Page 1

AUTO BOOSTER

User manual ........................................ 3 - 39

Betriebsanleitung ................................ 40 - 76

Manuel d’Instructions ......................... 77 - 115

Gebruikershandl eiding ....................... 116 - 153

Manual de instrucciones ..................... 154 - 193

Manuale di istruzioni ........................... 194 - 232

107319143 e

Page 2

Page 3

Index

1 Safety precautions and warnings ...........................................................................................4

2 Description 2.1 Application ....................................................................................6

2.2 Operation elements ......................................................................6

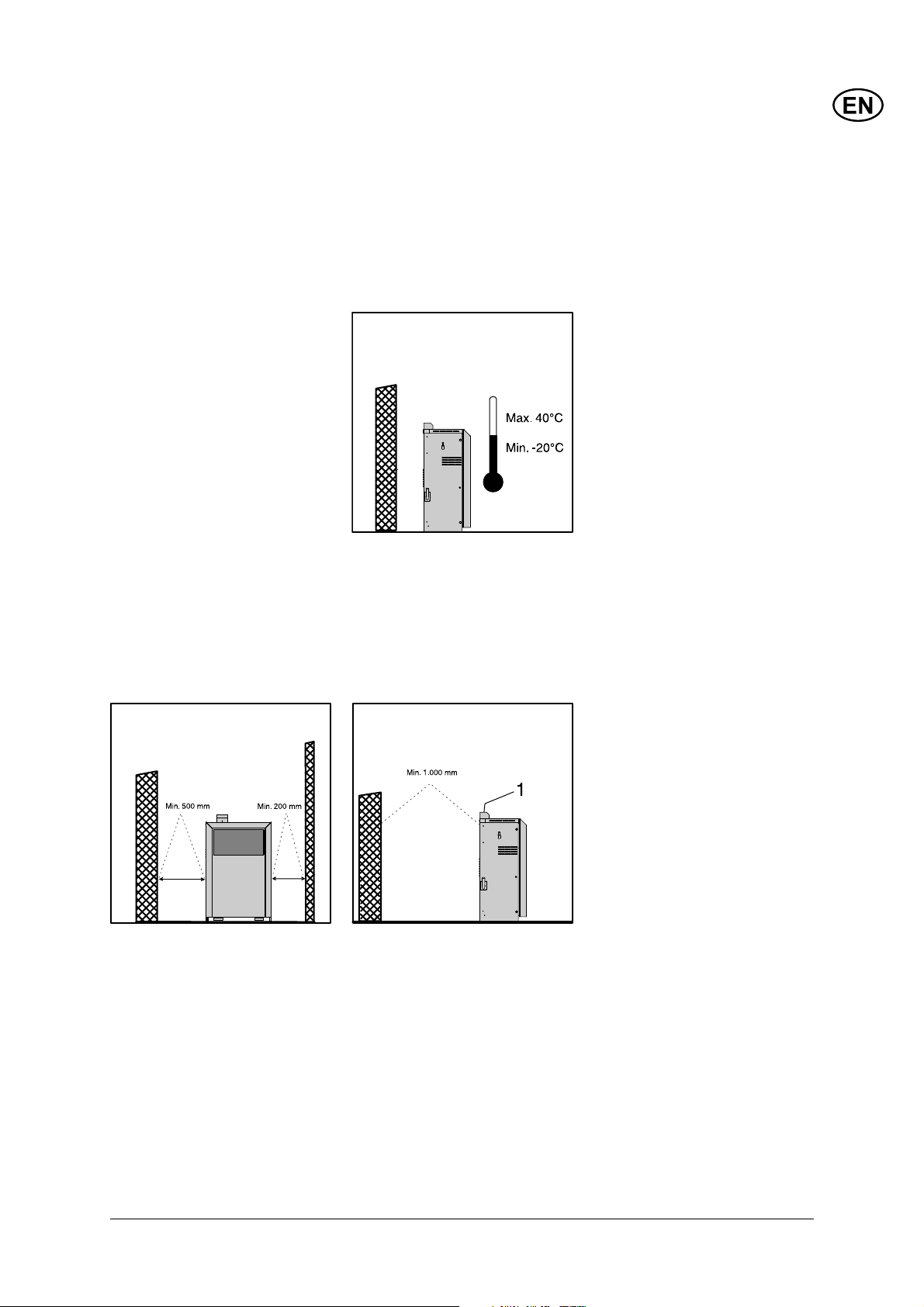

3 Installation 3.1 Temperature conditions ................................................................7

3.2 Condition of distance ....................................................................7

3.3 Foundation / level ling ..................................................................7

3.4 Water connection ..........................................................................8

3.5 Mains power connection ...............................................................8

3.6 Mounting of wash boom ...............................................................9

3.7 Venting of h.p. pump, fuel pump and detergent pumps ..............10

3.8 Connecting to external fuel supply .............................................12

3.9 OPTIONAL: Water softener, drain hose......................................13

4 Operation 4.1 Setting up the AUTO BOOSTER ................................................14

4.1.1 Coin operation / free operation ........................................14

4.1.2 Coin selector settings ......................................................14

4.1.3 Teaching the coin selector to accept a token ...................16

4.1.4 Setting coin value on timer ..............................................17

4.1.5 Maintenance of coin selector ...........................................19

4.1.6 Programs and program selector ......................................19

4.1.7 Temperature setting .........................................................20

4.1.8 Detergent A, B and C ......................................................21

4.1.9 OPTIONAL: Water Softener settings ...............................22

4.2 Running the AUTO BOOSTER ...................................................23

4.2.1 Starting up .......................................................................23

4.2.2 Stopping the AUTO BOOSTER .......................................25

4.2.3 Programs .........................................................................26

4.2.4 Foam brush, mounting & dismounting .............................29

4.2.5 Circulation frost protection ...............................................30

4.2.6 Functional diagrams ........................................................30

5 Maintenance .........................................................................................32

5.1 Coin selector ..............................................................................33

5.2 Hour counters .............................................................................33

5.2 Oil .........................................................................................33

5.3 Water fi lter ..................................................................................34

5.4 Cleaning of high-pressure nozzle ...............................................34

5.5 Fuel fi lter ....................................................................................34

5.6 Disposable waste .......................................................................35

6 Trouble Shooting 6.1 General trouble shooting ............................................................36

6.2 Error messages .........................................................................37

7 Technical Data .........................................................................................38

8 Warranty .........................................................................................39

9 EC Declaration of Conformity .........................................................................................39

3

Page 4

1 Safety Precautions and Warnings

Symbols used to mark instructions

Only let instructed people operate the machine.

General

When using the high-pressure

hot water washer all existing

national regulations must be

observed. Beyond the instruction manual and the current

national legal regulations for

prevention of accidents, also

the approved rules for safe

working must be observed.

Any method of use endangering

the safety of persons or equipment is forbidden.

Before use

Before starting up your highpressure hot water washer

check that it is in a regular

condition. Electric plugs and

couplings must be watertight.

Check the electric cables at

regular intervals for damage

and wear. Only use the high-

Before starting up

your high-pressure

washer for the fi rst

time, this instruc-

tion manual must

be read through carefully. Save

the instructions for later use.

Safety instructions marked with

this symbol must

be observed to

prevent danger to persons.

pressure hot water washer if the

electric cable is all right (damaged electric cables can cause

electric shock!)

Important instructions

Connection to public drinking

water supply must be performed in accordance with the

applicable regulations in your

country.

IMPORTANT: Only use water

without impurities!

Before each use of your highpressure hot water washer

check the most important visual

parts.

High-pressure jets can be dangerous if misused. Never direct

the water jet towards people,

pets, electric wiring, or the machine itself.

Spray handle and lance are affected by a thrust during operation - therefore always hold the

spray lance fi rmly with both

hands.

This symbol is

used to mark

safety instructions that must

be observed to

prevent damage

to the machine and its performance.

This symbol

indicates tips

and instructions

to simplify work

and to ensure a safe operation.

Never try to clean clothes or

footwear on yourself or other

persons.

Operator and anyone in immediate vicinity of the site of cleaning should take action to protect

himself from being struck by

debris dislodged during operation.

Check that cleaning will not

result in dangerous substances

(e.g. asbestos, oil) being

washed off the object to be

cleaned and harming the environment.

Do not clean sensitive surfaces

made of rubber, fabrics or the

like with the zero nozzle. With

the fl at jet nozzle keep a distance of at least 15 cm to the

surface to be cleaned.

Never let children operate the

machine.

Do not use the machine if the

electric cable or the high-pressure hose are damaged.

4

Page 5

Do not cover the machine during operation or use it in a room

without adequate ventilation !

If any of the machines overload protection devices trips

(machine stops unintended),

release the trigger of the spray

handle. Lock the spray handle

with locking device and turn

the start/stop switch to position

„OFF“.

Refer to section “6 Trouble

Shooting”.

Never start the cleaner without

water supply. Even a short water defi ciency can damage the

sleeves of the pump.

Operation

Avoid damage to the electric

cables such as squeezing, pulling, knots etc. and keep them

away from sharp or hot objects.

Avoid damage to the high-pressure hose such as running over

by vehicles, squeezing, pulling,

knots/kinks etc. and keep it

away from oil and sharp or hot

objects, as such may cause the

hose to burst.

The cleaner can be used in

zones classifi ed as ZONE 2.

Important! Never use the

machine in an environment

where there could be a danger

of explosion (according to EN-

50014).

Important! When the system

has been in operation and

thereafter stopped, there might

still be a working pressure in

the pipeline and high-pressure

hoses. Therefore you should

pay special attention to the following:

• Never dismount the highpressure hose from the

machine during operation.

Disconnect the machine and

relieve the high-pressure

hose of pressure prior to

dismounting.

• Never dismount the highpressure hose from the

outlet point before it has

been securely closed and

the high-pressure hose has

been relieved of pressure.

• Prior to any service interference in the machine it

should be disconnected and

the system relieved of pressure by activating the trigger

of the spray handle.

