Nilfisk-Advance MC 2C-700 PE, MC 5M-910 PLUS, MC 5M-225 PLUS, MC 3C-810 PE, MC 3C-165 PE Instructions For Use Manual

...Page 1

MC DE, MC PE, MC PE PLUS -

Instructions for use

106169306 c (09.2015)

EN-DE-FR-NL-ES-DA-NO-SV-FI

Page 2

Copyright © 2015 Nilfisk A/S

User manual ...................................................................................................................... 3 - 17

Betriebsanleitung ............................................................................................................... 18 - 33

Manuel d‘instructions ......................................................................................................... 34 - 48

Gebruikershandleiding....................................................................................................... 49 - 64

Manuale di istruzioni .......................................................................................................... 65 - 80

Instruktionsbog .................................................................................................................. 81 - 96

Instruksjonsbok.................................................................................................................. 97 - 111

Instruktionsbok .................................................................................................................. 112 - 126

Käyttöohje.......................................................................................................................... 127 - 141

Page 3

3

MC DE, MC PE, MC PE PLUS

Original Instructions

Contents

1 Safety Precautions and Warnings ................................................................................................4

2 Description .....................................................................................................................................5

2.1 Intended use .............................................................................................................................5

2.2 Operating elements ..................................................................................................................5

3 Before starting the pressure washer ...........................................................................................6

3.1 Setting up the pressure washer (does not apply to MC 2C-180/700 PE /

MC 3C-165/810 PE) .................................................................................................................6

4 Operation and use .........................................................................................................................6

4.1 Connections..............................................................................................................................6

4.1.1 Connecting the lance to the spray gun ..........................................................................6

4.1.2 Connecting the high pressure hose and the water hose ............................................... 7

4.1.3 Fuelling ..........................................................................................................................7

4.2 Start the washer .......................................................................................................................7

4.2.1 Switching on the washer when it is connected to a water supply ..................................7

4.2.2 Switching on the washer when it is connected to open tanks (suction mode) ..............8

4.2.3 Start machine ................................................................................................................8

4.3 Using detergents ......................................................................................................................9

5 After using the washer ..................................................................................................................9

5.1 Stop the pressure washer .........................................................................................................9

5.2 Disconnecting supply lines .....................................................................................................10

5.3 Storing the washer (frost-protected) ......................................................................................10

6 Maintenance .................................................................................................................................11

6.1 Maintenance plan ...................................................................................................................11

6.2 Maintenance work ..................................................................................................................11

6.2.1 Clean water fi lter .........................................................................................................11

6.2.2 Clean high pressure nozzle .........................................................................................11

6.2.3 Checking the oil level (does not apply to MC 2C-180/700 PE / .................................. 12

MC 3C-165/810 PE) .................................................................................................... 12

6.2.4 Changing the pump/gear oil (does not apply to MC 2C-180/700 PE /

MC 3C-165/810 PE) .................................................................................................... 12

6.2.5 Check of V-belts...........................................................................................................13

7 Troubleshooting ...........................................................................................................................14

8 Further information ......................................................................................................................15

8.1 Recycling the pressure washer ..............................................................................................15

8.2 Guarantee ...............................................................................................................................15

8.3 Technical data .........................................................................................................................16

8.4 EC Declaration of Conformity ................................................................................................. 17

Page 4

4

MC DE, MC PE, MC PE PLUS

Original Instructions

Symbols used to mark instructions

Before starting

up your high-

pressure washer

for the fi rst time,

this instruction

manual must be read through

carefully. Save the instructions

for later use.

Safety instructions

marked with this

symbol must

be observed to

prevent danger

to persons.

This symbol is used

to mark safety

instructions

that must be

observed to prevent

damage to the machine and its

performance.

This symbol

indicates tips

and instructions to

simplify work and to

ensure a safe operation.

