Page 1

ATTIX 995-0H/M SD XC Type 22

Quick Start Guide

2

3

ø

7

ø

2

6

3

ø

5

ø

0

302003356 C

Page 2

ATTIX 995-0H/M SD XC Type 22

A

1.

1.

2

3

ø

7

ø

2

6

3

ø

5

ø

0

2.

3.*

*)

2

Option / Optional accessories

Page 3

ATTIX 995-0H/M SD XC Type 22

A

1.

1.

Type P2

2.

3.

7.

4.

5.

6.

8.

*)

Option / Optional accessories

3

Page 4

ATTIX 995-0H/M SD XC Type 22

A

1.

2.

1.

3.

4.

7.

5.

6.

8.

*)

4

Option / Optional accessories

Page 5

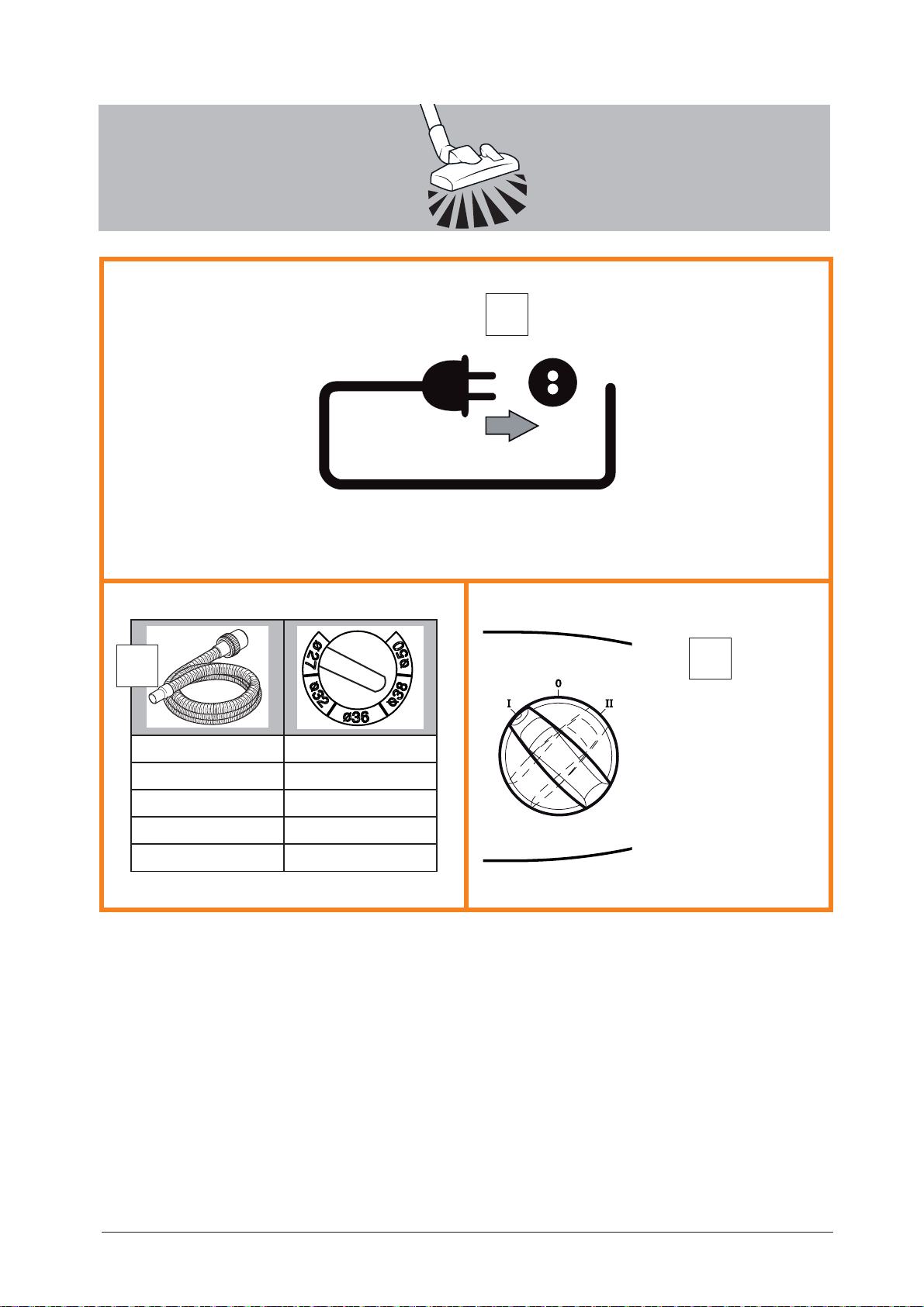

B

1.

ATTIX 995-0H/M SD XC Type 22

2.

ø27 ø27

ø32 ø32

ø36 ø36

ø38 ø38

ø50 ø50

3.

0 =

I =

II =

*)

Option / Optional accessories

5

Page 6

ATTIX 995-0H/M SD XC Type 22

10 sec .

B

*)

6

Option / Optional accessories

Page 7

ATTIX 995-0H/M SD XC Type 22

C

1.

Type P2

2.

1.

3.

4.

5.

*)

Option / Optional accessories

7

Page 8

ATTIX 995-0H/M SD XC Type 22

D

2

3

ø

7

ø

2

6

3

ø

5

ø

0

1.

