Nissan Bluebird 1969 1973 User Manual

f

0

j

1

1R1

1M

o

o

@

7

o

I

r

t

Jot

oomm

llI

IP

cJ

I

0

4

V

J

2

y

7

F

4

V

DRAKE

PUBLlSHERS

ffi

INC

r

DATSU

O

MAINTENANCE

BY

Quick

RANGE

DRAKE

1969

AUTOMOTIVE

Reference

1973

REPAIR

EDITORS

Indel

MAINTENANCE

ENGINE

ELECTRICAL

FUEL

SYSTEM

COOLING

BRAKES

FRONT

SUSPENSION

SYSTEM

SYSTEM

TUNE

Tho

purpose

eference

We

ndeavor

specifications

the

Publisher

rors

or

Upon

ompitingthe

impls

make

this

source

omissions

elying

manual

of

to

at

UP

this

the time

on

not

with

the

manual

which

rporato

be

formation

combination

elul

5

21

39

67

77

81

STEERING

REAR

DRIVE

CLUTCH

TRANSMISSION

BODY

SPECIFICATIONS

WORK

SUSPENSION

91

95

99

107

115

119

89

to

provide

the

perform

manufacturing

While

for

manufacturing

herein

photograph

utomobila

normal

he

the

late

publication

Ipon

t

ible

contained

of

of

held

tool

ryeffort

we

illustration

ervice

design

have

owner

operations

changes

made

changes

tried

nd

mechanic

nd

to

typographical

be

to

nd

attain

brief

te

l1to

with

to

date

up

cy

and

DRAKE

PUBLlSHERS

381

NEW

PARK

AVENUE

YORK

ING

SOUTH

N

Y

1CXJ16

ISBN

87749

302

2

Published

Dlake

Palk

381

NewYolk

@Dlake

Printed

in

Publishers

Avenue

NY10016

Publishels

in

the

1973

United

by

Inc

South

Inc

States

1973

of

America

able

of

Contents

MAINTENANCE

VALVE

FAN

ENGINE

OIL

COOLANT

Nissan

COMPRESSION

Test

BATTERY

IGNITION

POINTS

CONDENSER

SPARK

CARBURETOR

Idle

CHECKING

Installed

DUAL

Cap

Point

Phase

TUNE

TROUBLE

DESCRIPTION

REMOVAL

INSTALLATION

DISASSEMBLY

Pistons

Cylinder

ASSEMBLY

CLEARANCE

BELT

FILTER

Long

Result

PLUGS

Limiter

POT

POINT

and

Difference

UP

and

Cylinder

Piston

Engine

OIL

Removal

Installation

and

PUMP

ELECTRiCAL

STARTER

Removal

OIL

Life

TIMING

Cap

ADJUSTING

Automatic

on

Engine

DISTRIBUTOR

Rotor

Head

GUIDE

SHOOTING

ENGINE

Connecting

Head

Head

Connecting

Coolant

Transmission

TUNE

DASH

Rods

Rods

SYSTEM

UP

Only

CHARGING

ALTERNATOR

6

6

6

6

7

7

7

8

8

9

9

9

10

10

11

11

11

12

12

12

12

14

15

Description

Removal

Installation

VOLTAGE

Descri

Measure

Adjustment

Charging

ALTERNATOR

FUSES

EMISSION

DISTRIBUTOR

Construction

Disassembly

Assembly

IGNITION

Construction

Descri

SPARK

Descri

Inspection

Cleaning

TROUBLE

HEATER

TROUBLESHOOTING

TROUBLESHOOTINQ

RADIO

Removal

22

23

24

24

2

27

27

28

29

30

36

36

3

TROUBLESHOOTING

SPEEDOMETER

TROUBLESHOOTING

TROUBLESHOOTING

NOISE

AIR

CLEANER ELEMENT

AUTOMATIC

CONTROL

AIR

CONTROL

Idle

Compensator

TEMPERATURE

Removal

CIRCUIT

REGULATOR

ption

of

Voltage

Relay

FUSIBLE

CONTROL

COIL

ption

PLUGS

ption

and

Regap

SHOOTING

UNIT

PREVENTION

FUEL

TEMPERATURE

REMOVAL

SYSTEM

AIR

VALVE

SENSOR

DESCRIPTION

LINKS

DIAGRAMS

IGNITION

HEADLIGHT

HORN

HEATER

RADIO

CHART

CLEANER

40

41

41

41

44

44

44

45

47

48

49

49

50

52

52

52

53

56

56

57

5

5

58

58

58

59

62

63

63

63

64

65

65

66

68

68

68

69

69

69

Installation 69

FUEL

40

40

PUMP

Removal

Inspection

Assembly

and

Disassembly

69

69

O

70

1

Table

of

Gontents

CARBURETOR

Removal

Disassembly

Float

Chamber

ANTI

BOOST

DIESELING

Removal

Installation

CONTROLLED

DECELERATION

Assembly

Cleaning

JETS

and

and

COOLING

DRAINING

WATER

Removal

Disassemb

Inspection

Installation

THERMOSTAT

Removal

RADIATOR

Removal

Inspection

MASTER CYLINDER

Removal

Installation

FRONT

DISC

Description

Removal

Disassembly

Inspection

Piston

Seal

Assembly

Pad

Replacement

REAR

BRAKE

Removal

Inspection

Assembly

FLUSHING

PUMP

y

and

Installation

and

Installation

BRAKE

and

Replacement

and

and

Disassembly

Installation

SOLENOID

Installation

Inspection

SYSTEM

BRAKES

Repair

DEVICE

3

3

3

74

74

4

74

RECOMMENDATIONS

STEERING

74

74

74

5

RECOMMENDATIONS

ASSEMBLY

STEERING

FRONT

GEAR

LINKAGE

REAR

SUSPENSION

STEERING

COMPONENTS

DRIVE

90

92

92

93

93

SUSPENSION

SHOCK

78

78

78

79

79

79

79

79

79

9

80

Removal

Inspection

Installation

DRIVE

RECOMMENDATIONS

REMOV

RELEASE

REPAIR

Refacing

ADJUSTMENT

INSTALLATION

MASTER

82

82

82

82

82

82

84

84

85

85

86

86

86

87

88

Removal

Disassembly

Inspection

Assembly

Installation

BLEEDING

REMOV

INSTALLATION

SPEED

4

Removal

RECOMMENDATIONS

ABSORBERS

SHAFf

CLUTCH

AL

BEARING

Pressure

Plate

CYLINDER

CLUTCH

TRANSMISSION

AL

TRANSMISSION

and

Installation

SYSTEM

96

96

96

96

97

97

102

102

103

103

104

104

105

105

105

106

106

106

106

109

III

113

113

113

2

Table

of

Gontents

FRONT

Removal

HOOD

Removal

Adjustment

TRUNK

Removal

Torsion

and

Sf

ARTER

DISTRIBUTOR

BODY

FENDER

and

Installation

Installation

and

LID

Installation

and

Removal

Bar

Adjustment

SPECIFICA

WORK

liONS

116

116

116

116

11

11

11

117

120

121

SPARK

VALVES

OIL

GENERAL

ELECTRICAL

MANUAL

CARBURETOR

CLUTCH

ENGINE

TUNE

LUBRICANTS

CAPACITIES

AUTOMATIC

PROPELLER

BRAKE

NOTES

PLUGS

PUMP

UP

CHASSIS

ALIGNMENT

TRANSMISSION

TORQUE

SAE

PRESSURES

TRANSMISSION

SHAFT

INFORMATION

WHEEL

122

122

122

123

123

12

131

134

136

138

138

139

140

144

146

14

a

llaiDteDlDce

Tune

up

VALVE

FAN

ENGINE

OIL

COOLANT

Nissan

COMPRESSION

Test

BATTERY

IGNITION TIMING

POINTS

CONDENSER

