Page 1

such as “CL-2” or “CL-3”. Consult your Niles

dealer, building contractor, or local building and

inspection department if unsure about which type

of wire is best for your application.

MS200 Mounting Location

Locating the MS200 in the center of a room

usually results in the most even IR receiving

coverage, especially if the room is square

shaped. Rooms that are L-shaped or long and

narrow require more careful consideration. With

these types of rooms, installing the MS200 closest to the primary location of the user will

ensure the best performance.

The MS200 is designed to surface-mount almost

anywhere. Convenient mounting locations for

the MS200 include:

• On the front panel of a television set, facing

the viewer.

• On the front surface of a wall, a cabinet,

an appliance, or a speaker grille.

• Behind a speaker grille (speaker grilles typically

reduce the effective range of an MS200 to 15').

Receiving Range and Pickup Angle

The receiving range of the MS200 will vary

according to the IR output strength of the remote

control being used. Remote strength varies

among brands by the number and size of the

batteries used, and how many IR emitters the

remote has. For example, remotes that operate

on two small AAA batteries and have only one

IR emitter are generally not as strong as remotes

that use the larger AA size batteries and have

two emitters. Tests with various manufacturers'

remote controls have shown that the operating

range can vary from a minimum of 18 feet to a

maximum of about 30 feet. The IR pickup angle

of the MS200 is 30° off-axis (horizontal and vertical) at 18'.

Infrared signals travel essentially line-of-sight.

They will not pass through or around solid

objects. Do not rely on an IR signal being able

to “bounce” off a wall or reflective object to the

MS200.

Avoiding Electrical Interference

Avoid locating the MS200 near any potential

sources of Electro-Magnetic Interference (EMI),

The most common sources are:

1. Light dimmers or variable speed controls for

ceiling fans. These controls emit more interference when turned down halfway. They

emit little or no interference when turned up

all the way (brightest or highest position).

2. Large appliances (air-conditioners, pumps,

motors, compressors; etc.).

3. AC line noise (noise brought into the system

via the wall outlet connected to the main

system unit).

Concealing the wire

If you are installing the wire into an existing

wall, take time to consider any possible obstructions which may be hidden inside the wall, such

as wood or metal studs, electrical, telephone or

other types of wiring, plumbing, AC or heating

conduit, old wall safes, etc.

If the MS200 cable needs to pass through any

cabinetry (or other obstruction) drill a hole

where the cable will run. Make sure the hole

accommodates the width of the cable.

Using the MS200 with the Intellipad Ci system.

The MS200 is fully compatible with the Niles

Intellipad Ci line, follow the wiring instructions

in Figure 4. For specific information see your

Intellipad Ci manual.

INSTALLATION

Determine a mounting location for the MS200.

If there is a potential source of EMI near the

proposed mounting location (e.g near an electrical dimmer) you must test to find the best (interference-free) position before mounting the

MS200 in place.

INTRODUCTION

The MS200 IR sensor is designed for use with

the Niles infrared extender systems.

Installed in a remote room location, the MS200

receives the IR commands transmitted from your

existing hand-held remotes in that room. The

commands are carried via a category 5 cable to

your A/V equipment in another room, and

instantly “repeated”.

The MS200 is compatible with all current Niles

infrared systems. It may be used along with, or

as an alternative to, the Niles TS100, MS100,

WS100, CS100 and MVC100IR sensors or the

IntelliPad

®

.

The MS200 is just one part of the three building

blocks necessary to complete a Niles IR repeating system:

• IR Main System Unit—Models MSU140,

MSU250, MSU480 and MSU440Z.

• IR Sensors/Keypads—Models WS100, TS100,

MS100, MS200, CS100, MVC100IR and the

Intellipad.

• IR Flashers—Models MF1, MF1VF, MF2,

MF2VF and the IRB1.

An IR sensor expansion hub, Model IRH610,

is available to provide additional sensor inputs

to your system.

