Page 1

ER 1300, 1600

Instructions for Use

Original Instructions

Kullanim Talimatlari

MODELS: 56111025(LPG/1300), 56111026(Petrol/1300), 56111027(Diesel/1300)

56111028 (LPG/1600), 56111029(Petrol/1600), 56111030(Diesel/1600)

9/10

FORM NO. 56091008

A-English

B-Türkçe

Page 2

A-2 / ENGLISH

TABLE OF CONTENTS

PAGE

Introduction ........................................................................................... A-3

Cautions and Warnings ........................................................................ A-4

Know Your Machine .....................................................................A-6 – A-9

Prepare the Machine for Use

General Information ............................................................................A-10

Pre-operational Checklist ........................................................A-11 – A-12

Hydraulic Oil ..................................................................................... A-11

Engine Oil ......................................................................................... A-11

Engine Coolant ................................................................................. A-12

Engine Air Filter ................................................................................ A-12

Fuel ...................................................................................................A-12

Install the Brushes .............................................................................. A-13

Filling the Solution Tank ...................................................................... A-14

Operating the Machine

Starting the Engine ............................................................................. A-15

Detergent System ....................................................................A-16 – A-17

Scrubbing ................................................................................A-18 – A-19

Wet Vacuuming .................................................................................. A-18

After Using the Machine

After Use .............................................................................................A-20

Shutting Down the Engine .................................................................. A-20

Maintenance

Maintenance Schedule ....................................................................... A-20

Lubricating the Machine ..........................................................A-20 – A-21

Side Broom Maintenance ................................................................... A-22

Squeegee Maintenance ......................................................................A-23

Squeegee Adjustment ........................................................................ A-23

Side Skirt Maintenance .......................................................................A-24

Debris Hopper Maintenance ............................................................... A-25

Troubleshooting .......................................................................A-26 – A-27

Technical Specifi cations .....................................................................A-28

A-2 - FORM NO. 56091008 - ER 1300, 1600

Page 3

ENGLISH / A-3

INTRODUCTION

This manual will help you get the most from your Nilfi sk Rider Scrubber. Read it thoroughly before operating the machine.

Note: Bold numbers in parentheses indicate an item illustrated on pages 6 – 9.

PARTS AND SERVICE

Repairs, when required, should be performed by your Authorized Nilfi sk Service Center, who employs factory trained service personnel, and maintains an inventory

of Nilfi sk original replacement parts and accessories.

Call the NILFISK DEALER named below for repair parts or service. Please specify the Model and Serial Number when discussing your machine.

(Dealer, affi x service sticker here.)

NAME PLATE

The Model Number and Serial Number of your machine are shown on the Nameplate on the machine. This information is needed when ordering repair parts for

the machine. Use the space below to note the Model Number and Serial Number of your machine for future reference.

MODEL NUMBER _______________________________________________________

SERIAL NUMBER ______________________________________________________

UN-CRATING

Upon delivery, carefully inspect the shipping crate and the machine for damage. If damage is evident, save all parts of the shipping crate so that they can be

inspected by the trucking company that delivered the machine. Contact the trucking company immediately to fi le a freight damage claim.

1 After removing the crate, remove the wooden blocks next to the wheels.

2 Check the engine oil and coolant levels.

3 Check the hydraulic oil level.

4 Read the instructions in the Preparing the Machine For Use section of this manual, then fi ll the fuel tank.

6 Place a ramp next to the front end of the pallet.

7 Read the instructions in the Operating Controls and Operating the Machine sections of this manual and start the engine. Slowly drive the machine forward

down the ramp to the fl oor. Keep your foot lightly on the brake pedal until the machine is off the pallet.

CAUTION!

Use extreme CAUTION when operating this machine. Be certain that you are thoroughly familiar with all operating instructions before

using this machine. If you have any questions, contact your supervisor or your local Nilfi sk Industrial Dealer.

If the machine malfunctions, do not try to correct the problem unless your supervisor directs you to do so. Have a qualifi ed company

mechanic or an authorized Nilfi sk Dealer service person make any necessary corrections to the equipment.

Use extreme care when working on this machine. Loose clothing, long hair, and jewelry can get caught in moving parts. Turn the Key

Ignition Switch OFF and remove the key before servicing the machine. Use good common sense, practice good safety habits and

pay attention to the yellow decals on this machine.

Drive the machine slowly on inclines. Use the Brake Pedal (23) to control machine speed while descending inclines. DO NOT turn

the machine on an incline; drive straight up or down.

The maximum rated incline for sweeping and scrubbing is 10.5%(6°). The maximum rated incline during transport is 16%(9°).

FORM NO. 56091008 - ER 1300, 1600 - A-3

Page 4

A-4 / ENGLISH

CAUTIONS AND WARNINGS

SYMBOLS

Nilfi sk uses the symbols below to signal potentially dangerous conditions. Always read this information carefully and take the

necessary steps to protect personnel and property.

DANGER!

Is used to warn of immediate hazards that will cause severe personal injury or death.

WARNING!

Is used to call attention to a situation that could cause severe personal injury.

CAUTION!

Is used to call attention to a situation that could cause minor personal injury or damage to the machine or other property.

Read all instructions before using.

GENERAL SAFETY INSTRUCTIONS

Specifi c Cautions and Warnings are included to warn you of potential danger of machine damage or bodily harm.

DANGER!

* This machine emits exhaust gases (carbon monoxide) that can cause serious injury or death, always provide adequate

ventilation when using machine.

WARNING!

* This machine shall be used only by properly trained and authorized persons.

* While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills. Clean only

while ascending (driving up) the ramp.

* To avoid hydraulic oil injection or injury always wear appropriate clothing and eye protection when working with or near hydraulic

system.

* Turn the key switch (50) off (O) and disconnect the batteries before servicing electrical components.

* Never work under a machine without safety blocks or stands to support the machine.

* Do not dispense fl ammable cleaning agents, operate the machine on or near these agents, or operate in areas where fl ammable

liquids exist.

* Do not clean this machine with a pressure washer.

CAUTION!

* This machine is not approved for use on public paths or roads.

* This machine is not suitable for picking up hazardous dust.

* Use care when using scarifi er discs and grinding stones. Nilfi sk will not be held responsible for any damage to fl oor surfaces

caused by scarifi ers or grinding stones.

* When operating this machine, ensure that third parties, particularly children, are not endangered.

* Before performing any service function, carefully read all instructions pertaining to that function.

* Do not leave the machine unattended without fi rst turning the key switch (50) off (O), removing the key and applying the parking

brake.

* Turn the key switch (50) off (O) before changing the brushes, and before opening any access panels.

* Take precautions to prevent hair, jewelry, or loose clothing from becoming caught in moving parts.

* Use caution when moving this machine in below freezing temperature conditions. Any water in the solution or recovery tanks or

in the hose lines could freeze.

* Before use, all doors and hoods should be properly latched.

SAVE THESE INSTRUCTIONS

A-4 - FORM NO. 56091008 - ER 1300, 1600

Page 5

ENGLISH / A-5

FORM NO. 56091008 - ER 1300, 1600 - A-5

Page 6

A-6 / ENGLISH

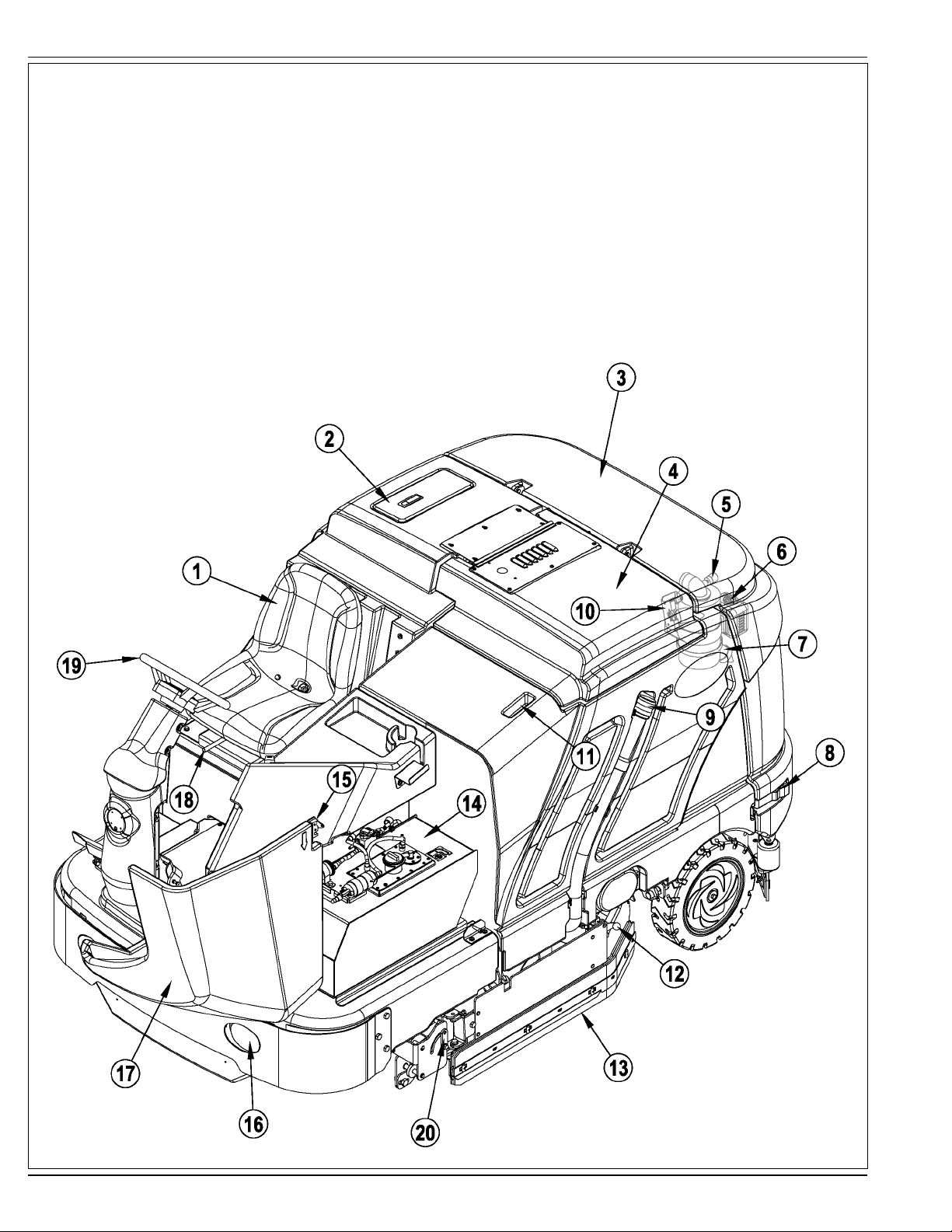

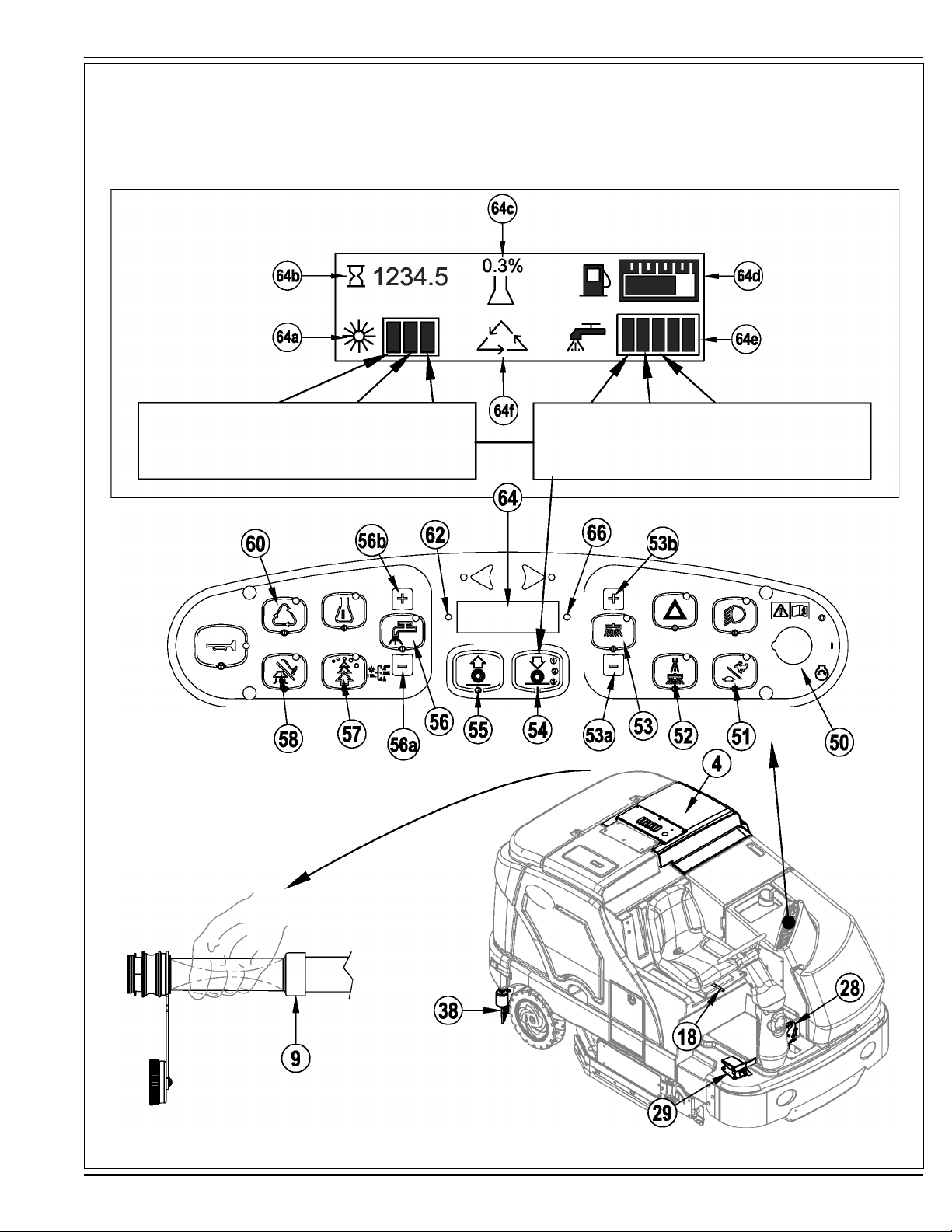

KNOW YOUR MACHINE

As you read this manual, you will occasionally run across a bold number or letter in parentheses - example: (2). These numbers refer to an item shown on these

pages unless otherwise noted. Refer back to these pages whenever necessary to pinpoint the location of an item mentioned in the text.

