Page 1

BA 450/530

BA 5321

08812876(1)2002-01

SERVICE MANUAL

Page 2

Nilfisk-Advance Italia S.p.A

Località Novella Terza

26862 Guardamiglio (Lodi) Italia

www.nilfisk-advance.com

Phone: +39 0377 451124

Fax: +39 0377 51443

Printed in Italy

Page 3

SERVICE MANUAL

GB

08812876(1)2002-01 49

INDEX

GENERAL INFORMATION 51

MACHINE LIFTING 51

MACHINE TRANSPORTATION 51

MACHINE PUSHING OR TOWING 51

OTHER AVAILABLE MANUALS FOR BA 450/530 51

SAFETY - ACCIDENT PREVENTION 52

GENERAL SAFETY RULES 52

TECHNICAL DATA 53

MAINTENANCE 55

SCHEDULED MAINTENANCE 55

MACHINE NOMENCLATURE 56

DETERGENT SUPPLY SYSTEM 58

DETERGENT TANK AND SUPPLY SYSTEM CLEANING 58

DETERGENT FILTER CLEANING 58

SOLENOID VALVE AND DETERGENT FLOW TAP REPLACEMENT 59

DETERGENT FLOW CABLE AND CONTROL LEVER REPLACEMENT 60

TROUBLESHOOTING 61

SMALL AMOUNT OF THE DETERGENT OR NO DETERGENT REACHES THE BRUSH 61

THE DETERGENT REACHES THE BRUSH ALSO WHEN THE MACHINE IS OFF 61

SWEEPING SYSTEM 62

BRUSH MOTOR ELECTRICAL INPUT CHECK 62

BRUSH MOTOR REPLACEMENT 63

BRUSH REDUCTION UNIT REPLACEMENT 64

BRUSH ROTATION CONSENT MICRO-SWITCH ADJUSTMENT 66

TROUBLESHOOTING 67

OPEN CIRCUIT 67

THE BRUSH DOES NOT ROTATE 67

RECOVERY SYSTEM 68

FLOAT SHIELD AND SUCTION PRE-FILTER CLEANING 68

SUCTION PRE-FILTER ASSEMBLY REPLACEMENT 69

TANK COVER GASKET AND COMPENSATION HOLE CHECK 70

SUCTION MOTOR ELECTRICAL INPUT CHECK 71

SUCTION MOTOR REMOVAL 72

SUCTION MOTOR BRUSH/CARBON BRUSH CHECK AND REPLACEMENT 73

RECOVERY WATER DRAIN PIPE REMOVAL 74

SUCTION CAP CHECK/CLEANING AND POSSIBLE FLAPS REPLACEMENT 75

DUST AND DEBRIS COLLECTION SYSTEM SUCTION CAP REMOVAL 76

TROUBLESHOOTING 77

DIRTY WATER SUCTION IS INSUFFICIENT OR THERE IS NO SUCTION 77

THE SUCTION CAP LEAVES LINING OR DOES NOT COLLECT WATER 77

TRACTION SYSTEM 78

TRACTION MOTOR ELECTRICAL INPUT CHECK 78

TRACTION MOTOR REMOVAL 80

TRACTION MOTOR BRUSH (OR CARBON BRUSH) CHECK AND REPLACEMENT 82

POTENTIOMETER ADJUSTMENT 84

TROUBLESHOOTING 85

OPEN CIRCUIT 85

THE MACHINE DOES NOT MOVE 85

Page 4

SERVICE MANUAL

GB

50 08812876(1)2002-01

ELECTRICAL SYSTEM 86

BATTERY REMOVAL 86

BATTERY MAINTENANCE AND RECHARGING 86

TRACTION ELECTRONIC BOARD REPLACEMENT 86

ELECTRICAL SYSTEM 87

SERVICE ELECTRONIC BOARD REPLACEMENT 87

TROUBLESHOOTING 88

COMPONENT LAYOUT 88

WIRING DIAGRAM BA 450/530 - after serial number 014106978 90

WIRING DIAGRAM BA 5321 - after serial number 1514570 94

WIRING DIAGRAM BA 5321D - after serial number 1514570 95

Page 5

SERVICE MANUAL

GENERAL INFORMATION

GB

08812876(1)2002-01 51

GENERAL INFORMATION

MACHINE LIFTING

MACHINE TRANSPORTATION

MACHINE PUSHING OR TOWING

OTHER AVAILABLE MANUALS FOR BA 450/530

The following manuals are available by Nilfisk Literature Service Department:

– BA 450/530 Part List – Nilfisk Form Number 08603654(2)00-12

– BA 450/530 Use and Maintenance Manual.- Nilfisk Form Number 08812382(2)2001-03

WARNING!

Do not work under the lifted machine if it is not securely fixed.

WARNING!

Before transporting the machine, ensure that:

• All doors and carters are closed

• The ignition key is not inserted

• The machine is fastened to the mean of transportation

WARNING!

Do not move the machine by pushing or towing it, unless you follow the procedures described

in the Use and Maintenance Manual. If you do not follow the specified procedures the machine

can be damaged.

Page 6

SERVICE MANUAL

GENERAL INFORMATION

GB

52 08812876(1)2002-01

SAFETY - ACCIDENT PREVENTION

Nilfisk uses the following symbols to indicate potentially dangerous situations. Always read carefully this

information and take the necessary precautions to protect people and objects.

GENERAL SAFETY RULES

Specific warnings and cautions to inform about potential damages to people and machine are shown below.

DANGER!

Indicates the risk of being injured or the risk of death.

WARNING!

Indicates the risk of being injured.

CAUTION!

Indicates the risk of light injuries to people, machine or other objects.

WARNING!

To perform maintenance/repair procedures, put the machine on a flat floor, turn the ignition key

to OFF position and disconnect the battery.

This machine must be used by qualified and authorized personnel only.

Keep the battery far from sparks, flames and smoke. During the normal operation explosive

gases are delivered.

Do not wear jewels when working near electrical components.

Do not work under the lifted machine if it is not securely fixed.

Do not operate the machine near inflammable liquids or vapors.

CAUTION!

Carefully read all maintenance/repair instructions before carrying out any maintenance/repair

procedure.

