Nilfisk-Advance 56381032, X4030D-EcoFlex, 56381037, X4830C-EcoFlex w/Side Broom, 56381033 Service Manual

...Page 1

Condor™ EcoFlex™, BR 1100 S/SC EcoFlex™, BR 1300 S/SC EcoFlex

™

Service Manual

Advance Models:

56381032 (X4030D-EcoFlex) 56381037 (X4830C-EcoFlex w/Side Broom)

56381033 (X4030C-EcoFlex w/Side Broom) 56381043 (X4030C-EcoFlex w/o Side Broom)

56381034 (X4530D-EcoFlex) 56381044 (X4530C-EcoFlex w/o Side Broom)

56381035 (X4530C-EcoFlex w/Side Broom) 56381045 (X4830C-EcoFlex w/o Side Broom)

56381036 (X4830D-EcoFlex)

Nilfisk Models:

56413006 (BR1000 S EcoFlex w/o Side Broom) 56413007 (BR1000 S C EcoFlex w/Side Broom)

56413010 (BR1300 S EcoFlex w/o Side Broom) 56413011 (BR1300 S C EcoFlex w/Side Broom)

English

7/11 Form No. 56043154

Page 2

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Parts and Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Transporting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Manuals Available for Your Machine . . . . . . . . . . . . . . . . . . . . . . . . . 5

Caution and Warning Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Emergency-stop Switch/Battery Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . 8

Technical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Machine Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

General Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Chassis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Major Chassis Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Main Control Programming Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Service Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

I/O Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

™

2Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Low-voltage Cut-out Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Battery Condition Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

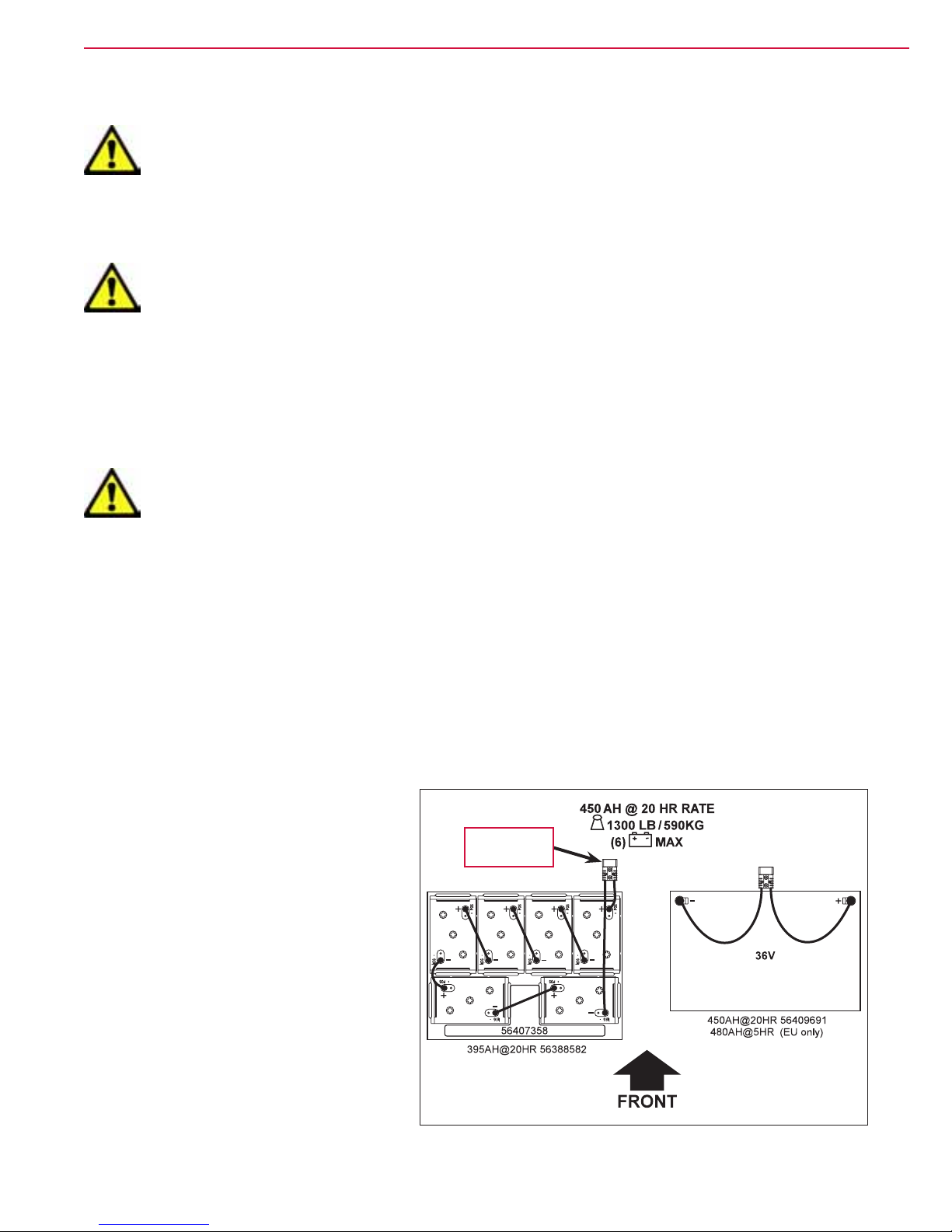

Battery Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Options and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Recovery System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

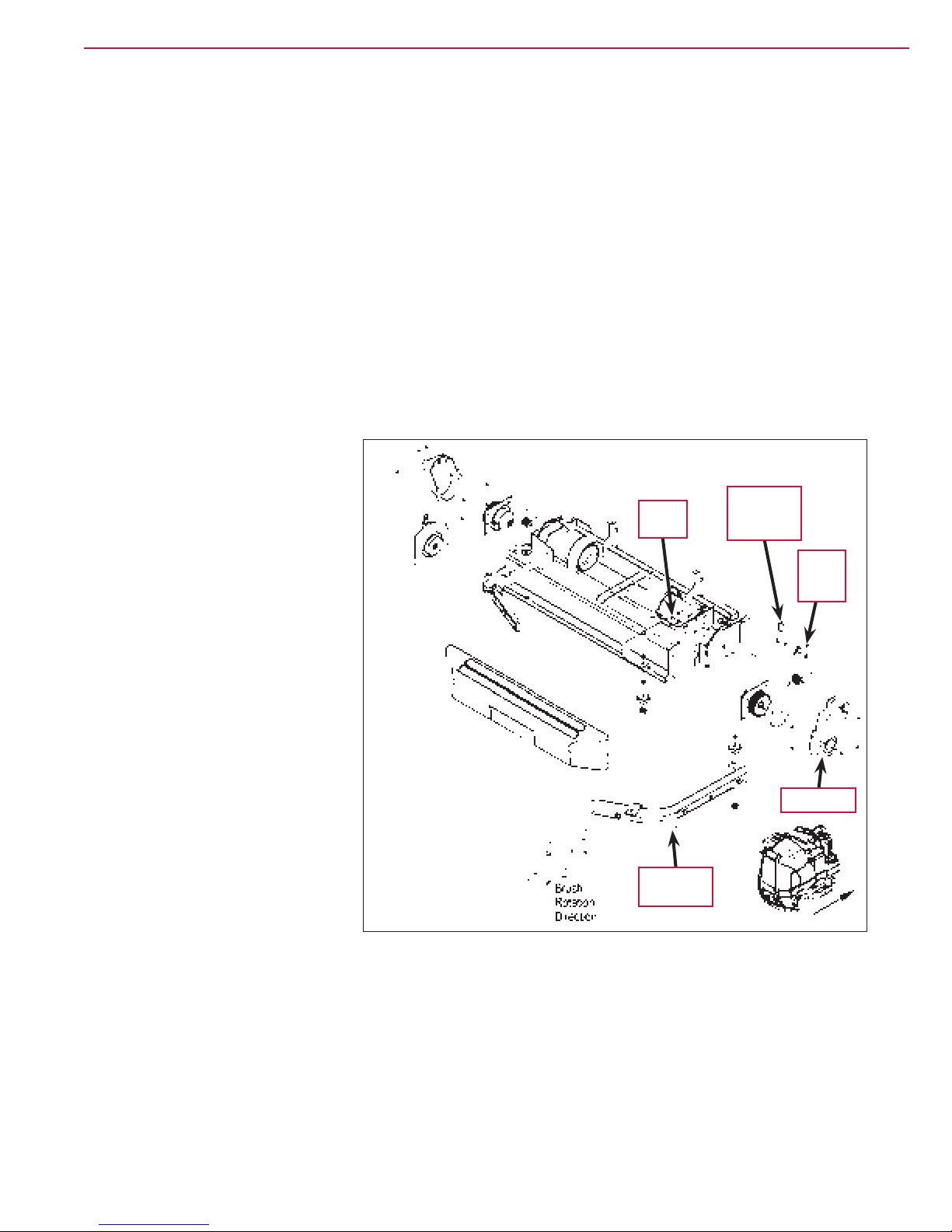

Scrub System, Cylindrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Page 3

™

Scrub System, Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Solution System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Contents 3Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Squeegee System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 122

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Specications . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . 129

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Sweep System, Side Broom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Wheel System, Non-traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Wheel System, Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Electrical Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Ladder Diagram, Rev. G . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Wiring Diagram, Rev. I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Detergent (EcoFlex™) System Plumbing Schematic . . . . . . . . . . . . . . . . . . . . 169

Detergent (EcoFlex™) System Preparation and Purging . . . . . . . . . . . . . . . . . 170

Page 4

™

General Information

Introduction

This manual will help you get the most from your Advance rider scrubber. Read it thoroughly before

servicing the machine.

Parts and Service

Repairs should be performed by your Authorized Advance Service Center, which employs factory-trained

service personnel and maintains an inventory of Advance original replacement parts and accessories.

Call the Advance dealer named below for repair parts or service. Please specify the Model and Serial

Number when discussing your machine.

4Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

(Dealer, afx service sticker here.)

Nameplate

The Model Number and Serial Number of your machine

are shown on the machine nameplate. This information

is needed when ordering repair parts for the machine.

Use the space below to note the Model Number and Serial

Number of your machine for future reference.

Model Number:

Serial Number:

Note that the Nameplate is attached to the rear of the

steering column.

Nameplate

Page 5

Transporting the Machine

Caution! Before transporting the machine on an open truck or trailer, make sure that:

• The machine is tied down securely.

• All access doors and covers are secured (tape and strap as needed).

• The battery/batteries are disconnected.

Towing

Caution! If the machine must be towed or pushed, make sure the Master On/Off Key Switch is

in the Off position. Do not move the machine faster than a normal walking pace (2-3

mph, 3-5 kph) and for short distances only.

Note: Disconnecting the wheel drive motor wiring connector will make a disabled machine easier

to push.

™

General Information 5Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Other Manuals Available for Your Machine

Electronic Databases

The manuals listed below can be found on Advance’s electronic supported databases. They are:

• Advance Dealer Customer Zone

• EzParts service / parts CD-ROM

• Nilsk-Advance website: www.nilsk-advance.com

Manuals

• Parts List - Form Number 56042467

• Instructions for Use - Form Number 56041986 (English, Spanish)

• Curtis Programmer Manual Number 56043101

Page 6

™

General Information 6Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Caution and Warning Symbols

Advance uses the symbols below to signal potentially dangerous conditions. Read this information carefully

and take the necessary steps to protect personnel and property.

Danger! Is used to warn of immediate hazards that will cause severe personal injury or death.

Warning! Is used to call attention to a situation that could cause severe personal injury.

Caution! Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property.

Read all instructions before using.

General Safety Instructions

Specic Cautions and Warnings are included to warn you of potential danger of machine damage or bodily

harm.

Warning!

• This machine is to be used only by correctly trained and authorized persons.

• Avoid sudden stops while on ramps or inclines when the tanks are full. Avoid abrupt sharp

turns. Use low speed down hills. Clean only while ascending (driving up) the ramp.

• Keep sparks, flame and smoking materials away from batteries. Explosive gases are vented

during normal operation.

• Charging the batteries produces highly-explosive hydrogen gas. Charge batteries only in

well-ventilated areas, away from open flame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical

components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense flammable cleaning agents, operate the machine on or near these agents, or

operate in areas where flammable liquids exist.

• Only use the brushes provided with the machine or those specified in the instruction manual.

The use of other brushes may impair safety.

Page 7

™

General Information 7Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Caution!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Do not use scarifier discs and grinding stones. Advance will not be held responsible for any

damage to floor surfaces caused by scarifiers or grinding stones. (This can also damage the

brush drive system.)

• When operating this machine, ensure that third parties, particularly children, are not

endangered.

• Before performing any service function, carefully read all instructions pertaining to that

function.

• Do not leave the machine unattended without first turning the key switch off (O), removing

the key and applying the parking brake.