1 Operator’s Seat

2 Solution Tank Fill Cover

3 Engine Cover

4 Recovery Tank Cover

5 Engine Air Filter Service Indicator

6 Coolant Overfl ow Tank

7 Engine Air Filter

8 Engine Cover Latch

9 Recovery Tank Drain Hose

10 Recovery Tank Tilt Out Latch

11 Recovery Tank Tilt Out Grip

12 Left Side Skirt Latch

13 Left Side Skirt

14 Fuel Tank (petrol tank shown)

15 Fuel Tank Cover Latch

16 Head Light

17 Fuel Tank Cover

18 Operator Seat Adjustment Lever

19 Steering Wheel

20 Double Scrub Skirt Holder

A-6 - FORM NO. 56091008 - ER 1300, 1600

Page 7

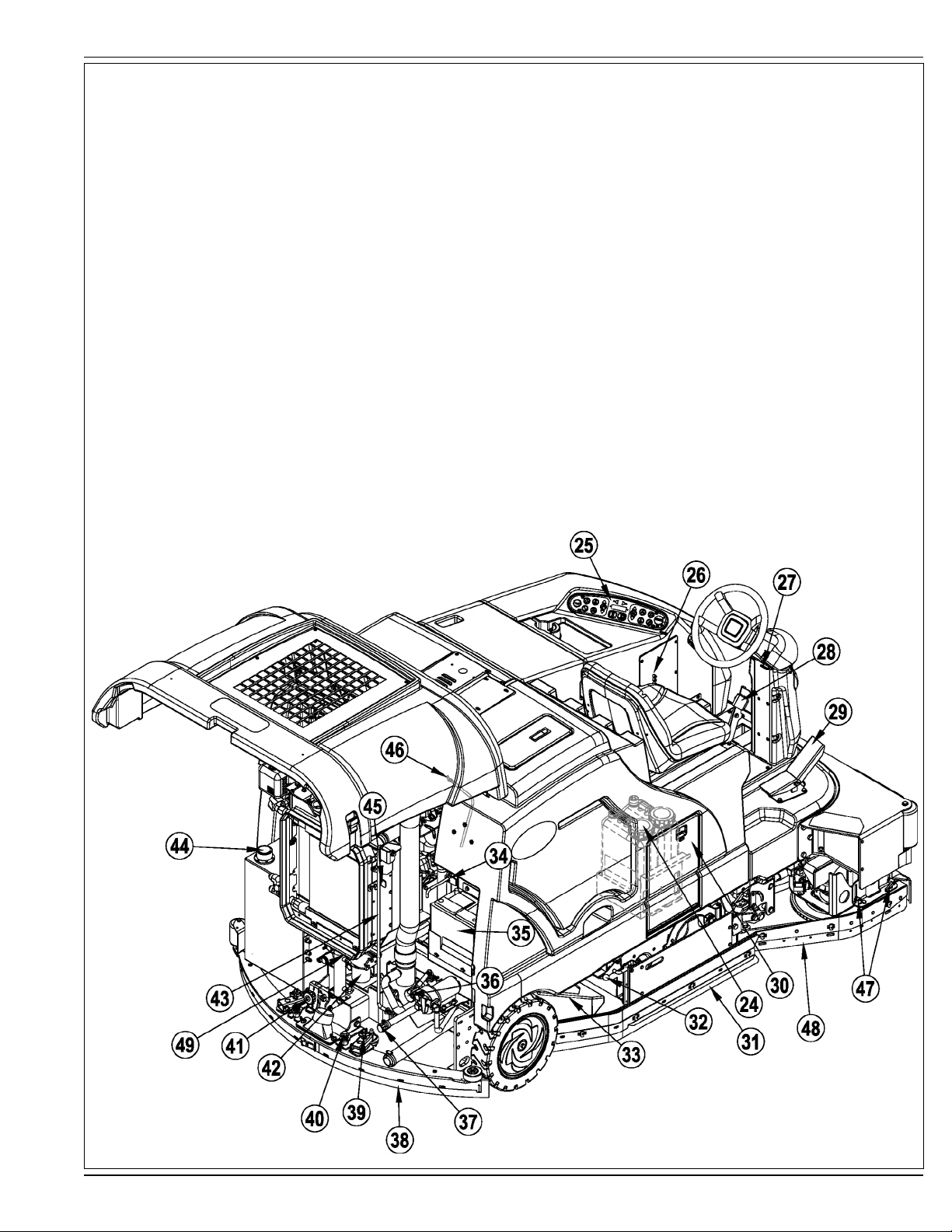

KNOW YOUR MACHINE

24 Detergent Cartridges (EcoFlex models only)

25 Control Panel

26 Circuit Breaker Panel (see Troubleshooting)

27 Steering Wheel Tilt Adjust Lever

28 Brake Pedal / Parking Brake

29 Drive Pedal, Directional/Speed

30 Detergent Cartridge Compartment

31 Right Side Skirt

32 Right Side Skirt Latch

33 Hopper

34 Tow Valve Lever

35 Battery

36 Solution Filter

37 Solution Tank Drain Hose

38 Squeegee Assembly

ENGLISH / A-7

39 Squeegee Height Adjust Knob

40 Squeegee Mount Wrench

41 Squeegee Tilt Adjust Knob

42 Engine Oil Filter

43 Engine Cover Prop Rod

44 Hydraulic Oil Reservoir Filler Cap

45 Oil Cooler Tilt Out Latch

46 Engine Oil Dipstick

47 Right Scrub Skirt Retainer Knobs

48 Right Scrub Skirt Assembly

49 Engine Oil Drain (under radiator)

FORM NO. 56091008 - ER 1300, 1600 - A-7

Page 8

A-8 / ENGLISH

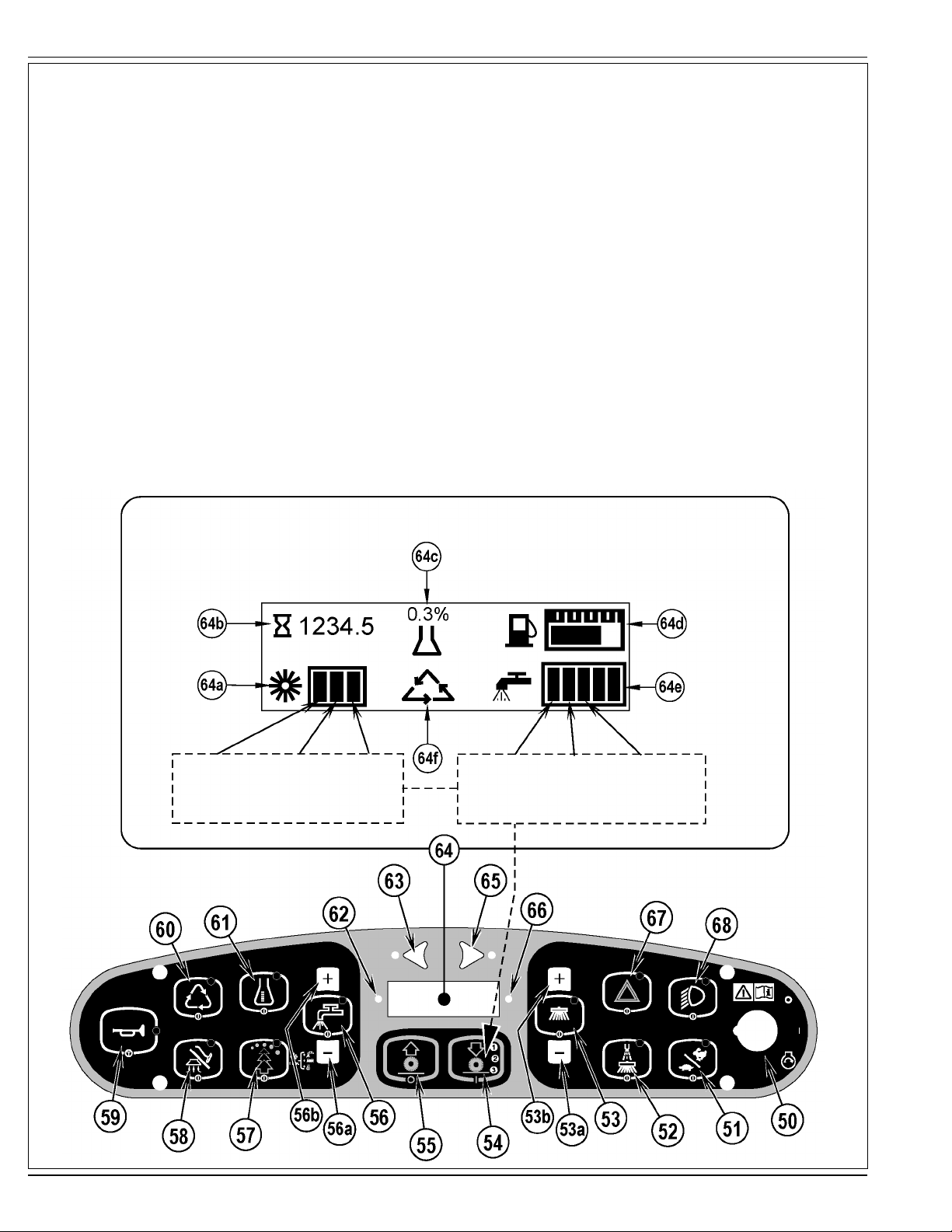

KNOW YOUR MACHINE

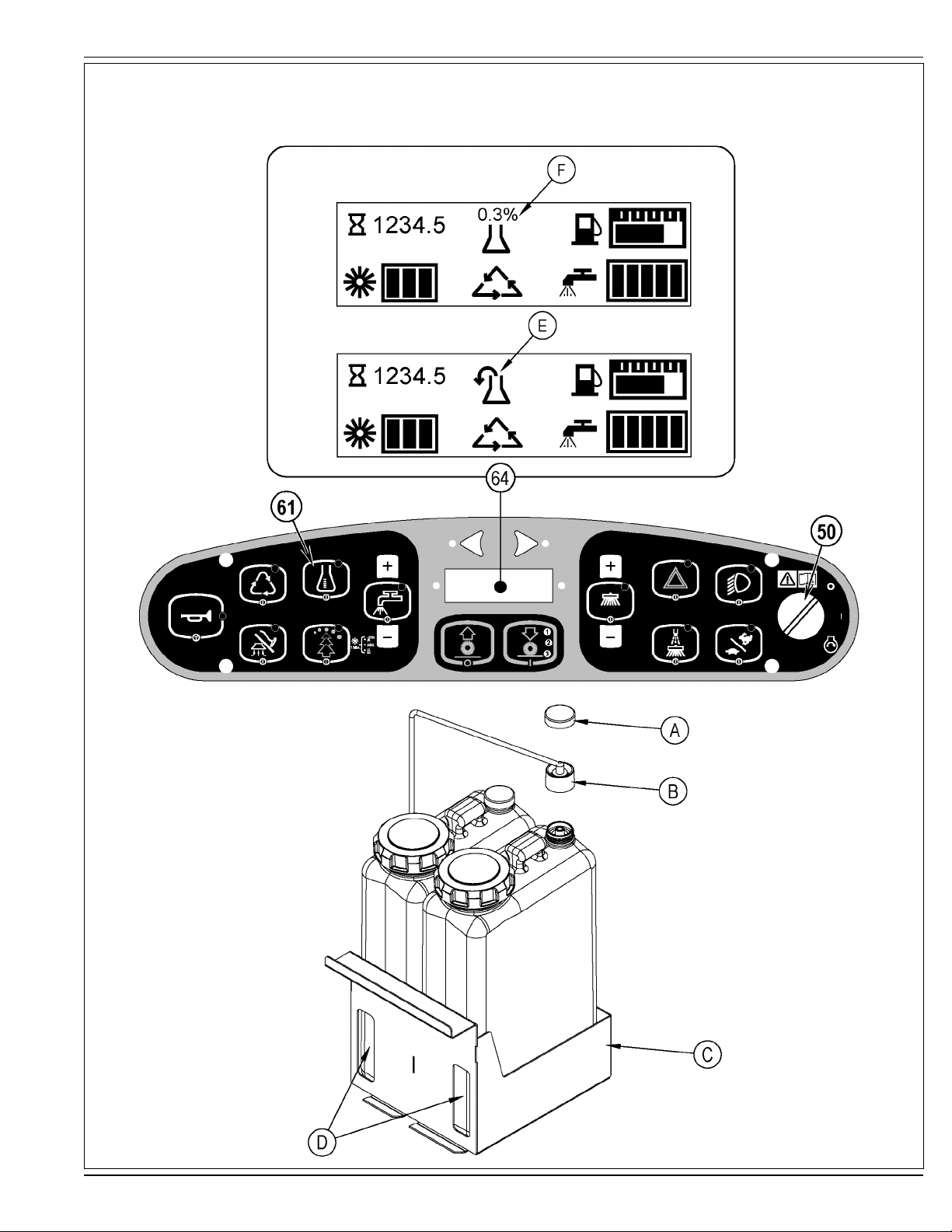

50 Key Switch

51 Engine Speed Switch

52 Dust Guard

53 Side Broom/Scrub ON / OFF Switch

53a Side Broom DOWN adjust Switch

53b Side Broom UP adjust Switch

54 Scrub ON / Scrub Mode Select

55 Scrub OFF

56 Solution Switch

56a Solution Flow Decrease Switch

56b Solution Flow Increase Switch

57 EcoFlex Switch

58 Vacuum/Wand Switch (see next page)

59 Horn Switch

60 Extended Scrub Switch (optional / see next page)

61 Detergent System (EcoFlex models only)

62 Warning Indicator Light (RED)

62a Parking Brake ON

62b Oil Pressure (Diesel)

62c Engine Service

62d Battery Low

62e Controller Fault

62f Hydraulic Temp

62g Low Fuel

62h Engine Temp

63 Left Turn Signal (optional)

64 Display

64a Scrub Pressure Indicator

64b Hour Meter

64c Detergent Indicator (if so equipped)

64d Fuel Gauge

64e Solution Flow Indicator

64f Extended Scrub Indicator (optional)

65 Right Turn Signal (optional)

66 Attention Indicator Light (YELLOW)

66a Solution Low

66b Hydraulic Filter Plugged

66c Non Critical Fault / Non Critical Engine Service

66d Glow Plug

66e Recovery Tank FULL

67 Emergency Flashers (optional)

68 Head Lights

(scrub 1) (scrub 2) (scrub 3)

press 1 time press 2 times press 3 times

A-8 - FORM NO. 56091008 - ER 1300, 1600

Flow Flow Flow

Rate 1 Rate 2 Rate 3

(scrub 1) (scrub 2) (scrub 3)

press 1 time press 2 times press 3 times

Page 9

ENGLISH / A-9

KNOW YOUR MACHINE

VACUUM / WAND SWITCH (58)

See Vac Wand Kit Instruction Sheet form number 56040944.

