AMERICAN-LINCOLN

TECHNOLOGY

OPERATOR'S

MANUAL &

PARTS LIST

Beginning with Serial No. 630951

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure

to read this book prior to operating or attempting any service or maintenance procedure to

your machine could result in injury to you or to other personnel; damage to the machine or to

other property could occur as well. you must have training in the operation of this machine

before using it. If you or your operator (s) cannot read English, have this manual explained

fully before attempting to operate this machine.

Si Ud. o sis operadores no pueden leer el Inglés, se hagen explicar este manual completamente

antes de tratar el manejo o servicio de esta máquina.

All directions given in this book are as seen from the operator's position at the rear of the machine.

6150

POWER

SWEEPER

ISO 9001

U

®

L

#

FILE A2287

Part No. 2-86-00188 Printed in the

American-Lincoln 1-1

6150

1996 American-Lincoln® USA

TABLE OF CONTENTS

MACHINE SPECIFICATIONS .................................................................................................................. 1-6

MACHINE DIMENSIONS ......................................................................................................................... 1-8

MACHINE PREPARATION ...................................................................................................................... 1-9

SAFETY PRECAUTIONS ........................................................................................................................ 1-10

SWEEPER CONTROLS/INSTRUMENTS ................................................................................................ 1-12

HORN BUTTON ................................................................................................................................ 1-12

LIGHT SWITCH ................................................................................................................................. 1-12

GLOW PLUG SWITCH ..................................................................................................................... 1-12

CHOKE CONTROL ........................................................................................................................... 1-12

KEY SWITCH ................................................................................................................................... 1-13

ENGINE SPEED SWITCH ................................................................................................................ 1-13

FUEL GAUGE .................................................................................................................................. 1-13

FOOT BRAKE .................................................................................................................................. 1-14

PARKING BRAKE ............................................................................................................................ 1-14

FOOT PEDAL ................................................................................................................................... 1-14

FORWARD MOVEMENT .................................................................................................................. 1-14

BACKWARD MOVEMENT ............................................................................................................... 1-14

WARNING BANK .................................................................................................................................... 1-15

ENGINE TEMP LIGHT ................................................................................................................ 1-15

ENGINE OIL PRESSURE LIGHT ................................................................................................ 1-15

CHARGING SYSTEM LIGHT ...................................................................................................... 1-15

DUST CONTROL LIGHT ............................................................................................................. 1-15

HOPPER TEMPERATURE LIGHT .............................................................................................. 1-15

DUMP DOOR LIGHT .................................................................................................................. 1-15

SEAT POSITION ADJUSTMENT ....................................................................................................... 1-16

TURN SIGNALS (OPTION) ............................................................................................................... 1-16

BACK-UP ALARM ............................................................................................................................ 1-16

BATTERY CONDITION METER ........................................................................................................ 1-16

FILTER SHAKER SWITCH ............................................................................................................... 1-17

DUST CONTROL SWITCH ................................................................................................................ 1-17

BROOM CONTROL LEVER .............................................................................................................. 1-17

SIDE BROOM LEVER ...................................................................................................................... 1-18

SIDE BROOM ADJUSTMENT ........................................................................................................... 1-18

MAIN BROOM LEVER ..................................................................................................................... 1-18

MAIN BROOM ADJUSTMENT .......................................................................................................... 1-18

HOPPER DOOR LEVER .................................................................................................................. 1-19

HOPPER LIFT LEVER ...................................................................................................................... 1-19

DEBRIS DOOR ................................................................................................................................. 1-19

DUST BAFFLE ................................................................................................................................. 1-20

HOPPER SAFETY ARM................................................................................................................... 1-20

HOPPER FILTER COMPARTMENT COVER..................................................................................... 1-20

FILTER PANEL LATCH ..................................................................................................................... 1-21

HOPPER TEMPERATURE SENSOR ............................................................................................... 1-21

ENGINE COMPARTMENT LATCH .................................................................................................... 1-21

HYDRAULIC RESERVOIR LEVER SIGHT GAUGE .......................................................................... 1-22

MAIN BROOM COMPARTMENT DOORS......................................................................................... 1-22

SEAT COMPARTMENT COVER ....................................................................................................... 1-22

SEAT COMPARTMENT LATCH ........................................................................................................ 1-23

BATTERY CHARGING CONNECTOR ............................................................................................... 1-23

HELPFUL HINTS FOR SWEEPING .................................................................................................. 1-24

OPERATING INSTRUCTIONS ................................................................................................................ 1-25

BATTERY MACHINE OPERATION ................................................................................................... 1-25

GAS/LP MACHINE OPERATION ...................................................................................................... 1-25

INSTRUCTIONS BEFORE STARTING ...............................................................................................1-26

PRE-START CHECK LIST................................................................................................................. 1-26

TO START BATTERY MACHINES .................................................................................................... 1-26

TO CHARGE BATTERIES ................................................................................................................. 1-26

TO START GAS ENGINE .................................................................................................................. 1-26

TO START PROPANE ENGINE ........................................................................................................ 1-26

TO START DIESEL ENGINE ............................................................................................................. 1-27

TO DRIVE SWEEPER FOR TRANSPORT ....................................................................................... 1-27

1-2 American-Lincoln

6150

TABLE OF CONTENTS

TO SWEEP WITH THE MACHINE .................................................................................................... 1-27

TO STOP SWEEPING ......................................................................................................................1-27

TO EMPTY DEBRIS HOPPER ......................................................................................................... 1-28

POST OPERATION CHECK LIST ..................................................................................................... 1-28

BATTERY CHARGING INSTRUCTIONS ............................................................................................ 1-28

MACHINE STORAGE ....................................................................................................................... 1-29

SERVICE CHART ................................................................................................................................... 1-30

SERVICE PRECAUTIONS ...................................................................................................................... 1-32

SERVICE INSTRUCTIONS ..................................................................................................................... 1-32

MAIN BROOM .................................................................................................................................. 1-32

TO CHECK THE MAIN BROOM SWEEP PATTERN ......................................................................... 1-32

TO ADJUST THE MAIN BROOM SWEEP HEIGHT ........................................................................... 1-32

TO REPLACE THE MAIN BROOM ................................................................................................... 1-32

MAIN BROOM LEVEL ADJUSTMENT .............................................................................................. 1-33

SIDE BROOM .................................................................................................................................. 1-33

TO CHECK THE SIDE BROOM SWEEP PATTERN ......................................................................... 1-33

TO CHANGE THE SIDE BROOM HEIGHT ADJUSTMENT ................................................................ 1-33

TO CHANGE THE SIDE BROOM ..................................................................................................... 1-33

HOPPER .......................................................................................................................................... 1-34

TO CLEAN HOPPER ........................................................................................................................ 1-34

TO CHECK HOPPER SEALS ........................................................................................................... 1-34

DUST CONTROL FILTER .................................................................................................................. 1-34

TO CHECK THE DUST CONTROL FILTER ....................................................................................... 1-34

TO CLEAN THE DUST CONTROL FILTER ........................................................................................ 1-34

TO CHANGE THE DUST CONTROL FILTER ..................................................................................... 1-35

DUST FLAPS ................................................................................................................................... 1-35

TO CHECK THE DUST FLAPS ......................................................................................................... 1-35

TO ADJUST THE DUST FLAPS ........................................................................................................ 1-35

BRAKES .......................................................................................................................................... 1-36

BRAKE PEDAL ADJUSTMENT ........................................................................................................ 1-36

HYDRAULIC SYSTEM SERVICE ..................................................................................................... 1-37

TO FILL THE HYDRAULIC RESERVOIR ........................................................................................... 1-37

TO CLEAN THE HYDRAULIC SYSTEM ............................................................................................ 1-37

TO DRAIN THE HYDRAULIC RESERVOIR ....................................................................................... 1-37

TO CLEAN THE HYDRAULIC SUCTION STRAINER ......................................................................... 1-38

TO REPLACE THE RETURN FILTER ELEMENT .............................................................................. 1-38

ENGINE AIR INTAKE SERVICE ........................................................................................................ 1-38

DIESEL AIR FILTER ....... ................................................................................................................... 1-39

TO REMOVE THE DIESEL AIR FILTER ELEMENT .......................................................................... 1-39

TO CLEAN THE DIESEL AIR FILTER ELEMENT .............................................................................. 1-39

TO INSTALL THE DIESEL AIR FILTER ELEMENT ............................................................................ 1-39

GAS AIR FILTER .............................................................................................................................. 1-39

TO REMOVE THE GAS AIR FILTER ELEMENT ............................................................................... 1-40

TO CLEAN THE GAS AIR FILTER ELEMENT ................................................................................... 1-40

TO INSTALL THE GAS AIR FILTER ELEMENT ................................................................................. 1-40

ENGINE COOLING SYSTEM SERVICE ........................................................................................... 1-41

HOSES ............................................................................................................................................ 1-41

RADIATOR........................................................................................................................................ 1-41

COOLANT LEVEL ............................................................................................................................ 1-41

DRIVE BELTS .................................................................................................................................. 1-42

BATTERY SERVICE ......................................................................................................................... 1-42

TO CHARGE THE MOTICE POWER BATTERIES ............................................................................ 1-43

LP SAFETY PRECAUTIONS .................................................................................................................. 1-44

LP GAS COMPONENTS .................................................................................................................. 1-45

LP GAS SYSTEM ............................................................................................................................ 1-45

LP LIQUID WITHDRAW SYSTEM .................................................................................................... 1-45

LP CHECKLIST ................................................................................................................................ 1-45

LP GAS VAPORIZER-REGULATOR QUICK CHECK ........................................................................ 1-46

LP FUEL TANKS .............................................................................................................................. 1-46

USE AND CARE OF LP TANKS ................................................................................................. 1-46

CHANGING LP FUEL TANKS .................................................................................................... 1-47

American-Lincoln 1-3

6150

TABLE OF CONTENTS

STORAGE OF LP FUEL TANKS ................................................................................................ 1-47

STANDARD METRIC ENGINE TORQUE REQUIREMENTS .................................................................... 1-48

HYDRAULIC TORQUE REQUIREMENTS ............................................................................................... 1-49

BOLT IDENTIFICATION CHART ............................................................................................................... 1-50

DECIMAL-METRIC CONVERSION TABLE .............................................................................................. 1-51

HARDWARE LEGEND............................................................................................................................ 1-52

HARDWARE ABBREVIATIONS .............................................................................................................. 1-58

ORDER PARTS ...................................................................................................................................... 1-59

HYDRAULIC SCHEMATIC DIAGRAMS ................................................................................................... 1-60

HYDRAULIC SCHEMATIC DIAGRAMS (3 CYL. KUBOTA) ...................................................................... 1-61

CHAPTER 2 ............................................................................................................................................ 2-1

FRONT WHEEL ...................................................................................................................................... 2-3

REAR WHEEL ........................................................................................................................................ 2-4

VAC FAN ................................................................................................................................................ 2-8

