Page 1

SCRUBTEC 770 SSCRUBTEC 770 S

SCRUBTEC 770 S

SCRUBTEC 770 SSCRUBTEC 770 S

SCRUBTEC 770 LSCRUBTEC 770 L

SCRUBTEC 770 L

SCRUBTEC 770 LSCRUBTEC 770 L

SCRUBTEC 784 SSCRUBTEC 784 S

SCRUBTEC 784 S

SCRUBTEC 784 SSCRUBTEC 784 S

Operator's

SCRUBTEC 784 LSCRUBTEC 784 L

SCRUBTEC 784 L

SCRUBTEC 784 LSCRUBTEC 784 L

SCRUBTEC 795 SSCRUBTEC 795 S

SCRUBTEC 795 S

Manual

U.S. Patent No. 6,760,947; No. 6,105,192; No. 6,493,896 (Deluxe Machines)

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this book

prior to operating or attempting any service or maintenance procedure to your ALTO machine could result

in injury to you or to other personnel; damage to the machine or to other property could occur as well. You

must have training in the operation of this machine before using it. If your operator(s) cannot read this

manual, have it explained fully before attempting to operate this machine.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

SCRUBTEC 795 SSCRUBTEC 795 S

SCRUBTEC 795 LSCRUBTEC 795 L

SCRUBTEC 795 L

SCRUBTEC 795 LSCRUBTEC 795 L

For new books write to: ALTO, 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 70935A 9/05 CLARKE TECHNOLOGY Printed in the U.S.A.

Page 2

Table of Contents

Operator Safety Instructions............................................................................................................................. 3

Introduction ....................................................................................................................................................... 4

Machine Specifications .................................................................................................................................... 5

Procedures For Transporting ........................................................................................................................... 7

Symbols Used On S & L Models...................................................................................................................... 8

Machine Control Panel S Models..................................................................................................................... 10

Machine Control Panel L Models ..................................................................................................................... 12

Display Screen For L Models ........................................................................................................................... 14

Machine Controls and Features ...................................................................................................................... 15

How To Prepare The Machine For Operation ..................................................................................................16

How To Install The Batteries ............................................................................................................. 16

Battery Maintenance........................................................................................................................... 17

How To Charge The Batteries ........................................................................................................... 18

How To Install The Brushes Or Pad Drivers ..................................................................................... 1 9

How To Remove The Brushes Or Pad Drivers ................................................................................. 19

How To Operate The Machine ......................................................................................................................... 20

How To Operate The One Touch System.......................................................................................... 2 0

Reprogramming One Touch ............................................................................................................. 20

How To Return One Touch To Factory Default Setting...................................................................... 20

How To Operate The Squeegee........................................................................................................ 21

How To Fill The Solution Tank........................................................................................................... 21

How To Traverse Machine ................................................................................................................. 22

How To Clean A Floor ........................................................................................................................ 22

Maintenance .....................................................................................................................................................23

How To Correct A Problem.............................................................................................................................. 28

Common Error Codes (SRUBTEC 770 L, 784 L & 795 L) .............................................................................. 29

Accessories...................................................................................................................................................... 30

Section II Parts and Service Manual

Solution Tank Assembly .................................................................................................................................. 32

Parts List ............................................................................................................................................33

Recovery Tank Assembly ................................................................................................................................. 34

Parts List ............................................................................................................................................35

Electrical Panel Assembly S Models ............................................................................................................... 36

Parts List ............................................................................................................................................37

Electrical Panel Assembly L Models ................................................................................................................ 38

Parts List ............................................................................................................................................39

Control Panel Assembly .................................................................................................................................. 40

Parts List ............................................................................................................................................41

Squeegee Swing Arm Assembly ..................................................................................................................... 42

Parts List ............................................................................................................................................43

Traverse System Assembly ............................................................................................................................. 44

Parts List ............................................................................................................................................45

Brush Head Assembly ..................................................................................................................................... 46

Parts List ............................................................................................................................................47

Brush Motor ...................................................................................................................................................... 48

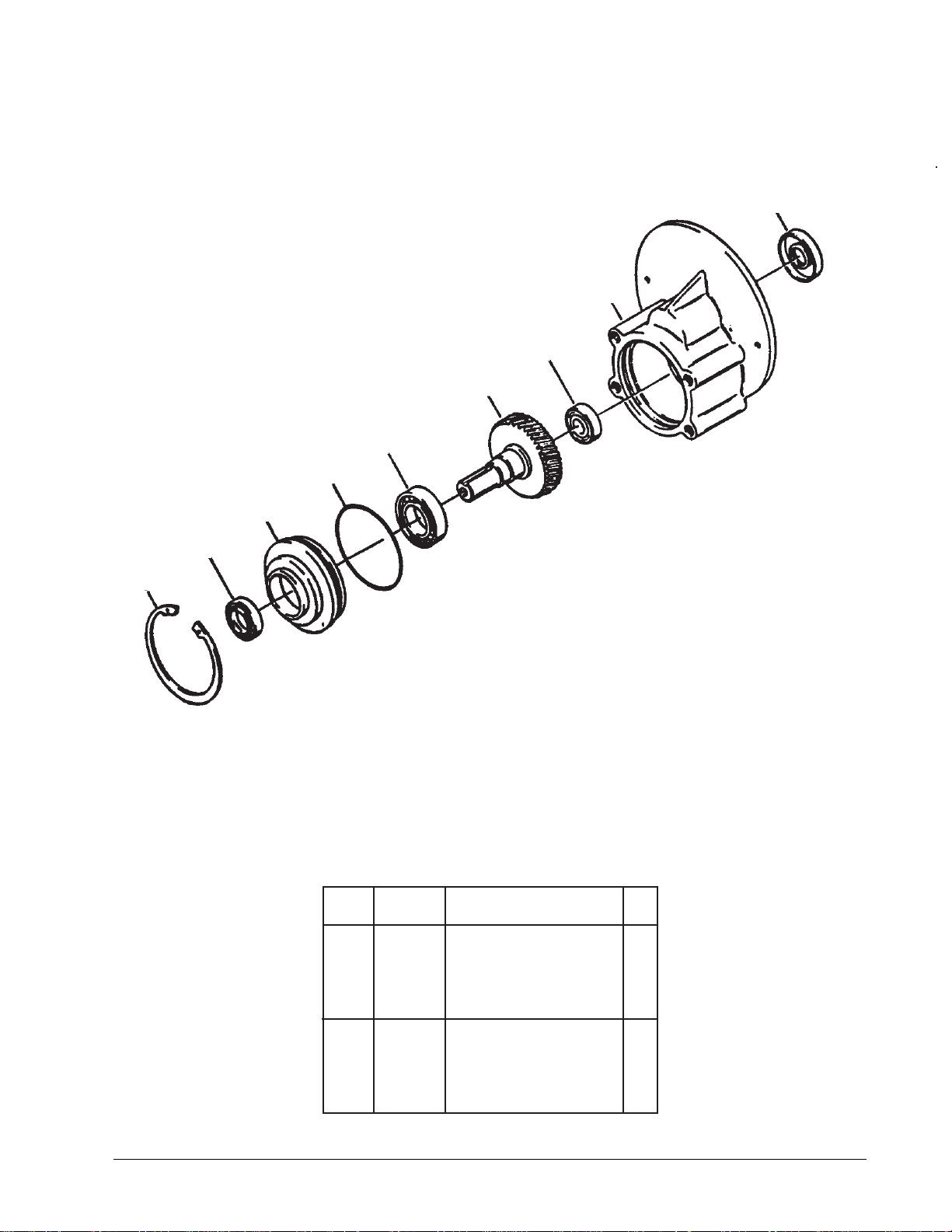

Gearbox ............................................................................................................................................................ 49

Vac Motor .......................................................................................................................................................... 50

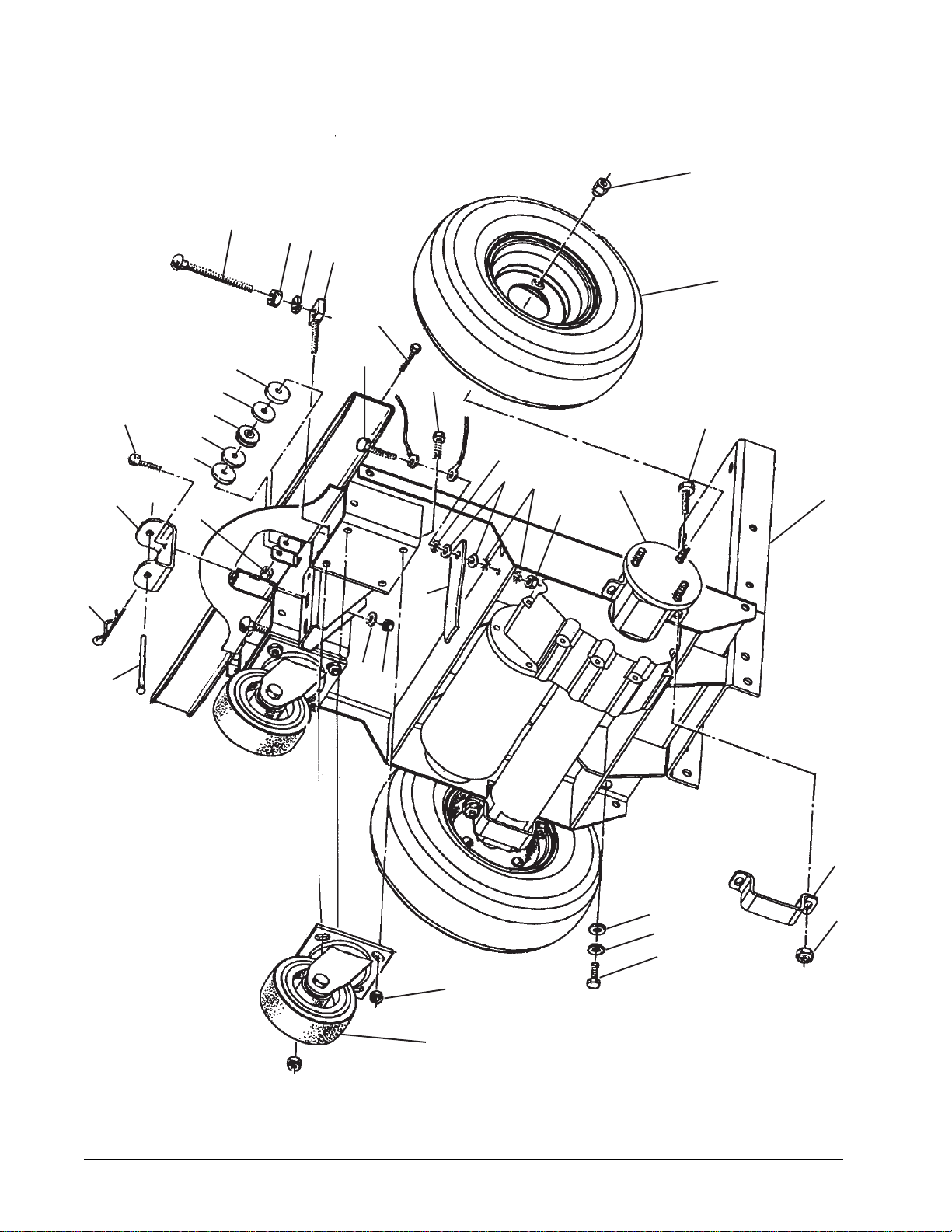

Imperial Transaxle Parts .................................................................................................................................. 51

Control Panel Connection Diagram S Models ................................................................................................ 52

Front of Machine Connection Diagram S Models............................................................................................ 52

Control Panel Connection Diagram L Models ................................................................................................. 53

Front of Machine Connection Diagram L Models ............................................................................................53

Electrical Plate Connection Diagram S Models .............................................................................................. 54

Electrical Plate Connection Diagram L Models ............................................................................................... 55

Control Housing Connection Diagram ............................................................................................................ 56

Electrical Schematic S Models ......................................................................................................................... 57

Electrical Schematic (Top) L Models ............................................................................................................... 58

Electrical Schematic (Bottom) L Models .......................................................................................................... 59

Page -2- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 3

OPERATOR SAFETY INSTRUCTIONS

DANGER: Failure to read and observe all DANGER statements could result in severe

bodily injury or death. Read and observe all DANGER statements found in

your Owner's Manual and on your machine.

WARNING: Failure to read and observe all WARNING statements could result in injury

to you or to other personnel; property damage could occur as well. Read

and observe all WARNING statements found in your Owner's Manual and

on your machine.

