JVP 3*

Version: 6.00, 14-09-2012

Software 1.11

*This guidance applies to JVP 3 (740023, SW 1.09)

Installation and User Guide

LMC 223 by Nilan

All rights reserved Page 2 of 33

Table of contents

Table of contents ............................................................................................................................ 2

Figure ............................................................................................................................................. 3

Tables ............................................................................................................................................. 3

General information before installation ................................................................ ........................... 4

Safety ............................................................................................................................................. 5

System Design ............................................................................................................................... 6

Operation and maintenance ........................................................................................................... 7

Starting the heat pump ................................................................................................................ 7

Pressure in ground source loop (ground pipe)............................................................................. 8

Filling the ground source loop with brine ..................................................................................... 8

Water pressure in the central heating loop ................................................................................ 11

Filling water in the central heating loop ..................................................................................... 12

Dirt filters in central heating and ground source loops ............................................................... 12

Maintenance and Warranty ....................................................................................................... 12

Operation ..................................................................................................................................... 13

Menu Selection ......................................................................................................................... 13

Service Menu ............................................................................................................................ 13

Setting values ........................................................................................................................... 13

Language .................................................................................................................................. 14

Menu Summary ............................................................................................................................ 15

Operating Status Menu ............................................................................................................. 15

Operating Mode Menus ............................................................................................................. 15

Main Menus .............................................................................................................................. 15

Function Description ..................................................................................................................... 20

Heat pump compressor ............................................................................................................. 20

Frequency-controlled compressor (variable capacity) ............................................................... 20

Ground pipe and brine .............................................................................................................. 20

Condenser and heating circulation pump .................................................................................. 20

Permitted area of action for the heat pump ............................................................................... 21

Auxiliary heating ........................................................................................................................ 21

Central heating.......................................................................................................................... 21

Curve control via outside temperature ....................................................................................... 22

Frost protection ................................................................................................ ......................... 23

Alarm Menu .................................................................................................................................. 24

High pressure alarm .................................................................................................................. 24

Low pressure malfunction ......................................................................................................... 24

Leakage ................................................................ .................................................................... 25

Installation .................................................................................................................................... 27

Electrical connection ................................................................................................................. 28

The heat pump must be connected to electrical installation by an authorised electrician. .......... 28

Floor heating loop ..................................................................................................................... 28

Ground source loop .................................................................................................................. 28

Testing for leaks: ....................................................................................................................... 30

Brine filling ................................................................................................................................ 30

Safety ground coil system ......................................................................................................... 30

Isolation of the tubes ................................................................................................................. 30

Drainage and collection tray ...................................................................................................... 30

Disposal of the heat pump ........................................................................................................ 30

Check list for brine/water pump system at start-up and commissioning ........................................ 31

All rights reserved Page 3 of 33

Figure

Figure 1: Example of system design ............................................................................................... 6

Figure 2: JVP 3 installed with Compact P ....................................................................................... 7

Figure 3: LMC 223 Control Unit .................................................................................................... 13

Figure 4: Curve Selection for external temperature compensation ................................................ 22

Figure 5: Structural ground source pump system diagram. ........................................................... 27

Figure 6: Example of layout of ground pipes in a collector. ........................................................... 29

Figure 7: Example of layout of ground pipes with collection inside footing. ................................... 29

Tables

Table 1: List of Alarms .................................................................................................................. 26

All rights reserved Page 4 of 33

General information before installation

Check that the following documents have been supplied with the unit:

- Installation and User Guide (this document)

- Wiring diagram

If you have any questions concerning installation after reading the guide, please contact your local

Nilan dealer. Find your local dealer here: www.nilan.dk/forhandlere

Control of the system is via a NILAN LMC 223 control unit, which offers a wide range of functions,

for example, menu-driven control, summer/winter operation, outside compensated control, etc.

Before the establishment of a geothermal system, any permits and approvals must be obtained

from relevant authorities.

The Geothermal heat pump JVP is designed for heating homes with low temperature heating systems with forward-flow temperatures of up to 45 °C.

All rights reserved Page 5 of 33

Safety

Always disconnect the electrical supply to the heat pump if any malfunction occurs

that cannot be remedied via the control unit.

If any malfunction arises on the electrical part of the heat pump, always contact a

licensed electrician to repair the fault.

Avoid direct contact with the heating system pipes in the heat pump, as they can

be very hot.

Many types of antifreeze are hazardous to health, dangerous when ingested, and

must be kept out of the reach of children.

To protect the heat pump from damage, it is supplied with the following safety

equipment:

Expansion systems for central heating and brine/ground source loop

Safety valves for central heating and brine/ground source loop

Low and high-pressure cut-off switches for compressor

Pressure guard brine loop/ground pipe (mandatory environmental

pressure switch)

Minimum/frost thermostat (cuts off the heat pump if the temperature

becomes too low in the brine loop)

The heat pump must be serviced in accordance with applicable legislation and

regulations to ensure that the system is responsibly maintained and complies with

safety and environmental requirements.

Responsibility for maintenance of the heat pump rests with the owner or user. The

ground source loop contains antifreeze, which can compromise groundwater if

spilled or leaked. Contact an authorised service technician immediately if you suspect there is a leak in your ground source heat system.

All rights reserved Page 6 of 33

System Design

Electrical installation/power supply (including safety switch) should be installed by an

authorised electrician.

Connect the unit according to the wiring diagram supplied.

Figure 1: Example of system design

Function of ground source heat system

The Geothermal heat pumpJVP is designed for heating homes with low temperature heating systems with forward-flow temperatures of up to 45 °C, for example floor heating systems.

System components (function)

The ground source heat system obtains heat from the ground through the ground pipe loop (3).