SPARK

CARBURETOR

Idle

CHECKING ADJUSTING

Installed

DUAL

Cap

Point

Phase

TUNE

TROUBLE

BELT

FILTER

Result

Limiter

POT

POINT

and

UP

CLEARANCE

OIL

Life

Long

PLUGS

Cap

Automatic

on

Engine

DISTRIBUTOR

Rotor

Difference

GUIDE

SHOOTING

Coolant

Head

Transmission

DASH

Only

6

6

6

6

7

7

7

8

8

9

9

9

10

10

11

11

11

12

12

12

12

14

15

I

IlaiDteDlDce

TUDe

up

Valve

the

ment

Remove

the

justed

the

is

Ilowest

locking

the

specified

with

camshaft

this

engine

necessary

cover

engi

valve

tilicates

camshaft

gasket

engine

clearance

engine

is

made

the

camshaft

with

rocker

point

nut

a

fuel

procedure

over

with

Remove

ne

clearance

Readjust

cover

appears

and

Valve

Cold

Warm

VALVE

adjustment

not

running

while

air

cleaner

cover

the

valve

arm

of

and

turn

clearance

gauge

between

Straighten

on

hand

bv

Temporarily

two

or

three

the

according

using

tlattened

check

for

clearance

I

Intake

Exhaust

Intake

Exhaust

CLEARANCE

the

engine

Each

completely

should

the

cam

the

is

the

each

to

position

replace

bolts

cover

as

necessary

a

new

leaks

is

performed

The

is

Unbolt

valve

be

lobe

adjusting

obtained

the

rocker

locking

valve

and

and

to

the

gasket

or

from

Unit

0

20

0

250010

0 25 0

0300

initial

cold

and

must

closed

at

Loosen

screw

as

nut

turning

each

the

warm

recheck

warranty

Replace

broken

the

gasket

mOl

008

0

010

012

adjust

remove

be ad

the

checked

arm

Repeat

valve

camshaft

up

if

the

in

with

that

base

until

and

cer

Run

the

the

the

the

the

old

FAN

BELT

Check

necessary

Adjust

0

lbl

nator

Check

Drain

Notes

as

a

cooling

corrective

b

dicates

Check oil

raise

Engine

including

Maximum

41

Minimum

31

The

315

is

A

An

U

U

oillilter

for

belt

to

applied

pulleys

if

and

milky

water

oil

dilution

it

up

oil

S

qts

S

qts

tension

0

472

oil

refill

measure

with

level

to

capacity

oillilterl

H

IL

cracks

in

midway

is

diluted

oil

the

leveli

leveli

is

of

or

It

when

ENGINE

oil

if

necessary

indicates

Isolate

extremely

with

If

below

H

level

OIL

FILTER

a

cartridge

damage

correct

is

thumb

between

OIL

with

the

gasoline

the

water

the

cause

low

type

Replace

if

detlection

pressure

fan

and

or

presence

and

viscosity

specitied

122

alter

gasoline

take

level

if

is

0

of

in

8

Ag1Adjusting

valve clearance

Fig

2

Drive

belt

tension

Percent

C0ncentralion

llaiDteDlDce

BoiHng

point

2

Sea

b

level

Q

0

system

k

i

em

HeUUre

coning

I

protection

FreeL

TUDe

up

Check

anv

leakage

stop

leakage

tive

replace

When

Note

installing

Do

leakage

Nissan

LLCis

taining

cooling

The

L

or

ethyl

and

away

temperature

sfers

heat

passages

must

not

coolant

the

year

Whenever

system

coolant

new

Without

With

for

should

Long

an

chemical

system

C

L

alcohol

can

must

heater

leaks

oil

is

If

tilter

not

Life

ethylene

does

be

can

thermostats

eniciently

in

the

be

mixed

be

any

be

Check

heater

past

found

retighten

retightening

as

an

oiltilter

overtighten

occur

COOLANT

Coolant

glycol

inhibitors

from

not

contain

It

will

used

cooling

with

used

throughout

coolant

tlushed

the

3m

50

gasketed

assembly

tighten

rusting

not

with

either

It

and

will

system

other

is

changed

and

level

6 0

1

65

I

just

is

no

by

oil

base

product

to

and

any

evaporate

flows

not

product

the

relilled

610

1

X

Imper

Y

I

Imper

flange

enough

longer

hand

filter

protect

corrosion

glycerine

high

freely

clog

The

seasons

the

I060C

2210F

I090C

228OF

U

S

gal

U

s

gal

effec

lest

con

or

or

tran

L L

This

cooling

with

Water

gal

gal

the

boil

low

the

lSOC

1240C

2SSor

Inlle

61UF

cap

lcity

620

U

S

6 0

S

I

I

1

t

1

Imper

U

Imper

gal

gal

S

gal

gal

If

to

When

it

becomes

compression

spark

determine

past

the

plugs

the

engine

piston

temperature

SoF

3SoC

3IOP

6

4t

6

81

COMPRESSION

necessary

it

is

The

whether

rings

should

and

throttle

5to

O

I

1

I

essential

purpose

there

head

be

heated

U

S

gal

Imper

gal

U

S

U

gal

i

Imper

gal

to

check

cylinder

to

of this

is

excessive

gasket

and

remove

test

etc

to

the

operating

choke

is

leakage

To

test

valves

an

to

opened

in

Cylinder

be

less

C

compression

than

80cf

OF

c

0

32

10

14

20

4

2

30

of

of

40 40

58

so

a

Fig

Protection

3

EG001

to

concentration

cylinders

the

highest reading

I

I

I

I

l

I

t

t

30

20 40 so

should

not

Dif

7

llaiDteDaDce

fCl

cnt

ll

llalh

or

hrokpll

Low

ornpn

n

ol

piqoll

he

i1

u

nn

mption

1

R

If

lindf

ell

l

i

intocylinder

n

nd

retest

II

adding

Illl

challn

II

s

pn

is

alve

IIllinder

dinder

the

help

the

past

Oil

and

ent

ja

not

Oil

1

akage

I

help

and

11

cylinder

from

comprc

indiL

low

ure

sticking

gasketed

water

past

water

sion

piston

ion

ring

ol1lpanit

ult

1

c

ll1pre

pOll

through

compression

oil

an

t

tn

compression

is

low

compres

in

is

the

compression

the

in

this

trouhle

in

an

nte

ring

in

cYlinders

Thi

rl

sion

a

Illall

the

Iwlp

hat

rings

low

01

seating

and

ion

surface

comhustion

low

gasketed

comhustion

two

improperlv

trouhle

bv

in

one

quantity

the