BROOM DOOR ....................................................................................................................................... 2-12

FLAP ASSEMBLY (WHEEL WELL) ........................................................................................................ 2-14

MAIN BROOM LEVER ............................................................................................................................ 2-16

MAIN BROOM IDLER ............................................................................................................................. 2-17

MAIN BROOM DRIVER .......................................................................................................................... 2-18

MAIN BROOM LIFT FRAME ................................................................................................................... 2-19

SIDE BROOM ASSEMBLY ..................................................................................................................... 2-20

SIDE BROOM LIFT SYSTEM .................................................................................................................. 2-22

SIDE BROOM LEVER ............................................................................................................................ 2-24

BROOM CHAMBER FLAPS AND SEALS............................................................................................... 2-26

BRAKE PEDAL ...................................................................................................................................... 2-28

FILTER SHAKER .................................................................................................................................... 2-30

SEAT AND FLOOR ASSEMBLY.............................................................................................................. 2-32

BATTERY SEAT COMPARTMENT .......................................................................................................... 2-34

STEERING COLUMN .............................................................................................................................. 2-36

EXHAUST PIPE (3 CYL. KUBOTA DIESEL) ............................................................................................ 2-37

KAWASAKI 20 HP MUFFLER ................................................................................................................ 2-38

KUBOTA 14 HP MUFFLER ..................................................................................................................... 2-39

FRONT BUMPER .................................................................................................................................... 2-40

HYDRAULIC OIL COOLER ...................................................................................................................... 2-41

VALVE - CCONTROL AND RELIEF ......................................................................................................... 2-42

VALVE - CONTROL AND RELIEF (3 CYL. KUBOTA GAS & DIESEL) ..................................................... 2-44

FORWARD/REVERSE CONTROL .......................................................................................................... 2-46

FORWARD/REVERSE CONTROL (3 CYL KUBOTA GAS & DIESEL) ..................................................... 2-48

RESERVOIR ........................................................................................................................................... 2-52

RESERVOIR (3 CYL. KUBOTA GAS & DIESEL) ..................................................................................... 2-54

FUEL TANK (GAS) .................................................................................................................................. 2-56

FUEL TANK (DIESEL) ............................................................................................................................. 2-58

HOPPER ASSEMBLY ............................................................................................................................. 2-60

HOPPER COVERS & GASKET ASSEMBLY .......................................................................................... 2-62

HOPPER LIFT ......................................................................................................................................... 2-64

HOPPER SIDES ..................................................................................................................................... 2-65

DUMP DOOR .......................................................................................................................................... 2-66

SAFETY ARM ......................................................................................................................................... 2-68

HYDRAULIC FILTER ............................................................................................................................... 2-69

HYDRAULIC FILTER (3 CYL KUBOTA GAS & DIESEL) .......................................................................... 2-70

HYDRAULIC PUMP (GAS/LP) ................................................................................................................ 2-71

HYDRAULIC PUMP (DIESEL) ................................................................................................................. 2-72

HYDRAULIC PUMP (3 CYL. KUBOTA GAS & DIESEL) .......................................................................... 2-74

ENGINE COVER ..................................................................................................................................... 2-76

ACCESS COVER ................................................................................................................................... 2-78

BATTERY ASSEMBLY ............................................................................................................................ 2-79

BATTERY COMPARTMENT (LEFT SIDE) ............................................................................................... 2-80

ENGINE (GAS) ....................................................................................................................................... 2-82

ENGINE ( 3 CYL. KUBOTA GAS)............................................................................................................ 2-84

ENGINE (3 CYL. KUBOTA DIESEL) ........................................................................................................ 2-86

1-4 American-Lincoln

6150

TABLE OF CONTENTS

ENGINE (3 CYL. DUAL FUEL-LP) ...........................................................................................................2-88

MOTOR PUMP ELECTRICAL ASSEMBLY .............................................................................................. 2-90

HYDRAULIC HOSE DIAGRAM (BATTERY) ............................................................................................. 2-92

HYDRAULIC HOSE DIAGRAM (3 CYL. GAS & DIESEL) ........................................................................ 2-94

HYDRAULIC HOSE DIAGRAM (2 CYL. GAS) ......................................................................................... 2-96

ELECTRICAL ASSEMBLY (LIGHTS & HORN) .........................................................................................2-98

BATTERY - ELECTRICAL ASSEMBLY (2 CYL KAWASAKI GAS & DIESEL).......................................... 2-99

BATTERY - ELECTRICAL ASSEMBLY (3 CYL KUBOTA GAS & DIESEL)............................................... 2-100

ELECTRICAL HARNESS ROUTING (BATTERY) ..................................................................................... 2-102

ELECTRICAL HARNESS ROUTING (2 & 3 CYL. IC) ............................................................................... 2-104

MACHINE HARNESS CONNECTIONS (BATTERY)................................................................................. 2-106

MACHINE HARNESS CONNECTIONS (2 & 3 CYL. IC) ........................................................................... 2-107

INSTRUMENT HOUSING ........................................................................................................................ 2-108

INSTRUMENT PANEL ............................................................................................................................. 2-110

POWER PANEL (BATTERY)................................................................................................................... 2-112

DECALS ................................................................................................................................................. 2-114

DECALS (con’t) ...................................................................................................................................... 2-116

POWER PANEL CONNECTION DIAGRAM (BATTERY) .......................................................................... 2-118

#2 MOTOR POWER PANEL CONNECTION DIAGRAM (BATTERY) ....................................................... 2-119

2-CYLINDER KAWASAKI LP (CE MODELS ONLY) ................................................................................ 2-120

NOTES .................................................................................................................................................. 2-122

INSTRUMENT PANEL CONNECTION DIAGRAM .................................................................................... 2-123

INSTRUMENT PANEL HARNESS DIAGRAM .......................................................................................... 2-124

ELECTRICAL SCHEMATIC (BATTERY)................................................................................................... 2-125

ELECTRICAL SCHEMATIC (GAS, LP, DIESEL) ...................................................................................... 2-126

3-CYLINDER KUBOTA ENGINE CONNECTION SCHEMATIC.................................................................. 2-127

2-CYLINDER KAWASAKI ENGINE CONNECTION SCHEMATIC ............................................................. 2-128

CHAPTER 3 - OPTIONS ......................................................................................................................... 3-1

OVERHEAD GUARD OPTION (GAS/LP/DIESEL) ................................................................................... 3-2

SEAT-SUSPENSION OPTION ................................................................................................................. 3-3

BACK-UP ALARM OPTION ..................................................................................................................... 3-4

REAR WORK LIGHT OPTION (BATTERY) .............................................................................................. 3-6

REAR WORK LIGHT OPTION (GAS & DIESEL) ..................................................................................... 3-7

BRAKE LIGHT OPTION .......................................................................................................................... 3-8

TURN SIGNAL OPTION (GAS & DIESEL) ............................................................................................... 3-10

HOPPER TEMPERATURE OPTION (BATTERY) ..................................................................................... 3-12

HOPPER TEMPERATURE OPTION (GAS/DIESEL/LP) .......................................................................... 3-14

LEFT HAND SIDE BROOM OPTION ....................................................................................................... 3-16

CLOGGED FILTER OPTION (BATTERY) ................................................................................................. 3-20

CLOGGED FILTER OPTION (GAS/DIESEL/LP) ...................................................................................... 3-21

VAC WAND OPTION (GAS/DIESEL/LP) ................................................................................................. 3-22

OVERHEAD GUARD OPTION (BATTERY).............................................................................................. 3-24

AMBER STROBE LIGHT w/o OVERHEAD GUARD ................................................................................ 3-25

AMBER STROBE LIGHT w/ OVERHEAD GUARD .................................................................................. 3-26

BATTERY OPTION .................................................................................................................................. 3-27

LP OPTION TANK ASSEMBLY ............................................................................................................... 3-28

LP OPTION ............................................................................................................................................. 3-30

SEAT BELT OPTION ............................................................................................................................... 3-32

SPARE PARTS KITS .............................................................................................................................. 3-33

WARRANTY ........................................................................................................................................... 3-35

American-Lincoln 1-5

6150

SPECIFICATIONS

SWEEP PATH 50 inches (127 cm) with single side broom

TRAVEL SPEED

Gas/LP Diesel Battery

0 - 5 MPH 0 - 8 MPH 0 - 4 MPH

TURNING RADIUS

Left 53.5 inches (136 cm)

Right 82.0 inches (208 cm)

AISLE WIDTH FOR U-TURN 90 inches (229 cm)

MAXIMUM RATED CLIMB

Gas/LP 8°

Diesel 8°

Battery 6°

DIMENSIONS

Length 87.00 inches (221 cm)

Width 51.50 inches (131 cm)

Height 53.00 inches (135 cm)

Height w/Overhead Guard 77.75 inches (197.5 cm)

WEIGHT

Gas/LP 2100 lbs. (955 kg)

Diesel 2100 lbs. (955 kg)

Battery 3420 lbs. (1555 kg)

POWER SOURCE

Gas/LP 20 HP (14.933 kw), 2 cylinder Liquid Cooled Kawasaki

Diesel 14 HP (10.450 kw), 2 cylinder Liquid Cooled Kubota

Battery 36 volt system, 2.5 HP (1.87 kw) series wound drive motor

62 inches (157.5 cm) with optional dual side brooms

ELECTRICAL SYSTEM

Gas/Diesel/LP 12 volts

Battery Powered 36 volts

HYDRAULIC SYSTEM

GAS/DIESEL/LP POWERED MACHINES

The engine furnishes power through a coupling to a fixed displacement hydraulic gear pump. The pump provides

controlled oil flow to various operator controlled hydraulic valves which supply hydraulic power to the hopper dump

system and motors on the rear wheel, main broom, side broom, and vacuum fan. Hydraulic system is protected by two

filters, 100 micron and a 25 micron.

BATTERY POWERED MACHINES

The battery powered electric motor furnishes power through a coupling to a fixed displacement hydraulic gear pump.

The pump provides controlled oil flow to various operator controlled hydraulic valves which supply hydraulic power to

the hopper dump system and motors on the main broom and side broom. Hydraulic system is protected by two filters,

100 micron and 25 micron.

STEERING

Fully Power Steering with single rear wheel steer.

BRAKES

Foot operated drum brakes on front wheels. Hand operated parking brake. When engaged, parking brake locks the

brake foot pedal in the down position.

MAIN BROOM

One-piece, disposable unit with poly core. Standard bristle type is Proex fiber. A variety of bristle types are available. No

tool broom installation or removal easily completed within five (5) minutes. Broom position can be placed into the free

float or restricted down position. Broom pattern is adjusted by control in operator’s compartment. Offers excellent

performance on rough or uneven surfaces.

