Nissan Bluebird Datsun 410 User Manual

h

r

1

SERVICE

MANUAL

r

to

f

DATSUN

J

MODEL

I

1

I

410

SERIES

f

4

4

w

A

A

ff

ty

l

rf

r

H

t

l

1

1

t

fr

J

4

1

f

r

i

1

l

r

NISSAN

OTEMACHI

NISSANI

MOTOR

BLDG

CAIUS

OTEMACHI

TOKYO

ADDRtSS

PHONES

JAPAN

211

NISMO

5281

1

CO

CHIYODA

TOKYO

9

LTD

KU

r

t

cr

11

r

t1f

r

jo

I

i

DlTSUI

BLUEBlRD

MODEL

P

0

41

L

Thls

DA

TSUN

mamtenance

major

manual

dlstnbutors

of

components

INTRODUCTION

has

been

comphes

and

dealers

the

Model

IS

P

descnbed

for

purpose

for

effective

L

410

In

detaIl

Each

In

of

serVlCe

assembly

addltlOn

asslstmg

of

com

and

the

IS

emphaslsed

be

used

mstructJOns

and

mspectlOn

as

replacements

prehenslve

assemblmg

It

shuuld

j

that

are

of

only

glven

these

genume

for

complete

assembhes

DA

TSUN

dl

manrlmg

Spare

Parts

i

SPECIFICA

TION

l

CONTENTS

I

t

t

I

Page

l

7

ENGINE

General

COOLING

LubrIcatlon

ServIce

Rocker

Removmg

OperatlOn

BRAKER

POINT

DistrIbutor

AdJustmg

FUEL

SYSTEM

Carburetor

The

Gasohne

Fuel

Fuel

Stramer

Pump

Adjustment

CLUTCH

TRANSMISSION

DIsassemble the

DIsassemble

r

FRONT

AXLE

Dlsassemblmg

Independent

PROPELLER

SpeclfIcatlons

SYSTEM

OperatIons

Mechamsm

Reflttmg

WIth

AND

the

and

the

1

Front

I

SHAFT

the

IGNITION

IgmtlOn

Tank

Inspectlon

TransmIssIon

TransmIssIon

the

SUSpenSIon

WIth

Engme

Engme

Tlmmg

Front

UNIVERSAL

Hub

Removed

TIMING

of

Engme

Case

Case

JOINTS

m

PosltlOn

ADJUSlMENT

For

4

Stage

Floor

1

1

3

10

16

20

34

37

42

42

44

r

Jf

1

48

48

r

i

ijf

1

55

59

60

65

4

r

1

170

i

t

h

8

I

lf

82

Slnft

f

4b

1

125

100

no

ll

lq

c

l

t

i

I

l

J

REAR

STEERING

Steermg

BRAKE

Front

Rear

Hand

AXLE

Brake

Brake

Brake

129

152

153

158

159

166

169

i

1

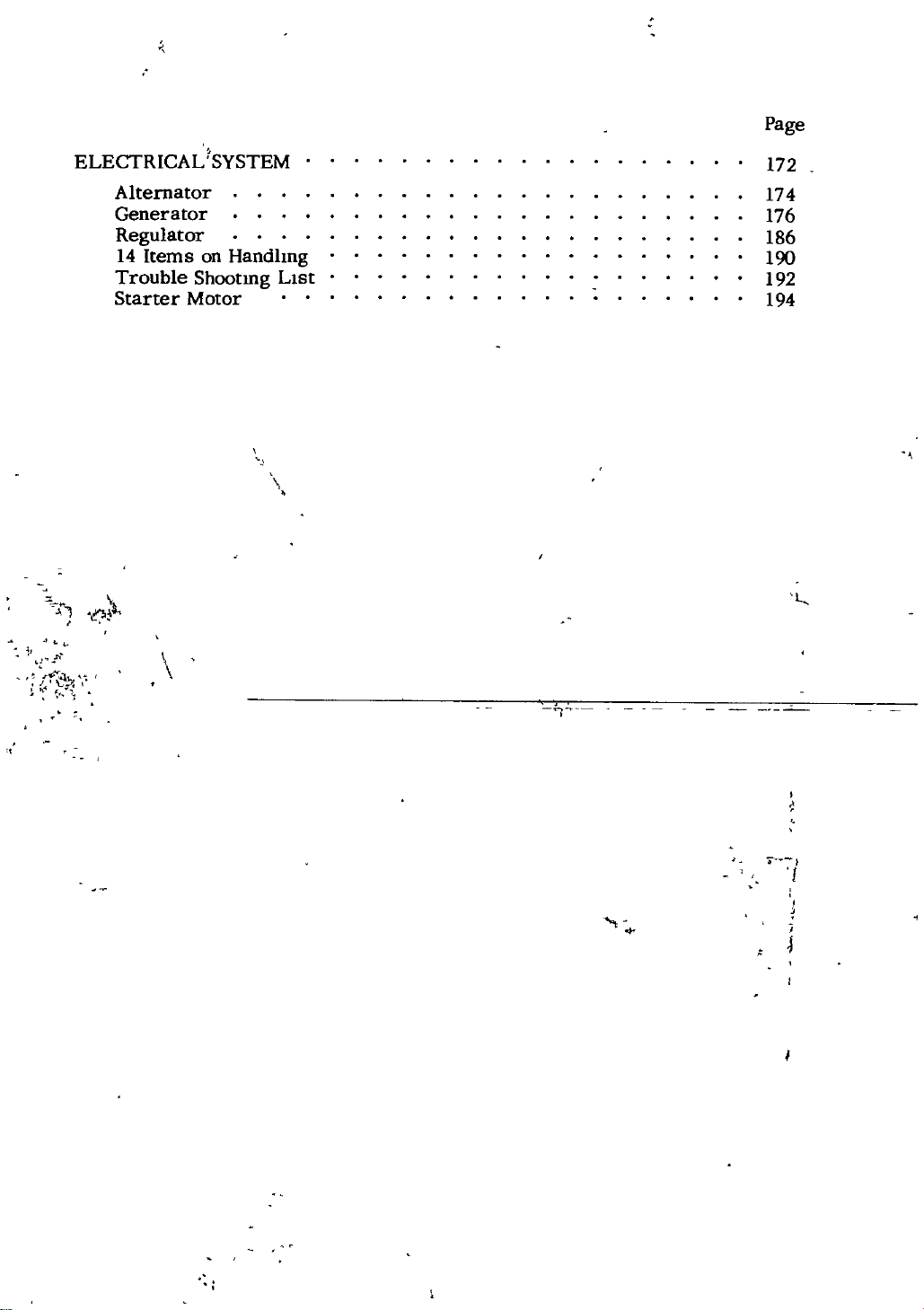

Page

ELECTRICAL

1

t

7

I

1

Alternator

Generator

Regulator

14

Trouble

Starter

l

n

Items

SYSTEM

on

Handhng

Shootmg

Motor

LIst

172

l74

l76

l86

190

192

194

1

I

J

5

P

ICIFICA

t

ION

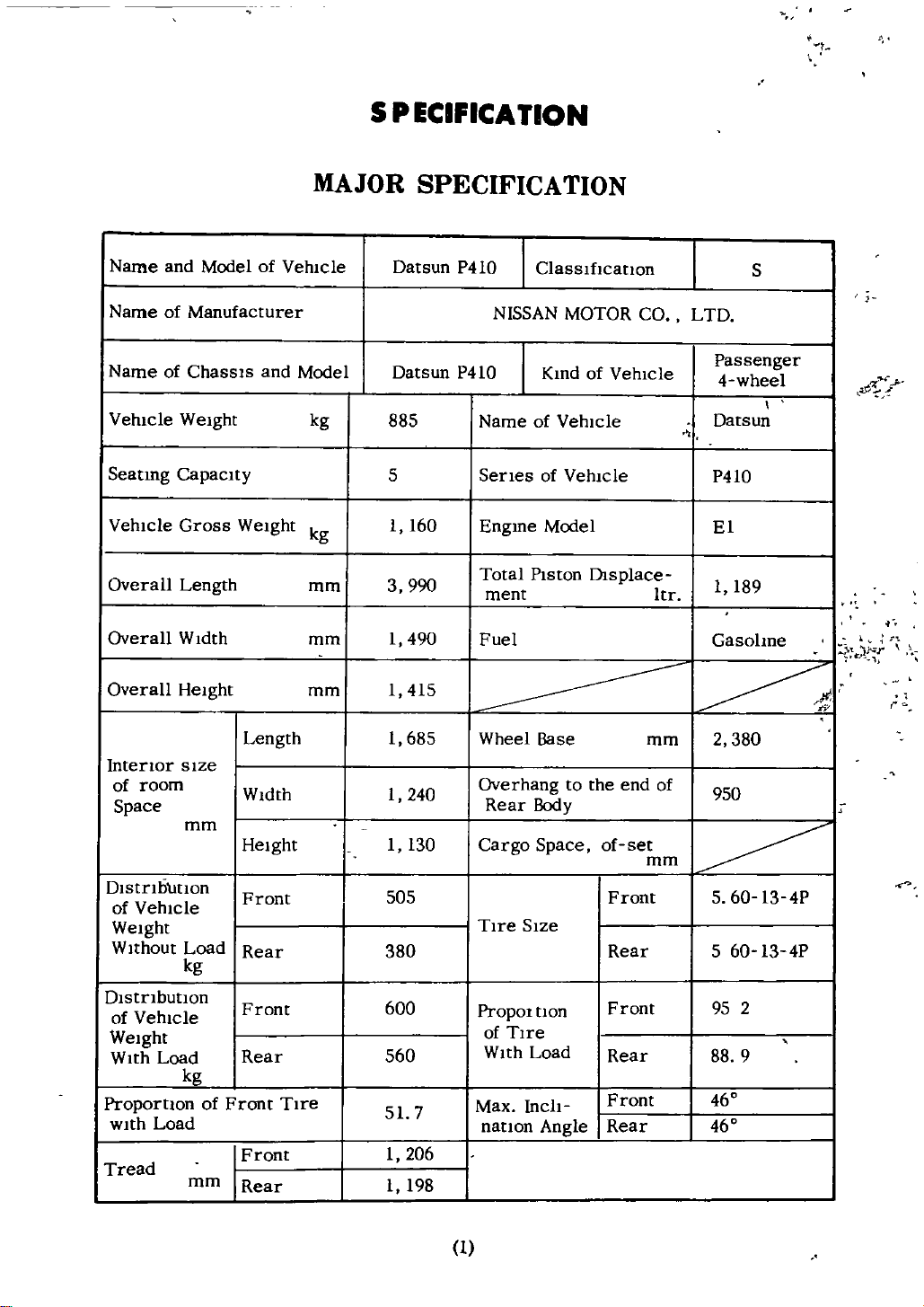

Name

Name

Name

VehIcle

Seating

VehIcle

Overall

Overall

Overall

and

of

Manufacturer

of

ChaSSIS

Weight

CapacIty

Gross

Length

WIdth

HeIght

Model

of

and

WeIght

VehIcle

Model

kg

kg

mm

mm

mm

MAJOR

SPECIFICATION

Datsun

Datsun

885

5

I

3

I

I

160

990

490

415

P410

NISSAN

P410

Name

SerIes

Engme

Total

ment

Fuel

ClassIfIcation

MOTOR

Kmd

of

of

VehIcle

of

VehIcle

Model

PIston

VehIcle

Olsplace

CO

S

LTD

Passenger

4

wheel

Datsun

P410

EI

I

Itr

189

Gasolme

d

c

i

r

InterIor

room

of

Space

DIstrIbutIOn

of

VehIcle

WeIght

WIthout

DIstrIbution

of

VehIcle

WeIght

WIth

Load

ProportIOn

wIth

Load

Tread

sIze

mm

Load

kg

kg

mm

I

I

I

505

380

600

560

51

I

I

685

240

130

7

206

198

Length

WIdth

HeIght

Front

Rear

Front

Rear

of

Front

TIre

Front

Rear

Wheel

Overhang

Rear

Cargo

TIre

PrOpOl

of

WIth

Max

nation

1

TIre

Base

Body

Space

SIze

tlOn

Load

Inch

Angle

mm

the

end

to

of

of

set

mm

Front

Rear

Front

Rear

Front

Rear

2

950

5

5

95

88

460

460

380

60

60

134P

13

4P

2

9

i

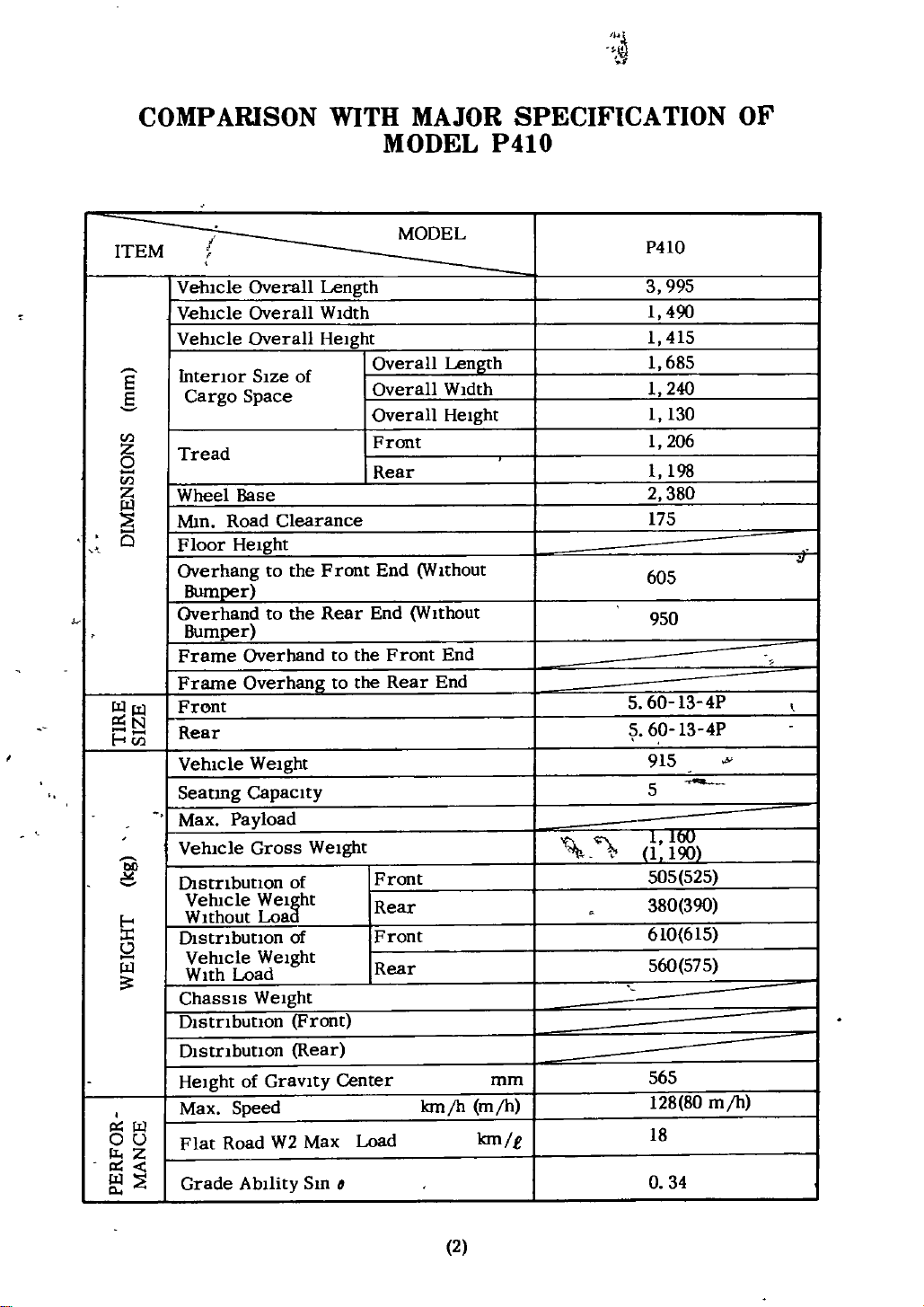

ITEM

Ww

r

r

au

r

c

tI

Z

a

CI

Z

w

Cl

ol

I

0

W

a

COMP

E

E

N

tI

llIl

w

z

W

E

ARlBON

F

VehIcle

VehIcle

VehIcle

Intenor

Cargo

Tread

Wheel

Road

Mm

Floor

Overhang

Bumoer

Overhand

Bumper

Frame

Frame

Front

Rear

VehIcle

Seatmg

Max

Payload

VehIcle

O1stnbutlon

Verncle

WIthout

O1stnbutlon

Verncle

W

lth

ChassIs

DIstnbutlon

Dlstnbutlon

HeIght

Max

Road

Flat

Grade

Overall

Overall

Overall

SIze

Space

Base

HeIght

to

to

Overhand

Overhang

WeIght

CapacIty

Gross

Wel

Loa

WeIght

Load

WeIght

of

