Nissan Altima Se 2005 Owner's Manual

K ELECTRICAL

A

B

SECTION SC

STARTING & CHARGIN G SYSTEM

CONTENTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Rest raint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Wiring Diagrams and Trouble Diagnosis .................. 2

PREPARATION ..... ................... ................... ................ 3

Special Service Tool ................................................. 3

Commercial Service Tools ........................................ 3

BATTERY .............................................. ...................... 4

How to Handle Battery ............................................. 4

METHODS OF PREVENTING OVER-DIS-

CHARGE ............................ ................................... 4

CHECKING ELECTROLYTE LEVEL .................... 4

SPECIFIC GRAVITY CHECK ............................... 5

CHARGING THE BATTERY ................................. 6

Trouble Diagnoses with Battery/Starting/Charging

System Tester .......................................................... 6

DIAGNOSTIC RESULT ITEM CHART .................. 8

STARTING SYSTEM .................................................. 9

System Description .................................................. 9

M/T MODELS ........................................................ 9

A/T MODELS .................................. ...... ....... ......... 9

CAN Communication System Descrip tio n ................ 9

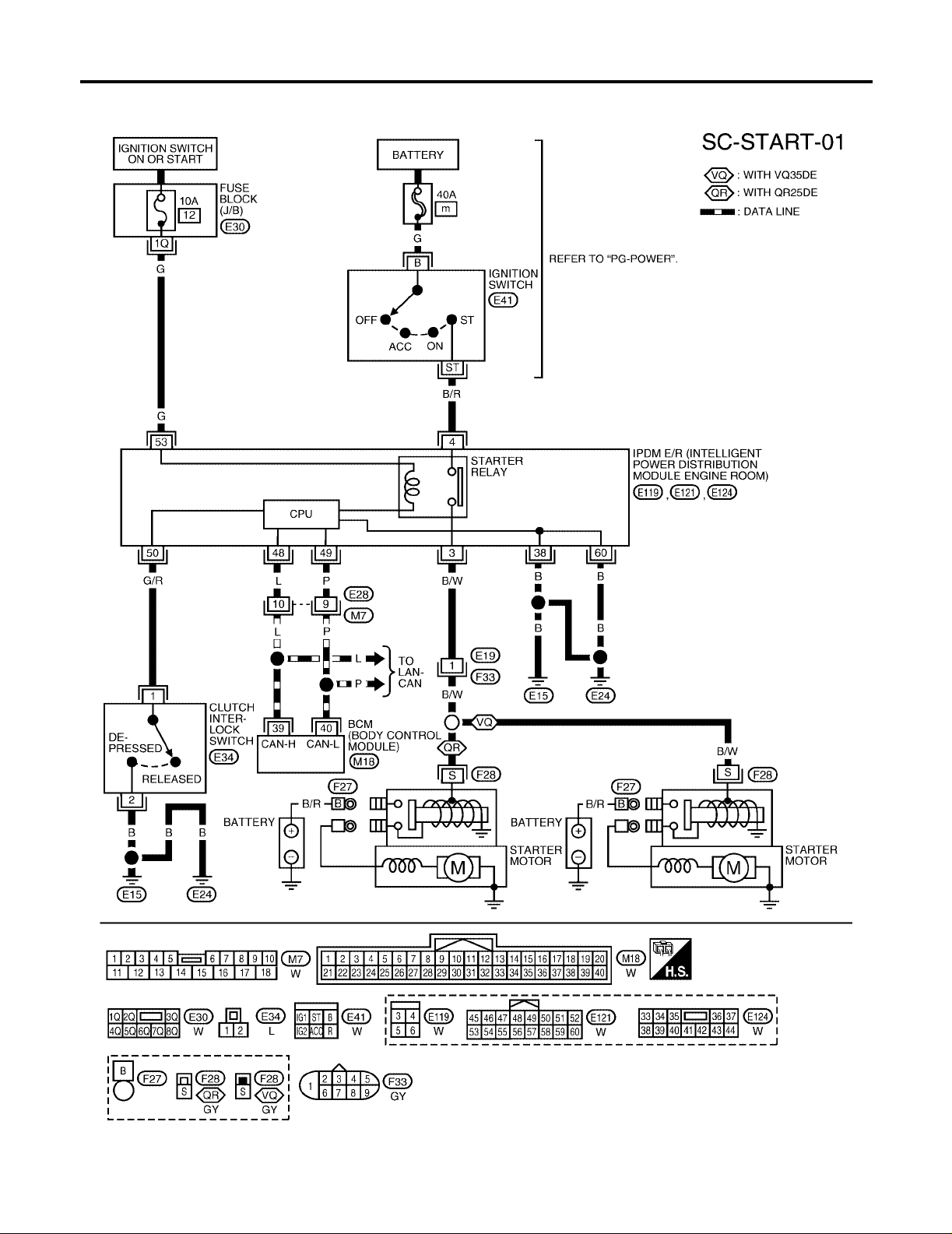

Wiring Diagram — START — ................................. 10

M/T MODELS ...................................................... 10

4 A/T MODEL .......................................................11

5 A/T MODEL ...................................................... 12

Trouble Diagnoses with Battery/Starting/Charging

System Tester ........................................................ 13

DIAGNOSTIC RESULT ITEM CHART ................ 13

WORK FLOW ...................................................... 14

DIAGNOSTIC PROCEDURE 1 ...........................15

DIAGNOSTIC PROCEDURE 2 ...........................16

MINIMUM SPECIFICATION OF CRANKING

VOLTAGE REFERENCING COOLANT TEM-

PERATURE ......................................................... 17

Removal and Installation ........................................17

M/T MODELS ..................................... ...... ....... ....17

Removal and Installation ........................................17

4-SPEED A/T MODELS . ....... .............................. 17

Removal and Installation ........................................18

5-SPEED A/T MODELS . ....... .............................. 18

Pinion/Clutch Check ...............................................20

CHARGING SYSTEM ...............................................21

System Description .................................................21

Wiring Diagram — CHARGE — ............................. 22

Trouble Diagnoses with Battery/Starting/Charging

System Tester ......................................................... 23

DIAGNOSTIC RESULT ITEM CHART ................ 24

WORK FLOW ......................................................25

DIAGNOSTIC PROCEDURE 1 ...........................26

DIAGNOSTIC PROCEDURE 2 ...........................27

DIAGNOSTIC PROCEDURE 3 ...........................28

MALFUNCTION INDICATOR ..............................29

Removal and Installation ........................................29

QR25DE ..............................................................29

VQ35DE .............................................................. 29

SERVICE DATA AND SPECIFICATIONS (SDS) ......31

Battery ....................................................................31

Starter .......................................................... ...........31

Generator ...............................................................31

C

D

E

F

G

H

I

J

SC

L

M

Revision: March 2005 2005 Altima

SC-1

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front sea t belt , helps t o redu ce th e r isk or s everi ty of injury to th e driv er an d front passenge r for c ertain

types of collisi on . Thi s s ys te m in cludes seat belt swi tch inp uts an d du al stage front air bag modules . T he SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information ne ce ss ary t o se rvi ce th e sy stem saf e ly is i nclu de d in th e SR S and SB se ct i on of th is Ser vic e Manual.

WARNING:

● To avoid rendering the SRS inoperativ e, which cou ld increase the risk of persona l injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, in cluding incorrect removal a nd installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For rem oval of Spiral Cable and Ai r

Bag Module, see the SRS section.

● Do not use electrical test equipme nt on any circuit related to the SRS unle ss instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnes ses or

harness connectors .

EKS008KU

Wiring Diagrams and Trouble Diagnosis EKS008KV

When you read wiring diagrams, refer to the following:

● GI-14, "How to Read Wiring Diagrams" .

● PG-4, "POWER SUPPLY ROUTING CIRCUIT" for power distribution circuit.

When you perfo rm trouble diagnosis, refer to the following:

● GI-10, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

● GI-26, "How to Perform Efficient Diagnosis for an Electrical Incident".