Take all necessary precautions to prevent hair, jewels and loose dresses from being caught by

the machine moving parts.

Battery charging produces explosive hydrogen gas. Charge the batteries only in good ventilated

areas and far from naked flames.

Do not smoke during battery charging.

Do not leave the machine unattended on an inclined floor.

Do not use the machine on slopes with an inclination higher than 2%.

Do not wash the machine with pressurized water.

Do not use the machine in too dusty areas.

This machine is not suitable for picking up hazardous dust.

If the temperature is below 0°, the water present into the reservoirs and into the pipes of the

machine could freeze.

During the use of this machine take care not to cause damage to people and children especially.

This machine cannot be used on public roads.

Page 7

SERVICE MANUAL

GENERAL INFORMATION

GB

08812876(1)2002-01 53

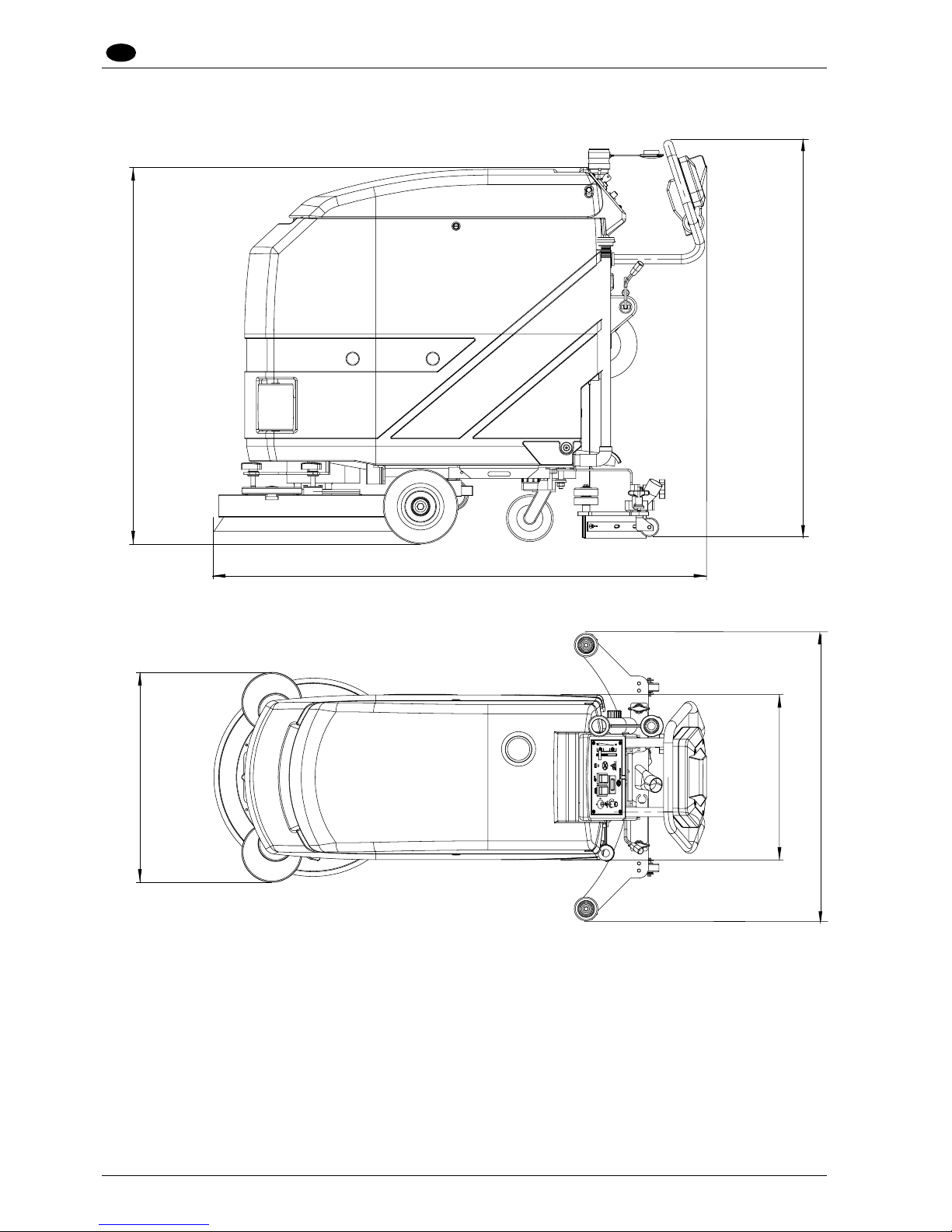

TECHNICAL DATA

Dimensions

BA 450 BA 530 BA 5321

Suction width 30 in (770 mm) 30 in (770 mm) 30 in (770 mm)

Sweeping width 17.7 in (450 mm) 20.8 in (530 mm) 20.8 in (530 mm)

Machine length 49 in (1250 mm) 52 in (1330 mm) 52 in (1330 mm)

Machine height at the maneuver handle 42.5 in (1078.5 mm) 42,5 in (1078,5 mm) 42,5 in (1078,5 mm)

Brush dimension Ø 450 mm (17.7 in) Ø 530 mm (20.8 in) Ø 530 mm (20.8 in)

Brush speed 180 RPM 180 RPM 180 RPM

Brush pressure on the floor 34 Kg 27 kg 27 kg

Forward maximum speed (*) 4.5 km/h 4.5 km/h 4.5 km/h

Reverse maximum speed (*) 2.2 km/h 2.2 km/h 2.2 km/h

Max slope 2 % 2 % 2 %

Detergent tank capacity 13.2 gal (55 liters) 13.2 gal (55 liters) 13.2 gal (55 liters)

Recovery water tank capacity 13.2 gal (55 liters) 13.2 gal (55 liters) 13.2 gal (55 liters)

Machine weight (without batteries) 134 kg 134 kg 134 kg

Machine weight (with standard batteries) 215 kg 215 kg 215 kg

Standard battery weight 81 Kg 81 Kg 81 Kg

Batteries

Standard batteries (no. 2 batteries) 12 Volt, 100 Ah 12 Volt, 100 Ah 12 Volt, 100 Ah

