@

@CQ@

@

u

ill

t

0f

1D

if

@

1cr

l

1

1

Man

la

f

9

t

Jor

h

lOP

j

O

@

f

I

r

r

f

d

1

I

INTER

Titles

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

141

144

146

150

159

EUROPE

available

WORKSHOP

NOW

VOLKSWAGEN

VOLKSWAGEN

VOLKSWAGEN

RENAULT

TOYOTA

TOYOTA

FORD

FORD

VOLVO

FORD

ENGINES

VAUXHALL

OPEL

ALFA

ROOTES

MERCEDES BENZ

FORD

RENAULT

FORD

TOYOTA

PEUGEOT

SAAB

CROWN

CORONA

ESCORT

CORTINA

140

CORTINA

KADETT

ROMEO

IMP

CAPRI

17

20M

COROLLA

403

99

R8

SERIES

VIVA

RANGE

1300

R16

MANUALS

1200

1200

1300

MK

1300

RANGE

16TS

404

1200

1300

II

GT

HB

RALL

230

1600

16TA

1100

A

A

1500

1300 1500

1600

HOLDEN

YE

KADETT

250

MODELS

etc

1200

ENGINES

1600E

HB

TORANA

1964

1964 1967

to

1967

to

1967

to

1968

1963 1968

1968 1969

1967

to

1969

1968

1969

1967

1962 1968

1959 1968

1963 1969

1965 1968

From

1965

to

Up

Since

1968

1969

Introduction

1970

r

I

1

f7

I

WORKSHOP

for

C

i

MANUAL

E

L

b

DATSUN

1300

Saloon

c c

Estate

1600 c

c

Copyright

lb

IC

11

IntIInlUrope

110

LIlDtIld

IYIIIIbIeinSpanish

AulJllt

AND

BY

R D

WRITIEN

RUSSEK

BY

LIMITED

DIVISION

DRIVE

W

3

City

2nd

edition

Pnntlld

January

n

England

1971

COMPILED

PETER

PUBLISHED

INTEREUROPE

AUTODATA

2

4

QUEENS

LONDON

ENGLAND

1970

W

av

1Ib1e

thRlUllh

Lan

MexICO

SA

ey

A

r

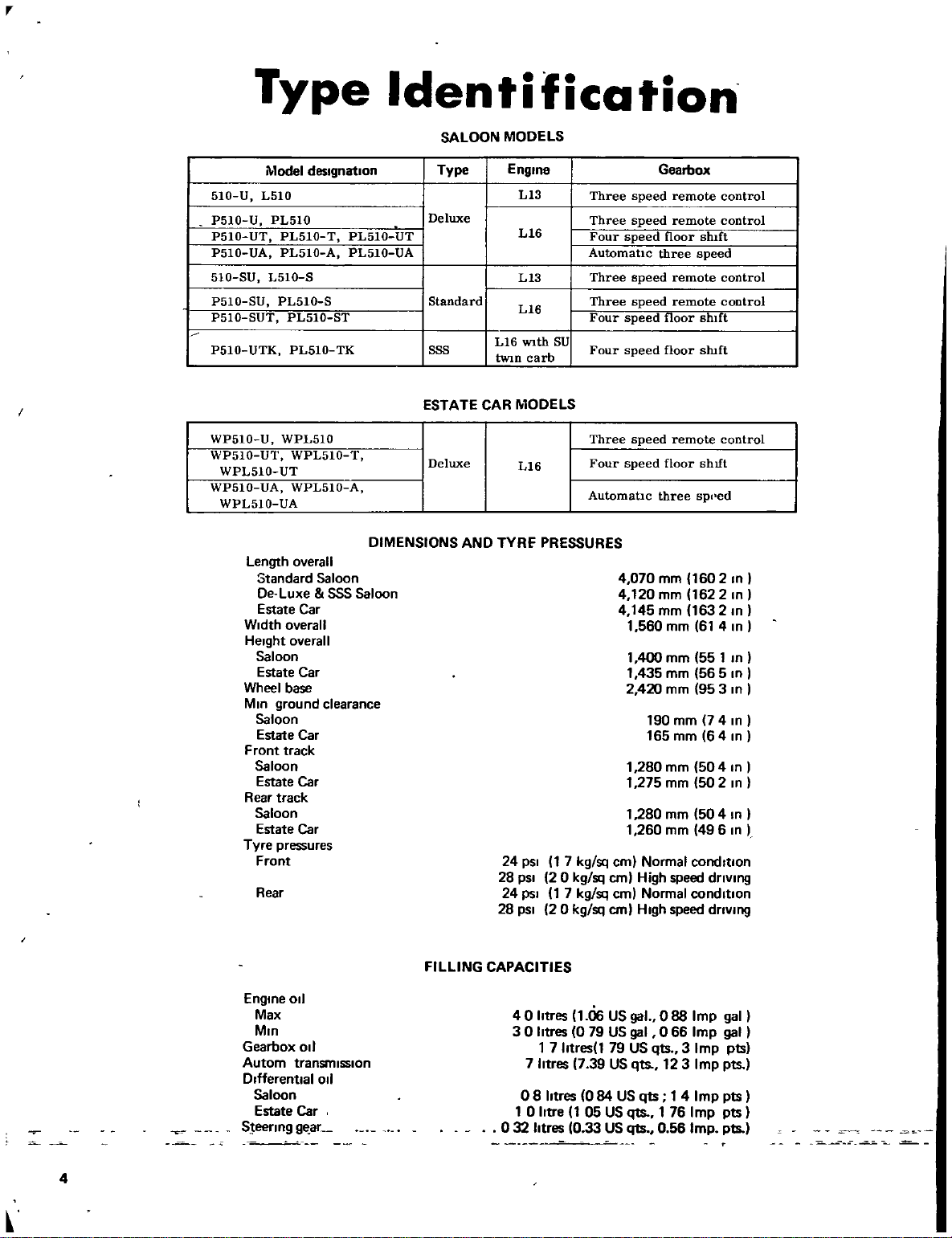

Type

Identification

SALOON MODELS

AND

CAR

L16

tWIn

TYRf

24

28

24

28

E

n9108

L13

L16

L13

L16

WIth

carb

MODELS

L16

pSI

pSI

psi

pSI

Three

Three

Four

AutomatIc

Three

Three

Four

SU

Four

Three

Four

AutomatIc

PRESSURES

1

7

kg

sq

20

kg

sq

1

7

kg

sq

20

kg

sq

Gearbox

speed

speed

floor

speed

three

speed

speed

floor

speed

floor

speed

speed

floor

speed

three

4

070

mm

4

120mm 162210

4

145

mm

mm

1

560

1400mm

1

435

mm

mm

2

420

190

165

280

mm

1

1

275

mm

1

280

mm

mm

1

260

em

Normal

em

High

em

Normal

em

High

remote

remote

remote

remote

remote

mm

mm

speed

speed

shIft

speed

shIft

sluft

shIft

ed

spl

1602

163210

61

551

56

953

74

64

504

50

50

496

driVing

condition

driVing

control

control

control

control

control

10

410

In

5

In

In

In

In

In

2

In

In

4

In

cornltlon

I

I

Model

designation

510

U

L510

P510

U

PL510

P510

UT

PL510

T

PL510

P510

UA

510 SU

P510

P510

P510

I

WP510

WP510

WP510

WPL510

WPL510

L510

SU

PL510

SUT

UTK PL510

U

UT

UA

PL510

PL510

WPL510

WPL510

UT

WPL510

UA

A

PL510

S

S

ST

TK

T

A

Type

Deluxe

UT

UA

Standard

SSS

ESTATE

Deluxe

DIMENSIONS

overall

Length

Standard

De

Estate

Width

Height

Luxe

overall

overall

Car

Saloon

SSS

Saloon

Saloon

Estate

Car

Wheel

base

MIO

ground

clearance

Saloon

Estate

Car

Front

track

Saloon

Estate

Rear

Car

track

Saloon

Estate

Car

Tyre

pressures

Front

Rear

Engine

Max

MIn

Gearbox

Autom

Differential

Saloon

Estate

SJeerlng

011

011

transmission

011

Car

aL

9e

FILLING

CAPACITIES

40htres

30htres079

17htresl79

7

htres739

08

10htre105

htres1033

032

htres

uiG

084

US

US

US

US

US

US

qts

qts

gal

gal

US

qts

qts

qts

0

88

Imp

3

4

Imp

Imp

Imp

Imp

Imp

Imp

gal

gal

pts

pts

pts

pts

Pts

0

66

123

1

1

76

0

56

4

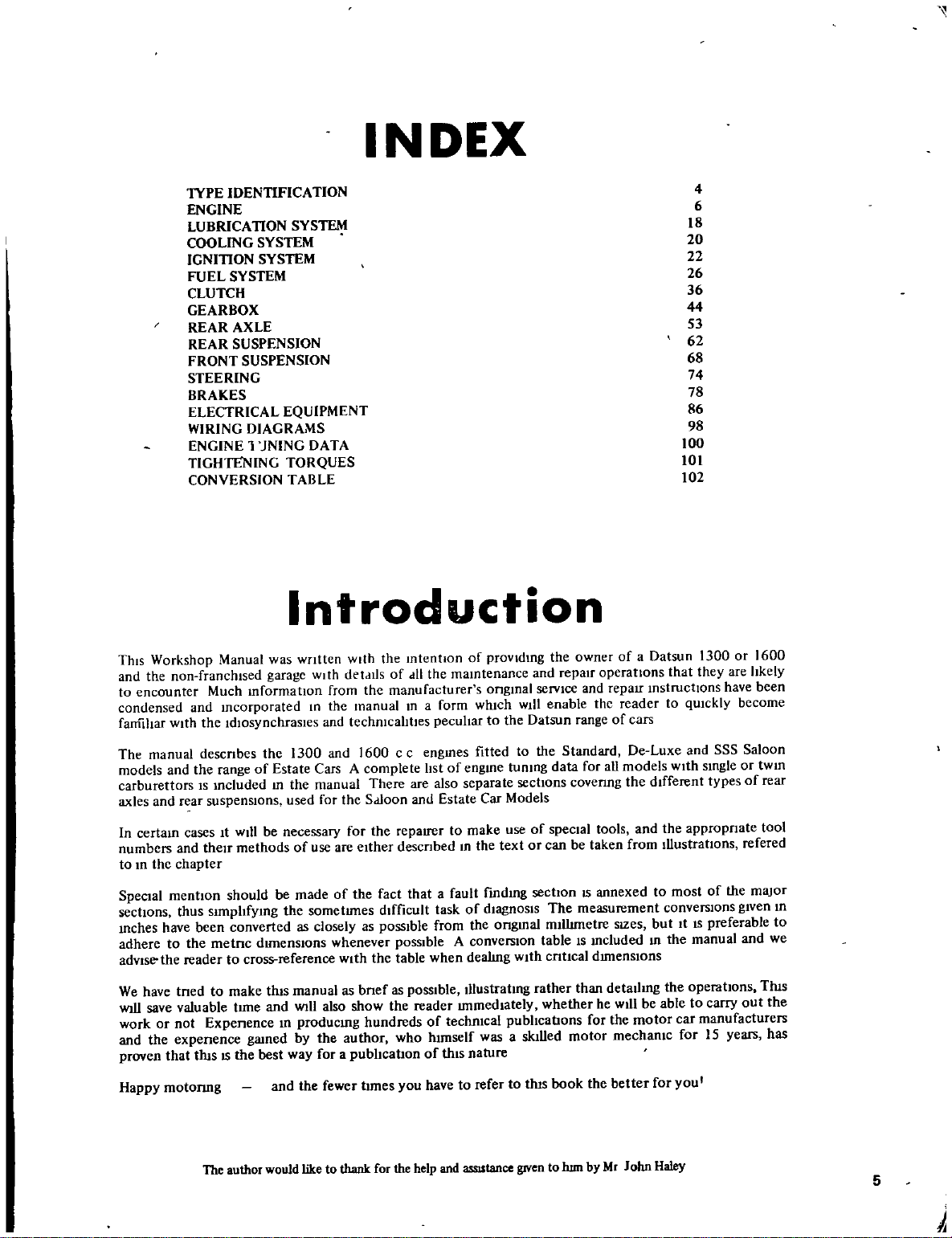

INDEX

l

This

Workshop

and

the

to

encounter

condensed

fanfihar

The

manual

models

carburettors

axles

and

In

certaIn

numbers

to

m

the

SpeCial

sechons

mches

adhere

adVise

We

have

WIll

save

or

work

and

the

proven

Happy

non

with

and

rear

cases

and

chapter

menlton

thus

have

to

the

reader

tned

valuable

not

expenence

that

motonng

lYPE

ENGINE

LUBRICATION

COOLING

IGNITION

FUEL

CLUTCH

GEARBOX

the

IDENTIFICATION

SYSTEM

AXLE

REAR

REAR

SUSPENSION

FRONT

SUSPENSION

STEERING

BRAKES

ELECTRICAL

WIRING

ENGINE

TIGHTENING

CONVERSION

Manual

franchised

Much

and

Incorporated

the

IdlOsynchrasles

descnbes

the

range

IS

Included

suspenSIOns

It

Will

thelf

methods

should

slmphfymg

been

converted

metnc

cross

to

make

to

tnne

Expenence

tillsISthe

SYSTEM

SYSTEM

SYSTEM

EQUIPMENT

DIAGRAMS

1

JNING DATA

TORQUES

TABLE

Introduction

was

garage

InformatIOn

the

of

Estate

m

be

be

dunenslons

reference

thiS

and

m

gamed

best

and

WrItten

1300

the

used

necessary

of

made

the

as

manual

WIll

prodUCIng

by

way

with

m

use

some

the

from

the

and

and

Cars

manual

for

the

are

of

tunes difficult

closely

whenever

With

as

also

the

for

a

fewer

wIth

the

detdlls

the

manual

techmcahtles

1600

A

complete

There

Sdloon

for

the

either

the

fact

as

pOSSIble

the

bnef

show

hundreds

author

pubhcatlOn

tnnes

IntentIon

of

dllthe

manufacturer

In

a

c c

engmes

hst

are

and

reparrer

descnbed

thatafault

pOSSible

table

when

as

pOSSible

the

reader

of

hunself

who

of

have

you

maIntenance

form

pecuhar

of

also

Estate

to

In

task

from

A

Iffimedlately

techmcal

thiS

to

of

providIng

s

ongInal

which

to

fitted

engme

separate

Car

make

the

text

findmg

of

diagnOSIS

the

ongInal

conversion