The ground stores heat, which it accumulates from the sun in the summer and releases the heat to

the ground pipe loop (3) in the winter. The temperature in the water/antifreeze mixture (= brine);

from the ground pipes (1). Brine to be protected against freezing form a freezing point of -20 °C to

-18 °C. To exploit the heat energy in the brine, the system uses a heat pump to transfer energy

from a low temperature in the brine to a higher temperature in the central heating system. Circulation pumps (8) maintain flow in both the ground pipe loop (3) and the central heating/floor heating

loop (10).

The heat pump consists of an evaporator (4), compressor (5), condenser (6) and an expansion

valve (7). These elements are connected and filled with a refrigerant in a closed cycle in a closed

system. The antifreeze in the ground source loop is heated by the ground and cooled in the evaporator. After the evaporator the refrigerant is compressed in the compressor and the temperature

and pressure of the refrigerant are increased. In the heat exchange process in the condenser, the

refrigerant then releases heat energy to the central heating water, and the temperature of the central heating water rises. After the condenser the refrigerant pressure is reduced in the expansion

valve, and the refrigerant continues into the evaporator where it cools the brine before flowing return into the ground pipe loop (2).

An auxiliary heating element (9) is installed in the central heating loop, which can supplement the

ground source loop in the event of particularly high heating demand.

All rights reserved Page 7 of 33

Operation and maintenance

When setting up the system, future service and maintenance should be taken into account.

Minimum clearance in front of the system of at least 1m is recommended.

Starting the heat pump

Before starting the heat pump, check the following:

Pressure in the central heating system, see Figure 5 no. 17

Pressure in the ground loop, see Figure 5 no. 17

Check that both the central heating loop and the ground source loop have been ventilated.

The central heating circuit has an excess flow valve or other circulation, which ensures the

flow, see Figure 5, no 28

Check list for brine/water pump system at start-up and commissioning (see page 29) must be reviewed before starting.

The heat pump can then be switched on at the safety switch.

The heat pump is shut off at the safety switch.

Figure 2: JVP 3 installed with Compact P

1 central heating inflow - (3/4”)

2 central heating return - (3/4”)

3 brine inflow from ground pipe - (1”)

4 brine return from ground pipe - (1”)

5 safety valve - brine loop

6 manometer - brine loop

All rights reserved Page 8 of 33

Pressure in ground source loop (ground pipe)

The pressure must be inspected as often as several times a day in the initial days. If necessary,

the system must be topped up with brine. See Figure 5, no. 17

Brine pressure will stabilise after a few days and inspection can then be reduced to once a month.

It is important that brine pressure is correct. Too little pressure in the ground source loop can/will

trigger the alarm device in the ground source heat system. (low pressure)

Brine may have to be added a couple of times during the first year in connection with ventilation of

the ground source loop.

Filling the ground source loop with brine

The brine in the ground source loop comprises water and antifreeze. Ethanol, IPA alcohol, ethylene glycol or propylene glycol.

The heat pump is equipped with a low-pressure switch, which ensures that the brine never becomes so cold that it freezes solid, and thus the ground source heat pump's heat exchanger is

protected against frost damage.

The frost protection mixture must be adapted to the operating temperatures in the ground source

loop. It is very important that the frost protection fluid is mixed thoroughly before it is added to the

ground source loop as no mixing takes place in the ground pipes. Failure to do so increases the

risk of the heat pump freezing, thus creating a potential risk of frost damage. Brine may only be

added/topped up by an authorised technician. Before loading, check that the ground coils are tight.

How to fill brine into the ground source loop before start:

Switch off the heat pump and the circulation pump at the main switch before filling

brine into the system

Shut off one valve at the circulation pump of the brine circuit. Figure 5: Structural

ground source pump system diagram.

All rights reserved Page 9 of 33

, item 18 and 19

By means of a combined filling and venting tank, the brine loop is filled through the

filler tap until the loop is compeletely full Figure 5: Structural ground source pump

system diagram.

All rights reserved Page 10 of 33

, item 13. Duration minimum 1 hour.

The shutter tap at the cirkulation pump in the brine loop Figure 5: Structural ground

source pump system diagram.

All rights reserved Page 11 of 33

item 18 and 19, is reopened, and the pump is filled up and vented

If brine has to be repeatedly added to the ground source loop, this indicates that the ground pipes

are leaking.

ALWAYS contact an authorised service technician immediately if you suspect leakage.

Water pressure in the central heating loop

The water pressure in the central heating loop must initially be inspected as often as several times

a day. Top up the system with water, if necessary, see Figure 5 item 13

The water pressure will stabilise after a few days and inspection can then be reduced to once a

month. If you have to add water to the central heating loop beyond the start-up phase, the system

must be checked for leaks.

All rights reserved Page 12 of 33

Filling water in the central heating loop

Switch off the heat and circulation pumps at the main switch.

Fill water into the central heating loop via the filler cock, Figure 5, item

13, until the correct water pressure is achieved, Figure 5, item 17

The automatic vents on the heat tank, central heating loop, etc., are

activated automatically when water is added to the system.

Add water to the system until the water pressure is correct. If the wa-

ter pressure disappears entirely during filling, filling must be restarted

right from the beginning.

Restart the heat pump at the main switch.

Dirt filters in central heating and ground source loops

Immediately after the heat pump has been commissioned, a certain amount of dirt can accumulate

in both loops. The dirt filter is located in the central heating string and in the ground pipe string outside the heat pump, as shown in Figure 5

The filters must be checked and cleaned several times daily after installation of the heat pump until

the filters remain clean. In normal operation of the heat pump, it should be sufficient to check the

filter twice a year.

Cleaning the dirt filters:

Switch off the heat pump at the main switch.

Close the shut-off valves on each side of the filter.