Battery voltage 24 V 24 V 24 V

Battery housing, dimensions

Height 295 mm (11.5 in) 295 mm (11.5 in) 295 mm (11.5 in)

Width 345 mm (13.5 in) 345 mm (13.5 in) 345 mm (13.5 in)

Length 350 mm (13.5 in) 350 mm (13.5 in) 350 mm (13.5 in)

General technical characteristics

Electrical system voltage 24 V 24 V 24 V

Brush motor 650 W - 1600 RPM 650 W - 1600 RPM 650 W - 1600 RPM

Suction motor 500 W - 3300 RPM 500 W - 3300 RPM 500 W - 3300 RPM

Traction motor 200 W - 120 RPM 200 W - 120 RPM 200 W - 120 RPM

Dirty water suction pressure 13 kPa 13 kPa 13 kPa

Air intake 31 l/sec 31 l/sec 31 l/sec

(*) BA 450/530 with traction motor only

Page 8

SERVICE MANUAL

GENERAL INFORMATION

GB

54 08812876(1)2002-01

S300161

Dimensions expressed by mm

998

560,5

443

770

BA 450 = 1250

BA 530 / CA 5321 = 1330

1078,5

Page 9

SERVICE MANUAL

GENERAL INFORMATION

GB

08812876(1)2002-01 55

MAINTENANCE

SCHEDULED MAINTENANCE

The machine proper and safe operation is granted by a careful and constant maintenance.

The following table sums up the scheduled maintenance. The indicated periods can be subjected to variations

according to working conditions. These must be defined by the person in charge for the maintenance.

For maintenance operation instructions see the following paragraphs.

See GENERAL INFORMATION and SAFETY - ACCIDENT PREVENTION

Maintenance operation On delivery

After use

(daily)

Every 25

hours (or

weekly)

Every 100

hours

Every 200

hours

Battery charging •

Battery liquid level and voltage

(Volt)

• •

Suction cap cleaning/check •

Float shield and suction pre-filter

cleaning

•

Tank cover gasket check

(vacuum chamber)

•

Detergent tank and supply

system cleaning

•

Detergent filter cleaning •

Hose and tank inspection •

Nut and screw tightening check •

Electric suction motor brush (or

carbon brush) check and

replacement

•

Electric traction motor brush (or

carbon brush) check and

replacement

•

Page 10

SERVICE MANUAL

GENERAL INFORMATION

GB

56 08812876(1)2002-01

MACHINE NOMENCLATURE

In this Manual you find numbers in brackets – example: (2). These numbers refer to the components indicated in

the two nomenclature pages. Refer to these pages each time you want to find the component mentioned in the

text.

1. Speed control potentiometer (*)

2. Main switch with key (*)

3. Brush switch

4. Suction switch

5. Battery condition indicator

6. Detergent flow control lever

7. Hour counter

8. Start/Stop activation panel

9. Suction cap lifting/lowering handle

10. Brush lifting/lowering pedal

11. Water recovery tank

12. Recovery tank automatic closing with float

13. Suction pre-filter

14. Detergent tank

15. Suction motor

16. Brush motor

17. Traction adjusting handles

18. Brush

19. Integrated battery charger (**)

20. Circuit panel

21. Traction motor (*)

22. Batteries

23. Suction cap assembly

24. Tank covers

25. Recovery water drain pipe

26. Detergent drain pipe

27. Tank assembly

28. Key (supplied with the machine)

29. Tank assembly fastening screw

30. Machine maneuver handle

31. Battery frame

32. Front wheel

33. Driving wheels (*)

34. Traction motor thermal fuse

35. Brush motor thermal fuse

36. Suction motor thermal fuse

37. Brush reduction unit

38. Suction cap balancing adjustment handwheel

39. Traction switch (*)

(*) BA 450/530 with traction motor only

(**) Optional

S300162

Page 11

SERVICE MANUAL

GENERAL INFORMATION

GB

08812876(1)2002-01 57

MACHINE NOMENCLATURE (CONTINUE)

S300163

Page 12

SERVICE MANUAL

DETERGENT SUPPLY SYSTEM

GB

58 08812876(1)2002-01

DETERGENT SUPPLY SYSTEM

DETERGENT TANK AND SUPPLY SYSTEM CLEANING

1. Empty the detergent tank (14) through the pipe (26).

2. Take the detergent flow control lever (6) in wide-open position, then activate the machine until the detergent

inside the machine is exhausted.

3. Carry out the Detergent filter cleaning (see the following procedure).

DETERGENT FILTER CLEANING

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Operating on the left lower side of the machine, remove the cover (A) and the wire gauze (B), clean and install

them again on the related support (C).

4. Carry out step 1. and 2. in the reverse order.

Figure 1

S300164

Remark: The wire gauze (B) must be correctly positioned on the support (C) housing (D).

Page 13

SERVICE MANUAL

DETERGENT SUPPLY SYSTEM

GB

08812876(1)2002-01 59

SOLENOID VALVE AND DETERGENT FLOW TAP REPLACEMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

7. Disconnect the battery (22) negative cable (-).

8. Disconnect the other cables of the batteries.

9. Remove the batteries (22).

10. Remove the battery frame (31).

11. Remove the screws (A) and the cover (B) of the electronic case, then disconnect the solenoid valve (D)

cables (C) from the electronic board connections (E) (connection electrical symbols: F1 and F4).

12. Disconnect the hoses (F and G).

13. Remove the solenoid valve (D) fastening screws (H).

14. Disconnect the tap (M) control lever (L) cable (I). If necessary loosen the cable sheath (O) fixing clamp (N).

15. Remove the solenoid valve assembly (D) with the tap (M).

16. Remove the pipe unions (Q and S) at the cabinet bench.

17. Remove the tap (M) from the solenoid valve (D).

18. Install in the reverse order of removal.

Figure 2

S300165

Remark: For the BA 5321 (USA) version, disconnect the solenoid valve (D1) cables by removing

the screw (P) and disconnecting the electrical connection (R).

Remark: When reinstalling, fix the sheath (O) by means of the clamp (N) in the same position (see

the print on the sheath); in this way the adjustment of the tap control remains unchanged.