Repair and Maintenance

Only carry through the maintenance operations described in

the operating instructions. Only

use original Nilfi sk-ALTO spare

parts.

Do NOT make any technical

modifi cations to the high-pressure hot water washer.

Warning! High-pressure hoses,

nozzles and couplings are

important for the safety when

operating the machine. Only

use the high-pressure hoses,

nozzles and couplings prescribed by Nilfi sk-ALTO!

For major repairs, please contact your nearest Nilfi sk-ALTO

service organisation.

Mains power connection

This product is intended for

stationary installation only

and is supplied without a

power cord! Only let an authorized electrician connect

the machine to the mains

supply !

The following points must be

observed:

• Check that the voltage

stated on the data plate

corresponds to your mains

voltage.

• Make sure that the power

cord contains the right

number of wires (including

ground wire) and that each

wire has the right dimensions to carry the load (amperage) stated on the data

plate of the machine.

• Make sure that the installation (cables, connection

points and fuses) is correctly

dimensioned for the load of

the machine - refer to the

data plate of the machine.

If not required by local legis

lation, we strongly recommend you to connect the machine to a power source with

a Residual Current Device

(RCD) which will disconnect

the power supply if the leakage current exceeds 30 mA

for 20 milli seconds !

See section “3.5 Mains power

connection” for further instruc-

tions.

Only let a qualifi ed electrician

maintain the electric installation.

Safety Devices

Safety Valve

The pressure side of the highpressure pump is fi tted with a

safety valve. This valve leads

the water back to the suction

side of the pump when the

spray handle is closed or if a

nozzle is blocked.

The safety valve is adjusted

and sealed by the producer.

THIS ADJUSTMENT MUST

NOT BE CHANGED !

Machine protection

The machine features an overcurrent protection and built-in

thermal protection of the motor.

In the event of increased power

consumption (maloperation)

and in the event of excessive

5

Page 6

motor temperature (obstructed

ventilation etc.), the entire

machine will automatically be

disconnected from the mains

supply.

Short circuit protection

The machine is equipped with

a short-circuit protection. In the

event of short-circuits in the

machine, the protective device

will disconnect the entire machine from the mains supply.

2 Description

2.1 Application This high-pressure hot water

washer has been developed

for stationary installation and

self service operation within car

washing

Section 4 describes how to use

the high-pressure hot water

washer.

2.2 Operation elements See foldout at the end of these

operating instructions.

Only use the high-pressure

hot water washer for purposes

described in this manual.

The safety precautions must be

observed to prevent damage

to the machine, the surface to

be cleaned or severe personal

injuries.

1 Wash boom / high pressure

hose

2 Main switch

3 Program selector switch

4 Water inlet (only machines

with optional water softening

unit)

5 Thermostat (temperature

adjustment)

6 Electric box

7 Water tank

8 Detergent container

9 Fuel container

10 Pressure gauge

11 Water softening unit (option)

12 Display (hour counters, error

messages)

13 Brush holder

14 Lance holder

15 Data plate

16 Lifting device

17 Coin selector

18 Assembly box, mains cable

19 "Free operation" switch

20 Heating element, frost pro-

tection

21 Tap (option)

22 No Scale

23 Adjustment of detergent

concentration

6

Page 7

3 Installation

3.1 Temperature conditions The hose, gun and lance are

3.2 Condition of distance In consideration of the cooling

The machine has been constructed for outdoor placement.

The min. ambient temperature

for the machine is –20°C and

the maximum ambient temperature is 40°C.

system of the machine and the

accessibility of service, there

must be free wall space on both

sides of the machine. To the

frost protected to -20°C provided by circulation of preheated

water through the system. The

lance must be placed in the

lance holder (14 ) after use in

order to circulate the water in

periods with frosty weather.

The machine features a fan

heater automatically starting up

when the temperature inside

the machine gets too low.

The adjustment of the thermal

sensor is effected in the electric

box. On delivery the adjustment

has been set at 5°C. This setting must not be lowered.

right 200 mm at a minimum, to

the left 500 mm at a minimum

and behind 300 mm.

The distance from the chimney

outlet to infl ammable material

must be 1,000 mm. This distance can be reduced to 300

mm by mounting a diverter. You

will fi nd diverter and instructions for mounting in the front

door.

3.3 Foundation / levelling Place the machine on a plane

fl oor.

Bolt the machine to the foundation through the 3 holes (Ø12

mm) in the bottom plate. Before

fastening, the machine must be

levelled.

The chimney (1) can be turned

180° by dismounting 4 pcs. M5

screws (under the top plate),

turning the chimney and remounting the screws.

Shape of foundation, see foldout at the end of this manual.

7

Page 8

3.4 Water connection The water connection is made

with a fl exible hose connected

to the water tank (7) of the

machine or to the optionally

mounted water-softening unit

(11).

perature and fl ow rate). If in

doubt, contact your Nilfi sk-ALTO representative. Also ensure

that the water supply hose is

protected against freezing between the outlet and the AUTO

BOOSTER.

The water hose can be lead in

through:

1. The bottom plate

2. The punch-out pieces in the

rear plate

(see foldout at the end of this

manual).

Make sure that the supply hose

is suited for the purpose (tem-

The connection can be made to

a public drinking water supply

network or a private water supply. Water quality: particle size

<50 μ. A shut-off cock should

be mounted on the water supply network in the immediate

vicinity of the machine. Make

sure that the water supply is

within the following specifi cations and that the water does

not contain particles such as

fl oating sand.

Min. water inlet pressure: 1 bar

(at the required fl ow rate of the

machine - see data plate.

Max. water pressure: 10 bar

Max. water inlet temp.: 30°C.

(Machine with optional water

softening unit - max. water

pressure: 6 bar)

All AUTO BOOSTER feature a

water break tank, and no further

protection against back-fl owing

water into the supply network is

required. The machine complies

with EN 1717.

If there is a risk of fl oating sand

or other impurities in the inlet

water, a sand fi lter (50 micron)

should be mounted between the

supply outlet and the internal

fi lter of the machine.

3.5 Mains power connection

8

CAUTION! An

authorized electrician must perform

the electrical

connection of the machine to

the main power supply. Refer to

section “1 Safety precautions

and warnings”.

The following precautions must

be observed:

• Make sure that the supply

cable is of the correct dimension (see voltage and load on

the data plate of the machine

(15)) and that it is suitable for

the specifi c environment.

Page 9

Assembly box, mains cable (see pos. 18 on foldout at the end of this manual)

The electric cable can be lead

in through:

1. The bottom plate

2. The punch-out pieces in the

rear plate and through the relief ring into the junction box.

(see foldout at the end of this

manual).

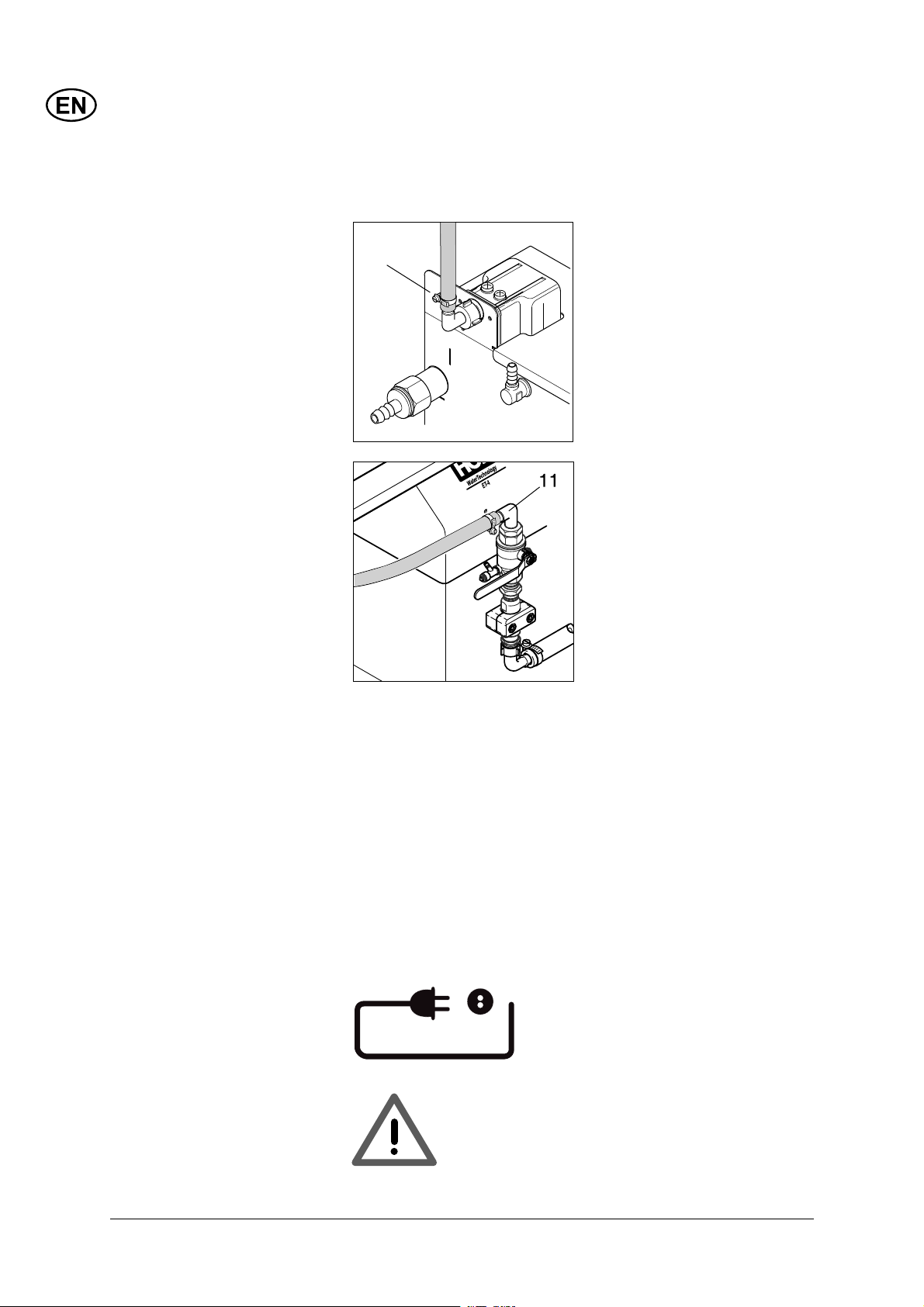

• Connect the phase cords of

the supply cable to the connection terminals L1, L2 and

L3. Connect the zero cord to

3.6 Mounting of wash boom Your AUTO BOOSTER comes

N. For single phase machines use L1 and N to connect

phase and zero cords.

