Page 1

MAGNETIC PRINTER

22 A1 13NS REV5

VARYPRESS 200

Site preparation guide

Page 2

Page 3

MAGNETIC PRINTER

NIPSON SAS

28, rue E. Thierry-Mieg - BP 257 - 90005 Belfort Cedex - France

Tel.: +33 (0)3 84 54 50 00 - Fax: +33 (0)3 84 54 52 18

http:/www.nipson.com - e-mail: info@nipson.com

VARYPRESS 200

Site preparation guide

MATERIEL

Document release:

REV0 July 2004. Creation.

REV1 Jan. 2006. Update with 90 m/min and operating conditions.

REV2 Jan. 2007. Information added about UPS.

REV3 July 2007. Update information about connection to the network.

REV4 Oct. 2007. Update operating conditions.

REV5 Fev. 2008 Update with pressure and ground loading/unit added.

22 A1 13NS REV5

Page 4

© NIPSON 2004

All rights reserved

We will be pleased to receive any suggestions concerning the form and content of this manual.

A sheet on which to write your remarks is provided at the end of this manual.

This document is for information purposes only. NIPSON cannot be held responsible for any damage caused by applying

instructions contained within it. Corrections or modifications to the content of this document may be made without notice;

they may be communicated to recipients in later updates.

22 A1 13NS REV5

ii

Page 5

Site preparation manual

VARYPRESS 200

Table of contents

1. GENERALITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.1 CHARACTERISTICS OF THE PRINTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 MACHINE PACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 TEMPERATURE AND HUMIDITY REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 AIR CONDITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 PAPER STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.6 TONER STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.7 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.7.1 Cleaning of the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.7.2 Cleaning of the room - dust accumulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1.8 SPECIFIC TOOL FOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

2. SITE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 PRINTER PHYSICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.1 Printer dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2.2 Air conditioning unit for write heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.2.3 Floor space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.2.4 Raised floor cutouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2.2.5 Installing a pumping system at the filtration unit outlet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.5.1 Standard filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

2.2.5.2 Option with internal smoke filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.2.6 Location of the T.E.D. printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

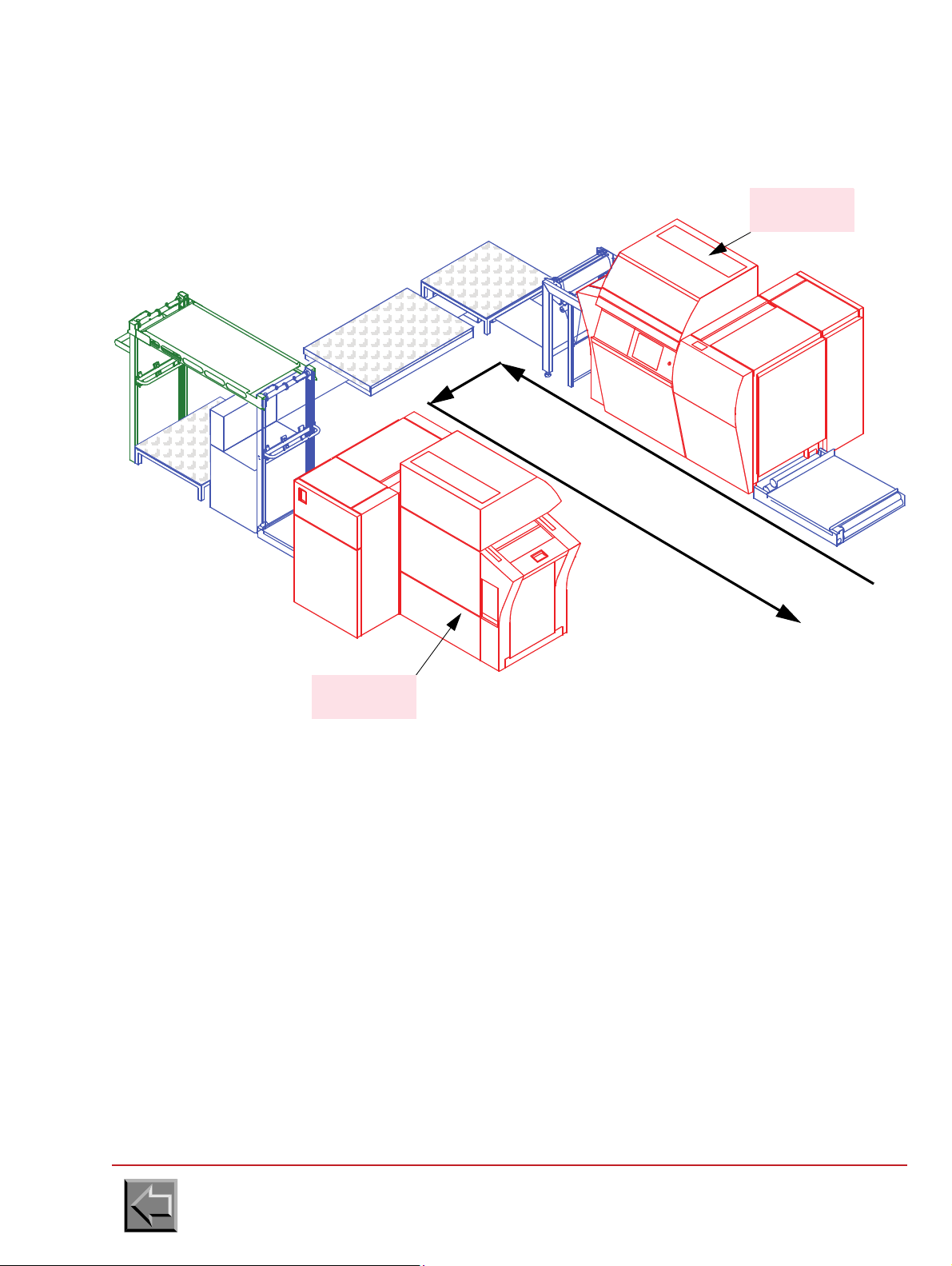

2.2.6.1 L-shaped installation (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.2.6.2 U-shaped installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

2.2.6.3 S-shaped installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

2.2.6.4 Z-shaped installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

2.2.6.5 I-shaped installation (in line) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.3 ELECTRICAL REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.3.1 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.3.2 Leakage current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.3.3 Mains power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2.3.4 Main circuit breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.3.5 Printer main cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2.3.6 Pre and post processing ground wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.3.7 Air conditioning unit for write heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.3.8 Electrical connection of web cleaner option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2.3.9 T.E.D. motorised loop (U-shaped or S or Z) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Return to Start

iii

Page 6

Site preparation manual

VARYPRESS 200

Table of contents

2.3.10 U.P.S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

2.4 REMOTE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

2.5 INTERFACE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.5.1 Printer with LAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.5.1.1 Connection to the factory network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

2.5.1.2 Connection to the adapted network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.5.1.3 Connection to the isolated network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

2.5.2 Connection of the printer to the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.5.2.1 VPServer connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.5.2.2 U_NetPSF connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.5.2.3 E_NetPSF connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.5.2.4 OpenPage connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

2.5.3 Connection to the host system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.5.3.1 VPServer connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.5.3.2 Connection to PRESS V4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

2.5.3.3 Connection to PRINTNET V3 from GMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

2.5.3.4 Connection to PRINTNET T from GMC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

2.5.3.5 Connection to OS390 + MVS from IBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

2.5.3.6 Connection to InfoPrintManager from IBM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

2.5.3.7 SDP Protocol Network Interface (OpenPage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

2.6 UNPACKING AND INSTALLATION PREPARATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.6.1 Unloading the lorry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.6.2 Unpacking the modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

2.6.3 Moving the printer to the customer's computer room . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-45

3. PRE / POST PROCESSOR DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1 IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 INTERFACE CONNECTOR DEFINITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.3 INPUT/OUTPUT SIGNALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.1 Signals from printer to pre-post processing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.3.2 SIGNALS FROM PRE-POST PROCESSING DEVICE TO PRINTER. . . . . . . . . . . . . . . . . . . . . . 3-5

3.3.3 Signals from camera system to printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

3.3.4 Output signals from printer to camera system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.4 ELECTRICAL SIGNAL SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.4.1 Signals from printer to the external device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.4.2 Signals from the external device to the printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

3.5 CABLES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.5.1 Cable between printer and pre/post processor devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.5.2 Common earth connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Return to Start

iv

Page 7

Site preparation manual

VARYPRESS 200

Table of contents

3.6 TIMINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3.6.1 Timing of the printer speed change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-12

3.6.2 start/stop signal steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3.7 REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.7.1 Using a pre processor device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3.7.2 Using a post processor device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3.7.3 Using a post processor device with a printer in S.E.D. mode . . . . . . . . . . . . . . . . . . . . . . . . 3-15

4. ST20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1 PRODUCT PACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 PHYSICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.2.1 Standard ST20 stacker dimensions and clearance areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2.2 Dimensions and clearance areas of ST20 90° . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2.3 Raised floor cutouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.1 Mains voltage supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.2 Mains connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.3 Main switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 AMBIENT OPERATING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.5 INTERFACE SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.5.1 Interface connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5.2 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5.3 Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.5.4 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.5.5 Electric specification of the signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.5.6 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

5. PAGE PRINTER IMPLEMENTATION PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Return to Start

v

Page 8

Site preparation manual

VARYPRESS 200

Table of contents

Return to Start

vi

Page 9

Site preparation manual

VARYPRESS 200

1. Generalities

1.1 CHARACTERISTICS OF THE PRINTER

The NIPSON printer is a non impact printer which uses a magnetographic printing process.

It is a page printer accepting continuous fanfold paper.

The VaryPress 200 printer is available in 3 speed models.

1. VaryPress 200-30:

the speed can be set at a speed ranging between 30 and 90 m/min (by step of 1m/min) or speed

can vary automatically between 30 and 90 m/min.

2. VaryPress 200-20:

the speed can be set at a speed ranging between 30 and 70 m/min (by step of 1m/min) or speed

can vary automatically between 30 and 70 m/min.

3. VaryPress 200-10:

the speed can be set at a speed ranging between 30 and 50 m/min (by step of 1m/min) or speed

can vary automatically between 30 and 50 m/min.

The pinless printer accepts caroll pinfeed paper and pinless paper.

The S.E.D. printer is composed of a printer and a paper turning system.

The first side (recto) is printed on the first passage of the sheet, then the second side is printed

(verso) after the paper has passed under the printer and been turned and the paper width shifted

horizontally. The first side is placed on the operator side.

The T. E. D. p ri nte r is composed of two printers. The first side (recto) is printed on theNipson

upstream printer, and the second side on the downstream printer after mechanical turning of the

paper.

VP200-10 VP200-20 VP200-30 -10 SED -20 SED

Simplex printing XXXXX

Duplex printing Option TED Option TED Option TED X X

Paper Pin-fed XX

X

(up to 70m/min)

XX

Paper Pinless Option Option X

Go to "Table of contents"

1-1

Option

(simplex)

Option

(simplex)

Page 10

Site preparation manual

VARYPRESS 200

The main printing characteristics are:

- Paper weight:

- for standard printer, 64 to 160 g/m

2

- for pinless using: with roll, 64 to 160 g/m2

fanfold, 64 to 90 g/m

2

these ranges can be increased from 40 to 250 g/m2 after tests at NIPSON

- Resolution: 600 DPI : 600 x 600 dots/square inch (555 dots/mm

300 DPI : 300 x 300 dots/square inch (140 dots/mm

2

)

2

)

- Printing orientation: 0º, 90º, 180º or 270º with respect to paper folds,

- Maximum print width: 18,45"

- Paper of different standard formats:

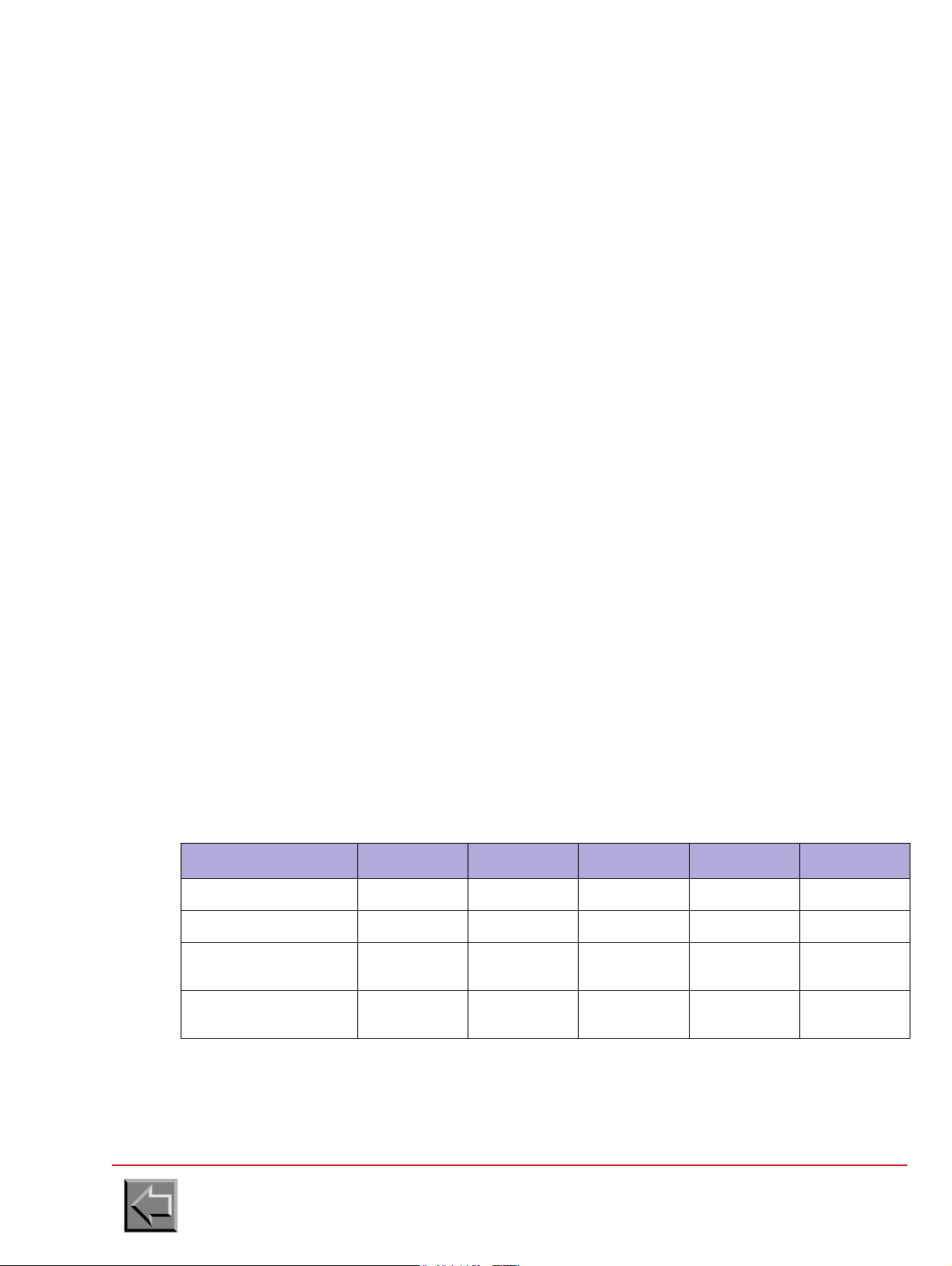

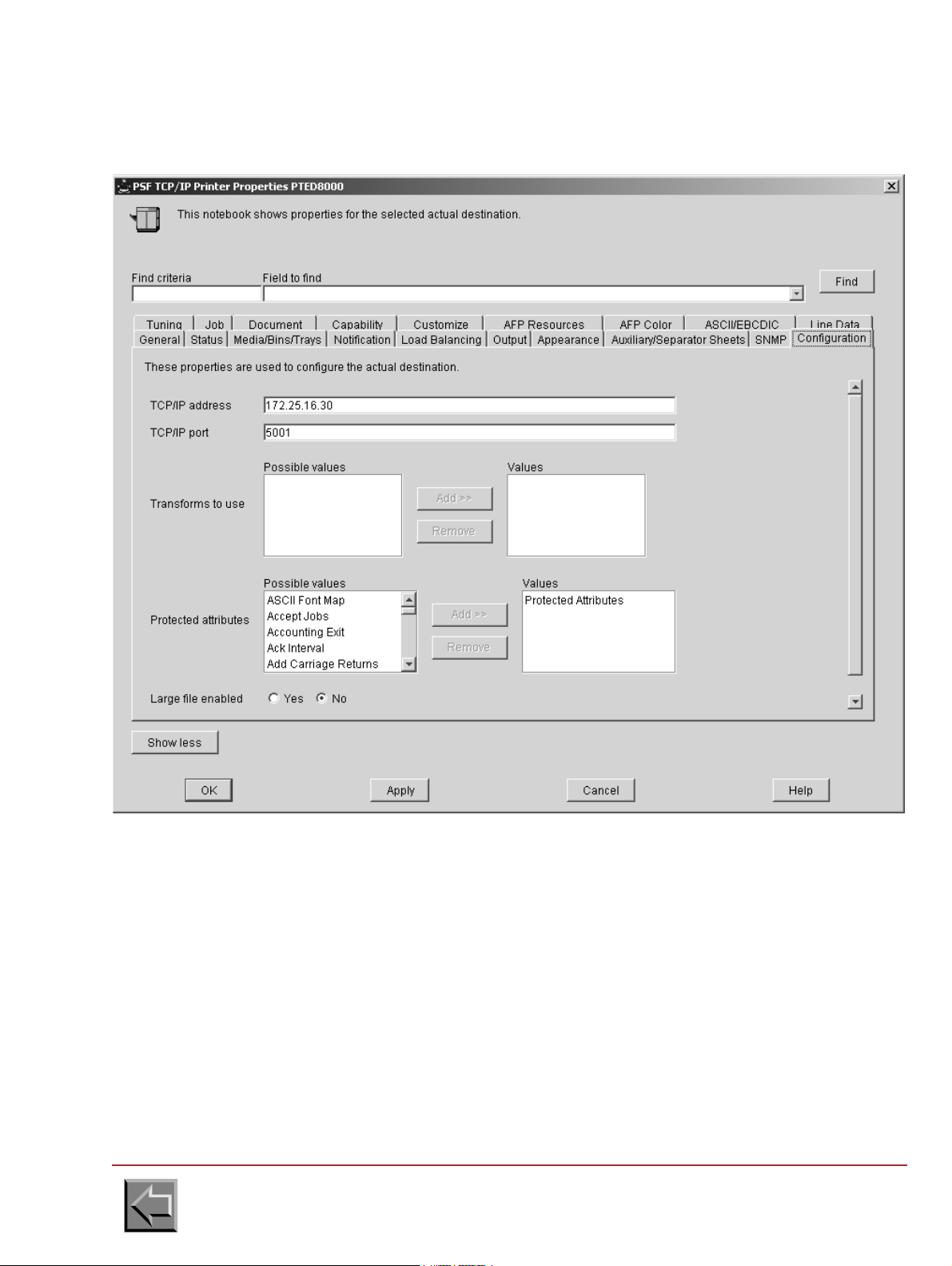

Machine Mini length Maxi length Mini width Maxi width

Simplex

Pin-fed

Simplex Pinless

TED Pinless & Pin-

fed

3"

76 mm

6"

152 mm

6"

152 mm

36"

915 mm

24"

610 mm

18" *

457 mm

6.5"

165 mm

6.5"

165 mm

6.5"

165 mm

20.5"

520 mm

20.5"

520 mm

20.5"

520 mm

SED

with ST20

* This height can be increased to 24" after test and if required the addition of the multi-loop

option.

1.2 MACHINE PACKING

Each module of the machine is secured to a pallet and covered with a sealed bag.

Each assembly is packed in a cardboard box which is fixed to the pallet.

The unpacking leaflet is fixed outside the packaging.

Dimensions of pallets Printing module Fixing module

Length 1700 mm 1780 mm

Depth 1600 mm 1130 mm

Height 1720 mm 1900 mm

NOTE: Printer unpacking, without packaging destruction requires a free height of at least 3.50 m.

