PLACEMENT CONSIDERATIONS

CONGRATULATIONS

SPECIFICATIONS

DESIGN PRINCIPLE

Infinite baffle. Specifically designed

for in-ceiling applications. Extended

bass response, ultra-wide dispersion

WOOFER

6-1/2” dual voice coil polypropylene

with a rubber surround

TWEETER

Dual 3/4” dome tweeters

RECOMMENDED AMPLIFIER

POWER

5 to 125 watts per channel RMS

FREQUENCY RESPONSE

45 Hz to 20 kHz +/- 3 dB

SENSITIVITY

91 decibels for 2.83 volts of pink

noise, measured at 1 meter on axis

IMPEDANCE

8 ohm nominal; 7 ohm minimum

OVERALL DIMENSIONS

9-1/4” diameter

MOUNTING DEPTH

3-3/8” (assumes 1/2” drywall)

CEILING CUT-OUT FOR RETROFIT

8” diameter

BEZEL FINISH

Pearl white ABS with non-glare finish

GRILLE COLOR AND MATERIAL

Pearl white, perforated aluminum

WEIGHT

7 lbs.

TOOLS REQUIRED

• Keyhole saw

• #2 Philips screwdriver or screwdriver bit

• Pencil

The CM650SI stereo input ceiling mount

loudspeaker offers Niles durability and

installation ease and is designed for

unobtrusive installations.

The CM650SI measures 9-1/4” in diameter. It features a weather-resistant dual

input 6-1/2” polypropylene co-axial

driver system with a rubber surround and

powder coated aluminum grilles, making

it suitable for bathroom and outdoor patio

applications. It employs a bracketless

mounting system: simply cut a hole in the

mounting surface and tighten the four

clamps via front-baffle screws. The flush,

MicroPerf

™

grille can be painted or cov-

ered to blend with the surrounding decor.

FEATURES & BENEFITS

INSTALLATION AND OPERATION GUIDE

Thank you for choosing a Niles Ceiling

Mount loudspeaker. With proper installation and operation, you’ll enjoy years

of trouble-free use.

CONTINUED OTHER SIDE

The CM650SI is designed to work well

in any standard ceiling. The mounting

surface must be at least 3/8” thick.

It will perform well in any air volume

greater than .5 cubic feet.

This speaker is designed to be minimally

affected by long lengths of speaker wire.

The CM650SI will accommodate speaker

wire between 12 and 22 gauge.

