Page 1

SW4000

Service Manual

Advance SW4000 Battery - 9084403010

Nilsk SW4000 Battery - 9084400010

Nilsk SW4000 Petrol - 9084401010

Nilsk SW4000 LPG - 9084402010

Advance (SW4000 BR) - 9084407010 (LPG)

English

2013-04 Form No. 1464811000

Page 2

Table of Contents

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Machine General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Manual Purpose and Field of Application . . . . . . . . . . . . . . . . . . . . . . 5

Other Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Visible Symbols On The Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Lifting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Machine Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Machine Nomenclature (know your machine) (SW4000 Battery) . . . . . . . . . . . . . .12

Control Panel (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Machine Nomenclature (know your machine) (SW4000 Petrol/LPG) . . . . . . . . . . . .16

Control Panel (SW4000 Petrol/LPG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Service and Diagnostic Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Scheduled Maintenance Table (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . .25

Scheduled Maintenance Table (SW4000 Petrol/LPG) . . . . . . . . . . . . . . . . . . . .26

Table of Contents 2Service Manual – SW4000

Chassis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chassis (main parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Dashboard Electronic Board Specications . . . . . . . . . . . . . . . . . . . . . . . . . .29

Wiring Diagram (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring Diagram (SW4000 Petrol/LPG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dashboard Electronic Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Dust Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Dust Guard System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Page 3

Table of Contents 3Service Manual – SW4000

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Relay/Electromagnetic Switch/Diodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Wiring Diagram (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Wiring Diagram (SW4000 Petrol/LPG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Component Locations (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Component Locations (SW4000 Petrol/LPG) . . . . . . . . . . . . . . . . . . . . . . . . . 68

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Fuse Check/Replacement (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . .75

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

General Wiring Diagram (SW4000 Battery) . . . . . . . . . . . . . . . . . . . . . . . . .83

General Wiring Diagram (SW4000 Petrol - LPG). . . . . . . . . . . . . . . . . . . . . . .86

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Engine System - Petrol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Engine System - LPG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

Hopper System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Hydraulic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

Optional and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Steering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Main Broom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Page 4

Table of Contents 4Service Manual – SW4000

Side Broom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .199

Wheel System, Non-Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Wheel System, Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Drive System Electronic Board Error Codes Table . . . . . . . . . . . . . . . . . . . . .207

Drive System Electronic Board Parameter Table. . . . . . . . . . . . . . . . . . . . . . 208

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .232

Page 5

Service Manual – SW4000

General Information

General Information

Machine General Description

The SW4000 is a “ride-on” industrial machine designed to clean/sweep oors, in civil or industrial environments, in one pass. The machine can be supplied in one of the following version:

• with a rechargeable battery, installed on the machine (SW4000 Battery)

• with a battery charged by a petrol engine, both installed on the machine (SW4000 Petrol)

• with a battery charged by a LPG gas engine (SW4000 LPG)

The machine is equipped with one main cylindrical broom, and one or two side disc brooms.

The rear hopper and a vacuum system allow for dust and dirt collection.

The hopper is equipped with a lifting system to discharge the collected debris.

Service Manual Purpose and Field of Application

The Service Manual is a technical resource intended to help service technicians when carrying out mainte-

nance and repairs on the SW4000, to guarantee the best cleaning performance and a long working life for the

machine.

Please read this manual carefully before performing any maintenance and repair procedure on the machine.

5

Other Reference Manuals

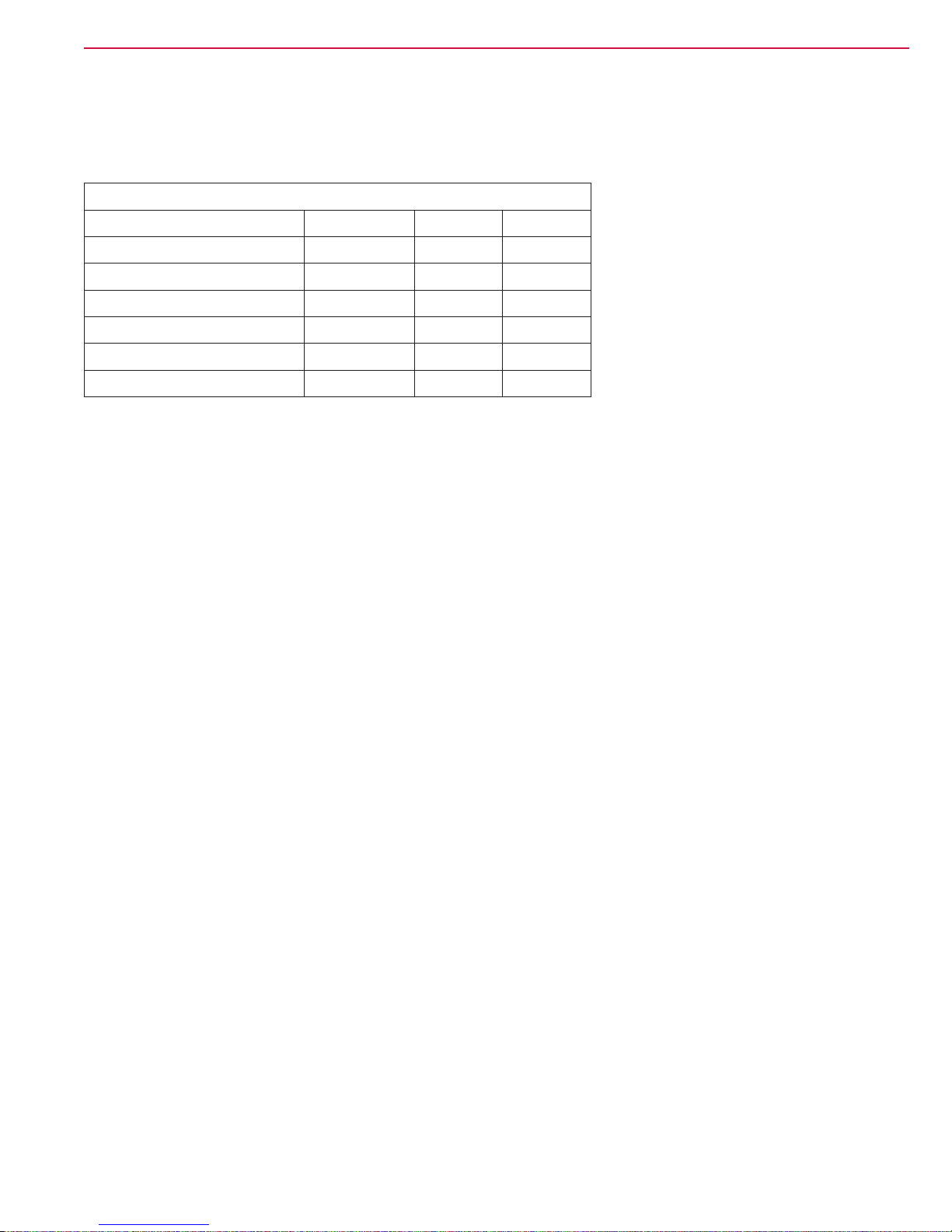

Model Product Code User Manual Spare Parts List

SW4000 Battery - Nilsk 9084400010 1464809000 1464810000

SW4000 Petrol - Nilsk 9084401010 1464815000 1464816000

SW4000 LPG - Nilsk 9084402010

SW4000 Battery - Advance 9084403010 1464818000 1464819000

Assembly Instructions Instruction Code Machines concerned

MTR/250 NON-MARKING MOTOR RING 1465241000

WORKING LIGHT KIT 1465245000

ROOF COVER KIT 1465247000

LEFT BROOM KIT 1465242000

PIVOTING LIGHT KIT 1465248000

NON-MARKING SKIRT KIT 1465241000

LEFT ARMREST KIT 1465249000

PROTECTION ROOF KIT 1465246000

24V DUST GUARD SYSTEM KIT 1465244000

SAFETY BELT KIT 1465248000

RIGHT SIDE BROOM SHIELD KIT 1465243000

LEFT SIDE BROOM SHIELD KIT 1465243000

MTR/250 NON-MARKING MOTOR RING 1465241000

WORKING LIGHT KIT 1465245000

These manuals are available at:

- Local Nilsk-Advance Retailer

- Nilsk-Advance website: www.nilsk.com - www.advance-us.com

SW4000 Battery Advance – SW4000 Battery/Petrol/LPG

Nilsk

Page 6

Service Manual – SW4000

General Information

Conventions

Forward, backward, front, rear, left or right are intended with reference to the operator’s position when driving.

Service and Spare Parts

Service and repairs must be performed only by authorised personnel or Nilsk Service Centers. The authorised

personnel is trained directly at the manufacturer’s premises and has original spare parts and accessories.

Contact Nilsk Retailer indicated below for service or to order spare parts and accessories, specifying the ma-

chine model and serial number.

(Apply Retailer label here)

6

Serial Number Label

The machine model name and serial number are

marked on the plate (see the example to the side).

Product number and year of production are marked

on the same plate.

This information is useful when requiring machine

spare parts.

Use the following table to write down the machine

identication data.

MACHINE model .............................................................................................

PRODUCT code ..............................................................................................

P200082

MACHINE serial number .................................................................................

ENGINE model ................................................................................................

ENGINE serial number ....................................................................................

Page 7

Service Manual – SW4000

General Information

Safety

The following symbols indicate potentially dangerous situations. Always read this information carefully and

take all necessary precautions to safeguard people and property.

Visible Symbols On The Machine

7

X %

Symbols

Danger! It indicates a dangerous situation with risk of death for the operator.

WARNING!

Carefully read all the instructions before

performing any operation on the machine.

DANGER!

Internal combustion engine.

Do not inhale exhaust gas fumes.

Carbon monoxide (CO) can cause brain

damage or death.

WARNING!

Do not wash the machine with direct or

pressurized water jets.

WARNING!

Do not use the machine on slopes with a

gradient exceeding the specications.

WARNING!

Hot parts, danger of burns.

WARNING!

Moving parts.

WARNING!

Moving parts. Danger of crushing.

WARNING!

Parts under voltage. Presence of corrosive

uids.

Warning! It indicates a potential risk of injury for people or damage to objects.

Caution! It indicates a caution related to important or useful functions.

Note: It indicates a remark related to important or useful functions.

General Instructions

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries.

(For SW4000 Battery/Petrol/LPG)

– Before performing any maintenance, repair, cleaning or replacement procedure remove the igni-

tion key, engage the parking brake and disconnect the battery (For SW4000 Petrol/LPG - Discon-

nect the battery connector).

– This machine must be used by properly trained operators only.

Page 8

Service Manual – SW4000

– Sharp turns must be made at slowest possible speed. Avoid: abrupt turns on incline, turns when

the hopper is lifted.