Revision: March 2005 2005 Altima

SC-2

PREPARATION

PREPARATION PFP:00002

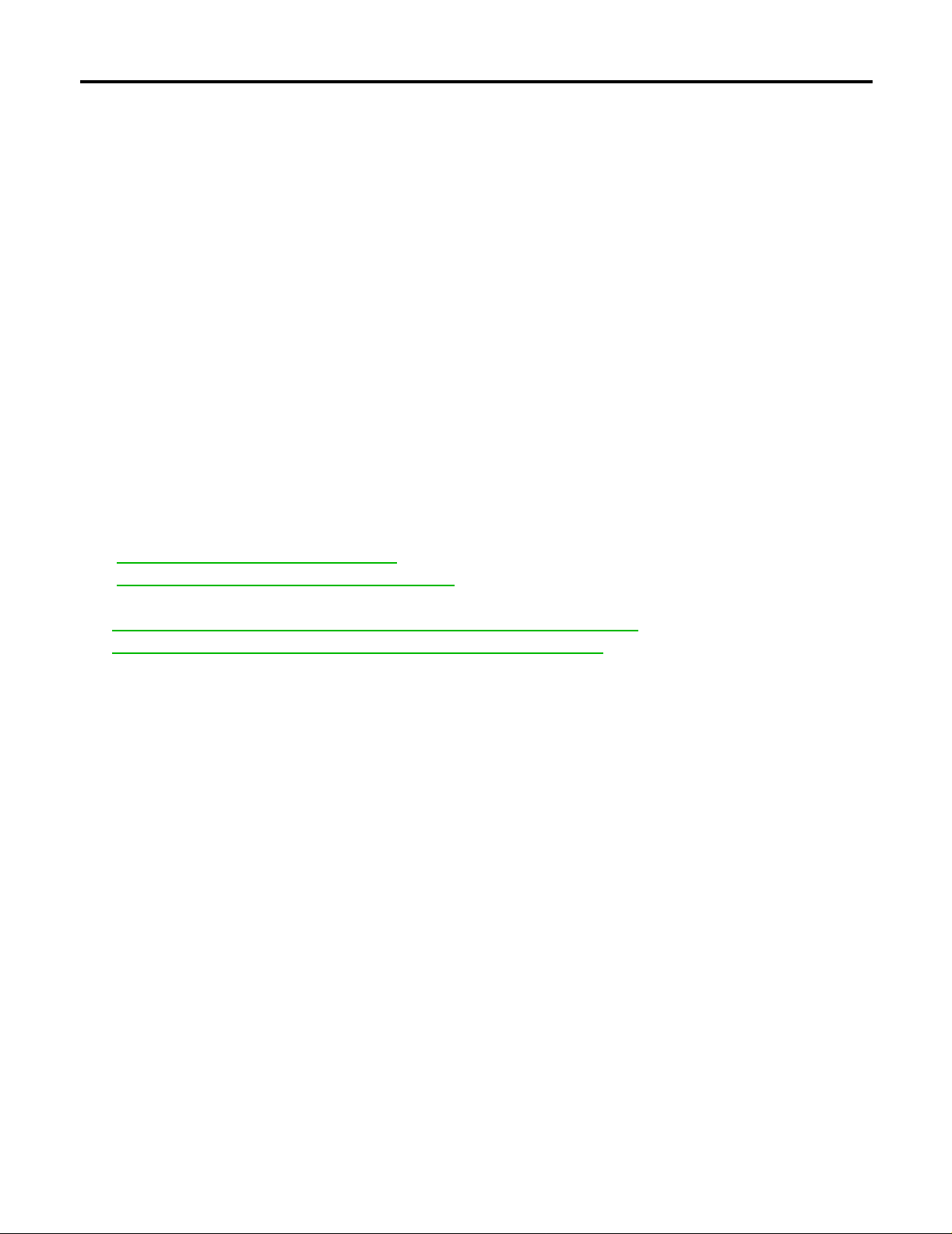

Special Service Tool EKS008KW

A

Tool number

Tool name

J-44373 Model 620

Battery/Starting/Charging system

tester

SEL403X

Description

Commercial Service Tools EKS008KX

Tool number

Tool name

Power tool Loosening bolts and nuts

PBIC0190E

Description

B

C

D

E

F

G

H

I

SC

M

J

L

Revision: March 2005 2005 Altima

SC-3

BATTERY

BATTERY PFP:AYBGL How to Handle Battery EKS008KY

CAUTION:

● If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

● After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

● Never add di stilled water through the hole used to check specific gravi ty.

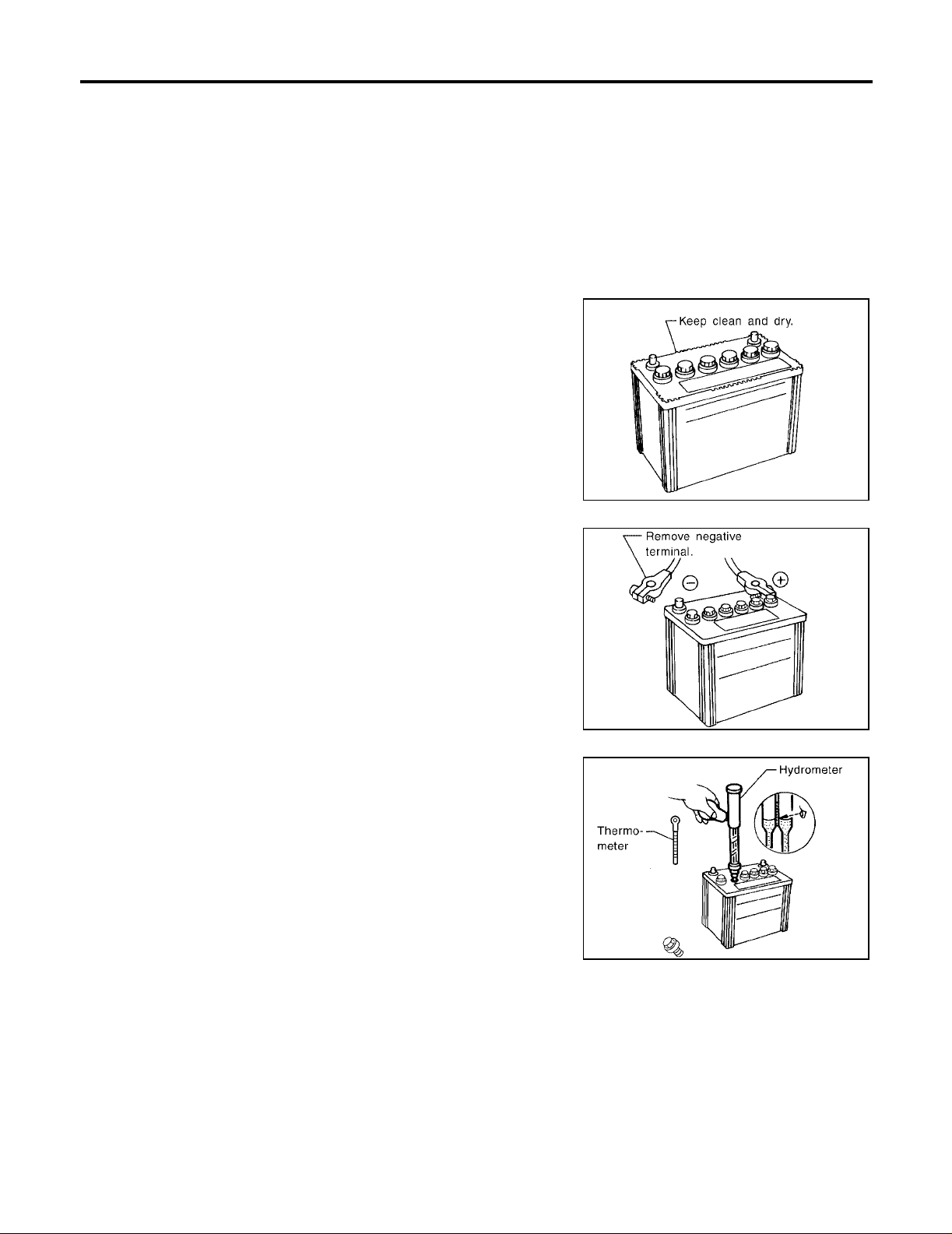

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging

a battery.

● The battery surface (particularly its top) should always be kept

clean and dry.

● The terminal connections should be clean and tight.

● At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance -fre e” .

MEL040F

● When the vehicle is not going to be used over a long period o f

time, disconnect the negative battery terminal.

MEL041F

● Check the charge condition of the battery.

Periodically ch eck the specific gravity of the el ectrolyte. Keep a

close check on charge condition to prevent over-discharge.

MEL042F

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fab rics , o r painted su rfac es . Afte r tou ch ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid contacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

Revision: March 2005 2005 Altima

SC-4

BATTERY

● Remove the cell plug using a suitable tool.

● Add distilled water up to the MAX level.