1 Safety Precautions and Warnings

High Pressure Washer SAFETY INSTRUCTIONS

107141898 D (07-2015)

Page 5

5

MC DE, MC PE, MC PE PLUS

Original Instructions

2 Description

2.1 Intended use This high pressure washer has

been designed for professional

use in

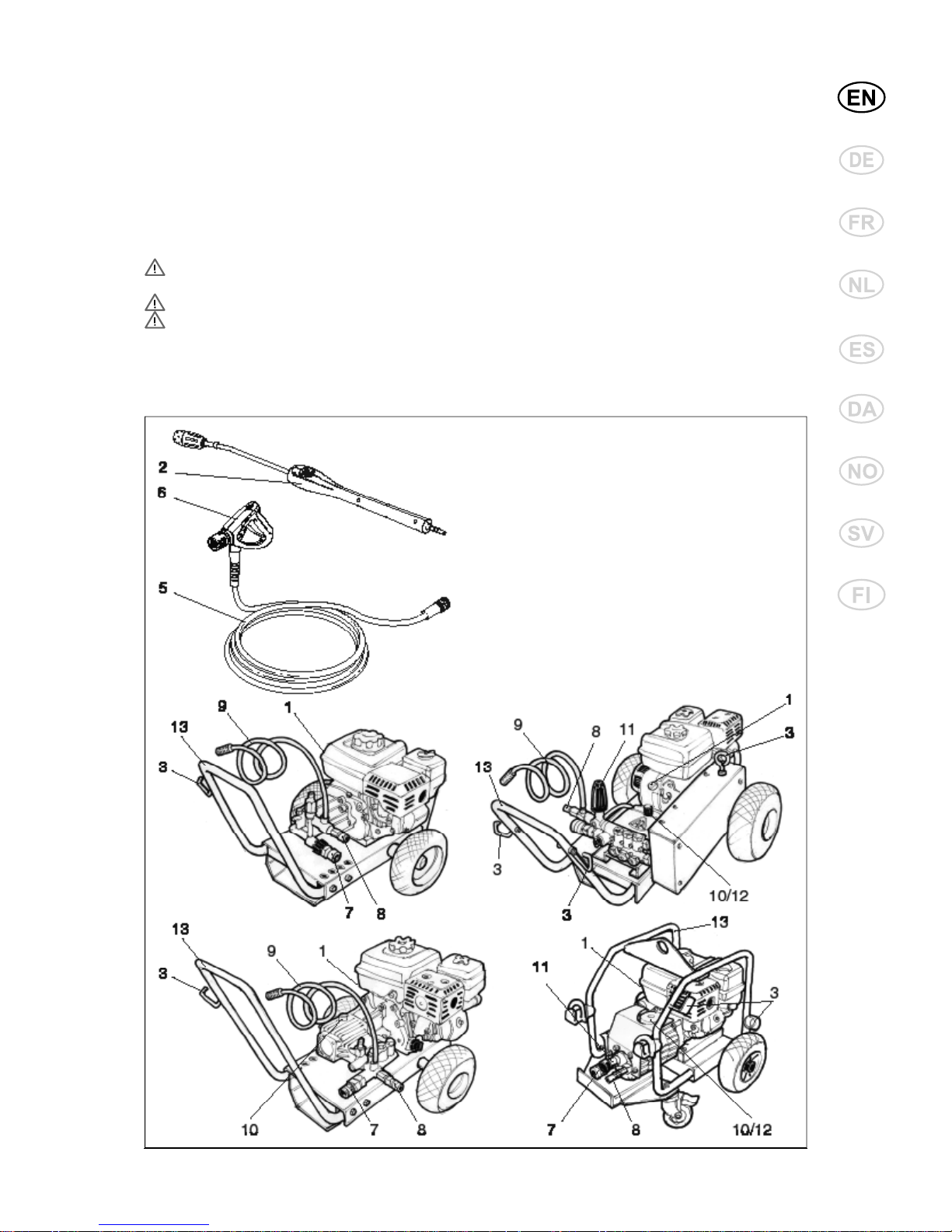

2.2 Operating elements

1 Start/stop switch

2 Lance

3 Holder for lance

4 Holder for high pressure hose

5 High pressure hose

6 Spray gun

7 Water connection and water

inlet fi lter

8 Connection for high pressure

hose

9 Detergent hose

10 Oil level gauge

11 Regulation of water volume

12 Filling of oil

13 Handle

- agriculture

- transport industry

- construction industry

etc.