Pull out filter and rinse until clean.

Replace the filter and open the shut-off valves. Then switch on the

heat pump at the main switch.

Maintenance and Warranty

The heat pump must undergo appropriate service in accordance with applicable laws and regulations in order to keep the plant maintained in good condition and to fulfill demands on safety and

environmental compliance. It is recommended that the owner / operator immediately after commissioning of the facility shall consult with a qualified service technician about the scope and

frequency of servicing.

The responsibility for maintenance of the heat pump is for the owner’s / user’s. Geothermal circuit

containing coolant that can harm groundwater by leakage. Immediately contact a qualified service

technician by suspected leaks in your geothermal system.

The installer of heat pump is obliged to provide an assurance to the owner / operator in accordance with applicable laws and regulations. For specific warranty terms refer to the owner / user

agreement with his supplier.

A prerequisite for warranty obligation is that servicing and maintenance is carried out as described.

All rights reserved Page 13 of 33

Operation

The JVP is equipped with a control unit (see below).

Figure 3: LMC 223 Control Unit

The control unit is used to control heat pump operation.

The unit has 2 diodes to the left of the display:

- the upper diode is illuminated when the heat pump is operating.

- the lower diode is illuminated when the auxiliary heating is operating.

The backlight in the display flashes when the system's alarm device is triggered.

Nilan LMC220 control unit is controlled solely by turning the knob to the right of the display. The

knob has three functions:

- Turn clockwise: Go to next menu item or increase the last value in the display.

- Turn anticlockwise: Go to previous menu item or reduce the last value in the display.

- Press: Select sub-menu, activate adjustment of value, or approve the last value.

The light in the display is illuminated when the unit is being operated. The light switches off after 30

seconds if the unit is not activated by the user. The control unit will revert to the start screen (status

menu) after five minutes if the unit is inactive.

Menu Selection

To switch between the menus, turn the knob.

Menus with an arrow at bottom right also have a sub-menu. To activate a sub-menu, press once

on the knob. To switch between sub-menu items, turn the knob. To exit the sub-menu, turn forward

or back until "Menu up" appears in the display. Then press the knob.

Service Menu

The sub-menus in the service menu are not accessible during normal operation. They are for use

in connection with installation and service.

Setting values

To set values in the display:

- Turn the knob until the value you wish to change is shown in the display.

- Press the knob to activate the value. The value will flash, if it can be changed.

- To change the value, turn the knob.

- Press the knob to accept the value shown. The value will stop flashing.

All rights reserved Page 14 of 33

Language

At the bottom of the service menu, you can select various languages:

- Turn the knob clockwise until the service menu is displayed.

- Press the knob to activate the service menu.

- Turn the knob until the LANGUAGE menu is shown in the display.

- Press the knob. The text in the display flashes.

- Turn the knob forward or back until the desired language is displayed.

- To approve the language, press once on the knob. The text stops flashing.

All rights reserved Page 15 of 33

Menu Summary

Operating Status Menu

The system's current operating status is displayed as the initial screen in the main menus.

OFF

The system is switched off. All functions are inactive, except:

- Alarm from ground pipe environmental pressure switch

- Circulation pump periodic test run and frost protection

START

Start heat pump. Circulation pumps start. Switch after a short time to operational

READY

The system is switched on but there is no current heat demand

HEATING

Room heating. Central heating temperature in the house at the desired value

WATER

Domestic hot water production

MANUAL

The user has activated manual operation via the service menu

ALARM

Alarm device triggered. The system continues to operate but with reduced function

STOP

The system was stopped due to a critical malfunction

Operating Mode Menus

In the OPERATION menu, the following operating modes can be selected:

OFF

No heating functions are active

SUMMER

Normal condition is domestic water. Central heating is not active

WINTER

Normal condition is central heating, which switches to domestic water as needed

AUTO

The system selects operating mode based on average outside temperature,

set summer temperature and a 3°C neutral zone

- Winter: After 24 hours under summer temperature minus neutral zone

- Summer: After 24 hours above summer temperature

When user function HEATING has been choice in "SELECT" in the "SERVICE",

summer/winter mode is chosen by an external signal on digital input DI4

Main Menus

Parameters in blue text below can be adjusted by authorized service personnel / user. The product

is delivered with factory settings as indicated.

Shaded cells must often change

STATUS *

HEATING

Readout of current operation status text

* Symbol indicates that a user function is active on the digital input

This is the main screen

OPERATION

WINTER

The unit's main switch and selection of overriding operating mode

In operating mode AUTO the choice can be by user function HEATING on digital input. [OFF, SUMMER, WINTER, AUTO]

T USER

EXT 15°C

Alternative setting selected via user function digital input

(shown only if a user function with setting is selected (COOL, DELAY)

READOUT

Sub-menu for display of current sensor and control data

T WATER

45°C

Domestic water tank temperature

T HEAT*

CURRENT

33°C

Central heating temperature

T HEAT*

SET 32°C

Current setting for central heating temperature. Recommended flow central

heating temperature is 30 ° C to 45 ° C. Fixed value or variable value using

outdoor compensation.

