Nissan 240SX 2000 Owner's Manual

MANUAL TRANSMISSION

GI

MA

CONTENTS

PREPARATION ...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools...........................................5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart.........................................6

MANUAL TRANSMISSION

M/T OIL............................................................................7

Checking M/T Oil.........................................................7

Changing M/T Oil.........................................................7

ON-VEHICLE SERVICE ..................................................8

Replacing Rear Oil Seal..............................................8

REMOVAL

INSTALLATION

Position Switch Check.................................................8

DESCRIPTION.................................................................9

Cross-sectional View...................................................9

Triple Cone Synchronizer..........................................10

SHIFT CONTROL..........................................................11

Components...............................................................11

REMOVAL AND INSTALLATION.................................12

Removal.....................................................................12

Installation..................................................................13

Air Breather Hose......................................................14

OVERHAUL ...................................................................15

Transmission Components........................................15

REPAIR FOR COMPONENT PARTS...........................16

Rear Extension..........................................................16

COMPONENTS

REMOVAL

INSTALLATION

DISASSEMBLY

ASSEMBLY

Transmission Case....................................................18

COMPONENTS

REMOVAL

INSTALLATION

Counter Gear Bearing ...............................................23

DISASSEMBLY AND ASSEMBLY

6th Coupling Sleeve and Synchronizer Hub.............24

.................................................................8

..........................................................8

.......................................................16

...............................................................16

........................................................16

........................................................17

.............................................................17

.......................................................18

...............................................................19

........................................................20

..........................................6

..............................23

SECTION

DISASSEMBLY AND ASSEMBLY

INSPECTION

Mainshaft Bearing Retainer.......................................24

DISASSEMBLY AND ASSEMBLY

6th Counter Gear and Baulk Ring.............................25

INSPECTION

Clutch Housing ..........................................................25

COMPONENTS

REMOVAL

INSTALLATION

Front Cover................................................................28

REMOVAL AND INSTALLATION

DISASSEMBLY

ASSEMBLY

Reverse Idler Gear....................................................29

INSPECTION

Main Drive Gear ........................................................29

REMOVAL AND INSTALLATION

DISASSEMBLY

INSPECTION

ASSEMBLY

Mainshaft ...................................................................31

REMOVAL AND INSTALLATION

INSPECTION BEFORE DISASSEMBLY

DISASSEMBLY

INSPECTION

ASSEMBLY

Counter Gear.............................................................36

REMOVAL AND INSTALLATION

INSPECTION BEFORE DISASSEMBLY