• Connect protective earth wire

to the earthing terminal.

• Check and measure the

protective earth connection

according to legislation.

• Connect the other end of the

cable to an approved socket

of a correct dimensioned

main supply.

Make sure that the cable is

properly guided and relieved

between the fi xed installation

and the machine and that the

cable is without any damage to

the insulation.

Also see notes in section

“1 Safety precautions and

warnings”!

Note: Beware

that the electric

cables of the

machine are not

mixed up. The

wires 1, 2, 3, 4

MUST keep the

illustrated positions.

with all high-pressure connections already made – the highpressure hose is led through

the wash boom with connection

to high pressure pump in one

end and spray handle in the

other.

Mount the wash boom (1) into

the hole/bracket in the top of

the AUTO BOOSTER (left side).

Slowly pull the high-pressure

hose out of the wash boom until

the full length is achieved.

Place the locking ring of the

boom in position and lock it by

tightening the two screws.

The wash boom and hose /

spray handle / lance are now

ready for use.

9

Page 10

/

+

%

3

#

-)4

35"

)3()

3.7 Venting of HP-pump,

fuel pump and detergent

pumps

When the AUTO BOOSTER is properly connected to supply water,

electrical installation and the wash boom / high-pressure hose

are fi tted, the AUTO BOOSTER’s hydraulic and fuel lines must be

vented before it is operational.

● Set thermostat (5) to 40 ºC.

● Fill fuel into the fuel container (9).

● Fill No Scale into the container (22).

● Fill detergent containers (8) with the appropriate detergents (see

section 4.1.8).

#

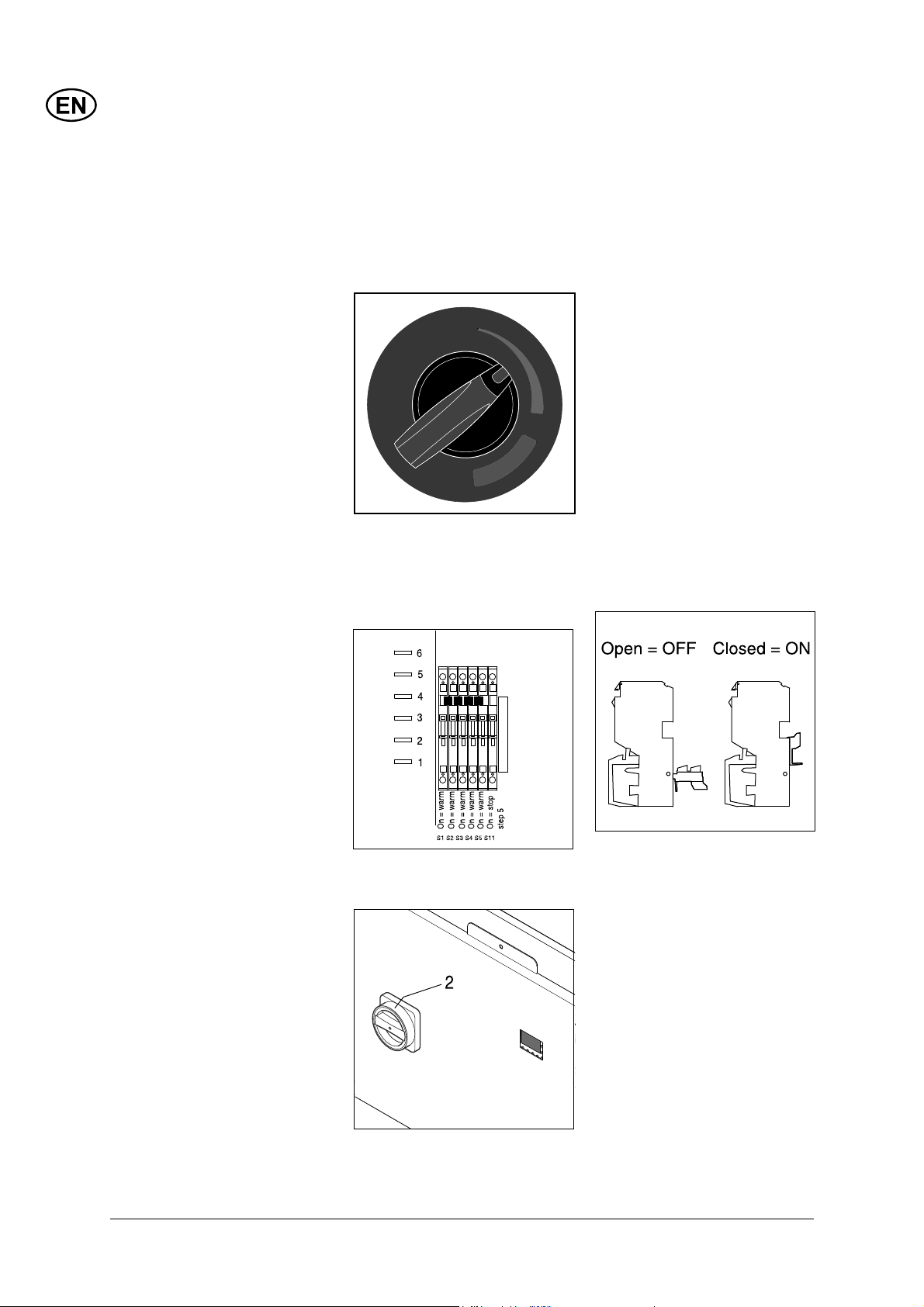

● Open electric box (6) and set all Cold / Hot switches (S1, S2, S3,

S4, S5) to “Hot” (= ON).

● Enable running without payment (19).

● Close electric box.

10

1. Turn the main switch, (2) to position “ON”.

!

"

$#

).054

Page 11

2. Activate the trigger of the spray handle on high-pressure hose,

and turn the program selector switch (3) to program 1. The AUTO

BOOSTER will start.

3. Let the water run until all air has escaped from the pump (even

water fl ow), and check that the burner is running and detergent A

is mixed into the water stream (foaming). Release the trigger of

the spray handle and wait a few seconds until the HP pump stops

(note that the burner will continue running until the temperature

in the break tank reaches 40 ºC.

4. Turn the Program selector to program 2 and activate the spray

handle again. Observe that waterfl ow decreases (pressure drop)

and that detergent B is mixed into the water stream. Run for 30

seconds to fully vent chemical pump B then close spray handle.

5. Turn the Program selector to program 4 and repeat step 5.

Chemical pump C is now vented.

6. Stop the AUTO BOOSTER by turning the Selector switch to position STOP.

The AUTO BOOSTER is now vented and ready for use.

11

Page 12

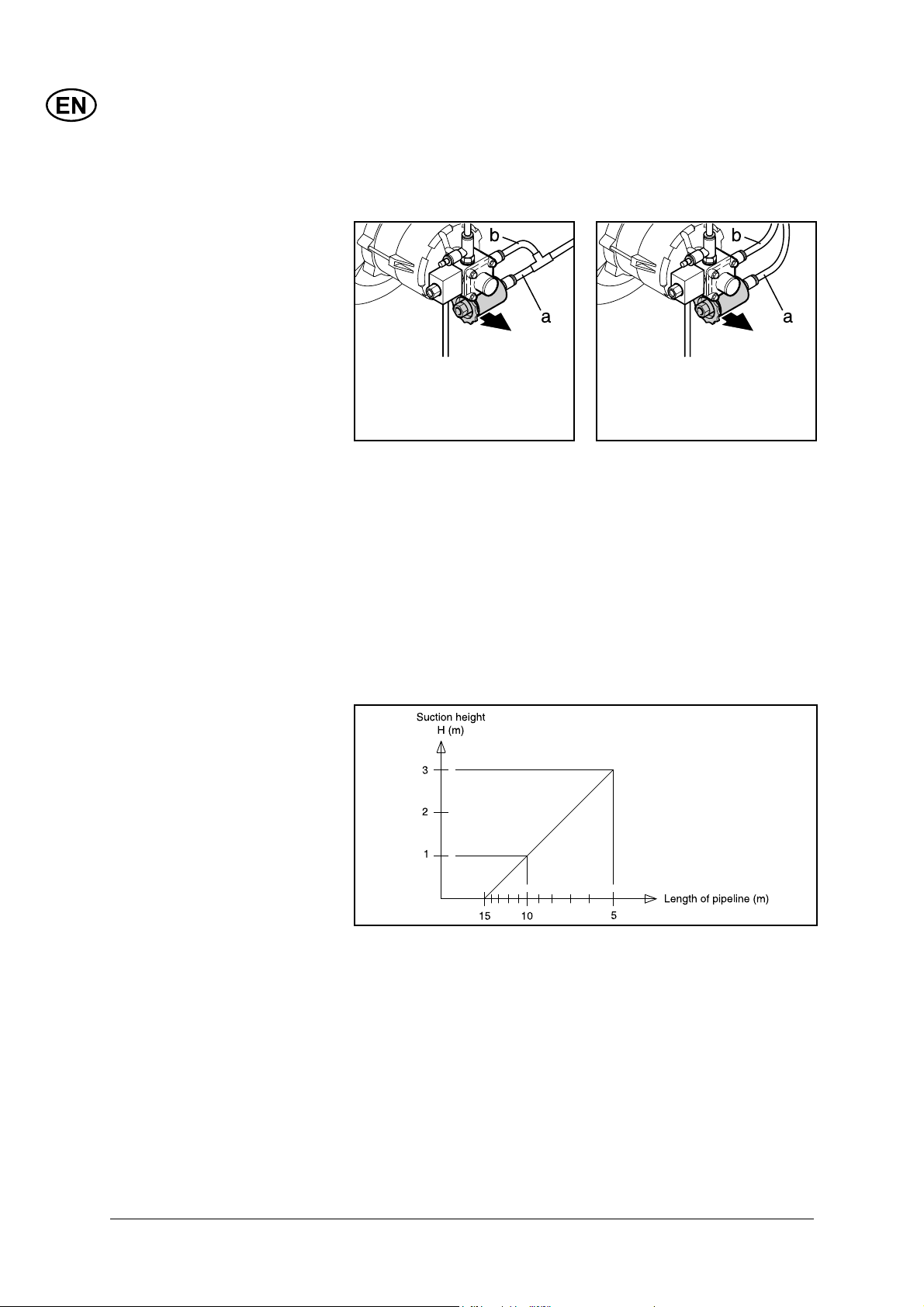

3.8 Connecting to external

fuel supply

The AUTO BOOSTER can be connected to an external fuel supply.