6"

152 mm

6"

152 mm

18"

457 mm

17"

432 mm

7.5"

190 mm

6.5"

165 mm

9.9"

251 mm

20.5"

520 mm

Go to "Table of contents"

1-2

Page 11

Site preparation manual

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

(°C)

(%)

15° dew point

11° dew point

Tolerated operating conditions with risks of

degradation of the print quality.

It may be necessary to reduce the print speed

or perform more preventive maintenances.

Recommended

operating

conditions

Relative humidity

VARYPRESS 200

1.3 TEMPERATURE AND HUMIDITY REQUIREMENTS

The conditions described here correspond to the current printers which are delivered with graphite

drums.

the old versions of printers with CrC drums have different operating conditions, those are described in

§ 6.3.2.2 of the product manual.

- Temperature: 15ºC to 26ºC (optimum 20ºC),

- Relative humidity: 5% to 70% (optimum 45-50%).

- Absolute ambient humidity: 1 to 9 g

H2O

/Kg

dry air

However maximal values of temperature and relative humidity must not be reached together (see

below).

- Atmospheric pressure must be between 562 and 780 mm Hg.

- Heat dissipation

The printer room must be able to remove heat generated by the printer.

CAUTION: Since the T.E.D. printer is composed of two standard printers, the heat given off

Average heat dissipation

heat dissipation

Go to "Table of contents"

with air extraction

heat dissipation

without air extraction

is double that of the standard machine.

Print speed

50 m/min 70 m/min 90 m/min

50 KBTU/h 50 KBTU/h 50 KBTU/h

12 Mcal/h 12 Mcal/h 12 Mcal/h

60 KBTU/h 84 KBTU/h

15 Mcal/h 21 Mcal/h

1-3

Page 12

1.4 AIR CONDITIONING

The air-conditioned room must be built according to current building standards and respect the

following points:

- Controlling and adjusting the temperature :

Temperature gradient should not exceed ± 4 ºC/h.

- Controlling and adjusting the relative humidity.

Relative humidity gradient should not exceed ± 8 %/h.

- Filtering the circulated air.

Signalling for conditions which are out of tolerance.

- Introduction of new air and evacuation of old air with rate determined according to the following

criteria:

Site preparation manual

VARYPRESS 200

-70 m

-45 m

3

/h per printer at 60 m/min and 100 m3/h per printer at 90 m/min

or

3

/h per person working in the room

or

- according to current legislation for the locality.

The maximum value from the three values determined above will be chosen as the minimum

air renewal rate required.

- The printer will be installed below an air outlet.

Go to "Table of contents"

1-4

Page 13

1.5 PAPER STORAGE

Toner is supplied in sealed containers which should be stored with cap upward.

Storage conditions

- Paper must not be removed from its original packaging.

- Isolate the cartons and rolls from the floor.

- To avoid a thermal shock, do not store the rolls and the cartons close to a heat source or

opened windows.

- The paper should be protected from physical shocks.

- The packaging must be opened only when the paper is to be used.

- Climatic conditions must be as close as possible to utilization conditions:

- temperature: 18 ºC to 30ºC,

- Humidity: 30 % to 70 % relative humidity.

Site preparation manual

VARYPRESS 200

Storage conditions outside these limits may be followed by a suitable stabilization period

before use.

- In case paper is stored in an area where the temperature is different from the printer room

temperature by more than 5ºC , it is necessary to respect minimum storage times for paper

brought into the printing room, according to the following table:

Difference of temperature Minimum stabilization

between paper storage time before use

room and printing room

The time required to eliminate a relative humidity difference in the paper depends on its

packaging and must be determined by measurements with hygrometric knife.

1.6 TONER STORAGE

Toner is supplied in sealed containers which should be stored with cap upward.

6ºC to 12ºC 2 days

12ºC to 18ºC 3 days

18ºC to 22ºC 5 days

22ºC to 28ºC 7 days

Storage conditions:

- Temperature: 18° to 30°C,

with a maximum temperature, even for short duration

(some hours), of 38º C.

- Relative humidity (RH): < 70 %.

Go to "Table of contents"

1-5

Page 14

1.7 CLEANING

1.7.1 Cleaning of the printer

The printer should be maintained and cleaned regularly to remove paper and toner particles which

may adhere to it.

For printer cleaning and toner box emptying, the customer must use a vacuum cleaner equipped

with an external absolute filter.

This vacuum cleaner can be ordered with the printer or be provided by the customer and placed at

the field engineer’s disposal during his intervention.

The main characteristics of the vacuum cleaner are:

- 100% main filter.

- Paper waste recovery bag with a capacity of 4-5 liters.

-Vacuum >

- Flexible hose with an external diameter of 32 mm.

Example: NILFISK vacuum cleaner (No. 3970-39).

1.80 m column of water.

It has the following accessories, which can be ordered separately under the following

references:

- Paper bag No. 815300.

- Absolute filter No. 115-650.

- Flexible hose No. 115-435.

Site preparation manual

VARYPRESS 200

1.7.2 Cleaning of the room - dust accumulation

It is recommended that the room of the machines and the associated systems answer the

specifications of the class ISO 8 of standard NF IN ISO 14644-1 relating to the cleanrooms

(corresponding about to the class 100 000 of the Federal Standard 209E).

The table below points out information of the classes concerned.

Standard and class number

Standard

Class ISO 8

Federal Standard 209E

class 100 000

If this recommendation is not respected, that will generate adaptations of the frequencies and

maintenance actions.

The cleaning of the system room and the surrounding areas must be made daily with a particular

care, preferably when the printer is not active, with suitable hardware (for example

NILFISK vacuum cleaner (see above)).

NF EN ISO 14644-1

Maximum permissible concentrations (particles/m3 of air) in

particles of size equal or higher than that given below

0,5 μm 1 μm 5 μm

3 520 000 832 000 29 300

3 530 000 24 700

A thorough cleaning under the raised floor and of the suspended ceiling should be planned to allow

clean passage of air and cables.

This should be done twice per year by professional cleaners.

Go to "Table of contents"

1-6

Page 15

Site preparation manual

VARYPRESS 200

1.8 SPECIFIC TOOL FOR INSTALLATION

To install the printer, the field engineer needs in addition with the standard tools (Allen wrenches,

screwdriver...):

- a pipe wrench of 22 mm

- a wrench of 27mm (flat type, open end)

- a wrench 1" 1/8 and 30 mm (No. 47291681-001)

Go to "Table of contents"

1-7

Page 16

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

1-8

Page 17

Site preparation manual

VARYPRESS 200

2. Site requirements

2.1 INTRODUCTION

This section provides the information required for the development of a layout of the printer

installation. This layout must be ready before the delivery of the printer.

The following subjects are covered:

- Physical specifications.

- Electrical specifications.

- Channel attachment.

2.2 PRINTER PHYSICAL SPECIFICATIONS

2.2.1 Printer dimensions

See figures page 2-2 and page 2-3 for standard printers, page 2-4 and page 2-5 for S.E.D. printer.

The printer is suitable for mounting on concrete or other non-combustible surface only.

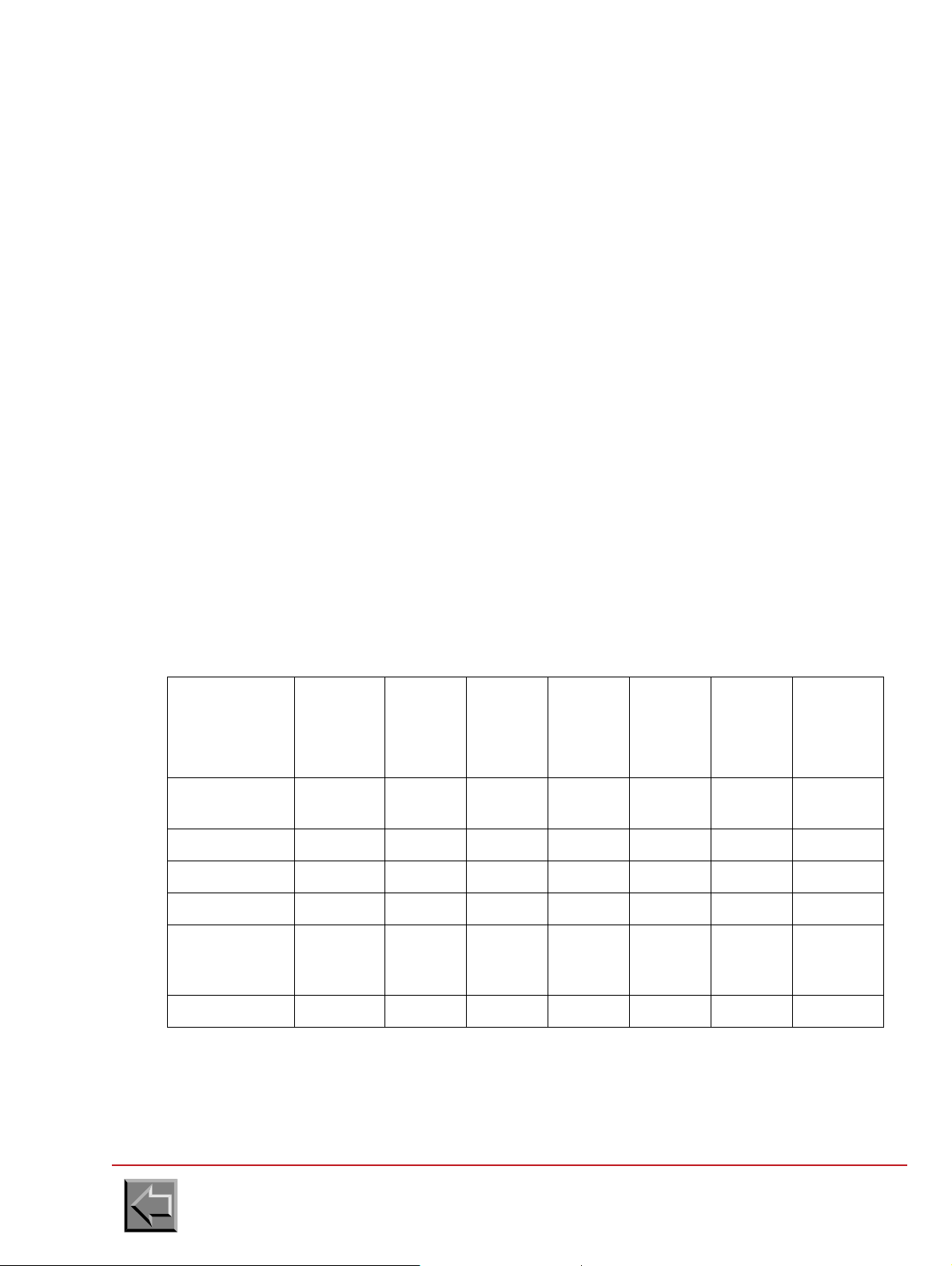

Dimensions and weights of units

2

Pressure

under

casters

2

Kg/cm

Length

mm

Printing

module

Fixing module 1410 1073 1720 600 900 400 270

Footbridge 1030 860 150 95 125

Unfolder 320 640 1600 80 120

Air-

conditioning

unit

850 1600 1425 540 600 400 240

940 740 1230 120 190 200

Depth

mm

Height

mm

Weight

Kg

Packed

weight

Kg

Ground

loading

Kg/m

Dust remover 840 790 1260 60 135

Go to "Table of contents"

2-1

Page 18

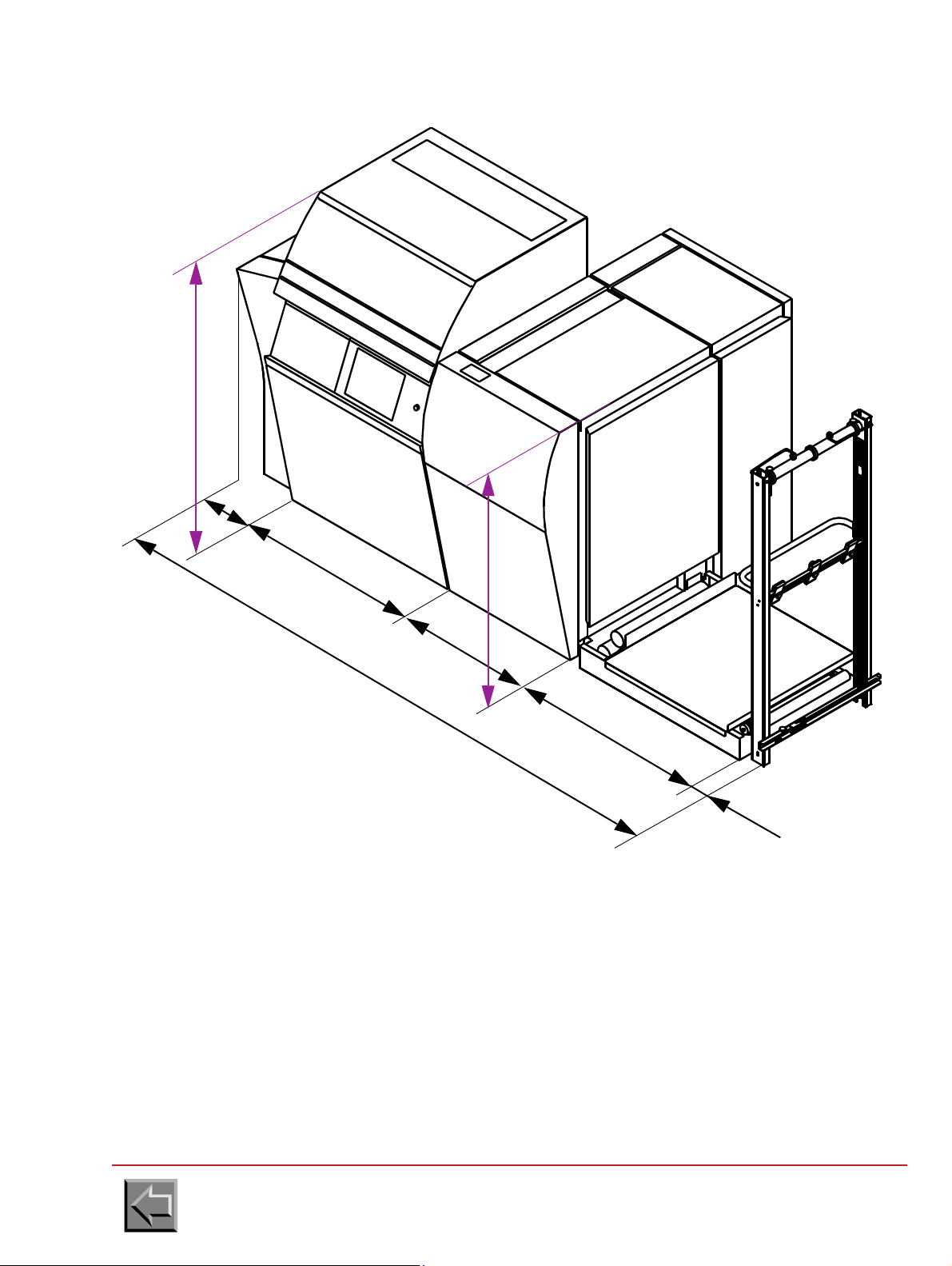

STANDARD PRINTER

Print

module

Fixing

module

Footbrige

1030

1000

790

410

3310

Unfolder

80

1720

1425

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-2

Page 19

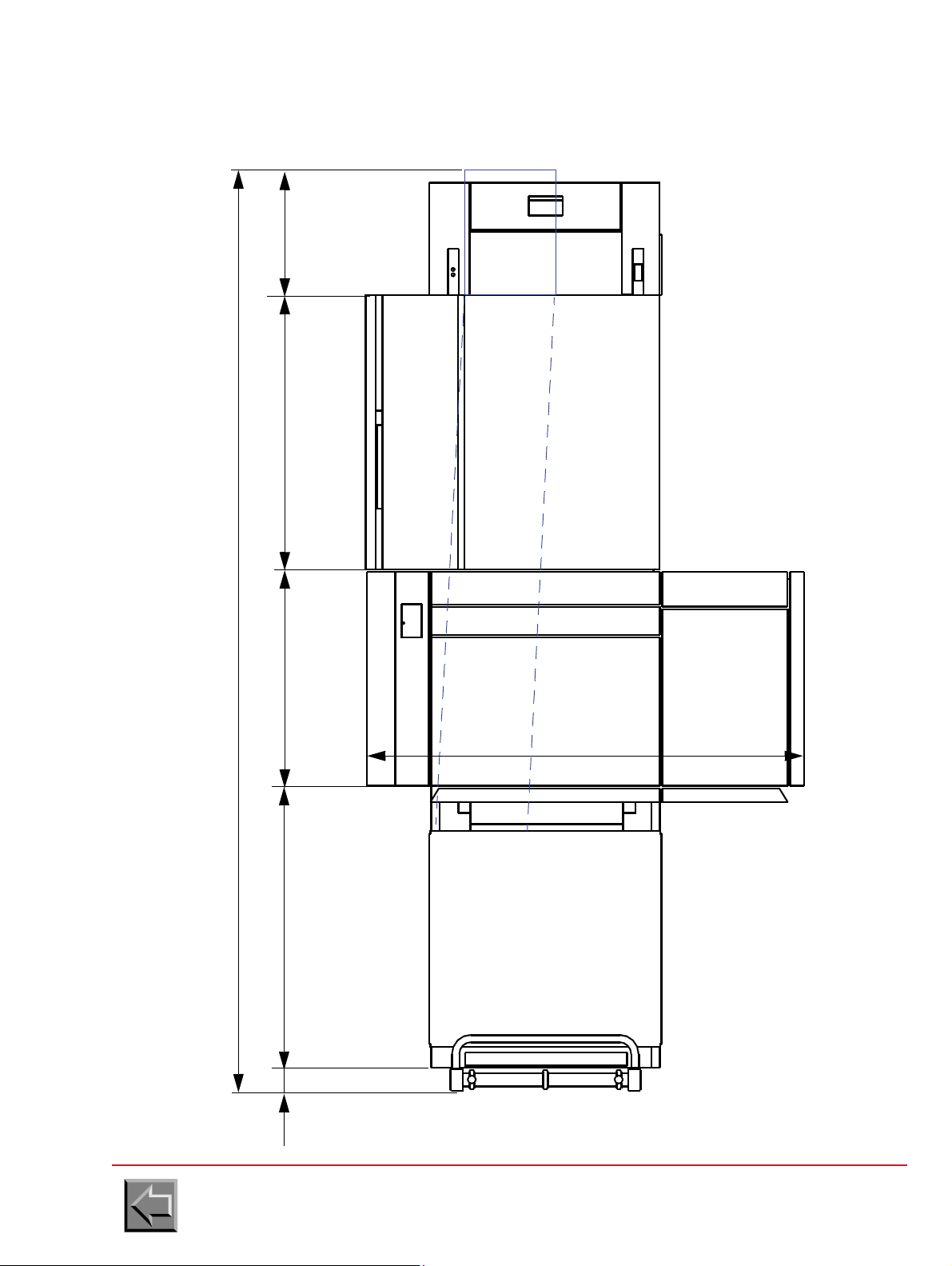

Site preparation manual

POST-PROCESSING

FLASH

FIXING

MODULE

PRINT

MODULE

FOOTBRIDGE / UNWINDER

1000790

2260

410

EXTRACTION

1600

1073

840

EXTRACTION

60

VARYPRESS 200

STANDARD PRINTER

Go to "Table of contents"