DISASSEMBLY

INSPECTION

ASSEMBLY

Shift Fork and Fork Rod............................................40

REMOVAL AND INSTALLATION

DISASSEMBLY AND ASSEMBLY

INSPECTION

SERVICE DATA AND SPECIFICATIONS (SDS).........42

General Specifications...............................................42

Gear End Play and Oil Clearance.............................42

Clearance Between Baulk Ring and Gear................43

...........................................................24

...........................................................25

.......................................................25

...............................................................25

........................................................27

........................................................28

.............................................................29

...........................................................29

........................................................29

...........................................................30

.............................................................30

........................................................32

...........................................................32

.............................................................34

........................................................37

...........................................................38

.............................................................39

...........................................................41

MT

..............................24

..............................24

...............................28

...............................29

...............................31

.....................31

...............................36

.....................36

...............................40

..............................41

EM

LC

EC

FE

CL

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

Available Snap Ring..................................................43

MAIN DRIVE GEAR SNAP RING

COUNTER FRONT BEARING SNAP RING

4TH COUNTER GEAR FRONT SNAP RING

COUNTER DRIVE GEAR SNAP RING

..............................43

................43

..............43

......................43

5TH & REVERSE SYNCHRONIZER HUB SNAP

......................................................................44

RING

6TH MAIN GEAR REAR SNAP RING

6TH SYNCHRONIZER HUB SNAP RING

........................44

...................44

MT-2

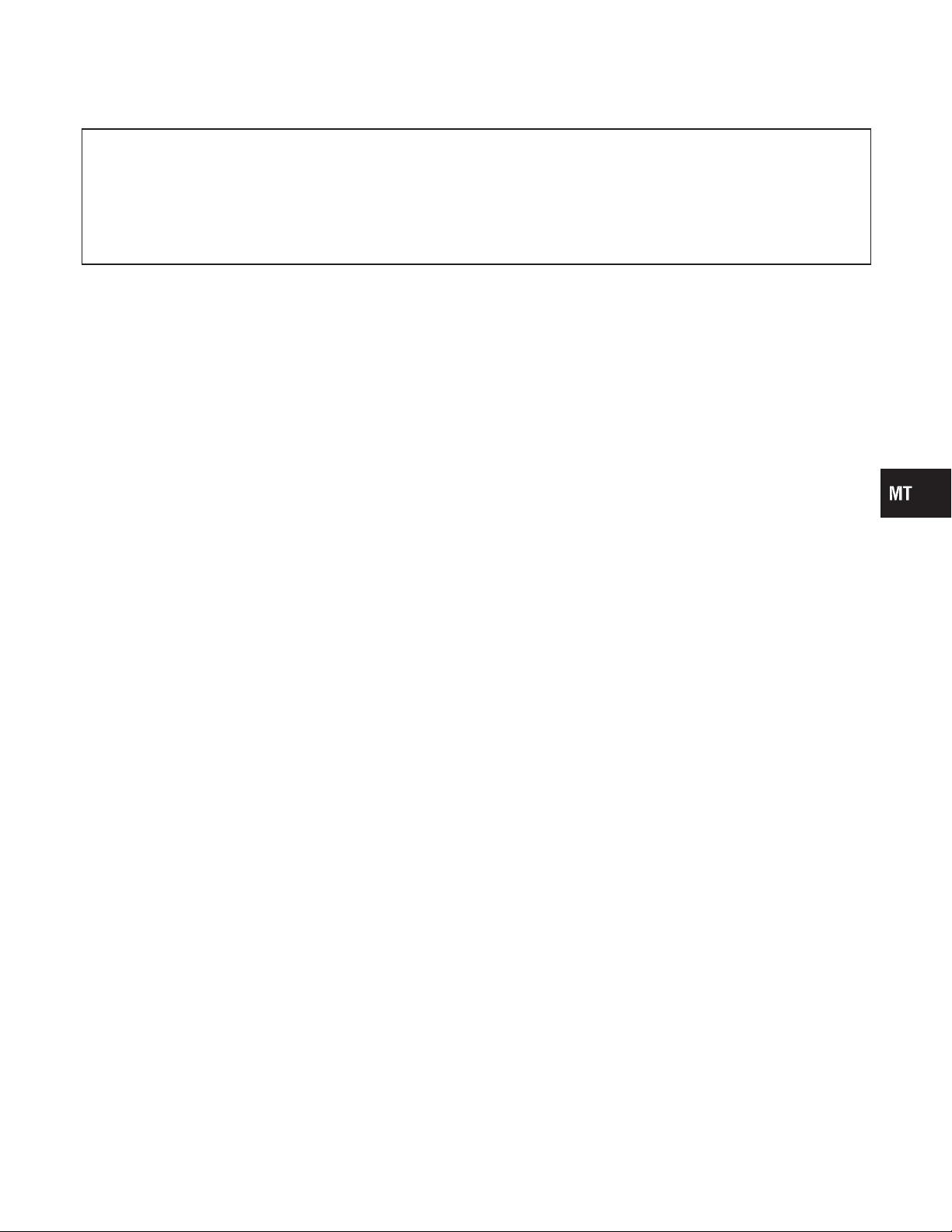

PREPARATION

Special Service Tools

Tool number

Tool name

ST23540000

Pin punch

KV32103100

Spring pressure

KV381054S0

Puller

Description

NT442

SMT066E

Special Service Tools

Removing and installing retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

Removing and installing bearing retainer spring

Removing rear extension oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

NMMT0001

GI

MA

EM

LC

EC

FE

CL

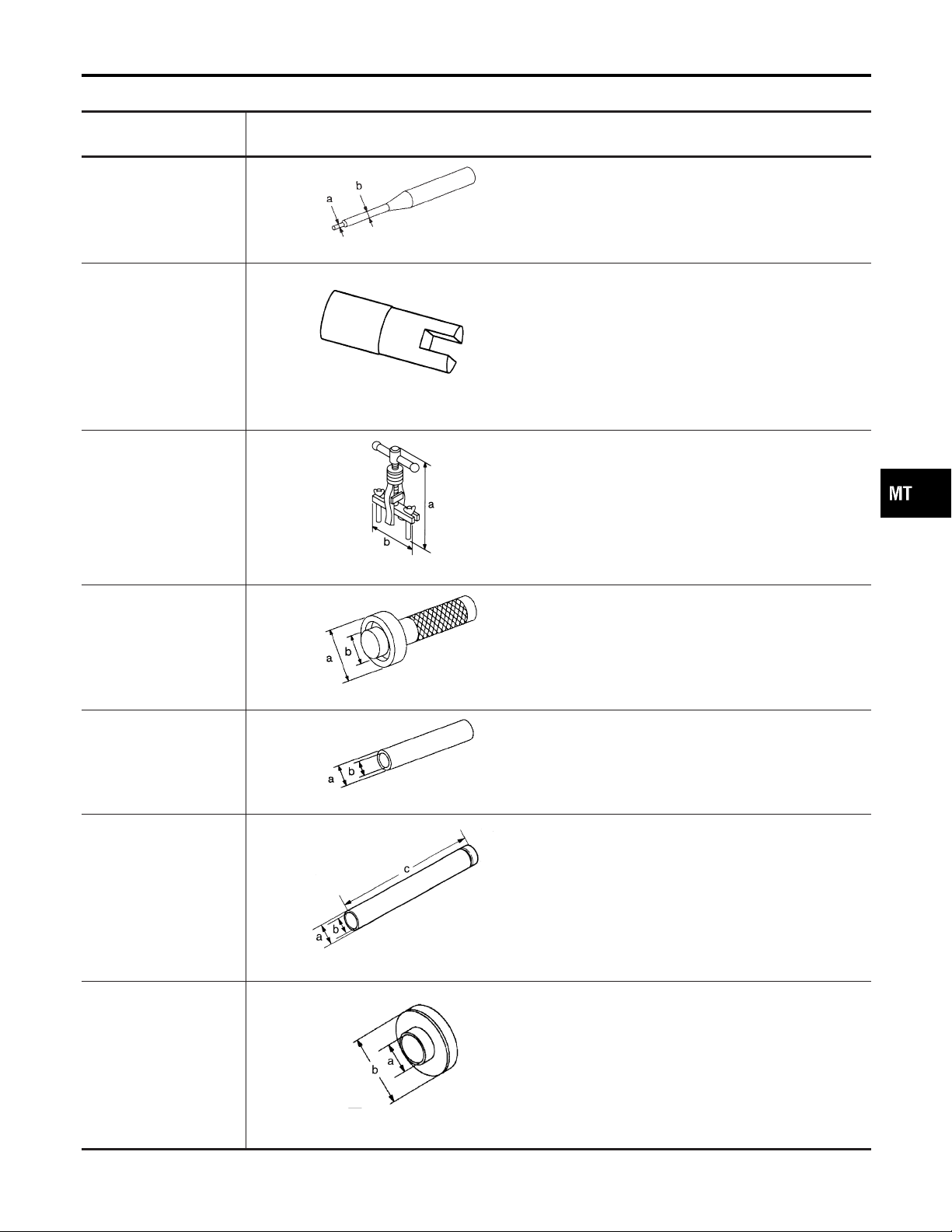

ST33230000

Drift

ST23860000

Drift

KV32102700

Drift

ST30032000

Drift

NT414

NT084

NT065

SMT067E

SMT068E

Removing and installing counter gear bearing

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

Installing 6th clutch hub

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

Installing the following:

I Main drive gear bearing

I 5th & reverse coupling sleeve, synchronizer hub,

or reverse main gear

I Mainshaft bearing

I 6th main gear

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

c: 410 mm (16.14 in)

Installing the following:

I Main drive gear bearing

I 5th & reverse coupling sleeve, synchronizer hub,

or reverse main gear

I Mainshaft bearing

I 6th main gear

a: 38 mm (1.50 in) dia.

b: 80 mm (3.15 in) dia.

