Page 1

1/00 revised 7/02 Form Number 56043056

ConvertaMAX™ 20/26

BA 550/650

SERVICE MANUAL

Advance MODELS 56397010, 56397011

56397580, 56397581

Nilfisk MODELS 56397012, 56397013

56397582, 56397583

Page 2

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 1

GENERAL INFORMATION ..................................................................................................................................................2

SAFETY INSTRUCTIONS....................................................................................................................................................3

SPECIFICATIONS & MAINTENANCE ............................................................................................................................. 4-6

PM CHECKLIST .................................................................................................................................................................7

KNOW YOUR MACHINE ............................................................................................................................................... 9-13

SOLUTION SYSTEM ................................................................................................................................................... 14-19

FUNCTIONAL OVERVIEW ..............................................................................................................................................14

SOLUTION SYSTEM TROUBLESHOOTING ............................................................................................................ 15-17

SOLUTION SOLENOID VALVE AND STRAINER REMOVAL.........................................................................................18

SOLUTION SOLENOID VALVE DISASSEMBLY AND CLEANING.................................................................................19

SOLUTION FLOW CONTROL VALVE REMOVAL ..........................................................................................................19

SCRUB BRUSH SYSTEM............................................................................................................................................ 20-27

FUNCTIONAL OVERVIEW ..............................................................................................................................................20

TROUBLESHOOTING GUIDE ................................................................................................................................... 21-24

SCRUB BRUSH DECK REMOVAL 20/550 ......................................................................................................................25

SCRUB BRUSH MOTOR/GEARBOX REMOVAL 20/550................................................................................................25

SCRUB BRUSH DECK REMOVAL 26/650 ................................................................................................................ 26-27

SCRUB BRUSH MOTOR/GEARBOX REMOVAL 26/650................................................................................................26

SCRUB BRUSH HEAD SWITCH ADJUSTMENT (machines built before March 2001) ..................................................28

SCRUB BRUSH HEAD SWITCH ADJUSTMENT (machines built after February 2001) .................................................29

RECOVERY SYSTEM.................................................................................................................................................. 30-35

FUNCTIONAL OVERVIEW ..............................................................................................................................................30

VACUUM/RECOVERY SYSTEM MAINTENANCE CHECKLIST.....................................................................................31

TROUBLESHOOTING GUIDE ................................................................................................................................... 31-33

MAINTENANCE OF FLOAT CAGE AND FLOAT DUCT .................................................................................................34

VACUUM MOTOR REMOVAL .........................................................................................................................................35

RECOVERY TANK REMOVAL ........................................................................................................................................35

VACUUM SWITCH REPLACEMENT AND ADJUSTMENT .............................................................................................35

SQUEEGEE SYSTEM.................................................................................................................................................. 36-37

SQUEEGEE TOOL BLADE REPLACEMENT ..................................................................................................................36

SQUEEGEE TOOL ANGLE ADJUSTMENT ....................................................................................................................36

WHEEL DRIVE SYSTEM ............................................................................................................................................. 38-45

FUNCTIONAL OVERVIEW ..............................................................................................................................................38

TROUBLESHOOTING GUIDE ................................................................................................................................... 39-41

CHAIN MAINTENANCE ...................................................................................................................................................42

CHAIN REMOVAL AND ADJUSTMENT ..........................................................................................................................42

WHEEL DRIVE MOTOR REMOVAL ................................................................................................................................42

DRIVE WHEEL REMOVAL ..............................................................................................................................................42

POTENTIOMETER (5K) TESTING AND REMOVAL (for machines built before December 1, 2000)..............................44

POTENTIOMETER INSTALLATION AND ADJUSTMENT (machines before December 1, 2000)..................................45

POTENTIOMETER (5K) TESTING AND REMOVAL (for machines built after December 1, 2000).................................46

POTENTIOMETER INSTALLATION AND ADJUSTMENT (machines after December 1, 2000)............................... 46-47

POTENTIOMETER (25K) TESTING ................................................................................................................................47

ELECTRICAL SYSTEM................................................................................................................................................ 48-53

BATTERIES / CHARGERS SPECIFICATIONS ...............................................................................................................48

INSTALL THE BATTERIES ..............................................................................................................................................48

DESCRIPTION OF THE BATTERY LOW VOLTAGE CUTOUT FEATURE .................................................................... 49

CHARGING BATTERIES .................................................................................................................................................50

BATTERY MAINTENANCE AND BATTERY TESTING ...................................................................................................50

ELECTRICAL COMPONENT LOCATION........................................................................................................................51

WIRING SCHEMATIC ......................................................................................................................................................52

WIRING DIAGRAM .......................................................................................................................................................... 53

Note: All references to right, left, front, or rear in this manual are as seen from the operator’s stand-point.

TABLE OF CONTENTS

revised 7/02

Page 3

2 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

INTRODUCTION

This manual will help you get the most from your ConvertaMAX™ 20/26 / BA 550/650. Read it thoroughly before servicing the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 9-10.

This product is intended for commercial use only.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfisk-Advance Service Center, who employs factory trained service personnel,

and maintains an inventory of Nilfisk-Advance original replacement parts and accessories.

Call the NILFISK-ADVANCE DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing

your machine.

(Dealer, affix service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering

repair parts for the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER

SERIAL NUMBER

TRANSPORTING THE MACHINE

CAUTION!

Before transporting the machine on an open truck or trailer, make sure that . . .

• The machine is tied down securely - see tie-down locations (26).

• All access doors and covers are secured (tape and strap as needed).

TOWING

CAUTION!

If the machine must be towed or pushed, make sure the Key Switch (Main Power) (18) is in the OFF position, disconnect wheel drive

motor wiring harness and do not move the machine faster than a normal walking pace (2-3 mph, 3-5kph) and for short distances only.

OTHER MANUALS AVAILABLE FOR YOUR MACHINE

The following manuals are available from the Nilfisk-Advance Literature Service Department (order according to model name, model number and machine’s serial

number):

• A Parts List and Operation Manual are available for each machine.

• The three Operation Manuals available for the BA 550/650 are multi-language: (Danish, Norwegian, Swedish, Finnish), (English, German, French,

Netherlands) or (Spanish, Portuguese, Italian, Greek)

GENERAL INFORMATION

revised 7/02

Page 4

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 3

SYMBOLS

Nilfisk-Advance uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take

the necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

GENERAL SAFETY INSTRUCTIONS

Specific Cautions and Warnings are included to warn you of potential exposure to machine damage or bodily harm.

WARNING!

• This machine should only be used by properly trained and authorized persons.

• Keep sparks, flame and smoking materials away from batteries. Explosive gases are vented during normal operation.

• Charging the batteries produces highly explosive hydrogen gas. Charge batteries only in well-ventilated areas, away from open

flame. Do not smoke while charging the batteries.

• Remove all jewelry when working near electrical components.

• Turn the key switch off (O) and disconnect the batteries before servicing electrical components.

• Never work under a machine without safety blocks or stands to support the machine.

• Do not dispense flammable cleaning agents, operate the machine on or near these agents, or operate in areas where flammable

liquids exist.

• Do not clean this machine with a pressure washer.

• Do not operate this machine on ramps or inclines of more than a 2 percent gradient.

CAUTION!

• This machine is not approved for use on public paths or roads.

• This machine is not suitable for picking up hazardous dust.

• Use care when using scarifier discs and grinding stones. Advance will not be held responsible for any damage to floor surfaces

caused by scarifiers or grinding stones.

• When operating this machine, ensure that third parties, particularly children, are not endangered.

• Before performing any service function, carefully read all instructions pertaining to that function.

• Do not leave the machine unattended without first turning the key switch off (O), removing the key and securing the machine.

• Turn the key switch off (O) before changing the brush(es), and before opening any access panels.

• Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

• Use caution when moving this machine in below freezing temperature conditions. Any water in the solution or recovery tanks

or in the hose lines could freeze.

SAVE THESE INSTRUCTIONS

CAUTIONS AND WARNINGS

Page 5

4 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

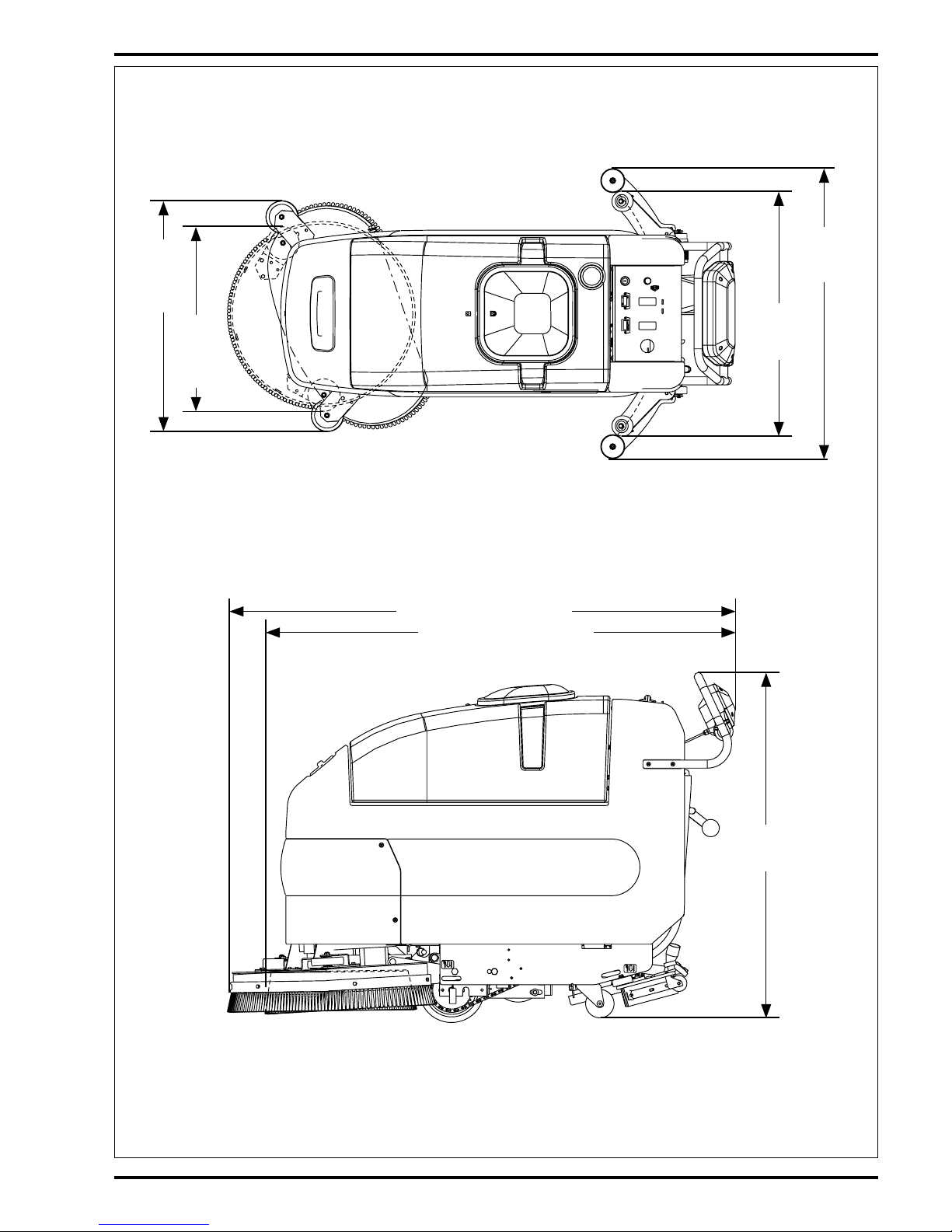

General Specifications English (Metric)

Machine Length

20” Models 64 in. (162cm)

26” Models 59 in. (149cm)

Machine Width with Squeegee

20” Models 30.5 in. (77cm)

26” Models 36.25 in. (92cm)

Machine Height 42.5 in. 108cm)

Machine Net Weight*

20” Models 362 lbs. (164kg)

26” Models 384 lbs. (174kg)

Machine Gross Weight**

20” Models 626 lbs. (284kg)

26” Models 648 lbs. (297kg)

Cleaning Width (scrubbing path)

20” Models 20 inches (51cm)

26” Models 26 inches (66cm)

Coverage Rate Per Hour (theory)

20” Models 28,000 sq. ft. (2600m2)

26” Models 34,500 sq. ft. (3205m2)

Coverage Rate Per Hour (average)

20” Models 9,000 sq. ft. (836 m2)

26” Models 11,300 sq. ft. (1050 m2)

Brush Diameter 20” Models (qty of 1) 20 inches (50.8cm)

Brush Diameter 26” Models (qty of 2) 13 inches (36cm)

Brush Speed (20”) 200 RPM

Brush Speed (2 x 13”) 220 RPM

Brush Pressure

20” Models Low - 45 lbs. (20kg) High – 80 lbs. (36kg)

26” Models Low – 70 lbs. (32kg) High – 110 lbs. (50kg)

Solution Tank Capacity 20 gal. (76l.)

Recovery Tank Capacity 20 gal. (76l.)

Vacuum Water Lift 63 inches (sealed)

14 inches (open hole adapter 1”)

Ramp Climbing Ability (gradeability) 2% grade

Sound power level as per ISO 3744 (at operator) 70 dB(A)/20µPa

Transport Speed (Maximum) 3.3 mph (5.3KPH)

Scrubbing Speed (Maximum) 3 mph (4.8KPH)

Power Source 24VDC Battery Pack (4) 6V/238 AH batteries

Battery Weight (each) 66lbs. (29.9kg)

Battery Compartment Size

Height 13.25 inches (33.6cm)

Width 15.5 inches (39.3cm)

Length 20.5 inches (52cm)

Battery Chargers Automatic 24V – 20A DC / 115V 60Hz AC

Wheel Drive Motor .5 hp, 373 watt

Brush Drive Motor (20” Models) (1) 1 hp, 746 watt

Brush Drive Motor (26” Models) (2) .75 hp, 560 watt

Vacuum Motor .75 hp, 570 watt

Machine Current (Average) 20” Models: 40 Amps 26” Models: 50 Amps

*Net Weight: Standard machine without options, empty solution and recovery tanks, without removable scrub brushes and no battery installed.

**Gross Weight: Standard machine without options, empty solution tank and empty recovery tank, with removable scrub brushes and 238 AH batteries.

SPECIFICATIONS

revised 9/00

Page 6

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 5

SPECIFICATIONS

TOP VIEW

SIDE VIEW

30.5 in.

(77cm)

20" Models

64 in. (162cm) 20" Models

59 in. (149cm) 26" Models

42.5 in.

(108cm)

26.5 in.

(67.3cm)

20"

Models

28.5 in.

(72.4cm)

26"

Models

36.25 in.

(92cm)

26" Models

Page 7

6 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

MAINTENANCE

MAINTENANCE SCHEDULE

Maintenance intervals given are for average operating conditions. Machines used in severe operational environments may require

service more often.

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries •

Drain/Clean and Check Tanks & Hoses •

Check/Clean/Rotate the Brushes/Pads •

Check/Clean/Adjust the Squeegee ••

Check/Clean Vacuum Shut-Off Float •

Check Each Battery Cell(s) Water Level •

Inspect and Clean Solution Filter •

Lubrication – Grease Fittings •

*Check Motor Carbon Brushes •

Note: See the individual machine system sections for maintenance information.

* Have Nilfisk-Advance:

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited Warranty

Statement.

Check vacuum motor carbon brushes (Qty 2) once a year or after 300 operating hours.

Note if the vacuum or brush motor carbon brushes are 9.5mm (3/8 inches) or shorter, replace them.

Check brush motor carbon brushes (Qty 4) once a year or after 500 operating hours.

Check wheel drive motor carbon brushes every 500 operating hours. The original length of each brush is 20mm (25/32 inches).

Replace when shorter than 9.5 mm (3/8 inches) to obtain the same motor efficiency as a new brush.

WARNING!

