Page 1

American-Lincoln

Operator's Manual

®

SMART

Sweeper/Scrubber

Beginning with Serial No. 692003

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure

to read this book prior to operating or attempting any service or maintenance procedure to

your machine could result in injury to you or to other personnel. Damage to the machine or to

other property could occur as well. You must have training in the operation of this machine

before using it. If you or your operator (s) cannot read English, have this manual explained

fully before attempting to operate this machine.

All directions given in this book are as seen from the operator's position at the rear of the machine.

For new books, write to:

Part No. 2-86-00321 2003 Printed in the

American-Lincoln, 1100 Haskins Road, Bowling Green, Ohio 43402

American-Lincoln® USA

ISO 9001

U

®

L

#

FILE A2287

AMERICAN-LINCOLN 1-1

SMART

Page 2

NOTES

1-2 AMERICAN-LINCOLN

SMART

Page 3

C

CONTROLS 20-32

D

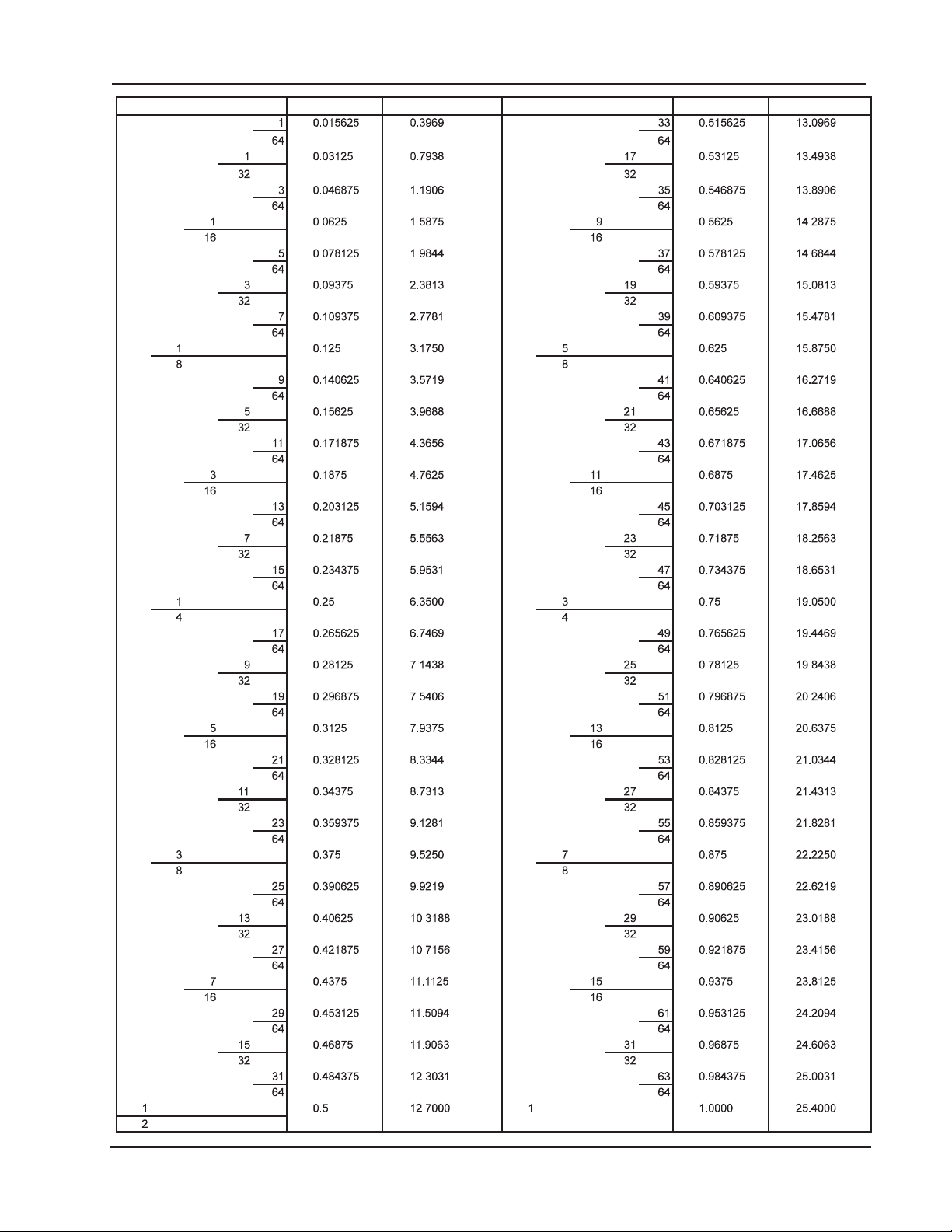

DECIMAL - METRIC CONVERSION T ABLE 5

DISCLAIMER 4

H

HARDWARE ABREVIA TIONS 6

HYDRAULIC TORQUE REQUIREMENTS 8

M

MACHINE PREP ARA TION 17, 18, 19

MAINTENANCE 44-58

O

OPERA TING INSTRUCTIONS 33-43

ORDERING P ARTS 10

INDEX

S

SAFETY PRECAUTIONS 1 1, 12

SPECIFICA TIONS 14, 15, 16

ST ANDARD HARDWARE & T ORQUE V ALUES 7

SYMBOLS 9

T

TROUBLESHOOTING 59, 60

AMERICAN-LINCOLN 1-3

SMART

Page 4

DISCLAIMER

DISCLAIMER

The information contained in this manual is believed correct at the time of publication. American Lincoln

assumes no responsibility or liability for unauthorized changes made to this manual or pages removed, causing

indirect or consequential damages resulting from the use of the information appearing herein.

WARNING!

In the event that machinery or controls described herein are modified in any way , or in the event that such

machinery or controls are not maintained in a proper manner , the instructional material contained herein may

be rendered inaccurate. The information contained herein is to be used only by persons knowledgeable in the

operation of machinery such as that described herein, or other persons being directly supervised by such

knowledgeable persons.

No portion of this manual may be reproduced without the express written consent of:

AMERICAN LINCOLN

Product Engineering

1 100 Haskins Road

Bowling Green, OH, 43402

(419) 352-751 1 Fax: (419) 373-4284

Copyright 2003 American Lincoln. All rights reserved.

Printed in USA March 2003

1-4 AMERICAN-LINCOLN

SMART

Page 5

DECIMAL - METRIC CONVERSION TABLE

FRACTION FRACTION

DECIMAL DECIMAL

MILLIMETER MILLIMETER

C-2001/9907

AMERICAN-LINCOLN 1-5

SMART

Page 6

HARDWARE ABREVIATIONS

AD J = Adjusting Screw

ADJ.SP = Adjusting Plunger Screw

BHM = Binding Head Machine Screw

BHS = Button Head Socket Screw

CAPT .SL = Captivated Slotted Screw

CAPT.WG = Captivated Wing Screw

FH M = Flat Head Machine Screw

FIL.HM = Filister Head Machine Screw

H HC = Hexagon Head Cap Screw

HH M = Hexagon Head Machine Screw

H I H D = ½ High Head Screw

HSHC = Hexagon Socket Head Cap Screw

HSFHC = Hexagon Socket Flat Head Cap Screw

KN H = Knurled Head Screw

MH H C = Metric Hexagon Head Cap Screw

PHM = Pan Head Machine Screw

RH D = Round Head Drive Screw

RH M = Round Head Machine Screw

RHW = Round Head Wood Screw

SH C = Shiny Crown Cap Screw

SHTB = Shoulder Thumb Screw

SQ = Square Head Screw

T B = Thumb Screw

T H M = Truss Head Machine Screw

WELD = Weld Stud

WG = Wing Screw

ABBREVIA TIONS-SCREWS

ABREVIA TIONS-SETSCREWS

HS = Hexagon Socket Setscrew

S = Slotted Setscrew

SH = Square Head Setscrew

KCP = Knurled Cup Point Setscrew

CP = Cup Point Setscrew

OP = Oval Point Setscrew

FDP = Full Dog Point Setscrew

HD P = Half Dog Point Setscrew

FP = Flat Point Setscrew

CO P = Cone Point Setscrew

1-6 AMERICAN-LINCOLN

SMART

Page 7

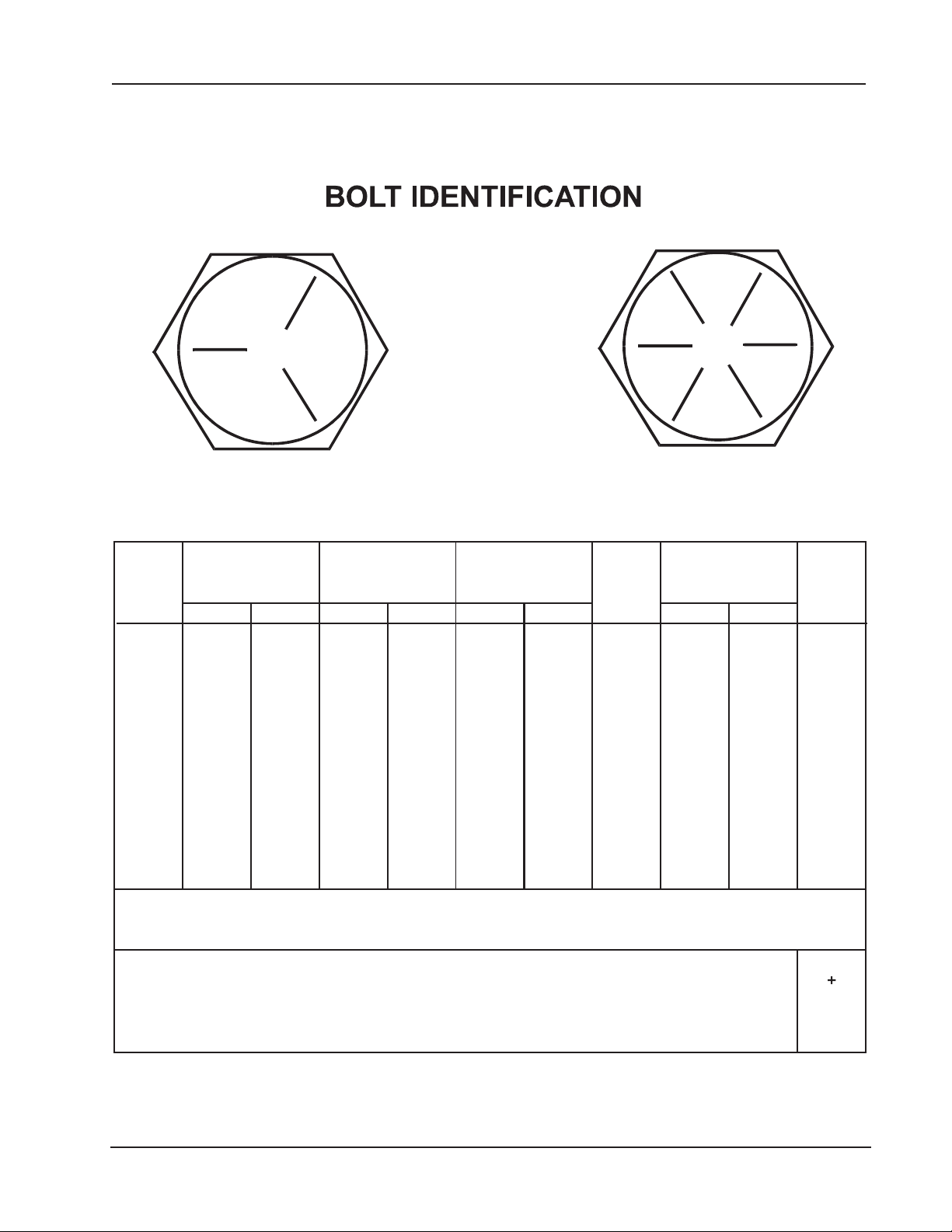

STANDARD HARDWARE & TORQUE VALUES

SAE - Grade 5

C

14

27

39

86

15

28

44

68

98

135

239

387

579

Grade

5

Plated

Grade

8

Plated

FFF

15

28

43

108

17

31

49

76

110

153

267

-

-

C

-

-

-

130

22

40

63

95

138

191

338

545

818

-

-

-

151

24

44

70

108

155

216

378

-

-

410H

Stainless

C

18

33

47

114

19

34

55

85

-

-

-

-

-

20

35

54

132

22

39

62

95

-

-

-

-

-

Screw

Size

*6

*8

*10

*1/4

5/16

3/8

7/16

1/2

9/16

5/8

3/4

7/8

1

C = Coarse Thread

F = Fine Thread

* = Torque values for #6 through 1/4 are lb./in. All others are lb./ft.