2.

3.

2

3

ø

7

ø

2

6

3

ø

5

ø

0

*)

8

Option / Optional accessories

Page 9

ATTIX 995-0H/M SD XC Type 22

CZ

G

S

T

GB

This document

This document contains the safety information

relevant for the appliance along with a quick

reference guide.

Prior to using the appliance for the

fi rst time, be sure to read this document through and keep it ready to

hand.

Further support

Detailed information on the appliance can

be found in the operating instructions,

which you can download from our web site

at www.nilfi sk-alto.com.

For further queries, please contact the Nilfi skAlto service representative responsible for your

country. See reverse of this document.

Important safety instructions

Symbols used to mark instructions

DANGER

Danger that leads directly to serious

or irreversible injuries, or even death.

2. Never use the vacuum cleaner without a

fi lter.

3. Switch off the appliance and disconnect the

mains plug in the following situations:

- Prior to cleaning and servicing

- Prior to replacing components

- Prior to changing over the appliance

- If foam develops or liquid emerges

Besides the operating instructions and the

binding accident prevention regulations valid in

the country of use, observe recognised regulations for safety and proper use.

Purpose and intended use

Since 1997, there is a new division of hazardous dusts and their assigned vacuum

machines. These are regulated by IEC 603352-69 (world wide) and by EN 60335-2-69

(European wide).

The safety label on the machine warns:

This appliance contains dust hazardous to

health. Emptying and maintenance operations,

including removal of the dust collecting means,

must only be carried out by authorised personnel wearing suitable personal protection. Operate only after the full fi ltration system has been

fi tted and checked.

F

NL

I

K

SF

R

R

SLO

HR

SK

WARNING

Danger that can lead to serious

injuries or even death.

CAUTION

Danger that can lead to minor

injuries and damage.

The appliance must

• only be used by persons, who have been

instructed in its correct usage and explicitly

commissioned with the task of operating it

• only be operated under supervision

• not be used by children

Before starting work, the operating staff must

be informed on

• use of the vacuum cleaner

• risks associated with the material to be

picked up

• safe disposal of the picked up material

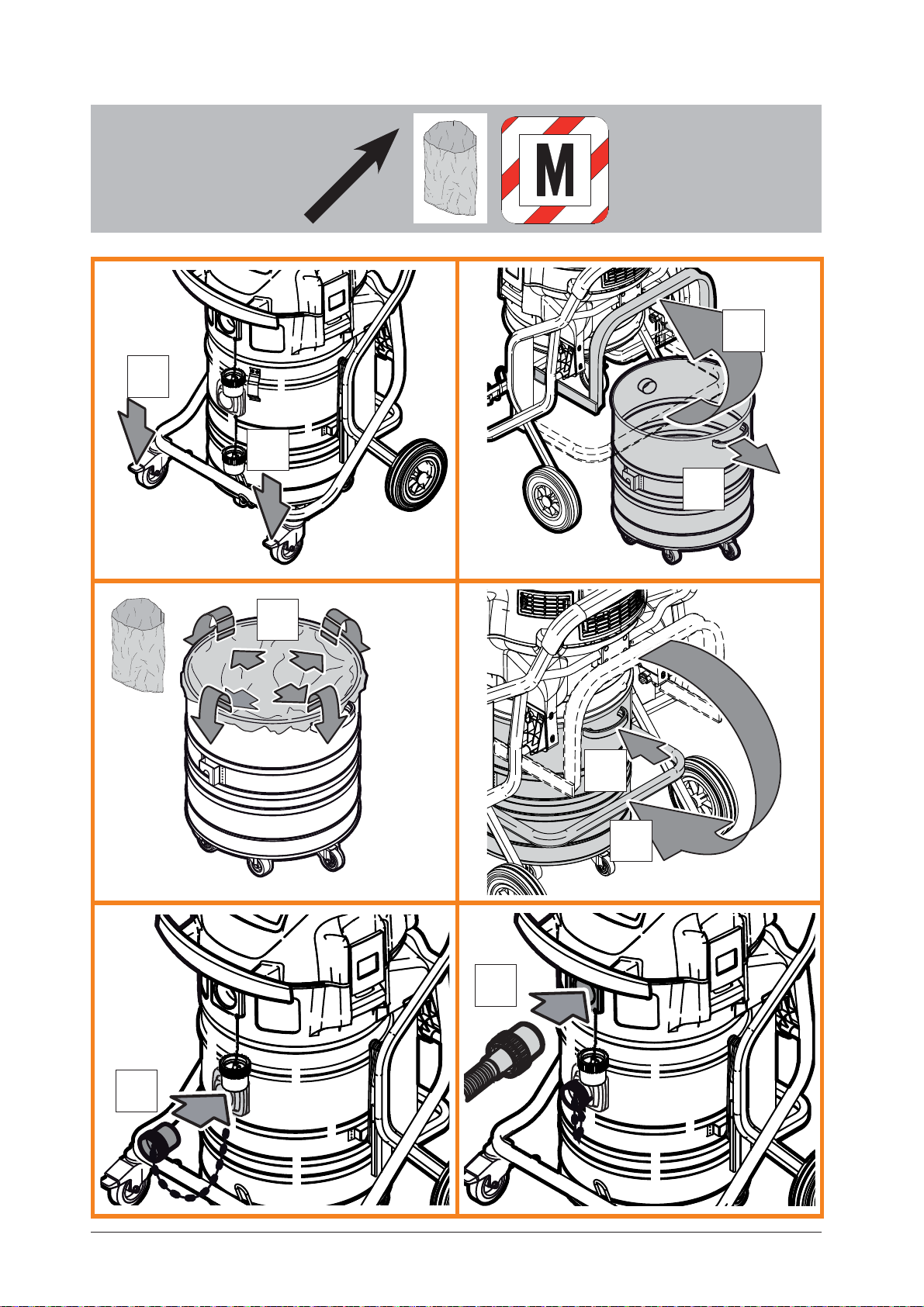

Dust Class M (medium). The dusts

which belong to this class are: dusts

with OEL values

1)