WARNING! Do not use combustion engine powered machines indoors unless adequate ventilation

is assessed by national labour authorities.

WARNING! Ensure, that any exhaust emissions are not in a vicinity of air intakes.

WARNING! Incorrect fuels shall not be used as they may prove hazardous.

Page 6

6

MC DE, MC PE, MC PE PLUS

Original Instructions

3 Before starting the pressure washer

3.1 Setting up the pressure

washer (does not apply

to MC 2C-180/700 PE /

MC 3C-165/810 PE)

1. Before using the pressure

washer for the fi rst time,

check it carefully to detect

any faults or damage.

2. In the event of any damage

contact your Nilfi sk dealer

immediately.

3. Check whether the oil level

is in the middle of the oil

inspection glass, oil cup or

dip stick. This also applies to

machines with gear.

4 Operation and use

4.1 Connections

4.1.1 Connecting the lance to

the spray gun

1. Pull the blue quick-release

grip (A) of the spray handle

backwards.

2. Insert the nipple of the spray

lance (B) into the quickrelease connection and

release it.

3. Pull forward the spray lance

or any other accessory to

ensure correct mounting

before starting the machine.

NOTE!

Always remove any dirt from

the nipple before connecting

the lanse to the spray gun.

A

B

Page 7

7

MC DE, MC PE, MC PE PLUS

Original Instructions

4.1.2 Connecting the high

pressure hose and the

water hose

1. Connect the high pressure

hose to the high pressure

inlet by means of the quick

coupling. Use max. 50 m

extension hose.

2. Before connecting the water

hose to the washer, rinse the

water hose briefl y to prevent

sand and other dirt from

entering into the washer.

3. Open the tap.

NOTE!

See chapter 8.3 for required

quantity of water and water

pressure.

In the case of poor water quality

(sand, etc.), we recommend

that a fi ne water fi lter is fi tted in

the water inlet.

4.1.3 Fuelling WARNING!

Always shut off the engine

and let it cool for at least two

minutes before fuelling.

Avoid spilling fuel.

If you do spill fuel when fuelling,

do not start the engine before

the spilled fuel has evaporated.

If the washer is on a trailer, any

fuel spills must be wiped up

before the machine is started.

Never expose the machine

to an open fl ame. Smoking is

prohibited during fuelling. Also

read the operating manual for

the fuel engine.

Note: Never operate the

ma chine in a closed room; the

exhaust fumes are dan ger ous.

Follow the safety instructions

in chapter 1!

4.2 Start the washer

4.2.1 Switching on the

washer when it is

connected to a water

supply

2. Unlock the spray gun and

activate it.

3. Lock the safety catch even

during short pauses.

NOTE!

Activate the spray

gun several times

at short intervals to vent the

system.

If it requires too much power to

start the engine, it can be

facilitated by removing the

spray lance and activate the

spray gun during startup.

1. Start the engine. (See the

operating manual for the fuel

engine.)

Page 8

8

MC DE, MC PE, MC PE PLUS

Original Instructions

4.2.2 Switching on the

washer when it is

connected to open

tanks (suction mode)

1. Before connecting the suction

hose to the washer, fi ll the

hose with water.

2. Start the washer.

3. Unlock the spray gun and

activate it.

4. When using this machine in

suction mode, fi rst ensure

that the system has been

bled of air by letting the

machine run without high

pressure hose and spray

lance mounted until all air

has escaped. On some

models you need to kink

the by-pass hose and / or

move the engine throttle to

minimum position to achieve

enough suction power.

During work breaks of more

than three minutes, switch off

the washer.

NOTE!

For automatic

suction from a tank, watercourse

or similar sup ply, the inlet hose

must be fi lled with water before

you start. The suction height

depends on the water temperature. Max. suction height (see

section 8.3 Technical Data) is

reached with cold water (up to

8°C). With 60°C warm water, the

ma chine must be under or at the

water level.