Gravlty

Speed

AbIlity

of

Clearance

the

the

of

ht

of

Front

Rear

W2

Max

Sm

WITH

Length

WIdth

HeIght

Front

Rear

to

to

WeIght

Center

Overall

Overall

Overall

Front

Rear

End

the

the

Front

Rear

Front

Rear

Load

MAJOR

MODEL

MODEL

End

WIthout

WIthout

Front

Rear

krn

Length

WIdth

HeIght

End

End

h

SPECIFICATION

P410

mm

m

jh

krn

t

P410

3

1

1

l

1

I

I

1

2

175

605

950

5

60

60

915

5

I

1

505 525

380

610 615

560 575

565

128

18

0

995

490

415

685

240

130

206

198

380

13

13

IOU

190

34

390

80

4P

4P

mfh

OF

t

6

2

1

I

r

au

r

w

p

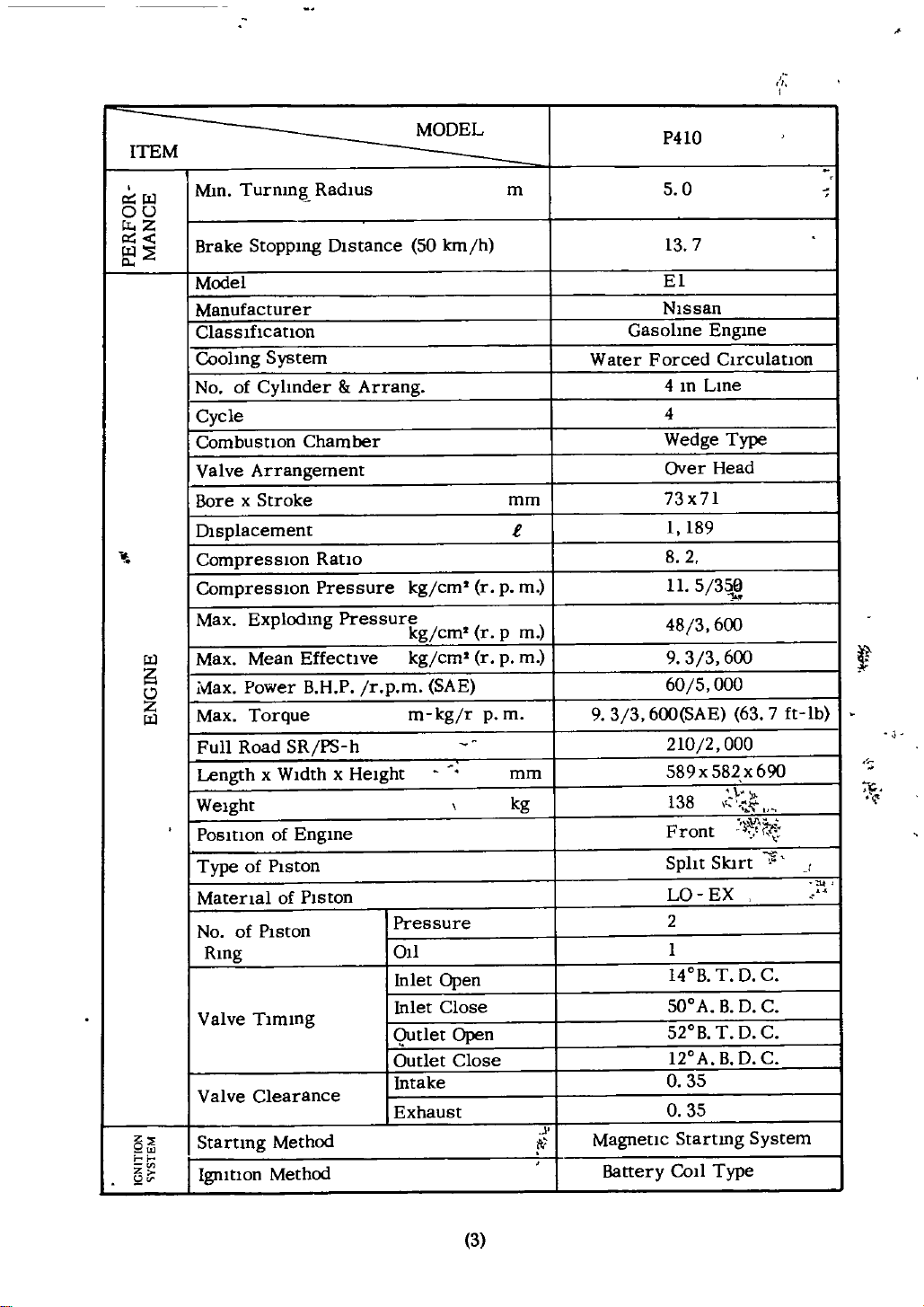

ITEM

w

z

W

ii

0

Z

w

z

QUJ

z

2

Turnm

Mm

Brake

Stoppmg

Model

Manufacturer

ClassIflCatlon

Coohng

No

of

System

Cylmder

Cycle

Combustlon

Valve

Arrangement

x

Bore

Stroke

DIsplacement

CompressIOn

CompressIOn

Max

Explodmg

Max

Mean

Power

lV1ax

Max

Torque

Full

Road

WIdth

Length

x

Weight

Position

Type

Matenal

No

of

of

PIston

of

PIston

Rmg

Valve

Tlmmg

Valve

Startmg

Ignition

Clearance

Method

Method

Effectlve

SR

Engme

of

PIston

RadIus

DIstance

Chamber

Ratlo

Pressure

BHP

PS

x

Arrang

Pressure

rpm

h

HeIght

MODEL

50

kg

kg

kg

m

Pressure

all

Inlet

Inlet

Qutlet

Outlet

Intake

Exhaust

lcm

cm

cm

cm

SAE

kg

Open

Close

Open

Close

P410

m

h

5

0

13

7

El

Nlssan

Water

Gasohne

Forced

Engme

Clrculatlon

4

m

Lme

4

mm

Wedge

Over

73x71

i

I

Type

Head

189

8 2

r

m

p

r

pm

r

m

p

115358

483600

9 3 3

600

605000

r

m

p

mm

kg

9 3 3

2

637ft

000

210

6oo

SAE

589x582x690

138

t

If

lb

y

It

0

Front

Slart

SpIlt

La

EX

2

I

T

140B

500

520B

120

0

0

I

itI

Magnetlc

Battery

Startmg

Coli

D C

ABD C

T

D C

ABD C

35

35

Type

System

3

i

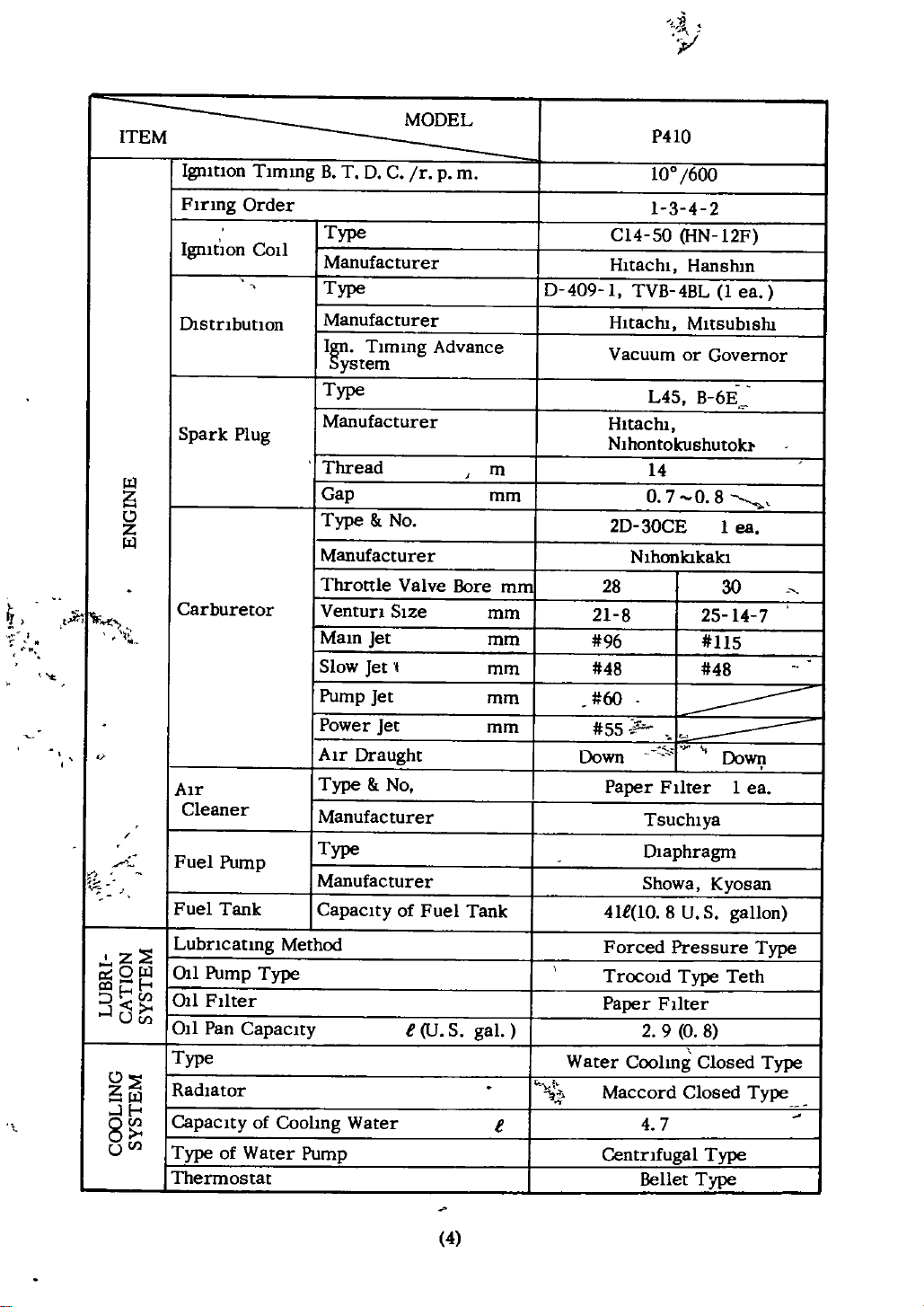

ITEM

Igmtlon

FIring

IgllltIOn

D1stnbutlOn

Tlmmg

Order

Coll

BTD C

Type

Manufacturer

Type

Manufacturer

I

Tlmmg

MODEL

rpm

Advance

0

409

C14

Hitachi

I

TVB

Hltacln

Vacuum

P410

100

1

S0

600

3 4 2

HN

Hanshm

4BL

MltsublsW

or

12F

l

ea

Governor

ystem

Type

Manufacturer

Spark

W

Z

0

Z

W

II

if

l

A

z

E

OW

r

G

1

hJ

J

UCIl

O

E

W

JI

8

UCIl

Plug

Carburetor

AIr

Cleaner

Fuel

Pump

Fuel

Tank

Lubncatmg

Chl

Pump

011

Filter

011

Pan

Type

Radiator

CapaCIty

of

Type

Thermostat

Method

Type

CapacIty

of

Coohng

Water

Thread

Gap

Type

Manufacturer

Throttle

Ventun

Malll

Slow

Pump

Power

AIr

Draught

Type

Manufacturer

Type

Manufacturer

Capacity

Water

Pump

m

J

mm

No 2D

Bore

S

mm

mm

mm

mm

mm

mm

Tank

gal

e

Jet

Jet

Jet

Jet

Valve

SIze

1

No

of

Fuel

e

U

Down

Water

L45

Hitachi

Nlhontokushutob

14

O

30CE

Nlhonlo

28

21

8

96

48

60

p

55

Paper

Tsuchlya

DIaphragm

Showa

41t

lO8U

Forced

TrocOld

Paper

2 908

Coohng

Maccord

4 7

Centnfugal

Bellet

7

FIlter

Pressure

Type

FIlter

B

0

8

kakl

25

115

48

S

Closed

Closed

Type

Type

6E

lea

30

14

DoWV

1

ea

Kyosan

gallon

Teth

Type

7

Type

Type

4

f

ITEM

o

w

0

E

w

Z

w

0

w

E

E

U

Ow

u

Z

z

w

O

W

U

w

0

0

Z

E

E

en

Z

E

wwrr

J

p

WU

p

z

o

i

rr

rr

w

00

E

J

r

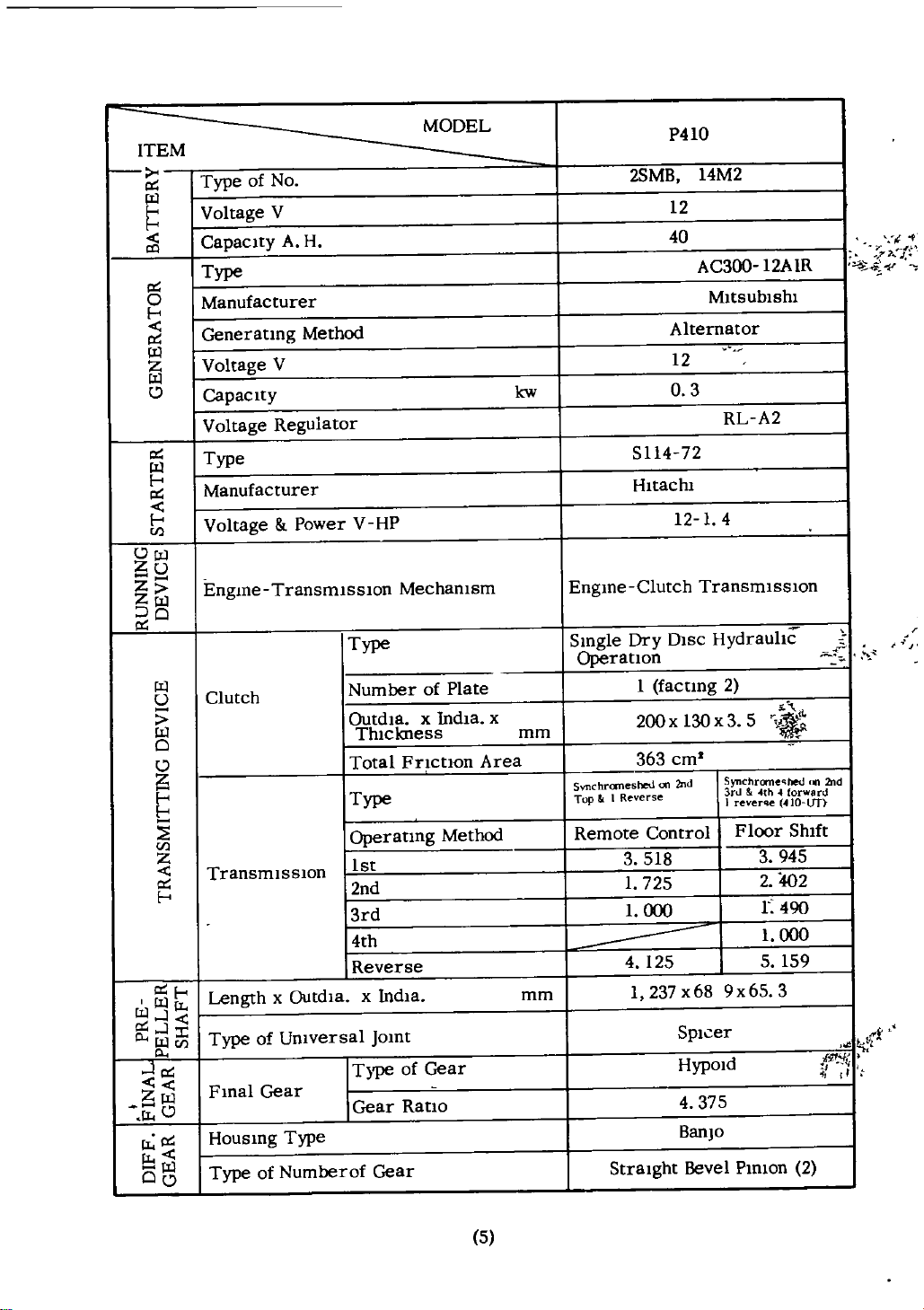

of

Type

Voltage

CapacIty

Type

Manufacturer

GeneratIng

Voltage

CapacIty

Voltage

Type

Manufacturer

Voltage

Engme

Clutch

TransmlsslOn

Length

of

Type

Fmal

Gear

Housmg

of

Type

No

V

A H

Method

V

Regulator

Power

TransmlsslOn

x

Outdla

Umversal

Type

Numberof

V

HP

Mechamsm

Type

Number

Outd18

ThIckness

Total

Fnctlon

Type

Operatmg

1st

2nd

3rd

4th

Reverse

x

IndIa

JOInt

of

Type

Gear

Ratio

Gear

MODEL

of

x

IndIa

Method

Gear

Plate

x

Area

mm

mm

kw

EngIne

Smgle

Operatlon

Svnchromeshetl

I

Reverse

Top

Remote

StraIght

25MB

5114