As a standard, the machine is supplied with a 33 l container.

You can choose between “one” and “two” -string connection, where

“one”-string only has one supply hose (a) and “two”-string has an

additional return hose (b) - see fi gure.

Please observe that in some countries only the “one” string system

is approved.

The fuel hose for the external fuel supply can be lead-in:

1. Through the bottom plate to the oil pump.

2. Through the punch-out pieces in the rear plate to the oil pump.

See foldout at the end of this manual.

Please observe the following restrictions to fuel line.

12

Page 13

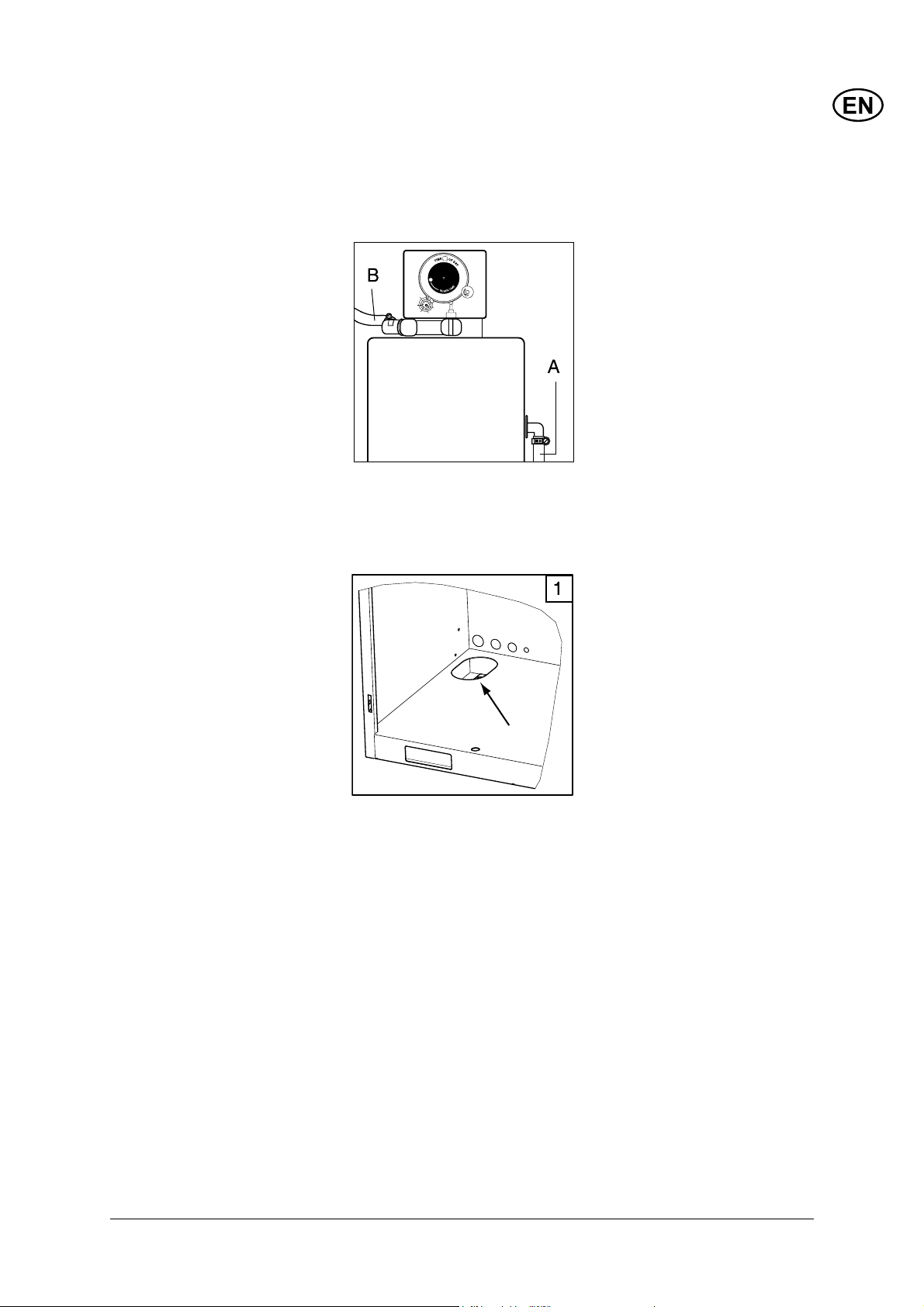

3.9 OPTIONAL: water

softener - drain hose

Your AUTO BOOSTER may be equipped with the optional water

softener of the type that regenerates automatically - depending on

the water hardness and the water consumption.

The water softener has two drain hoses - one at each side. One

is for overfl ow (A), the other is used during regeneration (B). Both

hoses are transparent with woven reinforcement.

Make sure that both drain hoses are guided through the bottom

chassis of the AUTO BOOSTER and connected to an appropriate

sewer or drainage, capable of sinking approximately 55 liters of

salty water during regeneration.

Pour fi lter-salt recommended by Nilfi sk-ALTO into the water softener container - it will accept maximum 25 kg.

Your water softener is now ready for use. Please refer to section

4.1.9 for setting of the automatic regeneration timing.

13

Page 14

4 Operation

4.1 Setting up the AUTO

BOOSTER

The AUTO BOOSTER is designed as a user-friendly, self-service product, where the user

can buy operation time to wash

his vehicle.

Several features are adjustable

by the owner, in order to provide a certain offering for a

certain price.

● The owner must decide which

payment to accept – coins

of national currency and/or

tokens,

● and how long washing time

should be assigned to specifi c

coins / tokens.

The AUTO BOOSTER provides

5 different program steps with

the possibility to add 3 different

detergents.

● The owner must decide if

the individual program steps

should run with hot (internally

heated, up to 60ºC) or cold

water.

● Also the detergent concentration of the 3 detergents

must be determined within

the range of Nilfi sk-ALTO

recommendations.

If the AUTO BOOSTER is optionally equipped with water softening unit (11), the owner must

decide, at which times (outside

of normal operation hours) the

regeneration of the softening

unit should take place.

4.1.1 Coin operation / free

operation

4.1.2 Coin selector

settings

Normally the AUTO BOOSTER

can only be started and used

when appropriate payment is

done.

By means of a “Free operation”

switch (19), the owner can decide to bypass or to disconnect

the payment system.

!!NOTE – The

circulation frost

protection will

NOT be operative

during Free Use –

payment cancelled!!

The coin selector (17) in the

AUTO BOOSTER is either.

● European type, accepts €, £

and CHF and tokens

or

14

● Scandinavian type, accepts

NOK, DKK, SEK and tokens.

Page 15

European label Scandinavian label

The type is shown at the label

on the side of the coin selector.

To ease access to the label and

coin selector switches, the coin

selector can be unclipped from

the front panel.

Upon reception of the AUTO

BOOSTER all the coins of the

currencies listed on the label

will be accepted.

European type:

● Blocking switch 7 = “ON”,

blocks all € - coins

● Blocking switch 9 = “ON”,

blocks all CHF-coins

● Blocking switch 10 = “ON”,

blocks all £ - coins

Scandinavian type:

● Blocking switch 7 = “ON”,

blocks all NOK - coins

● Blocking switch 9 = “ON”,

blocks all DKK-coins

● Blocking switch 10 = “ON”,

blocks all SEK – coins

Example 1: An owner in

Germany wants the AUTO

BOOSTER coin selector to accept only € - coins.

● Blocking switch 7 must be in

“OFF” position to accept €

coins (0.50€ - 1.00€ - 2.00€).

The owner can “block” coins

of the currencies not valid in

his country with the “blocking

switches” on the side of the coin

selector .

● Blocking switches 9 and 10

must be “ON” to disable CHF

and £ coins.

Example 2: In Denmark, only

Danish Kroner, DKK, should be

accepted. On the Scandinavian

coin selector set switches as

follows:

● Blocking switch 9 must be in

“OFF” position to accept DKK

coins (5 DKK – 10 DKK – 20

DKK)

Blocking switches 7 and 10

must be “ON” to disable NOK

coins and SEK coins.

On both coin selectors the

“Blocking switches 1,2,3,4,5,6”

can further be used to disable

coins of wide tolerances. For

normal operation they should all

be left in the “OFF” – position.

15

Page 16

The “Blocking switches

11,12,13,14,15,16” are all used

only to teach the coin selector to recognize user defi ned

tokens. Leave these in “OFF”position for now.

The Switch 8 is designated

“Teach switch”. Leave this

“OFF” for normal operation.