compression

arc

the

likelihood

improperly

in

any

if

adding

this

could

and

if

surface

Tune

or

more

seated

can

result

may

excessive

or

more

of

engine

spark

defective

two

oil

in

any

adding

this

chambers

plug

pressure

adjacent

does

be

could

cylinder

valve

from

usuallv

fuel

cvlin

holes

is

that

not

leakage

two

ad

oil

does

can

up

Full

Permissible

value

climates

Frigid

Tropical

Other

climates

climates

Over

OverI10

r

I

oil

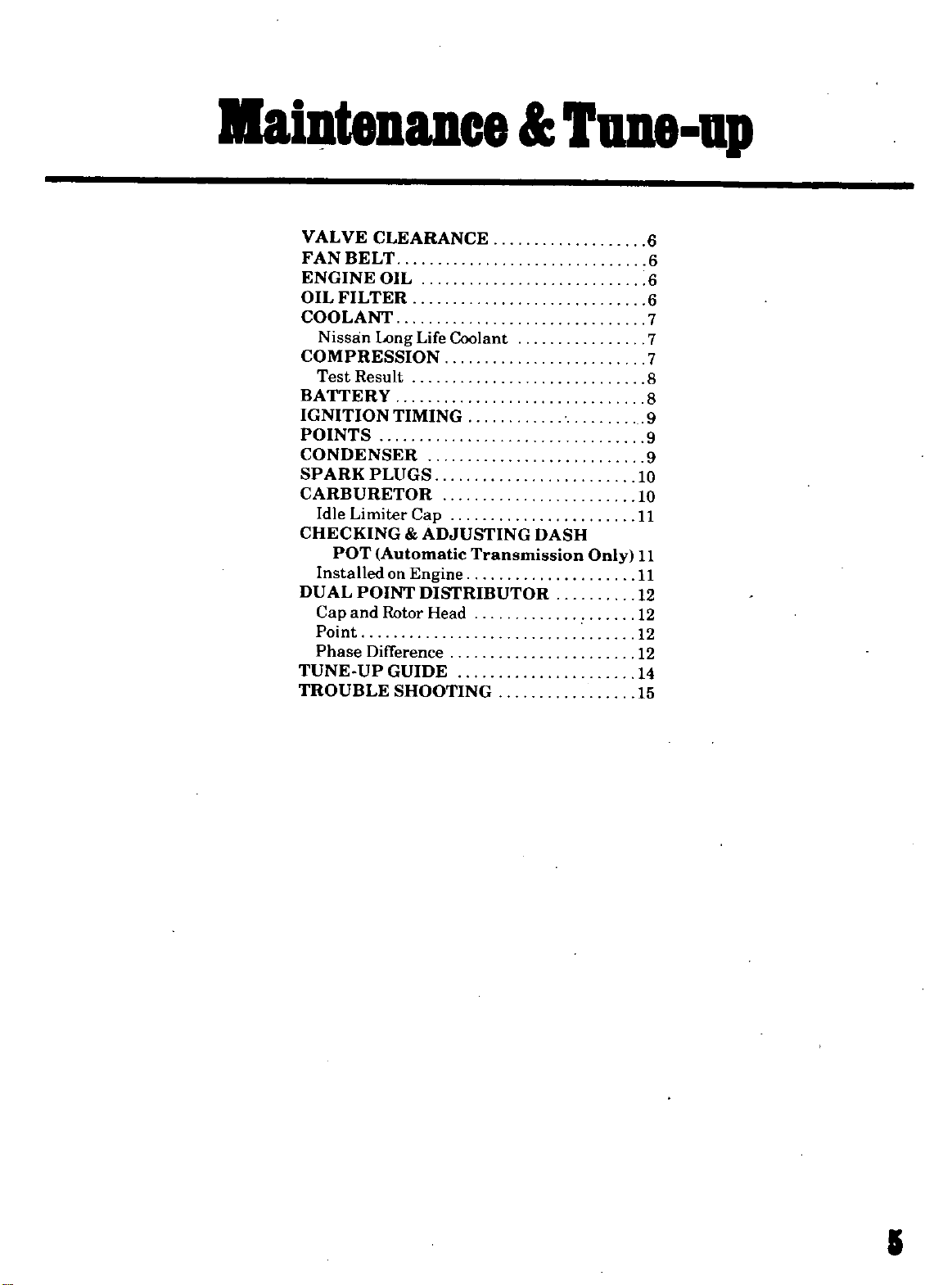

Fig4Testing

compression

pressure

be

charge

value

at

20ne

6SoF

I

28

1

23

126

8

nmpre

i

at

p

Standard

Minimum

Check

Unscrew

level

bring

0

787

Measure

trolyte

Clean

solution

and

rpm

electrolyte

If

the

in

top

dry

ion

c

1

128 350

each

the

above

the

of

wi h

prC

1

350

lluid

level

the

specitic

of

battery

baking

compressed

Sl1re

BATTERY

level

liller

is

low

up

approximately

plates

soda

in

each

cap

add

gravity

and

and

batterv

and

inspect

distilled

Do

not

overlill

of

battery

terminals

water

air

Topofbattery

cell

water

0

with

Rinse

394

lluid

elec

011

ET002

5

Checking

Fig

be

must

ween

to

to

hold

In

terminals

down

addition

cumulation

cause

may

connector

a

tightening

petroleum

clean

clamp

to

of

blistering

straps

vaseline

specific

to

and

current

acid

and

terminals

gravityofbattery

from

current

positive

prevent

leakage

and

dirt

of

the

corrosion

coat

to

protect

on

material

of

electrolyte

leakage

terminal

prolonged

of

top

covering

straps

them

them

bet

to

ac

battery

After

with

from

corrosion

l1aiDteDIDce

TUDe

up

Check

points

spark

for condition

Thoroughly

mark

on

and

front

Warm

Install

plug

Set

Check

iBefore

timing

If

Loosen

distributor

Adjust

Lock

thaI

up

a

wire

idling

ignition timing

light

necessary

ignition

distributor

timing

IGNITION TIMING

plugs

oIl

wipe

crank

Top

set

cover

engine

timing

and

speed

can

is

pulley

install

of

adjust

screw

be

timing

correct

light

to

Dead

sufticiently

approximately

moved

set

and

distributor

dirt

and

and

timing

on

No

tachometer

a

if it

Center

itasfollows

to

such

bv

to

5

screw

dust

1

an

hand

B

cylinder

800

is

by

TDC

and

from

indicator

rpm

50BT

the

extent

make

breaker

timing

spark

D

use

that

sure

full

contact

correct

the

earn

Note

on

l

of

Point

0

0177

Dwell

49to55

Clean

for loose

Check

meter

be

also

range

When

swings

gradually

pointer

resistance

Clean

and

Do

not

gap

0

to

angle

degrees

outlet

et

condenser

Condenser

checked

to

condenscr

largely

back

does

and

that

and

apply

wick

apply

0217 in

CONDENSER

condenser

of

screw

Retighten

capacity

insulation

using

measure

normal

is

and

the

to

not

stay

replacement

grease

point

a

large

intinite

still

dwell

distributor

lead

testcr

rapidly

or it

is

necessary

and

excessively

wire

if

necessary

witb

resistance

adjusting

by

resistance

the

tester

and

side

points

and

a

When

gap

grease

check

capacit

value

pointer

moves

zero

are

to

V

may

its

thc

in

Ignition

t

5

Retard

Z

1

Check

normal

Make

6

Fig

timing

Advance

the

pitting

sure

Adjusting

side

side

distributor

and

they

ignition timing

POINTS

wear

are

in

breaker

Replace

correct

points

if

necessary

alignment

for

ab

for

7

Fig

Fig

Checking

8

Checking

ignition timing

distributor

point

gap

llainteDance

Tune

up

Condeneer

Hctard

Micro

Advance

Micro

Condenser

side005IF

Farad

Farad

5MlltMega

Remove

cleaner

that

thev

insulator

spect

both

center

excessively

028

File

to

plugs

0

Tighten

Idle

mixture

CO

meter

mixture

thoroughly

Warm

Continue

idling

Adjust

speed

transmission

up

speed

throttle

is

oide

and

Inspect

are

0

031

plugs

it

engine

engine

800

capacity

0

22IF

insulation

ohms

SPARK

clean

of

and

worn

center

in

to

CARBURETOR

adjustment

When

is

essential

warmed

adjusting

rpm

L

resistance

plugs

each

spark

the

specitied

lor

cracks

ground

replace

electrode

using

11

0

to

preparing

and

sulliciently

operation

1

in

N

PLUGS

and

electrodes

l1at

proper

15

0ftlb

requires

to

calibrated

tor

screw

range

in

a

plug

heat

chips

with

Set

adjusting

to

have

one

so

tor automatic

sand

Make

range

If

new

the

torque

the

adjust

the

minute

that

Check

they

spark

gap

use

meter

engine

blast

sure

tooL

of

idle

Check

the

Adjust

centage

Repeat

and

1

In

wheel

are

to

a

on

rush

On

make

with

And

lever

cent

Idling

at

Readjust by

justing

out

Notes

a

specillcations

5

0 5

5

Caution

a

On

model

range

Be

lock

b

Hold

accelerator

automatic

the

and

CO

Do

ignition

idle

adjusting

1

is

the

procedures

above

at

automatic

check

sure

both

chocks

brake

out

dangerously

sure

that

selector

then

check

in D

idle

650

rpm

percentage

screw

not

attempt

timing

0

5

so

800

should

to

apply

front

transmission

the

position

speed

turning

or

pedal

15

5

that

rpm

transmission

and

pedal

adjustment

lever

the

are

1

5

idle

to

if

neceesary

800

rpm

screw

so

as

described

CO

be

done

parking

rear

while

stepping

Otherwise

equipped

in

N

position

specitications

Insure

tollows

as

0

5

in

or

out

adjusting

screw

down

adjust

retard

