Nissan Bluebird 1977 User Manual

Jt

I

i

ft

f

l

S

l

Ei

i

1P

I

SeRleOsA3ciJ

eNGINes

DAN

11

e

3

L

S

rA

6

0

i

N

I

I

t

f

1

f

l

j

l

I

f

r

II

I

t

r

Fj

4i

to

J

1

l

1

I

l

i

I

I

1

1

i

t

I

J

I

if

I

If

t

t

s

1

J

loiI

4

I

1

l

ll

f

t

t

w

V

Z

1j

YiJ

lt

1

h

t

l

l

I

if

ll

e

t

r

t

I

i

i

f

L

h

Jo

41

I

r

I

l

i

to

1

I

r

oL

l

t

t

c

11

f

1

t

rt

f

1

if

F

j

i

J

r

J

rs

X

I

t

F

r

jr

1

l

r

v

l

S

IENTI

VORKSIIOI

DATStIN

IC

I

IUANIJAL

UBLI

1600

ATIONS

SERIES

No

88

1300

r

i

I

5l

f

if

AIJTOMATI

SED

Repair

SIfRIE

Ip

o

N

VA

and

1

13

L16

With

and

SCIENTIFIC

BRISBANE

v

i

iI

t

ON

MANIJAL

LI4

Specifications

Maintenance

SYDNEY

MELBOURNE

9

1

S

1600

510

sss

TRANSMISSIONS

Specifications

PUBLICA

I

t

nONS

DURHAM

LONDON

e

u

4

i

J

PICKln

Data

1

1

ft

t

t

t

1

1

1

r

f

1

II

ti

J

Ii

T

if

w

t

ic

1

t

l

J

f

i

l

o

li

1

t

r

wi

t

Q

if

t

lt

d

I

t

t

0

V

i

t

1

I

t

f

L

i

t

l

t

l

l

rt

1

Vo

Ji4

i

4

t

lf

f

1

I

l

tC

J

I

fJ

f

11

t

J

t

t

Ci

P

1

f

o

1

t

s

t

F

l

f

1

w

i

li

tt

1l

4

tf

i

A

f

j

4l

b

T

1

61

I

r

tt

1

1

t

Jt

oI

t

i

t

f

it

r

1t

l

P

t

J

t

If

e

e

q

t

1

r

1

1

1

Ij

f

o

1

d

t

t

t

f

f

l

f

f

4

j

J

1

1

1

11

l

1

1

y

1

l

1

1

i

ot

i

i

i

J

ft

i

t

i

r

t

l1

t

1

1

t

J4

1

t

l

t

J

rr

1

t

Jx

I

r

e

OL

t

E

4

isof

0

r

Ii

t

v

ot

lPiO

J

li

t

V

c

P

5 J

J

r

J

Lr

I

rr

t

i

J

Ltr

rl

I

J

J

1

i

1

I

tj

r

J

j

J

J

c

v

J

i

M

II

v

t

1

f

j

r

t

1

1

1

e

1

J

Y

i

fI

lt

j

I

1

0

t

j

v

1

4

t

I

1

j

r

a

j

T

U

i

I

r

J

t

PUBLISHED

BY

SCIENTIFIC

j

J

PUBLICATIONS

PTYLTO

t

t

AustrahaJ

89 97

Jones

Stre

t

ULTIMO

PhO

tt

P

d

NSW

2007

Umt4

Hetton

HETION

TYNE

Phone

Lyons

AND

Hetton

England

Industnal

HOLE

LE

WEAR

Estate

DHS

ORH

Ie

Hole

2443

21T6I1

j

Pnnted

by

Tjmes

Pnnters

Smgapore

@

informatIOn

at

to

be

While

onus

made

Copynght

at GPO

our

for

the

tlme

taken

mto

every

precaution

can not

repalT

operations

f

F

I

J

I

I

t

1

4

RegIstered

The

available

sources

need

contests

descTlbed

vertently

by

Sydney

FlfSt

Reprmted

Repnnted

Repnnted

Repnnted

In

thiS

workshop

of

consideratIOn

be

SCIentIfIc

EdItIon

ISBN

manual

wTltmg

IS

accepted

or

for

December

November

85566

research

Any

taken

for any

transnussJOn

December

May

June

IS

by

for

Sdn Bhd

PubhcatIons

1972

1977

039

2

deTlved

and

subsequent

the

operator

to

ensure

any

errors

Ltd

Pty

by

post

1971

1973

1975

the

from

from

latest

other

modificatIOns

the

accuracy

miSinterpretatIOn

or

omiSSIOns

as

book

a

models

available

of

of

inad

will

the

the

n

N

owum

Sclentlfic

Corp

Il

M

E

Slme

Austrahan

l

o

Auto

P

ServIces

anll

AIItech

MuIler

PublIcations

LE

J

v

Canada

New

1

J

SouthAfrica

United

r

1

Repco

Zealand

Pubhshers

E

Kingdom

Fredenck

SCjentIfic

HETION

USA

OVERSE

Parts

Canada

Bookshop

Co

82

Industnes

Distnbutors

Ltd

HOLE

PubhcatlOns

and

Borg

aspects

82

Eden

13

St

Tory

Export

Vlctona

Urnt

TYNE

WIshes

Warner

of

preparIng

S

REPRES

Ltd

325

TaranakI

Newmarket

St

Welhngton

15

HIgh

Works

4

Hetton

and

West 6th

St

Pty

WEAR

F

to

Ltd

thIS

ENTATIVES

WellIngton

Ltd

St

Edgware

Lyons

N

thank

FaIrfield

manual

Avenue

Auckland

and

140

PO

Box

Hampton

Industnal

DH5

ORH

IJ

T

NlSSan

Target

2016

Road

fJ

Motor

for

help

Vancouver

Rd

ill

Glenfield

Johannesburg

MIddlesex

London

Estate

IOBC

Auckland

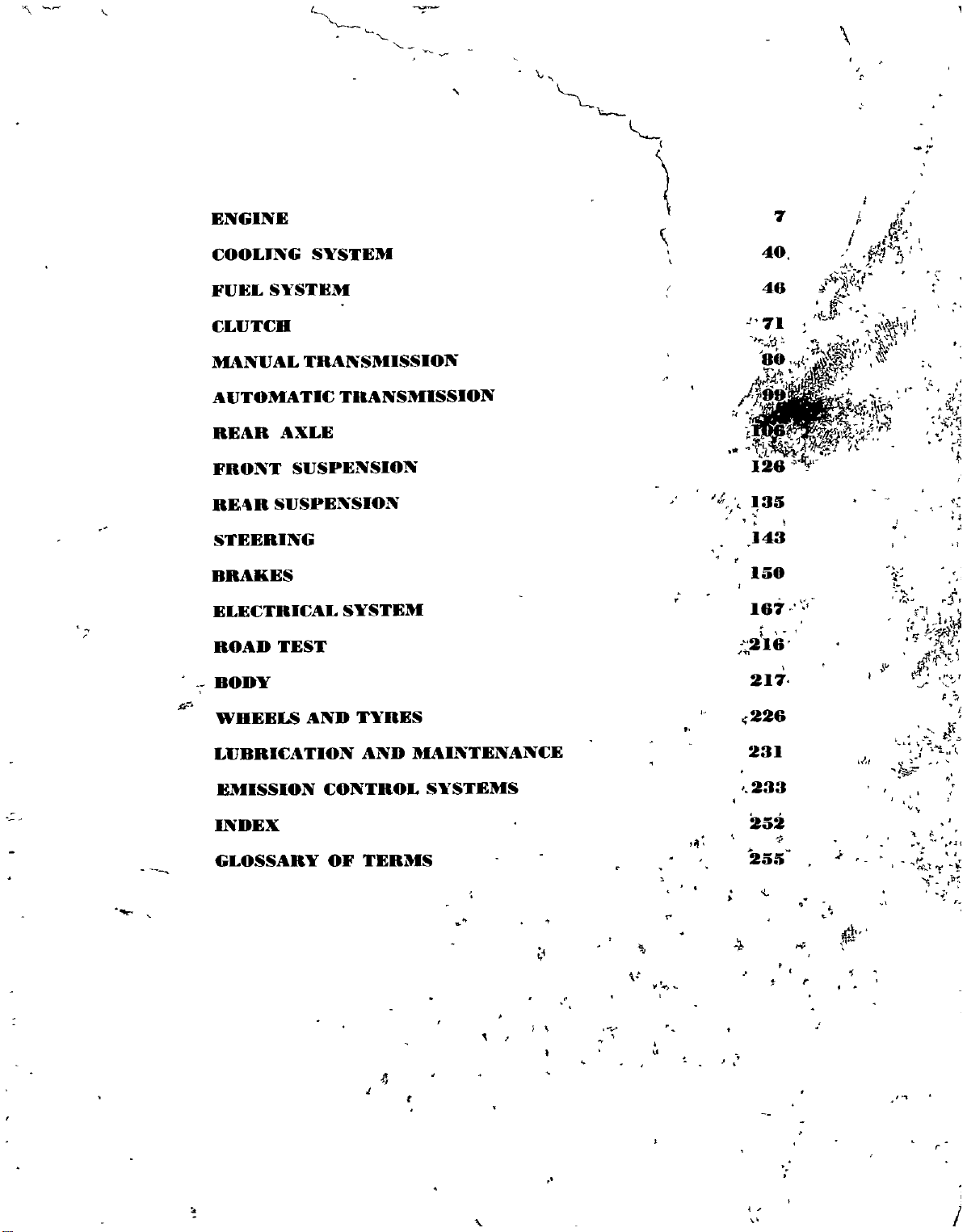

ENGINE

COOLING

FUEL

CLUTCH

MANUAL

SYSTEM

SYSTEM

TRANSIUISSION

7

40

46

f

i

r

J

i

jp

1

t

J

r

t

I

1

1

1

t

V

f1

i

i

0

d

AUTOMATIC

REAR

FRONT

RRotR

STEERING

BRAKES

ELECTRICAL

ROAD

BODY

WHEELS

LUBRICATION

EMISSION

INDEX

GLOSSARY

TRANSMISSION

AXLE

SUSPENSION

SUSPENSION

SYSTEM

TEST

AND

CONTROL

OF

TYRES

AND

TERMS

MAINTENANCE

SYSTEMS

1

1

I

35

143

150

167

216

217

i

j

1

1

1IM

ff

l

rr

1

t

f

226

I

231

233

1

w

l

252

4

255

lt

p

1

b

v

J

f

r

I

f

SCIENTD1C

Bool

Pagea

No

MOTOR

Austin

AustIn

AustIn

Allegro

Allegro

i

t

1

ChrysIer

1

Galant

Galant

Dalslm

1000

510

180B

Sunny

r

i

Ford

Capn

Consul

CortlDa

i

l

t

b

I

1600

Cortma

Cortma

Excort

Escort

Falcon

6

Rican

t

J

1

Falcon

t

Falcon

1

If

H

Avenger

Hunter

New

VEIDCLFS

lillO

1300

Met

1

OHV

lillO

1300 1973

OHC

1500 1750

1973

MrtsuInslu

GA GB

1300 1600 1971

GCGD

1774

600

77

1200

1300

1400

1968

72

16OB

120Y

I

Mk

Zephyr

62

1956

1200

I

Mk

71

1964

Mk

III

1971

Mk

74

Mk

Mk

XK to

XYtoXB

yl

1970

XR

1966

XA

1971

1960

I

II

to

71

and

76

74

III

2000

1972

cyl

6

V8

V8