– Do not lift the hopper when the machine is on incline. The machine loses stability on incline or

when the hopper is full.

– Keep the batteries away from sparks, ames and incandescent material. During the normal op-

eration explosive gases are released.

– Do not wear jewels when working near electrical components.

– Do not work under the lifted machine without supporting it with safety stands.

– When working under the open hood, ensure that it cannot be closed by accident.

– Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids

or vapors: This machine is not suitable for collecting dangerous powders.

– (For WET batteries only). Keep the battery away from sparks, ames and incandescent material.

During the normal operation explosive gases are released.

(For SW4000 Petrol/LPG)

– Carbon monoxide (CO) can cause brain damage or death.

– The internal combustion engine of this machine can emit carbon monoxide.

– Do not inhale exhaust gas fumes.

– Only use indoors when adequate ventilation is provided, and with the help of an assistant.

General Information

8

(For SW4000 Petrol/LPG)

– Be careful: fuel is highly ammable.

– Do not smoke or bring naked ames in the area where the machine is refuelled or where the fuel

is stored.

– Refuel outdoors or in a well-ventilated area, with the engine off.

– Turn off the engine and let it cool down for a few minutes, then remove the fuel tank plug.

– Leave at least a space of 4 cm in the ller to allow the fuel to expand.

– After refuelling, check that the fuel tank cap is rmly closed.

– If any fuel is spilled while refuelling, clean the tank area and allow the vapors to evaporate be-

fore starting the engine.

– Do not let fuel come into contact with the skin; do not breathe fuel vapors. Keep out of reach of

children.

– Do not tilt the engine too much to avoid fuel spillage.

– When moving the machine, the fuel tank must not be full and the fuel valve must be closed.

– Do not lay any object on the engine.

– Stop the engine before performing any procedure on it. To avoid any incidental start, disconnect

the spark plug cap or disconnect the battery negative terminal.

– See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of

this Manual.

– (For LPG version). Do not use the machine in case of gas leaks. Disconnect the fuel hose and

replace the LPG tank. If the gas leak persists, disconnect the fuel hose and contact the Nilsk-

Advance Service Center.

Page 9

Service Manual – SW4000

(For SW4000 Battery)

– (For WET batteries only). Battery charging produces highly explosive hydrogen gas. Keep the

battery cover open during battery charging and perform this procedure in well-ventilated areas

and away from naked ames.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries, damages to materials or equipments.

(For SW4000 Battery/Petrol/LPG)

– Carefully read all the instructions before performing any maintenance/repair procedure.

– When working near the hydraulic system, always wear protective clothes and safety glasses.

– Pay attention to hot parts when working near the engine, the mufer, the manifold and the

cooler.

– This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

– Close attention is necessary when used near children.

– Use only as shown in this Manual. Only Nilsk-Advance recommended accessories must be used.

– Check the machine carefully before each use, always check that all the components have been as-

sembled before use. If the machine is not perfectly assembled it can cause damages to people and

properties.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the

machine moving parts.

– To avoid any unauthorized use of the machine, remove the ignition key.

– Do not leave the machine unattended without being sure that it cannot move independently.

– Do not use the machine on slopes with a gradient exceeding the specications.

– Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent

instability.

– Use only brooms supplied with the machine or those specied in the User Manual. Using other

brooms could reduce safety.

– Before using the machine, close all doors and/or covers as shown in the User Manual.

– Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

– Use the machine only where a proper lighting is provided.

– Working lights have to be used only to enhance visibility on the oor to be cleaned, but they do

not authorize anyone to use the sweeper in dark environments.

– If the machine is to be used where there are other people besides the operator, it is necessary to

install the pivoting light.

– While using this machine, take care not to cause damage to people or objects.

– Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

– Do not lean liquid containers on the machine, use the relevant can holder.

– The storage temperature must be between 0°C and +40°C.

– The machine working temperature must be between 0°C and +40°C.

– The humidity must be between 30% and 95%.

– Always protect the machine against the sun, rain and bad weather, both under operation and

inactivity condition. Store the machine indoors, in a dry place. This machine must be used in dry

conditions, it must not be used or kept outdoors in wet conditions.

– Do not use the machine as a means of transport, or for pushing/towing.

General Information

9

Page 10

Service Manual – SW4000

– The machine maximum capacity, operator’s weight not included, is 100 kg (the weight of waste).

– In case of re, use a powder re extinguisher, not a water one.

– Adjust the operation speed to suit the oor conditions.

– Avoid sudden stops when the machine is going downhill. Avoid sharp turns. Drive at slow speed

when going downhill.

– This machine cannot be used on roads or public streets.

– Do not tamper with the machine safety guards.

– Follow the routine maintenance procedures scrupulously.

– Do not allow any object to enter into the openings. Do not use the machine if the openings are

clogged. Always keep the openings free from dust, hairs and any other foreign material which

could reduce the air ow.

– (Only for versions equipped with DustGuard™ system). Pay attention during machine trans-

portation when temperature is below freezing point. The water in the tank or in the hoses could

freeze and seriously damage the machine.

– Do not remove or modify the plates afxed to the machine.

– When the machine is to be pushed for service reasons (lack of fuel, engine break-down, etc.), the

speed must not exceed 4 km/h.

– In case of machine malfunctions, ensure that these are not due to lack of maintenance. If neces-

sary, request assistance from the authorised personnel or from an authorised Service Center.

– If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

– To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant

chapter of this Manual, must be performed by the authorised personnel or by an authorised Ser-

vice Center.

– (For WET batteries only). When lead batteries (WET) are installed on this machine, do not tilt

the machine more than 30° from its horizontal position to prevent the highly corrosive acid to

leak out of the batteries. If the machine must be tilted to perform any maintenance procedure,

remove the batteries.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials

(batteries, oils, etc.), which are subject to standards that require disposal in special centres (see

the User Manual).

General Information

10

(For SW4000 Petrol/LPG)

– While the engine is running, the silencer warms up; do not touch the silencer when it is hot to

avoid burns or res.

– Running the engine with an insufcient quantity of oil can seriously damage the engine. Check

the oil level with the engine off and the machine on a level surface.

– Never run the engine if the air lter is not installed, because the engine could be damaged.

– Technical service procedures on the engine must be performed by an authorised Dealer.

– Only use original spare parts or parts of matching quality for the engine. Using spare parts of

lower quality can seriously damage the engine.

– See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of

this Manual.

(For SW4000 Battery)

– Before using the battery charger, ensure that frequency and voltage values, shown on the ma-

chine serial number plate, match the electrical mains voltage.

– Do not pull or carry the machine by the battery charger cable and never use the battery charger

cable as a handle. Do not close a door on the battery charger cable, or pull the battery charger

cable around sharp edges or corners. Do not run the machine on the battery charger cable.

– Keep the battery charger cable away from heated surfaces.

Page 11

Service Manual – SW4000

– Do not use the machine if the battery charger cable or plug is damaged. If the machine is not

working as it should, has been damaged, left outdoors or dropped into water, return it to the

Service Center.

– Before performing any maintenance procedure, disconnect the battery charger cable from the

electrical mains to avoid any risk of re, electric shock or injuries.

– Do not smoke while charging the batteries.

Guide lines to bacteria control and other dangers coming from the presence of microbes in the DustGuard™ system.

To prevent the operators and other people from developing infections caused by microbes and Legionella that

may ourish in the dust guard system, take the following precautions:

– If possible, ll the tank with cold water (< 20°C).

– DO NOT use stagnant water to ll the tank.

– DO NOT use recycled water, undrinkable water or water that has been in contact with the soil.

– Adjust and turn the nozzles towards the oor only, from preventing possible inhaling.

– Do not store the machine outdoors or near sources of heat.

– Do not over-ll the tank. Fill the tank sufciently so that it can be emptied by using the system.

– Empty the tank every 10 hours or once a week, according to the use.

– If the machine is not used for more than one week, empty the tank completely, and let it dry.

– If the tank cannot be cleaned regularly, consider using a biocide that can kill or exert a control-

ling effect on Legionella bacteria. Biocide must be chosen according to the local regulations and

must be used according to the relevant instructions and cautions, to avoid that the personnel

gets affected by dangerous chemical substances.

– If chemical products have to be used in the water tank, it is mandatory to apply the relevant

information and caution labels of the product.

General Information

11

Machine Lifting

Warning! Donotworkundertheliftedmachine,ifitisnotsecurelyxed.

Machine Transportation

Warning! Before transporting the machine, make sure that:

All covers are closed.

The tanks are empty.

The battery connector is disconnected.

The machine is securely fastened to the means of transport.

