t

l

Fust

Second

COPYrIght

All

be

nlltted

mechanical

without

L

r

PublrcatlOns

I

reserved

rlghts

reproduced

m

any

the

Pnntmg

Pnntmg

Thm

I

Prmtmg

1972

@

No

stored

form

part

In

a

or

photocopymg

written

prlor

September

Clymer

retrleval

by

1972

June

1973

Apnl

Pubhcahons

thIs

of

publicatIOn

system

means

any

recordmg

permIssIon

1972

or

of

or

trans

electronic

otherwIse

Clymer

may

1

I

I

I

J

r

r

u

i

Pnnted

In USA

J

g

i

I

I

7

1rt

w

r

C6

v

t

hJ

1i

tV

iJ

0

L

r

0

w

L

L

I

fO

S

bLJ

f

3

t

ON

OA1

I

o

r

t

t

1

1

v

l

6

I

I

I

0

QEPAlR

AND

PICK

UP

9611

912

Yo

v

t

I

J

r

I

I

I

l

L

I

r

l

j

1

it

I

l

r

1

I

7

f

c

C

I

1

I

if

r

j

published

oYMEQ

Ia

d

W

Y

r

11

1

NORTH

r

VIRGIL

pu

automobIles

AVENUE

by

P

flUCJO

d

u

of

motorcycles

and

ANGE1

LOS

ES

ON

10

clu

d

CALIFORNIA

ly

goOO4

r

CON1EN1S

I

CHAPTER

GENERAL

CHAPTER

PERIODIC

CHAPTER THREE

TROUBLESHOOTING

ONE

INFORMATION

Introduction

Model

TWO

MAINTENANCE

RoutIne

Pen

odic

EqUIpment

Starter

ChargIng

EngIne

Igmtlon

Fuel

system

Exhaust

Identification

checks

checks

system

system

emIssIon

control

SpecIficatiOns

lubncation

EngIne

Recommended

Clutch

TransmIssiOn

Brakes

Steenng

TIre

Wheel

and

wear

balancIng

analysIs

and

lubncants

suspension

dImensIons

and

maIntenance

6

1

t

V

9

t

4

1

CHAPTER

ENGINE

CHAPTER

ENGINE

FOUR

AND

IGNITION

EqUIpment

Battery

Spark

plugs

DIstrIbutor

Igmtlon

FIVE

LUBRICATION

Descnptlon

Lubncation

timIng

cIrcuIt

TUNE

SYSTEM

UP

Idle

speed

Dwell

angle

CompressIon

Valve

clearance

AddlllOnal

Oil

pump

and

setting

checks

Idle

test

adjustment

20

mIXture

27

II

CHAPTER

ENGINE

CHAPTER

FUEL

1

CHAPTER

COOLING

Cylmder

Crankshaft

PistOns

Cyhnder

Camshaft

Valve

Camshaft

Mamfolds

011

Fuel

SYSTEM

Air

Fuel

Fuel

DescnptIon

Water

Fan

SIX

mechamsm

pump

pump

SEVEN

cleaner

strlllner

pump

EIGHT

SYSTEM

pump

clutch

block

and

head

connectmg

dnve

rods

Carburetor

Emission

Engme

Engme

Pistons

Cyhnder

Engme

Engme

Service

Carburetor

Fuel

tank

Thermostat

Radiator

control

removal

dISassembly

and

connectmg

head

mspectIon

reassembly

and

data

speCifications

devIces

and

31

rods

replllr

62

84

CHAPTER

ENGINE

CHAPTER

EMISSION

CHAPTER

CLUTCH

NINE

ELECTRICAL

Starter

Overrunmng

ChargIng

Alternator

Alternator

Voltage

Exhaust

Crankcase

Air

TRANSMISSION

Clutch

Master

ClrcUlt

regulator

TEN

CONTROL

emiSSIOn

mJectlon

ELEVEN

cyhnder

Operating

Withdrawal

Clutch

system

Clutch

data

clutch

output

emission

system

cyhnder

lever

bleedmg

and

SYSTEM

assembly

SYSTEM

control

control

AND

adjustment

speCIfications

DRIVESHAFT

DIstrIbutor

Condenser

Igrntlon

cod

SpeCifications

Spark

plugs

modifications

Engme

Evaporative

Exhaust

TransmissIon

TransmissIon

Dnveshaft

Dnveshaft

Automatic

system

emiSSion

data

data

and

transmIssIon

control

and

speCIfications

speCIfications

checks

91

114

127

CHAPTER

DIFFERENTIAL

TWELVE

DIfferentIal

Rear

axle

Codspnng

Shock

absorber

Rear

suspensIOn

axle

Rear

REAR

and

shaft

AXLE

suspension

arm

AND

REAR

Wheel

Seals

Rear

Axle

SpecificatIons

SUSPENSION

beanngs

spnng

case

149

CHAPTER

FRONT

CHAPTER

BRAKES

CHAPTER

BODY

THIRTEEN

AXLE

Wheel

StabilIzer

TenSion

Spnng

Transverse

Lower

FOURTEEN

Brake

Master

Front

Rear brakes

Front

FIFTEEN

ELECTRICAL

Wmng

SWitches

Instrument

Heater

FRONT

hub

rod

and

ball

pedal

cylInder

diSC

drum

and

and

strut

lInk

Jomt

brakes

brakes

meters

bearmg

assembly

SYSTEM

fuses

SUSPENSION

and

panels

AND

STEERING

Front

suspension

Wheel

alignment

Posture

adJustment

Steenng

SpeCificatIons

Wheel

cylInders

Brake

system

Handbrake

Service

data

Wmdshleld

Wmdslueld

Headlamps

diagrams

WIrIng

system

wipers

washers

adjustment

bleedIng

and

speCificatIons

168

187

205

CHAPTER

BODY

INDEX

SIXTEEN

Front

Bumpers

Hood

Doors

body

lock

trIm

control

Door

Trunk

Seats

Tad

locks

gate

223

and

and

regulators

rear

bumper

235

lId

I

CHAPTER

ONE

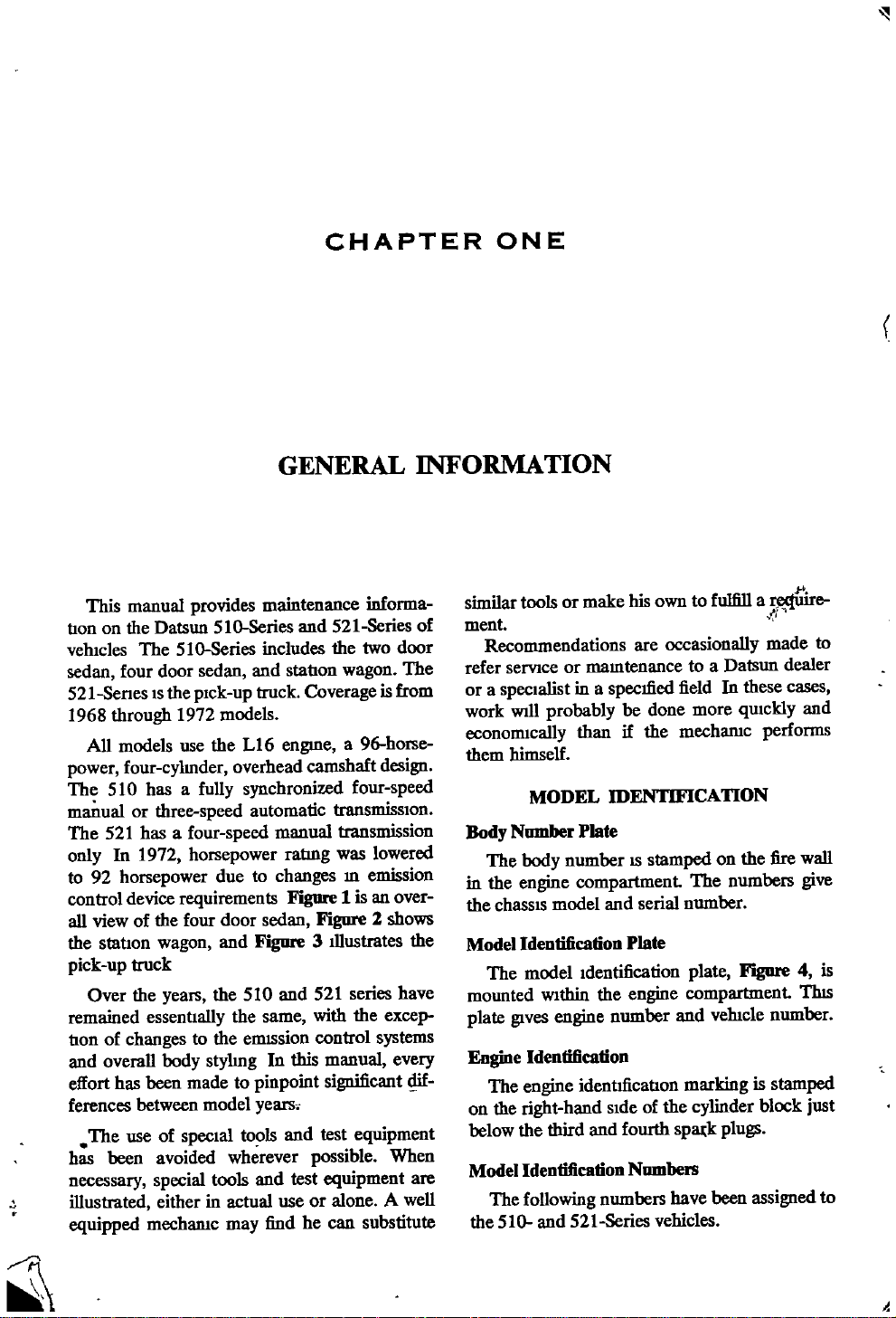

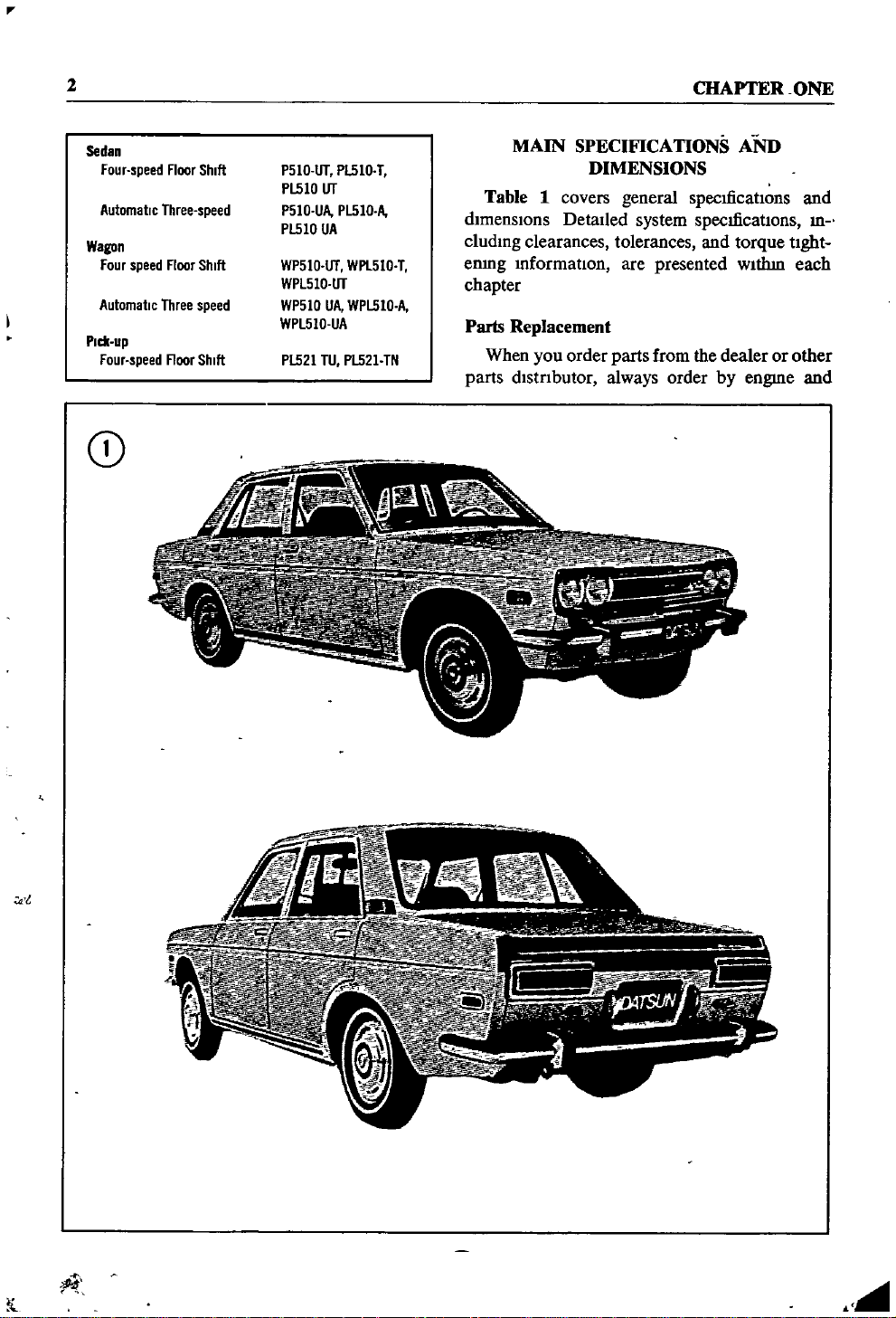

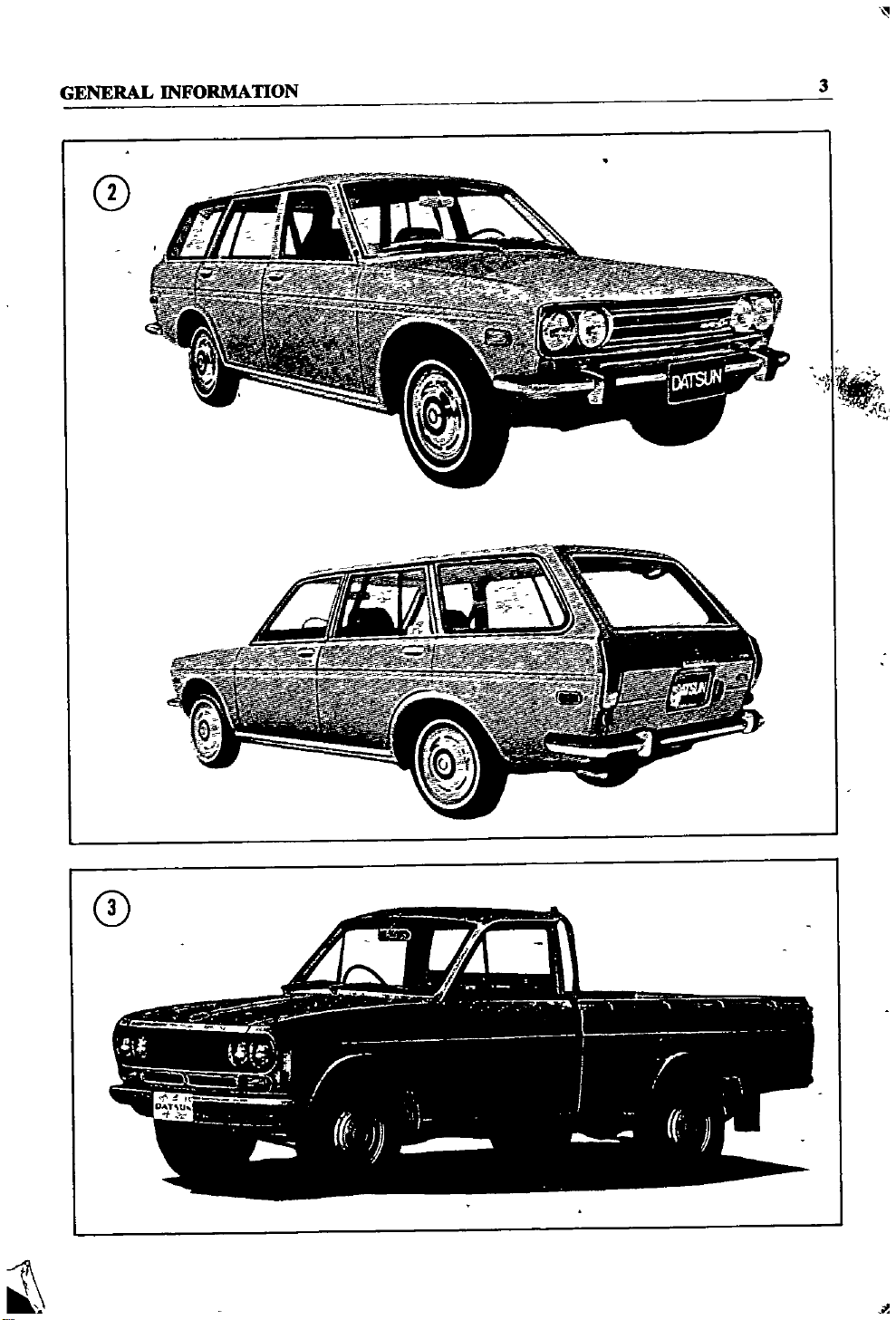

This

tIon

on

vehlcles

sedan

521

Senes

1968

through

All

power

The

510

manual

The

521 hasafour

In

only

92

to

control

view

all

the

station

pick

up

Over

remained

tion

of

and

overall

has

effort

ferences

The

has

been

necessary

illustrated

equipped

manual

the

Datsun

The

door

four

the

IS

1972

models

four

or

1972

cylmder

has

three

use

a

horsepower

device

requirements

of

the

four

wagon

truck

the

years

essentIally

changes

body

been

made

between

of

use

SpecIal

avoided

special

either

mecharuc

provides

510

Series

510

Series

sedan

and

pIck

fully

speed

truck

up

models

the

L16

overhead

synchronized

automatic

speed

horsepower

due

to

door

and

Figure

the

510 and

the

the

to

emISsion

stylmg

to

pinpoint

model

tools

wherever

tools

and

in

actual

may

GENERAL

maintenance

and 521

includes

station

Coverage

engme

camshaft

manual

ratIng

changes

Figure

sedan

Figure

3

521

same

with

control

this

In

years

and

possible

test

use

or

find

he

informa

Series

two

the

wagon

is

a

96