EXTENDED SCRUB SWITCH (60)

See Extended Scrub Kit Instruction Sheet form number 56040945.

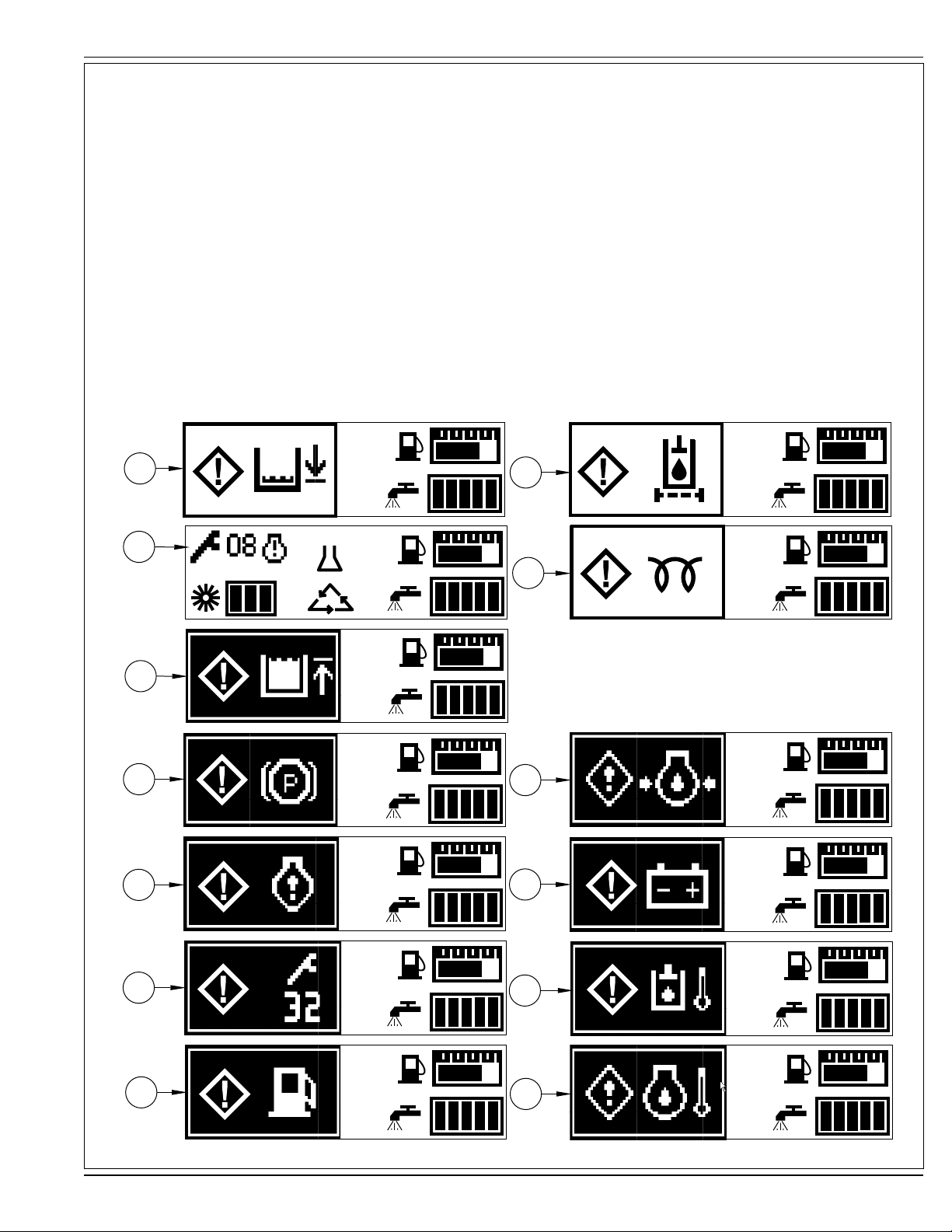

IF ANY OF THE WARNING / ATTENTION ICONS MARKED(X) BELOW ARE DISPLAYED PLEASE CONTACT YOUR ADVANCE

AUTHORIZED SERVICE CENTER.

66a

66c

X

66e

62a

62c

66b

X

300:1

66d

62b

X

62d

X

62e

X

62g

X

62f

X

62h

X

FORM NO. 56091008 - ER 1300, 1600 - A-9

Page 10

A-10 / ENGLISH

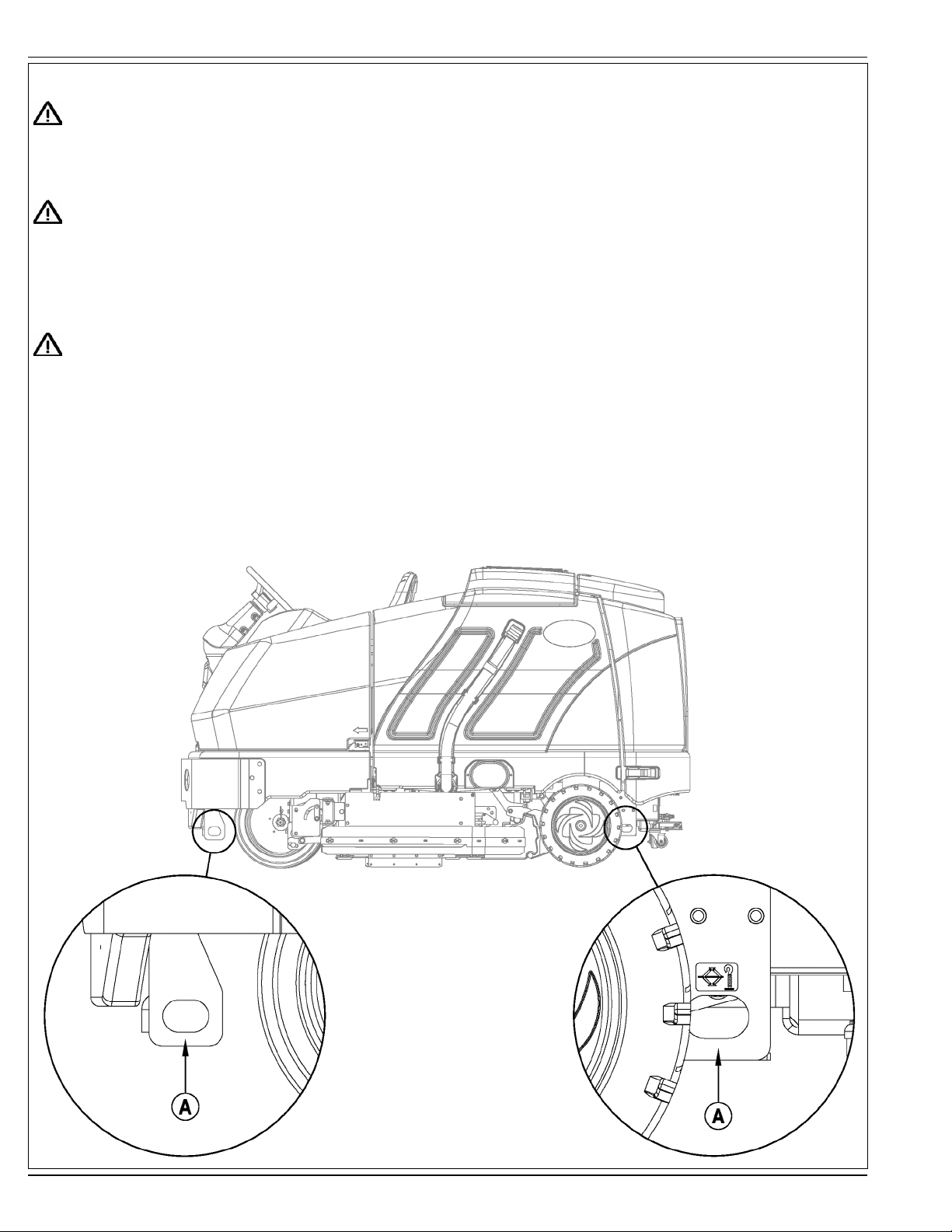

JACKING THE MACHINE

CAUTION!

Never work under a machine without safety stands or blocks to support the machine.

• When jacking the machine, do so at designated locations - see Tie Down / Jacking Locations (A) in Figure 1.

TRANSPORTING THE MACHINE

CAUTION!

Before transporting the machine on an open truck or trailer, make sure that . . .

• All access doors are latched securely.

• The machine is tied down securely - see Tie Down / Jacking Locations (A) in Figure 1.

• The machine Parking Brake (28) is set.

TOWING OR PUSHING A DISABLED MACHINE

CAUTION!

The machine’s drive propelling pump is manufactured with an adjustable tow valve. This valve prevents damage to the hydraulic

system when the machine is being towed/pushed short distances without use of the engine.

The tow valve is controlled by the Tow Valve Lever (34) which is accessed by opening and propping the Engine Cover (3). Pull The Tow Valve Lever (34) out; this

disengages the hydrostatic lock between the motor and pump.

The hydrostatic pump can be damaged if the machine is towed with the valve in the normal working position (Tow Valve Lever (34) pushed IN). Note: If the tow

valve is left in free wheeling position (Tow Valve Lever (34) pulled OUT) the hydrostatic pump can’t drive the machine FWD or REV. No damage will result, just

reset the valve to the normal working position by pushing the lever IN. Tow or push the machine no faster than a normal walking pace (2-3 miles per hour) and for

short distances only. If the machine is to be moved long distances the front drive wheel needs to be raised off the fl oor and placed on a suitable transport dolly.

FIGURE 1

A-10 - FORM NO. 56091008 - ER 1300, 1600

Page 11

ENGLISH / A-11

PRE-OPERATIONAL CHECKLIST

Before Each Use:

* Inspect the machine for damage, oil or coolant leaks.

* Squeeze the rubber dust cup on the Engine Air Filter (7) to release built-up dust.

* Check the engine coolant level (6).

* Check the engine oil level (46).

* Check the hydraulic oil level (44).

* Check the Fuel Gauge (64d) on the gasoline/petrol, and diesel models.

* Check the Fuel Gauge located on the LP tank for LPG model.

* Check the Air Filter Service Indicator (5).

In the Driver’s Seat:

* Be sure that you understand the operating controls and their functions.

* Adjust the seat to allow easy reach of all controls.

* Insert the Master Key and turn the Ignition Key Switch (50) to the ON position. Check for proper operation of the Horn (59), Hour Meter (64b) and Headlights

(68). Turn the Ignition Key Switch (50) OFF.

* Check the Brake Pedal (28). The pedal should be fi rm and should not go all the way down. The latch should hold the pedal when applied.

(Report all defects immediately to service personnel).

Plan Your Cleaning in Advance:

* Arrange long runs with a minimum of stopping or starting.

* Allow 2-3” (5.08-7.62cm) of scrub path overlap to ensure complete coverage.

* Avoid making sharp turns, bumping into posts, or scraping the side of the machine.

HYDRAULIC OIL

Open and prop the Engine Cover (3) to access the hydraulic oil reservoir. Remove the Fill Cap (44) from the tank and look to the bottom of the fi ller screen. If

the oil level is below the bottom of the fi ller screen, add 10W30 motor oil until the bottom of the fi ller screen is covered (oil level should not be higher than 1/2”

(12.7mm) above the bottom of the fi ller screen). Change the oil if major contamination from a mechanical failure occurs.

ENGINE OIL – GASOLINE / PETROL & LPG

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the fi rst 35 hours of

operation and every 150 hours after that. Use any SF or SG rated oil meeting API specifi cations and suited to seasonal temperatures. Refer to

the Engine System section for oil capacities and additional engine specifi cations. Replace the oil fi lter with every oil change.