Length 36 inches (91.5 cm)

Diameter 14 inches (35.5 cm)

Bristle Length 3.25 inches (8.26 cm)

1-6 American-Lincoln

6150

SPECIFICATIONS

SIDE BROOM

Rotary, disposable type. May be raised, lowered, and adjusted using controls in operator’s compartment. Broom is

retractable to prevent damage caused by hitting walls and racks. No tool broom installation or removal.

Diameter 21 inches (53.4 cm)

FILTER SYSTEM

One panel filter offers a total filter area of 78 square feet (7.25 m²) and controls dust particles down to two microns in

size utilizing pre-clean baffling system. No tool panel filter installation or removal in less than two minutes. Panel filter

cleaned utilizing patented ‘beater bar’ shaker controlled by the operator. A high volume, 9 inch vacuum fan provides

excellent dust control. Filter can be washed.

HOPPER

Constructed of steel, hopper provides adequate ground clearance and floating flaps.

Capacity 10 ft.³ (283 L)

Weight Capacity 700 lbs. (317.5 kg)

BROOMS CONTROLS

A separate lever raises and lowers the main broom which allows it to be set in the restricted down or free float position.

Side broom raise/lower level.

DUMPING SYSTEM

Variable dump empties debris from ground level up to 60 inches.

CONTROLS

A single foot pedal controls travel speed, forward and reverse direction. Equipped with hopper raise/lower lever,

brooms and vacuum on/off lever, filter shaker and horn buttons, key start ignition, battery condition meter (battery

machines only), hour meter, fuel gauge (gas machines only), hydraulic oil level, sight gauge and throttle control.

TIRES

Front Two 16" Pneumatic Two 16” Solid Urethane

Rear One 16" Pneumatic One 16” Solid

STANDARD EQUIPMENT

Headlights Dash Lights Taillight

Timed Shaker System Transport Tie Down Cutouts Adjustable Seat

OPTIONAL EQUIPMENT

Overhead Guard Non-Marking Tires Solid Pneumatic

Vacuum Wand Turn Signals Brake Light

Clogged Filter Indicator Vacuumized Right Curb Broom Hydraulic Oil Cooler

Dual Curb Brooms Back-Up Alarm Strobe Amber Light

Stainless Steel Hopper Rear Work Light Safety Tape

Solid Cushion Tires Arm Rests & Seat Belts

Wet Sweep By-Pass Hopper Fire Safety Sensor

WARRANTY

Our general conditions of business are applicable with regard to the guarantee. Subject to change as a

result of technical advances. The guarantee is invalidated if the machine is not operated in accordance

with these instructions or otherwise abused. The guarantee is invalidated if the machine is not serviced as

described.

MACHINE DATA

Gas/LP/Diesel Battery

R

MACHINE NAME

MODEL

WEIGHT

IP X3

DATE / SERIAL NUMBER

RATED POWER

MAX OPERATING SLOPE

LWA

B

American-Lincoln 1-7

6150

c

c

0

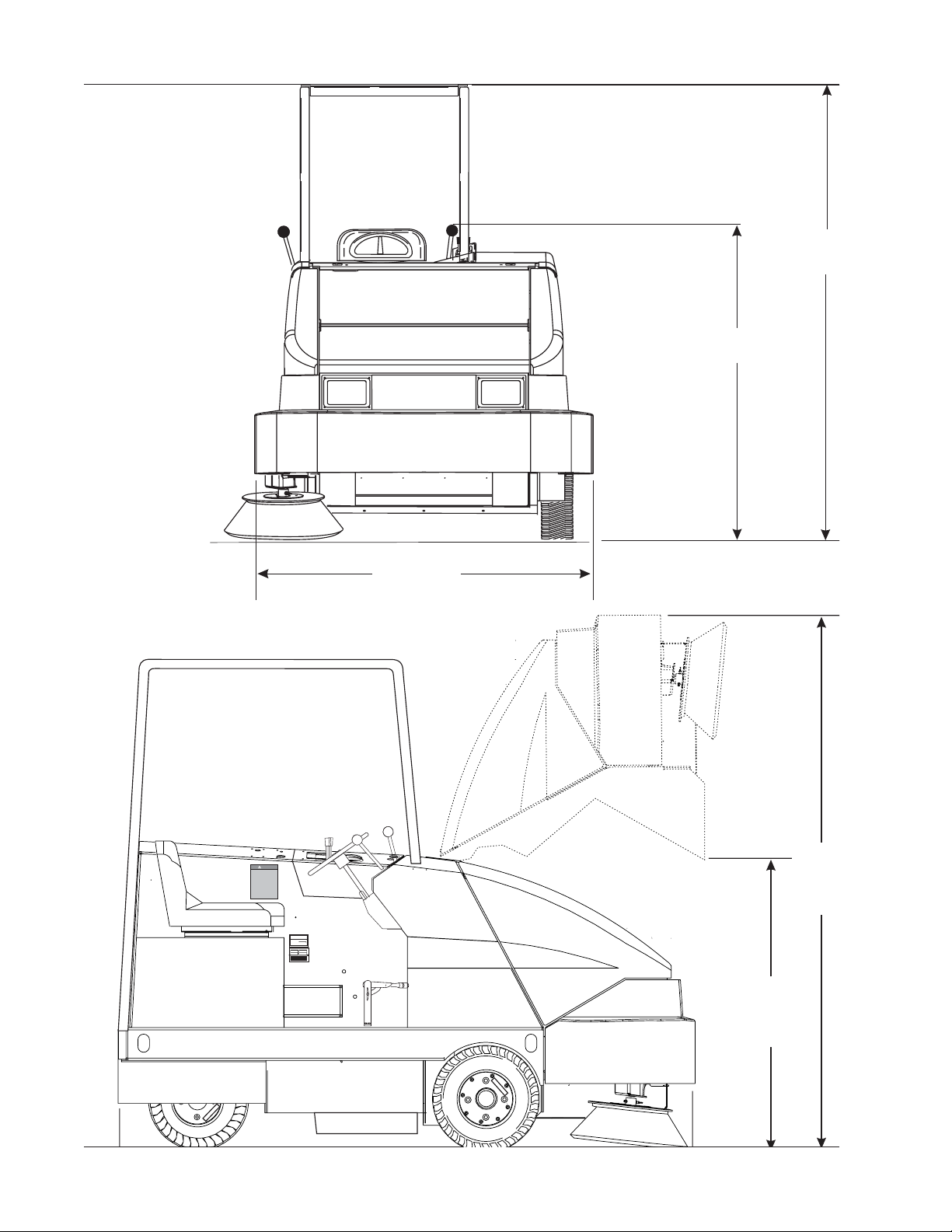

MACHINE DIMENSIONS

53.00"

135 cm

77.7

197

54.75 "

139 cm

WARNING

88.0

223

MODELNO. SERIAL NO.

60.00 "

147 cm

1-8 American-Lincoln

6150

MACHINE PREPARATION

YOUR SWEEPER HAS BEEN SHIPPED COMPLETE, BUT DO NOT ATTEMPT TO OPERATE WITHOUT

READING AND FOLLOWING THESE INSTRUCTIONS.

PREPARATION

1. Uncrate the sweeper and carefully remove packing material.

2. Inspect the battery connections.

3.^ Fill fuel tank with appropriate fuel.

3.* Install motive power batteries. (See Battery Installation Instructions)

4.* Charge batteries using instructions provided with charger. (See Battery Charging Instructions)

WARNING

Risk of personal injury. Never fill fuel tank while engine is running. Always be sure gasoline container and sweeper

are electrically connected prior to pouring fuel. This can easily be done by providing an insulated wire (Perma-

nently attached to the container) with a battery clip attached to the other end.

4.^ Check engine crankcase oil level.

5.^ Check radiator coolant level. Permanent type antifreeze is added at the factory to provide pro tection

to approximately -35° F (-2° C) To retain this level of protection always add 1/2 part water to 1/2

part antifreeze.

6. Check fluid level in hydraulic reservoir which is located in the engine compartment. The hydraulic

reservoir is full when fluid can be seen in the sight glass on the side of the reservoir. To get an accurate

reading the hopper must be in the “DOWN” position. If fluid is required add HYDRAULIC FLUID ONLY.

Use Ford Automatic Transmission Fluid Type “F”.

^For Gas/LP/Diesel Machines Only

*For Battery Machines Only

American-Lincoln 1-9

6150

SAFETY PRECAUTIONS

THE FOLLOWING STATEMENTS ARE USED THROUGHOUT THIS MANUAL AS INDICATED IN THEIR

DESCRIPTIONS:

DANGER

To warn of immediate hazards which will result in severe personal injury or death.

WARNING

To warn of hazards or unsafe practices which could result in severe personal injury or death.

CAUTION

To warn of hazards or unsafe practices which could result in minor personal injury.

ATTENTION

To warn of unsafe practices which could result in extensive equipment damage.

NOTE

To give important information or to warn of unsafe practices which could result in equipment damage.

THE FOLLOWING INFORMATION SIGNALS POTENTIALLY DANGEROUS CONDITIONS TO THE OPERATOR OR EQUIPMENT. READ THIS MANUAL CAREFULLY. KNOW WHEN THESE CONDITIONS CAN EXIST.

THEN, TAKE NECESSARY STEPS TO TRAIN MACHINE OPERATING PERSONNEL.

FOR THE SAFE OPERATION OF THIS MACHINE, READ AND UNDERSTAND ALL WARNINGS,

CAUTIONS AND NOTES.

WARNING

Machines can ignite flammable materials and vapors. Do not use with or near flammables such as: gasoline, grain

dust, solvents and thinners.

WARNING

Heavy machinery. Improper use can cause personal injury.

WARNING

Operate only when lids, doors, and access panels are securely closed.

WARNING

Use care when reversing machine in confined area.

WARNING

When servicing the machine disconnect the battery first to prevent possible injury.

WARNING

When working on the machine, empty hopper, disconnect battery, clear area of people and obstructions, use

additional people and proper procedures when lifting the machine.

WARNING

Always empty the Hopper and Disconnect Battery before doing maintenance.

WARNING

You must have training in the operation of this machine before using it. READ THE INSTRUCTION BOOK.

WARNING

Do not operate this machine unless it is completely assembled.

WARNING

Do not use this machine as a step or furniture.

1-10 American-Lincoln

6150

SAFETY PRECAUTIONS

WARNING

Be careful when operating the machine on a ramp or incline. Always move slowly on a ramp. Do not turn this

machine on a ramp. Do not stop and leave this machine on a ramp.

WARNING

Stop and leave this machine on a level surface. When you stop the machine, put the power switch in the “OFF”

position and Engage the parking brake.

WARNING

To prevent injury, and damage to the machine, do not lift the machine or move it to an edge of a stair or loading

dock.

WARNING

Lead acid batteries generate gases which can cause an explosion. Keep sparks and flames away from batteries.

NO SMOKING. Charge batteries only in area with good ventilation.

WARNING

Always wear eye protection and protective clothing when working near batteries. Remove all jewelry. Do not put

tools or other metal objects across the battery terminals, or the tops of batteries.