CAUTION: Failure to read and observe all CAUTION statements could result in

damage to the machine or to other property. Read and observe all

CAUTION statements found in our Owner's Manual and on your machine.

DANGER: Failure to read the Owner's Manual prior to operating or attempting any service or

maintenance procedure to your ALTO machine could result in injury to you or to other

personnel; damage to the machine or to other property could occur as well. You must

have training in the operation of this machine before using it. If your operator(s) cannot

read English, have this manual explained fully before attempting to operate this

machine.

DANGER: Operating a machine that is not completely or fully assembled could result in injury or

property damage. Do not operate this machine until it is completely assembled.

Inspect the machine carefully before operation.

DANGER: Machines can cause an explosion when operated near flammable materials and

vapors. Do not use this machine with or near fuels, grain dust, solvents, thinners, or

other flammable materials. This machine is not suitable for picking up hazardous dust.

DANGER: Lead acid batteries generate gases which can cause an explosion. Keep sparks and

flames away from batteries. Do not smoke around the machine. Charge the batteries

only in an area with good ventilation. Make sure that you unplug the AC charger from the

wall outlet before operating the machine.

DANGER: Working with batteries can be dangerous! Always wear eye protection and protective

clothing when working near batteries. Remove all jewelry. Do not put tools or other

metal objects across the battery terminals, or the tops of the batteries.

DANGER: Using a charger with a damaged power cord could result in an electrocution. Do not

use the charger if the power cord is damaged.

WARNING: Operating this machine from anywhere other than the back of the machine could result in injury

or damage. Operate this machine only from the rear.

WARNING: This machine is heavy. Get assistance before attempting to transport or move it. Use two able

persons to move the machine on a ramp or incline. Always move slowly. Do not turn the

machine on a ramp. If operating machine on a gradient over 2%, do not stop, turn or park.

Read the "Procedures For Transporting" in this manual before transporting.

WARNING: Machines can topple over if guided over the edges of stairs or loading docks and cause injury

or damage. Stop and leave this machine only on a level surface. When you stop the machine,

turn the key "OFF". Set the parking brake.

WARNING: Maintenance and repairs performed by unauthorized personnel could result in damage or

injury. Maintenance and repairs must be performed by authorized ALTO personnel only.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 3 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 4

WARNING: Any alterations or modifications of this machine could result in damage to the machine or

injury to the operator or other bystanders. Alterations or modifications not authorized by the

manufacturer voids any and all warranties and liabilities.

WARNING: Electrical components of this machine can "short-out" if exposed to water or moisture. Keep

the electrical components of the machine dry. Wipe the machine down after each use. For

storage, keep the machine in a dry building.

WARNING: Operating a machine without observing all labels and instructional information could result in

injury or damage. Read all machine labels before attempting to operate. Make sure all of the

labels and instructional information are attached or fastened to the machine. Get replacement

labels and plates from your ALTO distributor.

WARNING: Wet floor surfaces can be slippery. Water solutions or cleaning materials used with this type of

machine can leave wet areas on the floor surface. These areas can cause a dangerous

condition for the operator or other persons. Always put "Caution" signs around/near the area

you are cleaning.

WARNING: Improper discharge of waste water may damage the environment and be illegal. The United

States Environmental Protection Agency has established certain regulations regarding

discharge of waste water. Also, city and state regulations regarding this discharge may be in

your area. Understand and follow the regulations in your area. Be aware of the environmental

hazards of chemicals that you dispose.

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage. Do

not use this machine as a step or furniture. Do not ride on this machine.

CAUTION: Your machine warranty will be voided if anything other than genuine ALTO parts are used on

your machine. Always use ALTO parts for replacement.

English

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable in the European Union and other European countries with separate

collection systems)

This marking shown on the product or its literature, indicates that it should not be disposed with

other household wastes at the end of its working life. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, please separate this from other

types of wastes and recycle it responsibly to promote the sustainable reuse of material resources.

Household users should contact either the retailer where they purchased this product, or their

local government office, for details of where and how they can take this item for environmentally

safe recycling.

Business users should contact their supplier and check the terms and conditions of the purchase

contract. This product should not be mixed with other commercial wastes for disposal.

Introduction

Introduction:

ALTO's newly designed Scrubtec 795, 784 & 770 automatic scrubbers are efficient and superior floor cleaning

machines. The Scrubtec 795 uses two brushes or pads to scrub a path 97 cm wide. The Scrubtec 784 uses

two brushes or pads to scrub a path 84 cm wide. The Scrubtec 770 uses two brushes or pads to scrub a path

71 cm wide. A squeegee wipes the floor while the vacuum motor removes the dirty solution from the floor - all

in one pass.

The Scrubtec 795, 784 & 770 automatic scrubbers come complete with six - 6 volt batteries, five battery

connector cables, two battery cables, either two brushes or two pad drivers, and one operator's manual.

Page -4- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 5

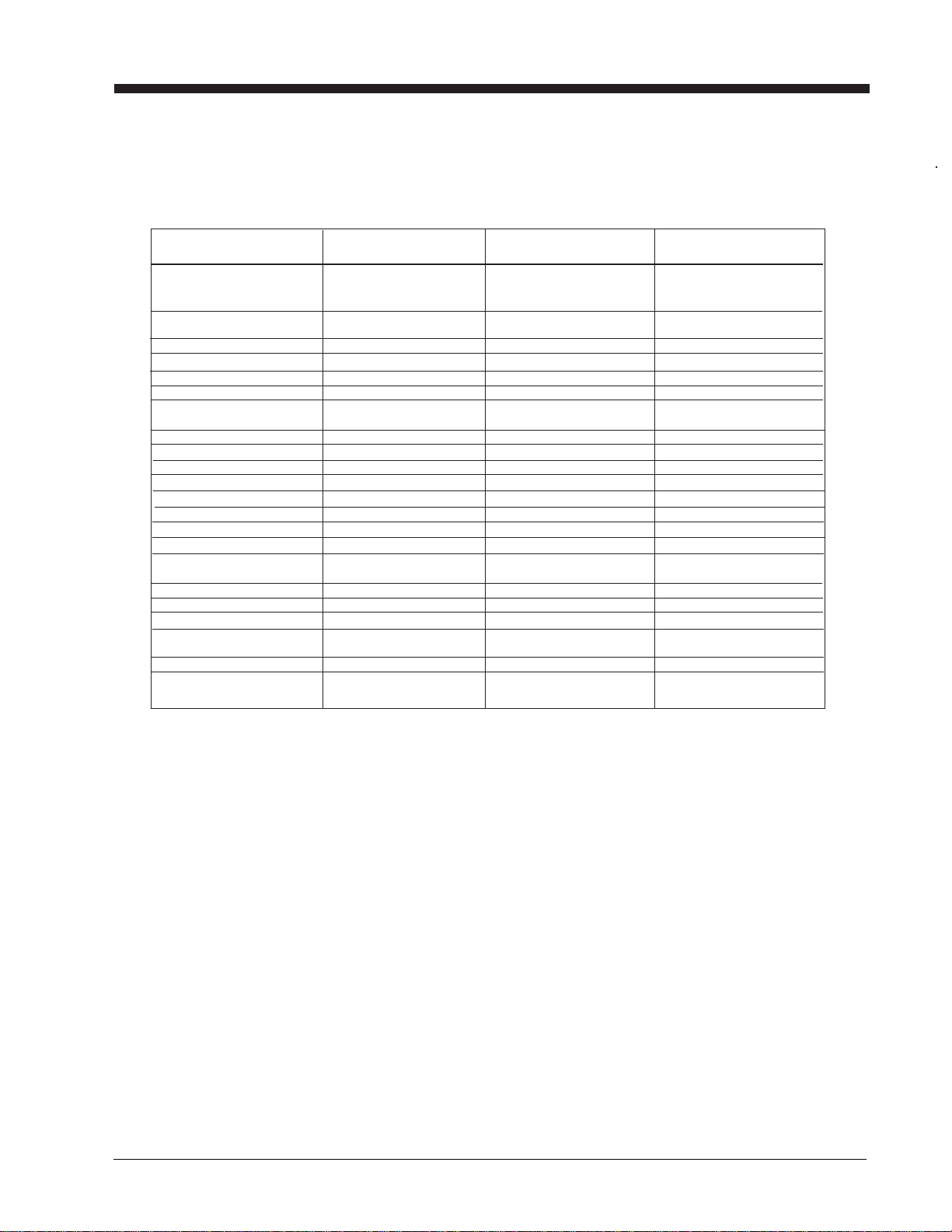

Machine Specifications

SPECIFICATIONS:

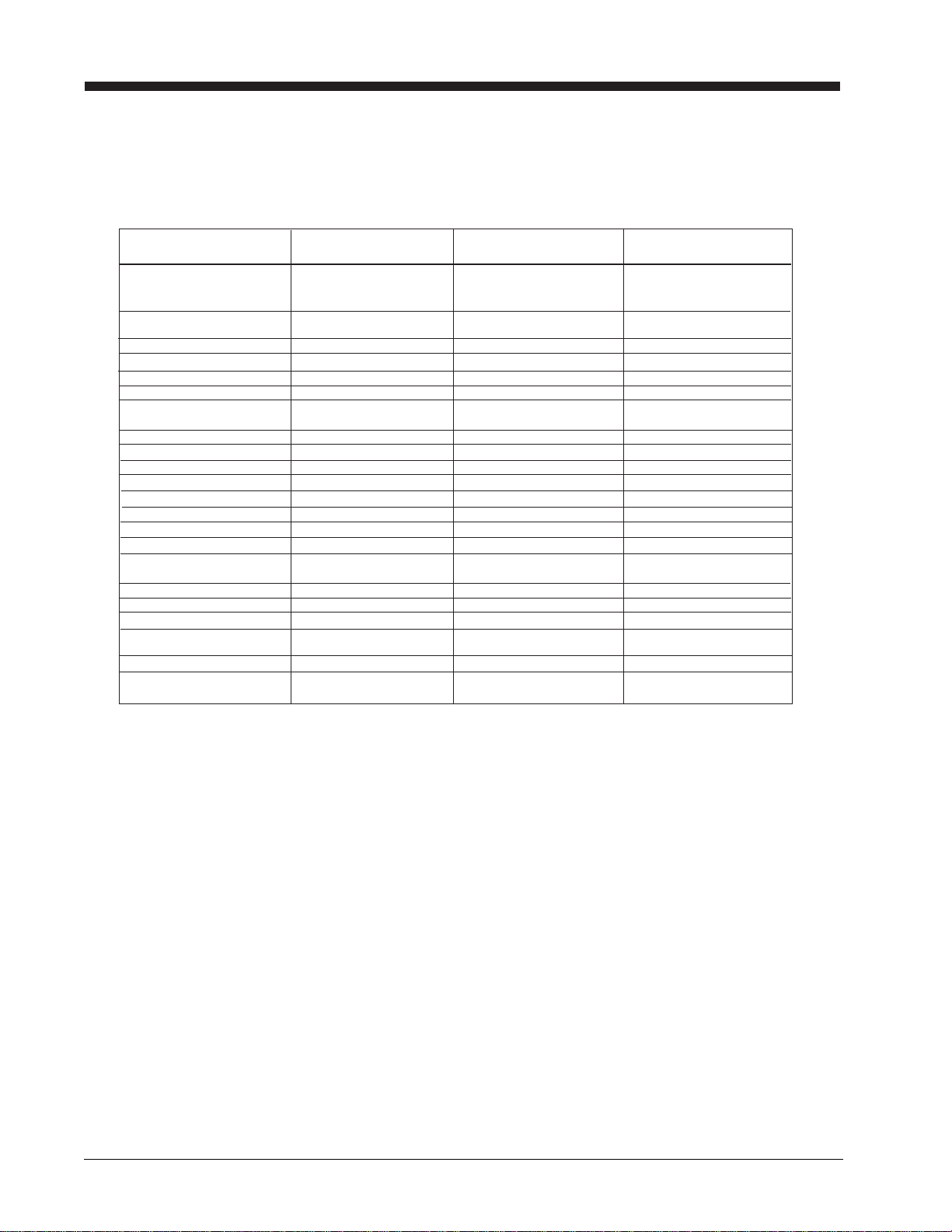

Model Scrubtec 795 S Scrubtec 784 S Scrubtec 770 S

Motor, Vac 1 HP (.74kw) three 1HP (.74kw) three 1HP (.74kw) three

stage tangential stage tagential stage tagential

discharge discharge discharge

Power Supply 36 volt (6-6V batteries) 36 volt (6-6V batteries) 36 volt (6-6V batteries)

250AH, 330AH 250AH, 330AH 250AH, 330AH

Solution Tank 30 gallon (114 liter) 30 gallon (114 liter) 30 gallon (114 liter)

Recovery Tank 30 gallon (114 liter) 30 gallon (114 liter) 30 gallon (114 liter)

Motors, Brush (2) 1 hp PM (.74kw) 1 hp PM (.74kw) 1 hp PM (.74kw)

Motor Traction .50 hp PM (.37kw) .50 hp PM (.37kw) .50 hp PM (.37kw)

Brushes (2) 19 inch (48cm) 17 inch (43cm) 14 inch (36cm)

w/.5" (1.5cm) overlap w/.5" (1.5 cm) overlap w/.5" (1.5 cm) overlap

Brush Speed 200 rpm 200 rpm 200 rpm

Brush Pressure Variable 150 lbs. - 220 lbs. Variable 150 lbs. - 220 lbs. Variable 150 lbs. - 220 lbs.