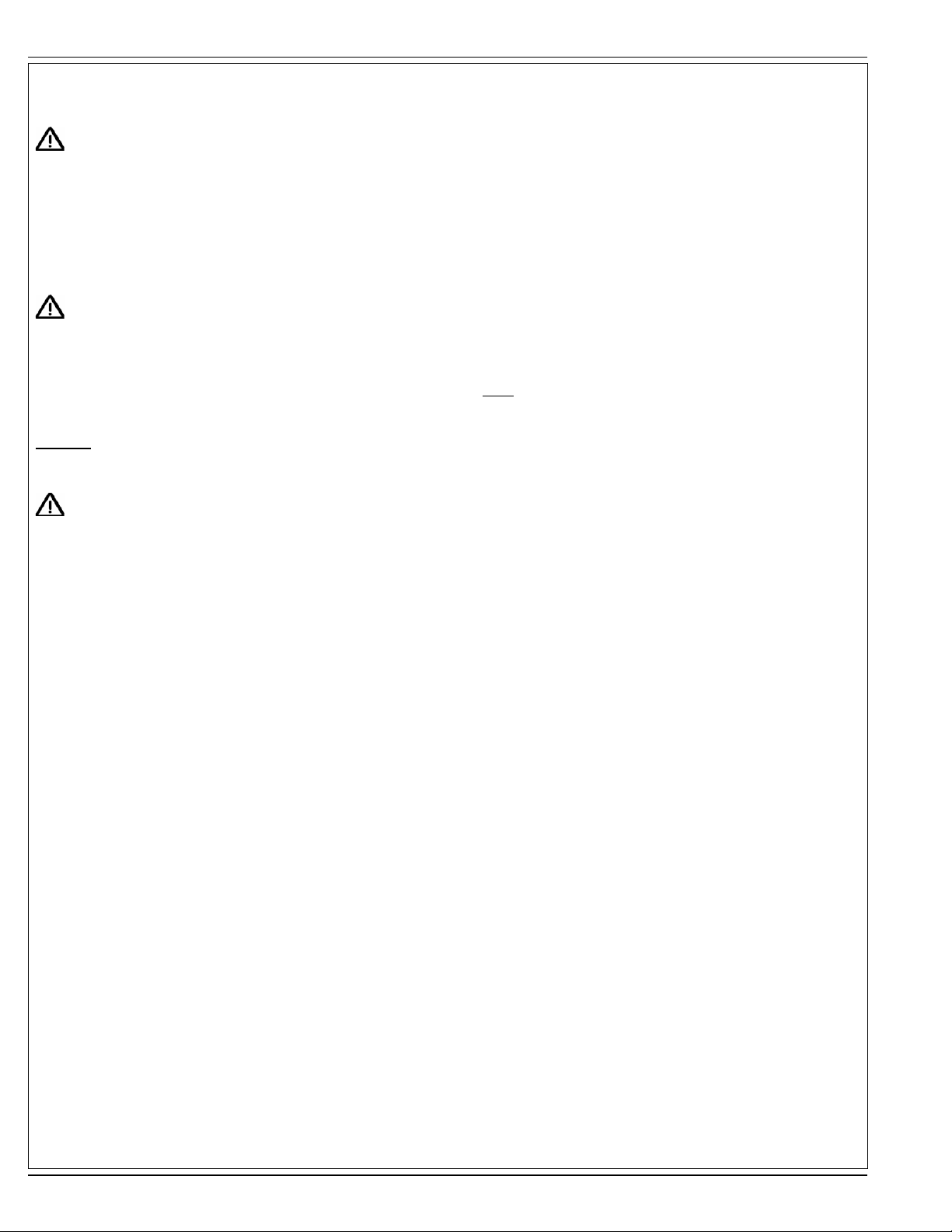

TEMPERATURE RANGE OIL WEIGHT

Above 60° F (15° C) SAE 10W-30

Below 60° F (15° C) SAE 5W-30

ENGINE OIL - DIESEL

Check the engine oil level when the machine is parked on a level surface and the engine is cool. Change the engine oil after the fi rst 35 hours

of operation and every 150 hours after that. Use CF, CF-4 or CG-4 oil meeting API specifi cations and suited temperatures (*important reference

the oil/fuel type note below for further diesel oil recommendations). Refer to the Engine System section for oil capacities and additional engine

specifi cations. Replace the oil fi lter with every oil change.

TEMPERATURE RANGE OIL WEIGHT

Above 77 °F (25 °C) SAE 30 or 10W-30

32 °F to 77 °F (0 °C to 25 °C) SAE 20 or 10W-30

Below 32 °F (0 °C) SAE 10W or 10W-30

* Diesel Lubricating Oil Note:

With the emission control now in effect, the CF-4 and CG-4 lubricating oils have been developed for use with a low-sulfur fuel used in on-road vehicle

engines. When an off-road vehicle engine runs on a high-sulfur fuel, it is advisable to employ the CF, CD or CE lubricating oil with a high total base number.

If the CF-4 or CG-4 lubricating oil is used with a high-sulfur fuel, change the lubricating oil at shorter intervals.

• Lubricating oil recommended when a low-sulfur or high-sulfur fuel is employed.

Fuel

Lubricating

Oil class

CF

CF-4

CG-4

O : Recommended X : Not recommended

Low sulfur

(0.5 % ≥)

OO

OX

OX

High sulfur Remarks

TBN ≥ 10

FORM NO. 56091008 - ER 1300, 1600 - A-11

Page 12

A-12 / ENGLISH

PRE-OPERATIONAL CHECKLIST

ENGINE COOLANT

CAUTION!

Do not remove the radiator cap when the engine is hot.

To check the engine coolant level, open and prop the Engine Cover (3) and observe the coolant level on the Coolant Recovery Tank (6). If the level is low add

automotive type anti-freeze appropriately diluted for the environment. Clean the radiator and oil cooler exteriors by washing with low-pressure water or using

compressed air every 30 hours. Service Note: The oil cooler tips out for easy cleaning.

ENGINE AIR FILTER

Check the Air Filter Service Indicator (5) before each use of the machine. Do not service the air fi lter unless the red fl ag is visible in the service indicator.

CAUTION!

When servicing the engine air fi lter elements, use extreme care to prevent loose dust from entering the engine. Dust can severely

damage the engine.

The engine air fi lter contains a Primary (outer) and a Safety (inner) fi lter element. The Primary Element may be cleaned twice before being replaced. The Safety

Element should be replaced every third time that the Primary Filter Element is replaced. Never attempt to clean the Inner Safety Element.

To clean the Primary Filter Element, unsnap the 2 clips at the end of the air fi lter and remove the end housing. Pull the primary element out. Clean the element

with compressed air (maximum pressure 100 psi) or wash it with water (maximum pressure 40 psi). DO NOT put the element back into the canister until it is

completely dry.

FUEL

WARNING!

• ALWAYS STOP THE ENGINE BEFORE FILLING THE FUEL TANK.

• DO NOT SMOKE WHILE FILLING THE FUEL TANK.

• FILL THE FUEL TANK IN A WELL-VENTILATED AREA.

• DO NOT FILL THE FUEL TANK NEAR SPARKS OR OPEN FLAME.

• USE ONLY THE FUEL SPECIFIED ON THE FUEL TANK DECAL.

On machines with diesel and gasoline engines, a decal near the Fuel Tank (14) fi ller neck shows the proper fuel to use in the machine. Before removing the cap

from the tank, wipe all dust and dirt from the cap and from the top of the tank to keep the fuel as clean as possible.

On machines with propane engines, a decal near the tank gives specifi c information about the proper type of tank to be used on the machine.

DIESEL ENGINE

Fill the tank with Number 2 Diesel Fuel if the machine will be used in an area where the temperature is 30° Fahrenheit (0° Celsius) or higher. Use Number 1

Diesel Fuel if the machine will be used in an area where the temperature is below 30° Fahrenheit (0° Celsius).

NOTE: If the diesel machine runs out of fuel completely, the fuel system must be bled before the engine can be re-started. To avoid this situation, fi ll the fuel tank

when the fuel gauge indicates 1/4 tank. Fuel tank capacity is 11 gallons (42 liters).

GASOLINE / PETROL ENGINE

FILL THE TANK WITH UNLEADED 87 OCTANE REGULAR GASOLINE. FUEL TANK CAPACITY IS 11 GALLONS (42 LITERS).

Note: Reference the separately supplied engine manufacture’s maintenance and operator manual for more detailed engine specifi cation and service data.

LPG ENGINE

Mount a standard 33 lb. liquid withdrawal propane tank on the machine, connect the fuel hose and open the shutoff valve on the tank. Wear gloves when

connecting or disconnecting the fuel hose. Shut the propane tank service valve OFF when the machine is not in use.

A-12 - FORM NO. 56091008 - ER 1300, 1600

Page 13

ENGLISH / A-13

INSTALL THE BRUSHES

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

1 Make sure the Scrub Deck is in the RAISED position, the Key Switch (50) is off (O) and the Parking Brake (28) is set.

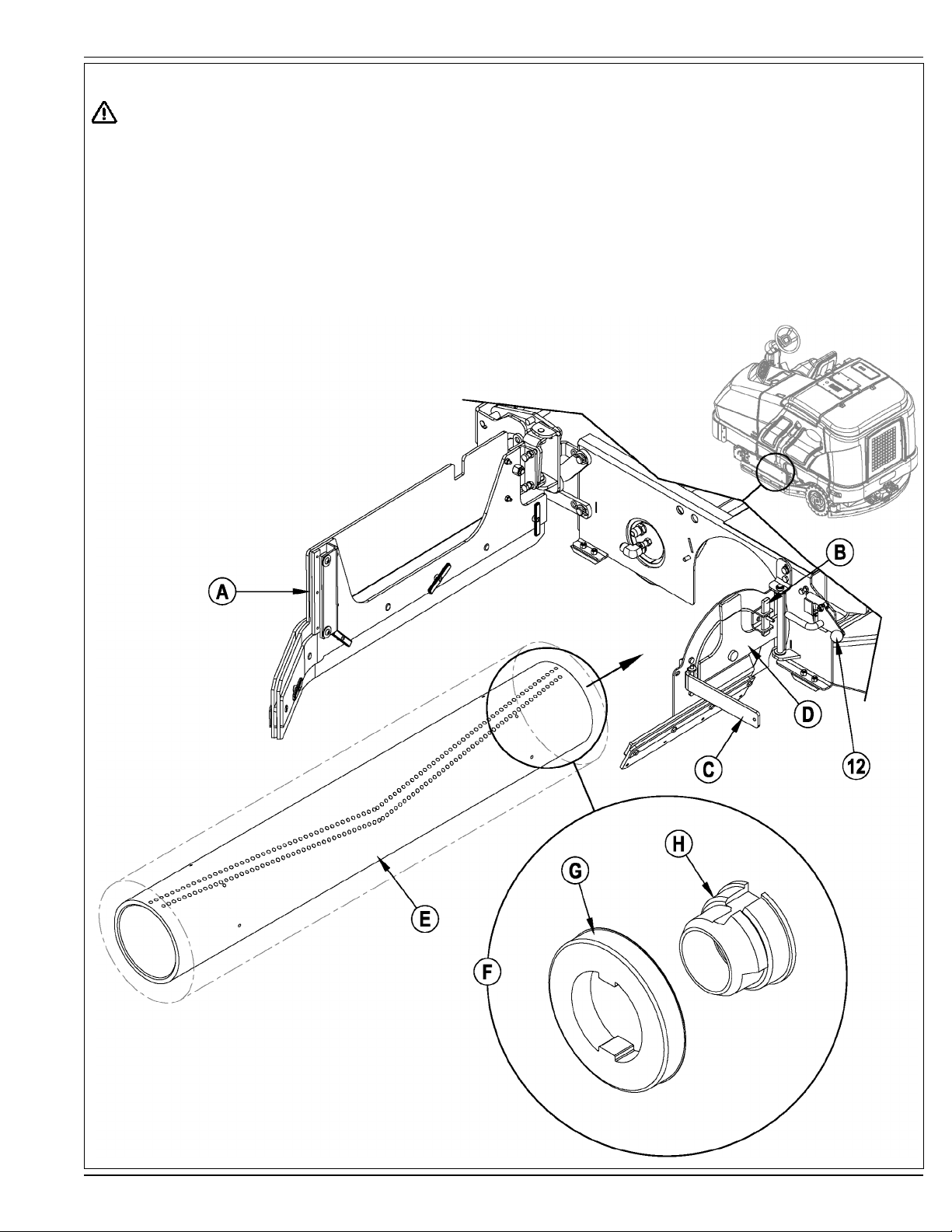

2 See Figure 2. Push down on the Side Skirt Latch (12 or 32) and swing the Skirt Assy (A) open as shown.

3 Lift up on Latch (B), swing Lever (C) out and pull to open the Idler Assembly (D).

4 Slide the Brush (E) into the housing, lift slightly, push and turn until it seats. NOTE: Figure 2 shows a closeup view (F) of the Brush Lugs (G) and the Brush

Drive Hub (H).

5 Swing the Idler Assembly (D) closed while holding Lever (C) at a 90 degree angle to the Idler.

6 Once the Idler Assembly (D) is closed, push Lever (C) in until Latch (B) can be slid back down in front of it.

7 Push down on the Side Skirt Latch (12 or 32), swing the Skirt Assy (A) closed and release the Latch.

NOTE: Refer to this section when rotating (fl ipping end-to-end) brushes according to the maintenance schedule.