that

in

percentage

equipped

in

brake

wheels

has

been

that

throttle

screw

sidel

CO

the

car

with

CO

idle

items

and

down

model

if

it

per

witb

will

made

the

per

still

ad

to

3

is

D

to

ad

10

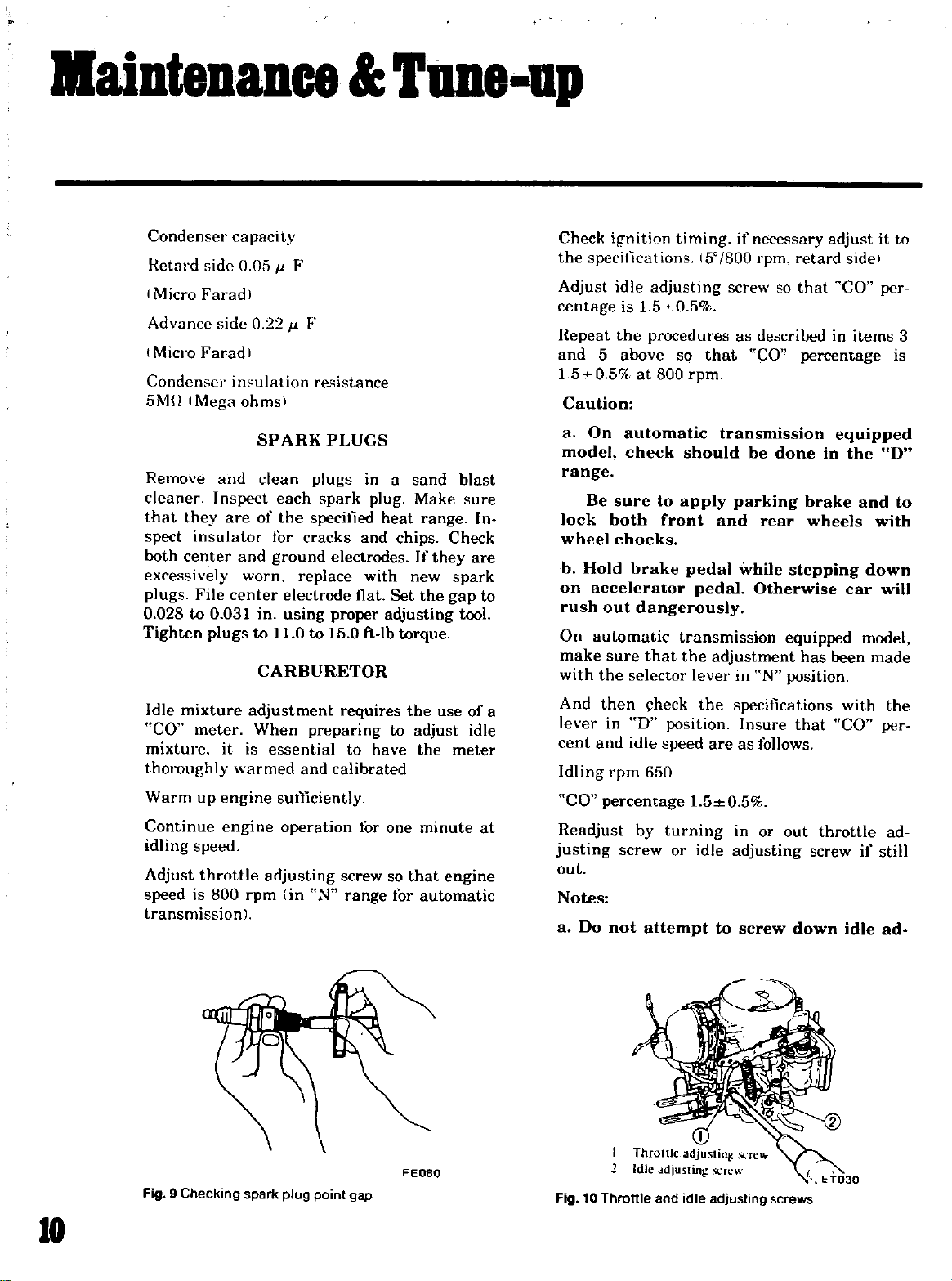

Fig9Checking

spark

plug

point

gap

EEOBO

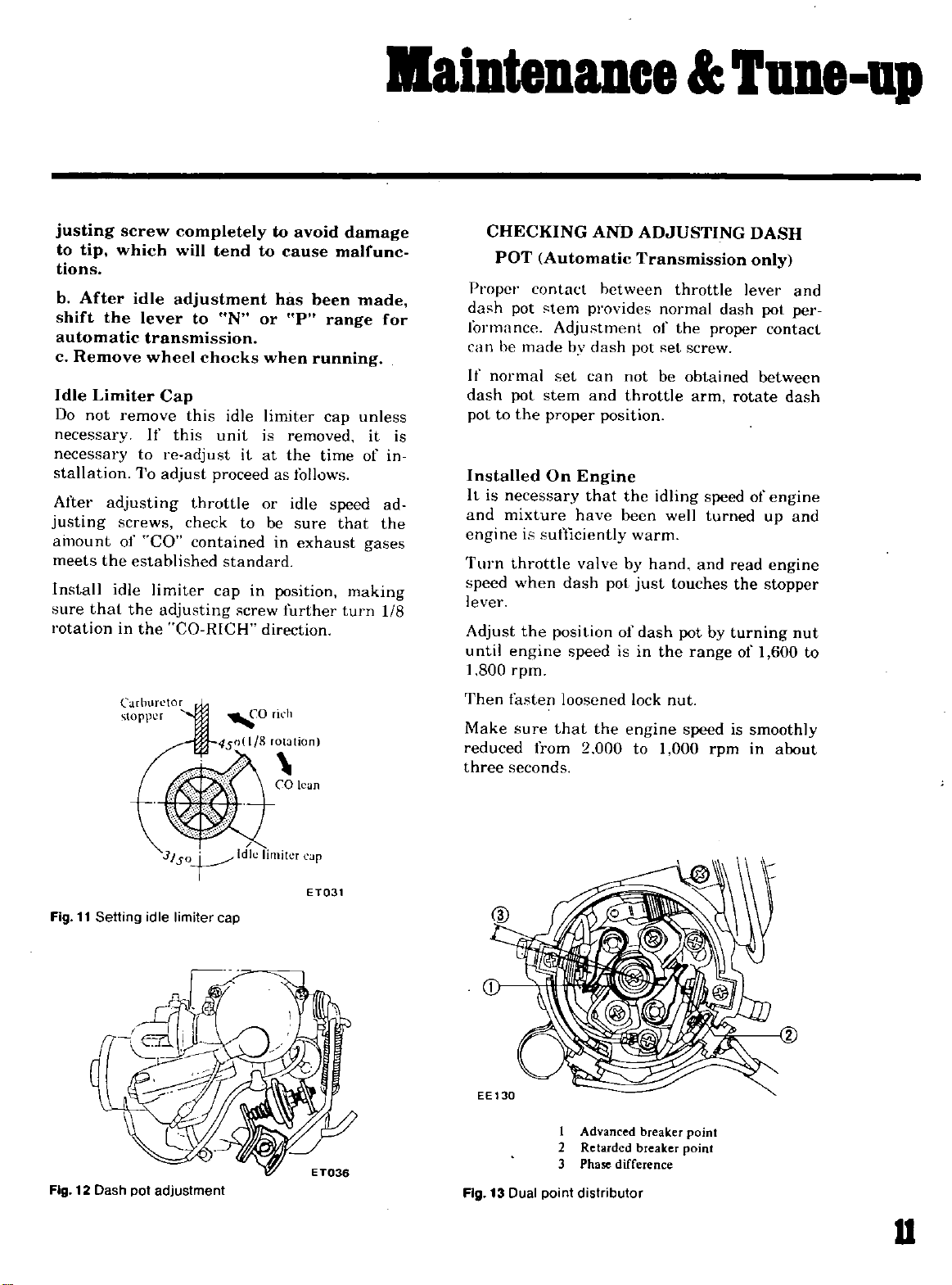

Fig

10

2

Throttle

and

idle

adjusting

screws

l1aiDteDlDce

TUDe

up

justing

to

tip

tions

b

After

shift

automatic

c

Remove

Idle

Do

not

necessary

necessary

stallation

After

justing

amount

meets

Install

sure

rotation

screw

which

the

Limiter

remove

adjusting

screws

of

the

idle

that

in

C

idle

lever

transmission

wheel

Cap

If

to

re

To

adjust

CO

estahlished

limiter

the

adjusting

the

rburctor

topper

completely

will

tend

adjustment

to

Not

chocks

this idle

this

unit

adjust

proceed

throttle

check

contained

standard

cap

CO

RICH

it

to

screw

to

or

when

limiter

is

at

or

be

in

direction

to

avoid

cause

has

plt

removed

the

as

follows

idle

sure

in

exhaust

position

further

h

alation

COlcan

damage

maIfunc

been

range

running

cap

time

speed

that

making

turn

made

unless

it

of

gases

for

the

1

CHECKING

POT

he

normal

to

is

contact

pot

made

pot

the

necessary

mixture

stem

Proper

dash

lonnance

can

If

dash

pot

is

in

Installed

ad

It

and

engineitsufticiently

Turn

throttle

when

speed

8

lever

Adjust

until

800

1

Then

Make

reduced

three

the

engine

rpm

fasten

sure

from

seconds

Automatic

Adju

bv

set

stem

proper

On

Engine

have

valve

dash

position

speed

loosened

that

2

AND

hetween

provides

tmenl

dash

can

and

position

that

pot

of

isinthe

the

000

ADJUSTING

Transmission

normal

of

set

pot

not

be

throttle

the

idling

been

warm

hand

by

just

dash

lock

engine

to

t

throttle

the

obtained

well

touches

pot

nut

speed

000

screw

arm

range

proper

speed

turned

and

by

rpm

dash

rotate

read

the

turning

of

is

DASH

only

lever

pot

contact

between

of

engine

up

engine

stopper

1

600

smoothly

in

about

and

per

dash

and

nut

to

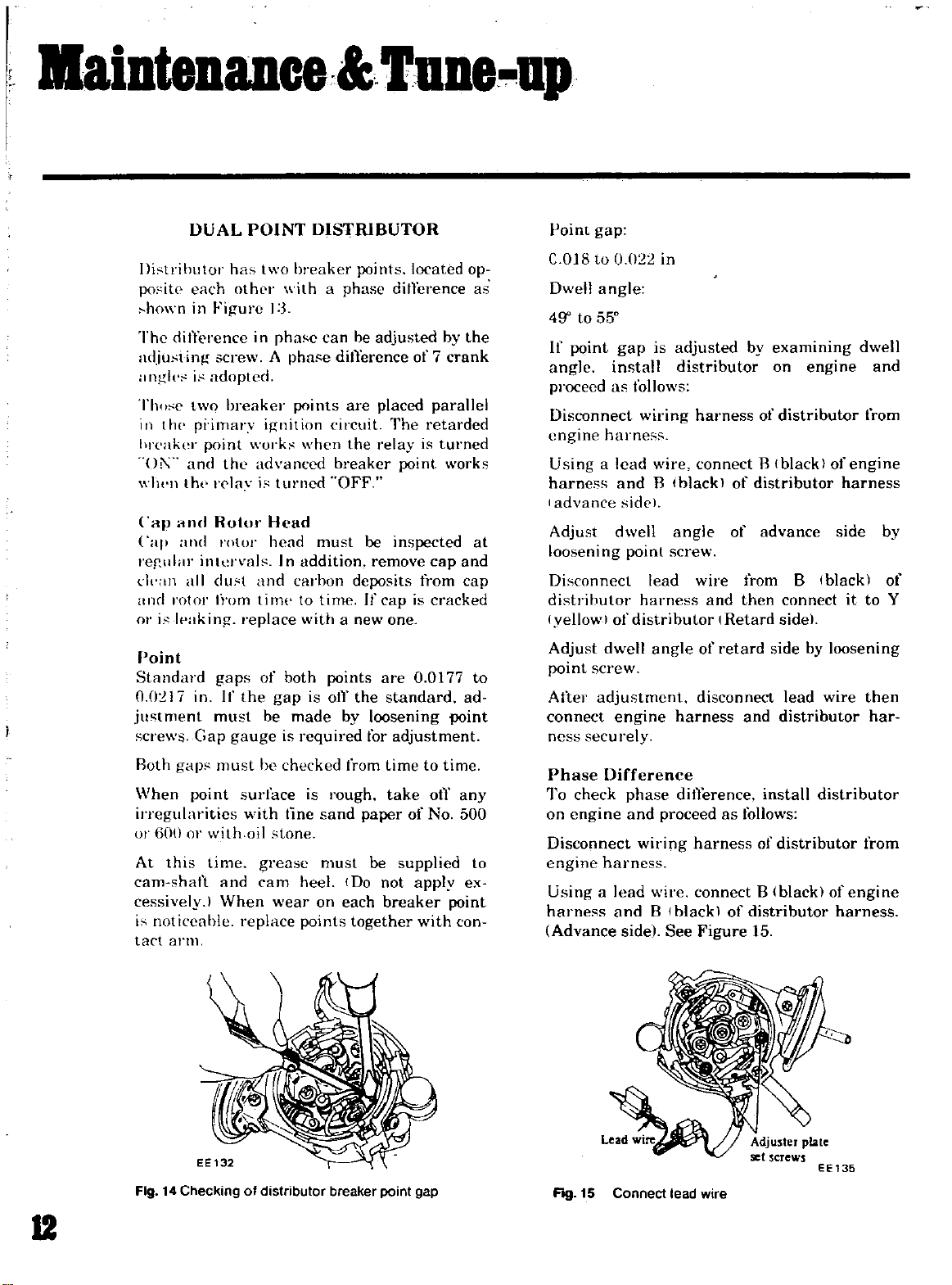

Fig11Setting

Dash

12

Fig

JIsoy1dle

idle

limiter

pot

adjustment

cap

limiter

Jp

ET031

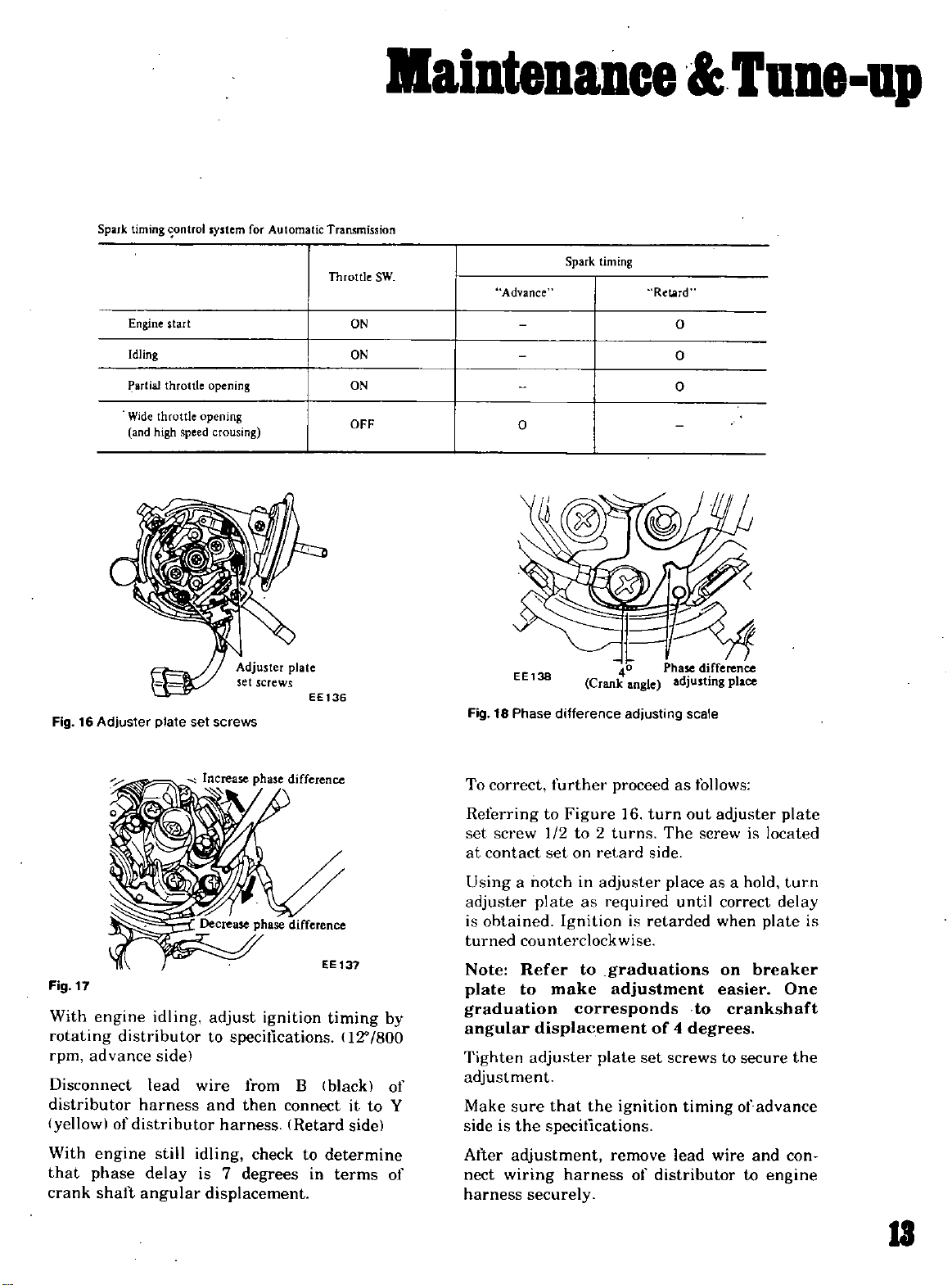

Fig

EE130

I

Advanced break

2

Retarded

3

Pha

difference

Dual

13

point

distributor

breaker

er

point

point

u

l1aiDteDlDce

uDe

up

DUAL

fitrihlltor

itp

ap

al

h

ilnf

0

Z17

wn

thp

01

iliaI

1Il

i

ditl

ting

h

e

and

lind

and

all

rotor

Ipaking

each

in

i

two

pi

in

po

The

adju

Th

in

hreaker

whtlllht

ref

e11

lnd

0

Point

Standard

0

justment

screwlS

Roth

When

Gap

point

irregularities

tiOt

or

At

canHhaft

cessively

i

tact

or

this

noticeable

an11

has

othl

Figure

rence

screw

adopted

breaker

imarv

point

the

laviturned

1

C

Rotor

rotor

inlervah

du

Ii

om

gaps

If

must

gauge

must

gap

with

time

and

1

When

POINT

two

r

I

in

pha

A

ignition

advanced

lIead

hend

and

t

time

replace

of

the

gap

be

he

surface

with

oil

slone

grease

carn

wear

replace

DISTRIBUTOR

breaker

with

a

e

can

phase

points

when

ork

must

Inaddition

carhon

to

time

with

both

points

is

made

is

required

checked

is

tine

sand

must

heel

on

points

points

phase

be

dill

erence

are

circuit

the

breaker

OFF

dc

If

a

new

ot1

the standard

by

from

rough

paper

Do

each

together

located

ditlcrence

adjusted

placed

The

relay

point

be

inspected

remove

sits

cap

one

are

loosening

for

adjustment

time

take

of

be

supplied

not

breaker

bv

of7crank

parallel

retarded

is

turned

works

and

cap

from

is

cracked

0

0177

point

to

time

ot1

any

No

500

applv

point

with

con

cap

ad

the

ex

Point

gap

018 to

op

as

C

Dwell

49

If

to

point

angle

proceed

Disconnect

engine

Using

harness and

I

advance

at

Adjust

loosening

Disconnect

distributor

vellowl

Adjust

to

to

point

After

connect

ness

securely

Phase

To

check

on

engine

Disconnect

engine

Using

harness

IAdvance

z

angle

550

gap

install

as

follows

a

lead

side

dwell

point

of

distributor

dwell

screw

adjustment

engine

Difference

phase

and

wiring

harness

a

lead

and

sidel

in

IS

wiri

harnes

wire

B

lead

harness

angle

proceed

wire

B

See

adjusted

distributor

harness

ng

connect

black

angle

screw

wire

and

of

disconnect

harness

dil1

erence

harness

connect

black

Figure

of

of

I

Retard

retard

as

of

by

examining

on

ofdistributor

B

black

distributor

advance

from

then

connect

side

lead

and

distributor

install

follows

of distributor

Iblackl

B

distributor

15

engine

of

side

Btblack

side

loosening

by

wire

distributor

of

harness

dwell

from

engine

harness

it

to

then

har

from

engine

and

by

of

Y

12

Fig14Checking

of

distributor

breaker

point

gap

Fog

15

Connecllead

EE135

wire

lIaiDteDance

TUDe

up

Fig

16

Spark

Adjuster

timing

Engine

Idling

Partial

Wide

and

throttle

throttle

high

plate

sontrol

start

speed

set

system

opening

opening

rousing

screws

for

Adjuster

set

screws

Automatic

plate

EE136

T

Throttle

smission

ON

ON

ON

OFF

SW

Fig

Advance

18

0

EEl38

Phase

Spark

difference

timing

adjusting

Retard

0

0

0

scale

17

Fig

With