design

four

transmisSIon

transmission

was

lowered

m

emission

is

1

an

2

illustrates

series

the

systems

manual

significant

test

equipment

equipment

alone

can

substitute

INFORMATION

similar

of

ment

door

the

are

refer

or

work

economIcally

them

Body

in

the

Model

mounted

plate

Engine

on

below the

Model

the

The

from

horse

speed

over

shows

have

excep

every

cif

When

A

well

toolsormake

Recommendations

servIce

a

SpecIaliSt

WIll

or

mamtenance

in

probably

than

himself

MODEL

The

the

chasSIS

The

The

the

Number

body

engine

Identification

gIves

right

number

compartment

model and

model

WIthin

engine

Identification

engine

hand

third

Plate

Identification

identrlicatlon

and

Identification

The

following

510

and52I

his

own

are

occasionally

done

the

field

mecharuc

a

specIfied

be

if

IDENTIFICATION

IS

stamped

serial

Plate

the

engine

fourth

and

sp8l

have

vehicles

number

SIdeofthe

numbers

Series

to

fulfill

to

more

Datsun

a

In

a

these

qUlckly

Ii

made

e

to

dealer

cases

and

performs

on

the

fire

wall

The numbers

number

plate

Figure

compartment

veh1cle

markingisstamped

cylinder

k

plugs

Numbel

ll

been

give

4

TIns

number

block

assigned

just

is

to

oj

2

CHAPTER

ONE

Sedan

Four

AutomatIc

Wagon

Four

AutomatIc

PIl Il

up

Four

CD

speed

speed

speed

Floor

Three

Floor

Three

Floor

Shift

speed

Shift

speed

Shift

P51OUTPl5lO

Pl510

UT

P51OUAPl5lO

Pl510

UA

WP510UTWPl510

WPL510

UT

WP510UAWPl5lO

WPL510

UA

Pl521TUPl521

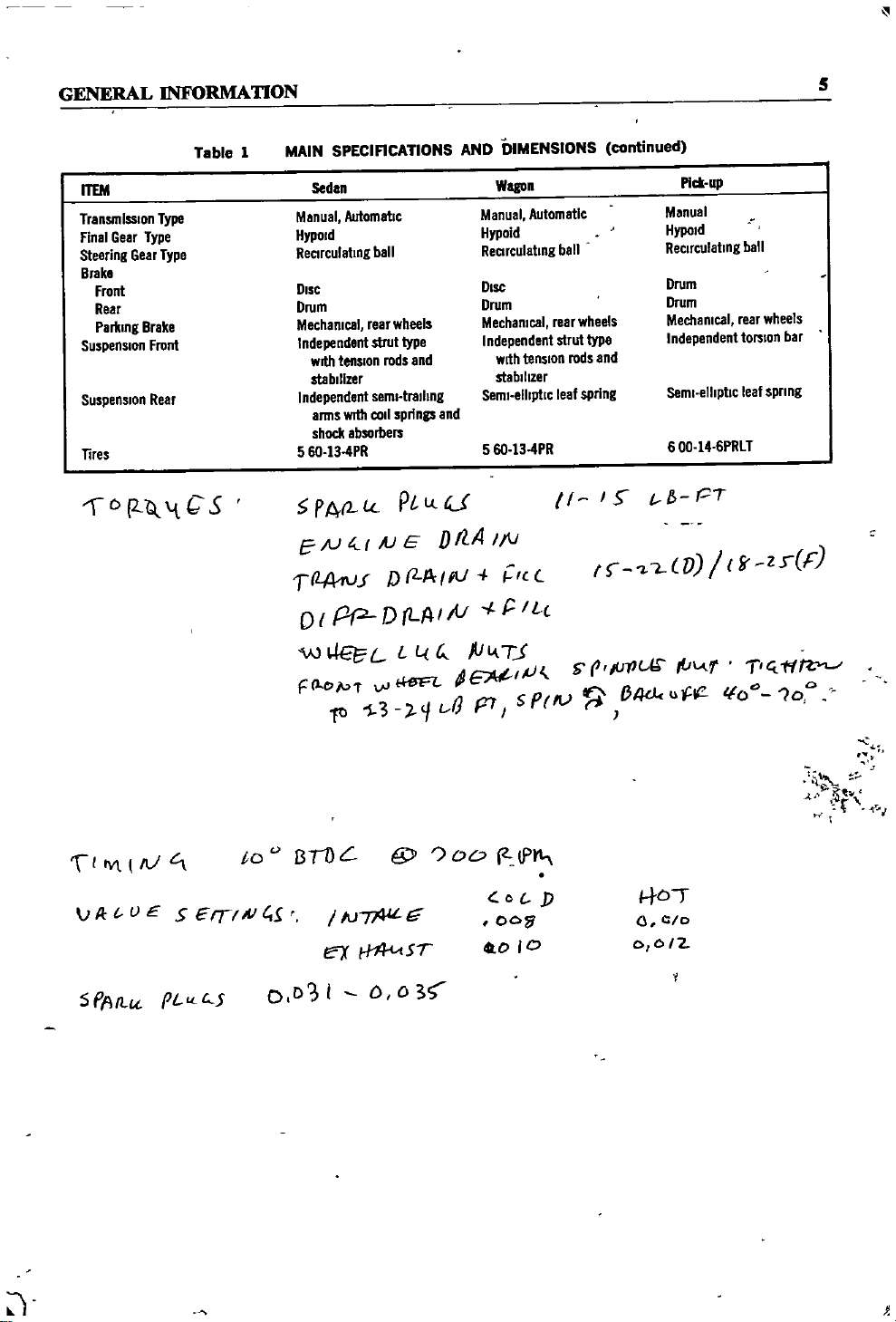

MAIN

T

A

Table

dImensIOns

cludmg

T

enrng

mformatlOn

SPECIFICATIONS

DIMENSIONS

1

covers

DetaIled

clearances

general

system

tolerances

are

presented

AND

specIfications

specIficatIOns

and

torque

Wlthm

and

ill

tlght

each

chapter

A

Parts

Replacement

TN

When

parts

you

dlstnbutor

order

parts

always

from

order

the

dealerorother

by

engme

and

d

1

GENERAL

CD

INFORMATION

3

J

i

x

CD

4

CHAPTER

ONE

chassIs

CD

carry

Service

L

co

1595

1

00988

P61lO1l

M

6600

cc

mm

510

rpm

LTD

bons

vehicle

hicle

forward

the

mechaniC

measurements

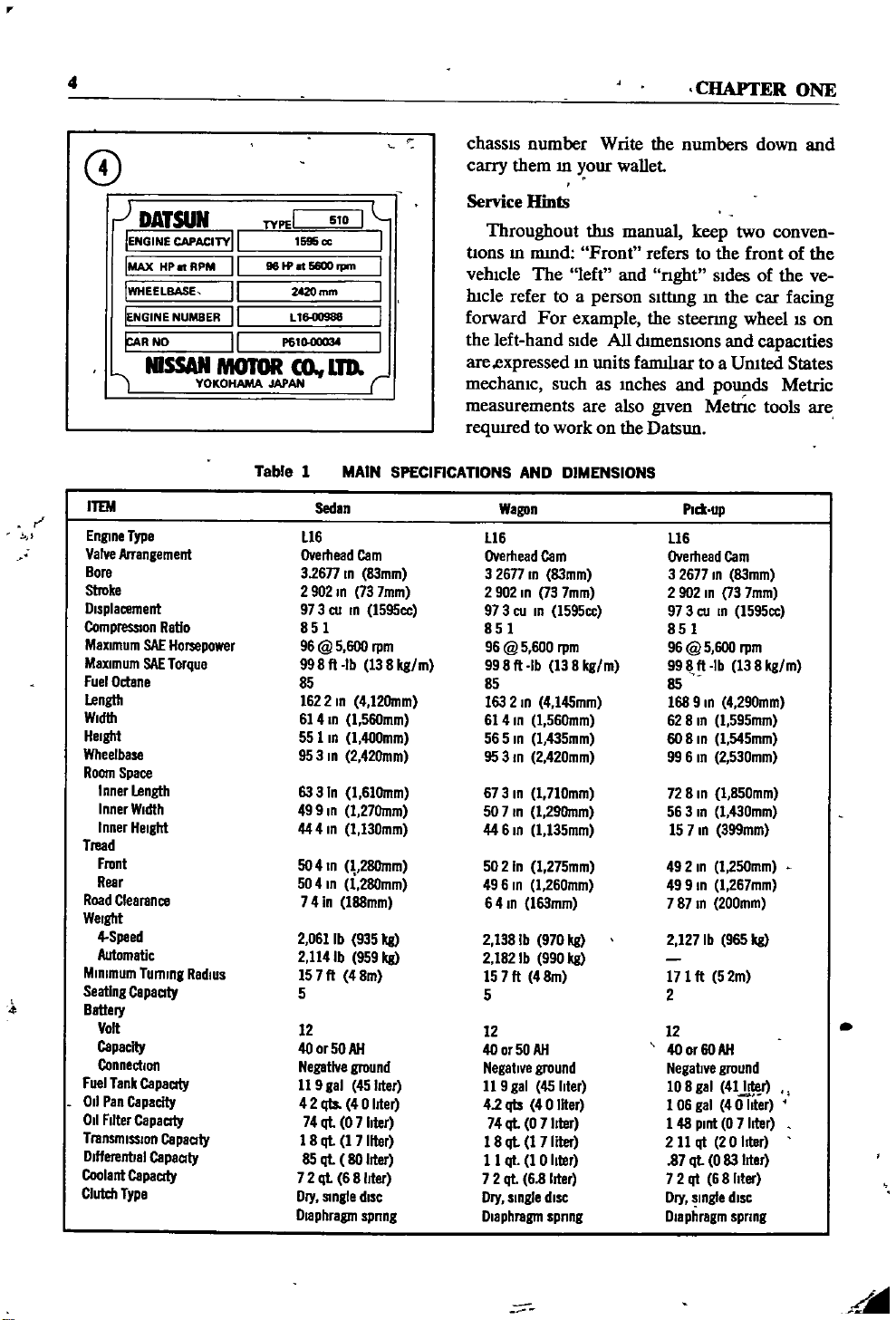

DATSUN

CAPACITY

IENGINE

RPM

HP

IMAX

IWHEELBASE

NUMBER

IENGINE

NO

FAR

NlSSAN

YOKOHAMA

TYPEI

MOTOR

961P

JAPAN

reqUITed

Table

1

MAIN

SPECIFICATIONS

ITEM

r

l

EnglDe

Valve

Bore

Stroke

Type

Arrangement

Displacement

Octane

Ratio

SAE

SAE

Hompower

Torque

CompressIOn

MaXimum

MaXimum

Fuel

Lengtb

Width

Height

Wheelbase

Room

Space

Inner

Length

Inner

Width

Inner

Height

Tread

Front

Rear

Road

Clearance

Sedan

L16

Overhead

3

26n

ID

2902

ID

97

3

cu

ID

851

96@5

600

998ft

Ib

85

1622ID4

ID

61 4

l

55

lID1400mm

95

3ID2

63

3 In161Omm

499ID1

44

4In1

50

4

ID

504

In

1

741n

l88mm

Cam

83mm

73

l595cc

rpm

138

12Omm

560mm

42Omm

27Omm

130mm

28Omm

280mm

7mm

m

kg

number

them

Write

the numbers

ill

your

wallet

Hints

The

For

to

to

such

work

thIs

Front

left

a

person

example

Side

All

units

ill

as

also

are

on

DIMENSIONS

manual

refers

and

sittIng

the

dimensIOns

fanuhar

illches

given

the

Datsun

nght

Throughout

ill

mmd

refer

left

hand

are

expressed

AND

Wagon

L16 L16

Overhead

3

2

97

851 851

96@5

998ft

85 85

163

61

565

95

673

507ID1

44

502In1

496

64IDl63mm

Cam

2677ID83mm

ID

902

3

4ID1

3

61D 1

cu

In

600

Ib

2ID4

ID

Cl

ID

ID

In

Cl

73

560mm

435mm

2

420mm

1

710mm

29Omm

135mm

275mm

260mm

7mm

l595cc

rpm

138

I45mm

Overhead

3

2

97

96@5

m

kg

9911

168

62

60

99

72

563In1

492In1

499ID1

787ID200mm

keep

to

the

sidesofthe

ill

the

steenng

and

Umted

to

a

and

pounds

Metnc

Plm

up

Cam

2677ID83mm

902

In

73

3

cu

ID

600

ftIb138

9ID4

8

In

595mm

Cl

8

ID

545mm

Cl

6In2

530mm

8ID1

850mm

430mm

15

7ID399mm

250mm

267mm

down

two

front

car

wheelIS

capacities

tools

7mm

1595cc

rpm

kg

290mm

conven

of

facing

States

Metric

m

and

the

ve

on

are

Weight

4

Speed

Automatic

Minimum

Seating

Turning

Capaaty

RadiUS

2

0611b

2

157ft

5

114Ib

48m

935

959

138

kg

kg

Ib

2

2

157ft

5 2

970

182Ib990

48m

kg

kg

127Ib965

2

171ft52m

kg

Battery

Volt

Capacity

Connection

Fuel

Tank

011

Pan

Capacity

011

Filter

Transmission

Dlflerenbal

Coolant

Capaaty

Clutch

Type

Capaaty

Capaaty

Capaaty 1 8

Capaaty

12

400rSOAH

Negative

ground

11

9

gal

42

qts40liter

74ql07

1 7

ql

85

80

ql

7 2ql6 8

Dry

Single

Draphragm

45

liter

liter

diSC

spnng

liter

liter

liter

12 12

400r50AH 40or60

Negative

11 9

gal

42

qb

74

0 7

ql

18ql1 7

11ql1 0

7 2

ql

Dry

slDgle

Diaphragm

ground

45

40

liter

Iller

liter

68

lIter

diSC

spnng

liter

liter

Negative

108

1

06

1

48

2 11qt20

87ql083lIter

7 2qt6 8

Dry

slDgle

Diaphragm

gal

gal

Pint

AH

ground

41J

40

0 7

Iller

Iller

diSC

spnng

r

Iller

liter

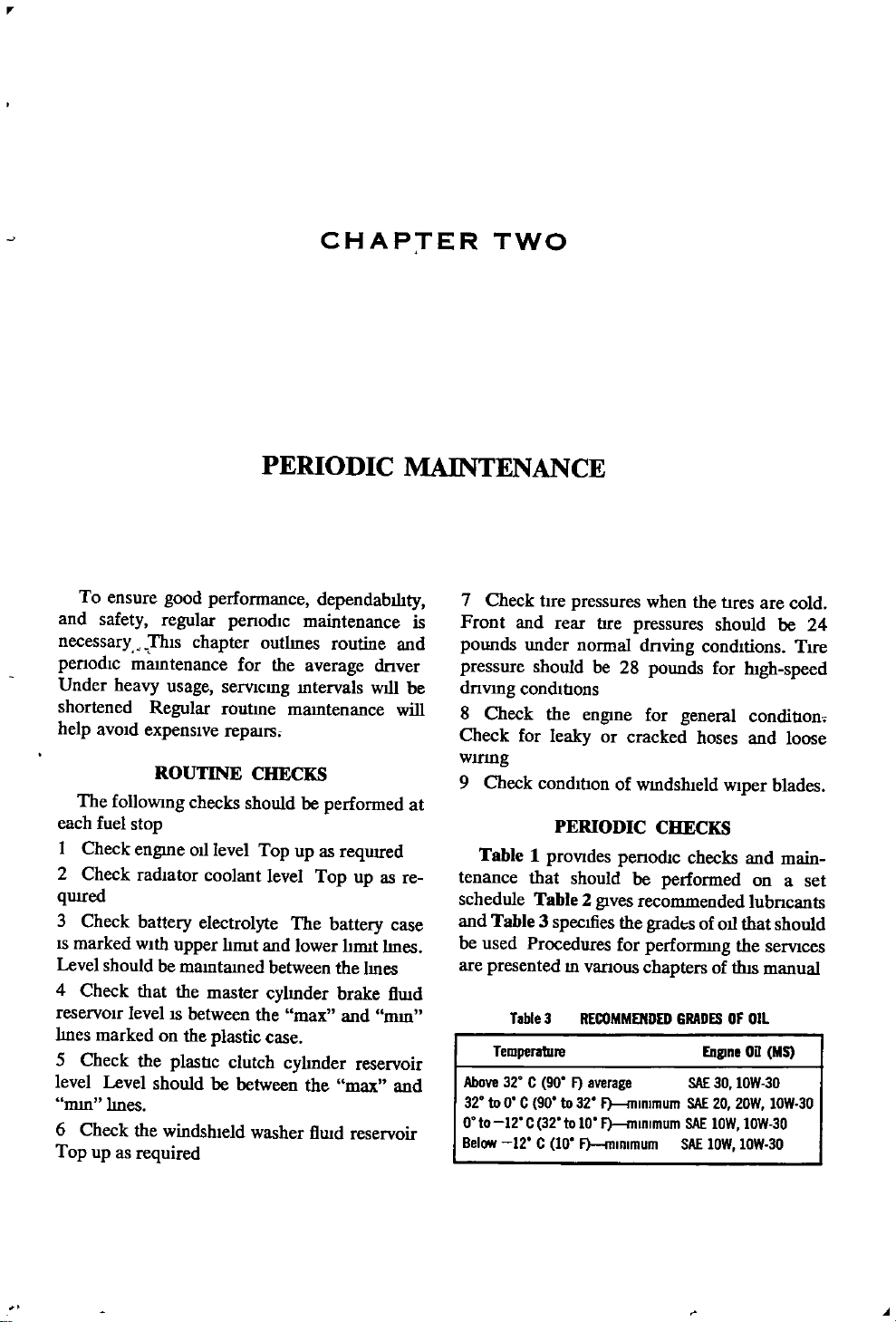

GENERAL

ITEM

Transmission

Final Gear

Steering

Brake

Front

Rear

Parking

Suspension

Suspension

Tires

INFORMATION

Type

Type

Gear

Type

Brake

Front

Rear

Table

5

AND

MAIN

1

SPECIFICATIONS

Sedan

Manual

Automatic

HypoJd

ReCIrculating

DIsc

Drum

Mechanical

Independent

with

tension

stabilizer

Independent

arms

wrtII

shock

absorbers