lnuUl

Hunter

1500

II

XW

70

76

XY

Mk

XB

Colt

Colt

1600

1600

6

76

76

74

II

cyl

148

149 192

2551192

200

05

192

17

224

87

88

256

110

224 208

III

224 278

8208173 108

184

68

288

60

240

59

176

81

192

20

192

62

290

155

272 226

154

272 190

156

240

80

176

79

188

37

Holden

GerolDl

j1

t

FX

FJ

FE

FC

c

HK

HK

HQ

HQ

Torana

Torana

T

orana

Torana

Torana

Torana

EK

HR

1968

1968

1969

1974

4

cyl

4

cyl

1974

EJ

HT

71

HT

71

HI

6

V8

HJ

LC

74

LH

76

HB

LC

196975ohv

LC

1969

LH

76

HG

HG

EH

eyl

1948

i8

U

LX

LJ

U

LX

HD

V8

6

cyl

6

6

TA

TA

75

4

FB

cyl

ohc

cyl

cyl

113 160

67

85

86

146

147

84

58

72

56

145

16

286

272

224

208

256

192 172

192

192

196

196

180

Honda

ElVIe

CIVIC

HondamatIc

Manual

139

140

176

176

240

327

267

215

215

188

194

240

200

120

287

295

197

350

339

298

129

202

208

241

124

192

239

135

172

188

121

128

m

tre

1

37

7

r

I

PUBLICATIONS

Leyland

OHV

Allegro

lillO

1300

OHC

Allegro

1500

1750

MannaI3I8

1971

75

Manna

1500

P76

V8

6

P76

cyl

BL

1100 1300

Mazda

616

Capella

73

1970

1500

1800

RX2 RI00

1000

MG

TCtoMGB

Moms

MlDor

Manna

MIDI

MmJ

1100

1800

Peugeot

403

Renaalt

12

DauphIne

R8

Toyota

Corolla

Corolla

Corona

Corona

Corona

Vabant

AP6

V8

R

S

VE

Heml

6

Galant

Veuxhall

VIva

Viva

Chevette

Volkswagen

Super

1971

Beetle

1200A

1954

Fastback

Transporter

Type

1800

Passat

1500

Golf

Rotanes

1300

1000

see

Leyland

72 64

1961

76

1971

MkIMk

404

RIO

and

1100

1200

2R

2000

12R

VC

VE VF

1965

70

AP5

AP6

VF

6

70

1962

VG VH

eyl

1970

under

see

HB

HA

HC

OHV

1256

bug

73 45

1100

1300

71

Type

1954

2

1700

2000

1300

1600

1500

1600

76 25

1973

76

1973

1750

1600

I

Mk

II

16R

18R

RT80

81

VC

cyl

74

Chrysler

90 76

ce

1302S

1600

1200

1500

3

1600

72

Bool

142

141

148

122

120

123

114

151

152

153

No

51

03

04

89

90

91

92

70

24

02

65

66a

31

32

34

74

73

83

69

78

52

57

46

47

48

MANUAL

PaIfS

192

160 291

180

180

160 134

212

200

305

160

320

204

96

236

224

276

146 106

224

122

160

134 158

164

176

107

240 217

224

186

176

256

160

220

174

145

280

224

183

200

140

160

239

1

224

240

260

232

167

272

205

240

168

168

235

I

h

tretioDS

277

274

324

196

199

96

187

174

171

97

95

88

317

J

SERIES

Volvo

Senes

WIth

Carb

With

Fuel

HARD

VINTAGE

Austm

A40

Devon

A40

Somerset

Jagoar

VII

Mks

XK

120

I

II2434

Mk

E

Type

1962

Staodanl

8

14

Ten

1955

aster

Spa

TR2

TR3

MOWERS

SMALL

Rover

Senesto1977

Small

EngInes

V

lcta

Seriesto1977

Scott

Bonnar

MOTOR

Honda

QA50

MmJblke

SL70

Cf90

50 65

CIS

StreetTfrad

125

Vert

250

350

100

125

OUTBOARDS

EnnrudeJoImson

34

hp

5

6

hp

1965

9

1964

hp

18

25

20

182025

3340

hp

40hpLark

MANUALS

Austm

1100

Hillman

Vahant

VJ

1500

Golf

Rovers

Mowers

Scott

Bonnar

140

es

Inject

TO

GET

MANUALS

Dorset

VIII

IX

140

150

4 2

3 8

69

1939

46

58

II

TR4

AND

ENGINFS

1976

CYCLFS

70

175 132

eal

TWIn

VertIcal

SmgIe

1964

72

74

73

hp

1960

hp

1960

74

1965

74

1965

IN

PRODUCfION

1300

New

Hunter

VK

1600

Mowers

AND

3 8

73

73

77

Bool

No

53

54

00

01 100

21

22

77

40 82

41

42

44

99

112

103

97

129

130

131

133

134

135

105

106

107

108 112

108

109

104

148

37

157

153

99

97

Pagea

212

196

106

274

274

202

148

126

168

160

128

64

128

96

112

112

128

112

64

96

80

112

128

112

224

182

341

346

376

374

177

198

260

260

300

250

172

147

237

281

124

134

105

130

231

138

92

m

treb

89

84

51

95

f

I

1

11

1

Ii

f

l

1

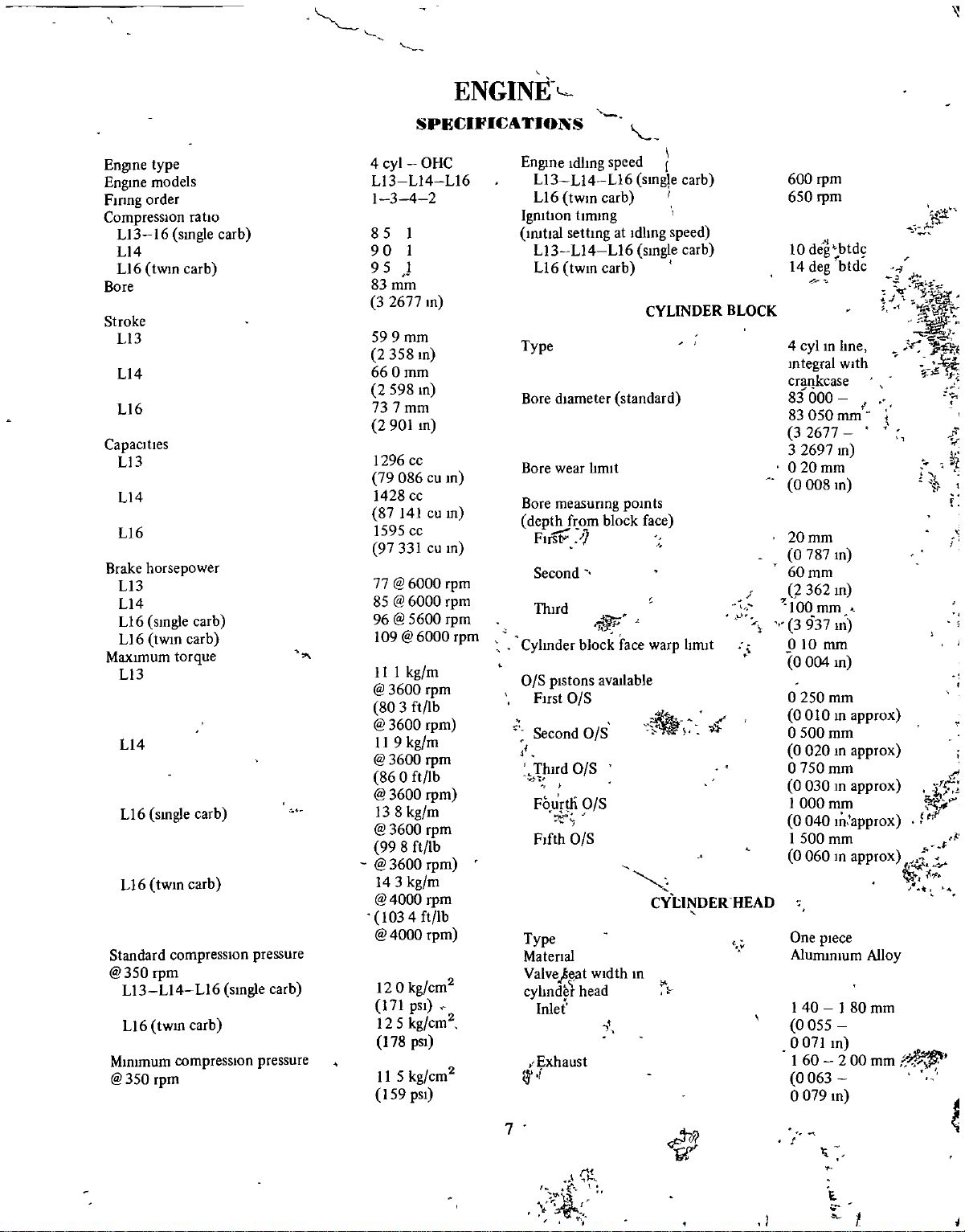

Engllle

type

models

Engllle

order

Fmng

CompressIOn

L13

16

L14

L16

Bore

slllgle

tWill

Stroke

L13

L14

L16

CapacIties

L13

L14

L16

Brake

horsepower

L13

L14

L16

slllgle

L16

twill

Maximum

L13

L14

L16

L16

Standard

@

350

L13

L16

Minimum

@

350

torque

single

tWin

compressIOn

rpm

L14

tWin

compressIOn

rpm

ratio

carb

carb

carb

carb

carb

carb

L16

carb

single

pressure

carb

pressure

4

cyl

L14

L13

4 2

1

3

85

90

95

J

83mm

2677

3

59

9

mm

2358

660mm

2598

73

7

mm

2901

cc

1296

79 086

cc

1428

87

141

cc

1595

97331

@

6000

77

85@6000

96

@

5600

109

@6000

III

kg

@

3600

803ftlb

@

3600

119

kg

@

3600

860ft

@

3600

13

8

kg

@

3600

998ft

3600

@

143

kg

4000

@

1034

@

4000

120

kg

171

pSI

125

kg

178

5

II

kg

159

SPECIFICA

OHC

L16

Ill

Ill

In

In

In

cu

cu In

cu In

rpm

rpm

rpm

m

rpm

rpm

m

rpm

lb

rpm

m

rpm

lb

rpm

m

rpm

ft

lb

rpm

cm2

cm2

pSI

cm2

pSI

ENGINE

TIO

EngIne

L13

L16

Igmtlon

InItIal

LJ3 LJ4 LJ6

Type

Bore

Bore

Bore

depth

rpm

CylInder

O

FIrStOS

Second

l

ThIrdOS

FourtJi

FIfth

Type

Matenal

Valve

cylInder

t

l

LJ6