4.1.3 Teaching the coin

selector to accept a

token

Both the European and the

Scandinavian coin selector can

be “taught” to recognize and

accept a user defi ned token.

The token can be assigned one

of six values by choosing one

of six “Teach Channels”, represented by the blocking switches

11,12,13,14,15 and 16 (see

4.1.4)

Teaching is done by setting the

coin selector to Teach Mode,

selecting a “Teach Channel”

and then entering a minimum of

10 tokens through the coin slot.

The procedure is similar for the

European and the Scandinavian coin selector, and can be

performed with the coin selector

in the machine.

Before beginning teaching

● Set AUTO BOOSTERr’s main

switch (2) to OFF.

● Set blocking switches

11,12,13,14,15,16 on coin

selector to OFF.

● Set teach switch 8 on coin

selector to OFF.

● Set AUTO BOOSTER’s main

switch (2) back to ON.

● On coin selector set Teach

Switch 8 ON to enter teach

mode.

● On coin selector set blocking

switch 13 – „TK13 C“ – to ON.

Teaching

● Enter Token min. 10 times

(use several tokens/coins to

have a better acceptance).

● On coin selector set blocking

switch 13 back to OFF position. One single click from

coin selector indicates that

the Token is accepted. (other

indications: Token not accepted – less than 10 entries

or invalid tokens - try again).

● Switch pin 8 back to OFF

position.

The coin selector is now tought

to recognize and accept the

Token as valid payment, and

the value assigned to the Token

depends on the chosen Teach

Channel (see 4.1.4).

Tokens and national coins can

be used simultaneously, when

their blocking switches are OFF.

16

Entering Teach Mode (in this

example Teach Channel 13 is

chosen)

Page 17

4.1.4 Setting coin value on

&

-)435")3()

!

"

4RANSFORMER

0ER

3IKR

4YPE%"3)

0RIM

3EK

%LEKTRODYN

6

6

(Z

!

/.

/.

!

&

!

&

4

./

./

#

4

!"

,

4

4

,

,

+

4

4

#

!"

4

./

+

,

,

,

./

&

!"

4IMERPRINT

!

3

333333

/RANGE/RANGE

/RANGE'RÍ

timer

0RIM

3EK

4YPE%"3)

3IKR

0ER

(Z

%LEKTRODYN

4RANSFORMER

4

,

,

!"

#

4

4

,

,

4

./

,

,

./

!"

+

+

#

./

./

4

4

4

-)435")3()

!

&

333333

!

&

/RANGE'RÍ

/RANGE/RANGE

Locate the Timer board inside

the AUTO BOOSTER’s electric

box.

3

!"

&

&

/.

/.

4IMERPRINT

!

On the “Minimum Price” switches choose the minimum price to be

paid for the AUTO BOOSTER to operate. On the “Time Setting”

switches choose the time value you want to assign to the minimum

price.

Minimum price setting:

Use pins to set minimum

price to activate machine. See coin table and

example following.

Interface to power supply and

AUTO BOOSTER control.

Time setting:

Use pins to set time value

of coin/token. See coin table and example following.

Factory programming

interface.

Interface and power supply

to coiner.

17

Page 18

See below tables for European and Scandinavian coin selectors:

EMP 8.000.00 v5/E/I/T Timer T220

Settings for EU Coin Selector

Coin type Currency Pulses

SW no.

0,50 EUR 1

1,00 EUR 2

2,00 EUR 4

1,00 CHF 2 Time setting (sec. / minimum price)

2,00 CHF 4

5,00 CHF 10

0,50 GBP 1

1,00 GBP 2

2,00 GBP 4

TK11 A 2 1 €, CHF, £

TK12 B 4 2 €, CHF, £

TK13 C 6 3 €, CHF, £

TK14 D 8 4 €, CHF, £

TK15 E 10 5 €, CHF, £

TK16 F 12 6 €, CHF, £

Price

SW no.

Sec's

Price Setting: Select minimum price (basis for time setting)

Minimum price switch

1234 567 8

0,50 1,00 2,00 4,00 8,00 16,00 32,00 64,00

Select time value in Sec's for selected "minimum price"

1234 567 8

10 20 40 80 160 320 640 1280

Example of setting in €-country:

Owner wants 2,5 € to be inserted before machine can start:

Flip SW1 & SW3 (0,50 € + 2,00 €) on "Minimum price switch".

Owner wants to assign 10 minutes to the minimum price 2,5 €:

Flip SW3, SW4, SW5 & SW6 (40+80+160+320=600 sec's = 10 minutes)

on "Time Setting Switch".

All other coin values will be adjusted proportionally by the timer - i.e. 1€

will be 240 sec's, or 4 minutes.

Owner also wants to use a token with an assigned value of 3 €:

As 1 € corresponds to 2 impulses, 3 € equals 6 impulses - so owner

teaches "TK13C" to recognize the token (see how in sect. 4.1.3).

Minimum price setting:

Use pins to set minimum price

Time setting:

Use pins to set time value of

minimum price.

18

Page 19

EMP 8.000.00 v5/E/I/T Timer T220

Settings for Scandinavian

Coin Selector

Coin type Currency Pulses

SW no.

5,00 NOK 1

10,00 NOK 2

20,00 NOK 4

5,00 DKK 1 Time setting (sec. / minimum price)

10,00 DKK 2

20,00 DKK 4

5,00 SEK 1

10,00 SEK 2

TK11 A 1 5

TK12 B 2 10

TK13 C 4 20

TK14 D 8 40

TK15 E 10 50

TK16 F 12 60

Price

SW no.

Sec's

DKK,NOK,SEK

DKK,NOK,SEK

DKK,NOK,SEK

DKK,NOK,SEK

DKK,NOK,SEK

DKK,NOK,SEK

Price Setting: Select minimum price (basis for time setting)

Minimum price switch

1234 567 8

0,50 1,00 2,00 4,00 8,00 16,00 32,00 64,00

Select time value in Sec's for selected "minimum price"

1234 567 8

10 20 40 80 160 320 640 1280

Example of setting in Norway:

Owner wants 5 NOK to be inserted before machine can start:

Flip SW2 & SW4 (1,00 NOK + 4,00 NOK on "Minimum price switch".

Owner wants to assign 2 minutes 30 sec's to the minimum price of

5,00 NOK.

Flip SW1, SW2, SW3 & SW4 (10+20+40+80 = 150 sec's = 2 min. 30

sec's) on "Time Setting Switch".

All other coin values will be adjusted proportionally by the timer - i.e. 10

NOK will be 300 sec's, or 5 minutes.

Owner also wants to use a token with an assigned value of 50 NOK:

As 5 NOK corresponds to 1 impulse, 50 NOK equals 10 impulses - so

owner teaches "TK15E" to recognize the token (see how in sect. 4.1.3).

4.1.5 Maintenance

4.1.6 Programs and

Program Selector

The EMP 800 is an extraordinarily robust coin selector and

operates relatively maintenance

free. However, it should be

cleaned at regular intervals

especially if it is operating in an

environment with high levels

of dust, smoke or nicotine. The

cleaning intervals are of course

dependent on the level of air

borne contaminants.

Modest use with minimum

contaminant levels indicates

the need to clean the top of the

coin path once a year. Open

the coin path door and wipe the

exposed surfaces with an alcohol moistened cloth. The light

sensors may be cleaned with a

soft brush or air spray duster.

When payment in done, the

user can choose freely between

the AUTO BOOSTER's washing programs within the time

paid for.

Indication of inserted payment followed by remaining time counting down when

program switch is not at STOP

19

Page 20

4 Programs without water softener (hard water)

Program Description Flow rate Temp. Detergent Water Memo

1 High pressure cleaning 100% Hot A (Super Plus / Auto Active) Hard

2 Foam brush 50% Hot B (Super Plus / Auto Active) Hard

3 Clear rinses 100% Cold Hard

4 Gloss rinses 50% Cold C (Auto Dry) Hard

5 Gloss rinses 100% Cold Hard Program blanked out

with label

5 Programs with water softener (soft water)

Program Description Flow rate Temp. Detergent Water Memo

1 High pressure cleaning 100% Hot A (Super Plus / Auto Active) Soft Detergent (AA) (insect

2 Foam brush 50% Hot B (Super Plus / Auto Active) Soft

3 Clear rinses 100% Cold Soft

4 Gloss rinses 50% C or H C (Active Wax) Soft

5 Gloss rinses 100% Cold Soft

Above examples are from Germany on how the AUTO BOOSTER should work with only 4 program steps on hard water and 5

program steps on soft water. If wanted, hot or cold water can be chosen freely on any of the programs (selector inside electric

box) and other detergents may be used.

-solver ex. 2005)

With soft water (<10 ºdH) we

recommend that you use 5 programs with the recommended

Nilfi sk-ALTO detergents.

with the recommended Nilfi skALTO detergents. Though for

best cleaning result we recommend to install the “Water softening” option when choosing 5

For water hardness’s between

programs.

10 ºdh and 20 ºdH you may

choose either 4 or 5 programs

If you choose to run with 4

program steps, we recommend

that you exchange the “Active

Wax” detergent with the “Auto

Dry” in program 4. Program

step 5 should not be used.

Use the extra "STOP" sticker (in

the plastic bag with coin labels)

to blank program 5 on the front

label.

If your water is hard (> 20 ºdH)

you must install a water soften-

ing unit (11).

4.1.7 Temperature setting The overall setting of the hot

water temperature, is done on

the Thermostat (5) (max 60º C).

#

Recommended temperature for

car cleaning: 40°C.

20

Page 21

Each program step can be

assigned either cold or hot

(thermostat temperature) water,

which is done on the 5 “Hot/

Cold” switches S1, S2, S3, S4,

S5 (one pr. program) located

inside the electric box.

An Open switch assigns cold

water.

A closed switch assigns hot

water.