Turn the key switch off and disconnect the battery before servicing the machine.

BATTERIES AND CHARGERS

Attention: See the electrical system manual section for battery installation and charger system requirements.

LUBRICATING THE MACHINE

Once a month, pump a small amount of grease into each grease fitting on the machine until grease seeps out around the bearings.

Grease fitting locations are:

• Rear Caster Wheel Axle & Swivel (2) per Assembly

Once a month, apply light machine oil to lubricate the:

•Drive Chain

• Squeegee Height Adjustment Caster Hardware

•Pivot Points For the Squeegee & Scrub Brush Linkage

Page 8

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 7

revised 7/02

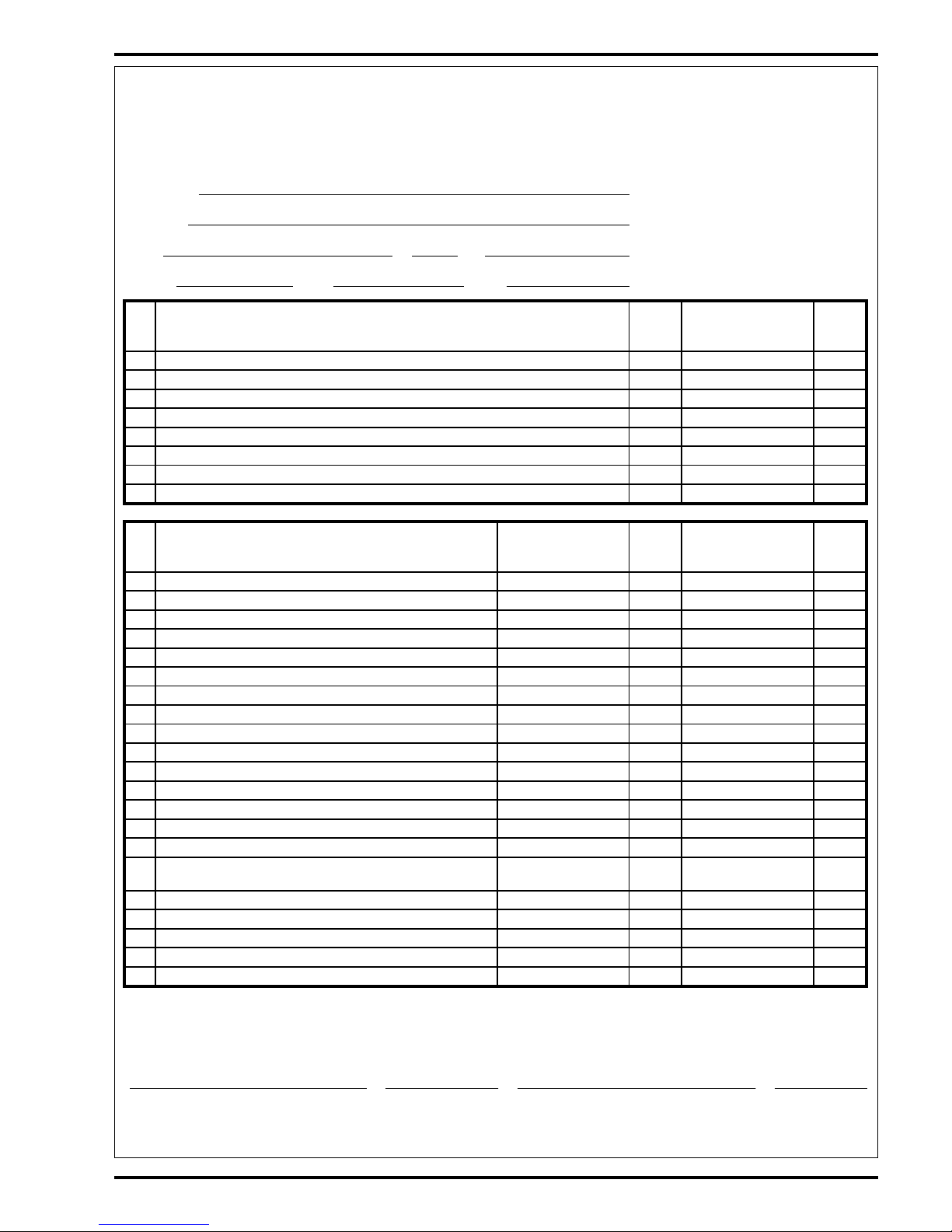

Copyright 2001 Nilfisk-Advance. 8/09/01

Advance ConvertaMAX 20/26 Models 56397010, 56397011, 56397580, 56397581

Nilfisk BA 550/650 Models 56397012, 56397013, 56397582, 56397583

PM Checklist

Defect Codes

Customer

A needs adjustment

B binding

Address

C dirty or contaminated

D damaged, bent or torn

City

St Zip L leaks

M missing

Model

Serial Hours W worn out

Ref

OPERATIONAL INSPECTION ITEMS

OK

Defect Codes

(circle)

Does

Not

Work

1Drive Paddle Operation (check for Fwd/Rev Drive & any neutral creep) A B D

2Drive System Performance (Speed Changes Min/Max) noisy sluggish

3 Scrub System (Raise/Lower, Brush Motor On/Off, Brush install & Remove Feature) A B D

4 Scrub Brush (pressure settings Normal & Heavy) A B

5 Squeegee System (Raise/Lower & Squeegee Tool pickup Performance) A B D

6Vacuum Performance (Sealed water lift 63" and 1- inch open hole adapter 14 inches) C L W

7 Solution Control (On/Off Manual /Auto and Flow Volume Min/Max) A B L

8Battery Charger (Auto turn ON & OFF) D

Ref

VISUAL INSPECTION ITEMS

Comments OK

Defect Codes

(circle)

Does

Not

Work

9 Scrub Brushes, check for wear and rotate D M W

10 Scrub Brush Motor(s), check for carbon brush wear 500 Hours B C W

11 Scrub Brush Motor(s), check gearboxes B D L

12 Brush Drive Plate Retainer Clips & flex couplers C D M

13 Scrub Deck Skirts and Side Wheels D M W

14 Solution Solenoid Valve C D L W

15 Solution Flow Control Valve and Linkage A B D W

16 Solution Tank, Delivery Hoses & Filter Clean filter screen C L

17 Vacuum Motor Carbon Brushes (wear limit 3/8”) 300 Hours B C W

18 Vacuum Motor Gaskets and Filters C D L

19 Vacuum Float Ball & Cage Assembly Clean float C D M

20 Recovery Tank Cover Gasket L M W

21 Recovery Tank Drain Hose & Cap C D L

22 Squeegee Pick-Up Hose Back flush C D L

23 Squeegee Tool & Blades (clean & rotate) A D W

24 Squeegee Tool Wheels (lubricate) Two side and two

floor

A D W

25 Battery Condition (load test, clean & water) C W

26 Front Drive Wheel Motor Check Carbon Brushes 500 Hours B C W

27 Front Drive Tire tread wear W

28 Drive wheel Motor Chain (Lubricate and tension) A B C W

29 Rear chassis Caster Wheels (Lubricate) tread wear W

NOTE: For additional service information see service manual form number 56043056 and

operators manual form numbers 56041459, 56041460, 56041461.

WORK COMPLETED BY: ACKNOWLEDGED BY:

Service Technician Signature Date Customer Signature Date

Page 9

8 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

BLANK PAGE

revised 9/01

Page 10

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 9

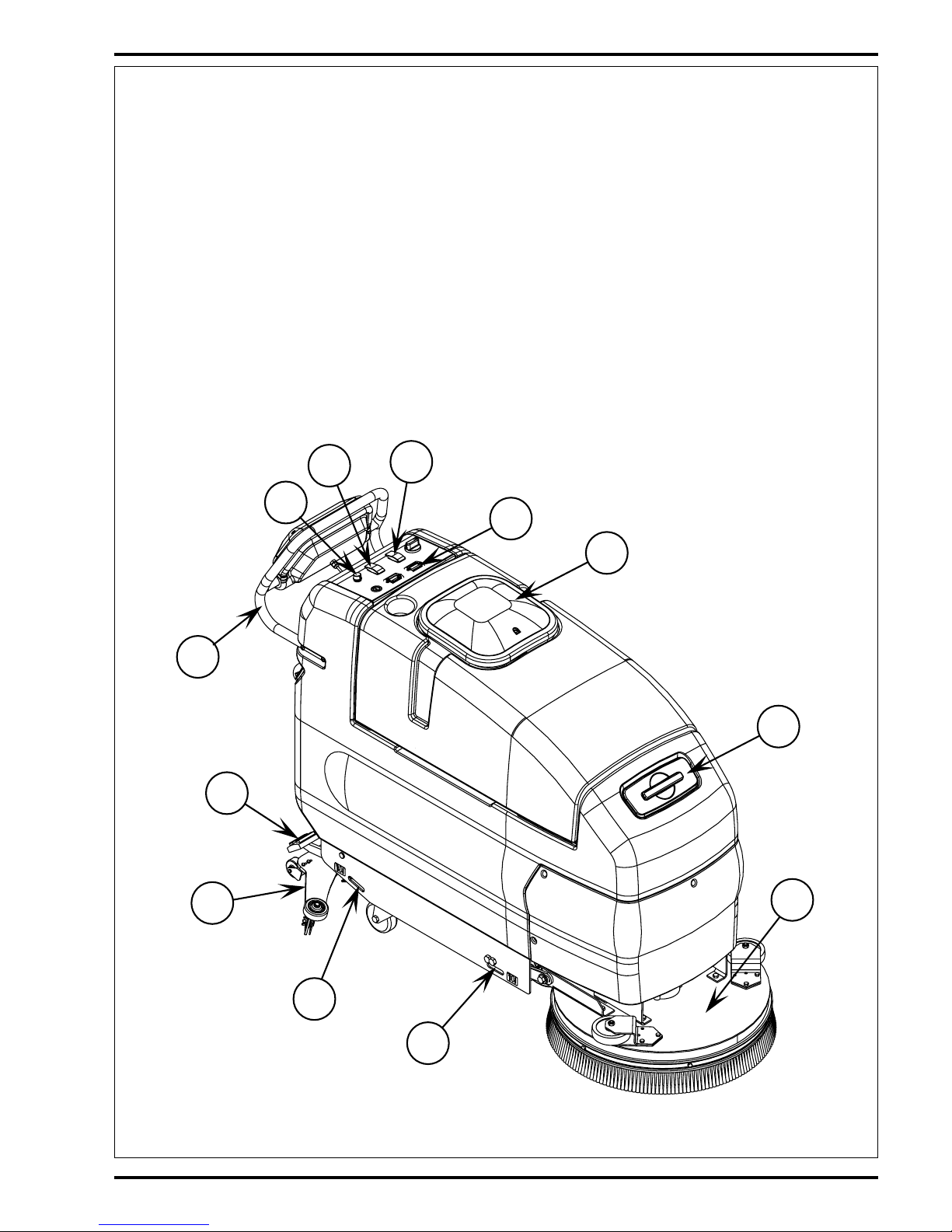

1 Solution Tank Fill Openings (2)

2 Recovery Tank Cover

3 Vacuum / Squeegee Lever

4 Brush Raise / Lower Pedal

5 Drive Paddle

6 Solution Drain Hose / Level Indicator

7 Recovery Drain Hose

8 Squeegee Adjustment Knob

9 Squeegee Blade Latch

10 Squeegee

11 Battery Charger Connector

12 Battery Fuel Gauge

13 Hour Meter

14 Solution Switch, ON-Momentarily ON-OFF

15 Brush Remove Switch

16 Solution Flow Control Knob

17 Speed Limit Control Knob

18 Master Key Switch

19 Auxiliary Circuit Breaker

20 Vacuum Motor Circuit Breaker

21 Brush Motor Circuit Breaker

22 Wheel Drive Circuit Breaker

23 Scrub Pressure Lever

24 Brush Deck

25 Operator Control Handle

26 Tie Downs

1

2

10

4

12

14

15

17

24

25

26

26

KNOW YOUR MACHINE

revised 9/01

Page 11

10 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

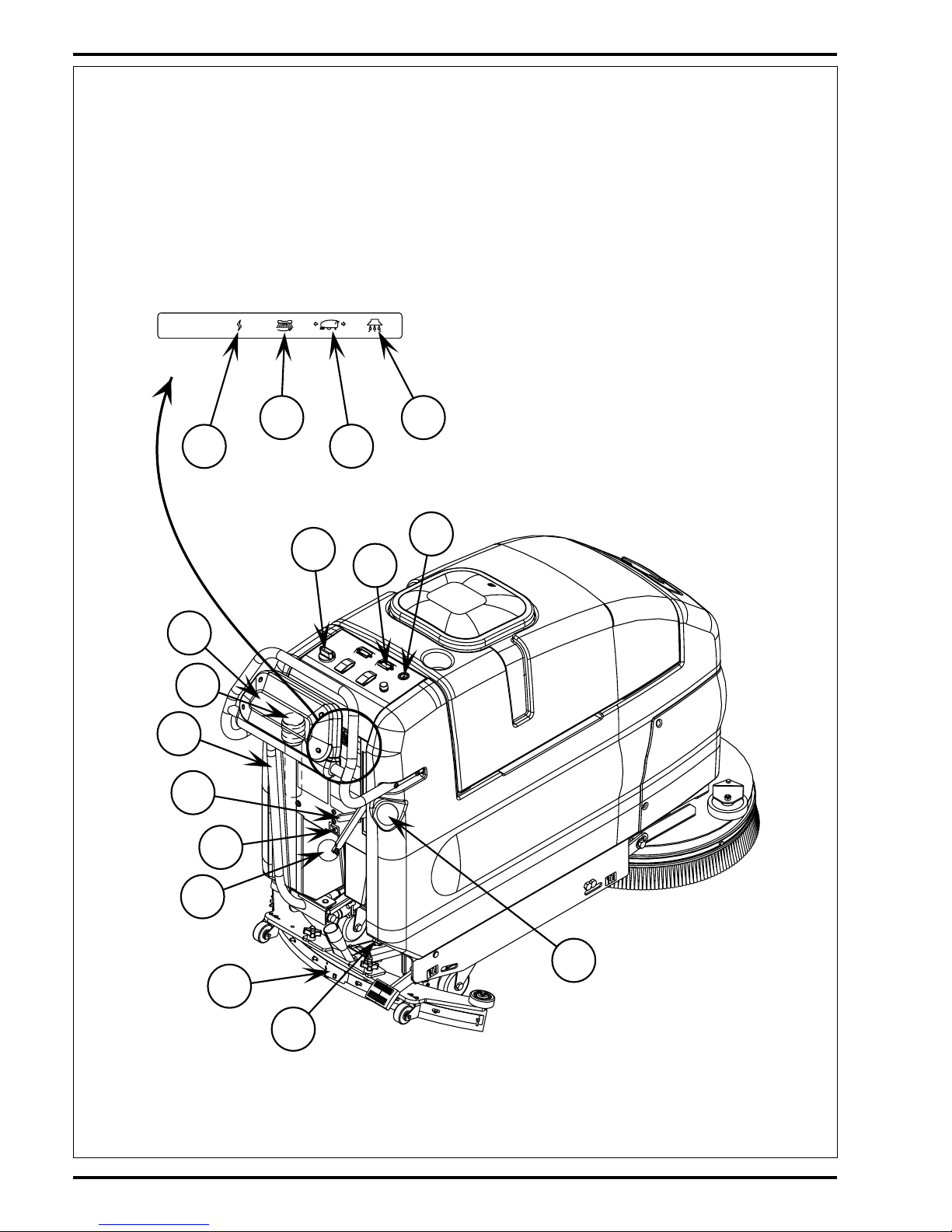

3

5

6

8

9

11

13

16

18

19

20

22

21

23

7

1

KNOW YOUR MACHINE

revised 9/01

Page 12

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 11

FUNCTIONAL DESCRIPTION OF CONTROL BUTTONS:

Solution Tank Fill (1) – Open to fill the solution tank, use non-foaming chemicals only (capacity 20 gal. / 75 liters)

Recovery Tank Cover (2) – Point of entry for waste water into tank. Also houses float ball which shuts off vacuum port to vac motor

when tank is full.