Brass

5

9

13

32

6

10

16

-

-

-

-

-

-

SAE - Grade 8

Type

F&T

&BT

C

20

37

49

120

-

-

-

-

-

-

-

-

-

F

23

41

64

156

-

-

-

-

-

-

-

-

-

Type

B, AB

21

34

49

120

-

-

-

-

-

-

-

-

-

NOTE

Decrease the torque by 20% when using thread lubricant

The torque tolerance is ± on torque values.

C2000/9905

AMERICAN-LINCOLN 1-7

SMART

Page 8

g

HYDRAULIC TORQUE REQUIREMENTS

HYDRAULIC TORQUE REQUIREMENTS

Refer to the following chart for torque values on all hydraulic hoses & fittings

Nominal O-Ring Face Seal End SAE O-Ring Boss End

SAE

Dash

Size

Thread

Size

Inch

Swivel Nut

Torque

LB-FT

-3

-4

-5

-6

-8

-10

-12

-14

-16

-20

-24

1 11/16-12

*

9/16-18

*

11/16-16

13/16-16

1-14

1 3/16-12

1 3/16-12

1 7/16-12

2-12

*

10-12

*

18-20

32-35

46-50

65-70

65-70

92-100

125-140

150-165

1 1/16-12

1 3/16-12

1 5/16-12

1 5/8-12

1 7/8-12

Ring face-seal-type end not defined for this tube size

Thread

Size

Inch

3/8-24

7-16-20

½-20

9/16-18

3/4-16

7/8-14

Str. Fittin

or Locknu

Torque

LB-FT

8-10

14-16

18-20

24-25

50-60

72-80

125-135

160-180

200-220

210-280

270-360

NOTE

Parts must be lightly oiled with hydraulic fluid

2

1-8 AMERICAN-LINCOLN

SMART

Page 9

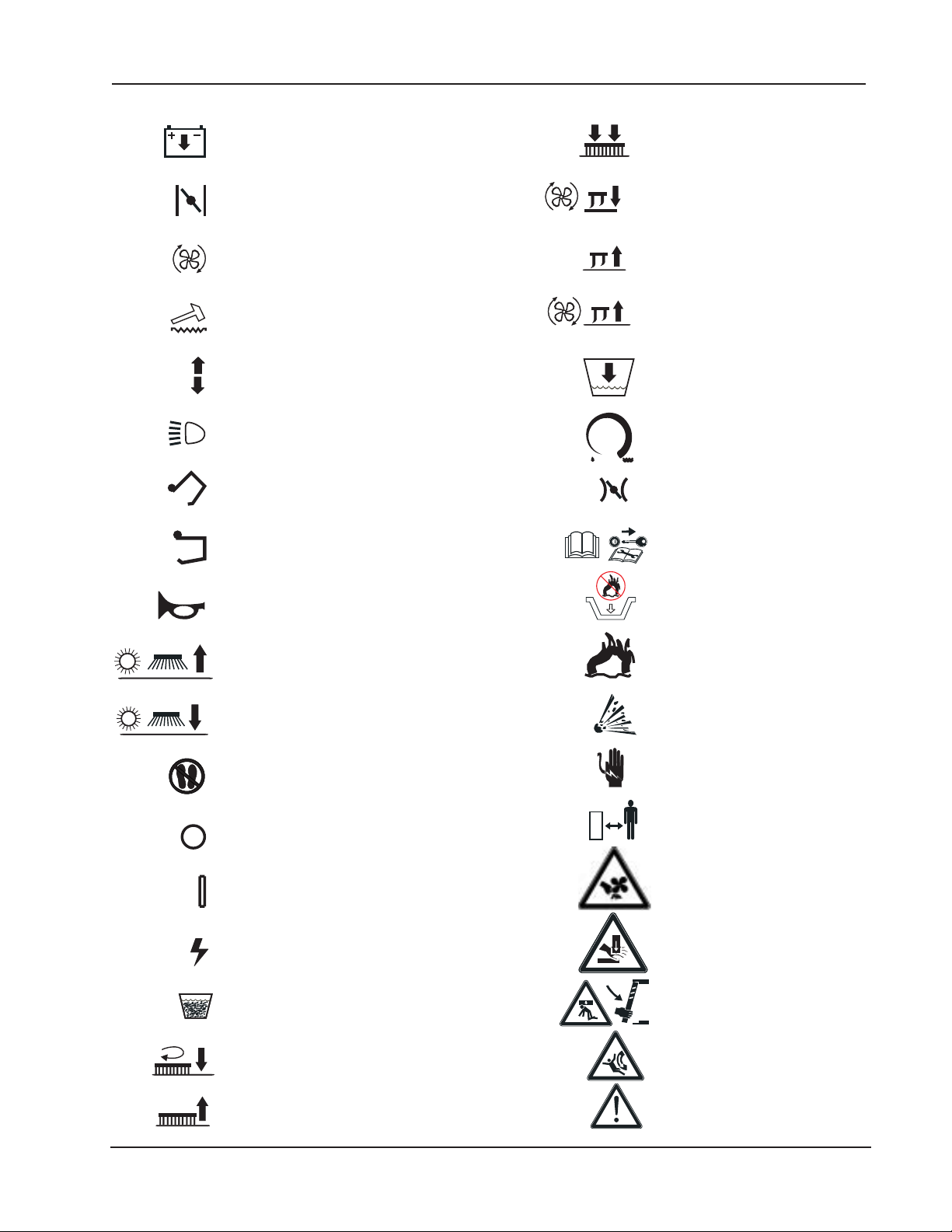

SYMBOLS

THESE SYMBOLS IDENTIFY CONTROLS, DISPLAYS/FEATURES, AND SAFETY SYMBOLS ON THE MACHINE.

Battery Charger

Choke

Fan On

Filter Shaker On

Forward/Reverse

Headlights

Hopper Dump

Hopper Return

Scrub Brush Down Heavy Pressure

Squeegee Down & Vacuum On

Squeegee Up & Vacuum Off

Squeegee Up & Vacuum On

Solution Tank Low

Solution Flow Control

Throttle

Read Machine Manual

Before Operating or Servicing

Horn

Main Broom & Side Broom Up

Main Broom & Side Broom Down

No Step

Off

On

Power

Recovery Tank High

No gas or combustibles in tank

Keep Away From Flames/

NO Smoking

Wear Eye Protection

Electrical Hazard

Stay Clear

Moving Fan Blade

Pinch Point/Crush Hazard

Cover or Hopper Could Close/

Engage Support

Scrub Brush Down & On

Scrub Brush Up and Off

Turn Key Off/Lock Wheel

Before Leaving Seat

WARNING! / ATTENTION!

AMERICAN-LINCOLN 1-9

SMART

Page 10

ORDERING PARTS

Parts may be ordered from ALTO distributors:

INTERNET

http://www.alto-online.com

ALTO HEADQUARTERS

Incentive International A/S

Kongens Nytorv 28

P .O. Box 2064

1013 Copenhagen K

Tel.: +45 72 18 10 00

Fax: +45 72 18 11 64

E-mail: incentive@incentive-dk.com

AUSTRIA

..

ALTO Osterreich GmbH

Metzgerstr. 68

5101 Bergheim/Salzburg

Tel.: +43 6624 5 64 00-14

Fax: +43 6624 5 64 00-55

E-mail: wap@salzburg.co.at

CROATIA

Wap ALTO Strojevi za ciscenje, d.o.o.

Siget 18a

10020 Zagreb

Tel.: +385 1 65 54 144

Fax: +385 1 65 54 112

E-mail: admin.wap@wap-sistemi.hr

CZECH REPUBLIC

ALTO Ceska Republika s.r.o.

Zateckych 9

14000 Praha 4

Tel.: +420 2 41 40 84 19

Fax: +420 2 41 40 84 39

E-mail: wap_p@mbox.vol.cz

Web: www.wap-alto.cz

FRANCE

ALTO France S.A.

B.P. 44, 4 Place d’Ostwald

67036 Strasbourg Cedex 2

Tel.: +33 3 88 28 84 00

Fax: +33 3 88 30 05 00

E-mail: info@alto-fr.com

GERMANY

ALTO Deutschland GmbH

Guido-Oberdorfer-StraBe 2-8

89287 Bellenberg

Tel.: +49 0180 5 37 37 37

Fax: +49 0180 5 37 37 38

E-mail: info@wap-online.de

GREAT BRITAIN

ALTO Cleaning Systems

(UK) Ltd.

Bowerbank Way

Gilwilly Industrial Estate, Penrith

Cumbria CA11 9BN

Tel.: +44 1 7 68 86 89 95

Fax: +44 1 7 68 86 47 13

E-mail: sales@alto-uk.com

NETHERLANDS

ALT O Nederland B.V.

Postbus 65

3370 AB Hardinxveld-Giessendam

Tel.: +31 18 46 77 20 0

Fax: +31 18 46 77 20 1

E-mail: info@alto-nl.com

SLOVENIA

Wap ALTO cistilni sistemi, d.o.o.

Letaliska 33

SLO-1110 Ljubljana

Tel.: +368 15 20 62 00

Fax: +368 15 20 62 10

E-mail: wap@siol.net

SLOWAKIA

Wap ALTO cistiace systemy s.r.o.

Remeselnicka 42

83106 Bratslavia-Raca

Tel.: +421 2 44 881 402

Fax: +421 2 44 881 395

E-mail: wap@gtinet.sk

Web: www.wap-alto.sk

SP AIN

AL TO Iberica S.L.

Calle de la Majada No. 4

28760 Tres Cantos - Madrid

Tel.: +34 91 8 04 62 56

Fax: +34 91 8 04 64 63

E-mail: info@alto-es.com

SWEDEN

ALT O Sverige AB

Aminogatan 18

431 04 Molndal

Tel.: +46 3 17 06 73 00

Fax: +46 3 17 06 73 41

E-mail: info@alto-se.com

..