HItachI

Clutch

Dlsc

Dry

I

factlng

200x130x3

363

em

2hd

on

Control

3

518

1

725

1

000

4

125

1

237

SpIcer

HypOld

4

BanjO

P4l0

14M2

12

40

AC300 12AIR

MItsublShl

Alternator

12

0

3

RL

72

l2

1

4

TransmIssIon

Hydrauhc

2

SynC

3n

I

reverqe

Floor

68

375

9

PInion

x

x

Bevel

i

A2

r

o

l

5

hedun2nd

hrane

4th

forward

410

Un

ShIft

3

945

2

402

r

490

1

000

5

159

65

3

l

L

f1f

J

I

tf

1

2

5

ITEM

O

E

W

1

1

WCJt

W

1

CIl

CIl

W

U

W

Cl

0

Z

5

I

E

W

1

CIl

CIl

W

I

cc

Z

0

CIl

Z

CIl

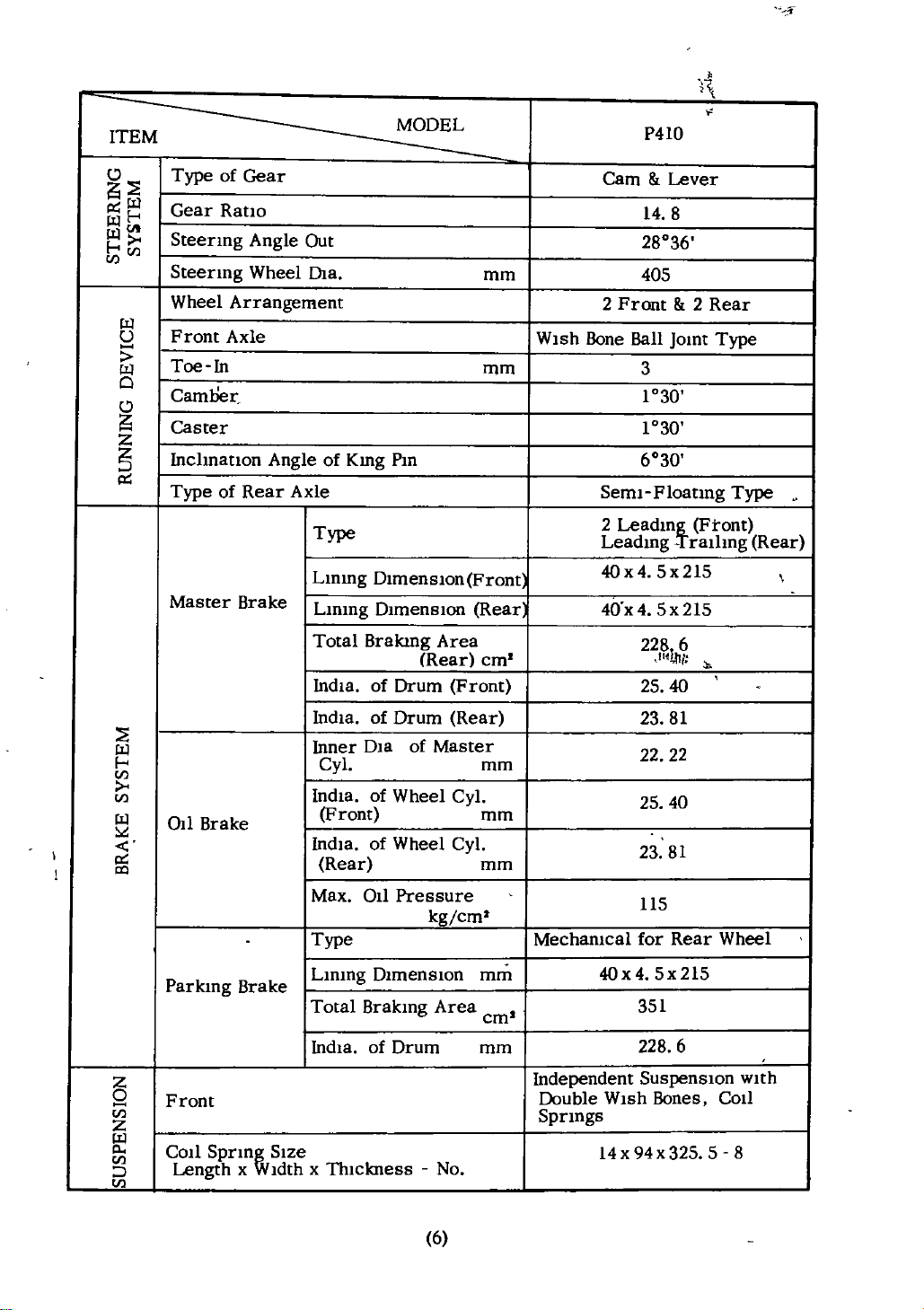

CIl

Type

Gear

Steermg

Steering

Wheel

Front

Toe

Camller

Caster

Inclmatlon

Type

Master

011

Brake

Parkmg

Pront

Call

SprIn

Length

of

Gear

Ratlo

Angle

Wheel

Arrangement

Axle

In

Angle

of

Rear

Brake

Brake

Size

IdthxTIuekness No

x

Axle

Out

Ola

of

Type

Lmmg

Lmmg

Total

India

IndIa

Inner

Cyl

India

Front

India

Rear

Max

Type

Lmmg

Total

India

Kmg

Brakmg

of

of

Dla

of

of

011

DlmenslOn

Brakmg

of

MODEL

Pm

DlmenslOn

Drum

Drum

of

Wheel

Wheel

Pressure

Drum

Area

Rear

Master

kg

Area

mm

mm

DlmenslOn

Front

Rear

em

Front

Rear

mm

Cyl

mm

Cyl

mm

em

mm

em

mm

Cam

2

WIsh

Bone

Seml

2

Leadmg

40x4 5x215

40

Meehameal

4Ox4

Independent

Double

WIsh

Sprmgs

14

P410

Lever

14

28036

405

Front

Ball

Jomt

3

1030

1030

6030

Floatmg

Leadm

x4

5x215

228

l

1hI

25

40

81

23

22 22

25

40

23

81

US

for

Rear

5x215

351

228

SuspenslOn

Bones

94x325

x

8

6

6

2

Rear

Type

Ftont

rallmg

5 8

Type

Rear

Wheel

WIth

COlI

6

r

ITEM

Z

Q

tIl

Z

W

p

tIl

J

tIl

W

iI

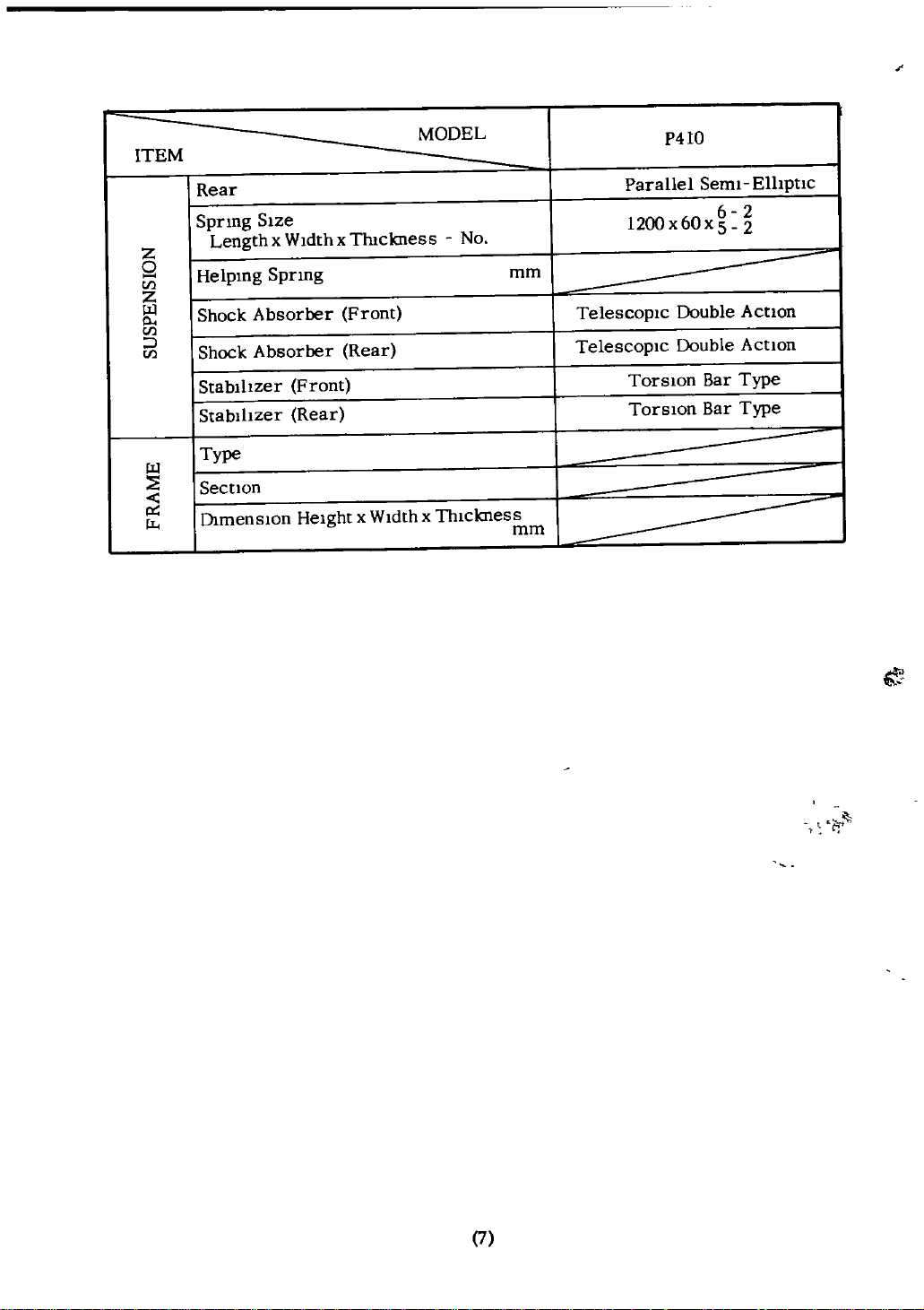

Rear

Sprmg

Length

Helpmg

Shock

Shock

Stabilizer

Stabilizer

Type

Section

O1menslOn

SIze

WIdthxThickness

x

Spnng

Absorber

Absorber

Front

Rear

Height

MODEL

Front

Rear

Widthxl111ckness

x

No

mm

mm

Parallel

1200x60x5

Telescopic

TelescopIc

TorSlOn

TorslOn

P410

Double

Double

Seml

Bar

Bar

Elhptlc

6 2

2

Action

Action

Type

Type

7

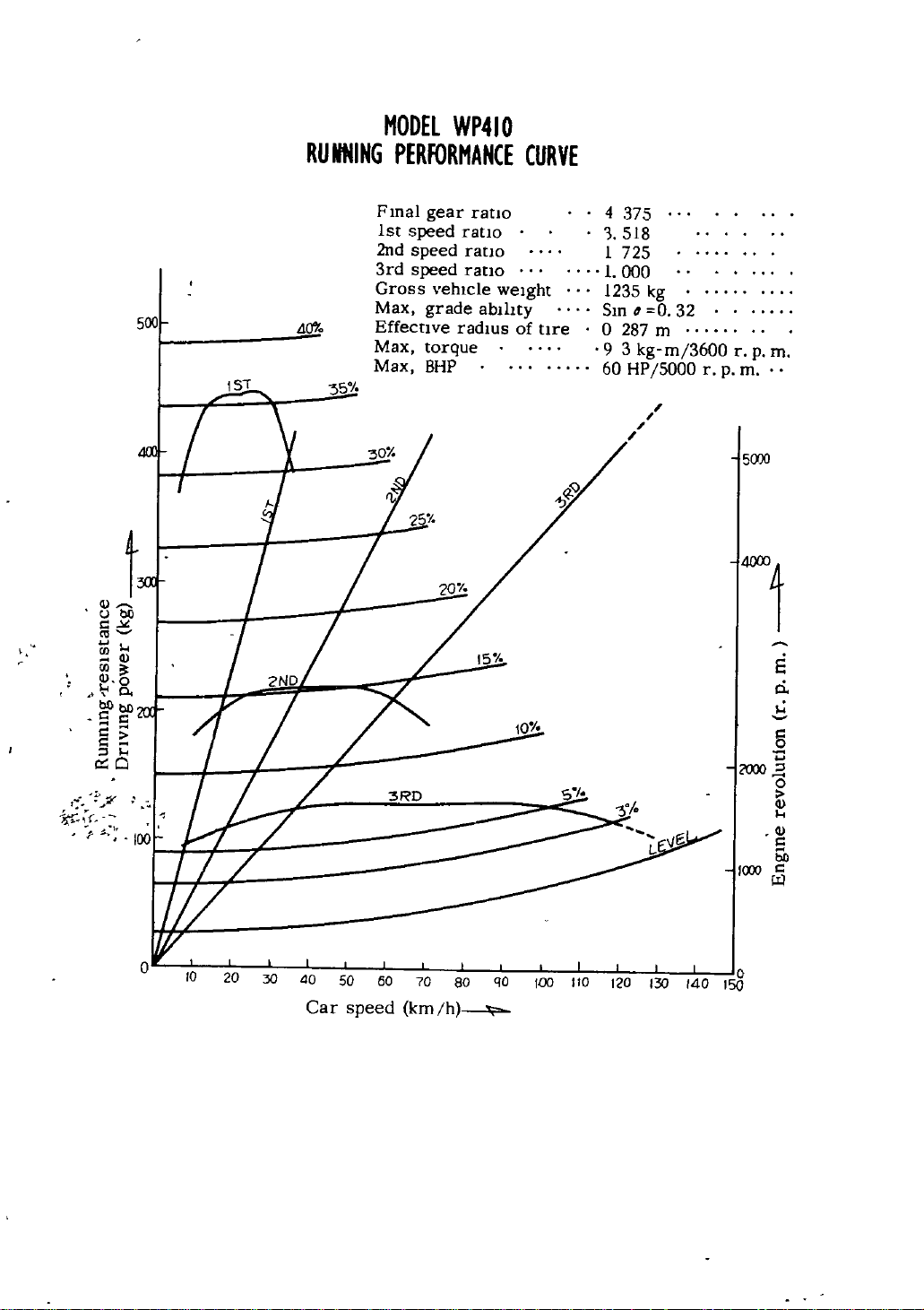

MODEl

RUNNING

WP4

10

PERFORMANCE CURVE

p

t

co

U

00

aJo

bllbll

t

t

t

0 0

8

bO

J

l

aJ

Cc

t

l

t

500

F

mal

1st

speed

2nd

speed

3rd

speed

Gross

Max

40

Effective

Max

Max

gear

vehicle

grade

torque

BHP

ratio

ratIO

ratIO

ratio

abIlIty

radIUS

weight

of

tire

4

1

1

1235

Sm

o

9

60

375

51S

725

000

287

3

HP

kg

6

0

32

m

3600

r

kg

m

5000

r

m

p

m

p

5000

t

E

ri

b

fT

c

p

30 40

Car

SO

speed

60

70

km

QO

100

80

h

110

o

150

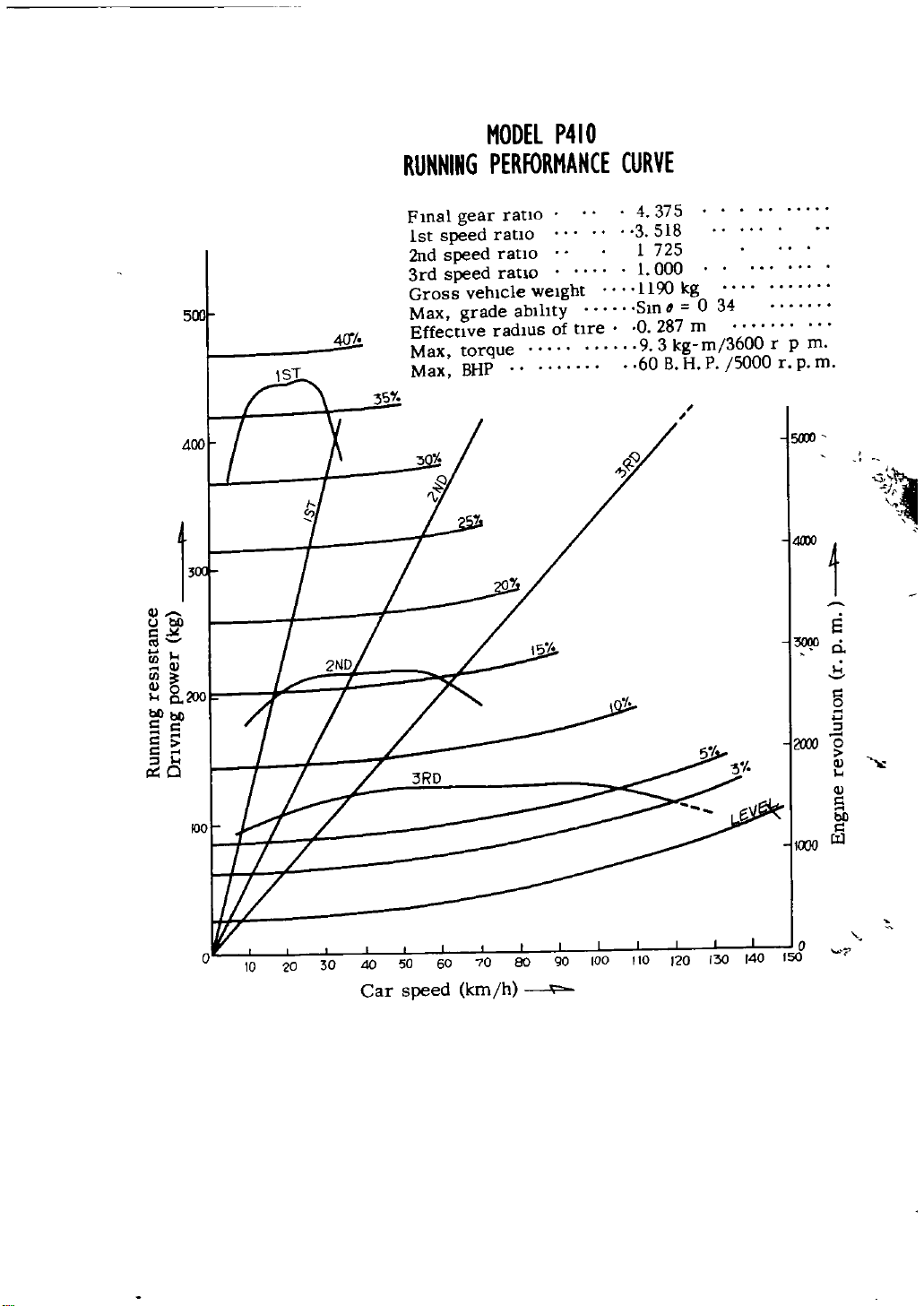

MODel P410

RUNNING

PERFORMANCE

CURVE

CJbO

C

CJl

bObO

c

M

c

l

lX

500

gear

vehicle

grade

torque

BHP

rano

ratlO

ratIo

ratio

ablhty

radlUs

weight

of

tIre

Fmal

1st

speed

2nd

speed

3rd

speed

Gross

Max

40

Effective

Max

Max

35

4

3

1

1

1190

Sm

0

9 3

60

375

518

725

000

leg

287

kg

BHP

0

34

m

3600

m

5000

rpm

r

p

5lOO

m

J

I

CIl

loi

I

CIl

m

8

M

M

I

O

3Ro

3000

1

6

0

I

l

CIl

I

CIl

c

M

bO

U

J

o

90

km

80

h

10

20

30

Car

speed

100

110

120

130 140

ISO

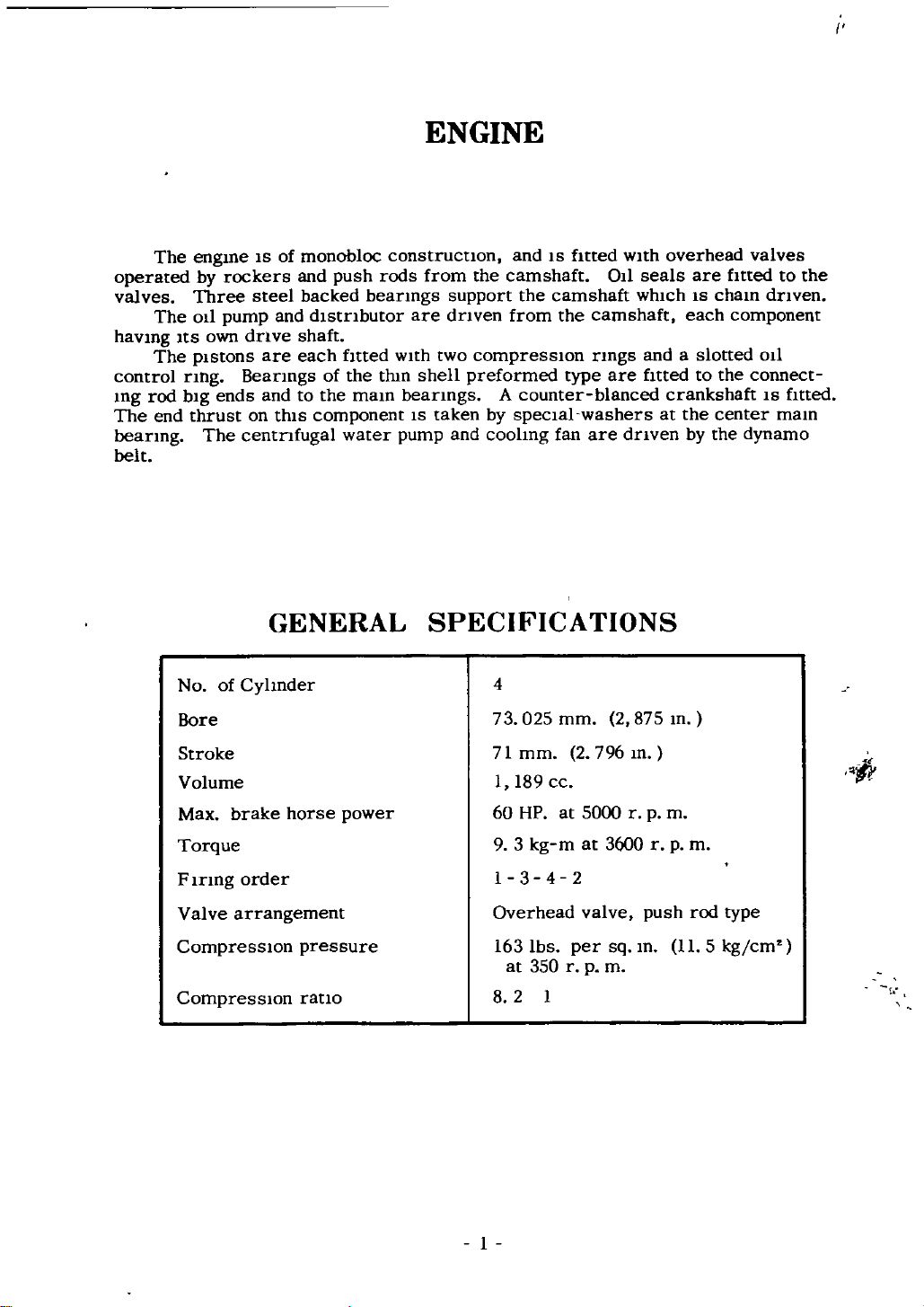

ENGINE

The

operated

valves

The OIl

havmg

The

control

rod

mg

The

end

beanng

belt

ItS

nng

bIg

engme

by

Three

own

pIstons

thrust

The

rockers

pump

dnve

Beanngs

ends

on

centnfugal

IS

steel

are

and

of

and

thIS

monobloc

and

push

backed

dlstnbutor

shaft

each

of

to

the

component

fItted

the

mam

water

construcnon

rods

beanngs

are

wIth

thm

beanngs

IS

pump

ENGINE

from

the

support

dnven

two

compresslOn

shell

preformed

taken

and

and

camshaft

the

from

A

counter

specIal

by

coohng

IS

fItted

camshaft

the

type

washers

fan

011

camshaft

rmgs

are

blanced