Squeegee Lever (3) – This lever controls both the squeegee and the vacuum motor. There are three positions: OFF, vacuum ON

and vacuum ON with the squeegee on the floor.

*Off

* Vacuum ON

This position lifts the squeegee slightly while leaving the vacuum turned on. This can be used for backing up during scrubbing,

or supplies vacuum for cleaning remote areas using an attachment.

* Vacuum ON with the squeegee on the floor

This position is for picking up solution while scrubbing.

Brush Raise / Lower Pedal (4) – Located at the right rear corner near the floor, this pedal is used to raise or lower the brush head.

Drive Paddle (5) – Located on top at the rear of the machine, the operator can make the machine go forward by pushing forward

on it, or reverse by pulling backward on it. The speed is variable depending on how far forward or backward the paddle is moved.

When the brush head is in the “DOWN” position, the brushes and solution will operate when the drive is engaged in either direction,

but will stop after the machine is stationary for 1 second.

Solution Drain Hose / Level Indicator (6) – Used to empty the solution tank and show current level of solution in tank, graduations

are marked on the side of the solution tank next to the hose.

Recovery Drain Hose (7) – Used to empty the recovery tank.

Squeegee Adjustment Knob (8) – Used to adjust the tilt of the squeegee. Turn knob clockwise to tilt the squeegee backwards and

counter-clockwise to tilt it forward.

Squeegee Blade Latch (9) – Holds rear squeegee blade and straps in place, release to replace rear blade.

Squeegee (10) – Picks up solution after scrubbing.

Battery Charger Connector (11) – Plug battery charger into this port to charge batteries.

Battery Fuel Gauge (12) – Shows current state of charge of batteries.

Hour Meter (13) – Displays number of hours machine has been used.

Solution Switch (14) – This switch is used to select the mode of operation for the solution system. There are 3 modes of operation

for this system. The modes are OFF, ON, MOMENTARY ON. Following is a description of each mode and how they are selected.

OFF: In this mode the solution flow is turned off.

ON: In this mode the solution flow will be turned on whenever the Drive Paddle (5) is in forward or reverse mode and the brush head

is down. The solution flow will be turned off otherwise.

MOMENTARY ON: – Solution can be dispensed by pressing and holding the solution button. Solution will be dispensed for as long

as the button is held. This is for pre-wetting the floor prior to scrubbing.

KNOW YOUR MACHINE

revised 9/01

Page 13

12 - FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650

Brush Remove Switch (15) – To remove the brush(es) from the machine, have the machine stationary and the Brush Deck (24) in

the “RAISED” position. Press the switch to the “REMOVE” position and release. The switch will snap to the OFF position, and the

brush(es) will drop to the floor.

Solution Flow Control Knob (16) – Turn this dial to the right to increase solution flow to the floor. Turn to the left, to decrease the

amount of solution flow to the floor. When the Drive Paddle (5) is released from either forward or reverse travel, the solution flow will

stop automatically, and resume when the drive is engaged.

Speed Limit Control Knob (17) – The Speed Limit Control Knob is used to adjust the maximum speed in both forward and reverse.

Master Key Switch (18) – The master power switch.

Auxiliary Circuit Breaker (19) – Provides overload protection. If it trips, it will pop out. To reset, wait one minute and press the button

back in. If any breaker trips repeatedly, have the machine serviced.

Vacuum Motor Circuit Breaker (20) – Provides overload protection to machine’s vacuum motor. If it trips, it will pop out. To reset,

wait one minute and press the button back in. If any breaker trips repeatedly, have the machine serviced.

Brush Motor Circuit Breaker (21) – Provides overload protection to machine’s brush motor(s). If it trips, it will pop out. To reset,

wait one minute and press the button back in. If any breaker trips repeatedly, have the machine serviced.

Wheel Drive Circuit Breaker (22) – Provides overload protection to machine’s wheel drive motor. If it trips, it will pop out. To reset,

wait one minute and press the button back in. If any breaker trips repeatedly, have the machine serviced.

Scrub Pressure Lever (23) – Two position lever provides two different scrubbing pressures.

TOP POSITION: – In this position the full weight of the scrub deck rests on the floor.

BOTTOM POSITION: – In this position the scrub pressure is approximately 30 pounds less.

Brush Deck (24) – Contains brush drive motor(s) and brush(es).

Operator Control Handle (25) – Operator holds onto this to control the machine.

KNOW YOUR MACHINE

revised 9/01

Page 14

FORM NO. 56043056 / ConvertaMAX™ 20/26 / BA 550/650 - 13

CONTROL MODULE DESCRIPTION

The ConvertaMAX™ 20/26 / BA 550/650 scrubbers have an electronic module that controls the activation of the scrub brush motors

for scrubbing and removal of the brushes/pads and the low voltage cutout function.

For normal scrubbing the brush motor(s) will activate only if the brushes are down and the Drive Paddle (5) (throttle) is in the forward

or reverse position.

For removal of the brushes/pads the scrub deck must be in the up position. To remove the brushes/pads simply depress the Brush

Remove Switch (15). The module will momentarily run the brush motor and then stop it quickly.

The low voltage cutout is adjustable for two different thresholds. The normal setting cuts out at 1.75 volts per cell and the alternate

setting cuts out at 1.83 volts per cell. The cutout level is selected by momentarily depressing the pushbutton switch located on the

module circuit board.

*Important Note: See the Low Voltage Cutout Level Selection manual section in the Electrical System and follow the instructions

for setting the low voltage cutout threshold.

DESCRIPTION OF THE BATTERY FUEL GAUGE

The Battery Fuel Gauge (12) uses a 10 bar LED display that indicates the state of the batteries charge, successively, bar by bar, from

full to empty. At 70% depth of discharge a single flashing light signals an energy reserve alert. At 80% of discharge, a double flashing

light signals an empty alarm. The battery gauge will retain the last state-of-charge condition even when the machine has been turned

off. The battery fuel gauge state-of-charge display indication is automatically reset to full charge when the battery pack is recharged.

KNOW YOUR MACHINE

revised 9/01

Page 15

14 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SOLUTION SYSTEM

FRONT

Solution

Solenoid Valve

(L1)

Solution Filter

Main Solution

Valve

To Brush(es)

Solution Flow

Control Knob

From Solution

Tank

FRONT

A

B

C

Drain Hose

FUNCTIONAL OVERVIEW

The 20-gallon (76 l.) capacity solution tank uses two fill openings one located in the front and another in the rear, which offers ease of filling. Plumbed

onto the tank outlet is a serviceable solution filter, to keep debris from entering the solenoid valve. Also fitted to the tank is flexible hose used to

indicate the solution level and to drain the tank for system maintenance.

See Figure 1. The solution system uses (2) valves to regulate the amount of solution dispensed onto the floor. The Knob (A) located on the control

panel operates the Main Solution Valve (B) that controls the needed flow volume demanded by the scrub brushes. The electrical solenoid valve

(L1) (C) and control panel mounted solution switch (S2) start and stop the solution flow (See Electrical Diagram).

During normal machine operation the (S2) solution switch when turned ON works in conjunction with the wheel drive controller components and

brush motor solenoid output to energize the (L1) solenoid valve. The solution will flow to the scrub brushes when the main flow control valve is

open, the scrub deck is lowered and the handle drive paddle (box) is pushed or pulled into Fwd or Rev. Note: When the solution On/Off switch

(S2) is turned Off, no flow can occur regardless of the main valve being On and the drive control paddle being activated.

FIGURE 1

FIGURE 2

revised 9/01

Page 16

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 15

SOLUTION SYSTEM

-

+

1

2

3

4

5

6

5124

3

10

61

11

987

2

S6

D2

L1

R1

R2

S2

K1

F2

A2

Voltage Cutout

Button

LIQ

.

GEL

.

A1

F3

P1

B-B+

P2

+24V -24V

S1

YEL/BLK

YEL/WHT

VIO/BLK

BLK/YEL

VIO

BLK

ORN/BLK

WHT/RED

#12

VIO/BLK

#10

BLK

VIO

Electrical Diagram (Solution Switch Closed in the Full ON Position)

*For complete description of all callouts see Electrical System Wiring Diagram.

TROUBLESHOOTING GUIDE

Problem Possible Cause

Inadequate or no solution flow No solution in the tank

Main solution flow control valve knob is in the off position

Clogged solution filter, valves and hoses

Defective solution solenoid valve (L1)*

Defective control panel solution switch (S2)**

*See Solenoid Troubleshooting flow chart Symptom One for electrical system diagnostics.

**See Troubleshooting flow chart Symptom Two.

FIGURE 3

revised 9/01

Page 17

16 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SOLUTION SYSTEM

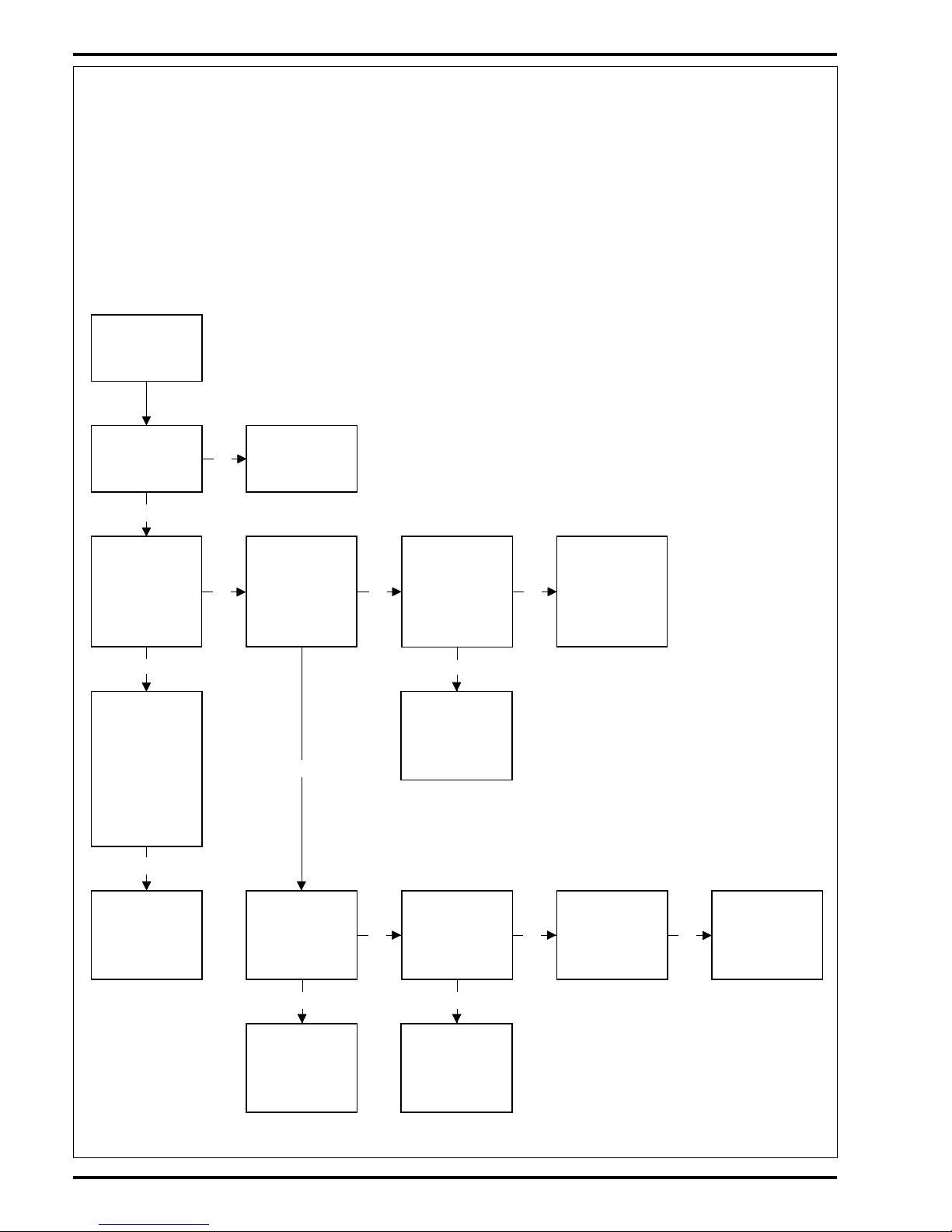

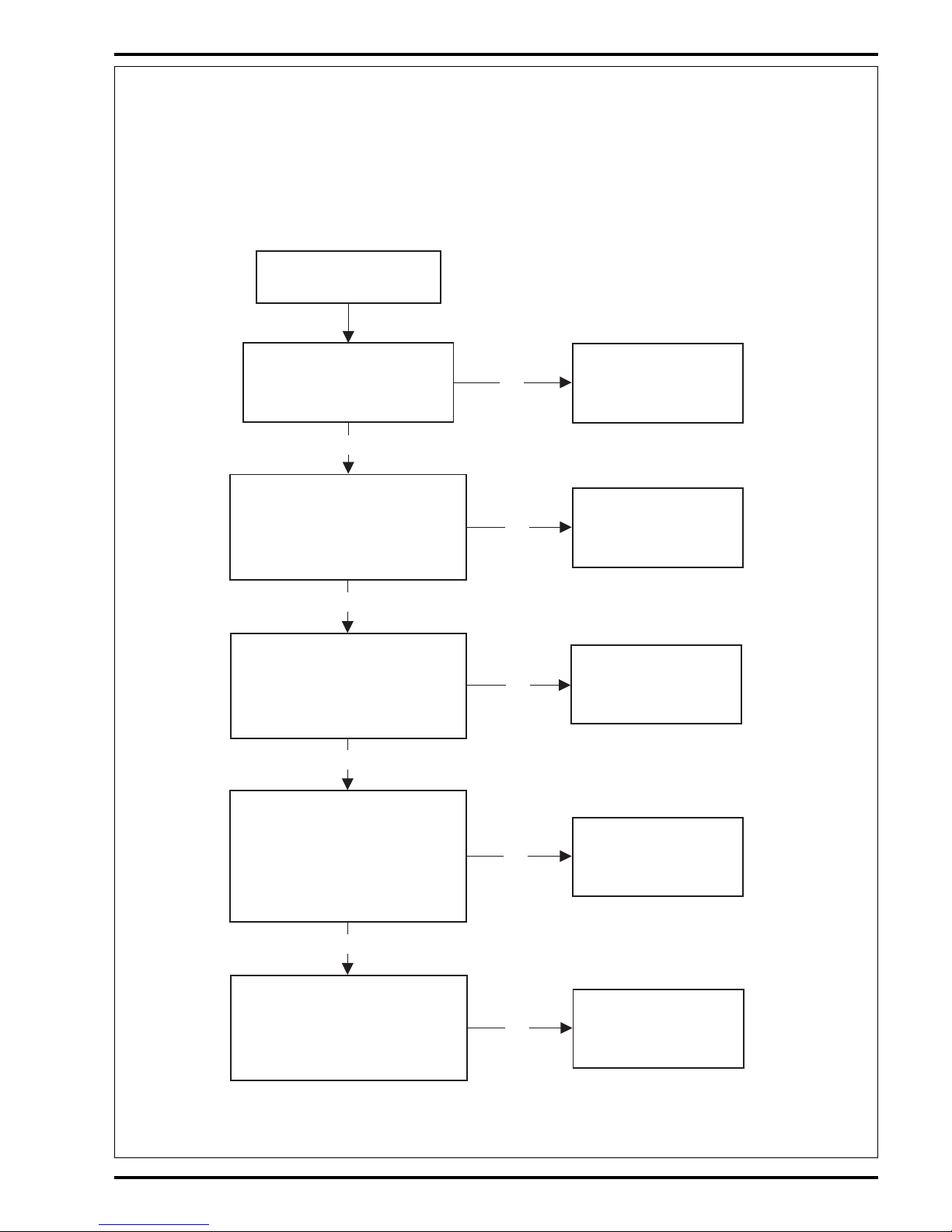

No

Yes

Yes

No

Yes

No No

Yes

Yes

No No

Yes

No

Yes

Solenoid will

not open, no

solution flow

(See Figure 3).