4.1.8 Detergents A, B and C

Nilfi sk-ALTO's suggestions for detergent addition per program step:

4 Programs, water hardness > 20° dH

Program Description Flow rate Temp. Detergent Water

1 High pressure cleaning 100% Hot A (Super Plus / Auto Active) Hard

2 Foam brush 50% Hot B (Super Plus / Auto Active) Hard

3 Clear rinses 100% Cold Hard

4 Gloss rinses 50% Cold C (Auto Dry) Hard

5 Gloss rinses 100% Cold Hard

5 Programs, water hardness < 10° dH or water softener installed

Program Description Flow rate Temp. Detergent Water

1 High pressure cleaning 100% Hot A (Super Plus / Auto Active) Soft

2 Foam brush 50% Hot B (Super Plus / Auto Active) Soft

3 Clear rinses 100% Cold Soft

4 Gloss rinses 50% C or H C (Active Wax) Soft

5 Gloss rinses 100% Cold Soft

The concentration of detergent

I

I

I

I

I

I

I

I

I

I

I

I

I

+

I

I

I

I

I

I

I

I

I

I

I

I

I

+

can be adjusted on the indi-

vidual detergent pumps. The

concentration of detergent in

the water jet can be adjusted

from 0 - 0.8 %.

21

Page 22

4.1.9 OPTIONAL: water

softener settings

The water softening unit (11) contains an electrical/mechanical

timer using a seven-days gear wheel for setting of the time of regeneration.

Set the timer as follows:

1. Dismount the plastic cover of the unit and the cover of the timer.

2. Turn the dial (A) by hand until the required regeneration time

appears in the window (B). Choose a time when the machine is

not in use.

3. Turn the timer knob (K) anti-clockwise until the present hour ap-

pears (L).

4. With all the pins (E) pulled out, turn the wheel (D) until day "1" is

opposite the day indicator (C). Then push in the pins of the days

on which the regeneration is required.

5. Turn on the water on the vacuum valve. Now the brine tank will

be fi lled with water. The valve will automatically close when the

correct volume has been reached.

6. Slowly turn the timer knob anti-clockwise until the knot (F)

pushes the actuator down to open the discharge piston (G).

Depending on the placement of the pins (E) this may require a

few attempts.

7. Let the valve suck water from the brine tank until the brine valve

closes.

8. Fill salt tablets into the brine tank.

9. Slowly turn the timer knob (K) anti-clockwise until the actuator

has released. Now the valve is back in operating position.

10. Repeat items 3 + 4.

22

Note: If the mains voltage disappears, the time must be reset.

Example: The dial (A) has been set at 23 (B). Pins (E) 1, 3, 5, 6, 7

are pressed in (day 1 = Monday).

The regeneration will be effected on Monday, Wednesday, Friday,

Saturday and Sunday at 23 o'clock.

Calculation of time between regenerations can be made as follows:

1. Check the hardness (°dH) of the water.

2. Determine an approximate water consumption (Q) per day.

3. 24,000/Q x °dH = Tmax.

Page 23

/

+

%

3

#

-)4

3

5"

)

3

()

Example:

Water hardness: 5°dH

Water consumption per day: 2,250 l/day.

Tmax = 24,000/2,250x5 = 2.13

This means that the regeneration must be effected every other day.

Specifi cations:

Capacity at 1°dH: 24,000 l

Salt consumption per regeneration: 1.5 kg

Container for salt: 25 kg

Time of regeneration: 30 min.

Water consumption per regeneration: 55 l

Units for water hardness:

1 °dH - German std.

= 0.56 Fd - French std.

= 0.80 Ed - English std.

4.2 Running the AUTO

BOOSTER

4.2.1 Starting up

Prior to setting the AUTO BOOSTER into operation the entire machine should be properly vented, (section 3.7), and the settings of

the paying system should be carried out (section 4.1.1 to 4.1.4).

1.Turn the main switch on the front of the electric box to position

“ON”.

!

"

$#).054

2. Observe that the display next to the coin input is illuminated and

shows “00:00”.

23

Page 24

3. Close the door of the AUTO BOOSTER, and lock the two keylocks.

"

"

!

B

"

!

4. Position the program selector switch (3) in position “STOP”.

5. The AUTO BOOSTER is now operative.

By inserting valid coins or tokens through the coin inlet, the display

will show the payment, summing up as more coins are inserted.

!! NOTE: The preset “minimum payment” (section

4.1.4) must be inserted before the AUTO BOOSTER

is allowed to start !!

When the program switch is turned from STOP to one of the

program steps, the AUTO BOOSTER will start and the display will

change to show the prepaid washing time in “minutes : seconds” –

counting down. The customer is free to choose between the programs during pay-time.

24

Page 25

Once the count-down has begun, it will continue towards zero,

no matter if the program selector switch is again placed in STOP

position.

Further coins can be inserted during the count-down, and will be

refl ected by adding the time-value of the coin to the value in the

display.

4.2.2 Stopping the

AUTO BOOSTER

!! NOTE: In case of emergency turn the program

selector switch (3) to STOP, or push the optional

“Emergency Switch” !!

When pay time runs out (display at 00:00) the AUTO BOOSTER

will automatically stop and relieve pressure from the hose/spray

handle, no matter where the program selector switch is positioned.

If working is terminated for more than 30 seconds during pay-time

(closed handle), the AUTO BOOSTER will enter standby mode,

and the HP pump will stop. Working can be resumed, as long as

pay time has not expired.

!! NOTE: Do not disconnect the AUTO BOOSTER

from main power supply, neither by turning AUTO

BOOSTERs main switch to position “OFF”, nor by

interrupting external installation switches as this will

leave the AUTO BOOSTERs automatic frost protection device inoperative, and the optional water

softening device will need new setting of regeneration clock. !!

25

Page 26

4.2.3 Programs

Running with soft water (< 15° dH) or with the optional “Water

softening device” we recommend the following wash sequence for a medium size car:

Program 1 - (use approx. 3

minutes).

- Hot (or Cold), High pressure

rinse with detergent “A”.

Move the lance along the car in

a “Z” pattern, down-up, keeping

the nozzle approx. 20 cm from

the bodywork, rinsing away bigger particles as mud, salt, sand

and insects.

Program 2 - (use approx. 6

minutes).

- Hot (or Cold), Low pressure

rinse with foam brush and

detergent “B”.

Attach the foam brush to the

bayonet coupling of the lance

(see 4.2.4), and brush-wash the

car, removing traffi c-fi lm and

“sticking objects”.

Program 3 - (use approx. 2

minutes).

- Cold (or Hot) High pressure

fl ushing without detergent.

Remove the foam brush (see

4.2.4.) and fl ush off all soap

remainders.

Program 4 - (use approx. 3

minutes).

- Hot (or Cold) Conservation

with wax, low pressure and

detergent “C”.

Apply wax over entire bodywork, and leave on for approx. 1 minute.

26

Page 27

Program 5 - (use approx. 2

minutes).

- Cold (or Hot) High pressure

fl ushing without detergent.

Flush off remainders of wax.

STOP

- Always place the Selector

switch in this position when

cleaning is completed.

NOTE: The owner can individually assign hot or cold to each

program step (section 4.1.7).

NOTE: Always

place the lance in

the lance holder,

in order for the

circulation frost

protection system

to work.

Running with hard water (>15° dH) without the optional “Water

softening device”, the wax-conservation will not be of good

quality. Thus we recommend that program step 5 is disconnected and turned into an extra STOP function by closing the

switch S11 (OFF).

The “Active wax” detergent in container “C” must be replaced by

the “Auto Dry” detergent (see sec. 4.1.6), and the wash sequence

for a medium size car will be:

27

Page 28

Program 1 - (use approx. 3

minutes).

- Hot (or Cold), High pressure

rinse with detergent “A”.

Move the lance along the car in

a “Z” pattern, down-up, keeping

the nozzle approx. 20 cm from

the bodywork, rinsing away bigger particles as mud, salt, sand

and insects.

Program 2 - (use approx. 6

minutes).

- Hot (or Cold), Low pressure

rinse with foam brush and

detergent “B”.

Attach the foam brush to the

bayonet coupling of the lance

(see 4.2.4), and brush-wash the

car, removing traffi c-fi lm and

“sticking objects”.

Program 3 - (use approx. 2

minutes).

- Cold (or Hot) High pressure

fl ushing without detergent.

Remove the foam brush (see

4.2.4.) and fl ush-off all soap

remainders.

Program 4 - (use approx. 3

minutes).

- Hot (or Cold) Conservation

with “Auto-Dry”, low pressure

and detergent “C”.

Apply “Auto-dry” over entire

bodywork, and let the water run

off by itself.

28

Page 29

STOP

- Always place the Selector

switch in this position when

cleaning is completed.

4.2.4 Foam brush, mounting

& dismounting

A soft foam brush is available for the AUTO BOOSTER to be used

during program step 2.

On the left-hand side of the AUTO BOOSTER is placed a holder for

storing the soft foam brush when not in use.

The soft foam brush is equipped with a female bayonet coup ling

that will accept the male bayonet coupling on the end of the spray

lance.

Attach the brush to the lance by pushing the brush fully onto the

lance (spring-loaded) and twist, until the bayonet couplings engage.

Remove the brush from the lance by reversing the above process.

29

Page 30

4.2.5 Circulation frost

protection

As standard the AUTO

BOOSTER is equipped with a

circulation device to protect the

hose, the spray handle and the

lance from freezing during periods with frost. Also, an internal, electrical heating element

will prevent the machine itself

from freezing. In order for the

system to operate, the AUTO

BOOSTER must not be disconnected from main electric supply (see note in sec.4.2.1)

A thermostat switch mounted

on the outside of the chassis of

the AUTO BOOSTER switches

ON the circulation frost protection system when the temperature is below the pre-set temperature and no coins have been

inserted in the slot.

Thus a separate pump starts

circulating preheated water

through the hose, spray handle

and lance.

The lance must be placed in

the holder at the left side of the

AUTO BOOSTER in order to

re-circulate the water (see note

in sec. 4.2.3). If the lance is

placed outside the holder, the

water will spill on the ground at

a rate of approximately 1.5 l/

min.