FIGURE 2

FORM NO. 56091008 - ER 1300, 1600 - A-13

Page 14

A-14 / ENGLISH

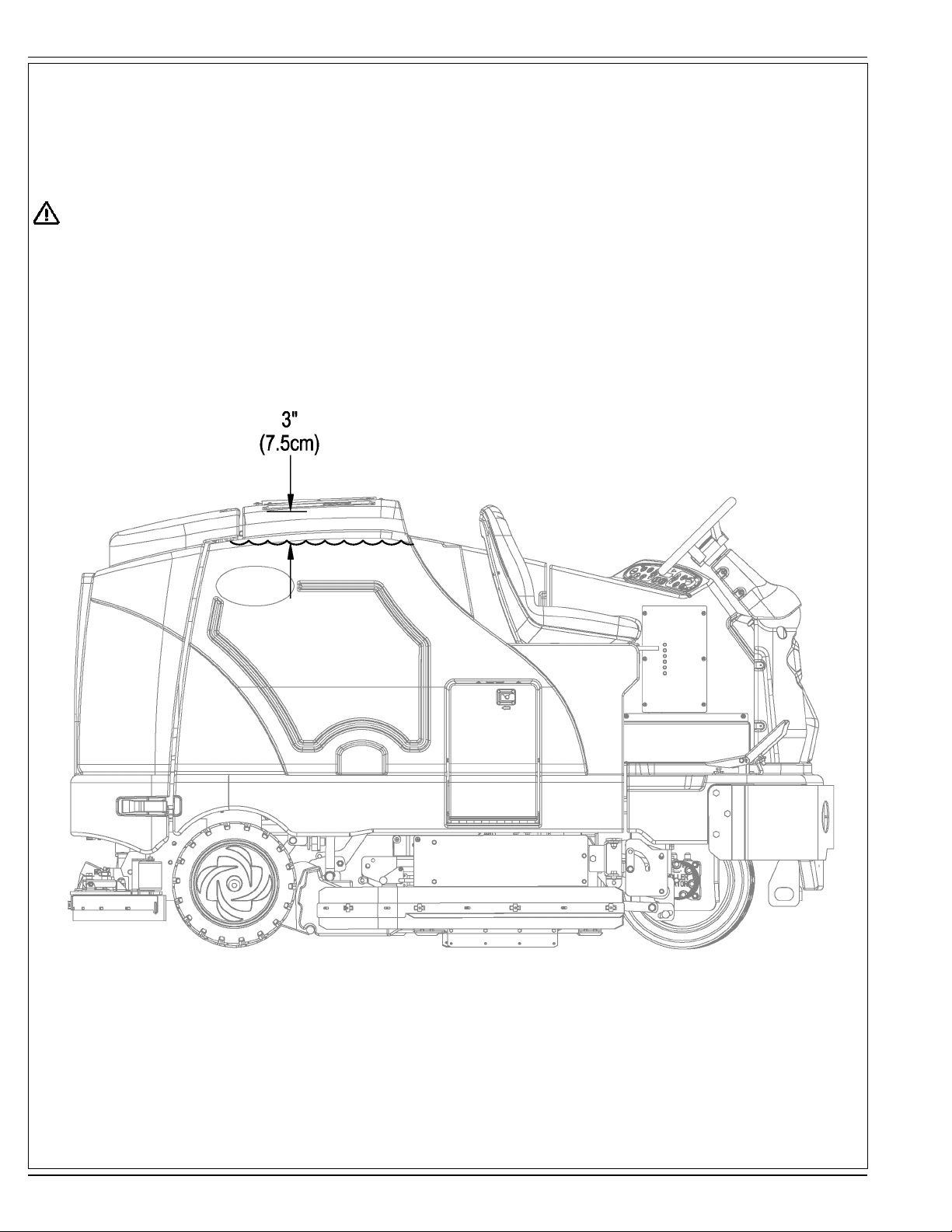

FILLING THE SOLUTION TANK

See Figure 3. Fill the solution tank with a maximum of 100 gallons (378.54 Liters) of cleaning solution. Do not fi ll the solution tank above 7.5 cm

(3 inches) from the bottom of the Solution Fill (2). The solution should be a mixture of water and the proper cleaning chemical for the job. Always

follow the dilution instructions on the chemical container label. NOTE: EcoFlex machines can either be used conventionally with detergent mixed

in the tank or the detergent dispensing system can be used. When using the detergent dispensing do not mix detergent in the tank, plain water

should be used.

CAUTION!

Use only low-foaming, non-fl ammable liquid detergents intended for machine application. Water temperature should not exceed 130

degrees Fahrenheit (54.4 degrees Celsius)

FIGURE 3

A-14 - FORM NO. 56091008 - ER 1300, 1600

Page 15

ENGLISH / A-15

OPERATING THE MACHINE

The ER 1300 / 1600 is a rider-type automatic fl oor scrubbing machine. It is designed to lay down cleaning solution, scrub the fl oor, and vacuum

dry all in one pass.

The controls on the ER 1300 / 1600 were designed with one touch operation in mind. For single pass scrubbing the user can simply depress one

switch and all scrub functions on the machine will be activated.

NOTE: Bold numbers in parentheses indicate an item illustrated on pages 6-9.

NOTE!: MAKE SURE THE FOOT PEDAL IS IN THE NEUTRAL POSITION. THE ENGINE WILL NOT CRANK IF THE FOOT PEDAL IS NOT IN

NEUTRAL. EITHER THE SEAT SWITCH MUST BE CLOSED OR THE BRAKE ENGAGED BEFORE THE ENGINE WILL START.

STARTING THE DIESEL ENGINE

1 Turn the key switch (50) clockwise to the RUN (ON) position. The glow plugs will activate for 10 seconds as indicated by the attention

indicator (66) and the glow plug icon (66d) on the display. If the engine is already warm, turn the key switch to the start position to crank the

engine. If the engine is cold, wait for the attention indicator and glow plug icon to turn off before cranking the engine. The engine should start

immediately. If the engine does not start within 15 seconds release the key, wait for approximately one minute and repeat the above steps.

2 Let the engine run at IDLE speed for fi ve minutes before using the machine.

3 Press the Engine Speed Switch (51) once to switch to FULL THROTTLE and move the machine around for two to three minutes at slow

speed to warm up the hydraulic system.

STARTING THE GASOLINE / PETROL ENGINE

1 Turn the Ignition Key Switch (50) clockwise to the START position and release it as soon as the engine starts. If the engine does not start

after cranking for 15 seconds, release the key, wait for 1 minute, then try again.

2 Let the engine run at “IDLE” speed for 5 minutes before using the machine.

3 Push the Engine Speed Switch (51) once to switch to “FULL THROTTLE” and move the machine around for 2 or 3 minutes at a slow speed to

warm up the hydraulic system.

STARTING THE LPG ENGINE

1 Open the service valve on the LP fuel tank.

2 Turn the Ignition Key Switch (50) clockwise to the START position and release it as soon as the engine starts. If the engine does not start

after cranking for 15 seconds, release the key, wait for 1 minute, then try again.

3 Let the engine run at “IDLE” speed for 5 minutes before using the machine.

4 Push the Engine Speed Switch (51) once to switch to “FULL THROTTLE” and move the machine around for 2 or 3 minutes at a slow speed to

warm up the hydraulic system.

ALWAYS operate the machine with the Engine Speed Switch at full throttle. Use the Drive Pedal (29) not the Engine Speed Switch (51) to

control the speed of the machine. The speed of the machine will increase as the pedal is pushed closer to the fl oor. Do not press the Drive Pedal

(29) until the engine has started.

NOTE!: If the operator leaves the seat without setting the brake, the engine will be turned off.

Engine Speed Switch (51):

There are three engine speed settings that can be selected by the engine speed switch (51) on the control panel.

1 “Idle” (1200 RPM – Petrol / LPG) (1300 RPM – Diesel). Use for warm up and cool down. The engine speed switch light will be off.

2 “Run” (2200 RPM). Use for transporting and most scrubbing operations. The engine speed light will be on.

3 “Turbo” (2400 RPM). Use only for heavy engine load situations such as heavy scrubbing on inclines. The engine speed light will be on.

4 To select between Idle and Run press and release the engine speed switch.

5 To select the Turbo speed, fi rst set the speed to Run. Then press and hold the engine speed switch for 2 seconds. To go back to Run speed,

press the switch again.

6 The ER 1300 / 1600 has an automatic idle feature that will reduce the engine speed to idle when the foot pedal (29) has been in the neutral

position for 20 seconds or more. The selected engine speed will automatically resume when the foot pedal is moved from neutral. If the

engine speed switch (51) is pressed while in idle-override, the automatic idle feature will be temporarily disabled until the next time the foot

pedal is moved from the neutral position. This can be useful during troubleshooting or if it is desired to let the machine run at full speed for

warming up.

FORM NO. 56091008 - ER 1300, 1600 - A-15

Page 16

A-16 / ENGLISH

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

The Detergent Cartridges (24) are located inside of the Detergent Cartridge Compartment (30). Fill the detergent cartridge with a maximum of

2.2 gallons (8.32 Liters) of detergent. SERVICE NOTE: Remove the detergent cartridge from the detergent box prior to fi lling to avoid spilling

detergent on the machine.

It is recommended that a separate cartridge be used for each detergent you plan to use. The detergent cartridges have a white decal on them so

you can write the detergent name on each cartridge to avoid mixing them up. When installing a new cartridge, remove the Cap (A) and place the

cartridge in the detergent box. Install the Dry Break Cap (B) as shown.

The system should be purged of previous detergent when switching to a different detergent. SERVICE NOTE: Move machine over fl oor drain

before purging because a small amount of detergent will be dispensed in the process.

To Purge When Changing Chemicals(SCRUB SYSTEM MUST BE OFF):

1 Disconnect and remove the detergent cartridge.

2 Turn the key switch (50) to the RUN (ON) position. Wait a few seconds for the start-up sequence to fi nish.

3 Press and hold the detergent switch (61) for approximately 2 seconds. Release the switch when the chemical purge icon (E) appears on the

display and the indicator on the detergent switch (61) starts fl ashing. NOTE: Once activated the purge process takes at least 20 seconds.

See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

To Purge Weekly(SCRUB SYSTEM MUST BE OFF):

1 Disconnect and remove the detergent cartridge. Install and connect a Cartridge fi lled with clean hot water.

2 Turn the key switch (50) to the RUN (ON) position. Wait a few seconds for the start-up sequence to fi nish.

3 Press and hold the detergent switch (61) for approximately 2 seconds. Release the switch when the chemical purge icon (E) appears on the

display and the indicator on the detergent switch (61) starts fl ashing. NOTE: Once activated the purge process takes at least 20 seconds.

See illustration on next page for Detergent System indicators. Normally one purge cycle is adequate to purge the system.

The Detergent Box (C) has Detergent Level Viewing Slots (D) for referencing the amount of detergent remaining in the cartridge(s). When the

detergent level is nearing the bottom of this slot it is time to refi ll or replace the cartridge(s).

Detergent Ratio (SCRUB SYSTEM MUST BE ON):

The detergent ratio default is .04%. The detergent mixture rate may be adjusted by pressing and holding the detergent switch (61) for two

seconds. Release the switch once the detergent switch light begins fl ashing. While the light is fl ashing, pressing and releasing the detergent

switch will cycle through the available percentages (.03%, .04%, .05%, .07%, .08%, 1.0%, 1.5%, 2.0%, 3.0%, or 3.8%). Once the desired

percentage is displayed on the screen (F), stop and it will lock in after 3 seconds.

The detergent mixture (F) will always be displayed when the detergent system is on.

Once set, the detergent fl ow rate automatically increases and decreases with the solution fl ow rate but the detergent ratio remains the same. If

an operator would prefer the fl exibility of setting different detergent dilutions ratios for different solution fl ow rates this specifi

found in the service manual. During scrubbing, the detergent system can be turned off at any time by pressing the Detergent ON/OFF Switch (61)

to allow scrubbing with water only. No detergent is dispensed until the scrub system is activated and the Drive Pedal (29) pushed forward.

SERVICE NOTE: Follow the “To Purge Weekly” instructions above if the machine is going to be stored for an extended period of time or if you plan

to discontinue use of the detergent (EcoFlex) system.

c programming can be

A-16 - FORM NO. 56091008 - ER 1300, 1600

Page 17

DETERGENT SYSTEM PREPARATION AND USE (ECOFLEX MODELS ONLY)

FIGURE 4

ENGLISH / A-17

FORM NO. 56091008 - ER 1300, 1600 - A-17

Page 18

A-18 / ENGLISH

SCRUBBING

WARNING!

Be sure you understand the operator controls and their functions.

While on ramps or inclines, avoid sudden stops when loaded. Avoid abrupt sharp turns. Use low speed down hills.

To Scrub...

Follow the instructions in preparing the machine for use section of this manual. Start the engine following the instructions in the appropriate “Starting the …

Engine” section.

1 See Figure 5. While seated on the machine, adjust the seat and steering wheel to a comfortable operating position using the adjustment controls (18 & 27).

2 Release the Parking Brake (28). To transport the machine to the work area, apply even pressure with your foot on the front of the Drive Pedal (29) to go forward or the

rear of the pedal for reverse. Vary the pressure on the foot pedal to obtain the desired speed.

3 Press the Solution Switch (56) and hold for 5 seconds to pre-wet the fl oor. NOTE: This will help prevent scarring of the fl oor surface when starting to scrub with dry

brushes. This must be done prior to pressing the Scrub ON Switch (54).

4 Press the Scrub ON Switch (54) once for Light Scrub (1), twice for Medium Scrub (2) or three times for Heavy Scrub (3) mode. Both the solution fl ow and detergent

(EcoFlex models) fl ow have 3 presets that coincide with the 3 scrub modes (see Display Panel (64)). The right side scrub brush pressure is also affected when

pressing this switch.

NOTE: The solution fl ow rate can be overridden simply by pressing the Solution Flow Decrease or Increase Switches (56a / 56b). Any subsequent scrub pressure

adjustments will reset the solution fl ow rate to correspond with the scrub pressure.

NOTE: The scrub, solution, vacuum, detergent (EcoFlex models) and side broom(s) / brush systems are automatically enabled when the Scrub ON Switch (54) is

pressed. Any individual system can be turned OFF or back ON by simply pressing its switch at any time during scrubbing. If you have installed the Extended Scrub

Kit, it will not be automatically activated. You must press the Extended Scrub Switch (60) to activate this system. The Extended Scrub system will not turn ON until the

water level in the recovery tank reaches a certain level and the clean solution has been used up.

5 When the Scrub ON Switch (54) is selected, the brushes, squeegee and side broom(s) / brush are automatically lowered to the fl oor. The scrub, solution, vacuum,

detergent (EcoFlex models) and side broom(s) / brush systems all start when the Drive Pedal (29) is activated.

NOTE: When operating the machine in reverse the squeegee automatically raises and the solution fl ow will stop.

6 Begin scrubbing by driving the machine forward in a straight line at a normal walking speed and overlap each path by 2-3” (5.08-7.62cm). Adjust the machine speed

and solution fl ow when necessary according to the condition of the fl oor.

The side broom height can be adjusted by pressing the Side Broom DOWN and UP Switches (53a/53b). The side broom(s) will return to the last used position each

time the sweep system is turned on. The side brooms have a misting function (Dust Guard) (52) for use in dusty conditions. NOTE: The “Dust Guard” (52) comes

on automatically with the Side Brooms (53) but can be turned OFF by pressing (52). NOTE: If equipped with Extended Scrub, the “Dust Guard” will shut off when the

machine runs out of clean solution.

