Nilfisk-Advance Convertamatic 24, Convertamatic 28, BA 625, Convertamatic 32, BA 725 Instruction Manual

...Page 1

Convertamatic™ 24, 26, 28, 32

BA 625, 725, 825

Instructions for Use / Instrucciones de uso

Advance Models: 56315000(24D-C), 56315001(26D), 56315002(28D),

56315003(24C-C), 56315004(28D-C), 56315005(28C-C), 56315006(X24D-C),

56315007(X24C-C), 56315008(26D-C), 56315009(X26D-C), 56315010(26C-C),

56315011(X26C-C), 56315012(X28D-C), 56315013(X28C-C), 56315804(32D-C)

56315805(X32D-C)

Nilfi sk Models: 56315800(625), 56315801(725), 56315802(725C), 56315803(825)

A-English

B-Español

11/04 revised 1/07 Form No. 56041596

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

Page

Introduction ..............................................................................A-3

Parts and Service ....................................................................A-3

Nameplate ...............................................................................A-3

Unpacking the Machine ...........................................................A-3

Cautions and Warnings ...........................................................A-4

Consignes de prudence et de sécurité ....................................A-5

Know Your Machine .......................................................A-6 – A-7

Control Panel ...........................................................................A-8

Preparing the Machine for Use

Batteries ..................................................................................A-9

Installing the Brushes ............................................................A-10

Filling the Solution Tank .........................................................A-11

Squeegee Installation ............................................................A-11

Detergent (AXP/EDS™) System ...............................A-12 – A-13

Operating the Machine

Wet Scrubbing ...........................................................A-14 – A-15

Wet Vacuuming .........................................................A-14 – A-15

After Using the Machine ........................................................A-16

Maintenance Schedule ..........................................................A-16

Servicing the Vacuum Motor ..................................................A-16

Lubricating the Machine ........................................................A-16

Maintenance

Charging the Batteries (Wet) .................................................A-17

Charging the Batteries (Gel) ..................................................A-17

Servicing the Squeegee ........................................................A-18

Adjusting the Squeegee ........................................................A-18

Servicing the Recovery Tank Switches ..................................A-19

Adjusting Disk Deck Skirt Height ...........................................A-20

Troubleshooting

Circuit Breakers Tripping .......................................................A-21

Poor Water Pickup .................................................................A-21

Squeegee Streaks .................................................................A-21

Swirl Marks ............................................................................A-21

No Solution Flow ...................................................................A-21

Scrub Deck Raises While Scrubbing (Cylindrical) .................A-21

No Detergent Flow (AXP/EDS) ..............................................A-21

Technical Specifi cations ........................................................A-22

A-2 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 5/05

Page 3

ENGLISH / A-3

INTRODUCTION

This manual will help you get the most from your Nilfi sk-Advance automatic scrubber/dryer. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 6-8 unless otherwise noted.

This product is intended for commercial use only.

P ARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk-Advance Service Center, who employs factory trained service personnel,

and maintains an inventory of Nilfi sk-Advance original replacement parts and accessories.

Call Nilfi sk-Advance for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

NAMEPLATE

The Model and Serial Number of your machine are shown on the Nameplate in the battery compartment. This information is needed when ordering

repair parts for the machine. Use the space below to note the Model and Serial Number of your machine for future reference.

Model _________________________________________

Serial Number ___________________________________

UNPACKING THE MACHINE

When the machine is delivered, carefully inspect the shipping packaging and the machine for damage. If damage is evident, save the shipping

carton (if applicable) so that it can be inspected. Contact the Nilfi sk-Advance Customer Service Department immediately to fi le a freight damage

claim. Refer to the unpacking instruction sheet included with the machine to remove the machine from the pallet.

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-3

Page 4

A-4 / ENGLISH

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk-Advance uses the symbols below to signal potentially dangerous conditions. Read this information carefully and take the

necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

WARNING!

* This machine should only be used by properly trained and authorized persons.

* While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while ascending

(driving up) the ramp.

* Keep sparks, fl ame and smoking materials away from batteries. Explosive gases are vented during normal operation.

* Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from open fl ame. Do not

smoke while charging the batteries.

* Remove all jewelry when working near electrical components.

* Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

* Never work under a machine without safety blocks or stands to support the machine.

* Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable liquids exist.

* Do not clean this machine with a pressure washer.

* Do not operate this machine on ramps or inclines of more than a 2 percent gradient.

* Only use the brushes provided with the appliance or those specifi ed in the instruction manual. The use of other brushes may impair safety.

CAUTION!

* This machine is not approved for use on public paths or roads.

* This machine is not suitable for picking up hazardous dust.

* Use care when using scarifi er discs and grinding stones. Nilfi sk-Advance will not be held responsible for any damage to fl oor surfaces caused

by scarifi ers or grinding stones.

* When operating this machine, ensure that third parties, particularly children, are not endangered.

* Before performing any service function, carefully read all instructions pertaining to that function.

* Do not leave the machine unattended without fi rst turning the key switch off (O), removing the key and securing the machine.

* Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

* Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

* Use caution when moving this machine in below freezing temperature conditions. Any water in the solution, recovery or detergent tanks or in

the hose lines could freeze, causing damage to valves and fi ttings. Flush with windshield washer fl uid.

* The batteries must be removed from the machine before the machine is scrapped. The disposal of the batteries should be safely done in

accordance with your local environmental regulations.

* Do not use on surfaces having a gradient exceeding that marked on the machine.

* All doors and covers are to be positioned as indicated in the instruction manual before using the machine.

* Refer to the battery charger OEM product manual for additional specifi c battery charger warnings.

SAVE THESE INSTRUCTIONS

A-4 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 5

ENGLISH / A-5

CONSIGNES DE PRUDENCE ET DE SECURITE

SYMBOLES

Les symboles reproduits ci-dessous sont utilisés par Nilfi sk-Advance pour attirer l’attention de l’opérateur sur des situations potentiellement

dangereuses. Il est donc conseillé de lire attentivement ces indications et de prendre les mesures adéquates en vue de protéger le personnel

et le matériel.

DANGER!

Ce symbole est utilisé pour mettre l’opérateur en garde contre les risques immédiats pouvant provoquer des dommages corporels graves,

voire entraîner la mort.

ATTENTION!

Ce symbole est utilisé pour attirer l’attention sur une situation susceptible d’entraîner des dommages corporels graves.

PRUDENCE!

Ce symbole est utilisé pour attirer l’attention de l’opérateur sur une situation qui pourrait entraîner des dommages corporels minimes, ou des

dommages à la machine ou à d’autres équipements.

Lire toutes les instructions avant d’utiliser l’appareil.

CONSIGNES GENERALES DE SECURITE

Les consignes spécifi ques de prudence et de sécurité mentionnées ici ont pour but de vous informer de la survenance de tout risque de

dommages matériels ou corporels.

ATTENTION!

* Cette machine ne pourra être utilisée que par du personnel parfaitement entraîné et dûment autorisé.

* Evitez les arrêts subits lorsque la machine est chargée et se trouve sur des rampes ou des plans inclinés. Evitez les virages serrés. Adoptez une vitesse

réduite lorsque la machine est en descente. Ne nettoyez que lorsque la machine monte la pente.

* Eloignez les batteries de toutes fl ammes, étincelles ou substance fumigène. Les gaz explosifs sont ventilés pendant le fonctionnement normal.

* De plus, du gaz hydrogène explosif s’échappe des batteries lorsqu’elles sont en charge. Ne procédez au chargement des batteries que dans une zone bien

ventilée, loin de toute fl amme. Ne fumez pas à proximité des batteries lorsqu’elles sont en charge.

* Otez tous vos bijoux lorsque vous travaillez à proximité de composants électriques.

* Positionnez la clé de contact sur off (O) et déconnectez les batteries avant de procéder à l’entretien des composants électriques.

* Ne travaillez jamais sous une machine sans y avoir placé, au préalable, des blocs de sécurité ou des étais destinés à soutenir la machine

* Ne déversez pas d’agents nettoyants infl ammables, ne faites pas fonctionner la machine à proximité de ces agents ou d’autres liquides infl ammables.

* Ne nettoyez pas cette machine avec un nettoyeur à pression.

* Ne faites pas fonctionner la machine sur des rampes ou pentes de plus de 2 pour cent.

* Utilisez uniquement les brosses fournies avec l’appareil ou celles spécifi ées dans le manuel d’instructions. L’utilisation d’autres brosses peut mettre la sécurité

en péril.

PRUDENCE!

* Cette machine n’est pas conçue pour une utilisation sur les chemins ou voies publics.

* Cette machine n’est pas conçue pour le ramassage des poussières dangereuses.

* Faites extrêmement attention lorsque vous utilisez des disques de scarifi cateur et des meules. Nilfi sk-Advance ne pourra en aucun cas être tenu pour

responsable des dommages occasionnés à vos sols par ce type d’équipement.

* Lors de l’utilisation de cette machine, assurez-vous que des tiers, et notamment des enfants, ne courent pas le moindre risque.

* Avant de procéder à toute opération d’entretien, veuillez lire attentivement toutes les instructions qui s’y rapportent.

* Ne laissez pas la machine sans surveillance sans avoir, au préalable, coupé le contact, enlevé la clé de contact (O) et tiré le frein à main.

* Positionnez la clé de contact sur off (O) avant de remplacer les brosses ou d’ouvrir tout panneau d’accès.

* Prenez toutes les mesures nécessaires pour éviter que les cheveux, les bijoux ou les vêtements amples ne soient entraînés dans les parties mobiles de la

machine.

* Faites attention lorsque vous déplacez cette machine dans un endroit où la température peut descendre sous 0°. L’eau contenue dans les réservoirs de

détergent, de récupération ou de solution ou dans les conduites risquerait de geler et par là même d’endommager les valves et raccords de la machine. Rincez

avec un liquide de lave-glace.

* Prenez soin d’enlever les batteries de la machine avant de mettre cette dernière au rebut. Pour ce qui est de l’élimination des batteries, conformez-vous aux

réglementations locales en matière d’environnement.

* N’utilisez pas sur des surfaces dont la pente dépasse celle mentionnée sur la machine.

* Toutes les portes et couvercles doivent être dans la position mentionnée dans le manuel d’instruction avant de mettre la machine en service.

* Consultez le manuel du fabricant du chargeur de batterie pour plus de consignes de sécurité spécifi ques sur le chargeur de batterie.