are

wIth

overhead

seals

whIch

andaslotted

fItted

crankshaft

at

dnven

each

the

by

are

IS

to

fitted

cham

component

the

center

the

valves

to

dnven

OIl

connect

IS

fItted

mam

dynamo

I

the

of

No

Cyhnder

Bore

Stroke

Volume

Max

brake

Torque

F

Valve

Inng

order

arrangement

CompresslOn

Compression

GENERAL

horse

power

pressure

rano

SPECIFICATIONS

4

73

025

mm

71

mm

I

l89

60

HP

3

9

1

3 4 2

Overhead

163

at

8 2

kg

Ibs

350

2

cc

at

m

per

rpm

I

796

5000

at

valve

2

3600

sq

m

r

875

push

m

m

fr

m

p

m

r

p

rod

type

11

5

cm

kg

1

ilft

EMGIME

t

l

RIG

SlOE

x

L

E7j

1

JJcc

0

Y

t

c

1

li c

t

1

JF

r

t

EMGIME

J

lt

r

v

I

SlOE

LEf

2

c

I

Ic

J

t

r

J

l

vI

e

An effICIent

runrung

lts

of

mamtance

Description

The

efficient

The

cap

engme

water

coolmg

system

the

an

fIller

remove

If

the

place

If

pOSSible

the

fan

controls

fIller

IS

lost

use

coohng

engme

system

cooled

IS

runmng

through

clean

COOLING

and

radIator

pressunsed

the

pressure

If

cap

soft

system

It

IS

mamtamed

IS

the

temperature

Toppmg

the

water

IS

therefore

and

and

overflow

of

major

necessary

by

thermostat

the

rehef

at

approximately

should

up

pIpe

SYSTEM

Importance

water

valve

the

of

only

Top

pump

coolant

be

up

to

to

pay

clrculatlon

mcorporated

0

4

kg

IS

reqUIred

when

ensure

paucular

per

above

occaslOnally

the

engme

the

combmed

m

sq

bOlhng

sausfactory

attentlOn

the

cm

pomt

IS

cold

radIator

Do

not

to

it

to

wIth

or

re

and

engme

of

the

Fill

to

IS

system

cold

wlthm

may

IS

1

cause

the

2

of

water

approxImately

Fig

bottom

5

r

l

1

1

I

t

l

t

t

f

0

f

f

I

1

to

flow

2

htres

of

through

the

Radiator

fIller

3

the

plug

overflow

well

Overfllhng

pipe

The

when

capacity

the

Thermostat

In

order

ratlng

IS

VIce

temperatures

fitted

consIsts

mushroom

engme

the

nse

so

openIng

full

should

from ItS

there

be

tern

to

and

IS

It

M

Durmg

mg

the

falls

the

Due

to

cyhnder

thus

generated

the

flow

of

The

the

up

la

lng

are

utlhzed

has

been

air

allow

then

set

by

at

open

decarbomsmg

by

Immersmg

requlslte

to

open

thermostat

housmg

fmally

to

bemg

of

valve

flow

thlS

head

ensunng

w1l1

valve

water

occaSlOn

the

car

two

capped

to

ease

completely

to

manufacturer

the

a

temperature

temperature

a new

ensure

located

metallIc

of

water

the

and

gradually

to

and

escape

top

wIthm

When

temperature

cyhnder

rapId

and

the

Itself

anse

the

Should

holes

It

from

through

up

It

the

thermostat

unIt

maXlmum

certam

m

the

water

bellows

the

engme

to

the

warmmg

expand

ultlmatelly

radiator

IS

detachable

It

can

hose

the

on

castmg

emptled

The

thermostat

and

of

76

IS

pohcy

The

should

effIcIency

hmlts

outlet

filled

IS

radiator

of

the

Jackets

up

the

permIttmg

be

reconnected

thermostat

the

top

It

the

thermostat

cannot

SO

II

to

test

m

water

valve

fltted

be

cold

wIll

removed

WhICh

When

IS

be

SoC

should

at

wlth

thIS

IS

temporarIly

water

qUlckly

The

bellows

therefore

to

be

the

essennal

opening

altered

thIS

raIsed

To

heat

may

It

the

a

m

a

avoid

tlght

sys

valve

open

open

IS

essentlal

asslst

front

volatlle

valve

so

to

thISabellows

of

the

hquled

closed

IS

restncted

2

Fig

under

these

to

cyhnd

Pellet

keep

whIch

and

condmons

the

engme

type

r

head

controls

on

startmg

Thermostat

ope

thermostat

The

but

a

the

de

1f

It

Overheating

Overheatlng

cyhnders

ment

Fan

shaft

the

loosenIng

which

movmg

Shde

fan

mg

gme

tlght

should

tween

falhre

Belt

The

fan

a

by

alternator

A

New

the

hold

the

the

belt

pulley

Adjustment