CAUTION!

To avoid damaging the fl oor, keep the machine moving while the brushes are turning (the brushes will turn OFF after a 2 second delay when the

drive pedal is placed in the neutral position).

Raise scrub deck and side scrub brush, if so equipped, when crossing speed bumps. Do not attempt to operate the scrub deck or side brush in the

down position when crossing speed bumps. Hydraulic pressure pushes down on the brushes and attempting to operate in the scrub mode over a

speed bump can cause damage to the machine.

7 When scrubbing, check behind the machine occasionally to see that all of the waste water is being picked up. If there is water trailing the machine, you may be

dispensing too much solution, the recovery tank may be full, or the squeegee tool may require adjustment.

8 The machine defaults to the EcoFlex cleaning mode (if detergent is installed) (EcoFlex Switch Indicator is lit) conserving solution and detergent. Press the EcoFlex

Switch (57) to override the EcoFlex cleaning mode and temporarily increase scrub pressure, solution fl ow and the detergent percentage. This will cause the indicator

to fl ash for one minute, solution fl ow rate will increase to the next level, scrub pressure will increase to the next level and the detergent ratio will increase to the next

higher percentage from the last one used (detergent system will be turned on if it was off).

NOTE: Pressing and holding the EcoFlex Switch (57) for 2 seconds disables the EcoFlex system. The only way to re-enable is to push the EcoFlex Switch (57) again.

Cycling the Key Switch (50) does not re-enable the system. The EcoFlex system will only function if the Scrub System (54) has been enabled.

9 For extremely dirty fl oors, a one-pass scrubbing operation may not be satisfactory and a “double-scrub” operation may be required. This operation is the same as a

one-pass scrubbing except on the fi rst pass the squeegee is in the up position (press the Vacuum Switch (57) to raise the squeegee). This allows the cleaning solution

to remain on the fl oor to work longer. The Side Skirts (13 & 31) can also be raised for double scrubbing if needed with the Skirt Holders (20). The fi nal pass is made

over the same area, with the squeegee and skirts lowered to pick up the accumulated solution.

10 The recovery tank has a fl oat switch that causes ALL systems to turn OFF except the drive system when the recovery tank is full. When this fl oat switch is activated,

the recovery tank must be emptied. The machine will not pick up water or scrub with the fl oat switch activated.

NOTE: The Attention Indicator Light (66) will light up YELLOW and the Recovery Full Icon (66e) will display when the fl oat switch is activated. If the control repeatedly

gives a full indication when the tank is not full check to make sure the fl oat moves freely.

11 When the operator wants to stop scrubbing, press the Scrub OFF Switch (55) once. This will automatically stop the scrub brushes, side broom(s) / brush, solution fl ow

and detergent fl ow. The scrub deck and side broom(s) / brush will raise up. The squeegee will raise up after a brief delay and the vacuum will stop after a brief delay

(this is to allow any remaining water to be picked up without turning the vacuum back on).

12 Drive the machine to a designated waste water “DISPOSAL SITE” and empty the recovery tank. To empty, pull the Drain Hose (9) from its storage area, then remove

the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). The Recovery Tank Drain Hose (9) can be

squeezed to regulate the fl ow. Refi ll the solution tank and continue scrubbing.

NOTE: Make sure the Recovery Tank Cover (4) and the Recovery Tank Drain Hose (9) cap are properly seated or the machine will not pick-up water correctly.

SERVICE NOTE: Refer to the service manual for optional programmability.

A-18 - FORM NO. 56091008 - ER 1300, 1600

Page 19

OPERATING THE MACHINE

FIGURE 5

ENGLISH / A-19

(scrub 1) (scrub 2) (scrub 3)

press 1 time press 2 times press 3 times

Flow Flow Flow

Rate 1 Rate 2 Rate 3

(scrub 1) (scrub 2) (scrub 3)

press 1 time press 2 times press 3 times

FORM NO. 56091008 - ER 1300, 1600 - A-19

Page 20

A-20 / ENGLISH

AFTER USE

1 When fi nished scrubbing, press the Scrub Off Switch (55). This will automatically raise, retract and stop all the machine systems (brush, squeegee, vacuum, solution and

detergent (EcoFlex models)). Then drive the machine to a service area for daily maintenance and review of other needed service up keep.

2 To empty the solution tank, remove the Solution Drain Hose (37) from its storage clamp. Direct the hose to a designated “DISPOSAL SITE” and remove the cap. Rinse the tank

with clean water.

3 To empty the recovery tank, pull the Recovery Tank Drain Hose (9) from its storage area. Direct the hose to a designated “DISPOSAL SITE” and remove the plug (hold the end

of the hose above the water level in the tank to avoid sudden, uncontrolled fl ow of waste water). The Recovery Tank Drain Hose can be squeezed to regulate the fl ow. Rinse

the recovery tank with clean water. Inspect the recovery and vacuum hoses; replace if kinked or damaged.

4 Remove the brushes, remove any string or banding that is wrapped around them, rinse in warm water and stand on end to dry. NOTE: Brushes should be fl ipped “end for end”

and rotated “front to back” daily for longest life.

5 Remove the squeegee, rinse it with warm water and re-install on mount.

6 Remove the Hopper (33) and clean thoroughly. Remove from the right side of the machine by opening the skirt, disconnecting the vacuum hose and then pulling out. NOTE:

Reconnect vacuum hose after re-installing.

7 Check the maintenance schedule and perform any required maintenance before storage

SHUTTING DOWN THE DIESEL / GASOLINE ENGINE

1 Put all controls to the OFF position.

2 Raise the squeegee, the scrub brushes, and the brooms.

3 Push the Engine Speed Switch (51) to change to “Idle” speed and let the engine idle for 30 seconds.

4 Apply the Parking Brake (28).

5 Turn the Key Ignition Switch (50) OFF and remove the key.

SHUTTING DOWN THE LPG ENGINE

1 Put all controls to the OFF position.

2 Raise the squeegee, the scrub brushes, and the brooms.

3 Turn the service valve on LP gas tank OFF.

4 Push the Engine Speed Switch (51) to change to “Idle” speed and let the engine idle until all the LP gas is dispelled from the line.

5 Apply the Parking Brake (28).

6 Turn the Key Ignition Switch (50) OFF and remove the key.

IMPORTANT NOTE: During normal operation the engine will continue to run for a short period of time (1-3 seconds) after turning the key OFF until all fuel is dispelled from fuel

system.

MAINTENANCE SCHEDULE

Keep the machine in top condition by following the maintenance schedule closely. Maintenance intervals given are for average operating conditions. Machines used in severe

environments may require service more often.

MAINTENANCE ITEM DAILY WEEKLY

Perform the “After Use” maintenance steps X

Check parking brake X

Check engine oil X

*Check / Clean / Rotate & fl ip the Brushes X

Check fi lter indicator and lights (hyd & air) X

Check engine coolant level X

Check hydraulic oil level X

Drain / Check / Clean Tanks & Hoses X

Check / Clean the Squeegee X

Clean the Hopper X

Purge Detergent System (EcoFlex only) X

Inspect main scrub head skid plates(replace if worn to 1/8”) X

MAINTENANCE ITEM 15 hrs. 30 hrs. 150 hrs. 300 hrs. 500 hrs. 1000 hrs.

Inspect and clean the Solution Filter X

Clean radiator and oil cooler X

Side Broom Maintenance X

Clean solution trough X

Inspect scrub housing skirts X

Perform engine maintenance X

Inspect and grease steering rack X

Change the hydraulic “charge” oil fi lter X

Change reservoir hydraulic oil and fi lter X

Flush the radiator X

Engine fuel fi lter(s) gas or lpg X

* See “INSTALL THE BRUSHES” section.

A-20 - FORM NO. 56091008 - ER 1300, 1600

Page 21

LUBRICATING THE MACHINE – FIGURE 6

Once a month, pump a small amount of grease into each grease fi tting on the machine until grease seeps out around the bearings.

Grease fi tting locations (or apply grease to) (A):

• Squeegee Caster Wheel Axle and Pivot

• Steering Rack

• Squeegee mount angle adjustment knob threads

Once a month, apply light machine oil to lubricate the (B):

• Squeegee tool end wheels

• Fuel Tank Cover Latch

• Recovery Tank Latch

• EcoFlex Cover Latch

• Brake Pedal (parking brake) linkage

FIGURE 6

ENGLISH / A-21

FORM NO. 56091008 - ER 1300, 1600 - A-21

Page 22

A-22 / ENGLISH

SIDE BROOM MAINTENANCE

The side broom(s) move dirt and debris away from walls or curbs and into the path of the main brushes. Adjust the side broom(s) so that the bristles are

contacting the fl oor from the (A) to (B) area shown in Figure 7 when the broom is down and running.

To adjust the Side Brooms...

1 The side broom(s) are adjusted simply by pressing either the Side Broom DOWN Switch (53a) or the Side Broom UP Switch (53b). NOTE: Broom setting

resumes each time brooms are lowered but adjustment will be needed as brooms wear or are replaced.

NOTE: The machine should be stored with the Side Brooms in the raised position. The Side Brooms should be replaced when the bristles are worn to a length of

3 inches (7.62 cm) or they become ineffective.

To replace a Side Broom...

1 Raise the Side Broom(s).

2 Remove the large Thumb Nut (C) and remove the Side Broom (D). NOTE: The right side Thumb Nut (C) has right handed threads and the left side Thumb

Nut (C) has left handed threads.

3 Install the new broom by sliding it UP onto the shaft and re-install the Thumb Nut (C).

FIGURE 7

A-22 - FORM NO. 56091008 - ER 1300, 1600

Page 23

ENGLISH / A-23

SQUEEGEE MAINTENANCE

If the squeegee leaves narrow streaks or water, the blades may be dirty or damaged. Remove the squeegee, rinse it under warm water and inspect the blades.

Reverse or replace the blades if they are cut, torn, wavy or worn.

To Reverse or Replace the Rear Squeegee Wiping Blade...

1 See Figure 8. Raise the squeegee tool off the fl oor, then unsnap the Center Latch (A) on the squeegee tool.

2 Remove the Tension Straps (B).

3 Slip the rear blade off the alignment pins.

4 The squeegee blade has 4 working edges as shown below. Turn the blade so a clean, undamaged edge faces toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

To Reverse or Replace the Front Squeegee Blade...

1 Raise the squeegee tool off the fl oor, then loosen the (2) Squeegee Mount Wrenches (40) on top of the squeegee and remove the Squeegee tool (38) from

the mount.

2 Remove both rear Tension Straps fi rst.

3 Remove all the wing nuts that hold the front blade in place, then remove tension strap and blade.

4 The squeegee blade has 4 working edges as shown below. Turn the blade so a clean, undamaged edge faces toward the front of the machine. Replace the

blade if all 4 edges are nicked, torn or worn to a large radius.

5 Install the blade, following the steps in reverse order and adjust the squeegee tilt.

SERVICE NOTE: Depending on the position of the Squeegee Mount Wrenches (40), you may not be able to rotate the wrench far enough to loosen or tighten

depending on which you are trying to do. In this case, simply lift UP on the Handle (C) and rotate the wrench in the direction necessary to acquire adequate turning

space and then allow the wrench to drop back DOWN into place on the hex. You can then either tighten or loosen as needed.

SQUEEGEE ADJUSTMENT

There are two squeegee tool adjustments possible, angle and height.

Adjusting the Squeegee Angle

Adjust the squeegee angle whenever a blade is reversed or replaced, or if the squeegee is not wiping the fl oor dry.

1 Park the machine on a fl at, even surface.

2 Lower the squeegee, move the machine ahead slightly and adjust the squeegee tilt and height using the Squeegee Tilt Adjust Knob (41) and Squeegee

Height Adjust Knobs (39) so that the rear squeegee blade touches the fl oor evenly across its entire width and is bent over slightly as shown in the squeegee

cross section.

FIGURE 8

FORM NO. 56091008 - ER 1300, 1600 - A-23

Page 24

A-24 / ENGLISH

SIDE SKIRT MAINTENANCE

CAUTION!

Turn the key switch off (O) and remove the key, before changing the brushes, and before opening any access panels.

The side skirt’s function is to channel the waste water to the squeegee, helping contain the water within the machines cleaning path. During normal use the blades

will wear in time.

To reverse or replace the scrub system side skirt(s) ...

1 See Figure 9. Push down on the Side Skirt Latch (12 or 32) and swing the Skirt Assy (A) open as shown.

2 Remove all the hardware that holds the blades to the skirt housings. NOTE: The main blades on each skirt assembly are held on with Tool-less Retainers.

Simply loosen the large Wing nuts (B) and then turn the Knobs (C) on the outside of the skirt assembly until they are horizontal and push through the slots.

The small inside Blade (D) is held on by (4) screws.

3 The skirt blades have 4 working edges as shown. Turn the blades so a clean, undamaged edge faces toward the center of the machine. Replace the blades

as a set if all 4 edges are nicked, torn or worn excessively.

SIDE SKIRT TILT ADJUSTMENT

The side skirt assemblies may periodically need to have their tilt in relation to the fl oor adjusted.

1 Make sure the scrub deck is in the raised position.

2 To adjust, loosen Nut (E), loosen Nuts (F) and then turn Screws (G & H) as follows.

Turn Screw (G) clockwise and Screw (H) counter-clockwise to lower the rear of the skirt assembly.

Turn Screw (G) counter-clockwise and Screw (H) clockwise to raise the rear of the skirt assembly.

NOTE: Initial tilt adjustment should be parallel to the fl oor with the deck raised. Make small adjustments to obtain good blade wiping. Do not lower the rear of the

blades too much to where they fold over excessively and cause unneeded blade wear.

FIGURE 9

A-24 - FORM NO. 56091008 - ER 1300, 1600

Page 25

DEBRIS HOPPER MAINTENANCE

CAUTION!

Turn the key switch off (O) and remove the key, before opening any access panels.