CONSERVEZ SOIGNEUSEMENT CES INSTRUCTIONS

revised 1/07

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-5

Page 6

A-6 / ENGLISH

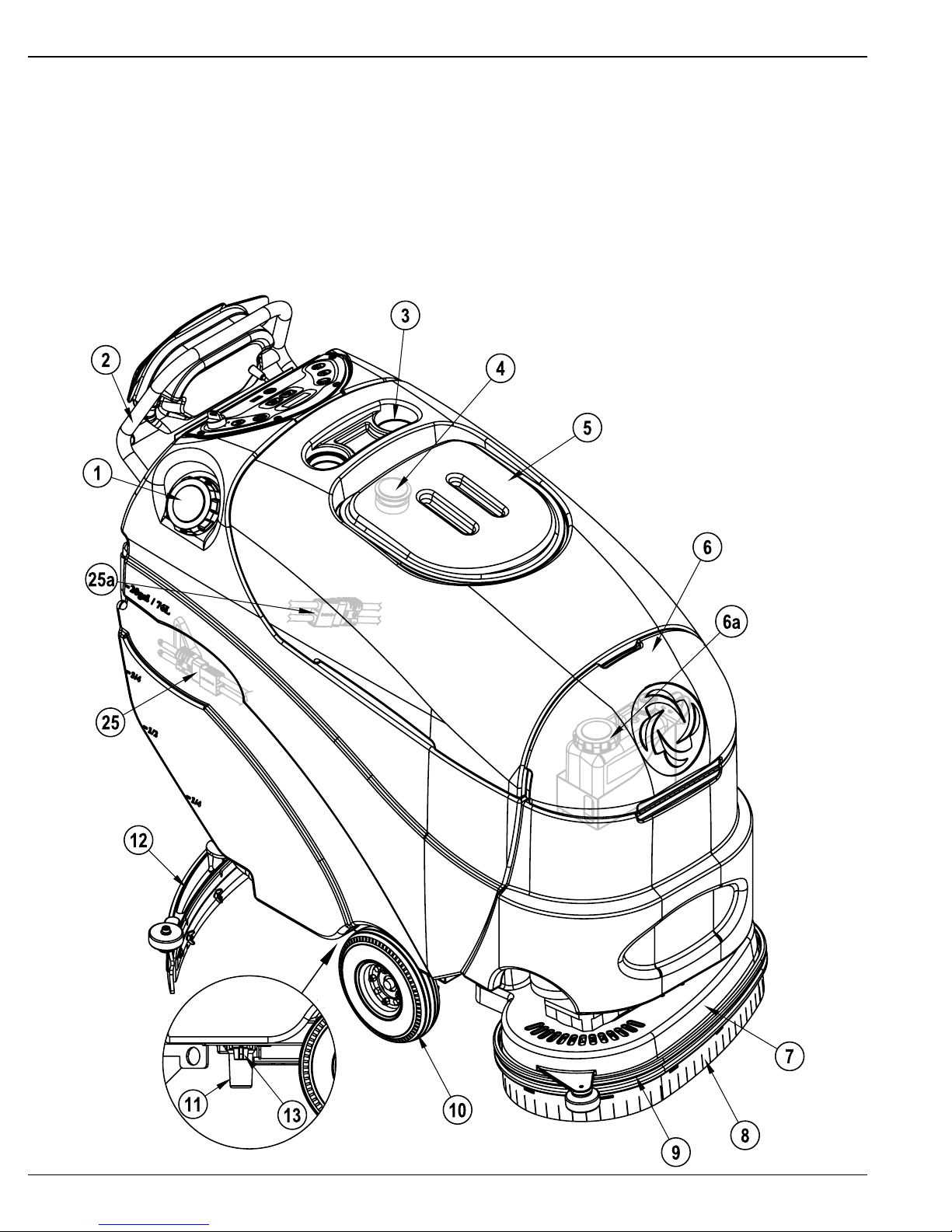

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item

shown on this page unless otherwise noted. Refer back to this page whenever necessary, to pinpoint the location of an item mentioned in the text.

NOTE: Refer to the service manual for detailed explanations of each item illustrated on the next 3 pages.

1 Solution Tank Fill

2 Operator Control Handle

3 Bottle Holders

4 Vacuum Motor Inlet Screen

5 Recovery Tank Cover

6 Detergent(AXP/EDS) Cartridge Access Cover

6a Detergent(AXP/EDS) Cartridge (AXP/EDS models only)

7 Scrub Deck

8 Scrub Deck Skirt

9 Scrub Deck Bumper

10 Drive Wheel

11 Solution Filter

12 Squeegee Assembly

13 Solution Shut-Off Valve

A-6 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 2/05

Page 7

KNOW YOUR MACHINE

14 Solution Drain Hose / Level Indicator

15 Squeegee Raise / Lower Lever

16 Onboard Battery Charger (Not found on all models)

17 Wheel Drive Circuit Breaker

18 Control Circuit Circuit Breaker

19 Squeegee Blade Latch

20 Squeegee Mount Thumb Nut

21 Squeegee Adjustment Knob

22 Recovery Tank Drain Hose

23 Debris Hopper (Cylindrical Models Only)

24 Idler Assembly (Cylindrical Models Only)

25 Battery Pack Connector (non onboard charger models only)

ENGLISH / A-7

25a Battery Pack Connector (onboard charger models only)

26 Squeegee Blade Tension Strap

27 Squeegee Blade Alignment Pins

28 Recovery Hose

29 Control Panel

30 Drive Paddle

31 Speed Limit Control Knob

32 Vacuum Shut Off Switch

33 Extended Scrub Filter (Optional)

34 Solution Manifold (Cylindrical Models Only)

revised 2/05

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-7

Page 8

A-8 / ENGLISH

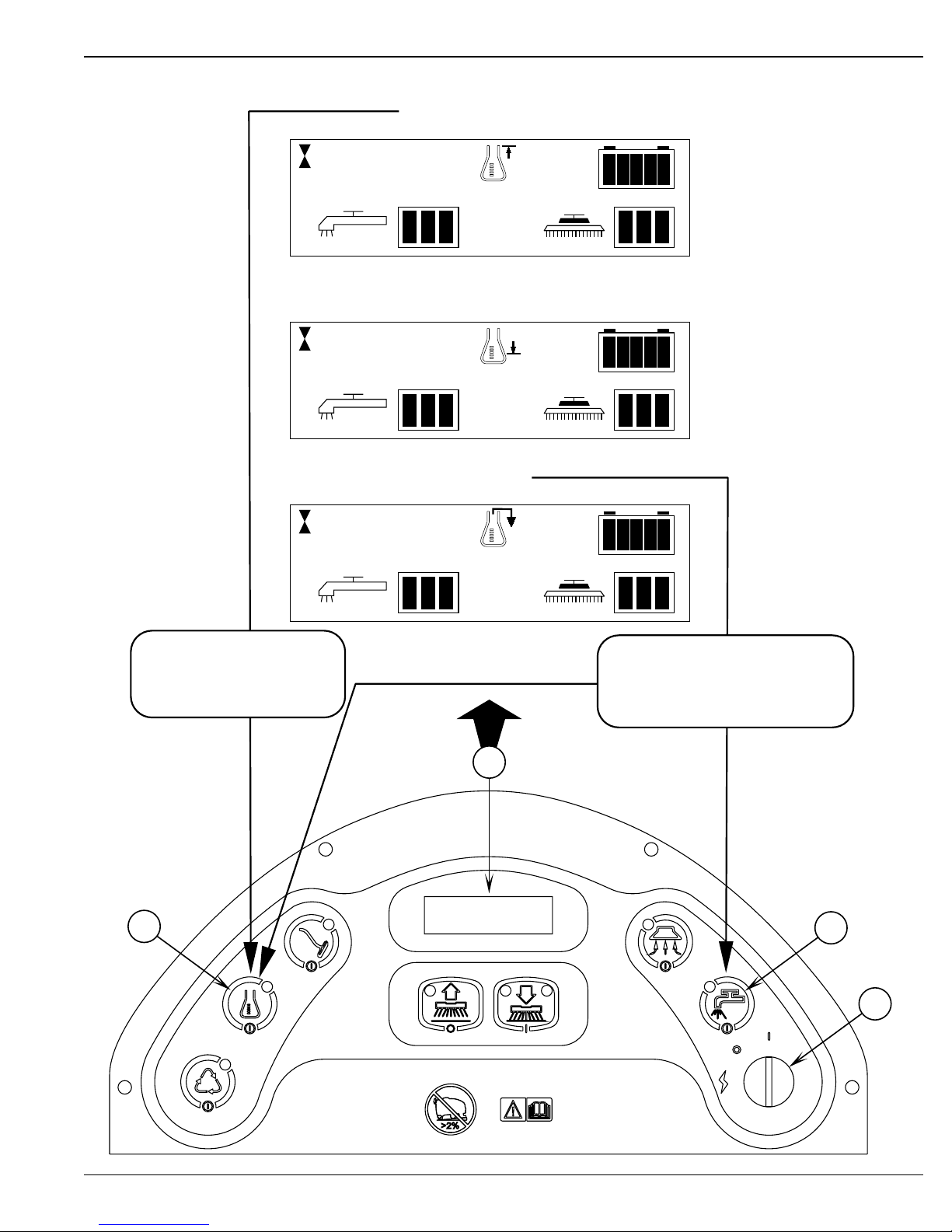

CONTROL PANEL

A Key Switch (Main Power)

B Solution Switch

C Vacuum Switch

D Display Panel

D1 Solution Flow Indicator

D2 Fault Indicator

D3 Hour Meter

D4 AXP/EDS Indicator

D5 Battery Indicator

D6 Scrub Pressure Indicator

D7 Recovery Tank FULL Indicator

D8 Battery Low Indicator

E Wand Switch (Dealer Installed Option)

F Detergent System (AXP/EDS models only)

G Extended Scrub System (Dealer Installed Option)

H Scrub OFF

I Scrub ON

D8

D7

D

!

!

D1

E

D2

D3

D4 D5

Ø.4

Regular Heavy Extreme Regular Heavy Extreme

Scrub Scrub Scrub Scrub Scrub Scrub

(press once) (press twice) (hold 5 sec.)