If the water being suctioned

contains particles, a suction

fi lter must be mounted on the

end of the hose.

In case of risk of running sands,

a sand fi lter must be attached.

4.2.3 Start machine

Start MC PE with electric starter

1. Start the engine by turning

the key (see the operating

instructions for the engine.

2. Check that the throttle lever

is adjusted correctly - need to

be in Run position.

Start MC DE 1. Switch on the ignition by

pushing the ON/OFF button

of the machine. The charging

+ oil light indicators will turn

on.

2. Move the throttle lever to

SLOW or RUN position.

3. Push the start button until

the machine starts. Now the

charging + oil light indicators

will turn off. If not, stop

the machine immediately

and contact Nilfi sk service

department.

4. The machine can be started

by means of the starter rope

if the battery has gone fl at.

See manual from Yanmar.

Page 9

9

MC DE, MC PE, MC PE PLUS

Original Instructions

4.3 Using detergents Detergent can be added by

means of the detergent injector.

1. Dilute detergent according

to the manufacturer's

instructions.

2. Set the pressure to the

lowest setting on the lance.

CAUTION!

Never allow

detergent to dry on

the surface to be cleaned as

this may cause damage.

5 After using the washer

5.1 Stop the pressure washer

1. Stop the engine.

2. Close the tap.

3. Operate the spray gun until

the wasser is depressurized.

4. Lock the safety catch.

Switching off MC PE with electric start

1. Stop the washer by moving

the throttle lever to STOP

position.

2. Switch off the ignition by

turning the key to OFF

position.

Page 10

10

MC DE, MC PE, MC PE PLUS

Original Instructions

5.2 Disconnecting supply

lines

1. Shut the fuel cock.

2. Remove the water hose from

the washer.

5.3 Storing the washer

(frost-protected)

1. Store the pressure washer in

a dry room without danger of

frost.

IMPORTANT!

If the high-pressure washer

is stored in a room with

temperatures around or

below 0°C, anti-freeze should

be drawn into the pump

beforehand:

1. Remove the water inlet hose

from the washer.

2. Remove the lance.

3. Start the washer and stop it

again after max. one minute.

4. Connect the suction hose

to the water inlet of the

washer and place it in a tank

containing anti-freeze.

5. Start the washer.

6. Hold the spray gun over the

tank containing anti-freeze

and activate it to start suction

of anti-freeze.

7. During suction operate the

spray gun two or three times.

8. Lift the suction hose from the

tank containing anti-freeze

and activate the spray gun to

pump out the remaining antifreeze.

9. Stop the washer.

Switching off MC DE

1. Stop the washer by moving

the throttle lever to STOP

position.

2. Switch off the ignition by

pushing the ON/OFF button.

The light indicators will now

turn off.

Page 11

11

MC DE, MC PE, MC PE PLUS

Original Instructions

6 Maintenance

6.1 Maintenance plan

weekly

every six

months or

500 operating

hours

as required

6.2.1 Clean water fi lter

•

6.2.2 Clean high pressure nozzle

•

6.2.3 Check oil level

•

6.2.4 Change oil - Note: First time after 50 hours

•

6.2.5 Check belts (only belt driven units)

•

Maintenance of motor according to separate operating instructions from the engine supplier

6.2 Maintenance work

6.2.1 Clean water fi lter

A water fi lter is fi tted on the

water inlet to prevent large

particles of dirt from entering

into the pump.

1. Unscrew the union nut.

2. Remove the fi lter and rinse it.

Replace damaged fi lter.

3. Tighten the union nut gently,

so as to avoid damaging the

gasket.

6.2.2 Clean high pressure

nozzle

A blocked nozzle causes

excessive pump pressure. It

must therefore be cleaned

immediately.

1. Stop the washer.

2. Remove the lance.

3. Clean the nozzle with a

needle.

4. Rinse the lance with water

from the nozzle side.

WARNING!

Use the cleaning needle only

when the spray lance has been

removed.

NOTE!

The fuel engine

stops automatically

if the oil level is low. You can

start the petrol engine again

once you have added oil (does

not apply to MC 2C-180/700

PE).