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MT-3

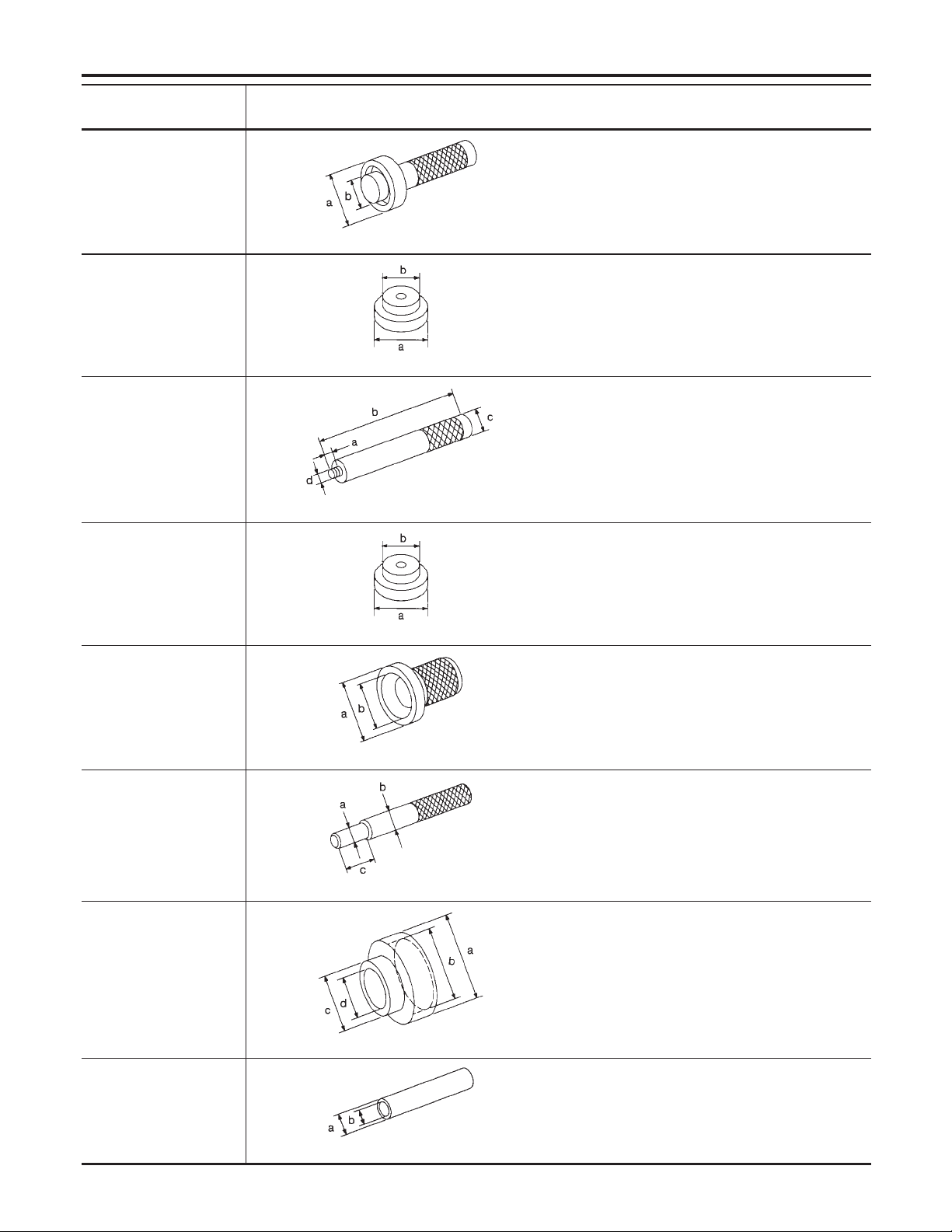

Special Service Tools (Cont’d)

PREPARATION

Tool number

Tool name

ST37830000

Drift

ST30621000

Drift

ST35325000

Drift handle

ST33061000

Drift

Description

Installing rear extension oil seal

a: 62 mm (2.44 in) dia.

b: 39 mm (1.54 in) dia.

NT084

Installing main drive gear bearing

(Use with ST35325000)

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

NT073

Use with ST30621000

a: 15 mm (0.59 in)

b: 215 mm (8.46 in)

c: 25 mm (0.98 in) dia.

d: M12 × 1.5P

NT416

Front cover oil seal

a: 38 mm (1.496 in) dia.

b: 28.5 mm (1.122 in) dia.

KV40100621

Drift

ST20630000

Drift

KV38102510

Drift

ST22360002

Drift

NT073

Installing counter gear

a: 76 mm (2.99 in) dia.

b: 69 mm (2.72 in) dia.

NT086

Removing counter gear bearing

Removing counter gear

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45 mm (1.77 in)

NT405

Installing reverse coupling sleeve and synchronizer hub

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.

c: 55 mm (2.17 in) dia.

d: 45 mm (1.77 in) dia.

NT476

Removing reverse coupling sleeve, synchronizer

hub and reverse main gear

a: 29 mm (1.14 in) dia.

b: 23 mm (0.91 in) dia.

NT065

MT-4

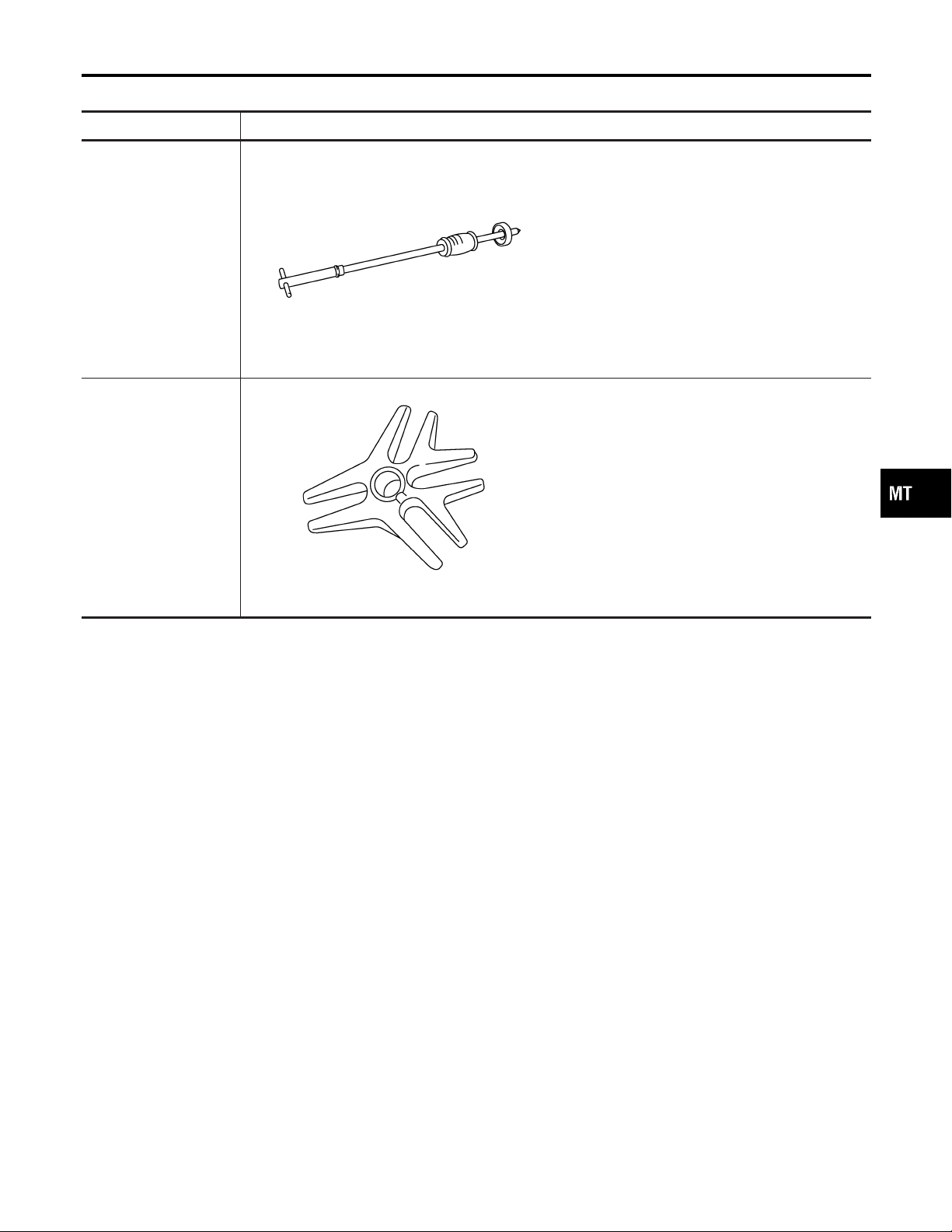

PREPARATION

Commercial Service Tools

Tool name Description

Slide hammer puller

SMT054E

Quick steering puller

Commercial Service Tools

Removing 6th coupling sleeve & synchronizer hub

assembly

(Use with quick steering puller)

Use with slide hammer puller

NMMT0002

GI

MA

EM

LC

EC

FE

CL

SMT055E

AT

PD

AX

SU

BR

ST

RS

BT

HA

MT-5

SC

EL

IDX

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

NMMT0023

NVH Troubleshooting Chart

NMMT0023S01

Use the chart below to help you find the cause of the problem. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

MANUAL TRANSMISSION

Reference page

SUSPECTED PARTS

(Possible cause)

Refer to MT-7, “Checking M/T Oil”.