6O134PR

5

rear

ball

strut

semi

coli

wheels

rods

springs

type

and

trailing

and

DIMENSIONS

Wagon

Manual

Automatic

Hypoid

ReCIrculating

DIsc

Drum

Mechanical

Independent

with

tension

stabilIZer

Semi

elliptiC

5

6O134PR

rear

ball

strut

leaf

wheels

rods

type

and

spring

continued

Pick

up

Manual

Hypold

ReCirculating

Drum

Drum

Mechanical

Independent

Semi

elliptic

6PRLT

600

14

ball

rear

torsion

leaf

wheels

bar

spnng

JP

S

IY

PAtl

1

S

S

f

prlc

B4dc

r

r

TJ

IL

IJ

5

11

c

c

PrlV

C

62

Q

S

1

PA

l

EN

2Aru

pP

I

o

W

e

F

l

ftl

PlLlU

AIIII

I

G

1t

J

Dt7

tV

Ii

dE

A

p7

111

ftiv

E

AJ

4

1

f

r

f

D

LA

L

l

L

vi

p

f

1

3

l

PT

t

f

zr

lfo

F

ff

1oo

4

L

UJ

I

u

ff

T

u

t

M

0

BTOL

AJ

UE

t

SEIT

to

A

C

1

IN

@

ex

I

c

pI

0103

5

D

OD

2

lP

O

G

Sf

0

3

00

j

oo

0

to

c

o

l

0

0

2

J

CHAPTER

TWO

To

ensure

and

safety

necessary

penodlc

Under

shortened

aVOId

help

The

each

fuel

1

Check

2

Check

qwred

3

Check

IS

marked

Level

4

Check

reservOir

marked

lInes

S

Check

level

mm

6

Check

Top

up

good

regular

TIns

mamtenance

heavy

usage

Regular

expensive

ROUTINE

followlDg

stop

engme

radiator

battery

With

should

be

that

levelISbetween

on

the

Level

should

lInes

windsh1eld

the

as

required

performance

chapter

semcmg

routme

checks

oil

level

coolant

electrolyte

upper

tamed

maID

the

master

the

plastic

plastic

be

PERIODIC

penodlc

outlInes

for

repaIrs

CHECKS

should

Top

hrmt

the

clutch

between

washer

maintenance

the

average

mtervals

mamtenance

be

up

level

The

and

lower

between

cylInder

max

case

cyhnder

dependability

routine

dnver

will

performed

as

requrred

up

battery

lnmt

the

brake

and

reservoir

max

reservoir

as

lInes

IIDes

mm

Top

the

flwd

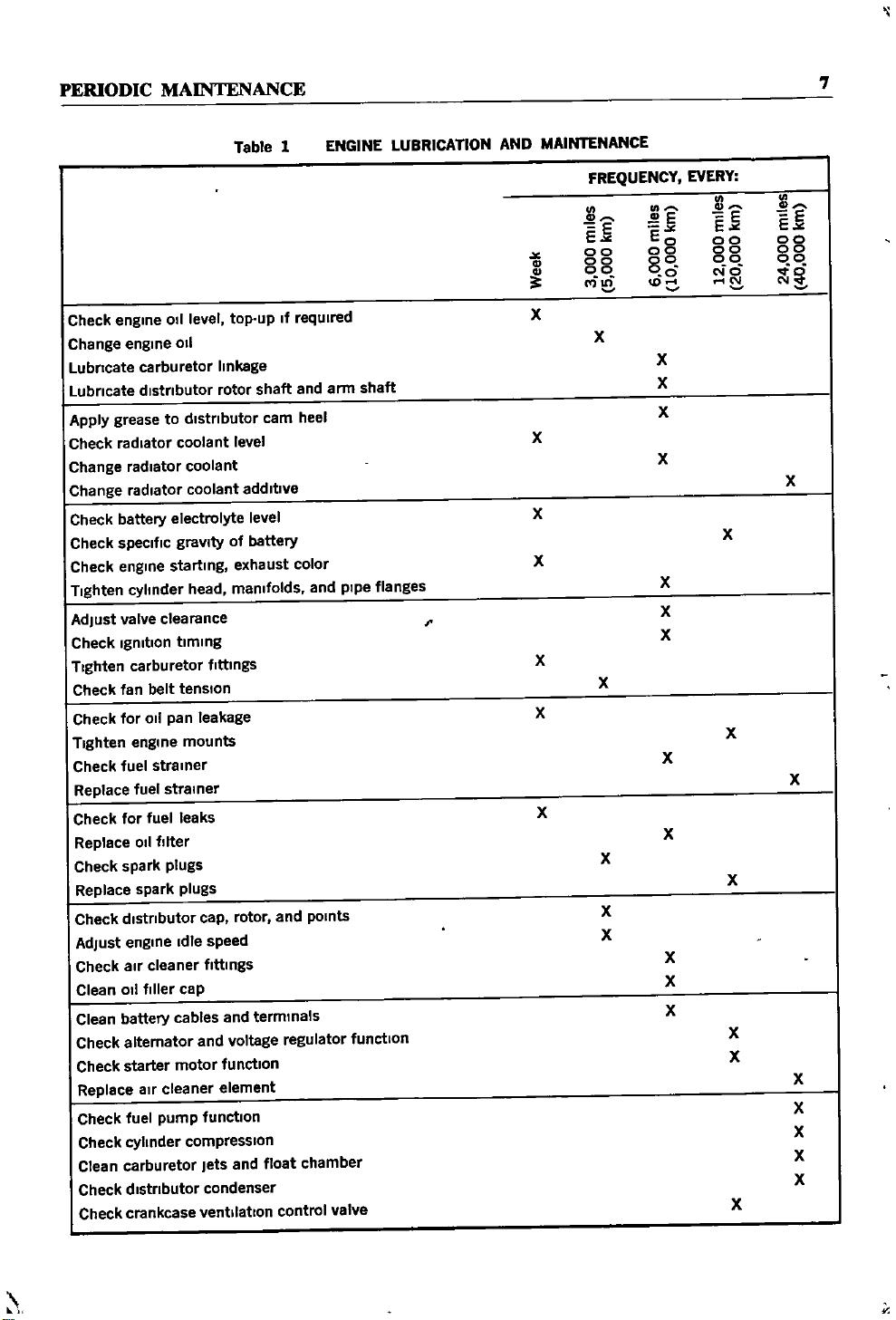

MAINTENANCE

7

Check

and

will

case

flwd

and

Front

is

pounds

pressure

be

dnvmg

at

re

8

Check

Check

wmng

Check

9

Table

tenance

schedule

and

Table

be

used

are

presented

Temperature

Above

32to0

Oto12 C

Below

and

for

Table

32C90

tire

rear

under

should

conditions

the

leaky

condition

PERIODIC

1

prOVIdes

that

Table

3

specIfies

Procedures

3

C

90to32

32

12C10

pressures

tire

pressures

normal

engIne

be

or

dnving

28

cracked

of

wmdshleld

penodIc

should

ID

F

tolO

be

2

gIves

the

for

vanous

RECOMMENDED

average

F

mlmmum

F

mlRlmum

F

mlmmum

when

the

tIres

should

conditions

pounds

for

for

general

hoses

CHECKS

checks

performed

recommended

of

grades

performmg

chapters

of

GRADESOFOIL

Engine

SAE

30

SAE2020W

SAE

IOW IOW

lOW

SAE

wiper

oil

are

h1gh

conditIon

and

and

on a

lubncants

that

the

tlus

on

IOW

IOW

cold

be

speed

loose

blades

main

should

semces

manual

MS

30

IOW

30

30

24

TIre

set

30

PERIODIC

MAINTENANCE

Table

7

1

ENGINE

LUBRICATION

AND

MAINTENANCE

Check

Change

Lubricate

Lubricate

Apply

Check

Change

Change

Check

Check

Check

Tighten

Adjust

Check

Tighten

Check

Check

Tighten

Check

Replace

Check

Replace

Check

Replace

Check

Adjust

Check

Clean

Clean

Check

Check

Replace

Check

Check

Clean

Check

Check

engine

engine

carburetor

distributor

grease

radiator

radIator

radiator

battery

specific

engine

cyhnder

valve

Ignition

carburetor

fan

belt

for

011

engine

fuel

strainer

fuel

for

fuel

011

spark

spark

dlstnbutor

engine

cleaner

air

011

filler

battery

alternator

starter

aIr

fuel

pump

cyhnder

carburetor

dlstnbutor

crankcase

011

to

electrolyte

gravity

starting

clearance

timing

tension

pan

strainer

leaks

filter

plugs

plugs

Idle

cap

cables

motor

cleaner

compressIon

level

011

distributor

coolant

coolant

coolant

head

leakage

mounts

cap

speed

fittings

and

function

Jets

condenser

ventilation

hnkage

rotor

fittings

rotor

and

voltage

function

element

and

top

shaft

level

additive

level

of

battery

exhaust

manifolds

terminals

float

If

up

cam

and

regulator

control

required

and

heel

color

and

POints

chamber

ann

valve

shaft

pipe

function

flanges

Eo

gq

X

X

X

EVERY

E

0

CD

X

X

X

X

X

X

X

X

X

E E

E E

00 00

00

00

NO

X

X

X

X

X

X

00

00

t

X

X

X

X

X

X

X

FREQUENCY

E

E

00 00

00

00

r61li

X

X

X

X

X

X

X

X

X

X

X

X

8

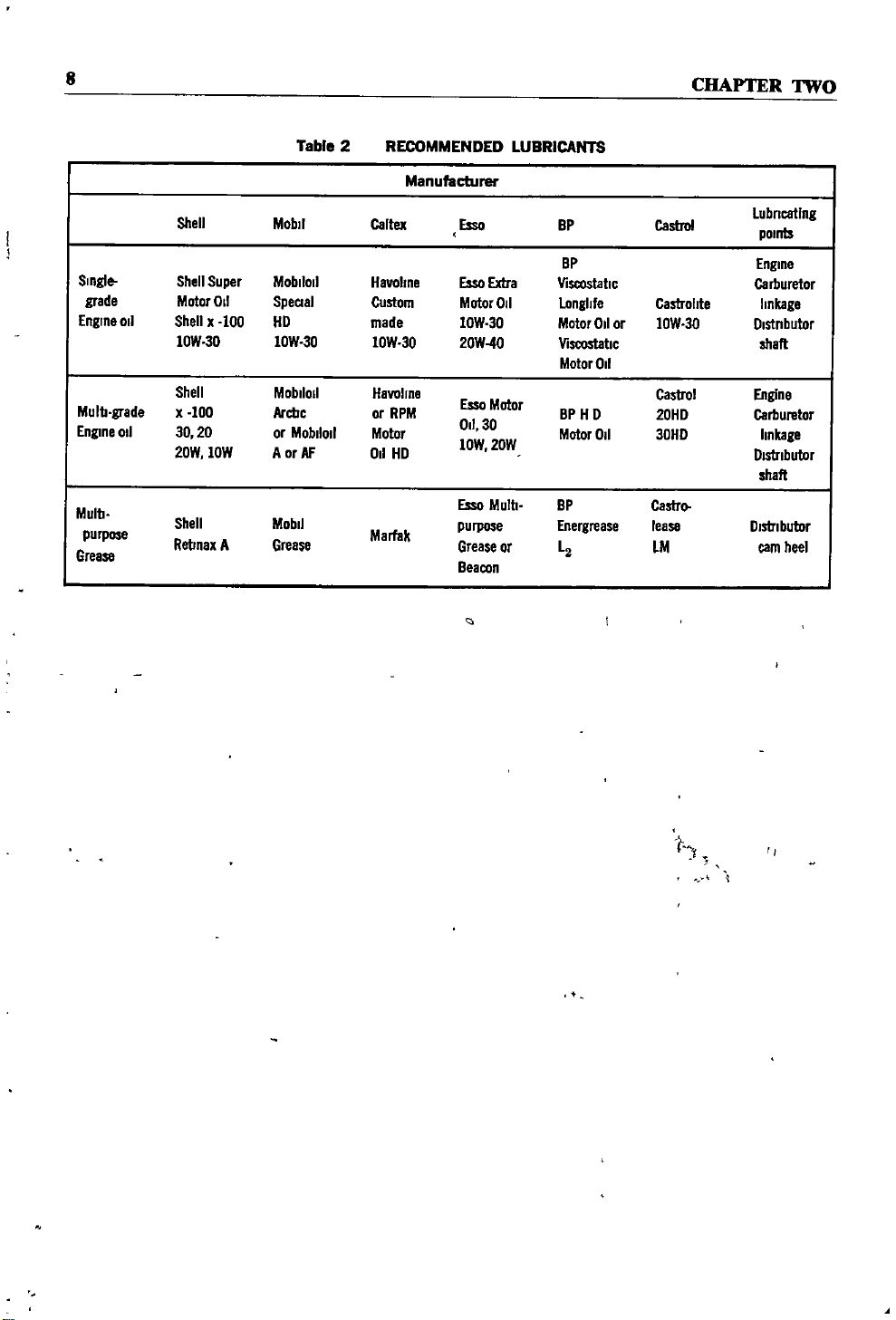

Table

2

RECOMMENDED

Manufacturer

LUBRICANTS

CHAPTER

TWO

Single

grade

ngme

Mulb

ngme

Mulb

purpose

Grease

011

grade

011

Shell

Shell

Motor

Shell

lOW

Shell

x

100

30

20

20W

Shell

Rellnax

Super

011

x

3D

lOW

A

100

Mobil

Moblloll

SpeCial

HD

IOW

30

Moblloll

Arcbc

or

Moblloll Motor

AorAF

Mobil

Grease

Caltex

Havahne

Custom

made

lOW

Havallne

or

RPM

011

HD

Marfak

Esso

Esso

Extra

Motor

011

IOW

30

3D

Esso

011

lOW

Esso

purpose

Grease

Beacon

20W

40

30

Motor

20W

Multl

or

BP

BP

ViscostatlC

longUe

Motor

011

ViscostatlC

Motor

011

BP

HD

Motor

011

BP

nergrease

Castro

Castrollte

or

IOW

30

Castrol

20HD

30HD

Castro

lease

LM

Lubncatlng

pomts

ngme

Carburetor

linkage

Dlstnbutor

shaft

Engine

Carburetor

hnkage

DIStributor

shaft

DIstnbutor

heel

eam

t

r

CHAPTER THREE

TROUBLESHOOTING

TroubleshootIng

1f

simple

always

Sible

alyzmg

Procedures

