INSTALLATION INSTRUCTIONS

CTS700-TOUCH

BY NILAN

Compact P / Compact P Polar - GEO (English)

Version 2.10 - 06.03.2017

TABLE OF CONTENTS

S

afety

Power supply................................................................................................................................................................................................................................................................... 4

Heat pump domestic hot water...................................................................................................................................................................................................................4

Heat pump for central heating.................................................................................................................................................................................................................... 4

Disposal............................................................................................................................................................................................................................................................................................. 5

Ventilation system....................................................................................................................................................................................................................................................5

Heatpump............................................................................................................................................................................................................................................................................5

General information

Introduction.................................................................................................................................................................................................................................................................................. 6

General information prior to installation.........................................................................................................................................................................................6

Unit type........................................................................................................................................................................................................................................................................................... 6

Product description..................................................................................................................................................................................................................................................6

The unit.................................................................................................................................................................................................................................................................................. 8

Overview of temperature sensors.......................................................................................................................................................................................................... 9

Dimensional drawing...........................................................................................................................................................................................................................................10

Pipe diagram.................................................................................................................................................................................................................................................................11

Accessories................................................................................................................................................................................................................................................................................ 12

Electrical preheating element for frost protection.......................................................................................................................................................... 12

Adjustable water comfort heater.........................................................................................................................................................................................................12

Electric heating element................................................................................................................................................................................................................................. 12

Pollen filter F7............................................................................................................................................................................................................................................................ 12

EM box ................................................................................................................................................................................................................................................................................ 12

CO2 sensor..................................................................................................................................................................................................................................................................... 12

Safety group.................................................................................................................................................................................................................................................................13

Safety features ........................................................................................................................................................................................................................................................13

Flexible silencing...................................................................................................................................................................................................................................................... 13

Trolley................................................................................................................................................................................................................................................................................. 13

SHW hot water tank ............................................................................................................................................................................................................................................ 13

Installation

Installing the unit.................................................................................................................................................................................................................................................................14

Transport into the dwelling......................................................................................................................................................................................................................... 14

Positioning of unit.................................................................................................................................................................................................................................................. 14

Ground collector circuit................................................................................................................................................................................................................................................15

Examples of the laying...................................................................................................................................................................................................................................... 15

Electrical installation

Safety.................................................................................................................................................................................................................................................................................. 17

Connections lists......................................................................................................................................................................................................................................................17

Control panel............................................................................................................................................................................................................................................................................18

Touch panel................................................................................................................................................................................................................................................................... 18

Control panel connection .............................................................................................................................................................................................................................. 18

Wall fittings ...................................................................................................................................................................................................................................................................19

Electrical connections unit....................................................................................................................................................................................................................................... 20

Safety.................................................................................................................................................................................................................................................................................. 20

Compact P....................................................................................................................................................................................................................................................................... 20

GEO3...................................................................................................................................................................................................................................................................................... 21

GEO6...................................................................................................................................................................................................................................................................................... 21

Electrical connections accessories................................................................................................................................................................................................................. 22

External electrical preheating element ........................................................................................................................................................................................ 22

Electric heating element................................................................................................................................................................................................................................. 23

Water comfort heater .......................................................................................................................................................................................................................................23

CO2 sensor..................................................................................................................................................................................................................................................................... 26

Cooker hood and EM box ................................................................................................................................................................................................................................27

Other electrical connections.................................................................................................................................................................................................................................. 28

User selection 1 ....................................................................................................................................................................................................................................................... 28

2

User selection 2 ....................................................................................................................................................................................................................................................... 29

E

xternal room temperature sensor................................................................................................................................................................................................... 30

Fire protection .......................................................................................................................................................................................................................................................... 30

Common alarm...........................................................................................................................................................................................................................................................31

External heat supply .......................................................................................................................................................................................................................................... 31

Connecting EHD damper ................................................................................................................................................................................................................................ 32

BAH Geothermal heater ................................................................................................................................................................................................................................. 33