rotating

advance

rpm

Disconnect

distributor

yellow

With

that

crank

engine

distributor

of

engine

phase

shaft

idling

side

lead

harness

distributor

still

delay

angular

adjust

to

specitications

wire

from

and

then

harness

7

degrees

check

idling

is

displacement

ignition

B tblack

connect

IRetard

to

in

timing

112

it

side

determine

terms

To

correct

Referring

set

screw

at

contact

Using

adjuster

ohtained

is

turned

Note

plate

by

800

graduation

angular

Tighten

of

to

Y

of

adjustment

Make

sideisthe

After

nect

harness

further

to

12

set

a

notch

plate

Ignition

counterclockwise

Refer

to

make

displacement

adjuster

sure

that

specilications

adjustment

wiring

securely

proceed

Figure

to2turns

on

retard

in

adjuster

as

required

to

graduations

adjustment

corresponds

plate

the

ignition timing

remove

harness

as

6

turn

The

side

place

until correct

is

retarded

4

of

set

screws

lead

of

distributor to

follows

out

adjuster

screw

as

when

on

easier

to

crankshaft

degrees

to

wire

a

is

hold

secure

of

located

plate

breaker

advance

and

engine

plate

turn

delay

is

One

the

con

13

lJaiDteDance

up

Tune

1J

lllitiun

1

Dislrihlltol

Idling

Dash

Spark

nd

t1illutl

tirnmll

I

linl

Dwellanglc

C

Id

r

lnd

n

ldjustmtnt

Manual

Automatic

pot

3djuslrnenl

Anli

die

ling

timing

lluottle

L18

L16

Lib

Thermo

1

fll

l

JP

n

iCf

lpadty

er

Trnnsmission

Transmission

solenoid

conlrol

switch

t5tO

620

switch

1t1T

lSuliliOIl

tightening

system

operating

AfT

MfT

AfT

operating

lanc

torque

angle

MfT

temperature

TUNE

degree

F

MH

deg

COil

degree

call

pm

em

kg

degK

degree

degree

or

OF

dcgr

e

in

e

e

rpm

lin

rpm

UP

GUIDE

5

IB

T O

C

0

45100

5510

49

to

55

retard

side005

advance

side022

5

800

50

retard

1

0 5

5

t

50

650

retard

0

5

1 5

t

1

600to1

800

Ib

35to55

30to48

side

side

0177

toO

02t7

0

range

350

400

450

5to13

4to55

H

Adjustmentofoperating

RC00

set

pressure

AfT

MfT

A T C

Air

cleaner

A TCValve

opening

pressure

temperature

fac

OD

mmHg

mmHg

Or

OF

inHg

inHg

37

5 to

480

t

500t20

20

4S

100

0

787

t8

9

t

19

0

787

7

t

to

1

8

llaiDteDlDce

TUDe

up

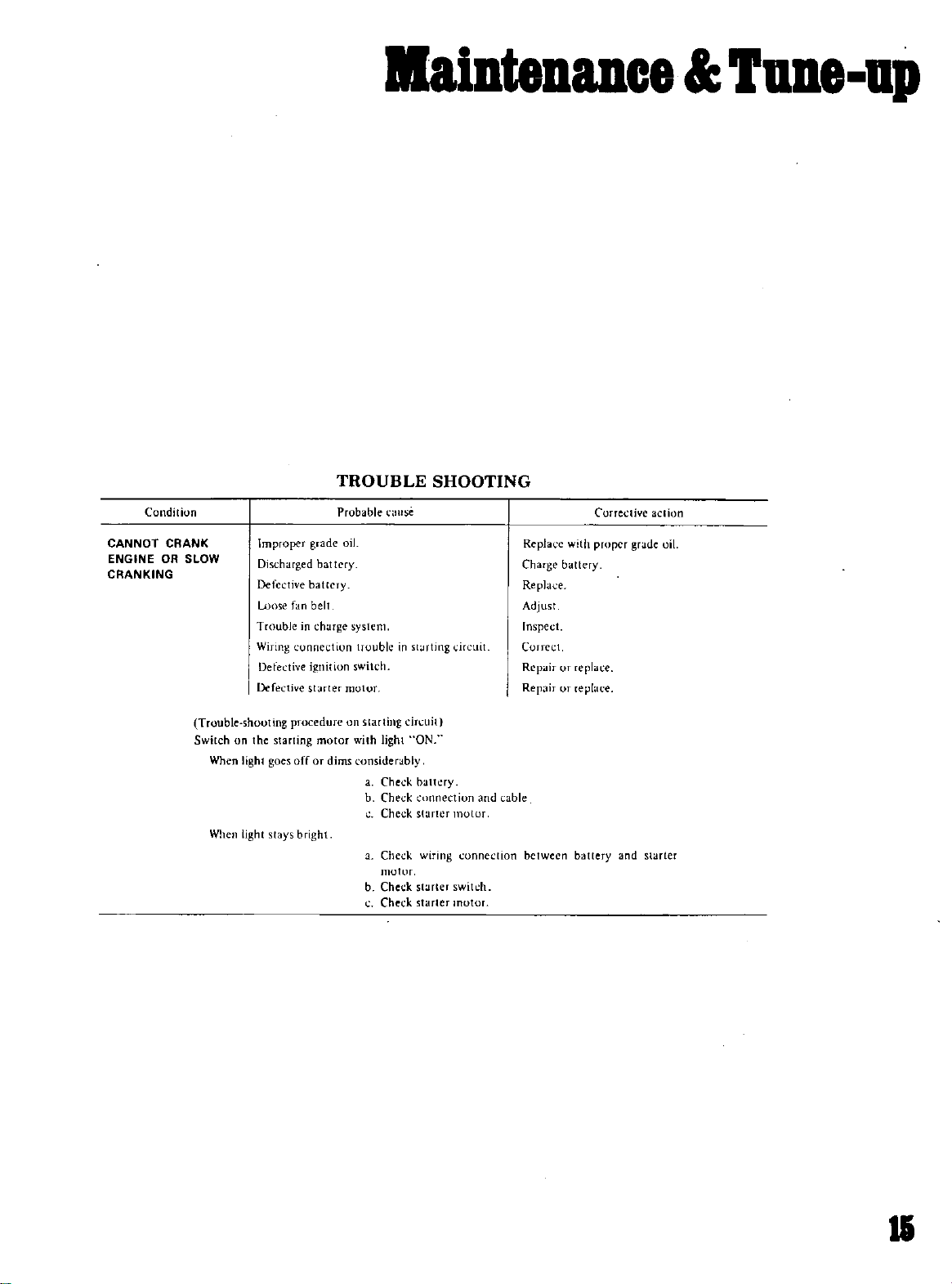

Condition

CANNOT

ENGINE OR

CRANKING

CRANK

StOW

T

Switch

ouble

When

When

shooting

on

light

light

Improper

DIscharged

Defective

Loose

T

wble

Wiring

Detective

Defc

the

starting

goes

51

grade

bat

battery

fan

belt

in

charge

onnectiun

igmllon

st

lrter

tive

procedure

motor

off

s

bright

TROUBLE

Probable

II

tery

system

trouble

switch

oloL

with

dims

starting

light

nsiderably

b

Check

Check

OllH

h

Check

in

cin

Che

Che

Chel

Sl

k

k

k

SHOOTING

Hting

uil

ON

baltery

nnection

s aller

wiring

starter

starter

switch

C

rel

tive

elion

c

Charge

with

Repla

ballery

proper

grade

il

Replace

Adjust

Inspect

n

Correcl

Repair

Repair

and

able

olur

cllOn

between

ulm

replace

replace

h

lttery

nd

Slarter

1

I

I

llaiDtelllDce

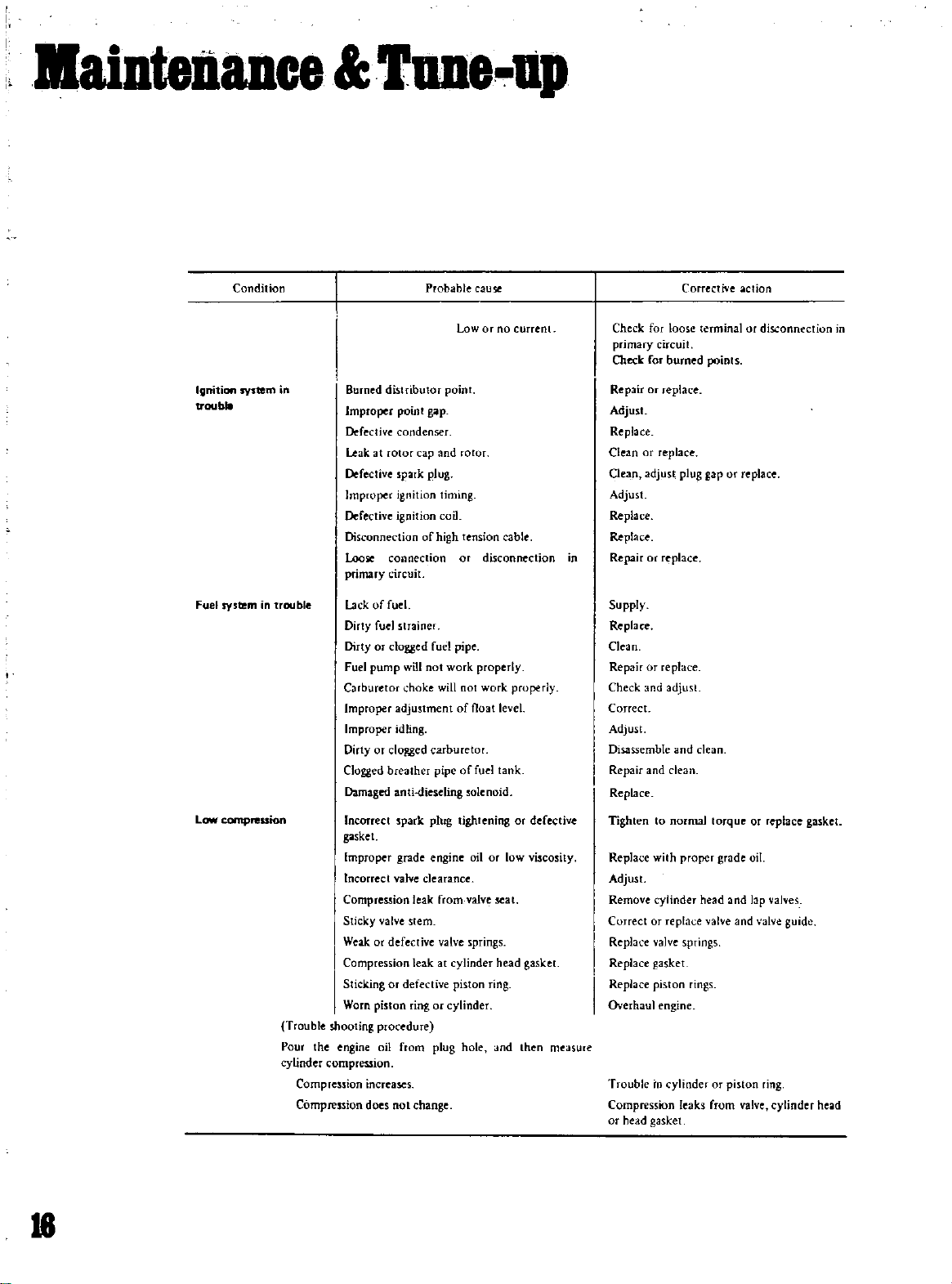

Condition

Ignition

system

trouble

Fuel

system

Low

compreuion

in

trouble

Trouble

Pour

cylinder

Compression

Compression

IUD8

Burned

Improper

Defective

leak

at

Defective

Improper

Defective

Disconnection

L005C

primary

la

k of fue

fuel

Dirty

Dirtyorclogged

Fuel

pump

Carburetor

Improper adjustment

Improper idling

or

Dirty

Clogged

Damaged

Incorrect

gasket

Improper

Incorrect

Compression

valve

Sticky

Weak

Compression

Slicking

Worn

piston

shooting procedure

the

engine

compression

increases

does

distributor

point

ondenser

rotor

spark

ignition

ignition

connection

Tcuit

strainer

willotwork

choke

do

breather

spark

grade

valve

leak

stem

defective

leak

or

defective

iI

from

not

change

Probable

gap

ap

plug

of

fuel

ed

carburetor

anti

dieseling

plug

engine

clearance

ing

plug

point

and

timmg

oil

high

will

pipe

fromvaIve

alve

at

cylinder

cylinder

cause

Low

or

rotor

tension

or

disconnection

pipe

properly

01

work

of

float

of

fud

olenoid

tightening

it

springs

piston

hole

UP

no

current

cable

properly

level

tank

or

low

seat

head

ing

nd

defective

viscosity

gasket

then

measure

in

Corrective

Check

for

loose

circuit

primary

Check

for

burned

Repair replace

Adjust

Replace

Clean

Clean

eplace

adjust plug

Adjust

Replace

Replace

Repair replace

Supp1r

Replace

Clean

Repair

Check

Correct

tnd

replace

adjust

Adjust

Disassemble

Repair

nd

nd

clean

Replace

to

with

normal

proper

Tighten

Replace

Adjust

Remove

cylinder

Correct

Replace

Replace

Replace

Overhaul

Trouble

Compression

or

head

replace

valve

gasket

pIston

engine

ill

gasket

cylinder

leak

action

terminalordisconnection

points

or

gap

replace

clean

or

torque

oil

grade

head

and

lap

alve

nd

springs

ngs

or

piston

valve

from

replace

valves

lIve

ring

cylinder

gasket

guide

head

18

llaiDteDlDce

Tune

up

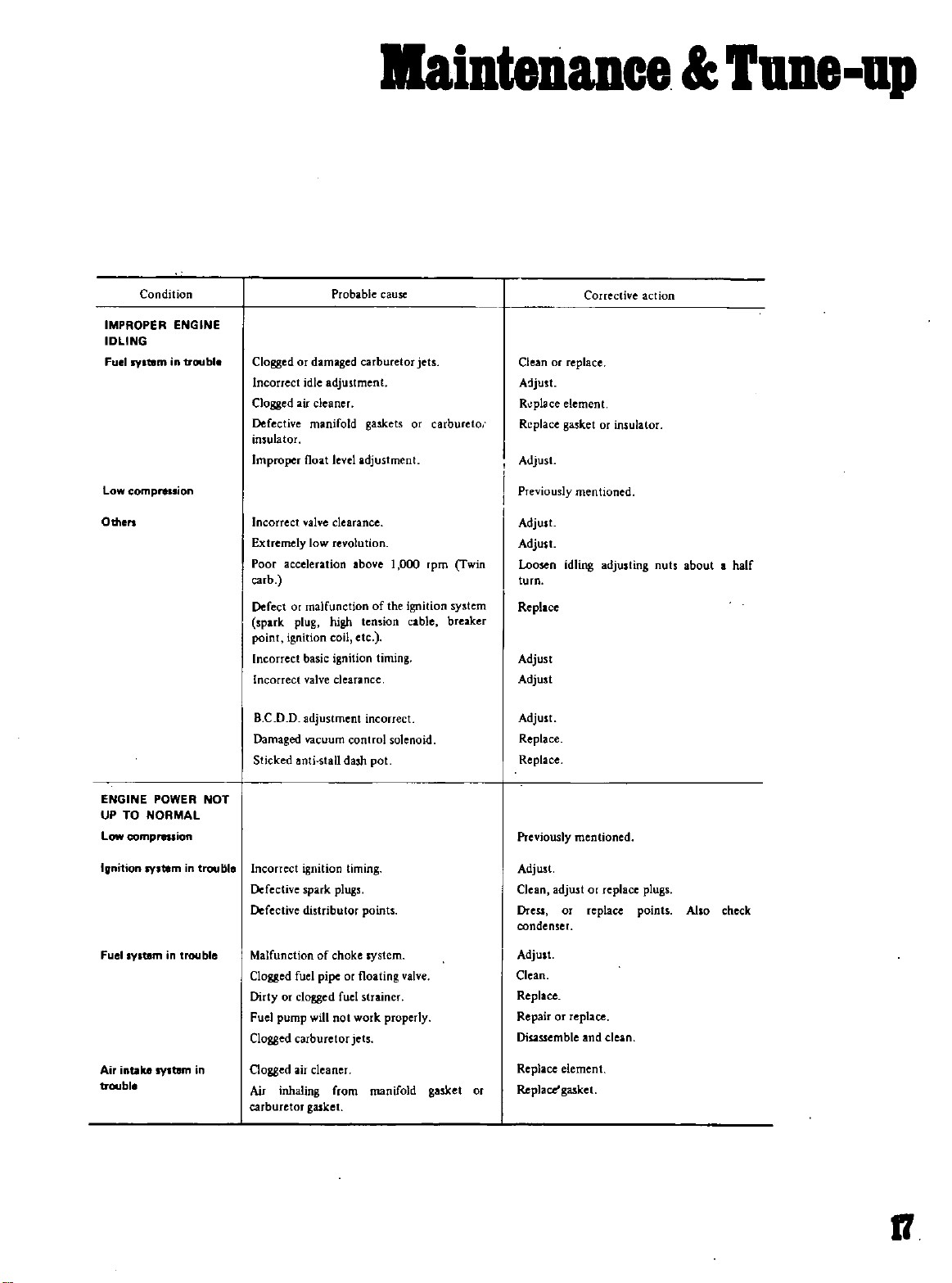

Condition

IMPROPER ENGINE

IDLING

Fuelsyltem

Low

compreSlion

Others

trouble

Probable

Cloggedordamaged

Incorrect

Clogged

Defective

insulator

Improper

Incorrect

Extremely

Poor

carb

Defect

point

Incorrect

Incorrect

Damaged

Sticked

spark

8

C D D

idle

cleaner