DENMARK

AL TO Danmark A/S

Industrikvarteret

9560 Hadsund

Tel.: +45 7218 21 00

Fax: +45 7218 21 05

E-mail: salg@alto-dk.com

NORWAY

ALT O Norge A/S

Bjornerudveien 24

1266 Oslo

Tel.: +47 22 75 17 70

Fax: +47 22 75 17 71

E-mail: info@alto-no.com

1. Use the model number, catalog number, and serial number when ordering.

2. Give the part number, description, and quantity of parts needed.

3. Give shipping instructions for either freight, UPS, or parcel post.

MACHINE CATALOG NUMBERS

505-320 SMART (40”) SWEEPER/SCRUBBER

505-321 SMART (46”) SWEEPER/SCRUBBER

505-322 SMART (40”) SWEEPER/SCRUBBER W/ DUST CONTROL

505-323 SMART (46”) SWEEPER/SCRUBBER W/ DUST CONTROL

1-10 AMERICAN-LINCOLN

SMART

Page 11

SAFETY PRECAUTIONS

ELECTRICAL HAZARD - Shocks can

cause serious personal injury

Disconnect battery before working

in this area

Repairs must be performed by

authorized personnel only

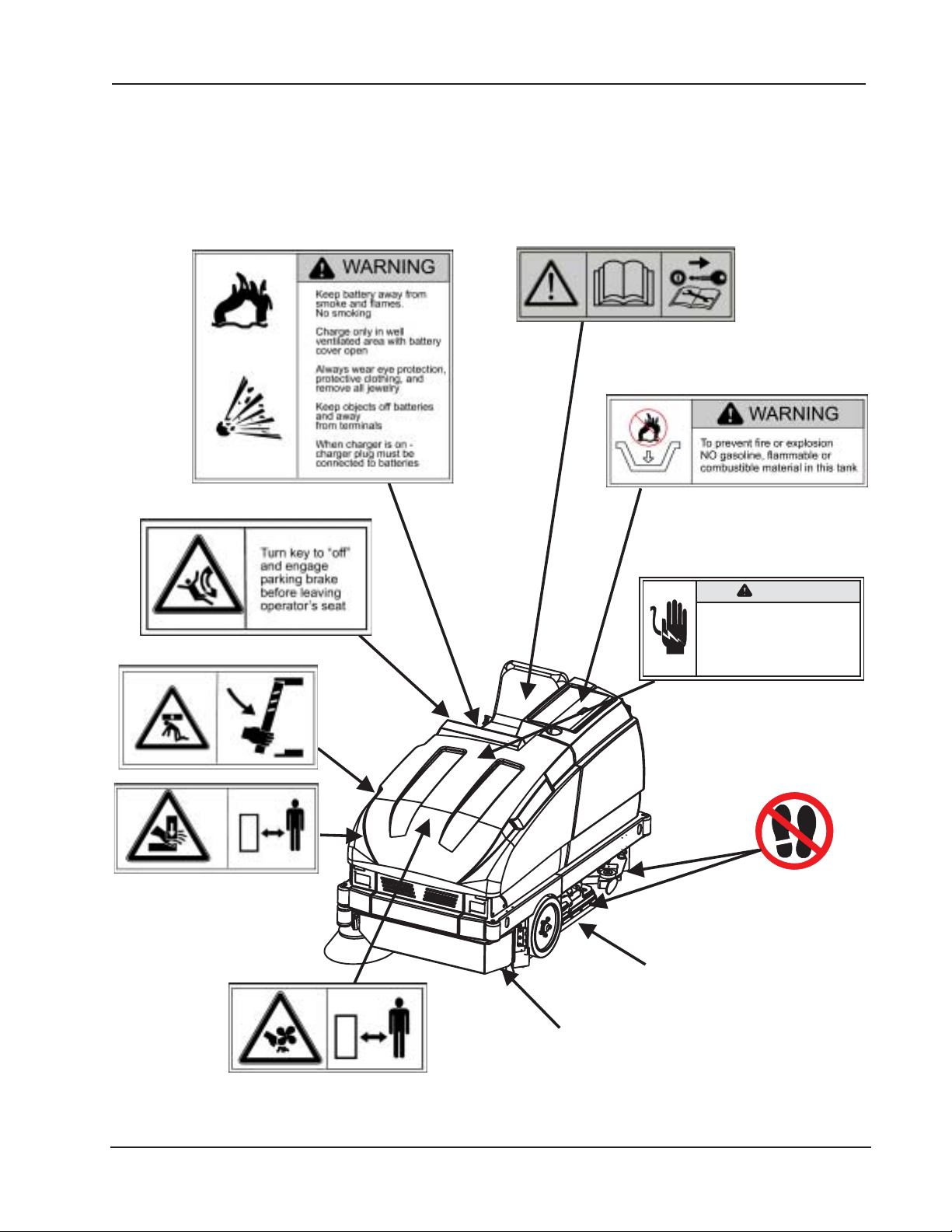

WARNING

The following safety labels are mounted on the machine

in the locations indicated. If the labels become damaged

or illegible replace with identical label.

Scrub deck presents hazard

for crushing, entanglement,

friction and abrasion

Dust Control Motor presents

hazard for shearing and cutting

Broom Chamber presents

hazard for entanglement,

friction and abrasion

AMERICAN-LINCOLN 1-11

SMART

Page 12

SAFETY PRECAUTIONS

HAZARD SERIOUSNESS LEVEL

Signal words (DANGER, WARNING and CAUTION) are used to identify levels of hazard seriousness. The

degree of severity is based on the likely consequences of human interaction with the hazard.

DANGER

T o warn of immediate hazards which will result in severe personal injury or death.

WARNING

T o warn of hazard or unsafe practices which could result in severe personal injury .

CAUTION

T o warn of hazards or unsafe practices which could result in minor personal injury .

A TTENTION

T o warn of unsafe practices which could result in extensive equipment damage.

NOTE

T o give important information or to warn of unsafe practices which could result in equipment damage.

For the safe operation of this machine, read and understand all WARNINGS, CAUTIONS AND NOTES.

PERSONAL SAFETY

• Read this manual carefully . The following information signals potentially dangerous conditions to the

operator or equipment. Know when these conditions can exist then take necessary steps to train

machine operating personnel.

• Dress appropriately; loose clothing, jewelry and other accessories may get caught in the machine and

cause physical injury .

• Wear OSHA/NIOSH protective eye wear or prescription glasses to protect eyes.

• Wear appropriate gloves when filling and/or draining tanks.

• Before operating machine, test brake mechanism, lights and back up alarm (if applicable).

• Observe maintenance schedule guidelines to assume optimal safe operation of the machine.

• Be aware of pinch pints that exist on the machine.

• Do not operate machine if you are tired, upset, ill, on medication or intoxicated.

• Be completely aware of your surroundings. STOP, LOOK, and LISTEN for other employees walking in

or around your cleaning area.

MACHINE SAFETY

• Operator must be properly trained to operate machine.

• Read this manual before operating machine

• Familiarize yourself with all components and safety features.

• Do not operate machine unless it is completely assembled.

• Do not use machine other than intended use.

• Report damages or maintenance problem immediately . Do not use machine until it has been repaired.

• Repairs should be done by authorized personnel.

• For storage, keep machine in a building.

• This machine is not at tow truck and should not be used for towing.

• Do not use this machine as a step or furniture.

• Do not operate machine on public highways, gravel, sand, grass and other unsafe surfaces.

1-12 AMERICAN-LINCOLN

SMART

Page 13

SAFETY PRECAUTIONS

• Be careful when operating the machine on a ramp or incline. Do not operate machine on incline greater

than 8° or longer than 100’. Always move slowly on a ramp. Do not turn this machine on a ramp.

• Do not stop and leave this machine on a ramp. Always stop the machine on a level surface, put the

power switch in the on position.

• T o prevent injury, and damage to the machine, do not lift the machine or move it to an edge of a stair or

loading dock.

• Turn off machine when unattended, filling, fueling or doing maintenance on machine (if applicable).

When carrying out maintenance, pull the key .

• Do not operate machine near flammable materials, fire or explosion may occur.

• Solution or recovery tank should not be filled with fuel or chemicals.

• Read label on cleaning solutions to verify it is safe for machine.

• Use a cleaning concentrate recommended by the chemical manufacturer.

• Water solutions or cleaning materials used can leave wet areas on floor surfaces causing dangerous

conditions for the operator or other persons. Always put CAUTION signs near area you are cleaning.

• Use care when reversing machine.

• Always empty the solution tank and recovery tank before doing maintenance.

• Unplug the battery first to prevent possible injury when servicing a machine.

• Lead acid batteries generate gases, which can cause an explosion. Keep sparks and flames away

from batteries. NO SMOKING . Charge batteries only in area with good ventilation.

• Always wear eye protection and protective clothing when working near batteries. Remove all jewelry .

• Do not put tools or other metal objects across the battery terminals, or the tops of batteries.

• Keep electrical parts of the machine dry .

• Make sure that all labels, decals, warnings, cautions and instructions are fastened to the machine.

• Get new labels and decals from American-Lincoln.

• Do not use machine to pick up dusts hazardous to health.

• Only use accessories according to this instruction manual. Use of other accessories may impair

safety.

AMERICAN-LINCOLN 1-13

SMART

Page 14

SPECIFICATIONS

CLEANING P A TH

Scrubbing 40 in. (101 cm)

46 in. (1 17 cm)

Sweeping 46in. (117 cm)

Edge Cleanin g 6 in. (15 cm) Right Side 46in. (1 17 cm) only

TRANSPORT SPEED 0-4.6 MPH (0 - 7.4kph)

OPERA TING SPEED 0-2.7 MPH (0 - 4.3kph)

POWER SUPPL Y (1) 36 Volt Wet Battery, 720 A H

For machine to operate properly , voltage reading should fall within 32-40 vdc.

Guaranteed power sound level: LWA max = 103 dBA

(Operator) Sound Pressure Level = 84.8

CHARGER 240 V ac, 3-phase, 60 Hz, 36 Vdc, 150 A

STEERING Rack & Pinion 90°-90° Hyd. Assist

Adjustable S teering Column

TURNING RADIUS

Left 59 in. (150 cm)

Right 59 in. (150 cm)

Aisle “U” Turn 87 in. (221 cm)

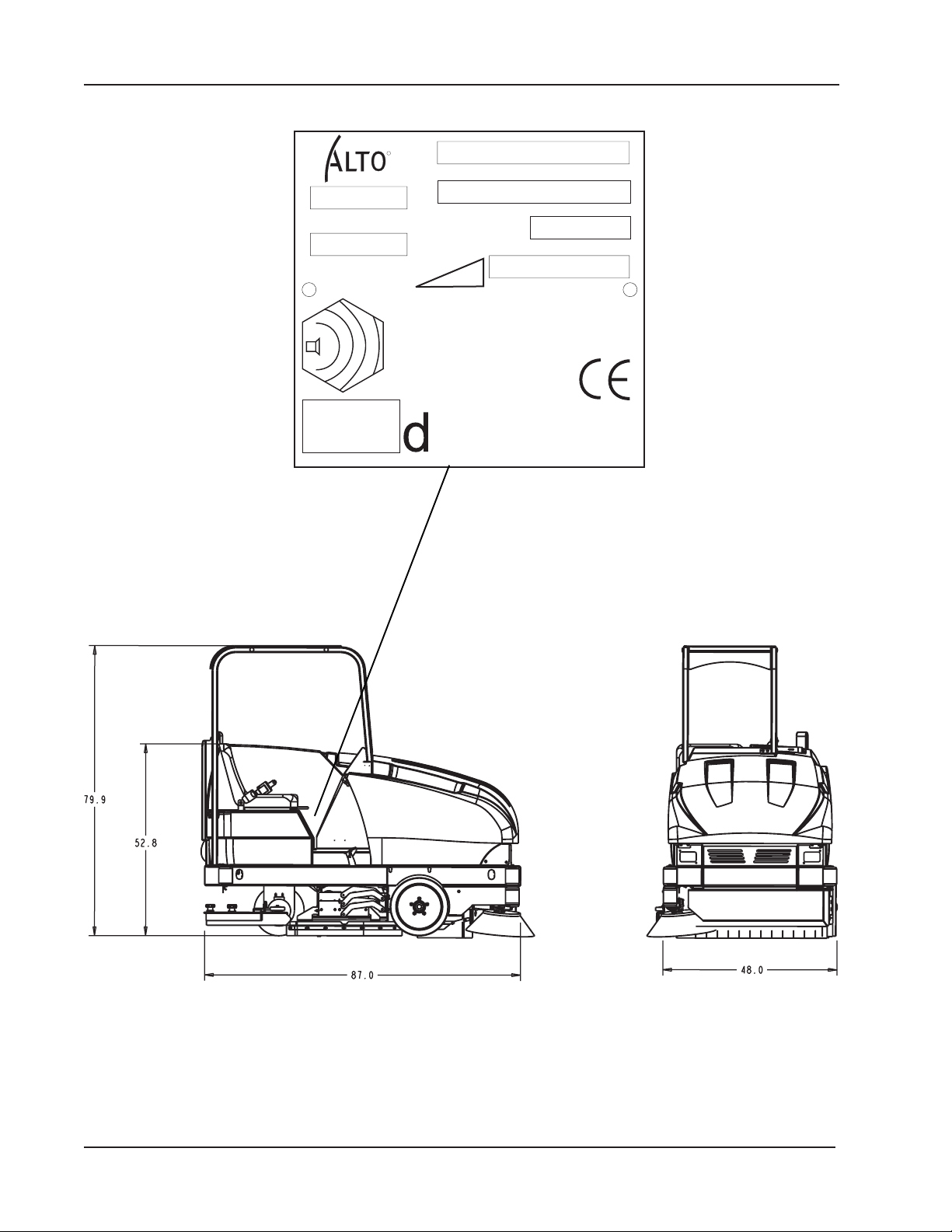

DIMENSIONS

Length 87 in. (221 cm)

Width 46 in. (1 16.8 cm)

Height 52 in. (132 cm)

Height w/Overhead Guard 79 in. (200.6 cm)

Wheel Base 37.6 in. (95.5 cm)

WEIGHT

St andard Machine (Battery) 1700 lbs. (765 kg.) without battery

VIBRA TION LEVELS

Steering Wheel <2,5m/s2

Seat <2,5m/s2

TIRES

Front (Battery) Solid Urethane Two (2)16 in (41cm) x 3.75 in (8.26 cm)

Rear (Battery) Solid Rubber One (1)16 in (41 cm) x 4.00 in (10.16cm)

RAMP CLIMBING

Transporting 8°

MAIN BROOM

One piece plastic core disposable type. Broom position can be set to “restricted down” or

“free floating”.