> 0.1 mg/m³ as well

as saw dust. The machine is tested in its

entirety by vacuums for this dust class. The

maximum degree of permeability is 0.1% and

the disposal must be low dust.

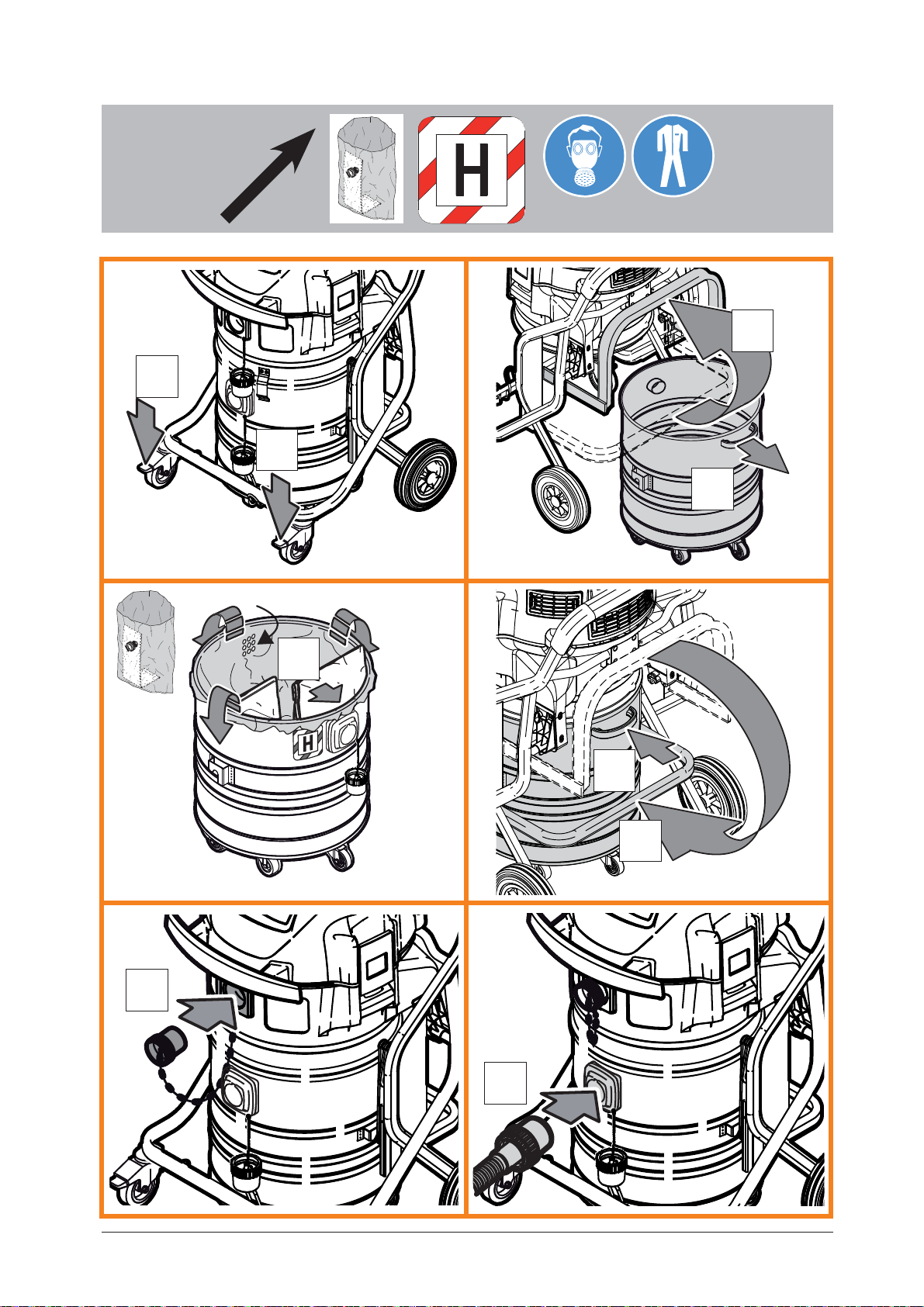

Dust Class H (high). The dusts which

belong to this class are: dusts with

OEL values

1)

, all carcinogenic dusts

and dusts which are mixed with pathogenic

agents. Vacuums for Dust Class H are tested

in their entirety and have a maximum degree of

permeability of 0.005%. The disposal must be

dust free.

Machines to be used in Zone 22 are

marked as Type 22 vacuums.

• These machines may be used for

picking up dust from dust class

L, M or H.