air

manifold

float

valve

low

acceleration

or

malfunction

plug

ignition

basic

alve

adjustment

vacuum

adjustment

level

clearance

revolution

high

coil

ignition

clearance

anti

stall

dash

cause

carburetor

gaskets

adjustment

above1000

of

the

tension

etc

timing

incorrect

control

solenoid

pot

jets

or

ignition

cable

carbureto

rpm

Twin

system

breaker

Clean

A1just

Replace

Adjust

i

Previously

I

I

Adjust

Adjust

Loosen

turn

Replace

Adjust

Adjust

Adjust

Replace

Replace

place

R

replace

element

gasket

mentioned

idling

Corrective

adjusting

insulator

action

nuts

aboutahalf

ENGINE

UP TO

Low

Ignition

Fuel

Air

trouble

POWER

NORMAL

comprnsion

syltem

system

ntake

syltem

trouble

NOT

trouble

in

Incorrect

Defective

Defective

Malfunction

Clogged

ignition

spark

distributor

fuel

of

pipe

Dirtyorclogged

Fuel

Clogged

Gagged

Air

carburetor

pump

carburetor

air

inhaling

will

cleaner

gasket

plugs

choke

fuel

not

from

timing

or

floating

work

jets

points

system

strainer

manifold

valve

properly

gasket

or

Previously

mentioned

Adjust

Clean

adjustorreplace

Dress

or

condenser

replace

Adjust

Clean

Replace

Repairoreplace

Disassemble

Replace

RepJace

and

element

gasket

clean

plugs

points

Also

check

fl

IlainteDance

TUDe

up

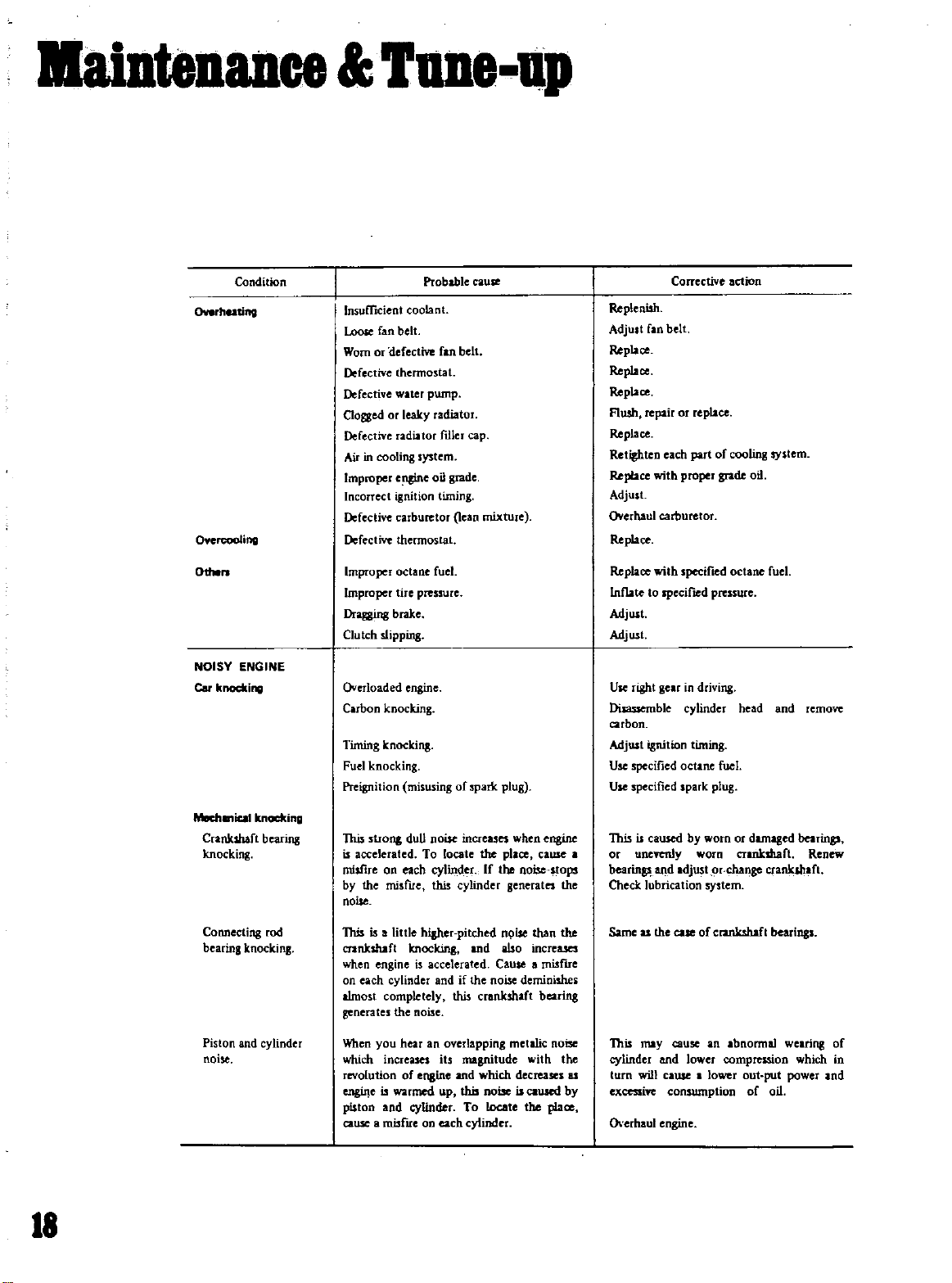

Owrheating

Owenooling

Othen

NOISY

Car

knodting

Mechmicll

Crankshaft

knocking

Condition

ENGINE

kncdtinll

bearing

fan

or

coolant

belt

defective

thermostat

water

Insufficient

Loose

Worn

Defective

Defective

Ooggedorleaky

in

cooling

dipping

knocking

knocking

knocking

strong

accelerated

the

radiator

e e

ignition

carburetor

thermostat

octane

tire

brake

engine

misusing

dull

misfut

Defective

Air

Improper

Incorrect

Defective

Defective

Improper

Improper

Dragging

Clutch

Overloaded

Carbon

Timing

Fuel

Preignition

ThU

is

misflTeoneach

by

noise

Probable

pump

radiator

system

oil

fuel

pressure

noise

To

cylinder

this

fan

mlct

grade

timing

locate

cause

belt

cap

lean

of

spark

increases

cylinder

mixture

the

If

plug

when

place

the

noise

generates

engine

cause

stop3

the

a

ReplenWt

fan

Adjust

Replace

Replace

Replace

Flush

repair

Replace

Retighten

with

Replace

Adjust

Overhaul

carburetor

Replace

with

Repbce

Inflate

to

Adjust

Adjust

Use

right

gear

Disassemble

carbon

Adjust

ignition

Use

specified

Use

specified

Thisiscaused

or

uneyen

and

bearinp

lubrication

Check

Corrective

belt

or

replace

part

proper

of

grade

each

specified

specifted

pressure

in

driving

cylinder

timing

octane

fuel

plug

spark

worn

by

worn

y

adjustorchange

system

action

cooling

oil

octane

head

or

damaged

crankshaft

system

fuel

and

crankshaft

remove

bearings

Renew

18

Connecting

bearing

knocking

Piston

and

noise

rod

cylinder

This

isalittle

crankshaft

when

on

each

almost

generates

When

which

revolution

engiI

piston

cause

engine

cylinder

completely

the

you

increases

e

is

warmed

and

a

misfue

hisher

knocking

is

noise

hear

of

enaine

cylinder

on

accelerated

andifthe

this

an

overlapping

its

up

each

pitched

and

crankshaft

magnitude

and

which

this

noi3e is

locate

To

cylinder

than

n9ise

also

increases

Causeamisfue

noise

deminiwi

bearing

metalic

with

decreases

caused

the

the

noise

the

place

as

the

Same

This

cylinder

u

turn

excessive

by

erhaul

may

and

will

engine

case

of

cause

an

lower

I

lower

cause

consumption

crankshaft

abnormal

compression

out

of

bearinas

wearing

put

power

oil

which

of

in

and

IlaiDteDance

TUDe

ail

Condition

Piston

pin

Water

pump

Others

ABNORMAL

COMBUSTION

fue

back

run

on

etc

Improper

Fuel

o

f8C1iYe

ignition

system

eylinder

noise

after

of

be

chain

play

will

timing

fire

of the

Run

spring

cause

at

piston

on

caused

on

be

heared

bushing

will

of

spark

or

jet

on

valve

back

each

ach

the

of

ankshaft

be

manifold

noaL

clearance

ryighest

To

locale

cylinder

by

uneven

alve

when

hur

plugs

chamber

after

fire

worn

surface

clearance

clutch

gasket

when

fire

and

the

This

may

pin

piston

Renew

piston

Replace

Adjust

the

Adjust

Disassemhle

Renew

bush

Adjust

ignition

e

specified

Replace

efnbecalburetor

Disas

the

Adjust

Adjust

Adjust

Remove

Replace

Corrective

cause

hole

water

tensionofchain

engine

and

them

level

head

it

with

Probable

noise

This

lowest

place

noise

This

damaged

of

An

Noise

An

Note

Wear

Note

fire

timing

Improper

Improper

trouble

in

Damaged

back

Defective

Improper

Uneven

hem

Improperly

Excess

is heared

end

dead

cause a

noise

may

bearingsorby

iding

parts

improper

of

timing

excessive

is

clutch

end

This

noise

disengaaed

on

clutch

noise

Uta

is

disenpged

ignition

heat

carburetor

fire after

carburetor

function

idling

adjusted

carbonincombustion

DaJ

llaged

valve

misfire

adjustment

pilot

range

and

pump

timing

spaTk

with

and

and

a

a

wear on

piston

and

adjust

plugs

new

gel

new

action

pin

a

with

new

new

drive

parh

and

check

needle

ridofcarbon

one

piston

usembly

one

main

shaft

check

pin

bearing

it

valve

or

EXCESSIVE

CONSUMPTION

Oil

I

OIL

Loose

Loose

Loose

Defective

crankshaft

Loose

fmproper

Loose

oil

drain