MT-15

MT-15

MT-15

MT-15

MT-15

MT-31

NMMT0023S0101

MT-31

MT-31

Symptom

OIL (Level low)

OIL (Wrong)

OIL (Level too high)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK PLUG RETURN SPRING AND

CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

INSERT SPRING (Damaged)

MT-6

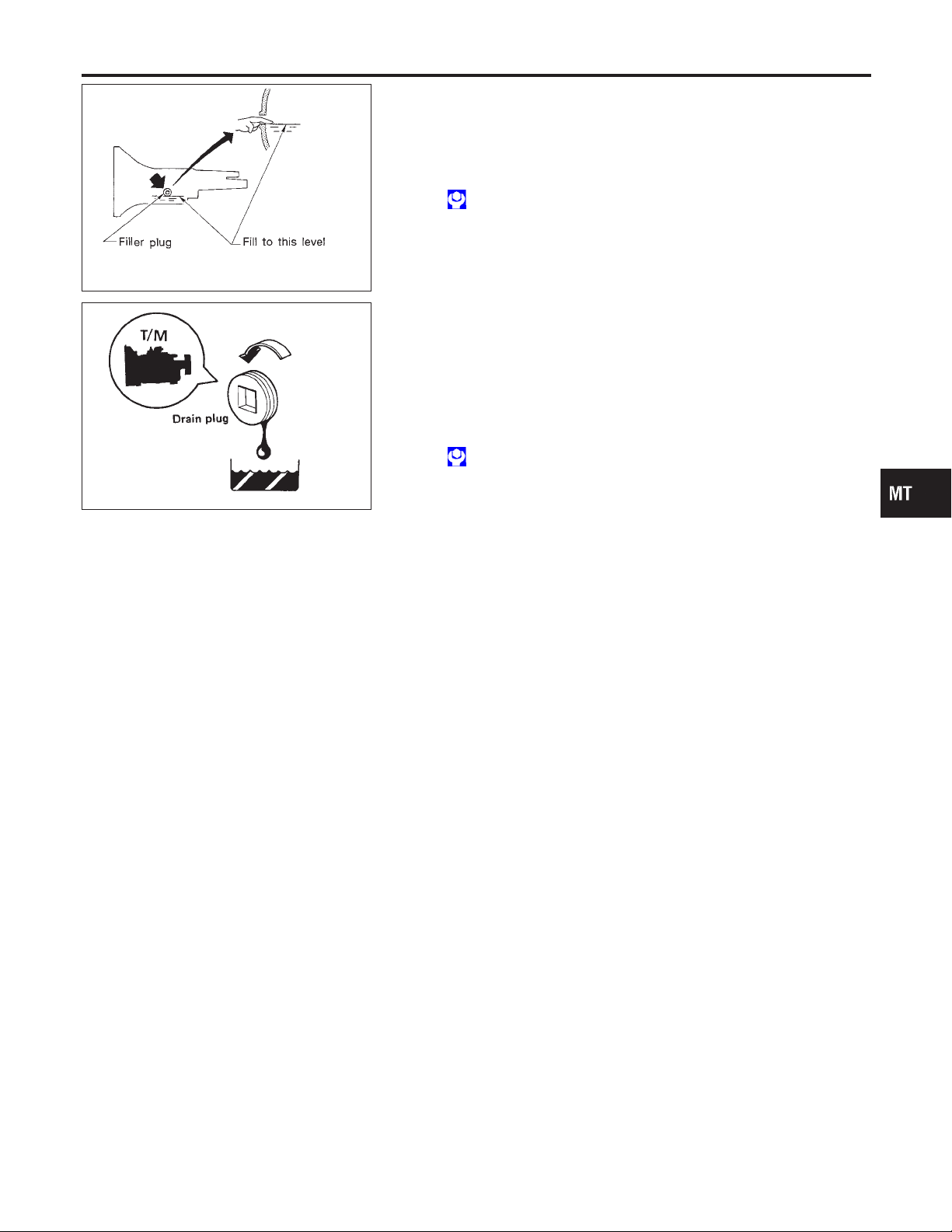

M/T OIL

Checking M/T Oil

SMA103

SMA255A

Checking M/T Oil

Never start engine while checking oil level.

1. Check manual transmission for leakage.

2. Check oil level.

Filler plug:

: 27 - 48 N·m (2.7 - 4.9 kg-m, 20 - 35 ft-lb)

Changing M/T Oil

Oil grade and viscosity:

Refer to “RECOMMENDED FLUIDS AND

LUBRICANTS”, MA-8.

Oil capacity:

FS6R92A 1.8 liters (3-7/8 US pt, 3-1/8 Imp pt)

Drain plug:

: 27 - 48 N·m (2.7 - 4.9 kg-m, 20 - 35 ft-lb)