Page 12

Service Manual – SW4000

Driver's seat with safety microswitch

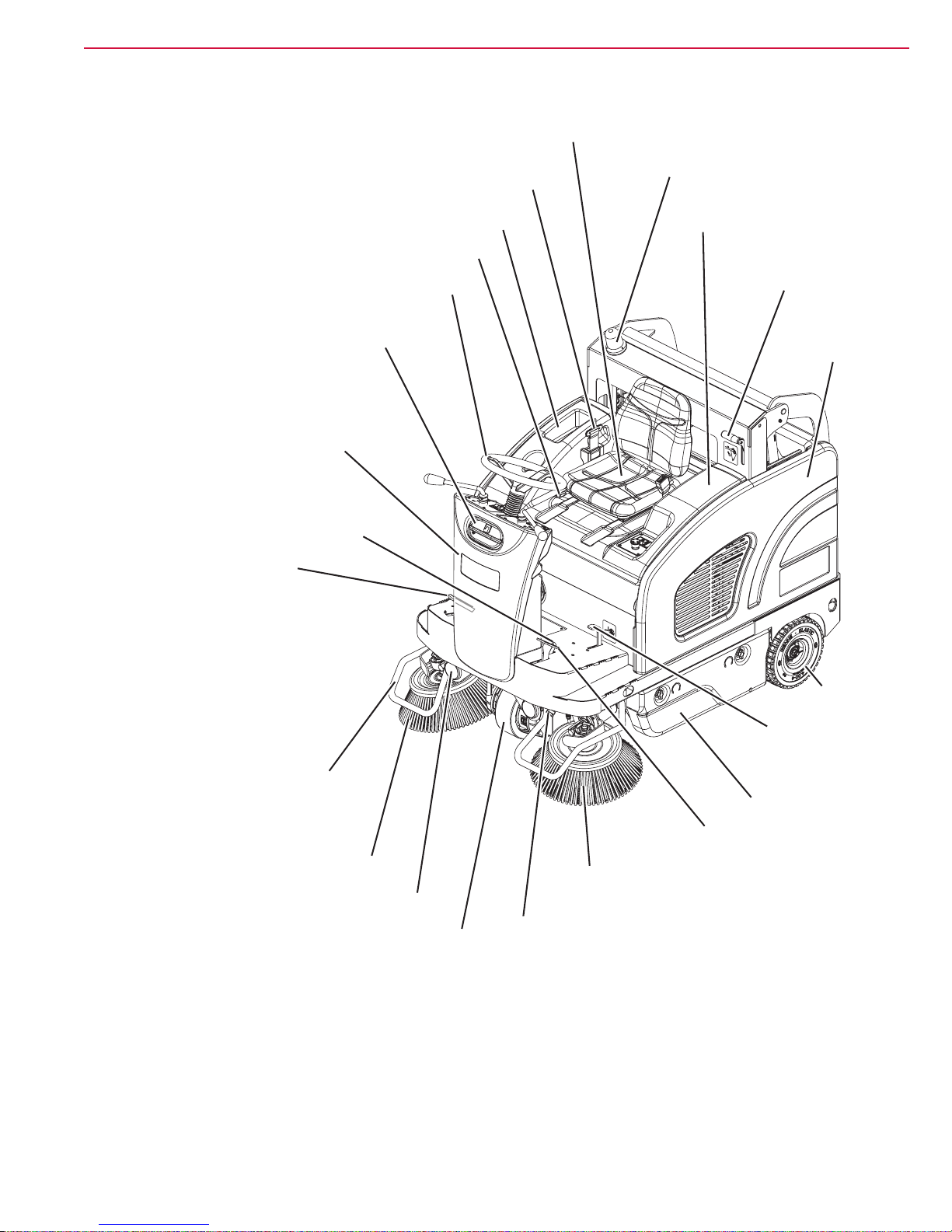

Machine Nomenclature (know your machine) (SW4000 Battery)

General Information

12

Seat position adjusting lever

Dust guard system

water filler neck plug

Front column / Dust guard

system water tank

Parking brake lever

Forward/reverse gear pedal

Safety belts

Can holder

Steering wheel

Flashing light

Battery compartment

hood

Hopper release

and discharge lever

Left

side

cover

Side broom guards

Right side broom

Working lights

Front driving and steering wheel

Rear

wheels

Front skirt

lifting pedal

Left door

Service brake pedal

Left side broom

Dust guard system nozzles

P200083

Page 13

Service Manual – SW4000

Serial number plate/technical

Machine Nomenclature (SW4000 Battery) (Continues)

data/conformity certification

Electronic

battery charger

Hopper manual

returning handle

Rear hood with

vacuum system

Dust filter

container

General Information

Drive pedal

Anchoring slots

for transport

(not for lifting)

13

Panel filter with

filter-shaker

Hopper

Anchoring slots for transport (not for lifting)

Right side cover

Right door

Main broom

Rear wheels

P200084

Page 14

Service Manual – SW4000

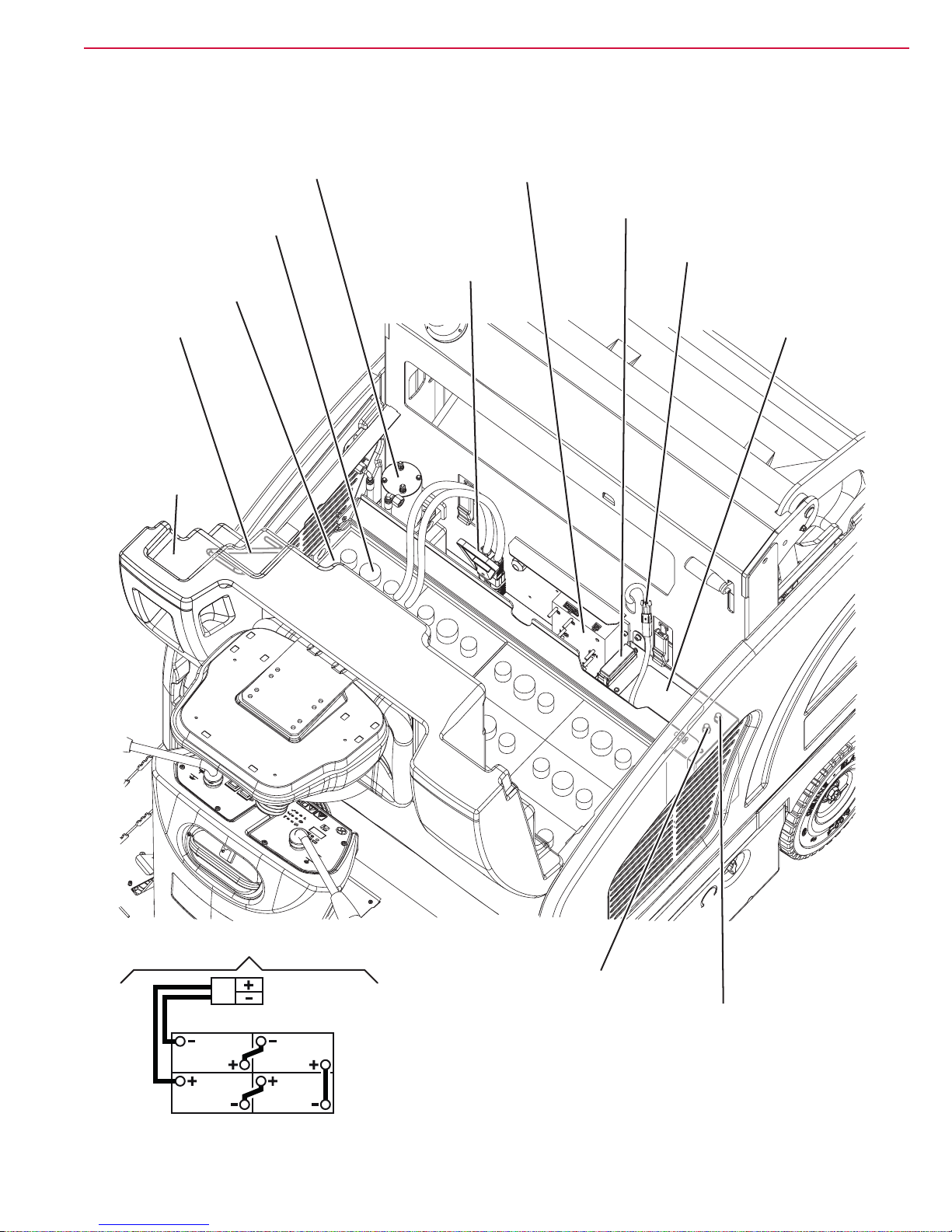

Hopper hydraulic

Machine Nomenclature (SW4000 Battery) (Continues)

lifting system

Battery caps

(for WET batteries only)

Lead batteries

(WET) or optional

gel batteries (GEL)

Open hood

safety rod

Battery

compartment

hood opening

handle

control unit

Battery

connector

Drive system electronic board

Fuseholder box

General Information

Vacuum system

motor connector

Electrical

component

box

14

Battery connection diagram

BATTERY

PLUG

6V

6V

6V

6V

Left side broom motor

circuit breaker

Right side broom

motor circuit breaker

P200085

Page 15

Service Manual – SW4000

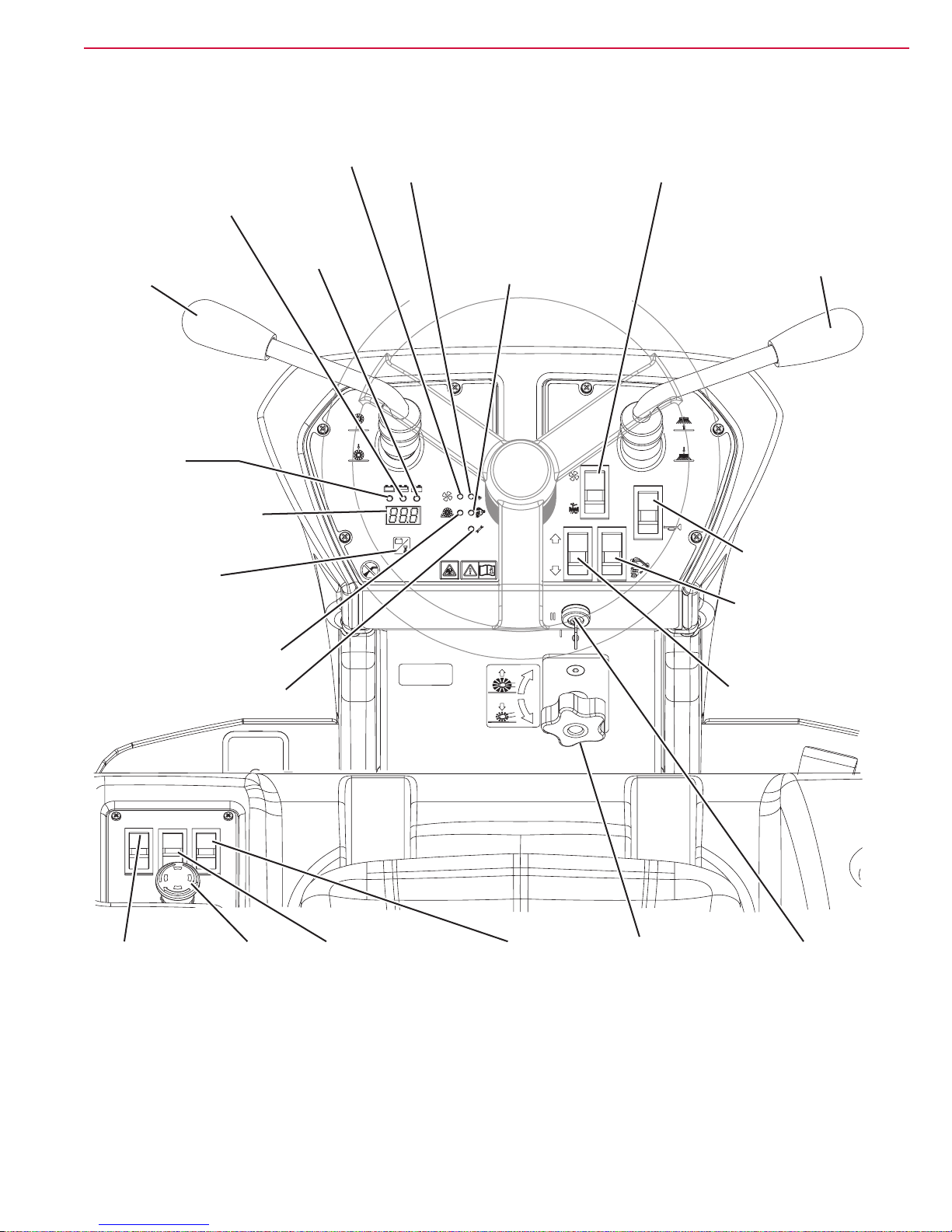

Switch for:

Vacuum system

Control Panel (SW4000 Battery)

General Information

15

Semi-discharged battery

warning light (yellow)

Main broom

lifting/lowering lever

Discharged

battery warning

light (red)

Display

Button:

• Working hours

• Battery voltage (V)

warning light

(green)

Charged

battery warning

light (green)

Dust guard system

warning light

(green)

• Vacuum system activation (upper part)

• Filter shaker activation (lower part)

Filter shaker switch

Hopper lifting

system warning

light (yellow)

Side broom

lifting/lowering lever

Horn switch

Hopper movement

enabling switch

Main broom overpressure

warning light (red)

Drive system malfunction

warning light (red)

Dust guard

system switch

Emergency

push-button

Hopper

lifting/lowering

switch

Working light

switch

Forward/reverse

gear switch

Main broom

height adjusting knob

Ignition key

P200086

Page 16

Service Manual – SW4000

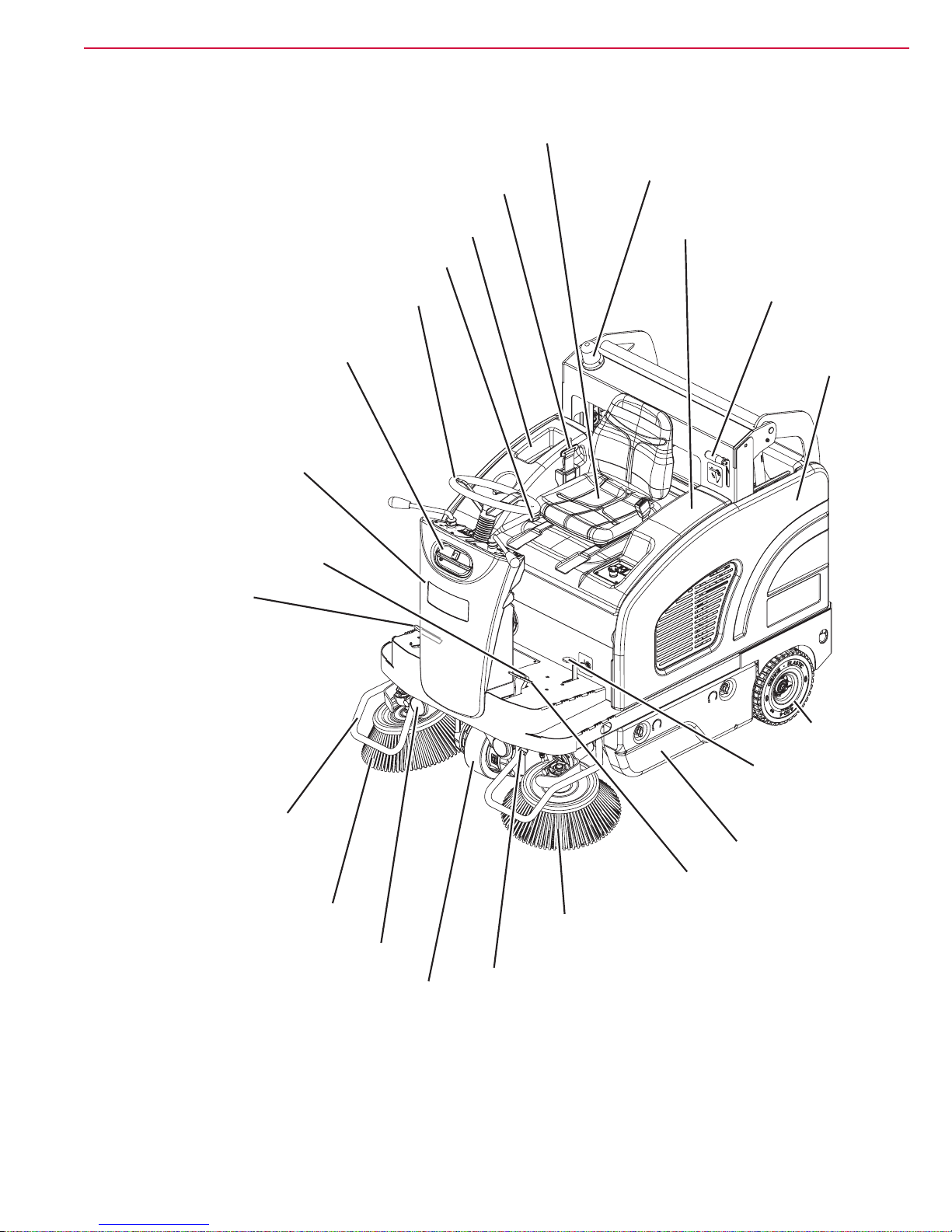

Driver's seat with safety microswitch

General Information

Machine Nomenclature (know your machine) (SW4000 Petrol/LPG)

Flashing light

Safety belts

16

Seat position adjusting lever

Dust guard system

water filler neck plug

Front column / Dust guard

system water tank

Parking brake lever

Drive pedal

Can holder

Steering wheel

Engine compartment

hood

Hopper release

and discharge

lever

Left

side

cover

Side broom guards

Right side broom

Working lights

Front driving and steering wheel

Rear

wheels

Front skirt

lifting pedal

Left door

Service brake pedal

Left side broom

Dust guard system nozzles

P200087

Page 17

Service Manual – SW4000

Serial number plate/technical data/

Machine Nomenclature (SW4000 Petrol/LPG) (Continues)

conformity certification

Filler plug

(SW4000 Petrol)

Hopper manual

returning handle

Rear hood with

vacuum system

Dust filter

container

Fuel tank

(SW4000 Petrol)

General Information

Drive pedal

Anchoring slots

for transport

(not for lifting)

17

Panel filter

with filter-shaker

Fuel opening/closing

valve (SW4000 Petrol)

Hopper

Right side cover

Right door

Main broom

Rear wheels

Anchoring slots for transport

(not for lifting)

P200088

Page 18

Service Manual – SW4000

Machine Nomenclature (SW4000 Petrol/LPG) (Continues)

Hopper hydraulic

lifting system control unit

Drive system electronic board

General Information

18

Open hood

safety rod

Engine

compartment

hood lifting

handle

Right side cover

Dynamotor

Engine

Batteries

Fuseholder box

Vacuum system

motor connector

Electrical

component

box

Choke lever

Engine serial number and model plate

LPG tank (SW4000 LPG)

LPG adjuster solenoid valve (SW4000 LPG)

LPG tank fastening band (SW4000 LPG)

Right side broom motor

circuit breaker

Left side broom motor

circuit breaker

Battery connection diagram

12V

12V

P200089

Page 19

Service Manual – SW4000

Switch for:

Vacuum

Control Panel (SW4000 Petrol/LPG)

General Information

19

Main broom

lifting/lowering

lever

Fuel reserve

warning light (yellow)

Display

Button:

• Working hours

• Battery voltage (V)

Main broom overpressure

warning light (red)

Drive system

malfunction warning

light (red)

system warning

light (green)

Dust guard

system warning

light (green)

Hopper lifting

system warning

light (yellow)

• Vacuum system activation (upper part)

• Filter shaker activation (lower part)

Filter shaker/vacuum system switch

Side broom

lifting/lowering lever

Horn switch

Hopper movement

enabling switch

Forward/reverse

gear switch

Dust guard

system switch

Emergency

push-button

Hopper lifting/lowering

switch

Working light

switch

Main broom height

adjusting knob

Ignition

key

P200090

Page 20

Service Manual – SW4000

General Information

Service and Diagnostic Equipment

Besides a complete set of standard meters, the following instruments are necessary to perform fast checks and

repairs on Nilsk-Advance machines:

Laptop computer charged with the current version of EzParts, Adobe Reader and (if possible) Internet con-

nection

• Digital Volt Meter (DVM)

• Amp clamp with possibility of making DC measurements

• Hydrometer

• Battery charge tester to check 12V batteries

• Static control wrist strap

• Dynamometric wrench set

• A copy of the User Manual and Spare Parts List of the machine to be serviced (provided with the machine

or available at www.advance-us.com or other Nilsk-Advance websites).

The following equipment is also available at Nilsk-Advance Centers:

• Italsea universal programmer, P/N 9097297000

20

P200091

Page 21

Service Manual – SW4000

General Information

Technical Data

Model SW4000 B SW4000 P SW4000 LP

Cleaning width with one side broom 38.3 in (975 mm)

with two side brooms 49.2 in (1,250 mm)

Main broom size (length x diameter) 27.6 x 13.4 in (700 x 340 mm)

Side broom diameter 17.7 in (450 mm)

Theoretical working capacity main broom 52,743 ft

with two side brooms 73,463 ft

with two side brooms 94,184 ft

Hopper capacity 19.8 US gal (75 liters)

maximum liftable weight 220 lb (100 kg)

maximum lifting height 62.6 in (1,590 mm)

Filter cleaning system Electrical lter shaker

area 75 ft

ltering capacity 4 µm

Power source 24 Volt batteries Power - 4,1 kW (5,5 CV) @ 3.600 giri/min

Engine model (*) - Honda GX-200

Tank capacity - 2 US gal

LPG Tank capacity - - 33 lb (15 Kg)

Main broom motor power 0.8 hp (600 W)

speed 550 rpm

Side broom motor power 0.12 hp (90 W)

speed 110 rpm

Vacuum motor power 0.35 hp (260 W)

Drive type Electric drive on front wheel

gearmotor power 1.35 hp (1,000 W)

forward speed 4.3 mi/h (7 km/h)

reverse speed 2.8 mi/h (4.5 km/h)

Maximum gradient when working 20 %

Hopper hydraulic control unit 0.33 hp (250 W)

Filter shaker motor 0.12 hp (90 W)

Total absorbed power 2.7 hp (2.0 kW)

Working autonomy 4,5 h 13 h 25 h

Dimensions

(length x width x height)

machine body 64.5 x 40.7 x 52.3 in (1,640 x 1,035 x 1,330 mm)

machine with side brooms 64.5 x 41.3 x 52.3 in (1,640 x 1,050 x 1,330 mm)

machine with ashing light 64.5 x 41.3 x 57.7 in (1,640 x 1,035 x 1,390 mm)

machine with FOPS protective roof (optional) 64.5 x 40.7 x 78.3 in (1,640 x 1,035 x 1,990 mm)

battery compartment 14.5 x 32 x 15.3

in (370x812x390

mm)

LPG tank maximum size (length x diameter) - - 28.3 x 11.8 in

2

/h (4,900 m2/h)

2

/h (6,825 m2/h)

2

/h (8,750 m2/h)

2

(7 m2)

(7,8 litres)