Verify scrub

brush(es) are

turning

See Brush System

Troubleshooting

Symptom 2 (part

A&B).

Separate the wiring

harness connector

that feeds the L1

solenoid (2 wires

Yel/Wht & Yel/Blk).

Test for 24V

Test the resis-

tance of the L1

solenoid coil. If it

reads infinity coil

is open or if it

reads 40 ohms or

less it is shorted

(a good coil

should read 63

ohms ±10%).

Check for 24V

(Pos.) from the

Yel/Wht L1 harness

feed wire to a

(Neg.) battery

standoff

Replace the L1

solenoid coil if

testing shows it

shorted or open.

Check for 24V

(Pos.) at the

Blk/Yel input wire

on the S2 solution

switch

Test continuity of

the Blk/Yel & #12

wires from the K1

solenoid to the S2

solution switch.

Repair or replace

Replace the S2

solution switch

Check for 24V

(Neg.) from the

Yel/Blk L1 harness

feed wire to a (Pos.)

battery standoff

Check for 24V

(Neg.) at the

Vio/Blk input wire

on the S2 solution

switch

Replace the S2

solution switch

Check diode D2

for continuity in

one direction only

If diode checks

open replace the

D2 diode

Replace the L1

solenoid valve

TROUBLESHOOTING GUIDE ELECTRICAL

Possible Symptoms

1 Solution solenoid valve will not open when the solution switch is in the full on position.

2 Solution solenoid valve will not open when the solution switch is in the momentary on position.

SYMPTOM ONE

Note: Do all testing with the key switch on, brush switch closed (scrub deck lowered) and the drive paddle activated

(pushed Fwd or pulled into Rev).

revised 9/01

Page 18

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 17

SOLUTION SYSTEM

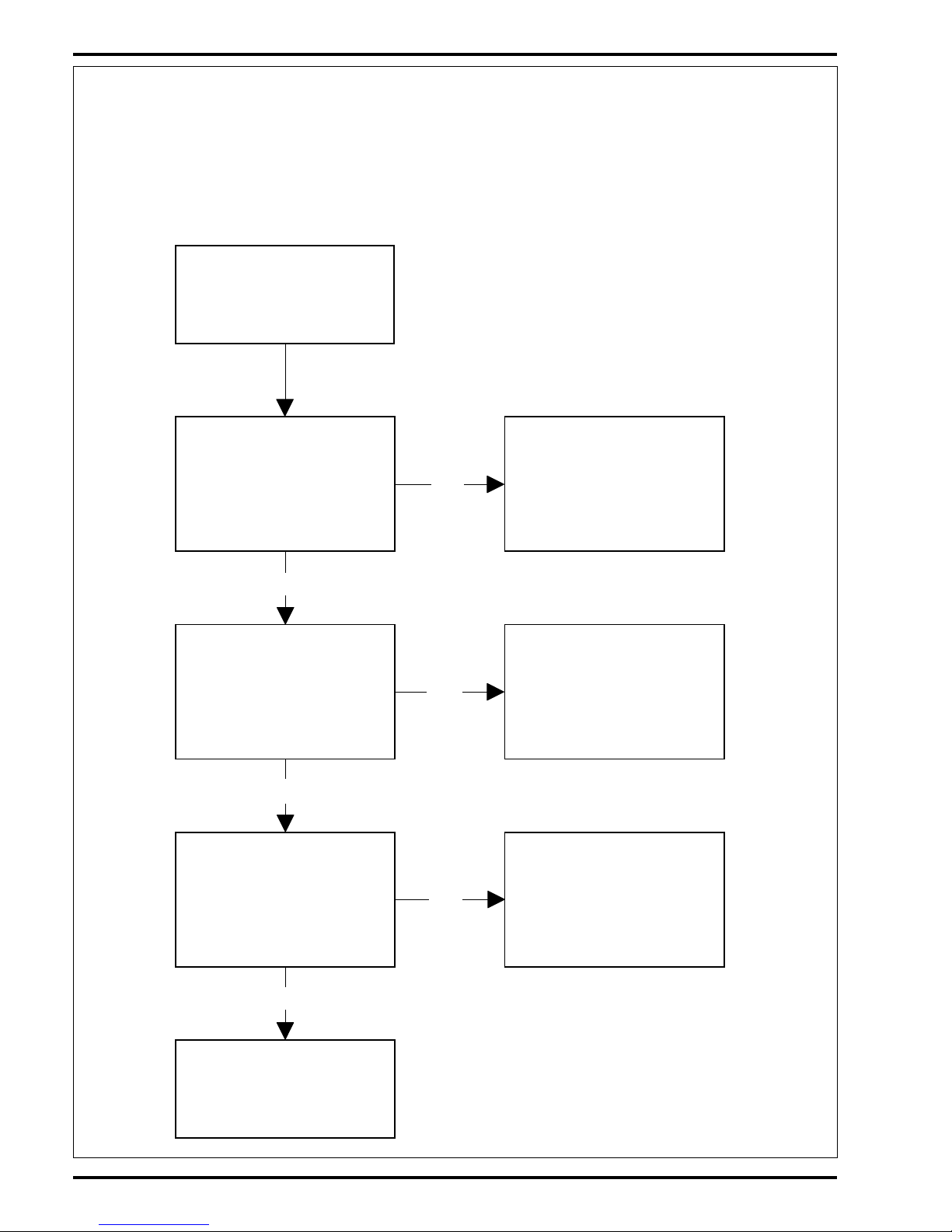

SYMPTOM TWO

Note: Test with the key switch on and the solution switch held in the momentary on position.

TROUBLESHOOTING GUIDE ELECTRICAL (CONTINUED)

No

Yes

No

No

Yes

L1 solenoid will not

open when the S2

switch is in the

momentary on

position, no solution

flow (See Figure 3).

Check for the 24V

input at the S2 solu-

tion switch, Vio &

Blk wires

Check for 24V (Pos.)

from the Vio S2

switch wire to a

(Neg.) battery

standoff.

Replace the S2

solution switch

Check for 24V (Neg.)

from the Blk S2

switch wire to a

(Pos.) battery

standoff.

Repair or replace

the Blk wire

Repair or replace

the Vio wire

revised 9/01

Page 19

18 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SOLUTION SYSTEM

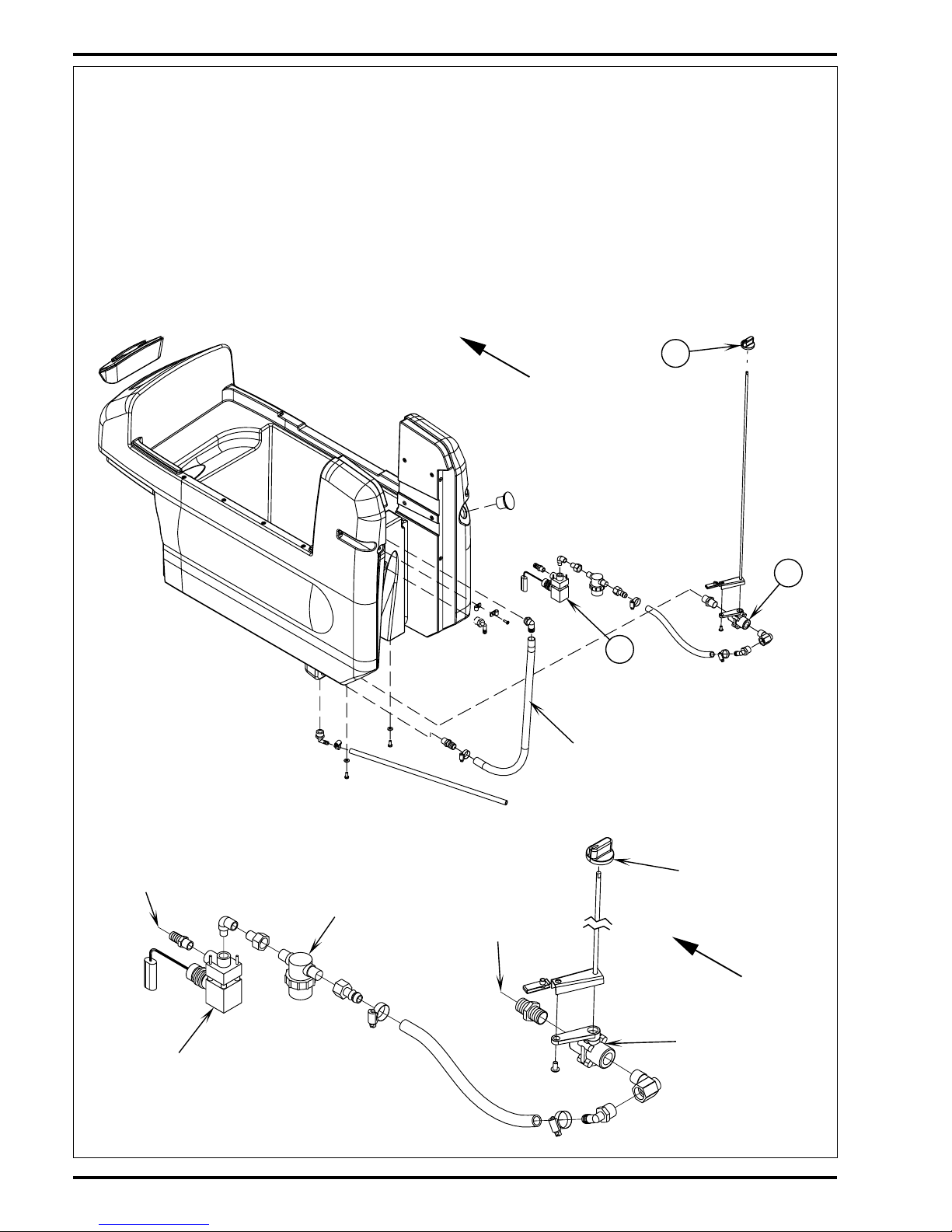

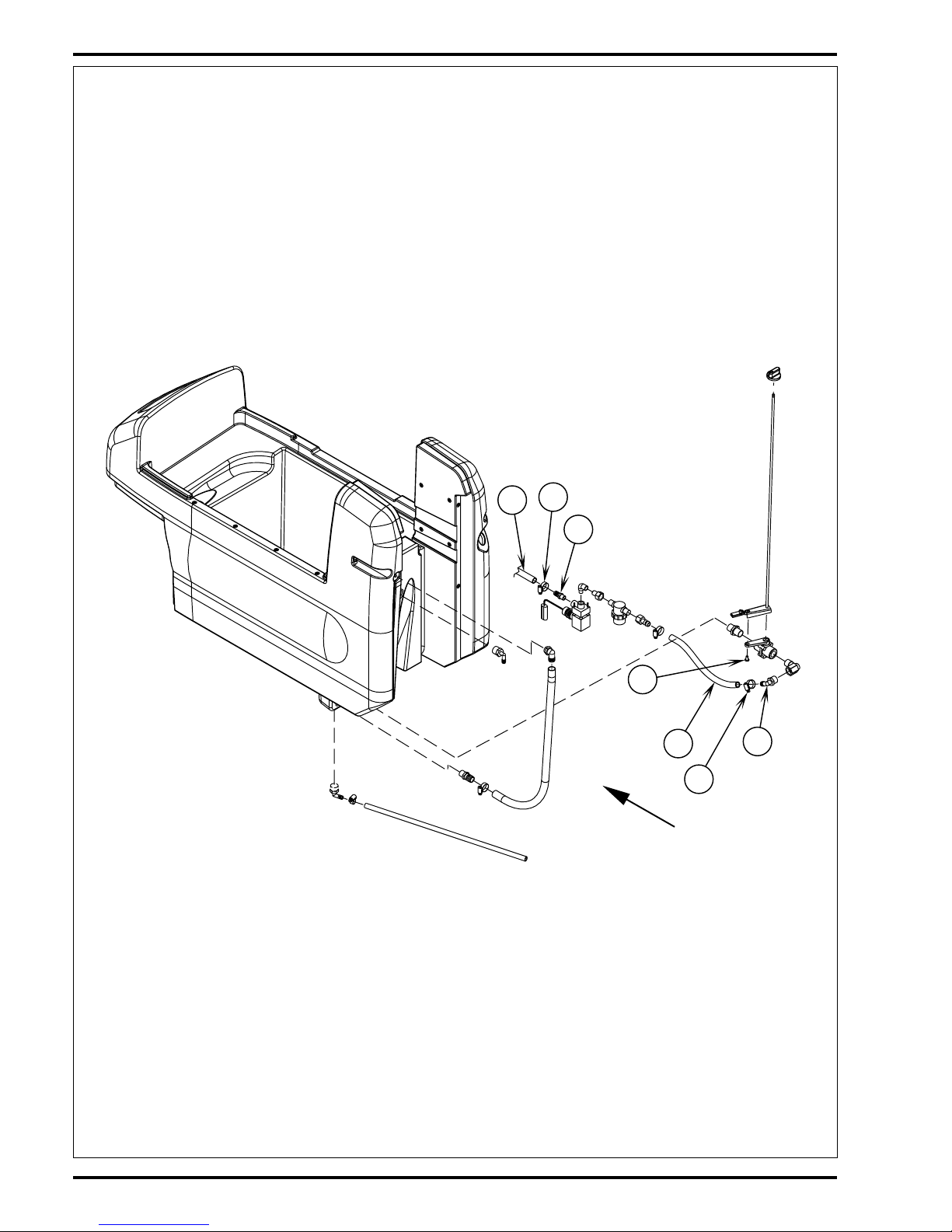

SOLUTION SOLENOID VALVE AND STRAINER REMOVAL

1 Drain the solution tank using the tank drain hose.

2 See Figure 4. Loosen (D) Hose Clamp and pry the Hose (E) from the Elbow Fitting (F) as shown.

3 Loosen the (G) Hose Clamp and remove the (H) solution feed hose from the (I) solenoid valve barb.

4 Loosen the solenoid valve mount anchor connector, and then disconnect the valves’ wiring harness connector.

5 Pull out from underneath the machine the combined valve and strainer assembly. Make service repairs as required and re-install in reverse order.

FRONT

H

I

F

E

M

D

G

FIGURE 4

revised 9/01

Page 20

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 19

SOLUTION SYSTEM

SOLENOID VALVE DISASSEMBLY AND CLEANING

1 Remove the solenoid valve. See the Solution Solenoid Valve And Strainer Removal section for instructions.

2 See Figure 5. Remove the (2) (J) Screws and nuts and disassemble the valve (be careful not to lose any internal parts).

3 Thoroughly wash dirt from block (K) and diaphragm (L).

4 After reassembling, test the solenoid valve for proper operation.

Note: Solenoid valve replacement seal kit (Viton) part number 56324247.

SOLUTION FLOW CONTROL VALVE REMOVAL

1 Drain the solution tank and also remove the squeegee tool from the machine (this allows the needed room to work on the valve).

2 See Figure 4. Loosen the Hose Clamp (D) and pull the Hose (E) off the valve elbow fitting (F).

3 Remove the Screw (M) that holds together both the water valve shaft arm and the solution valve arm.

4 Separate the control arms and work the shaft up and off the valve to allow the clearance for removal.

5 Turn the valve out of the solution tank connection and remove it from the machine. Note it is not necessary to remove the tank drain hose, just compress

the hose to allow needed clearance to remove the valve.

revised 9/01

J

FRONT

K

L

J

FIGURE 5

Page 21

20 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SCRUB BRUSH SYSTEM

+

1

2

3

4

5

6

5

12

4

3

10

61

11

987

2

-

+

S6

D2

L1

R1

R2

S2

K1

F2

A2

Battery Switch

LIQ.