L

RO

B

RU

S

V

ROK

1. Do not use any unsafe work techniques.

AL

1)

OEL = Occupational exposure limit

Original instruction

9

Page 10

GB

G

S

T

ATTIX 995-0H/M SD XC Type 22

F

NL

I

K

SF

R

R

SLO

HR

SK

L

RO

B

• Zone 22 is defi ned as environments

where fl ammable dusts are present for

short periods only (e.g. less than 10

hours per year).

• Type 22 machines are suitable for use as

dust extractors.

The air fl ow in safety vacuum systems has to

be strictly controlled to achieve a minimum

fl ow rate of V

= 20 m/s in the suction hose.

min

The vacuum cleaner ATTIX 995-0H/M SD XC

Type 22 is suitable for picking up:

• Non fl ammable liquids (fl ashpoint 55 °C or

higher).

• Sawdust and dusts hazardous to health,

including dusts with OEL values, carcinogenic dusts and dusts containing germs

and pathogens.

• Flammable, dry dust in Zone 22.

Use the cleaner only if it is certain that no active sources of ignition can be sucked in.

Conductive extraction equipment, e.g. extraction hoods on machines and conductive parts

of machining equipment (e.g. equipment

in protective class II) that are not earthed

through the cleaner, must be earthed in some

other way to prevent electrostatic charges.

When picking up fl ammable dust in Zone 22,

the dirt tank must be emptied as required, but

always after use.

It must be assured that dust not accumulate

on the appliance by regular cleaning.

The vacuum cleaner is suitable for commercial use, such as e.g. in

• Hotels, Schools, Hospitals, Factories,

Shops, Offi ces, Hire shops

Any other use is considered as improper use.

The manufacturer accepts no liability for any

damage resulting from such use. The risk for

such use is borne solely by the user.

Proper use also includes proper operation,

servicing and repairs as specifi ed by the

manufacturer. See operating instructions.

Operation

Depending on how hazardous the dust is, the

cleaner must be fi tted with appropriate fi lters:

Type of dust Filter bag/waste bag

• Non-hazardous

dust

• Wood dust

• Non-carcino-

Waste bag

(5 pcs.)

Order No.

302001480

genic dust with

OEL values

>0.1 mg/m³ (observe any additional national

regulations)

• Explosive dust,

dust explosion

class St1, St2,

St3 in Zone 22

• All dusts with

OEL values

• Explosive dust,

dust explosion

Safety fi lter

bag (5 pcs.)

Order No.

302003473

class St1, St2,

St3 in Zone 22

RU

ROK

The vacuum cleaner must be used only, if all

fi lters, as well as the fi lter for the motor cooling air, are attached and without damage.

S

V

The cleaner is not suitable for extraction on

machining equipment in operation that could

produce sources of ignition.

When dust removers are used, the rate at

which air is exchanged in the room must be

adequate if the exhaust air from the vacuum

cleaner is blown into the room (please observe regulations valid in your country).

AL

10

• All dusts with

OEL values

• Explosive dust,

dust explosion

class St1, St2,

St3 in Zone 22

• All dusts with

OEL values

• Explosive dust,

dust explosion

class St1, St2,

St3 in Zone 22

1)

OEL = Occupational exposure limit

Filter element

“H”

Order No.

107400564

Motor cooling

fi lter “TYPE

22”

Order No.

107400041

Original instruction

Page 11

ATTIX 995-0H/M SD XC Type 22

G

S

T

GB

Before picking up dust with occupational

exposure limit values:

1. Check that all the fi lters are present and

properly fi tted.

2. Do not use the cleaner with damaged or

missing antistatic clamp. Risk of explosion due to static discharge in explosive

atmospheres.

3. The hose diameter and the setting for the

suction hose diameter must be the same.

4. When the motor is running, hold the

suction hose shut. For safety reasons, an

acoustic warning sounds if the air speed in

the suction hose drops to below 20 m/s.

Transport

1. Before transporting the dirt tank, close all

the locks.

2. Make sure that both plugs are inserted in

fi ttings.

3. Do not tilt the cleaner if there is liquid in

the dirt tank.

4. Do not use a crane hook to lift the cleaner.

Storage

1. Store the appliance in a dry place, protected from frost.

Electrical connection

1. It is recommended that the vacuum

cleaner should be connected via a residual

current circuit breaker.

2. When picking up fl ammable dust in zone

22, extension lines, couplings and adapters must not be used.

3. Arrange the electrical parts (sockets, plugs

and couplings) and lay down the extension lead so that the protection class is

maintained.

4. Connectors and couplings of power supply cords and extension leads must be

watertight.

Extension lead

1. As an extension lead, only use the version

specifi ed by the manufacturer or one of a

higher quality. See operating instructions.

2. When using an extension lead, check the

minimum cross-sections of the cable:

Cable length Cross section

< 16 A < 25 A

up to 20 m 1.5 mm

20 to 50 m 2.5 mm

2

2

2.5 mm

4.0 mm

2

2

Maintenance, cleaning and repair

During the following work, ensure that dust is

not unnecessarily spread around. Wear a P2

breathing mask.

Only carry out maintenance work described in

the operating instructions.

Always pull out the mains plug before cleaning and maintenance of the vacuum cleaner.

During maintenance and cleaning, handle the

vacuum cleaner in such a manner that there

is no danger for maintenance staff or other

persons.