• Turn the key switch off (O) and remove the key before changing the brushes, and before

opening any access panels.

• Take precautions to prevent hair, jewelry or loose clothing from becoming caught in moving

parts.

• Use caution when moving this machine in below-freezing temperature conditions. Any

water in the solution, recovery or detergent tanks, or in the hose lines could freeze, causing

damage to valves and fittings. Drain the tanks and purge with windshield washer fluid.

• The batteries must be removed from the machine before the machine is scrapped.

The disposal of the batteries should be done safely and in accordance with your local

environmental regulations.

• Do not use on surfaces having a gradient exceeding that marked on the machine.

• All doors and covers are to be positioned as indicated in the instruction manual before using

the machine.

Caution! Do not pressure-wash the operator control panel, circuit breaker panel or any

electrical areas of the machine.

Page 8

™

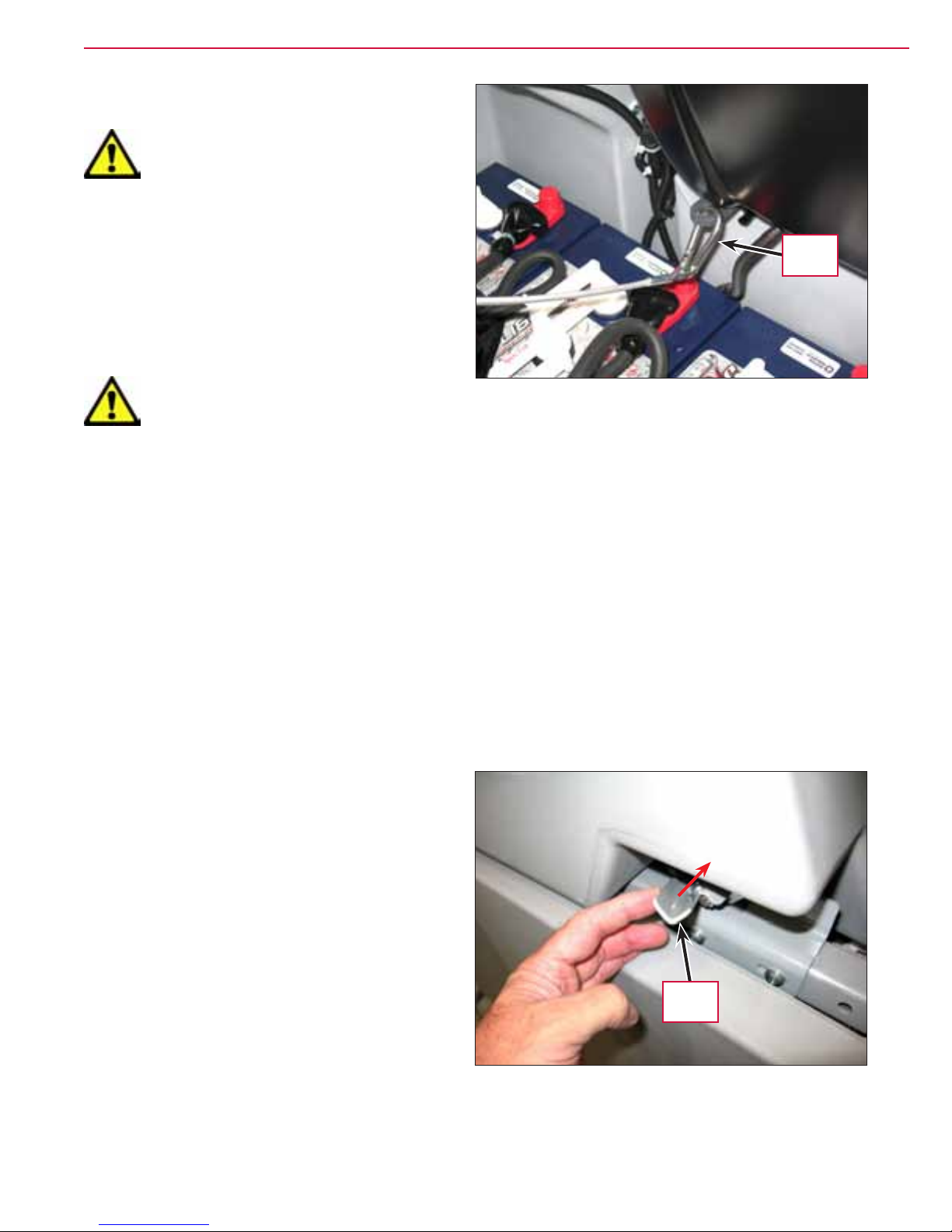

Emergency-stop Switch/Battery Disconnect

The Emergency-stop/Battery Disconnect is the red

lever located to the right of the Operator’s seat. In

the event of an emergency, press the Emergency-

stop/Battery Disconnect

the machine) to disconnect the battery from the

machine. This will stop all machine functions.

in (toward the rear of

General Information 8Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Emergency-stop/

Battery Disconnect

Save These Instructions

Page 9

™

Technical Specifications

General Specifications Common to All Models

Machine Length 73.5 in. [187 cm]

Machine Height 58.5 in. [148.6 cm]

Machine Height (w/overhead guard 84 in. [213 cm]

Machine Body Width 40 in. [101.6 cm]

Solution Tank Capacity 70 gal. [265 L.]

Recovery Tank Capacity 70 gal. [265 L.]

Sound pressure level as per IEC 60704-1 (at operator) 72 dB(A)

Vibrations at the Hand Controls (ISO 5349-1) 1.12 m/s

Vibrations at the Seat (EN 1032) 0.35 m/s

Transport Speed (Fwd. Maximum) 5.5 mph [8.9 kph]

Transport Speed (Rev. Maximum) 4.8 mph [7.7 kph]

Gradeability (Transport) 14.5% / 8°

Gradeability (Working –Scrubbing) 10.5% / 6°

Wheel Drive Motor 1.75 HP, 1300 watt

Vacuum Motor (3 stage) .75 HP, 560 watt

Vacuum Water Lift for one motor

Vacuum Water Lift for two motors

(Sealed) 68 in.

(Open Hole Adapter 1”) 14 in.

(Sealed) 74 in.

(Open Hole Adapter 1”) 27 in.

Power Source (Batteries)

Battery Weight (395 amp) STD (6) 6 volt @ 20 hour rate 121 lbs. [55 kg]

Battery Weight (450 amp) Opt. (1) Mono-block @ 20 hour rate 919 lbs. [417 kg]

Battery Compartment Size (approximate)

Height (Max.) 19 in. [48.2 cm]

Width (Max.) 20 in. [50.8 cm]

Length (Max.) 31.75 in. [80.6 cm]

Maximum Wheel Floor Loading (Center Front) 116 psi / 119.9 kg/cm

Maximum Wheel Floor Loading (Left Rear) 86 psi / 88.9 kg/cm

Maximum Wheel Floor Loading (Right Rear) 81 psi / 83.7 kg/cm

Battery Chargers – see the Electrical System/Specifications section.

2

2

General Information 9Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

2

2

2

Page 10

™

General Information 10Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Specifications Common to Deck Size

Model designations: 40” = Condor 4030 D/C; 45” = Condor 4530 D/C; 48” = Condor 4830 D/C

40” 45” 48”

Machine Width

with Squeegee

Scrub Brush Size

Brush Diameter - Disc (2) 20 in. [50.8 cm] (3) 16 in. [40.6 cm] (3) 17 in. [43 cm]

Outside Scrub Brush Diameter -

Cylindrical (inside core is 5 in.)

Scrub Brush Length (two per

machine)

Scrub Brush

Motors

Scrub Brush

Speed

Minimum Aisle Turn Width 84 in. [214 cm] 84 in. [214 cm] 84 in. [214 cm]

Machine Net

Weight*

Machine Gross

Weight**

Cleaning Width

(scrubbing path)

Coverage Rate

Per Hour

English 49 in. “F” 54 in. “G” 57 in. “H”

Metric 78 cm “F” 87 cm “G” 91 cm “H”

8.5 in. [21.6 cm] 8.5 in. [21.6 cm] 8.5 in. [21.6 cm]

38.37 in. [97.4 cm] 43.62 in. [110.8 cm] 46.62 in. [118.4 cm]

Disc

(1) 3.0 HP

2240 watts

(3) 1.5 HP

1120 watts

(3) 1.5 HP

1120 watts

Cylindrical All Cylindrical Models use (2) 1.5 HP 1120 watts Disc 240 RPM 225 RPM 225 RPM

Cylindrical 630 RPM 630 RPM 630 RPM

English 1,845 lbs. 1,845 lbs. 1,845 lbs.

Metric 837 kg 837 kg 837 kg

English 3,545 lbs. 3,545 lbs. 3,545 lbs.

Metric 1608 kg 1608 kg 1608 kg

English 40 in. 45 in. 48 in.

Metric 101 cm 114 cm 122 cm

English @ 3.5

mph

Metric @ 5.6

kph

61,600 ft

5722 m

2

2

69,300 ft

6438 m

2

2

73,920 ft

6867 m

2

2

*Net Weight: Standard machine without options, empty solution and recovery tanks, without removable

scrub brushes and no batteries installed.

** Gross Weight: Standard machine without options, full solution tank and empty recovery tank, with

removable scrub brushes and 450 AH batteries.

*** Listings for watts are maximum values.

Page 11

Dimensions

™

General Information 11Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Page 12

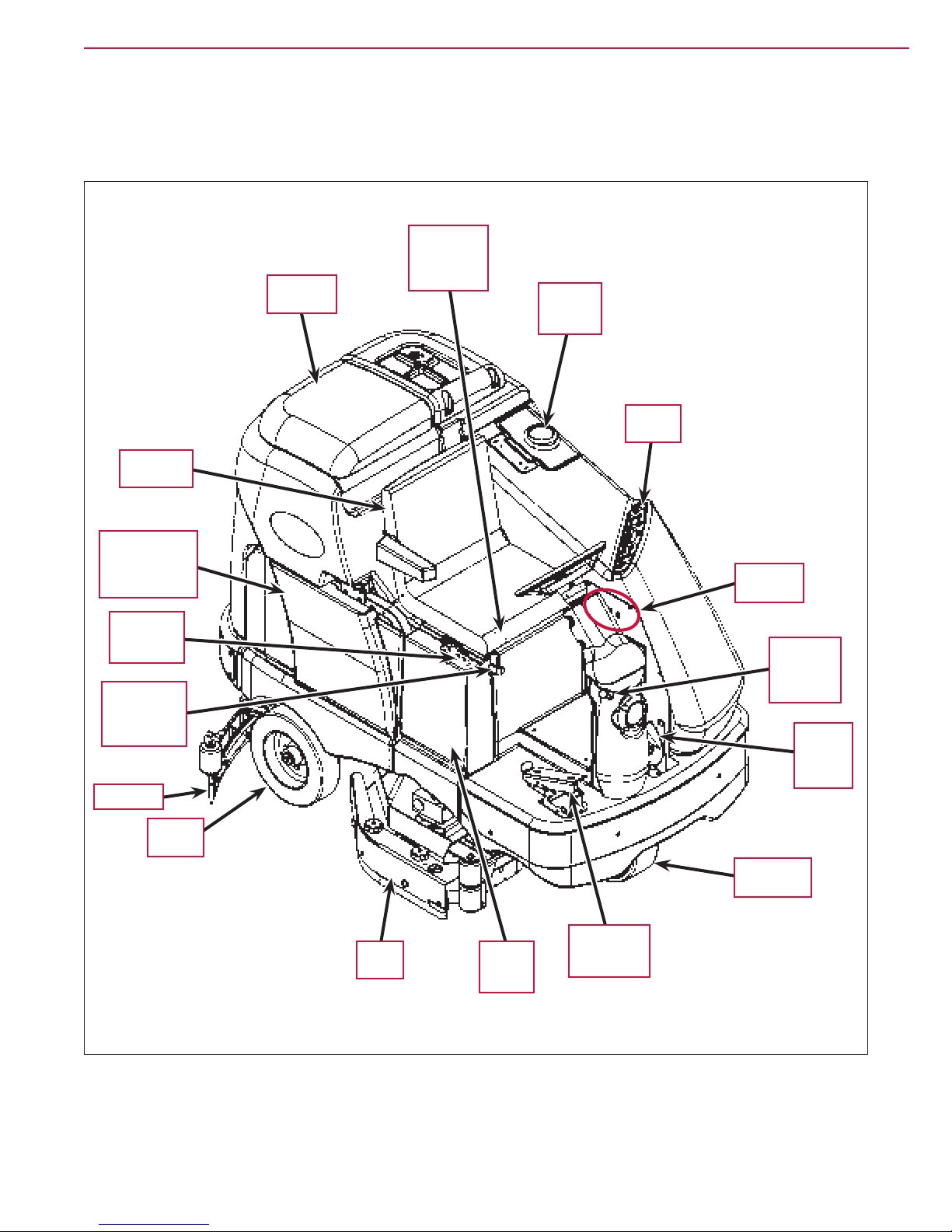

General Machine Overview

Major Machine Components

Recovery

Tank Lid

Operator’s

Seat

Operator’s

Seat

Adjustment

Lever

™

Solution

Tank Fill

Cover

Control

Panel

General Information 12Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Battery