WIRING CONSIDERATIONS

P ACKAGE CONTENTS

• 1 Piece Speaker With Grille

• 1 Piece Hole Template/Paint Mask

®

FEATURES & BENEFITS

PLACEMENT CONSIDERATIONS

WIRING CONSIDERATIONS

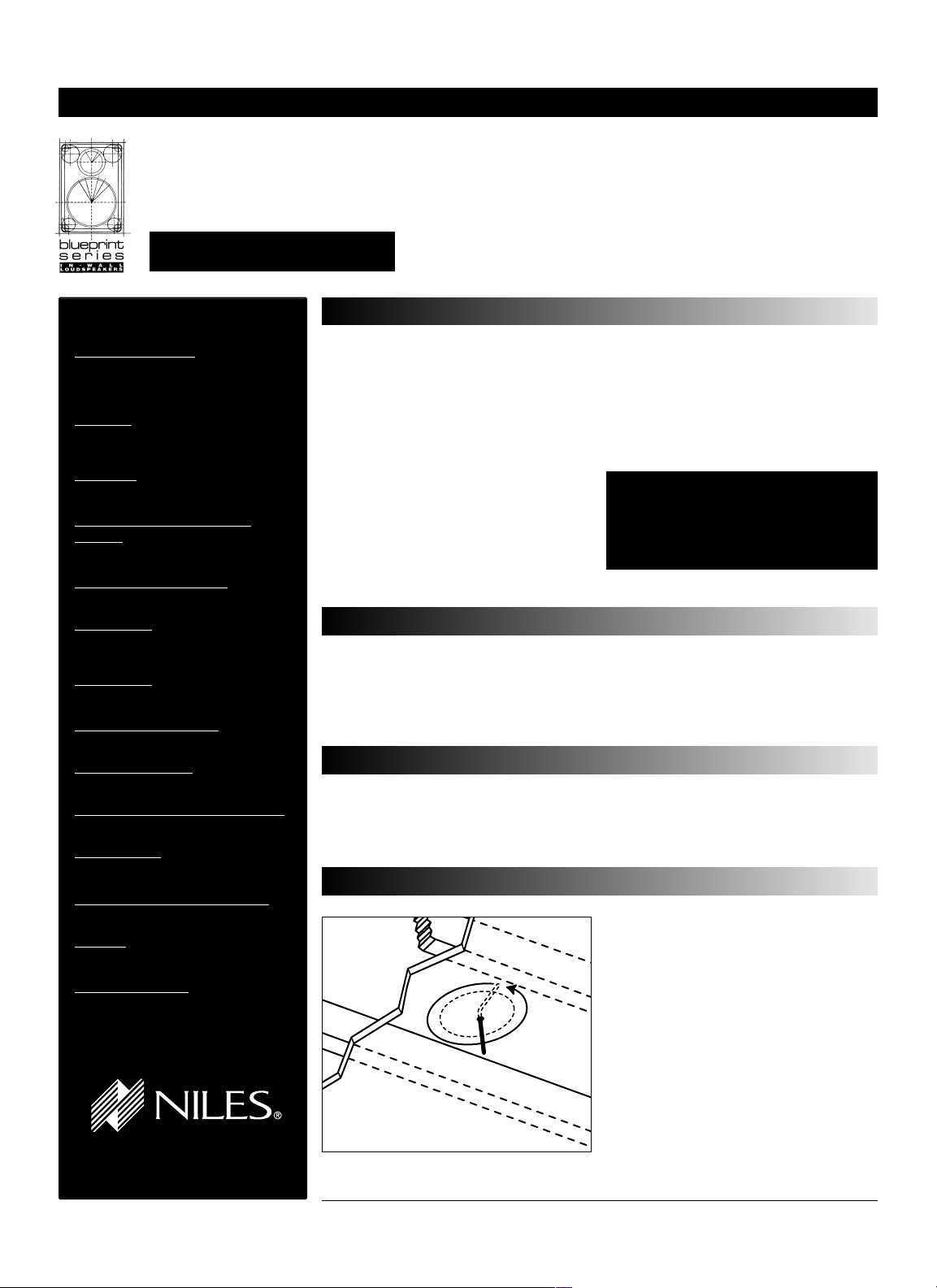

1. Cut a foot-long piece of coat hanger.

Bend the wire (creating a right angle) leaving 4-3/4” at one end for the CM650SI

(this allows for the extra width of the

mounting dogs). Poke the “L-shaped” wire

into the pilot hole and turn it in a complete circle and move it into the ceiling

cavity to make sure you have approximately 3-3/8” of depth. If the coat hanger

movement is obstructed by anything, fill

the hole(s) with spackle and try another

location (See Figure 1).

INSTALLATION PROCEDURE

INSTALLATION PROCEDURE

CM

650

SI

CEILING MOUNT

Figure 1

Checking for obstructions

behind the ceiling surface.

B LENDING H IGH F IDELITY

AND

A RCHITECTURE

®

REMOVING THE GRILLE

PAINTING THE SPEAKERS AND GRILLES

INSTALLATION AND OPERATION GUIDE

NILES AUDIO CORPORATION

www.nilesaudio.com

NILES AUDIO CORPORATION

12331 S.W. 130 Street Miami, Florida 33186 Tel: (305) 238-4373 Fax: (305) 238-0185

©1999 Niles Audio Corporation. All rights reserved. Niles, the Niles logo, Blueprint Series In-Wall Loudspeakers, and Blending High Fidelity and Architecture

are registered trademarks of Niles Audio Corporation. MicroPerf is a trademark of Niles Audio Corporation. All other trademarks are the property of their

respective owners. Because we constantly strive to improve our products, Niles reserves the right to change product specifications without notice. The technical and other information contained herein is not intended to set forth all technical and other specifications of Niles products. Additional information can be

obtained on-line at www.nilesaudio.com or by calling Niles at 1-800-289-4434. Printed in Taiwan 5/99 DS00253A

2. Locate the hole template and remove

the inside portion of it. Save this part—it

may be used as a paint mask. Use the

inside of the template to trace the outlines

at the desired location on the ceiling or

wall. With a keyhole saw, cut along the

penciled lines.

BE CAREFUL NOT TO CUT THROUGH

ANY EXISTING WIRING.

3. Attach the speaker wires to the speaker.

Be sure that proper phasing is observed.