In the maintenance area

1. Use fi ltered compulsory ventilation

2. Wear protective clothing

3. Clean the maintenance are so that no harmful substances get into the surroundings.

Before removing the vacuum cleaner from the

area contaminated with harmful substances:

1. Clean the outside of the vacuum cleaner,

wipe it clean or pack the vacuum cleaner

in well sealed packaging

2. and avoid spreading deposited harmful

dust.

Warning: Do not reuse the essential fi lter element after removal out of the appliance (only

for class H appliances).

During maintenance and repair work all

contaminated parts that could not be cleaned

satisfactorily must be:

1. packed in well sealed bags

2. disposed of in a manner that complies with

valid regulations for such waste removal.

At least once a year, a Nilfi sk-ALTO technician or an instructed person must perform a

technical inspection including fi lters, air tightness and control mechanisms. According to

AA.22.201.2 appliances in class H must have

their fi ltration effi ciency checked once a year.

If the effi ency of the fi lter does not fulfi l the

requirements for dust class H, the fi lter must

be replaced, and the new fi lter must be tested

according to AA.22.201.2.

I

K

SF

R

R

SLO

HR

SK

L

RO

B

RU

S

V

ROK

AL

1)

OEL = Occupational exposure limit

Original instruction

11

Page 12

GB

G

S

T

ATTIX 995-0H/M SD XC Type 22

F

NL

I

K

SF

R

R

SLO

HR

SK

Guarantee

Our general conditions of business are applicable with regard to the guarantee.

Unauthorised modifi cations to the appliance,

the use of incorrect brushes in addition to

using the appliance in a way other than for the

intended purpose exempt the manufacturer

from any liability for the resulting damage.

Tests and approvals

Electrical tests must be per formed in accordance with the provisions of safety regulations

(BGV A3) and to DIN VDE 0701 Part 1 and

Part 3. In ac cord ance with DIN VDE 0702

these tests must be performed at regular

intervals and after repairs or modifi cations.

Risks

Electrical components

DANGER

Electric shock due to faulty mains

connecting lead.

Touching a faulty mains connecting lead can result in serious or

even fatal injuries.

1. Do not damage the mains

power lead (e.g. by driving over

it, pulling or crushing it).

2. Regularly check whether the

power cord is damaged or

shows signs of ageing.

3. Have the faulty mains connecting lead replaced by your

Nilfi sk-Alto service representative or a qualifi ed electrician

prior to using the appliance

again.

DANGER

The upper section of the vacuum

cleaner contains live components.

Contact with live components leads

to serious or even fatal injuries.

L

RO

B

RU

S

V

ROK

1. Never spray water on to the

upper section of the vacuum

cleaner.

CAUTION

Damage due to unsuitable mains

voltage.

The appliance can be damaged as

a result of being connected to an

unsuitable mains voltage.

1. Ensure that the voltage shown

on the rating plate corresponds

to the voltage of the local mains

power supply.

AL

1)

12

OEL = Occupational exposure limit

Original instruction

Page 13

ATTIX 995-0H/M SD XC Type 22

G

S

T

GB

Picking up liquids

Picking up liquids.

Due to their construction vacuum

cleaners with a removable tank (SD)

do not have an automatic level indicator. There is a risk of damage to

the vacuum cleaner due to overfi lling

or of damage due to leakage of the

picked up liquid.

1. Never pick up more than 40 litres

at once.

2. Switch off the vacuum cleaner

and empty the dirt tank.

Hazardous materials

Hazardous materials.

Picking up hazardous materials

can lead to serious or even fatal

injuries.

1. The following materials must

not be picked up by the vacuum

cleaner:

- hot materials (burning cigarettes, hot ash, etc.)

- fl ammable, explosive, aggressive liquids (e.g. petrol,

solvents, acids, alkalis, etc.)

- mixtures of fl ammable dusts

with liquids

- explosive substances or

substances considered to

be similar in §1 of the law on

explosives

- fl ammable dusts with an extremely low minimum ignition

energy <1 mJ (also observe

national regulations).

- Highly reactive dusts or

dusts with a high affi nity to

oxygen

CAUTION

WARNING

WARNING

When the vacuum cleaner has

been used with dust classifi ed as

“H”, it is necessary to clean the

machine thoroughly before using

the machine with dust classifi ed as

“M” or lower.

Spare parts and accessories

CAUTION

Spare parts and accessories.

For picking up fl ammable dust in

Zone 22: Only use accessories

which are certifi ed by the manufacturer of the Type 22 machine.

The use of other accessories can

cause danger of explosion.

The use of non-genuine spare

parts and accessories can impair

the safety of the appliance.

1. Only use spare parts and accessories from Nilfi sk-Alto.

2. Use only the brushes supplied with the vacuum cleaner

or specifi ed in the operating

manual.

Emptying dirt tank

CAUTION

Picking up environmentally hazardous materials.

Materials picked up can present a

hazard to the environment.

1. Dispose of the dirt in accordance with legal regulations.

I

K

SF

R

R

SLO

HR

SK

L

RO

B

RU

S

V

WARNING

For dusts like titanium and magnesium additional requirements

apply, consult your national labour

authorities or the manufacturer of

the vacuum cleaner.