deahng

tllustratmg

was

nature

refertotills

the

and

selVlce

will

enable

the

Datsun

to

the Standard

data

tumng

secltons

Models

use

of

speCial

or

can

sechon

The

mtlhmetre

tableISmcluded

With

cnhcal

rather

whether

pubhcatIons

a skilled

book

owner

repalf

and

range

for

covenng

be

IS

measurement

than

for

motor

the

ofaDatsun

operatIOns

repalf

the

reader

of

all

tools

taken

annexed

SIZes

dlffienslons

detailing

he

Will

the

mechamc

better

cars

De

models

the

and

from

motor

Instructions

Luxe

different

the

Illustraltons

to

conversIOns

but

In

be

able

for

20

22

26

36

44

S3

62

68

86

100

101

102

that

to

qUickly

and

with

appropnate

most

It

the

the

car

for

you

4

6

18

74

78

98

1300

are

they

have

SSS

smgle

types

of

the

IS

preferable

manual

operahons

to

carry

manufacturers

15

years

I

or

hkely

become

Saloon

or

of

refered

major

gIVen

and

out

1600

been

tWIn

rear

tool

m

to

we

Tills

the

has

The

wouldliketothank

author

for

the

help

and

3SSIStance

gtven

to

bunbyMr

John

Haley

5

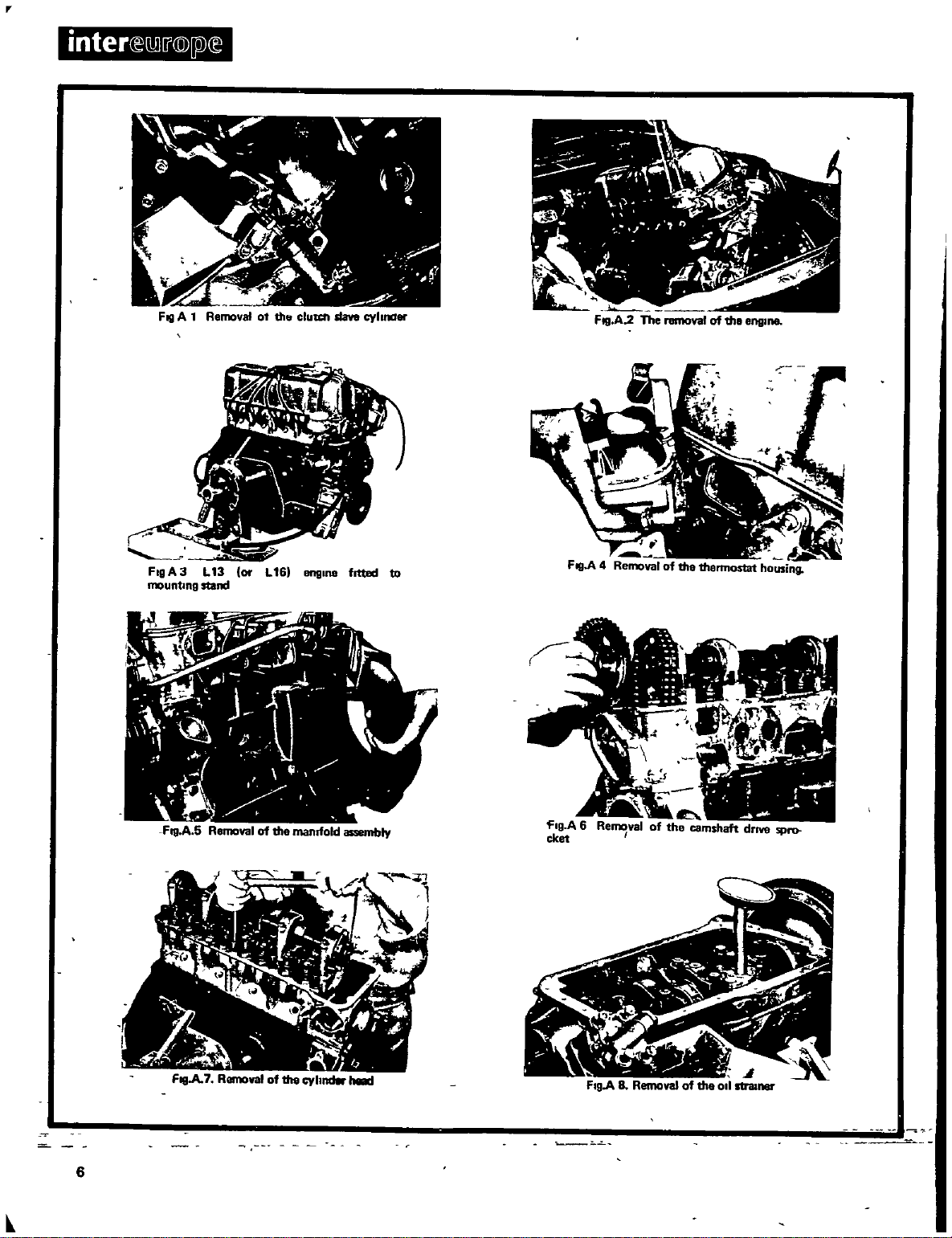

inter

llil

Fog

A

@

p

1

Removal

fd

f7

Of

Jb

trel

n

i

removal

of

the

cluu

n

r

slave

1

cyhllller

t

r

Fog

A2The

the

engll

A5Removal

FIlI

if1

or

L

161

0

engIne

of

the

manifold

flUBd

assembly

10

fgA6

eket

Removalofthe

FIIA7

6

cyhnder

h8I

F

g

A

8

Removalofthe

oil

straaner

Engine

The

1300

engines

crankshaft

The

with

1600

eqUIpped

head

manifolds

other

has

Drain

the

disconnect

rocker

radiator

radiator

pipe

wiring

Unit

Remove

Remove

heater

from

and

box

hoses

automatic

temperature

the

or

Speedometer

gearchange

front

pipe

shaftatthe

Jack

up

mounting

handbrake

Remove

to

carefully

forwards

the

the bolts

crossmember

11ft

and

c c

a

The

c c

engine

with

twin

a

single

coolant

the

follOWing

breather

radiator

hosesIffitted

starter

clutch

disconnect

cable

linkage

first

Silencer

front

the

gearbox

bracket

cable

clamps

the

upwards

and

single

1300

pistons

twin

slave

secunng

engine

front

INTRODUCTION

1600

overhead

and

1600

IS

available

S U

carburettors

and

choke

ENGINE

engine

parts

hose

torque

models

motor

sender

cylinder

flat

connector

exhaust

and

slightly

the

Fit

a

lifting

and

uSing

c c

carburettor

and

radiator

only

accelerator

alternator

Unit

centre

mounting

the

front

gearbox

a

SUitable

engines

camshaft

c

c

engines

In two

compression

Removal

gearbox

Battery

converter

COIling

A1and

Fig

from

pipe

pipe

and

remove

engine

hooktothe

In

crane

are

4

cylinder

andafive

differ

versions

with

gnll

011

bonnet

one

different

ratio

and

upper

cooling

fan

and

linkage

COil

011

pressure

ItS

reversing

from manifold

assembly

the

crossmember

mounting

engine

a

tilted

or

hOIst

whereas

air

choke

return

light

the

poSition

only

of

which

cylinder

remove

cleaner

and

hoses

pulley

then

propeller

rear

and

brackets

hangers

FIgA

in

line

beanng

In

size

the

and

lower

from

fuel

cable

sender

spnng

SWitch

the

engine

the

and

e

2

Remove

wrench

Turn

strainer

IS

or

timing

and

Remove

assemblies

Remove

tool

Remove

baffle

Remove

and

of

handpress

Remove

nuts

spnngs

camshaft

lifter

Thoroughly

inspection

operations

carbon

chambers

from

g

I

nspect

the

chain

the

ST44630000

plate

the

which

and

Fig

any

the

ST49010000

engine

Fig

chain

the

big

keeping

the

flywheel

the

rear

and

the

piston

gudgeon

should

ThereISalso

the

valve

remove

Remove

bushes

A

12

clean

and

Blowout

depOSits

cylinder

of

the

and

overhaul

cylinder

over

A

8

Remove

dnve

end

011

the

pin

not

the

the

Remove

ENGINE

before

from

parts

head

for

removing

and

remove

timing

the

011

sprocket

beanng

them

In

and

the

for

the

rear

seal

and

cylinder

WithaSUitable

nngs

WithaSUitable

exceed

special

rocker

springs

rocker

camshaft

the

Inspection

all

parts

attempting

all

passages

the

head and

the

parts

assembly Fig

the

the

chain

cover

thrower the

FIgA

9

pistons

caps

the

sets

In

main

beanng

main

beanng

11ft

out

the

block

net

mandrel

the

diameter

tool

ST4484000D

loosen

anns

by

taking

valves

Withaconventional

and

of

dirt

011

With

of

valves

as

the

but do

follows

top

A

cylinder

and

sump

chain

crankshaft

and

correct

caps

cap

crankshaft

FIgA

11

piston

the

of

the

the rocker

presSing

care

not to

Overhaul

and

water

to

carry

compressed

pistons

not

7

USing

bolts

h

llJd

the

Internal

tensloner

connecting

assembly

uSing

Fig

Remove

nng

outer

piston

down

scale

out

air

combustion

remove

special

wonn

order

a

special

A

11

expander

diameter

and

pin

piVOt

the

score

before

overhaul

Remove

metal

011

and

gear

rod

tne

a

lock

valve

the

valve

Remove

cover

and

remove

Remove

the

mountings

Mount

the

ST37200510

A3

Flg

Remove

unscrew

the thermostat

Remove

Remove

Remove

rocker

Remove

FlgA

thedIStnbutor

the

the

cover

the

6

the

gearbox

the

clutch

the

follOWing

011

engine