T OUT

12°C

Outside temperature

EVAP. T

-2°C

Evaporator temperature, Indicates the temperature of the cooled brine in the

evaporator

CP CAP

60 %

Current compressor capacity (%)

(shown only if compressor speed control is selected)

CURVE

+/- 0°C

Raises or lowers the calculated curve setting a fixed value (°C) [-9..9] (shown

only if curve control is selected) - See the menu CENTRAL HEAT

* Version 1.09 displayed T HEAT as T RETUR

All rights reserved Page 16 of 33

... Menu continued from previous page:

SET

Menu normally hidden

(to activate this menu, press knob for 8 secs while the Status Menu is active)

HEATING

PUMP

AUX

OFF

Auxiliary heating released for operation (for both domestic water and central heating)

[OFF, ON]

DELAY

AUX 30m

Delaying connection of auxiliary heating gives the heat pump a better chance to meet

demand

[0..60]

RESTART

CP 30m

Compressor restart time to prevent unnecessary wear (between two consecutive starts)

[2..60] minutes

STOP

CP 10m

Minimum stop time for the compressor (time from stop to start)

[0..15] minutes

COMPRESS

MIN OFF°C

Minimum outside temperature for compressor operation. If colder, stopped compressor

and EL takes over [OFF, -25..-10] °C

COMPRESS

MAX 47°C

Max temperature to permit compressor running. (stop to avoid pressure overload of

condenser)

[40..80] Max. Temperature is Twater (T2) for SHWt and Theat (T1) for central heating.

T SUMMER

15°C

Level for automatic switch between summer and winter operation

[0..30]

CP LEVEL

RPM

Select compressor operating mode on/off or RPM regulation

[1 LEVEL, RPM]

STOP %

10

Compressor stop capacity

(shown only when RPM compressor level selected)

ST DIFF%

40

Compressor start difference

(shown only when RPM compressor level selected)

U MIN %

25

Minimum voltage to frequency converter

(shown only when RPM compressor level selected)

U MAX %

100

Maximum voltage to frequency converter

(shown only when RPM compressor level selected)

U START%

70

Initial voltage to frequency converter

(shown only when RPM compressor level selected)

U 60°C %

MIN 30

Compressor RPM limit in heating operation as a function of the current setting - curve

max. [MIN, OFF] (shown only when RPM compressor level selected)

U 40°C %

MIN 20

Compressor RPM limit in heating operation as a function of the current setting - curve

min. [MIN, OFF] (shown only when RPM compressor level selected)

GAIN

7

Enhancement of PI regulator (factory setting: 5 % per ℃)

(shown only when RPM compressor level selected)

TN

3m

PI regulator integration period (factory setting: 5 minutes)

(shown only when RPM compressor level selected)

VENT HI

50

Capacity for transfer between high/low ventilator speed

U LOW %

50

Voltage for low ventilator capacity

U HI %

100

Voltage for high ventilator capacity

CIRCPUMP

CONTIN

Select operating mode for central heating circulation pump (on/off only with buffer tank)

[CONTIN, ON/OFF]

Important:

The parameters menu HEATPMP must be set by authorized service personnel.

Parameters in gray boxes changed as required, while the other parameters should not be

changed.

All rights reserved Page 17 of 33

... Menu continued from previous page:

DOMESTIC

WATER

Geothermal heat pump JVP is designed for HEATING

For SHW it should only be used as back-up or as preheating

HEATING

OFF

Heat source selection for domestic water production

[OFF, HP, AUX, HP+AUX]

MINIMUM

35°C

Temperature setting for auxiliary heating (if released and selected)

[5..80]

SETTING

45°C

Temperature setting for heat pump compressor

[5..60]

NEUTRAL

ZONE 4°C

Dead time for connecting. Heating starts at setting minus this value

[1..9]

CP CAP

60 %

Compressor capacity during domestic hot water production. (Factory setting 60 %)

LEGIO

DAYS OFF

Legionella function frequency (auxiliary heating must be released for operation)

[OFF, 7..30] days

CENTRAL

HEAT

CTR HEAT

HP+AUX

Heat source selection for room heating

[OFF, HP, AUX, HP+AUX]

T HEAT

MIN 35°C

Setpoint of the housing central heating temperature and setpoint-heating [5 0.60].

Recommended central heating temperature is 30 ° C to 45 ° C. By TEMP CTR, AMB

COMP will restrict the central heating temperature, downwards, and must therefore

be adjusted the curve.

T HEAT

MAX 45°C

The maximum permitted setpoint for the building central heating temperature

[5 0.60] By TEMP CTR, AMB COMP will restrict the central heating temperature up

to MAX

NEUTRAL

ZONE 3°C

Dead time for connecting. Heating starts at setting minus this value

[1..9]

TEMPCTRL

MIN

Central heating temperature control function

[MIN, OUT COMP]

CURVE

SELECT

5

Outside temperature compensation curve (Curve Menus displayed if selected under

CONTROL) [DEF, 1..10]

CURVE

+/- 0°C

Raises or lowers the calculated curve setting a fixed value (°C)

[-9..9]

CURVE 20

DEF 50°C

Manually-selected five-interval out/in curve (at -20, -10, 0, 10 and 20 °C) for central

heating temperature [5..60]

CURVE 10

DEF 45°C

CURVE 0

DEF 40°C

CURVE+10

DEF 35°C

CURVE+20

DEF 30°C

Parameters menu, DOMESTIC WATER and CENTRAL HEAT needs to be set by authorized service personnel

Parameters in gray boxes changed as required, while the other parameters should not be changed

* Version 1.09 displayed T HEAT as T RETUR

All rights reserved Page 18 of 33

DEFROST

TYPE

OFF

Choosing the defrosting method

[OFF, HOTGAS, AIR, AIR+HG]

MAN DEFROST

OFF

Not a function of Geothermal heat pump system

ICE LEVEL

-2 °C

Not a function of Geothermal heat pump system

ICE ACC

20 m

Not a function of Geothermal heat pump system

STOP T

8 °C

Not a function of Geothermal heat pump system

MAX TIME

8 m

Not a function of Geothermal heat pump system

DEFROST

CAP 80 %

Not a function of Geothermal heat pump system

NUM HG

0

Not a function of Geothermal heat pump system

NUM AIR

0

Not a function of Geothermal heat pump system

LAST DE-

FROST 0 m

Not a function of Geothermal heat pump system

INTERVAL

240 m

Not a function of Geothermal heat pump system

MIN TEMP

-15 °C

Minimum evaporator/brine temperature. (frequency converter operation only)

Important:

The parameters in menu DEFROST must be set by authorized service personnel.