An extra thermostat is located

inside the cabinet of the AUTO

BOOSTER to switch ON the

electrical heating element in

the cabinet, if the inside temperature drops below the pre-set

temperature.

!!NOTE – The

circulation frost

protection will

NOT be operative

during Free Use –

payment cancelled!!

4.2.6 Functional diagrams The following three functional diagrams describes the operation of

the AUTO BOOSTER in cold, hot and frost protection mode.

COLD:

30

Page 31

HOT:

FROST:

31

Page 32

5 Maintenance

To ensure the most optimal maintenance of your auto BOOSTER, you should consider making a “Service Contract” with Nilfi sk-ALTO. In this way your TRUCK BOOSTER will always be ahead of potential

problems.

Though paying attention to a few things will ensure a prolonged and reliable operation of your AUTO

BOOSTER.

Therefore it will be a good idea to follow the schedule of maintenance below. All times are intended as

a guide and the maintenance should be made at more frequent intervals if required.

Day Week Month Year Winter

Fuel Check fuel level. Start machine and check

that the boiler is working. If not, see sec-

tion 3.7.

Detergent Check level in all detergent containers. x

Oil, high pres-

sure pump

Coin collector Empty coin collector. x

Washing

brush

Hose/lance Check hose/lance for wear and leaks.

Nozzle Check spray picture. Clean the nozzle if

Water break

tank

Detergent /

fuel containers

Water softening unit (option)

Water softening unit (option)

Water softening unit (option)

Water fi lter Clean the water fi lter of the water break

Fuel fi lter Replace fuel fi lter (see section 5.6). x

Lance holder Check the lance holder for foreign bodies.

Frost protection

Check oil level. Refi ll if necessary. Send for

a Nilfi sk-ALTO service technician as soon

as possible to have the cause of the oil

consumption established.

Check the washing brush for wear and

impurities. Replace if necessary.

Replace if necessary.

necessary (see section 5.5).

Empty the water break tank and clean it of

impurities.

Empty the containers and clean them

of impurities. Also clean the fi lters in the

detergent containers.

Check the level of salt tablets. If necessary

refi ll with salt tablets above the water level

in the brine tank.

Empty the brine tank and clean it.

Check the setting of the timer. Adjust if

necessary (see section 4.1.7). x

tank (see section 5.4).

If necessary, dismount it by loosening 4

bolts.

Check that the heating unit starts in the

machine and that water is running through

the lance when the temperature drops be-

low 4°C. NOTE: The surface of the heating

unit may be very hot !

x

x

x

x

x

x

x

x

x

x

x

x

32

Page 33

Drain Check the drain of the washing place. x

Outdoor ther-

mostat

Clean the outdoor thermostat at the bot-

tom of the front door with a dry cloth.

x

Locks Lubricate locks with acid-free oil. x

Machine Check machine functions, payment, deter-

gent, hot/warm switch, hose, brush, lance.

x

5.1 Coin selector See section 4.1.5.

5.2 Hour counters Your AUTO BOOSTER features built-in hour counters that keep

track of the number of working hours on your machine.

By turning the program selector switch (3) to position 1, the display will show working hours of pump and boiler and version no. of

software.

+

-

By turning the program selector switch to position 2, the working

hours with various detergents will show.

By turning the program selector switch to position 3, the total number of start-ups of the machine will show.

By turning the program selector switch to position 4, the display will

show the total number of minutes paid for.

The fi gures will only show when no coins have been inserted.

5.3 Oil Your AUTO BOOSTER is equipped with an electronic “oil sensor”,

which monitors the level of lubricant oil in the high-pressure pump. If

the oil level (by malfunction or excessive wear) should drop to a low

level, the pump will stop and the display shows "Pump oil level low".

+

-

Topping up the oil cup of the pump will be possible, but you should

send for a Nilfi sk-ALTO service technician as soon as possible to

disclose the cause of the oil loss.

33

Page 34

PROTECT THE ENVIRONMENT

5.4 Water fi lter To avoid debris entering the water break tank and the high-pres-

Waste oil and oil sludge must be removed as laid down in the

instructions.

sure pump, water fi lters are fi tted at the water inlet of the water

break tank and the pump. Depending on the purity of the water, this

fi lter will have to be cleaned at regular intervals.

The fi lter can be removed by unscrewing the union nut (1).

If the fi lter is clogged up by impurities, the machine will stop because of water shortage. The display will show "Water level low"

"E10".

NOTE: Do not forget to turn off the water before cleaning the fi lter.

5.5 Cleaning of high

pressure nozzle

5.6 Fuel fi lter Open the door to gain access to

A clogging up in the nozzle will cause the pump pressure to increase above normal operating pressure, and cleaning of the

nozzle is required immediately.

1. Stop the cleaner and detach the spray lance by loosening the

screw on the quick connector.

2. Clean the nozzle with the cleaning tool.

IMPORTANT: ONLY use the cleaning tool when the spray lance

is detached.

3. Flush the spray lance backwards with water.

4. If the pressure is still too high, repeat items 1-3.

the fuel pump.

34

Clean fi lter:

1. Unscrew fi lter cap (1).

2. Clean/replace fuel fi lter (2).

3. Dispose of cleaning solution/damaged fi lter

in accordance with the

disposal regulations.

Page 35

5.7 Disposable waste This high-pressure hot water washer consists of parts, which can

affect the environment when thrown away. Parts that can pollute

are as follows:

Oil, painted/zinc-coated parts, plastics/plastic-coated parts.

Therefore, it is important to follow the laws concerning the removal

of polluting and dangerous materials when replacing spare parts or

disposing of high-pressure hot water washer.

It is recommended that you bring the rejected parts to waste disposal areas or recycling plants that are approved for the destruction of these types of materials.

35

Page 36

6 Trouble Shooting

You have chosen the best quality and therefore deserve the best service. The AUTO BOOSTER

features an “Error detection system” that will stop the AUTO BOOSTER in case of a severe error that

needs immediate attention. The display in the inspection window (12) will indicate the nature of the

error.

Though the user can correct some of these errors, you should note the error and contact the nearest

Nilfi sk-ALTO service organization. To avoid unnecessary disappointments, you should check this section before contacting the nearest Nilfi sk-ALTO service organization.

6.1 General trouble shooting

Symptom Reason Action

Machine will not start > A fuse has blown • Change the fuse.

(NO ERROR indication) > Power disconnected • Connect power.

Fuses blow > Installation does not • Change to an installation.

correspond to the ampere corresponding to the ampere

consumption of the machine consumption of the machine

at a minimum.

Change the fuse.

Working pressure too low > Nozzle worn • Replace the nozzle.

> Wrong spray lance • Replace the spray lance

(see section 4.1.4).

> Nozzle partly clogged up • Clean the nozzle

(see section 5.5).

No detergent > Detergent container empty • Fill up with a detergent.

> Filter in container clogged up • Clean the fi lter.

Too much detergent > Wrong dosing • Read about recommended

dosing (see section 4.1.8).

Working pressure fl uctuating > Air in the system • Vent the system

(see section 3.7).

> Detergent container empty • Fill up with a detergent.

> Water inlet fi lter clogged up • Clean fi lter (see sect. 5.4).

No working pressure > Nozzle clogged up • Clean nozzle (see sect. 5.5).

> No inlet water • Check that the shut off cock

of the water inlet is open.

Check that the water supply

meets the requirements

(see section 3.4).

> Water inlet fi lter clogged up • Clean fi lter (see sect. 5.4).

Machine starts and > Leaky hose/ • Repair leak.

stops pipeline/spray handle

> Water shortage • Check the water supply -

open ? suffi cient pressure ?

Check and clean the water

inlet fi lter (see sect. 5.4).

36

Page 37

6.2 Error messages

If your AUTO BOOSTER does not heat the water although heating has been chosen for the actual program step, the reason may be that the fuel container is empty or that one of the overheat melting fuses

has blown/cut out. The two fuses are located at the top of the boiler and MUST ONLY be exchanged by

an Nilfi sk-ALTO service technician.

Error Message Reason Action

Illegal sensor comb. > Lack of water • Check your water supply

– open?, suffi cient pressure?

• Check and clean inlet fi lter,

(see sect. 5.4).

> Declutching of thermal relay • Check ventilation.

or motor winding protector • Check fuses.

> Defective or mal-adjusted • Call Nilfi sk-ALTO service.

fl ow sensor / pressure switch

> Defective or mal-adjusted • Call Nilfi sk-ALTO service.

fl ow sensor

No fl ame detected > No fl ame is detected when it • Check your fuel supply,

should be present and refi ll is necessary.

> Fuel fi lter clogged • Call Nilfi sk -ALTO service.

> Fuel container empty • Refi ll with fuel.

E1

E5

> Flame sensor soothed or • Call Nilfi sk -ALTO service.

defective

Illegal fl ame detected > Flame detected when it should • Flame sensor not mounted

NOT be present in place. Mount sensor.

> Flame sensor defective • Call Nilfi sk -ALTO service

Pump oil level low > Shortage of oil in high • Top up with oil.

pressure pump

E6

E3

Water level low > Lack of water in water tank • Check your water supply

– open?, suffi cient pressure?

• Check and clean inlet fi lter,

(see sect. 5.4).

Each time a fault is present, a counter will show the number of times the fault has been registered.