2-3

Page 20

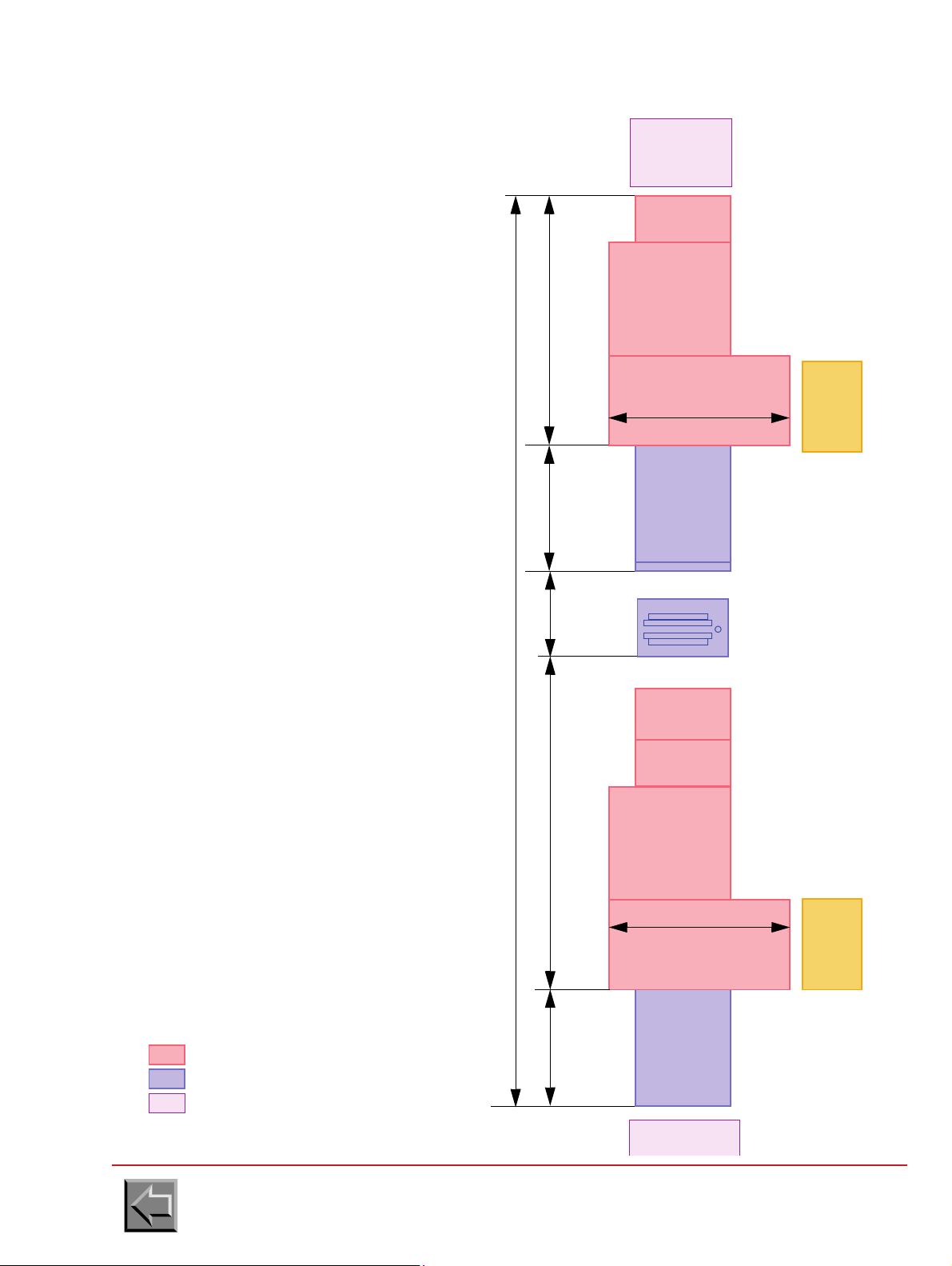

S.E.D. PRINTER

1030

1000

790

500

3400

80

1720

1425

Print

module

Fixing

module

Footbrige

Unfolder

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-4

Page 21

S.E.D. PRINTER

PRINTER

FOOTBRIDGE

103080

UNFOLDER

PAPER CHUTE

POST-PROCESSING

1000790

3400

500

1600

maxi.

PRE-PROCESSING

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-5

Page 22

Site preparation manual

1000

510

8

0

0

Rear view

Overflow pipe

80 mm

VARYPRESS 200

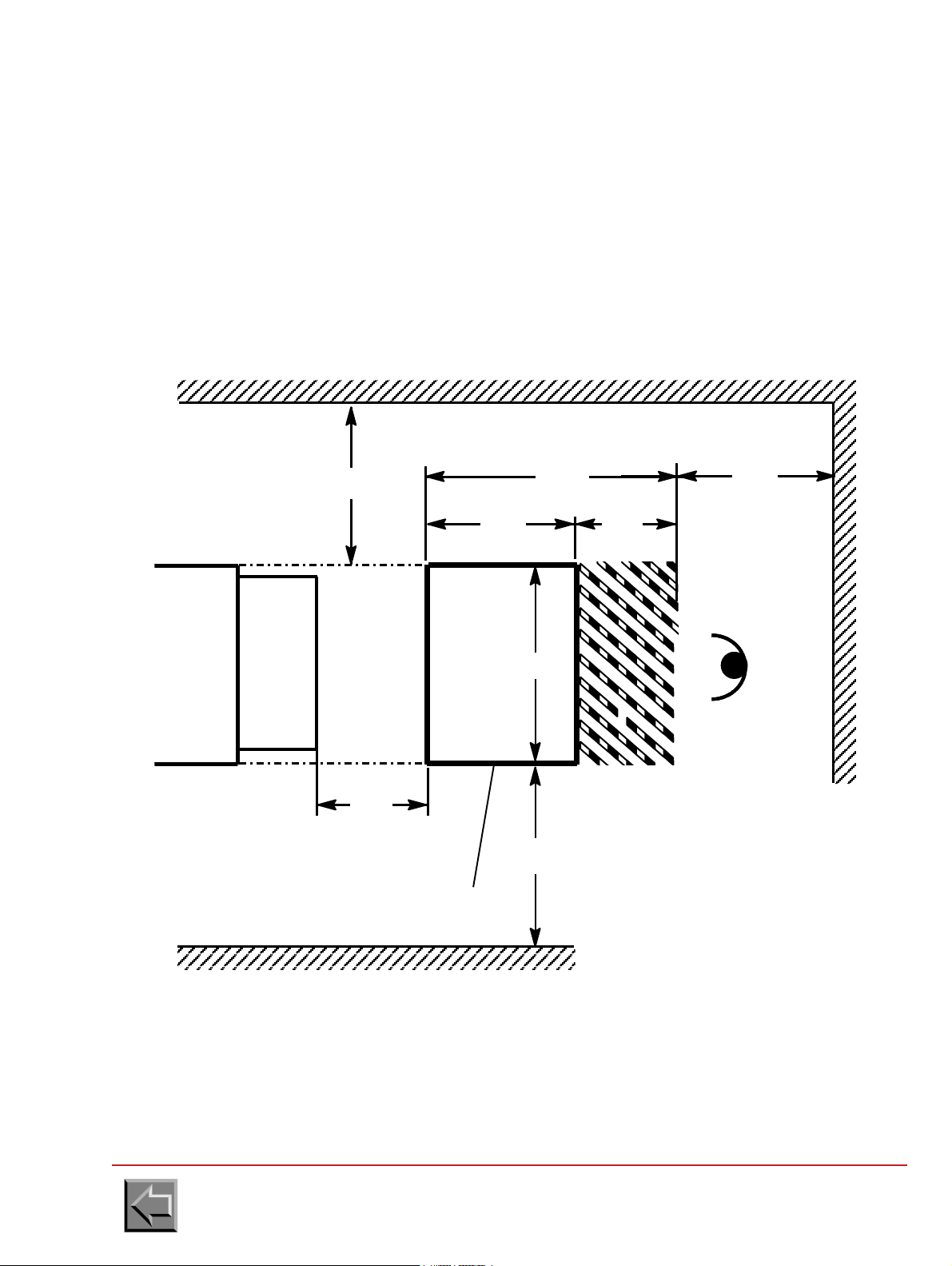

2.2.2 Air conditioning unit for write heads

Dimensions

Lenght: 800 mm

Width: 510 mm

Height: 1000 mm

Weight: 80 Kg

It is recommended to insert a water collecting pan under the air-conditioning unit because water can

flow by the overflow pipe when the air-conditioning unit has an incident (failure of the water level

sensor, the resistance or the thermostat).

When the buildings are wet, it is recommended to use the air-conditioning to drain the ambient air

(complementary information on operation is given in the air-conditioning unit manual).

To dehumidify the ambient air, it is necessary either to join this overflow pipe to the sewer, or to

collect water in a collecting pan under the air-conditioning unit.

Go to "Table of contents"

2-6

Page 23

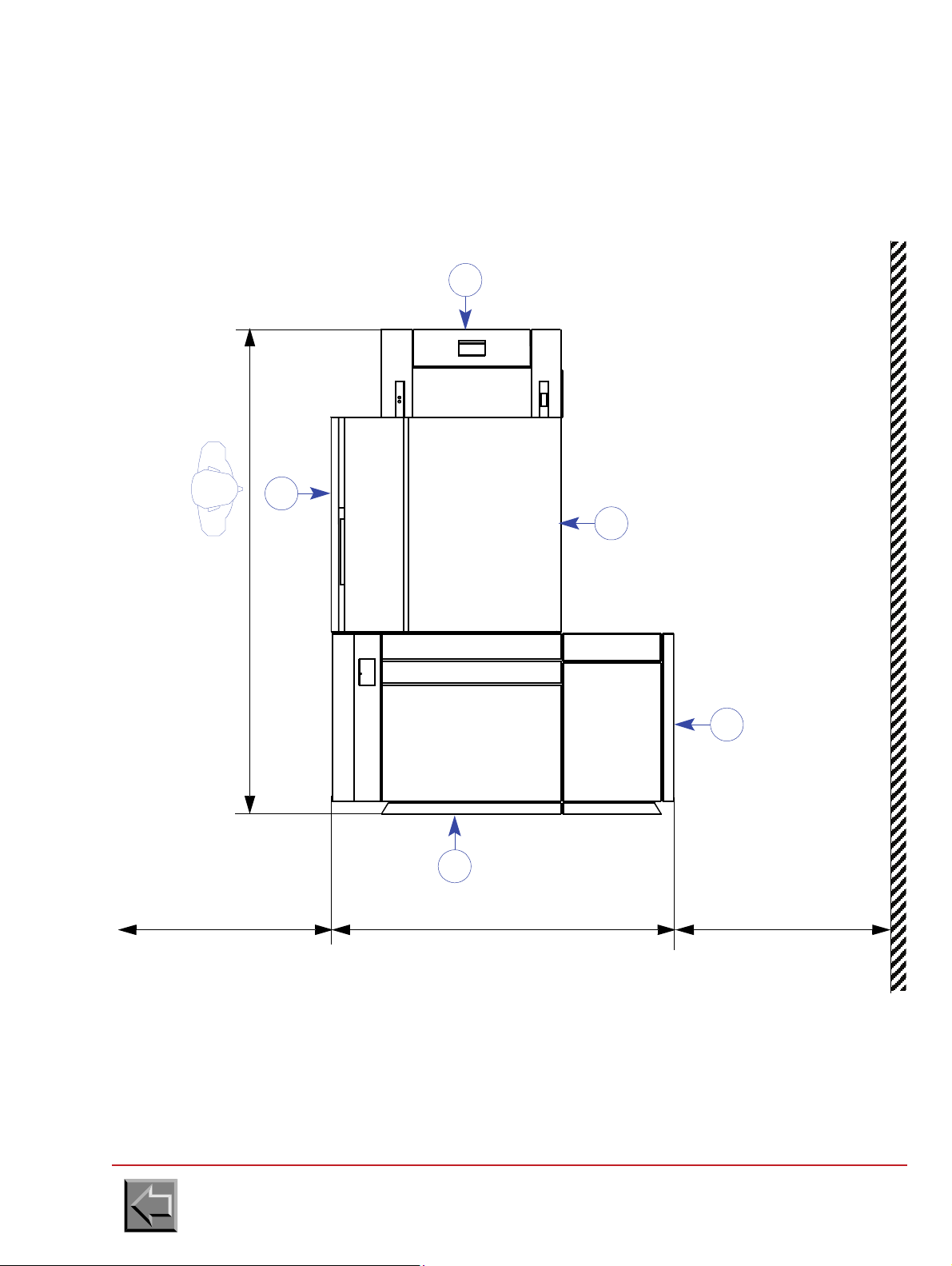

Layout

FOOTBRIDGE

VARYPRESS 200

Air conditioning unit

OPERATOR

1000 maxi

Cable L=1.9m

Pipe L=1.7m

FOOTBRIDGE

VARYPRESS 200

OPERATOR

1400 maxi

300 maxi

Air conditioning unit

1500 maxi

The air-conditioning

unit must be

positioned in this

area

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-7

Page 24

2.2.3 Floor space requirements

2260

1600 10001000

1

4

2

3

PRE-PROCESSING

4

PRINTER

POST-PROCESSING

The floor space requirements defined in this section are the minimum requirements. If the printer is

installed in too small an area, problems will occur when operating the printer.

Site preparation manual

VARYPRESS 200

1 Operator reference side.

2 Access for paper loading, paper splicing, toner refilling and write heads cleaning.

3 Access for paper unloading.

4 Access for field engineer.

Go to "Table of contents"

2-8

Page 25

Doors and covers opening

890

2315

500

Filter door

Toner bottle door

Side door

Front door

790

790

835

460

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-9

Page 26

2.2.4 Raised floor cutouts

FIXING

MODULE

PRINT

MODULE

POST-PROCESSING

PLAN VIEW

PRE-PROCESSING

1

2260

1600

840

6

4

5

70x70

200

150

100

100

260

3

565

350

600

70x70

If the floor is a standard computer room raised floor, cut the floor tiles according to figure 1-4 for the

power and interface cables.

Site preparation manual

VARYPRESS 200

1 Operator reference side.

2 8 casters and 4 jacks enabling machine immobilization following installation

3 Raised floor cutout for interface cables.

4 Raised floor cutout for power cables

or

5 Framework chute passage for power cables (5).

6- Floor cutout for connecting the pre/post-processing interfaces.

Go to "Table of contents"

2-10

Page 27

Site preparation manual

Ø200

Ø315

2100 m3/h (optimum)

VARYPRESS 200

2.2.5 Installing a pumping system at the filtration unit outlet

2.2.5.1 Standard filtration

Characteristics at printer output

- Air temperature: 80ºC

- Air outlet dimensions: diameter 200 mm or diameter 315 mm

- Optimum air flow: 2100 m

3

/h at printer output

Recommendations

- Installation will be carried out in compliance with current building safety standards.

- Check that there is no back pressure at the air flow outlet outside the building.

Characteristics of NIPSON turbine (can be provided by the customer):

50 Hz

60 Hz

Air flow rate Voltage Maxi. current Power

3

2800 m

3360 m

/h

3

/h

380V - 420V tri 10.7 A 5.5 kW

380V - 420V tri 17 A 9.5 kW

Characteristics of hot air and smoke extraction with NIPSON turbine

- Pipe diameter: 200 mm

- maximum length: 20 m

-

maximum number of elbow joints

: 3 with 90º bend

or 2 with 90º bend + 2 with 45º bend

Go to "Table of contents"

2-11

Page 28

Simplex installation

The turbine can be delivered with the

provided by the customer

Delivered with the printer

printer or provided by the customer

Turbine installation,

interior or external

direct starter

auxiliary command cable

1,720 m

0,5 m

mains

input

ground

Flexible pipe

of 1 m

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-12

Page 29

Site preparation manual

valve Ø 200

ground

Flexible pipe

of 1 m

The turbine can be delivered with the

provided by the customer

Delivered with the printer

printer or provided by the customer

Turbine installation

interior or external

1.720 m

0,5 m

hood

direct starters

auxiliary command cable

mains

input

VARYPRESS 200

Example of duplex installation

Go to "Table of contents"

2-13

Page 30

valve Ø 200

ground

Flexible pipe

of 1 m

Turbine installation

interior or external

1.720 m

0,5 m

hood

direct starters

auxiliary command cable

mains

input

The turbine can be delivered with the

provided by the customer

Delivered with the printer

printer or provided by the customer

Site preparation manual

VARYPRESS 200

Another example of duplex installation

Go to "Table of contents"

2-14

Page 31

Site preparation manual

Filtration option

included in the

printer

Smoke filters

2.2.5.2 Option with internal smoke filtration

This option is available for VaryPress 200-10 and VaryPress 200-20 printers but not for VaryPress

200-30 printers.

VARYPRESS 200

Go to "Table of contents"

2-15

Page 32

Site preparation manual

RECTO

PRINTER

input

output

paper

passage

RECTO

PRINTER

VERSO

PRINTER

INPUT

FOOTBRIDGE

POST-

PROCESSING

POST-

PROCESSING

PRE-

PROCESSING

LOOP

SHORT HOOD

TURNER

1 0304440

2550

2200

VERSO

PRINTER

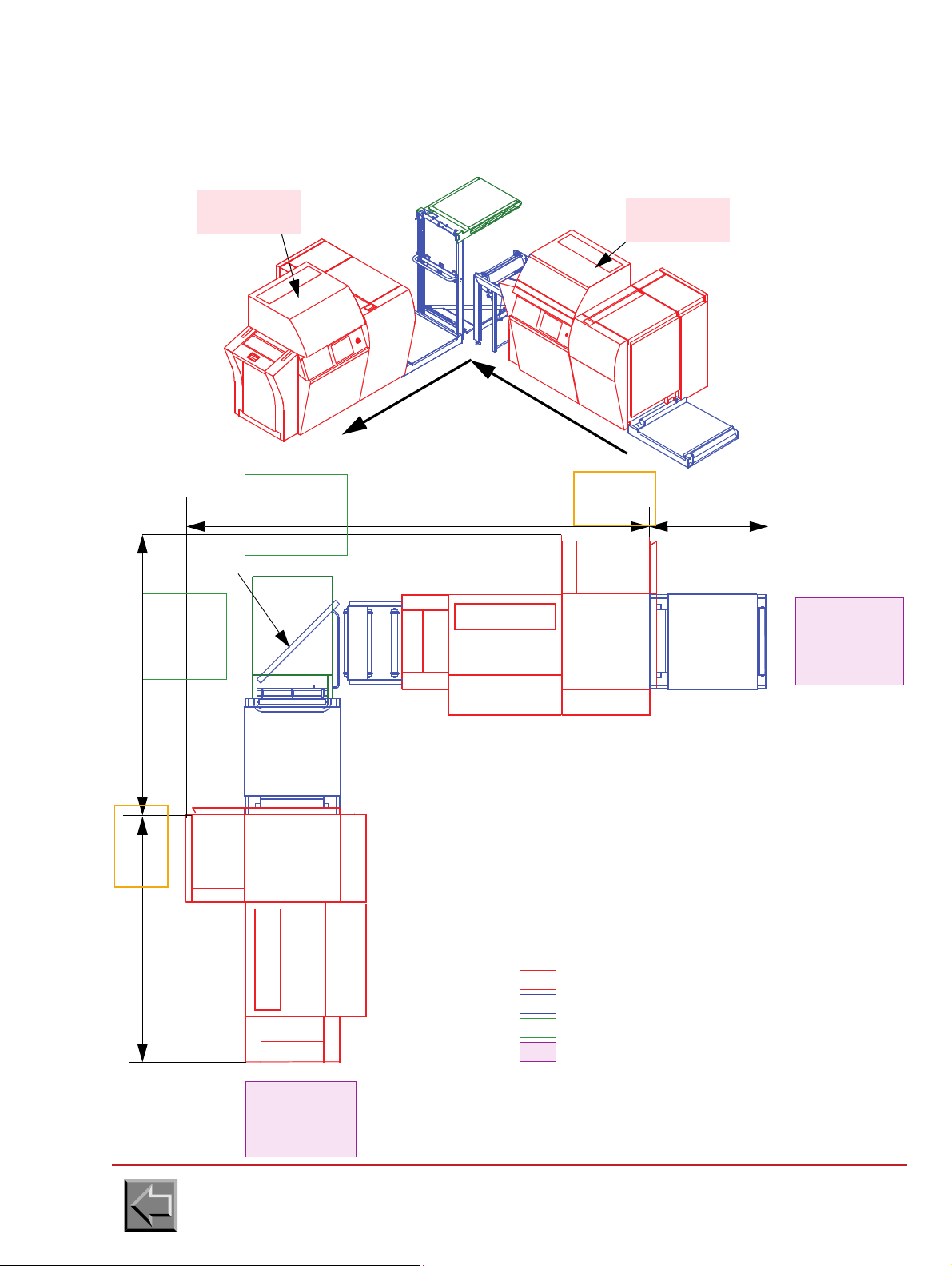

NIPSON printer

Complement for L T.E.D. option

Complement for double simplex

Pre/post-processing

FOOTBRIDGE

T. E . D.

POST-

PROCESSING

AIR

CONDITIONING

UNIT

AIR

CONDITIONING

UNIT

2.2.6 Location of the T.E.D. printer

2.2.6.1 L-shaped installation (standard)

VARYPRESS 200

Go to "Table of contents"