Speed, Forward Variable to 230 ft./min. Variable to 230 ft./min. Variable to 230 ft./min.

Speed, Reverse Variable to 180 ft./min. Variable to 180 ft./min. Variable to 180 ft./min.

Charger 36V, 21A, 115V/60hz 36V, 21A, 115V/60hz 36V, 21A, 115V/60hz

Length 68.28 inches (173 cm) 67 inches (170 cm) 65.0 inches (165 cm)

Width - Machine 40.33 inches (102 cm) 35.70 inches (91 cm) 30.0 inches (76 cm)

Height 43.75 inches (112cm) 43.75 inches (112 cm) 43.75 inches (112 cm)

Cleaning Rate 42,000 sq ft/hr 35,000 sq ft/hr 29,700 sq ft./hr

(3,901 sq. m/hr) (3,252 sq. m/hr) (2,750 sq ft./hr)

Cleaning Swath 38 inch (97 cm) 33 inch (84 cm) 28 inch (71 cm)

Grade Cleaning 6° Incline 6° Incline 6° Incline

Weight w/Batteries (330AH) 1025 lbs. 465kg 1015 lbs. 460kg 1005 lbs. 456kg

Shipping Weight 1328 lbs. 602kg 1318 lbs. 598kg 1308 lbs. 593kg

w/batteries (330AH)

Noise (EN ISO 3744:1995) <70 dBA <70 dBA <70 dBA

Vibration <2.5 m/s

2

<2.5 m/s

2

<2.5 m/s

2

(EN ISO 2631-1: 1997 (E))

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 5 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 6

Machine Specifications

SPECIFICATIONS:

Model Scrubtec 795 L Scrubtec 784 L Scrubtec 770 L

Motor, Vac 1 HP (.74kw) three 1HP (.74kw) three 1HP (.74kw) three

stage tangential stage tagential stage tagential

discharge discharge discharge

Power Supply 36 volt (6-6V batteries) 36 volt (6-6V batteries) 36 volt (6-6V batteries)

250AH, 330AH 250AH, 330AH 250AH, 330AH

Solution Tank 30 gallon (114 liter) 30 gallon (114 liter) 30 gallon (114 liter)

Recovery Tank 30 gallon (114 liter) 30 gallon (114 liter) 30 gallon (114 liter)

Motors, Brush (2) 1 hp PM (.74kw) 1 hp PM (.74kw) 1 hp PM (.74kw)

Motor Traction .50 hp PM (.37kw) .50 hp PM (.37kw) .50 hp PM (.37kw)

Brushes (2) 19 inch (48cm) 17 inch (43cm) 14 inch (36cm)

w/.5" (1.5cm) overlap w/.5" (1.5 cm) overlap w/.5" (1.5 cm) overlap

Brush Speed 200 rpm 200 rpm 200 rpm

Brush Pressure Variable 140 lbs. - 220 lbs. Variable 140 lbs. - 220 lbs. Variable 140 lbs. - 220 lbs.

Speed, Forward Variable to 230 ft./min. Variable to 230 ft./min. Variable to 230 ft./min.

Speed, Reverse Variable to 180 ft./min. Variable to 180 ft./min. Variable to 180 ft./min.

Charger 36V, 21A, 115V/60hz 36V, 21A, 115V/60hz 36V, 21A, 115V/60hz

Length 68.28 inches (173 cm) 67 inches (170 cm) 65.0 inches (165 cm)

Width - Machine 40.33 inches (102 cm) 35.70 inches (91 cm) 30.0 inches (76 cm)

Height 43.75 inches (112cm) 43.75 inches (112 cm) 43.75 inches (112 cm)

Cleaning Rate 42,000 sq ft/hr 35,000 sq ft/hr 29,700 sq ft./hr

(3,901 sq. m/hr) (3,252 sq. m/hr) (2,750 sq ft./hr)

Cleaning Swath 38 inch (97 cm) 33 inch (84 cm) 28 inch (71 cm)

Grade Cleaning 6° Incline 6° Incline 6° Incline

Weight w/Batteries (330AH) 1025 lbs. 465kg 1015 lbs. 460kg 1005 lbs. 456kg

Shipping Weight 1328 lbs. 602kg 1318 lbs. 598kg 1308 lbs. 593kg

w/batteries (330AH)

Noise (EN ISO 3744:1995) <70 dBA <70 dBA <70 dBA

Vibration <2.5 m/s

2

<2.5 m/s

2

<2.5 m/s

2

(EN ISO 2631-1: 1997 (E))

Page -6- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 7

PROCEDURES FOR TRANSPORTING

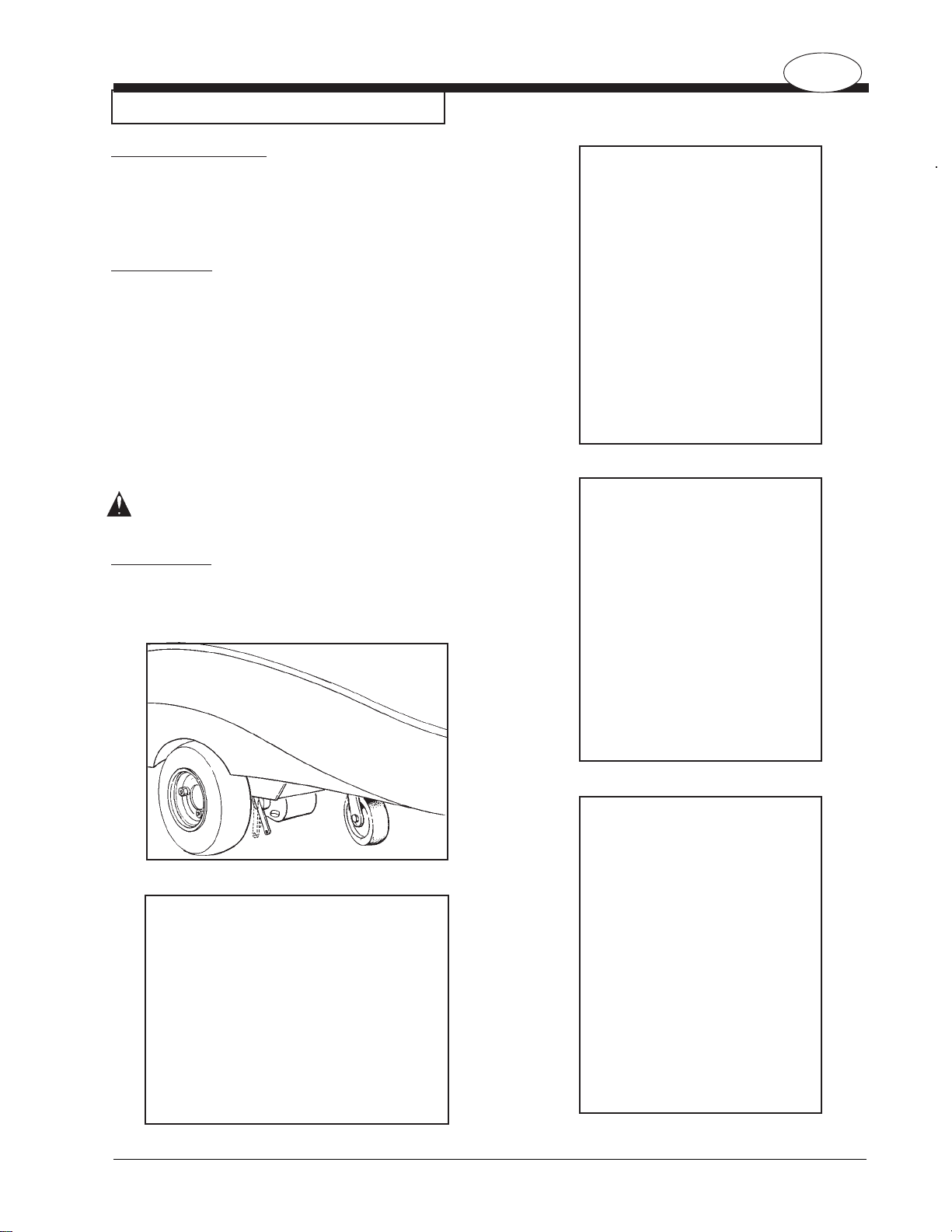

How To Put The Machine In A Van Or Truck

WARNING: The machine is heavy. Make sure you use two able persons to assist

the machine in climbing the ramp.

1. Make sure the loading ramp is at least 2.4m long, and strong enough to support the machine.

2. Make sure the ramp is clean and dry.

3. Put the ramp in position.

4. Remove squeegee assembly, brush housings, & brushes or pad drivers before loading.

5. Turn key switch "ON".

6. Align the machine on a level surface 3.1m in front of the ramp.

7. Put the traverse speed switch in the "HI" position.

8. Press one or both forward switches.

9. Push the machine to the top of the ramp.

10. Turn the key switch "OFF".

11. Fasten the machine to the vehicle.

How To Remove The Machine From A Van Or Truck

1. Make sure there are no obstructions in the area.

2. Make sure the unloading ramp is at least 2.4m long and strong enough to support the machine.

3. Make sure the ramp is clean and dry.

4. Put the ramp in position.

5. Unfasten the machine.

WARNING: The machine is heavy. Make sure you use two able persons to assist in

moving the machine down the ramp.

6. Turn the key switch "ON".

7. Carefully and slowly, drive the machine to the top of the ramp by pressing and holding either of the forward

switches and the reverse switch.

8. Put the traverse speed switch to the mid range speed setting. As the machine begins to travel down the

ramp, maintain a slow downward speed by pressing either of the forward switches.

9. Replace squeegee assembly, brush housings, & brushes or pad drivers after the machine is unloaded

and ready to use.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 7 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 8