Passive cooling function..................................................................................................................................................................................................................................34

Plumbing installation

Condensate drain................................................................................................................................................................................................................................................................ 36

Important information ..................................................................................................................................................................................................................................... 36

Domestic hot water tank............................................................................................................................................................................................................................................ 37

Connection overview.......................................................................................................................................................................................................................................... 37

Connection .................................................................................................................................................................................................................................................................... 37

Hot water circulation.......................................................................................................................................................................................................................................... 38

Solar coil............................................................................................................................................................................................................................................................................ 38

Softened water ........................................................................................................................................................................................................................................................ 38

Central heating...................................................................................................................................................................................................................................................................... 39

Water connection list.......................................................................................................................................................................................................................................... 39

Brine circuit................................................................................................................................................................................................................................................................... 40

Check list for the central heating system prior to start-up.................................................................................................................................... 41

Plumbing connections for accessories........................................................................................................................................................................................................ 42

Safety group ............................................................................................................................................................................................................................................................... 42

Safety group with anti-scald protection....................................................................................................................................................................................... 43

Hot water heater (accessory) .................................................................................................................................................................................................................. 44

Output chart, hot water heater...............................................................................................................................................................................................................45

Domestic hot water tank................................................................................................................................................................................................................................ 46

Connecting to SHW hot water................................................................................................................................................................................................................... 47

Connecting to DHW hot water................................................................................................................................................................................................................... 47

Ventilation mounting

Duct system.............................................................................................................................................................................................................................................................................. 48

Legislation...................................................................................................................................................................................................................................................................... 48

Ducts..................................................................................................................................................................................................................................................................................... 48

Unit.......................................................................................................................................................................................................................................................................................... 48

Extract air........................................................................................................................................................................................................................................................................ 49

Supply air......................................................................................................................................................................................................................................................................... 49

Roof stack....................................................................................................................................................................................................................................................................... 49

Initial regulation................................................................................................................................................................................................................................................................... 50

Important information...................................................................................................................................................................................................................................... 50

Initial regulation connectors...................................................................................................................................................................................................................... 50

Pressure fall diagram......................................................................................................................................................................................................................................... 50

Start-up

Central heating...................................................................................................................................................................................................................................................................... 51

Filling with water..................................................................................................................................................................................................................................................... 51

Topping up water.................................................................................................................................................................................................................................................... 51

Check the particle filter................................................................................................................................................................................................................................... 51

Troubleshooting

Emergency operation..................................................................................................................................................................................................................................................... 52

Emergency operation domestic hot water................................................................................................................................................................................. 52

Emergency operation central heating.............................................................................................................................................................................................53

Domestic hot water.......................................................................................................................................................................................................................................................... 54

Errors and solutions domestic hot water..................................................................................................................................................................................... 54

Compact P / Compact P Polar - GEO (English)

BY NILAN

3

Safety

Power supply

CAUTION

A

lways disconnect mains electricity to the unit if a fault occurs which cannot be rectified via the

control panel.

CAUTION

I

f a fault occurs on the electricity-conducting elements of the unit, always contact an

authorised electrical installer to rectify the fault.

CAUTION

A

lways disconnect mains electricity to the unit before opening the doors, e.g. for installation,

inspection, cleaning and filter change.

Heat pump domestic hot water

CAUTION

A

void direct contact with the heating system pipes in the heat pump as they can get very hot.

CAUTION

T

o protect the heat pump against damage, it is fitted with the following safety equipment.

• High-pressure cut-out switch for compressor

The heat pump must undergo suitable service inspections under applicable legislation and regulations

t

o keep it in good condition and in compliance with safety and environmental requirements.

Responsibility for maintenance of the heat pump rests with the owner/user.

Heat pump for central heating

CAUTION

To secure the heat pump against damages, it is fitted with the following safety equipment

• Expansion systems for central heating and buffertank

• Safety valve for central heating and buffertank

• Low and high pressure switch for compressor

The heat pump must undergo suitable service inspections under applicable legislation and regulations

t

o keep it in good condition and in compliance with safety and environmental requirements.