720 Ah battery 1990 lbs. (896 kg)

Length 36 in (91.4 cm)

Diameter 10 inches (25.4 cm)

Optional Bristle T ype Nylon (High density)

Proex

Nylon Eight (8) Row

SIDE BROOM

Side Broom Size 16 inches (40.6 cm) Diameter

1-14 AMERICAN-LINCOLN

SMART

Page 15

INSTRUMENTS AND CONTROLS

Main/Side Broom Switch Key Switch

Headlight/T aillight Switch (option) Hour Meter

Squeegee Switch Recovery High Light

3 Position Scrub Deck Switch Dust Control Switch (with certain models)

Horn Button Solution Low Light

Solution Control Knob ESP (Option)

Hopper Up/Down Switch Filter Shaker Switch

Hopper Open Light Squeegee and V acuum Wand (Option)

SCRUBBING SYSTEM

Brush Size-46” (1 16.84 cm) Three (3) 16” (40.6cm) Diameter

Brush Size-40” (101.4 cm) T wo (2) 20” (51cm) Diameter

Brush Lift Hydraulic Actuator

Scrub Pressure Normal: 140 lbs. / Heavy: 200 lbs.

SQUEEGEE

Rear Accu-Trac™ 46 in(1 16.8 cm) Swing, break away ,

Side 26 in (66 cm) Easy Change

T ANKS

Solution T ank 55 Gallons (208 liter)Polyethylene

Recovery T ank 55 Gallons (208liter)Polyethylene

Solution Metering V ariable to 3.0 GPM (11.4 lpm)

Drain Hose 48 in (122 cm)

Clean Out Port 5.7 in (14.5 cm) heavy debris

SPECIFICATIONS

w/no tool squeegee replacement

HOPPER

Capacity 2.5 cu.ft.(71liter)

DUMP AND LIFT

Dump Height 14 in (35.6 cm.)

SYSTEM FLUID CAP ACITIES

Hydraulic System 4.7 Gallons (17.79 Liters)

OPTIONAL EQUIPMENT

Back-Up Alarm Headlight/Taillights ESP System

Overhead Guard Squeegee Wand Fire Extinguisher

Spray and Vac Wand Linatex Squeegee 720 AH Battery

Black Nylon Brush Polyethelyne Panel Filter Arm Rest (RH only)

Polypropylene Brush Smart Cart (Battery Roll-Out Cart) Seat Belt

Clean Grit Brush Strobe Light (Amber) W/O OHG

Supergrit Brush Strobe Light (Amber) W/OHG

WARRANTY

Our general conditions of business are applicable with regard to the guarantee. Subject to change as a

result of technical advances. The guarantee is invalidated if the machine is not operated in accordance with

these instructions or otherwise abused. The guarantee is invalidated if the machine is not serviced as

described.

AMERICAN-LINCOLN 1-15

SMART

Page 16

SPECIFICATIONS

MACHINE DAT A

R

MACHINE NAME

MODEL

WEIGHT

IP X3

LWA

DATE / SERIAL NUMBER

RATED POWER

MAX OPERATING SLOPE

B

1-16 AMERICAN-LINCOLN

SMART

Page 17

Fig 1

MACHINE PREPARATION

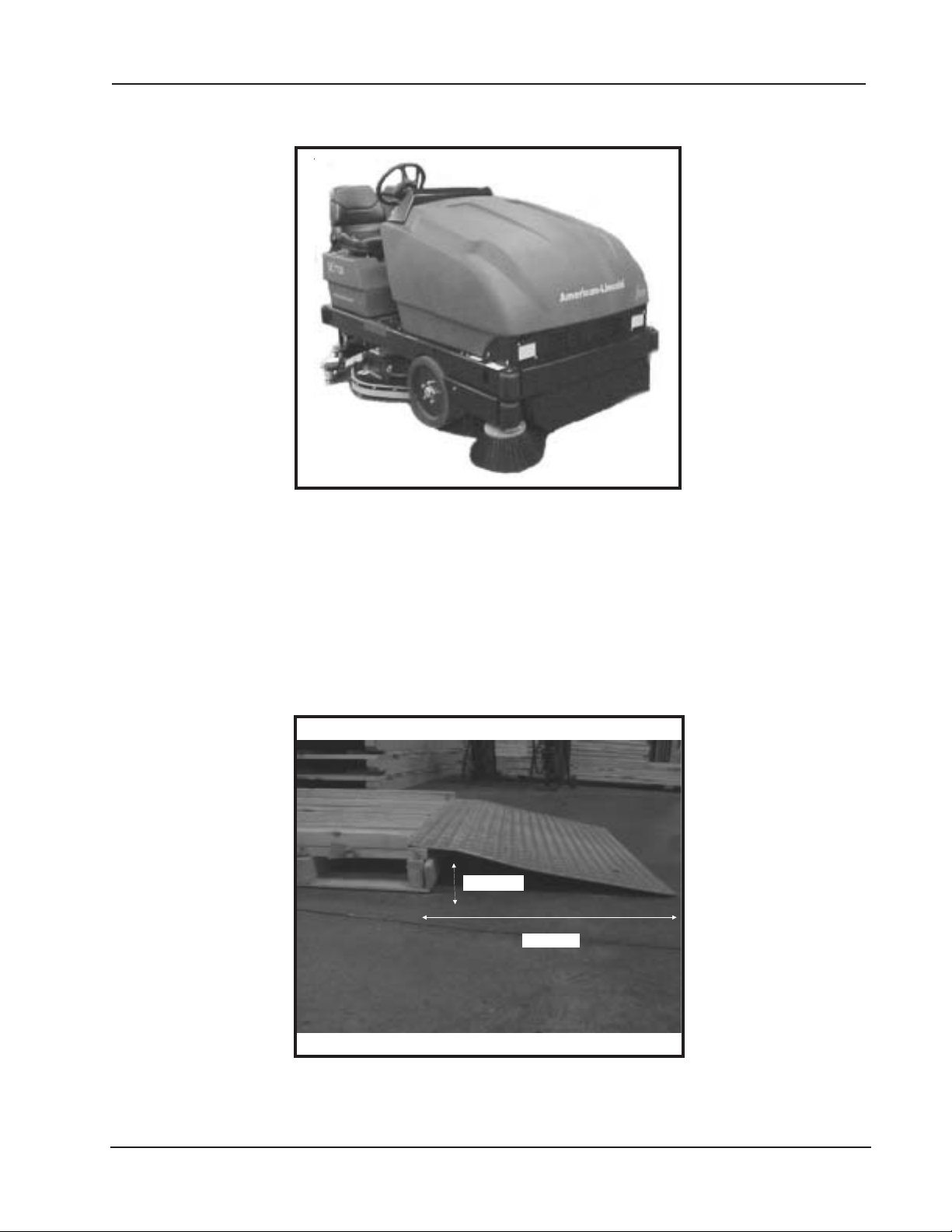

Y our SMART battery machine has been shipped complete, but do not attempt to operate without reading the

following instructions:

UNP ACKING AND ASSEMBLING MACHINE

The SMART is shipped on a pallet and held in place with wooden block to stop the machine from moving.

1) Remove wooden blocks holding machine in place.

2) Position a 1 1° and 48” ramp on base of pallet.

11 DEGREE

48 INCHES

Fig 2

AMERICAN-LINCOLN 1-17

SMART

Page 18

MACHINE PREPARATION

3) Push machine down the ramp onto a flat surface.

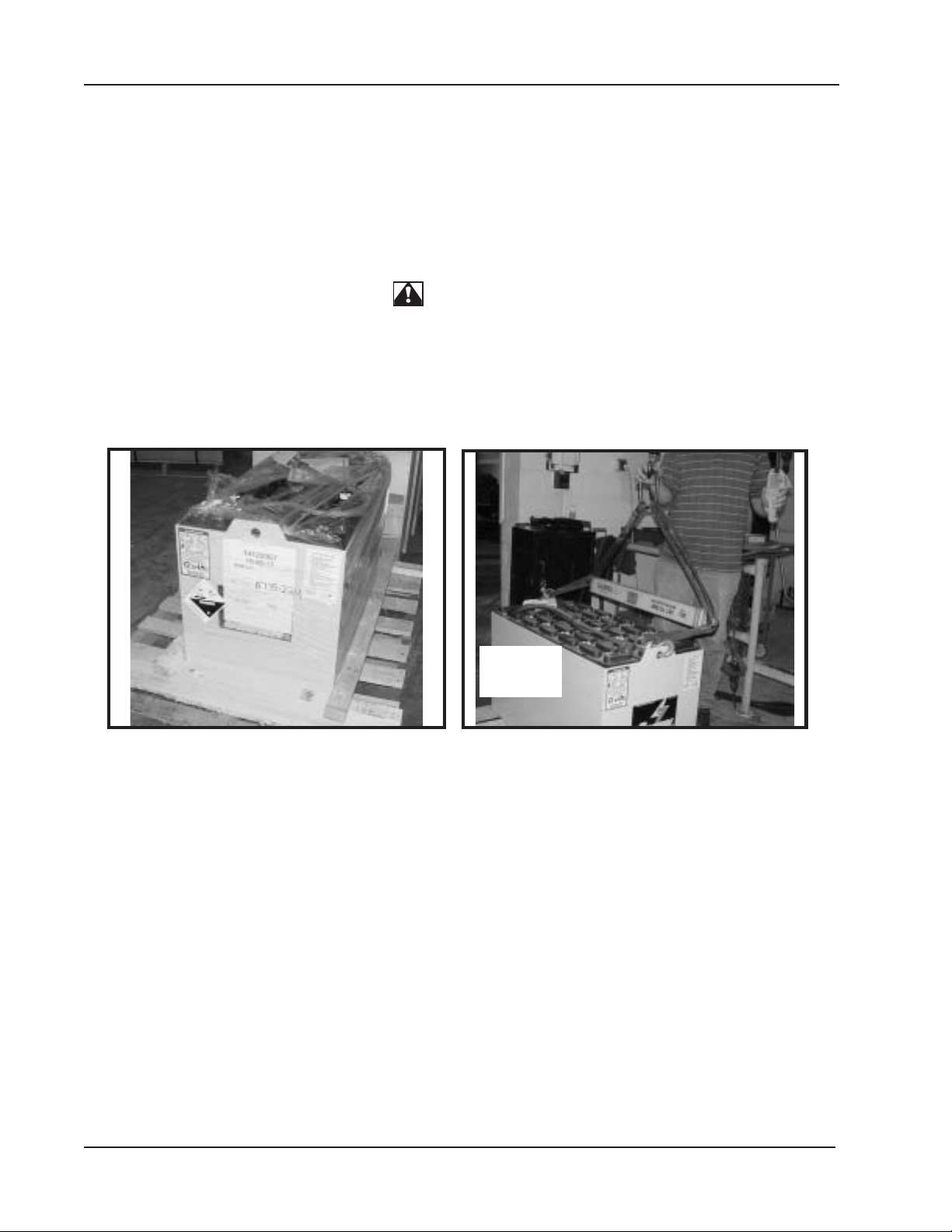

4) Install battery .