INSTALLATION CONSIDERATIONS

Wiring MS200 Sensors

From every IR Sensor location, you must “home-

run” a cable back to the main system unit. “Homerun” means an individual cable is connected

between each IR Sensor and the main system unit.

You should never

daisy-chain (connect in parallel)

two or more IR Sensors to a single input. (Figure 2)

Type of Cable

The MS200 connects to the Niles Infrared Main

Systems Unit or IRH610 sensor expansion hub

with an individual home run of category 5 cable.

When running wires inside walls, most states and

municipalities in the U.S. specify that you must

use a special type of wire. Usually, the requirement is that the wire has a specific “CL” fire rating,

12334567

OVER PLEASE

8

FEATURES AND BENEFITS

The MS200 offers a number of improvements

over other miniature IR sensors.

• Plasma-proof performance— allows placement of the MS200 near plasma displays.

• CFL interference resistant— expands installation flexibility to areas with fluorescent lighting.

• Works under most lighting conditions, including indirect sunlight— eliminates environmental restrictions.

• Universal system— compatible with virtually all

brands of A/V equipment and remote controls.

• Excellent IR receiving range— you get 18' to

30' of remote control range (depending upon

the strength of your handheld remote).

• 100% factory tested for pickup range

and angle.

• Small size of only 11/16" wide x 1-1/16 high x

3-1/8" deep— fits almost anywhere.

• 10' connecting cable included.

• Available in black, white or silver.

• Printed circuit board design uses surface

mount technology (SMT), assuring high

reliability.

• Two year parts and labor warranty.

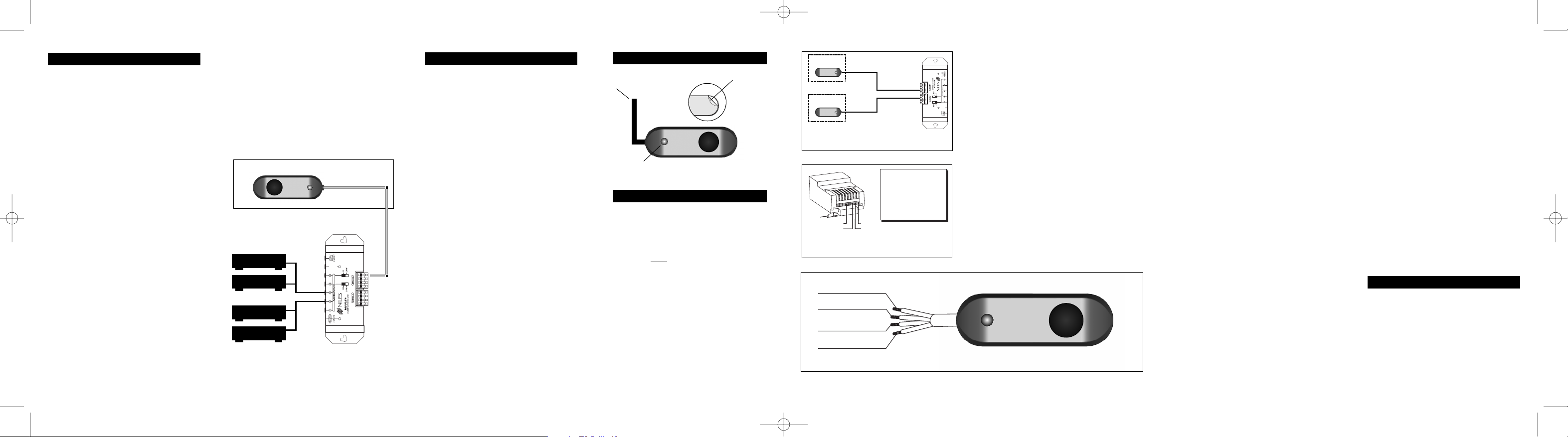

MS200 PARTS GUIDE

Blue

“Flashback”LED

Adhesive-

Backed

Strip for

Mounting

10 Feet of

Connecting Wire

Room 1

Room 2

MS200

Main

System

Unit

Figure 2 : Home run the Sensor

cable from each sensor to the MSU.