14.2 x 15 x 8.7 in

(360 x 380 x 220 mm)

-

(720 x 300 mm)

21

Page 22

Service Manual – SW4000

General Information

Technical Data (Continues)

Model SW4000 B SW4000 P SW4000 LP

Weight kerb weight without batteries 954 lb (433 Kg) - -

kerb weight - 1,126 lb (511 Kg) 1,135 lb (515 Kg)

total kerb weight (*) 1,816 lb (824 Kg) 1,309 lb (594 Kg) 1,371 lb (622 Kg)

front axle kerb weight (*) 696 lb (316 Kg) 553 lb (251 Kg) 560 lb (254 Kg)

rear axle kerb weight (*) 1,120 lb (508 Kg) 756 lb (343 Kg) 811 lb (368 Kg)

gross vehicle weight (GVW) 2,215 lb (1,005

Kg)

Wheel specic pressure on the oor (front - rear wheels, in running conditions) (**) 130 - 58 lbf/in

(0.9 - 0.4 N/mm2)

Sound pressure level at workstation (ISO 11201, ISO 4871, EN 60335-2-72) (LpA) 65 ±3 dB(A) 75 ±3 dB(A)

Machine sound pressure level (ISO 3744, ISO 4871, EN 60335-2-72) (LwA) 86 dB(A) 94 dB(A)

IP protection class X3

Dust guard system water tank (optional) capacity 5.3 US gal (20 liters)

U-turn space (right - left) 75.6 - 74.4 in (1,920 - 1,890 mm)

Vibration level at the operator’s arms (ISO 5349-1) < 98 in/s

Vibration level at the operator’s body (ISO 2631-1) < 19.6 in/s

(< 0.5 m/s2)

1,708 lb (775 Kg) 1,770 lb (803 Kg)

2

2

116 - 29 lbf/in

(0.8 - 0.2 N/mm2)

2

(< 2.5 m/s2)

< 35.4 in/s

(< 0.9 m/s2)

2

2

22

(*) With operator on board, without batteries and with hopper empty.

(**) Machines have been tested under the following conditions:

• With operator on board (165.3 lb - 75 kg)

• Battery of maximum size

• Brooms of maximum size

• Full Tanks

• Optional components installed

• Weight on wheels checked

• Print on the oor checked on cement for each single wheel

Result expressed as maximum value for both front and rear wheels

Machine material composition and recyclability

Type

Aluminium 100 % 0.0 % 0,0 % 0,0 %

Electric motors - various 29 % 10.8 % 21,1 % 21,1 %

Ferrous materials 100 % 53.5 % 48,3 % 48,8 %

Wiring harnesses 80 % 1.2 % 0,8 % 0,8 %

Liquids 100 % 0.4 % 0,5 % 0,5 %

Plastic - non-recyclable material 0 % 1.0 % 0,9 % 0,8 %

Plastic - recyclable material 100 % 9.8 % 8,6 % 8,4 %

Polyethylene 92 % 7.0 % 6,0 % 5,9 %

Rubber 20 % 4.1 % 3,5 % 3,5 %

Cardboard - paper - wood 100 % 12.2 % 10,3 % 10,2 %

Recyclable

percentage

SW4000 B

weight

percentage

SW4000 P

weight

percentage

SW4000 LP

weight

percentage

Page 23

Service Manual – SW4000

Technical Data (Continues)

Caution! If the machine is to be used at ambient temperatures below +10°C, the oil should be

changed with equivalent oil having a viscosity of 32 cSt. For temperatures below 0°C,

use an oil with lower viscosity.

Hydraulic oil technical data

AGIP ARNICA 46 32

Viscosity at 104 °F (40 °C) in

Viscosity at 212 °F (100 °C) in

Viscosity index / 150 157

Flash point COC °F (°C) 419 (215) 396 (202)

Pour point °F (°C) -32.8 (-36) -32.8 (-36)

Density at 15 °C (59 °F) lb/gal (kg/l) 1.9 (0.87) 1.9 (0.865)

2

/s (mm2/s) 0.07 (45) 0.05 (32)

2

/s (mm2/s) 0.012 (7.97) 0.009 (6.40)

General Information

23

Page 24

Service Manual – SW4000

Dimensions

General Information

24

1330 mm (52.4 in)

1065 mm (42 in)1640 mm (64.6 in)

P200092

Page 25

Service Manual – SW4000

General Information

Maintenance

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

Warning! Read carefully the instructions in the Safety chapter before performing any

maintenance procedure.

The following tables provides the scheduled maintenance. The intervals shown may vary according to particu-

lar working conditions, which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

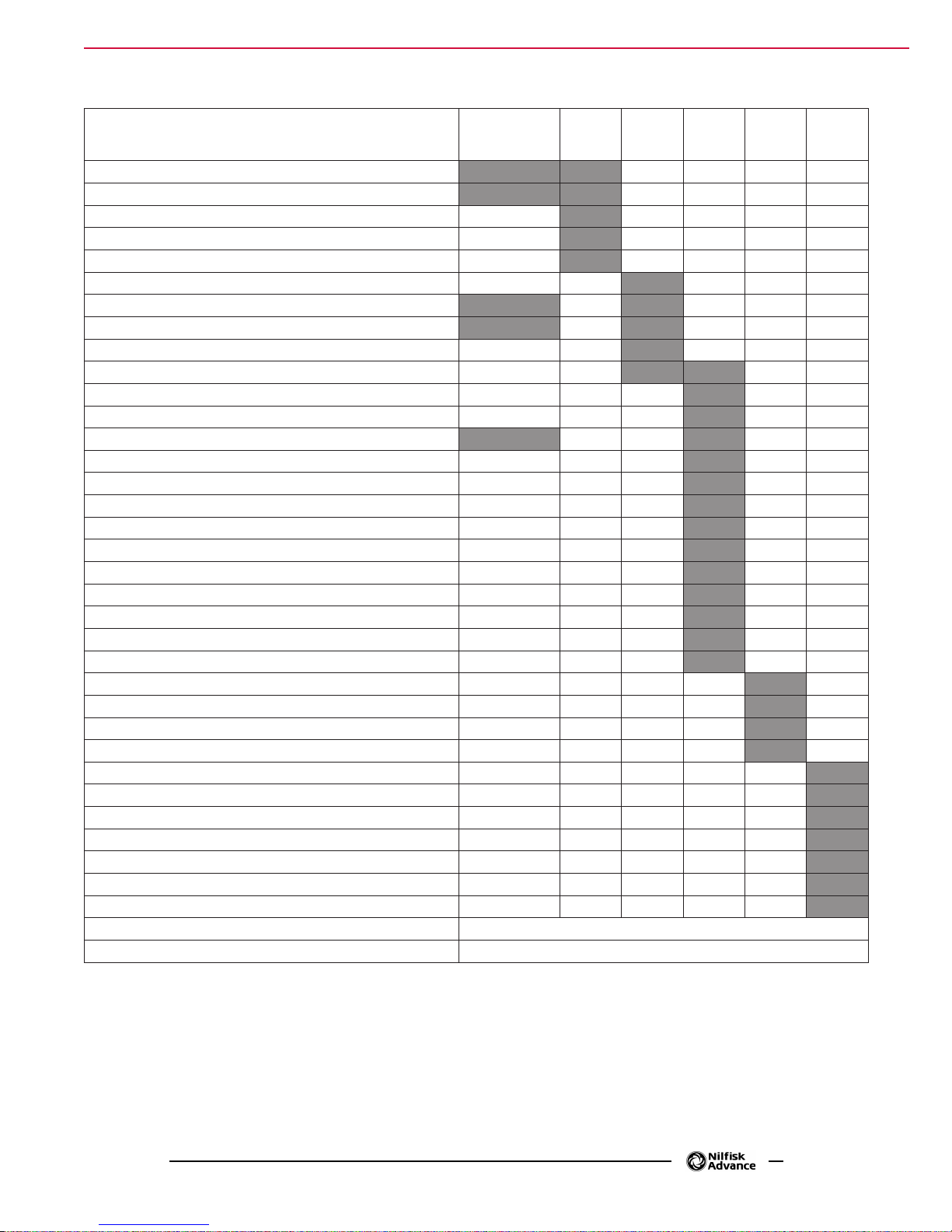

Scheduled Maintenance Table (SW4000 Battery)

Procedure

Battery charging (1)

Battery (WET) uid level check (2)

Side and main broom height check

Service brake cable adjustment (3)

Hopper dust lter check and cleaning (“A” method) (4)

Hopper hydraulic lifting system oil level check (2)

Skirt height and operation check

Dust guard system water lter check and cleaning

Hopper dust lter check and cleaning (“B” method) (4)

Filter shaker operation check

Main broom driving belt check

Brake adjustment

Nut and screw tightening check (5)

Steering chain cleaning

Safety system operation check (2)

Brake pad check/adjustment/replacement (3)

Hopper dust lter check and cleaning (“C” method) (4)

Main broom driving belt replacement

Hopper gasket integrity check

Lifted hopper sensor operation check/adjustment

Motor carbon brush check and replacement

Hydraulic system oil change (6)

Upon

delivery

Every

10

hours

Every

50

hours

Every

100

hours

Every

200

hours

Every

year

25

(1) Daily or after using the machine.

(2) Or before start-up.

(3) Or more frequently if the machine is used on slopes.

(4) Or more often in dusty areas.

(5) And after the rst 8 running-in hours.

(6) Change the hydraulic system oil for the rst time after 500 hours, then every 2,000 hours or every year.

Page 26

Service Manual – SW4000

General Information

Scheduled Maintenance Table (SW4000 Petrol/LPG)

Procedure

Engine oil level check (1)

Battery uid level check (2)

Side and main broom height check

Engine air lter check (1)

Service brake cable adjustment (3)

Hopper dust lter check and cleaning (“A” method) (4)

Hopper hydraulic lifting system oil level check (2)

Skirt height and operation check

Dust guard system water lter check and cleaning

Engine air lter cleaning (4) (4)

Hopper dust lter check and cleaning (“B” method) (4)

Filter shaker operation check

Main broom driving belt visual inspection

Brake replacement

Engine oil change (5) (6)

Spark plug check/cleaning

Nut and screw tightening check (6)

Steering chain cleaning (*)

Safety system operation check (2)

Engine lter trap cleaning

Engine bafe plate cleaning

Fuel lter cleaning (7)

Brake pad check/adjustment/replacement (3)

Hopper dust lter check and cleaning (“C” method) (4)

Main broom driving belt replacement

Hopper gasket integrity check

Lifted hopper sensor operation check/adjustment

Fuel valve lter cleaning (Petrol)

Engine paper air lter replacement

Spark plug replacement

Engine idle speed check/adjustment

Valve clearance check/adjustment (7)

Hydraulic system oil change (8)

Supply hose replacement (LPG)

Engine combustion chamber check Every 500 hours (7)

Fuel hose check/replacement (Petrol) Every 2 years (7)

Upon

delivery

Every

10

hours

Every

50

hours

Every

100

hours

Every

200

hours

26

Every

year

(1) Daily or after using the machine.