Compartment

(underneath

recovery tank)

Machine

Battery

Connector

Emergencystop Switch/

Battery

Disconnect

Squeegee

Rear

Wheel

Scrub

Deck

Side

Access

Panel

Circuit

Breakers

Steering

Wheel

Tilt/Adjust

Knob

Brake

Pedal/

Parking

Brake

Drive/Steer

Wheel

Drive Pedal,

Direction/

Speed

Page 13

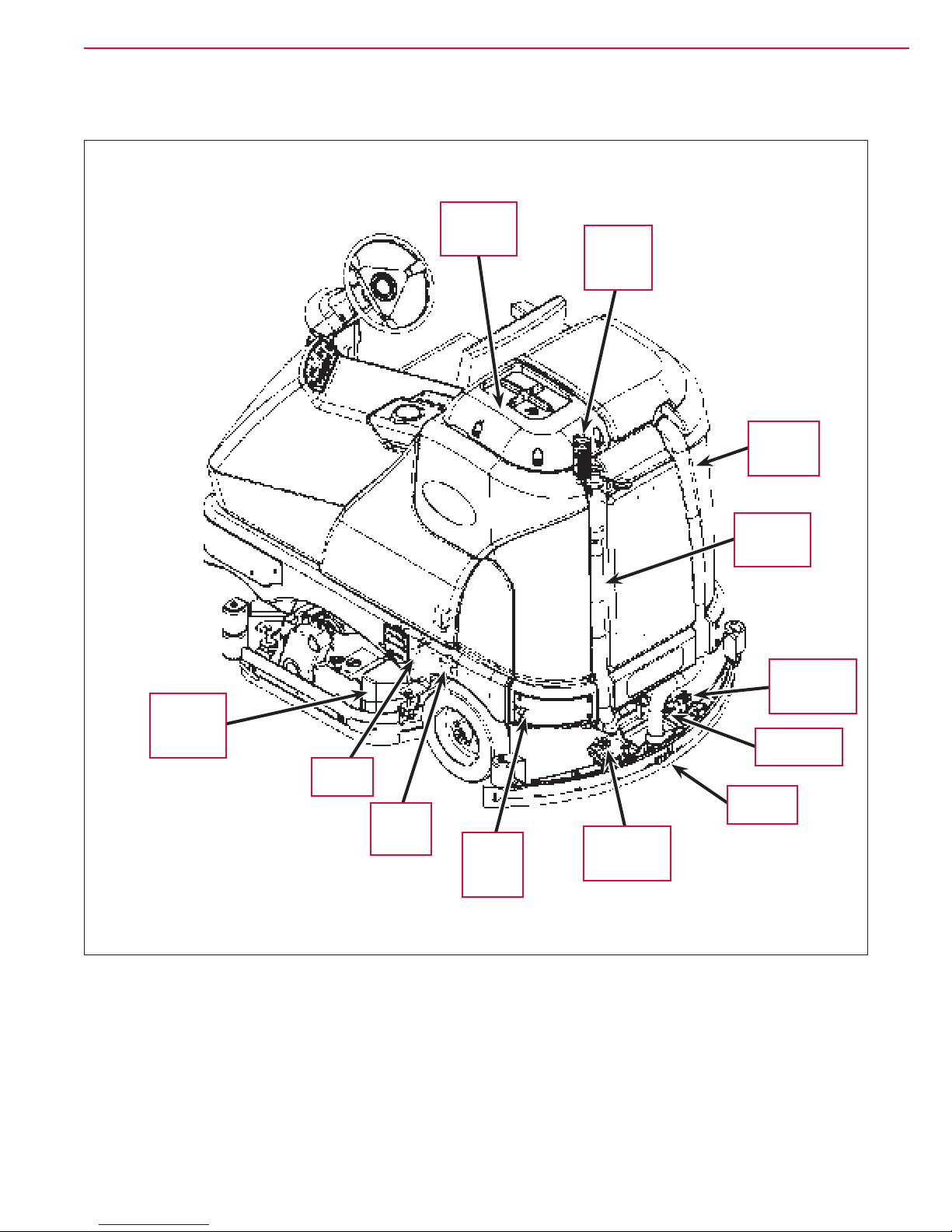

™

Top

Cover

Assembly

General Information 13Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Recovery

Tank

Shutoff

Valve

Squeegee

Vacuum

Hose

Hopper

(cylindrical

models

only)

Solution

Filter

Solution

Shutoff

Valve

Solution

Tank

Drain

Hose

Recovery

Tank

Drain Hose

Squeegee

Height

Adjust Knob

Squeegee Tilt

Adjust Knob

Squeegee

Assembly

Squeegee

Height

Adjust Knob

Page 14

™

General Information 14Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

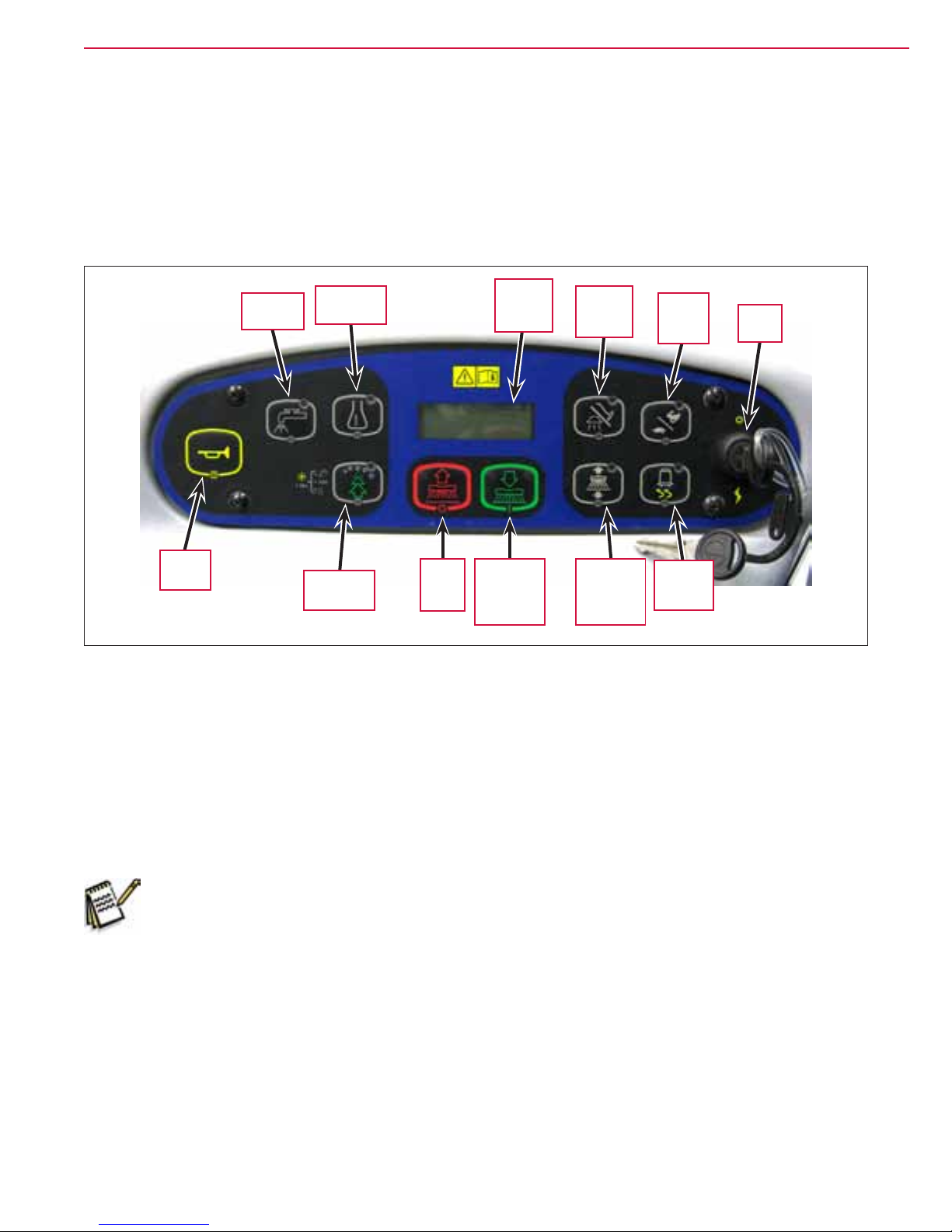

Control Panel

Switch and Button Functions

The controls on your rider scrubber were designed with one-touch operation in mind. For single-pass

scrubbing, the user can simply depress one switch and all systems on the machine will be ready to go. For

most single-pass scrubbing operations, the operator should only need to use the middle switches on the

control panel. These are the red Scrub Off and the green Scrub On/Pressure Increase Switches.

Horn

Button

Solution

Switch

Detergent

Switch

EcoFlex™

Button

Scrub

Off

Switch

Control

Panel

Display

Scrub On/

Pressure

Increase

Switch

Vacuum/

Wand

Switch

Side

Broom

On/Down

Switch

Scrub

Speed

Switch

Traction

Control

Switch

Key

Switch

• Key Switch – main power switch; controls the battery input to the machine’s main control board and the

wheel drive speed control.

• Scrub On/Pressure Increase Switch – functions as follows:

If the scrub system is off, pressing this switch once will put the machine into the Auto Scrub mode. The

following will occur:

– The scrub system will be enabled with the scrub pressure set to the #1 normal setting.

Note: Press the switch twice for #2 heavy scrub setting, and three times for the #3 extreme scrub

setting. Pressing the switch a fourth time will return the system to the normal scrub setting.

– The scrub deck and squeegee will automatically be lowered. On cylindrical models equipped with side

brooms, the side brooms will be lowered.

– The vacuum system will be enabled.

– The solution and detergent systems will be enabled. Note that both the solution and detergent ow

rates will correspond to the selected scrub pressure mode.

– As soon as the drive pedal is moved from its neutral position, the scrub brushes and side brooms (if

installed) will start turning, and the solution, detergent and vacuum systems will switch on.

Page 15

™

General Information 15Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

◦ If the direction is forward, the solution and detergent ow will also start automatically.

◦ If the direction is reverse, the solution and detergent ow will be stopped and the squeegee will be

raised just enough to clear the oor surface.

Note: The solution, vacuum and detergent systems are automatically enabled when the Scrub On

Switch

is pressed to put the machine into the Auto Scrub mode. Any individual system can

be toggled off and on by simply pressing the corresponding system switch at any time during

scrubbing.

If the machine is already scrubbing, pressing the Scrub On/Pressure Increase Switch will increase the

scrub pressure to the next higher setting (toggling from regular to heavy, heavy to extreme, then back to

normal). The Scrub Pressure Indicator will show the selected scrub pressure (one, two or three bars) in the

Control Panel Display.