Parameters in gray boxes changed as required, while the other parameters should not be

changed.

All rights reserved Page 19 of 33

... Menu continued from previous page:

ALARMS

ALARM 0

NONE

Display of up to three current alarms

Data readout (code and text) for each alarm line. Reset in the event of power outage

ALARM

LOG

Alarm log stores and displays the last 16 active alarms

NOT reset in the event of power outage

AL 0: 13

T2 SHORT

Most recent active alarm

AL 1: 20

PRESSURE

Next most recent active alarm

Service menu activated using key combination:

SERVICE

Service menu for set-up, testing and troubleshooting

Normally hidden menu (activated by holding the button down for 8 seconds while the

status menu is active)

LMC 223

VER 1.09

Unit type identification and software version number

RESTART

CP 914s

Seconds until release of compressor restart

Can be reset for service purposes

USER

FUNCT

Menu for setting user-selected functions

SELECT

NONE

Select user function in digital input DI4

[NONE, DEFROST, COOL, DELAY, HEATING)

MANUAL

Manual activation of relay outlets

ACTIVATE

NO

Activation of manual operation

[NO, YES]

COMPRESS

OFF

Start compressor

[OFF, ON]

AUX

OFF

Start auxiliary heating

[OFF, ON]

3-WAY

OFF

Activate 3-way valve for domestic water

[OFF, ON]

BRINE

PUMP

OFF

Start ground pipe brine pump

[OFF, ON]

CIRCPUMP

OFF

Start central heating circulation pump

[OFF, ON]

OPERTIME

Operating hours counter

HEAT

PUMP

8206h

Indicates how long the heat pump has been switched on

COMPRESS

2184h

Compressor

AUX

514h

Auxiliary heating

3-WAY

0h

3-way valve for domestic water

BRINE

PUMP

4740h

Ground pipe brine pump

CIRC

PUMP

2948h

Central heating circulation pump

SETUP

GUIDE

Menu which leads the user through the selections that have to be made to set up the

system

...

LANGUAGE

ENGLISH

Section of user interface language

[ENGLISH, DANISH, GERMAN]

Important:

The parameters in menu SERVICE must only be set by authorized service personnel.

Parameters in gray boxes changed as required, while the other parameters should not be

changed.

All rights reserved Page 20 of 33

Function Description

Heat pump compressor

The system is protected with high and low-pressure switches that can stop the compressor and

trigger an alarm.

By heating demand the heat pump compressor starts when the temperature has dropped to setpoint minus the neutral zone. When the compressor is operating the central heating temperature is

raised up to the respective set point before it goes out. The neutral zone helps to avoid frequent

start / stop.

Frequency-controlled compressor (variable capacity)

The frequency is controlled by a PI regulator. The PI regulator parameters are set in the HEATING

PUMP menu.

OTo avoid frequent ON / OFF couplings on the compressor because of the large hysteresis on

central heating temperature, the compressor starts only when the PI controller's capacity reaches

above 40%. The compressor stops when PI regulator capacity falls to under 10 %.

If the compressor continues to start/stop at short intervals, it may be necessary to set a wider neutral zone (in the CENTRAL HEAT / NEUTRAL ZONE Menu).

Ground pipe and brine

The brine pump always runs with the compressor and starts 1 minute before and runs 1 minute

longer. After a week of inactivity, the pump starts briefly to prevent blockage.

The environmental pressure switch triggers an alarm and stops the system if there is a leak in the

brine system.

Condenser and heating circulation pump

The system has a water-cooled condenser with a circulation pump.

To prevent excessive condenser pressure in the event of failure of the high pressure switch, hot

water is circulated in the central heating system until the temperature falls below the set maximum

value for the compressor, before the compressor is started.

After a week of inactivity, there is a brief periodic test run.

In addition the pump has the following operating modes, which depend on the overriding control

mode:

- Winter operation: The pump runs constantly.

- Summer operation: The pump is inactive (except for brief periodic test run).

All rights reserved Page 21 of 33

Permitted area of action for the heat pump

- Brine temperature to the evaporator from ground hoses -5 °C to +20 °C

- Central heating flow temperature +24 °C to +55 °C

It is recommended to use JVP for central heating systems with a flow temperature of 30 °C to 45

°C, to obtain an energy-efficient operation and less wear on the heat pump compressor.

Installation location:

- Room temperature 5 °C to 35 °C and a relative humidity of 30-70%

Auxiliary heating

A 2.0 kW electric water heater is connected as a supplement to the heat pump, in the event that it

cannot supply the desired heating, for example, in cold and windy weather.

The auxiliary heating must be released for operation by the user. The auxiliary heating is activated

if the forward water temperature falls below the minimum set value (minus neutral zone). The system thus ensures that the heat pump supplies the greatest share of energy. At the same time, the

user, even during extraordinary demand, is ensured a well-defined comfort. The heat pump is delivered with optional additional heating turned off (OFF) as factory setting.

The auxiliary heating will also be used as a reserve supply and to maintain normal comfort in situations where the heat pump is not operating due to installation work, a fault, etc. Under these

circumstances, the compressor settings are overridden so that the auxiliary heating is not controlled by minimum values.

Central heating

During regular heat pump operation, compressor capacity is adjusted thus maintaining a predetermined central heating temperature in the house. The required central heating temperature depends

on the heating demand in the house, which in turn depends on its size, insulation and the outside

temperature. Several different temperature compensation modes can be selected. These can be

activated separately or simultaneously.