dIameter

wear

measunng

Fust

Second

Thud

S

pistons

r

Inlet

Exhaust

i

S

IdlIng

L14

tWIn

tIming

settIng

tWin

from

J

block

O

O

t

O

Eeat

t

c

head

carb

carb

lImit

block

avaIlable

S

S

S

Width

speed

L16

at

IdlIng

standard

pOInts

face

t

I

single

I

speed

single

CYLINDER

face

warp

CYtINDER

In

l

carb

carb

IInut

BLOCK

J

HEAD

600

650

10

deg

14

deg

4

cyl

Integral

crankcase

83000

83

050

3

2677

3

2697

o

20

0008

20mm

0787

60mm

2

362

7

100mm

910mm

0004

o

250

0010

o

500

0

020

0750

0030

I

000

0040

I

500

0060

One

AlumInIUm

I

40

0055

0071

160

0063

o

079

rpm

rpm

mm

piece

In

mm

In

on

In

In

In

mm

on

mm

In

mm

on

mm

In

mm

In

In

In

btd

btdc

lIne

WIth

39371

approx

approx

approx

approx

approx

I

80

200mm

Alloy

mm

w

r

J

i

fe

to

Y

f

iL

t

Fr

Wt

7

1J

K

i

C

J

4

t

I

y

yl

jIl

c

rJ

i

i

2

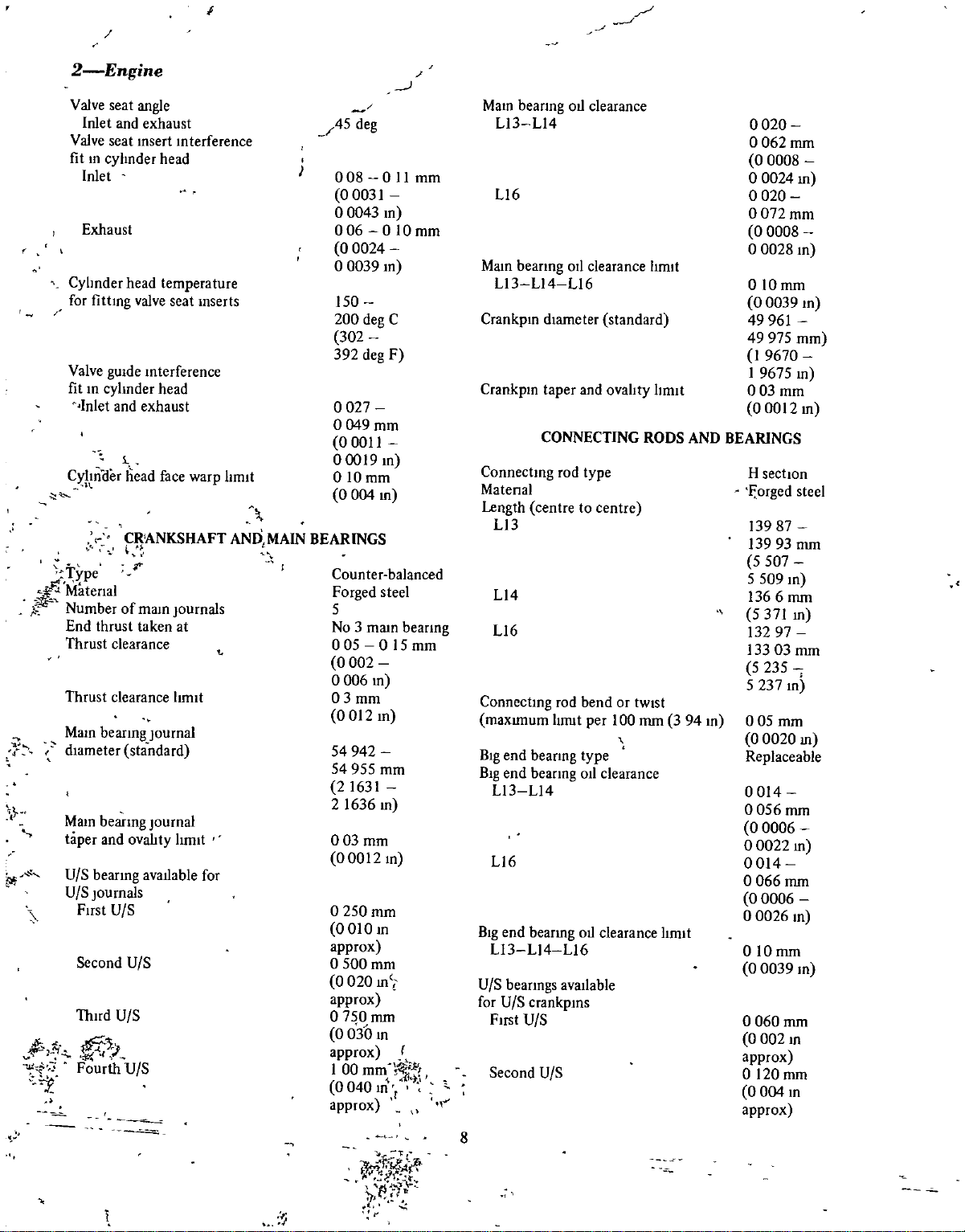

Engine

Valye

seat

Inlet

Valve

seat

m

fit

cyhnder

Inlet

Exhaust

Cyhnder

for

fittmg

Valve

gUide

fit

m

cylmder

Inlet

Cylulder

Type

Matenal

Number

End

thrust

Thrust

clearance

Thrust

clearance

Mam

beanngJournal

diameter

Mam

beanng

and

taper

VIS

beanng

VIS

Journals

Fust

VIS

Second

Third

ffi

Fourth

and

head

valve

and

1

iiead

CR

of

standard

ovahty

VIS

VIS

VIS

angle

exhaust

msert

mterference

head

tempera

seat

mterference

head

exhaust

face

ANKSHAFT

mam

Journals

taken

at

IUTIlt

Journal

hmlt

avaIlable

warp

ture

mserts

for

hmlt

AND

MAIN

1

j45

J

BEARINGS

Counter

Forged

5

No

o

0006

03mm

54

54955

2

003

o

approx

o

approx

0750

approx

I

approx

deg

008

00031

00043

006

00024

00039

150

200

302

392

o

027

o

049

00011

00019

o

10mm

0

004

3

05

0002

0012

942

21631

1636

00012m

250

OOIOm

500

0020

0

O

JO

00

0040

deg

deg

mm

mam

m

mm

mm

mm

mm

mm

Ii

d

0

II

m

01Omm

m

C

F

m

m

balanced

steel

0 15

m

mm

on

m

m

I

u

r

Ot

r

tt

r

I

t

l

J1tJ

mm

beanng

mm

I

T

A

t

Maon

L13

L16

Mam

L13

Crankpon

Crankpon

Connectmg

Matenal

Length

L13

L14

L16

Connectmg

maxnnum

Big

BIg

L13

L16

end

Big

L13

VIS

for

VIS

FITSt

Second

8

beanng

L14

beanng

LI4

diameter standard

taper

CONNECTING

rod

centre

rod

lumt

end

beanng

end

beanng

L14

bearmg

L14

beanngs

crankpms

VIS

VIS

oIl

clearance

clearance

oIl

L16

and

type

to

bend

per

type

011

oIl

L16

avaIlable

J

ovahty

centre

or

100

clearance

clearance

RODS

tWIst

mm

hmlt

hmlt

hmlt

394

AND

BEARINGS

m

o

020

0062

mm

00008

o

0024

m

o

020

0072

mm

00008

o

m

0028

o

IOmm

m

00039

49961

49

I

003

975

9670

I

9675

mm

00012

H

sectIOn

Forged

139

87

139

93

5507

5

509

1366

5371

mm

m

on

steel

mm

m

mm

m

13297

133

03

mm

5235

5

m

237

005

mm

00020

m

Replaceable

0014

0056mm

00006

00022

0014

o

00026

o

o

approx

o

approx

066

00006

IOmm

00039

060

0

002

120

0004

m

mm

m

m

mm

m

mm

on

Thud

Fourth

FIfth

SIxth

Type

DIameter

Length

Clearance

Interference

Type

L13

L16

Matenal

Removal

DIameter

DIameters

FIrSt

Second

U

U

U

L14

O

S

UIS

S

S

In

pIston

fit In

standard

O

S

O

S

3

Engine

250

GUDGEON

rod

PISTONS

PINS

mm

o

0010

approx

o

mm

500

0

020

approx

0750

mm

0030

approx

100mm

0040

approx

Interference

In

rod

20995

21

000

0

8266

08268

72 00

25

mOl

72

8346

2

28445

o

008

mm

0010

00003

00004

0015

0033

mm

00006

00013

In

Thud

In

In

FourthOS

S

O

FIfthOS

In

PIston

Skut

measunng

clearance

pOInt

bore

In

fit

mm

In

In

In

Gudgeon

DIstance

LocatIOn

pIn

below

bore

i

offset

centre

lIne

PISTON

gudgeon

of

RINGS

r

Number

Width

compressIOn

In

Upper

Lower

compressIOn

72

83

77

mm

83

3

296

3

m

298

83

84 02

3

305

3

308

97

mm

In

4

0

r

8447

84 52

mm

3

326

3

328m

18 6

mm

In

732

9

o

025

045

o

mm

It

11

l

0001

00018

o

004134

pm

J

i

t

950

050

1

003740

4

f

k

1

I

V

In

mm

In

gudgeon

r

li

t

J

pin

3

20mm

In

0078

20mm

007810

control

011

Flat

top

Invar

slipper

Concave

Invar

slipper

Cast

Top

82

99

83

04

3

267

3

269

strut

skut

top

strut

skIrt

alumInIUm

of

cylinder

mm

In

Clearance

Upper

Lower

S

83

22

27

83

mm

3

276

3

In

8347

83

3

3288

278

286

52

mm

In

011

compressIOn

L13

L14

L16

compressIOn

L13 L14

control

L13

L14

10

grooves

i

L16

L16

40mm

015610

0040

0073

00016

00029

o

045

0078

00018

00031

0030

o

063

00012

o

0025

025

o

0

063

0001

00025m

mm

mm

mm

mm

e

f

10

10

10

j

9

Engine

Rmg

Upper

Lower

gap

compressIOn

compressIOn

023

o

o

38

00091

0015

015

mm

m

030mm

Type

Free

Outer

length

LI3

Ll4

VALVE

00059

00118

In

0

011

k

t

iff

control

o

0

00118

15

0059

30

mm

m

VALVES

Ji

II

it

if

i1

J

J

tC

i

fl

o

I

f

y

t

Head

13

l

t

lt