1)

OEL = Occupational exposure limit

Original instruction

ROK

AL

13

Page 14

GB

G

S

T

ATTIX 995-0H/M SD XC Type 22

NL

I

SF

R

Recycling the cleaner

Make the old cleaner unusable immediately.

1. Unplug the cleaner.

2. Cut the power cord.

3. Do not discard of electrical appliances with

household waste.

As specifi ed in European Directive 2002/96/EC on old electrical

and electronic appliances, used

electrical goods must be collected

separately and recycled ecologically. Contact your local authorities

or your nearest dealer for further

information.

R

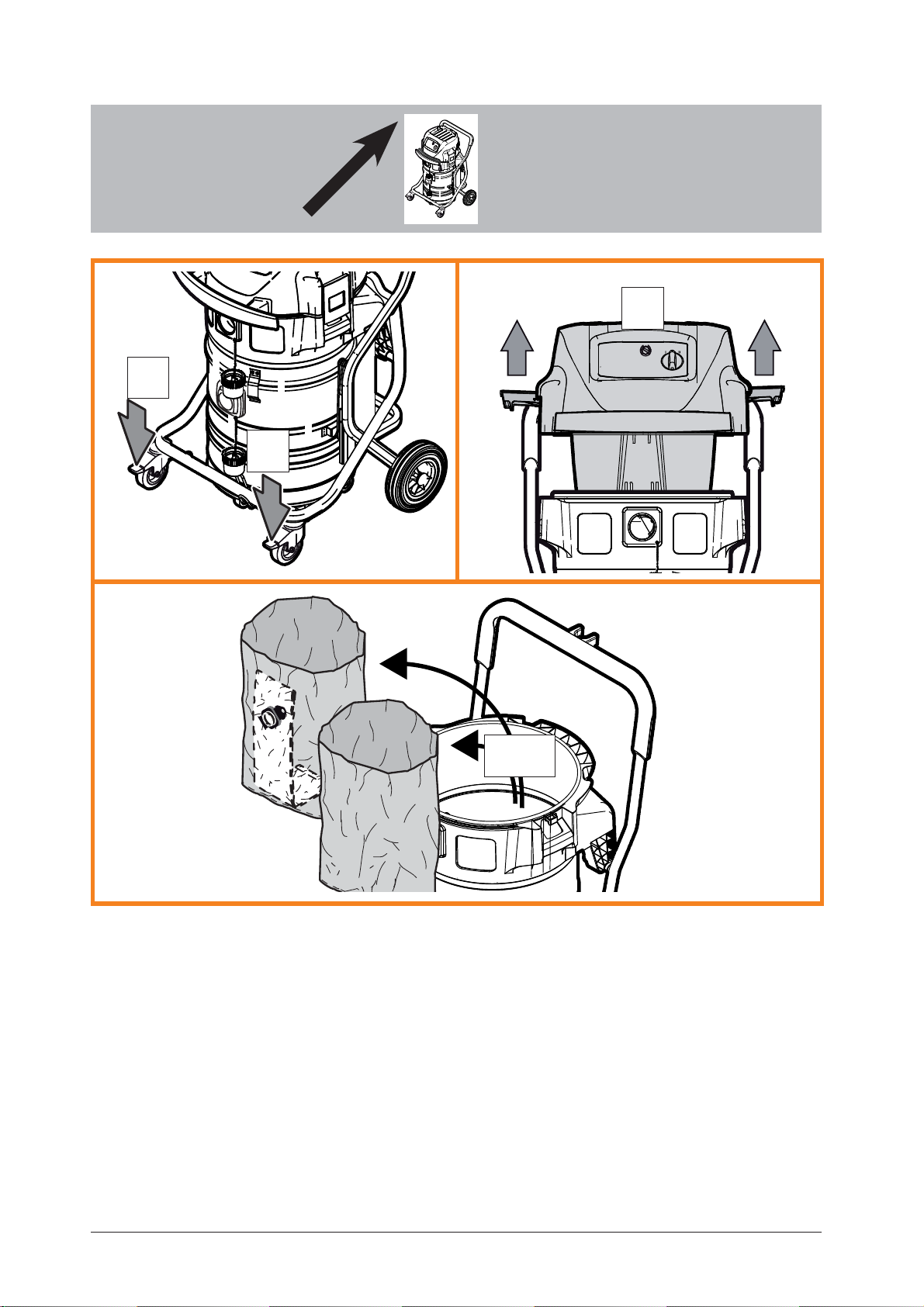

Quick reference guide

Pages 2 – 8 feature a pictorial quick reference guide, which is designed to help you

when starting up, operating and storing the

appliance.

This quick reference guide does not replace

the separate operating instructions, which describes the appliance in detail. The operating

instructions also contain further information

on the operation, maintenance and repair of

the appliance.

Meaning of the symbols

The instructions for actions are subdivided

into 4 sections, which are represented by

symbols.

2

3

ø

7

ø

2

6

3

ø

5

ø

0

A Before starting

SLO

HR

SK

RO

B

RU

S

V

B Control / Operation

C Replacing the fi lter element

“H”

2

3

ø

7

ø

2

6

3

ø

5

ø

0

D After fi nishing work

An asterisk (*) indicates a model variant or

special accessories.

Check whether your appliance is equipped

with the control elements or special accessories depicted. If not, please proceed to the

next action.