E10

37

Page 38

7 Technical Data

Model AUTO BOOSTER AUTO BOOSTER AUTO BOOSTER

5-20D 5-20 D 5-20 D

107370850 107370852 107370855

NP5 NP5 NP5

NP3 coil NP3 Coil NP3 Coil

Voltage V 400 400 230

Number of phases 3 3 3

Frequenzy Hz 50 50 50

Total current cons. A 10.8 10.8 15.3

Power consumption kW 4.5 4.5 4.5

Water connection:

Max. pressure, inlet water bar 10 / (6*) 10 / (6*) 10 / (6*)

Min. pressure, inlet water bar 1.0 1.0 1.0

Max. temperature, inlet water °C 30 30 30

Pump pressure bar 100 100 100

Flow Qiec l/h 500 500 500

Flow reduction l/h 300 300 300

Heating tank, volume liter 31 31 31

Spray lance:

Nozzle type .0370 .0370 .0370

Dimensions (H x W x D) mm

Weight kg 280 280 280

1670x1025x715 1670x1025x715 1670x1025x715

*) Applying to machines with the optional water softening equipment.

Sound pressure level LpA measured in accordance with ISO 11202 [DISTANCE 1m] [FULL LOAD]:

69 dB(A).

We reserve the right to make alterations.

38

Page 39

8 Warranty

Your Nilfi sk-ALTO product is

guaranteed for 12 months from

date of purchase (purchase

receipt must be presented) on

the following conditions:

• that defects are attributable

to fl aws or defects in materials or workmanship. (Usual

wear and tear as well as

misuse are not covered by

the guarantee).

• that repairs have not been

carried out or attempted by

other than Nilfi sk-ALTO-trained service staff.

• that only original accessories have been applied.

• that the product has not

been exposed to abuse such

as knocks, bumps or frost.

• that the instructions in the

manual have been carefully

observed.

A warranty repair comprises the

replacement of defective parts,

but it does not cover freight and

packaging charges. Besides we

refer to national Sale of Goods

Act.

Any illegitimate guarantee

repair will be invoiced. (I.e. malfunctions due to causes mentioned in section “6 Trouble

shooting” of the instruction

manual).

9 EU Declaration of Conformity

EU Declaration of Conformity

Product:

Type:

Description:

The design of the unit corresponds to the

following pertinent regulations:

Applied harmonised standards:

Applied national standards and technical

specifi cations:

Anton Sørensen

General Manager, Technical Operations EAPC

High Pressure Washer

AUTO BOOSTER

400 V 3~, 50 Hz - 230 V 1~, 50 Hz - IP X5

EC Machine Directive 2006/42/EC

EC Low-voltage Directive 2006/95/EC

EC EMV Directive 2004/108/EC

EN 60335-2-79 (2006), EN 55014-1 (2006),

EN 55014-2 (2001), EN 61000-3-2 (2006)

DS EN 60335-2-79

Nilfi sk-ALTO

Division of Nilfi sk-Advance A/S

Industrivej 1

DK-9560 Hadsund

Hadsund, 01.03.2009

39

Page 40

+

-

(A)

(B)

1

2

3

4

5

6

DC IN

7

PUT

8

9

10

11

12

13

14

15

E

S

C

+

M

I

T

S

U

B

I

S

H

I

O

K

B

B

A

B

B

A

Page 41

http://www.nilfi sk-advance.com

HEAD QUARTER

DENMARK

Nilfi sk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: (+45) 4323 8100

E-mail: mail.com@nilfi sk-advance.com

SALES COMPANIES

ARGENTINA

Nilfi sk-Advance srl.

Edifi cio Central Park

Herrera 1855, Offi ce 604

Ciudad Autónoma de Buenos Aires

Tel.: (+54) 11 6091 1571

AUSTRALIA

Nilfi sk-Advance

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Tel.: +61 2 8748 5900

E-mail: info@nilfi sk-advance.com.au

AUSTRIA

Nilfi sk-Advance GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: 0662 456 400-14

E-mail: info.at@nilfi sk-advance.com

BELGIUM

Nilfi sk-Advance n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Tel.: (+32) 2 467 60 50

E-mail: info.be@nilfi sk-advance.com

CANADA

Nilfi sk-Advance

240 Superior Boulevard

Mississauga, Ontario L5T 2L2

Tel.: (+1) 905 564 1149

E-mail: info@advance.ca.com

CHILE

Nilfi sk-Advance de Chile

San Alfonso 1462

Santiago

Tel.:(+56) 2 684 5000

E-mail: Pablo.Noriega@nilfi sk-advance.com

CHINA

Nilfi sk-Advance (Suzhou)

Building 18, Suchun Industrial Estate

Suzhou Industrial Park

215021 Suzhou

Tel.: (+86) 512 6265 2525

CZECH REPUBLIC

Nilfi sk-Advance

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Tel.: (+420) 24 14 08 419

DENMARK

Nilfi sk-Advance A/S

Industrivej 1

9560 Hadsund

Tel.: +45 7218 2100

E-mail: salg.dk@nilfi sk-advance.com

FINLAND

Nilfi sk-Advance Oy Ab

Piispantilankuja 4

02240 Espoo

Tel.: +358 207 890 600

E-mail: asiakaspalvelu.fi @nilfi sk.com

FRANCE

Nilfi sk-Advance

26 Avenue de la Baltique

Villebon sur Yvette

91944 Courtabouef Cedex

Tel.: (+33) 1 69 59 87 00

E-mail: info.fr@nilfi sk-advance.com

GERMANY

Nilfi sk-ALTO

Division of Nilfi sk Advance

Guido Oberdorfer Strasse 10

D-89287 Bellenberg

Tel.: (049) 73 06 72 125

E-mail: info.de@nilfi sk-alto.com

GREECE

Nilfi sk-Advance SA

8, Thoukididou str.

164 52 Argiroupolis

Tel.: +30 210 911 9600

E-mail: nilfi sk-advance@clean.gr

HOLLAND

Nilfi sk-Advance

Versterkerstraat 5

1322 AN Almere

Tel.: (+31) 36 546 07 00

E-mail: info.nl@nilfi sk-advance.com

HONG KONG

Nilfi sk-Advance Ltd.

Room 2001 HK Worsted Mills

Industrial Building

31-39 Wo Tong Tsui Street

Kvai Chung

Tel.: (+852) 24 27 59 51

HUNGARY

Nilfi sk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Tel: (+36) 24475 550

E-mail: info@nilfi sk-advance.hu

INDIA

Nilfi sk-Advance India Limited

349, Business Point,

No 201,2nd fl oor, above Popular Car World,

Western Express High way, Andheri ( East),

Mumbai - 400 069

Tel.: (+91) 223 2174592

IRELAND

Nilfi sk-Advance

1 Stokes Place

St. Stephen’s Green

Dublin 2

Tel.: (+35) 3 12 94 38 38

ITALY

Nilfi sk-Advance SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Tel.: +39 0377 41 40 46

E-mail: mercato.italia@nilfi sk-advance.it

JAPAN

Nilfi sk-Advance Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45 548 2571

KOREA

Nilfi sk-Advance

Kumwon B/D 3F, 471-4, Gunja-Dong

Gwangjin-Ku

Tel.: (+82) 2497 8636

MALAYSIA

Nillfi sk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (+603) 62753120

MEXICO

Nilfi sk-Advance de Mexico, S. de R.L. de C.V.

Prol. Paseo de la Reforma 61, 6-A2

Col. Paseo de las Lomas

01330 Mexico, D.F.

Tel: +52 55 2591 1002 (switchboard)

E-mail: info@advance-mx.com

NEW ZEALAND

Nilfi sk-Advance

Danish House

6 Rockridge Avenue

Penrose, Auckland 1135

Tel.: (+64) 95 25 00 92

NORWAY

Nilfi sk-ALTO

Division of Nilfi sk-Advance

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 70

E-mail: info.no@nilfi sk-alto.com

POLAND

Nilfi sk-Advance Sp. Z.O.O.

05-800 Pruszków

ul. 3-go MAJA 8

Tel.: +48 22 738 37 50

PORTUGAL

Nilfi sk-Advance

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: +35 121 911 2670

E-mail: mkt.pt@nilfi sk-advance.com

RUSSIA

Нилфиск-Эдванс

127015 Москва

Вятская ул. 27, стр. 7

Россия

Tel.: (+7) 495 783 96 02

E-mail: info@nilfi sk.ru

SINGAPORE

Nilfi sk-Advance Pte. Ltd.

40 Loyang Drive

Singapore 508961

Tel.: (+65) 6759 9100

SPAIN

Nilfi sk-Advance S.A.

Torre D’Ara

Paseo del Rengle, 5 Pl. 10

08302 Mataró

Tel.: (+3) 4 93 741 2400

E-mail: mkt.es@nilfi sk-dvance.com

SWEDEN

Nilfi sk-ALTO

Division of Nilfi sk-Advance

Aminogatan 18

Box 40 29

431 04 Mölndal

Tel.: (+46) 31 706 73 00

E-mail: info.se@nilfi sk-alto.com

SWITZERLAND

Nilfi sk-Advance

Ringstrasse 19

Kircheberg/Industri Stelzl

9500 Wil

Tel.: (+41) 719 23 84 44

E-mail: info.ch@nilfi sk-advance.com

TAIWAN

Nilfi sk-Advance Taiwan Branch

1F, No. 193, sec. 2, Xing Long Rd.

Taipei

Tel.: (+88) 6227 002 268

THAILAND

Nilfi sk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2 275 5630

TURKEY

Nilfi sk-Advance Profesional Temizlik

Ekipmanlari Tic. A/S.

Necla Cad. No. 48

Yenisahra / Kadiköy

Istanbul

Tel.: (+90) 216 470 08 - 60

E-mail: info.tr@nilfi sk-advance.com

UNITED KINGDOM

Nilfi sk-Advance Ltd.

Unit 24

Hilllside Business Park

Kempson Way

Bury St. Edmunds

Suffolk IP32 7EA

Tel.: (+49) 01284 763163

E-mail: sales.uk@nilfi sk-advance.com

UNITED ARAB EMIRATES

Nilfi sk-Advance Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Tel.: (+971) 553 2626 82

USA

Nilfi sk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel.: (+1) 763 745 3500

VIETNAM

Nilfi sk-Advance Representative Offi ce

No. 51 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Tel.: (+04) 761 5642

E-mail: nilfi sk@vnn.vn

Loading...

Loading...