the

spark plugs

inlet

crankshaft

the fan

fuel

ENGINE

flywheel

cover

filter

In

attachment

hOUSIng

and

exhaust

pulley

pump

and

water

a

SUitable

pulley

drive

the

SUitably

together

parts

cap

together

and

FIgA

and

Dismantling

starter

With

With

Alternator

drain

stand

and

Stand

remove

4

manifolds

the

water

cam

and

motor

plug

If

With

the

the

a

centre

the

clutch

and

011

available

ST37100000

the

dlstnbutor

Flg

pump

crankshaft

Mark

pressure

spark

A

5

dnven

bracket

Special

fuel

the

punch

plug

Remove

pump

sprocket

clutch

plate

engine

SWitch

Tool

leads

and

See

and

Check

cylinder

uneveness

heads

are

the

1600

means

of

the

clearance

exceeds10

face

Check

the

In

accordance

If

necessary

out the

by

USing

between

must

0

heating

073

old

micrometers

not

mm

checking

and

used

c

a

valve

the

the

exceed

the

c

straight

mm

replace

Insert

valve

00029

clearance

head

for

If

replace

for

the

edge placed

0

0039

seats

the

valve

and

Check

for

select

headto150

engine

Withafeeler

With

cylinder

Internal

stems

0048

In

IS

Cylinder

cracks

and

necessary

and

Single

the

gauge

In

regrind

damage

dimenSions

Inserts

the

Valve

and

and

the

mm

00019

for

exhaust

Insert

to

head

the

twin

mating

across

or

given

To

correct

guides

external

valve

the

mating

note

FgA 13

the

wear

replace

Insert

200oC

In

valves

valve

that

carburettor

surface

the

head and

cylinder

and

If

In

Fig

300

che

gUides

for

stem

faces

for

different

necessary

the

Fig

burrs

cylinder

verSions

for

flatness

checking

If

the

clearance

headtoblock

A14andA15

Inserts

A

16

3900F

the

tolerance

ThiS

clearance

Inlet

valves

An

easy

the

Into

and

way

or

of

by

reface

bore

fit

and

of

gu d

7

r

inter

E2C0

FillA

rocket

9

@

0

F

Removal

1

1

of

the

crankshaft

challl

S

o

0

cf

Inl

Ex

FillA

cyhrder

FIllA

forfl

L16

t

heult

11

Removal

block

13

Checlul19

WIth

twin

Q

F

r

r

I

I

FIlIA

carb

OtA

IlIt

14

net

J

r

1

St8nd8nI

1

of

the

baffle

the

cyhnder

Ll3

With

i

La

HU

valve

Il8

plata

heud

SIngle

1

DIA

IlIA

1

inwt

and

rt

and

Ll6

cub

Almm

DIA

Azmm

DIA

Dlmm

DIA

D2mm

DIA

I

I

ExheuU

r

Inl

Llmm

t

2mm

FI

A

12

41016

326

FIllA

L16

cub

016

8

Exhal51

37O37 016

1 1

15

VeIve

Inlet

U3

and

S

gle

410

57037

37637 8 41 6

324

141

1620

TWlD

Standard

Ll6

cub

45 016

450

41 8

326

324

8

20

16

to

gUIde

diameter

valve

hole

8

i

nte

ferbiGD

J

W

A16Ch

FI9

Inner

II

A

18

Fig

C81bunmon

I

8

d

Valves

r

r

I

c1ung

0

11

031

51

farL16

rrt

V

rettD

11

0011

CheckIng

51

0

L

13

far

andL16

the

valve

l

I

J

r

I

r

camshaft

the

D

T

010

beanng

F

17

IingIo

lm

I

l

CII

wIth

IM

l11

J

twIn

FIlIA19

squ

5144

j

Ill

IIInng

01

r

wrth

for

bora

A

21

MlI8SUnng

F

of

8

doallllU98

The

FigA22

nne

JIlIIII18

the

of

cyllncllr

F

by

The

of8mlcrom8lar

nng

the

bore

pilllln

by

d

cyl

of

the

9

ImII

B

Fog

pISton

A

26

Flngs

CheckIng

the

ade

cl

ence of

the

FIgA24

ce In

FI9A

the

maIn

the

29

beaFlngs

CheckIng

CheckIng

bore

cyhnd

the

pIston

the

running

runnIng

clearance

clearan

for

Ftg

bends

A

Xl

or

FillA28

CheckIng

twIsts

CheckIng

the

the

connectIng

crankshaft

end

rod

for

float

0

o

30

FogA

FUIHlllt

10

Checlllllg

the

crenkshaft

sprocklJt

for

FogA31

The

camshaft

drIVe

mechanam

I

and

move

It

from left

10m

0

0079

10

1

press

Valve

10

valve

gUide

the

the

heads

valve

the

taking

The

the

speCified

sprongs

plate

rotate

and

191

1

stem

valve

stem

valve

the

The

out

head

Fmally

and

check

head

valve

free

Also

for

PosItion

the

gUides

the

3

JOOF

00079

the

between

Check

Check

valve

If

the

replace

machine

grooves

Measure

than

valve

surface

slowly

sprmg

Fig

cylinder

A

TECHNICAL DATA

Measurethe

outside

inSide

wear

limitISC

Check

the

limits

camshaft

A 20

Fig

005

10m

Visually

surface

exceeds01

Check

FlgA

shown

the

carbon

SUitable

diameter

the

blackets

the

camshaft

given

The

The

0002010

check

the

same

mm

the

cylinder

211The

10

Fig

depOSit

tool

InSide

1

camshaft

Indication

the

A 22

TECHNICAL DATA

When

rebonng

speclahsed

IS

necessary

oversize

workshopISdealing

to

piston

TECHNICAL DATA

the

average

When

piston

piston

valueofthe

the

cyhnder

across

cyhnder

clearance

the

guide

the

old

has

gUides

observmg

stem

face

for

for

distortion

10

edge

If

necessary

off

only

dimenSions

length

test

distortion

spring

edge

valve

diameter

of

the

replace

10m

00039

for

In

sectIOn

block

way

0

0039

bores

measunng

If

ridge

The

all bores

mfonn

sets

Its

piston

bores

to

nght

needs

and

gUide

heated

been

are

available

ream

the

the

Valves

pitS

grooves

particular

IS

worn

gnnd

enough

are

Valve

sprmgs

of

the

the

valve

by

the

spnng

The

clearance

should

not

specifications

spnng

Camshaft

of

camshaft

the

In

wear

and

TECHNICAL DATA

runout

on

the

Cylmder

for

flaws

as

the

cylinder

In

regnnd