6 tWIn

Head

Stem

Inlet

Clearance

Inlet

dIameter

LI4

dIameter

dIameter

and

exhaust

In

mlet

LI6

carb

exhaust

gUide

sIngle

bore

carb

38

1

42

I

65

33mm

30

1

8mm

0 31

0015

0045

00

mm

50

In

0

mm

m

In

m

mm

00006

00018

Exhaust

0040

o

r

I

Valve

length

Inlet

Exhaust

J

l

d

itr

VaJve

Inlet

LI3

Ll6

Valve

Inlet and

Valve

Hot

hft

and

LI4

twm

face

clearance

exhaust

carb

angle

exhaust

LI6

smgle

carb

Inlet

5Jt

i

l

if

lj

Exhaust

00028

45

o

o

070

mm

00016

1159mm

456

m

1160mm

In

457

100mrl

03937

10

5

mm

04l24m

deg

25

mm

0010

30

mm

0012

In

m

m

30

mm

In

m

Ll6

Inner

LI6

Length

Outer

LI3

Ll6

Inner

Ll6

Length

OUJer

Ll3

LI6

Inner

LI6

at

load

valve

closed

Ll4

load

at

valve

open

Ll4

Cold

Inlet

Exhaust

o

o

20

0008

25

mm

mm

m

Valve

spnng

squar

eness

OOIOm

3

oj

10

1

r

t

hmlt

r

SPRINGS

y

t

1

J

6

j

t

@

26

eb

59

J

4

t

4

Hehcal

12

48

I

m

89

52

00

20472

44

85

7657

1

400mm

@

29

2

322

k

57

m

1

@

64 39

71011b

38

9

mm

@

27

5

30

5

k

53

In

1

@

60 62

67241b

35mm

@116

13 0 k

38

m

1

25 58

@

28661b

30

0

mm

@677

74

7

k

118m

@

149

164611b

30

7

mm

45

@

4

50

2k

307m

@10009

11667Ib

mm

245

2

24

8

k

96

Ini

5i31f

lb

Olf

I

6

Inm

0063

m

J

1f

i

mm

mm

mm

19

g

tl

r

m

m

g

fJ

r

t

f

J

r

g

g

I

I

i

l

l

A

t

r

g

t

1

w

i

f

1

ft

l

j

j

C

t

1

i

i

Engine

5

DRIVE

Sprocket

cham

fit

Light

One

bolt

peg

fit

Light

Key

and

and

Type

Length

Inner

Ou

ter

diameter

diameter

VALVE

GUIDES

Renewable

0

mm

59

232111

8000

8

018

mm

11

11

04718

985

996

m

mrn

03154

03150

Type

Camshaft

Fit

on

Method

ctankshaft

on

Fit

Method

sprocket

camshaft

of

secunng

sprocket

crankshaft

of

secunng

CAMSHAFf

04723111

Fitted

cyhnder

GUide

Inlet

Exhaust

Type

Number

Camshaft

CamshaWJournal

Camshaft

Camshaft

L13

4

L16

Camshaft

beanng

Beanng

M

CfiTshaft

f

11

dJ

J

0

r

J

1

P

lmshaft

qr

Cf

L

t

J

t

yr

t

r

u

t

J

I

height

head

yalve

to

of

Journal

bearmg

lobe

Ll4

twm

Journal

clearance

clearance

bend

tih

above

stem

1ft

j

ll

beanngs

aj

hft

Ll9

carb

nd

float

I1I1

clearance

diameter

wear

diameter

smgle

to

hmlt

t

l

r

q

CAMSHAFT

hmlt

carb

pump

max

rotor

Idle

bolts

nuts

LUBRICA

end

pressure

filter

filter

WRENCH

bolts

bolt

104

0

409

0417111

p

0015

o

045

00006

00018

0040

0070

00016

00028

Overhead

4

47949

47962

1

8877

1

8883

o

10

mm

00039

48

000

48016

1

8898

1

8904

6

65

mm

0261

7

00

0275

o

038

0076

00015

00026

o

10mm

0

0039

008

00031

00150m

005

0

002

mm

mm

mm

mm

mm

106mm

m

m

mrn

m

m

mrn

m

m

m

m

m

0

38

m

mrn

Pump

Outer

clearance

body

Inner

clearance

Inner

clearance

Ou

pressure

Rehef

Free

Length

Rehef

Ou

capacity

Sump

Sump

Cylmder

Mam

end

Big

Camshaft

type

rotor

rotor

max

and

outer

JTlax

valve

length

at

valve

Without

mcludmg

head

beanng

beanng

sprocket

to

tIp

at

spnng

load

opemng

TORQUE

cap

11

It

f

nON

SETTINGS

Eccentnc

021

0

009

o

12mm

012mm

0005

0

I

142

57mm

2

24

39mm

540

I

38

42

kg

l54

59

7

rotor

mm

lOW

0005

11

J

m

2

I

cm2

kg

171

pSI

i

l

m

m

cm2

00

pSI

J

111

t

I

fYl

fl

f

t

ra

l

k

J1

1h

w

o 4

0

6

Engine

bolts

Sump

011

pump

Flywheel

Rear

engme

to

transmISSIOn

Rear

engme

to

crossmember

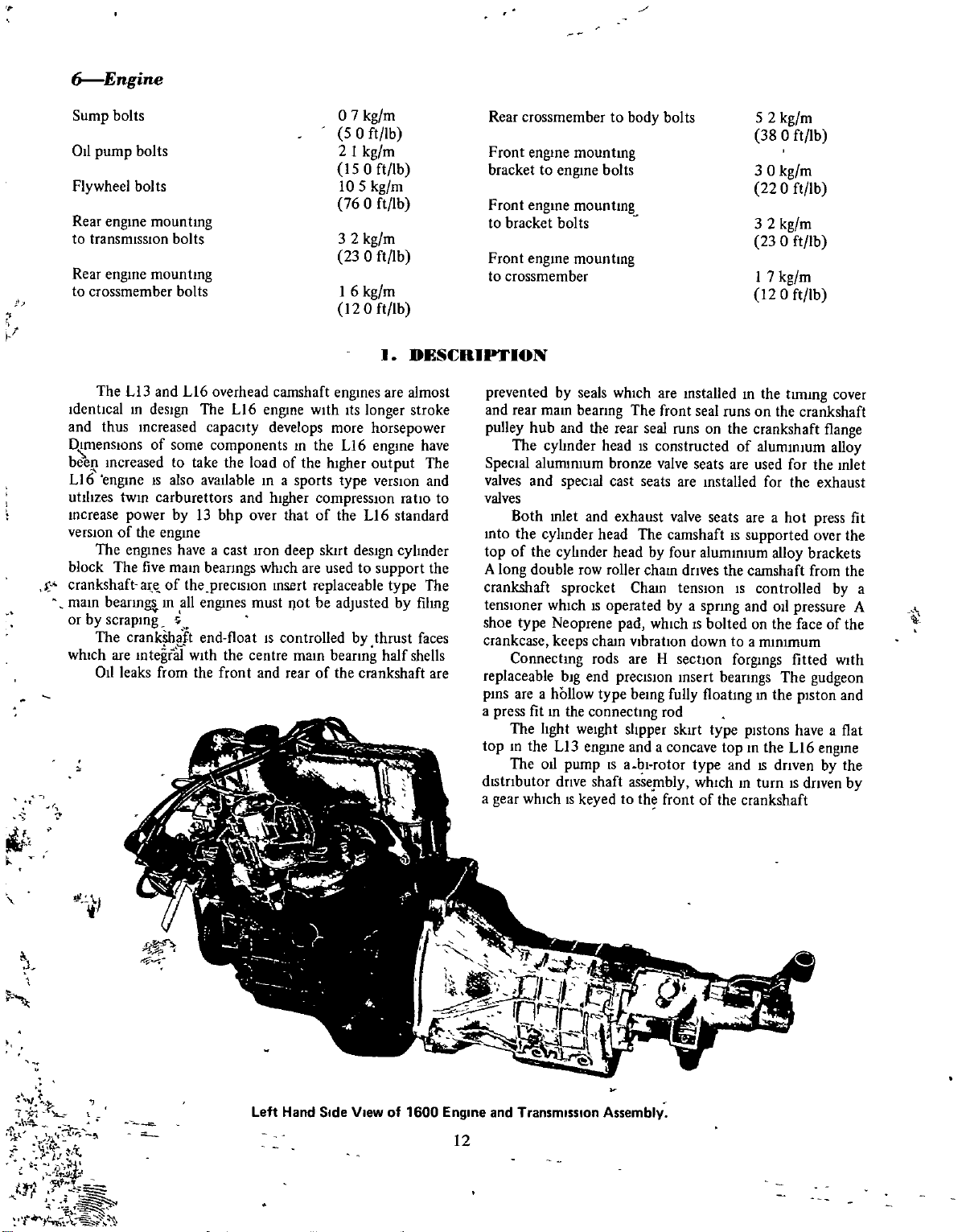

The

IdentIcal

and

thus

DImenSIOns

b

n

mcreased

L16

engme

utlhzes

mcrease

versIon

block

crankshaft

mam

or

which

by

The

The

bearIn

scrapmg

The

are

011

of

leaks

bolts

bolts

mountmg

mountmg

L13

m

deSIgn

mcreased

of

IS

twm

power

the

engInes

five

aH

cran

mtegraJ

bolts

bolts

and

L16

The

some

take

to

also

avaIlable

carburettors

by13bhp

engme

have

mam

of

the

m

al1

engInes

end

1t

With

from

the

overhead

capacIty

L16

camshaft

engrne

develops

components

the

load

m

and

hIgher

over

a

cast

Iron

bearIngs

precIsIon

whIch

msert

must

floatIScontrol1ed

the

centre

front

and

m

of

a

sports

that

deep

l

mam

rear

the

are

ot

o 7

m

kg

50

ft

lb

2

1

m

kg

0

ft

lb

IS

105

kg

0

ft

76

3

m

2

kg

230ft

1

m

6

kg

120ftlb

I

ItS

L16

type

longer

are

horsepower

engme

output

versIOn

engmes

wIth

more

the

hIgher

compressIOn

of

the

L16

slmt

deSIgn

used

to

support

replaceable

be

adjustedbyfilmg

thrust

by

the

half

crankshaft

bearIng

of

m

lb

lb

DESCRIPTION

almost

stroke

haye

The

and

ratIo

standard

cyhnder

the

The

type

faces

shel1s

are

to

Rear

crossmember

Front

engme

bracket

Front

to

Front

to

prevented

and

pul1ey

to

engme

bracket

engme

crossmember

rear

mam

hub

The

SpecIal

valves

valves

alurmrnum

and

Both

mto

the

cyhnder

of

the

top

A

double

long

crankshaft