All rights reserved Page 22 of 33

Curve control via outside temperature

You can pre-program the house's return flow setting in accordance with the outside temperature, if

OUT COMP is selected as the control mode for central heating. This requires that the outdoor sensor is mounted.

The desired heating temperature is set to an outdoor temperature of -20 ° C, -10 ° C, 0 ° C, 10 ° C

and 20 ° C. On the basis of these temperatures, the central heating temperature is determined by

interpolating between the points for a given outside temperature, see Figure 4

For outside temperatures under -20 °C and over 20 °C, the programmed forward central heating

temperature is used for -20 °C and 20 °C respectively.

In the control menu CTR HEAT MIN and MAX are set. MIN and MAX can limit the control curve

upwards and downwards.

You can select from 10 pre-programmed curves or create a user-defined one.

Outside temperature

central heating temperature

Figure 4: Curve Selection for external temperature compensation

All rights reserved Page 23 of 33

Frost protection

A number of functions are built into the system to prevent frost damage. These functions are always active regardless of the operating modes and settings selected (including OFF). Any missing

or defective temperature sensors or system components can of course render this protection ineffective:

- When the outside temperature falls below 2 °C, the central heating circulation pump will

start. With that, any spaces under the eaves and any attic space are secured and you can

also monitor water temperature.

- If the central heating or room sensors fall below 2 °C, all circulation pumps will start, along

with the heat pump and auxiliary heating, and temperatures will, if possible, be raised to

5°C.

All rights reserved Page 24 of 33

Alarm Menu

The Alarm Menu displays any alarms and an alarm overview for the last 16 alarms. (see ALARMLOG).

If an alarm is triggered, the backlight in the display will flash. Operating status switches to ALARM

or STOP. You can read the cause of the alarm in the ALARM sub-menu.

The alarm is displayed with an alarm code. When the cause of the alarm is removed, the alarm

switches automatically from active to inactive and the backlight stops flashing.

To acknowledge an alarm, press the knob in the sub-menu ALARM when the alarm is displayed.

The alarm is then deleted from the alarm log.

Active alarms cannot be acknowledged before the system has registered that the alarm cause has

been eliminated.

There are three alarm levels:

INFO : General information for the user that does not affect operation.

WARNING : Given in the event of alarms, which permit continued operation with small

inconveniences.

CRITICAL : This type of alarm means that operation stops entirely or is significantly reduced.

High pressure alarm

Refrigerant pressure in the condenser is too high. This is due to the fact that the heat pump cannot

clear the heat it is producing. The central heating water is circulating too slowly.

Possible causes:

1. Dirt filter in the central heating system is clogged

2. There is air in the central heating system – ventilate the system

3. There is insufficient water in the central heating system.

4. The “hot pump” to the central heating system is not running. The pump should

buzz quietly when operating

Check 1 – 4 and correct the fault. Acknowledge the alarm by pressing the knob in the Alarm submenu when the alarm is displayed.

Low pressure malfunction

Refrigerant pressure in the evaporator is too low. This is due to the fact that there is not enough

heat coming from the ground source loop. Either the brine is circulating too slowly or the brine is

too cold when it returns from the ground loop.

Possible causes:

1. There is air in the ground pipes – ventilate the ground heat loop/ground pipes

2. There is insufficient brine in the ground pipes

3. The brine has frozen in the heat exchanger. The “cold pump” will be very hot

4. The “cold pump” to the ground pipes/ground source loop is not running. The

pump should buzz slightly while operating

Check 1 – 4 and correct the fault. Acknowledge the alarm by pressing the knob in the Alarm submenu when the alarm is displayed. Contact a service technician if the low pressure switch shuts

down the system again after a few minutes. Don not attempt to start the system repeatedly, as this

increases the risk of frost damage to the heat pump evaporator.

All rights reserved Page 25 of 33

Leakage

The pressure is too low in the ground pipes/ground source loop. This may mean that the ground

pipes are leaking.

Check the following:

1. Are all cocks open that should be open?

2. Is there enough brine in the system? Top up if necessary.

Check 1 – 2 and correct the fault. Acknowledge the alarm by pressing the knob in the Alarm submenu when the alarm is displayed. Call a service technician if you cannot locate the fault yourself.