Cylinder

for

excessive

pOInts

the

bores

at

the

specifications

Rebormg

must

With

the

workshop

available

are

To

obtain the

skirt

as

shown

to

cylinder

have

as

shown

If

thiS

replacmg

press

to

10

valve

gUide

specified

scores

and

wear

for

burrs

down

the

matenal

shown

valve

springs

sprong

plaCing

against

exceed16

the camshaft

Journals

cylinder

1

damage

can

be

dial

gauge

block

and

cracks

head

the

bore

for

are

Within

of

the

top

cyhnders

be

doneatthe

operations

and

fmlshed

10

clearance

been

finish

In

movement

10

150

oversize

cracks

to

valve

In

a

between

checked

block

wear

the

cylinder

are

of

are

FlgA

Fig

When

When

steel

the

and

thiS

replacmg

new

the

2000C

the

dimenSion

to

running

and

other

mspectmg

and

0

20 10

on

a

valve

remove

to

A17andA18

Fig

and

replace

pressure

square

square

the

10m

are

given

bearings

wear

If

head

assembly

andIfthese

as

should

Check

and

If

the

ovallty

cylinder

the

limits

bore

given

same

of

thiS

procedure

hsted

bore

Size

23

and

honed

24

A

usmg

exceeds

gUide

of

02

clearance

corrosion

0 5

Check

edge

top

0063

In

replace

shown

not

the

deViation

and

bores

10

time

nature

10

check

0 2

valve

after

300

10m

damage

the

10m

gnndlng

and

pitS

If

less

the

on

to

and

of

the

10

section

and

the

IS

found

The

exceed

the

exceed

mating

taper

are

remove

USing

section

As

Five

section

measure

add

the

the

a

feeler

spnng

oversize

replace

grooves

head

00118101

0

0394

diameter

With

relevant

fit In

at

pin

00013

uSing

10m

0

0012

not

scale

room

394

10m

109

the

In

In

the

the

In

of

are

1

to

a

be

scale

With

a

pullmg

3307

beyond

pins

seiZing

the

piston

The

cyhnder

nng

023

0381010

030mm

o15030

and

results

fit In

fit

for

A 27

FI

I

or

twist

10m

and

have

the

rods

bends

00020

feeler

force

Ibs

1

the

piston

and

correct

under

gaps

mm

the

10

DATA

a

connecting

of

For

of003

nngs

bore

should

gudgeon

accordance

finger

the

10m

and

be

cyhnder

are

for

the

In

the

nng

compression

compres

limit

compare

piston

a

10

thickness

1

0215

cyhnder

Pistons

wear

Side

as

shown

section

piston

gap

the

gudgeon

In

The

and

rod

spring

bores

kg

hners

0441

are

available

the

worn

gudgeon

scratches

clearance

TECHNICAL DATA

nngs

Fig

ring

the

section

gudgeon

a

tight

The

should

10

FIgA 25

mto

A

261

nng

prn

measured

TECHNICAL

pin

press

be

and

of

0 15

hole

should

Interf

erence

0015 0033

the

The

gauge

00016

should

If

of

the

there

Check

Check

the

piston

given

Place

piston

Upper

Second

011

nng

Wear

a

Measure

and

dimenSions

heading

the

temperature

connecting

In

Connecting

Check

connecting

In

IS

length

allowed

the

connecting

rod

aligning

a

permiSSible

A

limit

rods

tool

bend

of

005

of 004

gauge

on

the

maximum

rmgs

If

necessary

10 the

specificatIOns

same

the

and

measure

beasfollows

00059

1

0

mm

pm

under

press

rod

gudgeon

00006

or

twistS

each

100

mm

In

should

0009100150

00059

0011810

the

exceeded

In

Fit

the

clearance

and

should

connecting

which

not

rod

should

exceed030

to

be

crankshaft

the

02

03

mm

10m

0011810

00079

1

and

check

00118

the

In

1

Crankshaft

Check

for

wear

ovahty

the

Journals

for

ovallty

o

05

Check

float

a

speCified

In

Check

1

10m

the

exceeds

and

and

taper

0

002

crankshaft

03

end

floatISbetween

the

end

crankplns

In

Crankshaft

The

checking

out

Check

Place

as

a

a

It

parallel

tl

lhtemng

cap

Main

beanngs

end

81g

Then

follows

the

piece

With

bean

remove

of

the

conditions

of

the

the

ngs

the

Plastlgage

crankshaft

and

The

end

10m

00118

floatasshown

Journals

maIO

and

of

boltstothe

and

cap

general

The

limitS

runout

floatatthe

In

005

and

end

bl

l

the

bearings

on

the

and

fit

follOWing

4 5 5 5

27

check

hmlt

replace

10

Fig

big

beanng

together

33

the

scores

are

0

IS

centre

the

0 15

mm

A

28

end

bearings

beanngs

and

torques

kgm

kgm

Width

cracks

03

a

total

beanng

clean

over

the

of

10m

centre

should

32

195

the

and

deViation

0002

the

Its

full

bearing

5

run

out

00012

If

the

shims The

00059

be

carned

bearings

Width

and

8Ibft

39

23

9lb

Plastlgage

In

end

ft

of

In

Its

1

11

inter

erlLJ

@

Pl

34

FI9A

connectIng

InstallatIonofthe

FIlIA

32

Expl

ded

rod

VI8W

vaJves

ooo

pISton

and

of

FillA

37

InstallatIOn

of

the

sKle

oil

seal

the

F

36

Chedung

19

A

38

FIlI

A

12

crankshaft

InstallatIOn

end

float

39

the

flywheel

of

FillA

rodaay

InstallatIOnofpISton

end

conllllCtmg

mter

i

l

@

jlJ

FogA

caps

t

E

l

ih

40

InstallatIOn

A

42

Fill

InstallatIOn

of

of

the

the

end

bill

cylinder

beerll18

head

FillA

s

c

41

Checking

the

side

play

I

of

the

bill

end

Fill

2

3

4

5

6

FillA46AdjUsting

A44The

1

Fuel

Cham

Cham

Cntnkshm

Camshaft

Cham

the

pump

guide

nSlone

guttie

valve

tIming

dflve

sprocket

IProcbt

clearance

V

1fW

of

the

FogA

43

chain

earn