-Turn the key to the “O” position

-Lift the hood up and pull the battery lever up to the right.

-Use a battery lifting device with a 2000 LB. (907KG) capacity to place the battery into the battery tray .

-Push battery lever down to the left to lock the battery into place.

-Plug the battery power connector into the machine power connector.

-Lower the hood into place.

5) Charge battery as shown in the manual. Read battery manufacturer literature for battery care and

maintenance.

WARNING

Do not charge batteries on a concrete grounded surface. Hydrogen gas is formed during the charging

operation and is explosive. Only charge batteries in a well ventilated area with the lid open. Avoid

any smoking, open flame, or electrical sparks.

USE A 2000 LB.

(907 KG) LIFTING

DEVICE TO

INSTALL BATTERY

Fig 3 Fig 4

UNP ACKING BATTER Y

The battery is shipped separately on a pallet wrapped in plastic as shown in figure 3. Remove the plastic and

use a 2000 LB. (907KG) capacity lifting device to lower the battery into the battery compartment as shown in

figure 4.

1-18 AMERICAN-LINCOLN

SMART

Page 19

BATTERY LEVER

MACHINE PREPARATION

LOCK BATTERY IN PLACE WITH LEVER

Fig 5

CONNECTING BATTERY

BATTERY POWER CONNECTOR

Fig 7

BA TTERY INST ALLA TION

1. Lift the machine front cover .

2. Rotate the battery lever to the right.

3. Lower the battery into place using a 2000 LB. (907 KG) capacity lifting device.

4. Rotate the battery lever to the left to lock the battery into place.

5. Connect battery wires according to manufacturer’s direction.

6. Connect the battery power connector to the machine power connector.

7. Lower the machine front cover into place.

Fig 6

MACHINE POWER CONNECTOR

Fig 8

WARNING

Do not leave charged batteries on concrete surface, they will discharge.

AMERICAN-LINCOLN 1-19

SMART

Page 20

CONTROLS

1

2

7

3

4

5

12

13

6

18

11

8

10

9

14

20

1. High recovery light.

2. Low solution light

3. Hopper open light.

4. Light switch.

5. ESP switch.

6. S pray Vac Wand switch.

7. Scrub brush switch.

8. Squeegee switch.

9. Main side broom switch.

10. Filter shaker/Dust control switch.

1 1. Hopper switch.

12. Battery condition meter/Hour meter.

13. Circuit breakers.

14. Solution flow knob.

15. Parking Brake.

16. Steering wheel adjustment lever .

17. Foot throttle.

18. Forward/Reverse switch.

19. Key switch.

20. Horn

Figure 9

15

16

17

19

1-20 AMERICAN-LINCOLN

SMART

Page 21

KEY SWITCH

Figure 10

KEY SWITCH

The keyed ignition switch is located on the ioperator’s console as shown in figure 10.

CONTROLS

The “OFF” position (O position) will shut off the machine. The IGN/ON position (I position) provides power to all

machine systems and accessories.

FORWARD

REVERSE

SWITCH

Figure 1 1

FORW ARD / REVERSE SWITCH

The forward/reverse switch is located on the operator’s console as shown in figure 11. Pressing the upper half

of the forward/reverse switch will result in the machine moving forward when the foot throttle is depressed.

Pressing lower half of the forward/reverse lever switch will result in the machine moving backward when the foot

throttle is depressed.

AMERICAN-LINCOLN 1-21

SMART

Page 22

CONTROLS

BATTERY CONDITION METER

Figure 12

BA TTERY CONDITION METER

The battery condition meter is located on the instrument panel as shown in figure 12. The condition meter

indicates the level of charge in the batteries. The batteries are sufficiently charged when all of the LED’s are

illuminated amber as shown on the ramp illustration. Charge the batteries when one red LED is illuminated on

the left at the bottom of the ramp diagram and the scrub brushes stop. Do not operate the machine.

HOUR METER

Figure 13

NOTE

To reengage, the key must be returned to the “OFF” position.

HOUR METER

The hour meter is located on the instrument panel as shown in figure 13. Tthe diplay will show the total hours

the machine has been in operation. The meter is activated when the key switch is placed in the ignition position.

The meter can be used to determine when maintenance should be done on the machine.

1-22 AMERICAN-LINCOLN

SMART

Page 23

CONTROLS

LIGHT

Figure 14

HEADLIGHT/T AILIGHT SWITCH (Optional)

The light switch is located on the instrument panel as shown in figure 14. By pressing on the lower half of the

switch the headlights and taillights will be activated. Pressing the upper half of the switch will turn off the lights.

HOPPER INDICATOR LIGHT

Figure 15

HOPPER OPEN LIGHT WARNING

The hopper open light switch is located on the instrument panel as shown in figure 15. When the hopper is

open, the light is illuminated the broom and the dust control fan will stop.

AMERICAN-LINCOLN 1-23

SMART

Page 24

CONTROLS

FILTER SHAKER

Figure 16

FIL TER SHAKER SWITCH (Only models with dust control)

The filter shaker switch is located on the instrument panel as shown in figure 16. By pressing and holding in

the upper half of the switch, it will activate the filter shaker motors for 20 to 30 seconds. Releasing the switch,

returns to the off position.

The dust control fan will stop when the filter shaker has been activated. The filter shaker will only operate with

the hopper in the “DOWN” position.

DUST CONTROL OFF

DUST CONTROL ON

Figure 17

DUST CONTROL SWITCH

The dust control switch is located on the instrument panel as shown in figure 17. To turn on the dust control

system for normal sweeping, press the lower half of the switch.

WARNING

Turn the dust control switch to the center “OFF” position while wet sweeping. Water will damage the

filter and cause premature filter failure.

1-24 AMERICAN-LINCOLN

SMART

Page 25

CONTROLS

SCRUB BRUSHES

Figure 18

SCRUB BRUSH SWITCH

The scrub brush switch is located on the left of the instrument panel as shown in figure 18. Pressing the top

half of the switch raises the scrub deck and turns off the brushes. The middle switch position lowers the

brushes to the normal down position for scrubbing. Pressing the lower half of the switch lowers the scrub deck

to the heavy down position, supplying additional downward pressure for extremely dirty surfaces.

NOTE

Lowering the scrub deck does not turn on the brushes. The brushes turn on automatically when the

machine moves forward or reverse.

SQUEEGEE

Figure 19

SQUEEGEE SWITCH

The squeegee switch is located on the the instrument panel as shown in figure 19. Pressing the lower half of

the switch lowers the squeegee and activates the squeegee vacuum. Pressing the upper half of the switch will

turn off the squeegee vacuum and raise the squeegee. In the middle position the switch will raise the

squeegee. In this position the vacuum remains on to allow vacuuming the water that is left in the squeegee

recovery hose. This prevents water from dripping on the floor with the squeegee raised. If the squeegee is

lowered and the direction of the machine is reversed (activated by the FWD/REV pedal) the squeegee will

automatically raise. Moving forward the squeegee will automatically return to the lowered position.

AMERICAN-LINCOLN 1-25

SMART

Page 26

CONTROLS

LOW SOLUTION LIGHT

Figure 20

LOW SOLUTION LIGHT

The low solution warning light is located on the instrument panel as shown in figure 20. The low solution

warning light illuminates when the solution tank is empty , marking the end of the scrubbing cycle.

HIGH RECOVERY LIGHT

Figure 21

HIGH RECOVERY LIGHT

The high recovery warning light is located on the instrument panel as shown in figure 21. The light will illuminate

approximately 5 minutes before the recovery tank is full, giving ample time to complete the scrubbing cycle,

before the mechanical float shuts off the vacuum to the recovery tank.

1-26 AMERICAN-LINCOLN

SMART

Page 27

CONTROLS

HOPPER

Figure 22

HOPPER LIFT SWITCH

The hopper lift switch is located on the instrument panel as shown in figure 22. The switch controls the

operation of the hopper lift system. To raise the hopper for dumping, press and hold the lower half of the

switch until the hopper reaches the desired height, then release. To close the hopper press in and hold the

upper half of the switch until the hopper closes completely then release.

WARNING

To prevent the hopper from closing while doing maintenance lock the hopper in the open position into place

with the safety arm.

MAIN BROOM

Figure 23

SIDE BROOM and MAIN BROOM SWITCH

The side broom and main broom switch is located on the instrument panel as shown in figure 23. By pressing

in the upper half of the switch, the side and main broom are raised and turned off. To lower and turn on both

brooms, press the lower half of the switch.

AMERICAN-LINCOLN 1-27

SMART

Page 28

CONTROLS

SPRAY VACCUM

Figure 24

SPRA Y AND V AC W AND SWITCH (Optional)

The spray and vac wand switch is located on the instrument panel as shown in figure 24. Pressing the bottom

half of switch turns on the vacuum motor and the solution pump. Pressing the top half of the switch turns the

vacuum motor and solution pump off.

ESP

Figure 25

ESP SWITCH (Optional)

The ESP switch is located on the instrument panel as shown in figure 24. The ESP switch transfers water from

the recovery tank through a filter and into the solution tank. When the switch is in the down position the pump

will operate when the high recovery light is illuminated. Clean the recovery tank when the tank is emptied.

NOTE

Do not place clean water in the recovery tank when using ESP option, the solution tank could become overfilled

during operation.

1-28 AMERICAN-LINCOLN

SMART

Page 29

CONTROLS

SIDE BROOM ADJUSTMENT KNOB

Figure 26

SIDE BROOM ADJUSTMENT

The side broom adjustment knob for changing the sweep height to compensate for broom wear, is located in

front of the machine to the right of the dust control filter as shown in figure 26. Turning the knob to the left

(counterclockwise) will lower the side broom.

MAIN BROOM ADJUSTMENT KNOB

Figure 27

MAIN BROOM ADJUSTMENT

The main broom adjustment knob for changing the sweep height to compensate for broom wear, is located in

front of the machine to the right of the dust control filter as shown in figure 27. Turning the knob to the left

(counterclockwise) will lower the main broom.

AMERICAN-LINCOLN 1-29

SMART

Page 30

CONTROLS

SOLUTION FLOW KNOB

Figure 28

SOLUTION FLOW KNOB

The solution flow knob is located on the instrument panel as shown in figure 28. Turning the knob clockwise will

increase the flow of solution and water. The farther the solution control knob is turned the heavier the flow of

water and solution will be. Turning the knob counterclockwise will decrease the flow of the water and solution.

T o turn the water and solution of f turn the knob all the way counterclockwise.

NOTE

For best results, discontinue application of solution 10 feet before stopping or making a 90° or 180°

turn.

HORN BUTTON

Figure 29

HORN BUTTON

The horn button is located on the instrument panel as shown in figure 29. The horn button is always active.

Pressing the horn button will sound the horn.

1-30 AMERICAN-LINCOLN

SMART

Page 31

CONTROLS

FOOT THROTTLE

Figure 30

FOOT THROTTLE

The foot throttle is located to the right of the brake pedal on the floor of the operator’s compartment as shown in

figure 30. This pedal controls the machine travel speed. Press the forward/reverse switch to chose the travel

direction, and then press down on the foot throttle to move set the machine in motion. Increase the foot

pressure to increase the travel speed.