1 See Figure 10. Push down on the Right Side Skirt Latch (32) and swing the Skirt Assy (A) open as shown.

2 Disconnect the small vacuum hose from the Screen (B) and slide the entire Hopper (C) out of the machine.

3 Remove the Screen (B) from the Hopper (C) and thoroughly rinse both to clear debris.

ENGLISH / A-25

FIGURE 10

FORM NO. 56091008 - ER 1300, 1600 - A-25

Page 26

A-26 / ENGLISH

TROUBLESHOOTING

If the possible causes listed below are not the source of trouble, it is a symptom of something more serious. Contact your Nilfi sk Service Center immediately for

service.

TRIPPING THE CIRCUIT BREAKERS

The circuit breakers are located on the Circuit Breaker Panel in the operator’s compartment; they protect electrical circuits and motors from damage due to

overload conditions. If a circuit breaker trips, try to determine the cause.

VACC1 Circuit Breaker (CB1 / 20 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

VACC2 Circuit Breaker (CB2 / 20 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

VACC3 Circuit Breaker (CB3 / 15 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

VACC4 Circuit Breaker (CB4 / 20 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

VACC5 Circuit Breaker (CB5 / 10 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

Ignition Circuit Breaker (CB 6 / 15 Amp) Possible cause may be:

1 Electrical short circuit (have your Nilfi sk Service Center or qualifi ed electrician check the machine)

Once the problem has been corrected, push the button in to reset the circuit breaker. If the button does not stay in, wait 5 minutes and try again. If the circuit

breaker trips repeatedly, call your Nilfi sk Service Center for service.

VACC1 Circuit Breaker (CB1)

Right Rear Stop/Turn Lamp

Left Rear Stop/Turn Lamp

Right Front Turn Lamp

Left Front Turn Lamp

Rear Tail Lamps

Head Lamps

VACC2 Circuit Breaker (CB2)

Wash Hose Solution Pump (M8)

Side Sweep Mist Pump (M5)

VACC3 Circuit Breaker (CB3)

Side Sweep Lift Actuator Motor (M7)

VACC4 Circuit Breaker (CB4)

Scrub Brush Solenoid (L4)

Scrub Pressure Down (L5)

Scrub Cylinder Lock Solenoid (L6)

Scrub Pressure Up (L7)

Side Sweep / Scrub Solenoid (L8)

Side Scrub Lift Solenoid (L9)

Main Solution Solenoid Valve (L10)

Side Scrub Solution Solenoid Valve (L11)

Extended Scrub Water Solution Solenoid

Chemical Pump

VACC5 Circuit Breaker (CB5)

Vacuum Motor Solenoid (L1)

Squeege Down Solenoid (L3)

Squeege Up Solenoid (L3)

Main Solution Pump (M4)

Extended Scrub Pump (M6)

IGN Circuit Breaker (CB6)

Glow Plug Relay

Main Power Relay

Backup Audible Alarm

Horn

Engine System (fuel pump and ignition system)

Dash Board Panel

A-26 - FORM NO. 56091008 - ER 1300, 1600

Page 27

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Poor water pick-up Worn or torn squeegee blades Reverse or replace

Squeegee out of adjustment Adjust so blades touch fl oor evenly

across entire width

Recovery tank full Empty recovery tank

Recovery tank drain hose leak Secure drain hose cap or replace

Recovery tank cover gasket leak Replace gasket / Seat cover properly

Debris caught in squeegee Clean squeegee tool

Vacuum hose clogged Remove debris

Using too much solution Reduce fl ow via control panel solution button

Poor scrubbing performance Worn brush Rotate or replace brushes

Wrong brush type Consult Nilfi sk

Wrong cleaning chemical Consult Nilfi sk

Moving machine too fast Slow down

Not using enough solution Increase fl ow via control panel solution button

Incorrect detergent ratio Verify dilution setting if EcoFlex equipped.

ENGLISH / A-27

Inadequate solution fl ow

or no solution

Machine does not run Tripped 15 Amp (CB6) circuit breaker Check for electrical short circuit & reset

No FWD/REV wheel drive Parking brake set Release parking brake

Vacuum shuts off and display shows

“FULL” when recovery tank is not full

No Detergent Flow (EcoFlex models

only)

Solution tank empty Fill solution tank

Solution lines, valves, fi lter or trough clogged Flush lines, trough and clean solution fi lter

Solution turned OFF Activate fl ow via control panel solution button

Solution solenoid valve plugged or defective

Main system controller Check error fault codes

Towing valve in wrong position Set correctly

Tripped circuit breakers Reset any tripped circuit breakers

Plugged squeegee hose Clear debris

Vacuuming large amounts of water

at a high travel speed

Empty detergent cartridge Fill detergent cartridge

Plugged or kinked detergent fl ow line Purge system, straighten lines to

Dry seal cap on detergent cartridge not sealed Reseat dry seal cap

Detergent pump wiring

disconnected or backwards

Clean or replace valve (see service manual)

(see service manual)

Slow down or disable auto shut-off feature

(see service manual)

remove any kinks

Connect or reconnect wiring

FORM NO. 56091008 - ER 1300, 1600 - A-27

Page 28

A-28 / ENGLISH

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model ER 1600 LPG ER 1600 Petrol ER 1600 Diesel

Model No. 56111028 56111029 56111030

Sound Pressure Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 11201) dB (A)/20μPa 84.5 84.5 84.5

Sound Power Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 3744) Lwa 99 99 99

Total Weight lbs/kg 4311 / 1955 4311 / 1955 4311 / 1955

Maximum Wheel Floor Loading (center front) N/mm

Maximum Wheel Floor Loading (left rear) N/mm2 / psi .53/77 .53/77 .53/77

Maximum Wheel Floor Loading (right rear) N/mm2 / psi .54/79 .54/79 .54/79

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Seat (EN 1032) m/s

Gradeability

Transport 16% (9°) 16% (9°) 16% (9°)

Cleaning 10.5% (6°) 10.5% (6°) 10.5% (6°)

Model ER 1300 LPG ER 1300 Petrol ER 1300 Diesel

Model No. 56111025 56111026 56111027

Sound Pressure Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 11201) dB (A)/20μPa 84.5 84.5 84.5

Sound Power Level

(IEC 60335-2-72: 2002 Amend. 1:2005, ISO 3744) Lwa 99 99 99

Total Weight lbs/kg 4311 / 1955 4311 / 1955 4311 / 1955

Maximum Wheel Floor Loading (center front) N/mm2 / psi .48/70 .48/70 .48/70

Maximum Wheel Floor Loading (left rear) N/mm

Maximum Wheel Floor Loading (right rear) N/mm2 / psi .54/79 .54/79 .54/79

Vibrations at the Hand Controls (ISO 5349-1) m/s

Vibrations at the Seat (EN 1032) m/s

Gradeability

Transport 16% (9°) 16% (9°) 16% (9°)

Cleaning 10.5% (6°) 10.5% (6°) 10.5% (6°)

2

/ psi .48/70 .48/70 .48/70

2

2

2

/ psi .53/77 .53/77 .53/77

2

2

0.32 m/s

0.2 m/s

0.32 m/s

0.2 m/s

2

2

2

2

0.32 m/s

0.2 m/s

0.32 m/s

0.2 m/s

2

2

2

2

0.32 m/s

0.2 m/s

0.32 m/s

0.2 m/s

2

2

2

2

A-28 - FORM NO. 56091008 - ER 1300, 1600

Page 29

Page 30

B-2 / TÜRKÇE

İÇİNDEKİLER

SAYFA

Giriş ...................................................................................................... B-3

Önlemler ve Uyarılar ............................................................................. B-4

Makinenizi Tanıyın .......................................................................B-6 – B-9

Makinenin Kullanıma Hazırlanması

Genel Bilgi .......................................................................................... B-10

İşletme Öncesi Kontrol Listesi .................................................B-11 – B-12

Hidrolik Yağı ..................................................................................... B-11

Motor Yağı ........................................................................................ B-11

Motor Soğutma Sıvısı ....................................................................... B-12

Motor Hava Filtresi ...........................................................................B-12

Yakıt ..................................................................................................B-12

Fırçaların Takılması ............................................................................ B-13

Çözelti Deposunun Doldurulması ....................................................... B-14

Makinenin Çalıştırılması

Motoru Çalıştırma ............................................................................... B-15

Deterjan Sistemi ......................................................................B-16 – B-17

Ovma .......................................................................................B-18 – B-19

Islak Vakumlama ................................................................................ B-18

Makinenin Kullanımından Sonra

Kullanım Sonrası ................................................................................ B-20

Motorun Kapatılması .......................................................................... B-20

Bakım

Bakım Çizelgesi .................................................................................. B-20

Makinenin Yağlanması ............................................................B-20 – B-21

Yan Süpürgenin Bakımı ...................................................................... B-22

Lastik Silecek Bakımı ......................................................................... B-23

Lastik Silecek Ayarı ............................................................................B-23

Yan Etekliğin Bakımı ........................................................................... B-24

Çöp Hunisinin Bakımı ......................................................................... B-25

Sorun Giderme ........................................................................B-26 – B-27

Teknik Özellikler .................................................................................. B-28

B-2 - FORM NO. 56091008 - ER 1300, 1600

Page 31

TÜRKÇE / B-3

GİRİŞ

Bu kılavuz, Nilfi sk Temizlik Arabasından en iyi verimi almanızda size yardımcı olacaktır. Makineyi çalıştırmadan önce kılavuzu baştan sona okuyunuz.

Not : Parantez içindeki koyu yazılmış sayılar 6 – 9 gösterilen parçalara işaret eder.

PARÇALAR VE SERVİS

Gerektiği zaman tamirler, fabrikada eğitilen servis personelini çalıştıran ve Nilfi sk–Advance’in orijinal yedek parçalarını ve aksesuarlarını sağlayan yetkili Nilfi sk

Service Center tarafından yapılmalıdır.

İSİM PLAKASI

Makinenizin Model numarası ve Seri numarası , makine üstündeki isim plakasında yer almaktadır. Bu bilgi, makine için yedek parça siparişi verirken gerekli

olacaktır. Aşağıdaki boşluğa, ileride bakmak için makinenizin model numarasını ve seri numarasını yazın.

MODEL NUMARASI _________________________________________________

SERİ NUMARASI___________________________________________________

MAKİNENİN KASADAN ÇIKARILMASI

Makine teslim edildiğinde, nakliye kartonunu ve makineyi hasar bakımından dikkatle inceleyin. Eğer bir hasar varsa, incelenmek üzere nakliye kartonunu saklayın.

Navlun hasar bildirisinde bulunmak için hemen nakliye şirketini arayın.

1 Kasayı çıkardıktan sonra, tekerleklerin yanındaki ahşap blokları çıkarın.

2 Motor yağı ve soğutucu seviyelerini kontrol edin.

3 Hidrolik yağ seviyesini kontrol edin.

4 Bu el kitabının Makinenin Kullanıma Hazırlanması bölümünü okuyun ve yakıt deposunu doldurun.

5 Paletin ön ucunun yanına bir rampa koyun.

6 Bu el kitabının Kontrollerin çalıştırılması ve Makine bölümlerinin çalıştırılması bölümünü okuyun ve motoru çalıştırın. Makineyi yavaşça rampadan yere sürün.

Makine paletten çıkana kadar ayağınızı hafi fçe fren pedalında tutun.

DİKKAT !

Bu makineyi çalıştırırken aşırı dikkat gösterin. Makineyi kullanmadan önce tüm çalıştırma talimatlarını anladığınızdan emin olun. Eğer

herhangi bir sorunuz olursa Nilfi sk Satıcısına başvurun. Eğer makine arıza yaparsa, size söylenmediği sürece makineyi kendiniz

tamir etmeye çalışmayın. Makinede gerekli değişiklikleri yapması için Nilfi sk Satıcısı servisine başvurun. Bu makineyle çalışırken

oldukça dikkat edin: Bol giysiler, uzun saç, mücevherler hareket eden parçalara sıkışabilir. Makinenin bakımını yapmadan önce

çalıştırma anahtarını OFF’a getirin ve anahtarı çekin. Makine üstündeki sarı etiketlere ve güvenlik uyarılarına dikkat edin.

Makineyi eğimlerde veya yokuşlarda yavaş kullanın. Yokuş aşağı inerken makine hızını kontrol etmek için Fren pedalını (23) kullanın.

Makineyi yokuştayken döndürmeyin ; dümdüz yukarı veya aşağı sürün.

Süpürme ve fırçalama için maksimum eğim 6 derecedir. Nakliye esnasında maksimum eğim 9 derecedir.

FORM NO. 56091008 - ER 1300, 1600 - B-3

Page 32

B-4 / TÜRKÇE

DİKKAT VE UYARI İŞARETLERİ

SEMBOLLER

Nilfi sk , potansiyel olarak tehlikeli durumları göstermek için semboller kullanır. Daima bu bilgileri dikkatle okuyun ve personeli ve malı

korumak için gerekli önlemleri alın.

TEHLİKE!

Ciddi kişisel yaralanmalara veya ölüme neden olacak tehlikeleri göstermek için kullanılır

UYARI!

Ciddi kişisel yaralanmalara yol açabilecek durumları göstermek için kullanılır.

DİKKAT !

Küçük kişisel yaralanmalara veya makine ve mala zarar verebilecek durumları göstermek için kullanılır.

Kullanmadan önce bütün talimatları dikkatlice okuyunuz.

GENEL GÜVENLİK TALİMATLARI

Potansiyel makine hasarları veya yaralanmalar konusunda uyarıda bulunmak için özel uyarı ve dikkat işaretleri kullanılır.

3

TEHLİKE!

• Bu makine ciddi yaralanmaya veya ölüme yol açabilecek egzoz gazlarını (karbon monoksit) çıkarmaktadır, makineyi kullanırken

daima uygun bir havalandırma sağlayın.

UYARI !

• Bu makine sadece uygun şekilde eğitilmiş ve yetkili kişiler tarafından kullanılacaktır.