Remark: when reinstalling the solenoid valve (D), the stamping orientation (T) must be as shown

in the figure; moreover, before installing the unions (Q and S) and the tap (M) clean the related

threads and apply LOCTITE 572 sealant.

Page 14

SERVICE MANUAL

DETERGENT SUPPLY SYSTEM

GB

60 08812876(1)2002-01

DETERGENT FLOW CABLE AND CONTROL LEVER REPLACEMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Operating under the machine left side, loosen the sheath (D) fixing clamp (C) and disconnect the cable (A)

from the tap lever (B).

4. Disconnect the sheath (D) from the fixing clamps along its run up to the lever (6).

5. Remove the handgrip (F) from the lever (G).

6. Remove the screws (H) and lightly slide the panel (I).

7. Remove the screws (L) and the control lever with the cable (M).

8. Install in the reverse order of removal and adjust the sheath terminal (D) position so that when the tap lever

(B) is in the position shown in the figure (closed) the control lever (G) is in “zero” flow position. When the lever

(G) is in maximum flow position, the lever (B) rotates about 90°.

Figure 3

S300166

Figure 4

S300167

Page 15

SERVICE MANUAL

DETERGENT SUPPLY SYSTEM

GB

08812876(1)2002-01 61

TROUBLESHOOTING

SMALL AMOUNT OF THE DETERGENT OR NO DETERGENT REACHES THE BRUSH

Possible cause:

1. The brush switch (3) is not to ON position or it is broken (turn it on or repair/replace it).

2. The detergent filter is obstructed/dirty (clean it).

3. The detergent flow control lever does not control the related tap anymore (check the control lever cable, from

the lever to the tap).

4. The detergent tap is stuck closed (replace the tap).

5. The solenoid valve is broken or there is an open circuit in the electrical connection (replace the solenoid

valve/repair the electrical connection).

6. There is debris in the detergent tank obstructing the output hole (clean the tank).

7. There is debris in the detergent pipeline obstructing the detergent flow (clean the pipeline).

THE DETERGENT REACHES THE BRUSH ALSO WHEN THE MACHINE IS OFF

Possible cause:

1. The solenoid valve is broken (replace it).

Page 16

SERVICE MANUAL

SWEEPING SYSTEM

GB

62 08812876(1)2002-01

SWEEPING SYSTEM

BRUSH MOTOR ELECTRICAL INPUT CHECK

1. Remove the brush (18).

2. Drive the machine on a level ground.

3. Turn the switch key (2) to OFF position.

4. If there is recovery water in the tank (11) remove it through the pipe (25).

5. If there is detergent in the tank (14) remove it through the pipe (26).

6. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

7. To operate on the brush motor (16) carefully lift the tank assembly (27) by means of the maneuver handle

(30).

8. Disconnect the battery (22) negative cable (-).

9. Disconnect the motor electrical cables (A) from the connection (B).

10. Connect the brush motor to the machine battery, as described in the underlying diagram, inserting the 30 A

fuse (D), for safety’s sake.

11. By means of an ammeter (C) check that the brush motor electrical input is 8-9 A at 24 V. If the input is greater,

disassemble the motor (see the procedure on the following page), clean the motor properly and then check

its moving parts.

If the above-mentioned procedures do not lead to a correct motor input it is necessary to replace the motor

(see the procedure on the following page).

12. Carry out steps from 1. to 9. in the reverse order.

WARNING!

This procedure must be performed by qualified personnel only.

WARNING!

Pay attention to the brush flange rotation while performing the following steps.

Figure 1

S300168

Figure 2

S300169

C

D

30A

Page 17

SERVICE MANUAL

SWEEPING SYSTEM

GB

08812876(1)2002-01 63

BRUSH MOTOR REPLACEMENT

1. Remove the brush (18).

2. Drive the machine on a level ground.

3. Turn the switch key (2) to OFF position.

4. If there is recovery water in the tank (11) remove it through the pipe (25).

5. If there is detergent in the tank (14) remove it through the pipe (26).

6. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

7. To operate on the brush motor (16) carefully lift the tank assembly (27) by means of the maneuver handle

(30).

8. Disconnect the battery (22) negative cable (-).

9. Disconnect the motor electrical cables (A) from the connection (B).

10. Cut the clamp (C).

11. Remove the nuts (D) and the brush motor (E).

12. Remove the spring pin (F) and the pinion (G) at the cabinet bench.

13. Remove the bearing (H) and the gasket (I).

14. Remove the wire gauze (L).

15. Install in the reverse order of removal.

CAUTION!

When reinstalling, take care of assemble the bearing (H) with the smaller side (M) facing the

pinion (as shown in the figure).

Figure 3

S300170

Figure 4

S300171

Page 18

SERVICE MANUAL

SWEEPING SYSTEM

GB

64 08812876(1)2002-01

BRUSH REDUCTION UNIT REPLACEMENT

1. Remove the brush (18).

2. Drive the machine on a level ground.

3. Remove the suction cap (see the related paragraph).

4. Turn the switch key (2) to OFF position.

5. If there is recovery water in the tank (11) remove it through the pipe (25).

6. If there is detergent in the tank (14) remove it through the pipe (26).

7. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

8. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

9. Disconnect the battery (22) negative cable (-).

10. Disconnect the other cables of the batteries.

11. Remove the batteries (22).

12. Remove the battery frame (31).

13. Disconnect the detergent pipe (A).

14. Disconnect the motor electrical cables (B) from the connection (C).

15. Cut the clamp (D).

16. Carefully lower the tank assembly (27) by means of the maneuver handle (30).

17. Lay down the machine on one side and set it down carefully on proper guards (E).

18. Carefully open the tank assembly (27) completely by means of the maneuver handle (30).

19. Operating on the brush installation area, remove the screw (G), the flange assembly (H) and recover the key

(I).

20. Remove the screws (L) and the reduction unit with the motor (M).

21. Remove the detergent pipe fixed on the holes (N).

22. Remove the three nuts (O) and separate the brush motor (P) from the reduction unit (Q).

23. Install in the reverse order of removal.

CAUTION!