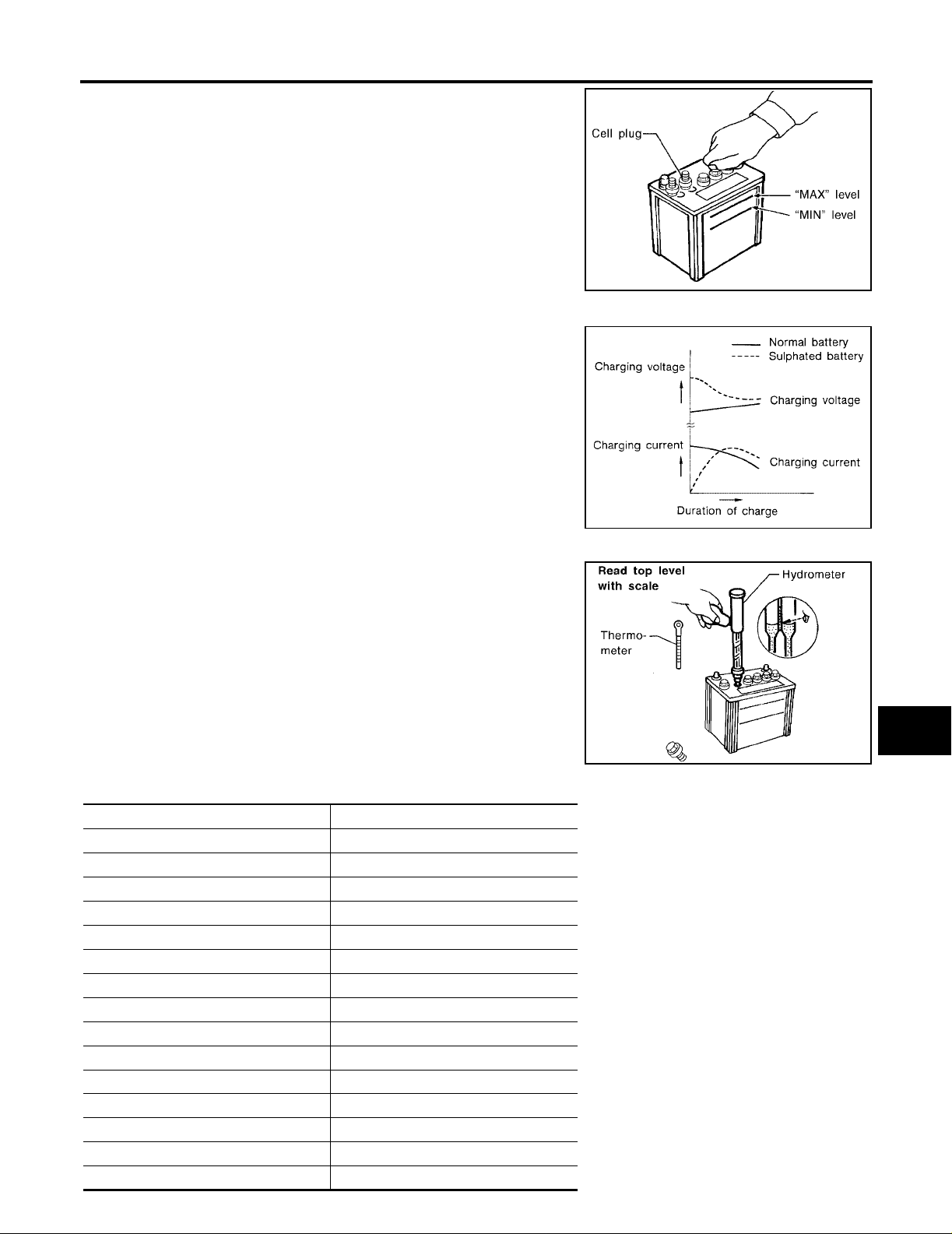

Sulphation

A battery will be completely discha rged if it is left unattended

for a long time and the specific gravity will become less than

1.100. This may result in sulphation on the cell plates.

To determine if a b attery h as been “sulph ate d”, no te its voltage

and current when charging it. As shown in the figu re, less current and higher voltage are observed in the initial stage of

charging sulphated batteries .

A sulphated battery may so metimes be brought back into service by means of a long, slow charge, 12 hours or more, followed by a battery capacity test.

A

B

C

MEL043F

D

E

F

G

SPECIFIC GRAVITY CHECK

1. Read hydrometer and thermom eter indications at eye level.

2. Use the following chart to correct your hydrometer reading

according to electrolyte temperature.

Hydrometer Temperature Correction

Battery electrolyte temperature °C (°F) Add to specific gravity reading

71 (160) 0.032

66 (150) 0.028

60 (140) 0.024

54 (130) 0.020

49 (120) 0.016

43 (110) 0.012

38 (100) 0.008

32 (90) 0.004

27 (80) 0

21 (70) −0.004

16 (60) −0.008

10 (50) −0.012

4 (40) −0.016

−1 (30) −0.020

−7 (20) −0.024

SEL709E

H

I

J

SC

MEL042FA

L

M

Revision: March 2005 2005 Altima

SC-5

BATTERY

Battery electrolyte temperature °C (°F) Add to specific gravity reading

−12 (10) −0.028

−18 (0) −0.032

Corrected specific gravity Approximate charge condition

1.260 - 1.280 Fully charged

1.230 - 1.250 3/4 charged

1.200 - 1.220 1/2 charged

1.170 - 1.190 1/4 charged

1.140 - 1.160 Almost discharged

1.110 - 1.130 Completely discharged

CHARGING THE BATTERY

CAUTION:

● Do not “quick charge” a fully discharged battery.

● Keep the battery away from open flame while it is being charged.

● When connecting the charger, connect the leads first, then turn on the charger. Do not turn on the

charger first, as this may cause a spark.