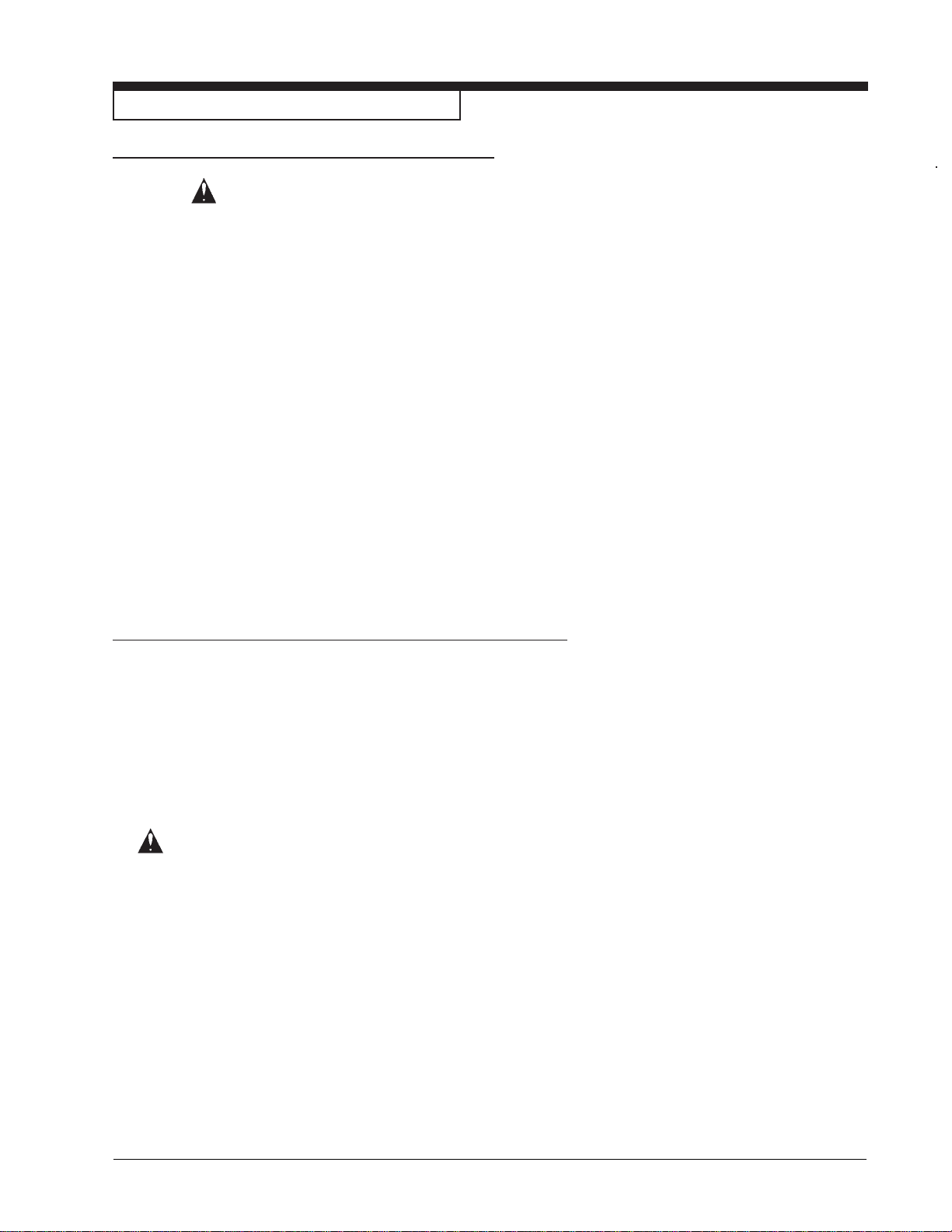

SYMBOLS USED ON SCRUBTEC 770, 784, 795

SYMBOLS USED ON

SCRUBTEC 770 S, 784 S & 795 S

SCRUBTEC 770 L, 784 L, 795 L

Hazard Alert Symbol On/Off Key Switch

SYMBOLS USED ON

SCRUBTEC 770 S, 784 S & 795 S

Additional Brush

Pressure

Brush Up/Down

Power

Traverse Speed Control

SYMBOLS USED ON

SCRUBTEC 770 L, 784 L & 795 L

Squeegee

Up/Down

Solution

Control

Brush Up/Down

Charge/Battery

Meter

Page -8- CLARKE TECHNOLOGY Operator's Manual -

Solution Control

Charge Indicator

Hour Meter

Switch

One Touch Switch

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 9

SYMBOLS USED ON SCRUBTEC 770, 784, 795

WARNING

READ OPERATOR'S

MANUAL BEFORE

OPERATING THIS

MACHINE

RISK OF FIRE

• Use only

commercially

available floor

cleaners and

waxes intended

for machine

operation.

• Do not use

flammable

materials.

RISK OF INJURY

OR DAMAGE TO

MACHINE

• Do not turn, stop

71018A

or leave machine

on a ramp or dock.

71015A

WARNING

READ OPERATOR'S

MANUAL BEFORE

OPERATING THIS

MACHINE

EXPLOSIVE GASES,

CAN CAUSE SEVERE

INJURY, DEATH

OR DAMAGE

TRANSFORMER.

• Keep flammable

materials away from

batteries. Charge in

a cool well ventilated

area.

BATTERIES

CONTAIN SULFURIC

ACID. CAN CAUSE

SEVERE INJURY.

• Avoid contact with

skin eyes, or

clothing. If contact,

flush with water.

Get medical

attention. If internal.

contact call physician.

WEAR

PROTECTIVE

EYE GEAR.

WARNING

MOVING PARTS.

CONTACT CAN

CAUSE SEVERE

INJURY.

• Do not place

hands or feet under

71017A

machine when in

use.

CLARKE TECHNOLOGY Operator's Manual -

WARNING

FALLING PARTS

CAN CAUSE

SEVERE INJURY.

• Make sure tank is

secure before

servicing.

71014A

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 9 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 10

MACHINE CONTROL PANEL SRUBTEC 770 S, 784 S & 795 S

Key Switch (See Figure #1, Item "A")

The key switch turns "ON" the power to the control panel. "0" is "OFF" and "I" is "ON".

Traverse Speed Switch (See Figure #1, Item "B")

The speed control varies from low to high speed. To increase the speed, turn the knob to the right. To decrease the

speed, turn the knob to the left.

Brush Up/Down Switch (See Figure #1, Item "C")

The brush switch has two positions: "Up" positions the brushes up; "Down" positions the brushes on the floor. The

brush motors start when the brushes are down and the traverse switch is depressed.

Increase Brush Pressure Switch (See Figure #1, Item D)

This switch is used to increase the brush pressure. Increased brush pressure may be required when stripping or

cleaning heavily soiled floors. To increase brush pressure, first lower the brushes by pressing the brush up/down

switch (Item "C") to the down position. This will lower the brushes to the normal scrub position. To increase brush

pressure, press and hold the switch (Item "D") until the desired brush pressure is reached or the brush deck stops

moving downward. To reposition the brush pressure to normal scrub, press the brush up/down switch (Item "C") to

the up position and after the brush deck is completely raised, then return the switch to the down position for normal

scrub.

Solution Control Knob (See Figure #1, Item "E")

The solution control knob regulates the flow of cleaning solution to the floor. To increase the flow turn the knob

clockwise. To decrease the flow, turn the knob counter-clockwise.

Forward Switch (See Figure #1, Item "F")

The forward switch turns the traverse motor "on" and if the brush motors are in the down position, it also activates the

brush motors and solution control module. Either the right or the left switch can be used.

Reverse Switch (See Figure #1, Item "G")

The reverse switch, when used in conjunction with one of the forward switches, causes the machine to reverse

direction. The reverse speed is 70% of the forward speed.

Charge / Battery Meter (See Figure #1, Item "H")

The charge/battery meter indicates the amount of charge that is left in the batteries while the machine is in use. When

the battery pack gets too low the red light will begin flashing and the brush/pad motors will shut off.

Circuit Breakers (See Figure #1, Item "I"-"M")

The circuit breaker reset buttons are located on the control panel. The breakers are located as follows: Item I & J Brush Motors (35A); Item K - Traverse Motor (30A); Item L - Vac Motor (25A); Item M - Actuator Motor, Brush Head (5A)

If a circuit breaker trips, determine which motor is not operating and turn the key switch "OFF". Wait five minutes and

push the reset button back in. Turn the key switch "ON", and try again. An authorized service person should be

contacted if the breaker trips again.

Hour Meter (See Figure #1, Item "N")

The hour meter indicates the number of hours the machine has operated. It runs only when the machine is moving

forward or reverse.

Page -10- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 11

MACHINE CONTROL PANEL SRUBTEC 770 S, 784 S & 795 S

F

M

L

E

G

K

C

J

B

F

D

A

I

H

N

CLARKE TECHNOLOGY Operator's Manual -

Figure #1

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 11 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 12

MACHINE CONTROL PANEL SRUBTEC 770 L, 784 L & 795 L

Key Switch (See Figure #2 Item "A")

The key switch turns "ON" the power to the control panel. "O" is "OFF" and "I" is "ON".

Traverse Speed Switch (See Figure #2, Item "B")

The speed control varies from low to high speed. To increase the speed, turn the knob to the right. To decrease the

speed, turn the knob to the left.

Squeegee Up/Down Switch (See Figure #2, Item "C")

The squeegee switch is used to raise and lower the squeegee and to turn on and off the vacuum motor. The squeegee will lower and the vacuum motor will turn on when the switch is placed in the lower position. To raise the squeegee, place the switch in the up position. The vacuum motor will stop, after a short delay, when the switch is placed in

the up position.

The middle switch position is used for the one touch control. The squeegee will raise and lower and the vacuum will

turn on and off automatically when the one touch control function is used. NOTE: The squeegee switch must be in

the middle position for the squeegee and vacuum to operate properly with the one touch feature.

Brush Up/Down Switch (See Figure #2, Item D)

To lower brush head, push the brush switch in the down (+) position. To increase brush pressure, continue to push

the brush switch in the down (+) position until the desired pressure is reached or until brush head travel stops. The

brush motors will start and solution will flow (provided the solution is turned "ON") when the machine begins to

traverse. To raise the brush head, push the brush switch in the up (-) position until the brush head travel stops or

desired position is reached.

Solution Flow Control (See Figure #2, Item "E")

The solution flow switch regulates the flow of chemical solution to the floor. To increase the flow, push the solution

flow switch in the down (+) position until desired flow is reached. To decrease the flow, push the solution flow switch

in the up (-) position until the desired flow is reached. To shut off the solution, push the solution flow switch in the up

(-) position until no indicators are visible on the display. NOTE: DO NOT run dry! NOTE: No solution will flow when

the machine does not traverse.

Forward Switch (See Figure #2, Item "F")

The forward switch turns the traverse motor "on" and if the brush motors are in the down position, it also activates the

brush motors and solution control module. Either the right or the left switch can be used.

Reverse Switch (See Figure #2, Item "G")

The reverse switch, when used in conjunction with one of the forward switches, causes the machine to reverse

direction. The reverse speed is 70% fo the forward speed.

One Touch (See Figure #2, Item "H")

The one touch button is a green button that lowers and raises the brush head and squeegee with one touch. NOTE:

For more information about the one touch feature see the section "How to Operate the Machine".

LCD Display (See Figure #2, Item "I")

The main display indicates the state of battery charge, brush head, solution and squeegee status. It will also display

machine run hours and error codes. NOTE: When the battery charger gets too low the battery display will begin

flashing and the brush/pad motors will shut off.

Display Button (See Figure #2, Item "J")

Pressing the black display button will toggle between the main machine functions and the hour meter. The hour

meter indicates the number of hours the machine has operated. It displays brush motor, vacuum motor, traverse

motor and total key on hours.)

Page -12- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 13

MACHINE CONTROL PANEL SRUBTEC 770 L, 784 L & 795 L

Circuit Breakers (See Figure #2, Item "K", "L", "M")

The circuit breaker reset buttons are located on the control panel. The breakers are located as follows: Item "L" and

"M" - Brush Motors (35A); Item N - Key Switch (5A).

If a circuit breaker trips, determine which motor is not operating and turn the key switch "OFF". Wait five minutes and

push the reset button back in. Turn the key switch "ON", and try again. An authorized service person should be

contacted if the breaker trips again.

G

F

C

D

E

I

B

F

A

M

K

J

L

H

CLARKE TECHNOLOGY Operator's Manual -

Figure #2

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 13 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 14

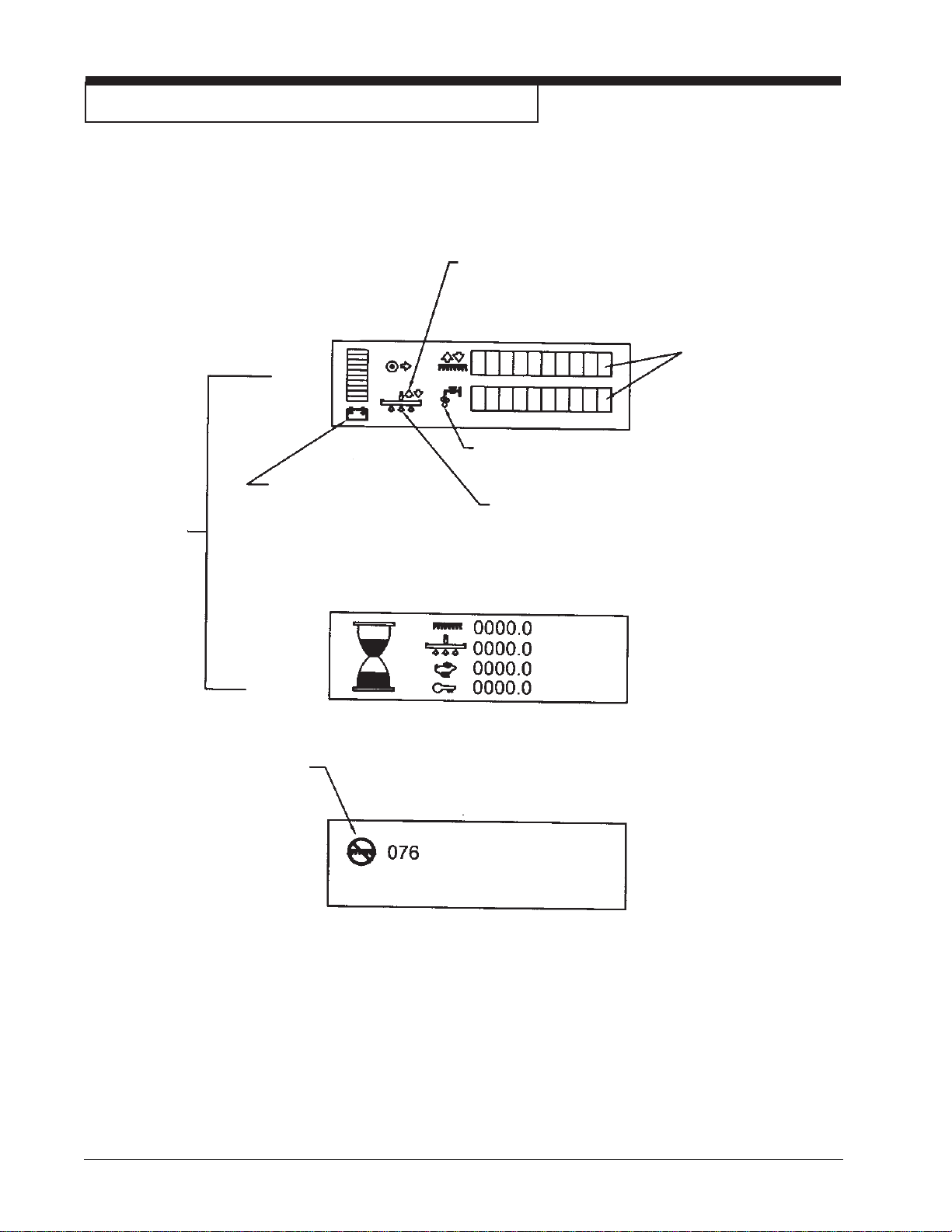

Display Screens For SCRUBTEC 770 L, 784 L, 795 L

Position arrow indicating current position

of squeegee (up or down)

Screens

Available

to Operator

SCREEN 1

“Battery” blinks when

low voltage occurs.