D

D6

C

F

G

H

A-8 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

B

A

I

revised 1/07

Page 9

ENGLISH / A-9

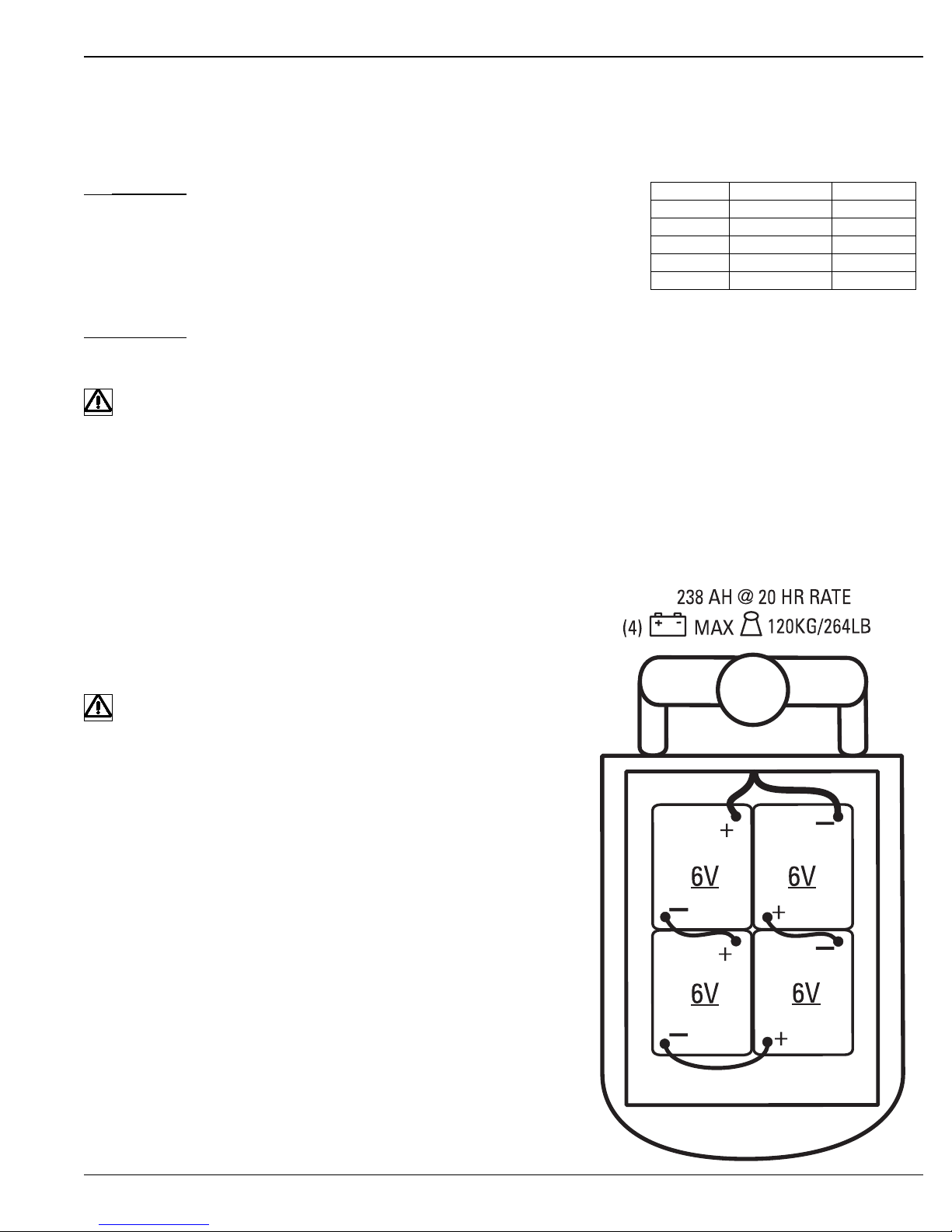

BATTERIES

If your machine shipped with batteries installed do the following:

• Check that the batteries are connected to the machine (25 / 25a).

• Turn ON the Key Switch (A) and check the Battery Indicator (D). If the gauge is completely

fi lled, the batteries are ready for use. If the gauge is less than full, the batteries should be

charged before use. See the “Charging The Batteries” section.

• IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE

OEM PRODUCT MANUAL FOR INSTRUCTIONS REGARDING SETTING THE CHARGER FOR

BATTERY TYPE (SEE CHART).

If your machine shipped without batteries installed do the following:

• Consult your Authorized Nilfi sk-Advance dealer for recommended batteries.

• Install the batteries by following the instructions below.

• DO NOT install two 12 volt batteries in your machine. This affects the stability of the

machine.

• IMPORTANT!: IF YOUR MACHINE HAS AN ONBOARD BATTERY CHARGER REFER TO THE

OEM PRODUCT MANUAL FOR INSTRUCTIONS REGARDING SETTING THE CHARGER FOR

BATTERY TYPE (SEE CHART).

AH/Rate MFG Algorithm

180 DEKA(gel) 6

195 US 4

238 US / Trojan 4 / 1

180 Exide 51

200 Exide 21

WARNING!

Use extreme caution when working with batteries. Sulfuric acid in batteries can cause severe injury if allowed to contact the skin

or eyes. Explosive hydrogen gas is vented from the batteries through openings in the battery caps. This gas can be ignited by any

electrical arc, spark or fl ame. Do not install any lead-acid battery in a sealed container or enclosure. Hydrogen gas from overcharging

must be allowed to escape.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to

prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Electrical components in this machine can be severely damaged if the

batteries are not installed and connected properly. Nilfi sk-Advance, a qualifi ed

electrician, or the battery manufacturer should install batteries.

1 Remove the batteries from their shipping crate and carefully inspect them for

cracks or other damage. If damage is evident, contact the carrier that delivered

them or the battery manufacturer to fi le a damage claim.

2 Turn the Master Key Switch (A) OFF and remove the key.

3 Tip the recovery tank to the side, locked position. Remove the battery cables from

inside the battery compartment.

4 Your machine comes from the factory with enough battery cables to install four 6

volt batteries. Carefully lift the batteries into the battery compartment and arrange

them exactly as shown in FIGURE 1. Secure the batteries as close to the back of

the machine as possible.

5 Install the battery cables as shown. Position the cables so the battery caps can

be easily removed for battery service.

6 Carefully tighten the nut in each battery terminal until the terminal will not turn.

Do not over-tighten the terminals, or they will be very diffi cult to remove for future

service.

7 Coat the terminals with spray-on battery terminal coating (available at most auto

parts stores).

8 Put one of the black rubber boots over each of the terminals and connect the

Battery Pack Connector (25 / 25a).

FIGURE 1

revised 1/07

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-9

Page 10

A-10 / ENGLISH

INSTALLING THE BRUSHES (DISC SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key,

before changing the brushes, and before

opening any access panels.

1 Make sure the Brush Deck (7) is in the RAISED

position. Make sure the Key Switch (A) is off (O).

2 If using pads, install the pads on the pad holders.

3 See Figure 2. To mount the Brushes (AA) (or

pad holders) align the Lugs (BB) on the brush

with the holes on the mounting plate and turn

to lock in place (turn the outside edge of brush

towards the rear of machine as shown (CC)).

FIGURE 2

INSTALL THE BRUSHES (CYLINDRICAL SYSTEM)

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Brush Deck is in the RAISED position.

Make sure the Key Switch (A) is off (O).

2 See Figure 3. To access the brushes loosen the

black knobs (one on each side) on top of the idler

assemblies (24) and remove the idler assemblies.

Slide the brush into the housing, lift slightly, push and

turn until it seats. Re-install the idler assemblies.

A-10 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

FIGURE 3

revised 1/07

Page 11

ENGLISH / A-11

FILLING THE SOLUTION TANK

Fill the solution tank with a maximum of 20 gallons (76 Liters) of cleaning solution. Do not fi ll the solution tank above 7.5 cm (3 inches) from the

bottom of the Solution Fill (1). The solution should be a mixture of water and the proper cleaning chemical for the job. Always follow the dilution

instructions on the chemical container label. NOTE: AXP/EDS machines can either be used conventionally with detergent mixed in the tank or the

AXP/EDS detergent dispensing system can be used. When using the AXP/EDS detergent dispensing do not mix detergent in the tank, plain water

should be used.

CAUTION!

Use only low-foaming, non-fl ammable liquid detergents intended for machine application. Water temperature should not exceed 130

degrees fahrenheit (54.4 degrees celsius)

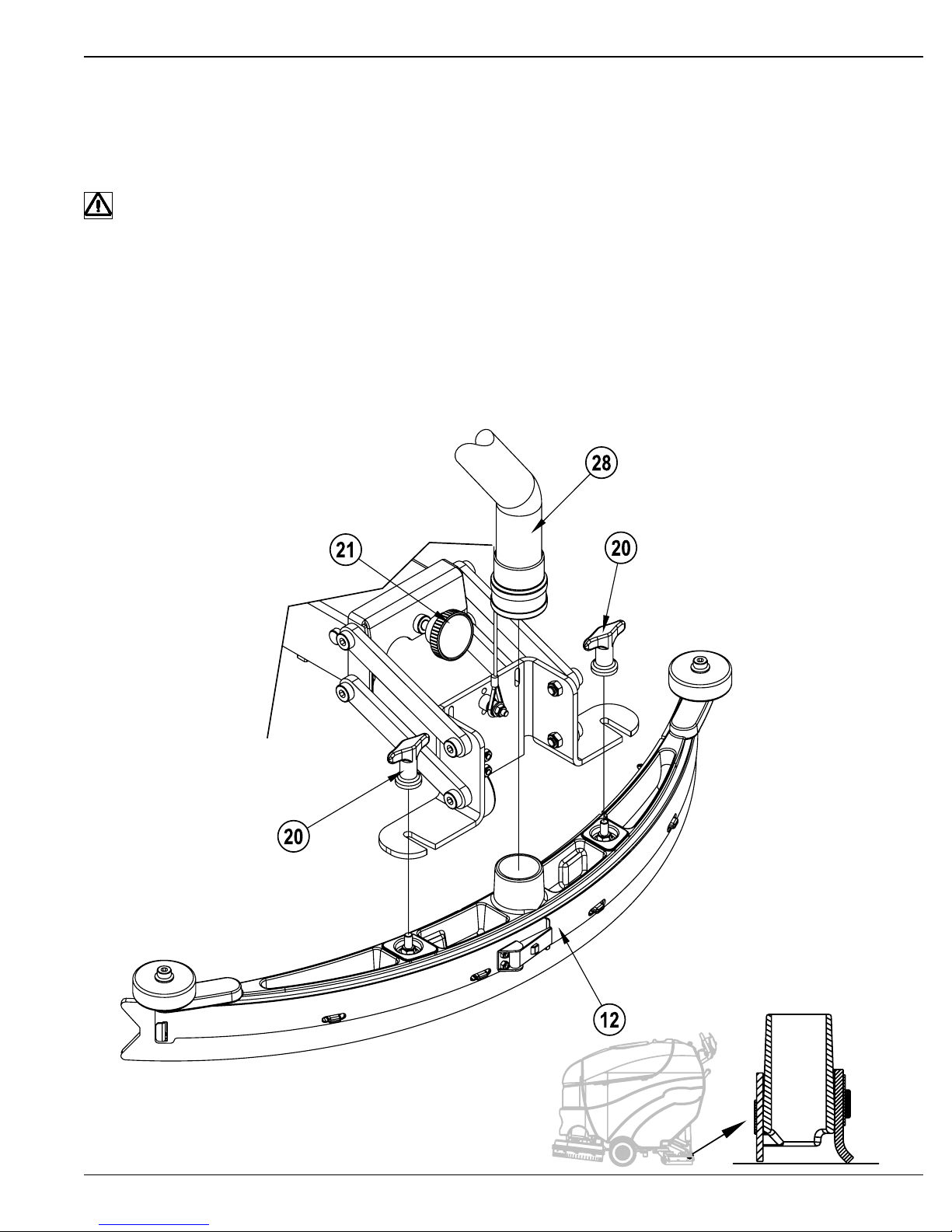

SQUEEGEE INSTALLATION

1 See Figure 4. Slide the Squeegee Assembly (12) onto the squeegee mount bracket and tighten the Squeegee Mount Thumb Nuts (20).

2 Connect the Recovery Hose (28) to the squeegee inlet.

3 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt using the Squeegee Adjustment Knob (21) so that the rear

squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown.