or

damaged

or

damaged

or

damaged

tightening

or

damag

plug

oil

pan

gasket

over

chain

oil

seal

in

locker

of

gasket

front

and

rear

of

cover

gasket

mter

oil

Tighten

Renew

Renew

Renew

Renew

much

Renew

it

gasketortighten

or

gasket

oil

tighten

seal

gasketortighten

and

gasket

tighten

it

it

with

but

ot

too

the

proper

it

it

torque

ed oil

pressure

switch

Renew

oil

pressure

switch

or

tighten

it

18

l1aiDteDIDce

TUDe

up

Excessive

consumption

Otben

POOR

See

the

of

the

power

Others

TROUBLE

FUNCTIONS

Oecreased

Condition

oil

FUEL

explanation

deerea

IN

oil

pressure

ECONOMY

OTHER

Cylinder

Improper

reversely

Damage

Worn

piston

of

Fatigue

Worn

valve

Inadequate

overheat

Engine

Exceeding

Defective

Fuel

leakage

Inadequate

Overheat

Defective

valve

Functional

Blocked

Increased

Blocked

Troubles

and

piston

location

assembled

piston

ing

valve

stem

quality

idling

acceleration

oil

quality

function

deterioration

oil

filter

clearance

oil

strainer

in

oil

Probable

rings

groove

oil

revolution

gauge

wear

of

piston

seal

of

of

in

pressure

cause

piston

and

lip

engine

ecovery

of

various

Corrective

Overhaul

cylinder

or

ring

gap

ng

Remount

Renew

Repair

ing

Renew

Replace

Renew

oil

Use

Previously

Adjust

Adjust

rings

or

piston

seal

valve

the

designated

it

it

piston

renew

mentioned

the

to

lip

or

Repairortighten

and

ings

piston

and

piston

with

guide

oil

designated

the

a

action

new

and

ring

new

connection

piston

cylinder

one

rpm

of

fuel

pipes

Use

the

designated

Previously

il

pump

regulator

oil

pump

sliding

switch

part

Disassemble

Repairorreplace

Renew

it

Disassemble

new

ones

Oean

it

it

Replace

mentioned

oil

and

with

pump

it

replace

a

new

oil

nd

with

one

a

the

repair

new

worn

or

enew

it

one

with

parts

20

ExcessiYe

sliding

wear on

pam

Scuffingofsliding

PO

the

Oil

Defective

pressure

decreases

quality

or

contamination

Previously

of

oil

Exchange

change

air

fuel

clearances

fuel

cleaner

mixture

pressure

mixture

Change

Previously

Check

Previously

Readjust

Previously

Check

Defective

Overheatorovercoal

Improper

Decreaseofoil

lnsufficient

Overheat

Improper

element

element

the

to

the

mentioned

the

oil

mentioned

fuel

system

mentioned

the

designated

mentioned

fuel

system

with

proper

clearances

and

IDgine

DESCRIPTION

REMOVAL

INSTALLATION

DISASSEMBLY

Pistons

and

Cylinder

ASSEMBLY

Cylinder

Piston

and

Engine

PUMP

OIL

Removal

Installation

Connecting

Head

Head

Connecting

Rods

Rods

22

23

24

24

27

27

27

28

29

30

36

36

37

21

r

B

DglDe

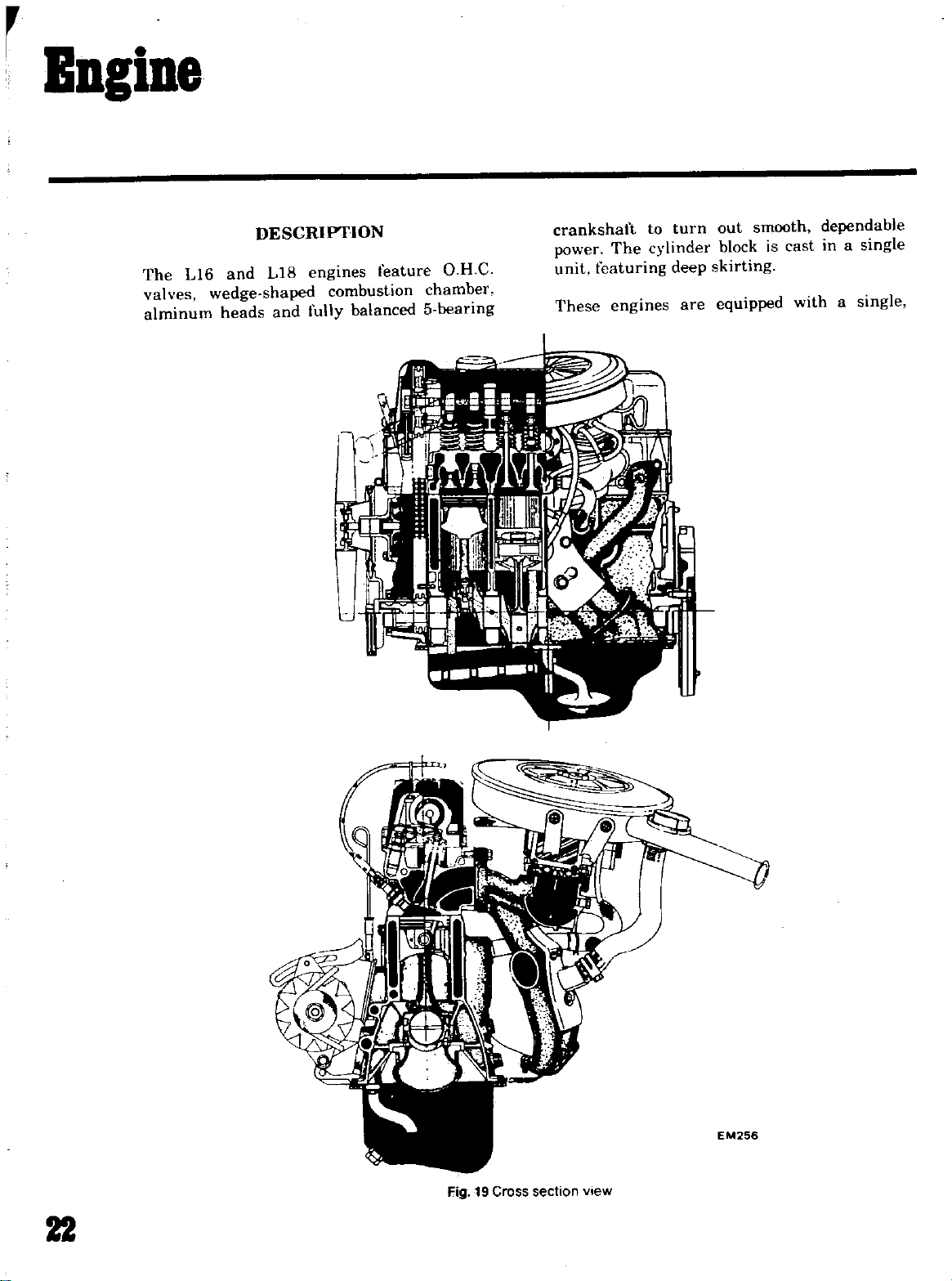

The

valves

alminum

L16

and

wedge

heads

DESCRIPTION

L18

engines

shaped

and

combustion

fully

feature

balanced

aHC

chamber

5

bearing

crankshaft

power

unit

featuring

These

to

The

cylinder

engines

turn

deep

are

out

smooth

block

skirting

equipped

dependable

cast

in

a

a

single

single

is

with

22

Fig

EM256

19

Cross

section

view

2

harreL

porates

a

Experience

to

remove

Scribe

hinges

unit

engine

alignmcnt

and

single

The

transmission

Completelv

and

transmission

Hcmove

remove

Hemove

Disconnect

battcrv off

Take

oil

by

removing

holts

lixing

sequence

Note

smission

If

cooling

Rcmove

downdraft

special

the

than

remove

blow

air

cleaner

the

the

hoth

equipped

pipes

engine

shown

has

engine

to

can

assembly

drain

hy

radiator

the

battery

car

upper

thc

of

the

remove

from

fan

device

remove

then

REMOV

marks

hood

the

lubricant

hosc

hosc

radiator

and

carburetor

to

that

with

be

from

cooling

ti

om

grille

cable

and

clamps

with

the

the

pulley

control

it

transmission

the

engine

separated

AL

hood

on

hinge

rocker

and

lower

Then

and

automatic

torque

radiator

that

emissiuns

much

is

around

system

radiator

take

from

cover

remove

loosen

convertor

only

engme

it

incor

easier

as

hood

hoses

out

tran

the

and

the

the

BngiD8

the

side

the

cylinder

cable

from

select

from

pre

tlange

a

bolts

starter

tube

by

little

cross

fuel

its

linkage

switch

Disconnect

the

rods

sembly

a

from

from

the

rear

mumer

disconncc

of

and

cross mem

of

the

pump

hoses

alter

and

reverse

the

the

engine

member

at

and

and

its

and

bv

side

thc

tube

and

gear

thcn

Disconnect

If

equippcd

engine

a

Disconncct

choke

Disconnect

n

tor

thcrmaI

Hemove

ret

urn

Disconnect

tlat

attaching

lamp

Disconnect

t

hen

rcmoving

memher

Disconnect

exhaust

Disconnect

and

in

center

Disconnect

ting

carrier

Jack

remove

ber

by

mounting

and

hand

attachment

wire

ignition

transmitter

the

spring

switch

remove

manifold

remove

tube

it

from

up

the

removing

thc

with

accelerator

at

the

clutcb

the

the

the

thc

the

the

assembly

the

the

thc

rear

insulator

brake

fuel

tube

heater

the

carburetor

wirings

coil

operating

speedometer

connector

plug

shift

rods

the

shail

cross

front

center

front

propeller

companion

transmission

engine

the

cable

from

remove

control

for

oil

pressure

and

s

shart

cro

bracket

exhaust

tuhe

tube

mounting

tixing

mounting

clamp

shaft

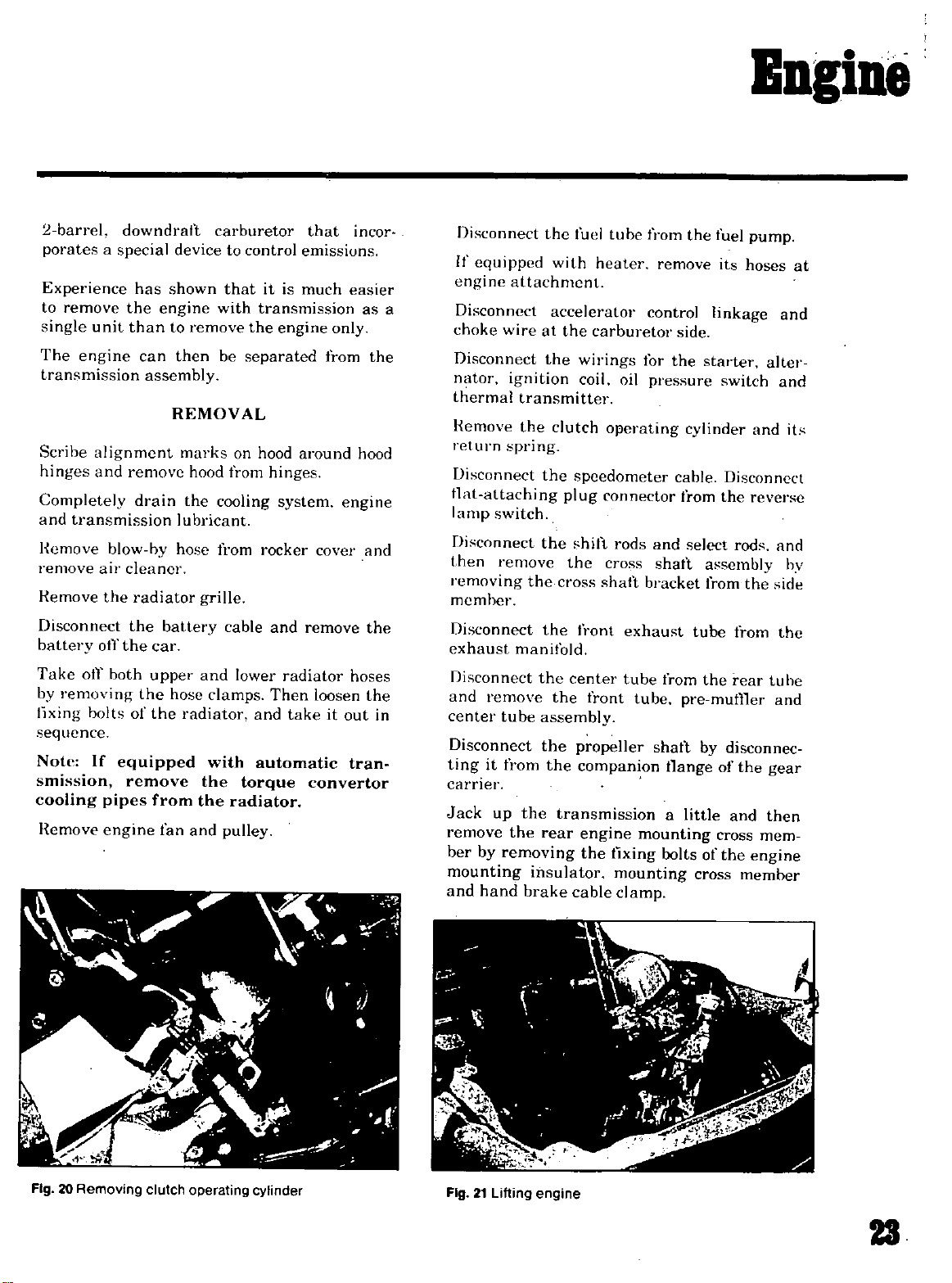

Flg20Removing

clutch

operating

cylinder

Fig