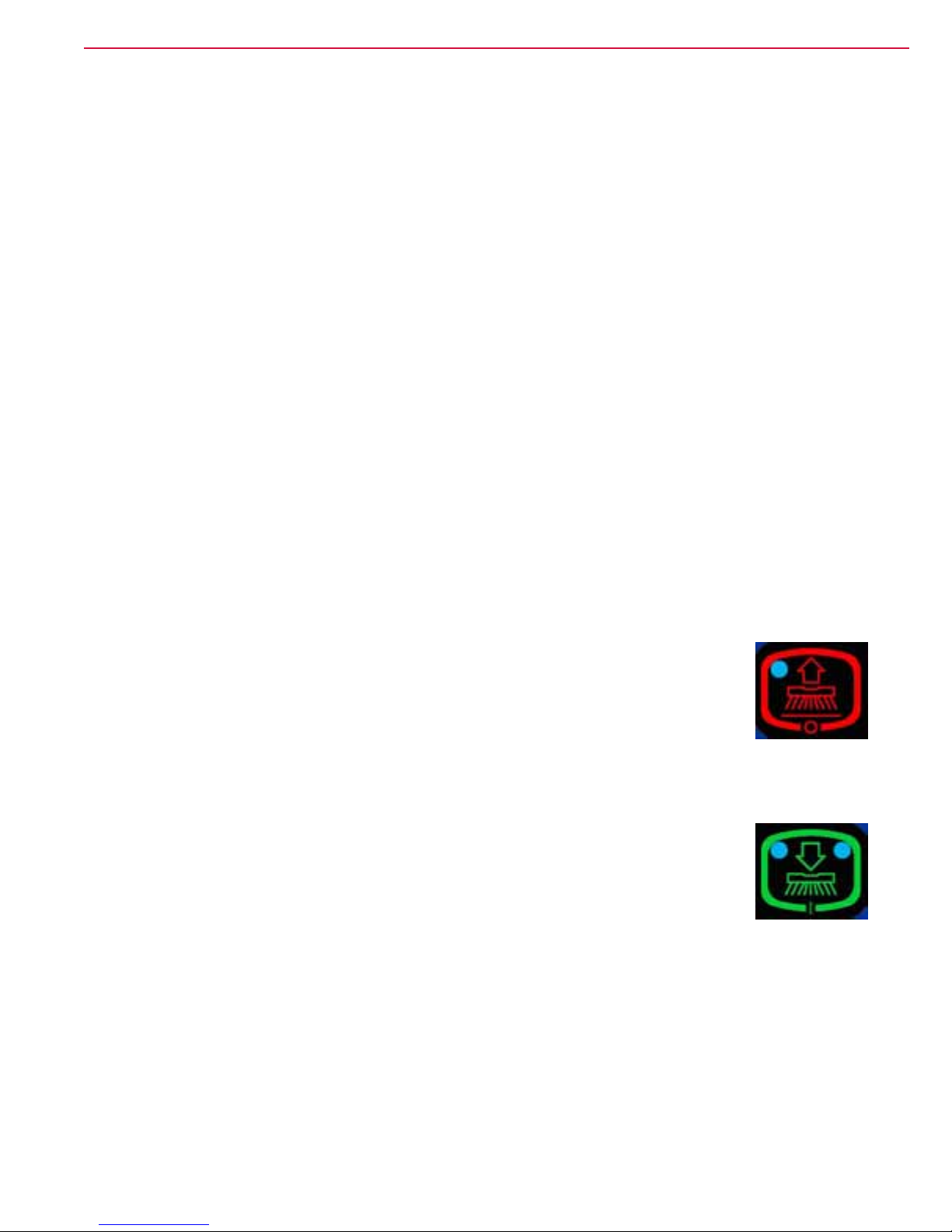

• Scrub Off Switch – Pressing this switch when the machine is in the scrub mode will cause the following to

occur:

– The scrub brushes will turn off and the scrub deck will be raised to the up position. On cylindrical

models equipped with side brooms, the side brooms will shut off and be raised.

– The solution and detergent ow will be stopped.

– Once forward machine motion stops, the vacuum/wand switch indicator light will start to blink. After

a user-programmable time delay, the squeegee will be raised and the vacuum motors will shut off.

Pressing the switch a second time before the vacuum time delay is complete will raise the squeegee

and turn off the vacuum motors immediately.

• Solution Switch – functions as follows:

– If the scrub system is off, pressing and holding this switch will switch on the solution ow to pre-

wet the oor. The solution ow will stop when the switch is released. Note this must be done prior to

pressing the Scrub On Switch and putting the machine into the Auto Scrub mode.

– If the machine is in the Auto Scrub mode, pressing this switch will disable the solution system. This is

used if you wish to scrub without adding additional solution to the oor.

– If the machine is in the Auto Scrub mode, you can use the Solution Switch to actuate the solution ow

override function. This override function allows you to select a different solution ow rate without

changing the scrub pressure. Note that the machine is programmed for two additional higher solution

ow rates plus the three normal default ow rates, for a total of ve solution ow rates.

To actuate the solution ow override function, press and hold the Solution Switch for three seconds until

the Solution System Indicator ashes, then release it. You’ll have three seconds to select the desired

solution ow rate by pressing the Solution Switch. The Solution Flow Indicator will show the selected

solution ow rate (one through ve bars) in the Control Panel Display. Note that if any scrub pressure

change is made while in the solution override mode, the solution ow will return to its default solution

ow rate.

• Detergent Switch – functions as follows:

– If the solution system is enabled, pressing this switch will toggle the detergent system off and on.

When the detergent system is on, the detergent pumps will be activated at a specic rate when the

drive pedal is actuated. The detergent pump will turn off when the drive pedal is in neutral or reverse.

– If the solution system is off, the detergent pump will not turn on.

Page 16

™

General Information 16Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

• Vacuum/Wand Switch – functions as follows:

– If the machine is in the Auto Scrub mode, pressing this switch once will raise the squeegee. The

vacuum motors will run for a short time delay, then shut off. If you press the switch twice, the vacuum

motors will shut off immediately. This is used if you wish to double-scrub (scrub without recovering the

solution).

– If the scrub system is off, the Vacuum/Wand Switch functions differently depending on whether the

seat switch is open (no operator in the seat) or closed (operator in the seat).

◦ If the operator is in the seat, pressing the switch will lower the squeegee and switch on the vacuum

motors. When the machine is moved into reverse, the squeegee will be raised, then lowered when

the machine is again moved forward. This mode is used to pickup water from the oor without

scrubbing or adding solution.

◦ If the operator is not in the seat, pressing the switch will toggle the vacuum motors on and off

to allow use of the vacuum wand. In this mode, the squeegee will not move up or down and the

recovery tank full indicator is ignored.

• Scrub Speed Switch – When the machine is operating in any one of its scrub settings, the machine’s

travel speed is reduced to 80 percent of the maximum transport speed pre-programmed into the speed

controller. Pressing the Scrub Speed Switch overrides the 80 percent of transport speed limit and increases

the scrub speed to 100 percent of transport speed.

• Traction Control Switch – regulates the drive wheel motor torque to minimize drive wheel slippage and

provide better traction.

• Side Broom On/Down Switch – lowers and raises the side brooms (only functional on cylindrical models

equipped with side brooms). Note that when the scrub system is switched on, the side brooms are lowered

to the same position they were in when the scrub system was last turned off (auto memory operating

position).

Note: You can raise or lower the side broom height to maintain the correct broom contact patterns

and compensate for normal broom wear. Refer to the Sweep System, Side Broom section for

instructions on setting the side broom height.

• EcoFlex

™

Button – The EcoFlex™ Button functions differently depending on whether the EcoFlex

™

mode is

set to Mode 1 or Mode 2. (Also refer to the Control System/Main Programming Options/ EcoFlex™ Mode

Selection section.) Note that in Mode 1 the detergent concentration is displayed as a ratio. In Mode 2 the

detergent concentration is displayed as a percent.

– In EcoFlex™ Mode 1, the detergent ratio is preset to 1:400. Pressing the EcoFlex

™

Button in Mode 1 will

do the following:

◦ The detergent ratio will change to the programmed ratio. (Also refer to the Solution System/

Maintenance and Adjustments/To Program the Detergent Ratio section.)

◦ The scrub pressure will increase to the next highest pressure.

◦ The solution ow rate will increase to the next highest rate.

After 60 seconds, or after you press the EcoFlex

and the scrub pressure and solution rate will return to their previous settings.

™

Button again, the detergent ratio will revert to 1:400,

Page 17

™

General Information 17Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

– In EcoFlex™ Mode 2, the default detergent ratio will be the programmed ratio. Pressing the EcoFlex

Button

in Mode 2 will do the following:

◦ The detergent concentration will change to the next highest (richest) concentration. For example,

if the programmed concentration is 0.4%, pressing the EcoFlex

™

Button will change it to 0.5%. (Also

refer to the Solution System/Maintenance and Adjustments/To Program the Detergent Ratio

section.)

◦ The scrub pressure will increase to the next highest pressure.

◦ The solution ow rate will increase to the next highest rate.

After 60 seconds, or after you press the EcoFlex

™

Button again, the detergent ratio will revert to the

programmed ratio, and the scrub pressure and solution rate will return to their previous settings.

• Horn Button – sounds the horn when pressed.

• Control Panel Display – displays the various icons that indicate scrub pressure, solution ow rate,

detergent ratio, battery charge state and a recovery tank full condition. The display also shows any error

conditions detected by the main control board.

Control Panel Indicators

™

In general the following guidelines apply to the control panel indicators:

• When the key switch is rst turned on all of the blue control panel indicator lights will turn on for one

second for an operational test.

• A blue indicator means that a system is on and running, or has been enabled and is ready to switch on

when the drive pedal is moved into forward or reverse.

• The indicators will be off when the system is disabled or switched off.

• The green EcoFlex

™

Indicator will be on when the system is in the low-concentration mode, and ash when

the 60-second burst of power function is active.

Solution

System

Indicator

Detergent

System

Indicator

Vacuum/

Wand

Indicator

Maximum

Scrub

Speed

Indicator

EcoFlex

Indicator

Scrub Off

Indicator

Scrub On/

Scrub Mode

Select

Indicators

Side

Broom

On/Down

Indicator

Traction

Control

Indicator

Page 18

™

General Information 18Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

• Scrub On/Scrub Mode Select Indicator:

– The left side indicator will light when the normal scrub mode is selected.

– The right side indicator will light when the heavy scrub mode is selected.

– Both the right and left indictors will light when the extreme scrub mode is selected.

– Both the right and left indictors will be off when the scrub system is off.

• Scrub Off Indicator:

– The indicator will light to indicate that the scrub system is off and is ready to be activated.

– The indicator will be off when the scrub system is enabled and/or switched on.

• Solution System Indicator:

– The indicator will light when the solution system is enabled and/or is switched on.

– The indicator will be off when the solution system is off.

– The indicator will ash when the solution tank (liquid level) oat switch senses a low solution level.

• Detergent System Indicator:

– The indicator will light when the detergent system is enabled and/or is switched on.

– The indicator will be off when the detergent system is off.

Note: The control board automatically recognizes that the machine has an operational detergent

system through its wiring harness connection.

• Vacuum/Wand Indicator:

– The indicator will light when the vacuum system is enabled and/or is switched on.

– The indicator will be off when the vacuum system is off.

– The indicator will ash when the vacuum system is operating in the time delay shutdown mode

(normally ve to 10 seconds).

• Maximum Scrub Speed Indicator:

– The indicator will light when the maximum 100% transport speed during scrubbing is enabled.

– The indicator will be off when normal scrub speed is enabled.

• Traction Control Indicator:

– The indicator will light when the traction control mode is enabled.

– The indicator will be off when the traction control mode is disabled.

Page 19

™

General Information 19Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

• Side Broom On/Down Indicator:

– The indicator will be on when the side brooms are in the down working position, enabled and switched

on.

– The indicator will be off when the scrub system is switched off and the brooms are in the raised

position.

• EcoFlex Indicator:

– The (green) indicator will be on when the EcoFlex™ low-concentration detergent mode is enabled.

– The (green) indicator will ash when the EcoFlex™ burst of power mode is enabled.

– The (green) indicator will be off when the EcoFlex™ full-concentration detergent mode is enabled.

Note: When the recovery tank becomes full (when in the auto scrub mode), the vacuum motors and

all other systems shut off except the drive motor. The LCD on the dash panel will display the

full tank icon.

Control Panel Display

The control panel display is a liquid

crystal display (LCD) that shows the

hour meter, battery charge indicator,

solution ow rate and scrub pressure.

Hour

Meter

If the detergent system is enabled, the

display will also show the detergent

system indicator and the current

detergent/solution ratio.

If an A2 Control Board error occurs,

the display will show a wrench icon

Error

Indicator

Error

Code

Number

Ø .4

29

to indicate an error, and display a

two-digit error code number. If more

than one error exists, the display will

sequence through the error codes at

Regular

Solution

Flow

one-second intervals. (Refer to the

Control System section for a list of the

A2 Control Board error codes.)

Caution Displays

If the recovery tank is full, the display will show a caution symbol

and the tank full icon.

Ratio

Heavy

Solution

Flow

Detergent

System

Indicator

Extreme

Solution

Flow

!

Normal

Scrub

Pressure

Battery

Indicator

Heavy

Scrub

Pressure

Extreme

Scrub

Pressure

If the battery charge level falls to a critical level, the display will

show a caution symbol and the battery-low icon.

!

Page 20

™

Circuit Breakers

The machine circuit breakers are located on the panel to

the left of the Operator seat.

General Maintenance

Maintenance After Use

General Information 20Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

1. When nished scrubbing, press the Scrub Off Switch. This will automatically raise the scrub deck and

squeegee, and switch off the solution, detergent and vacuum systems.

2. Drive the machine to a service area for daily maintenance, and check the machine for any additional

maintenance or service that may be needed.

3. To empty and clean the solution tank:

a. Remove the Solution Tank Drain

Hose

from its storage clamp.

b. Direct the Solution Tank Drain Hose

to a designated disposal site and

remove the Solution Tank Drain

Hose Plug

.

Recovery Tank

Drain Hose Plug

c. Rinse the tank with clean water.