SCREEN 2

Example

3

Water “droplets” off when solution is off and

they are flashing when solution is on.

Arrows indicating vacuum status.

They are flashing when vac is on

and off when vac is off.

SCREEN 3 (Diagnostic)

Indicators are on all

the time showing

current settings.

The Diagnostic only. It will not show unless a fault with

the machine occurs. When the fault happens the icon

and error code will be displayed.

See "Common Error Codes" at end of "Maintenance

Section".

Page -14- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 15

MACHINE CONTROLS & FEATURES

Squeegee Lift Handle ("S Class" models only) See

Figure #3a, 3b, & 3c.

The squeegee lift handle is located below the control

handles on the right side. It is used to raise or lower the

squeegee. The vac motor is turned on when the handle is

lowered.

Parking Brake (Optional)See Figure #4.

The parking brake prevents movement of the machine.

The brake is located on the left hand side of the transaxle

motor. Turn the key switch off or disconnect the power to

the battery to apply the brake.

There is a mechanical lever located on the brake. This

lever is an override. To manually release the brake, rotate

the lever toward the rear of machine (counter clockwise).

To return the brake to normal or to apply the brake, rotate

the lever towards the front of the machine (clockwise).

NOTE: If the lever is left in the override position, the

brake will not function with the key switch, and the

machine will not operate.

CAUTION: Do not activate the brake while the ma-

chine is moving.

EN

Figure #3a

Float Shut Off See Figure #5.

The shut-off switch for the vac motor is located in the

recovery tank. It automatically turns off the vac motor

when the recovery tank is full.

Figure #4

Figure #3b

Figure #5

CLARKE TECHNOLOGY Operator's Manual -

Figure #3c

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 15 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 16

HOW TO PREPARE THE MACHINE

FOR OPERATION

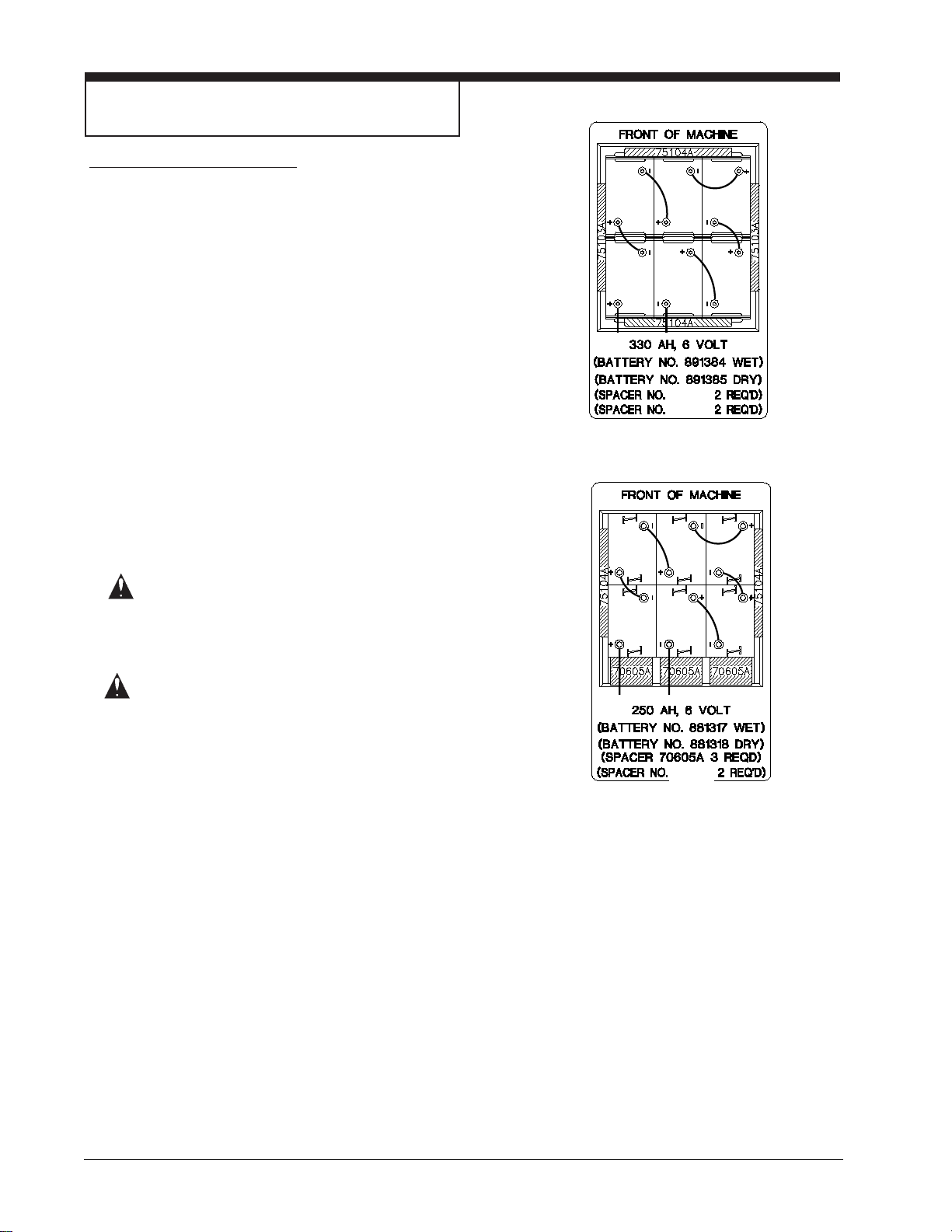

How To Install The Batteries

The Scrubtec machines use six 6-volt batteries. The

batteries are located in the battery compartment

under the recovery tank.

To Install the batteries, follow this procedure:

1. Turn key switch off.

2. Make sure both tanks are empty.

3. Disconnect the hoses from the recovery tank

(upper tank) & unplug the vac motor and float

switch.

4. Remove the tank support bracket.

5. Remove the recovery tank.

6. Place the batteries in the solution tank as

shown in figures 6a and 6b.

WARNING: Lifting batteries without

help could result in an

injury. Get help to lift the

batteries. The batteries are

heavy.

38720B

Figure #6a

38722B

38722B

38720B

38722B

38720B

38722B

38722B

WARNING: Working with batteries can

be dangerous. Always

wear eye protection and

protective clothing when

working near batteries.

NO SMOKING!

7. Connect the battery cables between

batteries and install long battery cable

assembly as indicated. See figure 6a and 6b.

8. Install the tank, reconnecting hoses and

plugging in vac motor and float switch

connectors. Install tank support bracket.

NOTE: Charge the batteries before using the

machine.

38722B

Figure #6b

Page -16- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 17

HOW TO PREPARE THE MACHINE

FOR OPERATION

Battery Maintenance

The electrical power to operate the machine comes from the

storage batteries. Storage batteries need preventive maintenance.

WARNING: Working with batteries can be dan-

gerous. Always wear eye protection and protective clothing when

working near batteries.

NO SMOKING!

To maintain the batteries in good condition, follow these

instructions:

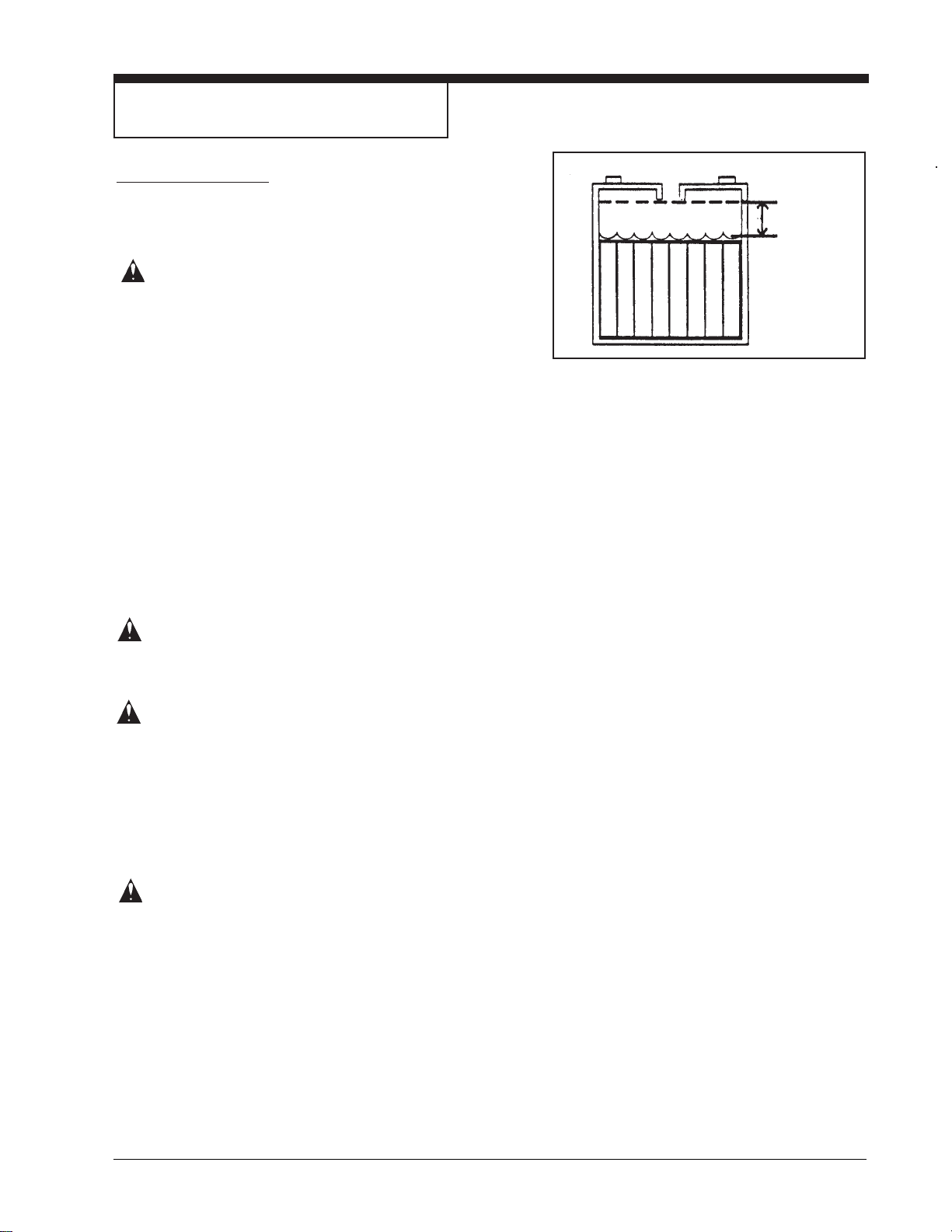

1. Keep the electrolyte at the correct level. The correct

level is between 6.35mm below the bottom of the tube

in each cell and above the tops of the plates. Check

the level of the electrolyte each time you charge the

batteries. See figure #7.