WARNING

Maintenance and repairs must be done by authorized personnel only. Tighten all fasteners. Keep adjustments

according to the specifications given in the service manual for the machine. Keep the electrical parts of the

machine dry. For storage, keep the machine in a building.

WARNING

Make sure that all labels, decals, warnings, cautions and instructions are fastened to the machine. Get new labels

and decals from American Lincoln.

WARNING

To maintain stability of this sweeper in normal operation, the counterweights, over-head guard, rear bumper guard

or any similar equipment installed by the manufacturer as original equipment, should never be removed. If it

becomes necessary to remove such equipment for repair or maintenance. This equipment must be reinstalled

before the sweeper is placed back in operation.

WARNING

The hopper could lower unexpectedly and cause personal injury. Engage the hopper safety arm before working

under the hopper.

WEEE Symbol Information

ENGLISH

Correct Disposal of This Product (Waste Electrical & Electronic Equipment)

(Applicable in the European Union and other European countries with separate

collection systems)

This marking, shown on the product or its literature, indicates that it should not be

disposed with other household wastes at the end of its working life. To prevent possible

harm to the environment or human health from uncontrolled waste disposal, please

separate this from other types of wastes and recycle it responsibly to promote the

sustainable reuse of material resources. Household users should contact either the

retailer where they purchased this product, or their local government office, for details

of where and how they can take this item for environmentally safe recycling. Business

users should contact their supplier and check the terms and conditions of the purchase

contract. This product should not be mixed with other commercial wastes for disposal.

American-Lincoln 1-11

6150

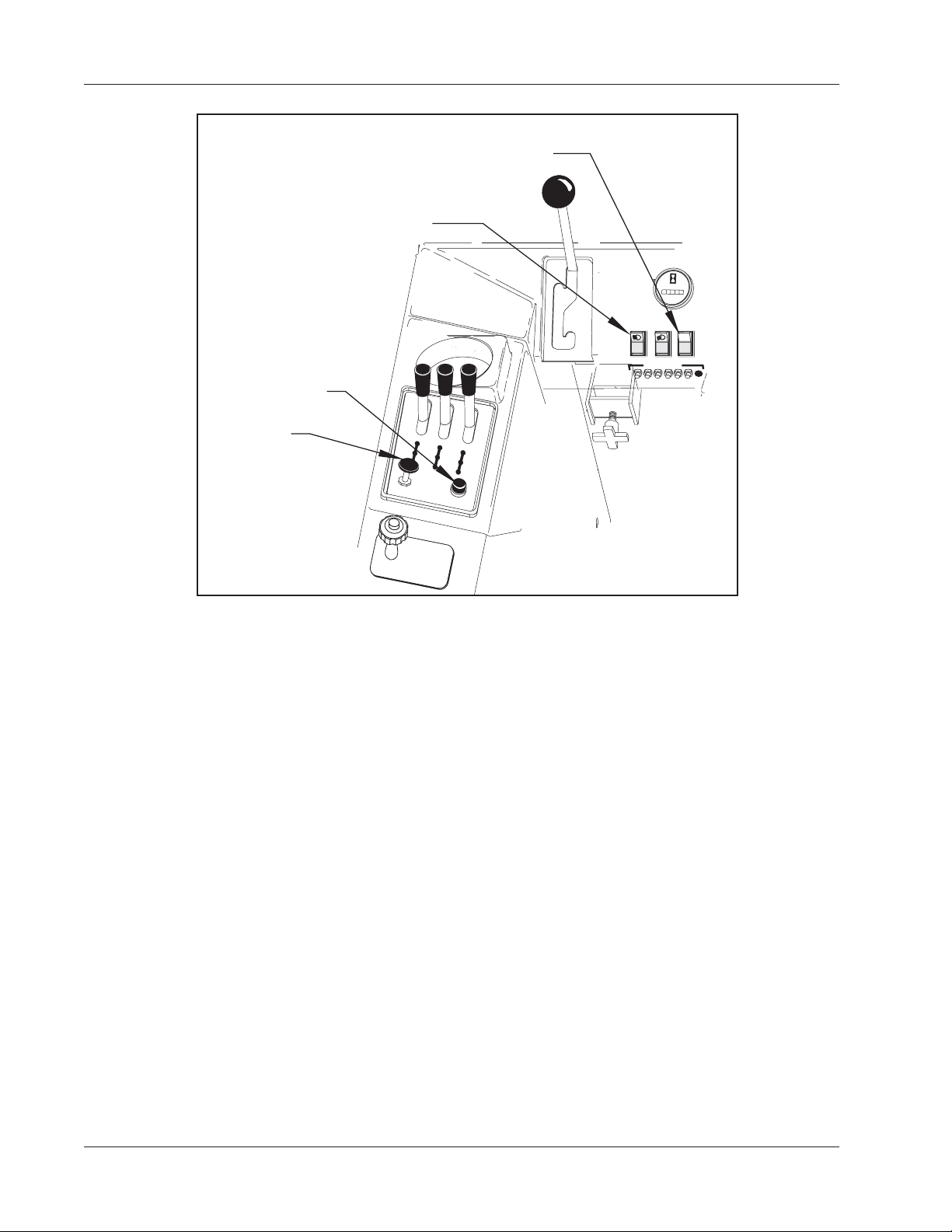

SWEEPER CONTROLS/INSTRUMENTS

GLOW

LIGHT

SWITCH

PLUG

SWITCH

LIGHTS

WORK

LIGHT

H

O

U

R

S

0

0

0

0

0

1

/1

0

GLOW

PLUG

MAIN BROOM

CIRCUT BREAKERS

1234

HORN

CHOKE

CHOKE

C0701A FIGURE 1

HORN BUTTON

The horn button is located on the left side console next to the choke control. Push the button to sound the horn.

The horn button is always active.

LIGHT SWITCH

The light switch is located on the instrument panel and controls the headlights, taillights and instrument panel

lights. To turn on the lights press the upper portion of the switch. The upper potion of the switch will illuminate to

indicate the lights are “ON”. The light switch is always active.

H

T

T

O

R

HORN

E

L

T

GLOW PLUG SWITCH (Diesel Only)

The glow plug switch is a momentary type rocker switch that is located on the instrument panel and is used to

start the diesel engine. It should be noted that under no circumstances should Ether or other starting aids be

used in conjunction with the glow plugs. To prevent damage to the glow plug switch, do not use for more than 60

seconds. They key switch must be placed in the “ON” position before using the glow plug switch.

CHOKE CONTROL

The choke control is located on the left side console and is used to aid in starting the engine. The choke

governs the mixture of air and fuel during the combustion cycle of the engine operation. The choke should be

pulled up during the start of the engine and then gradually pushed back down after engine warm up.

To turn on the choke for “Cold” starting, pull “UP” on the control.

To turn off the choke once engine has been started gradually push the control “DOWN”.