NMMT0061

GI

MA

EM

LC

NMMT0062

EC

FE

CL

AT

PD

AX

SU

BR

ST

RS

BT

HA

MT-7

SC

EL

IDX

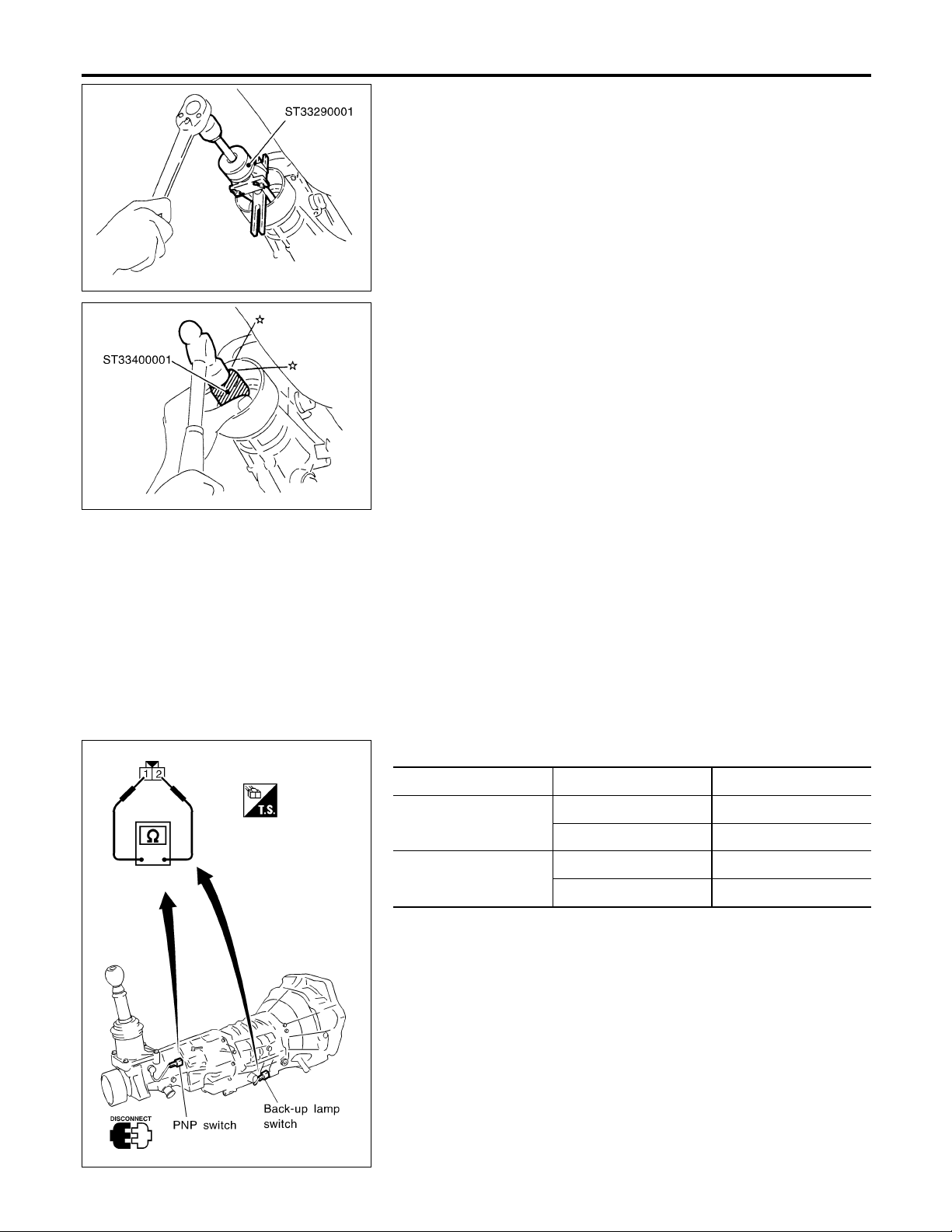

Replacing Rear Oil Seal

ON-VEHICLE SERVICE

FMT001

FMT002

Replacing Rear Oil Seal

REMOVAL

NMMT0003

NMMT0003S01

1. Remove the propeller shaft.

2. Using a oil seal puller (SST), remove the oil seal.

INSTALLATION

NMMT0003S02

1. Apply multi-purpose grease to the oil seal lips. Then, drive the

oil seal with a drift (SST) until the oil seal is flush with the end

surface of the case.

CAUTION:

I Do not reuse the removed oil seal. Always use a new oil

seal.

I Install the oil seal so that it is fit level without inclination.

2. Install the propeller shaft.

CAUTION:

If oil has leaked during this operation, check the oil level after

completing the operation.