(2) Or before start-up.

(3) Or more frequently if the machine is used on slopes.

(4) Or more often in dusty areas.

(5) Or every 6 months.

(6) And after the rst 20 running-in hours.

(7) Maintenance procedures to be performed by an authorised Honda dealer.

(8) Change the hydraulic system oil for the rst time after 500 hours, then every 2,000 hours or every year.

Page 27

Service Manual – SW4000

4

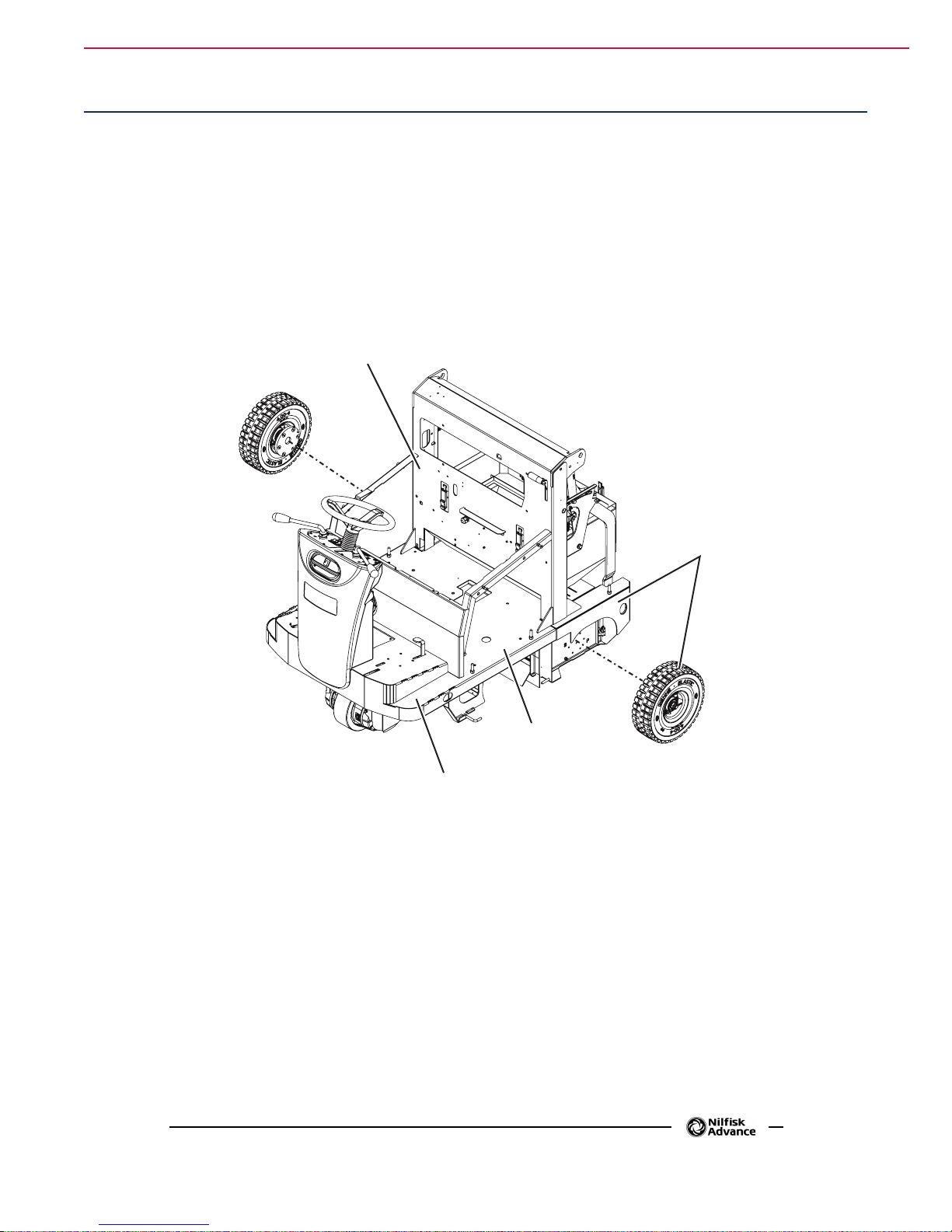

Chassis System

Chassis System

Chassis (main parts)

1. Front side supporting the steering assembly and side brooms.

2. Center side supporting batteries/engine with dynamotor and main broom.

3. Rear side supporting the hopper and rear wheels on hubs.

4. Central holder for separating wall between engine compartment/vacuum system compartment, and for

supporting the hopper lifting linkages.

27

3

2

1

P200093

Page 28

Control System 28Service Manual – SW4000

Control System

Functional Description

The machine is started by the ignition key (SW1), located on the steering column.

The key starts the machine when turned to II, thus powering the relay (K4). The relay (K4) stays on even when

the key returns to I. All the accessories (except the buzzer) are on only when the relay (K4) is on too.

Ahead of the ignition key (SW1) there is the emergency push-button (SW0). The key circuit is protected by the

relevant fuse (F4).

The machine different functions are mainly controlled by the switches located on the main dashboard (on the

steering column) and on the secondary dashboard (beside the driver’s seat) and by the 2 broom levers.

For functions not requiring an electronic management, the switches operate directly or by means of relays,

on the relevant drives. For functions requiring timers or electronic controls, the commands generated when

operating the switches are read by the dashboard electronic board (EB2) which drives the outputs directly or

by means of external relays.

The electric drive system control is made by the forward/reverse gear switch (SW2) and the gear pedal (R1)

which provide signals to the drive system electronic board (EB1).

For all the details concerning the described functions, see the relevant chapters.

Page 29

Control System 29Service Manual – SW4000

DashboardElectronicBoardSpecications

The dashboard electronic board performs the following:

a. HOUR COUNTER: By default, the 3-digit display (A) shows the number of hours stored in the hour

counter. The hour counter proceeds with counting, only when the main broom turns. When the hour

counter reaches 999, the next numbers are shown by the 3 more meaningful digits by adding a (low)

dot for separating thousands (i.e.: 1234 will be shown as 1.23).

b. BATTERY VOLTAGE DISPLAY: by pressing the push-button (B) (with the machine running)

the display will switch from the 3-digit hour counter (A) to the battery voltage. The display will

automatically return to the hour counter 5” after the last pressing of the push-button (B).

c. MAIN BROOM MOTOR PROTECTION: By reading the voltage drop on main broom fuse (FA), the

main broom motor amperage (M4) is monitored. If the voltage drop is higher than 40mV, the warning

light (C) starts ashing. If this condition persists, after a time inversely proportional to the value of

voltage drop detected, the broom motor is stopped (the warning light continues to ash). To reset,

turn the ignition key on and off (SW1).

A

B

C

P200219

Page 30

Control System 30Service Manual – SW4000

EF

d. BATTERY PROTECTION: Battery charge status is shown by the 3 LEDs depending on the type of

battery (WET/GEL) according to the following diagram:

WET GEL

1 Green LED on (xed) V>22.0 V>22.2

2 Yellow LED on (xed) 22.0>V>20.4 22.2>V>21.6

3 Red LED ashing V>20.4 V>21.6

When the red LED starts ashing, broom function is automatically deactivated.

e. BATTERY TYPE DISPLAY (WET/GEL): Each time the machine is turned on with the ignition

key, the 3 battery charge LED indicators show the battery type as follows:

Battery Type Flashing pattern

WET 4 ashes of the RED warning light

GEL 4 ashes of the GREEN warning light

f. PROCEDURE FOR BATTERY SETTING (WET/GEL): Hold the push-button (B) down while

you turn the key on and hold it for 5 sec. The 3 LEDs will then show again the current setting with

the continuous ashing of the corresponding LED (see the previous step), while further pressing

the push-button (B) will change the current setting. The last setting will be stored when (B) is not

pressed for more than 5 sec.

g. TIMED FUNCTION ACTIVATION: BROOM, VACUUM and FILTER SHAKER are turned on and

off by pressing the relevant controls and according to the conditions of the relevant sensors as shown

in their respective chapters

OTHER INDICATIONS WITH DEDICATED WARNING LIGHTS: fuel reserve warning light

(D), vacuum system warning light (E), dust guard system warning light (F), hopper lifting warning

light (G), main broom overpressure warning light (C), drive system diagnostic warning light (I).

G

D

B

C

I

P200220

Page 31

Wiring Diagram (SW4000 Battery)

Control System 31Service Manual – SW4000

HOPPER

TEMPERATURE

REVERSE GEAR

BUZZER (BZ1)

FILTER SHAKER/

VACUUM SYSTEM

SWITCH (SW3)

HORN SWITCH (SW6)

SENSOR (S4)

HORN (HN)

VACUUM SYSTEM

FILTER SHAKER

RELAY (K1)

DISPLAY

ELECTRONIC

BOARD FUSE (F3)

J1.1 - Electronic board power supply +

J1.14 - Electronic board congurator return

J1.13 - Key return

J1.11 - Vacuum system relay power supply

J1.12 - Filter-shaker relay power supply

J2.4 - Control panel switch power supply (-)

J1.15 - Fire alarm signal

J2.2 - Vacuum system activation signal

CONTROL PANEL ELECTRONIC BOARD (EB2)

J1.17 - Water pump activation signal

J2.3 - Filter-shaker activation signal

J2.1 - Control panel switch power supply (+)

J1.4 - Broom fuse voltage drop reading +

J1.5 - Broom fuse voltage drop reading -

J1.2 - Broom activation lever signal

J1.10 - Broom electromagnetic switch power supply

J1.8 - Lifted hopper signal

J1.7 - Drive system electronic board diagnostic signal

J1.18 - Machine moving signal

J1.9 - Electronic board power supply -

POSITIVE SIGNAL

(FROM MACHINE ON “K4”)

BATTERY NEGATIVE TERMINAL

RELAY (K2)

HOPPER LIFTING

SENSOR (S1)

HOPPER LOWERING

RELAY (K3B)

MAIN BROOM

LEVER SENSOR (S2)

A

HOPPER LIFTING

RELAY (K3A)

HOPPER ENABLING

SWITCH (SW4)

HOPPER LIFTING/LOWERING

SWITCH (SW5)

DUSTGUARD™

SWITCH (SW8)

DUSTGUARD™

PUMP RELAY (K6)

SIDE BROOM

LEVER SENSOR (S3)

SIDE BROOM

RELAY (K5)