GEL

.

A1

F3

P1

B-B+

P2

+24V -24V

S1

M

M

M3

M4

S3

BLKVIO/BLK

#10#14

BLK

#12

#16

BRN

ORN/BLK

WHT/RED

#8

BRN/WHT

GRA

VIO

GENERAL BRUSH SYSTEM FUNCTIONAL OVERVIEW

The ConvertaMAX™ 20 / BA 550 models use (1) scrub brush (20 inch Dia.) driven by a single 1HP 24VDC-combination motor/gear unit. The

ConvertaMAX™ 26 / BA 650 models use (2) scrub brushes (two 13 inch Dia.) driven by two 3/4HP 24VDC combination motor/gear units. The

scrub deck is raised and lowered manually by a rear mounted foot pedal.

Control Module Scrub System Functions

The ConvertaMAX™ 20/26 / BA 550/650 scrubbers have an electronic timer module (A2) that controls the activation of the scrub brush motors,

special scrub brush removal feature and a low voltage cutout function.

Scrub Brush Removal Function

For removal of the scrub brush(es) automatically the scrub deck must be in the up position and the drive system in neutral. To remove the scrub

brush(es) simply depress the control panel remove switch (S3). The timer module will momentarily run the brush motor and then stop it quickly,

where the brush inertia causes the brush to easily spin it’s self off of the scrub brush motor drive cap.

Low Voltage Cut-Out Function

The purpose of the special low battery voltage cutout function is to help prolong battery life. The brush motor(s) and solution solenoid valve will

turn off automatically and cease to function when the batteries discharge to 1.75 volts per cell or 1.83 volts per cell on alternate setting. Note: See

the battery system section for instructions for selecting (setting) the two different thresholds (wet cell, lead acid or gel, maintenance free). Special

Service Note: On all the 24V and 36V machines a minimum recharge voltage of 2.09 volts per cell must be reached to allow the scrub brush and

solution systems (to reset) function again. A 24V-battery pack must increase to a 25.1-volt minimum and a 36V battery pack to 37.6 volts.

Scrub Brush Motor Function

See Figure 1. To turn ON (energize) the K1 brush motor solenoid the operator must lower the brush deck to close the S6 brush switch and move

the drive paddle (Fwd or Rev) to activate the wheel drive.

These two operator functions described above deliver the required control circuit inputs, one positive and two negative, to start and stop the scrub

brush motor(s). The Pos. control circuit-input starts with the S1 key switch closed and a Pos. voltage input to the pin 11 on the A2 timer module.

The pin #11 is connected directly to pin #3 inside the module. The BRN wire from pin #3 sends the required Pos. control circuit input to the K1

coil terminal. One of the two Neg. circuit inputs is triggered when the machine is put in motion. The A1 speed control’s P1 connection sends a

Neg. input signal to the timer module pin #4. The second Neg. input is initiated when the S6 brush switch is closed sending a Neg. voltage signal

to the timer pin #9. With the two Neg. inputs completed the timer circuit closes an internal relay that sends from pin #2 (ORG/BLK wire) the needed

Neg. control circuit voltage to the K1 coil terminal. This then completes the K1 coil circuit (Pos. & Neg.) and pulls in the load contact making the

brush motor(s) run.

Electrical Diagram

*For complete description of all callouts see Electrical System Wiring Diagram.

FIGURE 1

revised 7/02

Page 22

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 21

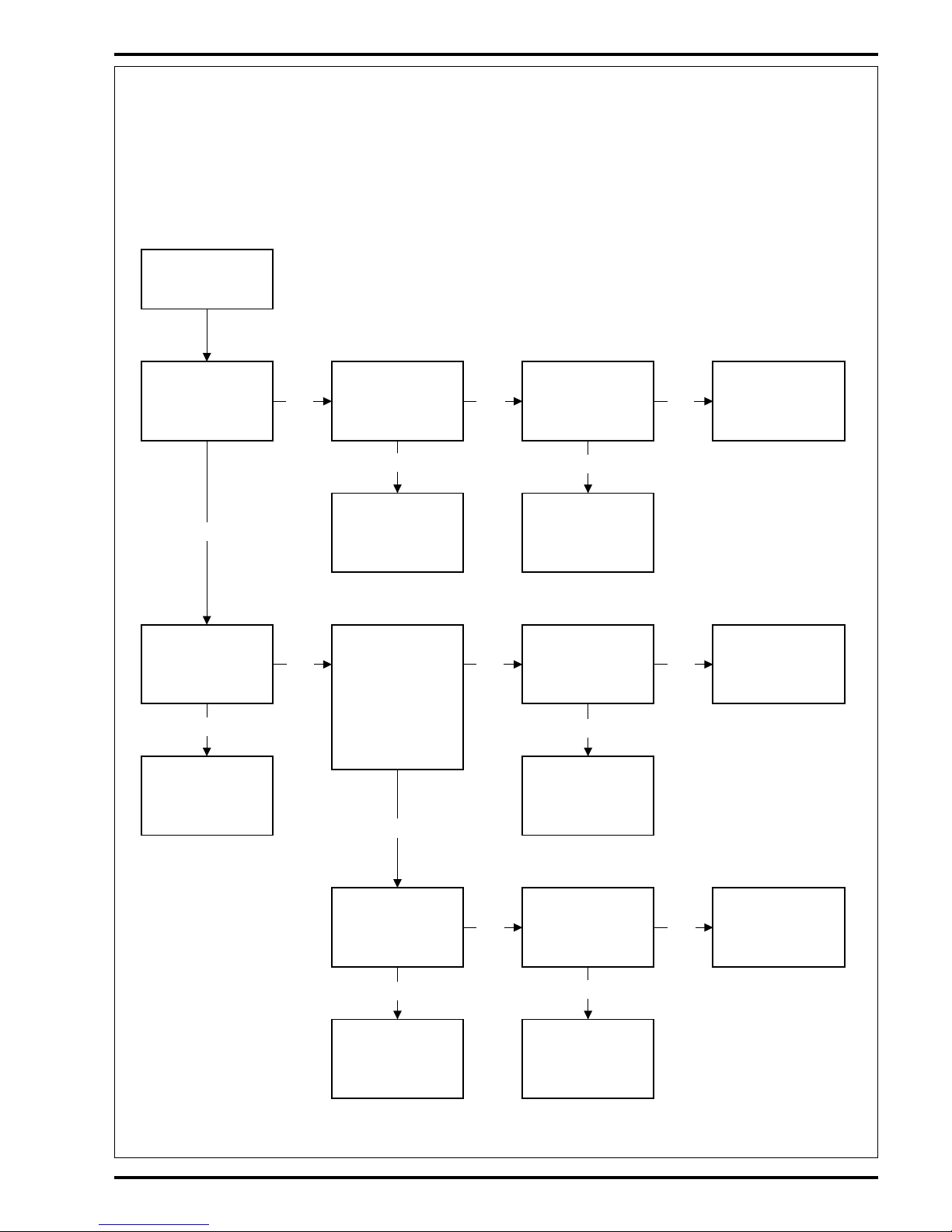

SCRUB BRUSH SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Possible Symptoms

1 Scrub brush motor(s) and solution solenoid valve do not work

2 Scrub brush motor(s) do not work

3 Scrub brush auto remove function does not work

SYMPTOM ONE

*Reference the Description of the Battery Low Voltage Cutout Feature in the Electrical System of this manual.

revised 9/01

Yes

No

No

Yes

Check the battery

meter, is it double

flashing?

Recharge battery

pack (the low voltage

cutout is functioning*)

Test the machine's

battery pack voltage

under load. Is it less

than 22 volts?

Voltage test reading

is above 22 volts.

See the scrub brush

system troubleshoot-

ing Symptom Two,

parts A & B.

Part A: The machine's low

voltage cutout is

functioning(*). Check to

see that the correct voltage

cutout threshold setting

has been selected (battery

type wet or gel).

Scrub brush

motor(s) & solu-

tion solenoid

valve do not work

(see Figure 1)

Part B: Also test each bat-

tery for any possible dead

cells. See Electrical Sys-

tem Battery Maintenance

& Battery Testing sections

and follow instructions.

Page 23

22 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SCRUB BRUSH SYSTEM

No

Yes

Yes

Yes

No

No

Scrub brush motor(s)

don't turn (See Figure 1).

Check continuity on the

F2 brush motor circuit

breaker.

Reset or replace the F2

circuit breaker (40A used

on C-20/550 models or

60A used on the C-26/650

models).

Check for 24V at the

wires #12 & #16 on the

K1 brush motor output

terminal

Check for 24V at brush

motor(s) M3 and M4 (the

model C-26 uses two

motors).

Repair or replace the

brush motor(s)

See part B scrub brush

control circuit

troubleshooting.

Check continuity on both

the #8 (neg.) & #16 (pos.)

wires to the M3 & M4

brush motor(s). Repair or

replace wiring.

SYMPTOM TWO

Brush Motor(s) Don’t Turn

Note: Do all testing with the key switch on, brush switch closed (scrub deck lowered) and the drive paddle activated (pushed Fwd or pulled into

Rev).

Part A: Scrub Brush Motor Load Circuit Troubleshooting Guide

TROUBLESHOOTING GUIDE (CONTINUED)

revised 9/01

Page 24

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 23

SCRUB BRUSH SYSTEM

Scrub brush(es)

don't turn (See

Figure 1).

Check for 24V at

the Neg. K1

Org/Blk coil wire

to a Pos. battery

standoff

Check for 24V at

the Pos. K1 Brn

coil wire to a Neg.

battery standoff

Check for a Pos.

24V at pin #11

(input) on the A2

Module.

Repair or replace

the pin #11 (Vio)

input wire.

Check for 24V (Neg.)

at the pin #4 input on

the A2 timer module.

Note: The control

handle drive paddle

must be activated

(Fwd or Rev) for the

speed control to

close the P1 output

circuit.

Replace the A2

timer module

Check for a Pos.

24V at pin #3

(output) on the A2

Module.

Check for a Neg.

24V at pin #9 on

the A2 timer

module

Yes

Yes

Yes

NoNoNo

Replace the K1

brush motor

solenoid

Repair or

replace the Brn

K1 coil wire

Yes

No

No

Yes

Yes

No No

Yes

Yes

No

Check for a Neg.

24V at the Gra P1

wire on the A1

speed controller

Replace the A1

speed controller

Repair or replace

the P1 controller

(output) wire.

Replace the A2

timer module

assembly

Check for 24V at

the Blk wire on

the S6 brush

switch to a Pos.

battery standoff.

Replace the S6

brush switch

Repair or replace

the Blk S6 brush

switch wire.

SYMPTOM TWO

Brush Motor(s) Don’t Turn

Note: Do all testing with key switch on, brush switch closed (scrub deck lowered) and drive paddle activated (pushed Fwd or pulled into Rev).

Part B: Scrub Brush Motor Control Circuit Troubleshooting Guide

TROUBLESHOOTING GUIDE (CONTINUED)

revised 9/01

Page 25

24 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SCRUB BRUSH SYSTEM

SYMPTOM THREE

Scrub Brush Auto Removal Function Does Not Work

Note: Do all testing with the key switch ON, scrub deck raised (S6 brush switch open*), drive system in neutral. To remove the scrub brush(es)

simply depress the control panel remove switch S3.

Circuit sequence detail: The S3 switch is closed and the pin# 10 input causes a brief negative output at pin#2 that energizes the K1 solenoid

and the brush motor(s) turn(s) momentarily. Next the A2 timer module de-energizes the solenoid and a negative output from pin #7 passes through

the bottom contacts of the brush solenoid to short the motors to ground.

TROUBLESHOOTING GUIDE (CONTINUED)

*Special Service Note: Before following all the troubleshooting steps shown above test the S6 brush switch with an Ohm meter to confirm an open

circuit. Also check the switch for proper adjustment (raised open/lowered closed).

**Special Service Note: This will be a brief pulse not a continuous voltage.

Yes

No

Yes

No

Yes

No

Scrub brush auto

removal function

does not work (See

Figure 1).

Check for 24V (Neg.)

at pin #10 found on the

A2 timer module. Note:

The S3 Switch must

be activated (closed).

Check for 24V

(Neg.)** at the

Wht/Red wire on the

K1 brush solenoid

(note the S3 switch

must be activated).

Check for 24V

(Neg.) at the Blk

wire on the S3 brush

remove switch

Replace the S3

brush remove

switch

Replace the A2

timer module

Check for a 24V

(Neg.)** at the K1

solenoid wires 12 &

16. This is the circuit

sequence that is

needed to short the

brush motor(s), stop

the motors quickly.

Check solenoid wiring and continuity of

the bottom contacts.

If contacts are open

when the S3 switch

is activated replace

the K1 solenoid.

revised 9/01

Page 26

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 25

SCRUB BRUSH SYSTEM

A

FRONT

C

B

E

D

A

E

B

D

C

F

G

H

K

J

I

Solution

Delivery Tube

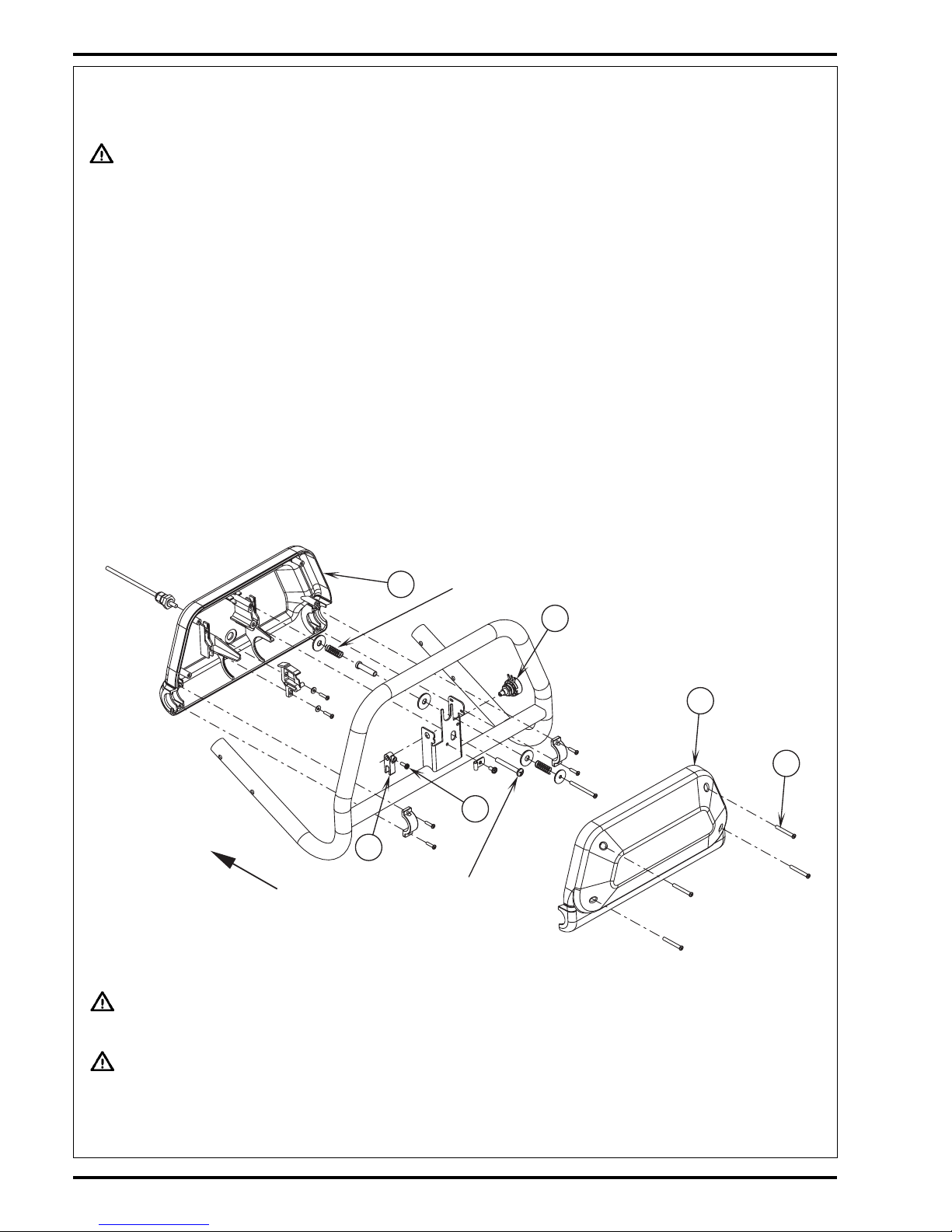

MODEL CONVERTAMAX™ 20/BA 550 SCRUB DECK REMOVAL

1 Disconnect battery connector assembly in the battery compartment.

2 Remove the brush head cover (held in place by 5 screws).

3 Lower the brush deck to the floor with a brush installed.

4 See Figure 2. Remove the solution delivery hose at the scrub deck solution tube.

5 Remove the hardware items (A,B,C,D & E) from the brush head brackets and lift linkage arms. Note: Do not loose the removable lift arm bushings.