dIStributor

FlgA

drIVing

45

slIaft

drive

FIttIng

geer

pOSItIon

crankshaft

of

sprocket

the

end

dIStrIbutor

I

13

on

stnp

the

wear

and and

regrind

bearings

bearings

Check

where

shown

o

1

mm

Check

replace

Check

wear

and

flywheel

If

the

worn

150

might

case

take

In reverse

gear

Apply

cylinder

gaskets

Place

With

order

valve

With

cotter

Fit

the rocker

holders

Assemble

rods

bearing

connecting

Tighten

39

8

front

the

gradual

working

shown

00061n

Install

In

Fig

If

the

seal

shows

contact

Fit

the

95

and

connecting

of

top

mark

the

the

are

and

the

necessary

In

0

the

If

the

for

limit

or

damaged

2000

be

engine

walls

and

the

the

Valve

cotter

a

suitable

lves

ha

are

for

shells

down the

lb

ft

steps

towards

In

the

A 37

Original

face

flywheel

105

the

faCing

beanng

limit

for

the

crankshaft

available

6 12

Crankshaft

sprockets

A

Fig

043

chain

necessary

clutch

If

necessary

run

of01

C

necessary

care

order

011toall

lock

valve

011

halves

combined

the

pistons

each

Into

rods

Arrange

of

the

In

A 36

Fig

Side

Fit

crankshaft

slgns

FItthe

kgm

cylinder

the

of010

big

Check

30 The

In

tenslOner

contact

out

mm

300

notto

pistons

plates

spring

seal

Inner

valve

arms

cylinder

and

main

engine

three

the

011

the

of

USing

68

rod

front

Journal

mm

end

to

In

25

50

and

and

Fig

re

uSing

0043

remove

3900F

to

split

damage

and

ENGINE

sliding

bearings

seat

Assemble

and

and

valve

compressor

and

With

gudgeon

main

the

caps

bearing

the

The

or

outside

which

seals

Into

rear

wear

rear

7

75

assembly

block

of

A 29

FIQ

00039

beanngs

SUit

the

undersize

1000

the

75

camshaft

tlmll19

run

out

and

31

mm

and 100

out

should

the

1

the

run

A

Flywheel

area

of

the

alr

or

replace

a

dial

gauge

In

IS

the

gear

and

the

ring

the

coolatnormal

Assembly

or

rotating

gears

In

poSition

the

outer

valve

rocker

the

valve

the rocker

pinS

A 34

Fig

bearing

Lift

the

cap

mark

arrow

bearing

four

stages

Check

should

be

rear

the

seal

011

uSing

IS

used

and

Installashim

end

plate

lock

washers

9Ib

ft

I

into

the

as

shown

the

le

e

gi

If

the

In

for

fit

undersize

25 50 75

for

timing

chain for

of

the

not

chainguIde

flywheel

the

and

exceeded

ring

by

tapping

gear

flywheel

air

parts

etc

and

valves

springs

gUide

A 32

Fig

rocker

pivot

piston

and

A 35

hOUSings

crankshaft

boltsto4 5

on

the

shouldbe

caps

starting

the

crankshaft

005 015

main

special

the

contact

In

and

A

38

Flg

correct

In

Fig

h

en

W

clearance

the

main

bearings

bearings

100

end

the

big

gears

wear

camshaft

exceed

for

for

damage

flywheel

the

replace

If

the

heating

It

off

Sometimes

Withachisel

Refit the

temperature

of

the

and

renew

fit

the

In

the

spring

Compress

when

springs

bushes

and

rings

and

and

caps

In

the

55

bearing

tightened

the

at

mm

bearing

tool

order

tighten

Install

cap

ST49370000

face

to

the

cylinder

A39with

lnsertlng

exceeds

beanngs

Undersize

for

bearings

and

replace

sprocket

the

limit

wear

Check

flywheel

ring

It

to

In

new

engine

all

valve

follOWing

retainer

the

fitting

The

connecting

place

and

bearings

kgm

to

cap

centre

end

playas

0002

as

shown

for

the

shift

bolts

the

from the

the

the

and

main

and

and

the

gear

about

thiS

ring

I

seals

gUide

valves

the

Spring

the

the

325

face

and

the

piston

piston

of

011

to

F

ensure

rings

and

neither

the

connecting

throughout

A

Fig

which

Fit

the

of

as

the

shown

434Ib

In

the

tlQhten

Fit

the

thrower

timing

the

to

chain

chain

IS

It

e

Fit

the

chain

should

reason

any

cover

block

When

With

between

cover

Fit

the

TDC

Install

IS

In

the

Fit

the

engine

strainer

engine

With

Fit

carburettor

0008

for

the

JOinting

Fit

the

In

part

Remove

alternator

011

filter

drain

The

of

procedure

Do

not

resting

engine

g

that the

parallel

rods

and

Check

Fig

ft

cylinder

Fig

hand

be 0

A 42

Note

It

A 43

on

must

gUide

tighten

20

head

Tighten

there

came

sprocket

the

Side

be42chain

FIt

40

should

cylinder

gasket

In

hole

the

crankshaft

marks

right

There

chain

tensloner

alwaysbereplaced

I

nstall

In

that

order

The

gasket

the

fitting

the

cylinder

the

The

crankshaft

position

the

position

fuel

slinger

to

interior

JOinting

the

In

exhaust

upper

difference

011

pump

pump

thennostat

the

by

compound

distributor

s

for

upper

head

pulley

on

shown

bottom

refIning

AdjUst

the

valve

compound

clutch

and

engine

pressure

and

engine

the

the

bracket

011

plug

installation

tlQhten

flnnly

With

with

o

but

engine

IS

the

follOWing

the

on

Its

th

recommended

piston

toorat

With

the

end

030

spreading

a

to

tightening

out

head

Install

crankshaft

COinCident

to

the

a

new

the

lower

With

should

gasket

faces

should

No

the

and

In

water

of

rear

valve

Inlet

on

the

gearbox

the

from the

alternator

SWitch

ENGINE

carned

nuts

mountings