FIGURE 4

revised 1/07

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-11

Page 12

A-12 / ENGLISH

DETERGENT (AXP/EDS) SYSTEM PREPARATION AND USE

COMMON INSTRUCTIONS:

The system should be purged of previous detergent when switching to a

different detergent. SERVICE NOTE: Move machine over fl oor drain before

purging because a small amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals:

1 Disconnect and remove the detergent cartridge.

2 Turn the Key Switch (A) ON and press the Detergent Switch (F) and the

Solution Switch (B) down for at least 2 seconds. NOTE: Once activated

the purge process takes 10 seconds. See illustration on next page for

Detergent System indicators. Normally one purge cycle is adequate to

purge the system.

To Purge Weekly:

1 Disconnect and remove the detergent cartridge. Install and connect a

Cartridge fi lled with clean water

2 Turn the Key Switch (A) ON and press the Detergent Switch (F) and the

Solution Switch (B) down for at least 2 seconds. NOTE: Once activated

the purge process takes 10 seconds. See illustration on next page for

Detergent System indicators. Normally one purge cycle is adequate to

purge the system.

When the Detergent Cartridge is almost empty a Display Panel (D) indicator

will come on. This “Low Detergent” indicator will remain on until you reset

the system. Once this indicator comes on you should be able to simply pour

an entire gallon bottle of detergent into the Cartridge to refi ll without worrying

about measuring. NOTE: Only reset the system when the cartridge is full.

When switching cartridges, the “Low Detergent” indicator is only accurate if the

replacement cartridge is at the same level as the cartridge being replaced.

To Reset:

1 Turn the Key Switch (A) ON and hold the Detergent Switch (F) down for 2

seconds. See illustration on next page for Detergent System indicators.

NON-REFILLABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Remove the Cap (AA) and place the cartridge in the detergent box. Install the

Dry Break Cap (BB) as shown.

REFILLABLE CARTRIDGE SPECIFIC INSTRUCTIONS:

Fill the detergent cartridge with a maximum of 1.25 gallons

(4.73 Liters) of detergent. SERVICE NOTE: Remove the

detergent cartridge from the detergent box prior to fi lling to

avoid spilling detergent on the machine.

It is recommended that a separate cartridge be used for each

detergent you plan to use. The detergent cartridges have

a white decal on them so you can write the detergent name

on each cartridge to avoid mixing them up. The detergent

cartridge has a Magnetic Slider (CC) on one end that needs

to be set to the proper dilution ratio according to the dilution

instructions on the manufacturer’s bottle. Slide the Magnet

Slider (CC) to the appropriate location on Detergent Dilution

Ratio Decal (DD). When installing a new cartridge, remove the

Cap (AA) and place the cartridge in the detergent box. Install

the Dry Break Cap (BB) as shown.

A-12 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 13

DETERGENT (AXP/EDS) SYSTEM PREPARATION AND USE

FULL (RESET)

Ø.4

DETERGENT LOW

Ø.4

PURGE

ENGLISH / A-13

Press (F) for 2

seconds to reset.

F

Ø.4

Press (F) & (B) for 2

seconds to purge.

D

B

A

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-13

Page 14

A-14 / ENGLISH

WET SCRUBBING

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only while

ascending (driving up) the ramp.

1 Follow the instructions in the Preparing The Machine For Use section of this manual.

2 Turn the Master Key Switch (A) ON (I). This will display the control panel indicator lights, reference the Battery Indicator and Hour Meter on the

Display Panel (D).

3 To transport the machine to the work area, push the Drive Paddle (30) forward to go forward or pull the Drive Paddle (30) backward to move the

machine in reverse. Vary the pressure on the Drive Paddle (30) to obtain the desired speed.

NOTE: Speed Control Knob (13) is used to control the maximum speed in either forward or reverse.

4 Press and hold the Solution Switch (B) for 5 seconds to pre-wet the fl oor. NOTE: This must be done prior to pressing the Scrub ON Switch (I).

5 Press the Scrub ON Switch (I) once for Regular Scrub or twice for Heavy Scrub mode. Hold this switch for 5 seconds for Extreme Scrub mode.

Both the solution system and detergent system have 3 fl ow rate presets that coincide with the 3 scrub modes (see Control Panel). NOTE:

There is a solution fl ow rate over ride function if you wish to increase solution fl ow without increasing scrub pressure. Hold the Solution Switch

(B) for 3 seconds (solution indicator will start fl ashing) and then let go. You then have 3 seconds to set a different fl ow rate by simply pressing

the Solution Switch (B) repeatedly until the Solution Flow Rate Indicator shows the rate you desire (Regular, Heavy or Extreme / see Control

Panel). Any subsequent scrub pressure adjustments will reset the solution fl ow rate to default.

NOTE: The solution, vacuum and detergent (AXP/EDS only) systems are automatically activated when the Scrub ON Switch (I) is pressed.

No further action is required other than lowering the squeegee (15). Any individual system can be turned OFF or back ON by simply pressing

its switch at any time during scrubbing. If you have installed the Extended Scrub Kit, it will not be automatically activated. You must press the

Recycle Switch (G) to activate this system. The recycle system will not turn ON until the water level in the recovery tank reaches a certain level.

6 Lower the squeegee with the Squeegee Raise / Lower Lever (15).

7 When the Drive Paddle (30) is in the neutral position, the scrub, vacuum, solution and detergent (AXP/EDS only) systems are activated but not

running. Grip the Operator Control Handle (2) and push the Drive Paddle (30) forward to start the scrub, vacuum, solution and detergent (AXP/

EDS only), and to move the machine forward. For best results, move the machine at a slow walking speed. Press the Solution Switch (B) once

to turn OFF while making sharp turns. Pull the Drive Paddle (30) backward to move the machine in reverse. The brushes will run while moving

the machine in reverse, but solution and chemical will not be dispensed.

CAUTION!

To avoid damaging the fl oor, keep the machine moving while the brushes are turning.

8 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This

operation is the same as a one-pass scrubbing except on the fi rst pass the squeegee is in the up position. This allows the cleaning solution to

remain on the fl oor to work longer. The fi nal pass is made over the same area, with the squeegee lowered to pick up the accumulated solution.

9 The recovery tank has an automatic shut-off switch that turns ALL systems OFF except the drive system when the recovery tank is full. When

this switch is activated, the recovery tank must be emptied. The machine will not pick up water or scrub with the switch activated. NOTE: All

other indicators vanish and a “Recovery Tank FULL” indicator (FF) turns on in the Display Panel when the switch is activated.

10 When the operator wants to stop scrubbing or the recovery tank is full, press the Scrub OFF Switch (H) once. This will automatically stop the

scrub brushes and solution fl ow and the scrub deck will raise UP. NOTE: the vacuum will stop after a 10 second delay, this is to allow any

remaining water to be picked up without turning the vacuum back on.

11 Raise the squeegee and drive the machine to a designated wastewater “DISPOSAL SITE” and empty the recovery tank. To empty, pull the

Recovery Tank Drain Hose (22) from its hanger, then open the cap (hold the end of the hose above the water level in the tank to avoid sudden,

uncontrolled fl ow of waste water). The Recovery Tank Drain Hose (22) can be squeezed to regulate the fl ow. Refi ll the solution tank and

continue scrubbing.

NOTE: Make sure the Recovery Tank Cover (5) and the Recovery Tank Drain Hose (22) cap is properly seated or the machine will not pick-up

water correctly. When the batteries require recharging the Battery LOW Indicator (D8) will come on and the vacuum motor will shut off after 30

seconds. Transport the machine to a service area and recharge the batteries according to the instructions in the Battery section of this manual.

WET VACUUMING

Fit the machine with optional attachments for wet vacuuming.

1 Disconnect the Recovery Hose (28) from the Squeegee (12).

2 Attach suitable wet pick-up tools to the hose (Available from Nilfi sk-Advance).

3 Turn the Master Key Switch (A) ON.

4 Press the Wand Switch (E) once to turn ON the vacuum motor.

SERVICE NOTE: Refer to the service manual for detailed functional descriptions of all controls and optional programmability.

A-14 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 15

ENGLISH / A-15

D

H

E

G

I

B

FF

!

A

GG

!

5

30

13

22

2

15

28

12

revised 6/05

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-15

Page 16

A-16 / ENGLISH

AFTER USE

1 Raise the brushes (or pads) and raise the squeegee. Move the machine to a service area.

2 Turn the Master Key Switch (A) OFF and remove the key.

3 To empty the solution tank, pull the Solution Drain Hose (14) off the elbow. Direct the hose to a fl oor drain or bucket. Rinse the tank with clean water. Inspect

the solution hoses; replace if kinked or damaged.

4 To empty the recovery tank, remove the Recovery Tank Drain Hose (22) from its hanger, then remove the cap (hold the end of the hose above the water level

in the tank to avoid sudden, uncontrolled fl ow of waste water). The Recovery Tank Drain Hose (22) can be squeezed to regulate the fl ow. Rinse the tank and

recovery tank switches (32) with clean water. Inspect the recovery and vacuum hoses; replace if kinked or damaged. SERVICE NOTE: Make sure you do not

get any water down the Vacuum Motor Inlet Screen (4) while cleaning.

NOTE: If you have the extended scrub option installed the system will need to be purged.

4a After each use, drain and rinse the recovery tank thoroughly and then fi ll the recovery tank about 1/3 full with clean water.

4b Push and hold the Extended Scrub Button (G) for 3 seconds ( the indicator will turn green) to initiate the purge function. The purge will run for 20 seconds.

NOTE: This is to fl ush any debris from the system. If you do not do this, the extended pump and(or) solenoid valve could become plugged up with debris.

5 Remove the brushes or pad holders. Rinse the brushes or pads with warm water and hang up to dry. Allow buffi ng pads to dry completely before using again.

NOTE: You can either remove the brushes manually or automatically by pressing and holding the Scrub OFF Switch (H) for 5 seconds (disk models only).

6 Remove the squeegee, rinse it with warm water and hang it up to dry.

7 Check the maintenance schedule below and perform any required maintenance before storage.

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean Tanks & Hoses (clean recovery tank switches & vacuum inlet screen) X

Check/Clean/Rotate the Brushes/Pads X

Check/Clean the Squeegee X

Clean Hopper on Cylindrical System X

Purge the Extended Scrub System(if installed) X

Check Each Battery Cell(s) Water Level (does not apply to gel cell batteries) X

Inspect Scrub Housing Skirts X

Inspect and clean Solution Filter X

Clean Solution Manifolds on Cylindrical System X

Purge Detergent System (AXP/EDS only) X

Lubricate the Machine X

* Check Carbon Brushes X

* Have Nilfi sk-Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The brush and drive motor carbon brushes check

every 500 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

8 Store the machine in a clean, dry place.

9 Turn the Master Key Switch (A) OFF (O) and remove the key.

SERVICING THE VACUUM MOTOR

Have your Nilfi sk-Advance Dealer check the carbon

motor brushes once a year or after 300 operating

hours.