4. To empty and clean the recovery tank:

a. Pull the Recovery Tank Drain Hose

from its storage area.

b. Direct the

Hose

Recovery Tank Drain

to a designated disposal site

Recovery Tank

Drain Hose

and remove the Recovery Tank

Drain Hose Plug

. (Hold the end of

the Recovery Tank Drain Hose above

the water level in the tank to avoid

sudden, uncontrolled wastewater

ow.) The Recovery Tank Drain Hose

can be squeezed to regulate the

ow.

c. Rinse the recovery tank with clean

water.

Hopper

Solution Tank

Drain Hose

Solution Tank

Drain Hose Plug

Vacuum

Hose

Page 21

™

General Information 21Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

d. Inspect the Solution Tank Drain Hose, Recovery Tank Drain Hose and Vacuum Hose for wear or damage.

Replace the if kinked or damaged.

5. Remove the brushes or pad holders. Rinse the brushes or pads in warm water and hang up to dry.

6. Remove the squeegee, rinse it with warm water, then reinstall.

7. Remove the Hopper on cylindrical systems and clean thoroughly. You can remove the Hopper from either

side of the machine by removing the skirt, tilting the Hopper up and away from housing, then pulling the

Hopper out.

8. Check the following maintenance schedule and perform any required maintenance before you store the

machine.

Maintenance Schedule

Maintenance Item Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks and Hoses X

Check/Clean/Rotate the Brushes/Pads X

Check/Clean the Squeegee X

Check/Clean Vacuum Shutoff Float X

Check/Clean the Vacuum Motor Foam Filter(s) X

Clean Hopper on Cylindrical System X

Check the Water Level in each Battery Cell X

Inspect Scrub Housing Skirts X

Inspect and Clean Solution Filter X

Check Foot/Parking Brake For Wear and Adjustment X

Clean Solution Trough on Cylindrical System X

Purge Detergent System X

Side Broom Maintenance X

Lubrication - Grease Fittings X

* Check Carbon Brushes X

* Inspect the vacuum motor carbon brushes every 300 operating hours. Check the brush and drive motor

carbon brushes every 500 operating hours.

Note: Refer to the individual machine sections in this manual for more detail on maintenance and

service repairs.

9. Store the machine indoors in a clean, dry place. Keep the machine from freezing. Leave the tanks open

to air them out.

10. Turn the key switch off (O) and remove the key.

Caution! Do not pressure-wash the operator control panel, circuit breaker panel or any

electrical areas of the machine.

Page 22

Machine Lubrication

™

General Information 22Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Once a month:

• Pump a small amount of grease into each grease

tting on the machine as shown until grease

seeps out around the bearings.

• Apply light machine oil to the components

shown.

Apply grease to:

• Squeegee Caster Wheel Axle and Pivot

Grease

Grease

• Steering Wheel Shaft Universal joint

• Steering Chain

• Squeegee mount angle adjustment knob threads

Apply light machine oil to:

• Squeegee tool end wheels

• Recovery Tank release latch

• Brake Pedal (parking brake) linkage

Lubrication Points

Oil

Oil

Grease

Oil

Oil

Grease

Grease

Grease

Page 23

Advance Condor EcoFlex™, Nilfisk BR 1100/1300 EcoFlex™

Disc and Cylindrical

PM Checklist

Defect Codes

Customer A needs adjustment

B binding

Address C dirty or contaminated

D damaged, bent or torn

City St Zip L leaks

M missing

Model Serial Hours W worn out

Ref

1 Steering

2 Drive Pedal Operation (check for Fwd/Rev drive and any neutral creep) A B D

3 Seat Safety Switch (when operator stands up machine is to stop) A D

4 Brakes (service and parking) A B W

Drive System Performance (reference Service Manual for Curtis drive

5

programmer speed changes)

6 Scrub System (Raise/Lower and auto scrubbing functions) A B

Scrub Brush Pressure Settings (see Service Manual programming, 3 different

7

modes)

8 Squeegee System (Raise/Lower and auto lift in reverse function) A B

Vacuum Performance (sealed water lift 70" and 1-inch open hole adapter 15

9

inches)

10 Solution Control (On/Off and flow volume Min/Max) A B L

11 Emergency Battery Disconnect Control Lever B D

Side broom Sweep System, Raise/Lower and auto sweep functions

12

(cylindrical only)

13 Tilt Steering Mechanism and Seat A B D

14 Optional Accessories (headlight, safety beacon, etc.) D

Main Control Board Special Program Options (check all applicable program

15

settings, reference Service Manual 56043154); Example, Fault Recall Mode,

etc.

16 Battery Charger Operation D

17 Chemical Detergent System Functions C L

Ref

18 Scrub Brushes, check for wear and rotate A B D W

19 Scrub Brush Motor(s) and disc machine gearboxes Carbon Brushes B L W

20 Scrub Brush Drive Belt, wear (cylindrical only) A D W

21 Scrub Brush Deck Actuator Motor A B D W

Brush Driver Plates (flex coupler and retainer clips)

22

(disc only)

23 Brush Idler Bearing Plate and Driver (cylindrical only) C W

24 Scrub Deck Skirts A B W

25 Solution Solenoid Valve C L

26 Solution Tank, Delivery Hoses and Filter Clean Filter Screen C L

27 Vacuum Motor Carbon Brushes Wear Limit 3/8" W

28 Vacuum Motor Cover Gasket and Filters L W

29 Vacuum Float Ball and Cage Assembly Clean Float C M

Operational Inspection Items

Visual Inspection Items

Comments OK

D M

OK

Defect Codes

(circle)

noisy sluggish

A B

C L W

A B D

Program as needed

A B

Defect Codes

(circle)

Does

Not

Work

Does

Not

Work

Copyright 2011 Nilfisk-Advance. Page 1 of 2 7/21/2011

Page 24

Ref

Visual Inspection Items (continued)

30 Recovery Tank Cover Gasket C D L

31 Recovery Tank Drain Hose and Cap Flush C L

32 Squeegee Pick-Up Tool and Hose Back flush C L

33 Squeegee Blades (clean and rotate) A C D W

34 Squeegee Mount Wheels (lubricate) 4 Grease Fittings A C W

35 Squeegee Lift Actuator Motor and Lifting Bar A B D

36 Battery Pack Condition (clean and water) Load Test C W

37 Front Drive Wheel Motor Carbon Brushes C W

38 Front Drive Tire Tread Wear W

39 Rear Brake Rotors and Disc Wear Adjust Free Play A B W

40 Drive Pedal Linkage (neutral return) Torsion Spring A B

41 Steering Chain (lubricate and tension) 1/4" Deflection A B C

Steering Column (knob and plunger spring) also

42

Universal Joint

43 Rear Wheels (bearing wear) Tread Wear C W

44 Sweep Debris Tray (cylindrical only) Rinse C

Comments OK

Grease A D

Defect Codes

(circle)

Does

Not

Work

Defect Codes A needs adjustment C dirty or contaminated M missing

B binding D damaged, bent or torn W worn out

L leaks

Note: For additional service information see Service Manual form number 56043154 and Instructions for

Use form number 56041633.

Work Completed By: Acknowledged By:

Service Technician Signature Date Customer Signature Date

Copyright 2011 Nilfisk-Advance. Page 2 of 2 7/21/2011

Page 25

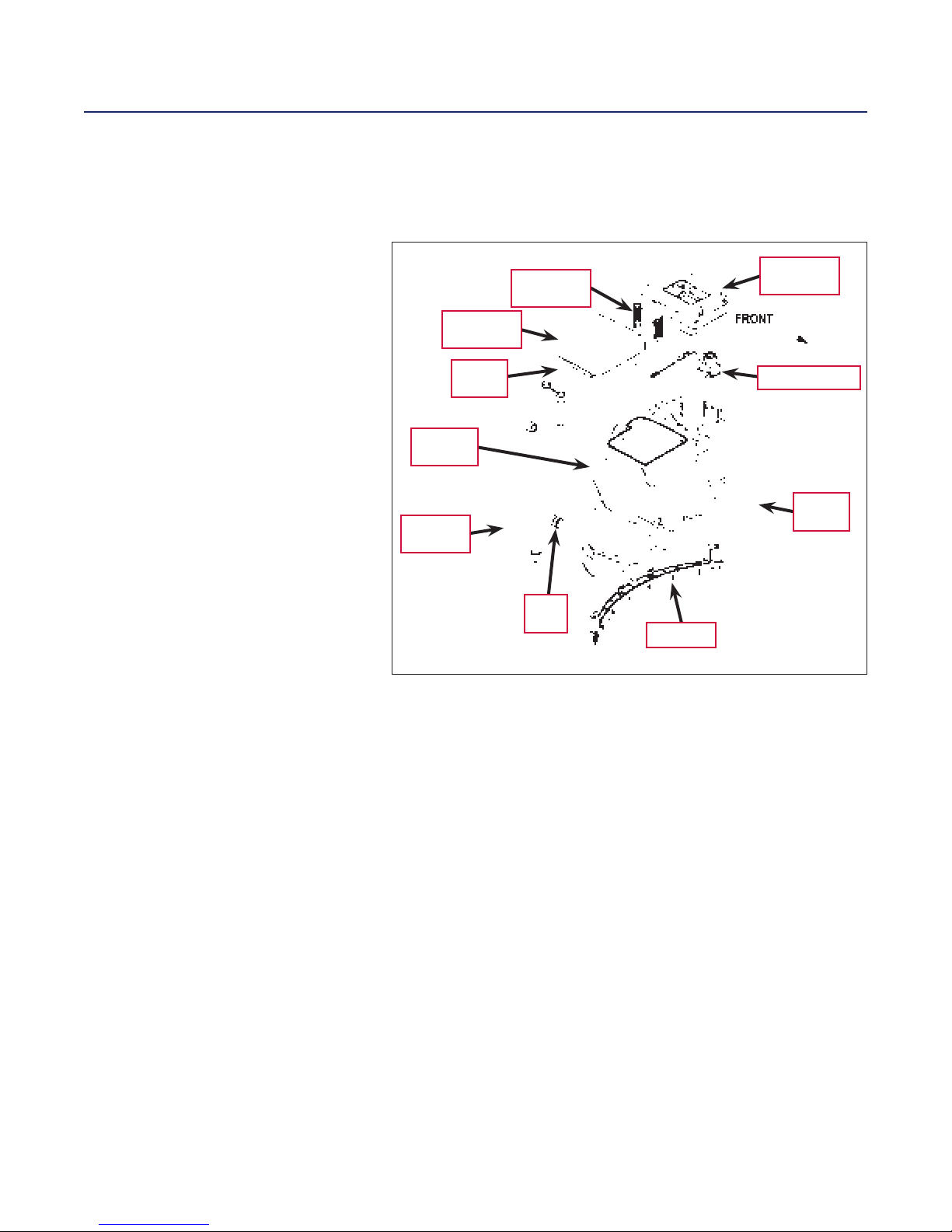

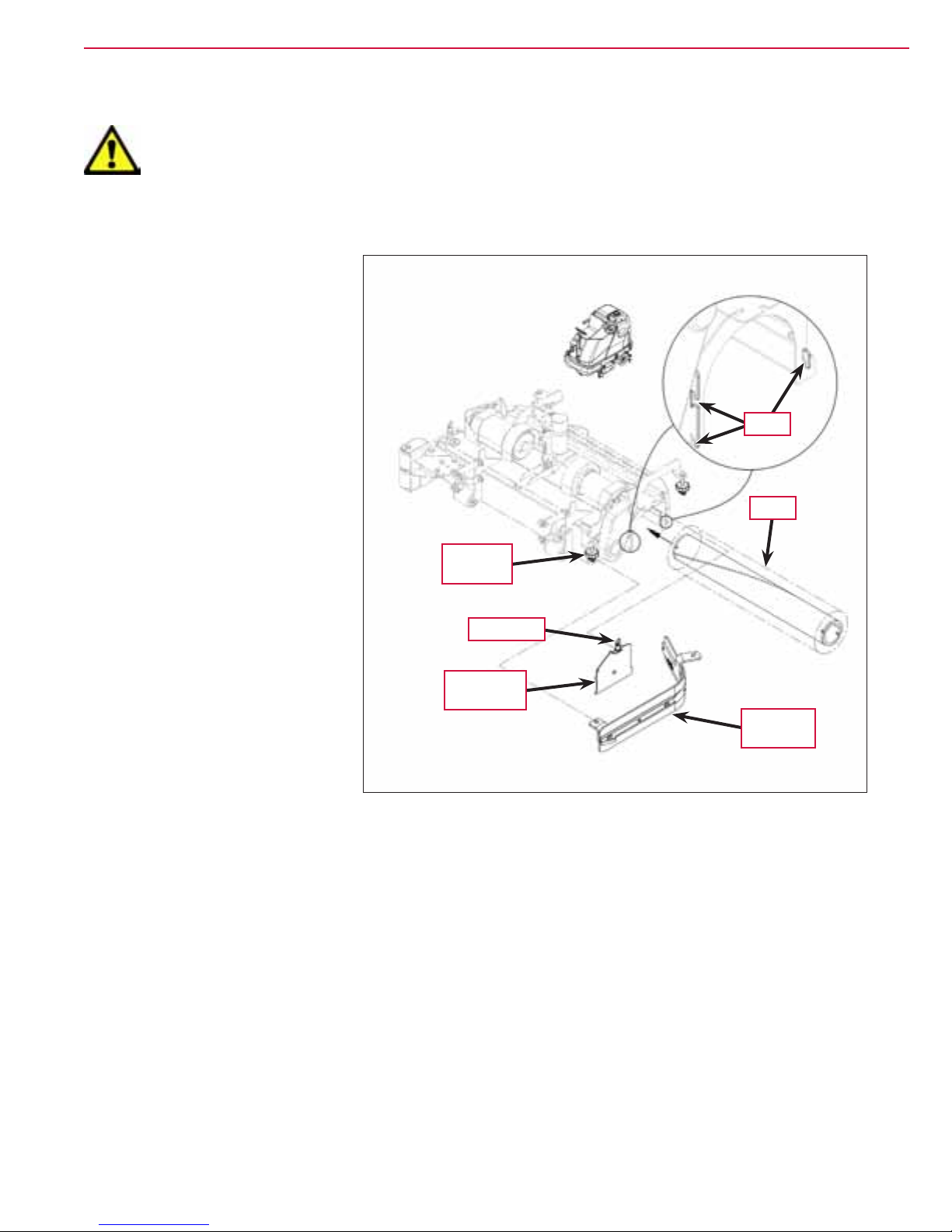

Chassis System

Major Chassis Components

Side Rear

Panel

™

25Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Chassis

Support

Side Panel

Assembly

Conduit (2)