1-12 American-Lincoln

6150

C0701-1

C0703/0005

FILTER

SHAKER

KEY

SWITCH

SWEEPER CONTROLS/INSTRUMENTS

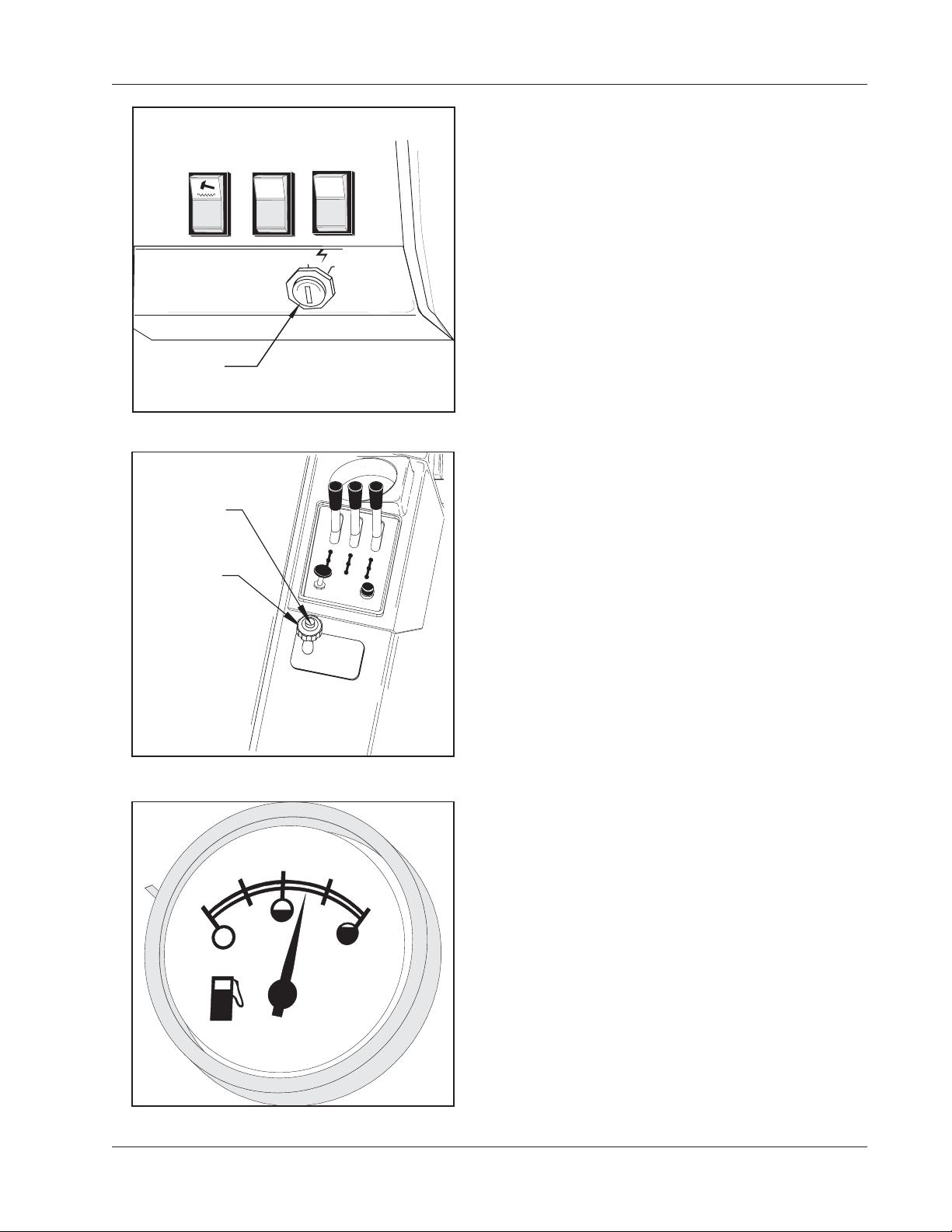

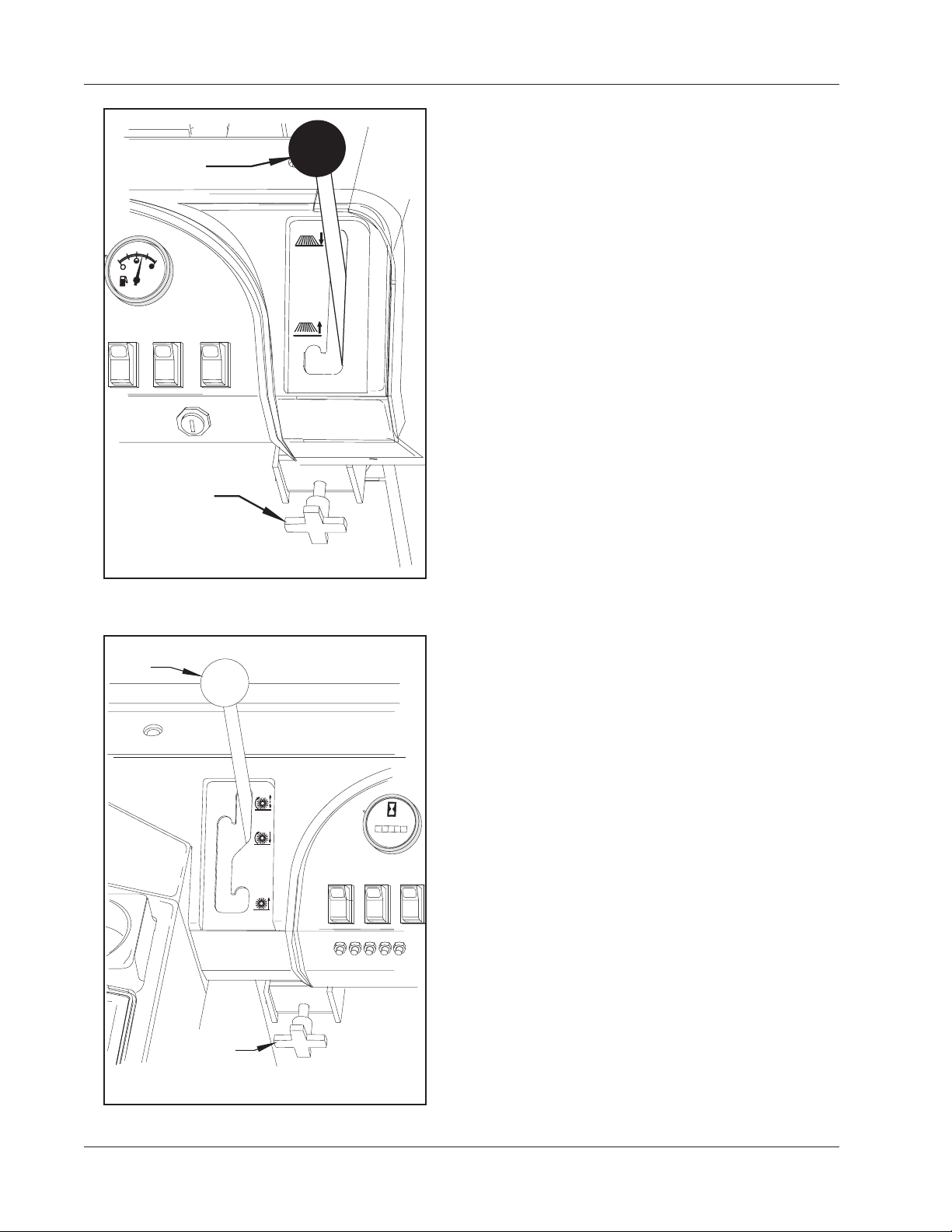

KEY SWITCH

The keyed ignition switch is located on the instrument

panel to the right of the steering column. The key switch

is a four position switch that controls power to the

sweeper systems and accessories.

BATTERY POWERED MACHINES

The “O ” position will shut off power to the machine

O

I

propulsion and sweeping systems.

The “I” position provides power to all sweeper systems and

accessories.

GAS/DIESEL/LP POWERED MACHINES

The “O” position will shut off the engine.

C0701-1 FIGURE 2

PUSH BUTTON

TO RELEASE

THROTTLE

C0702 FIGURE 3

1/2

The “I” position provides power to all sweeper systems and

accessories.

THROTTLE

The engine speed is controlled by a locking push-pull

control which is located on the operator’s compartment

side console.

C

H

O

K

E

H

O

R

N

The position of the throttle determines the operating speed

of the engine. The position is variable from idle to max

engine speed and may be adjusted to suit operating

conditions.

THROTTLE

The locking feature of the engine throttle control consists

of a rubberized push button that unlocks the control for

adjustment.

Push down on the button while positioning the control to

the desired setting, then release the button to unlock the

throttle in place.

Pull up on the throttle to increase engine speed.

Push down on the throttle to decrease engine speed.

0

4/4

FUEL GAUGE

The fuel gauge is located on the instrument panel and

indicates the level of fuel in the tank. The fuel gauge is

powered by the key switch. The key switch must be in

the “I” position for the fuel gauge to work. The fuel gauge

is not included on machines that use Battery or Liquid

FUEL

Propane fuel.

C0703 FIGURE 4

American-Lincoln 1-13

6150

C

C-0704

R

OLES

SWEEPER CONTROLS/INSTRUCTIONS

1/2

4/4

MAINBROOM

FOOT

BRAKE

LIGHTS

CIRCUTBREAKERS

1234

H

O

U

R

S

0

0

0

0

0

1

/

1

0

WORK

GLOW

LIGHT

PLUG

5 6 OPTION

American-Lincoln

APPLY

BRAKE

TO

0

FUEL

FILTER

DUST

ENGINE

SHAKER

CONTROL

SPEED

2

1

SIDEBROOM

IDLE

OFF

ACC

IGN/ON

START

FOOT BRAKE

The foot brake pedal is located on the floor of the

operator’s compartment to the left of the directional

control pedal.

To stop, apply foot pressure to the brake pedal.

PARKING BRAKE

The parking brake lever is located on the operator’s

compartment left side panel near the floor. When engaged

the parking brake “locks” the foot pedal in the down

position.

-0704

C0704 FIGURE 5

H

O

U

R

S

0

0

0

0

0

1

/10

PARKING

WORK

GLOW

LIGHTS

LIGHT

PLUG

BRAKE

CIRCUTBREAKERS

American-Lincoln

5 6 OPTION

C-0705

MAINBROOM

TO

RELEASE

BRAKE

1234

C0705 FIGURE 6

- To engage the parking brake, place the lever in

the upright position.

- To disengage the parking brake, move the lever for

ward.

- To Adjust The Parking brake “Grab” Turn the knob on

the top of the lever.

1/2

4/4

0

FUEL

FILTER

DUST

SHAKER

CONTROL

SIDEBROOM

O

I

- To increase “Grab” Turn the knob in a clockwise

direction.

- To decrease “Grab” Turn the knob in a counterclockwise direction.

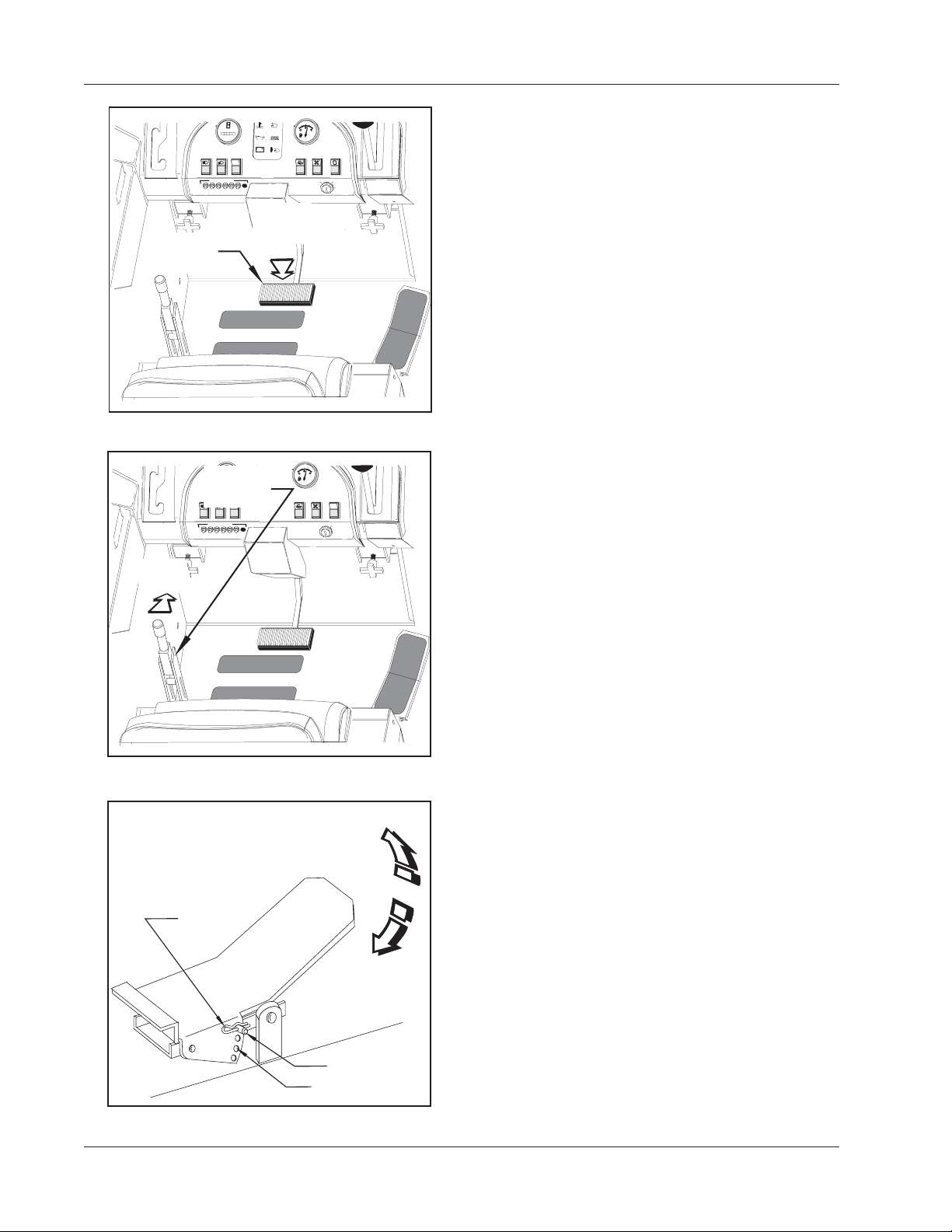

FOOT PEDAL

The Foot Pedal is located on the floor of operator’s

compartment to the right of the brake pedal. The foot

pedal provides control of direction/speed and has an

automatic safety feature that limits foot pedal travel while

the hopper is raised. The pedal height is adjustable to

provide for operator comfort.

TO GO FORWARD: Place pressure on the upper portion

of the pedal. Speed increases when additional pressure is

placed on the pedal.