ROK

AL

14

1)

OEL = Occupational exposure limit

Original instruction

Page 15

ATTIX 995-0H/M SD XC Type 22

EU / GB 230 V

U [V] V 230

f [Hz] Hz 50/60

PIEC [W] W 2 x 1100

IP IP 54

3

m

Air fl ow rate

Vacuum

Sound pressure level at a

distance of 1m, EN 60704-1

Working sound pressure

level

/h

l/min

hPa/mbar

kPa

dB(A) 70 ± 2

dB(A) 67 ± 2

2 x 216

2 x 3600

230

23

EC conformity declaration

NILFISK-ADVANCE A/S

Sognevej 25

DK-2605 Brøndby

Product:

Model:

Description:

The design of this appliance complies

with the following provisions:

Applied harmonized standards:

Applied national standards and technical

specifi cations:

Vacuum cleaner for wet and dry operation

ATTIX 995-0H/M SD XC Type 22

230-240 V~, 50/60 Hz, 2x1200W

Dust Class M and H

ATEX Zone 2 2

II 3D Ex tD A22 T135 °C IP54

EC - Machinery Directive 2006/42/EC

EC - Directive EMC 2004/108/EC

EC - Explosive Atmosphere directive 94/9/

EC „ATEX“

EN ISO 12100-1 (2004), EN ISO 12100-2

(2004), EN 55014-1 (2006), EN 55014-2

(2001), EN 61000-3-2 (2006), EN 1127-1

(2007), EN 61241-10 (2004)

EN 60335-2-69 (2009)

IEC 60335-2-69 (2008)

Anton Sørensen

General Manager EAPC

Technical Operations Brøndby, 01.06.2008

189

Page 16

http://www.nilfi sk-advance.com

HEAD QUARTER

DENMARK

Nilfi sk-Advance Group

Sognevej 25

DK-2605 Brøndby

Tel.: (+45) 4323 8100

E-mail: mail.com@nilfi sk-advance.com

SALES COMPANIES

ARGENTINA

Nilfi sk-Advance srl.

Edifi cio Central Park

Herrera 1855, Offi ce 604

Ciudad Autónoma de Buenos Aires

Tel.: (+54) 11 6091 1571

AUSTRALIA

Nilfi sk-Advance

48 Egerton St.

P.O. Box 6046

Silverwater, N.S.W. 2128

Tel.: +61 2 8748 5900

E-mail: info@nilfi sk-advance.com.au

AUSTRIA

Nilfi sk-Advance GmbH

Metzgerstrasse 68

5101 Bergheim bei Salzburg

Tel.: 0662 456 400-14

E-mail: info.at@nilfi sk-advance.com

BELGIUM

Nilfi sk-Advance n.v-s.a.

Riverside Business Park

Boulevard Internationalelaan 55

Bâtiment C3/C4 Gebouw

Bruxelles 1070

Tel.: (+32) 2 467 60 50

E-mail: info.be@nilfi sk-advance.com

CANADA

Nilfi sk-Advance

240 Superior Boulevard

Mississauga, Ontario L5T 2L2

Tel.: (+1) 905 564 1149

E-mail: info@advance.ca.com

CHILE

Nilfi sk-Advance de Chile

San Alfonso 1462

Santiago

Tel.:(+56) 2 684 5000

E-mail: Pablo.Noriega@nilfi sk-advance.com

CHINA

Nilfi sk-Advance (Suzhou)

Building 18, Suchun Industrial Estate

Suzhou Industrial Park

215021 Suzhou

Tel.: (+86) 512 6265 2525

CZECH REPUBLIC

Nilfi sk-Advance

VGP Park Horní Počernice

Do Čertous 1/2658

193 00 Praha 9

Tel.: (+420) 24 14 08 419

DENMARK

Nilfi sk-Advance A/S

Industrivej 1

9560 Hadsund

Tel.: +45 7218 2100

E-mail: salg.dk@nilfi sk-advance.com

FINLAND

Nilfi sk-Advance Oy Ab

Piispantilankuja 4

02240 Espoo

Tel.: +358 207 890 600

E-mail: asiakaspalvelu.fi @nilfi sk.com

FRANCE

Nilfi sk-Advance

26 Avenue de la Baltique

Villebon sur Yvette

91944 Courtabouef Cedex

Tel.: (+33) 1 69 59 87 00

E-mail: info.fr@nilfi sk-advance.com

GERMANY

Nilfi sk-ALTO

Geschäftsbereich der Nilfi sk Advance AG

Guido-Oberdorfer-Strasse 10

D-89287 Bellenberg

Tel.: +49 (0) 180 5 37 37 37

E-mail: info.de@nilfi sk-alto.com

GREECE

Nilfi sk-Advance SA

8, Thoukididou str.

164 52 Argiroupolis

Tel.: +30 210 911 9600

E-mail: nilfi sk-advance@clean.gr

HOLLAND

Nilfi sk-Advance

Versterkerstraat 5

1322 AN Almere

Tel.: (+31) 36 546 07 00

E-mail: info.nl@nilfi sk-advance.com

HONG KONG

Nilfi sk-Advance Ltd.

Room 2001 HK Worsted Mills

Industrial Building

31-39 Wo Tong Tsui Street

Kvai Chung

Tel.: (+852) 24 27 59 51

HUNGARY

Nilfi sk-Advance Kereskedelmi Kft.