Chassis

Weldment

Pin Plate

Weldment

Support

Edge

Trim

Page 26

™

Control System

Functional Description

Overview

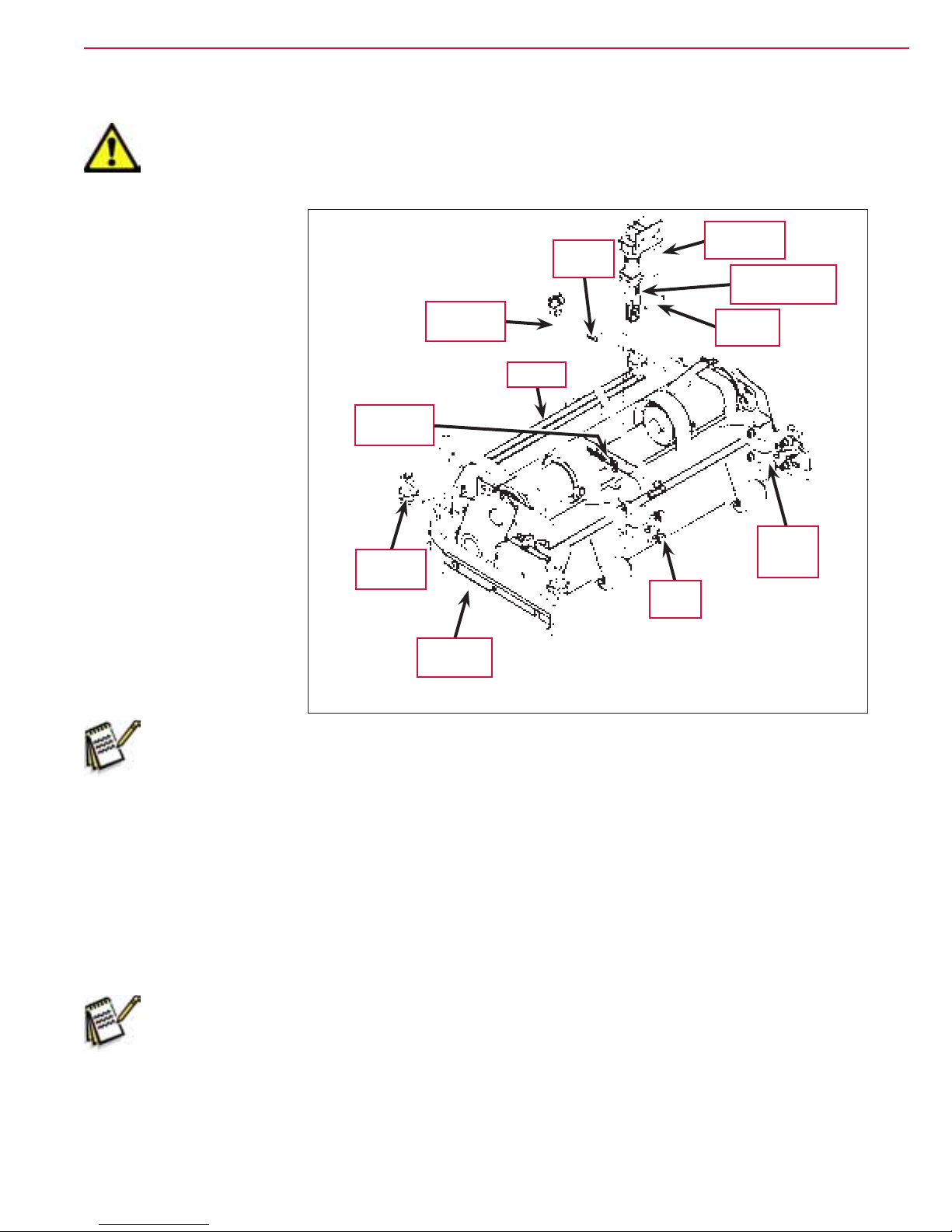

The control system consists of the A2 Control Board Assembly, the A3 Switch/Display Panel Assembly and

associated sensors and circuitry.

A2 Control Board Assembly

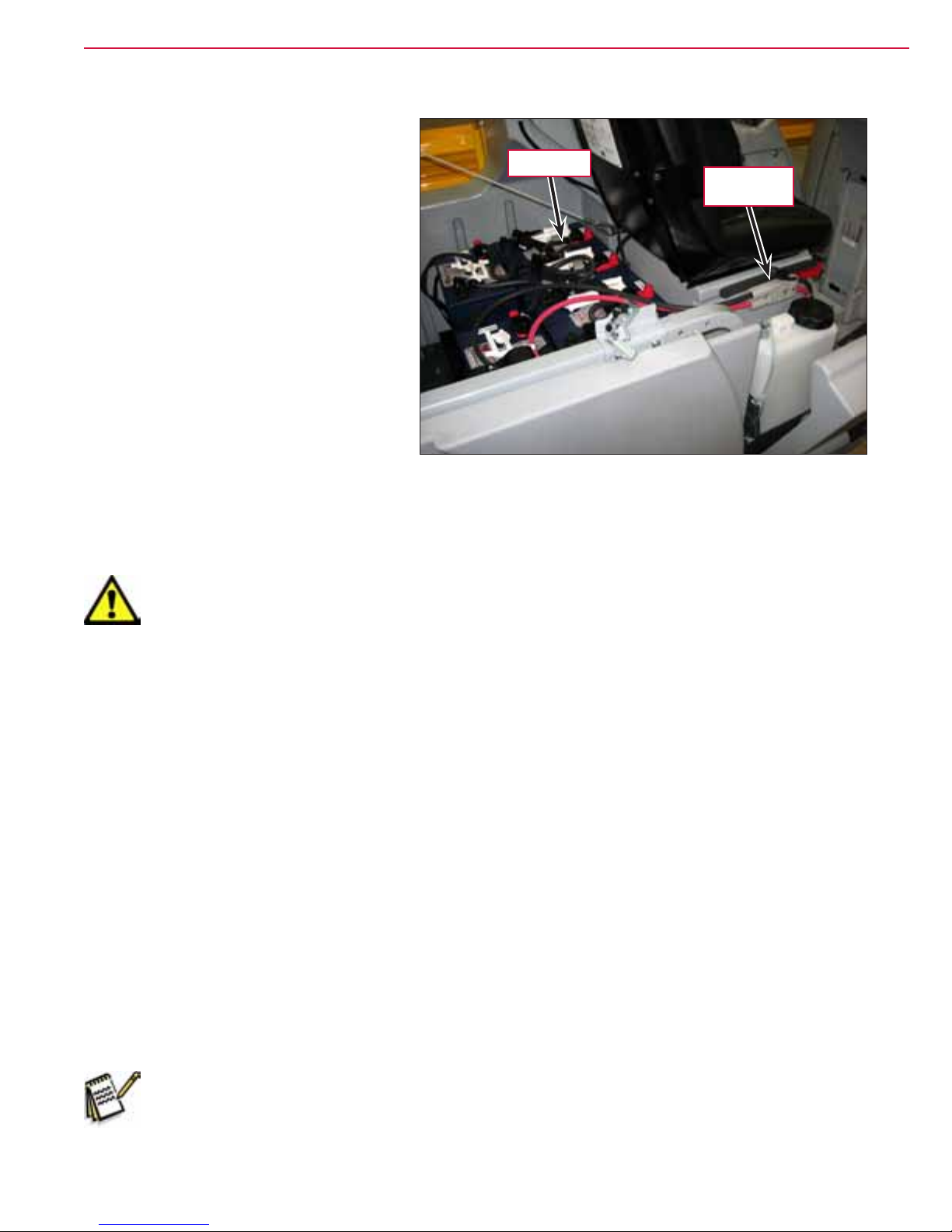

The A2 Control Board Assembly, sometimes referred to the

main controller, communicates with the Curtis A1 Speed

Controller

and the A3 Switch/Display Panel Assembly to

coordinate the operation of the various machine systems.

The A2 Control Board Assembly is fastened to the Electrical

Mount

behind the electrical panel cover assembly to the

left of the Operator seat.

A2 Control Board

Assembly

Electrical

Mount

26Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

One primary function of the A2 Control Board Assembly is

to position the scrub brushes relative to the oor surface

using a lift actuator motor. The A2 Control Board Assembly

continuously monitors the brush motor current draw to

maintain the desired scrub pressure on the oor.

Curtis A1

Speed

Controller

• If the brush motor current drops below the desired

range, the A2 Control Board Assembly switches on the

lift actuator motor to move the scrub deck downward

until the brush motor current draw is within the

correct range for the scrub pressure selected.

• If the brush motor current rises above the desired

range, the A2 Control Board Assembly switches on the

lift actuator motor to lift the scrub deck upward until

the brush motor current draw is again within the

correct range for the scrub pressure selected.

Note: Refer to the Scrub System section in this

manual for a complete explanation of

scrub deck operation.

A secondary function of the A2 Control Board Assembly is to detect any system failures and display the

corresponding error code on the display panel, or store it in the control board’s recall memory mode. The

error codes are used to help service technicians determine the fault and to guide in repairing a specic

system malfunction quickly.

Note: See the Troubleshooting section for further information.

The A2 Control Board Assembly also allows you to change program settings for a set of specic machine

functions. See the Main Control Programming Options section in this manual for further information.

Page 27

A3 Switch/Display Panel Assembly

The A3 Switch/Display Panel Assembly is the user

interface that includes the various system switches and

buttons, and the control panel display. The A3 Switch/

Display Panel Assembly sends the operator inputs via a

CAN BUS to the A2 Control Board Assembly.