2-16

Page 33

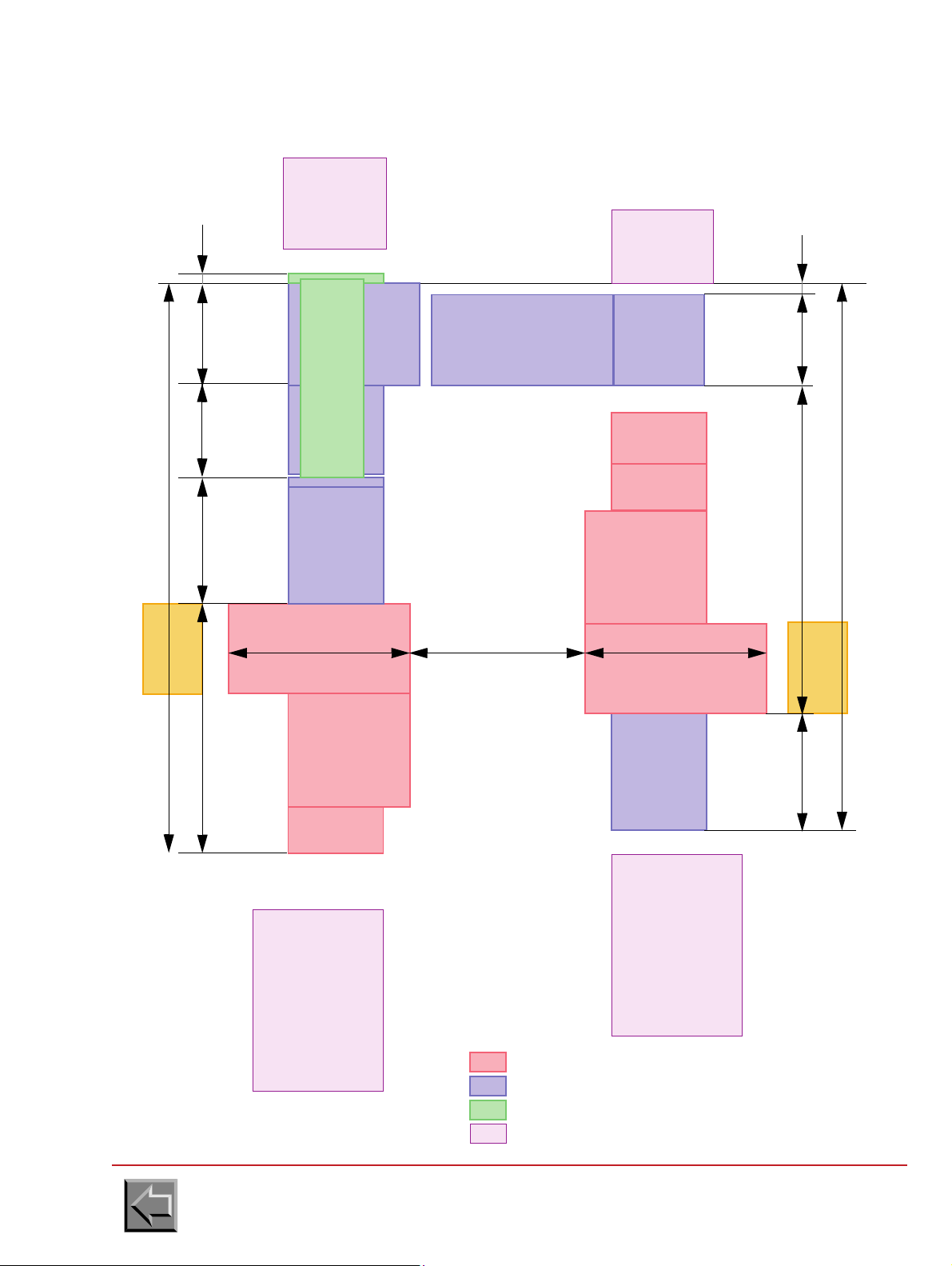

2.2.6.2 U-shaped installation

RECTO

PRINTER

VERSO

PRINTER

input

output

passage

paper

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-17

Page 34

3040

1030

PRINTER

RECTO

INPUT

FOOTBRIDGE

LOOP

90011802200

5070

800

4970

T. E. D .

or PRE-

PAPER

PROCESSING

PROCESSING

PRINTER

INPUT

FOOTBRIDGE

UNFOLDER +

UNFOLDER

TURNER

TURNER

LOOP

LONG HOOD

or PRE-

PAPER

PROCESSING

POST

PROCESSING

POST

PLATFORM

VERSO

U-shaped installation

NIPSON printer

Complement for U T.E.D. option

Complement for double simplex

Pre/post-processing

80

1600 1600

100

1600 to 2300

790

AIR

CONDITIONING

UNIT

AIR

CONDITIONING

UNIT

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-18

Page 35

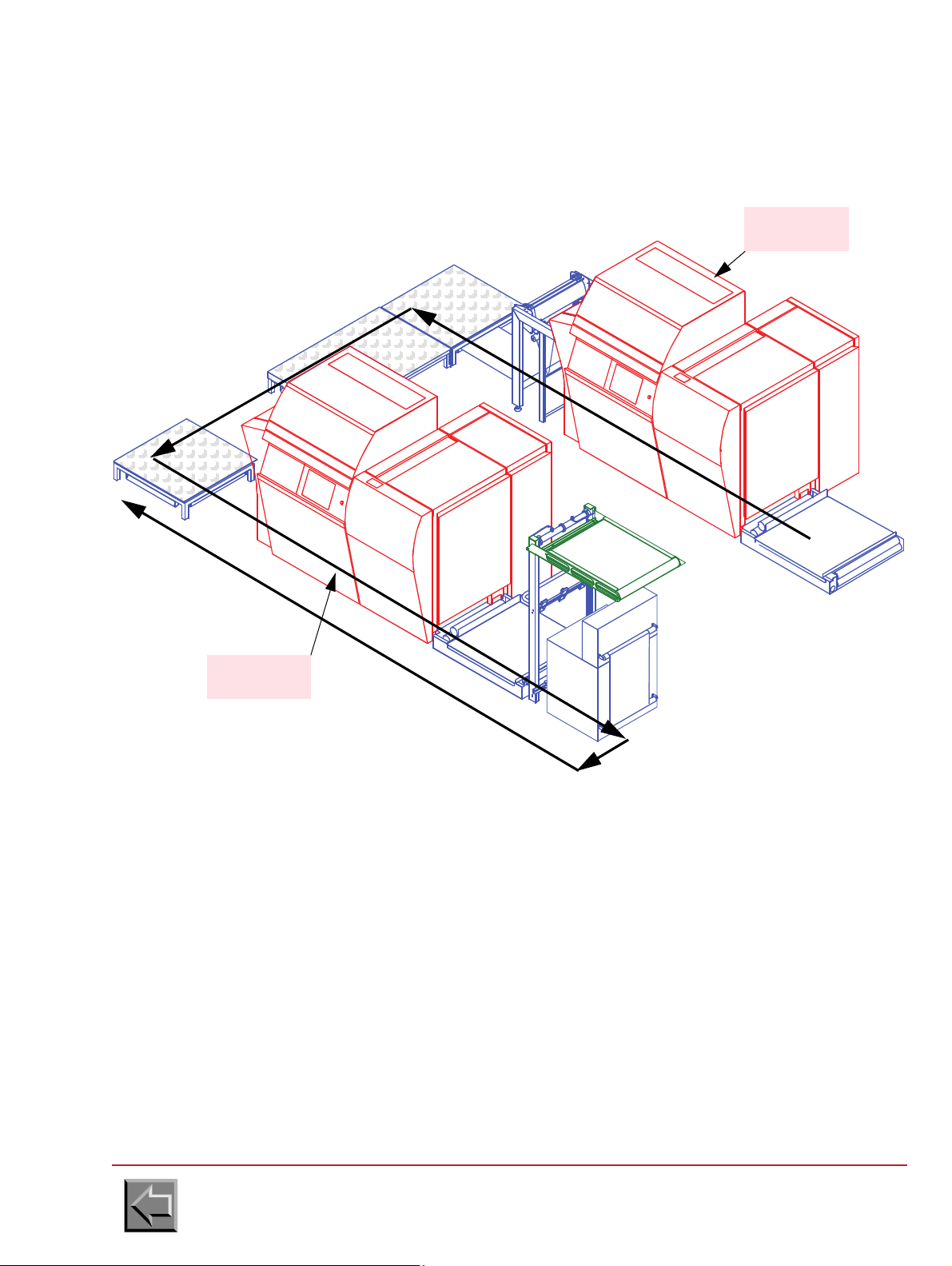

2.2.6.3 S-shaped installation

input

output

paper

passage

VERSO

PRINTER

RECTO

PRINTER

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-19

Page 36

Site preparation manual

3040

1030

RECTO

PRINTER

INPUT

FOOTBRIDGE

LOOP

9001180 2200

5220

800

4970

T. E. D .

PRE-

PROCESSING

PROCESSING

INPUT

FOOTBRIDGE

UNFOLDER +

TURNER

TURNER

LOOP

HOOD

POST

PROCESSING

POST

PLATFORM

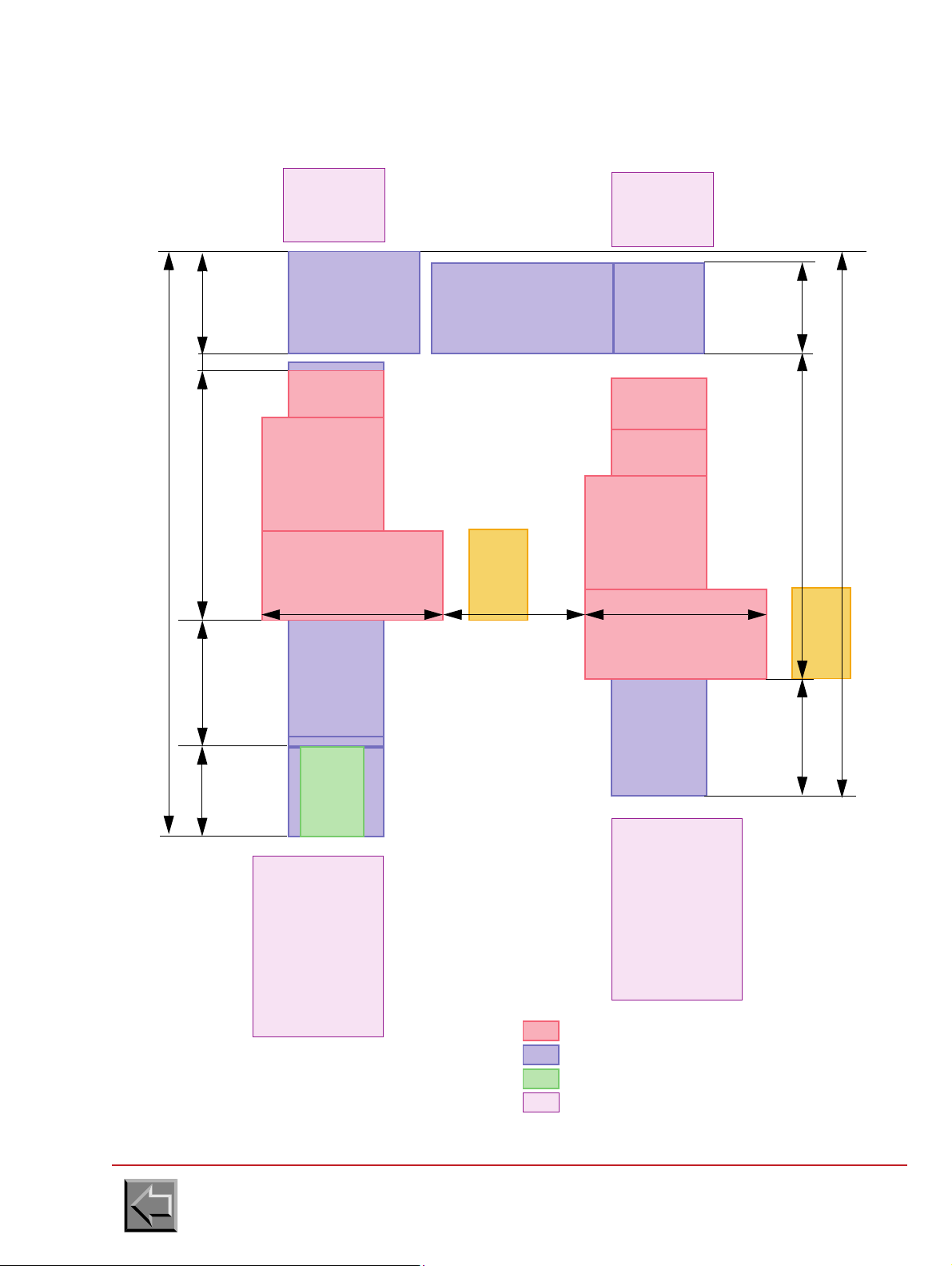

S-shaped installation

NIPSON printer

Complement for S T.E.D. option

Complement for double simplex

Pre/post-processing

1600

790

PROCESSING

POST

VERSO

PRINTER

1600 1300 to 2000

150

AIR

CONDITIONING

UNIT

AIR

CONDITIONING

UNIT

VARYPRESS 200

Go to "Table of contents"

2-20

Page 37

2.2.6.4 Z-shaped installation

RECTO

PRINTER

input

output

paper

passage

VERSO

PRINTER

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-21

Page 38

Z-shaped installation

900 1180 2200

5070

800

3040

1030

4070

PRE-

TRAITEMENT

1600

790

PROCESSING

POST

1600

1300 to 2000 1600

RECTO

PRINTER

INPUT

FOOTBRIDGE

LOOP

T.E.D.

INPUT

FOOTBRIDGE

UNFOLDER +

TURNER

TURNER

LOOP

SHORT HOOD

PLATFORM

VERSO

PRINTER

NIPSON printer

Complement for Z T.E.D. option

Complement for double simplex

Pre/post-processing

AIR

CONDITIONING

UNIT

AIR

CONDITIONING

UNIT

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-22

Page 39

2.2.6.5 I-shaped installation (in line)

RECTO

PRINTER

input

output

paper

passage

VERSO

PRINTER

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-23

Page 40

Site preparation manual

Pre/post-processing

RECTO

PRINTER

INPUT

FOOTBRIDGE

LOOP

900 1180 2200

8350

1030

T. E. D .

PRE-

PROCESSING

INPUT

FOOTBRIDGE

UNFOLDER +

TURNER

i-shaped installation

NIPSON printer

Complement for i T.E.D. option

1600

PROCESSING

POST

VERSO

PRINTER

1600

3040

AIR

CONDITIONING

UNIT

AIR

CONDITIONING

UNIT

VARYPRESS 200

Go to "Table of contents"

2-24

Page 41

Site preparation manual

VARYPRESS 200

2.3 ELECTRICAL REQUIREMENTS

2.3.1 Installation conditions

a. An insulated grounding connector that is identical in size, insulation material, and thickness to

the grounded and ungrounded branch-circuit supply connectors except that it is green with or

without one or more yellow stripes is to be installed as part of the branch circuit that supplies

the unit or system.

b. The grounding connector mentioned above is to be grounded to earth at the service equipment

or other acceptable building earth ground such as the building frame in the case of a high rise

steel frame structure.

c. The plug receptacles in the vicinity of the unit or system are all to be of a grounded type, and

the grounding connectors serving these receptacles are to be connected to earth ground at the

service equipment or other acceptable building earth ground, such as the building frame in the

case of a high rise steel frame structure.

d. The printer is compatible with the electric networks TT, TN (the neutral is connected to the

earth), and IT (the neutral is isolated from the earth).

2.3.2 Leakage current

Never operate the machine with grounding connector disconnected.

2.3.3 Mains power

Caution: Since the T.E.D. printer is composed of two printers, its power consumption is double that

of the standard machine.

The standard printer can operate with the following three phase mains power:

a. 400V - 50 Hz or 60 Hz

Voltage tolerance: +10 %, -10 %

Frequency tolerance: + 1 Hz

Four-wire power cable: 3 phases and ground.

b. Power consumption:

WARNING

The machine has a high leakage current. Grounding circuit

continuity is vital for safe operation of machine

Print speed

50 m/min 70 m/min 90 m/min

Power consumption during printing

with flash power value: 100%

Power consumption during printing

with flash power value: 80%

Power consumption on standby 1 kW 1 kW 1 kW

Current consumption 27 A 36 A 45 A

Go to "Table of contents"

19 kW 25 kW 33 kW

15 kW 20 kW 27 kW

2-25

Page 42

Site preparation manual

2

0

8

V

4

0

0

V

Transformer 40 kVA

for 1 printer

L1

L2

L3

L1

L2

L3

Ground

Ground

400 V

Printer

breaker

80 A

Customer

breaker

125 A

Curve D

Cable 25 mm

2

- AWG 4

Cable 16 mm

2

- AWG 6

2

0

8

V

4

0

0

V

Transformer 80 kVA

for 2 printers

L1

L2

L3

L1

L2

L3

Ground

Ground

400 V

Printer A

breaker

80 A

Customer

breaker

250 A

Curve D

L1

L2

L3

Ground

Printer B

breaker

80 A

Cable 50 mm

2

- AWG 1 Cable 16 mm2 - AWG 6

VARYPRESS 200

A transformer 208V/400V can be used to connect the printer(s)

Go to "Table of contents"

2-26

Page 43

2.3.4 Main circuit breaker

20 cm

Earth wire

Tags

D

internal

= 8 mm

NOTE: If the printer is directly connected to the mains, a "mushroom" emergency stop button

must be placed in the installation (responsibility of the customer). It must cut any source of

energy on the whole installation.

This emergency stop button must separate the contacts with a distance of at least 3 mm.

50 Hz:

- The gauge of the printer circuit breaker is 80A.

The circuit breaker of the printer is a protection member.

- The capacity of the customer emergency stop button circuit must be 80 A (curve D), and if

there is a differential breaker, its capacity must be 300 mA (because of the high leakage

current).

60 Hz:

- The gauge of the printer circuit breaker is 80A.

The circuit breaker of the printer is a protection member.

Site preparation manual

VARYPRESS 200

- The capacity of the customer emergency stop button circuit must be 80 A / 400 V (curve D) (or

125A in 208V, see figure on previous page), and if there is a differential breaker, its capacity

must be 300 mA (because of the high leakage current).

2.3.5 Printer main cable

50 Hz printers are supplied with cable.

Since the 60 Hz printers are supplied without cable, the installer must check that the main cable

complies with local standards:

- The 60 Hz cable must have 4 conductors AWG 6 minimum (16 mm

- The color of the wires must comply with local standards.

- On the printer end, the conductors must be fitted with closed D8 type terminal tags.

- On the mains power supply box end, the conductors must be fitted with tags compatible with

the type of box.

2

).

There are 2 ways of feeding the main cable under the machine, see paragraph 2.2.4.

Go to "Table of contents"

2-27

Page 44

Site preparation manual

VARYPRESS 200

2.3.6 Pre and post processing ground wire

The pre and post processing ground wires must be fitted, on the printer end, with closed D5 type

terminal tags.

2.3.7 Air conditioning unit for write heads

Mains power :

- 230V 50Hz or 60Hz

- Power consumption: 2 kW

Connect the air conditioning unit to a circuit breaker, 15A, 2 poles (Curve D).