NOTE: Check the level of electrolyte prior to charging the

batteries. Be sure the plates in each cell are covered with

electrolyte . Do not top off the cells prior to charging the

battery. Electrolyte expands during charging. As a result,

the electrolyte could overflow from the cells. Always top off

the cells with distilled water after charging.

CAUTION: Irreversible damage will occur to

the batteries if the electrolyte level

does not cover the plates. Keep the

electrolyte at the correct level.

Correct fill level

Figure #7

CAUTION: Machine damage and discharge

across the tops of the batteries can

occur if the batteries are filled

above the bottom of the tube in

each cell. Do not fill the batteries

up to the bottom of the tube in each

cell. Wipe any acid from the

machine or the tops of the batteries. Never add acid to a battery

after installation.

CAUTION: Tap water may contain contami-

nants that will damage batteries.

Batteries must be re-filled with distilled water only.

2. Keep the tops of the batteries clean and dry.

Keep the terminals and connectors clean. To clean the

top of the batteries, use a damp cloth with a weak

solution of ammonia or bicarbonate of soda solution.

To clean the terminals and connectors, use a terminal

and connector cleaning tool. Do not allow ammonia or

bicarbonate of soda to get into batteries.

3. Keep the batteries charged.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 17 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 18

HOW TO PREPARE THE MACHINE

FOR OPERATION

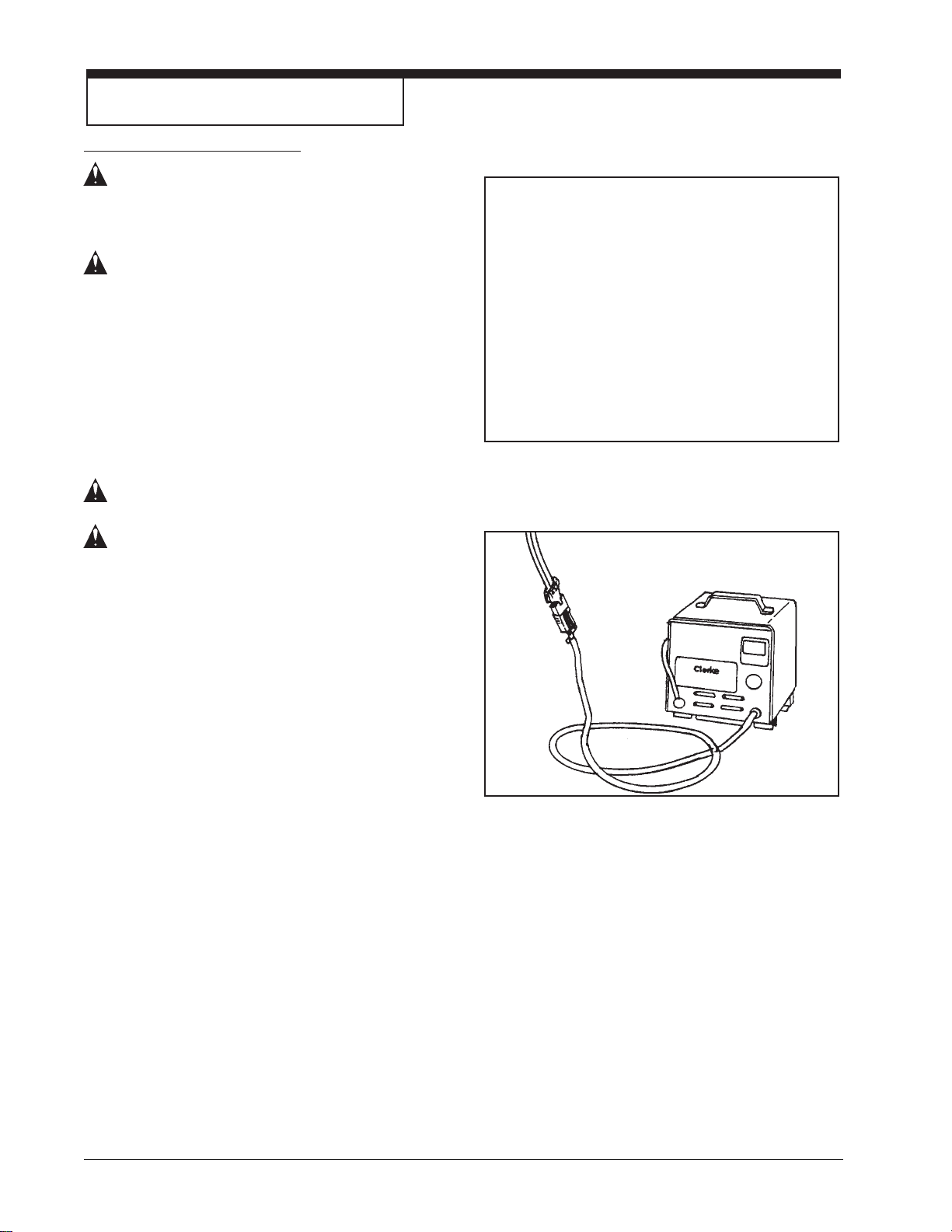

How To Charge The Batteries

WARNING: Charging the batteries in an area

without adequate ventilation could

result in an explosion. To prevent an

explosion, charge the batteries only

in an area with good ventilation.

WARNING: Lead acid batteries generate gases

which could explode. Keep sparks

and flames away from batteries. NO

SMOKING!

To charge the batteries, follow this procedure:

1. Make sure the key switch is in the “OFF” position.

2. Before charging the batteries, the battery compartment

needs to be vented. To vent compartment, tip up the

recovery tank until it locks in the open position (see

figure #8). To close the tank, pull up on the arm and then

slowly lower the tank to the closed position.

CAUTION: Before raising tank, be sure tank is

empty.

WARNING: Do not operate or perform

maintenance on the machine while

the recovery tank is in the open

position. The tank can be

accidentally bumped and it may slam

shut.

Figure # 8

3. Put the charger on a flat surface. Make sure the vents

on the sides are at least two inches away from walls

and other objects. Make sure there are no objects near

the vents on the bottom of the charger.

4. Disconnect the battery pack connector from the

batteries.

5. Connect the DC connector on the charger to the battery

pack connector. See figure #8A.

6. Connect the battery charger AC cord located at the rear

of the machine to a 10 amp (min) 230V properly

grounded wall receptacle.

7. Observe indicator light to ensure the charging process

has started. Flashing light(s) indicates that the

batteries are being charged. Steady on green light

indicates the batteries are fully charged.

NOTE: Make sure you plug into a circuit that is not loaded by

other equipment. Wall breakers may be tripped and no

charge will occur.

WARNING: Never charge a GEL battery with an

unsuitable battery charger. Carefully

follow the instructions given by the

manufacturer of the batteries and

battery charger.

NOTE: To prevent permanent damage to the batteries, avoid

their complete discharge. Never leave the batteries

completely discharged, even if the machine is not being

used. When recharging the batteries, keep the recovery tank

open. After every 20 recharging cycles, check the level of the

electrolyte and if necessary top off with distilled water.

Figure 8A

Page -18- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 19

HOW TO PREPARE THE MACHINE

FOR OPERATION

How To Install The Brushes Or Pad Drivers

To install the brushes or pad drivers on the machine,

follow this procedure:

1. Turn the key switch "ON".

2. Put the brush switch in the "UP" position.

3. Turn the key switch "OFF".

4. Go to the front of the machine.

5. Unlatch right and left brush housings and remove

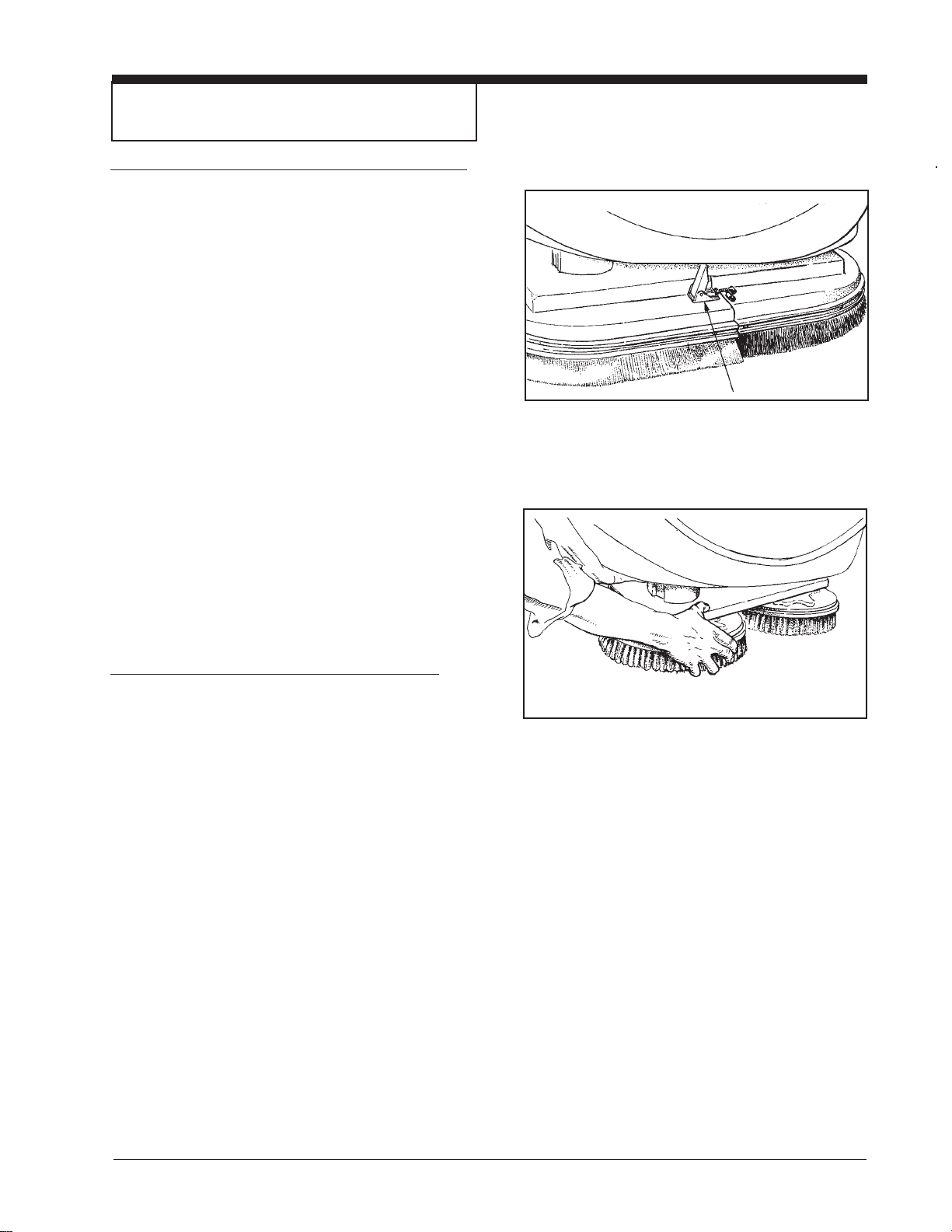

them. See figure #9.

6. Put a brush or pad driver under the brush motor plate.

See figure #10.

7. Align the lugs on the motor gimbal with the slots in the

brush gimbal.

8. Pull the brush up until the gimbal locks.

9. Repeat steps 6, 7, and 8 to install the second brush

or pad driver.

How To Remove The Brushes Or Pad Drivers

To remove the brushes or pad drivers from the machine,

follow this procedure:

1. Turn the key switch "ON".

2. Put the brush switch in the "UP" position.

3. Turn the key switch "OFF".

Figure #9

Figure #10

4. Go to the front of the machine.

5. Push down on two sides of the brush or pad driver until

the gimbals release.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 19 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 20

HOW TO OPERATE THE MACHINE

How to Operate the One Touch System ("L Class" models only)

One touch cleaning is a feature on the new Scrubtec Walk-behind

Scrubber. The factory defaults for this setting are two bars of

brush pressure and four bars for solution flow and squeegee in

the down position.

1. Press and release the green button for all cleaning

functions to begin, see figure #11, item A.

2. The squeegee and brush head lower to the floor and the

vacuum starts. NOTE: The squeegee switch must be in the

center position for the squeegee to operate with the one

touch feature, see figure #11, item B.

3. The brushes and solution will begin only when you begin to

traverse.

B

A

4. The cleaning will be at the factory default settings, however

you can reprogram these settings to your specifications.

See “Reprogramming One Touch” section below.

5. To end cleaning process, press the green button again and

solution will stop; brushes will raise; after a short delay

squeegee will raise; and the motor will turn off.

NOTE: It is intended that this be done while traversing. If you

stop and do it, some solution can be left on the floor.