Before installing the new reduction unit, fill in with oil of the type and quantity indicated by the

reduction unit data plate.

Figure 5

S300172

Figure 6

S300173

Page 19

SERVICE MANUAL

SWEEPING SYSTEM

GB

08812876(1)2002-01 65

BRUSH REDUCTION UNIT REPLACEMENT (Continue)

Figure 7

S300174

Page 20

SERVICE MANUAL

SWEEPING SYSTEM

GB

66 08812876(1)2002-01

BRUSH ROTATION CONSENT MICRO-SWITCH ADJUSTMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

7. Disconnect the battery (22) negative cable (-).

8. Carefully lower the tank assembly (27) by means of the maneuver handle (30).

9. Remove the screws (A) and the activation panel (C) cover (B).

10. With the activation panel (C) deactivated, check that the micro-switch (E) actuator (D) is in the cam (I)

housing (F).

11. Activate the panel (C) and check that the actuator (D) is at the positions (G and H) and activates the

micro-switch (E) (a “click” must be heard).

If necessary, reach the required condition by loosening the screws (L) and adjusting the cam position (I)

and/or loosening the screws (M) and adjusting the micro-switch position (E). Tighten the screws.

12. Install in the reverse order of removal.

13. Carry out some tests to check the brush rotation consent.

Figure 8

S300175

Figure 9

S300176

CAUTION!

If the micro-switch electrical connections (N) have been disconnected, take care to connect them

again correctly.

Page 21

SERVICE MANUAL

SWEEPING SYSTEM

GB

08812876(1)2002-01 67

TROUBLESHOOTING

OPEN CIRCUIT

The thermal fuse (35) determines the open circuit. This system allows to prevent the brush motor circuits from

being damaged under overload conditions.

If there is an open in the electrical circuit, the possible causes are the following.

Brush motor; the thermal fuse (35) activates and opens the electrical circuit.

Possible cause:

1. There are bulky debris or cords around the brush or between the brush and its flange (remove the brush and

the debris or cords).

2. The brush motor electrical input is too high (check the electrical input).

Wait at least 2 minutes after the break and, when the problem is solved, push the thermal fuse button (35).

THE BRUSH DOES NOT ROTATE

Possible cause:

1. To avoid damaging the floor, the brush motor turns off automatically when the machine stands still in the

same position (the brush cannot stand still in the same position).

2. The battery voltage is to low (charge the battery).

3. The electrical motor brushes are worn (replace the electrical motor brushes).

4. The electrical motor has a malfunction (repair or replace the electrical motor).

5. The thermal fuse (35) is deactivated (remove the cause of deactivation).

6. The brush ON/OFF switch (3) is broken (replace it).

7. The reduction unit has a malfunction (repair or replace it).

8. The brush rotation consent micro-switch is not correctly adjusted or is broken (adjust or replace it).

9. The wiring harness is damaged (repair it).

10. The electromagnetic switch is broken (replace it).

Page 22

SERVICE MANUAL

RECOVERY SYSTEM

GB

68 08812876(1)2002-01

RECOVERY SYSTEM

FLOAT SHIELD AND SUCTION PRE-FILTER CLEANING

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Lift the cover (24) of the tanks.

4. If necessary drain the water from the recovery tank (11) through the pipe (25) to visually inspect the shield

(A).

5. Check that the shield (A) and the float (B) are clean; if necessary disengage the retainers (C), open the shield

and clean it. Then place them into their correct position and engage the retainers.

6. Lift the cover (D) and check that the pre-filter (E) is clean; if necessary clean it with water and then with

compressed air. Then place the filter and the cover into their correct position.

7. Carry out step 1., 2., 3. in the reverse order.

Figure 1

S300177

Page 23

SERVICE MANUAL

RECOVERY SYSTEM

GB

08812876(1)2002-01 69

SUCTION PRE-FILTER ASSEMBLY REPLACEMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Lift the cover (24) of the tanks.

4. Drain all the water from the recovery tank (11) through the pipe (25).

5. Disengage the retainers (A) and open the shield (B) by disengaging it from the pre-filter assembly. Recover

the float (C).

6. Rotate the pre-filter assembly (D) in the direction indicated by the arrow to disengage the four retainers (E)

from their housings, then remove it upwards, overcoming the gasket (F) resistance.

7. Clean the tank housing (G) and the new pre-filter assembly area (H).

8. In the area (H) apply a thin coat of AREXONS spray silicone (silicon waterproofing lubricant).

9. Carry out step 5. and 6. in the reverse order.

10. Lift the cover (I) and check that the pre-filter (L) is clean.

11. Carry out step 1., 2., 3. in the reverse order.

Figure 2

S300178

Page 24

SERVICE MANUAL

RECOVERY SYSTEM

GB

70 08812876(1)2002-01

TANK COVER GASKET AND COMPENSATION HOLE CHECK

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Lift the cover (24) of the tanks.

4. Check that the tank cover gasket (A) is clean.

If necessary replace the gasket (A) after removing it from its housing (B). When assembling the new gasket, install

its joint (C) as shown in the figure.

5. Check that the gasket (A) seal surface (D) is integral and adequate for the gasket.

6. Check that the compensation hole (E) is not obstructed.

7. Carry out step 1., 2., 3. in the reverse order.

Figure 3

S300179

Remark: The gasket (A) creates suction pressure that is necessary for the suction of recovery

water.

Remark: The hole (E), allowing to compensate the air in the cover interspaces, contributes to

create suction pressure.

Page 25

SERVICE MANUAL

RECOVERY SYSTEM

GB

08812876(1)2002-01 71

SUCTION MOTOR ELECTRICAL INPUT CHECK

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. To operate on the suction motor (15) carefully lift the tank assembly (27) by means of the maneuver handle

(30).

7. Apply amperometric pliers (A) on a cable of the suction motor (B).

8. Activate the suction motor by means of the button (4) and check that the motor electrical input is about 20 A

at 24 V. If the electrical input is greater carry out the motor brush check (see the procedure on the following

pages). If necessary, disassemble the suction motor (see the procedure on the following page), clean it and

check its moving parts.

If the above-mentioned procedures do not lead to a correct motor input it is necessary to replace the motor

(see the procedure on the following page).