alternator

the

The

to

prevent

have

the

generator

may

runnmg

WIth

of

the

water

Adjustment

IS

dnven

belt

V

can

belt

clamp

the

dynamo

over

IS

should

shp

towards

the fan

then

away

dynamo

belt

10toIS

thIS

be

bolts

mm

and

be

the

r

from

fItted

m

made

from

be

yet

caused

crankshaft

19mtlOn

cIrculate

to

I

the

also

dnvmg

by

Fig

posmon

the

and

onto

by

the

sufflclently

belt

the

slack

by

crank

fIrst

3

engme

bnng

en

be

a

slack

too far

and

the

m

fan

belt

exceSSIve

retarded

or

loss

of

water

Fig

mcorrect

3

Fan

carbon

carburetor

Belt

deposlt

Adjustment

the

adJust

4

pulley

After

when

the

the

midspan

correct

tenslOn

IS

pushed

has

fIrmly

been

obtamed

securely

lock

m

It

pOSItlOn

agam

Front

Freezmg

connectlons

Ice

be

used

or

bollmg

low

very

the

strength

mamtamed

WIth

up

m

accordance

Top

If

and

use

Protection

On

dUring

When

It

IS not

There

other

at

tern

and

The

WIre

to

opened

The

drammg

When

all

that

A

water

Precausions

the

m

to

advantage

WIll

temperature

advised

by

water

when

up

the

coohng

agam

cars

where

frosty

heavy

suffICIent

two

are

the

base

the

car

dram

ensure

that

so

completely

water

suitable

been

has

may

hose

result

toppmg

reduces

WIth

by

weather

dram

taps

that

any

should

has

notIce

dramed

occur

wlll

by

mstruCtlons

the

system

system

Draining

anti

frost

merely

cocks

of

the

must

should

they

obstructlOn

be

been

fIrst

stop

but

When

make

the

up

the

freeze

to

obVIate

IS

Immment

radIator

be

on

are

carried

dramed

cleaned

should

at

water

care

frost

sure

manufacturers

WIth

antl

degree

IS

has

to

cover

to

one on

level

be

tested

cleare

the

be

the

clrculatlOn

must

IS

that

freeze

of

supphed

cold

be

dramed

IS not

any

the

the

block

ground

freed

out

when

engme

from

then

bottom

be

taken

expected

the

protection

WIth

used

damage

the

coohng

radiator

left

Both

while dram

at

frequent

This

by

the

should

the

system

affIxed

of

not

strength

The

solutlon

the

run

the

due

hand

taps

should

the

wire

engme

to

the

radIator

and

ma

to

run

or

when

of

strength

as

afforded

contamer

mIxture

the

followmg

to

freezmg

system

and

engme

Side

of

must

mg

mtervals

be

done

may

IS

be

run

the radIator

or

cause

with

the

car

the

solUtion

of

necessary

Solutlon

precautlons

must

WIth

the

cyhnder

be

opened

by

Immediately

be

flushed

hot

foratlmed

m

the

bollmg

the

muff

IS to

IS

the

solutlon

ExceSSive

must

mto

a

of

the

be

completely

rugs

to

msertmg

out

mdlcatmg

lower

A

fully

be

used

m

clear

must

coohng

and

block

dram

a

the

by

mmute

that

muff

fact

must

be

musks

piece

the

hose

closed

made

co

be

system

dramed

and

the

taps

to

the

can

m

up

be

toppmg

ltamer

taken

the

sys

of

water

ensure

a

to

up

I

are

Flushing

To

and

scale

clear

runnmg

when

takmg

It

comes

mserted

sediment

WIth

ThIS

ring

up

radiator

Side

down

the

top

the

ensure

sediment

It

out

clear

mto

method

IS exceSSIve

completely

and

connectlOn

Radiator

effICient

water

out

the

let

m

from

taps

of

the

clrculatlon

the

m

preferably

the

dUring

radIator

the

and

water

radIator

spring

the

operator

flush

dram

drammg

flushmg

m

flow

before

The

taps

WIll

the

m

of

the

the

system

putting

water

to

may

fmd

reverse

through

coolant

At

ensure

5

mtervals

serve

It

the

should

more

way

should

m

that

well

bottom

and

anti

to

to

be

freeze

be

allowed

a

Stlff

they

but

effICient

the

flow

hose

reduce

are

m

the

perloc

hcally

m

to

piece

not

cases

practice

turn

connectlon

formation

the

winter

run

WIre

of

becommg

where