The air conditioning unit is supplied with one connector (to plug on the air conditioning unit) but

without the main cable, the installer must install a cable which complies with the local standards:

- Three-wire power cable, hard use type (SJT or equivalent): Single-phase and ground.

-

The plug must complies with the local standards (e.g. for USA & Canada: 250V 15 A, ref 6-15R)

2.3.8 Electrical connection of web cleaner option

Mains voltage 400 V - 3 phases 208 V - 3 phases

Frequency 50 Hz 60 Hz

Motor output 1.1 kW 1.3 kW

Motor voltage 230/400 V 120/208 V

Air displacement

Connect the web cleaner to a circuit breaker, 3A, 3 poles (Curve C).

Go to "Table of contents"

135 m

3

/h 135 m3/h

2-28

Page 45

Site preparation manual

Mains power :

- 230V 50Hz or 60Hz

- 1 phase + Neutral

- Power consumption: 1 kW

Connect the motorised loop to a

circuit breaker, 15A (Curve D).

VARYPRESS 200

2.3.9 T.E.D. motorised loop (U-shaped or S or Z)

Go to "Table of contents"

2-29

Page 46

2.3.10 U.P.S.

3

4

5

6

7

TB2

Ph

N

G

Ph

N

G

P90

on ALFIX board

47292035-407 min.

U.P.S.

U.P.S.

supply

output

Main

supply

Jumpers to remove

TB2

U.P.S.

P90-2

P90-3

before connecting

the U.P.S.

P90-1

Source

Dry

contacts

input

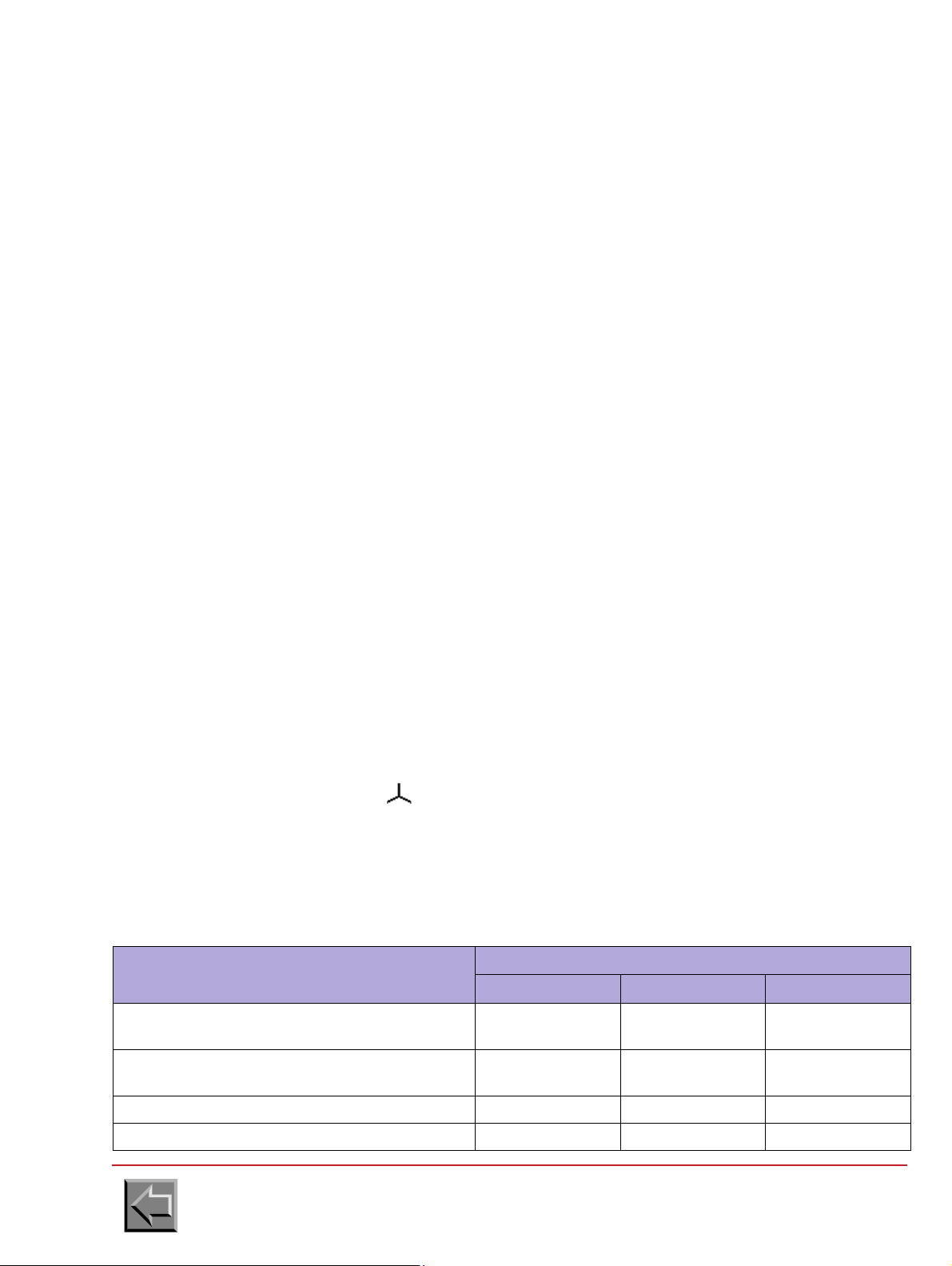

To ensure the P. C . safety, a U.P.S. can be added with the following characteristics:

- U.P.S. 1000 VA

- need of a dry contact board.

The U.P.S. and the dry contact board are not supplied by NIPSON but the following

equipments are recommended because they were tested with the printer:

Manufacturer U.P.S. Board, dry contacts

Site preparation manual

VARYPRESS 200

LIEBERT GXT2-1000 2UAPC

Smart UPS 1000VA

RELAYCARD-INT board,

dry contacts / AS400

Connection to the printer:

- Remove the jumpers across terminals TB2 3-4 and TB2 5-6 and plug the U.P.S.

- Unplug the P90 connector of ALFIX and plug the output of the dry contacts on ALFIX board

using one female Micro connector, 1x3 (pitch: 2,5).

Go to "Table of contents"

2-30

Page 47

2.4 REMOTE MAINTENANCE

The remote maintenance system must be installed to enable the field technicians and engineers

to remotely access the printer requiring a diagnostic or an intervention (software update ...).

Required Equipment

1. An analogical telephone line reserved for connection of the modem, providing direct-number

access (direct line or possibility of line selection when connecting to the telephone

switchboard).

2. A telephone line making it possible to converse and give instructions during the remote

maintenance session.

3. An electrical socket close to the printer in order to plug in the modem.

4. A modem: USRobotics Sportster 33600 fully equipped (to find out about the modem

characteristics required, contact International Technical Support tel.: +33 (0)3-84-54-59-59 or

fax +33 (0)3-84-54-52-55).

5. A cable to connect the modem to the PC (9-pin female connector EIA232 for P.C.).

Site preparation manual

VARYPRESS 200

6. A cable to connect the OpenDrive PC to the connectors panel.

7. A PPU3 connection cable.

8. A piece of Velcro tape (to fix the modem).

NOTE: Parts 1. to 3. are provided by the customer.

Parts 4. and 5. are provided by the local maintenance.

Parts 6. to 8. are delivered with the printer.

Go to "Table of contents"

2-31

Page 48

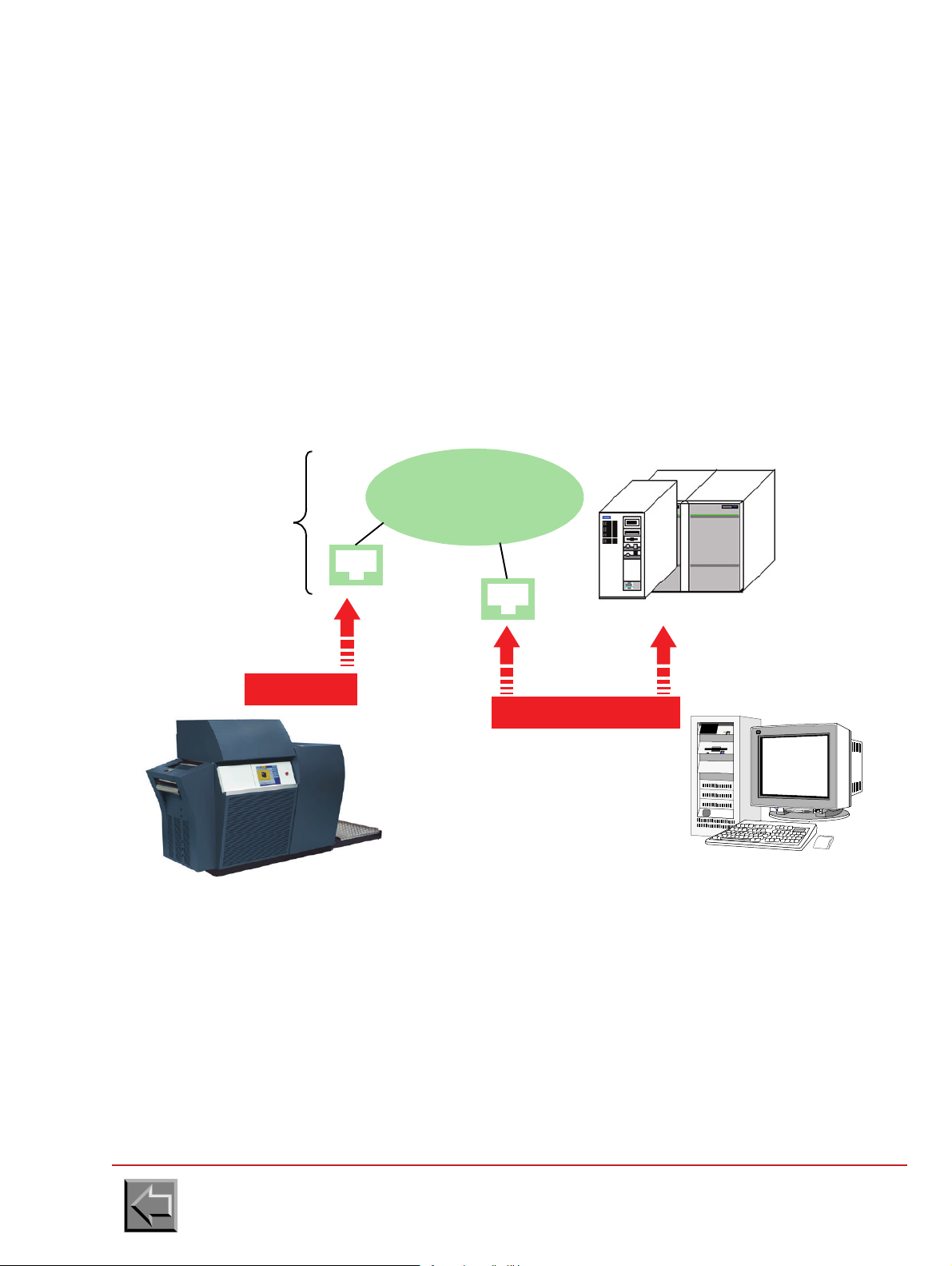

Site preparation manual

Gateways

Bull, IBM, DEC, Unix...

2 Ethernet cables

Ethernet cable

10/100/1000 BaseT 20 m

10/100/1000 BaseT

PRINTER

Print Server Platform

Sockets

RJ45

Check

the presence

Ethernet LAN

(Factory)

10 m

2.5 INTERFACE CONNECTION

PELV (Protected Extra-Low Voltage) safety notice

To ensure the extra-low voltage integrity of the equipment, connect only equipment with mainsprotected electrically-compatible circuits to the internal ports.

CAUTION: Your printer will be connected to a host system. If Nipson does not deliver this system,

to avoid very nasty surprise with the installation, please check the compatibility of this system and

the version recommended by Nipson.

web site http://bbs.nipson.com ; Call center tel.: +33 (0)3 84 54 59 59.

2.5.1 Printer with LAN

2.5.1.1 Connection to the factory network

VARYPRESS 200

Go to "Table of contents"

2-32

Page 49

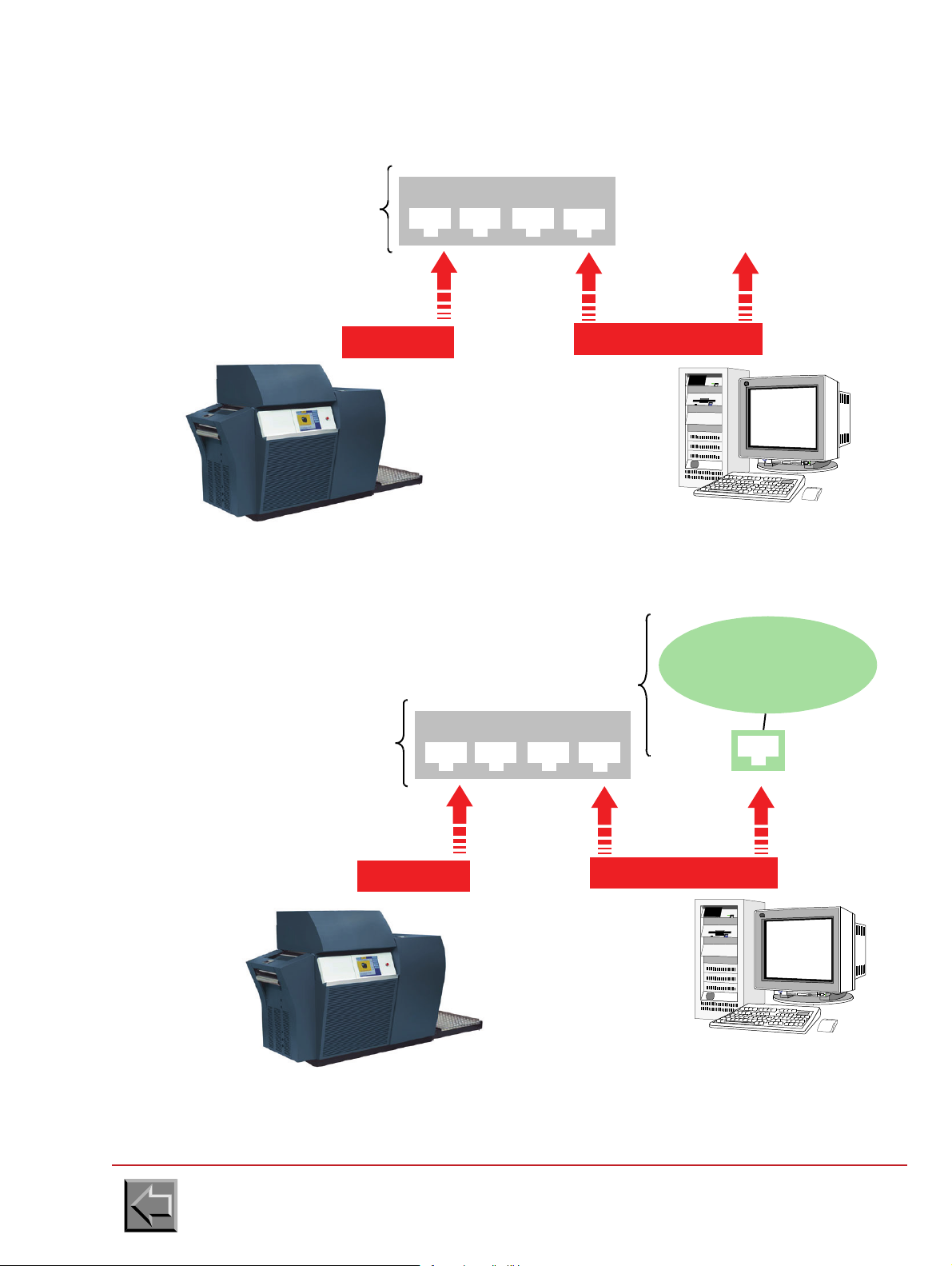

Site preparation manual

2 Ethernet cables

10/100/1000 BaseT

Print Server Platform

Ethernet cable

10/100/1000 BaseT 20 m

PRINTER

supplies

to provide

Switch or HUB 10/100/1000 BASE-T

10 m

Check the

presence

Ethernet LAN

(Factory)

2 Ethernet cables

10/100/1000 BaseT

Print Server Platform

RJ45

Ethernet cable

10/100/1000 BaseT 20 m

PRINTER

supplies

to provide

Switch or HUB 10/100/1000 BASE-T

Note: The platform acts as bridge

separating two fields from network LAN.

10 m

2.5.1.2 Connection to the adapted network

VARYPRESS 200

2.5.1.3 Connection to the isolated network

Go to "Table of contents"

2-33

Page 50

Site preparation manual

VARYPRESS 200

2.5.2 Connection of the printer to the network

The customer is responsible for preparing the printer connection to the Ethernet network of the firm

before the printer is supplied.

Configure the printer network address as described in paragraph 3.2.5.16 of the Product Manual (in

Configuration -> Change network configuration).

WARNING: expression "Broadcast Address of Printer" doesn't mean a gateway address. For

gateway address configuration , please contact Nipson International Support.

2.5.2.1 VPServer connection

The Ethernet cable is provided with the printer, and needs to be connected to the Ethernet network

of the company.

2.5.2.2 U_NetPSF connection

The Ethernet cable is provided with the printer, and needs to be connected to the Ethernet network

of the company.

The IPDS licence for the U_NetPSF connection has to be ordered to NIPSON during the installation

of the printer.

2.5.2.3 E_NetPSF connection

The Ethernet cable is provided with the printer, and needs to be connected to the Ethernet network

of the company.

The IPDS licence for the E_NetPSF connection has to be ordered to NIPSON during the installation

of the printer.

This licence has a lifetime of 1 year and has to be extended every year.

2.5.2.4 OpenPage connection

The Ethernet cable is provided with the printer, and needs only to be connected to the Ethernet

network of the company.

Go to "Table of contents"

2-34

Page 51

Site preparation manual

VARYPRESS 200

2.5.3 Connection to the host system

2.5.3.1 VPServer connection

Refer to the VaryPress PrintServer user guide.

2.5.3.2 Connection to PRESS V4

PRES software from PrintSoft is configured by the registry of Windows.

Launch regedit and select directory:

HKEY_LOCAL_MACHINE\SOFTWARE\PrintSoft\PReS\IPDS\prn1

- The main parameters to be configured are:

DeviceName=TCPIP,192.90.225.108,5001

DeviceSpeed=HIGH

DEV_UNITS=1

PageBuff=2

PRSTRACE=0

QUESIZE=125

ACK_PAGES=100

TCPMaxWrite=8192

TCPMaxTimeout=180

SRA=0

IOCAType=1

Rel_Metrics=0

PrintDebug=Off

"QUESIZE" parameter should indicate the number of lead pages of the printer. The value of 127

suits simplex printer. For duplex printer, use the value of 250 to ensure that the printer operates

correctly, especially during restarts. "Device Name" parameter must be updated with printer TCP

address and port value given by the customer.

Go to "Table of contents"

2-35

Page 52

Site preparation manual

VARYPRESS 200

2.5.3.3 Connection to PRINTNET V3 from GMC

PrintNet configuration

PRINTNET software from GMC is associated with a configuration file named printnet.ini.

This file contains a group called [Machines]" which should contain the logic name associated with

the printer, for example IPDS600 for a 600DPI printer.

Printnet.ini must also contain a group defining the characteristics of the printer. The logic name of

the printer in the [Machines]" group is the name of this group (for example "[IPDS 600]"). The

important parameters are the height and the width of printing in dots. The "FontCaps" parameter

must be equal to 2. The PrintCaps" parameter must be equal to 0 for a standard machine and to 64

for a SpotColor equipped machine.