PEDAL LOCK

BRAKE PEDAL

Figure 31

P ARKING BRAKE

The parking brake is located on the floor of the machine left of the foot throttle as shown in figure 31. To set the

parking brake, press down on the foot pedal and the press down the lock. To unlock the parking brake, push

down on the upper portion of the foor pedal and release.

AMERICAN-LINCOLN 1-31

SMART

Page 32

CONTROLS

SEAT ADJUSTMENT LEVER

Figure 34

SEA T POSITION ADJUSTMENT

The seat position adjustment lever is located on the front of the seat to the left as seen in figure 34. The lever is

spring loaded to the lock position. To adjust the seat, push the lever to the left and move the seat to the desired

position and then release the lever to lock the seat into place.

SAFETY FEA TURES

SEA T SAFETY SWITCH - Machine will not move and p arking brake will set if this switch is not activated.

SPEED INTERLOCK - Maximum machine speed will be reduced while scrub brushes are in use.

BRUSHES OFF IN NEUTRAL - Scrub brushes automatically disengage when machine is idle.

AUTOMA TIC RECOVERY V ACUUM SHUT -OFF - V acuum fans will shut down when recovery tank is full.

1-32 AMERICAN-LINCOLN

SMART

Page 33

OPERATING INSTRUCTIONS

NOTE

Before starting the engine, perform the pre-start checklist.Before starting the engine, perform the pre-start

checklist.

PRE-START CHECKLIST

Check hydraulic fluid level.

Check all systems for leaks.

Check brakes and controls for proper operation.

Check broom patterns.

Check hydraulic fluid level.

Check hydraulic connections for leaks.

Check brakes and controls for proper operation.

Check broom pattern.

Check to ensure that all covers, panels and access doors are securely closed.

SOLUTION AND RECOVERY

TANK COVER

Figure 35

SOLUTION TANK

Figure 36

TO FILL SOLUTION T ANK

Open the solution lid located on the top left side of the machine as shown in figure 36. Fill tank with 55 gallons

of water and the correct mixture of American Lincoln Commercial cleaner for the job on hand. Close the

solution tank.

AMERICAN-LINCOLN 1-33

SMART

Page 34

OPERATING INSTRUCTIONS

TO ST ART MACHINE

Turn key to “I” position.

TO TRANSPORT MACHINE

1. Make sure the brushes and squeegees are in the up or raised position with all other controls in the off

position.

2. Release the parking brake.

3. Push the forward/reverse switch to desired position (up for forward and down for reverse)

4. Push down on the foot throttle to obtain desired travel speed.

5. Release the foot throttle to slow down or stop when on a flat surface. To slow the machine when

decending down an inclined surface reduce foot pedal pressure.

NOTE

The pedal proportional braking sytem is designed to regulate machine speed according to the foot thottle

position. This sytem is designed to bring the machine to a stop in controlled manner. When driving down an

inclined surface, reduce foot pedal pressure rather than releasing the foot throttle. This will provide a controlled

stop and prevent the drive wheel from locking.

WARNING

Do not turn the steering wheel sharply when the machine is in motion. The sweeper is very

responsive to movement of the steering wheel. Do not make sudden turns.

1-34 AMERICAN-LINCOLN

SMART

Page 35

REAR SQUEEGEE

Figure 38

TO BEGIN THE CLEANING OPERA TION

1. Select the operating mode

NORMAL = ESP

2. Lower brushes to the desired position.

SCRUB DECK = NORMAL RANGE OR HEA V Y

3. Place the squeegee switch in the lower position.

SQUEEGEE BLADE = LOWER

4. Move solution control knob to the desired setting and begin operation.

OPERATING INSTRUCTIONS

SCRUBBING THE A VERAGE FLOOR WITH LIGHT TO MEDIUM SOILAGE

In this operation, cleaning is accomplished in one pass, with simultaneous solution feed, scrubbing and dirty

water pick up. The rate of solution feed and the speed of travel required will vary with floor condition. This

knowledge will come with operator experience.

AMERICAN-LINCOLN 1-35

SMART

Page 36

SOLUTION

CONTROL

VALVE

OPERATING INSTRUCTIONS

SOLUTION

TANK

RECOVERY

TANK

STRAINER

SOLUTION

CONTROL

VALVE

SCRUB

BRUSH

SQUEEGEE

FLOOR CONTACT

Fig. 39

THE NON-RECYCLING OR ST ANDARD SCRUBBING MODE

During the scrubbing process, detergent solution water from the solution tank is fed to the solution line. There it

is fed to the floor where three disc scrubbing brushes work to dislodge soil. Af ter scrubbing, the dirty solution is

vacuumed from the floor and discharged into the containment chamber in the forward portion of the recovery

tank, where a system of baffles helps to clarify the solution.

Sensors in each tank will indicate, by lights on the control panel, when the water in the solution tank is too low

or when the water in the recovery tank is too high.

1-36 AMERICAN-LINCOLN

SMART

Page 37

OPERATING INSTRUCTIONS

SOLUTION

TANK

STRAINER

SOLUTION

PUMP

RECOVERY

TANK

STRAINER

SOLUTION

CONTROL

VALVE

SCRUB

BRUSH

SQUEEGEE

FLOOR CONTACT

Fig. 40

ESP OPERA TING MODE

During the scrubbing process, filtered water from the solution tank is fed to the solution line, where it combines

with detergent. This mixture is then fed to the floor where two or three disc scrubbing brushes work to dislodge

soil. Af ter scrubbing, the dirty solution is vacuumed from the floor and discharged into the recovery tank. At

intervals, a float switch activates the recycling pump, which sends filtered solution from the recovery tank to the

solution tank.

AMERICAN-LINCOLN 1-37

SMART

Page 38

/000

SIDE AISLES

OPERATING INSTRUCTIONS

MAIN AISLE

P4134

SCRUBBING P ATH

· Scrub in straight paths. Do not bump posts. Do not scrape the sides of the machine.

· When the machine is in motion, do not push the directional/speed control pedal all the way forward.

· Plan your sweeping and scrubbing in advance. Try to arrange long runs with minimum stopping and

· Pick up oversize debris before sweeping.

· Allow a few inches of overlap of sweep and scrub paths. This will eliminate leaving dirty patches.

· Allow a few inches of overlap of sweep and scrub paths. This will eliminate leaving dirty patches.

· Don’t turn steering wheel to sharply when machine is in motion. The machine is very responsive to

· Try to follow as straight a path as possible. A void bumping into posts or scraping the sides of the

1

This is the same as starting in “high” and will put a strain on the motor and drive system.

starting. Sweep debris from narrow aisles out into main aisle ahead of time. Do an entire floor, or

section at on time.

movement of the steering wheel; so avoid sudden turns.

machine.

SIDE AISLES

Fig. 41

· When placing the machine in motion, avoid slamming the directional control pedal all the way

forward suddenly. This is equivalent to starting out in “HIGH” and puts needless strain on the drive

system. Periodically , turn the sweeping broom end for end to prevent the bristles from “settling” in

one direction.

TO STOP THE CLEANING OPERA TION

Discontinue the cleaning operation when the low solution light or the high recovery light illuminates, this

indicates the solution tank is empty or recovery tank is full. Discontinue the scrubbing cycle, put all controls in

the forward position for transport and drive to the drain area.

NOTE

After stopping, perform these post operation checks.

1-38 AMERICAN-LINCOLN

SMART

Page 39

POST OPERA TION CHECKLIST

Check Battery Condition and recharge, if necessary.

1. Check all flaps for wear , damage and adjustment.

2. Drain and clean recovery tank.

3. Clean recovery tank screen and float.

4. Check scrub brushes for wear or damage.

5. Check rear and side squeegee for wear, damage and adjustment.

6. Clean the debris in hopper

7. Check main and side broom for wear or damage.

OPERATING INSTRUCTIONS

DRAIN HOSE

Fig. 42

DRAIN HOSE PLUG

TO DRAIN RECOVERY TANK

PLACE HOSE OVER DRAIN

DRAIN HOSE PLUG

DRAIN HOSE

Fig. 43

WHEN REPLACING DRAIN HOSE

CLIP ON DRAIN HOSE PLUG

FACES OUT

Fig. 44

Fig. 45

TO DRAIN RECOVER Y T ANK

The drain hose for the recovery tank is located on the back of the machine. To drain the tank, remove and lower

the hose and place in a suitable floor drain as shown in figure 44. Open the drain hose plug as shown in figure

42 and 43.

IMPORTANT

Improper discharge of wastewater will damage the environment and is illegal. The U.S.

Environmental Protection Agency has established certain regulations regarding discharge of

wastewater. The local city and state regulations regarding wastewater discharge may be in effect in

your area. Understand and follow the regulations in your area. Be aware of the environmental

hazards associated with the substances you dispose of.

AMERICAN-LINCOLN 1-39

SMART

Page 40

OPERATING INSTRUCTIONS

RECOVERY TANK HOSE

RECOVERY TANK SCREEN

RECOVERY TANK HOSE

Fig. 46

KNOB

Fig. 48

DRAIN HOSE PLUG

DRAIN HOSE

RECOVERY TANK

CLEAN OUT DOOR

Fig. 47

RECOVERY TANK

CLEAN OUT DOOR OPEN

Fig. 49

RECOVERY TANK

When the draining operation is complete, open the recovery tank clean out door as shown in figure 49 and flush

the recovery drain hose as shown in figure 46. Clean the recovery tank and recovery tank screen as shown in

figure 47. Close the recovery tank clean out door , drain hose plug, the recovery tank lid and clip the drain hose

into place as shown in figure 48.

1-40 AMERICAN-LINCOLN

SMART

Page 41

OPERATING INSTRUCTIONS

DISK SCRUB BRUSHES

Fig. 50

DISK SCRUB BRUSH

Fig. 51

Inspect the disk scrub brushes and replace when the bristles are reduced to ¾ in length as shown in figure 50

and 51. To order replacement brushes, see scrub brush options in this manual.

SIDE BROOM

MAIN BROOM

Fig. 52

Fig. 53

Inspect the main and side broom. When the bristles are worn to 1 1/2 inch length replace the main broom as

shown in figure 52 and replace side broom when bristles are worn to 3 1/2 inch as shown in figure 53.

AMERICAN-LINCOLN 1-41

SMART

Page 42

OPERATING INSTRUCTIONS

REAR SQUEEGEE

TOP OR REAR SQUEEGEE

BOTTOM OF REAR SQUEEGEE

Fig. 54

SIDE SQUEEGEE

Fig. 55

Fig. 56

Inspect the rear and side squeegee blades for wear. If the wiping edge becomes rounded, remove and reinst all

so the unworn edge is now the wiping edge. This process can be repeated until all four edges are worn. If the

squeegee blade has become rippled, it will need to be replaced.

1-42 AMERICAN-LINCOLN

SMART

Page 43

OPERATING INSTRUCTIONS

DUST CONTROL

KNOB

DUST CONTROL

PANEL FILTER

Fig. 57 Fig. 58

DUST CONTROL KNOB

The dust control knob is used to hold the dust control filter cover down as shown in figure 57. The dust control

filter is located under the front cover and will need to be removed periodically for cleaning or replacement.

Removal of the filter panel requires no tools. The front cover must be opened to gain access to the filter

compartment. The panel filter is held in place by a hinged frame and knob. T o remove the p anel filter, turn the

knob counterclockwise and lift the hinged frame. The panel filter can now be lifted out and cleaned or replaced.

T o inst all the replacement panel filter , place a new filter in the machine, lower the frame and twist the knob

clockwise to lock the filter in place.

FILL WITH

HYDRAULIC FLUID

CHECK FLUID LEVEL

Fig. 59

HYDRAULIC RESERVOIR LEVEL SIGHT GAUGE

The sight gauge is located on the right side of the machine under the front cover as shown in figure 59. The sight

gauge is used to indicate the level of fluid in the reservoir. The fluid level must be visible in the sight gauge when

the hopper is in the down position.