tenslOner

shoe

type

crankcase

Connectmg

replaceable

are

press

gear

The

m

The

a

fit

hght

the

011

whIch

pms

a

top

dIstrIbutor

a

mountmg

engme

mountmg

bolts

mountmg

seals

by

beanng

and

cyLmder

specIal

mlet

and

cyhnder

row

sprocket

whIch

Neoprene

keeps

end

bIg

hollow

m

the

weIght

L13

engIne

pump

dnve

IS

keyed

to

body

bolts

whIch

The

the

rear

head

IS constructed

bronze

cast

exhaust

head

The

headbyfour

roller

Cham

IS

operated

pad

cham

VIbration

are

rods

preCISIon

type

bemg

connectmg

shpper

and

IS

bl

a

shaft

asse

to

the

bolts

are

mstal1edmthe

seal

front

seal

runs

valve

seats

seats

are

mstalled

valve

camshaft

alummlUm

cham

drIves

tensIon

a

by

sprmg

whIchISbolted

down

H

section

msert

fully

floatmg

rod

skIrt

a

concave

rotor

type

whIch

mbly

front

of

runs

on

the

of

are

are

seats

IS

supported

the

camshaft

IS

and

to

forgmgs

bearIngs

type

pIstons

m

top

andISdrIven

m

the

crankshaft

5

2

kg

380ft

0

3

kg

220ftlb

3

2

kg

23

0

1

7

kg

120

on

the

crankshaft

alummlUm

used

for

a

alloy

controlled

OIL

on

the

a

mmlmum

The

m

the

the

turn

m

lb

m

m

ft

lb

m

ft

lb

tlmmg

crankshaft

for

the

the

exhaust

hot

press

over

brackets

from

pressure

face

fitted

gudgeon

pIston

haveaflat

L16

engIne

by

IS

drIven

coyer

flange

al10y

mlet

the

the

by

of

the

WIth

and

the

by

fit

a

A

Jf

t

Itt

y

il

ff

J

J

t

1

Yi

i

t

t

l

r

l

1

l

10

tJ

li

f

t

I

4

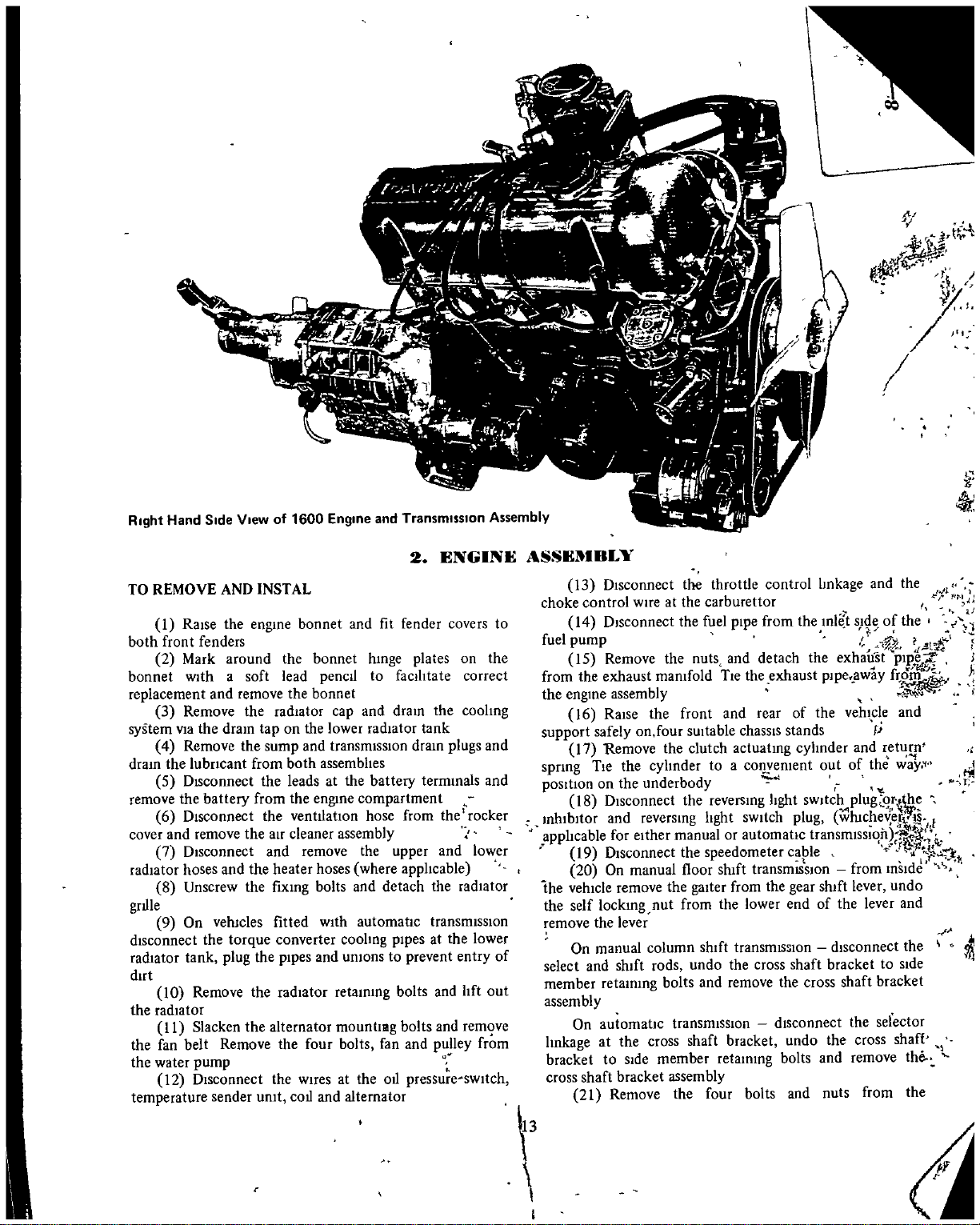

Left

Hand

Side

View

of

1600

l

Engone

12

and

Transmission

Assembly

t

5

I

t

r

t

v

Hand

RIght

TO

REMOVE

Raise

I

both

front

2

Mark

bonnet

wIth

replacement

3

Remove

vra

system

4

Remove

drain

the

lubricant

5

Disconnect

remove

cover

radiator

6

and

7

8

the

Disconnect

remove

Disconnect

hoses

Unscrew

grille

9

On

disconnect

radiator tank

dirt

Remove

10

radiator

the

Slacken

II

the

fan

belt

water

the

temperature

12

pump

Disconnect

SIde

fenders

and

the

battery

vehicles

the

Remove

sender

V

AND

the

around

a

remove

drain

and

torque

plug

soft

the

the

the

the

the

ew

INSTAL

engine

tap

sump

from

the

from

the

and

the

the

the

umt

of

1600

bonnet

the

lead

the

radiator

on

the

and

both

leadsatthe

the

ventilatIOn

air

cleaner

remoye

heater

fixing

fitted

converter

pipes

radiator

alternator

the

four

the

wlfes

coil

Engone

and

bonnet

pencil

bonnet

cap

lower radiator

transmission

assemblies

engine

assembly

hoses

bolts

and

wIth

cooling

umons

and

retaining

mountlllg

boIts

at

and

alternator

and

TransmiSSion

2

fit

fender

hinge

plates

to

facilitate

and

drain

drain

battery

compartment

hose

from

the

upper

where

apphcable

detach

automatic

pipes

to

prevent

bolts

boIts

fan

and

the

011

pressure

ENGINE

covers

the

tank

plugs

terminals

theIrocker

and

the

radiator

transmiSSIOn

at

the

entry

and

and

pulley

0

Assembly

to

on

the

correct

coohng

and

and

lower

lower

of

hft

out

remove

from

switch

ASSE

choke

ti

ue

from

the

support

spring

posItion

inhibitor

apphcable

the

the

remove

select

member

assembly

hnkage

bracket

cross

13

14

1

pump

IS

the

engine

16

17

18

19

20

vehicle

self

On

On

BL

control

safely

Tie

on

the

manual

and

shaft

21

Y

Disconnect

wIre

Disconnect

Remove

exhaust

assembly

Raise

Remove

the

the

Disconnect

and

either

for

Disconnect

On

manual

remove

locking

lever

shift

retaining

automatic

the

at

SIde

to

bracket

Remove

at

the

mamfold

the

on

Jour

the

cylinder

underbody

reverSing

manual

the

nut

column

rods

bolts

transmiSSIOn

cross

member

assembly

the

the

throttle

the

carburettor

the

fuel

nuts

TIe

and

front

sUitable

clutch

to

the

reversing

hght

the

speedometer

floor

shift

gaiter

the

from

un

0

Shdlft

and

shaft

retaining

four

pipe

and

detach

the

rear

chaSSIS

actuating

a

cO

lYement

sWitch

or

automatic

transmISsion

from

lower

transmISsIOn

the

cross

remove

bracket

bolts

control

from

exhaust

hght

the

the

disconnect

bolts

of

stands

cyhnder

plug

ca

gear

end

shaft

undo

and

t

i

the

t

exhaust

vehicle

the

disconnect

bracket

shaft

the

nuts

S

v

away

and

of

from

lever

lever

the

cross

remove

from

and

of

e

fj

ret

the

9

J

inSide

to

bracket

selector

l

PIP

frifp

and

way

i

undo

shaff

the

Jl1

n

h

wlucheveiI

is

i

and

Sl

thde

the

the

linkage

the

mle

the

plpe

the

out

sWltctplug

transmlsslqi1n

le

shIft

of

cross

and

I

2

I

I

I

l

I

j

r

l

t

j

t

y

e

r

d

t

R

bracket

0

assembly

e

NOTE

not

and

pomt

propeller

transmISSion

NOTE

to

disconnect

the

rear

22

the

at

transmission

23

to

mountmg

24

transmiSSIOn

engme

25

transmISSIOn

the

crossmember

26

hooks

which

engme

the

weight

TO