Reprogramming One Touch

If you do not want to use the factory default settings, you may

reprogram the setting by following the procedures below:

1. Place the machine in the desired scrub condition by using

the one touch and individual switches.

2. Press and hold the green one touch button until you see the

LCD display flash, then release the button. NOTE: The time

required should be approximately 5 seconds.

3. When you activate or deactivate the one touch, it will now be

set to your preference for cleaning. These settings will

remain until you disconnect power or reprogram them.

NOTE: When programming one touch, be sure squeegee

is in automatic (middle) position, otherwise you may

program squeegee either up or down all the time.

Figure #11

How to Return One Touch to Factory Default Settings

To restore the factory settings, follow the procedures below:

1. Press and hold the green one touch button until you see the

LCD display flash two times (5 seconds between flashes),

see figure 11. NOTE: The time required for this will be

approximately 10 seconds.

2. The settings should be returned to 4 bars of solution and 2

bars of brush pressure. NOTE: The squeegee vac switch

must be in the middle position for default settings to work.

Page -20- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 21

HOW TO OPERATE THE MACHINE

How To Operate the Squeegee

("S Class" models only)

The squeegee wipes the floor while the vacuum motor

removes the dirty solution from the floor. Use your right

hand to lower or raise the squeegee handle. To operate the

squeegee, follow this procedure:

1. To lower the squeegee and start the vac motor move

the squeegee lever to the right and down. See figure

#12.

2. To raise the squeegee, lift the squeegee lever up.

See figure #13.

Note: The center position lets the vac motor continue to

run with the squeegee off the floor to avoid drips.

How to Fill The Solution Tank

CAUTION: Make sure water or solution

does not enter the opening for

the vacuum motor See figure #14.

The solution tank can be filled in the front or through the

clear drain hose at the rear of the machine. To fill the

solution tank follow this procedure:

1. Remove the solution tank lid. See figure #15.

2. Fill the solution tank with water.

3. Add a cleaning chemical to the water. for the

correct amount, follow the directions shown on the

container.

WARNING: Water solutions or cleaning materials

used with this type of machine can

leave wet areas on the floor surface.

These areas can cause a dangerous

condition for the operator or other

persons. Always put CAUTION signs

near the area you are cleaning.

Figure #12

Figure #13

Figure #14

Figure #15

WARNING: Machines can ignite flammable

materials and vapors. Do not use

with or near flammables such as

gasoline, grain dust, solvents, and

thinners. Only use a cleaning concentration recommended by the chemical

manufacturer.

WARNING: ALTO recommends a maximum

water temperature of 120°F(49°C)

4. Replace the solution tank lid.

5. When filling the machine from the rear, position the

clear drain hose against bracket and insert hose

as shown in figure 16. Solution level can be viewed

from the back of the machine.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 21 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Figure #16

Page 22

HOW TO OPERATE THE MACHINE

How To Traverse Machine

NOTE: Put the machine in the slow traverse speed (see

figure #17). Use the machine in an area that has no

furniture and objects until you can do the following:

1. Move the machine in a straight direction, forward and

backward.

2. Stop the machine safely.

3. Move the machine in a straight direction after you turn

the machine.

To move the machine, follow this procedure:

1. Turn the key switch “ON” position.

2. Put the brush switch in the "UP" position.

3. Raise the squeegee.

4. To go forward, push one or both of the yellow forward

switches (see figure #18).

5. To stop the machine, release the yellow forward

switches.

6. To go backward, push in on the white reverse button and

one of the yellow forward switches at the same time (see

figure #19).

7. To turn the machine, push the rear of the machine to the

side.

8. When you stop the machine, turn the key switch "OFF".

How to Clean a Floor

WARNING: Water solutions or cleaning materi-

als used with this type of machine

can leave wet areas on the floor

surfaces. These areas can cause a

dangerous condition for the operator

or other persons. Always put CAUTION signs near the area you are

cleaning.

To clean a floor, follow this procedure:

1. Put the water and a cleaning chemical in the clean

solution tank.

2. Turn the key switch "ON". If one touch feature is used,

press the green button and proceed to step 6 (deluxe

models only).

Figure # 17

Figure #18

3. Lower the squeegee.

4. Put the brush switch in the "DOWN" position.

Figure #19

5. Adjust the flow of clean solution to the flow desired.

6. Move the machine across the floor in the forward

direction.

7. Make a 1800 turn.

NOTE: When you make more passes across the floor, let

the brushes clean approximately 5cm of the

area already cleaned by the brushes.

NOTE: During most cleaning procedures, apply and

remove the solution in one operation.

Page -22- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 23

HOW TO OPERATE THE MACHINE

How to Clean a Very Dirty Floor

To clean a very dirty floor, follow this procedure:

1. Apply solution to the floor.

2. Do not lower the squeegee.

3. Do not activate the vacuum motor.

4. Lower the brushes and scrub the floor.

5. Leave the solution on the floor long enough for the

solution to begin cleaning the floor.

6. Scrub the floor again with additional solution, picking

up all the solution with the squeegee

MAINTENANCE

WARNING: Maintenance and repairs must be

done by authorized personnel only.

WARNING: Always empty the solution tank and

recovery tank before doing any

maintenance.

WARNING: Keep all fasteners tight.

These Maintenance Procedures Must Be Done Every Day

Keep the machine clean, it will need fewer repairs and

have longer life.

Do These Procedures When You Begin Your Work

Period

1. Turn off key switch.

2. Unplug charger from AC outlet and wrap cord around

bracket at rear of machine.

3. Make sure the recovery tank lid is on correctly (see

figure #20).

4. Make sure the Screen filter over the vacuum motor

is clean and in position (see figure #20).

5. Make sure the valve on the recovery drain hose is

clean. Tightly close the valve.

6. Make sure brush housings and skirts are in

position on the brush head.

Figure #20

7. Make sure the brushes are in position and

installed correctly

8. Check the installation of the squeegee and

squeegee hose.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 23 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 24

MAINTENANCE

Do These Procedures When You End Your Work

1. Drain the solution tank (Figure #21, item A) and the

recovery tank (Figure #21, item B). To drain the tanks

, follow this procedure:

a. Turn the key switch “OFF”.

b. Remove the drain hose from the back of the

machine.

c. Put the end of the hose over a drain or bucket.

d. Recovery Tank:

Turn the valve housing to the left (see figure

#22). To open the valve completely, turn the

housing fully to the left and pull the housing

off of the valve.

Solution Tank:

When hose is lowered below water level, the

water will drain (see figure 23).

2. Flush the tanks. To flush the tanks, put clean water

in the tank through the opening on top of the tank.

3. If a tank or drain hose has an obstruction, use a high

pressure water hose to flush the tank or hose. Put the

water hose into the drain hose.

B

Figure #21

A

4. Leave the tanks and the drain valves open to dry in the

air.

5. Check the squeegee blade. Use a cloth to clean the

squeegee blade. If the squeegee blade is damaged

or worn, turn or replace the blade.

6. Check and clean the recovery lid gasket. Use a mild

cleaning solution and rinse the parts in clean water.

Check the batteries and add distilled water as needed.

The correct level is within 6.35mm of the bottom of the

tube in each cell.

CAUTION: Tap water may contain

contaminants that will damage

batteries. Batteries must be

re-filled with distilled water

only.

WARNING: Lead acid batteries generate

gases which can cause an

explosion. NO SMOKING.

Always wear eye protection and

protective clothing when

working near batteries.

Use a clean cloth and wipe the surface of the machine.

Figure #22

Figure #23

Charge the batteries. See the instruction in the section

of this book called “How To Charge The Batteries”.

Page -24- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 25

MAINTENANCE

These Maintenance Procedures Must Be Done Every

Week:

WARNING: Maintenance and repairs must be

done by authorized personnel only.

Always empty the solution tank and

the recovery tank before doing any

maintenance. Keep all fasteners

tight.

WARNING: Always wear eye protection and pro-

tective clothing when working near

batteries. Do not put tools or other

metal objects across the battery terminals or the tops of the batteries.

CAUTION: To prevent damage to the machine,

and discharge across the tops of the

batteries, do not fill the batteries

above the bottom of the tube in each

cell. Wipe any acid from the machine or the tops of the batteries. Do

not add acid to battery after installation.

NOTE: Always turn off key switch before servicing the

machine.

Figure #24

WARNING: Always wear eye protection and

protective clothing when working

near batteries. NO SMOKING!

1. To inspect batteries, tip up recovery tank until it locks

in up position. See Figure #24.

2. Disconnect the batteries. Use a cloth and a solution

of ammonia or bicarbonate of soda to wipe the top of the

batteries. Clean the battery terminals. Reconnect the

batteries.

3. Check the hoses for leaks, obstructions and other

damages.

4. Check and clean the filter screen in the solution hose.

To clean the screen, follow this procedure:

a. Turn the connector to the left.

b. Remove and clean the filter screen.

c. Install the filter screen in the hose. Turn the

connector to the right to connect the hose.

5. Use a grease gun to lubricate the drive wheel and the

casters. See figure #25.

Figure #25

6. Check tire pressure. Tire pressure should be about 50

psi (3.45 bar).

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 25 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 26

MAINTENANCE

7. Check the squeegee and the scrub brushes or the pad

drivers for damage.

8. Check the squeegee and the vacuum hose for dam

age, leaks and obstructions.

Maintenance For The Squeegee

To remove the squeegee, follow this procedure:

1. Remove the squeegee assembly by loosening the two

knobs that attach the squeegee to the machine. Pull

the squeegee assembly off. See figure #26.

2. Inspect the squeegee blade.

3. If the blade is worn, turn the blade so that a new edge

is in the wiping position.

4. Reinstall squeegee assembly on the machine.

How To Adjust The Squeegee

The following adjustments are set at the factory, however

they may require slight adjustment.

Adjusting Squeegee Pressure:

To adjust the pressure, refer to Figure #27. Proper

adjustment will produce a uniform flare along the rear

blade when the machine is moved forward. To increase

pressure, tighten the nuts on each side of the swing arm.

To decrease the pressure, loosen the nuts on each side.

Figure #26

Figure #27

Adjusting Squeegee Tilt:

The tilt of the squeegee causes the rear blade to raise up

in the center or on the ends, depending on which

direction the tilt is changed. For tilt adjustment, refer to

figure # 28. Loosen left and right screw "X". In order to

Figure #28

bring the rear blade down in the center, tip "Y" down. To

bring both ends down, tip "Y" up. Make very small

adjustments and try it until a uniform flare is achieved.

Changing the tilt may also require readjusting the squeegee pressure.

Page -26- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 27

MAINTENANCE

Adjusting Squeegee Blades

When properly installed the front blade should be approximately .06 above the rear blade. See figure #29.

Adjusting Squeegee Support Wheels:

The support wheels should be set at .12 above the floor

with the rear blade touching the floor. See figure #31.

WARNING: Maintenance and repairs

must be done by authorized personnel only .

WARNING: Electrical repairs must be

done by authorized personnel only.

Consult your ALTO Authorized Service Person to do

the service procedures.

Use only genuine ALTO parts.

.12

Figure #29

How to Clean the Solution Line

If the solution line becomes clogged, pull the filter

assembly out from behind the brush housing (Figure

#30 and remove the filter screen (Figure # 31) and

clean or replace it. Push filter assembly back inside

frame.

Figure #30

CLARKE TECHNOLOGY Operator's Manual -

Figure #31

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 27 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 28

HOW TO CORRECT PROBLEMS IN THE MACHINE

PROBLEM CAUSE ACTION

The machine does not remove all the

water from the floor.

The batteries do not give the normal

running time.

The squeegee is up

The vacuum tank is full.

The screen filter is dirty.

There is an obstruction or damage in the

squeegee, squeegee hose or standpipe.

The vacuum motor is not running.

The squeegee hose is disconnected.

The squeegee blade is damaged, worn, or

incorrectly installed.

The squeegee pressure is not correctly

adjusted.

The gaskets on the cover of the recovery

tank are damaged.

The battery terminals are dirty or damaged.

The electrolyte level is too low.

Lower the squeegee.

Drain the tank.

Clean the screen filter.

Remove the obstruction or repair the damage.

Check for tripped breaker. Have an authorized

service person make repairs.

Connect the hose.

Turn or replace the squeegee blade.

Correctly install the squeegee blade.

Adjust the pressure of the squeegee.

Replace the gaskets.

Clean the terminals and connectors. Replace

the damaged cables. Charge the batteries.

Add distilled water to each cell and charge the

batteries.

The batteries are not fully charged.

The charger is damaged.

The battery is defective.