IMPORTANT!

Motor damage resulting from failure to

service the carbon brushes is not covered

under warranty. See the Limited Warranty

Statement.

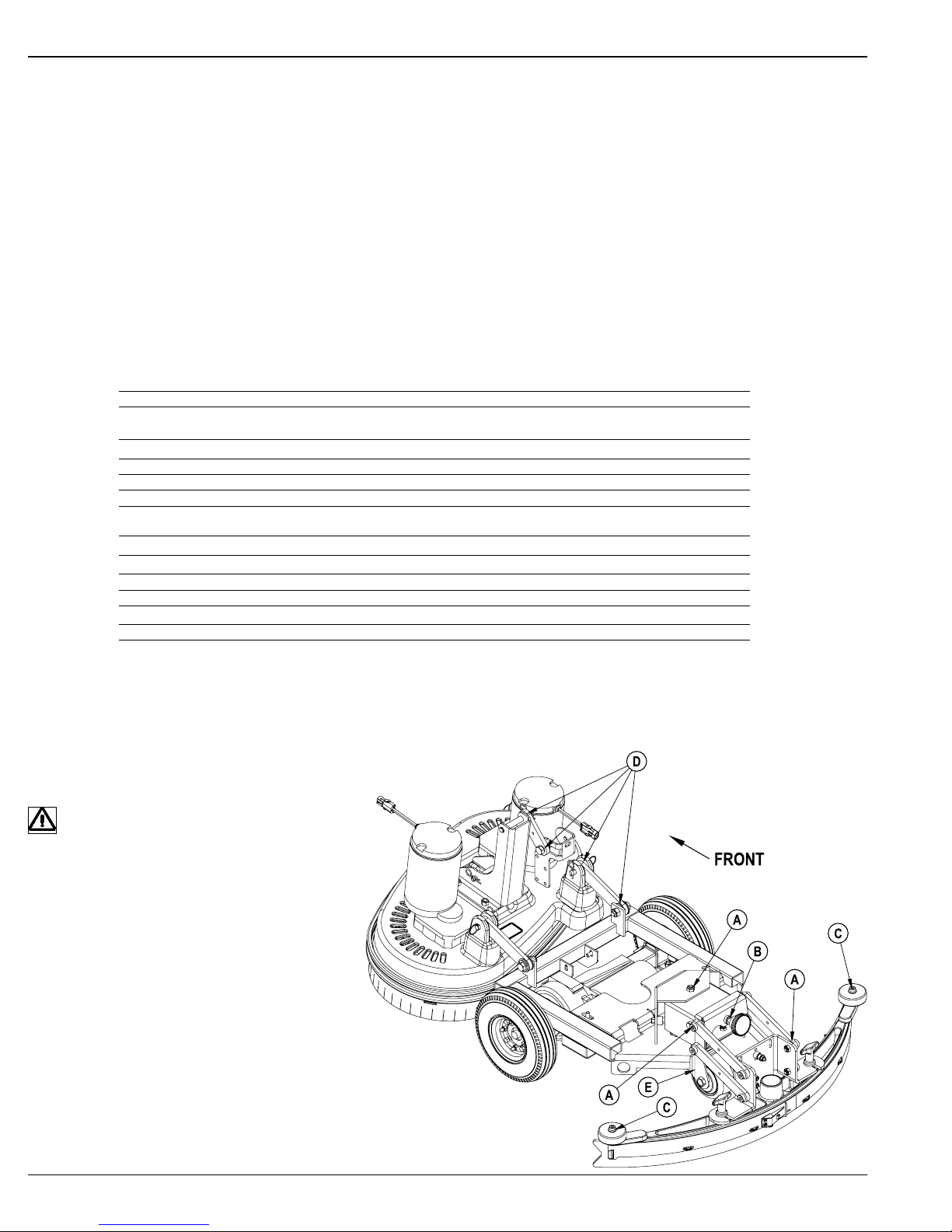

LUBRICATING THE MACHINE

Once a month, apply light machine oil to lubricate the:

• General Pivot Points For the Squeegee Linkage

(A).

• Squeegee mount angle adjustment knob threads

(B).

• Squeegee Tool end wheels (C).

• General Pivot Points For the Brush Linkage (D).

• Scrub deck bumper wheels.

Once per quarter, Grease the following

• Rear Caster Wheel Swivel (E).

A-16 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 4/06

Page 17

ENGLISH / A-17

CHARGING WET BATTERIES

Charge the batteries each time the machine is used or when the Battery Indicator (D) is reading less than full.

WARNING!

Do not fi ll the batteries before charging.

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

If your machine shipped with an onboard battery charger do the following:

Turn the Key Switch (A) OFF. Unwind the electrical cord from the side of the onboard charger and plug it into a properly grounded outlet. Refer to the OEM product manual for more

detailed operating instructions.

If your machine shipped without an onboard battery charger do the following:

Disconnect the batteries from the machine and push the connector from the charger into the Battery Pack Connector (25). Follow the instructions on the battery charger. SERVICE

NOTE: Make sure you plug the battery charger into the connector with the handle attached to it.

CAUTION!

To avoid damage to fl oor surfaces, wipe water and acid from the top of the batteries after charging.

CHECKING THE BATTERY WATER LEVEL

Check the water level of the batteries at least once a week.

After charging the batteries, remove the vent caps and check the water level in each battery cell. Use distilled or demineralized water in a battery

fi lling dispenser (available at most auto parts stores) to fi ll each cell to the level indicator (or to 10 mm over the top of the separators). DO NOT over-

fi ll the batteries!

CAUTION!

Acid can spill onto the fl oor if the batteries are overfi lled.

Tighten the vent caps. Wash the tops of the batteries with a solution of baking soda and water (2 tablespoons of baking soda to 1 liter of water).

CHARGING GEL (VRLA) BATTERIES

Charge the batteries each time the machine is used or when the Battery Indicator (D) is reading less than full.

WARNING!

Charge batteries in a well-ventilated area.

Do not smoke while servicing the batteries.

When Servicing Batteries...

* Remove all jewelry

* Do not smoke

* Wear safety glasses, rubber gloves and a rubber apron

* Work in a well-ventilated area

* Do not allow tools to touch more than one battery terminal at a time

* ALWAYS disconnect the negative (ground) cable fi rst when replacing batteries to prevent sparks.

* ALWAYS connect the negative cable last when installing batteries.

CAUTION!

Your voltage regulated lead acid (VRLA) battery will deliver superior performance and life ONLY IF IT RECHARGED PROPERLY!

Under or overcharging will shorten battery life and limit performance. Be sure to FOLLOW PROPER CHARGING INSTRUCTIONS!

DO NOT ATTEMPT TO OPEN THIS BATTERY! If a VRLA battery is opened, it loses its pressure and the plates become oxygen

contaminated. THE WARRANTY WILL BE VOIDED IF THE BATTERY IS OPENED.

If your machine shipped with an onboard battery charger do the following:

Turn the Key Switch (A) OFF. Unwind the electrical cord from the side of the onboard charger and plug it into a properly grounded outlet. Refer to the OEM product manual for more

detailed operating instructions.

If your machine shipped without an onboard battery charger do the following:

Disconnect the batteries from the machine and push the connector from the charger into the Battery Pack Connector (25). Follow the instructions on the battery charger. SERVICE

NOTE: Make sure you plug the battery charger into the connector with the handle attached to it.

IMPORTANT: Make sure you have an appropriate charger for use on Gel cell batteries. Use only “voltage-regulated” or “voltage-limited”

chargers. Standard constant current or taper current chargers MUST NOT be used. A temperature-sensing charger is recommended, as

manual adjustments are never accurate and will damage any VRLA battery.

revised 5/05

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-17

Page 18

A-18 / ENGLISH

SERVICING THE SQUEEGEE

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and inspect

the blades. Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 5. Raise the squeegee tool off the fl oor, and then unsnap the Center Latch (19) on the squeegee tool.

2 Remove the Tension Straps (26).

3 Slip the rear blade off the Alignment Pins (27).

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee tool off the fl oor, loosen the (2) Thumb Nuts (20), disconnect the Recovery Hose (28) and remove the Squeegee Assembly

(12) from the mount.

2 Remove both rear Tension Straps (26) fi rst.

3 Remove all the wing nuts that hold the front blade in place, then remove the tension strap and blade.

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

ADJUSTING THE SQUEEGEE

Adjust the squeegee angle whenever a blade is reversed or replaced, or if the squeegee is not wiping the fl oor dry.

To Adjust the Squeegee Angle...

1 Park the machine on a fl at, even surface and lower the squeegee.

2 While moving the machine forward slowly, turn the Squeegee Adjustment Knob (21) until the rear squeegee blade folds over evenly across the

entire width of the squeegee as shown below.

FIGURE 5

A-18 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

Page 19

ENGLISH / A-19

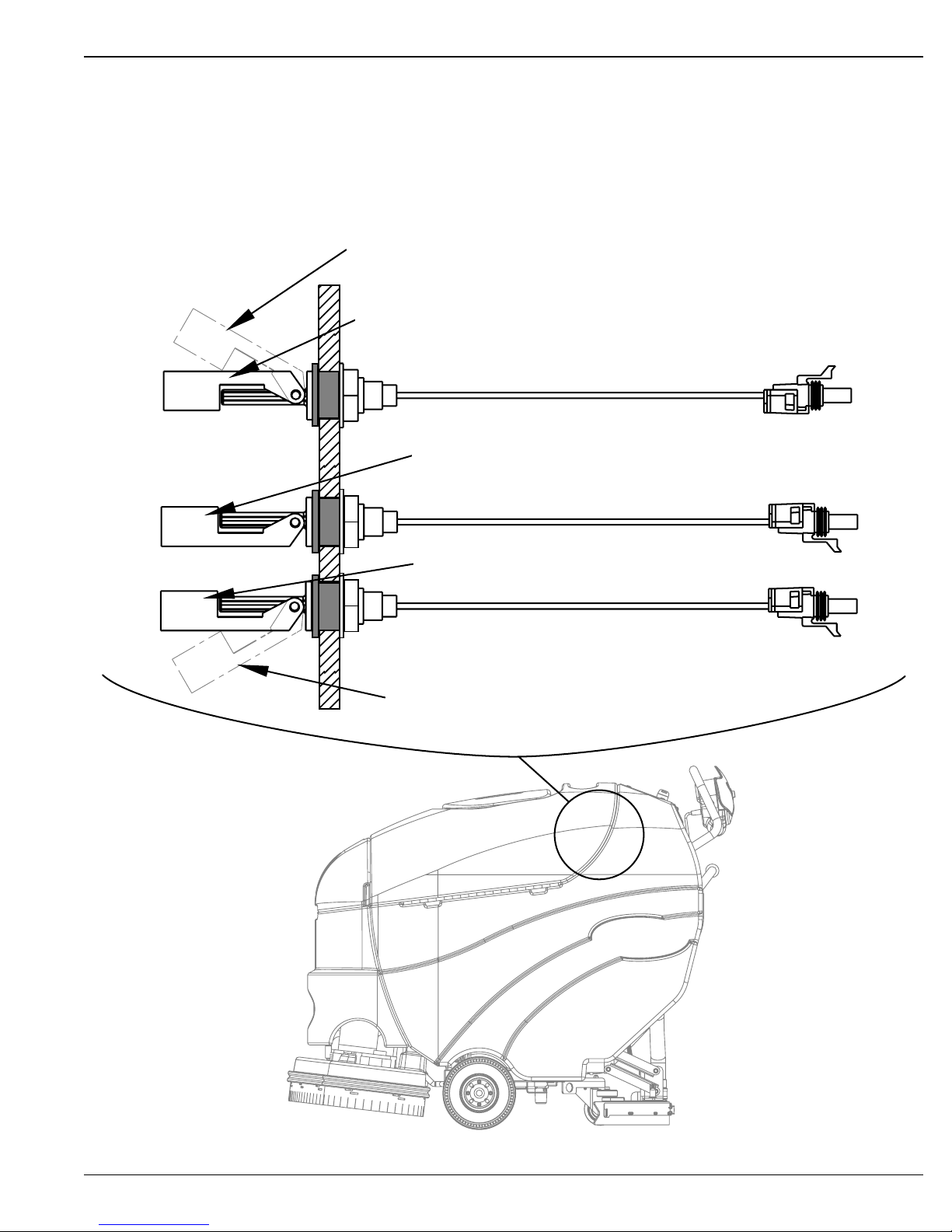

SERVICING THE RECOVERY TANK SWITCH(ES)