Page 12

12

MC DE, MC PE, MC PE PLUS

Original Instructions

6.2.3 Checking the oil level

(does not apply to

MC 2C-180/700 PE /

MC 3C-165/810 PE)

1. Check whether the oil level

is in the middle of the oil

inspection glass, oil cup or

dip stick. Top up with oil if

necessary (see section 8.3

for type of oil).

6.2.4 Changing the pump/

gear oil (does not apply

to MC 2C-180/700 PE /

MC 3C-165/810 PE)

1. Before changing the oil,

allow the pressure washer to

become warm.

2. Unscrew/open the plugs/lid at

the top and the bottom of the

pump.

3. Allow the oil to drain into a

suitable container (min. 1 l

capacity) and dispose of oil in

compliance with regulations.

4. Mount plug at the bottom of

the pump.

5. Fill pump with fresh oil (see

8.3 for oil type and quantity).

6. Check the oil level (see

6.2.3).

Page 13

13

MC DE, MC PE, MC PE PLUS

Original Instructions

1. Remove the spark plug cable.

2. Dismantle the cover of the

V-belts.

3. Check the belts for any

damage or missing tension.

4. If required, replace the belts.

5. Mount the cover.

6. Mount the spark plug cable.

6.2.5 Check of V-belts

Page 14

14

MC DE, MC PE, MC PE PLUS

Original Instructions

7 Troubleshooting

Fault

Pressure drop

Pressure fl uctuations

In suction mode

Excess pressure

The motor does not start

Cause

> Air in the system

> High-pressure nozzle

blocked/worn

> Pressure control on the lance

is not set correctly

> Engine speed too low

> Warm/loose belts

> Lack of water

> Pump/accessories partially

frozen

> Water inlet hose is too long or

its cross-section too small

> Lack of water caused by

blocked water fi lter

> Warm/loose belts

> Lack of water because max.

permissible suction height

has not been heeded

> Water too hot

> Pump draws in air (only

possible in suction mode)

> Engine’s throttle control is

defective (accessory)

> Low fuel level

> Low oil level in engine

> The pump is blocked or

frozen

Remedy

• Vent the system by operating

the spray gun several

times at short intervals. If

necessary, dismount the

lance (see section 4.2.2).

• Clean/replace the highpressure nozzle.

• Set the required working

pressure.

• Contact Nilfi sk Service

Department.

• Contact Nilfi sk Service

Department.

• Open the tap.

• Thaw machine and

accessories.

• Use prescribed size of water

inlet hose.

• Clean the water fi lter in the

water connection (never

operate the machine without

water fi lter mounted!)

• Contact Nilfi sk Service

Department.

• See chapter 4.2.2.

• See chapter 4.2.2.

• Check that the suction set is

air-tight. Repeat aeration.

• Give less gas/contact Nilfi sk

Service Department.

• Open fuel cock/fi ll with fuel.

• Fill with oil.

• Thaw machine/contact Nilfi sk

Service Department.

Page 15

15

MC DE, MC PE, MC PE PLUS

Original Instructions

• Fill with oil.

• Fill with oil

• Clean.

• Fill the detergent tank.

• Adjust the lance to low

pressure.

> Low oil level in engine

> Low oil level in pump(does

not apply to MC 2C-180/700

PE)

> Injector is dirty or suction

hose is blocked

> Detergent tank is empty

> The lance is not set to low

pressure

The motor stops

When a detergent injector is

used

Fault

Cause

Remedy

8 Further information

8.1 Recycling the pressure

washer

If the pressure washer is

discarded, make it unusable

immediately

1. Dismount the ignition plug.

The pressure washer contains

valuable materials that should

be recycled. Contact your local

waste disposal site. If you have

any queries, please contact

your local authorities or your

nearest dealer.

8.2 Guarantee Your Nilfi sk product is

guaranteed for 12 months from

date of purchase (purchase

receipt must be presented) on

the following conditions:

• that defects are attributable

to fl aws or defects in

materials or workmanship.