In a typical system (Figure 1) the MS200 remote

room sensors are placed in convenient locations

and are connected to a main system unit. The

main system unit is connected to power via its

12VDC power supply. In this example, the

MSU250 main system unit powers 2 MF2

MicroFlashers™ which are attached to the front

panel sensor windows of four A/V components.

MS200 IR Sensor in a remote location.

Figure 1

Main

System

Unit.

3-30V

AC/DC

STATUS

IN

Red = 12V+

Black = Ground

Yellow = Data

White = Status

1 = Green/White - 12V

2 = Green - DATA

3 = Orange/White - GROUND

4 = Blue - EMPTY

5 = Blue/White - STATUS

6 = Orange - EMPTY

7 = Brown/White - EMPTY

8 = Brown - EMPTY

1 = 12V

2 = DATA

5 = STATUS

3 = GROUND

Tab

Down

Figure 4 : Suggested wiring of MS200 to either

a Niles screwless connector or an RJ45 jack.

3-30V

AC/DC

STATUS

IN

Figure 5 : Wiring legend

DS00325ACN/MS200 1/8/04 9:53 AM Page 1

Page 2

SPECIFICATIONS

IR System

Compatible with virtually all brands of remotes

using carrier frequencies between 26 kHz and

100 kHz.

IR Receiving Range

Varies, depending on remote strength; typically

18-30'.

IR Receiving Angle

30° off-axis (horizontal and vertical) at 20'.

Mounting

Surface-mount. Self-adhesive mounting strip

included.

Unit Dimensions

Overall Unit: 2" Long x 1/2" Wide x 1/2" High.

IR Test LED Off:

Optical Interference.

IR Test LED On or Flickering:

Electromagnetic Interference.

EMI (Electromagnetic Interference)

Identify the source of the interference. The most

common sources of electromagnetic interference are listed in the Installation Considerations

section on page 8. To eliminate EMI try the following methods:

1. Move the sensor or the sensor cable away

from the EMI source

or move the source of

the EMI away from the sensor or the cable.

2. Connect the Sensor’s GND terminal to true

earth ground (if this isn’t feasible use the main

system unit’s GND terminal).

There are many methods for reducing interference. Which solution is best for you depends

on your situation. Contact Niles Technical

Support at 1-800-289-4434 if you require

further assistance.

The conditions which sometimes combine to

create a feedback loop are:

1. Both a sensor and a flasher are located within

the same room.

2. There is some low-level noise or interference

on your system.

You can eliminate optical feedback by replacing

any IRB-1 “flooding flasher” with an MF1 or

MF2 MicroFlasher™ and covering all flashers

with the supplied IR blocking covers.

Identifying the type of interference

The blue “flash-back” LED on the front of the

MS200 is a useful trouble-shooting aid.

If the MS200 does not work, and the LED does

not light at all:

Test the remote control(s) by

operating the A/V equipment directly. Replace

the batteries if needed. Double check the cable

connections on all MS200’s main system unit

and on the IR main system unit. Consult your IR

main system unit’s manual for more detail.

If the MS200 does not work, and the LED “flick-

ers” blue or remains solidly lit:

Cover up the

Sensor with a piece of cardboard (your hand will

actually create electromagnetic interference

under some conditions). Observe the IR test LED.

(MSU140, MSU250, MSU480 MSU440Z,

IntelliControl).

The bi-color blue/green LED on the front of the

MS200 is a useful troubleshooting aid.

The blue LED should light only when a remote

command is being received. If the LED on the

MS200 “flickers”, and the MS200 functions normally, there is no cause for concern, some stray

IR signal are being received by the MS200 but

are not being repeated.

1. Test the remote control(s) by operating the

A/V equipment directly. Replace the batteries

if needed.