If the recovery tank fl oat switch(es) become dirty it can impair their proper operation. A dirty vacuum shut off switch can cause the vacuum motor to

not function at all or to not shut off when the tank is full. Dirty extended scrub system switches can prevent the optional extended scrub system from

functioning properly.

If daily rinsing of the recovery tank does not suffi ce to keep the switches clean you may need to disassemble them for cleaning. It is very important

that they be reassembled correctly in order to function. See Figure 6 for the correct orientation of the switch fl oat arms.

Refer to the service manual for detailed disassembly and cleaning instructions.

Float should move up & down freely.

FIGURE 6

ON

ON

ON

OFF

OFF

Factory installed Vacuum Shut-Off Switch. Float on TOP.

Optional Extended Scrub Start Switch. Float on BOTTOM.

Optional Extended Scrub Stop Switch. Float on BOTTOM.

Float should move up & down freely.

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-19

Page 20

A-20 / ENGLISH

ADJUSTING THE DISK DECK SKIRT HEIGHT

CAUTION!

Turn the Key Switch (A) OFF (O) and remove the key, before changing the brushes, and before opening any access panels.

The disk deck skirt height can be adjusted for wear.

To Adjust the Disk Deck Skirt Height...

1 Raise the Scrub Deck (7), turn the Key Switch (A) OFF and remove the key from the machine.

2 See Figure 7. Pull the Scrub Deck Bumper (9) UP to the top edge of the scrub deck so that it is not holding the skirt in place as shown. NOTE:

Before removing the Scrub Deck Skirt (8) take note of which one of the 3 different levels of slots the skirt was installed at. Some machines have

a large clamp which needs to be loosened and removed prior to removing the bumper.

3 To lower the skirt, move it down to the next level of slots as shown. Service Note: Install the skirt starting at the fi rst alignment pin on the right

as shown and work it around the deck in a counter-clockwise direction until it is on all alignment pins.

4 Pull the Bumper (9) back down over the Skirt (8). NOTE: Make sure the skirt alignment pins are inserted into the lower inside channel of the

bumper and make sure the skirt does not slip off any of the alignment pins.

FIGURE 7

FRONT VIEW

Skirt Alignment Pins should be in

lower slot of bumper.

Bumper Cross Section

9

Move skirt down to next level of slots to lower the skirt.

Always install skirt starting from the fi rst

alignment pin on the right.

8

FRONT

Work skirt around in counter-clockwise direction.

A-20 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 21

ENGLISH / A-21

CIRCUIT BREAKER TRIPPING

Circuit breakers protect electrical circuits and motors from damage due to overload conditions. If a circuit breaker trips, turn the Master Key Switch

(A) OFF and remove the key. Then try to determine the cause. Once the problem has been corrected, reset the circuit breaker by pushing the

button in. If the button does not stay in, wait 5 minutes and try again. If the circuit breaker trips repeatedly, call Nilfi sk-Advance for service.

Possible cause for the Control Circuit Circuit Breaker (18) tripping may be:

1 Short circuit in the wiring - have your Nilfi sk-Advance Service Technician service the machine

Possible causes for the Wheel Drive Circuit Breaker (17) tripping may be:

1 Debris wrapped around the drive wheel axle.

2 Worn out drive motor bearings.

3 Continuous use on ramps.

POOR WATER PICKUP

1 Recovery tank full, vacuum shut-off switch activated or dirty

2 Blocked vacuum system (squeegee and hoses)

3 Disconnected or damaged vacuum hoses

4 Incorrectly adjusted squeegee

5 Recovery tank cover gasket damaged

SQUEEGEE STREAKS

1 Debris under the squeegee blade

2 Worn, nicked or torn squeegee blade

3 Incorrectly adjusted squeegee

SWIRL MARKS

1 Running the machine with dry brushes or pads (no cleaning solution)

2 Incorrect brushes or pads for the application

3 Debris caught in brushes (or pads)

NO SOLUTION FLOW

1 Solution Shut-Off Valve (13) closed.

2 Solution Filter (11) clogged.

3 Solution pump bad.

SCRUB DECK RAISES WHILE SCRUBBING (CYLINDRICAL)

1 Debris caught between brushes and brush housing.

2 Bad brush Motor bearing.

NO DETERGENT FLOW (AXP/EDS)

1 Empty detergent cartridge.

2 Plugged or kinked detergent fl ow line.

3 Detergent pump wiring disconnected or wired incorrectly.

4 Dry seal cap on detergent cartridge not sealed.

revised 5/05

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - A-21

Page 22

A-22 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model Convertamatic™ 24D-C Convertamatic™ 26D Convertamatic™ 28D

Convertamatic™ X24D-C Convertamatic™ 26D-C Convertamatic™ 28D-C

Model No. 56315000 56315001 56315002

56315006 56315008 56315004

Voltage, Batteries V 24V 24V 24V

Battery Capacity Ah 238 238 238

Protection Grade IPX3 IPX3 IPX3

Sound Pressure Level (ISO 11201) dB(A) 70 70 70

Sound Power Level (ISO 3744) dB(A) Lwa 87.6 Lwa 87.6 Lwa 87.6

Gross Weight lbs. / kg 780 / 354 780 / 354 780 / 354

Vibrations at the Hand Controls (ISO 5349-1) m/s

2

.23m/s

2

Gradeability 2% (10) 2% (10)2% (1

Model Convertamatic™ 24C-C Convertamatic™ 26C-C Convertamatic™ 28C-C

Convertamatic™ X24C-C Convertamatic™ X26C-C Convertamatic™ X28C-C

Model No. 56315003 56315010 56315005

56315007 56315011 56315013

Voltage, Batteries V 24V 24V 24V

Battery Capacity Ah 238 238 238

Protection Grade IPX3 IPX3 IPX3

Sound Pressure Level (ISO 11201) dB(A) 66 66 66

Sound Power Level (ISO 3744) dB(A) Lwa 87.6 Lwa 87.6 Lwa 87.6

Gross Weight lbs. / kg 780 / 354 780 / 354 780 / 354

Vibrations at the Hand Controls (ISO 5349-1) m/s

2

.23m/s

2

Gradeability 2% (10) 2% (10)2% (1

Model BA 625 BA 725

Model No. 56315800 56315801

Voltage, Batteries V 24V 24V

Battery Capacity Ah 238 238

Protection Grade IPX3 IPX3

Sound Pressure Level (ISO 11201) dB(A) 70 70

Sound Power Level (ISO 3744) dB(A) Lwa 87.6 Lwa 87.6

Gross Weight lbs. / kg 780 / 354 780 / 354

Vibrations at the Hand Controls (ISO 5349-1) m/s

2

.23m/s

2

Gradeability 2% (10)2% (1

Convertamatic™ X26D-C Convertamatic™ X28D-C

56315009 56315012

.23m/s

.23m/s

2

2

.23m/s

.23m/s

2

0

)

2

0

)

BA 725C

56315802

2

.23m/s

0

)

Model Convertamatic™ 32D-C BA 825

Convertamatic™ X32D-C

Model No. 56315804 56315803

56315805

Voltage, Batteries V 24V 24V

Battery Capacity Ah 238 238

Protection Grade IPX3 IPX3

Sound Pressure Level (ISO 11201) dB(A) 70 70

Sound Power Level (ISO 3744) dB(A) Lwa 87.6 Lwa 87.6

Gross Weight lbs. / kg 780 / 354 780 / 354

Vibrations at the Hand Controls (ISO 5349-1) m/s

2

Gradeability 2% (10)2% (1

.23m/s

2

.23m/s

2

0

)

X = AXP(Chemical Injection) (IE: Convertamatic™ X24C-C)

-C = Onboard Charger (IE: Convertamatic™ 24C-C)

EDS = EDS(Chemical Injection) (BA 725 EDS)

C = Cylindrical (BA 725C)

A-22 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 23

Page 24

B-2 / ESPAÑOL

ÍNDICE

Página

Introducción .............................................................................B-3

Componentes y servicio ..........................................................B-3

Placa de identifi cación .............................................................B-3

Desembalaje de la máquina ....................................................B-3

Precauciones y advertencias ...................................................B-4

Conozca su máquina ......................................................B-6 - B-7

Panel de control .......................................................................B-8

Preparación de la máquina para su utilización

Baterías ...................................................................................B-9

Instalación de los cepillos ......................................................B-10

Llenado del depósito de solución ..........................................B-11

Instalación de la boquilla .......................................................B-11

Sistema de detergente (AXP/EDS™) .........................B-12 - B-13

Manejo de la máquina

Fregado en húmedo ..................................................B-14 – B-15

Aspiración en húmedo ................................................B-14 - B-15

Después de la utilización de la máquina ...............................B-16

Programa de mantenimiento .................................................B-16

Mantenimiento del motor de aspiración .................................B-16

Lubricación de la máquina .....................................................B-16

Mantenimiento

Recarga de las baterías (líquido) ..........................................B-17

Recarga de las baterías (gel) ................................................B-17

Mantenimiento de la boquilla .................................................B-18

Ajuste de la boquilla ..............................................................B-18

Mantenimiento de los interruptores

del depósito de recuperación ................................................B-19

Ajuste de la altura del zócalo de la plataforma de disco .......B-20

Localización de averías

Disparo de los disyuntores del circuito ..................................B-21

Mala recogida del agua .........................................................B-21

Estrías de la boquilla .............................................................B-21

Marcas de giro .......................................................................B-21

No hay fl ujo de la solución .....................................................B-21

La plataforma de limpieza se eleva

durante el fregado (cilíndrica) ................................................B-21

Especifi caciones técnicas ......................................................B-22

B-2 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

Page 25

ESPAÑOL / B-3

INTRODUCCIÓN

Este manual le ayudará a obtener el máximo rendimiento de su limpiadora/secadora automática Nilfi sk-Advance™. Léalo con atención antes de

utilizar la máquina.