All rights reserved Page 26 of 33

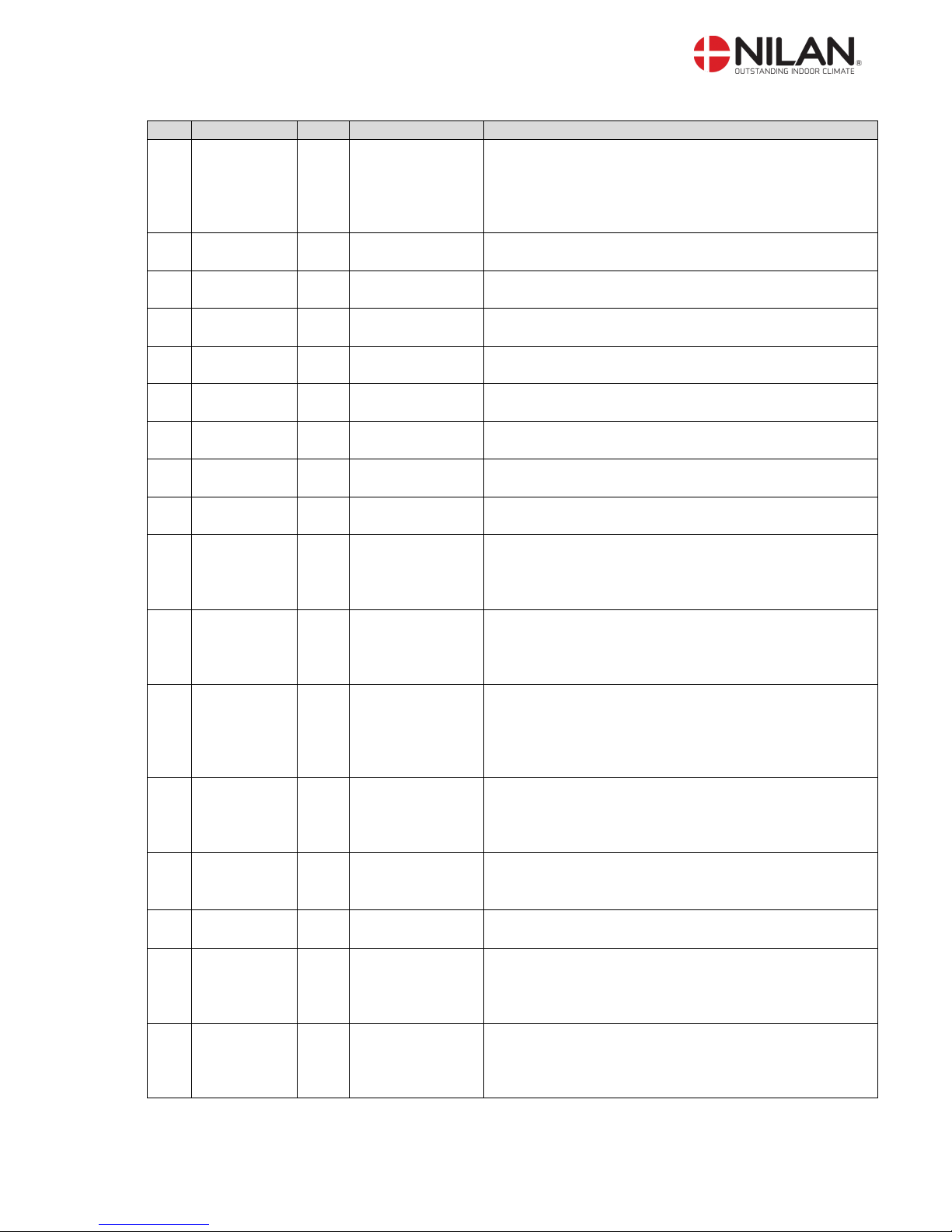

No.

Text

Type

Action

Description

5

DATABASE

I

--

The control unit has been reset to the factory setting

and requires a renewed default setting. This occurs,

for example, if software is updated with a new program that differs significantly from the old one.

- Make the desired settings via the menu system

10

T1 OPEN

C

STOP

Central heating temperature sensor disabled

- Check connection. Replace sensor if necessary

11

T1 SHORT

C

STOP

Central heating temperature sensor disabled

- Check connection. Replace sensor if necessary

12

T2 OPEN

C

STOP

Domestic water temperature sensor disabled

- Check connection. Replace sensor if necessary

13

T2 SHORT

C

STOP

Domestic water temperature sensor disabled

- Check connection. Replace sensor if necessary

14

T3 OPEN

W

7°C presumed

Outside temperature sensor disabled

- Check connection. Replace sensor if necessary

15

T3 SHORT

W

7°C presumed

Outside temperature sensor disabled

- Check connection. Replace sensor if necessary

16

T4 OPEN

W

Deactivate room

control

Brine temperature sensor disabled

- Check connection. Replace sensor if necessary

17

T4 SHORT

W

Deactivate room

control

Brine temperature sensor disabled

- Check connection. Replace sensor if necessary

32

LOW PRS

C

Stop compressor

auxiliary heating

takes over heating

Low pressure alarm. The heat pump will start automatically two minutes after the alarm has

disappeared.

33

HIGH PRS

W

Stop compressor

auxiliary heating

takes over heating

High pressure alarm. The heat pump will start automatically 2 minutes after the alarm has disappeared.

See also Alarm 34.

34

RESTART

C

Stop compressor

auxiliary heating

takes over heating

Safety shut-off from compressor high pressure. After

three high-pressure alarms (code 33) within 12 hours,

alarm 34 is triggered. Alarm 34 includes manual reset. The compressor will not restart until you have

acknowledged Alarm 34 in the Alarm Menu.

34

RESTART

W

Aux heating

takes over after 5

mins.

Safety shut-off from compressor high pressure and

low pressure

- Compressor restarts when user acknowledges the

alarm

50

FROST

W

Circulation

pumps are started.

Temperature for domestic water, central heating or

room sensor has fallen below 2°C for more than two

hours. Frost protection function is active

53

LÆK

W

Aux. heatin takes

over after 5 mins.

Ground pipe environmental pressure switch

- Check system for leaks

54

OVERHEAT

C

STOP

Forward or domestic water overheated to 90°C or

more

- Check relays and contacts to compressor and auxiliary heating

70

LEGIO

I

--

The Legionella function has not been performed within the deadline in two successive weeks.

- Insufficient heat energy supplied from brine or auxiliary loop

Table 1: List of Alarms

All rights reserved Page 27 of 33

Installation

Figure 5: Structural ground source pump system diagram.

All rights reserved Page 28 of 33

Electrical connection

The heat pump must be connected to electrical installation by an authorised electrician.

2x230 V, N + PE, - 13 A, 50 Hz

1x230 V, N + PE, - 20 A, 50 HZ

Supply cable: 4x1,5mm², HO5W-F

The supplied electrical diagram shows how to

connect the system to the grid

Floor heating loop

IMPORTANT: An overflow valve must be installed (Figure 5, no. 28) in the floor heating loop with a

fixed-speed circulation pump. Alternatively, individual thermostats must be installed to maintain

sufficient flow.