to

the

flushed

through

should

the

remove

radiator

and

of

With

and

agam

until

clogged

fur

up

of

out

be

the

I

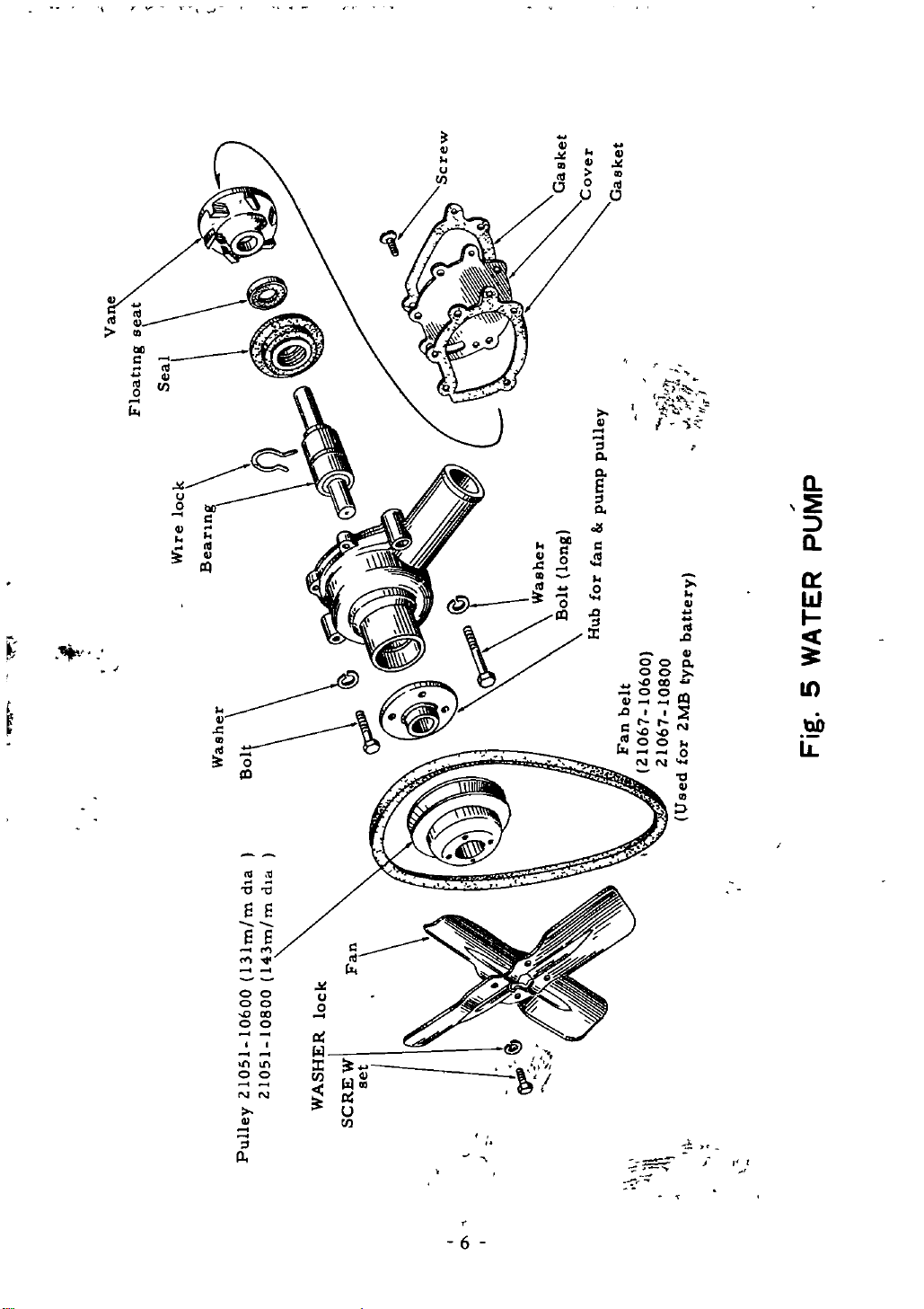

Gasket

seat

Sea

o

pulley

l

v

II

l

rt

tilT

f

I

F10attng

pumP

6

an

rOT

ub

H

J

f

r

batteTY

type

10800

10600

belt

zMB

Fan

foT

Zl061

Z1061

used

pUMP

WATER

5

Fig

dta

dt3

m

m

3m

lo

p3ltn

lock

10800

10600

l

l

ZlO

ZlO

pulley

II

i

0

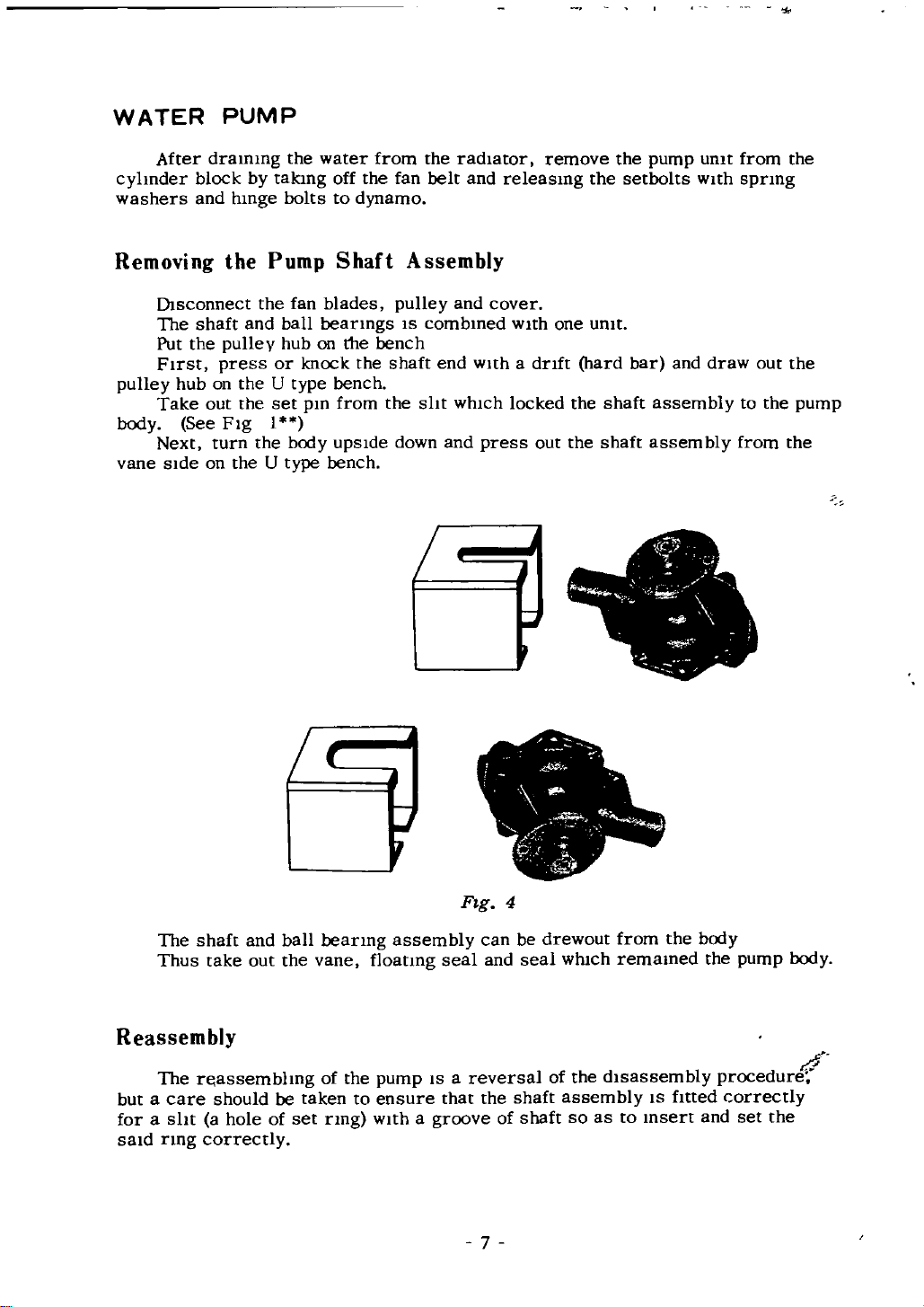

WATER

PUMP

After

cyhnder

washers

Removing

Dlsconnect

The

Put

the

First

pulley

body

vane

hub

Take

See

Next

side

drammg

block

and

the

shaft

pulley

press

on

out

Fig

turn

on

by

hmge

and

the

the

the

the

the

takmg

bolts

Pump

the

ball

hub

or

U

set

1

U

type

water

fan

blades

beanngs

on

knock the

type

pm

body

bench

the

off

to

dynamo

Shaft

the

bench

from

upside

from

fan

Assembly

pulley

IS

bench

shaft

the

down

the

belt

and

combmed

end

which

sht

and

radiator

and

with

press

releasmg

cover

with

a

locked

dnft

out

remove

one

the

the

the

umt

hard

shaft

shaft

the

setbolts

bar

umt

pump

with

and

assembly

assembly

draw

from

spnng

out

to

from

the

the

the

pump

the

The

shaft

Thus take

Reassembly

The

r

a

care

but

forasht

said

nng

correctly

and

out

assembhng

should

a

hole

of

4

Fig

from

remamed

IS

to

msert

the

fmed

body

the

I

y

procedure

correctly

and

pump

set

lxxly

1

the

ball

beanng

vane

the

of

taken

be

set

nng

the

to

assembly

floatmg

pump

ensure

with

a

seal

IS

a

that

groove

can

and

reversal

the

of

be

seal

shaft

shaft

drewout

WhICh

of

the

assembly

so

dlsassemb

as

7

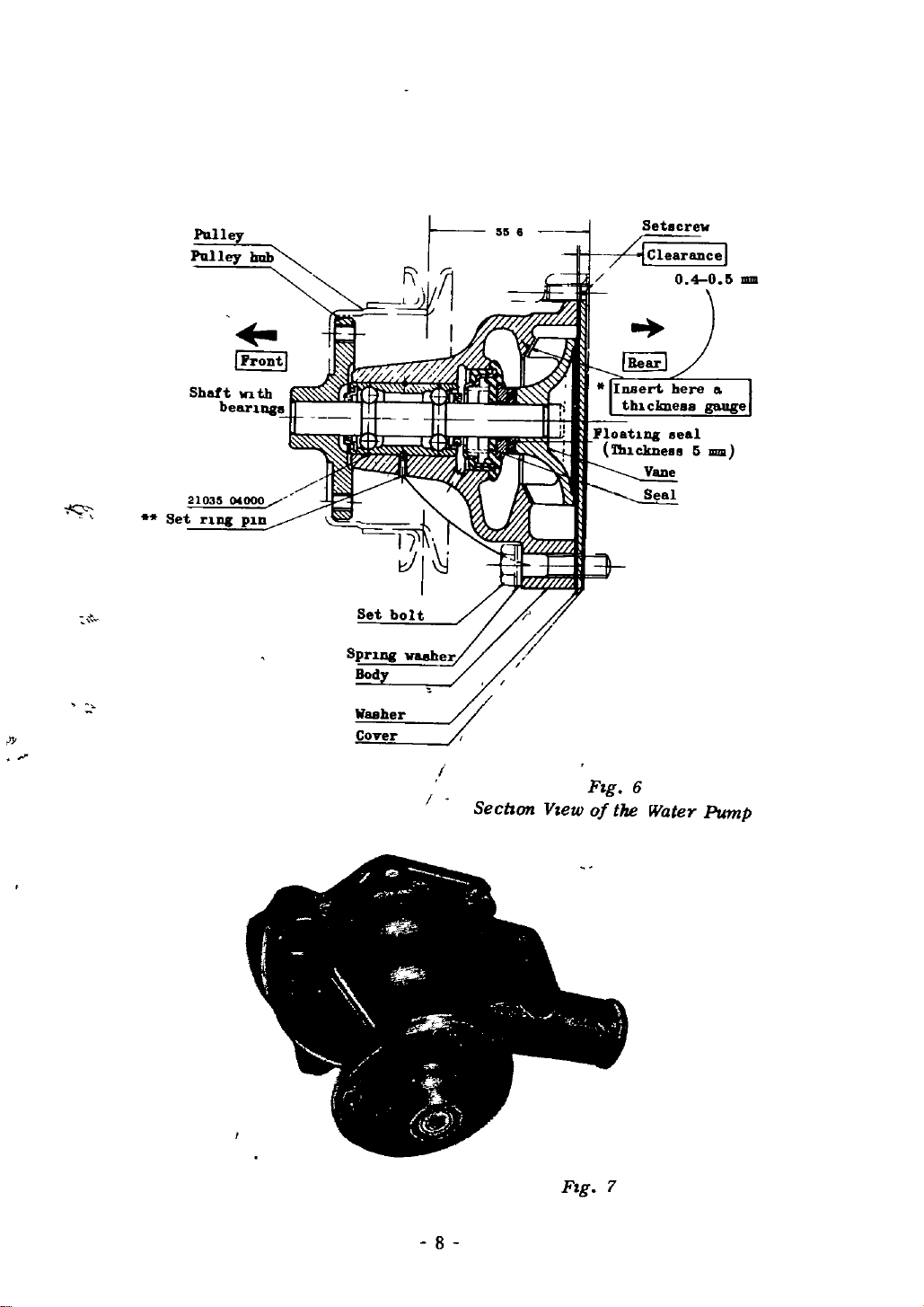

crew

Set

Pu

lley

21035

rUle

1mb

I

frontl

0

p1n

000

Waaher

Cover

6

Flg

f

Secnon

Vlew

of

the

Water

Pump

Pulley

K

ll

Set

7

FIg

8

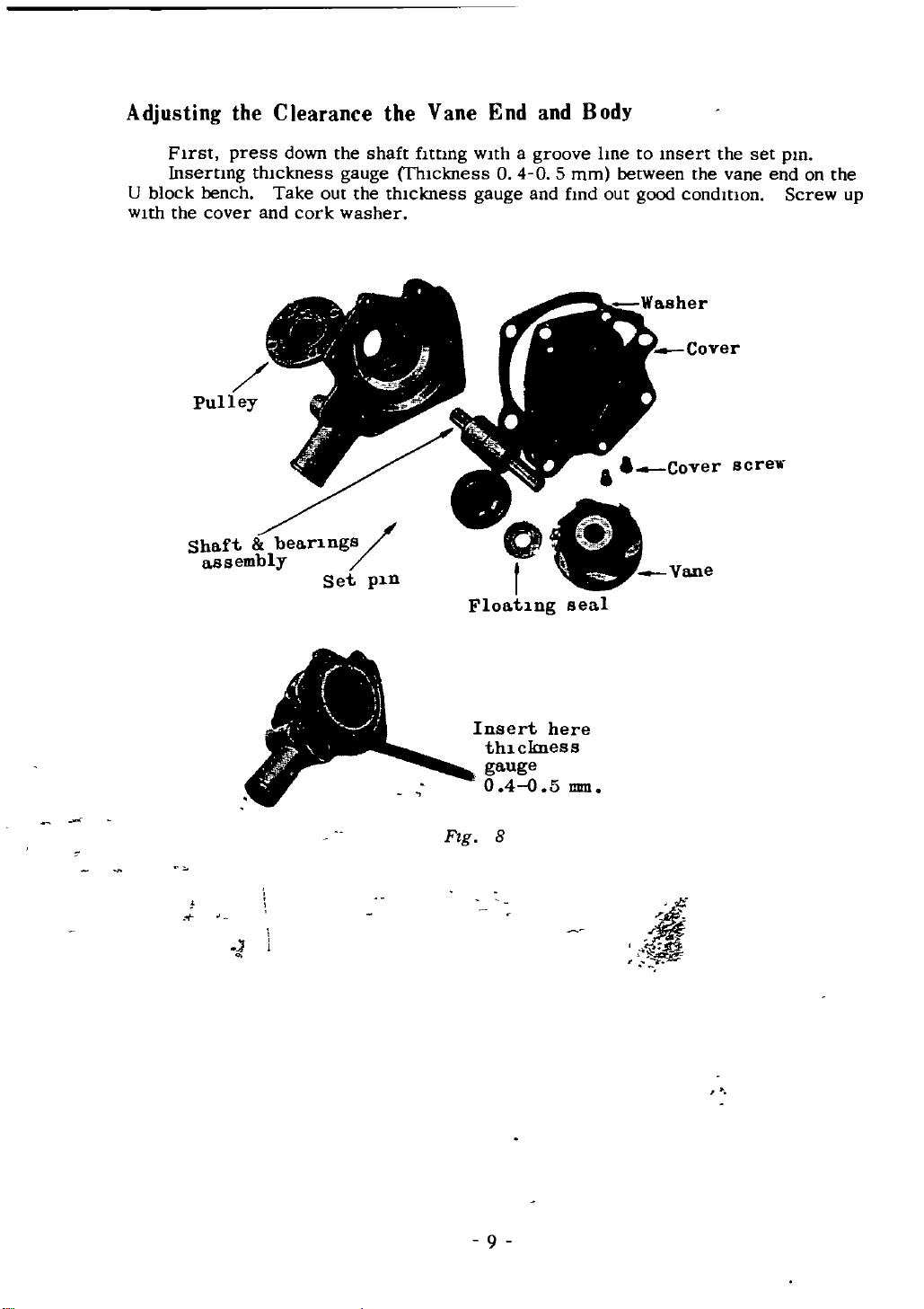

Adjusting

the

Clearance

the

Vane

End

and

Body

U

WIth

FIrst

inserting

block

the

bench

cover

Shaft

assembly

press

down

thIckness

Take

and

bear1ngs

1

4

i

4r

ii

cork

I

1

out

Set

r

I

the

gauge

the

washer

J

shaft

thIckness

p1n

fItting

fhlckness

WIth

a

O4O

gauge

o

f

Float1ng

Insert

th1ckness

gauge

0

40

groove

and

5

here

5

mm

find

sea

mm

line

out

l

to

between

good

Insert

Vane

the

the

condmon

vane

screT

set

end

pin

Screw

on

the

up

8

Fig

1

ff

9

Circulation

LUBRICATION

Pressure

non

drammg

case

OllIS

ways

of

the

From

mto

the

sIde

via

connecung

end

and

mgs

ends

rear

the

cate

mto

the

apertures

bearmg

Side

pets

camshaft

Journal

camshaft

small

case

camshaft

ummg

case

the

to

forms

such

A

element

passes

nular

so

that

from

and

to

the

crankcase

mam

of

the

cam

m

the

are

rocker

the

rockers

engme

enters

of

the

through

regIster

amount

twice

cham

the

011

engme

part

IS

filled

proportion

through

through

space

This

the

thiS

IS

driven

drawn

non

the

engme

shaft

crankshaft

dnlhng

all

engme

mdlvldual

rotates

thrust

durmg

to

provide

and

returns

of

round

space

011

pomt

lubncauon

011

pump

adjustable

rellef

011

gallery

011ways

m

shaft

sump

from

a

gallery

WIth

plate

of

OIl

gears

sump

the

WIth

holes

the

IS

can

back

from

mto

the

valve

The

bearings

the

bracket

and

via

the

and

two

a

to

case

lubncatlon

VIa

The

mam

011

the

of

element

the

sealed

only

Into

IS

The

the

pump

on

flow

to

the

The

cyhnder

then

the

center

on

lubncates

dnlhngs

grooves

small

thus

pass

revolutIOn

From

a

dram

filter

OIl

under

011

m

the

center

top

escape

the

used

011

camshaft

rehef

the

011

the

right

then

mam

through

connectmg

to

drams

push

the

m

hole

allowmg

mto