AMERICAN-LINCOLN 1-43

SMART

Page 44

MAINTENANCE

SERVICE CHART

Check items for proper operation. If service is required, please contact an authorized American-Lincoln

T echnology distributor . For best performance, replace worn parts with genuine American-Lincoln part s.

EVERY eight (8) HOURS or DAILY check and clean/adjust if necessary:

1 Inspect panel filter for damage and clean them.

2 Inspect and clean hopper.

3 Inspect and clean recovery tank screens and filters.

4 Check hydraulic fluid level.

5 Check all flaps for wear or damage.

6 Check brooms for wear or damage, adjust as required.

7 Check brake pedal and parking brake.

8 Check hydraulic oil filter.

9 Check battery electrolyte level.

1 0 Check all fluid system components for leaks.

50 HOUR (WEEKL Y) MAINTENANCE CHECKLIST

11 Check solution tank (recycling or ESP system).

1 2 Check solution filter screen (recycling or ESP system).

13 Check recovery tank.

1 4 Check recovery tank screens and filters.

15 Inspect scrub brushes for wear or damage.

16 Inspect rear and side squeegees for wear or damage.

17 Check battery electrolyte level.

1 8 Check all hydraulic hoses for wear or cuts.

19 Rotate main brush.

20 Clean or replace panel filter .

21 Lubricate squeegee casters.

100 HOUR MAINTENANCE CHECKLIST

22 Lubricate front wheel bearings.

23 Lubricate all moving joints.

250 HOUR MAINTENANCE CHECKLIST

24 Lubricate squeegee casters.

2 5 Clean solution tank and filter screen.

26 Replace hydraulic filter element.

27 Clean hydraulic reservoir.

1-44 AMERICAN-LINCOLN

SMART

Page 45

MAINTENANCE

3, 13, 14

11, 12, 25

5, 6

4, 8,

26, 27

5, 19

21, 24

7

9, 17 18

1, 20

6

2

22, 23

5

16

15

AMERICAN-LINCOLN 1-45

SMART

16

6

Page 46

MAINTENANCE

For safety , read and follow the service precautions below. Know the hazards associated with the equipment

you are working on to prevent personal injury or damage to equipment.

For service assistance, consult your nearest American-Lincoln dealer . For best performance replace worn

parts with genuine American-Lincoln parts.

Refer all maintenance and service requirements to qualified maintenance personnel.

DO NOT attempt to service this machine until you have read and understand all safety warnings associated

with the equipment you are working on.

WARNING

• Maintenance and repairs must be done by authorized personnel only.

••

• Electrical repairs must be done by authorized personnel only. Consult your American-Lincoln

••

Authorized Service Person to do service procedures. Use only genuine American-Lincoln

parts.

••

• Always park on a level surface, turn key off, and engage parking brake before working on

••

the machine to keep it from creeping or rolling.

••

• Maintenance and repairs must be done by authorized personnel only. Always empty the

••

solution tank and the recovery tank before doing any maintenance. Keep all fasteners tight.

Keep adjustments according to the specifications as shown in the Service Manual for this

machine.

••

• Always wear eye protection and protective clothing when working near batteries. Do not put

••

tools or other metal objects across the topes of the batteries. NO SMOKING.

••

• To prevent damage to the machine, and discharge across the tops of the batteries, do not fill

••

the batteries above the bottom of the tube in each cell. Wipe any acid from the machine or

the tops of the batteries. Do not add acid to a battery after installation.

••

• The hopper could fall and cause serious injury. Always engage the hopper safety arm before

••

working under the hopper.

••

• To maintain the stability of this machine in normal operation, the overhead guard, or similar

••

equipment installed by the manufacturer as original equipment should not be removed. If it

becomes necessary to remove such equipment for repair or maintenance, this equipment

must be reinstalled before machine is placed back in operation.

1-46 AMERICAN-LINCOLN

SMART

Page 47

MAINTENANCE

LIFT MACHINE

FRONT COVER

TO ACCESS

BATTERY

Fig. 60

MACHINE POWER CONNECTOR

BATTERY POWER CONNECTOR

Fig. 61

CONNECT POSITIVE TO

POSITIVE AND NEGATIVE

TO NEGATIVE

Fig. 62

BA TTERY CHARGING INSTRUCTIONS

When the battery conditioning meter is illuminated with one red LED light, the battery needs to be recharged.

T o prevent interruption of the cleaning cycle, charge the battery after using.

1. Lift the machine front cover .

2. Disconnect the battery power connector from the machine power connector .

3. Plug the battery power connector into the battery charger .

4. Follow manufacturer’s charging instructions provided on the charger.

5. Maintain electrolyte level in battery , check after charging. Add distilled water as needed.

AMERICAN-LINCOLN 1-47

SMART

Page 48

MAINTENANCE

• Do not remove the battery from the machine if there is waste in the solution tank.

WARNING

••

• Hydrogen gas is formed during the charging operation and is explosive! Only charge

••

batteries in a well-ventilated area with the lid open. Avoid any open flame or electrical

sparks. Pulling out the charger plug, with the charger still on, will cause an arc and must be

avoided.

••

• Batteries are heavy. Use lifting device with specified rated capacity.

••

••

• Always remove jewelry, wear protective clothing, and face protection when working near

••

batteries.

••

• Lead acid batteries generate gases, which cause explosions. Keep sparks and flames away

••

from batteries charge the batteries only in area with good ventilation. NO SMOKING!

••

• To prevent an explosion, disconnect the AC plug from the receptacle before connection or

••

disconnect the DC plug on the charger.

••

• The battery box can slide off a forklift and cause severe personal injury or damage to

••

equipment. Ensure that the battery box is properly secured to the forks of the forklift during

transport, drive and stop with caution.

BATTERY LEVER

BATTERY COMPARTMENT

Fig. 63 Fig. 64

CONNECT A 2000 LB. (907 KG)

CAPACITY LIFTING DEVICE

CONNECTING BATTERY

Fig. 65

Fig. 66

BA TTERY REMOV AL

When removing batteries

1. Lift the machine front cover to access battery compartment.

2. Unplug the battery power connector from the machine power connector.

3. Rotate the battery lever to the right.

4. Lift the battery out using a 2000 LB. (907 KG) capacity lifting device.

1-48 AMERICAN-LINCOLN

SMART

Page 49

BA TTERY REMOV AL WITH THE BA TTERY ROLLOUT OPTION

When removing batteries

1. Lift the machine front cover to access battery compartment.

2. Unplug the battery power connector from the machine power connector.

3. Line up battery cart locator pins with slots in frame and lock in place.

4. Rotate the battery lever to the right.

5. Roll battery out on to cart.

LINE UP BATTERY CART LOCATOR PINS

TO THE SLOTS IN THE FRAME

BATTERY CART

MAINTENANCE

BATTERY CART

Fig. 67

BATTERY LEVER

Fig. 69

BATTERY CART

Fig. 68

BATTERY LEVER

Fig. 70

AMERICAN-LINCOLN 1-49

SMART

Page 50

MAINTENANCE

DISK SCRUB BRUSHES

Fig. 71

DISK SCRUB BRUSH

Fig. 72

REPLACING SCRUB BRUSHES

1. Raise the scrub brush deck by pressing the “Scrub Brush” switch on the instrument panel.

2. Press the brush latches in to release the scrub brush.

3. Remove the old scrub brush.

4. Snap the new scrub brush into place.

REPLACING P ADS ON A P AD DRIVER

Install a new pad when the old one is worn or dirty . The pad driver assembly is removed and installed the same

way a standard scrub brush is (See replacing the scrub brush).

1. The pad driver is held in place by a ring. Pull the pad driver straight down to remove it.

2. Remove the pad holder using the spring wire retainer .

3. Replace the worn pad.

1-50 AMERICAN-LINCOLN

SMART

Page 51

LOOSEN KNOB

TO CHANGE SQUEEGEE BLADE

REMOVE NUT AND TURN

SQUEEGEE BLADE OVER

MAINTENANCE

Fig. 73

TOP OR REAR SQUEEGEE

BOTTOM OF REAR SQUEEGEE

Fig. 74

Fig. 75

REPLACING REAR SQUEEGEE

The squeegee will require service when the inner edge of the blades become round with wear, imp airing the

wiping action or water pick up.

1. Loosen the four aluminum knobs.

2. Remove the squeegee tool and turn upside down to service the blades or the caster wheels. The

squeegee blades are designed to rotate to use an unworn edge.

3. Loosen the clamp bolts.

4. Install blades so that the outer blade is 3/16" longer than the inner blades. This is achieved by

assembling the top edge of the blade against the squeegee tool weldment.

5. Reinstall the squeegee clamp band and tighten the clamp bolt.

AMERICAN-LINCOLN 1-51

SMART

Page 52

MAINTENANCE

FLUSH OUT THE RECOVERY TANK WITH

A WATER HOSE OR PRESSURE WASHER

Fig. 76

DRAINING THE RECOVERY T ANK

Drive the machine to a draining area. Loosen the knobs on the recovery clean out door and pivot the door to the

left as shown in figure 76. With the water hose flush out the bottom of the recovery tank clean out door to

remove larger particles of debris.

SOLUTION TANK DRAIN HOSE

SOLUTION TANK DRAIN HOSE

Fig. 77 Fig. 78

DRAINING THE SOLUTION T ANK

Lift the cover on the solution/recovery tank. Locate the solution tank drain hose as shown in figure 77. Pull the

hose out as shown in figure 78. Open the solution tank drain plug and let the solution tank drain. Clean out and

flush the solution tank with a water hose. Tighten the solution tank plug and tuck the solution tank drain hose

into place.

1-52 AMERICAN-LINCOLN

SMART

Page 53

MAINTENANCE

MAIN BROOM

Fig. 79

MAIN BROOM

T o prevent the broom from setting in one direction and to provide the maximum life of the broom it is

recommended that the broom be turned end over end periodically .

MAIN BROOM ADJUSTMENT KNOB

Fig. 80

ADJUSTING THE MAIN BROOM HEIGHT

The main broom adjustment knob for changing the sweep height to compensate for broom wear is located in

front of the machine as shown in figure 80. Turning the knob to the left (counterclockwise) will lower the main

broom. When changing the sweep height adjustment, it is recommended the knob be adjusted one turn at a

time. Af ter adjusting, recheck the sweep pattern to determine if further adjustment is necessary .

TURN KNOB CLOCKWISE = INCREASE SWEEP P A TTERN WIDTH

TURN KNOB COUTERCLOCKWISE = DECREASE SWEEP P A TTERN WIDTH

AMERICAN-LINCOLN 1-53

SMART

Page 54

MAINTENANCE

MAIN BROOM ACCESS DOOR

Fig. 81

MAIN BROOM ACCESS DOOR

The main broom access door is located in front of the left side tire of the machine as shown in figure 81. The

door provides access to the main broom for service or inspection. The hopper must be raised to access.

WARNING

Engage hopper safety arm while accessing the main broom

BROOM LIFT ARM

WITH KNOBS REMOVED

BROOM LIFT ARM KNOBS

Fig. 82

Fig. 83

REPLACING THE MAIN BROOM

The Main Broom should be replaced when the bristles become worn to less than 1 1/2”. The main broom is

held in place by the right side broom door. This feature provides for easy removal and installation of the main

broom without the need for special tools or equipment. Lift the hopper to gain access to the main broom

compartment. Loosen the main broom access door knob and open the main broom access door . Rotate and

remove the broom lift arm knobs counterclockwise to the left as shown in figure 82 and 83.