SMT056E

Position Switch Check

Switch Gear position Continuity

Back-up lamp switch

Except reverse No

PNP switch

Except neutral No

MT-8

NMMT0004

Reverse Yes

Neutral Yes

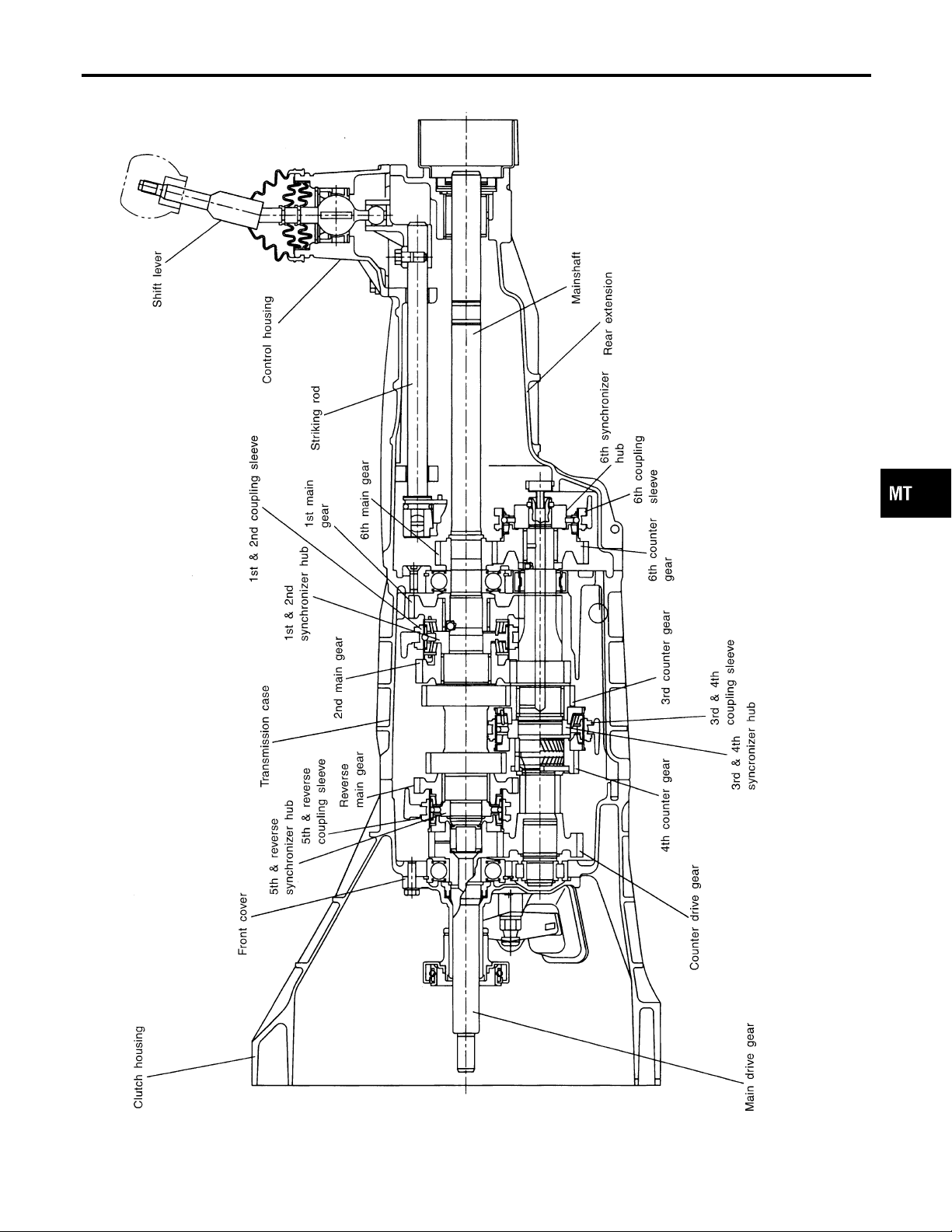

DESCRIPTION

NMMT0005

Cross-sectional View

Cross-sectional View

NMMT0005S01

GI

MA

EM

LC

EC

FE

CL

AT

PD

AX

SU

BR

ST

RS

BT

HA

MT-9

FMT003

SC

EL

IDX

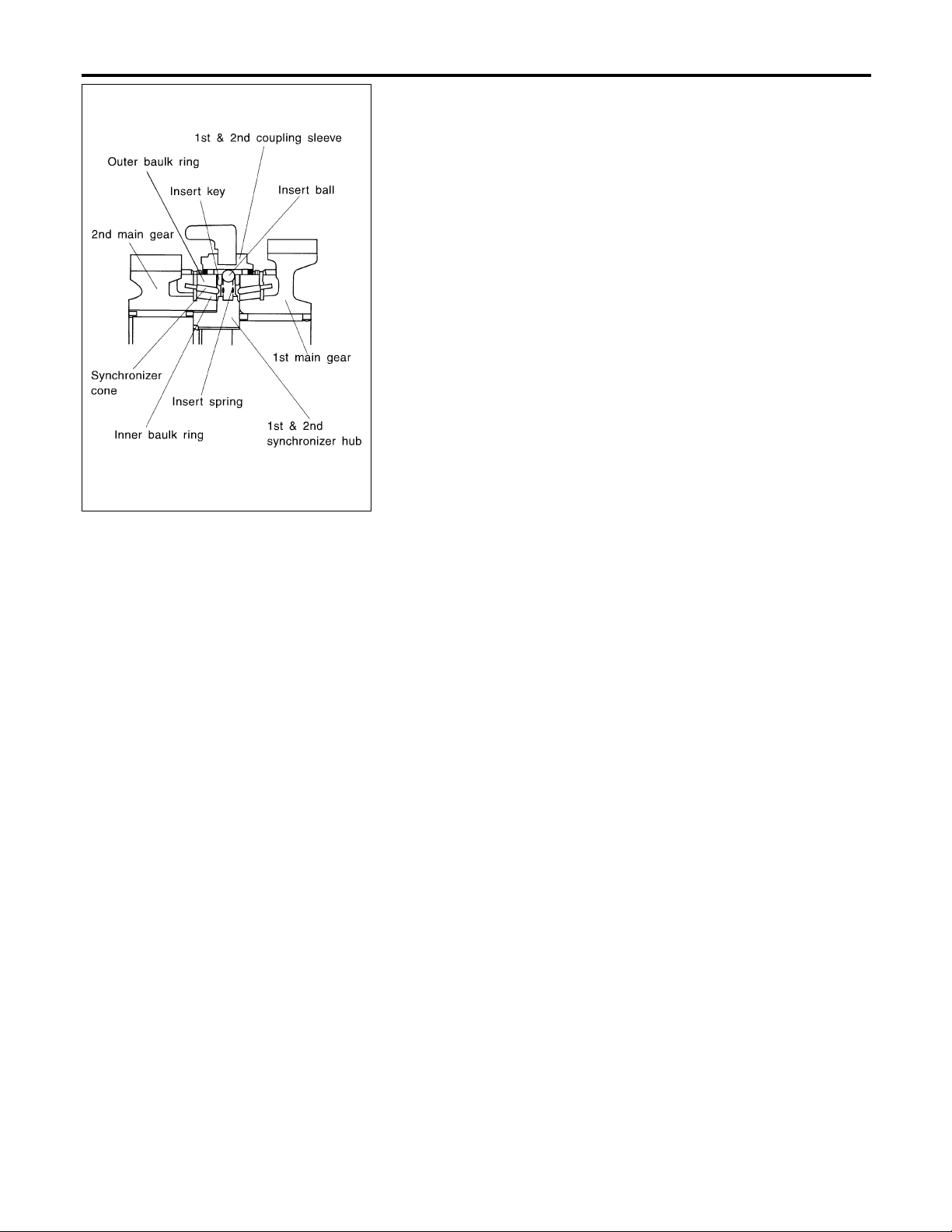

Triple Cone Synchronizer

DESCRIPTION

JMT060E

Triple Cone Synchronizer

NMMT0005S03

The triple conesynchronizer is usedfor the 1st,2nd, and 3rdgears.

Made up mainly of the outer baulk rings, inner baulk rings and

synchronizer cones, the triple cone synchronizer is designed to

provide smoother shifting operations, by obtaining higher synchronization through the three co-axial cone-shaped surfaces where

friction is borne.

This triple cone synchronizer, using the inner surface of the inner

baulk ring and the cone-shaped area of the gear as friction

surfaces, in addition to the two friction surfaces of the existing

double cone synchronizer mechanism, generates higher synchronization.