Machine parameters for NIPSON's printers, IPDS 600 and IPDS 300 groups:

- [IPDS 600]

MachineType=131

MaxWidth=11070

MaxLength=21600 with a VP200, 21450 with a VP400

nonprintablemargin=0

Resolution_x=600

Resolution_y=600

FontCaps=2

Charset=ANSI

PrintCaps=0

Negative=1

BitmapFormats=255

;SpotColors=

Lde=C:\GMC\PMANAGER\ipds600\pmlouts

Overlay=C:\GMC\PMANAGER\ipds600\pmovls

Font=C:\GMC\PMANAGER\ipds600\pmfonts

Prt=C:\GMC\PMANAGER\ipds600\pmprt

Charset=ANSI

- [IPDS 300]

MachineType=132

MaxWidth=5535

MaxLength=10800 with a VP200, 10725 with a VP400

nonprintablemargin=0

Resolution_x=300

Resolution_y=300

FontCaps=2

Charset=ANSI

PrintCaps=0

Negative=1

BitmapFormats=255

;SpotColors=

Lde=C:\GMC\PMANAGER\ipds300\pmlouts

Overlay=C:\GMC\PMANAGER\ipds300\pmovls

Font=C:\GMC\PMANAGER\ipds300\pmfonts

Prt=C:\GMC\PMANAGER\ipds300\pmprt

Charset=ANSI

Go to "Table of contents"

2-36

Page 53

Site preparation manual

VARYPRESS 200

PRINTMANAGER connection

The PRINTMANAGER software is associated with a configuration file named pm_ipds.ini.

This file contains a group called "[PrintManager]" which should contain the logic name associated

with the printer, for example IPDS600 for 600 DPI printer (parameter "DefLoginName").

It must contain an "[IPDS]" group which contains the controller type ("ControllerType" parameter)

equal to NIPSON, the emulated printer ("KompatibleType" parameter) equal to 3900 and the buffer

size (" PageBuffer" parameter) equal to 127 for a STANDARD machine and (" PageBuffer_Duplex "

parameter) equal to 250 for a T.E.D. machine.

The value of Max_Transfer_Length parameter must be in accordance with printer configuration,

parameter "IPDS data buffer size".

On the other hand, in using IBM channel connection the group " [PrintManager] " must contain the

printer address on IBM channel ("Channel" parameter), the mode ("Channel_Mode" parameter) set

to 0 and the type of interface board ("Card_Type" parameter equal to PCI or an other value in

accordance with GMC engineer).

NipsonSplitOverlays must be equal to:

- 0 for VARYPRESS 200, VARYPRESS 400 and NIPSON7000

- 1 for N8000

- 2 for VaryPress Txxx.

In using TCP/IP connection the group " [PrintManager] " must contain the type of interface board

("Card_Type" parameter equal to TCP). Moreover, for this connection, in the file pm_ipds.ini, a

special group named "[TCP_IP]" which contains printer address ("TCP_Address" parameter ) and

IP port ("IP_Port" parameter ) must be added.

Don't cancel unused parameters, insert a " ; " character at the beginning of the line for disabled it.

- Example of pm_ipds.ini:

[PrintManager]

Language=English

ErrorLevel=30

JobErrorLogFile=No

DailyErrorLogFile=No

LogFileToView=Machine

JobReport=1

DefLoginName=IPDS480

LoginState=0

EndofJobPart=0

JDE_Filter=type

IndexFile=1

DataScanDestination=NONE

- [IPDS]

Channel=8

Channel_Mode=0

Card_Type=TCP

ControllerType=NIPSON

KompatibleType=3900

PageBuffer=125

PageBufferDuplex=250

StackReceivedPage=0

Go to "Table of contents"

2-37

Page 54

Site preparation manual

VARYPRESS 200

WaitResetTime=10

Max_Transfer_Length=16

AutoRestartAfterPaperEnd=Yes

DefaultFontMetrics=FIXED

ResponseTimeout=120

Exception_UndefinedCharacter=0

Exception_PrintOutsidePage=0

Exception_AllOther=0

PrintExceptionNumber=0

UseNewLoadImageCommand=1

PictureCompression=2

OverlayCompression=2

PagesPerAcknowledge=1

AutoRestartAfterException=Yes

CleanPageBufferAfterException=Yes

IgnoreEmptyDoubleByteSections=Yes

LCA_Programm=C:\GMC\PM_IPDS\BOOT\LCA.BIN

CCA_Programm=C:\GMC\PM_IPDS\BOOT\PCI_dwn.BIN

JPEGQuality=70

EPSResolution=machine

EPSBitsPerPixel=1

UsePageSegments=1

NumberOfPagesegments=127

IntercomTraceLevel=0

SpotColor1=BLUE

SpotColor2=RED

SpotColor3=MAGENTA

SpotColor4=GREEN

SpotColor5=CYAN

SpotColor6=YELLOW

SpotColor7=BROWN

IncrementalRestartPage=0

InterkomPCIDelay=50

NipsonSplitOverlays=0

- [TCP_IP]

IP_Port=5001

TCP_Address=172.25.16.32

BufferSize=1452

WARNING: Many customers use several release of PrintManager. Check in WIN.INI file the

content of group [PrintNet]. The PM_IPDS.INI " parameter must be equal to the

directory of used pmanager.exe file.

Go to "Table of contents"

2-38

Page 55

Site preparation manual

VARYPRESS 200

2.5.3.4 Connection to PRINTNET T from GMC

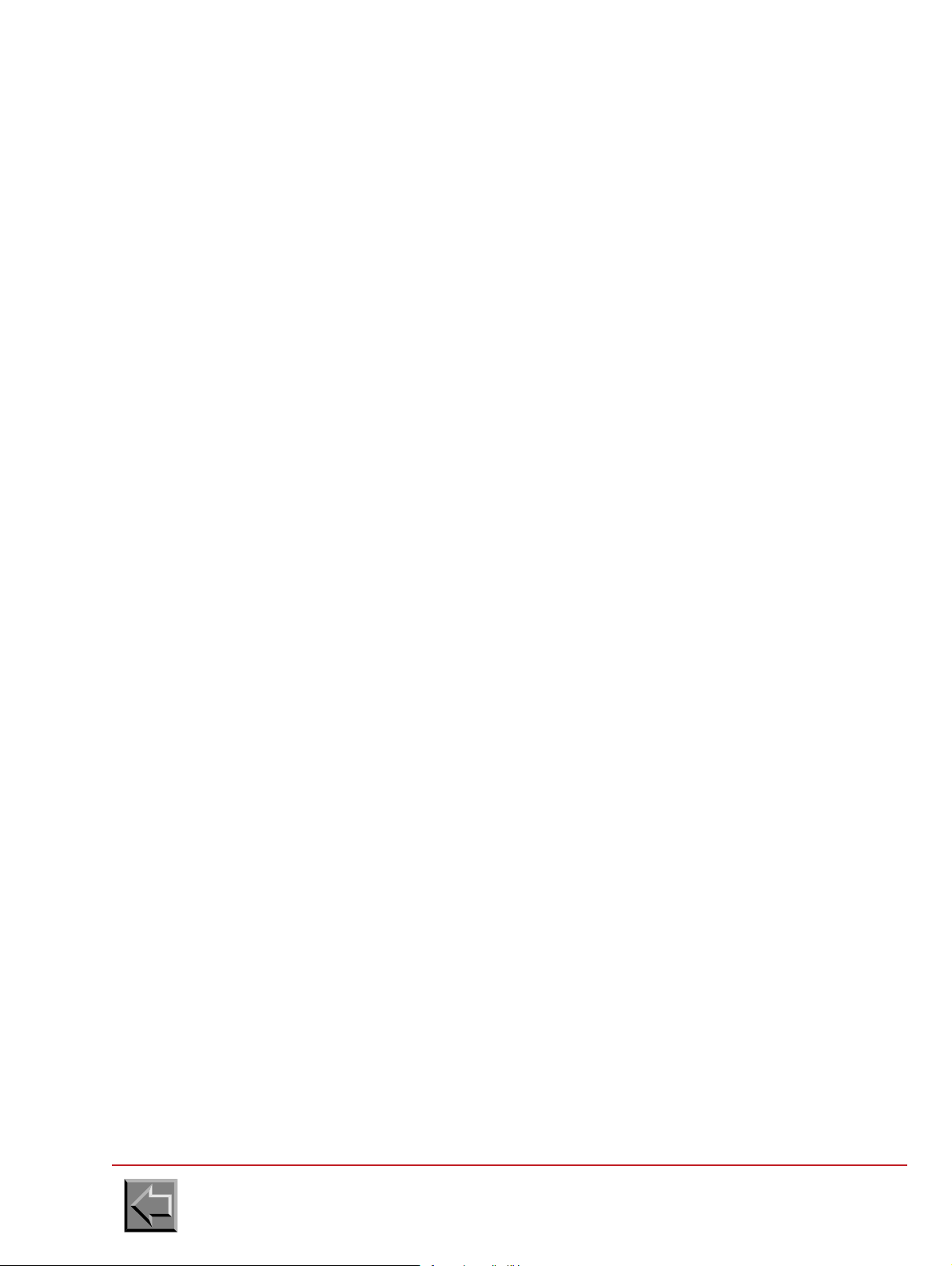

The printing characteristics must be as follows:

Go to "Table of contents"

2-39

Page 56

Site preparation manual

VARYPRESS 200

The connection configuration must be as follows, with the Page Buffer parameter set to 128 in case

of a simplex printer and 256 for a duplex printer.

Go to "Table of contents"

2-40

Page 57

Site preparation manual

VARYPRESS 200

2.5.3.5 Connection to OS390 + MVS from IBM

The site system engineer must register the printer on the IBM system and check that the PSF

software is installed.

If the printer replaces another printer already connected to the host system, the registration exists.

The system engineer has therefore nothing to modify.

The IBM system must be linked to the Ethernet network, once the TCP/IP software has been

installed and actuated.

For example, to add a printer with OS/390 or MVS, follow these steps:

1. Printer registration in the JES2.

(see IBM documentation: JES2 Initialization and Tuning Reference)

It is a printer in page mode, commanded by an FSS (Functional SubSystem). The printer has

no physical address (unit), there is therefore no need to register it in the hardware

configuration.

Example of registration in the JES2PARM member:

FSSDEF(FSS7000) PROC=APSW7000

PRT20 FSS=FSS7000,MODE=FSS,PRMODE=(PAGE,LINE),CLASS=I,

TRKCELL=YES,UCS=0,NPRO=0,START=NO

There are three ways to activate printer parameters:

- system re-initializing; this way is never used because the high using rate of the system

- enabling dynamically printer parameters by using JES2 command "ADD". Example:

ADD FFSDEF(FSS7000) PROC=APSW7000

ADD FSS=FSS7000,MODE=FSS,PRTMODE=(PAGE,LINE),CLASS=I,

TRKCELL=YES,UCS=0,NPRO=0,START=NO

- enabling dynamically printer parameters by using InfoPrint Server capability (only with version

of OS/390 greater or equal to 3.8). In this case, the first and only parameter of the command is

"INV". See PSF documentation, about InfoPrint Server and Printer Inventory references.

Example:

ADD FSS=FSS7000,INV=toto

Where "toto" is the name of the database file containing printer parameters

2. Creation of the PSF procedure associated with the preceding registration:

(see IBM documentation: PSF/MVS System Programming Guide)

//APSW7000 PROC

//*

//**************************************** THE PSF WRITER PROCEDURE ************************************

//* IN PROCLIB LIBRARY

//*

//STEP01 EXEC PGM=APSPPIEP,REGION=4096K

//JOBHDR OUTPUT PAGEDEF=A08584, /* JOB SEPARATOR PAGEDEF */

// FORMDEF=0101LA,CHARS=GT5F /* JOB SEPARATOR FORMDEF */

//MSGDS OUTPUT PAGEDEF=L08080, /* MESSAGE DATASET PAGEDEF */

// FORMDEF=0101LA /* MESSAGE DATASET FORMDEF */

//FONT01 DD DSN=SYS1.FONTLIBB,DISP=SHR /* SYSTEM FONTS */

// DD DSN=SYS7.FONTLIB,DISP=SHR /* */

//PSEG01 DD DSN=SYS1.PSEGLIB,DISP=SHR /* SYSTEM PAGE SEGMENTS */

// DD DSN=SYS7.COMMON.AFPLIB,DISP=SHR /* */

Go to "Table of contents"

2-41

Page 58

Site preparation manual

VARYPRESS 200

//OLAY01 DD DSN=SYS1.OVERLIB,DISP=SHR /* SYSTEM OVERLAYS */

// DD DSN=SYS7.COMMON.AFPLIB,DISP=SHR /* */

//PDEF01 DD DSN=SYS1.PDEFLIB,DISP=SHR /* SYSTEM PAGEDEFS */

// DD DSN=SYS7.COMMON.AFPLIB,DISP=SHR /* */

//FDEF01 DD DSN=SYS1.FDEFLIB,DISP=SHR /* SYSTEM FORMDEFS */

// DD DSN=SYS7.COMMON.AFPLIB,DISP=SHR /* */

//* */

//PRT20 CNTL

//PRT20 PRINTDEV FONTDD=*.FONT01, /* FONT LIBRARY DD */

// OVLYDD=*.OLAY01, /* OVERLAY LIBRARY DD */

// PSEGDD=*.PSEG01, /* SEGMENT LIBRARY DD */

// PDEFDD=*.PDEF01, /* PAGEDEF LIBRARY DD */

// FDEFDD=*.FDEF01, /* FORMDEF LIBRARY DD */

// JOBHDR=*.JOBHDR, /* JOB HEADER SEPARATOR OUTPUT */

// JOBTRLR=*.JOBHDR, /* JOB TRAILER SEPARATOR OUTPUT */

// DSHDR=*.JOBHDR, /* DATA SET HEADER SEPARATOR */

// MESSAGE=*.MSGDS, /* MESSAGE DATA SET OUTPUT */

// BUFNO=30, /* NUMBER OF WRITE DATA BUFFERS */

// PAGEDEF=L08080, /* DEVICE PAGEDEF DEFAULT */

// FORMDEF=0101LA, /* DEVICE FORMDEF DEFAULT */

// CHARS=GT5F, /* DEVICE DEFAULT FONT SET */

// TRACE=NO /* BUILD INTERNAL TRACE */

// FAILURE=WCONNECT, /* ATTEMPT RECONNECT */

// DISCINTV=0, /* NO TIME OUT */

// MGMTMODE=IMMED, /* MAINTAIN SESSION */

// IPADDR=`192.44.50.150', /* IP ADDRESS OF NIPSON PRINTER */

//PRT20 ENDCNTL

//* */

Go to "Table of contents"

2-42

Page 59

Site preparation manual

VARYPRESS 200

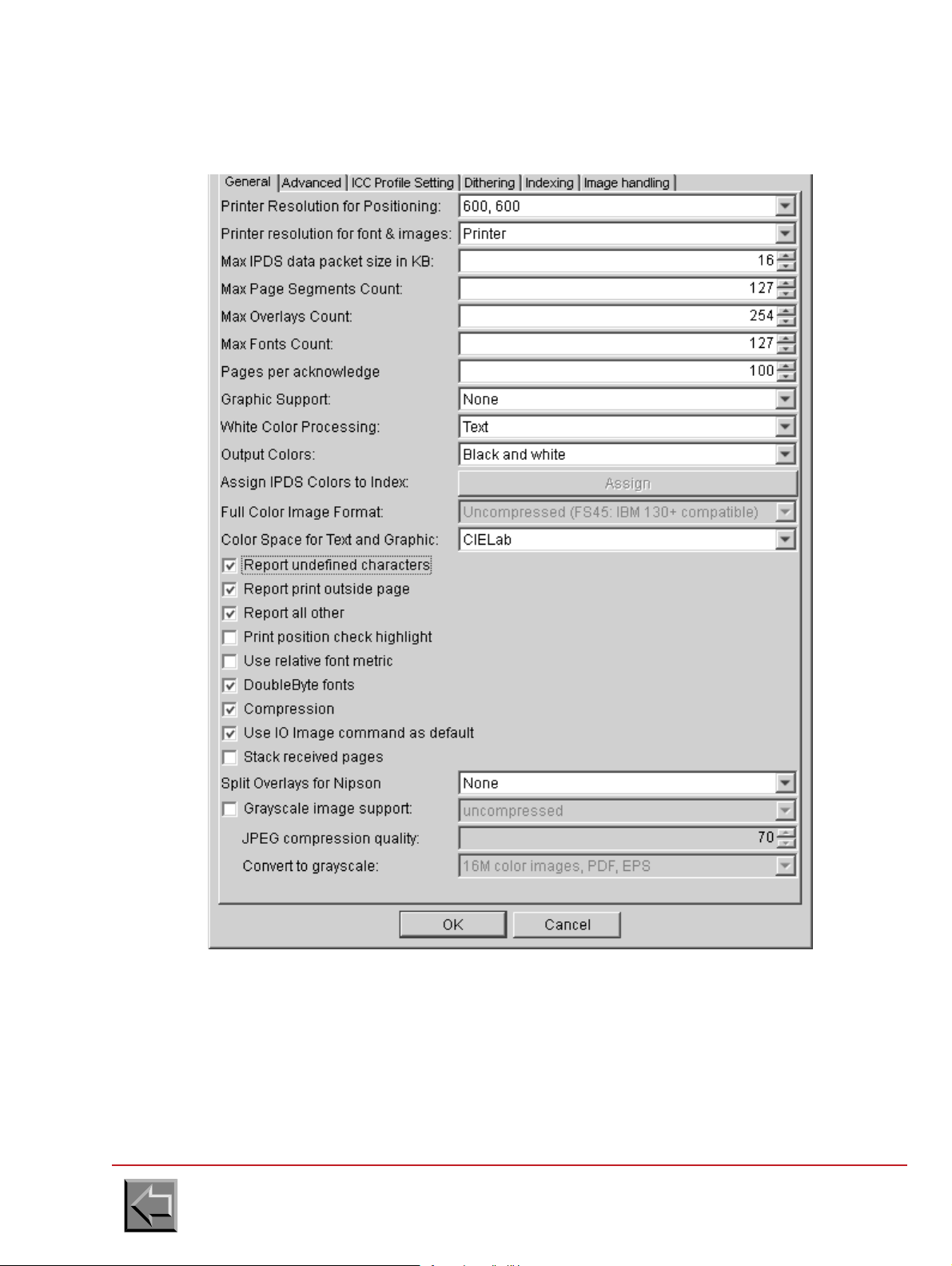

2.5.3.6 Connection to InfoPrintManager from IBM

In the printer properties, configure the Configuration tab and Adjustments tab as follows:

Go to "Table of contents"

2-43

Page 60

Site preparation manual

VARYPRESS 200

2.5.3.7 SDP Protocol Network Interface (OpenPage)

- Internet @: supply the printer @

- Port number: 1090 (data)

NOTE 1: In the case of an OpenPage connection of type XTI, put 1050 for the port number.

NOTE 2: The port numbers and the type of acquisition (XTI or TCP) can be modified by the

administration menus of the printer.

Go to "Table of contents"

2-44

1091 (commands)

Page 61

Site preparation manual

VARYPRESS 200

2.6 UNPACKING AND INSTALLATION PREPARATION

So that the printer is unpacked and installed in the best possible conditions, the following points

must be considered when preparing the site.

2.6.1 Unloading the lorry

- Easy access for the lorry.

- Unloading bay required.

- Trolley required.

2.6.2 Unpacking the modules

- Outside: prepare a waterproof cover in case of rain.

- Inside: trolley required.

2.6.3 Moving the printer to the customer's computer room

- Trolley required, apart from the transporter's.

- If there are access ramps, a winch may be needed, depending on the slope.

- If there are stairs, a suitable trolley is required.

- Width of corridors: preferably greater than 1.20 m.

- In case of soft" floors (carpet, ...), prepare boards or a pallet truck.

- If there are lifts, check that the dimensions are compatible, and prepare a steel sheet to

facilitate movement into the lift.

ATTENTION

If there is a great difference of temperature or relative humidity

between the installation room (see § 1.3) and the packed machine, it

is necessary to keep the printer in its packing during a few hours

The fact of not respecting this instruction can involve risks of

before proceeding to the installation.

deterioration of the material.