1-54 AMERICAN-LINCOLN

SMART

Page 55

REMOVE BROOM LIFT ARM

MAINTENANCE

BROOM LIFT ARM

BROOM IDLER

BROOM IDLER

Fig. 84

Fig. 86

SLIDE BROOM ONTO

BROOM IDLER

Fig. 85

Fig. 87

INSTALLED BROOM

Fig. 88

Remove broom lift arm as shown in figure 84 and 85. Remove the main broom from the from the broom idler

exposing the main broom compartment as shown in figure 86. Check and clean out the main broom

compartment before installing the new main broom. Slide the main broom onto the broom idler as shown in

figure 87. Replace the broom lift arm and rotate the broom lift arm knobs clockwise to tighten into place as

shown in figure 88. Adjust the main broom to 1-1/2” to 2” sweep p attern.

AMERICAN-LINCOLN 1-55

SMART

Page 56

MAINTENANCE

SIDE BROOM ADJUSTMENT KNOB

SIDE BROOM

The side broom (Fig. 89) sweeping angle is not

adjustable. However , the height of the side

broom can be adjusted to compensate as the

broom becomes worn from use. Always check

and adjust the sweep pattern after changing the

side broom.

Fig. 89

ADJUSTING THE SIDE BROOM HEIGHT

Turn the side broom adjustment knob (Fig. 90)

to change the side broom sweep height.

Recheck for proper sweep pattern after

adjustment.

Fig. 90

Fig. 91

Turn the adjustment knob counterclockwise to

INCREASE the sweep pattern width.

Turn the adjustment knob clockwise to

DECREASE the sweep pattern width.

REPLACING THE SIDE BROOM

Change the side broom (Fig. 91) when the

bristles become worn to less than 3 inches

length.

1. Park the machine on a smooth level

surface, turn key switch to “O” Position and

engage parking brake.

2. Place the side brooms switch in the “UP”

position.

3. Remove the lock pin that holds the broom

flange to the motor shaft.

4. Disassemble the flange from the broom by

removing the screws that hold the flange to

the broom.

5. Assemble the flange to the replacement

broom and fasten using the hardware

removed.

6. Install the replacement broom on the shaft

and insert the lock pin.

1-56 AMERICAN-LINCOLN

SMART

Page 57

MAINTENANCE

DUST CONTROL

PANEL FILTER

Fig. 92 Fig. 93

HOPPER

The hopper (Fig. 92) houses the debris compartment, the dust control filter and the removable dust baffle. For

maximum performance and service life, keep the hopper clean and inspect the seals and flaps daily . Clean

the hopper prior to parking the sweeper at the end of the day . A clean hopper will make inspecting the flap s

and seals much easier and will prevent premature deterioration of hopper components. Do not leave the

hopper full of debris while in storage or when parked for extended periods of time. Once the hopper has been

emptied the insides of the hopper should be rinsed out with water.

DUST CONTROL FIL TER

The dust control filter (Fig. 93) should be checked daily for damage and cleaned if necessary . A damaged filter

must be replaced to prevent damage to other dust control system components. Inspect the filter for tears in

the filter media or excessive dirt lodged in the pleats. A tear in the filter media will allow dirt to pass through

the filter and can be easily seen as a dirty patch on the top side on the filter . Cleaning of the filter is

necessary when the filter shaker fails to adequately clean the pleats.

CHECKING THE DUST CONTROL FIL TER

1. Park the machine on a smooth level surface, turn the key switch to the “O” position and engage the

parking brake.

2. Raise the hopper lid for access to the filter compartment.

3. Turn the filter latch, lift the filter frame and remove the filter .

4. Inspect the panel filter for tears and clean or replace if necessary .

5. Reinstall the filter , lower the filter frame and engage the filter latch.

6. Close the hopper cover.

CLEANING THE DUST CONTROL FIL TER

Clean the dust control filter when the shaker fails to adequately clear the filter. The filter can be cleaned with

compressed air not to exceed 100 PSI. To clean the filter with compressed air, apply the compressed air to

the top side of the panel to back flush the lodged dirt from the filter pleats. Be careful to not damage the filter

media while cleaning. The filter can be cleaned with a solution of soap and water . If this cleaning method is

used do not use the filter until it has completely dried.

REPLACING THE DUST CONTROL FIL TER WHEN DAMAGE IS EVIDENT

1. Park the machine on a smooth level surface, turn the key switch to the “O” position and engage the

parking brake.

2. Open the hopper compartment cover to gain access to the filter compartment.

3. Turn the latch on the hinged frame counterclockwise and lift the frame .

4. Remove the filter panel.

5. Install replacement filter , lower the hinged frame and engage the latch.

6. Lower the filter compartment cover .

AMERICAN-LINCOLN 1-57

SMART

Page 58

MAINTENANCE

DUST FLAPS

The dust flaps are very important to sweeping and dust control and are susceptible to damage and should be

inspected daily and maintained in good condition.

CHECKING THE DUST FLAPS

The dust flaps are used on the wheel well, broom chamber and broom door . Inspect the flaps daily and replace

any flap that shows signs of wear or deterioration. All flap s should be replaced when worn or damaged to the

point that they can no longer perform their normal function. The adjustable flaps have slotted mounting holes to

facilitate adjustment.

ADJUSTING THE DUST FLAPS

Adjust the flaps so there is a 1/8" to 1/16" gap between the floor and the bottom edge of the flaps. The rear

flapadjustment is 1/16" (16 cm.) above the floor .

1. Park the machine on a smooth level surface and engage the parking brake.

2. Loosen the flap retaining screws and adjust the flap to clear the floor and leave a 1/16" to 1/8" gap.

3. Tighten flap retaining screws while holding flap in position.

4. Drive the machine on a smooth surface and recheck the flaps for proper floor clearance.

FILLING THE HYDRAULIC RESERVOIR (Fig. 94)

1. Access to the hydraulic reservoir is located in the

engine compartment.

2. Open the hydraulic reservoir breather filter cap.

3. Remove any debris that is in the breather filter

cap screen.

4. Fill the reservoir until the fluid is at the “FULL” line on

the hydraulic fluid sight gauge. The sight gauge is

located on the center side of the hydraulic reservoir.

5. Close the hydraulic reservoir breather filter cap.

6. Close the engine compartment cover .

FILL WITH

HYDRAULIC FLUID

CLEANING THE HYDRAULIC SYSTEM

1. Put a drop cloth on the floor.

2. Drive the machine onto the drop cloth.

3. Set the parking brake.

CHECK FLUID LEVEL

4. Open the hood.

5. Put a container under the reservoir drain to catch the

Fig. 94

reservoir fluid. Pivot the reservoir out.

6. Remove the drain plug. The reservoir fluid will drain.

Do not use the drained fluid to refill the hydraulic

reservoir. Dispose of the used fluid.

7. Flush the interior of the hydraulic reservoir with clean

fluid.

FILTER

8. Put the reservoir plug, removed in step six, back in the

hydraulic tank drain and tighten it. A pipe thread

sealer is required on the plug.

9. Open the breather filter cap.

10. Fill the reservoir with new MOBIL Multipurpose A TF or

equilvalent Dextron III. The capacity of the tank is

4.7 gal (17.79 liters). Fill to the “FULL” line on the

hydraulic fluid sight gauge.

1 1. Close the breather filter cap.

12. Replace the hood.

REPLACING THE RETURN FIL TER ELEMENT (Fig. 95)

Fig. 95

1. Replace the return filter element after 250 hours of machine run time.

2. Unscrew the fasteners from the filter assembly cover and retain.

3. Remove the cover and the compression spring and retain.

4. Discard the old filter element.

5. Position the new filter element inside the filter body.

6. Put the compression spring in position. Wipe the cover magnet free of any metal filings or debris.

7. Place O-ring (moisten with clean hydraulic fluid) and cover into position.

8. Reattach fasteners to the filter cover .

9. Clean any hydraulic reservoir fluid spills. The fluid can damage painted surfaces of the machine.

1-58 AMERICAN-LINCOLN

SMART

Page 59

TROUBLESHOOTING

PROBLEM

Machine moves slowly or

erratically

Machine does not move

Poor water pickup at

squeegee

PROBABLE CAUSE

1. Battery charge low

2. Brakes dragging

3. Loose connection at foot pedal

4. Drive circuit overloaded

1. Blown fuse

2. Battery unplugged

1. Recovery tank full

2. Squeegee is worn or damaged

3. Clogged suction hose or pick-up tool

4. Loose connections between suction hose

and squeegee

5. Vacuum motors not running

6. Plugged filter

REMEDY

1. Change

2. Adjust

3. Repair

4. Remove obstruction, put drive pedal

in neutral

5. Adjust

1. Check fuse & replace if necessary

2. Plug in battery

1. Empty tank

2. Examine squeegee rubber blade for

cuts or worn spots & replace if

necessary

3. Disconnect suction hose from

squeegee, flush squeegee & hoses

4. Check all hose connections for

looseness or damage

5. Reset circuit breaker or repair loose

connection

6. Clean filter element in vacuum manifold

Water spills from

squeegee

Squeegee leaves wet

spots

Squeegee makes

excessive noise

7. Vacuum float cage clogged

8. Vacuum float shut off

9. Air leaks in suction hose and connection

10.Air leaks at recovery tank cover and/or

manifold hose

11.Drain hose or drain plug leakage or not

closed properly

1. Side squeegee blades have poor contact

with floor

2. Squeegee blades worn or damaged

3. Too much solution being applied before

making turns

4. Brushes rotating opposite direction

1. Lift actuator out of adjustment

2. Squeegee wheels out of adjustment

1. Blades worn or damaged

7. Clean perforated metal thoroughly

8. Excessive solution in recovery tank.

Excessive foam buildup, change

cleaning chemical mixture (use A-L

approved materials)

9. Repair or replace hose and connection

10.Repair or replace seal or hose

11.Close, repair, or replace drain plug

in recovery tank

1. Readjust blades for proper contact

2. Replace & adjust

3. Shut off solution flow 5-10 ft. Before

turning

4. Check switch positions

1. Adjust

2. Adjust

1. Replace

AMERICAN-LINCOLN 1-59

SMART

Page 60

TROUBLESHOOTING

PROBLEM

Poor scrubbing action

Water splashes from sides

of scrub deck

Poor sweeping

PROBABLE CAUSE

1. Worn scrubbing brushes

2. Incorrect method of operation

3. Wrong cleaning agent or mixture

4. Poor solution distribution

5. Brushes won’t turn

1. Scrub deck bumpers, poor contact with floor

2. Squeegee blades word or damaged

3. Too much solution

1. Broom jammed

2. Hopper full

3. Broom not adjusted properly

4. Worn or damaged flaps

5. Worn broom

REMEDY

1. Inspect brushes. Replace if brushes are

worn to 3/4” or less.

2. Check scrubbing procedure, brush

pressure, solution flow & cleaning agent

used - all are important to the process

3. Use A-L recommended materials

4. Check solution strainer & feed hoses for

obstructions - clean if necessary.

Check valve & rest of solution control

system for proper operation.

5. Check wiring connections

1. Readjust blades for proper contact

2. Replace & adjust

3. Shut off solution flow 5-10 ft. before

making turns

1. Remove any obstruction

2. Empty

3. Refer to broom adjustment in

maintenance section

4.

Inspect for damage - replace or adjust

by referring to maintenance section

5. Inspect for damage or wear - refer to

maintenance section

Sweep does not

function

Poor dust control at main

broom

Hopper will not lift

1. Hopper is raised

2. Hopper switch out of adjustment

1. Broom chamber & hopper flaps worn

2. Impellor fan failure - shaft key broken or

electric motor not operating

3. Filter plugged

1. Load too heavy

2. Defective lift actuator

1. Lower hopper

2. Adjust hopper switch

1. Check condition of flaps. Replace torn or

badly worn flaps. Side flaps can be

adjusted of not damaged.

2. Check & repair

3. Engage shaker switch or check filter

1. Low dump partial load

2. Repair or replace actuator

1-60 AMERICAN-LINCOLN

SMART

Loading...

Loading...