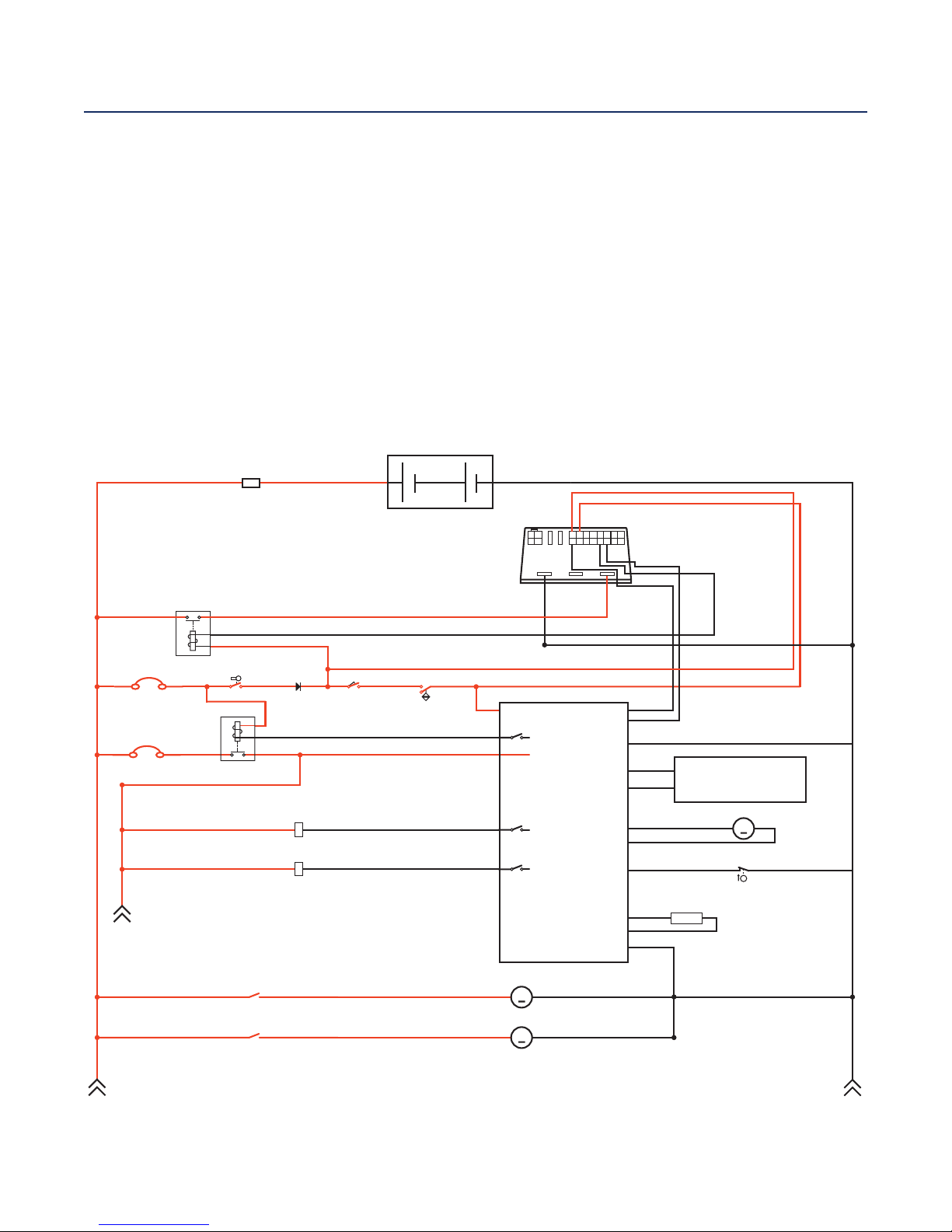

Control System Wiring Diagram

™

Control System 27Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

F1

Circuit Breaker, 3 Amp

F2

Circuit Breaker, 15 Amp

B+

B+

F4

Fuse, 250 A

K7

S1

Key Switch Seat Switch

K5

D1

Diode

+

S2

Battery Interlock Switch

(for roll-out Battery)

36V Battery

S3

-

A1

Speed

Controller

16

15

8

B-

Bat -

Bat +

A2 Control

Board

Assembly

4

3

B+

Motion

Direction

Bat + 8V

Bat -

CAN H

CAN L

Battery Ground

A3

Switch/Display

Panel Assembly

B-

Circuit Description

The A2 Control Board Assembly is connected by several inputs to battery negative:

The A2 Control Board Assembly gets positive battery voltage from two inputs:

• When the key switch, seat switch and battery interlock are closed, positive voltage is supplied to the A2

Control Board Assembly.

• When the key switch is closed, positive voltage is supplied to the coil side of contactor K5. When K5

contacts close, positive voltage is supplied to the A2 Control Board Assembly.

The A3 Switch/Display Panel Assembly gets voltage from two outputs on the A2 Control Board Assembly.

The A3 Switch/Display Panel Assembly communicates with the A2 Control Board Assembly via a CAN BUS

connection (CAN H and CAN L).

Page 28

™

Control System 28Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Main Control Programming Options

Fault Recall Mode

Whenever the A2 Control Board Assembly detects an electrical system error or fault, one or more error

codes are displayed and stored by the A2 Control Board Assembly. You can recall error codes (if any) from

previous machine operation for troubleshooting purposes, To recall stored error codes:

1. Turn the key switch off.

2. Press and hold the solution switch.

3. While holding the solution switch, turn the key switch on.

4. Continue to hold the solution switch until the solution system indicator turns on.

5. Release the solution switch. The solution system indicator turns off and the scrub off indicator will light.

The display will show a wrench icon indicating that you are in fault recall mode.

• If there are no previous error codes stored, the display will show the no-fault wrench icon

asking you to reset the machine (no fault). Skip to step 7.

• If error codes have been stored, the display will show the wrench icon and error number(s) next to the

wrench. If more than one error code is stored, the display will toggle through all the errors stored.

6. • If you want to save the codes, skip to step 7.

• To clear the stored error codes, press the scrub off switch. The display will now show key switch icon

asking you to reset the machine.

7. To exit the fault recall mode, turn the key switch off.

To Restore the Scrub Pressures to the Factory Default Settings

1. Turn the key switch off.

2. Press and hold the scrub on switch.

3. While holding the scrub on switch, turn the key switch on.

4. Continue to hold the scrub on switch until the display shows key switch icon. The factory default scrub

pressures have now been restored.

5. Turn the key switch off.

To Enable/Disable the Fault Detection

Note that the factory default for fault detection is ON.

Normally the main control unit will perform checks of the electrical system during operation. If a fault

occurs in a particular system, that system (and possibly others) will be shut down. This can make

troubleshooting the system difcult. This option will allow service personnel to disable some of the fault

detection checks to facilitate troubleshooting. This will not disable the over-current protection on any of the

systems. To turn the fault checking on or off:

1. Turn the key switch off.

2. Press and hold both the scrub off switch and solution switch.

Page 29

™

Control System 29Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until both switch indicators turn on. The display will show a wrench icon

indicating fault detection mode.

5. Release both switches. The solution system indictor light will blink and the scrub off indicator will stay

on.

6. Press the solution switch to toggle the fault detection between enabled/on (wrench icon with no cross) or

disabled/off (wrench icon with cross).

7. Press the scrub off switch to save the new setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

To Display the Control Board Revision Level

1. Turn the key switch off.

2. Press and hold both the scrub off switch and traction control switch.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until the scrub off and traction control indicators light.

5. Release both switches. The scrub off and traction control indicators will switch off. The display will show

MAIN REVISION of the A2 control board assembly, the DISPLAY REVISION of the A3 switch/display

the

panel assembly and the key switch icon.

6. Turn the key switch off.

Monitor Mode

The control system allows the ve machine settings listed below to be quickly checked in the monitor mode

to view the machine’s specic setup. To enter the monitor mode and view the current machine settings:

1. Turn the key switch off.

2. Press and hold the detergent switch.

3. While holding the detergent switch, turn the key switch on.

4. Continue to hold the detergent switch until the detergent system indicator switches on.

5. Release the detergent switch. The display

will show the following current machine

programmed settings:

• Scrub deck type and size,

• Detergent mode on/off,

• Fault detection on/off,

• Vacuum motor selection – VACUUM–SINGLE (one motor) or VACUUM–DUAL (two motors).

6. To exit the monitor mode, turn the key switch off.

Page 30

™

Control System 30Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Scrub Deck Down Time Adjustment

Note that the factory default deck down time is two seconds.

When scrub on switch is pressed, the control board will automatically lower the deck for two seconds. The

time that the deck is lowered is adjustable from one second to three seconds in 0.1-second increments.

To adjust the scrub deck down time:

1. Turn the key switch off.

2. Press and hold the scrub on and solution switches.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until both switch indicators turn on.

5. Release both switches. The display will now show a clock icon in the upper left corner with a number

indicating the scrub deck down time period.

6. Press the scrub on switch to increment the time period. Each press of the switch increments the scrub

deck down time 0.1 seconds. For example, the time will increment from 2.0 seconds to 2.1 seconds, and

so on. The deck down times range from 1.0 to 3.0 seconds.

7. Press the scrub off switch to save the new setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

Normal (Light) Scrub Setting Adjustment

Note that the factory default settings for the normal scrub setting are: Scrub pressure – one bar, Solution

ow rate – one bar.

The scrub pressure and solution ow rate for the normal scrub setting can be programmed to better suit a

particular application. This allows you to select a higher solution ow rate with normal scrub pressure, or

a normal solution rate with heavier scrub pressure, etc., as the normal scrub setting. To change the normal

scrub settings:

1. Turn the key switch off.

2. Press and hold the scrub on and scrub speed switches.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until the scrub speed indicator turns on and the normal scrub on

indicator blinks.

5. Release both switches. The display will now show a scrub icon (either disc or cylindrical) with the

current scrub pressure setting.

6. Press the scrub on switch to increment the scrub pressure setting as shown by the number of bars in the

display.

7. Press the scrub off switch to save the new scrub pressure setting and move to the solution ow rate

setting. The display will now show the solution icon with gauge. The normal scrub indicator will stop

blinking and the solution system indicator will blink.

8. Press the solution switch to increment the solution ow rate as shown by the number of bars in the

display.

Page 31

™

Control System 31Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

9. Press the scrub off switch to save the new solution ow rate setting and move to the detergent

concentration setting. The display will now show the detergent icon with a 0, + or – next to it. The

solution system indicator will stop blinking and the detergent indicator will blink.

10. Press the detergent switch to scroll through and select the 0, + or – character in the display.

• Selecting 0 will not change the detergent concentration in the detergent ratios.

• Selecting + will increase the detergent concentration in the detergent ratios by 10 percent.

• Selecting – will decrease the detergent concentration in the detergent ratios by 10 percent.

11. Press the scrub off switch to save the detergent concentration setting and display the key switch icon.

12. Turn the key switch off. The new settings will be saved until changed again.

Heavy Scrub Setting Adjustment

Note that the factory default settings for the heavy scrub setting are: Scrub pressure – two bars, Solution

ow rate – two bars.

The scrub pressure and solution ow rate for the heavy scrub setting can be programmed to better suit

a particular application. This allows you to select a higher solution rate with heavy scrub pressure, or a

normal solution rate with heavy scrub pressure, etc., as the heavy scrub setting. To change the heavy scrub

settings:

1. Turn the key switch off.

2. Press and hold the scrub on and detergent switches.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until the detergent indicator turns on and the heavy scrub indicator

blinks.

5. Release both switches. The display will now show a scrub icon (either disc or cylindrical) with the

current scrub pressure setting.

6. Press the scrub on switch to increment the scrub pressure setting as shown by the number of bars in the

display.

7. Press the scrub off switch to save the new scrub pressure setting and move to the solution ow rate

setting. The display will now show the solution icon with gauge. The solution system indicator will

blink.

8. Press the solution switch to increment the solution ow rate as shown by the number of bars in the

display.

9. Press the scrub off switch to save the new solution ow rate setting and move to the detergent

concentration setting. The display will now show the detergent icon with a 0, + or – next to it. The

solution system indicator will stop blinking and the detergent indicator will blink.

10. Press the detergent switch to scroll through and select the 0, + or – character in the display.

• Selecting 0 will not change the detergent concentration in the detergent ratios.

• Selecting + will increase the detergent concentration in the detergent ratios by 10 percent.

• Selecting – will decrease the detergent concentration in the detergent ratios by 10 percent.

11. Press the scrub off switch to save the detergent concentration setting and display the key switch icon.

Page 32

™

Control System 32Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

12. Turn the key switch off. The new settings will be saved until changed again.

Extreme Scrub Setting Adjustment

Note that the factory default settings for the extreme scrub setting are: Scrub pressure – three bars, Solution

ow rate – three bars.

The scrub pressure and solution ow rate for the extreme scrub setting can be programmed to better suit

a particular application. This allows you to select a higher solution rate with extreme scrub pressure, or a

normal solution rate with extreme scrub pressure, etc., as the extreme scrub setting. To change the extreme

scrub settings:

1. Turn the key switch off.

2. Press and hold the scrub on and vacuum/wand switches.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until the vacuum/wand indicator turns on, and the normal and heavy

scrub indicators blink.

5. Release both switches. The display will now show a scrub icon (either disc or cylindrical) with the

current scrub pressure setting.

6. Press the scrub on switch to increment the scrub pressure setting as shown by the number of bars in the

display.

7. Press the scrub off switch to save the new setting and move to the solution ow rate setting. The display

will now show the solution icon with gauge. The normal and heavy scrub indicators will stop blinking

and the solution indicator will blink.

8. Press the solution switch to increment the solution ow rate as shown by the number of bars in the

display.

9. Press the scrub off switch to save the new solution ow rate setting and move to the detergent

concentration setting. The display will now show the detergent icon with a

0, + or – next to it. The

solution system indicator will stop blinking and the detergent indicator will blink.

10. Press the detergent switch to scroll through and select the 0, + or – character in the display.

• Selecting 0 will not change the detergent concentration in the detergent ratios.

• Selecting + will increase the detergent concentration in the detergent ratios by 10 percent.

• Selecting – will decrease the detergent concentration in the detergent ratios by 10 percent.