gallery

pressure

enters

casmg

mto

bolt

and

through

sump

throughout

pump

via

the

valve

passes

hand

passes

big

dnll

block

lubri

back

rod

camshaft

left

hand

the

tappa

As

the

front

m

the

a

the

tlmmg

of

the

for

the

the

tlmmg

hole

back

therefore

and

the

and

the

an

bottom

IS

and

the

as

gear

fIlter

which

a

bolted

small

the

by

and

IS

umt

mto

a

short

IS

situated

hole

and

the

left

verucal

dehvered

mto

IS

provided

at

F

the

hand

through

the

g

hollow

shaft

rear

1

side

left

center

by

of

mternal

an

the

hand

ecentnc

crank

bolt

oil

side

and

Draining

The

On

new

011

Dram

It

any

Never

are

never

011

new

after

sludge

Oil

Pan

IS

pan

recondmoned

and

the

first

the

011

or

sedIment

use

petrol

completely

a

when

metal

I

000

the

or

paraffIn

dispersed

pressIng

Ian

engme

whIch

engmes

and

may

for

from

With

the

subsequently

hot

IS

have

flushIng

the

the

draIn

sump

SInce

warm

accumulated

purposes

engIne

10

plug

must

at

OIl

lubricatIOn

be

draIned

Intervals

flows

Such

of

freely

cleamng

system

and

refilled

5

000

and

Ian

takes

with

with

medIUms

and

wIll

remaIn

to

contammate

Oil

Pressure

The

The

pressure

the

engme

Refilling

normal

warnIng

drops

or

any

below

serIOUS

fresh

operatmg

hght

011

011

whIch

8

Ib

damage

sq

This

pressure

IS

embodied

m

may

may

under

result

IS

cause

60

m

these

lb

the

premature

per

mstrument

cIrcumstances

II

I

11

bearmg

m

sq

panel

faIlure

If

the

hght

do

not

attempt

011

run

to

When

from

the

fIller

the

engme

Before

pOSSIble

the

readmg

reach

Check

sump

upIfnecessary

still

off

m

sludge

at

of

the

Oil

ammed

011

bearmg

ment

tatmg

classls

to

for Low Oil

Check

by

on

after

ascertam

and

the

sump

sale

the

stramer

the

011

and

unIt

Release

The

If

the

pressure

overhaul

parts

the

sump

means

pump

011

reflllIng

testing

Always

the

IS

that

rectify

release

engme

WIll

IS

removal

onflce

It

should

before

level

of

refIllmg

that

clean

no

unIOn

bemg

Valve

beanngs

be

and

the

only

the

sump

and

the

level

wIpe

be

readmg

Pressure

011

of

the

dIp

If

the

warnmg

the

the

and

aIr

on

defectIve

the

fault

valve should

reduced

the

remedy

of

the

mIslead

of

the

dIp

remembered

In

stick

sump

gauge

choked

not

leakage

the

suction

are

fIttmg

engme

do

the

the

worn

A

not

the

011

stick

dIpstick

engme

and

lIght

SWItch

stramer

eXIsts

remove

be

complete

of

replace

necessl

from

pour

the

top

with

SIde

ex

the

operdtor

ensure

clean

IS

the

that

the

WIth

time

011

that

In

too

qUickly

as

to

the

the

vehicle

a

non

fluffy

must

be

quantity

cloth

allowed

as

It

of

IS

as

before

for

0

may

lubncant

near

new

1

overflow

level

takmg

011

j

c

c

m

as

to

c

r

c

j

I

3

I

r

r

2

4

j

0

C

3

I

I

tb

j

i

f

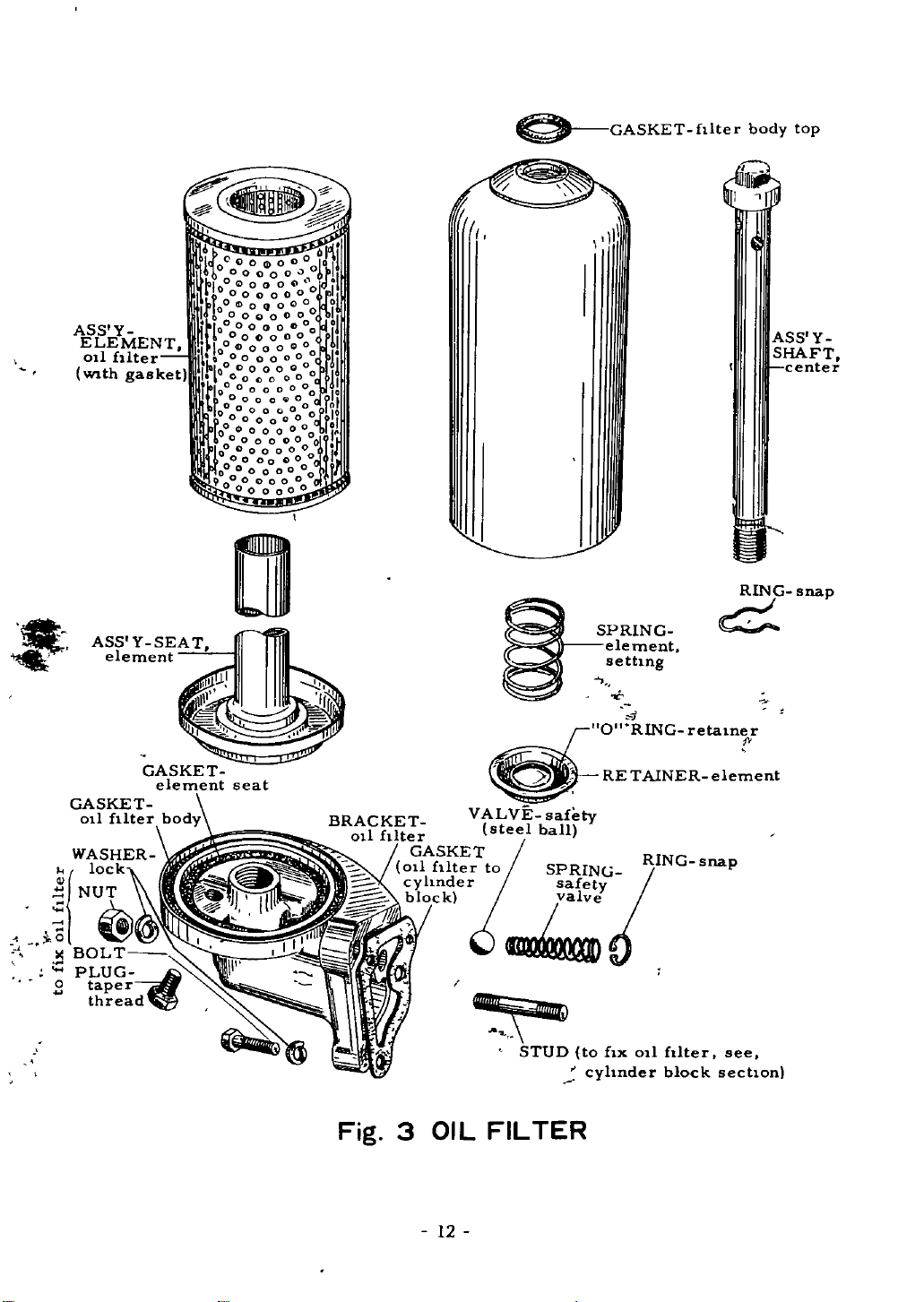

Removing

new

A

every

gallery

It

15

The

of

IS

only

the

fIlter

000

km

fIlter

the

necessary

torms

engme

By

element

to

pass

part

To

unscrew

Filter

should

of

remove

the

the

be

mam

the

fItted

center

011

fllter

2

OJl

FJg

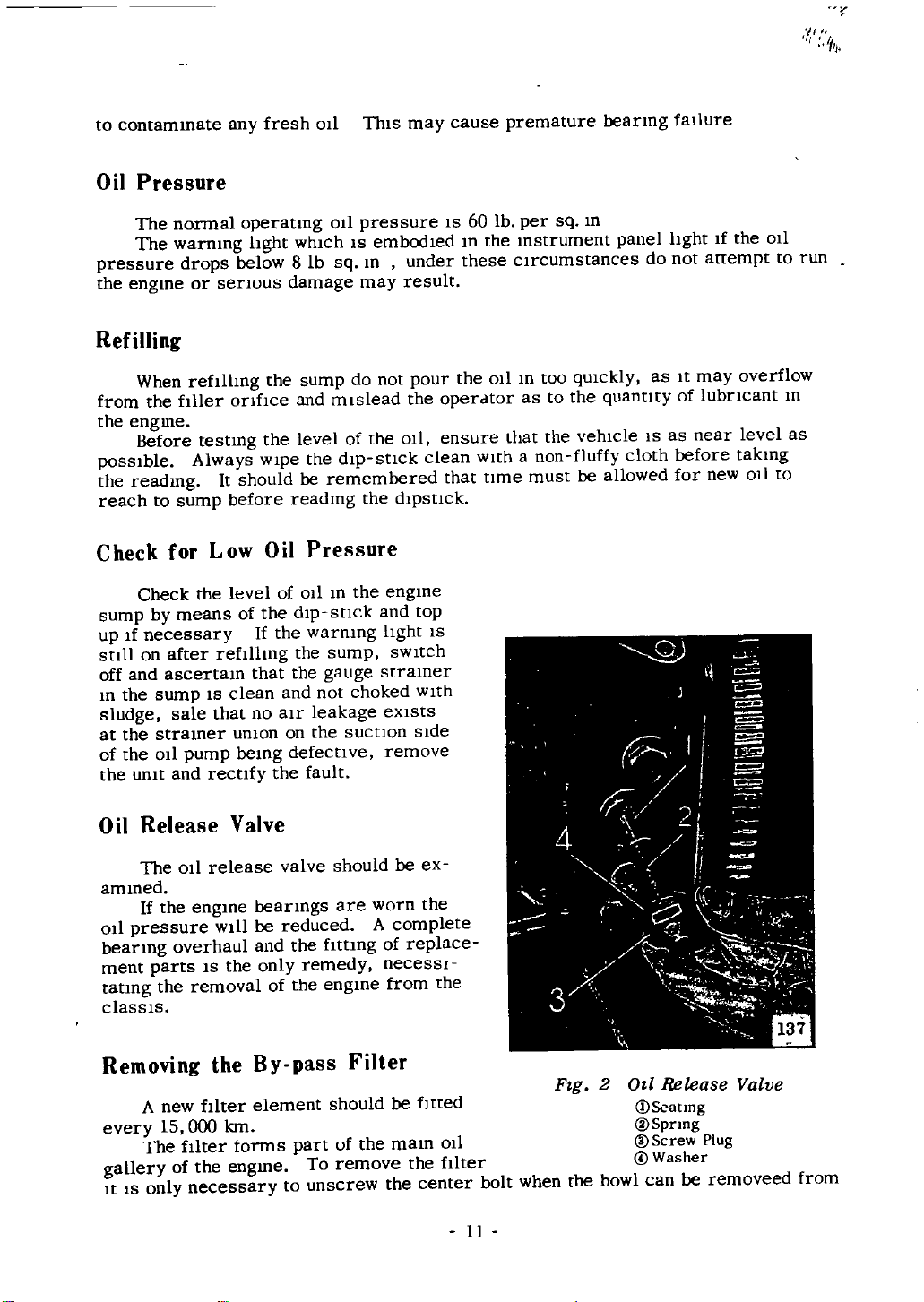

Release

Valve

DScatmg

@Spnng

@Screw

@

bolt

when

the

bowl

can

11

Washer

be

Plug

removeed

from

ASS

ELEMENT

011

With

Y

fllter

gasket

GASKET

fllter

body

ASS

SHAFT

center

top

Y

o

ASS

GASKET

011

element

filter

Y

GASKET

SEAT

element

body

r

1

seat

BRACKET

011

filter

GASKET

011

fllter

cyhnder

o

RING

retainer

sna

C

ele

p

PRING

element

settIng

c

O

RlNG

RETAlNER

V

ALVE

steel

to

k

safety

ball

safety

RING

snap

ent

SPRINGI

I

STUD

to

cyhnder

fix

011

fllter

block

see