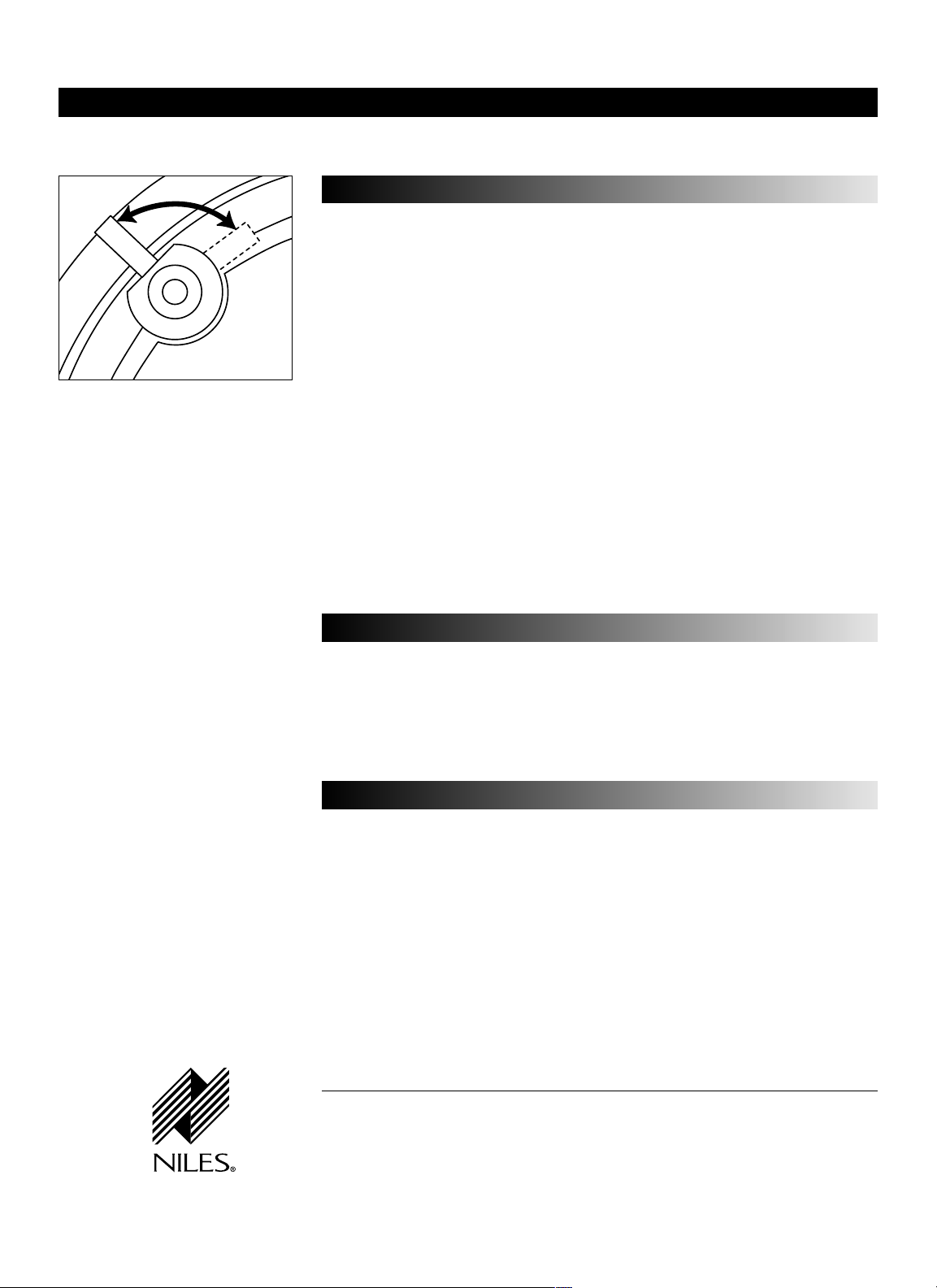

4. There are four clamps which hold the

speaker in place. The clamps are tightened via four front-baffle screws. To

install the speaker, first rotate the clamps

inward. Insert the speaker into the cutout

and tighten the clamps by turning the

screws clockwise. DO NOT OVER

TIGHTEN THESE SCREWS. Over-tightening the clamps may make the grille difficult to install (See Figure 2).

NOTE: The screws will be easier to turn

if you “prime” them first. Before

installing the speaker, turn the screws in

and then turn them back out to their

original positions.

5. Install the grille into the speaker. The

grille fits tightly. This is to prevent the

grille from becoming loose over time.

Some effort and care is required when

installing them.

To remove the grille from the CM650SI,

obtain a small paper clip (size #1, common) and bend the last quarter inch of it

into an “L” shape. Holding the paper

clip with a pair of pliers, insert the end

with the “L” into a hole near the edge of

the grille. Remove the grille by pulling

the paper clip towards you.

The CM650SI may be painted. The

plastic will readily accept most any kind

of paint.

The speaker must be masked prior to

painting them. The inside portion of the

hole template can be used as a paint

mask. Remove the outside portion of the

template by gently pulling along the perforation. Affix the mask to the front of the

speaker using a piece of tape.

Fold the tape onto itself to form a doublesided loop. Affix the tape to the tweeter

and place the mask onto the speaker.

The grille should be painted before it is

installed. The best results will be

obtained by using a spray gun or airless

sprayer, thinning the paint (prevents clogging of grille holes) and by applying several light coats instead of one heavy one.

INSTALLATION PROCEDURE CONTINUED.

INSTALLATION PROCEDURE CONTINUED.

REMOVING THE GRILLE

PAINTING THE SPEAKERS AND GRILLES

Figure 2

Detail of Mounting System

Loading...

Loading...