toms

These

several

must

systematic

TROUBLESHOOTING

The

erly

1

2

3

4

5

6

7

8

9

Items

necessary

ance

functlon

done

define

be

to

Subsequent

areas

m

and

give

are

not

approaches

have

one

approach

followmg

troubleshoot

Voltmeter

Hydrometer

Compression

Vacuum

Fuel

Pressure

Meter

Dwell

Tachometer

StroboscopiC

Exhaust

1

through

for

The

followmg

of

each

lOgically

steps

which

thiS

chapter

lOgical

the

only

thmg

eqUipment

an

Ammeter

Gauge

Gas

Analyzer

exhaust

mstrument

the

Datsun

symptoms

could

can

The

as

mvolve

cause

analyze

methods

methods

to

solvmgaproblem

m

EQUIPMENT

is

necessary

engme

and

Ohmmeter

Tester

Gauge

Trming

8

elDlSSion

is a

are

bnef

Light

essentlal

description

be

first

closely

testIng

the

typical

of

There

common

a

control

relatlvely

must

step

as

pos

and

symptoms

symp

isolation

may

but

lOgical

to

prop

Item

comph

of

testIng

voltmeter

mstrument

an

It

volt

type

ohmmeter

is

reqUired

and

hghts

ammeter

An

chargmg

generator

to

mstruments

ammeter

work

Ammeter

the

should

which

found

ammeter

and

procedures

check

VOM

ranges

thougll

Voltmeter

For

a

an

good

use

factory

Ih

moUve

be

all

An

and

open

and

The

for

automotIve

amperes

tery

and

ammeter

inexpensive

all

The

motIve

ignitlon

is

covenng

have

excludes

in instrument

measures

to

short

circwts

measures

should

use

startIng

for

s volt

and

and Ohmmeter

and

reqUIred

0

an

accuracy

the

electncal

check

electncal

and

electncal

cover

useful

is

current

tlusmanual

m

shorted

ohmmeters

fit

easily

are

often

electncal

For

20

systems

automotIve

volts

of

common

panels

reSiStance

contInUity

for

testing

current

010and0100

for

checkmg

The

wmdmgs

combme

any

small

tool

for

mto

too

salls

is

about

auto

fuses

starter

use

Several

auto

One

bat

an

box

Hydrometer

A

hydrometer

condition

9

is

ity

the

Compression

The

of

the

compressiOn

and

electrolyte

charge

Tester

is

in

tester

necessary

It

measures

each

measures

cell

to

check

specific

compression

battery

grav

10

CHAPTER

THREE

pressure

when

properly

Inder

and

Vacuum

The

for

an

results

prOVIde

Connect

In

tIon

vacuum

engme

readIng

NOTE

for

Figure

WIth

InterpretatIons

WIthout

preSSIOn

Fuel

Pressure

ThIS

pump

fuel

pressure

Dwell

dwell

A

grees

remaIn

thIS

angle

the

dwell

gap

Many

testIng

manufacturer

the

the

on

Tachometer

A

tachometer

WIth

exhaust

turung

formed

strument

01000

6

000

lower

of

detecting

bUllt

In

up

Interpreted

valve

condltlOn

Gauge

vacuum

gauge

Inexpenenced

when

conSIdered

valuable

the

advance

and

should

every

companng

clues

the

vacuum

hose

let

It

warm

be

Subtract1Inch

1000

1

shows

readIngs

Gauge

Instrument

performance

gauge

Meter

meter

cam

closed

angle

rotatIon

while

determmed

IS

IS

tachometers

of

Incorporate

Datsun

emission

and

carburetor

at

the

specified

for

thIS

or

or

speeds

000

0

2

8

000

The

changes

each

cylInder

IndIcate

IS

easy

mechanIC

WIth

to

pOSSIble

gauge

from

the

on

steady

measures

dIstnbutor

the

thoroughly

up

at

altitude

feet

of

numerous

Results

to other

VItal

IS

Often

combIned

are

that

the

engmeISrunnIng

by

accurate

an

Intended

a

dwell

meter

s

InstructIon to

essential

IS

control

adjustments

Idle

of

IS

rpm

25

purpose

Instruments

InStrument

to

use

to

other

WIth

carburetor

18

22

from

tYPical

are

tests

for

vacuum

a

the

dIstance

the

breaker

IndIcatIon

for

deVices

speed

one

Extended

lack

should

rpm

The

readIngs

general

but

dIfficult

Interpret

findIngs

trouble

aTconnec

Start

Vacuum

Inches

reading

readIngs

conclusive

not

such

as

evaluatIng

gauge

breaker

pOInt

of

for

tunIng

well

as

measure

tunIng

must

The

WIth

a

range

range

accuracy

be

cyl

The

can

the

to

the

com

fuel

and

de

In

pOInts

SInce

gap

pOInt

and

Follow

dwell

Datsuns

IgmtIOn

be

per

best

In

of

0

capable

Stroboscopic

tImIng

cylInder

shaft

on

the

bghts

hghts

must

bghts

bght accordIng

tIons

Exhaust

least

One

the

tIVIty

conduct

tIVIty

present

checkIng

control

amateur

ISolate

and

1

Turn

most

are

cedures

wmmgfur

good

engIne

probably

and

NIne

when

the

at

trouble

together

normally

ThIS

pulley

the

block

be

all

Of

bkely

Instrument

taIlpIpe

of

of

Starter

cures

Engme

on

likely

at

H

the

test

starter

Timing

Instrument

f1ashmgabght

By

No

1

at

bne

pulley

dunng

are

neon

Neon

tunmg

used

be

can

Analyzer

Instruments

to

and

exhaust

the

heat

at

the

exhaust

This

the

effectIveness

adjustments

mechanIC

system

The

followmg

cranks

the

headhghts

the

fault

Check

descnbed

e

battery

turn

the

the

H

shorted

it

usmg

If

the

lights

crankIng

solenOId

short

not

checkthe

Light

pernuts

fires

the

that

Instant

Withareference

up

the

tIming

bulb

bghts

in

dImly

used

In

to

the

descnbed

be

owned

samples

measures

gas

varYIng

IS

a

Instrument

but

to

conSIder

STARTER

troubles

very

battery

the

the

in

wom

s

and

headlIghts

dIDl

lIghts

to

ground

the

procedures

remain

the

engme

the

two

to

ground

solenoid

accurate

at

the

posItIon

can

procedure

and

types

ddticult

are

bt

areas