and

011

to

2 8 3 4

mm

the

are

3

of

bolts

and

the

cylinder

011

when

a

gasket

be

cover

of

and

1

dlstnbutor

Fig

and

the

the

on

both

valve

cold

gasket

assembly

high

out

points

and

coolant

ring

nght

the

clearance

cylinder

types

Use

timing

sealInthe

front

coated

check

Then

the

be

the

cylinder

A 45

Inlet

water

011

engine

tappets

and

engine

011

bolts

are

gaps

angles

numbers

00079

JOinting

torque

special

distributor

and

With

links

the

cylinder

less

water

elbow thennostat

cylinder

sump

Sides

cold

tenSion

mounting

opposite

to

the

on

20

kgm

of

the

00118

compound

head

borts

of

5 0

of

bolts

and

tool

drive

chain

Fig

camshaft

the

timing

between

and and

block

front

front

cover

cover

and

between

check

drivesothat the offset

fit

With

that

than

pump

In

Its

outlet

block

coating

slinger

Fig

and

the rocker

the

leadtothe

cover

JOinting

does

It

the

block

0 15

compressIOn

elbow

A 46

025

fuel

stand

mountings

level

dipstick

Installation

in

reverse

should

order

be

completely

Then

tlQhten

water

or

anti

lubricant

each

gudgeon

2

big

ST49010000

timing

the

cover

the

the

In

60

each

and

A 44

IS

same

246lb

end

I

either

In

kgm

marks

marks

Install

removed

upper

and

pin

bearings

the

should

fit

the

With

sprockets

on

on

ThiS

cylinder

compound

Interfere

not

difference

height

and

the

mm

0059

Set

the

engine

stroke

hOUSing

Refit the

and

enclose

new

the

manifolds

to

020

mm

0010

cover

hosetothe front

distributor

and

fit

Ignition

and

the

to

the

nuts

freeze

the

removal

engine

Fill

and

noted

until

the

other

Fit

Side

ft

Side

order

36

go

to

011

the

the

the

the

seal

for

front

upper

In

slot

011

the

gasket

and

mm

In

uSing

the

COil

water

the

the

2

at

IS

14

Technical

Data

Valve

Inlet

Exhaust

Valve

Inlet

Exhaust

Valve

L13and

L16wrrC

Valve

Valve

Inlet

Exhaust

Valve

L13

L16

Valve

113

L16

L16

clearance

clearance

head

Inlet

Exhaust

Inlet

Exhaust

stem

length

11ft

and

wrrc

spnng

diameter

L16wSC

dla

L16wSC

outer

Inner

free

hot

cold

Inl

length

Engine

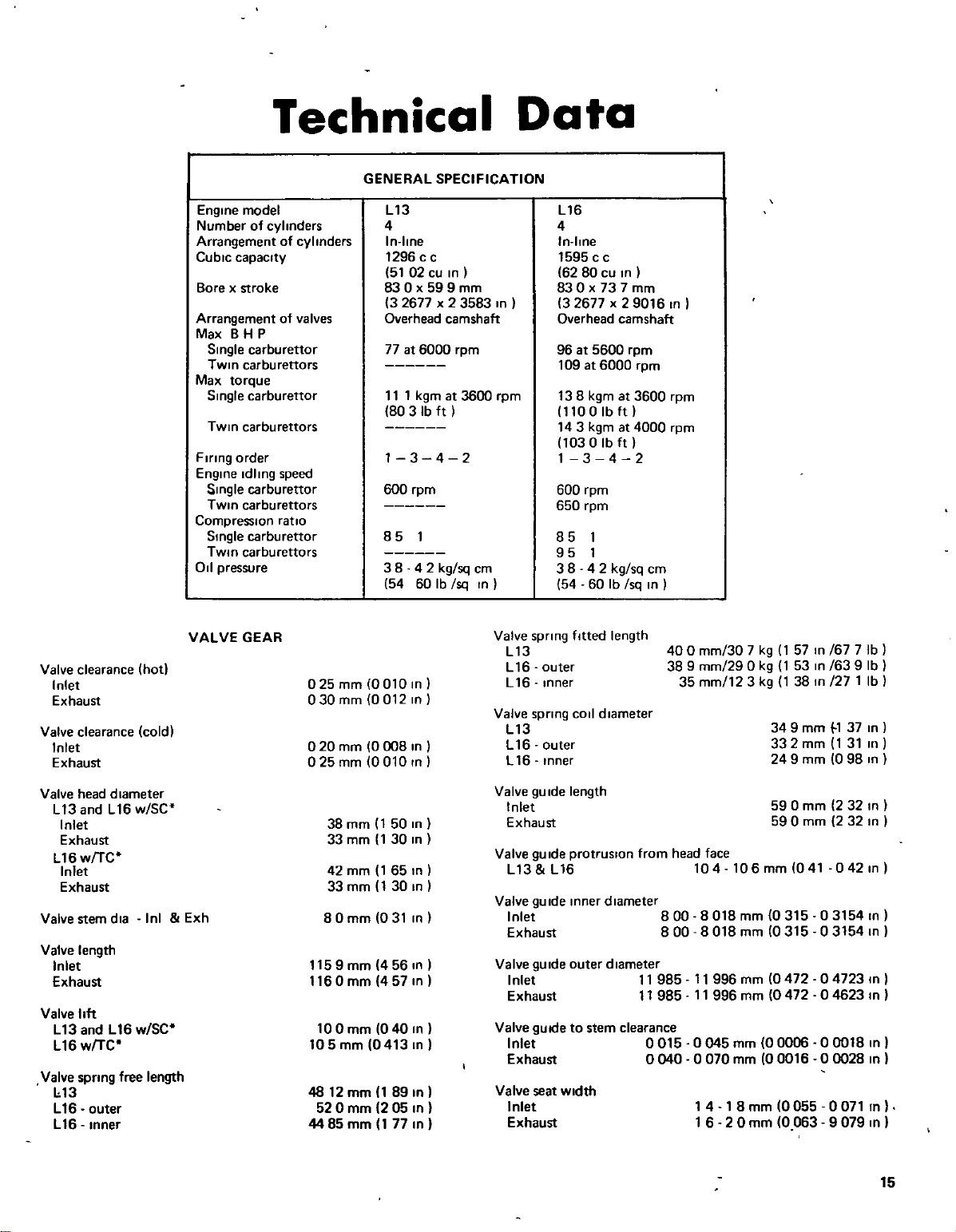

Number

Arrangement

Cubic

Borexstroke

Arrangement

MaxBH

Single

TWin

Max

torque

Single

TWin

Flnng

Engine

Single

TWin

Compression

Single

TWin

011

pressure

VALVE

Exh

model

of

cylinders

capacity

P

carburettor

carbu

carburettor

carburettors

order

Idling

carburettor

carburettors

carburettor

carburettors

GEAR

of

of

rettors

speed

ratio

cylinders

valves

025

030

020

025mm

42

80mm

1159mm

1160mm

100mm

105mm

4812mm

52

44

mm

mm

mm

38mm

33

33mm

0

85

GENERAL

mm

mm

mm

mm

L13

4

In

1296

830x59

Overhead

77at6000

11

803Ib

1

600

85

38

54 60

0010

0012

0008

0010

150

1

1

130

031

456In

4571n

040

0413

189In

2

1

line

51

02

3

2677x2

1

kgm

3

rpm

1

4

In

In

In

In

In

30

In

65

In

In

In

In

In

05

In

77

In

SPECIFICATION

c c

cu In

9

mm

3583

camshaft

rpm

at

3600

ft

4 2

2

kg

sq

Ib

Isq

In

rpm

cm

In

Valve

L13

L

L16

Valve

L13

L16

L16

ValveguIde

Inlet

Exhaust

ValveguIde

L13 L16

Valve

Inlet

Exhaust

Valve

Inlet

Exhaust

Valve

Inlet

Exhaust

Valve

Inlet

Exhaust

16

spnng

outer

Inner

spnng

outer

Inner

gUide

gUide

guide

seat

L16

4

In

line

1595

c c

62 80

cu In

830

x 737mm

32677

Overhead

96at5600

109

at

6000

13 8

kgm

1100Ib

143

kgm

1030Ibft

1

3 4 2

600

rpm

650

rpm

85

1

95

1

38

4 2

54 60

fitted

COIl

diameter

length

protrusIOn

Inner

outer

to

stem

Width

x

2

camshaft

rpm

at

ft

at

kglsq

Ib

Isq

length

diameter

diameter

clearance

9016

rpm

3600

4000

from

11

11

cm

In

0015

0040

985

985

800

800

In

400

389

rpm

rpm

head

35

mm

mm

mm

face

104

8018

8018

11

996

11

996

0045

0070

1418

1

6 2 0

30

7kg1

29

0kg1

12 3kg1

34

332mm

24

59

59

106mm

mm

0315

mm

0315

mm

0472

0472

mm

00006

mm

mm

00016

mm

mm

57

In

In

53

38

In

9

mm

9

mm

0

mm

0

mm

041

0055

0

0639079

167

163

271

03154

03154

04723

04623

00018

00028

0071

1

37

1

31

0

98

2

32

2

32

0421n

7

Ib

9

Ib

Ib

In

In

In

In

In

In

In

In

In

In

In

In

In

15

r

Valve

Valve

Inlet

Exhaust

Valve

Inlet

Camshaft

Camshaft

L13

L16

Camshaft

All

Max

camshaft

Camshaft

clearance

Camshaft

diameter

seat

seat

gUide

end

lobe

L16wSC

w

TC

Journals

Journal

bearing

angle

Insert

Interference

CAMSHAFT

play

lift

run

SC

Inl

Interference

0027

diameter

out

to

beanng

Inner

Single

Exh

fit

008

006

fit

0049

AND

o

47949

0038 0076

48

00048016

carburettor

0

11

0 10

TIMING

0838

47962

4J

PISTONS

mm

00031

mm

00024

mm

00011

00043

00039

00019

In

In

mm

GEAR

mm

00031

0

0151n

mm

0

261

665

7

00

mm

887718883

vm

005

mm

mm

00015

mm

TC

1

TWin

00026

8898

carburettors

0

1

0002

8904

275

In

In

In

In

In

In

Matenal

Type

Piston

Standard

1

st

2ndOS

3rt

4th O

5th O

Width

Top

011

Piston

Pin

diameter

Pin

Pin

piston

Pin

end bush

diameters

O

S

OS

S

S

of

nng

second

control