MT-10

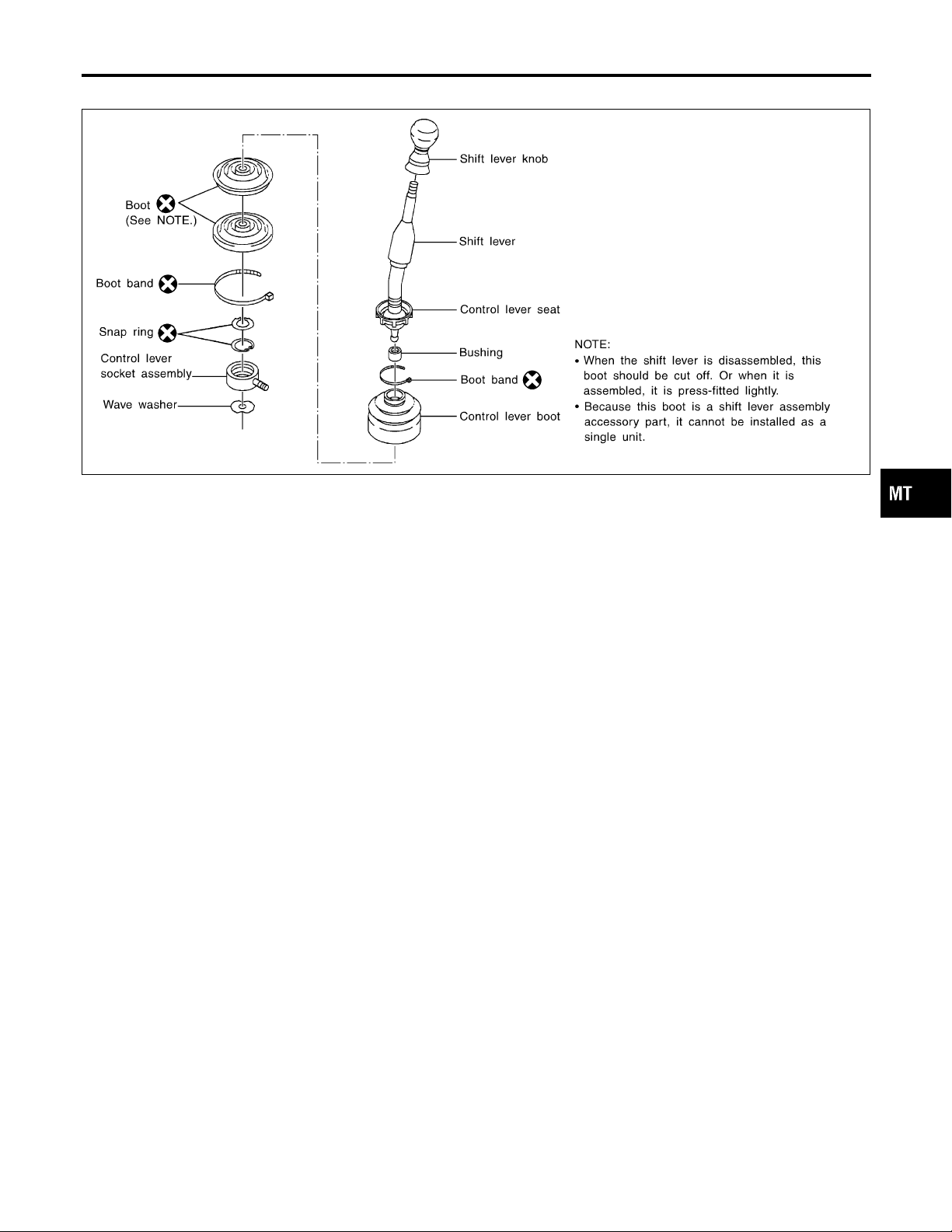

SHIFT CONTROL

Components

Components

NMMT0063

GI

MA

EM

LC

EC

FE

CL

JMT069E

AT

PD

AX

SU

BR

ST

RS

BT

HA

MT-11

SC

EL

IDX

Removal

NMMT0006

REMOVAL AND INSTALLATION

Removal

NMMT0006S01

FMT004

1. Remove battery negative terminal.

2. Remove shift lever with control housing from transmission.

3. Remove clutch operating cylinder from transmission. Tighten

clutch operating cylinder to the specified torque. Refer to CL-5,

“CLUTCH SYSTEM”.

CAUTION:

Never depress the clutch pedal during removal.

4. Disconnect speed sensor, back-up lamp switch, rear heated

oxygen sensor and PNP switch harness connectors.

5. Remove starter motor from transmission.

: 41 - 52 N·m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

6. Remove propeller shaft. Refer to PD-5, “Remova and Installation”.

I Insert plug into rear oil seal after removing propeller shaft.

I Be careful not to damage spline, sleeve yoke and rear oil

seal when removing propeller shaft.

7. Remove exhaust tube mounting bracket from transmission.

Refer to FE-11, “EXHAUST SYSTEM”.

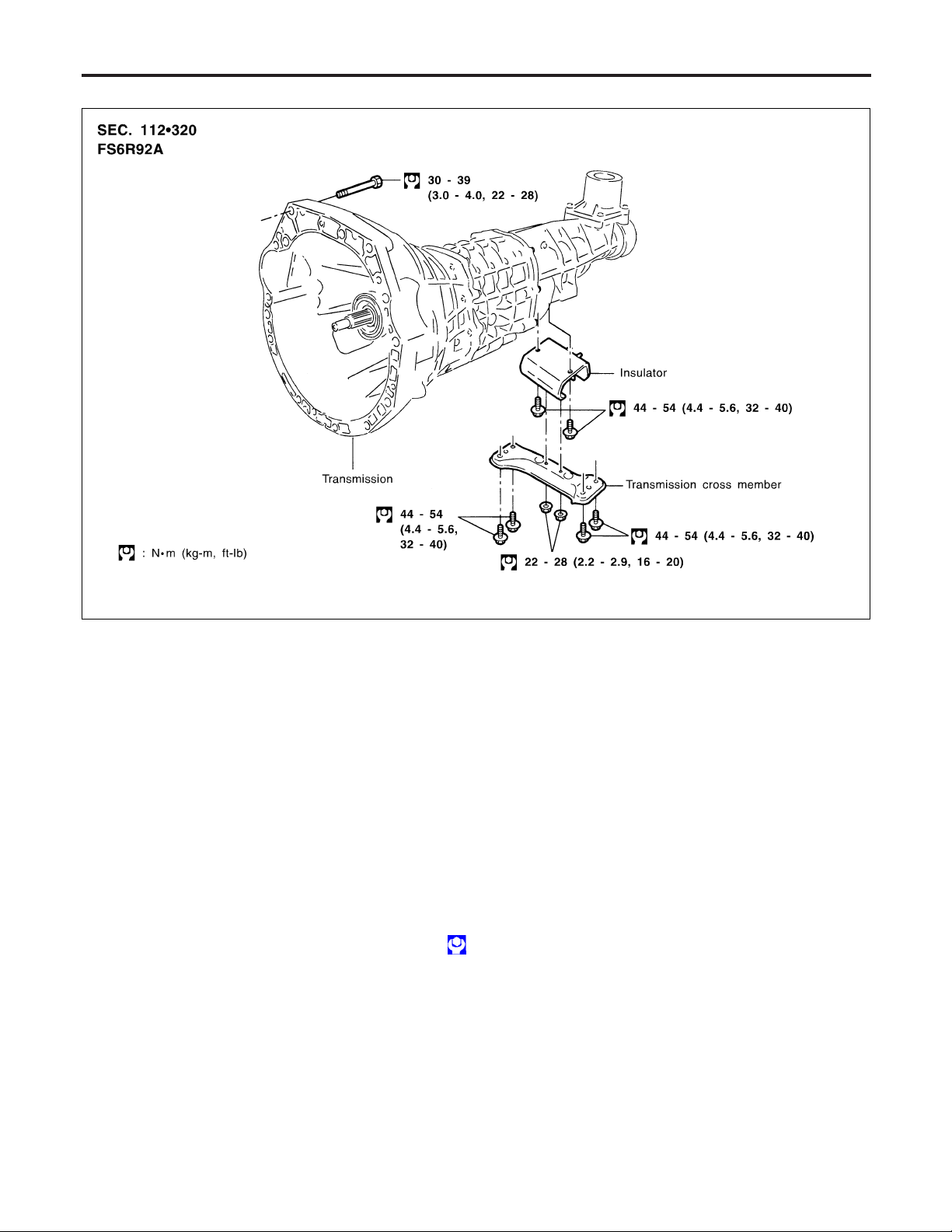

8. Support manual transmission with a jack.

9. Remove engine rear member.

10. Lower manual transmission as much as possible.

MT-12

REMOVAL AND INSTALLATION

WARNING:

Support manual transmission while removing it.

Installation

I Install in the reverse order of removal.

Removal (Cont’d)