Nota: Los números que aparecen en negrita entre paréntesis indican elementos ilustrados en las páginas 6-8, a menos que se indique lo

contrario.

Este producto está destinado exclusivamente a uso comercial.

COMPONENTES Y SERVICIO

Las reparaciones, cuando sean necesarias, deben ser realizadas por su Centro Autorizado de Servicio Nilfi sk-Advance que utiliza personal de

servicio formado en fábrica y lleva un inventario de piezas de repuesto y accesorios Nilfi sk-Advance originales.

Llame a Nilfi sk-Advance para lo referente a piezas de repuesto y servicio. Por favor, especifi que el Modelo y Número de Serie cuando hable de su

máquina.

(Distribuidor, coloque aquí la pegatina de su servicio.)

PLACA DE IDENTIFICACIÓN

El Número de Modelo y de Serie de la máquina se indican en la placa de identifi cación instalada en el compartimento de las baterías. Esta

información es necesaria a la hora de solicitar repuestos para la máquina. Utilice el siguiente espacio para anotar el Modelo y el Número de Serie

de su máquina para futuras consultas.

Modelo ________________________________________

Número de Serie ________________________________

DESEMBALAJE DE LA MÁQUINA

Cuando reciba la máquina, examine con atención el cartón de embalaje y la máquina, con el fi n de comprobar si existe algún daño. Si observa

algún daño, guarde la caja de embalaje para que se pueda inspeccionar. Póngase en contacto inmediatamente con el Departamento de Servicio al

Cliente de Nilfi sk-Advance para presentar una reclamación por daños en transporte.

Después de retirar la caja, corte las correas de plástico y retire los bloques de madera que están al lado de las ruedas. Utilice una rampa para

bajar la máquina rodando de la paleta al suelo.

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-3

Page 26

B-4 / ESPAÑOL

PRECAUCIONES Y ADVERTENCIAS

SÍMBOLOS

Nilfi sk-Advance utiliza los símbolos que aparecen a continuación para indicar situaciones potencialmente peligrosas. Lea

cuidadosamente esta información y emprenda las acciones que resulten necesarias para proteger a personas y objetos.

¡PELIGRO!

Se utiliza para advertir de peligros inmediatos que pueden producir graves daños personales o la muerte.

¡ADVERTENCIA!

Se utiliza para llamar la atención sobre una situación que puede causar graves daños personales.

¡PRECAUCIÓN!

Se utiliza para llamar la atención sobre una situación que puede causar daños personales leves o daños a la máquina u otros objetos.

Lea todas y cada una de las instrucciones antes de utilizar el aparato.

INSTRUCCIONES GENERALES DE SEGURIDAD

Se incluyen Precauciones y Advertencias específi cas que le advierten de los posibles riesgos de daño a la máquina o daño corporal.

¡ADVERTENCIA!

* Sólo deben utilizar esta máquina las personas autorizadas y con la formación adecuada.

* Si se encuentra sobre una rampa o inclinación, evite las paradas bruscas cuando lleve carga. No tome las curvas bruscamente. Utilice una

velocidad lenta si va cuesta abajo. Limpie sólo yendo cuesta arriba.

* Mantenga las chispas, llamas y materiales de fumadores alejados de las baterías. Durante el funcionamiento normal se desprenden gases

explosivos.

* Al recargar las baterías se produce gas de hidrógeno altamente explosivo. Recargue las baterías exclusivamente en zonas bien ventiladas,

lejos de llamas sin proteger. No fume mientras recarga las baterías.

* Quítese todas las joyas cuando trabaje cerca de componentes eléctricos.

* Ponga el conmutador en posición de apagado (O) y desconecte las baterías antes de revisar los componentes eléctricos.

* No trabaje nunca debajo de la máquina sin colocar antes bloques o soportes de seguridad en los que apoyar la máquina.

* No aplique sustancias limpiadoras infl amables ni utilice la máquina sobre estas sustancias, cerca de ellas, ni en zonas en las que haya líquidos

infl amables.

* No lave la máquina con una limpiadora a presión.

* No haga funcionar esta máquina en rampas o en pendientes superiores al 2 por ciento.

* Use solamente los cepillos suministrados junto con el aparato o aquellos especifi cados en el manual de instrucciones. El uso de otros cepillos

puede afectar a la seguridad.

¡PRECAUCIÓN!

* Esta máquina no ha sido aprobada para su uso en vías públicas.

* Esta máquina no es apta para la recogida de polvo peligroso.

* Tenga cuidado cuando utilice discos de escarifi cación y piedras abrasivas. No se podrá responsabilizar a Nilfi sk-Advance de daño alguno a las

superfi cies de los suelos causado por escarifi cadores o piedras abrasivas.

* Cuando utilice la máquina, asegúrese de que no existe peligro para terceras personas, especialmente niños.

* Antes de proceder a cualquier función de servicio, lea con atención todas las instrucciones relativas a dicha función.

* No deje la máquina sin vigilancia sin antes haber puesto el conmutador en posición de apagado (O), haber quitado la llave y haber aplicado el

freno de estacionamiento.

* Apague el conmutador de llave (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los paneles de acceso.

* Tome las debidas precauciones para evitar que el pelo, las joyas o las prendas sueltas queden atrapados entre los componentes móviles.

* Tome las precauciones adecuadas cuando esté moviendo esta máquina mientras hiela. El agua de la solución, los depósitos de recuperación

o detergente y de las tuberías puede congelarse, causando daños a las válvulas y accesorios. Limpie con limpiaparabrisas.

* Retire las baterías de la máquina antes de su desguace. Las baterías deben desecharse de forma segura, de acuerdo con la reglamentación

medioambiental local.

* No utilice la máquina en superfi cies con pendientes superiores a las indicadas en la máquina.

* Antes de utilizar la máquina, todas las puertas y cubiertas deberían estar colocadas como se indica en el manual de instrucciones.

* Consulte el manual del producto OEM del cargador de batería para obtener advertencias adicionales sobre el cargador de batería específi co.

GUARDE ESTAS INSTRUCCIONES

B-4 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 27

ESPAÑOL / B-5

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-5

Page 28

B-6 / ESPAÑOL

CONOZCA SU MÁQUINA

A lo largo de este manual encontrará números o letras en negrita entre paréntesis – por ejemplo: (2). Estos números se refi eren a un objeto que se

muestra en dicha página, a menos que se indique lo contrario. Consulte esta página siempre que sea necesario para encontrar la localización de

un objeto mencionado en el texto. NOTA: Consulte el manual de servicio para obtener explicaciones más detalladas de cada objeto ilustrado en

las siguientes 3 páginas.

1 Llenado del depósito de solución

2 Manilla de control del operario

3 Portabotellas

4 Criba de entrada del motor de aspiración

5 Tapa del depósito de recuperación

6 Cubierta de acceso al cartucho de detergente (AXP/EDS)

6a Cartucho (sólo modelos AXP/EDS) de detergente (AXP/EDS)

7 Plataforma de limpieza

8 Zócalo de la plataforma de limpieza

9 Parachoques de la plataforma de limpieza

10 Rueda motriz

11 Filtro de la solución

12 Conjunto de boquilla

13 Válvula de cierre de la solución

B-6 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

Page 29

CONOZCA SU MÁQUINA

14 Tubería de drenaje de la solución / Indicador de nivel

15 Palanca de elevación/descenso de la boquilla

16 Cargador de batería a bordo (no se encuentra en todos los

modelos)

17 Disyuntor del motor de la tracción de rueda

18 Disyuntor del circuito de control

19 Pestillo de la cuchilla de la boquilla

20 Tuerca de palomilla de montaje de la boquilla

21 Botón de ajuste de la boquilla

22 Tubería de drenaje del depósito de recuperación

23 Tolva de residuos (sólo modelos cilíndricos)

24 Conjunto en vacío (sólo modelos cilíndricos)

25 Conector del conjunto de baterías (sólo modelos sin

cargador a bordo)

ESPAÑOL / B-7

25a Conector del conjunto de baterías (sólo modelos con cargador a

bordo)

26 Correa de tensión de la cuchilla de la boquilla

27 Pasadores de alineación de la cuchilla de la boquilla

28 Tubería de recuperación

29 Panel de control

30 Paleta de tracción

31 Botón de control del límite de velocidad

32 Interruptor de apagado de la aspiración

33 Filtro de depurador ampliado (opcional)

34 Colector de la solución (sólo modelos cilíndricos)

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-7

Page 30

B-8 / ESPAÑOL

PANEL DE CONTROL

A Conmutador de llave (principal)

B Conmutador de la solución

C Interruptor de aspiración

D Panel de visualización

D1 Indicador de fl ujo de la solución

D2 Indicador de error

D3 Cronómetro

D4 Indicador AXP/EDS

D5 Indicador de batería

D6 Indicador de la presión del fregado

D7 Indicador de llenado del depósito de recuperación

D8 Indicador de batería baja

E Interruptor de vara (opción instalada por el distribuidor)

F Sistema de detergente (sólo modelos AXP/EDS)

G Sistema de depurador ampliado (opción instalada por el distribuidor)

H Fregado apagado

I Fregado encendido

D8

D7

D

!

!

D1

E

D2

D3

D4 D5

Ø.4

D6

Fregado Fregado Fregado Fregado Fregado Fregado

regular fuerte extremo regular fuerte extremo

(pulsar una vez) (pulsar dos veces) (mantener 5 seg.)

D

C

F

G

H

B-8 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

B

A

I

revised 1/07

Page 31

ESPAÑOL / B-9

BATERÍAS

Si su máquina se entrega con baterías instaladas, realice lo siguiente:

• Compruebe que las baterías estén conectadas a la máquina (25 / 25a).

• Encienda el conmutador de llave (A) y compruebe el indicador de batería (D). Si el indicador está

completamente lleno, las baterías están listas para el uso. Si el indicador no está lleno, las baterías

deberían cargarse antes de la utilización. Consulte la sección “Recarga de las baterías”.

• ¡IMPORTANTE!: SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE

BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM PARA OBTENER

INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA

(VER TABLA).

Si su máquina se entrega sin baterías instaladas, realice lo siguiente:

• Consulte con su distribuidor autorizado Nilfi sk-Advance en cuanto a las baterías recomendadas.

• Instale las baterías siguiendo las instrucciones indicadas a continuación.

• NO instale dos baterías de 12 voltios en su máquina. Esto afectará a la estabilidad de la máquina.

• ¡IMPORTANTE!: SI SU MÁQUINA ESTÁ EQUIPADA CON UN CARGADOR DE

BATERÍA A BORDO, CONSULTE EL MANUAL DEL PRODUCTO OEM PARA OBTENER

INSTRUCCIONES SOBRE EL AJUSTE DEL CARGADOR PARA EL TIPO DE BATERÍA

(VER TABLA).