sunbght

bnght

manufacturer

a

by

the exhaust

the

SInce

rates

IndIcatIon

good

VItal

IS

of

exhaust

IS

too

are

common

are

or

slowly

If

the

bghts

or

the

battery

Tune

up

andd

connectIng

and

on

drastIcally

Remove

bnght

the

or

wmng

solenoid

large

if

the

and

preCISe

of

the

be

seen

pOInter

xenon

to

Xenon

s

thisISthe

here

mechanic

home

gases

thermal

different

thermal

for

accurately

expenSIve

buying

relatIvely

symptoms

not

at

are

connecting

using

chapter

connectIom

WIres

to

try

the

the

in

gIven

or

dun

trouble

To

starter

wmng

may

ISolate

IgnitIon

Instant

crank

Marks

SUltable

strobe

see

strobe

Use

InStruC

from

conduc

gases

conduc

of

gases

emIssion

for

easy

all

very

WireS

the

Check

check

crank

starter

starter

Chapter

slIghtly

be

ternunals

cranks

to

up

on

and

the

an

to

dun

pro

the

is

in

the

the

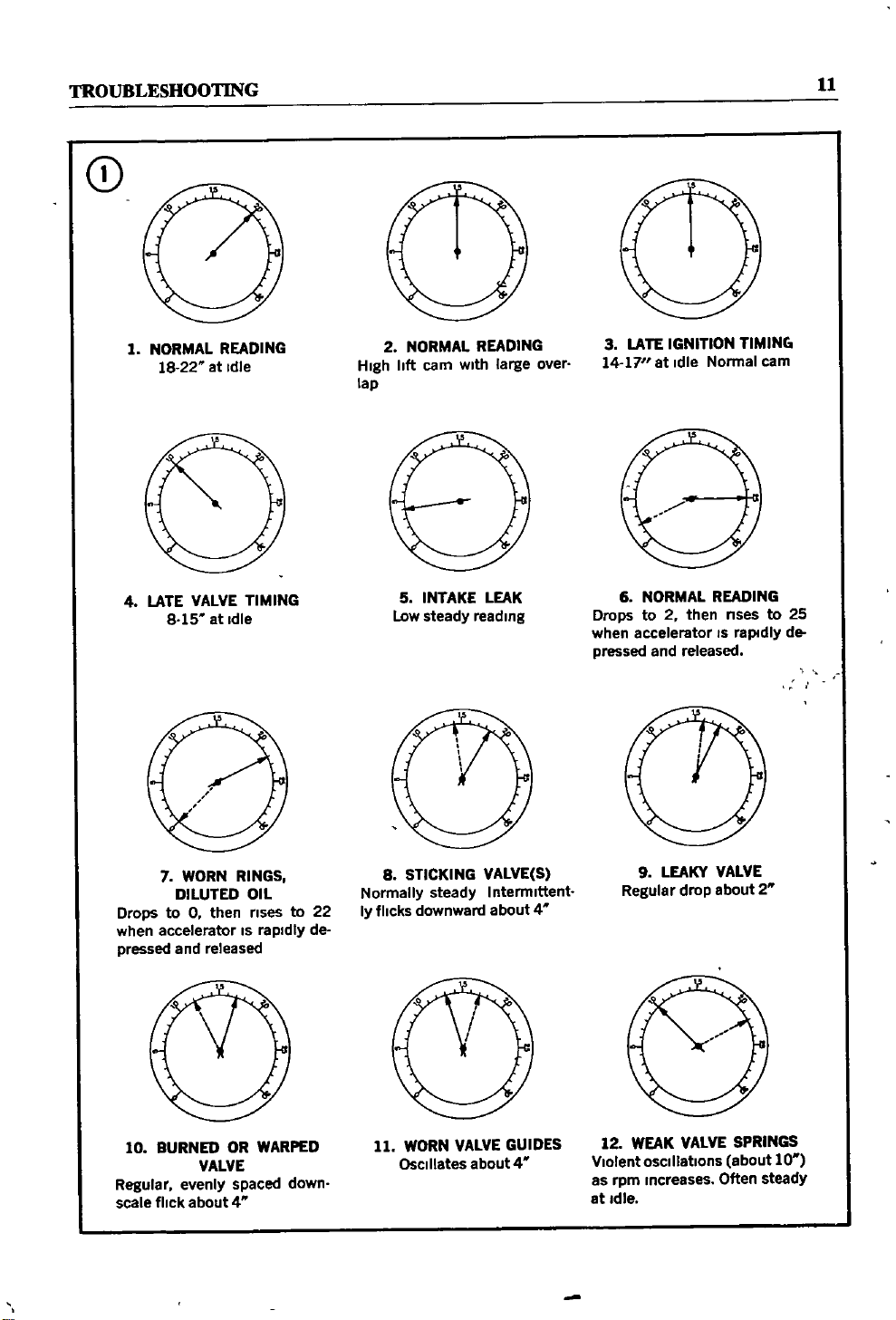

TROUBLESHOOTING

CD

11

1

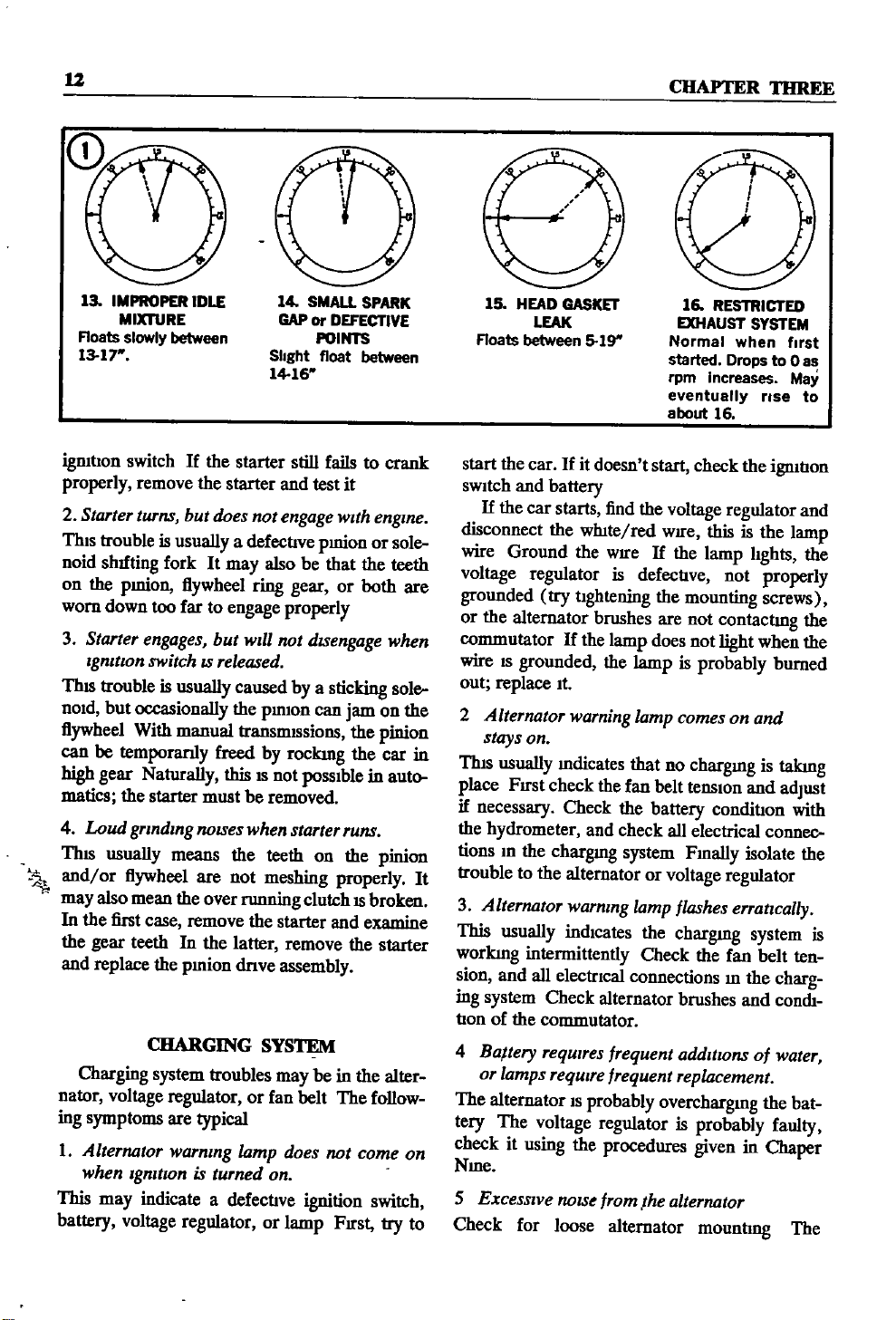

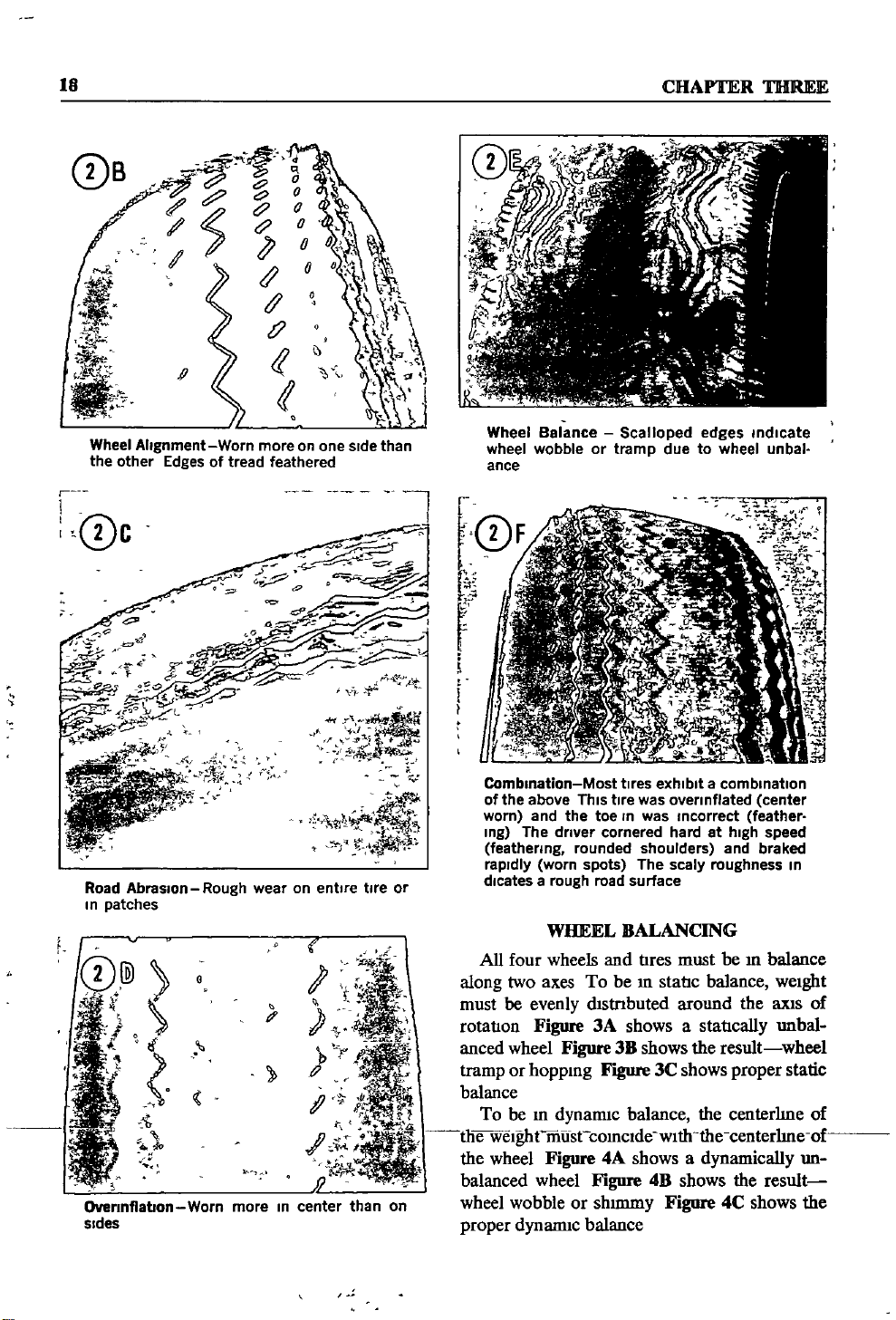

NORMAL

18

4

LATE VALVE

22atIdle

815at

READING

TIMING

Idle

High

lap

2

NORMAL

11ft

5

Low

cam

INTAKE

steady

READING

With

reading

large

LEAK

over

3

14 17

6

Drops

when

pressed

LATE

at

NORMAL

to2then

accelerator

and

IGNITION

Idle

released

Normal

READING

nses

IS

raptdly

TIMINe

cam

to

25

de

7 WORN

DILUTED

to0then

Drops

when

accelerator

pressed

and

10

BURNm

VALVE

Regular evenly

scale

flick

about

released

OR

spaced

4

RINGS

OIL

rises

IS

WARPED

rapidly

to

down

LEAKY

drop

VALVE

VALVE

about

SPRINGS

about

Often

2

1O

steady

VALVE

8

STICKING

Normally

22

1y

de

11

flicks

steady

downward

WORN

OsCillates

VALVE

about

IntermIttent

about

GUIDES

4

S

4

12

Violent

as

at

Regular

rpm

Idle

9

WEAK

OSCillations

Increases

12

CHAPTER

THREE

13

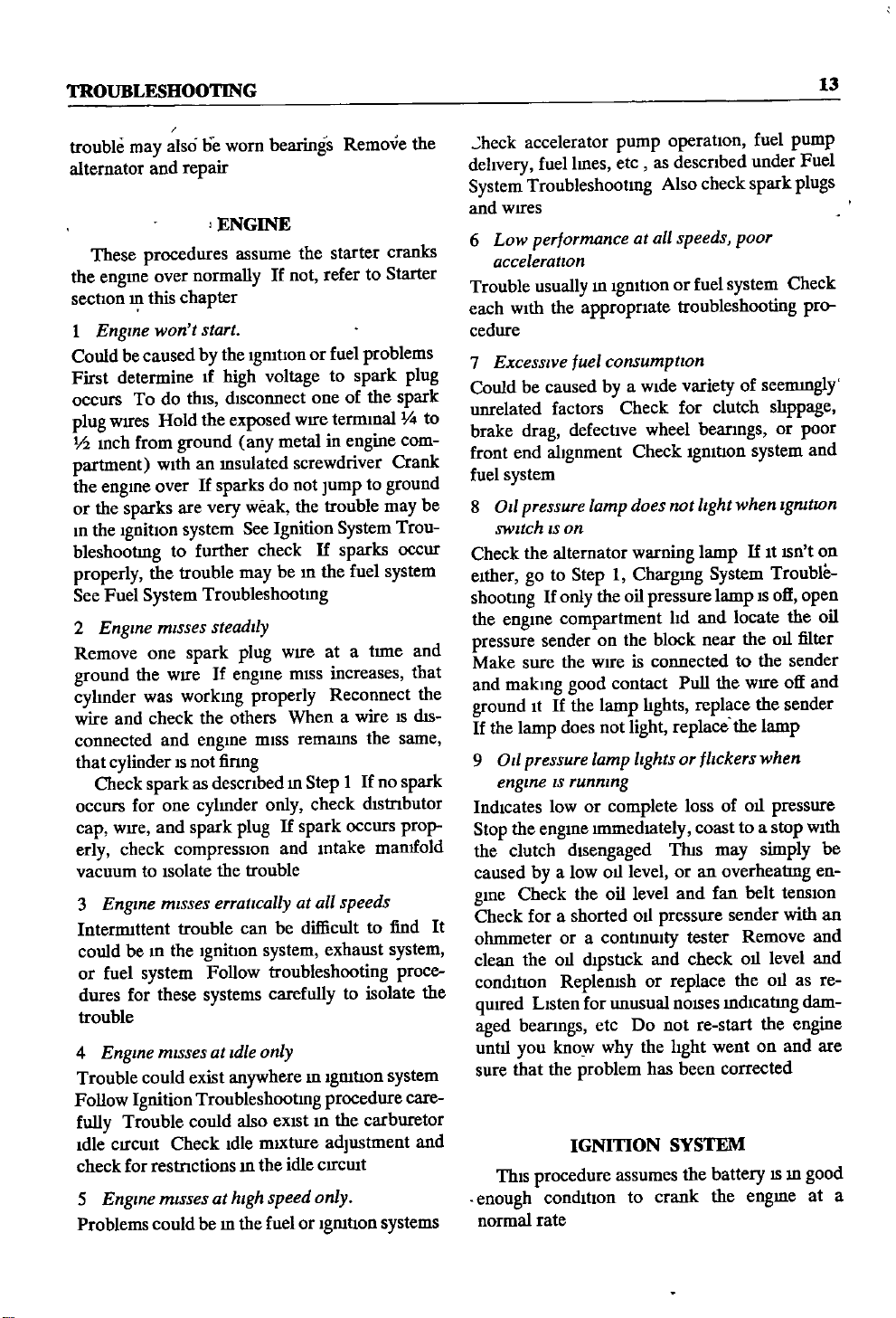

IMPROPER

MIXTURE

Roats

slowly

13

17

ignItIOn

properly

2 Starter

This trouble

noid

shlfting

on

the

worn

3 Starter

pInion

down

IgmtlOn

trouble

TIns

nOid

but

flywheel

can

be

high

gear

matics

4

Loud

TIns

usually

and

or

also

may

In

the

first

the

gear

and

replace

Charging

nator

voltage

ing

symptoms

Alternator

1

when

This

may

battery

IDLE

between

switch

remove

turns

If

but

is

usually

fork

the

flywheel

too

far

engages

switch

is

usually

occasionally

With

manual

temporanly

Naturally

starter

the

grinding

means

flywheel

mean

the

case

remove

In

teeth

the

pmion

CHARGING

system

regulator

are

warning

IgmtlOn

indicate

voltage

regulator

the

starter

starter

does

a

It

may

to

engage

but

IS

released

the

freed

this

must

noISes

are

not

over

the

troubles

typical

is

turned

a

14

GAPorDEFECTIVE

Slight

14

16

still

and

not

engage

defective

also

ring

gear

properly

will

not

caused

the teeth

byasticking

pmlOn

transmissions

by rockmg

IS

not

be

removed

when

starter

meshing

running

starter

the

remove

latter

dnve

assembly

SYSTEM

may

or

fan

does

lamp

on

defective

or

lamp

SMALl

SPARK

POINTS

float

between

fails

to

test

it

with

engine

or

pInion

that

the

both

or

be

dISengage

can

jam

the

the

poSSible

in

runs

the

on

properly

clutchISbroken

and

examine

the

beinthe

belt

The

follow

come

not

ignition

Frrst

crank

sole

teeth

are

when

sole

on

the

pinion

car

auto

pinion

starter

alter

switch

try

in

It

on

to

15

HEAD

Roats

between

start

the

sWitch

and

If

the

disconnect

wire

Ground

voltage

grounded

the

alternator

or

commutator

wire IS

out

replace

2

Alternator

stays

This

usually

Frrst

place

if

necessary

the

hydrometer

tions

m

trouble

3

Alternator

This

usually

workmg

sion

and

ing

system

tlon

of

the

4

Baltery

or

lamps

The

alternator

The

tery

check

it

Nme

ExceSSive

5

Check

GASKET

LEAK

car

19

5

Ifitdoesn

battery

car

starts

the

wlute

the

regulator

try

tightening

brushes

If

the

grounded

It

warning

on

mdicates

check

Check

and

the

chargmg

to

the

alternator

warmng

indicates the

intermittently

all

electncal

Check

commutator

reqUires

require

IS

probably

voltage

the

using

noISe

for

loose

16

RESTRICTm

EXHAUST

find

wire

is

lamp

the

the

t

the

red

defective

lamp

lamp

that

fan

the

check

Normal

started

rpm

eventually

about

start

voltage

Wire

If

the

the

are

does

no

belt

battery

all

when

Drops

Increases

16

check

regulator

thisisthe

lamp

not

mounting

not

contactmg

not

light

is

probably

comes

on

chargmg

tension

condition

electrical

the

system Fmally

or

voltage

lamp

regulator

flashes erratically

chargmg

Check

the

fan

connections

alternator

frequent

frequent

m

brushes

additiOns

replacement

overchargmg

regulatorisprobably

procedures

from

alternator

giveninChaper

he

alternator

mountmg

SYSTEM

first

to

rrse

igllltlon

hghts

properly

screws

when

burned

and

is

takmg

and

adlust

connec

isolate

system

belt

the

charg

and

cODlh

water

of

the

faulty

as

0

May

to

and

lamp

the

the

the

with

the

ten

bat

The

is

TROUBLESHOOTING

13

trouble

alternator

the

section

1

Could

First

occurs

plug

Y2

These

engme

Engme

be

determine

wires

lOch

may

m

caused

To

from

partment

the

engme

the

or

sparks