It is possible to connect an external run signal to the pump control unit (see wiring diagram) from

eg a floor heating system.

Starting with software version 1.10 of LMC223, this works as an external summer-/winter shift. In

the controller menu SERVICE SELECT USER FUNK can be select HEATING. . When HEATING is

chosen you make and extreme change between winter - and summer operation. The controller is

forced to run in winter operation when the digital input 4 is close. Conversely, the control is forced

to run in summer operation when the digital input 4 is open. In winter operation the pump in central

heating is running. User Function HEATING assumes that the system is in DRIFT-AUTO.

Ground source loop

When setting up a ground source loop, there are a number of clearance requirements which must

be complied with to ensure efficient and trouble-free operation. Furthermore, local authorities often

stipulate their own requirements for installation and approval of the system before it is commissioned.

All rights reserved Page 29 of 33

Figure 6: Example of layout of ground pipes in a collector.

Figure 7: Example of layout of ground pipes with collection inside footing.

All rights reserved Page 30 of 33

Testing for leaks:

As cracks in the pipes can occur during handling/transport, it is important to pressure test the pipes

individually for leaks immediately before covering with earth. Testing for leaks should be carried

out in accordance with the applicable regulations.

Brine filling

After completed and substantiated testing for leaks, the system can be filled with brine. Brine filling

should be performed by an authorised technician. Brine can be purchased ready-mixed with corrosion inhibitors or the fluid can be mixed before filling. We recommend that you use ready-mixed

brine containing corrosion inhibitors. If mixing the brine yourself, the water quality must be appropriate to brine and to the materials in the system. In the case of ready-mixed brine, product safety

data sheets are enclosed which document the composition of the brine. Brine and water must be

mixed thoroughly before filling; a bulk container can be used, for example. Use a powerful pump to

remove air pockets from the ground pipes before filling them with brine. Calculate pumping time for

filling the system at an established pumping rate. It will not take less than the calculated pumping

time to fill the system with brine. Prevent air from entering the ground pipes during filling.

Safety ground coil system

The ground source heating pipes are equipped with a low pressure switch which triggers an alarm

in the event of a fall in pressure in the ground pipe. In the event of an alarm, the system must be

disconnected and prevented from restarting automatically. The ground pipe system must be dimensioned as a closed system with a standing pressure of 150-250 kPa.

Isolation of the tubes

All piping to and from the ground tubes / geothermal heating circuit must be insulated up to the

heat pump, so that no condensation occur on the cold pipes.

Drainage and collection tray

There may be advantageously established drains condensate from the heat pump and water from

the safety valve during heat pump. It is mandatory to established collection tray at the safety valve

on the collector side.

Disposal of the heat pump

Please contact your municipality or its authorized installer, when the heat pump must be disposed,

as the heat pump and brine must be disposed in accordance with applicable laws.

All rights reserved Page 31 of 33

Check list for brine/water pump system at start-up and commissioning

The check list must be followed at start-up and commissioning of the complete heating system.

Reference is made to the text in the manual for further details.

Before the system is put into opereation the following item must be checked and notes made.

Brine circuit

Control

Yes/No

Memo

Date

Brine heat/source circuit is tight?

Brinetype

N/A

Brine concentration %

N/A

%

The brine concentrationen, freezing temperature

(registered -20°C til -18°C)

N/A

°C

The brine is properly mixed prior to filling of the

circuit?

The brine cicuit is purge of air?

The pressure of the brine circuit, bar gauge

N/A

bar

Any leakage from the relief valve must be collected. Brine must not run into any sewers

The brine circuit is connected correctly to the heat

pump (which can be damage)

Design flow of brine circuit

N/A

m3/h

Actual flow brine circuit

N/A

m3/h

There is risk of low pressure cut-out failures and risk of freezing the evaporator of the heat pump, if

these instructions are not followed.

All rights reserved Page 32 of 33

Central heating circuit

Control

Yes/No

Memo

Date

The heating circuit is tight?

The heating circuit is purged of air after filling the

system

Pressure of the heating circuit, bar gauge

N/A

bar

The safety valve of the heating circuit is mounted

correctly and has correct opening pressure

The is a bypass, which ensures a sufficient flow

through the condenser (eliminates HP cut-out)

The circulation pump must be dimensioned for the

specific installation

The circulation pump is in constant operation or is

controlled by the heat pump

Strainer is mounted

Strainer has been cleaned after circulation of water

The design flow of the heating circuit

N/A

m3/h

The actual flow of the heating circuit

N/A

m3/h

All rights reserved Page 33 of 33

Electircal supply and controls

Control

Yes/No

Memo

Date

The mains supply, protection and connection, must

be according to the wiring diagram and manual.

Chosen form of regulation in the control, fixed or

variable heating temperature

N/A

Fixed

Variabel

Selected setpoint Elected curve for central heating

temperature

N/A

°C

curve

The ourdoor sensor is mounted when weather

compensation is used (variable temperature of

central heating).

Central temperature compliance requirements for

max. 45 ° C

In case a remote running signal from the heat system is used, connection must be made and heat

pump controller configured for this

Supplementing electrical heating element is activated if required, after the system has been filled

with water and put into operation

The recommended seetings of the controls, described in the manual, are checked. Any

adjustments are noted for later reference.

The mains supply, protection and connection, must

be according to the wiring diagram and manual.

JVP 3 with 3 kW HP out-put

(acc. to EN14511, 0/35°C)

Evaporator

(brine circuit)

Condenser

(central heating circuit)

Flow approx.

0,66 m3/h (0,19 l/s)

0,52 m3/h (0.14 l/s)

Pressuredrop

heat exchanger approx.

10 kPa

10 kPa

Temperature change approx.

3°C

5°C

Loading...

Loading...