9. Carry out steps from 1. to 7. in the reverse order.

Figure 4

S300180

WARNING!

This procedure must be performed by qualified personnel only.

WARNING!

Do not touch uncovered electrical components while performing the following steps.

Page 26

SERVICE MANUAL

RECOVERY SYSTEM

GB

72 08812876(1)2002-01

SUCTION MOTOR REMOVAL

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. To operate on the suction motor (15) carefully lift the tank assembly (27) by means of the maneuver handle

(30).

7. Disconnect the battery (22) negative cable (-).

8. Disconnect the suction motor (D) electrical cables (B and C) from the connection (A).

9. Remove the motor fastening screws (E).

10. Remove the suction motor (D) and the joint (F).

11. Recover the gasket (G) that is between the motor and the structure.

12. Install in the reverse order of removal.

Figure 5

S300181

Page 27

SERVICE MANUAL

RECOVERY SYSTEM

GB

08812876(1)2002-01 73

SUCTION MOTOR BRUSH/CARBON BRUSH CHECK AND REPLACEMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. To operate on the suction motor (15) carefully lift the tank assembly (27) by means of the maneuver handle

(30).

7. Disconnect the battery (22) negative cable (-).

8. Remove the cover (A) (that is pressurized) from the suction motor (B).

9. Remove the brushes (C).

10. Check if the brushes are worn. The brushes are worn when there is not sufficient contact with the motor

armature, because of their use, of the contact surface which is not integral or because the thrust spring is

broken, etc.

11. If necessary, remove the brushes to replace them, by disengaging the lead-in wires (D). It is advisable to

replace all the brushes at the same time.

12. Install in the reverse order of removal.

Figure 6

S300182

Page 28

SERVICE MANUAL

RECOVERY SYSTEM

GB

74 08812876(1)2002-01

RECOVERY WATER DRAIN PIPE REMOVAL

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the retaining flange (A) inside the tank (11).

6. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

7. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

8. Pull out the terminal (B) from the tank and remove the recovery water drain pipe (C).

9. Before reinstalling the recovery water drain pipe, clean the hole (E). Ensure that the gasket (D) is present,

then warm its end (B) with hot water (to make it become softer) and insert it in the hole (E).

10. Carry out step 6. and 7. in the reverse order.

11. Install the retaining flange (A) after applying on its surface (F) a thin coat of AREXONS spray silicone (silicone

waterproofing lubricant).

12. Carry out steps from 1. to 4. in the reverse order.

Figure 7

S300183

Figure 8

S300184

Page 29

SERVICE MANUAL

RECOVERY SYSTEM

GB

08812876(1)2002-01 75

RECOVERY SYSTEM

SUCTION CAP CHECK/CLEANING AND POSSIBLE FLAPS REPLACEMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Lower the suction cap assembly (23) by means of the handle (9).

4. Disconnect the suction pipe (A) from the suction cap (C) and from the tank (Q); check that the internal part

of the pipe is free from dirt; otherwise clean it.

5. Remove the handwheels (B) and the suction cap assembly (C).

6. Check that the hole (D) and the spaces (E) are free from dirt; otherwise clean them.

7. Check that the edges (I) of the front and rear flaps (F and G) lay down on the same level, along their length;

otherwise adjust their height as described below:

– Disengage the retainer (L) and loosen the screws (M) to adjust the rear flap (G); then tighten the screws

and engage the retainer.

– Loosen the nuts (N) to adjust the front flap (F); then tighten the nuts.

8. Check that the front and rear flap (F and G) are integral and free from cuts and lacerations; otherwise replace

them as described below. Check that the front corner (H) of the rear flap is not worn; if the rear corner is

integral overturn the flap. If the rear corner is worn, replace the flap as described below:

– To replace (or overturn) the rear flap (G) disengage the retainer (L), remove the screws (M) and the

retaining strip (O). Install in the reverse order of removal.

– To replace the front flap (F) remove the nuts (N) and the retaining strip (P). Install in the reverse order

of removal.

After the flap replacement (or overturning), adjust their height as described by the previous step.

9. Reinstall the suction cap assembly (C) in the correct position and screw down the handwheels (B).

10. Connect the suction pipe (A) to the suction cap (C) and to the tank (Q).

11. If necessary, adjust the balancing handwheel (R) of the suction cap.

Figure 9

S300185

Page 30

SERVICE MANUAL

RECOVERY SYSTEM

GB

76 08812876(1)2002-01

RECOVERY SYSTEM

SUCTION CAP CHECK/CLEANING AND POSSIBLE FLAPS REPLACEMENT

(Continue)

Figure 10

S300186

SISTEMA DI RACCOLTA DETRITI E POLVERE

DUST AND DEBRIS COLLECTION SYSTEM SUCTION CAP REMOVAL

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. Lower the suction cap assembly (23) by means of the handle (9).

4. Disconnect the suction pipe (A) from the suction cap (B).

5. Remove the handwheels (C) and the suction cap assembly (B).

6. Install in the reverse order of removal and, if necessary, adjust the balancing handwheel (D) of the suction

cap.

Figure 11

S300187

Page 31

SERVICE MANUAL

RECOVERY SYSTEM

GB

08812876(1)2002-01 77

RECOVERY SYSTEM

TROUBLESHOOTING

OPEN CIRCUIT

The thermal fuse (36) determines the open circuit. This system allows to prevent the suction motor circuits from

being damaged under overload conditions.

If there is an open in the electrical circuit, the possible causes are the following.

Suction motor; the thermal fuse (36) activates and opens the electrical circuit.

Possible cause:

1. The motor is damaged (check the motor brushes/electrical input).

Wait at least 2 minutes after the break and, when the problem is solved, push the thermal fuse button (36).

DIRTY WATER SUCTION IS INSUFFICIENT OR THERE IS NO SUCTION

Possible cause:

1. The float automatic closing (12) is activated because the water recovery tank (11) is too full (empty the water

recovery tank).