● If battery electrolyte temperature rise s above 60°C (140°F ), stop charging . Always charge battery

at a temperature below 60°C (140°F).

Charging Rates

Amps Time

50 1 hour

25 2 hours

10 5 hours

5 10 hours

Do not charge at more than 50 ampere rate.

NOTE:

The ammeter reading on your battery charger will automatically decrease as the battery charges. This indicates that the voltage of the battery is increasing normally as the state of charge improves. The charging amps

indicated above refer to initial charge rate.

● If, after charging, the specific gravity of any two cells varies more than .050, the battery should be

replaced.

Trouble Diagnoses with Battery/Starting/Charging System Tester EKS008KZ

CAUTION:

When working with batteries, always wear appropriate eye protection.

NOTE:

● To ensure a complete and thorough diagnosis, the battery, starter and generator test segments must be

done as a set from start to finish.

● If battery surface charge is detected while testing, the tester will prompt you to turn on the headlights to

remove the surface charge.

● If necessary, the tester will prompt you to determine if the battery temperature is above or belo w 0°C

(32°F). Choose the a pp r opr ia te se le ct io n b y p r es sing t h e up or d own a rr ow bu tt o n, t h en pr ess “E NT E R” t o

make the selection.

Revision: March 2005 2005 Altima

SC-6

BATTERY

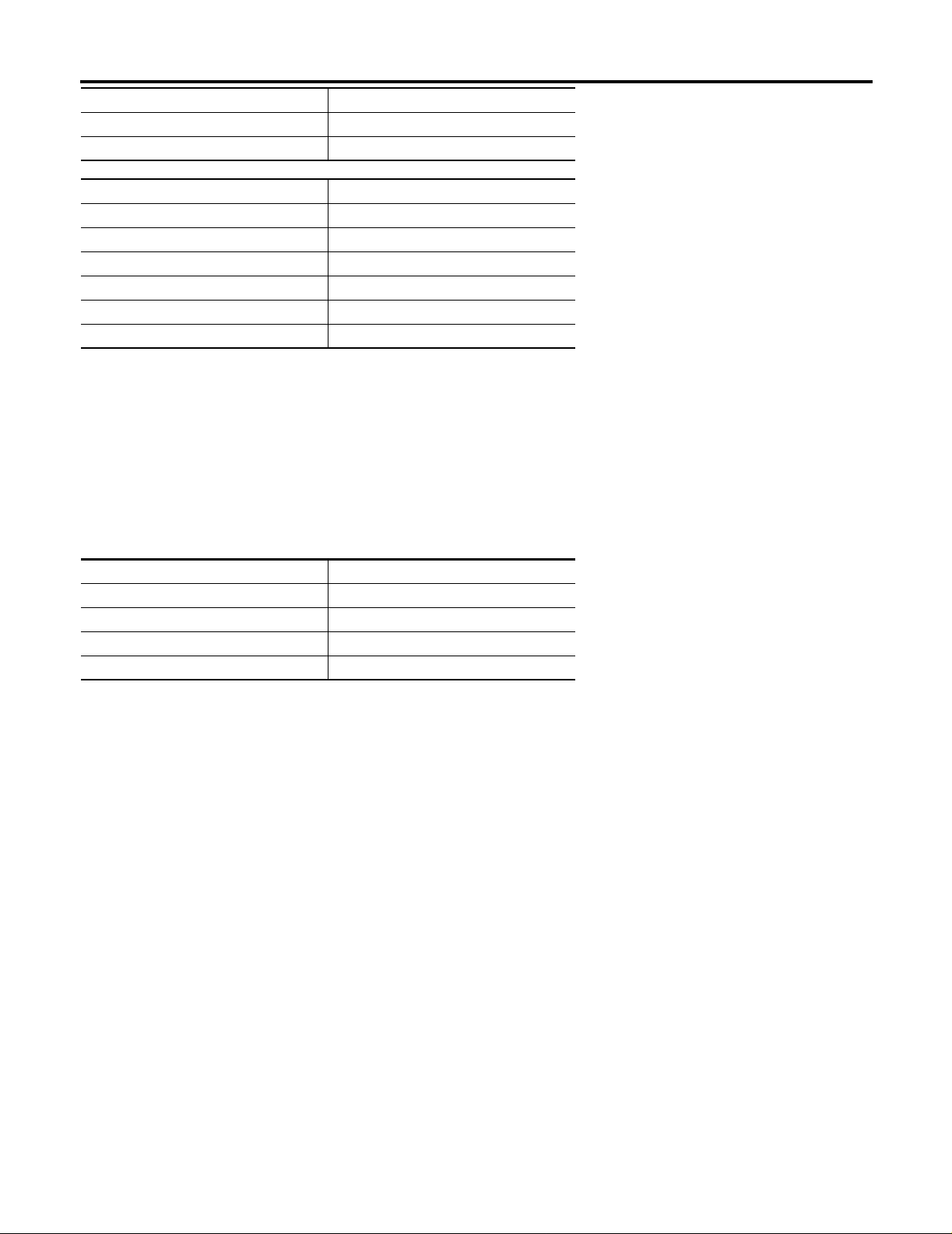

1. Turn of f all l oads on the vehi cle e lectr ica l sys tem. C lean o r rep a ir

as necessary.

2. Visually inspect the battery, battery terminals and cable ends

with ignition switch in “OFF” position.

NOTE:

The contact surface between the battery terminals, cable ends

and tester leads m ust be clean for a valid tes t. A poor connection will prevent testing and a “CHECK CONNECTION” message will appear during the test procedures. If this occurs, clean

the battery post and terminals, reconnect them an d restart the

test.