Go to "Table of contents"

2-45

Page 62

Site preparation manual

VARYPRESS 200

Go to "Table of contents"

2-46

Page 63

Site preparation manual

VARYPRESS 200

3. Pre / post processor devices

3.1 IDENTIFICATION

The specification defines a protocol for exchange of data and hardware interface between the

printer and two pre and post processing and a camera system.

3.2 INTERFACE CONNECTOR DEFINITION

1. Pre post-processing device 1 connector (on printer interface side)

D-SUB 37 pins , Female

Nº PIN SIGNAL Nº PIN SIGNAL

1 TXD1_H 20 TXD1_L

2 RXD1_H 21 RXD1_L

3 VITRD1+ 22 0V (VITRD1-)

4 PP1PRT+ 23 0V (PP1PRT-)

5 +12V (NTPI1+) 24 NTPI1-

6SDP1+25SDP1-

7NC26NC

8NC27NC

9 PP1CNT+ 28 0V (PP1CNT-)

10 PP1MA+ 29 0V (PP1MA-)

11 M VP1+ 3 0 MVP1-

12 MVPSEC1+ 31 MVPSEC1-

13 SDPSEC1+ 32 SDPSEC1-

14 PP1DMAR+ 33 0V (PP1DMAR-)

15 PP1DARR+ 34 0V (PP1DARR-)

16 PLIPTC1+ 35 PLIPTC1-

17 IMPRESS1+ 36 IMPRESS1-

18 NC 37 NC

19 NC

Go to "Table of contents"

3-1

Page 64

Site preparation manual

VARYPRESS 200

2. Pre post-processing device 2 connector (on printer interface side)

D-SUB 37 pins , Female

Nº PIN SIGNAL Nº PIN SIGNAL

1 TXD2_H 20 TXD2_L

2 RXD2_H 21 RXD2_L

3 VITRD2+ 22 0V (VITRD2-)

4 PP2PRT+ 23 0V (PP2PRT-)

5 +12V (NTPI2+) 24 NTPI2-

6SDP2+25SDP2-

7NC26NC

8NC27NC

9 PP2CNT+ 28 0V (PP2CNT-)

10 PP2MA+ 29 0V (PP2MA-)

11 MVP2+ 30 MVP2-

12 MVPSEC2+ 31 MVPSEC2-

13 SDPSEC2+ 32 SDPSEC2-

14 PP2DMAR+ 33 0V (PP2DMAR-)

15 PP2DARR+ 34 0V (PP2DARR-)

16 PLIPTC2+ 35 PLIPTC2-

17 IMPRESS2+ 36 IMPRESS2-

18 NC 37 NC

19 NC

3. Camera system connector (on printer interface side)

D-SUB 9 pins , Female

Nº PIN SIGNAL Nº PIN SIGNAL

1PLIPTC+6 NTPI3-

2PLIPTC-7 0 V

3 CAMCNT+ 8 0 V (CAMCNT-)

4+12V (NTPI3+)90 V (INCCAM-)

5 INCCAM+

Go to "Table of contents"

3-2

Page 65

Site preparation manual

1/6"

VARYPRESS 200

3.3 INPUT/OUTPUT SIGNALS

3.3.1 Signals from printer to pre-post processing device

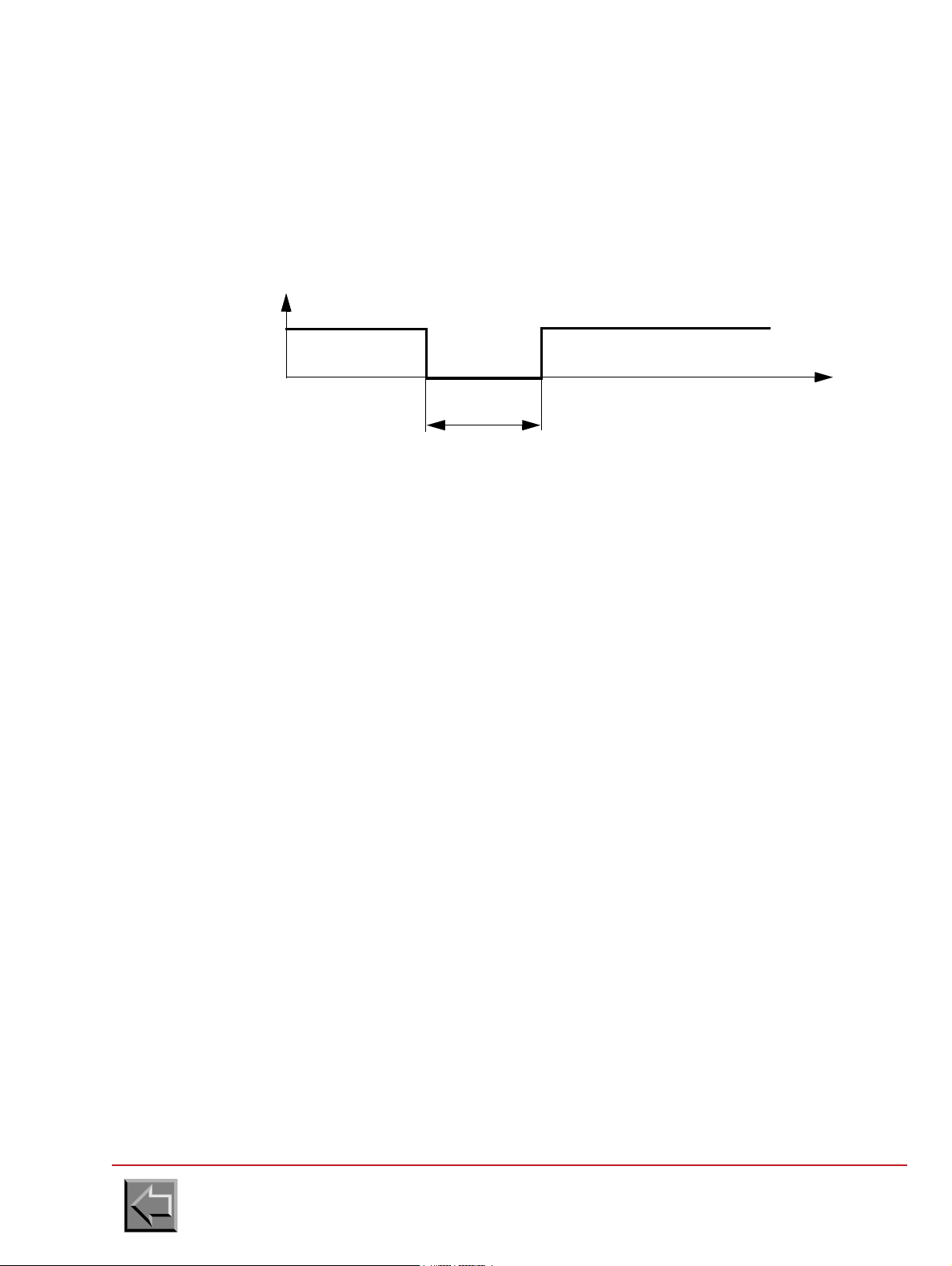

1. 1/6 of an inch displacement signal 1 (NTPI1) and (NTPI2)

The printer generates a positive pulse for each 1/6 inch paper movement. This signal is

designed to synchronize the Pre-Post-Processing device with the printer.

The ratio between low and high signals is one.

2. Paper movement direction (SDP1) and (SDP2)

This signal indicates the paper movement direction to the Pre-Post Processing device.

"0": Forward paper movement

"1": Backward paper movement

3. Paper movement direction switch contact (SDPSEC1) and (SDPSEC2)

This signal indicates the paper movement direction to the Pre-Post Processing device.

"0": Forward paper movement

"1": Backward paper movement

NOTE: This signal is the same as SDP1/2 with the difference that it is activated by a contact

switch only.

4. Paper movement (MVP1) and (MVP2)

The signal indicates to the Pre-Post Processing device that the paper is going to move. This

signal is activated at least 2 seconds before the printer starts.

NOTA: The two seconds anticipation time does not occur when a paper feed is activated.

This signal can be used by the post-processing device to start or stop the elements which

would otherwise always run..

"0": paper movement

"1": no paper movement

5. Paper movement switch contact (MVPSEC1) and (MVPSEC2)

Definition : See paper movement.

NOTA: This signal is the same as MVP1/2 with the difference that it is activated by a contact

switch only.

Go to "Table of contents"

3-3

Page 66

Site preparation manual

1L

0L

22ms < T < 25ms

VARYPRESS 200

6. Serial connection (RXD1_H, RXD1_L) and (RXD2_H, RXD2_L)

The printer transmits information to the Pre-Post Processing device through a serial

connection in differential mode ( RS422).

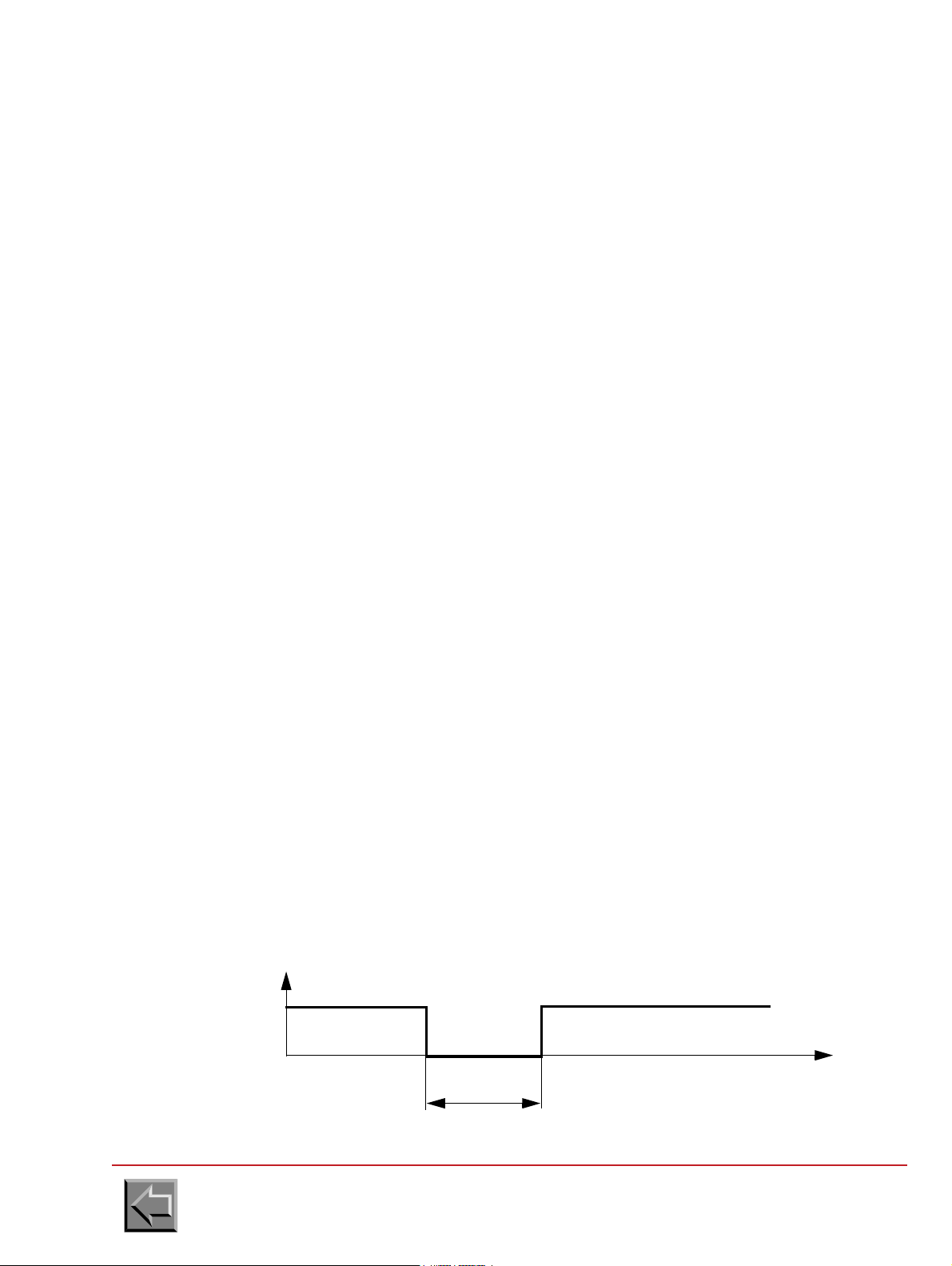

7. Sheet detection (PLIPTC1) and (PLIPTC2)

The printer generates a pulse every sheet of paper feed.

8. Printing state (IMPRESS1) and (IMPRESS2)

This signal indicates to the Pre-Post Processing device that the printer is in the printing state.

"0": printer in printing state

"1": printer is not in printing state

Go to "Table of contents"

3-4

Page 67

Site preparation manual

1L

0L

500ms < T < 1s

T

VARYPRESS 200

3.3.2 SIGNALS FROM PRE-POST PROCESSING DEVICE TO PRINTER

1. Pre-post processing device connected (PP1CNT) and (PP2CNT)

This signal indicates to the printer that a Pre-Post Processing Device is connected (but not

necessarily ready).

If the Pre-Post Processing Device is present, the printer can disable its internal stacker.

"0": connected

"1": not connected

2. Pre-post processing device ready (PP1PRT) and (PP2PRT)

Indicates to the printer that the Pre-Post Processing Device is ready for operation. This signal

is also used for an emergency stop (Hard stop).

"0": ready

"1": not ready

3. Speed reduce (VITRD1) and (VITRD2)

Request a speed reduction from the printer.

"0": speed reduction

"1": no speed reduction

4. Printer start/stop by pre-post processing device (PP1MA) and (PP2MA)

The Pre-Post Processing Device number 1 transmits this signal to start or stop the printer (Soft

stop).

NOTA: This signal only used when PP1/2DMAR and PP1/2DARR are not used.

"0": stop

"1": start

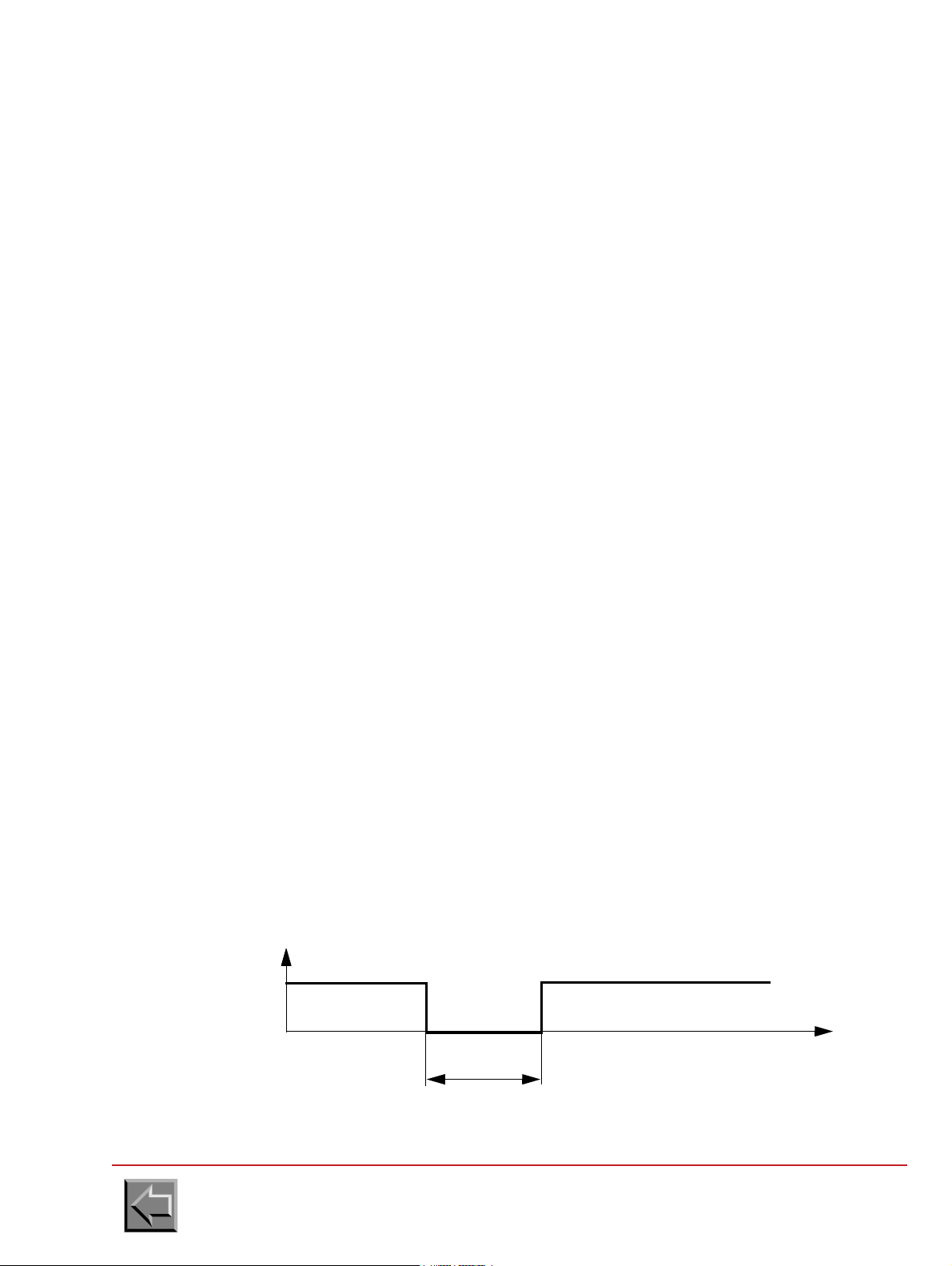

5. Start request by pre-post processing device (PP1DMAR) and (PP2DMAR)

This signal indicates to the printer that it start.

NOTA: This signal is used with PP1/2DARR when PP1/2MA is not used.

"0": start command

"1": no start command

Go to "Table of contents"

3-5

Page 68

Site preparation manual

1L

0L

500ms < T < 1s

T

VARYPRESS 200

6. Stop request by pre-post processing device (PP1DARR) and (PP2DARR)

This signal indicates to the printer that it stop.

NOTE: This signal is used with PP1DMAR when PP1MA is not used.

"0": stop command

"1": no stop command

7. Serial connection (TXD1_H , TXD1_L) and (TXD2_H , TXD2_L)

The post-processing device number 1 transmits the information to the printer through a serial

connection in differential mode (RS422).

3.3.3 Signals from camera system to printer

1. Camera system connected (CAMCNT)

This signal indicates to the printer that a camera system is connected and ready.

"0": connected

"1": not connected

2. Camera signal (INCCAM)

An intelligent system (camera) to check the presence of the print and an indication of the

degradation of the print by an incident.

"0": no incident

"1": incident

Go to "Table of contents"

3-6

Page 69

Site preparation manual

1/6"

1L

0L

22ms < T < 25ms

VARYPRESS 200

3.3.4 Output signals from printer to camera system

1. 1/6 of an inch displacement signal 3 (NTPI3)

The printer generates a positive pulse for each 1/6 inch paper movement. This signal is

designed to synchronize the Camera system with the printer.

The ratio between low and high signals is 50%.

2. Sheet detection (PLIPTC)

The printer generates a pulse every sheet of paper feed.