2. The float shield (12) or the suction filter are dirty (clean them).

3. The tank cover (24) is not correctly positioned (place it correctly).

4. The tank cover gasket is not efficient or the compensating hole is obstructed (remove the causes).

5. The suction cap or suction pipe obstructed or damaged (clean/repair/replace them)

6. The battery voltage is to low (charge the battery).

7. The Electrical motor brushes are worn (replace the electrical motor brushes).

8. The electrical motor has a malfunction (repair or replace the electrical motor).

9. The thermal fuse (36) is deactivated (remove the cause of deactivation).

10. The suction ON/OFF switch (4) is broken (replace it).

11. The wiring harness is damaged (repair it).

12. The suction motor electromagnetic switch is broken (replace it).

THE SUCTION CAP LEAVES LINING OR DOES NOT COLLECT WATER

Possible cause:

1. There is debris under the suction cap lip (remove them)

2. The suction cap flap lips are torn or worn (replace the flaps)

3. The suction cap is unbalanced (balance it by means of the handwheel (38)).

Page 32

SERVICE MANUAL

TRACTION SYSTEM

GB

78 08812876(1)2002-01

TRACTION SYSTEM

TRACTION MOTOR ELECTRICAL INPUT CHECK

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

7. Disconnect the battery (22) negative cable (-).

8. Disconnect the other cables of the batteries.

9. Remove the batteries (22).

10. Remove the battery frame (31).

11. Remove the screws (A) and the electronic case cover (B).

Disconnect the traction motor (D) cables (C) from the connection (I) (electrical symbol T4) to the electronic

board and from the connection (L).

12. Lift the driving wheels (E) a few centimeters from the ground by inserting adequate shims under the brush

(18) or under the front wheel (32). Then securely fix the machine in this position so that the driving wheels

(E) can turn freely without touching the ground during the following tests.

13. Connect the traction motor to the machine battery, as described in the underlying diagram, inserting the 10

A fuse (F), for safety’s sake.

14. With an ammeter check that the motor electrical input is about 3-4 A at 24 V. If the electrical input is greater

carry out the motor brush check (see the procedure on the following pages). If necessary, disassemble the

traction motor (see the procedure on the following page), clean it and check its moving parts.

If the above-mentioned procedures do not lead to a correct motor input it is necessary to replace the motor

(see the procedure on the following page).

15. Carry out steps from 1. to 12. in the reverse order.

WARNING!

This procedure must be performed by qualified personnel only.

WARNING!

Pay attention to the driving wheel (E) rotation while performing the following steps.

Page 33

SERVICE MANUAL

TRACTION SYSTEM

GB

08812876(1)2002-01 79

TRACTION MOTOR ELECTRICAL INPUT CHECK (Continue)

Figure 1

S300188

Figure 2

S300189

G

F

10A

Page 34

SERVICE MANUAL

TRACTION SYSTEM

GB

80 08812876(1)2002-01

TRACTION MOTOR REMOVAL

1. Remove the brush (18).

2. Drive the machine on a level ground.

3. Remove the suction cap (see the related paragraph).

4. Turn the switch key (2) to OFF position.

5. If there is recovery water in the tank (11) remove it through the pipe (25).

6. If there is detergent in the tank (14) remove it through the pipe (26).

7. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

8. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

9. Disconnect the battery (22) negative cable (-).

10. Disconnect the other cables of the batteries.

11. Remove the batteries (22).

12. Remove the battery frame (31).

13. Remove the screws (A) and the electronic case cover (B).

Disconnect the traction motor (D) cables (C) from the connection (M) (electrical symbol T4) to the electronic

board and from the connection (N).

14. Carefully lower the tank assembly (27) by means of the maneuver handle (30).

15. Remove the left wheel (F) and the snap ring (G).

16. Lay down the machine on one side and set it down carefully on proper guards (H).

17. Remove the right wheel (I).

18. Remove the four screws (L).

19. Remove the motor assembly with the reduction unit (D).

20. Install in the reverse order of removal.

Figure 3

S300190

Page 35

SERVICE MANUAL

TRACTION SYSTEM

GB

08812876(1)2002-01 81

TRACTION MOTOR REMOVAL (Continue)

Figure 4

S300191

Figure 5

S300192

Page 36

SERVICE MANUAL

TRACTION SYSTEM

GB

82 08812876(1)2002-01

TRACTION MOTOR BRUSH (OR CARBON BRUSH) CHECK AND

REPLACEMENT

1. Remove the brush (18).

2. Drive the machine on a level ground.

3. Remove the suction cap (see the related paragraph).

4. Turn the switch key (2) to OFF position.

5. If there is recovery water in the tank (11) remove it through the pipe (25).

6. If there is detergent in the tank (14) remove it through the pipe (26).

7. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

8. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

9. Disconnect the battery (22) negative cable (-).

10. Disconnect the other cables of the batteries.

11. Remove the batteries (22).

12. Remove the battery frame (31).

13. Carefully lower the tank assembly (27) by means of the maneuver handle (30).

14. Lay down the machine on one side and set it down carefully on proper guards (A).

15. Carefully open the tank assembly (I) completely by means of the maneuver handle (30).

16. Remove the two screws (B) and lightly slide the tap-solenoid valve assembly (C).

17. Clean the exterior part of the traction motor (L) from dirty and dust, then mark the reciprocal position (D)

between the cover (E) and the motor body.

18. Remove the screws (F) and the cover (E).

19. Check if the two brushes (G) are worn. The brushes are worn when there is not sufficient contact with the

motor armature, because of their use, of the contact surface which is not integral or because the thrust spring

is broken, etc.

20. If necessary, remove the brushes to replace them, by disengaging the lead-in wires (H).

It is advisable to replace all the brushes at the same time.