3. Connect the red tester le ad clamp to the positive battery terminal, and the black to the negative terminal.

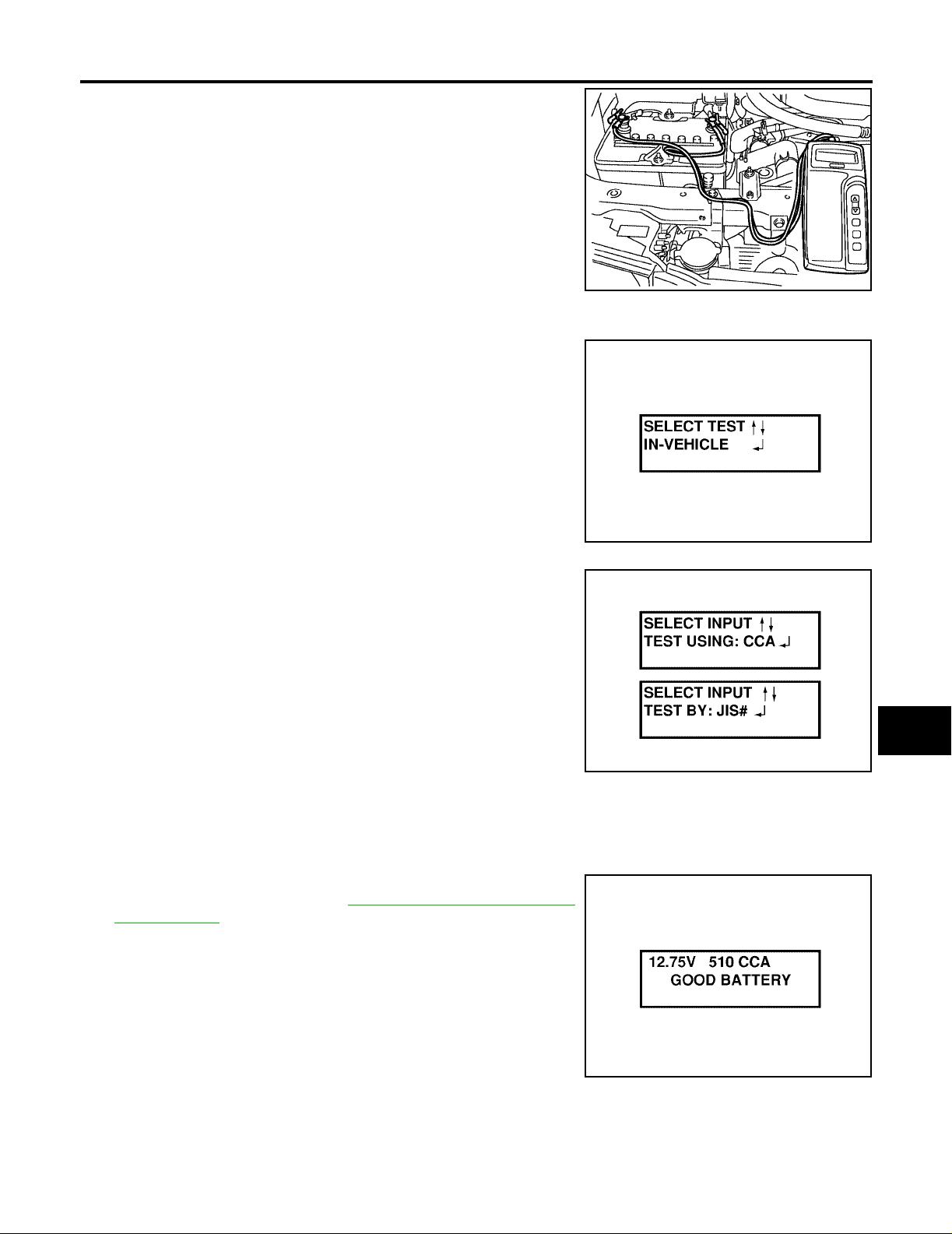

4. The tester will turn on automatically. Using the arrow keys,

select “IN-VEHICLE” on the tester and then press the “ENTER”

key.