The batteries are disconnected.

The cleaning is not even.

The machine does not run. The machine loses power.

The scrub brushes or pads are worn.

There is damage to the brush assembly,

casters or the solution valve.

The brush motors are not running

The solution level is low.

Charge the batteries for a full 16 hour charge.

Have an authorized service person repair the

charger.

Check voltage of each cell while discharging.

Connect the batteries.

Replace the scrub brushes or pads.

Have an authorized service person make

the needed repairs.

Check for tripped breaker, reset. Check

for loose connections.

Fill the solution tank.

NOTE: If the motors continue to stop

consult an authorized service person.

Reset the circuit breaker.

Check wire connection to traverse motor.

Replace the fuses.

Check the batteries connections.

Check parking brake overide lever

position (if installed)

NOTE: If the motors continue to stop,

consult an authorized service person.

Page -28- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 29

SCRUBTEC 770 L, 784 L, 795 L

Common Error Codes

ERROR

CODE

3100

3101

3102

3103

3104

3105

7600

7603

7800

7802

9000

2F01

CAUSE

Probable short circuit of

output device.

Open circuit on brush motors

or brush motor wiring.

Possible short circuit on

brush motors or wiring.

Open circuit on traction motor.

Traction motor current has

exceeded current limit for the

fold back time.

Brushes not fitted.

Drive system activated prior

to turning key switch "ON".

ACTION

Check the traction, brush and vac motor

connections on the trio and check wiring

from these connectors down to the

traction, brush and vac motors.

Check the brush motor connection on

the trio and check the wiring from this

connector down to the brush motor.

Check the traction motor connection on

trio and wiring down to motor.

Excessive driving up an incline, or

machine driven up against an obstacle

or step.

Brushes

Release traverse switch and reactivate.

NOTICE: IF ERROR CODE/FAULT OCCURS TURN KEY SWITCH OFF AND THEN BACK ON.

For further codes and explanations, contact a ALTO Service Center.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 29 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 30

SCRUBTEC 770 / 784 / 795

Accessories - 2/05

ACCESSORIES

Description Part No.

Power Wand System Kit 10892A

ESP Recycle System Kit 10894A

Soft Caster Asm. 521 2 7 A

Care Kit 146 07A

Squeegee Asm., Optional 74 cm (770 model only) 188 18 A

Drive Wheel, Foam Filled 599 55A

Imperial Electric Parking Brake Kit 106 84A

Battery Maintenance System 533 90 A

Optional Squeegee Blades

Machine Blade Type Material Length Part No.

770 Inner Optional Urethane, Ribbed 65.7 cm 309 5 1A

770 Inner Optional Urethane, Notched, 1.5mm 65.7 cm 309 55A

770 Inner Optional Urethane, Ribbed 91.1 cm 309 5 2A

770 Inner Optional-Grout Urethane, Notched 1.5mm 91.1 cm 30957 A

784 Inner Optional Urethane, Ribbed 102.2 cm 3 09 53 A

784 Inner Optional-Grout Urethane, Notched 1.5mm 104.1 cm 3 0958A

795 Inner Optional Urethane, Ribbed 116.8 cm 3 09 54 A

795 Inner Optional-Grout Urethane, Notched 1.5mm 116.8 cm 3 0959A

770 Outer Optional Nitrile, Solid 71.4 cm 30938 A

770 Outer Optional Nitrile, Solid 97.8 cm 30936 A

784 Outer Optional Nitrile, Solid 107 cm 30 937 A

795 Outer Optional Nitrile, Solid 122 cm 30 939 A

Brushes: Size Description Part No.

43.2 cm Poly 114 2 4 B

43.2 cm Grit-Heavy 11425B

43.2 cm Grit-Medium 11430B

43.2 cm Grit-Lite 10384A

43.2 cm Soft Nylon 108 7 5 A

35.6 cm Poly 114 2 7 B

35.6 cm Grit-Heavy 11426B

35.6 cm Grit-Medium 11431B

35.6 cm Grit-Lite 10383A

35.6 cm Soft Nylon 108 7 4 A

48.3 cm Poly 114 3 4 B

48.3 cm Grit-Heavy 11433B

48.3 cm Grit-Medium 11432B

48.3 cm Grit-Lite 10385A

48.3 cm Soft Nylon 114 3 5 B

Pad Drivers: Size Part No.

48.3 cm 17524B

43.2 cm 17520C

35.6 cm 17521C

Page -30- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 31

SCRUBTEC 770 SSCRUBTEC 770 S

SCRUBTEC 770 S

SCRUBTEC 770 SSCRUBTEC 770 S

SCRUBTEC 770 LSCRUBTEC 770 L

SCRUBTEC 770 L

SCRUBTEC 770 LSCRUBTEC 770 L

SCRUBTEC 784 SSCRUBTEC 784 S

SCRUBTEC 784 S

SCRUBTEC 784 SSCRUBTEC 784 S

SCRUBTEC 784 LSCRUBTEC 784 L

SCRUBTEC 784 L

SCRUBTEC 784 LSCRUBTEC 784 L

SCRUBTEC 795 SSCRUBTEC 795 S

SCRUBTEC 795 S

SCRUBTEC 795 SSCRUBTEC 795 S

SCRUBTEC 795 LSCRUBTEC 795 L

SCRUBTEC 795 L

SCRUBTEC 795 LSCRUBTEC 795 L

Section II

Parts and Service Manual

(70935A)

U.S. Patent No. 6,760,947; No. 6,105,192; No. 6,493,896 (Deluxe Machines)

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 31 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 32

33

34

35

CLARKE TECHNOLOGY

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Solution Tank Assembly Drawing 9/05

1

36

37

38

40

39

2

3

46

47

4

5

6

7

To Electrical Panel

32

31

30

29

30

31

28

21

24

23

21

27

45

43

44

26

25

22

21

42

41

24

20

19

16

17

12

18

8

9

10

11

12

13

14

15

Page -32- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 33

CLARKE TECHNOLOGY

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Solution Tank Assembly Parts List 9/05

Ref # Part No. Description Qty

1 881317 Battery - 250 AH - 6 Volt 6

2 842406 Series Cable - 9" ("S" Models) 5

2 842406 Series Cable - 9" ("L" Models) 4

2 40860A Fused Cable ("L" Models) 1

3 40613A Battery Cable, Black ("L" Models) 1

4 40612A Battery Cable, Red ("L" Models) 1

5 61713A Tank Support Bracket 1

6 170892 Washer, Lock 1/4 2

7 170915 Screw, 1/4-20 x 3/4 Hex 2

8 962027 Screw, 8-32 x 1/2 PN 2

9 50966A Latch 1

10

11 60480A Hose Bracket 1

12 80108A Screw, 10-24 x 1/2 PN 4

13 30598A Drain Hose 1

14 51346A Spring, Hose 1

15 872010 Hose Clamp 1

16 98465A Clamp, Metal 1

17 980657 Washer, Lock 1/4 1

18 962139 Screw, 1/4-20 x 5/8 Hex 1

19 61590A Hose Hanger Bracket 1

20 59614A Battery Drain Valve 1

21 53571A Hose Clamp 4

22 30453A Hose 1

23 822802 Elbow 1

24 30445A Solution Hose 2

25 50358A Connector 1

26 838517 Filter Screen 1

27 830214 Hose Adapter 1

28 50359A Solution Adapter 1

29 53568A Hinge 1

30 980614 Washer, 1/4 External 6

31 85395A Screw, 1/4-20 x 1/2 PN 6

32 30655A Front Cover 1

33 81105A Nut, 3/8-16 ESNA 2

34 930645 Washer, 3/8 Flat 2

35 962798 Screw, 10-24 x 1/2 PN 1

36 30498A Solution Lid 1

37 38020A Strap 1

38 920296 Nut, 10-24 ESNA 2

39 50966A Keeper, Latch 1

40 930090 Rivet, 5/32 x 9.16 2

41 962666 Screw, 10-24 x 3/4 PN 1

42 962522 Screw, 3/8-16 x 2 Hex 2

43 87054A Washer, 3/8 Fender 2

44 80289A Screw, 10 x 1/2 Tapping PN 2

45 50248A Clamp, Hose 2

46

46 40857A Cable, Battery Charger ("L" Models) 1

47 40855A Cable, Battery ("S" Models) 1

891384 Battery - 330 AH - 6 Volt 6

30590E Solution Tank 1

40856A Cable, Electrical Panel ("S" Models) 1

NOTE: indicates a change has been made since the last publication

of this manual.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 33 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 34

CLARKE TECHNOLOGY

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Recovery Tank Assembly Drawing 2/05

1

2

5

3

7

37

38

39

36

34

6

35

33

3

26

27

28

4

23

22

9

24

13

8

9

10

11

12

15

16

17

14

20

18

20

32

Page -34- CLARKE TECHNOLOGY Operator's Manual -

20

30

29

25

31

21

19

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

11

Page 35

CLARKE TECHNOLOGY

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Recovery Tank Assembly Parts List 9/05

Ref # Part No. Description Qty

1 962798 Screw, 10-24 x 1/2 PN 1

2 30057A Recovery Lid 1

3 920296 Nut, 10-24 ESNA 2

4 30065A Gasket, Lid 1

5 38020A Strap 1

6 962666 Screw, 10-24 x 3/4 PN 1

7 58069A Vac Filter 1

8 39338A Stand Tube 1

9 837304 O-Ring 2

10 82100A Locknut 1

11 41809A Contact 4

12 43402A Housing, Blue 2

13 920797 Nut 1

14 643418 Gasket, Vac 1

15 58533A Vac Motor Spacer 3

16 45019A Vac Motor (order 2 each #11 and #19) 1

17 87026A Washer, 1/4 Flat 3

18 85728A Screw, 1/4-20 x 4 Hex 3

19 43401A Housing, Black 2

20 872010 Clamp 3

21 674110 Vac Exhaust Hose 1

22 962957 Screw, 10-16 x 1/2 PN 2

23 52206A Chain 1

24 30620A Squeegee Adapter 1

25 35192A Squeegee Hose 1

26 30227A Drain Housing 1

27 30226A Drain Plug 1

28 52560A O-Ring 1

29 30225A Drain Body 1

30 832002 Drain Valve Clamp 1

31 35165A Recovery Drain Hose 1

32 61591A Recovery Tank Support 1

33 87622A Washer, Nylon 1

34 80043A Shoulder Screw 1

35 30068A Hinge Pin (included with item #36) 2

36 30673A Tank, Recovery, 770 S 1

36 30697A Tank, Recovery, 770 L 1

36 30698A Tank, Recovery, 784 S 1

36 30699A Tank, Recovery, 784 L 1

36 30700A Tank, Recovery, 795 S 1

36 30701A Tank, Recovery, 795 L 1

37 40002A Float Switch

38 56459A Strain Relief (included in item #37) 1

39 87612A Seal 1

(includes items, #38 & 2 ea. #11& #12)

1

NOTE: indicates a change has been made since the last publication of

this manual.

CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795 - 35 -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 36

21

CLARKE TECHNOLOGY

SCRUBTEC 770 S / 784 S / 795 SSCRUBTEC 770 S / 784 S / 795 S

SCRUBTEC 770 S / 784 S / 795 S

SCRUBTEC 770 S / 784 S / 795 SSCRUBTEC 770 S / 784 S / 795 S

Electrical Panel Assembly Drawing 9/05

Drawing # 10849E

39

38

10

36

34

33

37

5

26

18

35

9

2

50

1

47

40

48

49

10

41

42

46

45

43

44

28

25

24

23

27

18

20

16

32

5

17

31

15

19

14

30

6

22

5

29

5

20

5

13

12

7

11

6

3

5

7

8

4

Page -36- CLARKE TECHNOLOGY Operator's Manual -

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795

SCRUBTEC 770 / 784 / 795SCRUBTEC 770 / 784 / 795

Page 37

CLARKE TECHNOLOGY

SCRUBTEC 770 S / 784 S / 795 SSCRUBTEC 770 S / 784 S / 795 S

SCRUBTEC 770 S / 784 S / 795 S

SCRUBTEC 770 S / 784 S / 795 SSCRUBTEC 770 S / 784 S / 795 S

Electrical Panel Assembly Parts List 9/05

Drawing # 10849E

Ref # Part No. Description Qty

1 962980 Screw, 6-32 x 1 2

2 962139 Screw, 1/4-20 x 5/8 2

3 85391A Screw, 1/4-20 x 5/8 PN 2

4 30594A Rear Cover 1

5 81104A Nut, ESNA 1/4-20 10

6 87007A Washer, 1/4 Flat 3

7 980651 Washer, 5/16 Flat 6