Go to "Table of contents"

3-7

Page 70

Site preparation manual

PRINTER

INTERFACE

EXTERNAL DEVICE

INTERFACE

Imax = 0.1 A

Umax = 100V DC

+

-

I

VARYPRESS 200

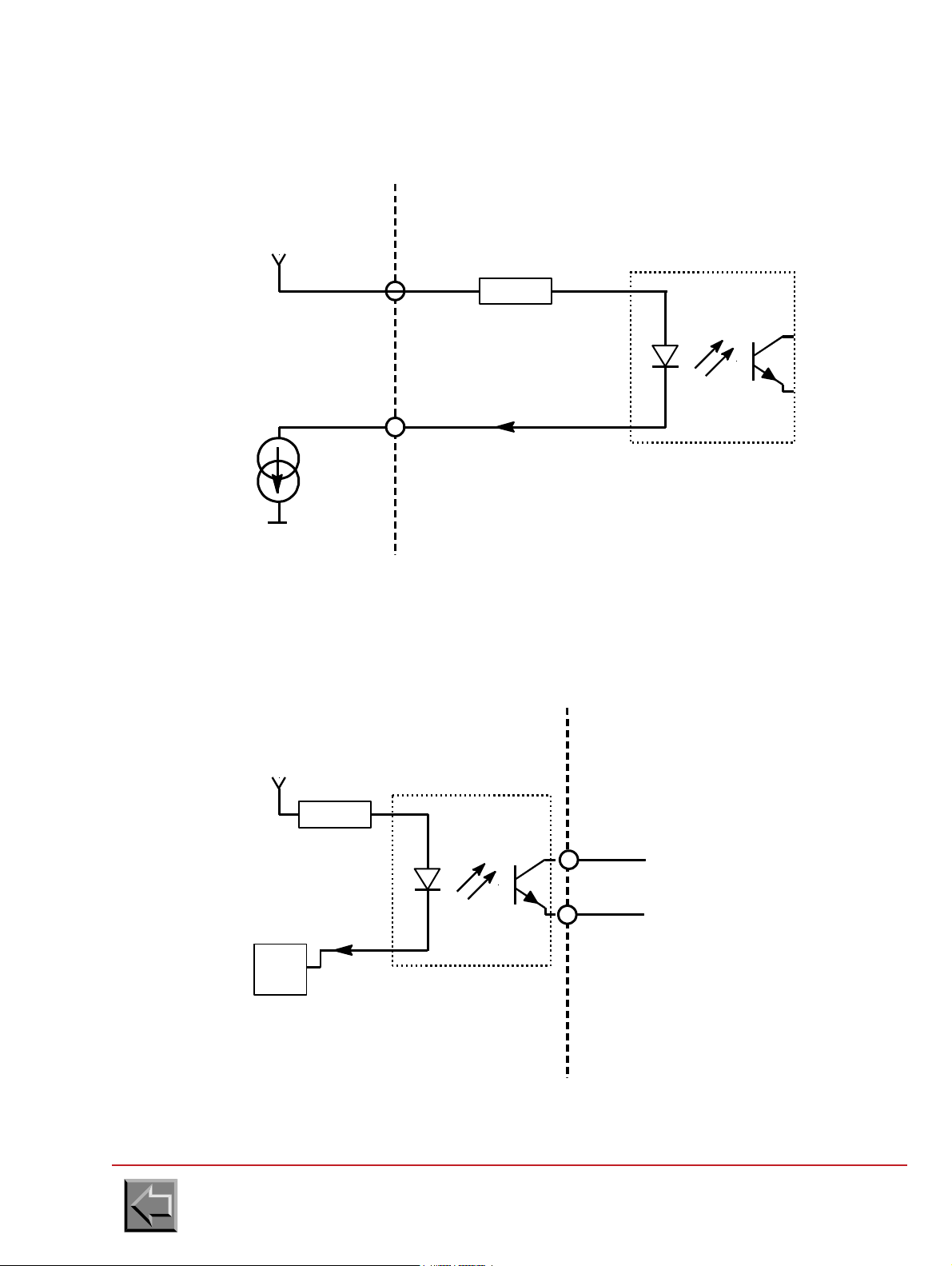

3.4 ELECTRICAL SIGNAL SPECIFICATION

3.4.1 Signals from printer to the external device

The output signal interface can be adapted to the external device interface in 4 different output

types:

-Switch

- Opto Isolated

- Current source

- Differential

Each output contains 2 pins marked +,- designed to adapt the printer interface to the Pre/Post-processing device interface.

NOTE: NTPI signal will only have an current source output.

PLIPTC signal will only have an opto isolated output.

The serial link output signal only exists in differential mode.

1. Output switch

- "0": switch closed

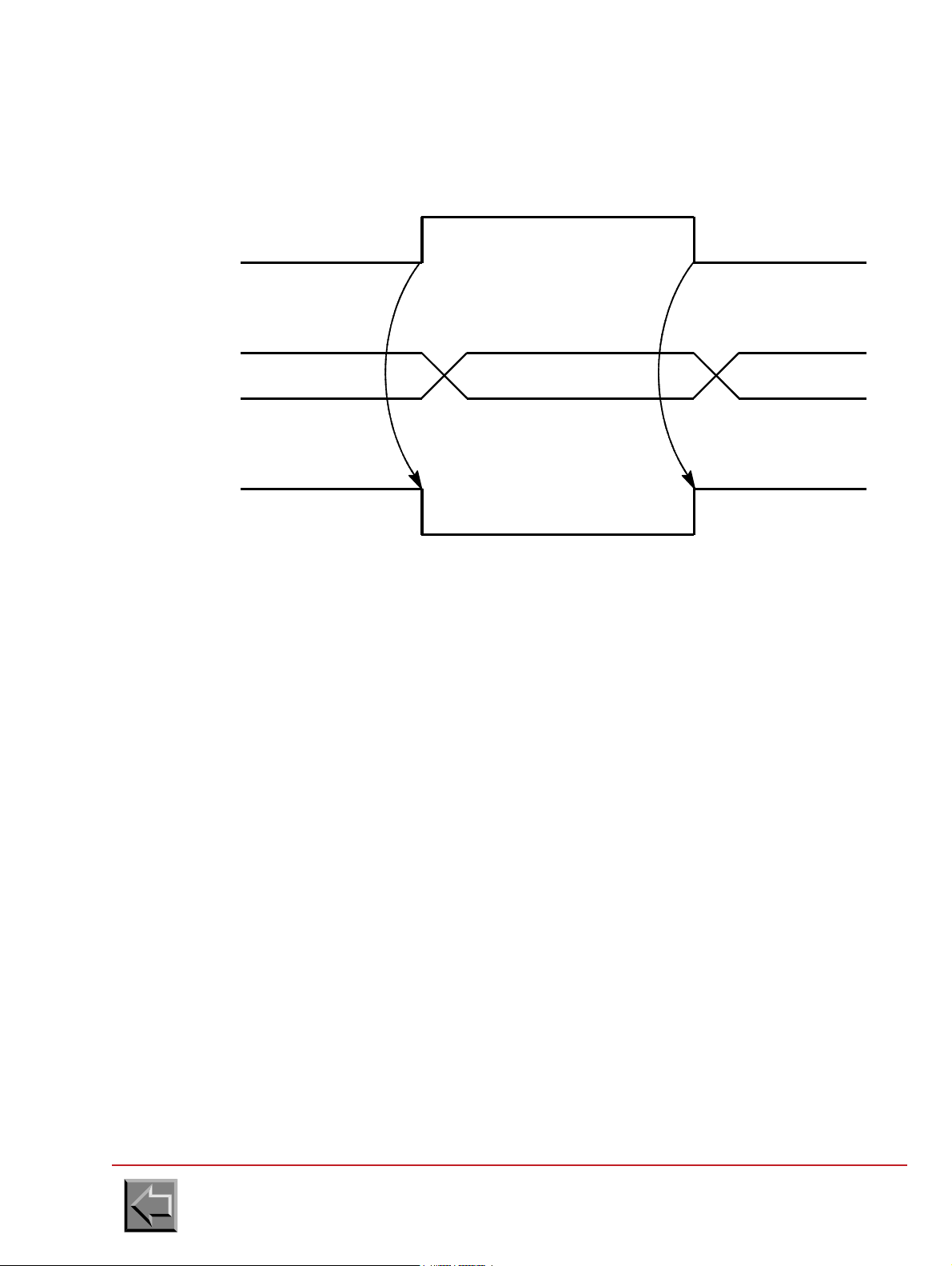

- "1": switch opened

Go to "Table of contents"

3-8

Page 71

2. Current source

PRINTER

INTERFACE

EXTERNAL DEVICE

INTERFACE

+

-

-

Source I

Courrent

R

I

+12V

0V

0 ohms < R < 400 ohms

PRINTER

INTERFACE

EXTERNAL DEVICE

INTERFACE

+

-

R

I

+5V

7407

MCT6

I maxi = 2 mA

"0": I = 10 mA

"1": I = 0 mA

Site preparation manual

VARYPRESS 200

3. Opto Isolated ouput

"0": I = 10 mA

"1": I = 0 mA

Go to "Table of contents"

3-9

Page 72

4. Differential serial output

PRINTER

INTERFACE

EXTERNAL DEVICE

INTERFACE

+

TX

RXD_H

RXD_L

+

-

Line

driver

3487

-

PRINTER

INTERFACE

EXTERNAL DEVICE

INTERFACE

+

-

100

I

+5V

470

+

-

2.2microF

0V 0V

74HC14

Site preparation manual

VARYPRESS 200

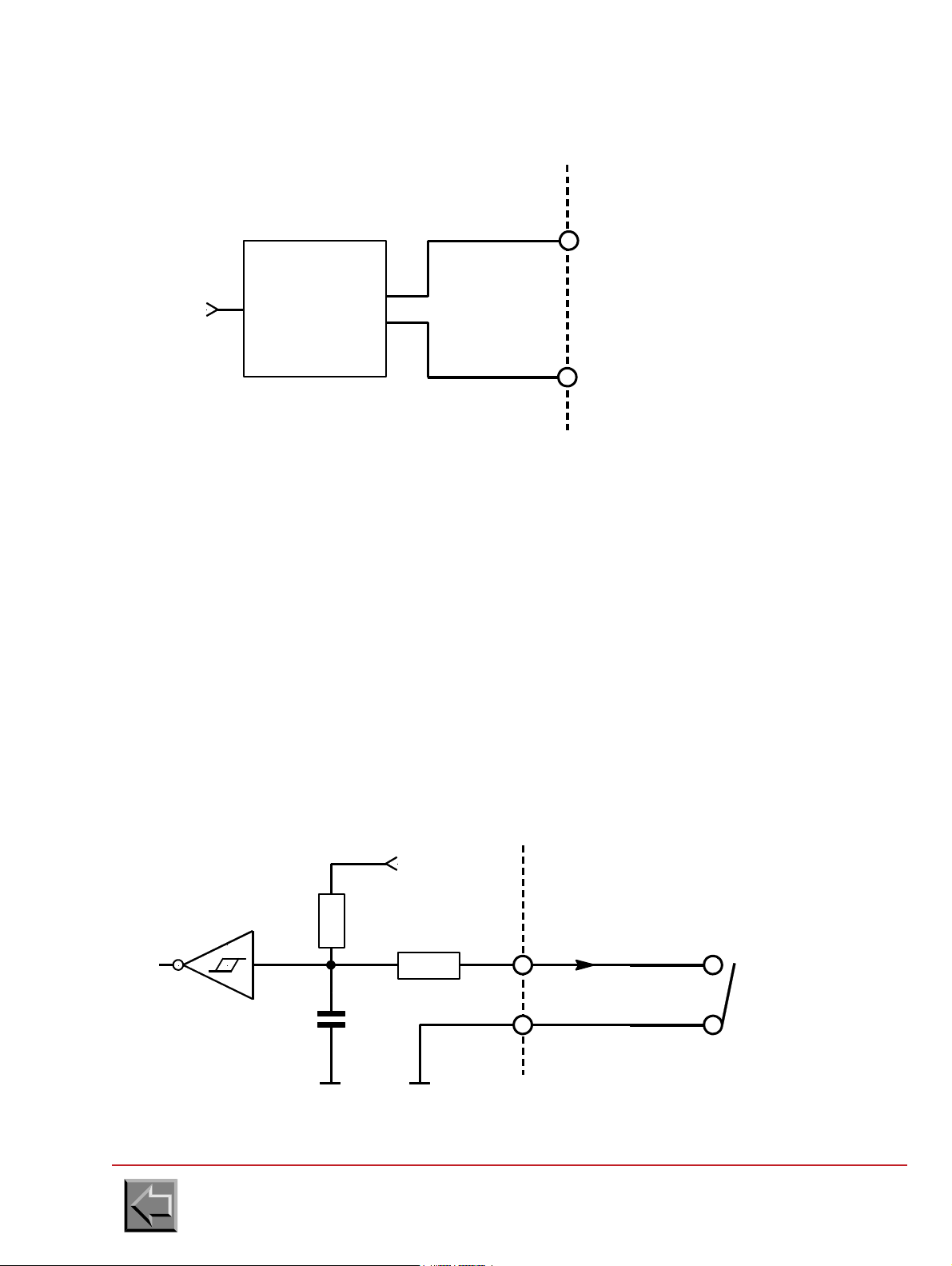

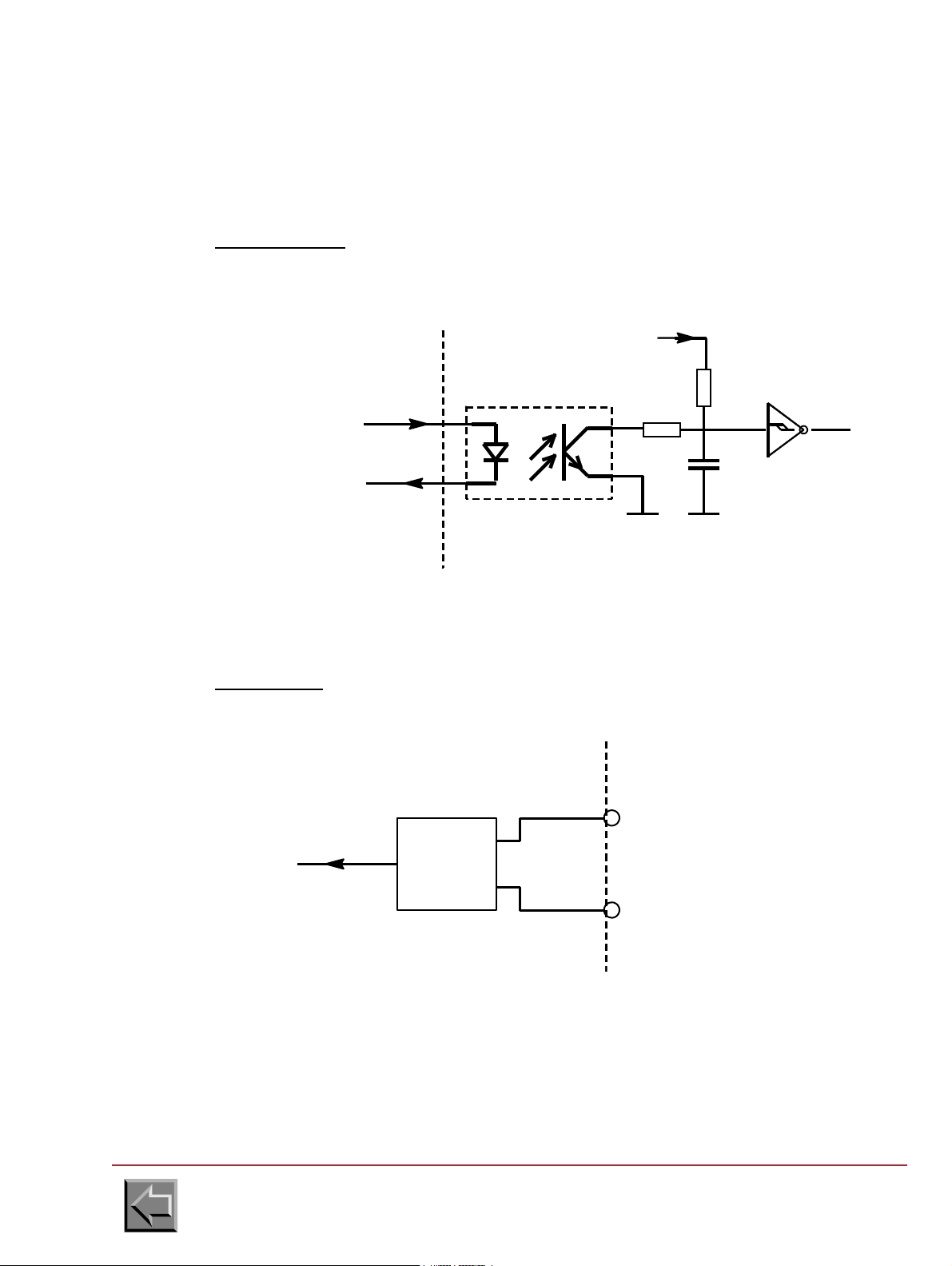

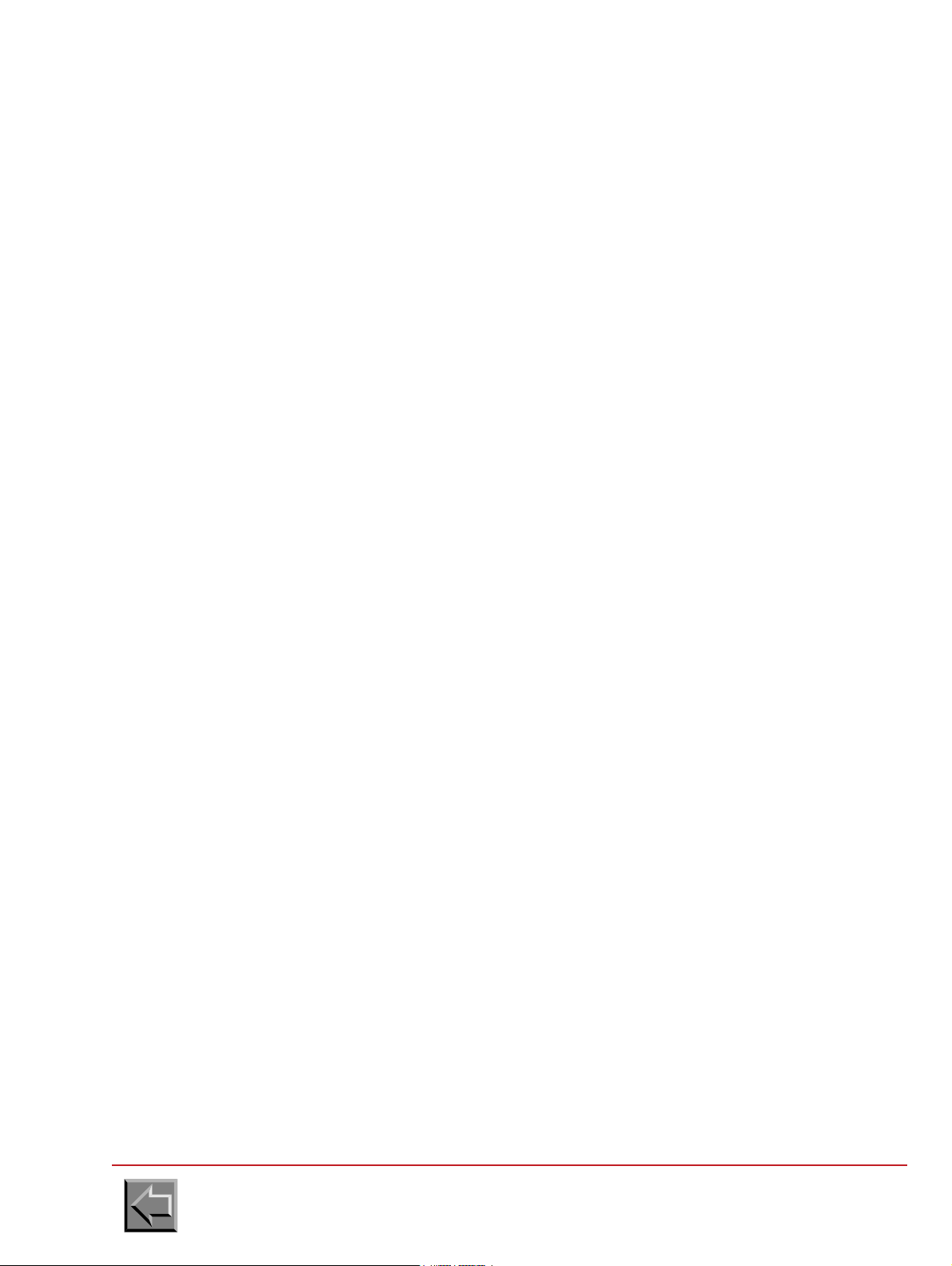

3.4.2 Signals from the external device to the printer

The input signal interface can be adapted to the printer interface in 3 different input types:

-Switch

- Opto Isolator

-Differential