GI

MA

EM

LC

NMMT0006S02

EC

FE

CL

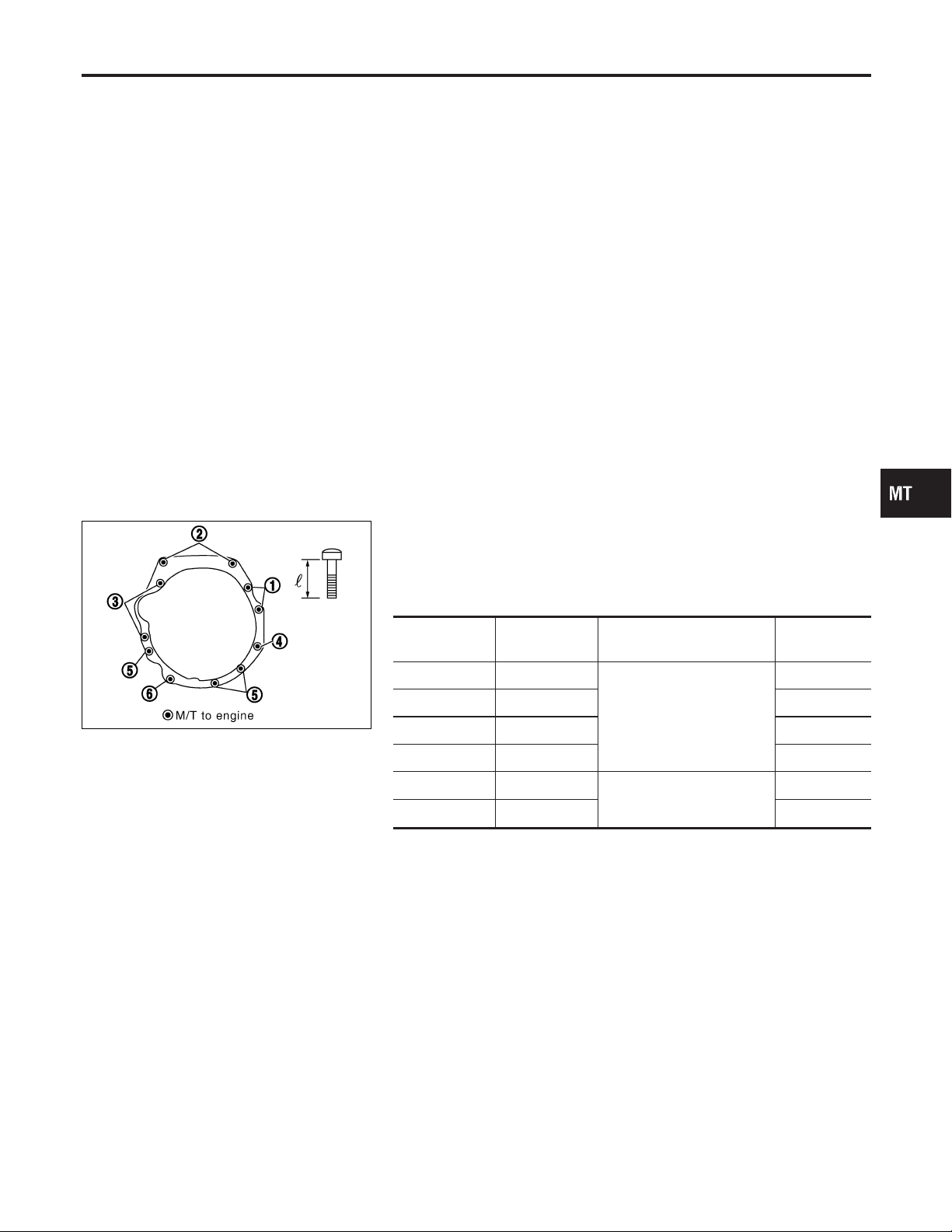

SMT058E

I Tighten bolt securing transmission.

CAUTION:

When installing the transmission, perform carefully so that the

main drive shaft of the transmission does not contact the

clutch cover.

Bolt No. PCS

1 2

2 2 63 (2.48)

3 2 113 (4.45)

4 1 98 (3.86)

5 3

6 1 95 (3.74)

Tightening torque

N·m (kg-m, ft-lb)

70 - 79 (7.1 - 8.1, 52 - 58)

30 - 39 (3.0 - 4.0, 22 - 28)

mm (in)

86 (3.39)

95 (3.74)

AT

PD

AX

SU

BR

ST

RS

BT

HA

MT-13

SC

EL

IDX

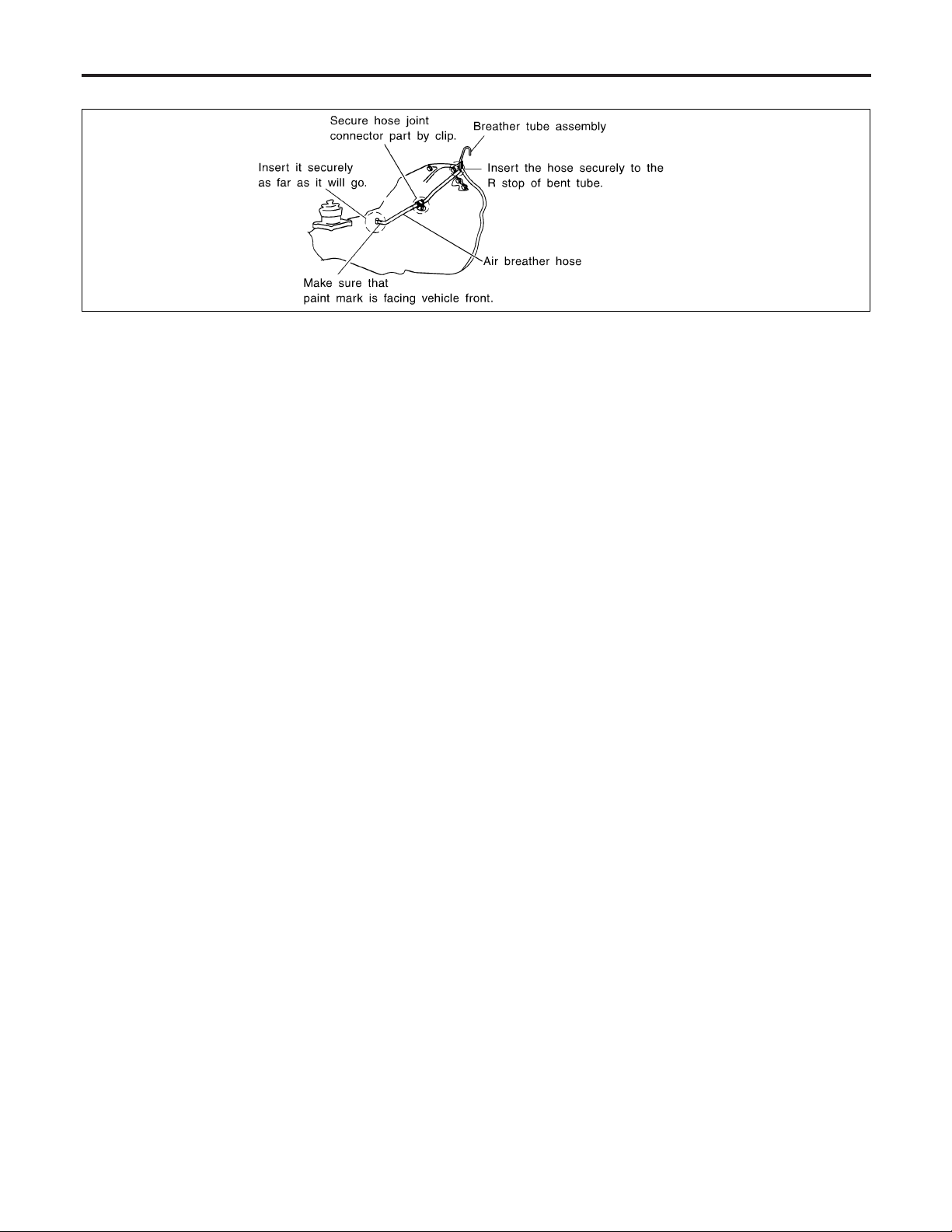

Air Breather Hose

REMOVAL AND INSTALLATION

Air Breather Hose

NMMT0006S03

JMT059E

Refer to the figure above when removing or installing the air

breather hose.

CAUTION:

Make sure there are no pinched or blocked areas in the air

breather hose caused by bending or winding when installing

it.

MT-14

Loading...

Loading...