(Usual wear and tear as well

as misuse are not covered

by the guarantee).

• that repairs have not been

carried out or attempted by

other than Nilfi sk-trained

service staff.

• that only original

accessories have been

applied.

• that the product has not

been exposed to abuse such

as knocks, bumps or frost.

• that the instructions in the

manual have been carefully

observed.

A warranty repair comprises the

replacement of defective parts,

but it does not cover freight and

packaging charges. Besides we

refer to national Sale of Goods

Act.

Any illegitimate guarantee

repair will be invoiced. (I.e.

malfunctions due to causes

mentioned in section “7

Trouble shooting” of the

instruction manual).

Page 16

16

MC DE, MC PE, MC PE PLUS

Original Instructions

8.3 Technical data

MC 2C-

180/700 PE

MC 3C-

165/810 PE

MC 5M-

240/870 PE

MC 5M-

225/910 PE

PLUS

MC 5M-

250/1000 PE

MC 5M-

250/1050 PE

PLUS

MC 7P-

220/1120 PE

PLUS

MC 5M-

195/1000 DE

Working pressure bar 180 165 240 225 250 250 220 195

Water fl ow (max) l/h 700 810 870 910 1000 1050 1120 1000

Water fl ow Q IEC l/h 650 750 800 840 930 1000 1010 950

Max. water inlet tem-

perature

°C 60 60 60 60 60 60 60 70

Min./max. water inlet

pressure

bar 1/10 1/10 1/10 1/10 1/10 1/10 1/10 1/10

Dimensions (LxWxH) mm

762 x

546 x 603

762 x

546 x 603

1041 x 546 x

635

1067 x 686 x

660

1041 x 546 x

635

1067 x 686 x

660

800 x 690 x

810

800 x 565 x

1010

Noise power level, LWA dB(A) 95.1 93.2 91 90.8 93.2 93.4 91.9 105

Thrust N 31.1 31.9 42.3 42.9 51.8 54.4 52.7 45

Suction height, primed

(at max. 8°C)

m 1.0 1.0 2.5 2.5 2.5 2.5 2.5 1.0

Oil quantity in pump/

gear

l - - 0.5 0.4 0.5 0.5 1.1 0.56/0.27

Oil quantity in motor l 0.5 1 1 11111.65

Oil type (motor/gear) SAE 15-40

Oil type (pump) SAE 15-40

Castrol Al-

phasyn 150

SAE 15-40

Vibrations < 2,5 m/s

2

We reserve the right to make alterations.

Page 17

17

MC DE, MC PE, MC PE PLUS

Original Instructions

8.4 EC Declaration of Conformity

We,

Nilfi sk A/S

Kornmarksvej 1

DK-2605 Broendby

DENMARK

Hereby solely declare, that the product:

Product Description Type

HPW - Professional - Mobile Petrol - diesel driven

MC 5M *.* DE, PE, PE PLUS

MC 2C */* PE

MC 3C */* PE

MC 7P */* PE PLUS

Is in compliance with the following standards:

Id and Version Title

EN 60335-1:2012+A11:2014 Household and similar electrical appliances - Safety - Part 1:

General requirements

EN 60335-2-79:2012 Household and similar electrical appliances - Safety - Part

2-79: Particular requirements for high pressure cleaners and

steam cleaners

EN 61000-6-1:2007 Electromagnetic compatibility (EMC) - Part 6-1: Generic stand-

ards - Immunity for residential, commercial and light-industrial

environments

EN 55012:2007+A1:2009 Vehicles, boats and internal combustion engines - Radio

disturbance characteristics - Limits and methods of measurement for the protection of off-board receivers

EN 50581:2012 Technical documentation for the assessment of electrical and

electronic products with respect to restriction of hazardous

substances

Following the provisions of:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

RoHS Directive 2011/65/EC

Noise Emission Directive 2000/14/EC – Conformity assessment procedure according to Annex V.