11. Press the scrub off switch to save the detergent concentration setting and display the key switch icon.

12. Turn the key switch off. The new settings will be saved until changed again.

Page 33

™

Control System 33Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Scrub Speed Switch Lockout

Note that the factory default setting for the scrub speed switch is FAST/SLOW - ENABLE.

The control system is programmed to limit the maximum travel speed while scrubbing to a value less

than that allowed when driving and not scrubbing. Pressing the scrub speed switch on the control panel

will override this speed limiting feature and allow scrubbing at a the higher speed. If you wish to prevent

scrubbing at this faster speed, you can disable the scrub speed switch override feature. To disable the scrub

speed switch override feature:

1. Turn the key switch off.

2. Press and hold the scrub speed switch.

3. While holding the scrub speed switch, turn the key switch on.

4. Continue to hold the scrub speed switch until the scrub speed and scrub off indicators both turn on.

5. Release the scrub speed switch. The scrub speed indictor light will blink.

6. Press the scrub speed switch to enable or disable the scrub speed switch override feature. FAST/SLOW

- ENABLE

high-speed scrub feature is turned off.

means that the high-speed scrub feature is turned on. FAST/SLOW - DISABLE means that the

7. Press the scrub off switch to save the setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

Detergent System Selection Mode

1. Turn the key switch off.

2. Press and hold the scrub off switch and the detergent switch.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until both switch indicators turn on.

5. Release both switches. The scrub off indicator will stay lit and the detergent system indicator will blink.

The display will now show a detergent bottle in the upper left corner indicating the detergent selection

mode.

6. Press the detergent switch to select between a normal detergent bottle icon indicating that the detergent

system is activated, or a detergent bottle with a cross through it indicating that the detergent system is

not activated.

7. Press the scrub off switch to save the new setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

EcoFlex™ Mode Selection

Note that the factory default setting for the EcoFlex™ Mode is OFF.

1. Turn the key switch off.

2. Press and hold the EcoFlex™ button.

3. While holding the button, turn the key switch on.

Page 34

™

Control System 34Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

4. Continue to hold the button for two seconds until the EcoFlex™ and scrub off indicators turn on.

5. Release the EcoFlex™ button. The display will now show the ECOFLEX MODE/

OFF

, ECOFLEX MODE/MODE 1 and ECOFLEX MODE/MODE 2 menu.

6. Press the EcoFlex™ button to scroll through the menu and select the desired

ECOFLEX MODE.

ECOFLEX MODE

OFF

ECOFLEX MODE

MODE 1

ECOFLEX MODE

7. Press the scrub off switch to save the setting and display the key switch icon.

MODE 2

8. Turn the key switch off. The new setting will be saved until changed again.

Vacuum Motor Configuration Option

Note that the factory default setting for the vacuum motor conguration is SINGLE (one vacuum motor).

All rider scrubber models covered in this manual can be equipped with optional dual vacuum motors. The A1

control board assembly must be programmed for the number of vacuum motors installed so that the current

overload protection will function correctly. To select the vacuum motor conguration:

1. Turn the key switch off.

2. Press and hold the scrub system off and vacuum/wand switches.

3. While holding both switches, turn the key switch on until the scrub off and vacuum/wand indicators

light.

4. Release both switches. The vacuum/wand indictor will ash. The control panel display will now indicate

the vacuum motor setting.

5. Press the vacuum/wand switch to toggle between

VACUUM - DUAL for two vacuum motors.

VACUUM - SINGLE for a single vacuum motor or

6. Press the scrub off switch to save the setting and display the key switch icon.

7. Turn the key switch off. The new setting will be saved until changed again.

Recovery Tank Full Detection Enable/Disable

Note that the factory default setting for the recovery tank full detection is ENABLE.

The Condor is equipped with a feature that will automatically shut off the vacuum and scrub systems

and display a recovery tank full icon on the control panel display when the recovery tank becomes full. If

problems are encountered with the vacuum shutoff feature, such as the vacuum shutting off even when the

recovery tank is not full, this feature can be turned off. To turn this feature on (enable) or off (disable):

1. Turn the key switch off.

2. Press and hold the vacuum/wand switch.

3. While holding the vacuum/wand switch, turn the key switch on.

4. Continue to hold the vacuum/wand switch until the vacuum/wand indicator turns on.

5. Release the vacuum/wand switch. The vacuum/wand indictor will blink and the scrub off indicator will

turn on. The display will now show a text message REC TANK FULL DETECT/ENABLE or DISABLE.

6. Press the vacuum/wand switch to toggle between ENABLE or DISABLE. ENABLE means that the

automatic shutoff feature is turned on. DISABLE means that the automatic shutoff feature is turned off.

Page 35

™

Control System 35Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

7. Press the scrub off switch to save the setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

Solution Flow in Reverse Enable/Disable

Note that the factory default setting for the solution ow in reverse option is ENABLE.

The solution ow is programmed to dispense solution when the machine backing up. To disable solution ow

when the machine moves in reverse:

1. Turn the key switch off.

2. Press and hold the EcoFlex™ button and the solution switch.

3. While holding both the button and switch, turn the key switch on.

4. Continue to hold the button and switch until the solution system and vacuum/wand indicators turn on.

5. Release the button and switch. The vacuum/wand indicator will turn off, the solution system indictor

will blink and the scrub off indicator will turn on. The display will now show the message

REVERSE

/ENABLE or DISABLE.

SOLUTION IN

6. Press the solution switch to toggle between SOLUTION IN REVERSE ENABLE or DISABLE. If you select

ENABLE, the solution ow will stay on when the machine is moving in reverse. If you select DISABLE,

solution ow will stop when the machine is moving in reverse.

7. Press the scrub off switch to save the setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

Indicator LED Intensity Selection Option

Note that the factory default setting for the indicator LED intensity is normal.

To change the intensity of the LEDs in the control panel indicators.

1. Turn the key switch off.

2. Press and hold the vacuum/wand and scrub speed switches.

3. While holding both switches, turn the key switch on.

4. Continue to hold both switches until the vacuum/wand and scrub speed indicators turn on. The display

will now show a light bulb icon in the upper left corner indicating the LED light intensity selection.

5. Release both switches. The scrub speed and scrub off indicators will light and the vacuum/wand

indicator will blink.

6. Press the vacuum/wand switch to select between the normal intensity or extra bright intensity levels.

7. Press the scrub off switch to save the setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

Page 36

™

Control System 36Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

Detergent and Solution Pump Purge

The EcoFlex™ detergent system has two purge (ush) programs to ensure that the detergent delivery hoses

and related components are kept open and clean. A general operational description in how the system

functions is found in the Solution System section. To activate the maintenance purge functions:

Method 1

1. Turn the key switch off.

2. Press and hold both the detergent and solution switches.

3. While holding the switches, turn the key switch on. The display will show the purge icon, the detergent

and solution pumps will run for approximately 20 seconds, then the pumps will shut off.

4. When the purge cycle is complete, turn the key switch off.

Method 2 (as described in the Instructions for Use)

1. Turn the key switch on.

2. Press and hold both the detergent and solution switches for three seconds. The detergent and solution

pumps will run for approximately 10 seconds.

3. When the purge cycle is complete, turn the key switch off.

Side Broom Function

1. Turn the key switch off.

2. Press and hold the side broom on/down switch.

3. While holding the switch, turn the key switch on.

4. Continue to hold the switch until the side broom on/down indicator turns on.

5. Release the switch. The display will now show SIDE BROOM/ENABLE or DISABLE.

6. Press the side broom on/down switch to toggle between SIDE BROOM ENABLE or SIDE BROOM DISABLE.

7. Press the scrub off switch to save the setting and display the key switch icon.

8. Turn the key switch off. The new setting will be saved until changed again.

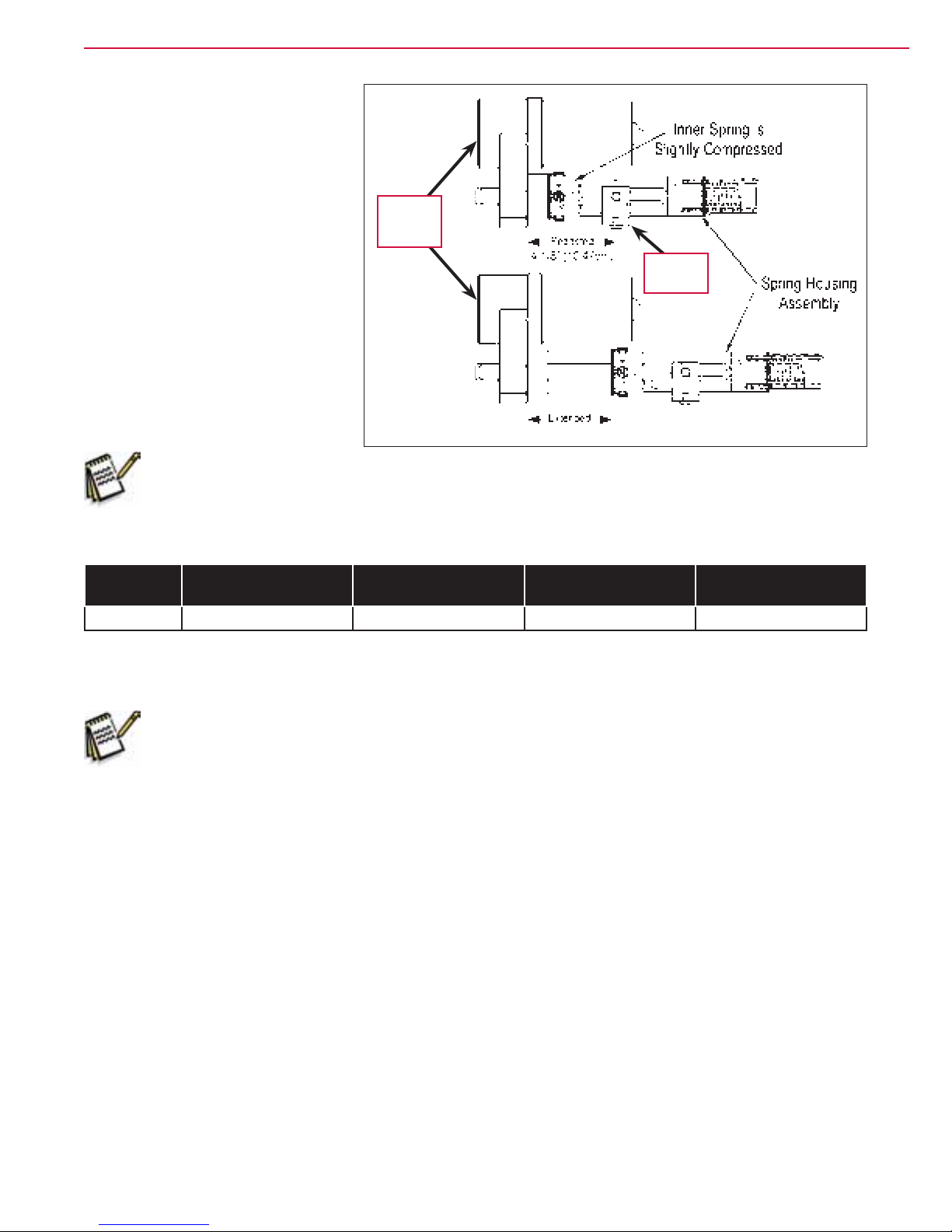

Side Broom Height Adjustment

The height of the side brooms is determined by the length of time the side broom actuator runs as it lowers

the side brooms. Note that:

• Increasing the side broom actuator run time lowers the side broom height.

• Decreasing the side broom actuator run time raises the side broom height.

To adjust the side broom height:

1. Turn the key switch off.

Page 37

™

Control System 37Service Manual – Condor™ EcoFlex™, BR 1100/1300 EcoFlex

2. Press and hold the side broom on/down and scrub off switches.

3. While holding the switches, turn the key switch on.

4. Continue to hold the switches until the side broom on/down indicator, scrub off indicator and both scrub

on indicators turn on.

5. Release the switches. The indicators will stay on and the display will now show the side broom actuator

down run time in seconds.

6. • Press the scrub on switch to increase the side broom actuator run time and lower the position of side

brooms.

• Press the side broom on/down switch to decrease the side broom actuator run time and raise the

position of side brooms.

Note that the side broom actuator run times range from 1.0 to 3.0 seconds.

7. Press the scrub off switch to save the side broom height. The actuator will raise the brooms to their up

position and the display will show a key switch icon.

8. Turn the key switch off. The machine is now reprogrammed to work with the new side broom height

setting.

Display Mode Selection

1. Turn the key switch off.

2. Press and hold the detergent switch and EcoFlex™ button.

3. While holding the detergent switch and EcoFlex™ button, turn the key switch on.

4. Continue to hold the button and switch for two seconds until the EcoFlex™ and detergent system

indicators turn on.