II. Rákóczi Ferenc út 10

2310 Szigetszentmiklos-Lakihegy

Tel: (+36) 24475 550

E-mail: info@nilfi sk-advance.hu

INDIA

Nilfi sk-Advance India Limited

349, Business Point,

No 201,2nd fl oor, above Popular Car World,

Western Express High way, Andheri ( East),

Mumbai - 400 069

Tel.: (+91) 223 2174592

IRELAND

Nilfi sk-Advance

1 Stokes Place

St. Stephen’s Green

Dublin 2

Tel.: (+35) 3 12 94 38 38

ITALY

Nilfi sk-Advance SpA

Strada Comunale della Braglia, 18

26862 Guardamiglio (LO)

Tel.: +39 0377 41 40 46

E-mail: mercato.italia@nilfi sk-advance.it

JAPAN

Nilfi sk-Advance Inc.

1-6-6 Kita-shinyokohama, Kouhoku-ku

Yokohama, 223-0059

Tel.: (+81) 45 548 2571

KOREA

Nilfi sk-Advance

Kumwon B/D 3F, 471-4, Gunja-Dong

Gwangjin-Ku

Tel.: (+82) 2497 8636

MALAYSIA

Nillfi sk-Advance Sdn Bhd

Sd 14, Jalan KIP 11

Taman Perindustrian KIP

Sri Damansara

52200 Kuala Lumpur

Tel.: (+603) 62753120

MEXICO

Nilfi sk-Advance de Mexico, S. de R.L. de C.V.

Prol. Paseo de la Reforma 61, 6-A2

Col. Paseo de las Lomas

01330 Mexico, D.F.

Tel: +52 55 2591 1002 (switchboard)

E-mail: info@advance-mx.com

NEW ZEALAND

Nilfi sk-Advance

Danish House

6 Rockridge Avenue

Penrose, Auckland 1135

Tel.: (+64) 95 25 00 92

NORWAY

Nilfi sk-ALTO

Division of Nilfi sk-Advance

Bjørnerudveien 24

1266 Oslo

Tel.: (+47) 22 75 17 70

E-mail: info.no@nilfi sk-alto.com

POLAND

Nilfi sk-Advance Sp. Z.O.O.

05-800 Pruszków

ul. 3-go MAJA 8

Tel.: +48 22 738 37 50

PORTUGAL

Nilfi sk-Advance

Sintra Business Park

Zona Industrial Da Abrunheira

Edifi cio 1, 1° A

P2710-089 Sintra

Tel.: +35 121 911 2670

E-mail: mkt.pt@nilfi sk-advance.com

RUSSIA

Нилфиск-Эдванс

127015 Москва

Вятская ул. 27, стр. 7

Россия

Tel.: (+7) 495 783 96 02

E-mail: info@nilfi sk.ru

SINGAPORE

Nilfi sk-Advance Pte. Ltd.

40 Loyang Drive

Singapore 508961

Tel.: (+65) 6759 9100

SPAIN

Nilfi sk-Advance S.A.

Torre D’Ara

Paseo del Rengle, 5 Pl. 10

08302 Mataró

Tel.: (+3) 4 93 741 2400

E-mail: mkt.es@nilfi sk-dvance.com

SWEDEN

Nilfi sk-ALTO

Division of Nilfi sk-Advance

Aminogatan 18

Box 40 29

431 04 Mölndal

Tel.: (+46) 31 706 73 00

E-mail: info.se@nilfi sk-alto.com

SWITZERLAND

Nilfi sk-Advance

Ringstrasse 19

Kircheberg/Industri Stelzl

9500 Wil

Tel.: (+41) 719 23 84 44

E-mail: info.ch@nilfi sk-advance.com

TAIWAN

Nilfi sk-Advance Taiwan Branch

1F, No. 193, sec. 2, Xing Long Rd.

Taipei

Tel.: (+88) 6227 002 268

THAILAND

Nilfi sk-Advance Co. Ltd.

89 Soi Chokechai-Ruammitr

Viphavadee-Rangsit Road

Ladyao, Jatuchak, Bangkok 10900

Tel.: (+66) 2 275 5630

TURKEY

Nilfi sk-Advance Profesional Temizlik

Ekipmanlari Tic. A/S.

Necla Cad. No. 48

Yenisahra / Kadiköy

Istanbul

Tel.: (+90) 216 470 08 - 60

E-mail: info.tr@nilfi sk-advance.com

UNITED KINGDOM

Nilfi sk-Advance Ltd.

Unit 24

Hilllside Business Park

Kempson Way

Bury St. Edmunds

Suffolk IP32 7EA

Tel.: (+49) 01284 763163

E-mail: sales.uk@nilfi sk-advance.com

UNITED ARAB EMIRATES

Nilfi sk-Advance Middle East Branch

SAIF-Zone

P.O. Box 122298

Sharjah

Tel.: (+971) 553 2626 82

USA

Nilfi sk-Advance Inc.

14600 21st Avenue North

Plymouth, MN 55447-3408

Tel.: (+1) 763 745 3500

VIETNAM

Nilfi sk-Advance Representative Offi ce

No. 51 Doc Ngu Str.

Ba Dinh Dist.

Hanoi

Tel.: (+04) 761 5642

E-mail: nilfi sk@vnn.vn

Loading...

Loading...