the

10

IgnitIOn

bleshootmg

properly

Fuel

See

2

Engme

Remove

ground

the

cyhnder

wire

and

connected

that

cylinder

Check

occurs

Follow

for

wrre

cap

check

erly

Engme

be

fuel

for

Engme

to

system

vacuum

3

Interrmttent

could

or

dures

trouble

4

Troublecould

Ignition

Trouble could

fully

Idle

crrcult

check

for

5

Engme

Problems

also

be

and

repair

ENGINE

procedures

over

normally

this

chapter

won

t

start

by

If

do

thiS

Hold

the

ground

With

an

msulated

over

If

sparks

are

very

system

to

further

the

trouble

misses

one

spark

wrre

work

check the

and

engme

not

IS

as

spark

one

cyhnder

and

spark

compressIOn

ISolate

misses

trouble

ill

the

these

misses

exist

Troubleshootmg

steadily

If

finng

descnbed

the

erratlcally

Ignition

Follow

systems

at

System

was

TroubleshootlOg

Check

restnctions

misses

at

could

be

ill

worn

bearings

assume

If

the

IgOltlon

voltage

high

dISconnect

exposed

metal

any

do

weak

See

Ignition

check

be

may

wrre

plug

engme

109

properly

others

miss

only

If

plug

and

trouble

can

be

system

troubleshooting

carefully

Idle

only

anywhere

also

eXist

Idle

mIXture

the

m

high

speed

the

fuel

Remove

the

starter

not

refer

or

fuel

to

one

of

wrre

termlOal

in

engine

screwdriver

not

Jump

trouble

the

System

If

sparks

the

10

at

mISs

increases

Reconnect

When

a

remams

10

1

Step

check

occurs

spark

mtake

all

at

speeds

difficult

exhaust

to

ill

IgOltlon system

procedure

10

the

adjustment

idle

crrcUlt

only

or

IgOltlon

cranks

to

Starter

problems

spark

the

spark

y

com

Crank

to

ground

may

Trou

occur

fuel

system

tune

a

wireISdIs

same

the

If

no

spark

dlStnbutor

prop

maOlfold

to

find

system

proce

isolate

carburetor

systems

the

plug

to

be

and

that

the

the

care

and

It

heck

dehvery

System

wrres

and

Low

6

acceleratIOn

Trouble

each

With

cedure

ExceSSive

7

Could

be

unrelated

brake

drag

front

end

fuel

system

8

011

pressure

switch

Check

either

shootlOg

the

englOe

pressure

Make

sure

and

makmg

ground

If

the

lamp

9

011

engme

Indicates

the

Stop

clutch

the

caused

Check

glOe

Check

ohmmeter

clean

the

condition

qurred

beanngs

aged

until

you

sure

that

This

enough

normal

accelerator

fuel

hnes

pump

etc

Troubleshootillg

performance

usually

the

fuel

caused

factors

defective

alignment

on

IS

the

alternator

to

go

Step1Chargmg

If

only

at

ill

IgOltlon

appropnate

consumptIOn

a

Wide

by

Check

Check

does

lamp

warning

the

oil

compartment

sender

it

pressure

englOe

If

IS

low

the

good

the

does

runmng

or

on

the

wrre

is

contact

lamp

not

light

lamp

lightsorflickers

complete

unmedmtely

dISengaged

oil

the

oil

contlOulty

dipstick

level

level

oil

for

by

a

a

or a

oil

low

shorted

RepleOlshorreplace

Listen

for

unusual

etc

Do not

why

assumes

the

to

know

the

problem

IGNITION

procedure

condition

rate

operation

as

descnbed

Also

check

all

speeds

or

fuel

troubleshooting

variety

clutch

for

wheel

beanngs

IgOltlOn

not

light

lamp

System

pressure

block

connected

hghts

hd

Pull

lamp

and

near

the

replace

replace

loss

coast

Tlus

may

or

an

and

fan

pressure

tester

and

check

nOISes

re

start

went

hght

has

been

SYSTEM

the

battery

crank

the

fuel

pump

under

Fuel

spark

plugs

poor

of

seemmgly

Check

system

shppage

or

poor

system

when

IgmtlOn

If

it

ISnton

Trouble

off

IS

open

the

locate

oil

the

wrre

the

when

oil

a

filter

sender

off

sender

lamp

pressure

stop

the

to

the

of

to

simply

overheatmg

belt

tensIOn

sender

with

Remove

oil

level

the

oil

as

mdlcatmg

the

engine

and

on

corrected

IS

ill

engme

pro

and

oil

and

With

be

en

an

and

and

re

dam

are

good

at

a

14

CHAPTER

THREE

I

No

The

only

butor

tnbutor

caused

ing

2

No

ThlS

secondary

from

the

end

Wire

msulated

sparks

distributor

or

for

burns

cracks

mg

pittmg

H

the

the

secondary

turn

the

open

burmng

rr

Just

to

spark

possible

or

cap

could

spark

for mOisture

cap

flashover

by

to

spark

mdicate

Circuits

center

about

screwdrIver

are

produced

cap

mOisture

etc

Check

or

cracks

cod

does

Wire

engme

Examme the

pittmg

necessary

voltagetoground

test

lampIfvoltage

bad

ably

good

If

tions

connect

and

is

present

the

fully

other

termmal

cOll

open

3

If

the

wrre

causes

correct

necnons

rotor

tnbutor

4

ThiS

plugs

Haveitchecked

one

voltage

to

cOll

the

measure

breaker

If

voltage

coli

but

No

voltage

Wire

between

Weak

spark

spark

to

ground

are

breaker

m

or

distnbutor Also

cam

Mlssmg

is

usually

plugs

is

and

Wire

from

the

pomts

termmal

not

lS

so

bad

the

pnmary

lobes

of

the

one

plug

causes

plug

any

plug

Frrst

post

11

Remove

the

not

for

over

and

With

at

not

present

distrIbutor

from

the

distnbutor

and

is

still

for

at

the

at tlus

the

small

check

breaker

pomt

caused

wrong

wrre

cracks

trouble

of

the

mch

Crank

the

dirt

rotor

Replace

produce

opens

the

so

points

looseness

the

the

cod

is

present

the

coli

connecting

not

ground

other

termmal

termmal

it

cannot

battery

points

gap

crrcuit

by

heat

are

a

defective

Examme

drrt

or

