearance

It

clearance

being

opposite

adjust

insert

of

the

is

adjusted

to

screw

0

rocker

the

adjusting

is

obtained

the

important

is

being

itB

Fig

014

must

peak

lock

a

slaken

valve

tappet

the

screw

gauge

until

and

that

back

9

insert

slot

and

in

feeler

and

the

screw

nut

to

note

set

the

be

on

the

Btem

recheck

of

driver

lock

between

the

while

the

of

the

in

nut

the

Raise

correct

the

the

valve

cam

Rocker

Rocker

Rocker

shaft

Length

OUter

inn

Outer

before

Inner

Reamer

dimension

mounting

Clearance

arm

Bore

Lever

diameter

bush

diameter

mounting

diameter

finished

ratio

after

9

Fig

356

15

19 01 19 04

15

o

19

1

85

89

01

012

43

Adjusting

4

15

15

0

19

the

Rocker

CYLINDER

Removing

88

mm

opening

Clearance

Drain water

the

HEAD

the

radiator

Cylinder

from

and

the

Head

cooling

cylinder

sYBtem

hlock

by

drain

cocks

One

is

the

should

situated

engine

be

for

mmo

90

mmo

the

side

use

and

radiator

of

it

retained

Disconnect

mm

05

battery

removing

037

mm

connecting

ing

14

Slacken

and

he

remove

extracting

the

both

the

lug

and

radiator

other

drained

future

the

from

the

the

inlet

If

negative

the

retaining

hose

anti

into

use

the

tube

at

hattery

to

the

freeze

a

tenninal

the

at

the

rear

suitable

cahle

terminal

clips

thennostat

backside

mixture

on

right

container

from

screw

the

of

hand

is in

the

and

post

hose

hous

ENGINE

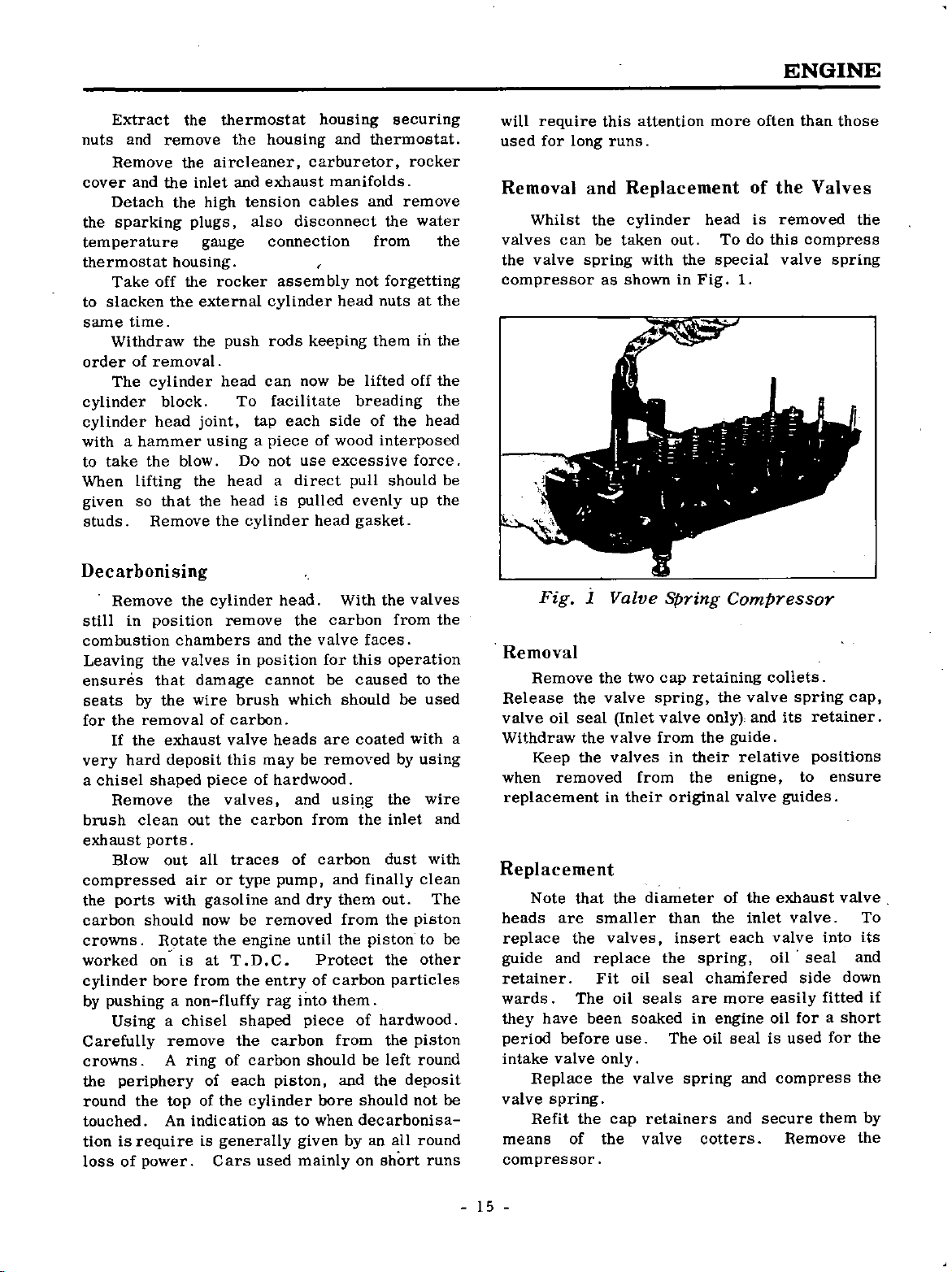

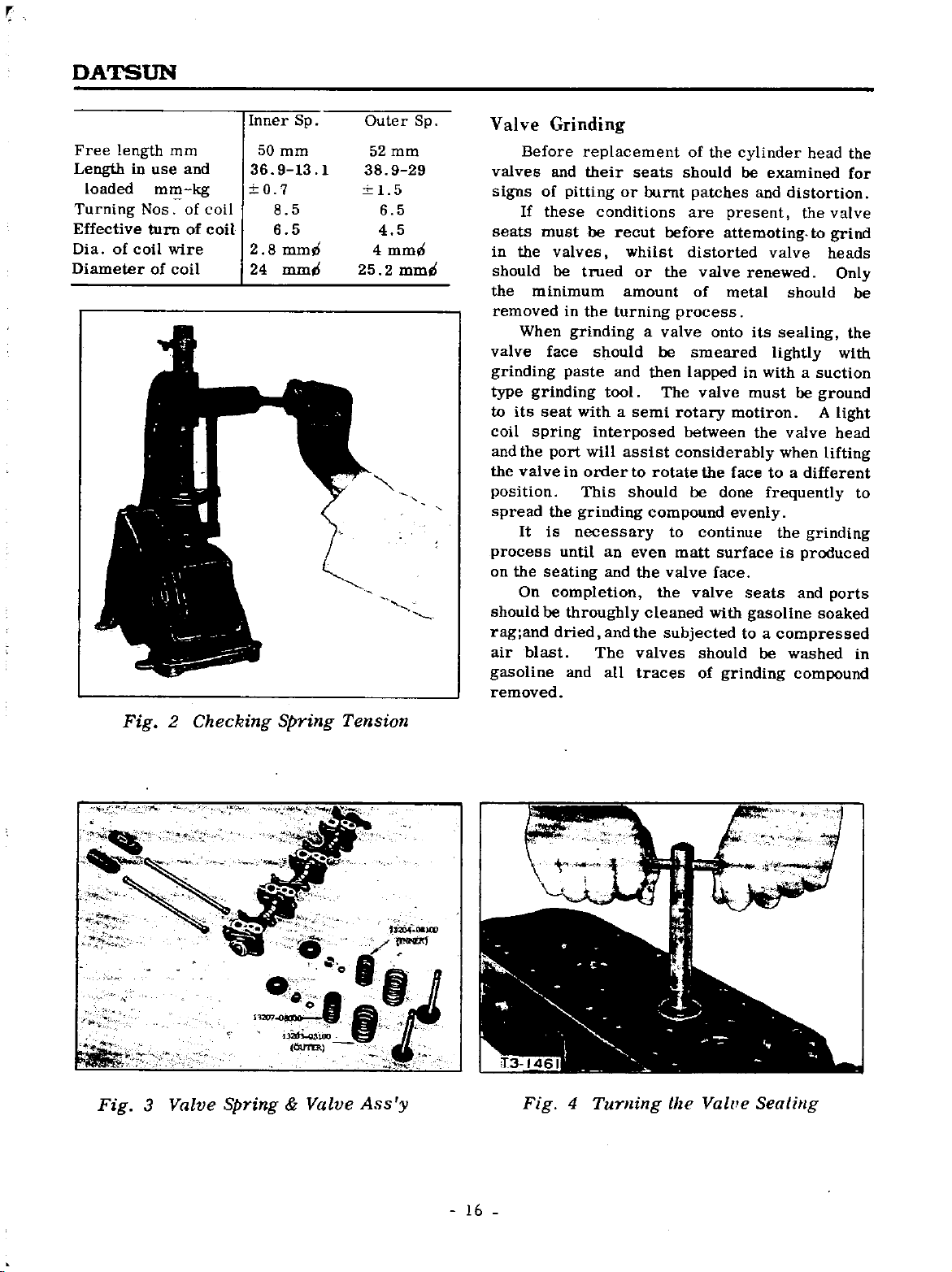

Extract

nuts

and

remove

Remove

and

cover

the

Detach

the

sparking

temperature

thermostat

off

Take

to

same

slacken

the

time

Withdraw

of

order

cylinder

cylinder

with

to

When

given

studs

The

take

a

removal

cylinder

head

hammer

the

lifting

so

Remove

block

that

Decarbonising

Remove

still

in

position

combustion

by

the

the

If

hard

Remove

clean

Blowout

ports

pushing

Using

periphery

the

is

require

of

the

that

the

removal

exhaust

deposit

shaped

ports

with

should