TO GO BACKWARD: Put pressure on the lower portion of

EVERSE

the pedal. Speed increases when additional pressure is

placed on the pedal.

-To increase braking action while sweeper is moving

NEUTRAL

forward, gently put pressure on the lower portion of the

pedal.

HAIRPIN

COTTER

FORWARD

-To Increase braking action while traveling in reverse,

gently put pressure on the upper portion of the pedal.

To adjust the foot pedal height for operator comfort

1. Remove the hairpin cotter from the adjustment pin.

2. Remove the adjustment pin from the foot pedal

assembly.

3. Align the holes in the lower bracket with one of the

C-0706

C0706 FIGURE 7

ADJUSTMENT

PIN

ADJUSTMENT

H

four adjustment holes on the foot pedal to set the

foot pedal height.

4. With the holes aligned at the desired height, insert

the adjustment pin

5. Reinstall the hairpin cotter.

1-14 American-Lincoln

6150

WARNING

ENGINE

SWEEPER CONTROLS/INSTRUMENTS

HOPPER

DUMP DOOR

LIGHT

DUST

CONTROL

LIGHT

HOPPER

TEMP.

LIGHT

ENGINE OIL

PRESSURE

LIGHT

CHARGING

SYSTEM

LIGHT

TEMP.

LIGHT

LIGHTS

1234

C-0707-1

HOURS

00000

WORK

LIGHT

CIRCUT BREAKERS

1

/

1

0

GLOW

PLUG

5 678

BANK

1/2

4/4

0

FUEL

-

+

FILTER

SHAKER

DUST

CONTROL

O

I

C0707-1 FIGURE 8

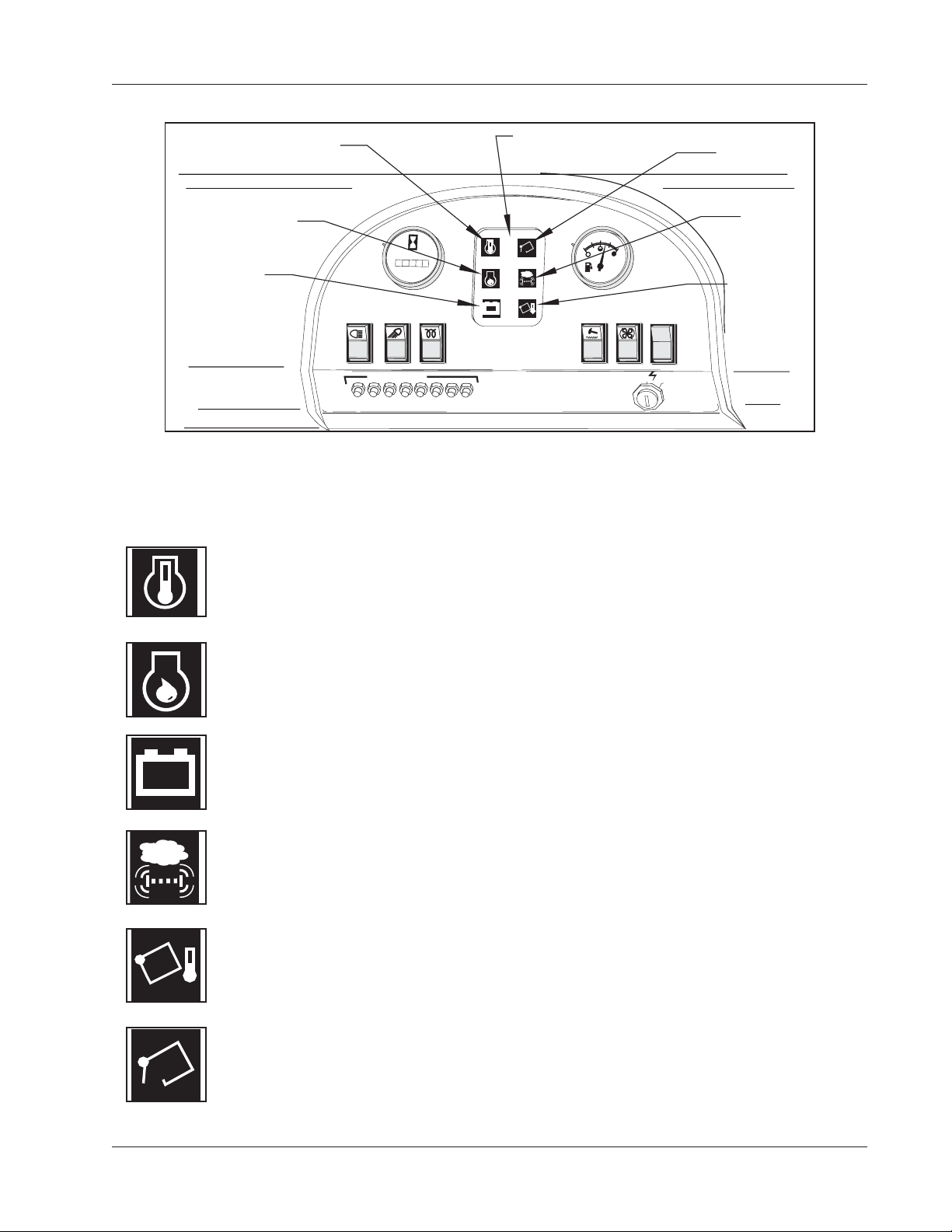

WARNING BANK

The Warning Bank is located on the instrument panel and provides the operator with six fault/status indicators

for engine and sweeper systems. The Operator should monitor the indicators while sweeping. It is very important

that the operator be familiar with the meaning of each indicator.

ENGINE TEMP LIGHT

The engine temperature light illuminates to indicate an engine cooling system fault. When this

occurs the operator must turn off the sweeper immediately and have the cooling system

serviced by a qualified service technician.

ENGINE OIL PRESSURE LIGHT

When the oil pressure drops below approximately 5 psi an automatic protection circuit shuts

down the engine and illuminates the light to indicate low engine oil pressure. When this occurs

have the sweeper serviced by a qualified service technician.

CHARGING SYSTEM LIGHT

-

+

The charging system light illuminates to indicate a charging system fault. When this occurs

the sweeper charging system is not working properly and must be serviced by a qualified

service technician.

DUST CONTROL LIGHT

The Dust Control Light Illuminates to indicate that the dust control filter is clogged. When this

occurs, stop sweeping and use the filter shaker to clear dirt and debris from the filter. After

using the filter shaker continue sweeping.

HOPPER TEMPERATURE LIGHT

When the temperature of the air moving through the dust control system in the hopper ex

ceeds 140° F, an automatic protection feature shuts down the dust control fan and illuminates

the hopper temperature light. When this occurs shut down the sweeper and carefully investi

gate for a possible fire in the hopper. The temperature switch must be manually reset.

DUMP DOOR LIGHT

The dump door light will illuminate when the dump door is not fully open. The light warns the

operator to open the hopper dump door completely before sweeping. Do not sweep when the

light is illuminated.

American-Lincoln 1-15

6150

SEAT

SWEEPER CONTROLS/INSTRUMENTS

POSITION

ADJUSTMENT

LEVER

TO

LOCK

C-0714

C0714 FIGURE 9

TURN SIGNAL

SWITCH

00000

WORK

LIGHTS

LIGHT

TO SIGNAL

RIGHT TURN

TO TURN

ON 4-WAY

FLASHER

TO SIGNAL

LEFT TURN

HOURS

1

/

1

GLOW

PLUG

0

4-WAY FLASHER

American-Lincoln

TO ADJUST

SWITCH

0

SEAT POSITION ADJUSTMENT

The seat adjustment lever is located on the right side of

the seat base. The lever is spring loaded to the “LOCK”

position.

To adjust the seat, push “FORWARD” on the lever and

move seat to desired position then release the lever to

“LOCK” the seat in place.

TURN SIGNALS - 4 WAY (OPTION)

The turn signal switch is located on the steering column

and functions the same as a typical automotive turn signal.

The operator must return the lever to the centered position

after the turn has been completed.

1/2

4/4

FUEL

-To signal a right hand turn move the lever to the “FORWARD” position.

-To signal a left hand turn position the lever to the “BACKWARD” position.

-To use the 4-way Flashers pull out on the turn signal lever.

C-0715

BACK UP ALARM (OPTION)

The backup alarm is activated by a switch in the foot pedal

C0715 FIGURE 10

and automatically emits a loud audible noise when the

machine is driven in reverse.

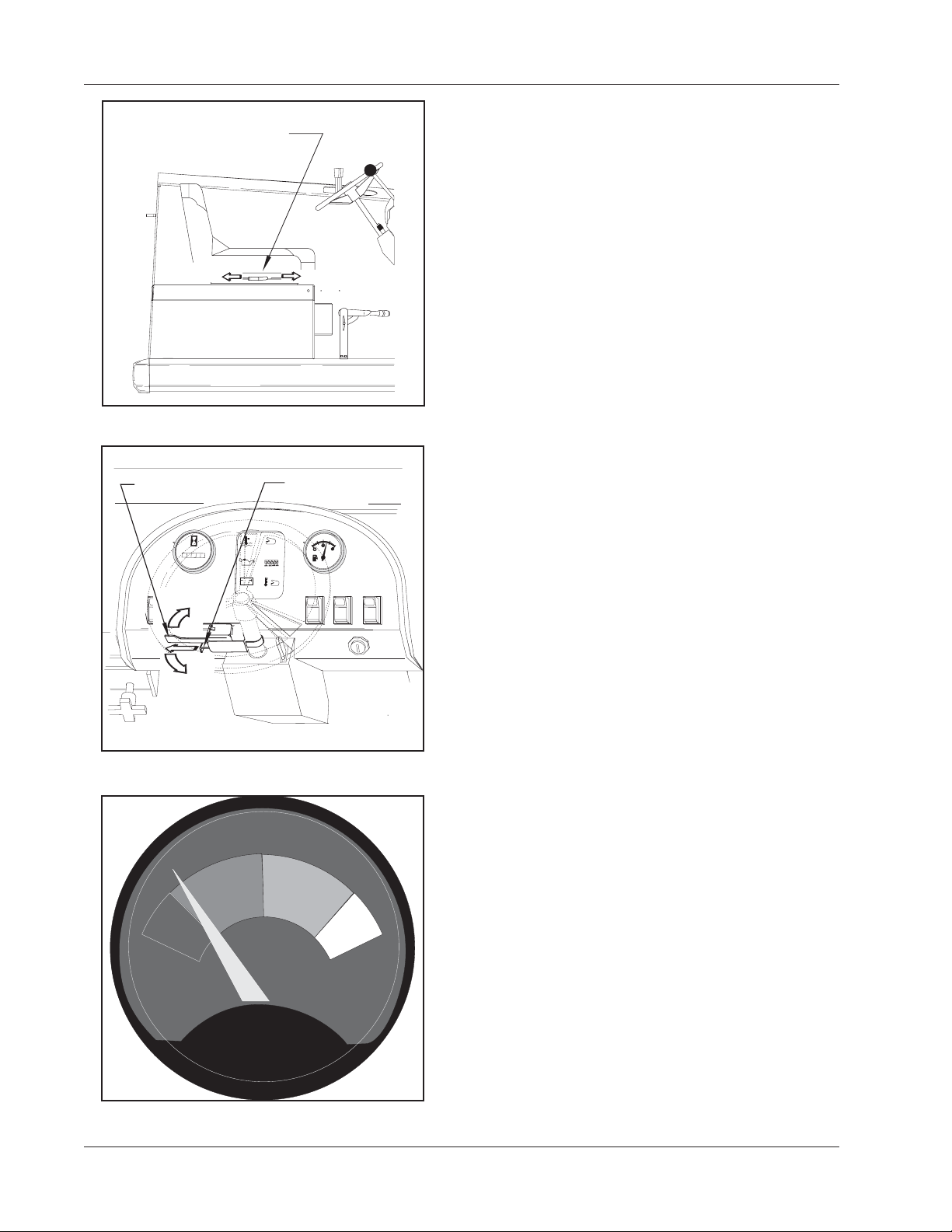

BATTERY CONDITION METER (Battery Power Only)

The battery condition meter is located on the right side of

the instrument panel. The condition meter indicates the

level of charge in the batteries. The batteries are sufficiently charges when the needle stays in the green area

on the gauge while the machine is being operated.