MAIN BROOM

ELECTROMAGNETIC

SWITCH (ES1)

B

C

D

E

P200094A

Page 32

Wiring Diagram (SW4000 Battery)

Control System 32Service Manual – SW4000

POSITIVE SIGNAL

(FROM MACHINE ON “K4”)

BATTERY NEGATIVE TERMINAL

A

LINE ELECTROMAGNETIC

SWITCH (ES0)

KEY CIRCUIT FUSE (F4)

IGNITION KEY (SW1)

MACHINE ON

RELAY (K4)

EMERGENCY

PUSH-BUTTON (SW0)

B

C

D

E

DRIVE SYSTEM

ELECTRONIC BOARD (EB1)

J2.15 - Key input

J2.11 - Lifted hopper input

J2.10 - Diagnostic warning light output

J2.7 - Machine moving signal

WORKING

LIGHT SWITCH

(SW9)

WORKING

LIGHT (L1)

WORKING

LIGHT (L2)

MACHINE ON

RELAY (K4)

P200094B

Page 33

Wiring Diagram (SW4000 Petrol/LPG)

Control System 33Service Manual – SW4000

FUEL RESERVE

SENSOR (S4)

REVERSE GEAR

BUZZER (BZ1)

FILTER SHAKER/

VACUUM SYSTEM

SWITCH (SW3)

HORN SWITCH (SW6)

HORN (HN)

DISPLAY ELECTRONIC

BOARD FUSE (F3)

J1.14 - Electronic board congurator return

J1.13 - Key return

J1.6 - Fuel reserve signal

J1.15 - Fire alarm signal

J2.2 - Vacuum system activation signal

CONTROL PANEL ELECTRONIC BOARD (EB2)

J2.3 - Filter-shaker activation signal

J2.1 - Control panel switch power supply (+)

J1.4 - Broom fuse voltage drop reading +

J1.5 - Broom fuse voltage drop reading -

VACUUM SYSTEM

RELAY (K1)

J1.1 - Electronic board power supply +

J1.11 - Vacuum system relay power supply

J1.12 - Filter-shaker relay power supply

J2.4 - Control panel switch power supply (-)

J1.17 - Water pump activation signal

J1.2 - Broom activation lever signal

J1.10 - Broom electromagnetic switch power supply

J1.8 - Lifted hopper signal

J1.7 - Drive system electronic board diagnostic signal

J1.18 - Machine moving signal

J1.9 - Electronic board power supply -

POSITIVE SIGNAL

(FROM MACHINE ON “K4”)

BATTERY NEGATIVE TERMINAL

FILTER SHAKER

RELAY (K2)

MAIN BROOM

LEVER SENSOR (S2)

HOPPER LIFTING

SENSOR (S1)

HOPPER LOWERING

RELAY (K3B)

HOPPER LIFTING

RELAY (K3A)

HOPPER ENABLING

SWITCH (SW4)

HOPPER LIFTING/LOWERING

SWITCH (SW5)

DUSTGUARD™

SWITCH (SW8)

DUSTGUARD™

PUMP RELAY (K6)

SIDE BROOM LEVER

SENSOR (S3)

SIDE BROOM

RELAY (K5)

MAIN BROOM

ELECTROMAGNETIC

SWITCH (ES1)

A

B

C

D

E

P200095A

Page 34

Wiring Diagram (SW4000 Petrol/LPG)

Control System 34Service Manual – SW4000

POSITIVE SIGNAL

(FROM MACHINE ON “K4”)

BATTERY NEGATIVE TERMINAL

A

LINE

ELECTROMAGNETIC

SWITCH (ES0)

KEY CIRCUIT FUSE (F4)

EMERGENCY PUSH-BUTTON (SW0)

IGNITION

KEY (SW1)

ENGINE SPARK

PLUG (SPK)

FRAME (FR)

DRIVE SYSTEM ELECTRONIC

BOARD (EB1)

WORKING LIGHT

SWITCH (SW9)

J2.15 - Key input

WORKING

LIGHT (L1)

WORKING

B

C

D

E

J2.11 - Lifted hopper input

J2.10 - Diagnostic warning light output

J2.7 - Machine moving signal

LIGHT (L2)

LPG SAFETY TIMER

RELAY (KT1)

LPG SAFETY

SOLENOID VALVE (EV1)

Only for LPG version

MACHINE ON

RELAY (K4)

DIODE

(D3)

ENGINE START

ELECTROMAGNETIC

SWITCH (ES2)

P200095B

Page 35

Component Locations

• Dashboard

• Dashboard electronic board (EB2)

• Ignition key (SW1)

Dashboard

electronic

board (EB2)

Control System 35Service Manual – SW4000

Dashboard

Ignition key

(SW1)

P200096

Page 36

Troubleshooting

Trouble Possible Cause Remedy

(For SW4000 Battery)

When turning the ignition key to “II”, the

display does not turn on and the machine

does not operate.

(For SW4000 Petrol/LPG)

“L O U” (A) (Low Voltage) display indication

(For SW4000 Petrol/LPG)

“H I U” (A) (High Voltage) ashing display

indication

Control System 36Service Manual – SW4000

The battery connector is disconnected. Connect the battery connector.

The fuse (F3) and/or (F0) is open. Check/replace the fuses.

The emergency push-button has been

pressed.

Battery voltage lower than 24.0 V.

Battery voltage higher than 32.4V.

Check and release the emergency pushbutton.

Decrease the main broom pressure on the

oor.

“L O U” (A) (Low Voltage) display indication

If the problem persists, it may be necessary

to calibrate the engine rpm (see Petrol

Engine – LPG Engine chapter).

Turn off the engine each time the machine is

stopped.

If the problem persists, it may be necessary

to calibrate the engine rpm (see Petrol

Engine chapter).

A

P200247

Page 37

Control System 37Service Manual – SW4000

Dashboard Electronic Error Codes

The drive system warning light (A) on the dashboard electronic board (EB2) shows the error codes of the drive

system electronic board (EB1). For the details, see the Wheel System, Drive chapter.

A

P200097

Page 38

Connectors on the dashboard electronic board

J1: MOLEX MINIFIT type, 18-ways vertical (A)

101112131415161718

123456789

Control System 38Service Manual – SW4000

A

P200221

PIN Description Electronic

board in/out

1 Electronic board power supply + in 24V 3A F10

2 Broom activation lever signal in 24V (when the description is ON) <1A S2

3 Engine on signal in 24V (when the description is ON) <1A K4.30

4* Broom fuse voltage drop reading + in 0V (when the description is OFF) <1A FA +

5* Broom fuse voltage drop reading - in 0V (when the description is OFF) <1A FA-

6 Fuel reserve signal in 0V (when the description is OFF) <1A S5

7 Drive system electronic board diagnostic signal in (24V) <1A EB1.J2.10

8 Lifted hopper signal in 24V (when the description is ON) <1A S1

9 Electronic board power supply - in 0V (when the description is OFF) 3A -B

10 Broom electromagnetic switch power supply out 0V (when the description is OFF) 1A ES1, K5

11 Vacuum system relay power supply out 0V (when the description is OFF) 1A K1.85

12 Filter shaker relay power supply out 0V (when the description is OFF) 1A K2.85

13 Return from key in 24V (when the description is ON) <1A K4.30/SW1

14** Electronic board congurator return (Battery) in 24V (when the description is ON) <1A K4.30

15 Fire alarm signal in 0V (when the description is OFF) <1A S4

16 Hopper lifting control out 0V (when the description is OFF) 1A K3A.85

V ref. I max. Connected to

17 Water pump activation signal in 24V (when the description is ON) <1A SW8.2

18 Machine moving signal in 0V (when the description is OFF) <1A EB1.7

Page 39

Control System 39Service Manual – SW4000

CBA

J1: MOLEX MINIFIT type, 18-ways vertical (A) (continues)

Further notes about dashboard electronic board (PIN - J1.14)

The dashboard electronic board (EB2) recognises if it has been assembled on a Battery or Petrol/LPG machine

version depending on the PIN J1.14 status:

• PIN J1.14 - connected to +24V = Battery version,

• PIN J1.14 - NOT connected = Petrol/LPG version .

Battery version (PIN - J1.14 at +24V)

SAFETY BATTERY FUNCTION: The battery loading status is displayed by means of 3 LEDs

(A) Green, (B) Yellow, (C) Red, up to the battery type installed (WET/GEL) as shown below:

Threshold values Threshold values of change

1 LED (A) Green xed <=> LED (B) Yellow xed 22,0 22,2

2 LED (B) Yellow xed <=> LED (C) Red ashing 1Hz 20,4 21,6

status (V, toll.±0,1)

WET GEL

The change status is ltered with a 3 sec. delay as regards to the battery tension reading.

When threshold value 2 is reached, the J1.10 output is automaticaly shutted off with 5 sec. delay.

Without any regards to the battery tension reading value the change values status 2 is xed. The only way to

reset the status is the machine switching off by using the ignition key (SW1).

P200247b

Page 40

Control System 40Service Manual – SW4000

J1: MOLEX MINIFIT type, 18-ways vertical (A) (continues)

Petrol/LPG version (PIN - J1.14 not connected)

The RPM value of the Petrol/LPG engine is xed to 2.750 rpm ± 50 rpm

The xed RPM value of the Petrol/LPG engine should be in any case as follows

• with the loaded batteries, engine On, all functions Off => the battery tension is between 27,0V and

31,0V

• with the loaded batteries, engine On, all functions On => the battery tension is higher than 24,0V

The dashboard electronic board (EB2) displays 2 alarms, shown by the display (A) and the LED (B) ashed, if

are not matched for more than 5 consecutive minutes the following conditions:

Shown on display Battery conditions Solution Alternative actions in case the

L O U V < 24,0V (Low Voltage) Avoid using the machine for long

H I U V > 32,4V (High

Voltage)

periods at maximum power or on

slopes: leave the engine running with

all features turned off for at least ten

minutes after each usage.

Turn the engine off when you are not

working: do not leave the machine

for long periods without using any

functions.

solution does not solve the problem

Recharge the battery with a suitable

charger and then adjust the engine RPM

(increase the engine RPM till reach

again the recommended tension ranges).

Adjust the RPM engine (reduce the

engine RPM till reach again the

recommended tension ranges).

AB AB

P200247a

Page 41

J2: MOLEX MINIFIT type, 4-ways vertical (B)

B

34

12

Control System 41Service Manual – SW4000

P200098

PIN Description Electronic

board in/out

1 Dashboard switch power supply (+) out 24V <1A SW3, SW8

2 Vacuum system activation signal in 24V (when the description is ON) <1A SW3.1

3 Filter-shaker activation signal in 24V (when the description is ON) <1A SW3.3

4 Dashboard switch power supply (-) out 0V <1A SW4

V ref. I max. Connected to

Page 42

Removal and Installation

Dashboard Electronic Board Disassembly/Assembly

Control System 42Service Manual – SW4000

Disassembly

1. Drive the machine on a level oor.

2. Turn the ignition key to “0” and engage the

parking brake.