sechon

Fig

01LFILTER

3

12

the

crankcase

ring

Remove

Wash

the

dry

bowl

Replacing

With

tIOn

In

the

with

the

the

flanged

Offer

center

011

of

Removing

the

out

bowl

up

the

to

the

center

the

bolt

the

complete

the

element

bowl

obviate

Filter

bolt

msert

end

towards

complete

Oil

with

Pan

any

a

with

the

new

the

and

note

pettol

contammaUon

washer and

element

the

element

assembly

element

the

so

assembly

that

Place

the

to

the

It

of

The

Take

IS

the

spring

the

engme

care

of

the

clean

lubrIcatmg

together

dIstance

bowl

of

and

not

to

components

It

IS

pIece

filter

secure

lose

Important

011

with

must

mto

the

the

over

rubber

collar

now

posItion

to

thorough

the

be

center

filled

by

sealing

m

POSI

means

bolt

with

The

Remove

cUring

the

cess

011

flange

pan

Removing

WIth

011ISdrawn

the

011

the

cleanmg

pipe

pIck

securmg

The

flange

stramer

purpose

NotIce

to

the

cover

rectly

when

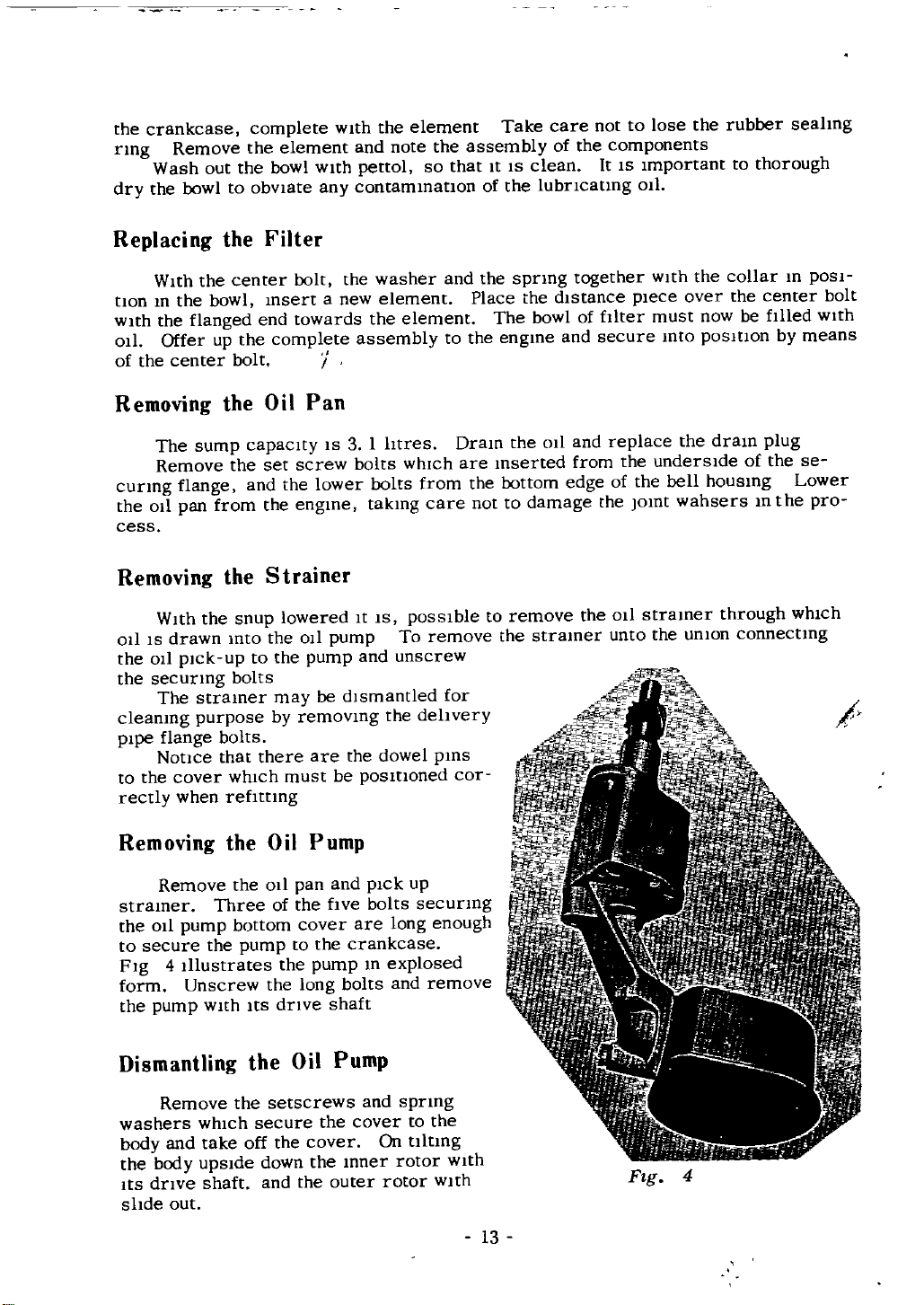

Removing

Remove

straIner

the

011

secure

pump

pump

4

Illustrates

Unscrew

to

FIg

form

the

sump

the

Three

the

With

the

and

from

the

snup

mto

up

bolts

bolts

that

whIch

refItung

the

the

bottom

pump

ItS

capacity

set

the

the

Strainer

lowered

the

to

the

may

by

there

must

Oil

Oil

of

to

the

the

drive

IS

screw

lower

engme

011

pump

pump

be

removmg

are

be

Pump

and

pan

the

fIve

cover

the

pump

long

shaft

3IInres

bolts

bolts from

takmg

It

IS

and

dIsmantled

the

dowel

posItIOned

pick

bolts

are

crankcase

m

bolts

which

care

possIble

To

remove

unscrew

the

delivery

pms

up

securing

long

enough

explosed

and

remove

for

Dram

are

cor

the

not

mserted

bottom

to

to

the

the

damage

remove

straIner

011

and

from

edge

the

replace

the

of

the

011

unto

the

Jomt

stramer

the

the

underSIde

bell

wahsers

unIOn

dram

of

housmg

through

connecung

In

plug

the

the

se

Lower

pro

which

Dismantling

Remove

washers

body

the

Its

slide

and

body

drive

WhICh

take

upSIde

shaft

out

the

the

off

setscrews

secure

the

down

and

Oil

the

cover

the

Pump

the

mner

outer

cover

and

On

rotor

spring

to

ultmg

rotor

the

WIth

WIth

Ftg

4

13

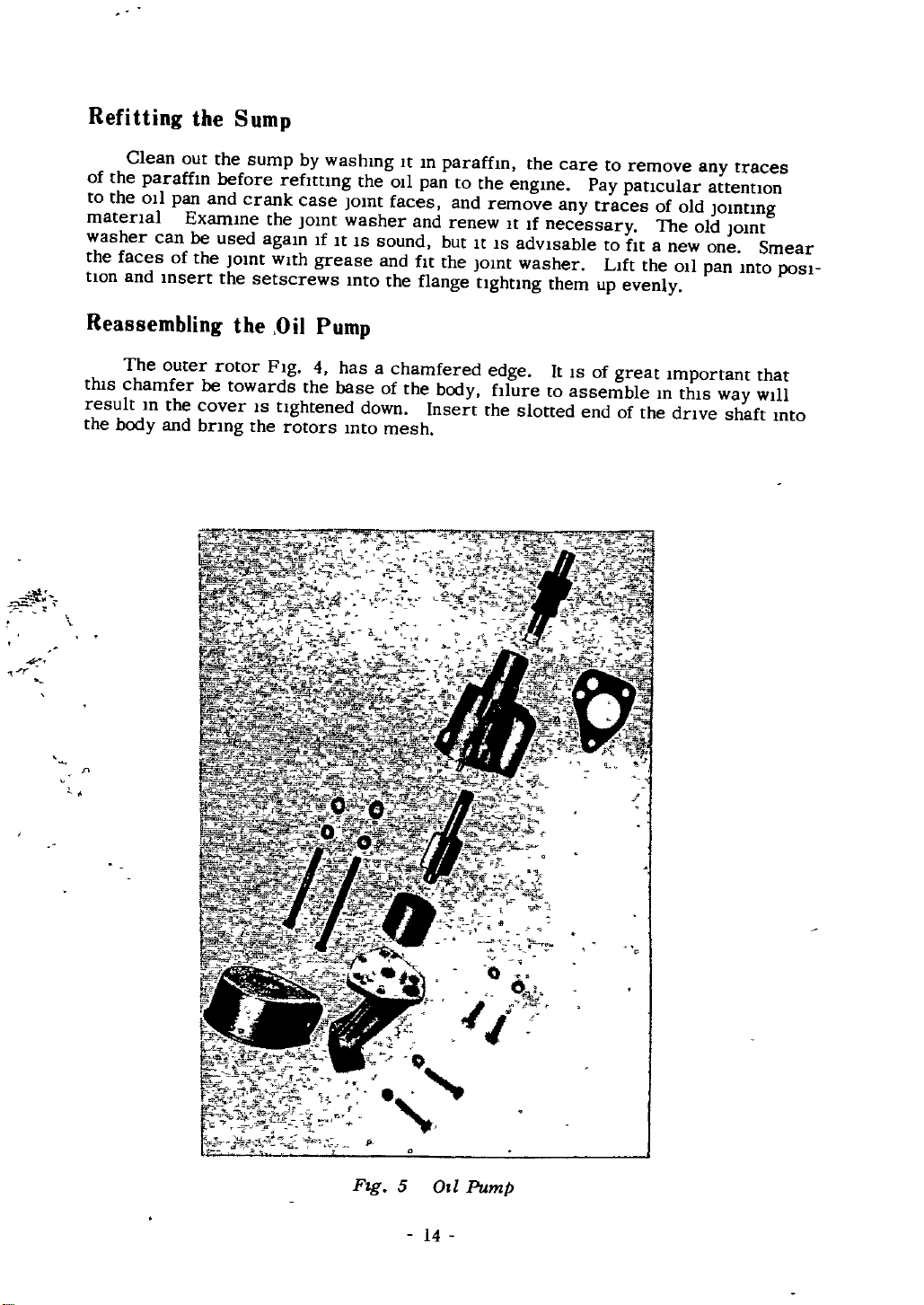

Refitting

the

Sump

Clean

of

the

paraffm

to

011

the

materIal

washer

the

non

can

faces

and

Reassembling

The

thIS

chamfer

result

the

10

body

pan

of

msert

outer

the

and

out

and

Examme

be

the

be

cover

brIng

the

before

used

Jomt

the

rotor

sump

crank

setscrews

the

towards

IS

the

by

refIttmg

case

the

Jomt

agam

WIth

Oil

Fig

tlghtened

rotors

washing

the

lomt

washer

If

IS

It

grease

mto

Pump

4

hasachamfered

the

base

down

mto

011

faces

sound

and

the

of

mesh

It

the

10

pan

and

fIt

flange

Insert

paraffm

the

to

and

renew

but

It

the

Jomt

tlghtmg

body

remove

IS

edge

fIlure

the

the

engme

It

1f

adVIsable

washer

slotted

care

any

necessary

them

It

IS

to

assemble

end

Pay

traces

up

of

to

remove

patlcular

fIt a

to

LIft

evenly

great

of

of

The

the

m

the

any

attentlon

old

Jomnng

old

new

one

011

pan

Important

thiS

drIve

Jomt

way

shaft

traces

mto

Smear

poSl

that

WIll

mto

t

r

1

y

n

o

l

fuo

f

0

i

P

Fzg

5

OJl

Pump

14

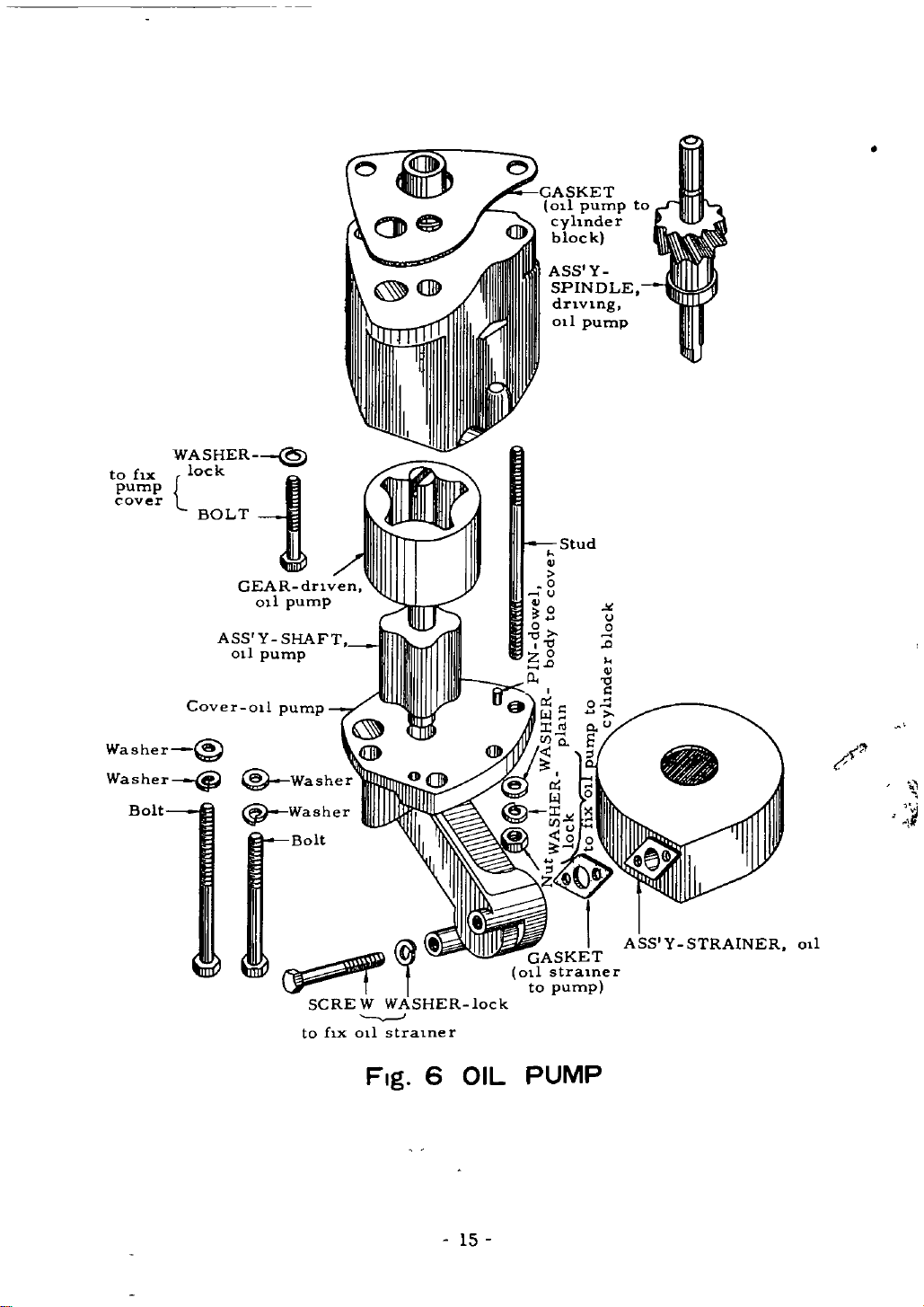

to

pump

cover

GASKET

011

cyhnder

bloc

ASS

SPINDLE

pump

k

Y

to

drlVlng

011

pump

WASHER

O

BOLT

k

I

Stud

ilx

i

0

u

Cover

ASS

0

Y

SHAFT

0

1

pump

oll

pump

0

00

0

D

p

U

o

D

Washer

Washer

Bolt

@

@

Washer

Washer

Bolt

SCREW

to

tf

t

1

ASS

Y

GASKET

ot

stramer

to

WASHER

ilx

0

1

stralner

Fig

lock

6

OIL

15

pump

PUMP

STRAINER

011

Loading...

Loading...