AH/Índice MFG Algoritmo

180 DEKA(gel) 6

195 US 4

238 US / Trojan 4 / 1

188 Exide 51

200 Exide 21

¡ADVERTENCIA!

Tome las máximas precauciones cuando trabaje con las baterías. El ácido sulfúrico de las baterías puede causar daños graves si

entra en contacto con la piel o con los ojos. Desde el interior de las baterías se libera gas explosivo de hidrógeno a través de unas

aperturas en las tapas de las baterías. Este gas puede incendiarse con cualquier arco eléctrico, chispa o llama. No instale baterías de

plomo-ácido en un contenedor cerrado. El gas de hidrógeno debido a la sobrecarga debe poder liberarse.

Cuando revise las baterías...

* Quítese todas las joyas

* No fume

* Lleve gafas de seguridad, un delantal de goma y guantes de goma

* Trabaje en una zona bien ventilada

* No permita que las herramientas toquen simultáneamente más de un terminal de batería

* Al sustituir las baterías, desconecte SIEMPRE en primer lugar el cable (de tierra) negativo

para evitar chispas.

* Al instalar las baterías, conecte SIEMPRE el cable negativo al fi nal.

FIGURA 1

¡PRECAUCIÓN!

Los componentes eléctricos de esta máquina pueden dañarse seriamente si

las baterías no están instaladas o conectadas correctamente. Las baterías

deben ser instaladas por Nilfi sk-Advance, un electricista cualifi cado o el

fabricante de las baterías.

1 Retire las baterías de su caja de embalaje e inspecciónelas para ver si existen grietas u

otros daños. Si los daños son evidentes, póngase en contacto inmediatamente con el

transportista que se las entregó para presentar una reclamación por daños en transporte.

2 Apague el conmutador principal de llave (A) y quite la llave.

3 Incline el depósito de recuperación hacia la posición lateral cerrada. Retire los cables de

la batería del interior del compartimento de las baterías.

4 Su máquina viene de fábrica con sufi cientes cables para instalar cuatro baterías de 6

voltios. Levante las baterías con cuidado para meterlas en el compartimento de las

baterías y colóquelas exactamente como se muestra en la FIGURA 1. Ponga las baterías

tan cerca de la parte trasera de la máquina como pueda.

5 Instale los cables de las baterías como se muestra. Ponga los cables de forma que

las cubiertas de las baterías puedan retirarse fácilmente para el mantenimiento de las

baterías.

6 Apriete con cuidado las tuercas de los terminales de las baterías hasta que el terminal

no gire. No apriete demasiado los terminales; de lo contrario será muy difícil retirarlos en

futuras operaciones de mantenimiento.

7 Bañe los terminales con revestimiento para terminales de baterías en pulverizador

(disponible en la mayoría de las tiendas de material para coches).

8 Ponga un manguito de goma negro encima de cada terminal y conecte el conector del

conjunto de las baterías (25 / 25a).

revised 1/07

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-9

Page 32

B-10 / ESPAÑOL

INSTALACIÓN DE LOS CEPILLOS (SISTEMA DE DISCO)

¡PRECAUCIÓN!

Apague el conmutador de llave (O) y quite la llave

antes de cambiar los cepillos y antes de abrir

cualquiera de los paneles de acceso.

1 Asegúrese de que el portacepillos (7) se

encuentre en la posición ELEVADA. Asegúrese

de que está apagado (O) el conmutador de llave

(A).

2 Si utiliza bayetas, instale las bayetas en los

portabayetas

3 Ver la Figura 2. Para montar los cepillos (AA) (o

los portabayetas), alinee las lengüetas (BB) del

cepillo con las ranuras de la bandeja de montaje

y gire para que se bloquee en su posición (gire el

borde exterior del cepillo hacia la parte trasera de

la máquina como se muestra (CC)).

FIGURA 2

INSTALACIÓN DE LOS CEPILLOS (SISTEMA CILÍNDRICO)

¡PRECAUCIÓN!

Apague el conmutador de llave (O) y quite la llave antes de cambiar los cepillos y antes de abrir cualquiera de los paneles de acceso.

1 Asegúrese de que el portacepillos se encuentre en la

posición ELEVADA. Asegúrese de que está apagado

(O) el conmutador de llave (A).

2 Ver la Figura 3. -Para acceder a los cepillos, afl oje

los botones negros (uno a cada lado) que están en la

parte superior de los conjuntos en vacío (24) y retire

los conjuntos. Deslice el cepillo en el contenedor,

levante ligeramente, empuje y gire hasta que se

asiente. Vuelva a instalar los conjuntos en vacío.

B-10 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

FIGURA 3

revised 1/07

Page 33

ESPAÑOL / B-11

LLENADO DEL DEPÓSITO DE SOLUCIÓN

Llene el depósito de solución con 20 galones (76 Litros) de solución limpiadora como máximo. No llene el depósito de solución por encima de 7,5

cm (3 pulgadas) de la parte inferior del depósito (1). La solución debe ser una mezcla de agua y el limpiador químico apropiado para la aplicación.

Siga siempre las instrucciones que aparecen en la etiqueta del envase del producto químico. NOTA: Las máquinas AXP/EDS pueden utilizarse

normalmente con detergente mezclado en el depósito o con el sistema de aplicación de detergente AXP/EDS. Al utilizar el sistema de aplicación de detergente AXP/

EDS, no mezcle detergente en el depósito; utilice agua.

¡PRECAUCIÓN!

Utilice únicamente detergentes líquidos no infl amables de bajo poder espumante que estén diseñados para aplicaciones de fregado

automático. La temperatura del agua no deberá superar los 130 grados Fahrenheit (54,4 grados Celsius)

INSTALACIÓN DE LA BOQUILLA

1 Ver la Figura 4. Deslice en conjunto de la boquilla (12) sobre la abrazadera de montaje de la boquilla y apriete las tuercas de palomilla de

montaje de la boquilla (20).

2 Conecte la tubería de recuperación (28) a la entrada de la boquilla.

3 Baje la boquilla, desplace la máquina hacia delante y ajuste la inclinación de la boquilla utilizando el botón de ajuste de la boquilla (21), de

modo que la cuchilla de la boquilla trasera toque el suelo homogéneamente en toda la anchura y se doble ligeramente como se muestra.

FIGURA 4

revised 1/07

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-11

Page 34

B-12 / ESPAÑOL

REPARACIÓN Y USO DEL SISTEMA DE DETERGENTE (AXP/EDS)

INSTRUCCIONES COMUNES:

Elimine del sistema el detergente anteriormente utilizado antes de cambiar a un detergente diferente.

NOTA DE SERVICIO: Desplace la máquina sobre un punto de drenaje en el suelo antes de eliminar el

detergente porque saldrá una pequeña cantidad durante el proceso.

Purgar al cambiar productos químicos:

1 Desconecte y retire el cartucho de detergente.

2 Encienda el conmutador de llave (A) y mantenga pulsado el conmutador de detergente (F) y

el conmutador de la solución (B) durante al menos 2 segundos. NOTA: Una vez activado, el

proceso de purga lleva 10 segundos. Consulte los indicadores del sistema de detergente en la

ilustración de la página siguiente. Por lo general, un ciclo de purga es adecuado para purgar el

sistema.

Purgar semanalmente:

1 Desconecte y retire el cartucho de detergente. Instale y conecte un cartucho lleno de agua limpia

2 Encienda el conmutador de llave (A) y mantenga pulsado el conmutador de detergente (F) y

el conmutador de la solución (B) durante al menos 2 segundos. NOTA: Una vez activado, el

proceso de purga lleva 10 segundos. Consulte los indicadores del sistema de detergente en la

ilustración de la página siguiente. Por lo general, un ciclo de purga es adecuado para purgar el

sistema.

Cuando el cartucho de detergente esté casi vacío se encenderá un indicador del panel de visualización

(D). Este indicador de “detergente bajo” permanecerá encendido hasta que reinicie el sistema. Cuando

se encienda este indicador, sólo tiene que verter una botella completa de un galón (3,7 litros) de

detergente en el cartucho para rellenarlo sin preocuparse de las medidas. NOTA: Reinicie el sistema

sólo cuando el cartucho esté lleno. Al cambiar de cartuchos, el indicador de “detergente bajo” sólo es

exacto si el cartucho de sustitución está al mismo nivel que el cartucho sustituido.

Para reiniciar:

1 Encienda el conmutador de llave (A) y mantenga pulsado el conmutador de detergente (F)

durante 2 segundos. Consulte los indicadores del sistema de detergente en la ilustración de la

página siguiente.

INSTRUCCIONES ESPECÍFICAS DEL CARTUCHO NO RELLENABLE:

Retire la tapa (AA) y coloque el cartucho en la caja de detergente. Instale la tapa sellada (BB) como se

muestra.

INSTRUCCIONES ESPECÍFICAS DEL CARTUCHO

RELLENABLE:

Llene el cartucho de detergente con 1,25 galones (4,73 litros) como máximo.

NOTA DE SERVICIO: Retire el cartucho de la caja de detergente antes de

llenarlo para no derramar detergente en la máquina.

Se recomienda utilizar un cartucho individual por cada detergente que prevea

usar. Los cartuchos de detergente tienen una pegatina blanca de modo que

puede escribir el nombre del detergente en cada cartucho para no mezclarlos.

El cartucho de detergente tiene un deslizador magnético (CC) en un extremo

el cual debe ajustarse a la cantidad de mezcla adecuada de acuerdo con las

instrucciones descritas en la botella del fabricante. Coloque el deslizador

magnético (CC) en la posición adecuada en la pegatina de cantidad de mezcla

de detergente (DD). Al instalar un nuevo cartucho, retire la tapa (AA) y coloque

el cartucho en la caja de detergente. Instale la tapa sellada (BB) como se

muestra.

B-12 - FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825

revised 1/07

Page 35

REPARACIÓN Y USO DEL SISTEMA DE DETERGENTE (AXP/EDS)

LLENO (REINICIO)

Ø.4

DETERGENTE BAJO

Ø.4

PURGA

ESPAÑOL / B-13

Pulse (F) durante 2

segundos para reiniciar.

F

Ø.4

Pulse (F) y (B) durante 2

segundos para purgar.

D

B

A

FORM NO. - 56041596 - Convertamatic™ 24, 26, 28, 32 / BA 625, 725, 825 - B-13

Page 36

B-14 / ESPAÑOL

FREGADO EN HÚMEDO

¡ADVERTENCIA!

Asegúrese de que comprende los controles del operador y sus funciones.

Si se encuentra sobre una rampa o inclinación, evite las paradas bruscas cuando lleve carga. No tome las curvas bruscamente.

Utilice una velocidad lenta si va cuesta abajo. Limpie sólo yendo cuesta arriba.

1 Siga las instrucciones de la sección Preparación de la máquina para el uso de este manual.