6 Remove (Qty 2) item (F) Hairpins and the (2) (G) Mount Pins from the (upper) scrub head lift linkage.

7 Pull the scrub head forward 12 inches (30 cm) to access the motor wiring terminal block.

8 Remove the motor wiring at the terminal block and then pull the brush head assembly completely from the machine. Note: See Figure 4 for the correct wiring

for the single scrub brush motor.

FIGURE 2

SCRUB BRUSH MOTOR/GEARBOX REMOVAL CONVERTAMAX™ 20/BA 550

1 Follow steps 1-8 of the Scrub Deck Removal section

above.

2 Turn the brush deck over, top of motor down.

3 See Figure 2. Remove the Hex Hd Screw (H) from the

motor output shaft and then pull the Clutch Plate (I) and

drive plate lug assembly (K) off from the shaft. Note: Do

not loose the shaft key.

4 Mark the location of the motor to the brush deck for proper

re-assembly.

5 Remove the (4) (J) Hex Hd Screws securing the motor to

the brush deck and separate.

revised 9/01

Page 27

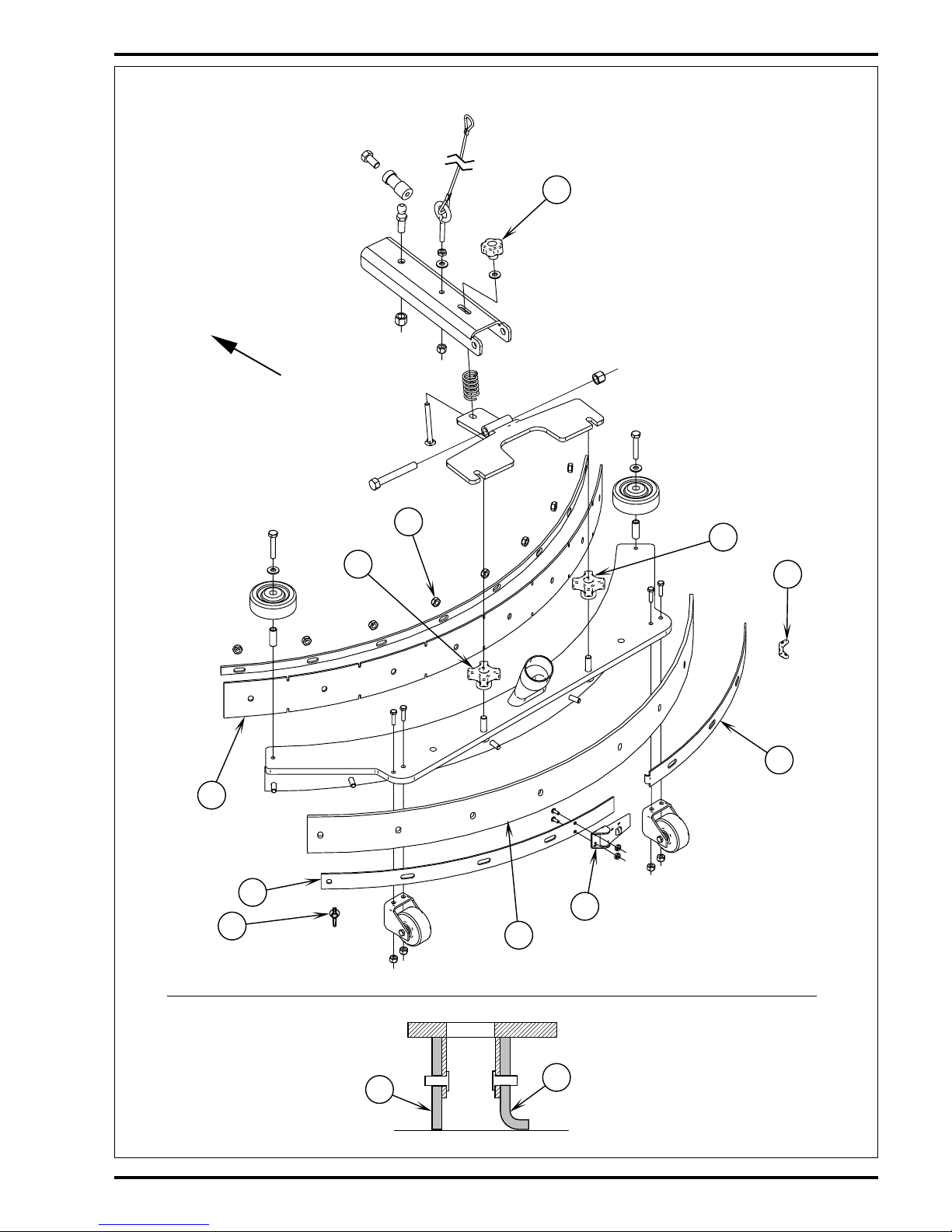

26 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SCRUB BRUSH SYSTEM

FRONT

T

S

X

U

Z

W

Y

L

CC

N

O

M

AA

BB

O

M

Q

P

R

V

FRONT

MODEL CONVERTAMAX™ 26/BA 650 SCRUB DECK REMOVAL

1 Follow steps 1-3 in the Scrub Deck Removal section for the ConvertaMAX™ 20.

2 See Figure 3. Remove the Solution Delivery Tube (L) at the solution solenoid valve.

3 Remove the hardware items (M, N, O, P, & Q) from the brush head Support Brackets (R) and lift linkage arms.

4 Remove (Qty 1) item (S) Hairpin and the Mount Pin (T) from the (upper) scrub head lift linkage.

5 Pull the scrub head forward 12 inches (30 cm) to access the motor wiring terminal block.

6 Remove the motor wiring at the terminal block and then pull the brush head assembly completely from the machine. Note: See Figure 4 for the correct

wiring for both the left and right scrub brush motors.

MODEL CONVERTAMAX™ 26/BA 650

SCRUB BRUSH MOTOR/GEARBOX

REMOVAL

1 Follow steps 1-6 in the Model ConvertaMAX™ 26/BA

650 Scrub Deck Removal section.

2 Turn the brush deck over, top of the motors down.

3 Remove the scrub brushes from the brush holders then

mark the location of the motor to the brush deck for proper

re-assembly.

4 See Figure 3. Remove the (3) (U) Hex Screws and (3) (V)

Nuts from each Flexible Coupler (W).

5 Next remove the (3) Hex Lock Screws (X) that connect

the coupler to the Drive Hubs (Y) and remove the brush

holder(s) (Z).

6 Remove the hardware items (AA & BB) that secure the

Hub (Y) to the output shaft on each gearbox. Then pull

the hub from the shaft and save the key.

7 Remove the (4) (CC) Screws and separate the motor/

gearbox assembly from the scrub deck that needs replacement.

8 Re-assemble in reverse order and test for proper opera-

tion. Note: Apply a small amount of grease or a product

called “Never Seize” to the gearbox output shaft when

reinstalling the Drive Hub(s) (Y).

FIGURE 3

revised 9/01

Page 28

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 27

SCRUB BRUSH SYSTEM

-

+

+

-

+

-

-

+

-

+

-

+

Ri ght*

Brush

Mot o r

Left*

Brush

Mot o r

Brush

Mot o r

Neg. Standoff

Neg. Standoff

To K1 Sol enoid

To K1

Sol enoid

26" Models

20" Models

Neg. Standoff

To K1

Sol enoid

Ri ght *

Brush

Mot o r

Left*

Brush

Mot o r

Wi t hout Jumper Plates With Jumper Plates

-

+

+

-

Jumper Plat es

-

+-+

CW rotation

from shaft end

CCW rotation

from shaft end

CW rotation

from shaft end

CCW rotation

from shaft end

Negative lead from right motor

Negati ve lead from left motor

Posi ti ve lead from ri ght motor

Negative lead from right motor

Nega ti ve lead from left motor

Pos. lead from rt motor

*Right and left are identified as seen from the rear of the machine.

FIGURE 4

revised 10/01

Page 29

28 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SCRUB BRUSH SYSTEM

11/32"

(8.7 mm) *

A

B

C

7/32"

(5.5 mm) *

A - Brush OFF (Raised Storage Position)

B - Brush ON (Brush Install Position)

C - Brush ON (Normal Scrub Position)

Stri ker Plate

Switch Mount

Bracket

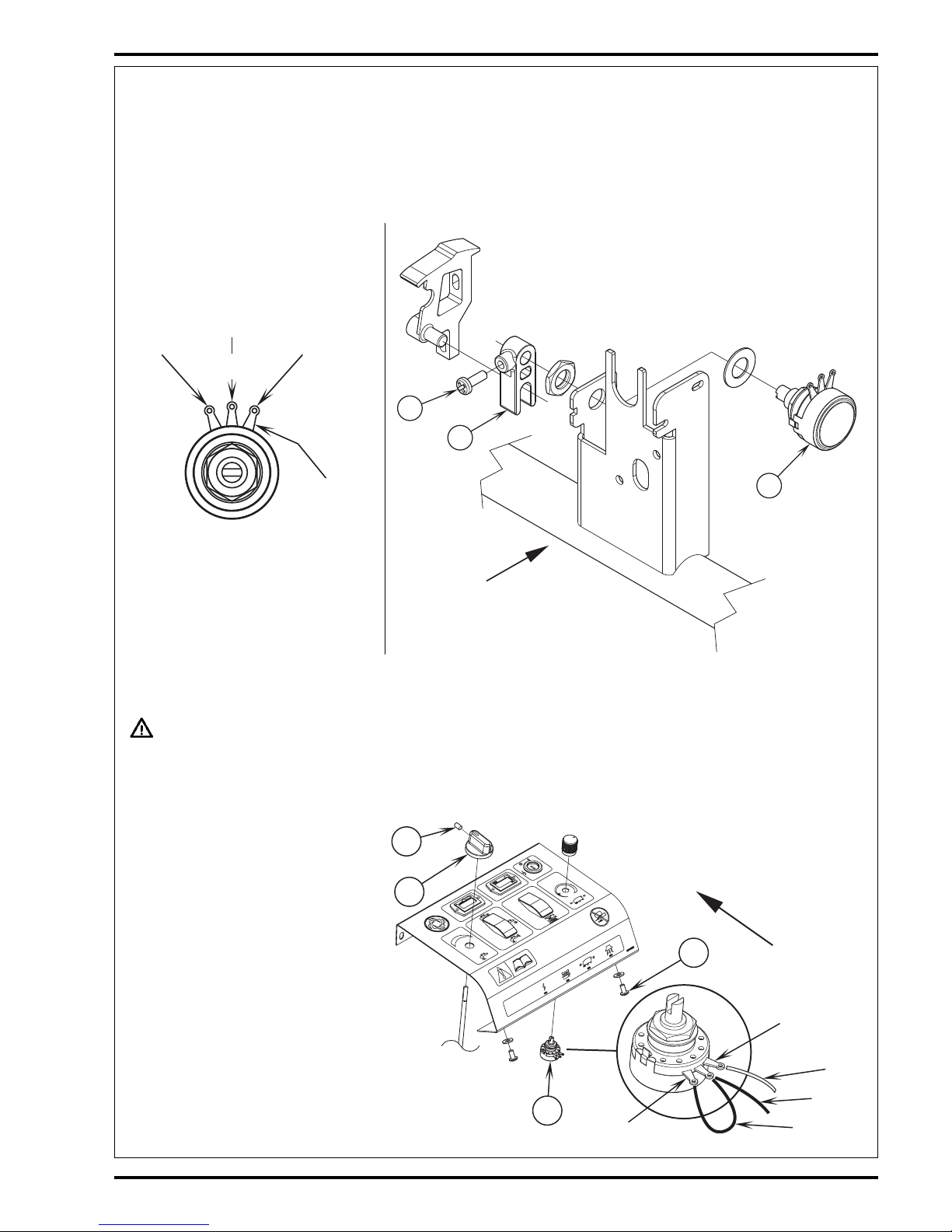

BRUSH HEAD SWITCH ADJUSTMENT (MACHINES BUILT BEFORE MARCH 2001)

WARNING!

Have the master key switch OFF when servicing the brush switch.

1 To access the brush switch remove the (5) screws securing the brush motor shroud then put the scrub brush deck in it’s UP stored position.

2 See Figure 5(A, B & C) below. These illustrations show the correct switch operational positions for the (A) raised storage position, (B) brush install position

and (C) normal scrub position.

3 With the key OFF, scrub deck raised, place scrub brush(es) underneath the drive disc(s) and lower deck for the automatic brush installation.

4 With the brush switch mounted loosely position the switch on the corner of the switch striker plate as shown in figure B. Note: The switch is mounted with

the roller not compressed and is in its normally closed position.

5 Turn the key ON, engage the drive paddle and install the brushes onto the drive disc(s) automatically. Note: The brush motor(s) will run.

6 Raise and lower the brush-head to test the switch for proper switch functions. Up the brush(es) should not run and down the brush should run.

FIGURE 5

*Note: Measurements given are approximate and intended only as a starting point for adjustment.

revised 9/01

Page 30

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 29

SCRUB BRUSH SYSTEM

FRONT

Front ViewSide View

Scrub deck in

raised position

Scrub deck in

lowered position

FIGURE 6

BRUSH HEAD SWITCH ADJUSTMENT (MACHINES BUILT AFTER FEBRUARY 2001)

WARNING!

Have the master key switch OFF when servicing the brush switch.

1 To access the brush switch remove the (5) screws securing the brush motor shroud then put the scrub brush deck in it’s UP stored position.

2 See Figure 6. Position the switch arm roller on the corner of the striker bracket as shown.

3 Push the switch and roller down to compress the switch (you will hear a click) then tighten the mounting screws to secure the switch adjustment. Note the

switch is now properly adjusted for an open circuit brush motors Off function.

4 Install scrub brush(es), lower the scrub deck, turn the key switch on and then engage the drive paddle to test that the brush motors run. Also cycle raise

and lower the brush deck to check the proper On and Off brush and drive paddle operations.

revised 9/01

Page 31

30 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

RECOVERY SYSTEM

FUNCTIONAL OVERVIEW

Vacuum / Recovery System General

Dirt and water are lifted off the floor into the recovery tank by airflow, created by a 3-Stage 24V vacuum motor. The wastewater and air enter the

vacuum system at the squeegee tool, through small openings (notches) located in the front squeegee blade. The small openings are the entrance

points for the water and air, and help speed up the airflow producing the suction to lift the wastewater off of the floor. The air and wastewater move

through the squeegee hose at high speed until it reaches the recovery tank. There the air slows down because of the increased volume (large

size) of tank. With the decreased air speed the heavier water falls to the bottom of the recovery tank. Then at the same time the airflow continues

through the tank, shutoff float, vacuum hose, vacuum motor and is exhausted out of the vacuum motor housing. No wastewater ever actually moves

through the vacuum motor, just clean air.