carbon

etc

in

the

prImary

the

ground

the

ismthe

cap

excessive

rr

spark

the

wrreis

excessIVe

coil wire

Hold

engme

and

trackmg

necessary

pomts

remove

dlStributor

from

trouble

the

carbon

for

both

any

H

breaker

for

Replace

points

open

withavoltmeter

the cOlllS

or

substitute

check

Temporanly

distrIbutor

to

groundIfvoltage

shorted

lS

present

mdicatesadefecnve

and

condinon

dirty

or

check

fouled

range

wrre

to

WIres

check the

Voltage

mdicates

the

Jump

condenser

or

loose

dirty

for

or

or

a

Examme

from

or

worn

damaged

mcorrect

dlStri

the

dis

track

With

rotor

check

burn

check

good

gap

and

check

prob

known

connec

dIs

the

cOll

care

at

thiS

battery

the

Other

con

burned

dis

the

are

ad

m

plug

trouble

symptom

5

Less

from

trode

or

electrode should

then

an

trode

H

requrred

electrode

occurs

cOll

carburetor

cedures

checked

I

or

Frrst

retor

carburetor throat

several

from

lS

mg

the

thereisfuelmthe

choke

stuck

overhaul

to

an

2

Usually

carburetor

3

Check

Inspect

for

required

4

Check

Clean

gap

can

3

Spark

polarity

voltage

a

relatively

Smce

from

the

From

to

to

when

wrres

must

Fuel

system

assume

and

detenmne

Remove

tlIDes

the

discharge

Will

Engme

depressed

fueltothe

carburetor

rr

so

If

necessary

the

be

faulty

Engme

Rough

runs

thiSiscaused

idle

Idle

stallmg

idle

the

foreign

Engme

IS

engme

idle

IDlXture

and

also

be

or

mcorrect

is

requrred

hot

the

center

center

20to40

cause

the

the

spark

be

FUEL

troubles

fuel

pump

that

properly

not

that

the

There

If

not

carburetor

lS

fuel

equipped

carburetor

at

setting

or

engme

miXture

overall

material

diesels

turned

the

regap

caused

spark plugs

weak

by

igmnon

to

cause

be

electrode

electrode

negative

electrode

to

Electron

to

percent

electron

hotter

flow

center

from

voltageispositive

connected

the

SYSTEM

must

or

fuellrnes

igmtlon

correctly

be iSolated

adjusted

start

fuellS

au

and

tube

the

not

fast

reachIng

cleaner

depress

should

each

fuel

pump

or

be

time

the

workmg

tank

Check

to

make

rebudd

the

whichever

Idle

by

misadJustment

Readjustasrequired

with

miss

and

idle

idle

speed

of

clean

to

speed

conchtlOn

and

contmues

off

and

spark

tlIDing

electron

a

cooler

is

hottest

the

outer

more

voltage

the

electrode

These

look

the

stream

the

lS

float

Make

the

certain

fuel

lS

has

the

into

accelerator

accelerator

not

dehver

system

automatic

itisnot

pump

determmed

system

a

frequent

adjustments

the

carburetor

overhaul

or

run

after

adjustments

flus

flow

elec

flow

elec

outside

This

The

at

pro

been

carbu

of

fuel

certam

of

see

this

lS

is

the

the

m

or

the

as

TROUBLESHOOTING

15

5

Stumbling

Check

speed

adjustment

6

Engine

This

mdlcates

fuel

pump

and

float

7

Black

Black

nuxture

Justment

sure

or

fuel

tank

valve

8

ExceSSIve

ThIS

may

fuel

mixture

ates

If

contraIlS

and Idle

pressure

certam

Fuel

Pump

1

Install

carburetor

2

Connect

WIthashort

3

Check fuel

Fuel

System

EXHAUST

The

followmg

the

justed

and

that

accurate

1

CO

content

Make

sure

mIXture

retor

Jets

necessary

pressIOn

2

CO

content

Check Idle

for

dIrty

choke

when

accelerator

mISses

pressure

needle

exhaust

exhaust

Check

Check

blocked

Check

fuel

be

another

Check

so

eqUIpped

not

being

speed

float

leaky

that

jets

Pressure

a

T

a

tube

are

fittmg

fuel

pump

chapter

Ignition

have

you

exhaust

too

Idle

speed

adjustment

and

channels

Check

and

vacuum

too

mixture

air

cleaner

If

so

equipped

acceleratmg

pump

at

hIgh

pOSSible

and

valve

smoke

smoke

Idle

for

return

for

means

mIXture

excessive

leaky

consumptIOn

mdIcatIon

that

or

left

Check

the

or

for

worn

proper

Testing

m

pressure

pressure

EMISSION

symptoms

and

carburetor

checked

anajyzer

gas

low

IS

not too

too

Clean

engme

test

hIgh

adjustment

and

diaphragm

speed

fuel

capacIty

and

hne

from

float

automatIc

that

the

out

Check Idle

excessIve

needle

the

fuel hue

gauge

as

as

ume

the

lean

and

condition

defectIve

Check

from

or

lacks

starvatIon

Clean

a

badly

Idle

fuel

pump

carburetor

or

worn

of

an

choke

manual

valve

SIZe

closetothe

to

described

CONTROL

you

to

specdicatIon

results

low

Check

Check

or

With

too

nch

carburetor

Idle

and Idle

power

Check

main

ovemch

speed

pres

needle

ovemch

oper

choke

mIXture

fuel

pump

Make

the

fittmg

in

have

on an

carbu

replace

a com

Check

automatIc

ad

the

ad

Idle

as

Jets

Jet

to

and

channels

Check

vacuum

3

Check

are

and

engme

test

Hydrocarbon

that

to

specIfication

gap

tnumg

leaks

Check

condItIon

1

SlIppage

ThiS

hIgh

is

gear

most

page park

handbrake

clutch

as

will

engme

tInued

engme

ThIS

when

penodlcally

Shppage

free

play

pressure

prevent

Drag

problem

clash

splines

Chatter

number

sag

engme

m

or

may

or

clutch

clutch

for

bIndIng

may

2

ThIS

gear

causes

warped

cessive

loose

shaft

3

A

gUIde

and

Check

misalIgned

4

Other

NOISe

usually

bearIng

Check

Idle

Check

too

early

valve

of

valves

MANUAL

noticeable

at

relatIvely

the

set

If

drlVing

slow

speed

ISasevere

slippage

results

all