- Measured noise level: 77-92 dB(A)

- Guaranteed noise level: 90-105 dB(A)

Hadsund 09-09-2015 Anton Soerensen

Senior Vice President – Global R&D

Place Date Name, Title Signature

Page 18

HEAD QUARTER

DENMARK

Nilfi sk A/S

Kornmarksvej 1

DK-2605 Brøndby

Tel.: (+45) 4323 8100

www.nilfi sk.com

SALES COMPANIES

ARGENTINA

Nilfi sk srl.

Edifi cio Central Park

Herrera 1855, 6th fl oor/604

Ciudad de Buenos Aires

Tel.: (+54) 11 6091 1571

www.nilfi sk.com.ar

AUSTRALIA

Nilfi sk Pty Ltd

Unit 1/13 Bessemer Street

Blacktown NSW 2148

Tel.: (+61) 2 98348100

www.nilfi sk.com.au

AUSTRIA

Nilfi sk GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: (+43) 662 456 400 90

www.nilfi sk.at

BELGIUM

Nilfi sk n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Tel.: (+32) 14 67 60 50

www.nilfi sk.be

BRAZIL

Nilfi sk do Brasil

Av. Eng. Luis Carlos Berrini, 550

40 Andar, Sala 03

SP - 04571-000 Sao Paulo

Tel.: (+11) 3959-0300 / 3945-4744

www.nilfi sk.com.br

CANADA

Nilfi sk Canada Company

240 Superior Boulevard

Mississauga, Ontario L5T 2L2

Tel.: (+1) 800-668-8400

www.nilfi sk.ca

CHILE

Nilfi sk S.A. (Comercial KCS Ltda)

Salar de Llamara 822

8320000 Santiago

Tel.: (+56) 2684 5000

www.nilfi sk.cl

CHINA

Nilfi sk

4189 Yindu Road

Xinzhuang Industrial Park

201108 Shanghai

Tel.: (+86) 21 3323 2000

www.nilfi sk.cn

CZECH REPUBLIC

Nilfi sk s.r.o.

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Tel.: (+420) 244 090 912

www.nilfi sk.cz

DENMARK

Nilfi sk Danmark A/S

Industrivej 1

Hadsund, DK-9560

Tel.: 72 18 21 20

www.nilfi sk.dk

FINLAND

Nilfi sk Oy Ab

Koskelontie 23 E

02920 Espoo

Tel.: (+358) 207 890 600

www.nilfi sk.fi

FRANCE

Nilfi sk SAS

26 Avenue de la Baltique

Villebon sur Yvette

91978 Courtabouef Cedex

Tel.: (+33) 169 59 87 00

www.nilfi sk.fr

GERMANY

Nilfi sk GmbH

Guido-Oberdorfer-Straße 2-10

89287 Bellenberg

Tel.: (+49) (0)7306/72-444

www.nilfi sk.de

GREECE

Nilfi sk A.E.

Αναπαύσεως 29

Κορωπί Τ.Κ. 194 00

Tel.: (30) 210 9119 600

www.nilfi sk.gr

HOLLAND

Nilfi sk B.V.

Versterkerstraat 5

1322 AN Almere

Tel.: (+31) 036 5460760

www.nilfi sk.nl

HONG KONG

Nilfi sk Ltd.

2001 HK Worsted Mills

Industrial Building

31-39, Wo Tong Tsui St.

Kwai Chung, N.T.

Tel.: (+852) 2427 5951

www.nilfi sk.com

HUNGARY

Nilfi sk Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklós-Lakihegy

Tel.: (+36) 24 475 550

www.nilfi sk.hu

INDIA

Nilfi sk India Limited

Pramukh Plaza, ‘B’ Wing, 4th fl oor, Unit

No. 403

Cardinal Gracious Road, Chakala

Andheri (East) Mumbai 400 099

Tel.: (+91) 22 6118 8188

www.nilfi sk.in

IRELAND

Nilfi sk

1 Stokes Place

St. Stephen’s Green

Dublin 2

Tel.: (+35) 3 12 94 38 38

www.nilfi sk.ie

ITALY

Nilfi sk SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Tel.: (+39) (0) 377 414021

www.nilfi sk.it

JAPAN

Nilfi sk Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45548 2571

www.nilfi sk.com

MALAYSIA

Nilfi sk Sdn Bhd

Sd 33, Jalan KIP 10

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (60) 3603 627 43 120

www.nilfi sk.com

MEXICO

Nilfi sk de Mexico, S. de R.L. de C.V.