Charge the batteries when the needle drops into the red

zone while operating the machine,

Do not operate the machine if the needle stays in the red

zone. Operating the sweeper with discharges batteries

with degrade battery life.

C-0718

C0718 FIGURE 11

1-16 American-Lincoln

6150

FILTER

BROOMS

SHAKER

C0717-1

FILTER

SHAKER

DUST

CONTROL

O

C0717-1 FIGURE 12

DUST

CONTROL

FILTER

SHAKER

DUST

CONTROL

SWEEPER CONTROLS/INSTRUMENTS

FILTER SHAKER SWITCH

The filter shaker switch is located on the instrument panel

below the fuel gauge. This is a momentary switch that will

activate the filter shaker motors for 20 to 30 seconds to

clear the dust control filter. The impeller fan will stop when

the filter shaker has been activated.

The filter shaker will only operate with the hopper in the

“DOWN” position. Use the filter shaker to clear the filter

when the dust control light on the warning bank illuminates

I

and just before dumping the hopper.

To activate the filter shaker press the upper portion of the

filter shaker switch momentarily and release. The filter

shaker will operate for 20 to 30 seconds.

DUST CONTROL SWITCH

The dust control is a two position switch that is located on

the instrument panel next to the engine speed switch. The

switch controls the vacuum fan in the dust control system.

To turn on the dust control system for “NORMAL” Sweeping, press on the top portion of the switch.

O

C0716-1

C0716-1 FIGURE 13

CONTROL

LEVER

O

N

OPEN

O

N

BROOMS

C

L

O

S

E

H

O

RAISE

P

P

E

R

H

D

O

O

P

O

CHOKE

C-0719

R

HORN

To Turn off the dust control system for sweeping in wet

I

conditions, press on the lower portion of the switch. This

will prevent the filter from being damaged by water pickup

while sweeping.

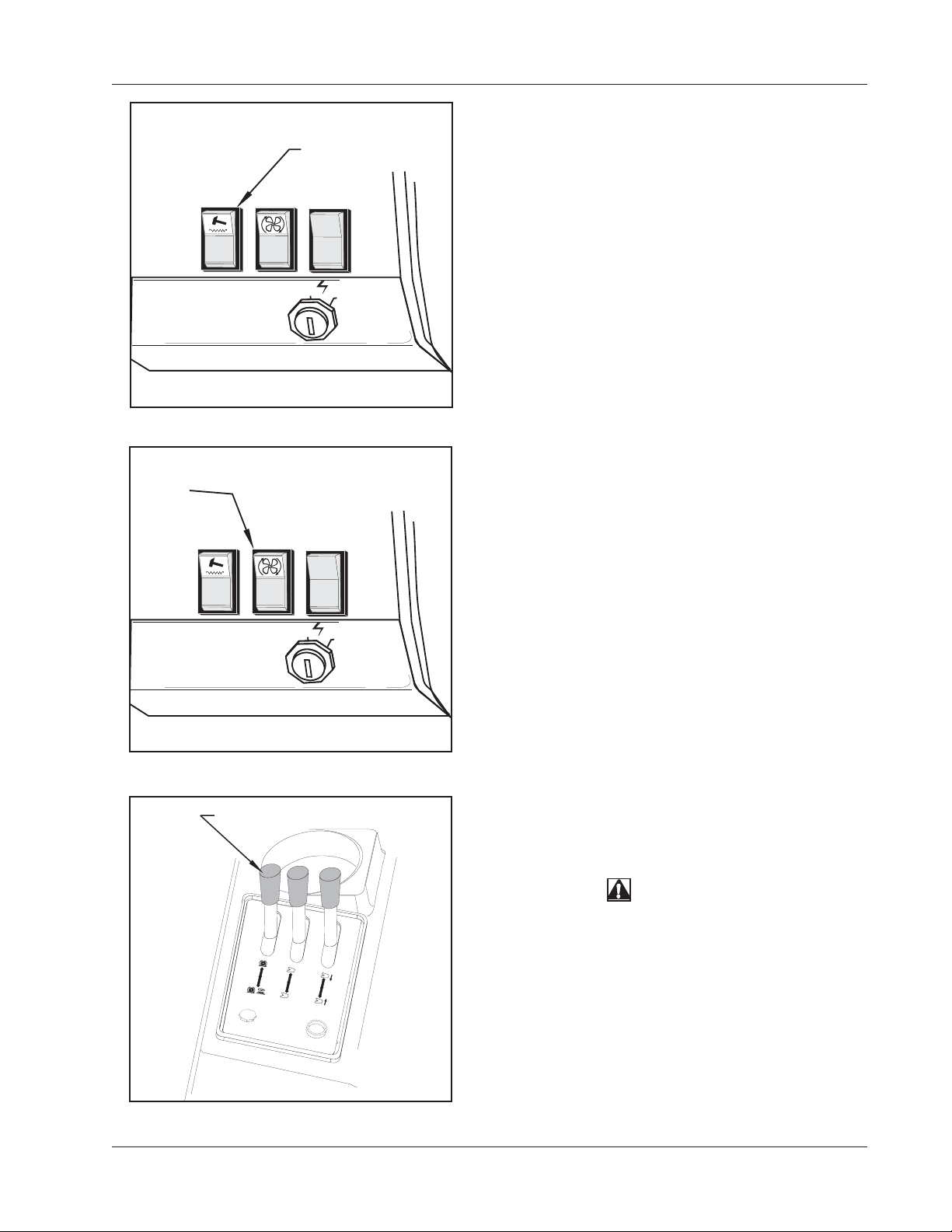

BROOMS CONTROL LEVER

The brooms control lever is located on the operator’s

compartment center console. The lever is a three position

hydraulic valve that controls hydraulic power to the main

broom and side broom.

WARNING

To prevent injury, Do not turn on the brooms

with the hopper raised.

LO

W

ER

To turn on the main broom only, move the lever to the

forward position.

P

E

R

To turn on the main broom and the side broom, move the

lever fully backwards.

To turn off the brooms and provide hydraulic power to the

hopper lift system place the lever in the center position.

C0719 FIGURE 14

American-Lincoln 1-17

6150

SWEEPER CONTROLS/INSTRUMENTS

SIDE BROOM

LEVER

1/2

4/4

0

FUEL

SIDE BROOM

ADJUSTMENT

DOWN

UP

SIDE BROOM

SIDE BROOM LEVER

The side broom lever is located on the right side of the

instrument panel. The side broom lever raises and lowers

the side broom. Use the brooms lever on the operator’s

center console to turn on the side broom.

To raise the side broom, pull the lever back into the “UP”

position.

To lower the side broom, move the lever out of the

detented “UP” position and move it forward to the “DOWN”

position.

SIDE BROOM ADJUSTMENT

The side broom lever has an adjustment for changing the

sweep height to compensate for broom wear. The side

broom adjustment is located under the right side of the

instrument panel.

To Adjust the side broom height turn the threaded knob.

C0720 FIGURE 15

MAIN BROOM

LEVER

FLOAT

SWEEP

UP

MAIN BROOM

MAIN BROOM

ADJUSTMENT

C-0721

C0721 FIGURE 16

LIGHTS

WORK

LIGHT

MAIN BROOM LEVER

The main broom lever is located on the left side of the

instrument panel. The main broom lever has three positions and controls the main broom sweep height. Use the

brooms lever on the operator’s center console to turn on

the main broom.

To lower the main broom, grasp the lever and move it to

the left out of the “UP” position and place in the “SWEEP”

or “FLOAT” position.

H

O

U

R

S

0

0

0

0

0

1

/

1

0

The “SWEEP” position is used for normal sweeping and

should be used under most sweeping conditions.

GLOW

PLUG

The “FLOAT” position is used for sweeping very uneven

surfaces only. Using the Float position will cause premature wear on the main broom if used under normal operating conditions for extended periods of time.

MAIN BROOM ADJUSTMENT

The main broom lever has an adjustment for changing the

sweep height to compensate for broom wear. The main

broom adjustment is located under the left side of the

instrument panel.

To Adjust the main broom height turn the threaded knob.

1-18 American-Lincoln

6150

S

SWEEPER CONTROLS/INSTRUMENTS

ON

OPEN

ON

B

CLOSE

R

O

O

M

S

H

O

P

P

E

R

H

D

O

O

C-0722

C

H

R

O

K

E

H

C0722 FIGURE 17

HOPPER

LIFT

LEVER

O

N

OPEN

O

N

B

C

R

L

O

O

S

O

E

M

S

H

O

P

P

ER

H

D

O

O

C-0723

C

H

R

O

K

E

H

C0723 FIGURE 18

O

O

O

RAISE

O

R

P

PPE

R

LOWER

A

IS

P

R

LOWER

HOPPER

DOOR

LEVER

E

E

R

N

R

N

DEBRI

DOOR

HOPPER DOOR LEVER

The hopper door lever is located on the operator’s compartment center console and is used to close and open

the hopper dump door. The lever is a three position

hydraulic valve that is spring loaded to the center position

which “HOLDS” the hopper door in position.

NOTE

To provide hydraulic power to the hopper controls, the

broom control lever must be in the center “Neutral”

Position

To ensure the door is fully open while sweeping, monitor

the Hopper Dump Door light on the Warning Bank . The

light will illuminate when the door is not fully open.

To open the hopper dump door for sweeping or dumping,

push the lever forward in the “OPEN” direction until the

hopper dump door light goes out.

To close the hopper dump door for dumping or transporting, pull the lever fully back in the “CLOSE” direction and

hold for 3 seconds or until you hear the door close.