• Rampalarda veya eğimlerde yükleme yaparken, ani duruşlardan kaçının. Köşeleri keskin bir şekilde dönmeyin. Yokuş aşağı

yavaş inin.

• Hidrolik sistemin yakınında çalışırken hidrolik yağ enjeksiyonunu veya yaralanmayı önlemek için daima uygun giysiler giyin ve

göz koruması takın.

• Elektrikli parçaların bakımını yaparken düğmeyi (O) kapatın ve bataryaları çıkarın.

• Makineyi destekleyen güvenlik blokları ve standartları olmadan kesinlikle makinenin altında durmayın.

• Alev alıcı temizleme malzemeleri kullanmayın, makineyi bu tip maddelerin yakınında veya alev alıcı sıvıların bulunduğu yerlerde

çalıştırmayın.

• Bu makineyi basınçlı yıkayıcı ile temizlemeyin.

DİKKAT !

• Bu makinenin kamu yollarında kullanılması onaylanmamıştır.

• Bu makine tehlikeli tozları toplamak için uygun değildir.

• Parlatma disklerini ve zımpara taşlarını kullanmayın. Nilfi sk, parlatma disklerinin veya zımpara taşlarının kullanımı sonucu zemin

yüzeylere gelebilecek (fırça tahrik sistemine de zarar verebilir) herhangi bir hasardan sorumlu olmayacaktır.

• Bu makineyi çalıştırırken, üçüncü tarafl arın, özellikle çocukların, tehlikede olmamalarını sağlayın.

• Herhangi bir servis işlemi yapmadan önce yapacağınız işlem ile ilgili olan talimatları dikkatle okuyun.

• Ana şalteri (0) kapatmadan, anahtarı çıkarmadan ve el frenini kullanmadan makineyi başıboş bırakmayın.

• Fırçaları değiştirmeden ve herhangi bir giriş panelini çıkarmadan önce ana şalteri (0) kapatın ve anahtarı çıkarın.

• Hareket eden parçalara saçın, mücevherlerin veya bol giysilerin sıkışmasını önlemek için gerekli önlemleri alın.

• Bu makineyi sıfırın altındaki sıcaklıktaki bir yere götürürken dikkat edin. Solüsyondaki veya toplama depolarındaki veya hortum

hatlarındaki su donabilir ve bu da valfl ara ve donanımlara zarar verir.

• Kullanmadan önce tüm kapılar ve kapaklar uygun bir şekilde mandallanmalıdır.

BU TALİMATLARI SAKLAYIN

B-4 - FORM NO. 56091008 - ER 1300, 1600

Page 33

TÜRKÇE / B-5

FORM NO. 56091008 - ER 1300, 1600 - B-5

Page 34

B-6 / TÜRKÇE

MAKİNENİZİ TANIYIN

Bu kılavuzu okurken, parantez içinde koyu harfl e yazılmış bir numara veya harf göreceksiniz- örnek: (2). Bu numaralar, aksi belirtilmedikçe, bu sayfalarda

gösterilen bir parçaya atıf yapmaktadır. Metinde bahsedilen bir parçanın yerini tam olarak belirlemek için gerekli olduğunda bu sayfalara bakınız.

1 Sürücü Koltuğu

2 Çözelti Deposu Doldurma Kapağı

3 Motor Kapağı

4 Geri Alma Deposu Kapağı

5 Motor Hava Filtresi Servis Göstergesi

6 Soğutma Sıvısı Geri Alma Deposu

7 Motor Hava Filtresi

8 Motor Kapağı Mandalı

9 Geri Alma Deposu Akıtma Hortumu

10 Geri Alma Deposu Kaldırma Mandalı

11 Geri Alma Deposu Kaldırma Tutamağı

12 Sol Yan Eteklik Mandalı

13 Sol Yan Etekliği

14 Yakıt Deposu (petrol deposu gösterilmiştir)

15 Yakıt Deposu Kapağı Mandalı

16 Far

17 Yakıt Deposu Kapağı

18 Operatör Koltuğu Ayarlama Kolu

19 Direksiyon

20 Çift Ovma Etekliği Tutucu

B-6 - FORM NO. 56091008 - ER 1300, 1600

Page 35

MAKİNENİZİ TANIYIN

24 Deterjan Kartuşları (yalnız EcoFlex modellerinde)

25 Kontrol Paneli

26 Devre Kesici Paneli (Sorun Giderme bölümüne bakın)

27 Direksiyon Eğimi Ayar Kolu

28 Fren Pedalı / El Freni

29 Sürme Pedalı, Yön/Hız

30 Deterjan Kartuşu Bölmesi

31 Sağ Yan Etekliği

32 Sağ Yan Eteklik Mandalı

33 Huni

34 Çekme Valfi Kolu

35 Batarya

36 Çözelti Filtresi

37 Çözelti Deposu Akıtma Hortumu

TÜRKÇE / B-7

38 Lastik Silecek Tertibatı

39 Lastik Silecek Yükseklik Ayar Düğmesi

40 Lastik Silecek Somun Anahtarı

41 Lastik Silecek Eğim Ayar Düğmesi

42 Motor Yağı Filtresi

43 Motor Kapağı Destek Çubuğu

44 Hidrolik Yağı Haznesi Doldurma Kapağı

45 Yağ Soğutucu Kaldırma Mandalı

46 Motor Yağı Seviye Çubuğu

47 Sağ Ovma Etekliği Tespit Somunları

48 Sağ Ovma Etekliği Tertibatı

49 Motor Yağı Boşaltma (radyatör altında)

FORM NO. 56091008 - ER 1300, 1600 - B-7

Page 36

B-8 / TÜRKÇE

MAKİNENİZİ TANIYIN

50 Kontak Anahtarı

51 Motor Hızı Anahtarı

52 Toz Muhafazası

53 Yan Süpürge/Ovma AÇMA / KAPAMA Anahtarı

53a Yan Süpürge AŞAĞI ayarlama Anahtarı

53b Yan Süpürge YUKARI ayarlama Anahtarı

54 Ovma AÇIK / Ovma Modu Seçimi

55 Ovma KAPALI

56 Çözelti Anahtarı

56a Çözelti Akışı Azaltma Anahtarı

56b Çözelti Akışı Arttırma Anahtarı

57 EcoFlex Düğmesi

58 Vakum/Boru Düğmesi (bkz. sonraki sayfa)

59 Korna Anahtarı

60 Uzatmalı Sopa Anahtarı (opsiyonel / sonraki sayfaya bakın)

61 Deterjan Sistemi (yalnız EcoFlex modellerinde)

62 Uyarı Gösterge Lambası (KIRMIZI)

62a Park Freni AÇIK

62b Yağ Basıncı (Dizel)

62c Motor Servis

62d Batarya Az

62e Kontrolör Arızası

62f Hidrolik Sıcaklığı

62g Yakıt Az

62h Motor Sıcaklığı

63 Sola Dönüş Sinyali (opsiyonel)

64 Ekran

64a Ovma Basıncı Göstergesi

64b Saat Sayacı

64c EDS Göstergesi (opsiyonel)

64c Deterjan Göstergesi (gerekli donanım varsa)

64e Çözelti Akım Göstergesi

64f Uzatılmış Ovma Göstergesi (opsiyonel)

65 Sağa Dönüş Sinyali (opsiyonel)

66 Dikkat Uyarı Lambası (SARI)

66a Çözelti Az

66b Hidrolik Filtresi Tıkalı

66c Kritik Olmayan Arıza / Kritik Olmayan Motor Servisi

66d Isıtma Bujisi

66e Geri Alma Deposu DOLU

67 Acil Durum Flaşörleri (opsiyonel)

68 Ön Farlar

(ovma 1) (ovma 2) (ovma 3)

1 kez basın 2 kez basın 3 kez basın

B-8 - FORM NO. 56091008 - ER 1300, 1600

Akış Akış Akış

Oranı 1 Oranı 2 Oranı 3

(ovma 1) (ovma 2) (ovma 3)

1 kez basın 2 kez basın 3 kez basın

Page 37

TÜRKÇE / B-9

MAKİNENİZİ TANIYIN

VAKUM / BORU DÜĞMESİ (58)

56040944 numaralı Vakum Çubuğu Kiti Talimat Belgesine bakın.

UZATMALI SOPA ANAHTARI (60)

56040945 numaralı Uzatmalı Sopa Kiti Talimat Belgesine bakın.

AŞAĞIDA İŞARETLİ (X) UYARI / DİKKAT SİMGELERİNDEN HERHANGİ BİRİ GÖRÜNTÜLENİYORSA LÜTFEN YETKİLİ NILFISK SERVİS

MERKEZİNİZLE İRTİBATA GEÇİN.

66a

66c

X

66e

62a

62c

66b

X

300:1

66d

62b

X

62d

X

62e

X

62g

X

62f

X

62h

X

FORM NO. 56091008 - ER 1300, 1600 - B-9

Page 38

B-10 / TÜRKÇE

MAKİNENİN KALDIRILMASI

DİKKAT !

Güvenlik standları veya blokları olmadan kesinlikle makinenin altında çalışmayın.

• Makineyi krikoyla kaldırırken, belirlenen yerlerden kaldırın – Şekil 1’deki Tespit / Krikoyla Kaldırma Yerlerine bakın.

MAKİNENİN NAKLİYESİ

DİKKAT !

Makineyi açık bir kamyon veya treylerde nakletmeden önce şunları kontrol edin:

• Tüm giriş kapıları güvenli bir şekilde mandallanmış olmalıdır.

• Makine sağlam bir şekilde tespit edilir - Şekil 1’deki Tespit / Krikoyla Kaldırma Yerlerine bakın.

• Makine el freni çekilmiş olmalıdır.

MAKİNENİN İTİLMESİ VEYA ÇEKİLMESİ

DİKKAT !

Bu makinenin sevk pompası , ayarlanabilir bir çekme valfıyla imal edilmiştir. Bu valf , makine motor kullanılmadan kısa mesafe

itildiğinde/ çekildiğinde hidrolik sisteme zarar gelmesini önler.

Çekme valfi , Motor Kapağı (3) açılıp kaldırıldığında ulaşılan Çekme Valfi Kolu (34) ile kontrol edilir. Çekme Valfi Kolunu (34) dışarı çektiğinizde; motor ve pompa

arasındaki hidrostatik kilit açılır.

Valf normal çalışma konumundayken (Çekme Valfi Kolu (34) İÇERİ itilmişken) çekilmesi halinde, hidrostatik pompa hasar görebilir. Not: Çekme valfi serbest

tekerlek konumunda bırakılırsa (Çekme Valfi Kolu (34) DIŞARI çekiliyken) hidrostatik pompa makineyi ileri ya da geri süremez. Herhangi bir hasar oluşmaz,

yalnızca kolu İÇERİ iterek valfi normal çalışma konumuna geri getirmeniz yeterlidir. Makineyi normal yürüme hızından (saatte 2-3 mil) daha hızlı olmayan bir hızda

ızca kısa mesafelerde itin ya da çekin. Makine daha uzun mesafelerde taşınacaksa, ön tahrik tekerleğinin zeminden yükseğe kaldırılması ve uygun bir

ve yaln

taşıma arabasına yerleştirilmesi gereklidir.

ŞEKIL 1

B-10 - FORM NO. 56091008 - ER 1300, 1600

Page 39

TÜRKÇE / B-11

ÇALIŞTIRMA ÖNCESİ KONTROL LİSTESİ

Her kullanımdan önce

* Makineyi hasar, yağ veya soğutucu sızıntısı bakımından kontrol edin.

* Oluşmuş tozu çıkarmak için motor yağ fi ltresi (7) üstündeki kauçuk toz kabını sıkıştırın.

* Motor soğutucu seviyesini (6) kontrol edin.

* Motor yağ seviyesini (46) kontrol edin.

* Hidrolik yağ seviyesini (44) kontrol edin.

* Benzinli ve dizel modellerde yakıt ölçme aletini (64d) kontrol edin.

* Propan modeli için LP deposunun üstünde bulunan yakıt ölçme aletini kontrol edin.

* Hava fi ltresi servis göstergesini (5) kontrol edin.

Sürücü koltuğunda

* Çalıştırma kontrollerini ve fonksiyonlarını anladığını

* Tüm kontrollere kolay ulaşacak şekilde koltuğu ayarlayın.

* Ana anahtarı sokun ve çalıştırma anahtarını (50) ON pozisyonuna getirin. Huninin 59), saat ölçerin (64b) ve farların 68) uygun çalışıp çalışmadığını kontrol

edin. Çalıştırma anahtarını (50) OFF’a getirin.

* Fren Pedalını (28) kontrol edin. Pedal sağlam olmalı ve sonuna kadar itilmemelidir. Mandal, uygulandığında pedalı tutmalıdır.

(Tüm kusurları derhal bir servis personeline bildirin).

Temizleme işleminizi önceden planlama

* Minimum durdurma veya çalıştırmayla uzun çalıştırmaları düzenleyin .

* Bütün alanı kapsamayı sağlamak için ovma yolunun 2-3” (5.08-7.62cm) üst üste gelmesine izin verin.

* Keskin dönüşler yapmaktan, direklere çarpmaktan veya makinenin yanını çizdirmekten kaçının .

HİDROLİK YAĞI

Hidrolik yağı haznesine erişmek için Motor Kapağını (3) açıp kaldırın. Depodan Doldurma Başlığını (44) çıkarın ve doldurma ekranının tabanına bakın. Yağ

seviyesi doldurma ekranının tabanından azsa, doldurma ekranının tabanı kaplanana kadar 10W30 motor yağı ekleyin (yağ seviyesi doldurma ekranının

tabanından 1/2” (12.7mm)’den daha yüksek seviyede olmamalıdır). Bir mekanik arızadan dolayı önemli bir kirlenme olması halinde yağı değiştirin.

MOTOR YAĞI – BENZİN (PETROL) VE LPG

Makine düz bir yüzeye park edilmiş ve motor soğukken, motor yağı seviyesini kontrol edin. Motor yağını ilk 35 saatlik kullanımdan sonra ve bundan sonra her 150