REMOVE

I

hose

and

2

remove

be

necessafY

3

carefully

away

shaft

rear

To

remove

the

see

tlOn

of

Detach

Remove

secunng

Interpose

and

and

transmISSIOn

Remove

crossmember

InstalasUitable

are

of

the

thermostatIc

two

the

engines

from

head

the

the

mlet

the

tIe

cylmder

Detach

Loosen

the

to

On

Detach

flange

the

rear

the

propeller

the

handbrake

rear

the

bolts

a

a

Jack

the

posItIoned

and

engme

rocker

the

au

bolts

whIch

manIfold

fitted

to

remove

hIgh

the

hIgh

rocker

the

and

propeller

handbrake

crossmember

two

transmISSIOn

wooden

and

take

assembly

four

bolts

the

to

IIftmg

at

the

With

assembly

cover

au

bleed

cleaner

secure

and

With

twm

the

arr

tensIOn

tensIOn

cover

WIthdraw

shaft

cable

shaft

cable

block

the

which

underbody

cable

front

sUitable

to

hose

assembly

the

remove

SU

cleaner

leads

leads

It

where

from

weight

or

cham

and

IIftmg

I

atr

cleaner

where

atr

carburettors

at

the

may

rear

ROCKER

shaft

from

be

necessary

It

runs

ItS

retammg

crossmember

between

of

the

attach

the

the

and

remove

to

the

rear

tackle

ventIlatIOn

fitted

thumb

cleaner

the

screw

assembly

au

cleaner

ssembly

the

spark

ataconvement

under

clIp

the

rear

rear

IIftmg

of

the

take

It

Will

plugs

the

AR

27

Remove

crossmember

28

assembly

and

also

29

upwards

the

transmiSSIOn

be

lIfted

secunng

Check

to

ensure

that

all

Gradually

to

clear

clearofthe

InstallatIon

attentIon

securely

weIght

vanous

antI

Ensure

IS

components

FIll

freeze

FIll

to

the

the

to

that

all

taken

If

the

radiator

necessary

crankcase

recommended

Start

and

operatmg temperature

f

ND

I

IVOTS

relevant

and

order

pOSItIons

head

ends

replacement

removmg

8

to

9

and

Lay

arm

before

Place

ensure

m

the

Unscrew

remove

these

to

the

the

the

around

that

relevant

taIse

the

on

the

vehicle

IS

a

reversal

followmg

the

engme

mountmgs

the

by

to

With

of

grade

run

the

attemptmg

arm

rocker

that

they

cylInder

the

the

Items

cylmder

front

bolts

notlung

Items

the

body

jack

pomts

and

mountmgs

the

engine

water

With

S

M

engme

and

check

arms

wIll

head

rocker

rocker

also

out

head

engme

the

engme

will

have

engme

and

at

untu

of

the

assembly

that

before

and

and add

the

ou

engine

un

forouand

to

m

a

be

mstalled

arm

PIvOtS

guides

m

order

mountmg

foul

been

WIth

the

the

engme

removal

IS

the

full

transmission

correct

tu

co

rf

kss

rack

from

and

on

the

disconnected

the

same

tune

assembly

procedure

mstalled

engme

connectmg

condItIoner

amount

It

reaches

water

the

or

lay

m

theu

the

from

the

to

ensure

to

transmISSIOn

assembly

front

tuted

lowenng

and

bolted

assembly

up

and

of

normal

leaks

valve

sprmg

them

out

ongmal

cylInder

yalve

stem

correct

front

can

With

the

or

the

m

NOTE

carefully

breakdown

the

J

each

PIvOtS

Dunng

which

dIslodged

NOTE

see

Carbon

4

Remove

rocker

5

UnclIp

rocker

6

Back

down

7

Withascrewdnver

IllustratIon

this

are

and

When

el

the

for

at

all

m

lead

cover

arm

off

as

operatIon

located

lost

rocker

filled

times

wntmUlty

the rocker

and

and

the

far

as

and

removlIIg

on

tensIOn

high

Mlshandlmg

rocker

remove

rocker

possible

manoeuvre

take

care

the

end

rocker

arm

bel1lg

cover

cover

the

pivOt

mto

push

leads

secunng

gasket

small

the

down

l

that

of

the

arms

removed

of

steady

locknuts

cylInder

on

out

the

valve

valve

ensure

should

leads

bolts

each

each

IS

adjacent

be

Will

and

spnng

and

screw

head

valve

rocker

rocker

stems

that the

handled

cause

detach

from

spnng

arm

gUides

are

cam

to

not

the

a

Its

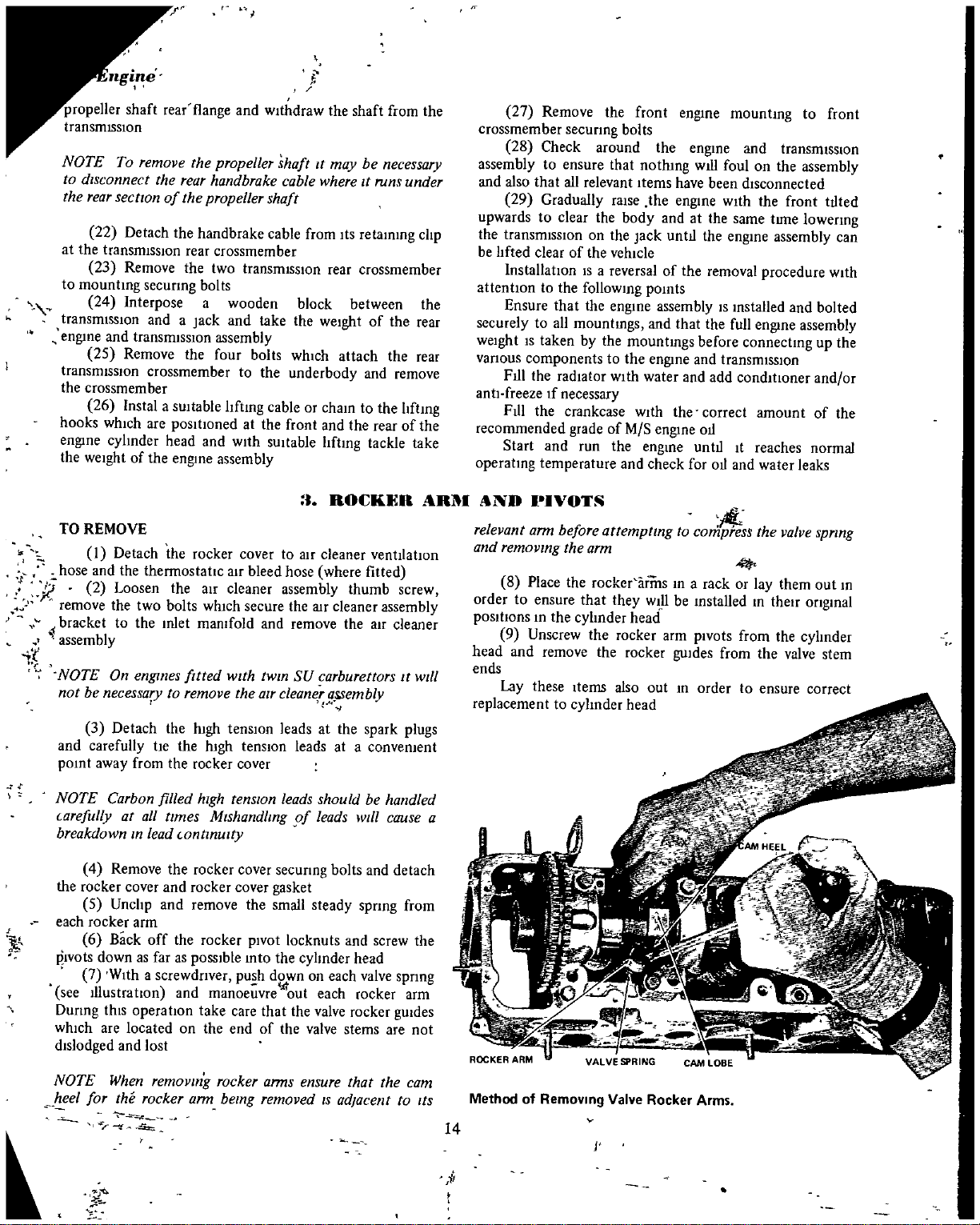

Method

of

RemOVing

Valve

Rocker

Arms

14

J

t

t

1

1t

f

l

If

TO

CHECK

Wash

1

wIth

dry

or

to

2

Check

damage

3

Check

vot

contact

p

4

Wear

compressed

components

correspondmg

TO

REMOVE

Disconnect

J

ventIlatIOn

cleaner

Smgle

by

pass

Disconnect

Disconnect

Disconnect

lever

Remove

off

the

Twm

carburettor

hose

thermostatic

2

Remove

3

Remove

applicatIon

hose

the

the

the

the

carburettor

apphcatlOn

all

components

an

rocker

the

the

rocker

surfaces

or

damage

will

necessitate

Pivotorrocker

AND

INSTAL

the

and

where

au

the

air

the

carburettor

dISconnect

where

fitted

dlStnbutor

choke

control

throttle

carburettor

remove

Engine

arm

arm

for

to

bleed

cleaner

vacuum

hnkage

to

Rocker

In

Pivot

to

wear

one

arm

rocker

fitted the

hose

assembly

s

the

cable

at

marufold

the

Cover

cleanmg

head

cam

and

or

damage

of

the

the

as

the

cover

mlet

as

follows

fuel

feed

pipe

the

carburettor

retammg

mlet

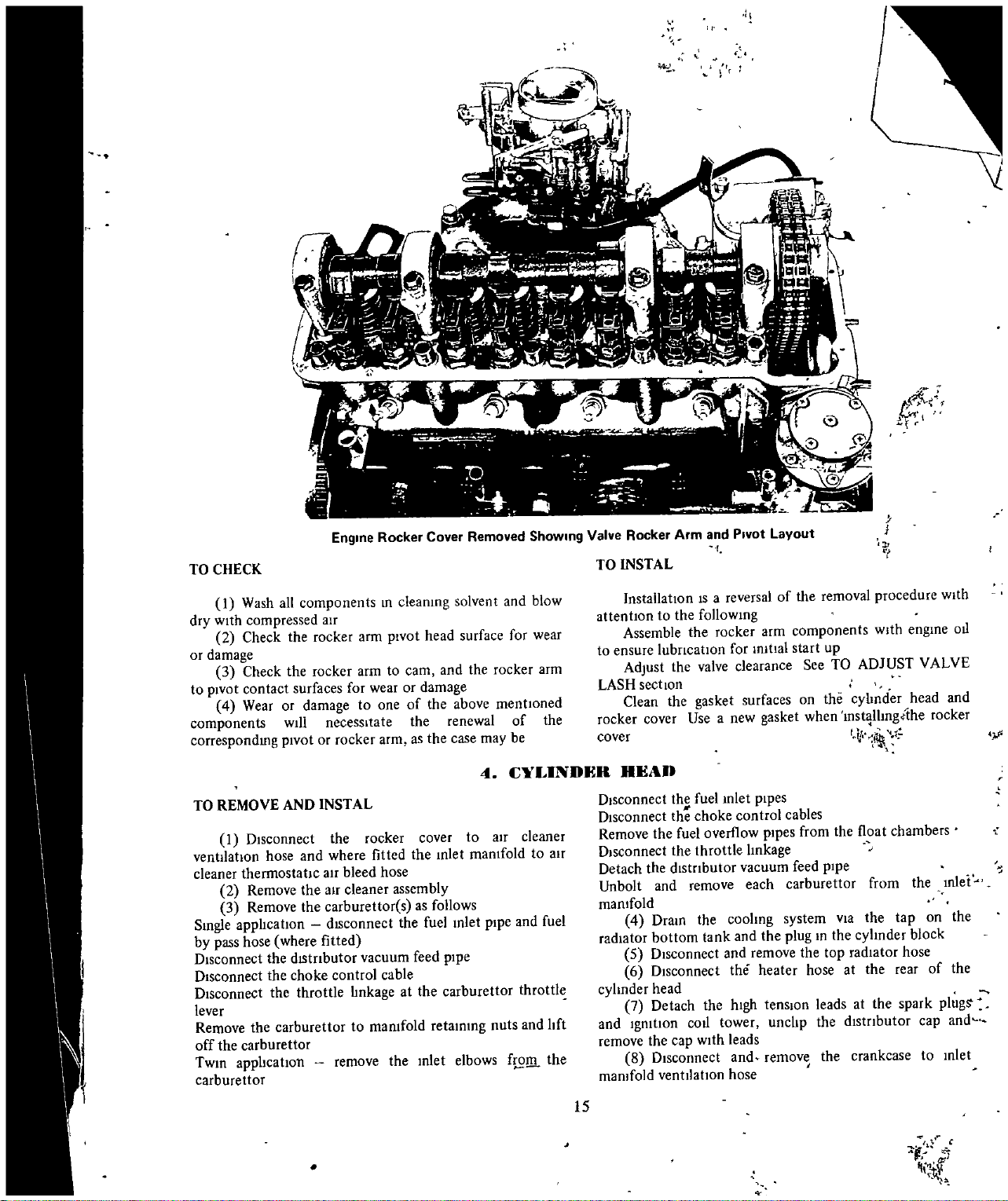

Removed

solvent

surface

the

above

renewal

case

to

mamfold

mlet

elbows