HOPPER LIFT LEVER

The hopper lift lever is located on the operator’s compartment center console. The lever is a three position hydraulic valve that controls the operation of the hopper lift

system. The lever is spring loaded to the center position

which stops hopper movement and “HOLDS” the hopper at

the present position.

NOTE

To provide hydraulic power to the hopper controls, the

broom control lever must be in the center “Neutral”

Position

To raise the hopper for dumping, move the lever back to

the “RAISE” position and hold until the hopper reaches the

desired height, then release.

WARNING

To prevent injury, Do not turn on the brooms with the hopper

raised.

To lower the hopper after dumping, move the lever forward

to the “LOWER” position until the hopper is fully lowered

and seated in the sweeper, then release.

DEBRIS DOOR

The hopper debris door provides the operator with easy

access to the hopper debris compartment for refuse

C-0724

disposal or visual inspection of the removable filter baffle

and hopper debris compartment. The debris door must be

C0724 FIGURE 19

closed while sweeping. Failure to close the door completely will cause poor dust control while sweeping.

American-Lincoln 1-19

6150

T

SWEEPER CONTROLS/INSTRUMENTS

DUST

BAFFLE

THREADED

KNOB

DUST BAFFLE

The dust baffle is located in the hopper and may be

removed for cleaning. The dust baffle is mounted to the

hopper with two threaded knobs for easy removal.

The debris door must be opened to gain access to the

dust baffle.

Remove and clean the dust baffle when debris becomes

lodged in the baffle passages.

To remove the baffle, turn the two threaded knobs counterclockwise and lift the baffle off the studs.

C-0726

C0726 FIGURE 20

HOPPER

SAFETY ARM

WARNING

MODELNO. SERIALNO.

6150

C-0727

C0727 FIGURE 21

TO

ENGAGE

DEBRIS

COMPARTMEN

COVER

HAND

HOLD

To install the baffle, position the baffle on the studs and

turn the two threaded knobs clockwise.

HOPPER SAFETY ARM

The hopper safety arm is located near the right front wheel

well. The safety arm will prevent the hopper from dropping

unexpectedly during service/maintenance.

WARNING

The Hopper Could Drop Unexpectedly And Cause Injury.

Engage The Safety Arm Before Working Under Hopper.

WARNING

For Safety Always Empty Hopper Before Servicing.

TO ENGAGE THE SAFETY ARM:

1. Empty hopper.

2. Set the parking brake.

3. Raise the hopper.

4. Lift safety arm to engage the slot on the hopper

frame.

5. When work has been completed, replace the safety

arm to the stowed position.

HOPPER FILTER COMPARTMENT COVER

The Hopper Filter Compartment Cover is located on the

top of the hopper and opens forward for access to the filter

compartment for service and inspection of the dust control

filter and operational hopper temp sensor.

Use the hand hold provided to open the cover.

Inspect the cover gaskets daily. Replace any cover

gaskets that show signs of deterioration. Failure to

maintain the gaskets in serviceable condition will degrade

dust control at the floor and will result in less than minimal

sweeping performance.

C-0776

C0776 FIGURE 22

1-20 American-Lincoln

6150

SWEEPER CONTROLS/INSTRUMENTS

TURN LATCH

TO RELEASE

FILTER

PANEL

C-0777

C0777 FIGURE 23

HOPPER

TEMPERATURE

SENSOR

RESET

BUTTON

LIFT

FRAME TO

REMOVE

FILTER

PUSH

TO

RESET

FILTER

PANEL

LATCH

FILTER PANEL LATCH

The filter panel is located in the hopper filter compartment

and will need to be removed periodically for cleaning or

replacement. Removal of the filter panel requires no tools.

The hopper cover must be opened to gain access to the

filter compartment. The panel filter is held in place by a

hinged frame and latch.

To remove the panel filter, turn the know counter clockwise

and lift the hinged frame.

The panel filter can now be lifted out and cleaned or

replaced. (See Filter Cleaning Instructions in the Manual.)

To install the replacement panel filter, lower the frame and

turn the knob clockwise to lock the filter in place.

HOPPER TEMP SENSOR (OPTION)

The temp sensor switch monitors the hopper air temperature near the vac fan. When the temperature of the air

moving through the hopper exceeds 140ºF the switch trips

which turns off the dust control fan and illuminates the

hopper temp light on the warning bank.

The hopper temp sensor is a resetable thermal switch

which is locates in the hopper filter compartment near the

vacuum fan intake.

C0778 FIGURE 24

-

ENGINE

COMPARTMENT

LATCH

LIFTTOOPEN

When the hopper temp light illuminates, carefully investigate for a possible fire in the hopper.

The sensor will not reset until the temperature in the

hopper has dropped below 133ºF.

To reset the temp sensor, press the reset button.

ENGINE COMPARTMENT LATCH

The engine cover encloses the entire engine, radiator and

hydraulic reservoir assembly. The cover can be swung

open to allow easy access to the engine and hydraulics

for service or inspection.

WARNING

Operate Only When Lids, Doors, And Access Panels Are

Securely Closed.

American-Lincoln

To open the cover, lift the cover latch lever up. Swing the

cover open.

The cover will latch automatically when the cover is

closed. After closing the engine cover, check to be certain

the latch has fully engaged.

C-0779

C0779 FIGURE 25

American-Lincoln 1-21

6150

SWEEPER CONTROLS/INSTRUMENTS

HYDRAULIC

SIGHT

GAUGE

C-0728

C0728 FIGURE 26

American-Lincoln

MAIN BROOM

COMPARTMENT

LATCH

HYDRAULIC RESERVOIR LEVEL SIGHT GAUGE

The sight gauge is located on the side of the hydraulic

reservoir in the engine compartment. The sight gauge is

used to indicate the level of fluid in the reservoir. Fluid level

must be visible in the sight gauge when the hopper is in

the down position.

MAIN BROOM COMPARTMENT DOORS

The main broom compartment doors are located behind

the front tires on both sides of the sweeper. The doors

provide access to the main broom for service or inspection.

WARNING

Operate Only When Lids, Doors, And Access Panels Are

Securely Closed.

Open the right side door to remove or replace the main

broom. The right side door is an integral part of the main

broom drive system and must be closed for operation.

Open the left side broom door for inspection. Check the

drive hub for banding and shrink wrap which have a

tendency to get tangled in the broom driver.

To open the main broom door, reach inside the hole in the

door and lift up on the latch handle.

The door latch will automatically engage when the door is

closed.

C-0729

LIFT TO OPEN

C0729 FIGURE 27

WARNING

American-Lincoln

c0731/0005

C0731 FIGURE 28

SEAT COMPARTMENT COVER

The seat compartment cover opens to allow easy access

to various components which will need to be inspected or

serviced periodically. The cover opens forward and has a

safety latch to hold the cover in the open position.

WARNING

Lead acid batteries generate gases which can cause an

explosion. Keep sparks and flames away from batteries.

NO SMOKING. Charge batteries only in area with good

ventilation and keep the seat cover open to vent explosive

hydrogen gas.

MODELNO. SERIALNO.

On battery powered machines the compartment below the

seat contains the charging connector for the batteries.

Use the safety latch to hold the cover open while charging

the batteries.

On Gas/Diesel/LP powered machines the seat compartment contains the fuel tank.

1-22 American-Lincoln

6150

LIFT TO HOLD

LIFT TO HOLD

SEAT COVER

OPEN

SEAT COVER

OPEN

C0732

C0732 FIGURE 29

BATTERY

CHARGING

CONNECTOR

TRABA DEL COMPARTIMIENTO

DEL ASIENTO

TO DISCONNECT

BATTERIES

FOR CHARGING

SWEEPER CONTROLS/INSTRUMENTS

SEAT COMPARTMENT LATCH

The seat compartment latch is located under the seat

compartment cover and is used to hold the cover open

while charging the batteries.

To hold the seat compartment cover open, lift the latch to

the vertical position and release the cover to rest on the

latch.

BATTERY CHARGING CONNECTOR

The batteries on battery powered machines are connected

to the machine through a heavy duty two conductor

connector. The connector allows an easy method of

disconnecting power to the machine for service or charging of the batteries.

C0730 FIGURE 30

Plug the charger into the connector to charge the batteries.

WARNING

Disconnecting the battery connector with the key switch in

the “I” position will cause sparks that could ignite explosive

hydrogen gas generated by the batteries. To prevent

serious injury or possible property damage, turn key switch

to “O” position before disconnecting battery cable from

machine charging or service.

American-Lincoln 1-23

6150

HELPFUL HINTS FOR SWEEPING

SIDE AISLES

MAIN AISLE

P4134/0001

P4134 FIGURE 31

HOW TO SWEEP

The sweeper is intended for use on hard relatively flat surfaces such as cement, asphalt, and wood block floors.

Exercise care when maneuvering to keep wheels from dropping off curbs or into pot holes. Do not sweep over

obstructions.

WARNING

Do Not Turn The Steering Wheel Sharply When The Machine Is In Motion. The Sweeper Is Very Responsive To

Movement Of The Steering Wheel. Do Not Make Sudden Turns.

The sweeper is designated for dry sweeping conditions. Wet clay and muddy type material will adhere to

surface of sweeping chamber and hopper. Sweeping performance will degrade if these surfaces are not kept

clean. Large heavy objects such as bricks, large stone, and iron parts should not be swept. Damage to the

main broom or other sweeping system components is possible. String, rope, wire or metal strapping longer than

18 inches should not be swept. These items have a tendency to wrap around moving parts. This can cause

damage or degrade sweeping performance.

SWEEPING GUIDELINES

In actual sweeping, there is no single pattern that can be set forth in this manual. Each installation has its own

conditions, and the operator can readily set his own pattern using these guidelines.

-Pick up large debris before sweeping with machine.

-Use the machine to sweep debris from narrow aisles into main aisle.

-After the machine has made a sweeping run, push the filter shaker control button for 20 to 30 seconds, the filter

shakers will unload accumulated dust from the filter media.

-Sweep debris from main aisle.

-Overlap of broom paths when sweeping. This will eliminate leaving dirty patches.

-Empty hopper when the sweeper leaves debris, while sweeping

-Sweep in straight paths. Do not bump posts. Do not scrape the sides of the machine.

NOTE

Replace main broom when bristles are worn to 1.75 inch (3.5 cm) length. To order replacement brooms, see MAIN

BROOM section of this manual. Replace side broom when bristles fail to sweep debris into the path of the main

broom. To order replacement brooms, see SIDE BROOM section of this manual.

SWEEPING VARIOUS TYPES OF DEBRIS

For heavy sand, dirt, or excessive scattered debris, travel slowly with machine to allow main broom to deliver

best results. Do not expect a completely clean surface on the first pass under these conditions. Sometimes it

is necessary to have extra broom pressure where debris is excessively heavy. See “Main Broom Adjustment” for