The vacuum system uses a shutoff float to prevent the tank from being overfilled and stops any water from being sucked into the vacuum motor.

Vacuum Motor Function

See Figure 2. The K2 vacuum motor solenoid is energized (turned on) when lowering the squeegee raise/lower lever. With the squeegee lever

lowered the S4 vacuum switch is closed and completes the control circuit that energizes K2 solenoid. With the load side of the K2 solenoid output

voltage complete the M1 vacuum motor will run.

Drain Hose

Squeegee

Vacuum Exhaust

Hose

Vacuum Motor

Cover Gasket

Recovery

Tank Cover

Recovery Tank

Squeegee Hose

Float Cage & Ball

Float Duct

FIGURE 1

revised 9/01

Page 32

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 31

RECOVERY SYSTEM

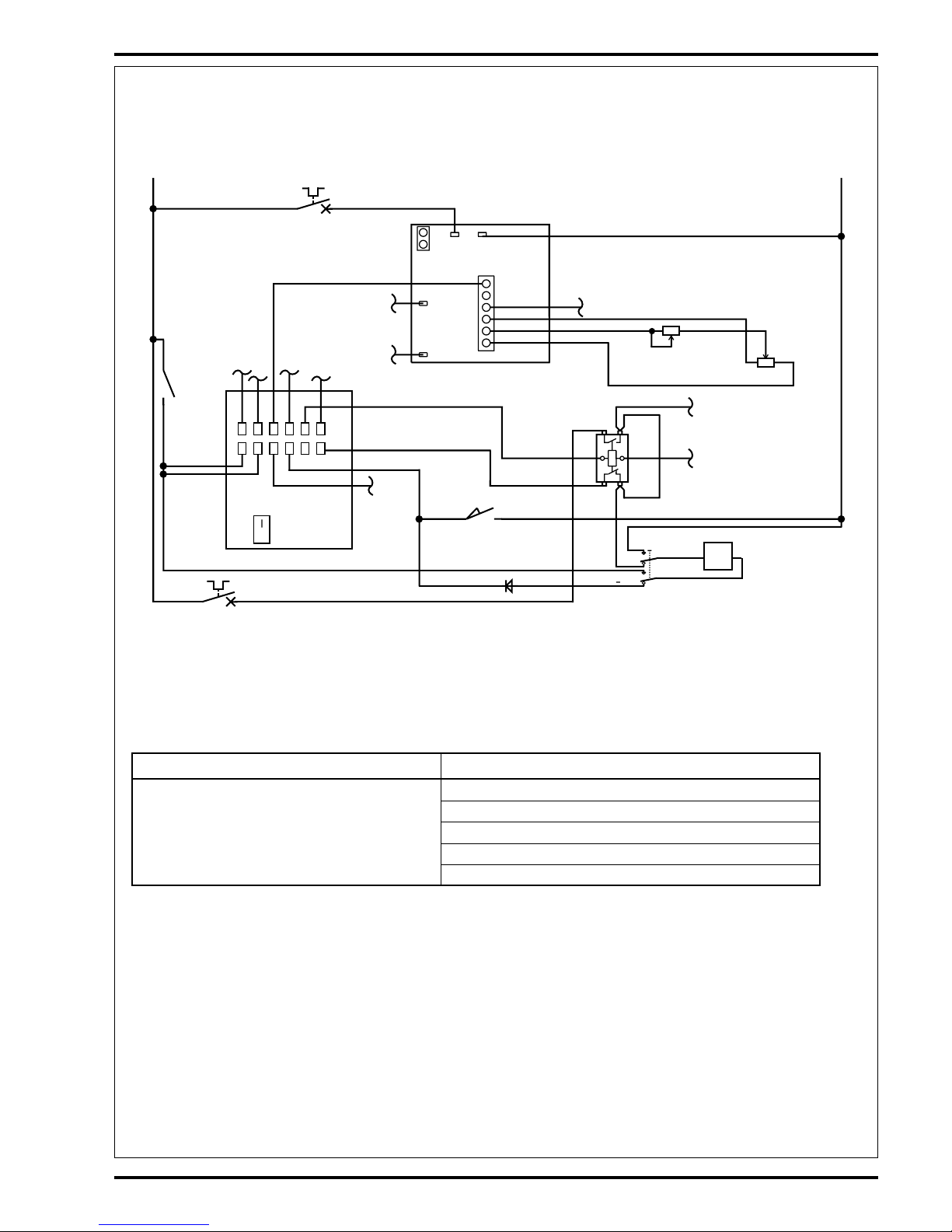

Electrical Diagram

*For complete description of all callouts see Electrical System Wiring Diagram.

VACUUM / RECOVERY SYSTEM SERVICE MAINTENANCE CHECKLIST

Whenever there is a vacuum problem, it’s best to check over the entire system. Use the checklist below as a guide, to thoroughly check the vacuum

system.

Clean built-up dirt from the inside of the squeegee tool.

Replace the squeegee blades if they are nicked or torn.

Inspect the hose between the squeegee tool and the recovery tank, rinse any built-up dirt from the hose. Replace the hose if it is kinked

or damaged.

Inspect and make sure the gasket on the recovery tank cover is sealing and not damaged.

Inspect and clean the vacuum motor float cage.

Make sure that the recovery tank drain valve seals airtight.

TROUBLESHOOTING GUIDE

If water flows around the ends of the squeegee tool, instead of being pulled into the tool, the vacuum system is not working properly. When a vacuum

system performs poorly, it is usually because of one of the following problems:

Vacuum Leak(s) – Air flowing into the vacuum system past a bad gasket or leaky hose, damaged tank, or a leaky drain valve. A vacuum leak

below the water line will create turbulence in the recovery tank, causing water to enter the vacuum motor.

Restriction(s) – Anything that blocks the flow of air through the system. Restrictions may also be caused by built-up debris in the squeegee tool,

vacuum hoses, float cage or wherever the airflow is forced to make a sharp turn.

Both leaks and restrictions decrease the quantity of air flowing through the squeegee tool. The air that does go through the squeegee tool moves

slower, so it has less pick-up power.

FIGURE 2

F4

+24V -24V

RED/GRNRED

BLK

M

M1

BLU

K2

D1

K2

BLK

RED/WHT

S4

VIO

RED

S5

F1

S1

revised 9/01

Page 33

32 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

RECOVERY SYSTEM

No

Yes

Yes

Yes

No

No

Vacuum motor will not

run (See Figure 2).

1. Try re-setting the

circuit breaker first.

2. Check continuity on

the F4 (30A) vac

motor circuit breaker

Replace the F4 (30A)

vac motor circuit breaker

Check for 24V at the

blue wire (output

terminal) on the K2 vac

motor solenoid to a Neg.

battery standoff.

Check for 24V at the

M1 vac motor

Repair or replace

the M1 vac motor

See part B vac motor

control circuit

troubleshooting guide.

Repair or replace

wiring to vac motor

TROUBLESHOOTING GUIDE ELECTRICAL

Possible Symptom

1 Vacuum motor will not run

SYMPTOM ONE

Note: Do all testing with the master key switch ON, vac switch S4 ON (squeegee lowered).

Part A: Vacuum Motor Load Circuit Troubleshooting Guide

revised 9/01

Page 34

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 33

RECOVERY SYSTEM

SYMPTOM ONE

Note: Do all testing with the master key switch ON, vac switch S4 ON (squeegee lowered).

Part B: Vacuum Motor Control Circuit Troubleshooting Guide

TROUBLESHOOTING GUIDE ELECTRICAL (CONTINUED)

No

Yes

Yes

No

No

Yes

No

Vacuum motor

will not run (see

Figure 2).

Check for 24V at

the Red/Wht and

Blk wires on the K2

vac motor solenoid

(small terminals).

Check for 24V at

the (Pos.) K2

Red/Wht solenoid

coil wire to a Neg.

battery standoff

Replace the

K2 vac motor

solenoid

Check for 24V at

the (Neg.) K2 Blk

solenoid coil wire

to a Pos. battery

standoff

Check for 24V at

Vio wire on the

S4 vac switch to a

Neg. battery

standoff

Repair or replace

the Blk wire back

to the Neg. battery

standoff

Replace the S4

vac motor switch

Repair or replace

the Vio wire back

to the S1 key

switch

revised 9/01

Page 35

34 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

RECOVERY SYSTEM

FRONT

A

B

E

C

D

F

G

L

J

H

I

K

M

MAINTENANCE OF FLOAT CAGE AND FLOAT DUCT

1 Open the recovery tank dome lid and lay it to the side, remove the two (A) Screws and pull the Float Duct (B) and float cage assembly (C) from vac motor

spacer (D).

2 Snap apart the two float cage halves (C) and flush clean the float ball and cage pieces.

3 Inspect the Gasket (E) and clean any debris from the inside of the float duct housing. Then re-install all parts in reverse order.

FIGURE 3

revised 9/01

Page 36

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 35

RECOVERY SYSTEM

12 3

FRONT

Q

O

P

N

1

2

3

R

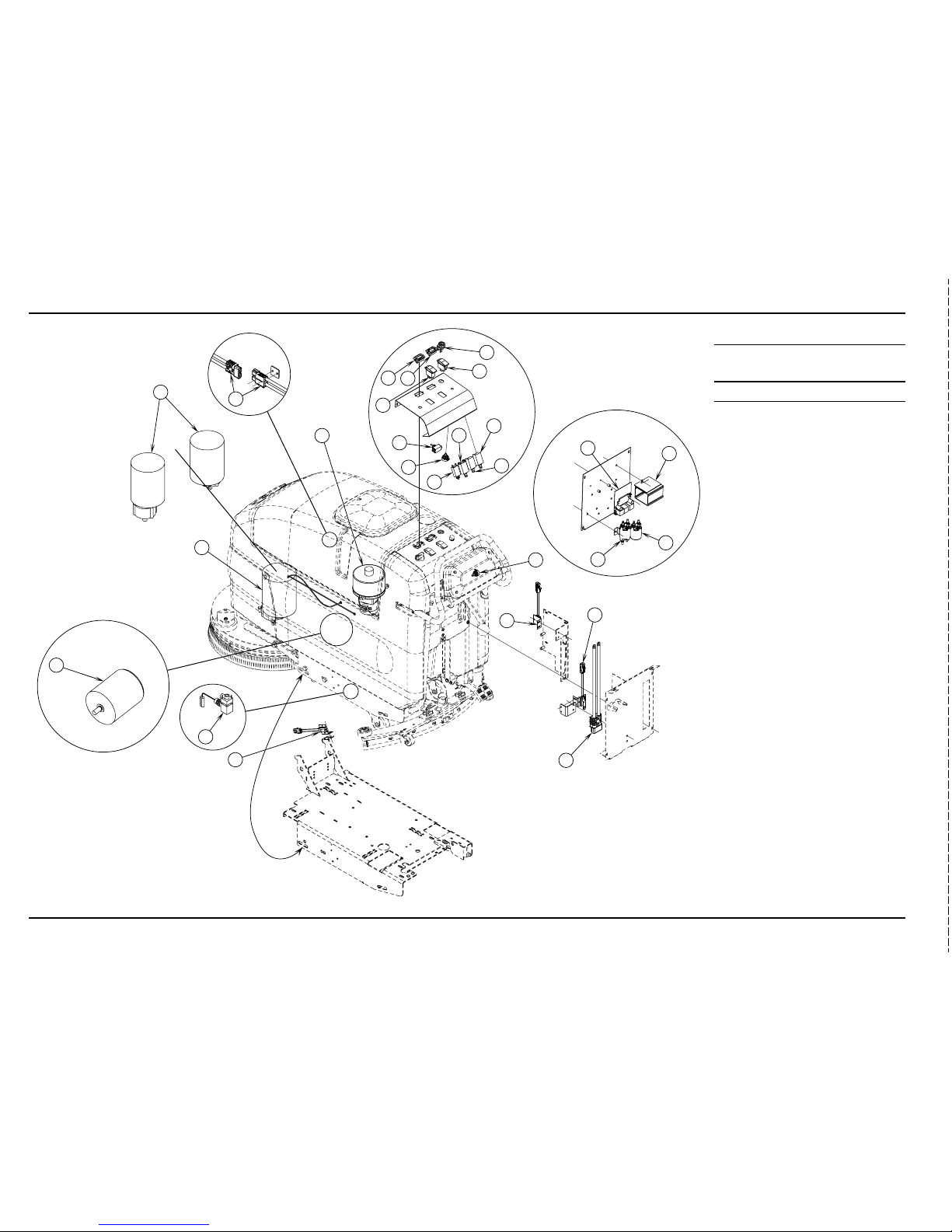

VACUUM MOTOR REMOVAL

1 Drain the recovery tank using the drain hose.

2 Swing open the recovery tank, secure with prop rod and disconnect the vacuum motor harness connector.

3 See Fig 3. Remove the vacuum motor Duct Cover (F) secured to the bottom of recovery tank bottom (qty 4 screws).

4 Loosen the exhaust hose clamp and remove Hose (M) from the vac motor discharge tube and completely remove the motor from its mount cavity.

5 Inspect the condition of the vac motor Gasket (G) inside the vac motor mount cavity.

6 Make service repairs to the vac motor and re-install by following steps in reverse order.

RECOVERY TANK REMOVAL

1 Follow steps 1-4 in the Vacuum Motor Removal section.

2 See Figure 3. Remove the Nut (H) and release the Tank Support Bar (I) and allow the tank to swing down to the side of the battery compartment box.

3 Loosen the hose clamp for the tank drain hose (J) and pull the hose free.

4 Remove the Tank End Panel (K) (3 screws) and remove the Squeegee Hose (L) from the tank connection.

5 Support the tank and remove the (4) screws from the hinge that attaches the tank to the top of the solution tank edge and pull the tank free from the machine.

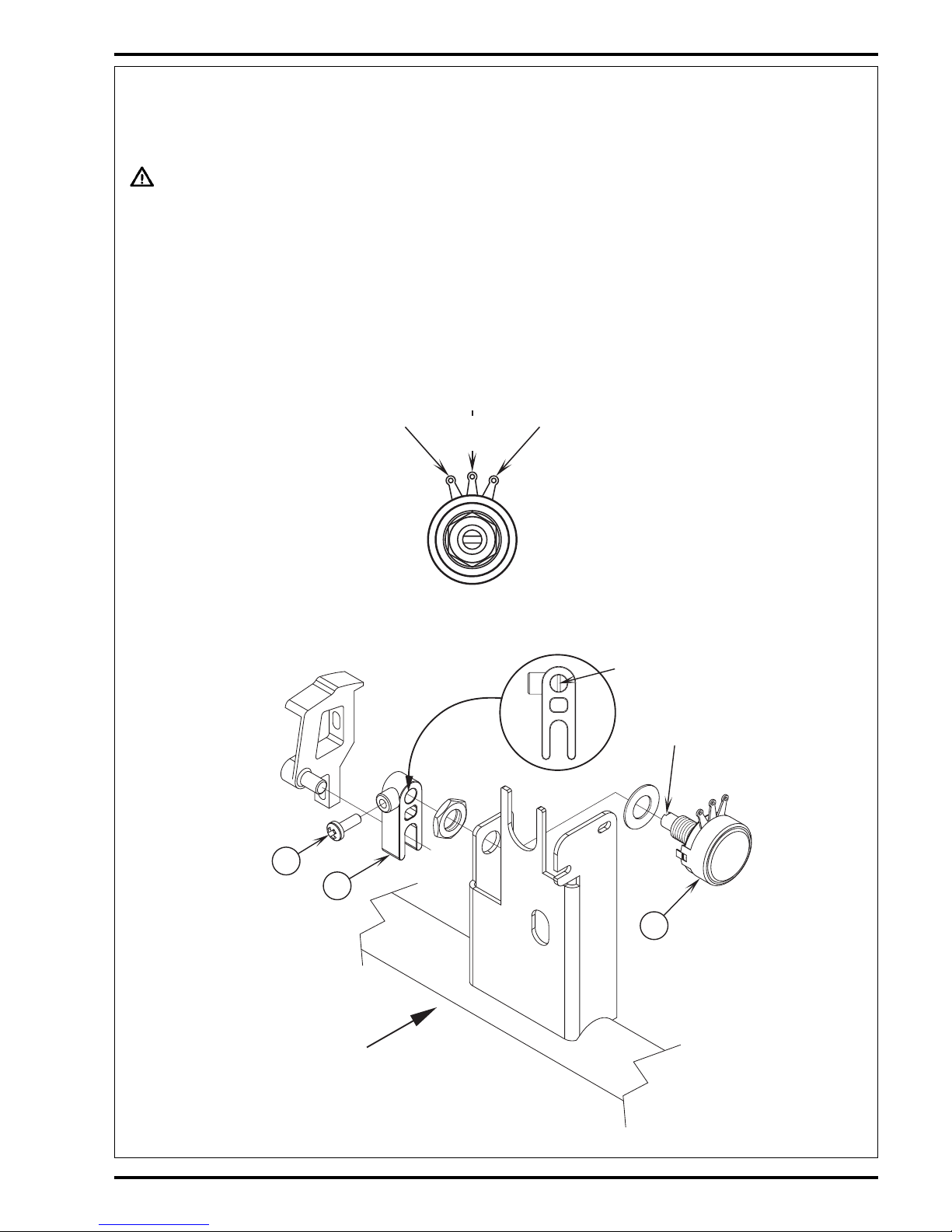

VACUUM SWITCH REPLACEMENT AND ADJUSTMENT

1 With the key switch OFF remove the back Electrical Panel (N) secured with (6) screws to access the Vacuum Switch (O) as shown in Figure 4.