or

plate

the

full

failure

usually

espeCially

be

bent

lmings

or

grabbing

of

thmgs

and

tIghtness

to

worn

release

nOIses

mdlcates

Clean

and

condItIon

level

speed

Check

breaker

Check

clearance

With

car on

ShIftto2nd

off

and

stallIfthe

will

CAUTION

from

grease

or

weak

clutch

cable

engagement

release

to

causes

excessive

pressure

cable

guide

Check

can

transmlSslon

or

mISaligned

plate

the

beanng

or

replace

WIth

too

hIgh

and

mIXture

spark

pomts

mtake

compressIOn

CLUTCH

when

slow

speed

level

a

gear

If

the

clutch

It

gIve

test

Perform

IS

suspected

IDSufliclent

on

the

sprmgs

and

dIfficult

when

downshIftmg

clutch

or

plate

sag

conditIOn

cause

tIns

of

transnusslOn

mountIng

pressure

a

or

dry

and

as

necessary

compression

adjustments

condItIon

plug

Check

too

IgnItIon

mamfold

small

test

acceleratIng

To

check

surface

clutch

and

release

is

good

shps

WIth

away

only

not

clutch

disc

clutch

Also

check

lever

arm

shIftIng

free

pedal

clutch

dISC

and

broken

of

Check

to

plate

defective

replace

release

If

neces

Check

m

slip

con

pedal

worn

which

and

The

play

mam

cable

frame

bolts

and

and

for

a

the

the

the

for

ex

or

16

Also

wear

certam

beanng

be

caused

DISassemble

be

caused

to

worn

check

TRANSMISSION

mesh

to

the

are

by

by

or

loose

DIsassemble

sary

uneven

1

Difficult

Make

lease

can

mgs

can

due

synchronIZer

replaceasrequIred

2

Gears

Generally

plunger

or

worn

fork

rod

aged

gears

slip

thIS

check

The

ball

DIsassemble

out

trouble

ball

trouble

groove

replaceasrequired

3

NOIse

If

nOISes

are

heard

clutch

disengaged

from

the

transmISSIOn

nOISes

either

smgly

qualIty

mISSIon

bearIngs

hIgh

speed

will

and

quantity

ReplaceorreplenISh

wIll

usually

and

speed

Worn

also

cause

a

or

nOIse

all

parts

gears

clutch

m

good

worn

gears

and

repaIr

msufficlent

sltdmg

mesh

of

occurs

and

can

damaged

wIth

the

the

nOIse

Several

orm

combmatIon

of

produce

cycltc

damaged

BRAKES

for

mlSaltgnment

pressure

condItion

shaft

as

plate

requIred

operatmg

or

parts

carefully

when

or

spnng

alsobecaused

bearings

carefully

engme

idlmg

IS

probably

Items

lubrIcant

knockIng

splInes

as

necessary

a

lugh

in

sound

and

and

The

trouble

andorbear

Also

stroke

defective

a

InSpect

the

mterlock

IS

weakened

worn

by

or

dam

mspect

and

and

conung

can

cause

Check

the

trans

Worn

humming

at

low

bushmgs

and

and

the

the

re

at

inated

brake

Itmngs

cyltnders

and

check

age

etc

4

Check

roundness Ensure

ferred

tion

to

make

Clean

drums

5

Check

Check

swollen

or

fectIve

6

Check

check

7

Check

contamInated

recommended

system

8

Check

rotors

loose

restrIcted

front

end

suchasbroken

Check

condItIon

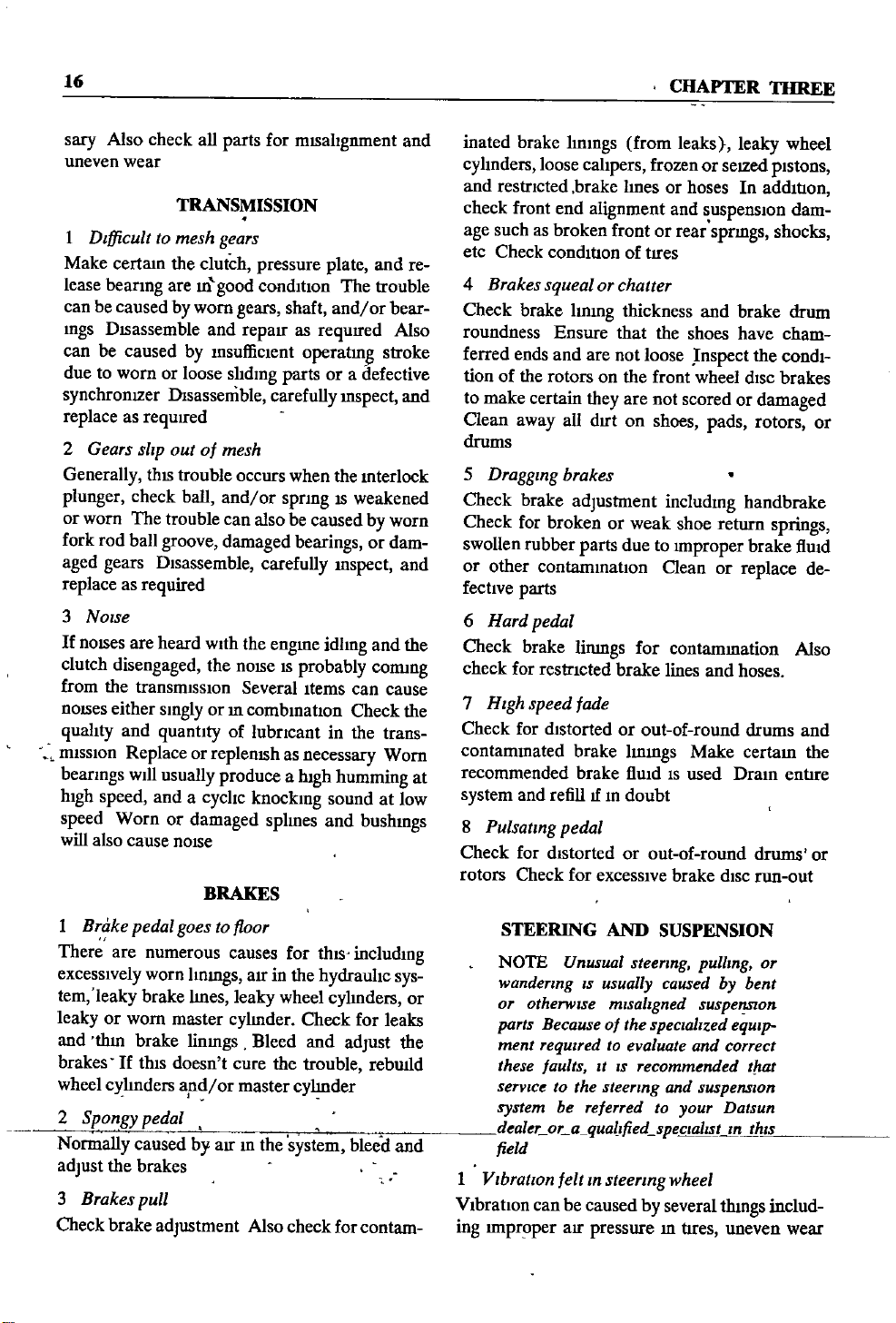

Brakes

squeal

brake

ends

and

of

the

rotors

certain

away

Draggmg

brake

for

broken

rubber

other

contammatIon

parts

Hard

pedal

brake

for

restrIcted

High

speed

for

dIstorted

and

refill

Pulsatmg

for

dIStorted

Check

lmmg

all

brakes

adjustment includmg

pedal

for

from

caltpers

brake lmes

alignment

front

of

or

chatter

thickness

that

are

not

on

the

are

they

dIrt

on

or

weak

due

parts

linmgs

brake

fade

or

brake

lmmgs

brake flUId

IfIndoubt

or

excessIVe

frozen

or

or

tIres

the

loose

front

not

shoes

to

Clean

for

lines

out

out

CHAPTER

leaks

or

seIZed

hoses

and

suspensIOn

rear

sprmgs

and

shoes

Inspect

wheel

scored

pads

shoe

return

unproper

or

contammation

and

of

round

Make

IS

used

of

round

brake

dISC

TIlREE

leaky

In

addItion

brake

have

the

dISC

or

damaged

rotors

handbrake

springs

brake

replace

hoses

drums

certam

Dram

drums

run

wheel

pIstons

dam

shocks

drum

cham

condI

brakes

or

flUId

de

Also

and

the

entIre

or

out

1

Brake

pedal

There

are

excessIvely

tem

leaky

or

thIn

If

cylmders

Spongy

the

Brakes

brake

worn

brake

caused

leaky

and

brakes

wheel

2

Normally

adjust

3

Check

goes

numerous

worn

Itnmgs

brake

lmes

master

linmgs

thIS

doesn

andor

pedal

by

brakes

pull

adjustment

to

floor

causes

leaky

cylmder

t

cure

master

aIr

m

aIr

Bleed

the

Also

for

in

the

wheel

the

system

check

thIS

hydraultc

cylmders

Check

and

trouble

cylmder

for

includIng

for

leaks

adjust

rebwld

bleedand

contam

sys

the

STEERING

NOTE

or

wandermgISusually

or

otherwise

Because

parts

ment

reqUired

these

faults

servIce

system

dealer

oca

Unusual

to

be

AND

of

to

It

the

steermg

referred

quallfied

SUSPENSION

steermg

caused

mIsaligned

the

speCialized

evaluate

IS

recommended

and

to

specrallst

pullmg

suspenszon

and

suspension

your

by

equIp

correct

Datsun

m

bent

thiS

t

tat

or

field

1

VibratIOn

VIbratIon

ing

lll1proper

can

felt

be

aIr

m

steermg

caused

pressure

by

wheel

several

tIres

m

thmgs

uneven

includ

wear

TROUBLESHOOTING

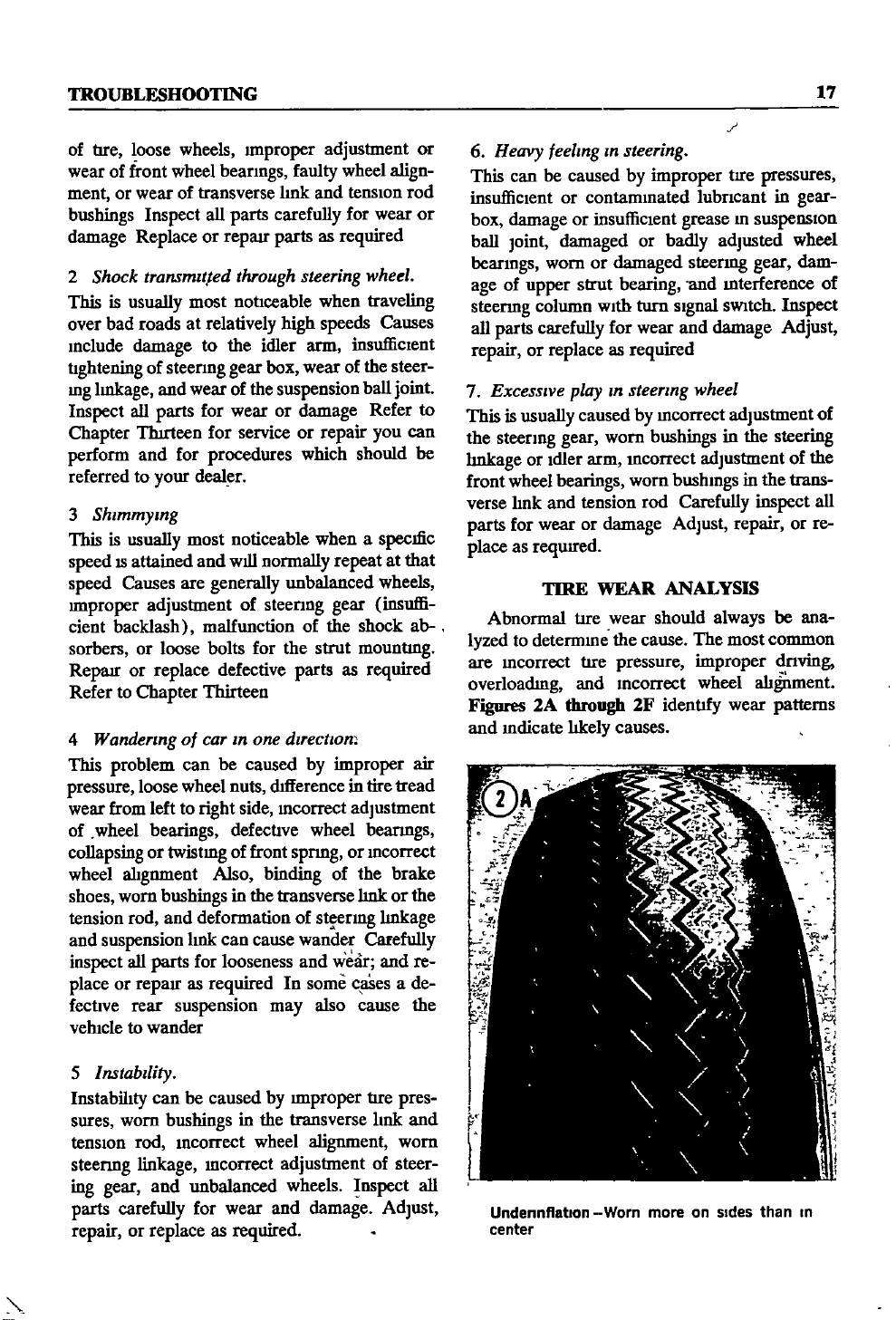

of

tIre

loose

wheels

wear

of

front

wheel

ment

or wear

bushings

damage

2

Shock

This

is

over

bad

Include

tIghtening

Ing

linkage

Inspect

Chapter

perform

referred

3

Shlmmymg

This

is

IS

speed

Causes

speed

unproper

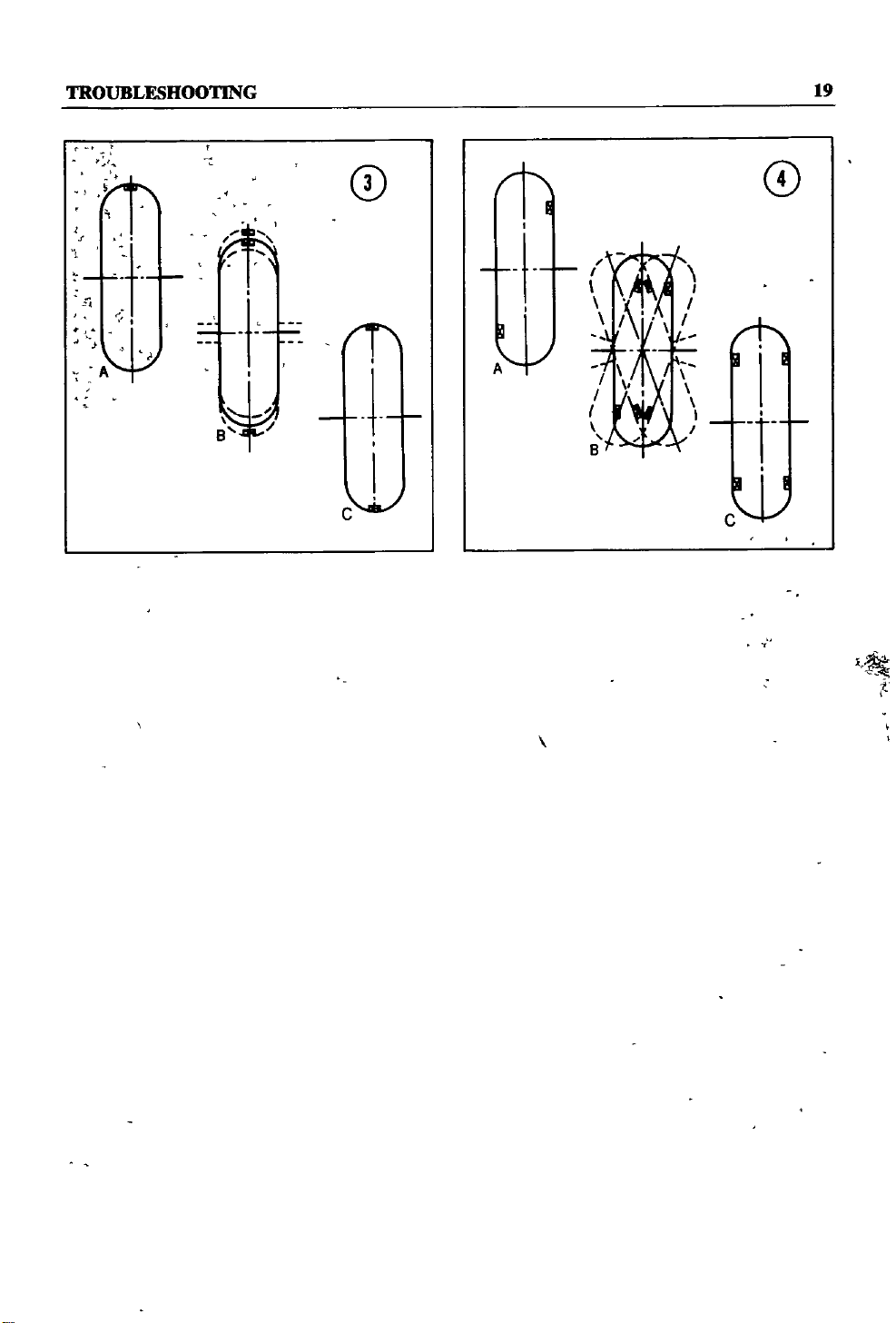

cient