3. Open the battery/engine compartment hood.

Disconnect the battery connector (SW4000

Battery) - Disconnect the batteries (SW4000

Petrol/LPG).

4. Remove the fastening screws (A) of the fairing

(B) from the steering column.

5. Slightly lift the steering column (B) by

disengaging it from the lower fastener (C).

6. Disconnect the dust guard system quick coupling

(D).

A

A

A

7. Retrieve the fairing (B).

8. Under the left side of the control panel,

disconnect the connectors (E) of the dashboard

electronic board (F).

9. Disengage the four nuts (G) and remove the

dashboard electronic board (F).

Assembly

10. Assemble the components in the reverse order of

disassembly, and note the following:

• Set the type of batteries installed on the ma-

chine (see Electrical System chapter).

B

C

B

A

G

E

F

G

D

P200101

Page 43

Dust Control System 43Service Manual – SW4000

Dust Control System

Functional Description

The dust raised in the compartment of the main broom, is collected in the rear cargo area by a ow of air generated by the dust control system.

The lter located between the vacuum system and the hopper, retains dirt which is then conveyed through a

feedbox into the hopper itself.

The operation of the system depends on the activation of the main broom.

By deactivating the main broom, the dust control system turns off automatically.

There is a vacuum system motor (M1) which is powered by the relay (K1) and protected by the fuse (F1).

The relay (K1) is directly controlled by the dashboard electronic board (EB2) according to the information re-

ceived by the vacuum system/lter shaker switch (SW3), by the sensor on the broom activation lever (S2), by

the machine moving signal received by the drive system electronic board(EB1) and by the lifted hopper sensor

(S1).

Normally the vacuum function is turned on when the main broom is lowered with the lever; it can, however,

be turned on or off independently with the push-button SW3, it turns off when the machine is stopped, when

the hopper is lifted and during activation the electric lter shaker.

There is an electric lter shaker motor (M2) which is powered by the relay (K2) and protected by the fuse (F2).

The relay (K2) is directly controlled by the dashboard electronic board (EB2) according to the information re-

ceived by the vacuum system/lter shaker switch (SW3): When the button is activated for a cycle of 20 seconds

during which it is driven 0.5 sec ON and 0.5 sec. OFF for continuously modulating the number of revolutions

and the resulting vibration frequencies of the lter.

The vibrating motor shakes the lter allowing dirt trapped in the folds of the same to fall by gravity into the

hopper.

This reduces lter maintenance and helps to maintain proper airow through the lter.

Wiring Diagram

VACUUM

SYSTEM FUSE (F1)

FILTER SHAKER

FUSE (F2)

FILTER SHAKER/VACUUM

SYSTEM SWITCH (SW3)

FILTER SHAKER RELAY (K2)

VACUUM SYSTEM RELAY (K1)

M2M1

FILTER SHAKER MOTOR

VACUUM SYSTEM MOTOR

DISPLAY ELECTRONIC

BOARD FUSE (F3)

J2.2 - Vacuum system activation signal

CONTROL PANEL ELECTRONIC

BOARD (EB2)

J2.3 - Filter-shaker activation signal

J2.1 - Control panel switch power supply (+)

VACUUM

SYSTEM RELAY (K1)

J1.1 - Electronic board power supply +

J1.11 - Vacuum system relay power supply

J1.12 - Filter-shaker relay power supply

J1.2 - Broom activation lever signal

J1.8 - Lifted hopper signal

J1.9 - Electronic board power supply -

J1.18 - Machine moving signal

FILTER SHAKER RELAY (K2)

MAIN BROOM

LEVER SENSOR (S2)

HOPPER LIFTING

SENSOR (S1)

POSITIVE SIGNAL

(FROM MACHINE ON “K4”)

BATTERY NEGATIVE TERMINAL

DRIVE SYSTEM

ELECTRONIC BOARD (EB1)

J2.11 - Lifted hopper input

J2.7 - Machine moving signal

P200102

Page 44

Component Locations

• Filter shaker/vacuum system switch (SW3)

• Vacuum system motor (M1)

• Gasket

• Filter shaker motor (M2)

Dust Control System 44Service Manual – SW4000

• Panel lter

• Vacuum system motor fuse (25 A - Battery) (30 A

Petrol/LPG) (F1)

• Filter shaker motor fuse (25 A - Battery) (30 A

Petrol/LPG) (F2)

Filter

shaker/vacuum

system switch (SW3)

Gasket

Filter shaker

motor (M2)

Filter shaker

motor fuse

(25 A - Battery)

(30 A Petrol/LPG) (F2)

Vacuum system

motor (M1)

Panellter

Vacuum system

motor fuse

(25 A - Battery)

(30 A Petrol/LPG) (F1)

P200103

Page 45

Dust Control System 45Service Manual – SW4000

CBB

Maintenance and Adjustments

Panel Dust Filter Cleaning and Integrity Check

Caution! Thedustltermustberegularlycleanedtomaintaintheefciencyofthevacuum

system.Followtherecommendedlterserviceintervalsforthelongestlterlife.

Warning! -Wearsafetyglasseswhencleaningthelter.

-Donotpuncturethelter.

-Cleanthelterinawell-ventilatedarea.

- Wear appropriate dust mask to avoid breathing in dust.

1. Drive the machine on a level oor, engage the parking brake and turn the ignition key to “0”.

2. Open the battery/engine compartment hood with the handle and fasten it with the support rod.

3. Disconnect the battery connector (SW4000 Battery) - Disconnect the batteries (SW4000 Petrol/LPG).

4. Disconnect the vacuum system motor connector (A).

5. Disengage the retainers (B) and remove the vacuum system hood (C).

B

B

A

P200223

Page 46

G

Panel Dust Filter Cleaning and Integrity Check (Continues)

Dust Control System 46Service Manual – SW4000

6. (Only for LPG SW4000). Disconnect the lter

shaker connector (K).

7. Loosen the knobs (D) and (E), then remove the

lter shaker assembly (F), by sliding it forward,

disengaging it by the knobs (D) and then by the

knobs (E).

8. (Only for SW4000 Battery and Petrol). Fasten

the lter shaker assembly (F) to the holder (G).

9. (Only for LPG SW4000). Remove the lter

shaker assembly (F).

10. Lift the dust lter (H) and remove it from the

machine.

11. Clean the dust lter using one of the methods

below:

Method “A”

Vacuum loose dust from the lter. Gently tap the lter against a at surface (with the dirty side down) to

remove dust and dirt.

Caution! Take care not to damage the

metallipwhichextendspast

the gasket.

12. Assemble the dust lter in the reverse order of

disassembly and note the following:

• Clean the lter housing.

• If the lter gasket is damaged or missing, it

must be replaced.

• Install the lter with the strainer facing up-

wards (arrow (I) upwards).

E

F

K

E

Method “B”

Vacuum loose dust from the lter. Blow compressed

air (maximum pressure 6 Bar) into the clean side of

the lter (in the opposite direction of the airow).

Method “C”

Vacuum loose dust from the lter. Then soak the lter

in warm water for 15 minutes, then rinse it under a

gentle stream of water (maximum pressure 2.5 Bar).

Let the lter dry completely before installing it back

into the machine.

For a better cleaning, it is allowed to wash the lter

with water and non-lathering detergents.

This provides better quality cleaning but reduces the

life of the lter, which will have to be replaced more

frequently. The use of inadequate detergents can

damage the lter.

Caution! Forpaperlter:Donotuse

water or detergents to clean it,

otherwise it can be damaged.

DHID

P200104

Page 47

Troubleshooting

Trouble Possible causes Remedy

Dust Control System 47Service Manual – SW4000

Dust/debris vacuuming is insufcient The lter is clogged Clean the dust lter by using the lter shaker

The vacuum system compartment gasket is

damaged

No vacuuming The fuse (F1) is open. Replace the fuse.

The switch (SW3) is not efcient Replace

The relay (K1) is not efcient Replace

The vacuum system is broken Repair/replace

The lter shaker does not operate. The fuse (F2) is open. Replace the fuse.

The lter shaker is disconnected. Connect the lter shaker connector.

The switch (SW3) is not efcient Replace

The relay (K2) is not efcient Replace

The lter shaker is broken Repair/replace

or by disassembling it.

Repair/replace

Page 48

Dust Control System 48Service Manual – SW4000

Removal and Installation

Filter Shaker Motor Disassembly/Assembly

Disassembly

1. Drive the machine on a level oor, engage the parking brake and turn the ignition key to “0”.

2. Open the battery/engine compartment hood with the handle and fasten it with the support rod.

3. Disconnect the battery connector (SW4000 Battery) - Disconnect the batteries (SW4000 Petrol/LPG).

4. Disconnect the vacuum system motor connector (A).

5. Disengage the retainers (B) and remove the vacuum system hood (C).

A

P200105

Page 49

Dust Control System 49Service Manual – SW4000

CBB

Filter Shaker Motor Disassembly/Assembly (Continues)

6. Release the fastening clamp and disconnect the lter shaker connector (K).

7. Loosen the knobs (D) and (E), then remove the lter shaker assembly (F), by sliding it forward,

disengaging it by the knobs (D) and then by the knobs (E).

8. At the workbench, remove the nuts (G) and remove the fastening clamps (H) of the lter shaker motor

(I). Retrieve the washers (J).

9. Remove the lter shaker motor (H), by disengaging the dowel (L) from its seat.

Assembly

10. Assemble the components in the reverse order of disassembly.

B

B

I

L

E

H

F

K

E

DD

J

G

P200106

Page 50

Dust Control System 50Service Manual – SW4000

Electric Vacuum Fan Motor Amperage Check

Warning! Thisproceduremustbeperformedbyqualiedpersonnelonly.

1. Clean the dust lter.

2. Open the battery/engine compartment hood with the handle and fasten it with the support rod.

3. Apply the amp clamps (A) on one cable (B) of the electric vacuum fan (C).

4. Turn the ignition key to “I”.

5. With the help of an assistant, carefully press on the driver’s seat to activate the microswitch, then turn

on the vacuum system and check that the electric fan motor amperage is within 7 and 9 A at 24 V.

Stop the vacuum system.

Turn the ignition key to “0”.

Remove the amp clamps (A).

If the amperage is higher, perform the following procedures to detect and correct it:

• Check that the F1 fuse is properly tightened

• Remove the electric fan motor (see the procedure in the next paragraph), and check the condition of

all its components.