rocker

mentIOned

may

4

an

pipe

nuts

Showing

and

blow

for

wear

arm

the

of

be

CYLINDER

cleaner

to

air

and

fuel

throttle

and

lift

the

fJ

2m

Val e

TO

INSTAL

InstallatIon

attentIon

Assemble

to

ensure

Adjust

LASH

Clean

rocker

cover

HEAD

Disconnect

Disconnect

Remove

Disconnect

Detach

Unbolt

mamfold

radiator

5

6

cyhnder

7

and

IgmtlOn

remove

8

mamfold

Rocker

to

lubncatlOn

section

cover

the

the

and

4

Dram

bottom

DIsconnect

Disconnect

head

Detach the

the

Disconnect

vent

Arm

the

the

the

valve

the

gasket

Use

fuel

thS

the

choke

fuel

the

throttle

dlstnbutor

remove

the

tank

cou

With

cap

lahon

P

and

IS

a

reversal

followmg

rocker

for InitIal

clearance

surfaces

a

new

mlet

control

overflow

vacuum

each

coohng

and

and

the

high

tower

leads

and

hose

vOt

Layout

arm

gasket

pipes

pipes

hnkage

the

remove

heater

tensIOn

unchp

remove

of

the

components

start

See

on

when

cables

from

feed

carburettor

system

m

plug

the

hose

leads

the

removal

up

TO

ADJUST

the

cyhnder

mstalhngilhe

t

the

float

pipe

Via

the

the

cyhnder

radiator

top

the

at

at

dlstnbutor

the

crankcase

J

procedure

With

1

iiI

chambers

from

tap

hose

rear

the

spark

engme

head

the

block

cap

to

VALVE

rocker

mlet

on

of

plug

Inlet

With

ou

and

the

the

and

15

C

7

1

w

I

p

r

I

J

f

I

I

Engine

9

remove

the

10

umt

11

the

fuel

pump

II2

tlie

cylmder

msulator

13

nuts

flange

14

manifold

mlet

mamfold

15

mamfold

exha

st

gaskefA

16

the

getach

mlet

Detach

Disconnect

Remove

head

the

mamfold

the

and

Remove

block

Remove

and

detach

Progressively

to

cylinder

Progressively

to

cylinder

malufold

Remove

rocker

cover

retammg

the

the

the

head

head

DIscard

1

the

water

wire

fuel

two

Withdraw

exhaust

the

exhaust

slacken

attachmg

slacken

attachmg

rocker

Discard

from

nuts

the

clip

pIpe

mlet

secunng

the

mamfold

and

Inlet

cover

the

and

the

and

fuel

pipe

and

nuts

nuts

and

rocker

iIJ

then

disconnect

temperature

outlet

the

fuel

pump

to

exhaust

from

the

remove

and

remove

and

exhaust

securIng

cover

pIpes

gasket

11ft

the

lift

1

sender

pump

mamfold

the

away

exhaust

away

mamfold

boIts

gasket

III

and

from

and

pipe

mlet

the

the

and

14

to

DImenSIons

when

NOTE

Adhered

cylmder

Under

hand

to

tools

pme

17

protruded

coyer

18

the

on

mark

cham

dimple

19

stamped

elther

a I

N

been

prevIOusly

These

adjacent

For

found

IS

the2number

camshaft

camshaft

20

SUItable

Remove

21

between

on

cham

hmmg

sUitable

I1lustra

the

The

crankshaft

tenslOner

cham

tlon

of

Camshaft

head

by

10

between

Remove

front

Rotate

IS

on

The

adjacent

or

2

numbers

to

the

example

be

to

on

sprocket

dowel

Usmg

bar

unscrew

the

bolt

Instal

tracks

the

tens

support

piece

Wooden

rocker

bumping

circumstances

the

porhon

the

alIgned

the

camshaft

sprocket

to

3

dependIng

readjusted

are

camshaft

a

If

aligned

the

a correct

and

the

special

of

sprocket

plunger

lOner

tool

of

wood

6

Wedge

and

Cylinder

wvers

fmnly

the

alumlll

external

two

the

of

crankshaft

and

clearly

sprocket

hmmg

the

mark

due

also

staIJiped

dowellqcatmg

2

number

With

the

sprocket

dowel

locatmg

fittmg

the

camshaft

uel

the

limmg

the

hmIng

and

from

bore

can

be

to

the

for

can

use

um

Holding

Head

be

with

screwdrivers

cover

TIming

are

Removed

dislodged

the

palm

and

head

bolts which

unlil

headtothe

the

VISible

0

With

tunIng

cylinder

penphery

mark

number

be

dimple

whether

to

I

on

limmg

boss

metnc

pump

also

wIll

the

stretchmg

on

the

cham

wIll

hole

sprocket

actuatmg

cham

cham

to

tlmmg

the

sprocket

holes

sprocket

be

adjacent

and

socket

retalmng

support

to

retam

prevent

found

0 mark

spanner

cam

becommg dislodged

readily

dimenSIOns

fabncated

shOWn

Chain

from

of

or

Similar

secure

hmIng

lark

the

hmmg

which

to

cham

boss

penphery

then

to

also

bolt

tool

down

the

cham

the

hmmg

from

from

IIT

I

the

the

the

IS

be

has

the

the

and

the

a

the

Correct

NOTE

cham

valve

and

IS

t111l1ng

t1mmg

If

dropped

22 With

remoYe

23

tool

disconnect

In

support

camshaft

and

progresslyely

through

IS

lostItWill

wver

Withdraw

the

the

loosen

unforeseen

the

off

to

readjust

the

tumng

sprocket

reverse

and

crankshaft

be

the

the

order

remove

necessary

the

cham

tumng

cm

valve

camshaft

cham

of

the

the

umstances

sproLket

to

t1mmg

firmly

sprocket

from

tlghtemng

cylinder

remove

wedged

the

head

the

and

the

from

sprocket

sequence

t1mmg

correct

sump

by

secunng

the

the

bolts

PosItIon

of

Support

Sprocket

Tool

to

WIthdraw

Camshaft

far

the

Lift

enough

cylinder

to

clear

head

the

upwards

tlmmg

from

cham

the

and

cylinder

support