2 Remove the (2) Switch Mount Screws (P), Nut Plate (Q) then separate the wiring connector and remove the switch from the machine.

3 With the squeegee Lift Lever (R) in the Up storage position (1) install the vacuum switch loosely to its mount bracket and reconnect the wiring.

4 See Figure 4. Move (push) the switch actuator arm roller against the squeegee lever to where it clicks then tighten the mounting screws.

5 Test with the key switch ON, the vacuum switch is in the open position (off) and the vac motor will not run. Move the squeegee lever to the next notch (2)

and the switch will click to its closed position (on) and the vac motor will run.

FIGURE 4

revised 9/01

Page 37

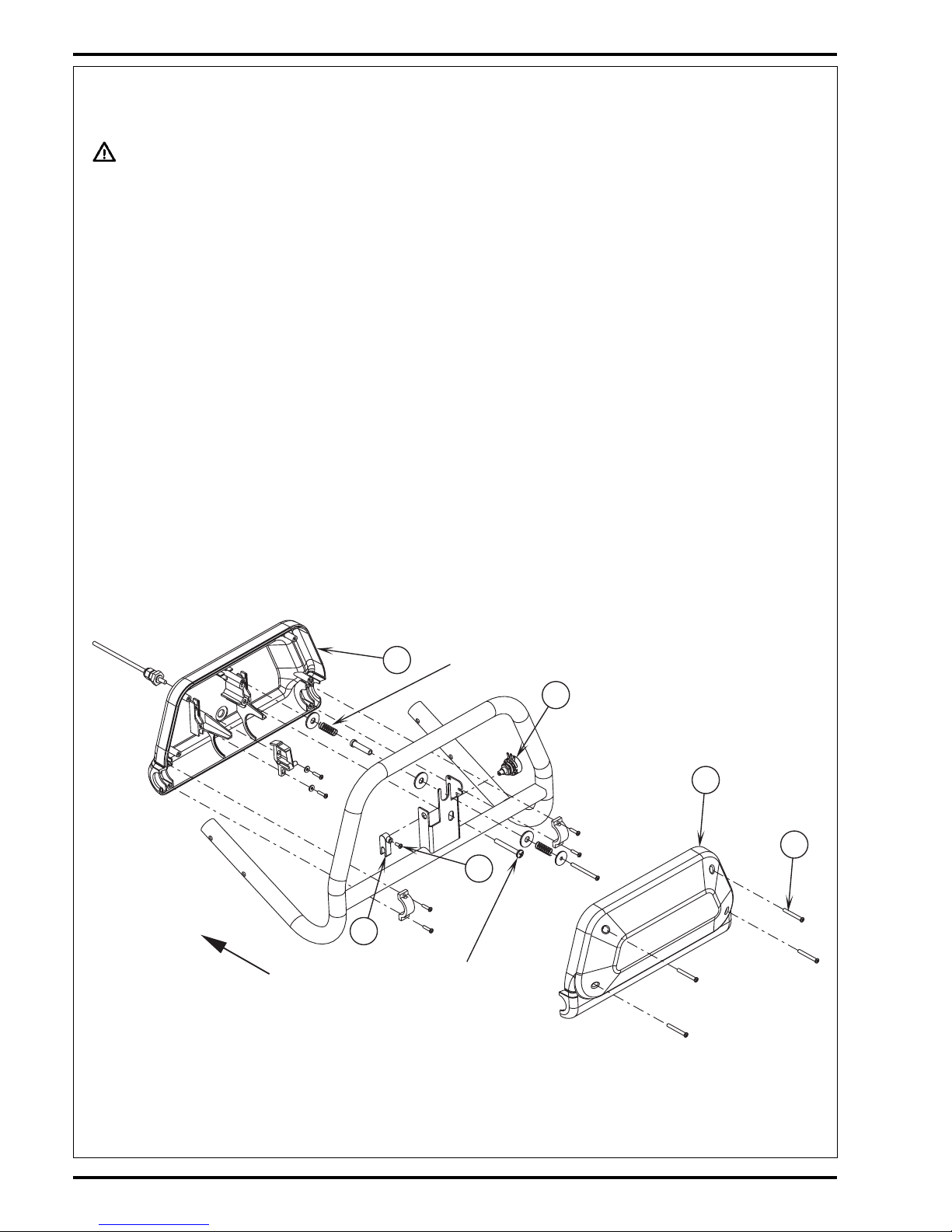

36 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

SQUEEGEE SYSTEM

SQUEEGEE TOOL BLADE(S) REPLACEMENT

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and inspect

the blades. Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 1*. Raise the squeegee tool off the floor, then unsnap the Center Latch (A) on the squeegee tool.

2 Remove the Wing Nut (B) from each end of the squeegee, then remove the Tension Straps (C).

3 Slip the Rear Blade (D) off the alignment pins.

4 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the blade if all

4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee tool off the floor, then loosen the (2) Thumb Nuts (E) on top of the squeegee and remove the squeegee tool from the mount.

2 Remove all the Hex Nuts (F) that hold the Front Blade (G) in place, then remove tension strap and blade.

3 The squeegee blade has 4 working edges. Turn the blade so a clean, undamaged edge points toward the front of the machine. Replace the blade if all

4 edges are nicked, torn or worn to a large radius.

4 Install the blade, following the steps in reverse order and adjust the squeegee.

SQUEEGEE ADJUSTMENT

Adjusting the Squeegee Angle

Adjust the squeegee angle whenever a blade is reversed or replaced, or if the squeegee is not wiping the floor dry.

1 Park the machine on a flat, even surface and lower the squeegee. Push the machine forward enough to have the squeegee wiping blade fold over to the

rear as shown in figure 2.

2 See Figure 1. Turn the Adjustment Knob (H) to tilt the tool forward (CCW) or backwards (CW), until the rear squeegee wiping blade touches the floor evenly

across its entire width.

revised 9/01

Page 38

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 37

SQUEEGEE SYSTEM

FRONT

H

F

B

C

C

E

A

B

E

D

G

FIGURE 1

FIGURE 2

G

D

*Note the 20” squeegee tool is shown, the 26” squeegee tool is similar in adjustment and blade replacement.

revised 9/01

Page 39

38 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

WHEEL DRIVE SYSTEM

-

+

1

2

3

4

5

6

R1

R2

A1

F3

P1

B-B+

P2

BLK

M

WHT/YEL

RED/BLU

M2

+24V

VIO

RED

S5

F1

S1

RED BRN/BLK

RED/BLKBRN/RED

-24V

VIO

ORN

GRN

YEL

(T1)

(T2)

(T3)

(T4)

M1

M2

GENERAL FUNCTIONAL OVERVIEW

A 1/2 horsepower permanent magnet 24V DC motor drives the ConvertaMAX™ models 20/26 & BA 550/650. See Figure 3. The motor output

is delivered to a single front mounted drive wheel driven by a chain. See Figure 1. The speed of the motor is regulated by a solid-state speed

control (A1), located in the rear handle electrical compartment. The potentiometer (R2), mounted in the drive paddle, regulates both machine

direction and variable speed demands. A second pot (R1) is mounted in the control panel and its knob can be adjusted to control the machines

maximum transport speed.

Drive Motor System Function

See Figure 1. With the key switch S1 closed the violet wire inputs 24V to the A1 speed controller to make it operational (power it up). The F3 (30

Amp) circuit breaker supplies the (Pos.) 24V power input to the T1 or B+ controller terminal (Brn/Blk wire). The black wire from the battery Negative

standoff supplies the (Neg.) 24V power input to the T2 or B- controller terminal. Moving the 5K Ohm R2 speed pot off its centered balanced neutral

setting activates the operator input to the speed control. Forward or reverse movement of the drive paddle rotates the pot shaft and its variable

resistance changes causing internal voltage input signal changes within the controller. These pot voltage related signals then energize the Fwd

and Rev directional relays that selects the motor polarity and final voltage level outputs at the M1 & M2 terminals.

FIGURE 1

Electrical Diagram

*For complete description of all callouts see Electrical System Wiring Diagram.

-

+

1

2

3

4

5

6

WHT

R1

R2

A1

(Partial)

VIO

ORN

GRN

YEL

BRN*

YEL

WHT*

GRN*

ORN

GRN

P1

Key Switch

25K Ohms

5K Ohms

FIGURE 2

This drawing shows additional controller input circuit detail. The R1 pot is shown at the Max speed limiting setting and the R2 pot in neutral.

*Handle wiring harness changed. Machines built after December 1, 2000 have different wire colors at R2 pot. Green wire changed to GRN/YEL,

brown wire changed to BLK #2 (wire with the number 2 printed on it) and white wire changed to BLK #1.

revised 7/02

Page 40

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 39

WHEEL DRIVE SYSTEM

FRONT

Chain

Drive Wheel

Drive Wheel Motor

R1 Potentiometer

(25,000 Ohms)

R2 Potentiometer

(5,000 Ohms)

WHEEL DRIVE TROUBLESHOOTING GUIDE

Problem Possible Cause

• No forward or reverse wheel drive. See Electrical Troubleshooting Flowcharts A & B.

• No wheel drive in one direction, Controller can’t change electrical polarity to wheel motor.

loss of either forward or reverse. Replace the (A1) speed control.

• Machine creeps (moves) in forward or • Check movement of the drive paddle spring centering device

reverse with only the key switch ON. (auto dead-man return to neutral components). Repair or replace

needed parts.

• The R2 drive pot is out of adjustment. Reset to neutral the 5000

Ohm drive paddle potentiometer (*).

• During normal machine transporting with the 5K The R1 (25,000 Ohm) speed limiting pot wiper is either open

drive paddle pot activated the operator also adjusts where the machine runs at minimum speed or the pot wiper

the control panel maximum speed limiting R1 pot and is shorted and runs at maximum speed. Replace the R1 pot (**).

does not affect the desired maximum machine speed

output.

* See Potentiometer Installation and Adjustment instructions in this manual section and reset the (5K) pot to neutral.

** See 25K Wheel Drive Speed Limit Potentiometer Testing instructions in this manual section.

FIGURE 3

revised 9/01

Page 41

40 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

WHEEL DRIVE SYSTEM

TROUBLESHOOTING GUIDE ELECTRICAL

Possible Symptom

1 No forward or reverse wheel drive

SYMPTOM ONE

Note: Do all testing with control panel R1 speed limiting pot in the maximum position, the drive wheel jacked up off the floor, key switch ON, and

the drive paddle activated (pushed Fwd or pulled into Rev.)

Part A: Wheel drive system motor load circuit troubleshooting guide

Note A: The drive wheel motor harness disconnect is located in the lower rear of the machine frame between the caster wheels.

No Fwd or Rev

wheel drive

(see Figure 1).

1. Try resetting the F3

drive motor circuit

breaker (30 Amp).

2. Still no drive check

the F3 breakers

continuity

Replace the F3

(30 Amp) wheel

drive circuit

breaker

No

Check for 24V at the

A1 speed controllers

Battery Pos. (+) &

Battery Neg. (-)

terminals.

Repair or replace the

battery input wiring to

the A1 speed controller

Separate the motor

wiring harness (see

note A) & check for

controller output volt-

age by activating the

drive paddle. Should

have 24V Fwd & 15V

in Rev.

Repair or replace

the M2 wheel drive

motor

Yes

See part B wheel

drive control circuit

troubleshooting

guide.

No

Yes

No

Yes

revised 9/01

Page 42

FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650 - 41

WHEEL DRIVE SYSTEM

SYMPTOM ONE

Note: Do all testing with control panel R1 speed limiting pot in the maximum position, the drive wheel jacked up off the floor, key switch ON, and

the drive paddle activated (pushed Fwd or pulled into Rev.)

Part B: Wheel drive system motor control circuit troubleshooting guide

Note A: Follow the potentiometer test instructions shown in the wheel drive system section.

Note B: The drive wheel motor harness disconnect is located in the lower rear of the machine frame between the caster wheels.

TROUBLESHOOTING GUIDE ELECTRICAL (CONTINUED)

No Fwd or Rev wheel

drive (see Figure 1).

At the A1 speed controller

check for 24V input, Vio wire

to Negative battery standoff

Repair or replace the

Vio control circuit

input wire.

Check the total resistance of the

drive paddle R2 pot. Remove

wires and measure across the two

outside terminals, should read

4500-5500 Ohms.

Test shows an open

(infinity) replace the R2

potentiometer with P.N.

56397029

Check the total resistance of

the speed limit R1 pot. Remove

wires and measure across the

two outside terminals, should

read approximately 25000

Ohms.

Separate the motor wiring harness

disconnect (see Note B) & check

for controller output voltage by

activating the drive paddle. Should

have 24V in Fwd & 15V in Rev.

Test shows an open

(infinity) replace the R1

potentiometer with P.N.

56397123

Replace the A1

speed controller

Check the functional operation of

the wiper resistance circuits (see

Note A) for both the 5K(R2) pot &

the 25K(R1) pot.

Test measurements should show a

variable resistance within spec. for

each individual pot when the pot

shaft is turned in both directions.

Replace the specified

pot(s) that's measure-

ments show an open

circuit.

Yes

Yes

Yes

Yes

No

No

No

No

No

revised 7/02

Page 43

42 - FORM NO. 56043056 ConvertaMAX™ 20/26 / BA 550/650

WHEEL DRIVE SYSTEM

CHAIN MAINTENANCE

• Every two months check the chain tension, 1/2 inch (13mm) deflection at mid point.

• Once a month check chain for binding and dryness, apply oil to lube the chain links.

• Yearly remove chain, clean and re-oil.

CHAIN REMOVAL AND ADJUSTMENT

Chain Removal:

WARNING!

Disconnect a battery cable at the battery pack before servicing.

1 See Figure 4. Loosen the Lock Nut (A) and back out Bolt (B) several turns to loosen the drive chain tension.

2 Remove the retainer clip from the chain’s master link, separate and remove the chain from the sprockets.

3 To re-install chain loosen the (3) (C) drive motor mount screws and push the drive motor all the way forward. Note: The reason for this step is to shorten

the distance between the sprockets to make it easier to reconnect the master link.