A

B

C

SEL404X

D

E

F

G

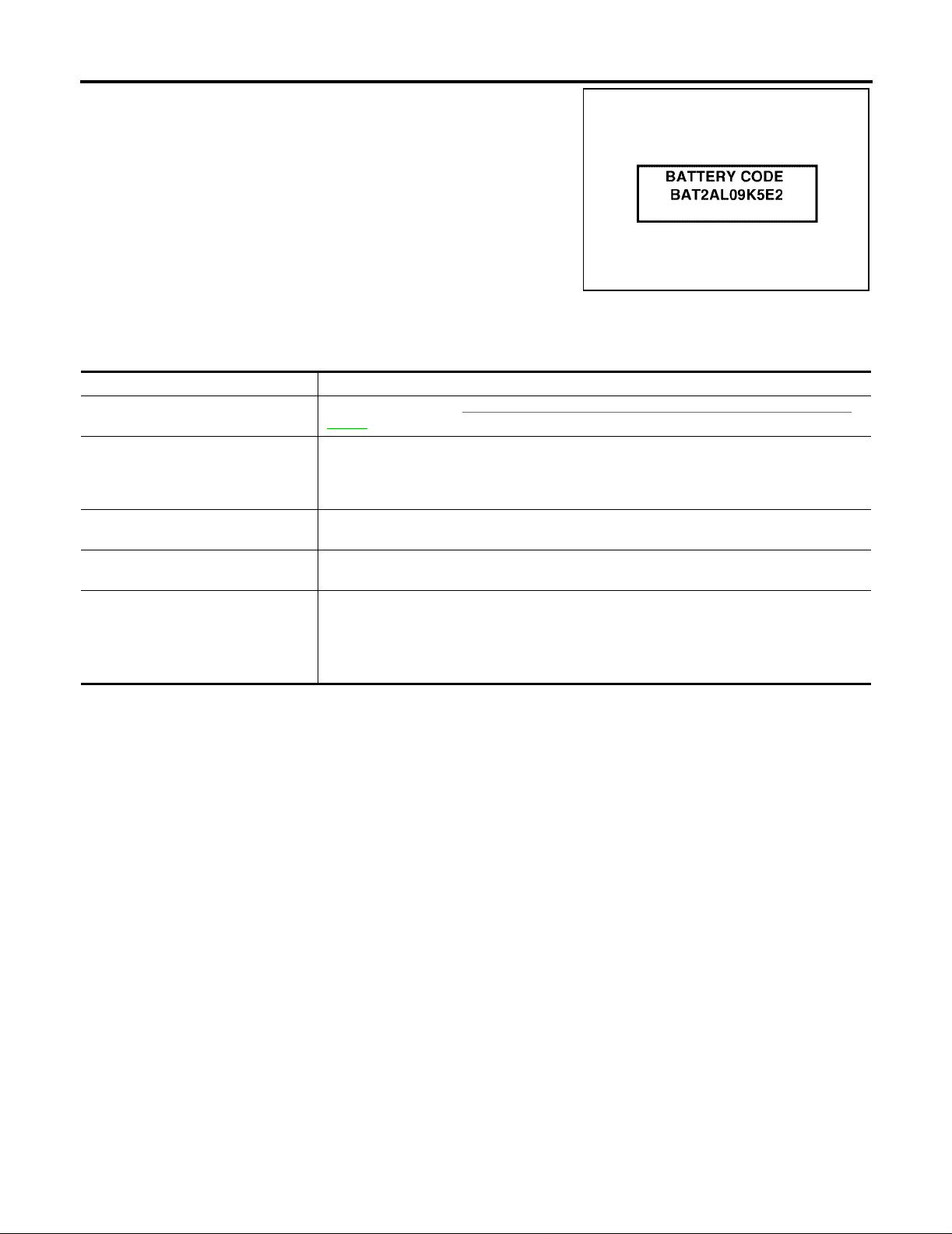

5. Locate the battery type and rating stamped or written on the top

case of the battery to be tested.

NOTE:

The battery type and rating w ill have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard.

Battery is stamped with a numb er such as:

80D26L: 80 (rank of outp ut), D (physical size-depth ), 26 (width

in cm). The last cha racter L (p ost con figurati on) is no t input i nto

the tester.

The tester requires the rating for the battery be entered exactly

as it is written or stamped on the battery. Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input directly.

6. Using the arrow and “ENTER” keys alternately, select the battery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use CCA or JIS.