running

length

running

Interference

grooves

clearance

clearance

fIt

20995

72 00 72 25

In

0008

In

small

0015

8299

83 22

8347

83

72

83 97 84

8447

o

PISTON

21

0010

0033

8304

83

8352

83

8452

025045

PIN

000

Cast

aluminium

type

Slipper

sklrt

mm

27

mm

mm

77

mm

02

mm

mm

mm

mm

08266

2

8346

mm

mm

00003

mm

00006

3267

3

2763278

3286

3

2963298

3

3053308

3326

2 0

mm

40

mm

0001

3

3

3328

0002

0

8268

2

8445

00004

00013

269

288

0

0 16

In

In

In

In

In

In

08

In

In

In

In

In

In

In

Distance

centre

8eanng

Standard

Side

playofbig

Connecting

clearance

Connecting

twist

Crankshaft

Number

Main

Journal

Max

Journal

Max

Journal

Crankshaft

Wear

limit

Crankpln

Max

crankpln

Max

crankpln

Thickness

shells

Main

beanng

clearance

Max

main

clearance

Crankshaft

from

shell

thickness

rod

rod

CRANKSHAFT

matenal

of

beanngs

dla

taper

end

Journal

of

main

running

bearing

bend

centre

bearing

bend

003

out

of

play

dla

taper

out

of

limlt

CONNECTING

to

ends

running

or

mm

round

round

beanng

0

running

0014

per

54

49

1

020

13297133

1

AND

942

827

498

1

506

020 030

0056

100

mm

MAIN

54

955

o

05015

96149975

1

835

o

062

RODS

03

mm

mm

mm

00012

BEARINGS

mm

mm

mm

mm

mm

mm

5235 5237

0059

0008 0012

00006 00022

In

per

Special

2

1631

003

mm

003

mm

0

03

mm

1

967

003mm

o

03

mm

0072

0

0008

o

12mm

005

mm

0593

3

forged

2

1636

00012

00012

002

0059

0012

1

9675

00121n

0

00722

0

0024

00047

0002

937

012

In

In

steel

In

In

In

In

In

In

In

In

In

In

In

PISTON

Piston

Side

Top

011

Top

nng

second

control

clearance

heIght

In

grooves

0040

0073

In

In

In

0045

Second

011

Piston

control

ring

gaps

0030

Top

Second

011

control

5

Matenal

Distortion

Max

Valve

of

distortion

seat

Insert

sealing

Inlet

Exhaust

Fit

Dnve

Chain

Chain

tensloner

CYLINDER

face

matenal

CAMSHAFT

0025

023

mm

0

015

015

RINGS

00016 00029

0078mm

00018

063

vm

0063

mm

038mm

030

030mm

HEAD

DRIVE

and

Spnng

20

mm

40

mm

000311n

00012

0001

00091 001501n

mm

0006 0012

0006

Aluminium

003

mm

o

1

mm

Aluminium

From

Double

011

pressure

008

0 16

In

0

0025

00025

00121n

00012

0004

Special

Hot

crankshaft

roller

In

In

L13

L16

In

In

In

alloy

In

In

bronze

cast

pressed

type

control

16

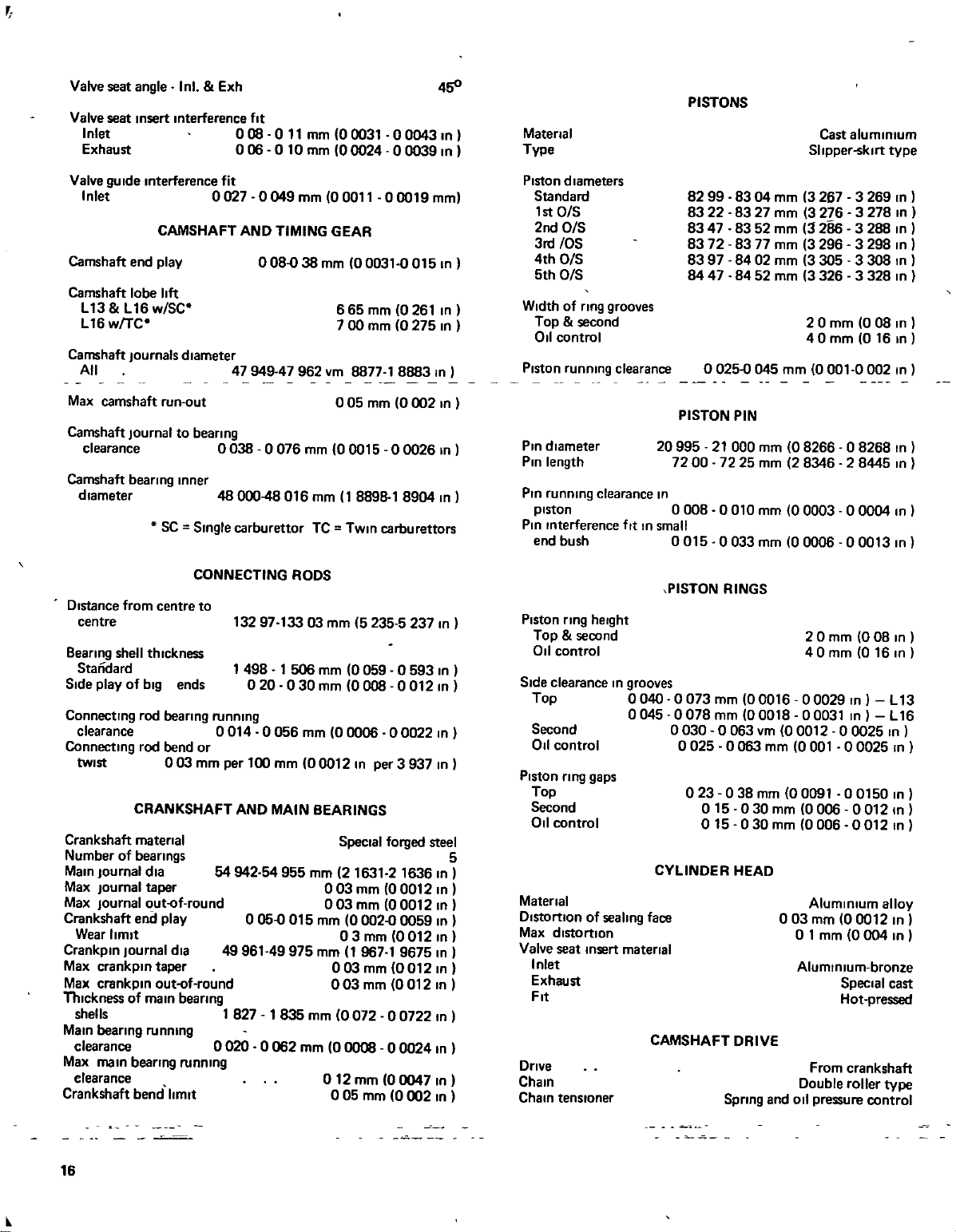

Trouble

Shooting

Lack

of

Overheating

ExceSSive

D

fficult

nOIsy

Engine

power

oil

starting

SYMPTOMS

consumptIon

PROBABLE

I

1

Poor

compresSion

Incorrect

Intake

Sticking

Valve

Piston

valves

valves

springs

rings

valve

broken

Ringsorcylinders

2

Ignition

Incorrect

DefectIve

Contact

3

Lackoffuel

Clogged

Clogged

Dirty

Faulty

Fuel

Insufficient

Looefan

Fan

Inoperative

Defective

Clogged

Incorrect

Incorrect

Incorrect

Radiator

Oil

DefectIve

Piston

grooves

Piston

Valve

Improper

Discharged

Loose

Defective

Burnt

PIstons

worn

Crankshaft

Connecting

ConnectIng

Piston

filter

belt

leaks

Ignition

spark

breakers

carburetor

fuel

fuel

tank

fuel

clogged

belt

worn

water pump

cooling

Ignition

valve

011

finS

piston

rings

or

cylinder

stem

0

connections

Ignition

valves

piston

piston

Improperly

pipe

pump

coolant

thermostat

used

or

1

or

beanngs

rod

rod

CAUSE

clearance Adjust

leaking

broken

worn

set

limIng

plugs

defective

Jet

or

damaged

system

liming

clearance Adjust

Clean

Clean

clogged

rings

worn

gUide

worn

worn

or

sticking

In

Replace

Replace

Change

defective

battery

system Adjust

Chargeorreplace

Clean

RepairOrreplace

nngs

bearings

be

nngs

or

or

l

and

cylinders

Journals

worn

pinS

badly

worn

damaged

Overhaul

Replace

or

Replace

I

or

Stralgten

Check

ACTIOtJ

valve

clearance

Lap

valve

seats

set

up

valve

valve

piston

engine

re

set

or

replace

carburetor

fuel

pipe

fuel

tank

fuel

or

replace

radiator

fan

fan

thermostat

or

pump

belt

belt

Replace

Replace

Replace

Overhaul

Re

Clean

Clean

Clean

Check

Clean

Top

Adjust

Replace

Replace

Repairorreplace

Clean

system

Re

set

timing

clearance

Refill

With

readlator

leak

piston

Piston

piston

as

to

and

Ignition

enqlne

correct

and

necessary

proper

tighten

Clean

Fnd011

Replace

Replace

bearings

crankshaft

replace

bearings

crankshaft

replace

or

replace

and

replace

TOBETAKEN

andguIdes

spring

rings

renew

adjust

element

oil

grade

finS

rectify

rings

rll1gs

or

bore

VISCOSity

battery

connections

check

plugs

valves

and

grind

and

gnnd

rod

parts

gap

cylinder

as

crankshaft

crankshaft

necessary

mterCE

lliJ

@

Plcel

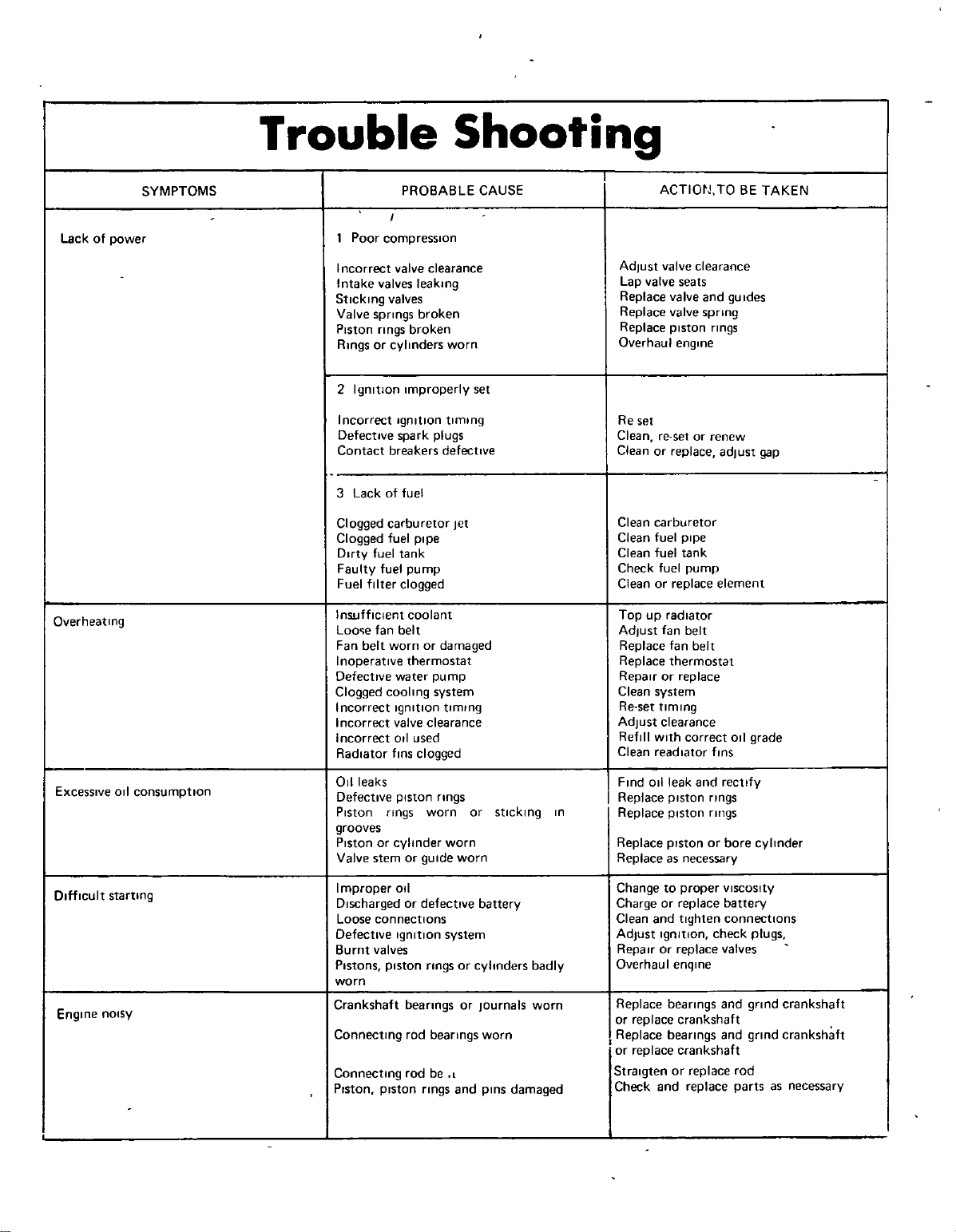

B1General

FIg

system

o

Frg

B3Tho

layout

oil

pump

of

tho

components

lubricatIOn

Fig

4

B

SectIOn

through

the0rehefvalvo

18

The

lubricating

rotor

type

the

by

IS

fined

to

filter

Remove

engine

body

together

poSition

The

II1stallatlon

procedure

No

1

cylinder

then

fIt

With

the

engine

hole

fining

recommended

21kgm

Separate

the

Single

from the

gears

011

distributor

to

the

the

the

bearer