2. Double check the cable connections on all

MS200's and on the main system unit. Look

for open, shorted or reversed wires.

3. Test for interference from the following

sources:

• Neon or halogen lights in the room.

• Light dimmers, beginning with those

closest to the MS200.

Observe the MS200’s LED while performing all

the tests. It is possible to have interference from

more than one source.

Eliminating optical feedback

In some installations, two conditions combine

to create an optical feedback loop. Symptoms

can include: poor range, intermittent operation

or no operation.

2. Use a small flathead screwdriver or your thumbnail to raise the locking tabs, exposing the holes

on the removable connector plug of the MSU.

3. Insert each wire into the appropriate hole on

the removable connector plug, and snap the

locking tab down. To help you, the connector

plug is keyed. Insert the smooth side of the

connector plug into the smooth side of

the socket. Don’t force the scalloped side

of the connector plug into the smooth side

of the socket.

4. Double-check all connections. This manual

contains instructions for the MS200 only.

For specific information on the adjustment

of your Niles Infrared system, please refer to

the instruction manual included with your

Niles IR main system unit.

OPERATION

Operation of the MS200 is straightforward.

Simply aim your hand-held remote at the

MS200. Your IR command is instantly repeated

to your A/V equipment. A blue “flash-back” LED

on the MS200 visually confirms the reception of

an IR signal.

TROUBLESHOOTING

This manual contains instructions for the MS200

only. For specific information on the adjustment

and operation of your Niles infrared extender

system, please refer to the instruction manual

included with your Niles IR main system unit

Clean and dry the mounting surface. Peel off the

protective layer on the self-adhesive pad and

firmly affix the MS200 to the mounting surface.

Testing for EMI (Electro Magnetic Interference)

1. Turn on the device. If it is a wall mounted

light dimmer turn the dimmer knob to the

halfway position.

2. Connect the MS200 to a main system unit

and plug in the 12VDC power supply.

3. Place the MS200 in the proposed mounting

location and observe the blue “Flashback” LED.

3. If it flickers or lights constantly. This indicates

a high level of electrical interference. Move

the MS200 housing to a location where the

LED does not light.

Extending the cable

Once the cable is in place, label the cable ends

for future reference. The MS200 is supplied with

10' of pre-stripped IR cable. The IR cable may

be lengthened as needed. The IR cable may be

lengthened by splicing it to a recommended IR

cable (See page 4, Installation Considerations—

Type of Cable). You may splice the MS200

cable to another cable by soldering or crimping

the connections. Make sure that you maintain

proper polarity and correct connections through

the splice.

Connecting to the main system unit

1. Strip 1/4" of insulation from the end of each

wire. Tightly twist the end of each wire until

no frayed ends remain.

910 12 13 1411

www.nilesaudio.com

Niles Audio Corporation

12331 S.W. 130 Street Miami, Florida 33186

Tel: (305) 238-4373 Fax: (305) 238-0185

©2004 Niles Audio Corporation. All rights reserved. Niles, the Niles logo and

Blending High Fidelity and Architecture are registered trademarks of Niles Audio

Corporation. MicroFlasher is a trademark of Niles Audio Corporation. Because we

strive to improve our products, Niles reserves the right to change product specifications without notice. The technical and other information contained herein is not

intended to set forth all technical and other specifications of Niles products.

Additional information can be obtained on-line at www.nilesaudio.com or by calling

Niles at 1-800-289-4434. 01/04 Printed in China DS00325ACN

MS200

MS200

Miniature Surface-Mount

IR Sensor

INSTALLATION & OPERATION GUIDE

B LENDING H IGH F IDELITY

AND

A RCHITECTURE

®

“TECH TIP”

The feedback LED can be disabled if it continues

to flicker or visual feedback is not desired. Discrete on

and off IR commands are available on the Niles

Technical support website for disabling the feedback

LED. The address is: nilesaudio.com/techsupport.

DS00325ACN/MS200 1/8/04 9:53 AM Page 2

Loading...

Loading...