21. Install in the reverse order of removal.

Figure 6

S300193

Page 37

SERVICE MANUAL

TRACTION SYSTEM

GB

08812876(1)2002-01 83

TRACTION SYSTEM

TRACTION MOTOR BRUSH (OR CARBON BRUSH) CHECK AND

REPLACEMENT (Continue)

Figure 7

S300194

Page 38

SERVICE MANUAL

TRACTION SYSTEM

GB

84 08812876(1)2002-01

POTENTIOMETER ADJUSTMENT

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

7. Disconnect the battery (22) negative cable (-).

8. Carefully lower the tank assembly (27) by means of the maneuver handle (30).

9. Remove the screws (A) and the activation panel (C) cover (B).

10. Connect a 20KOhm tester to the connections (D and E) of the potentiometer (G) and check the following

values under the following conditions:

– With the activation panel (C) deactivated: 2.40÷2.60 KOhm

– With the activation panel (C) in the forward limit switch position: 4.80÷5.00 KOhm

– With the activation panel (C) in the backward limit switch position: 0.00÷0.25 KOhm

11. To obtain the above conditions, loosen the screw (H) and turn the potentiometer shaft (I) as necessary.

Tighten the screw.

If necessary, loosen the screws (L) and adjust the cam (M) position.

12. Carry out steps from 1. to 9. in the reverse order.

13. Carry out speed change tests

CAUTION!

Pay attention not to invert the connecting cables to the potentiometer (G) electrical connections

(D, E, F)

Figure 8

S300175

Figure 9

S300195

Page 39

SERVICE MANUAL

TRACTION SYSTEM

GB

08812876(1)2002-01 85

TROUBLESHOOTING

OPEN CIRCUIT

Possible cause:

1. There are bulky debris or cords under the machine or around the driving wheels (remove the debris).

2. The motor is damaged (check the motor brushes/electrical input).

3. The slope is excessive (drive only on the maximum slope allowed)

Wait at least 2 minutes after the break and, when the problem is solved, push the thermal fuse button (34).

THE MACHINE DOES NOT MOVE

Other possible cause:

1. The battery voltage is to low (charge the battery).

2. The potentiometer inside the activation panel (8) is misadjusted or broken (adjust or replace it).

3. The potentiometer (1) is broken (replace it).

4. The traction electronic board has a malfunction (replace it).

5. The thermal fuse (34) is deactivated (remove the cause of deactivation).

6. The wiring harness is damaged (repair it).

7. The switch (39) is to OFF position.

Page 40

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

86 08812876(1)2002-01

ELECTRICAL SYSTEM

BATTERY REMOVAL

1. Drive the machine on a level ground.

2. Turn the switch key (2) to OFF position.

3. If there is recovery water in the tank (11) remove it through the pipe (25).

4. If there is detergent in the tank (14) remove it through the pipe (26).

5. Remove the key (28) from its housing and remove the tank assembly fastening screw (29).

6. Carefully lift the tank assembly (27) by means of the maneuver handle (30).

7. Disconnect the battery (22) negative cable (-).

8. Disconnect the other cables of the batteries.

9. Remove the batteries (22).

10. If necessary, remove the battery frame (31).

11. Install in the reverse order of removal.

BATTERY MAINTENANCE AND RECHARGING

See Use and Maintenance Manual

TRACTION ELECTRONIC BOARD REPLACEMENT

1. Remove the batteries (See the previous procedure).

2. Remove the screws (A) and the electronic case cover (B).

3. Disconnect all the electrical connections of the board (C) (See the wiring diagram).

4. Remove the screws (D) and the traction electronic board (C).

5. Install in the reverse order of removal.

Figure 1

S300196

REMARK: It is not necessary to perform the electronic programming of the new boards.

Page 41

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

08812876(1)2002-01 87

ELECTRICAL SYSTEM

SERVICE ELECTRONIC BOARD REPLACEMENT

1. Remove the batteries (See the previous procedure).

2. Remove the screws (A) and the electronic case cover (B).

3. Disconnect all the electrical connections of the board (C) (See the wiring diagram).

4. Disengage the retainers (D) and remove the service electronic board (C).

5. Install in the reverse order of removal.

Figure 2

S300197

REMARK: It is not necessary to perform the electronic programming of the new board.

Page 42

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

88 08812876(1)2002-01

TROUBLESHOOTING

See the previous chapters related to the use of the electrical system.

Other possible malfunction causes are:

1. The battery is discharged or its connections are not efficient (charge the battery or clean the connections).

2. The battery charger is not efficient (replace it).

3. The thermal fuses are deactivated (activate them).

4. The wiring harness is cut or shorted to ground (repair it)

5. The safety micro-switch (41) is not efficient (replace it).

COMPONENT LAYOUT

1. Batteries

2. Brush motor

3. Brush motor switch

4. Battery charger

5. Reset thermal fuse

6. Traction motor

7. Battery type switch

8. Hour counter

9. Ignition key switch

10. Electromagnetic switch

11. Brush rotation consent micro-switch

12. Traction speed control potentiometer (5KOhm)

13. Traction speed control potentiometer (47KOhm)

14. Relay electronic board (services)

15. Traction control electronic board

16. Detergent supply solenoid valve

17. Traction switch

18. Suction motor

19. Suction motor switch

Page 43

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

08812876(1)2002-01 89

Figure 3

S300198

Page 44

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

90 08812876(1)2002-01

WIRING DIAGRAM BA 450/530 - after serial number 014106978

With traction with battery charger

08812796

S300199

Page 45

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

08812876(1)2002-01 91

WIRING DIAGRAM BA 450/530 - after serial number 014106978

Without traction with battery charger

08812797

S300200

Page 46

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

92 08812876(1)2002-01

WIRING DIAGRAM BA 450/530 - after serial number 014106978

With traction without battery charger

08812798

S300201

Page 47

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

08812876(1)2002-01 93

WIRING DIAGRAM BA 450/530 - after serial number 014106978

Without traction without battery charger

08812799

S300202

Page 48

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

94 08812876(1)2002-01

WIRING DIAGRAM BA 5321 - after serial number 1514570

S300203

Page 49

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

08812876(1)2002-01 95

WIRING DIAGRAM BA 5321D - after serial number 1514570

S300204

Page 50

SERVICE MANUAL

ELECTRICAL SYSTEM

GB

96 08812876(1)2002-01

FINE

Page 51

Nilfisk-Advance, Inc.

14600 21st Avenue North

Plymouth, MN, 55447-3408

www.nilfisk-advance.com

Phone: 800-989-2235

Fax: 800-989-6566

©2002 Nilfisk-Advance, Inc.,

Plymouth, MN 55447-3408

Printed in the U.S.A.

Loading...

Loading...