four

by

When

the

punched

Check

108

the

securrng

system

pump

bonom

011

before

OIL

distributor

and

With

bolts

IS

IS

at

011

pump

the

Refit the

engine

1521bft

body

pump

Inoorpotating

drive shaft

of

It

PUMP

the

the

carned

replaCing

T 0

C

mark

engagement

distributor

011

OIL

cover

bolt

body

Lubrication

DESCRIPTION

IS

a

the

can

Removal

drain

splash

dnve

position

and

on

Tighten

PUMP

from the

and

pressure

reach

out In

the

the

take

Fig

feed

a

the

guard

cover

the

and

engll1e

and

regulator

flow

beanng

andafull

front

spindle

reverse

011

pump

In

ItS

drive

spindle

of

the

and

the

spindle

drive

the

SeealsoFlgA2

Dismantling

pump

out

the

B

3

system

011

and

serves

InstallatIOn

Oil

remove

The

011

order

the

set

compression

In

facing

vIa

fill

the

mounting

body

pump

ronslstlng

valve

filter

locations

remove

the

pump

to

engine

the

the

the

engine

bolts

I

by

drrve

and

A

strainer

the

purpose

the

011

IS

the

removal

stroke

front

front

distributor

with

to

unscrewing

and

driven

pump

held

so

cover

of

driven

front

that

1

of

and

the

the

System

surfaces

damage

a

dImenSIons

Free

Fitted

Opening

The

assembly

procedure

111

5

Tighten

of

3 0 3 5

The

removed

When

no

circumstances

element

location

011

the

filter

from

refitting

should

of

for

Replace

length

length

pressure

of

Make

011

kgm

IS

and

the

the

filterISshown

wear

are

the

sure

pressure

21 7

of

filter

use

be

replaced

Also

as

as

follows

OIL

PUMP

0

the

rehef

253Ib

OIL

the

replaceable

replaced

element

any

check

necessary

pump

pump

FILTER

on

tools

every

In

Assembly

IS

cover

valve

ft

the

do

6000 miles

Fig

the

FIgB

38

a

reversal

gasket

cap

cartridge

cylinder

not

The

B

5

spring

4

42

of

IS

nut

to

overtighten

filter

for

The

57

mm

39

mm

kg

the

properly

a

torque

type

block

body

10

000

weakness

rehef

2

24

1

54

54

597

dlsmanthng

fitted

reading

and

can

hand

by

and

under

With

km

or

valve

In

In

Ib

be

the

The

Clean

Items

2

3

4

5

6

all

Check

result

Check

outer

005

found

Check

body

0008

oranew

Check

across

clearance

inserting

In If

a

on

Check

necessary

Cheek

parts

In

ThiS

flat

OIL

the

pressure

the

rotors

12

0

be

to

clearance

the

111

pump

the

end

the

between

a

necessary

surface

the

renew

the

fllJief

PUMP

a

In

0

clearance

The

mm

greater

play

If

thiS

Joint

feeler

rotor

SUitable

pump

losses

maximum

0002 0005

a

betWeen

must

clearance

body

must

of

float

face

the

gauge

the

drive

the

rotor

IiIWe

InspectIOn

solvent

body

If

necessary

between

seat

new

not

exceed015

IS

be

the

rotors

of

the

rotor

IMust

pump

shaft

set

sprlll

t

and

and

for

wear

the

clearance

of

outer

the

excessive

fined

by

body

ends and

not

body

for

excessive

for

proper

Overhaul

check

the

Worn

bearrng

the

replace

lobes

of

the

must

In

If

the

rotors

should

rotor

and

mm

021

a

setofrotors

new

placingastraight

and

measuring

the

straight

0

be

wear

f

1I

13

carefully

or

aACI

exceed

can

follOWing

body

Inner

exceed

not

clearance

be

the

10

edge

mm

scores

tile

IidIng

faces

and

fined

pump

006

edge

the

by

0005

lapped

021

kg

sq

kg

Data

From

mm

cm

sq

cm

cm

sq

Pressurefeed

Rotor

distributor

012mmI0

020005111

0

12mm

0006 0008

75

mm

3fiii

54

60

14

2 171Ib

54

60

0005

m

Ib

Ibsqin

system

224

1

54

sq

sq

pump

shaft

In

I

In

I

In

In

In

ln

Technical

Type

Pump

type

IS

If

Drive

Clearance

outer

Clearance

tipS

Celarance

and

body

011

pressure

Free

Fitted

Opening

011

pressure

speed

Oil

pressure

2000

between

rotor

between

between

length

length

rpm

rehef

pressure

at

idhng

at

lhot

Inner

rotor

outer

valve

and

rotor

spring

101

38 42

0

05

015

38

4 2

2

kg

19

mter

M

j

@

Pl

C

1

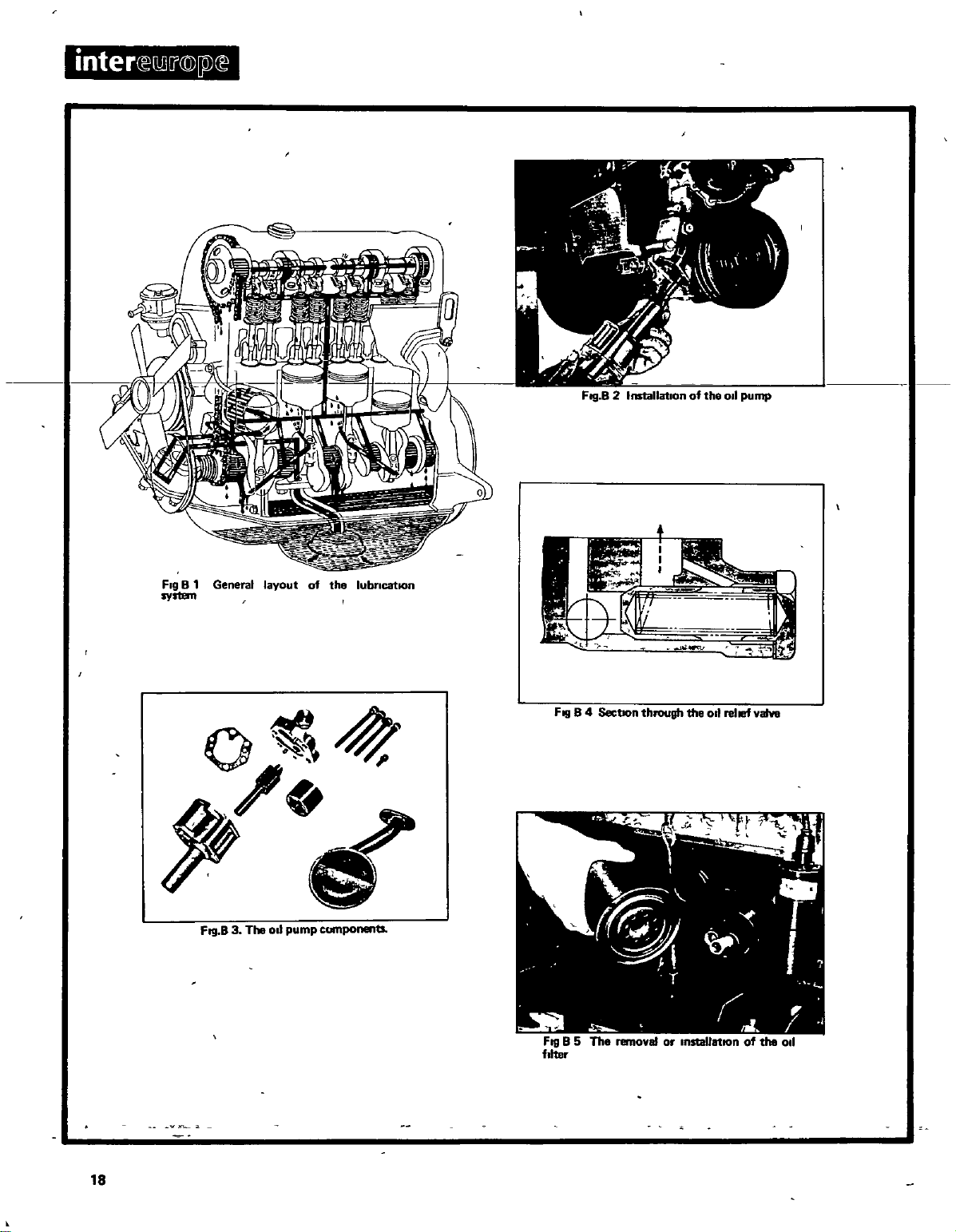

Fill

General

OY

arrangement

of

the

cooling

FIlI

c4DlSIllantllng

of

thefan

V V

00

o

clu1dl

o

OperatIon

SpIder

FIlI

C 5

Fill

parts

plate

assembly

C

3

Exploded

V

fIW

Dust

cover

linnl9

v

Drum

of

fan

the

c1u1l

h

J

of

the

radiator

and

component

20

It

DESCRIPTION

Cooling

System

The

cooling

radiator

water

Jacketsincylinder

To

remove

system

completely

unsaew

recommended

design

malfunction

Replace

vanes

With

cooling

The

before

In

IIlCrease

losses

temperature

In

operate

the

the

or

the

pump

models

ThiS

engine

and

the

system

It

the

and

the

If

there

engine

should

IS

refitted

effiCiency

of

the

system

pump

head

WATER

the

centrifugal

water

that the

manufacture

an

exchange

water

IS

running

protector

be cleaned WIth

With

clutch

the

engine

compartment

fan

clutch

is

a

closed

fan

and

PUMP

and

remow

from

pump

water

If

water

If

pump

excessIVe

to

air

IS

It

To

IS

recommended

the

front

FAN

conditIOning

of

the

thermostatically

compartment

Increases

Will

pressunsed

clutch

block

type

the fan

the

pump

the

pump

has

wear

prevent

cover

CLUTCH

coohng