block

tool

16

I

t

I

1

Ii

IMPORTANT

head

to

crowns

the

If

ongmal

pnor

positIOn

to

contactmg

Do

not

sprocket

support

make

cylznder

head

the

have

tool

sure

pistons

rotate

been

removed

it

IS

essentzal

that

headISmstalled

I

e

when

removal

the

Installed

the

the

then

will

be

camshaft

when

valves

cham

the

posslbllzty

ellmmated

untzl the

on

the

installing

are

clearofthe

the

with

sprocket

camshaft

EJ

the c

p

camshaft

was

removed

val

the

of

cham

tzmmg

and

thecham

In

Its

and

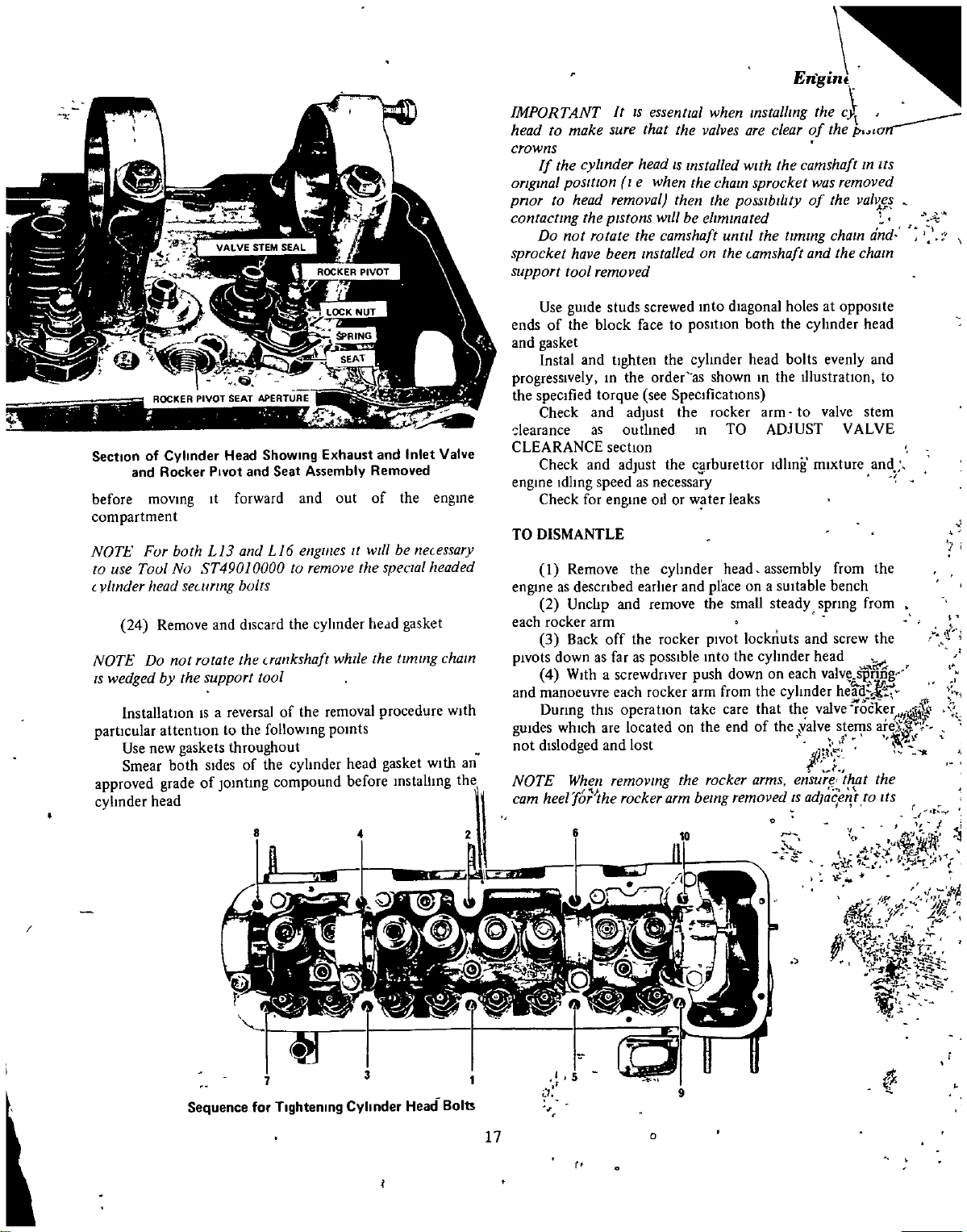

Section of

and

before

movmg

compartment

use

vlmder

wedged

InstallatIOn

For

Tool

head

24

Do

NOTE

to

c

NOTE

IS

particular

Use

new

Smear

approved

oylmd

Cylinder

Rocker

both

No

Remove

not

the

by

attention

gaskets

both

grade

d

h

ST490i

sewrmg

rotate

IS

of

Head

PivOt

It

forward

Li3

and

support

a

reversal

to

throughout

sides

JomtIng

Showing

and

and

0000

bolts

discard

the

crankshaft

tool

the

of

Seat

Assembly

and

Li6

to

remove

the

the

of

folloWIng

the

cylinder

compound

Exhaust

out

It

engl

les

cylmder

while

removal

pOInts

head

before

and

Removed

of

wLll

the

special

hedd

the

procedure

gasket

Inlet

Valve

the

engme

be

necessary

headed

gasket

timing

With

mstaltIng

cham

with

an

the

ends

and

progressIVely

the

slearance

CLEARANCE

engme

TO

engine

each

piVOtS

and

guides

not

NOTE

cam

1

Use

gUIde

the

of

gasket

and

Instal

specified

Check

Check

Idling

Check

for

DISMANTLE

Remove

I

as descnbed

2

Unclip

rocker

3

Back

down

4

With a

manoeuvre

Dunng

which

dislodged

When

heel

fof1he

block

In

torque

and

as

and

speed

engIne

arm

off

as

thiS

are

and lost

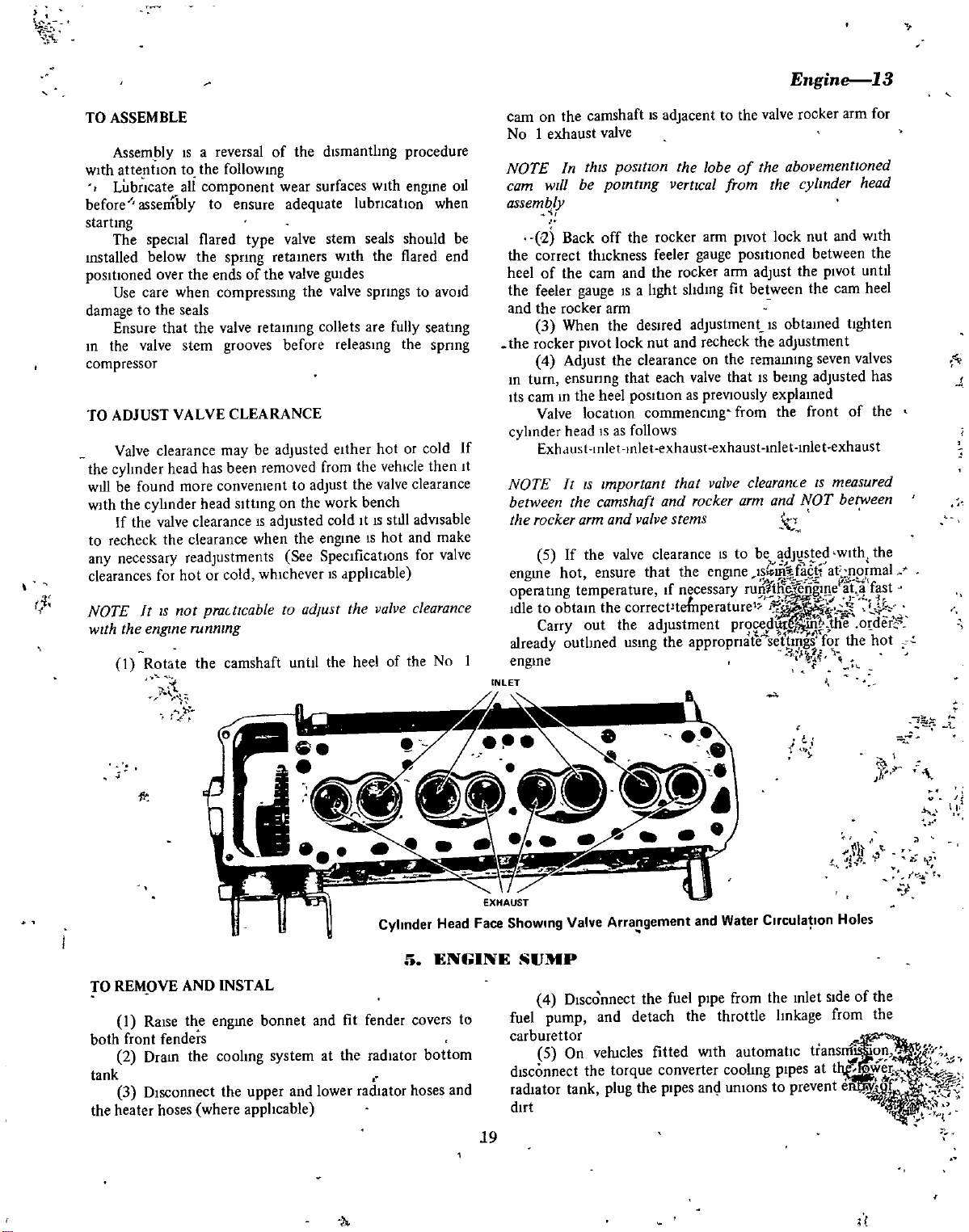

studs

tighten

the

adjust

outlined

sectIOn

adjust

the

and

the

as

far

screwdnver

each

operation

located

removmg

rocker

screwed

face

to

the

order

see

Speclfical1ons

the

the

as

necessary

011

or

cylinder

and

earlier

remove

rocker

pOSSible

rocker

on

the

arm

mto

dIagonal

pOSll1on

cylInder

as shown

both

head

rocker

m

TO

cl1rburettor

water

leaks

head

on

ace

pJ

small

the

locknuts

piVOt

the

mto

down

push

arm

from

take

care

the

end

rocker

removed

bemg

holes

the

bolts

the

In

arm

ADJUST

Idling

assembly

a

SUitable

steady

cylinder

on

the

cylmder

that

the

of

arms

o

cylinder

IllustratIOn

to

mixture

spnng

and

head

each

the

valve16

valve

91

fl

ensure

IS

adJ

at

opposite

evenly

valve

VALVE

from

bench

screw

valv

he

s e s

that

tu

iid

e

1

head

and

to

stem

and

the

from

the

10

s

ru1g

gke

the

to

ItS

1

to

4Y

L

jf

1

t

J

r

s

If

ar8

1

U

r

t

r

I

J

I

j

ii

1

t

i

1

r

11

I7

i

t

t

7

7

17

o

4

l

J

12

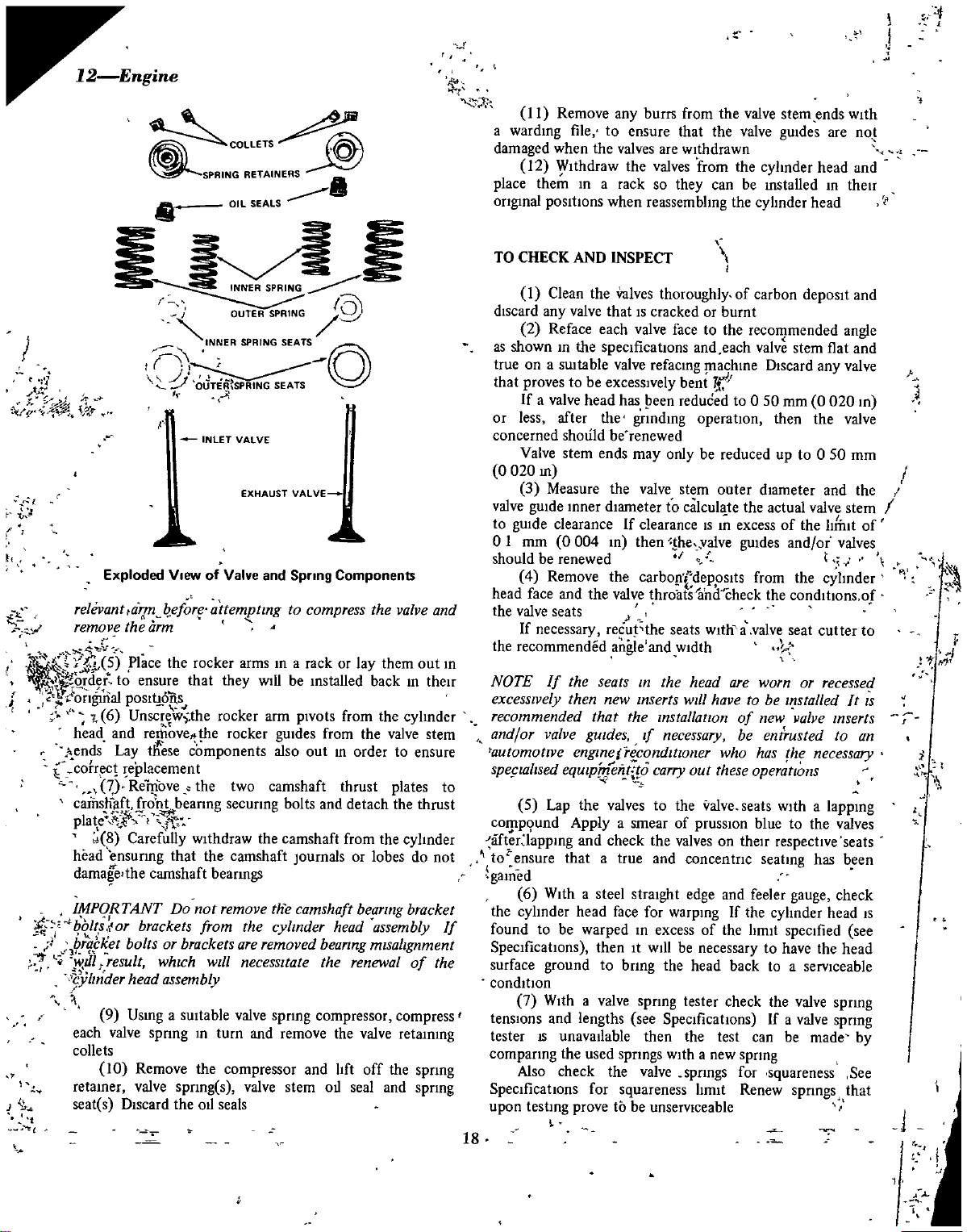

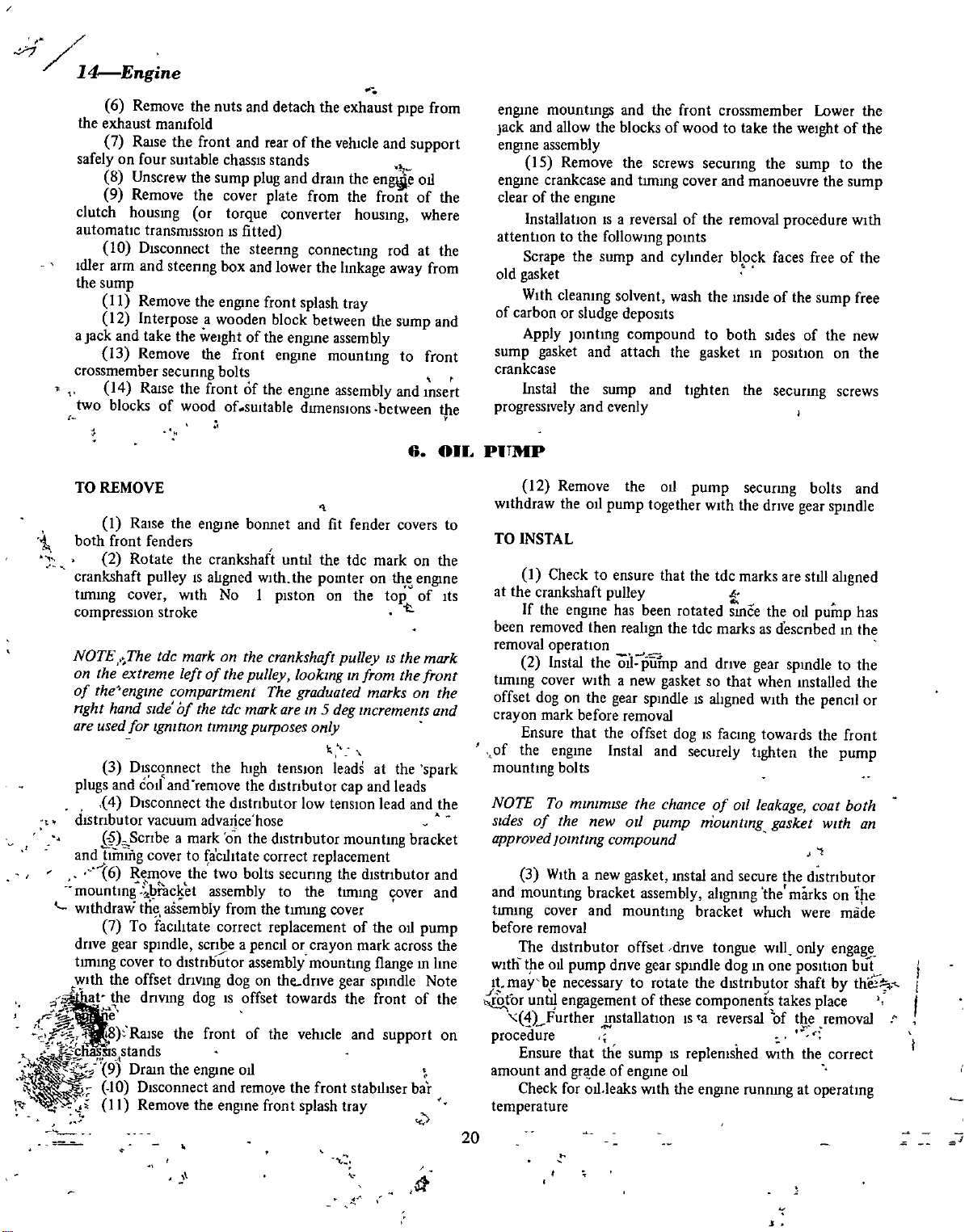

Engine

I

ro

m

SPRING

RETAINERS

OIL

SEALS

A

A

I

the

and

valve

SPR

SEATS

SEATS

and

In

will

arm

gUIdes

also

camshaft

the

camshaft

tHe

cylmder

removed

spnng

remove

NG

VALVE

Spring

to

compress

a

rack

be

Installed

pivots

out

bolts

Journals

camshaft

compressor

and

stem

9

Q

Components

or

lay

from

from

the

In

order

thrust

and

detach

from

or

bearmg

head

beanng

the

renewal

the

valve

hft

off

011

seal

valve

In

cyhnder

valve

to

plates

the

cyhnder

out

ensure

thrust

do

and

theu

stem

to

not

the

them

back

the

the

lobes

bracket

assembly

If

misalignment

of

the

compress

retaInIng

the

spnng

and

spnng

In

t

18

J

0

to

l

r

l

V

l

relevant

1

remove

f

r

j

i

J

order

iigmal

4

head

ends

cofrec

plat

head

damaethe

IMPORTANT

l

i

bracket

1

f

dl

I

J

gylmder

each

f

I

Exploded

a

rm

the

iirm

place

to

ensure

posIl

6

Unsc

and

tliese

Lay

eplacement

7

Re

caii1s

i

e

8

Carefully

ensurIng

camshaft

s

or

brackets

boltsorbrackets

result

head

9

USIng

valve

spnng

J

It

View

before

the rocker

ons

f

ove

kbeanng

1fro

n

f

that

Do

which

assembly

a

sUItable

OUTER

SPRING

INNER

l

OIhiRlsPRING

INLET

VALVE

EXHAUST

of

Valve

attemptmg

arms

that

they

the

w

rocker

rocker

the

remove

components

the

two

secunng

withdraw

the

camshaft

bearings

remove

not

from

are

will

neceSSItate

valve

In

turn

coHets

spnng

the

the

011

compressor

s

seals

Remove

IO

retaIner

v

seat

s

valve

DIscard

I

Remove

I

a

wardIng

CHECK

I

2

shown

on

proves

when

12

them

pOSitIOns

Clean

any

Reface

a

WIthdraw

valve

In

sUitable

to

damaged

place

ongInal

TO

discard

as

true

that

Ifavalve

or

less

after

concerned

valve

to

gUIde

I

o

should

head

the

the

NOTE

excessively

recommended

and

automotive

spepallsed

c01J1p

to

ensure

should

Valve

stem

3

Measure

Inner

gUide

clearance

mm

0004

be

renewed

4

Remove

face

and

valve seats

If

necessary

recommended