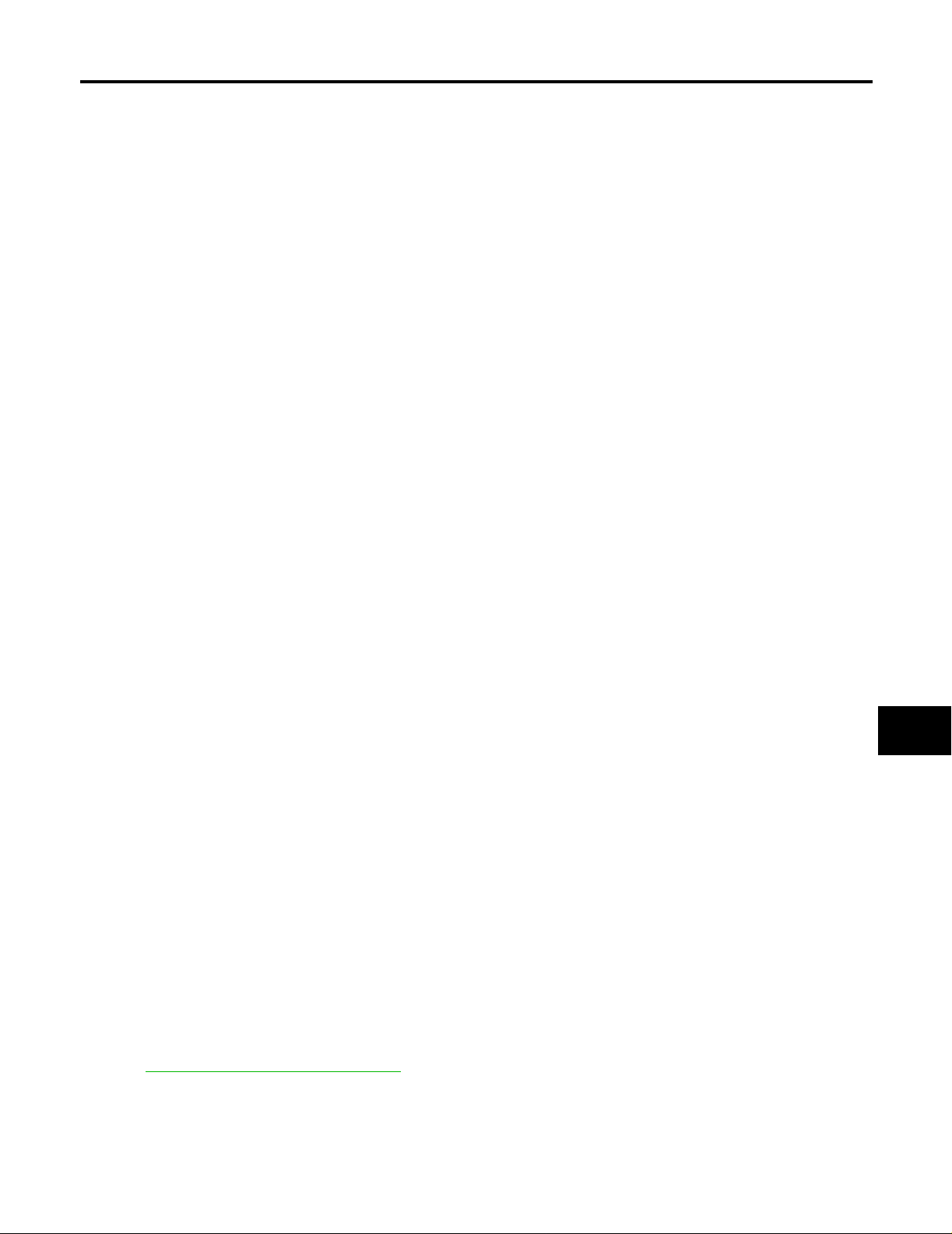

7. Press “ENTER” to begin the test. Diagnosis results are displayed on the tester. Refer to SC-8, "

DIAGNOSTIC RESULT

ITEM CHART" .

SEL405X

H

I

J

SC

SEL406X

L

M

SEL407X

Revision: March 2005 2005 Altima

SC-7

BATTERY

8. Press “ENTER”, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the “DIAGNOSTIC SCREEN” for test results.

NOTE:

● If necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selection by pressi ng the up or down arrow button and then pres s

the “ENTER” button to make the se le cti on .

● When testing a battery installed in a vehicle that has recently

been driven, select “BEFORE CHARGE”.

● If the battery h as just be en slow c harged du e to a “CHAR GE

& RETEST” decision by the tester, and the tester asks the user “BEFORE CHARGE/AFTER

CHARGE”, select “AFTER CHARGE”.

DIAGNOSTIC RESULT ITEM CHART

Diagnostic item Service procedure

GOOD BATTERY

REPLACE BATTERY

BAD CELL-REPLACE

GOOD-RECHARGE

CHARGE & RETEST

Battery is OK. Refer to SC-13, "

Tester" .

Replace battery.

Before replacing battery, clean the battery cable clamps and battery posts. Perform battery

test again with Battery/Starting/Charging system tester. If second test result is “Replace Battery”, then do so. Perform battery test again to confirm repair.

Replace the battery. Perform battery test again with Battery/Starting/Charging system tester

to confirm repair.

Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12 hours.) Perform battery test again with Battery/Starting/Charging system tester.

Perform the slow battery charging. (Initial rate of charge is 10A for 12 hou rs.)

Perform battery test again with Battery/Starting/Charging system tester to confirm repair.

NOTE:

If the tester asks the user “BEFORE CHARGE/AFTER CHARGE”, select “AFTER

CHARGE”.

Trouble Diagnoses with Battery/Starting/Charging System

SEL576X

Revision: March 2005 2005 Altima

SC-8

STARTING SYSTEM

STARTING SYSTEM PFP:23300

System Description EKS008L0

M/T MODELS

Power is supplied at all times:

● through 40A fusible link (letter m , located in the fuse and fusible link box)

● to ignition switch terminal B.

With the ignition switch in the START position, power is supplied:

● from ignition switch terminal ST

● to intelligent power distribution module engine room (IPDM E/R) terminal 4.

With the ignition switch in the ON or START position, power is supplied:

● through 10A fuse [No. 12, located in the fuse block (J/B)]

● to IPDM E/R te rminal 53.

When the clutch pedal i s depre ssed, g round is supplie d to IP DM E/R t erminal 50 through the clu tch int erlock

switch and body grounds E15 and E24.

Provided that the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN lines, the

IPDM E/R grounds the starter relay and power is supplied:

● from terminal 3 of the IPDM E/R

● to terminal S of the start e r motor windin gs.

The starter motor plunger clos es and pro vide s a close d circui t betwee n the ba ttery and the starter m otor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor op erates.

In the event that the CAN communication line fails between the IPDM E/R and the BCM, the IPDM E/R will

default to a starter rela y re qu es t ON s igna l as l on g as t he i gn iti on swi t ch r e mai ns i n th e START or ON positi on .

A

B

C

D

E

F

G

H

A/T MODELS

Power is supplied at all times:

● through 40A fusible link (letter m , located in the fuse and fusible link box)

● to ignition switch terminal B.

With the ignition switch in the START position, power is supplied:

● from ignition switch terminal ST

● to IPDM E/R te rminal 4.

With the ignition switch in the ON or START position, power is supplied:

● through 10A fuse [No. 12, located in the fuse block (J/B)]

● to park/neutral (PNP) switch terminal 1 (with 4 A/T) or terminal 5 (with 5 A/T).

With the selector lever in P or N position, power is supplied:

● through PNP switch terminal 2 (with 4 A/T) or terminal 1 (with 5 A/T)

● to IPDM E/R te rminal 53.

Provided the IP DM E/ R rece ives a st arter relay requ est ON si gnal from th e BCM ov er th e CAN li nes, the IPD M

E/R grounds the starter relay and power is supplied:

● from terminal 3 of the IPDM E/R

● to terminal S of the start e r motor windin gs.

The starter motor plunger clos es and pro vide s a close d circui t betwee n the ba ttery and the starter m otor. The

starter motor is grounded to the cylinder block. With power and ground supplied, the starter motor op erates.

In the event that the CAN communication line fails between the IPDM E/R and the BCM, the IPDM E/R will

default to a starter rela y re qu es t ON s igna l as l on g as t he i gn iti on swi t ch r e mai ns i n th e START or ON positi on .

I

J

SC

L

M

CAN Communication System Description EKS008L1

Refer to LAN-21, "CAN COMMUNICATION" .

Revision: March 2005 2005 Altima

SC-9

STARTING SYSTEM

Wiring Diagram — START — EKS008L2

M/T MODELS

WKWA2905E

Revision: March 2005 2005 Altima

SC-10

Loading...

Loading...