Pirineos #515 Int.

60-70 Microparque

Industrial WSantiago

76120 Queretaro

Tel.: (+52) (442) 427 77 00

www.nilfi sk.com

NEW ZEALAND

Nilfi sk Limited

Danish House

6 Rockridge Avenue

Penrose, Auckland 1061

Tel.: (+64) 9526 3890

www.nilfi sk.com.au

NORWAY

Nilfi sk AS

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 80

www.nilfi sk.no

PERU

Nilfi sk S.A.C.

Calle Boulevard 162, Of. 703, Lima 33Perú

Lima

Tel.: (511) 435-6840

www.nilfi sk.com

POLAND

Nilfi sk Sp. Z.O.O.

Millenium Logistic Park

ul. 3 Maja 8, Bud. B4

05-800 Pruszków

Tel.: (+48) 22 738 3750

www.nilfi sk.pl

PORTUGAL

Nilfi sk Lda.

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: (+351) 21 911 2670

www.nilfi sk.pt

RUSSIA

Nilfi sk LLC

Vyatskaya str. 27, bld. 7/1st

127015 Moscow

Tel.: (+7) 495 783 9602

www.nilfi sk.ru

SINGAPORE

Den-Sin

22 Tuas Avenue 2

639453 Singapore

Tel.: (+65) 6268 1006

www.densin.com

SLOVAKIA

Nilfi sk s.r.o.

Bancíkovej 1/A

SK-821 03 Bratislava

Tel.: (+421) 910 222 928

www.nilfi sk.sk

SOUTH AFRICA

WAP South Africa

12 Newton Street

Spartan 1630

Tel.: (+27) 11 975 7060

www.wap.com.za

SOUTH KOREA

Nilfi sk Korea

3F Duksoo B/D, 317-15

Sungsoo-Dong 2Ga

Sungdong-Gu, Seoul

Tel.: (+82) 2497 8636

www.nilfi sk.co.kr

SPAIN

Nilfi sk S.A.

Torre d’Ara,

Passeig del Rengle, 5 Plta. 10

a

08302 Mataró

Tel.: (34) 93 741 2400

www.nilfi sk.es

SWEDEN

Nilfi sk AB

Taljegårdsgatan 4

431 53 Mölndal

Tel.: (+46) 31 706 73 00

www.nilfi sk.se

SWITZERLAND

Nilfi sk AG

Ringstrasse 19

Kircheberg/Industri Stelz

9500 Wil

Tel.: (+41) 71 92 38 444

www.nilfi sk.ch

TAIWAN

Nilfi sk Ltd

Taiwan Branch (H.K)

No. 5, Wan Fang Road

Taipei

Tel.: (+88) 6227 00 22 68

www.nilfi sk.tw

THAILAND

Nilfi sk Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2275 5630

www.nilfi sk.co.th

TURKEY

Nilfi sk A.S.

Serifali Mh. Bayraktar Bulv. Sehit Sk. No:7

Ümraniye, 34775 Istanbul

Tel.: +90 216 466 94 94

www.nilfi sk.com.tr

UNITED ARAB EMIRATES

Nilfi sk Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Tel.: (+971) (0) 655-78813

www.nilfi sk.com

UNITED KINGDOM

Nilfi sk Ltd.

Nilfi sk House, Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BQ

Tel: (+44) (0) 1768 868995

www.nilfi sk.co.uk

UNITED STATES

Nilfi sk Inc.

14600 21st Avenue North

Plymouth, MN-55447

Tel.: (+1) 800-989-2235

www.nilfi sk.com

VIETNAM

Nilfi sk Vietnam

No. 51 Doc Ngu Str.

P. Vinh Phúc, Q.Ba Dinh

Hanoi

Tel.: (+84) 761 5642

www.nilfi sk.com

Loading...

Loading...