21

Lilting

engine

23

IDgine

Remove

engine

Hook

t

hooks

cylinder

the

rear

At

this

transmission

adequate

tension

chain

make

take

body

transmission

Reverse

nect

any

engine

replaced

them

the

mounting

with

which

head

lifting

stage

of

block

it

cleared

care

side

the

parts

mounting

and

tixing

cable

are

one

lower

gradually

wire

and

that

so

that

do

not

INSTALLATION

removal

to

power

bolts

insulators

chain

or

installed

at

the

the

hoist

up

adjusting

the

on

the

accessories

touch

procedure

the

engine

insulators

unit

securing

front

jack

Idraw

engine

engine

body

weight

to

cross

to

on

and

placed

oil

the

tilts

At

installed

the

but

steadily

the

member

the

stringers

the

engine

the

other

under

the

jack

observing

position

in

order

this

lifting

on

engine

do

not

until

have

is

taken

front

and

con

been

the

the

the

the

at

at

by

DlSASSEMBL

Remove

Thoroughly

removing

Place

Remove

Remove

of

to

Remove

Remove

Install

using

and

Set

Remove

Remove

Remove

Remove

Remove

engine

bolt

water

engine

transmission

drain

drain

assembly

fan

and

engine

oil

tilter

oil

pressure

engine

holes

drain

on

oil

level

clutch

tension

high

spark

thermostat

engine

plugs

fan

mounting

attachment

securing

plug

the

stand

gauge

assembly

plugs

from

on

pulley

switch

cable

housing

engine

oil

the

R

H

to

alternator

Y

and

engine

cylinder

coolant

stand

by

block

bracket

24

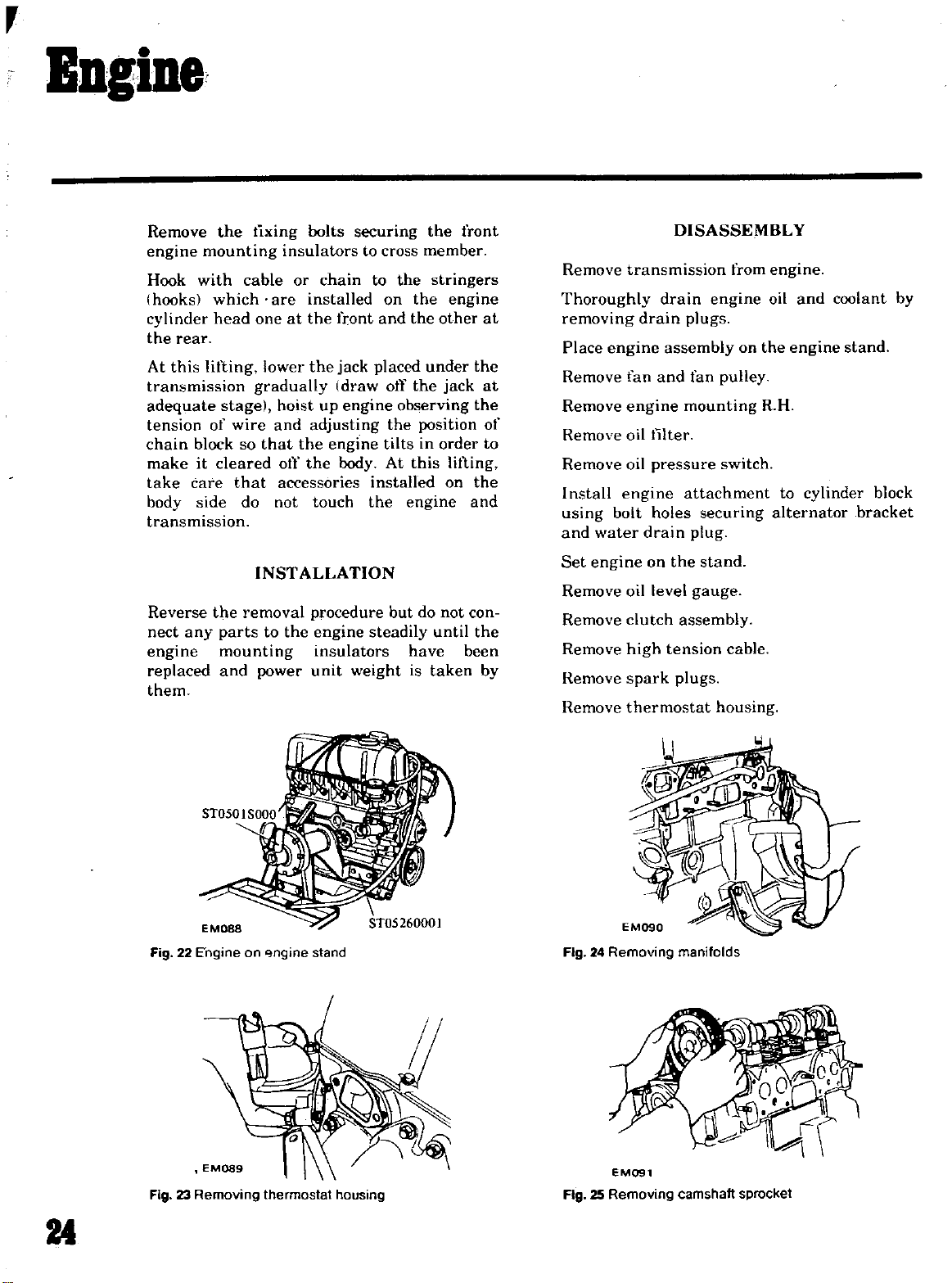

Fig22Engine

Fig23Removing

on

ngine

thermostat

stand

housing

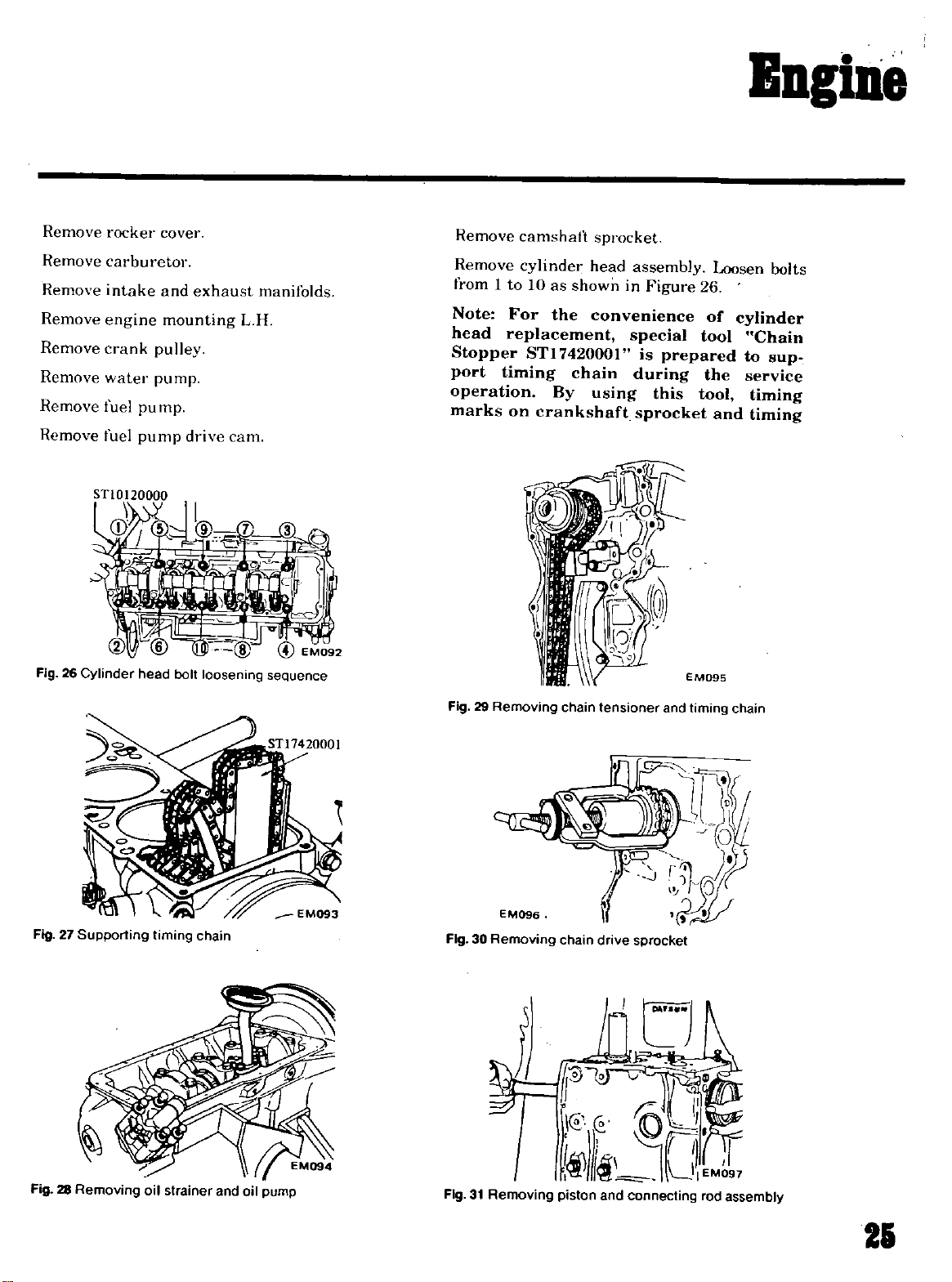

Fig24Removing

EM091

Fig25Removing

manifolds

camshaft

sprocket

BDgiDe

Remove

Remove

Remove

Remove

Remove

Remove

Remove

Remove

Fig26Cylinder

rocker

carburetor

intake

engine

crank

water

fuel

fuel

cover

and exhaust

mounting

pullev

pump

pump

pump

head

bolt

drive

L

earn

loosening

manifolds

H

sequence

Remove

Remove

from

Note

head

Stopper

port

operation

marks

29

fig

camshaft

cylinder

1to10

For

replacement

STt742000I

timing

crankshaft

on

Removing

as

the

By

sprocket

head

shown

convenience

chain

using

chain

assembly

in

special

tensioner

Figure

is

prepared

during

this

sprocket

and

26

tool

the

tool

EM095

timing

Loosen

of

and

bolts

cylinder

Chain

to

sup

service

timing

timing

chain

Fig27Supporting

28

Removing

Fig

timing

oil

strainer

chain

and

1r

j

W

k

Jp

I

rod

assembly

r

EM096

drive

Fig30Removing

oil

pump

Fig

31

Removing

chain

piston

and

sprocket

connecting

21i

r

I

IDgine

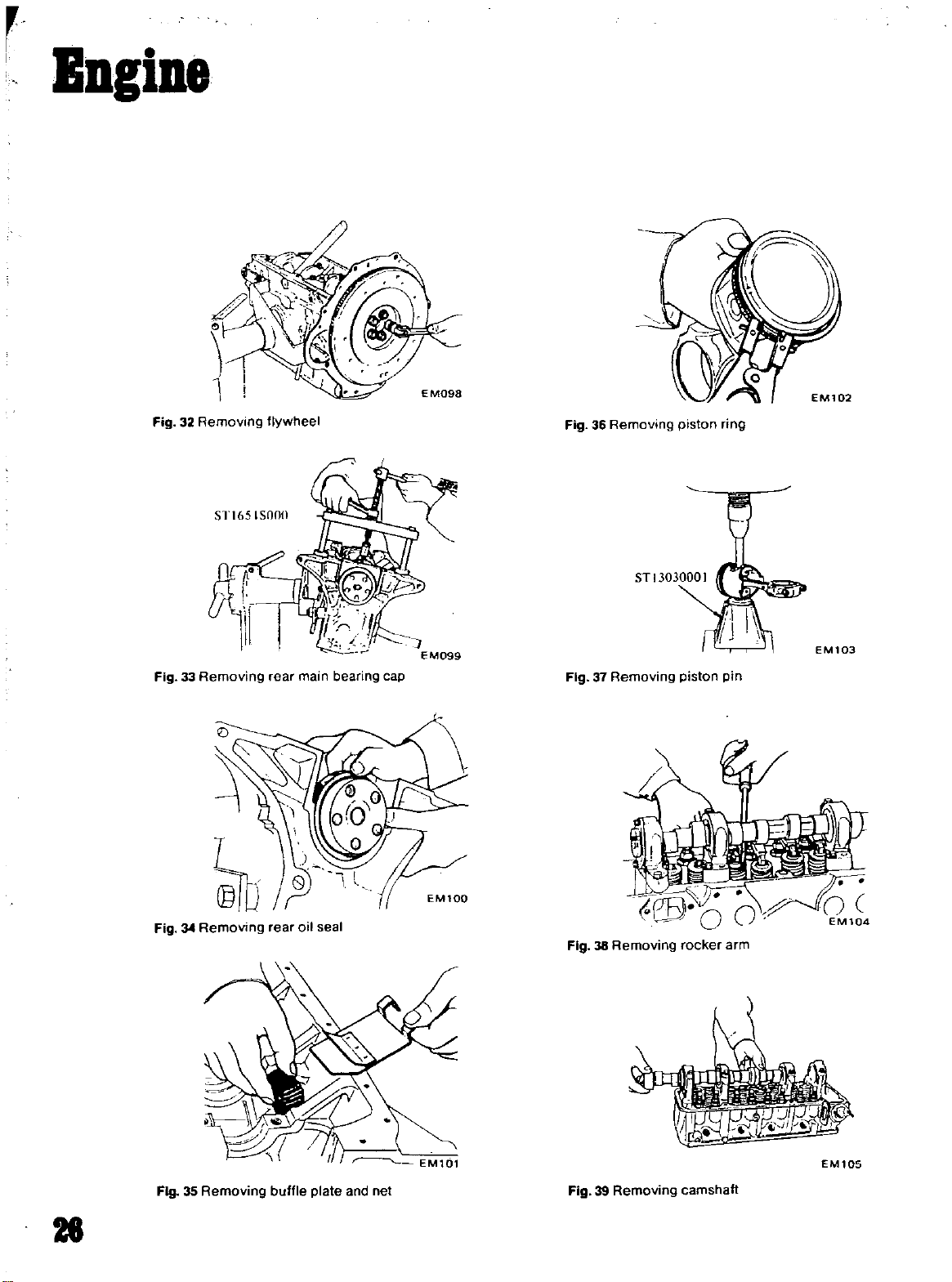

Fig

32

Removing

STl651S000

flywheel

Fig36Removing

piston

EM1Q2

ring

Fig33Removing

Fig34Removing

rear

rear

main

oil

seal

bearing

cap

J

EM099

Fig

Fig

37

38

ST

Removing

I

Removing

I

3030001

I

piston

rocker

EM103

pin

arm

28

Fig35Removing

buffle

plate

and

EM105

net

Fig39Removing

camshaft

BDgine

chain

aligning

much

Invert

Remove

Remove

Remove

Remove

Remove

Remove

and

chain

Hemove

Take

them

Hemove

Remove

Use

Cap

and

rear

del

H

emove

will

engine

oil

oil

front

chain

timing

oil

piston

otr

in

order

tlywheel

main

special

Puller

rear

be

unchanged

timing

pan

pump

cover

tensioner

chain

thrower

drive

and

connecting

bearing

tool

ST1651S0000

main

bearing

oil

marks

and

oil

and

sprocket

connecting

Be

careful

Crankshaft

seal

strainer

drive

its

crankshaft

rod

caps

caps

So

the

will

spindle

rod

bearings

not

Main

to

remove

Keep

be

worm

to

drop

them

work

saved

gear

assembly

and

keep

it

Bearing

center

in

for

Take

Head

valve

rocker

care

rocker

arm

not

by

pivot

pressing

to

lose

lock

valve

down

nut

and

valve

rocker

Cylinder

so

Loosen

remove

spnng

Note

guide

Hemove

Note

damage

lohes

Remove

Take

seal

Note

intact

liable

or

Precautions

Use

make

matter

camshaft

At

this

camshaft

valves

not

care

valve

collet

Be

sure

Because

to

be

thoroughIv

sure

that

to

out of

time take

lose

and

valve

to

leave

the

alignment

ASSEMBLY

cleaned

oil

holes

bearings

valve

rocker

camshaft

bearing

parts

are

care

spring

guide

Particularly

clear

and

center

of

not

cam

seat

bearing

toreign

to

oil

is

Remove

Remove

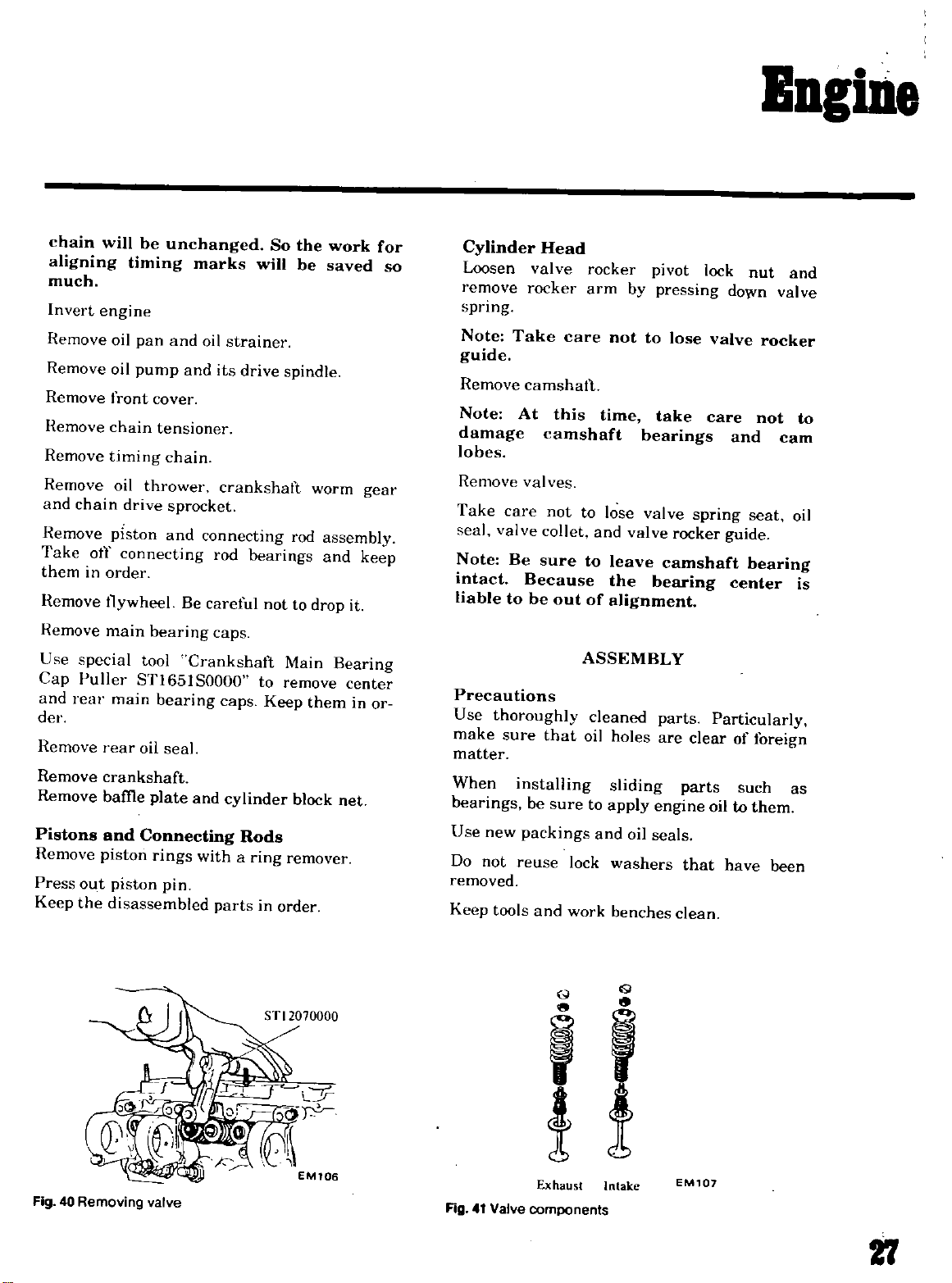

Pistons

Remove

Press

Keep

Fig

all

the

40

Removing

crankshaft

baffie

and

Connecting

piston

t

piston

disassembled

plate

rings

pin

valve

and

with

cylinder

Rods

a

parts

ring

in

STl2070000

block

remover

order

EM106

net

When

bearings

Use

new

Do

not

removed

Keep

41

Fig

installing

reuse

tools

Valve

be

sure

packings

and

G

i

Exh

aust

components

lock

work

to

apply

and

sliding

oil

washers

benches

G

t

Intake

parts

engine

seals

clean

EM107

oiltothem

that

have

such

as

been

rz

r

I

BDgme

Keep

at

hand

ure

H

a

nd

order

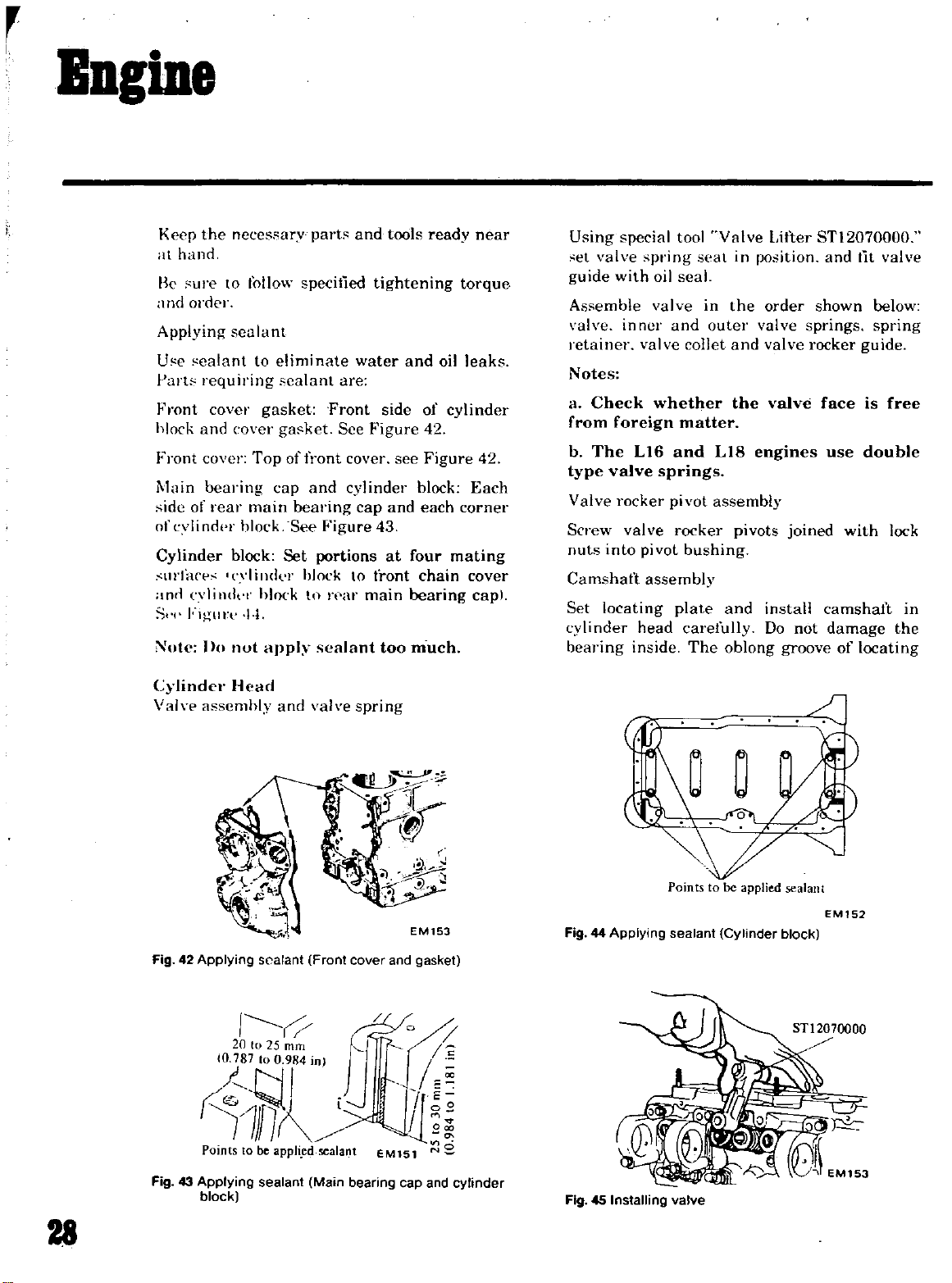

Applying

U

e

Part

Front

hlock

Front

Main

ide

of

of

cvlindl

Cylinder

urlan

and

j

SrI

Not

Vain

the

necessary

to

sealant

ealant

requiring

cover

and

cover

cover

bearing

rear

r

block

o

n

ylindt

lgurl

110

nut

l

H

Cylind

assemhly

follow

Top

main

hlock

lilldl

1

I

to

eliminate

gasket

gasket

cap

hlock

apply

ad

and

specitied

sealant

affront

bem