Responsibility for maintenance of the heat pump rests with the owner/user.

4

Disposal

V

entilation system

Nilan units mainly consist of recyclable materials. They should therefore not be

d

isposed of with household refuse. Take them to your local recycling centre.

Heatpump

Conserning disposal og units with heat pumps, it ist important to contact the

l

ocal authorities for information about correct handling of these. The heatpump

contains the refrigerant R134a, which is harmful to the environment if not

handled corectly.

Compact P / Compact P Polar - GEO (English)

BY NILAN

5

General information

Introduction

General information prior to installation

T

he following documents are supplied with the unit:

• Installation instructions/Software instructions

• User manual

• Wiring diagram

The instructions can be downloaded from the Nilan website: http://www.nilan.dk/da-dk/forside/

download

If you have further questions on unit installation after reading the instructions, contact your nearest

Nilan distributor, who can be found on www.nilan.dk/forhandlere.

The purpose of these instructions is to give the installer advice on correct installation and maintenance

of the unit.

The unit must be started up immediately after installation and connection to the duct system. In

periods where the ventilation system is not in operation, humid air from the rooms may penetrate into

the ducts and form a condensate. The condensate may leak out of the valves and damage furniture and

floors. In addition, condensate may form inside the unit, damaging the unit's electronics and fans.

The unit is supplied fully tested and ready for operation.

Unit type

Product description

C

ompact P GEO is a ventilation unit with an integral heat exchanger that also produces hot water for

domestic use as well as central heating via an ground source heat pump.

Compact P is designed for air flows of up to 275 m3/h at 100 Pa external counter-pressure. Compact P

XL can handle air flows up to 430 m3/h at 100 Pa external counter-pressure.

The ventilation part draws the humid, vitiated air out of the dwelling via the bathroom, WC, kitchen and

utility room and introduces fresh air into the habitable rooms, i.e. living room, bedrooms and office. The

could outdoor air is heated up in the heat exchanger (heat recovery) by the warm extract air.

In addition to a (counterflow) heat exchanger, Compact P has an integral heat pump. The heat pump

uses the heat remaining in the extracted air following heat recovery in the heat exchanger to produce

hot water. In case of high hot water consumption, there is a 1.5 kW electric supplement heater in the

hot water tank, which can also be used to heat the water.

In the winter, the heat pump can be used to heat the supply air during periods in which not domestic hot

water is being produced. The supply air can be heated up to 34 ºC.

As it is a reversible heat pump, it can be used in summer to cool the supply air. Compact P is able to cool

the supply air by up to 10 ºC. However, it will not function as an air conditioning unit, as it operates with

a relatively low air change rate. Cooling of the supply air removes humidity from the indoor air,

providing good comfort for persons in the dwelling, even if the indoor temperature is high. Compact P is

able both to provide cooling and produce domestic hot water, so it could be said that the cooling of the

supply air is "free of charge".

6

The energy-efficient and low-noise GEO ground source heat pump heats the home via floor heating or

l

ow-temperature radiators. It extracts energy form the ground. The heat pump has an electrical power

supply to help it to function during very cold periods. The GEO can cool the dwelling during the summer

by passive cooling, using either the floor heating system or fan coils.

The GEO ground source heat pump can also be used to help produce hot water for domestic use, either

by pre-heating the water in a buffer tank, or directly in a Compact P hot water tank, if bought with a

solar coil.

Compact P / Compact P Polar - GEO (English)

BY NILAN

7

The unit

Compact P: GEO:

1. Duct connections

2

. Front panel for filter changes

3. Control panel (touch screen)

4. Extract air filter

5. Outdoor air filter (this is the location for F7

pollen filter, if one is installed

6. Counterflow heat exchanger

7. Heat pump for ventilation and domestic hot

water

8. Automatic control system

9. Fans

10. 100% bypass damper

11. Pre-heating element (Polar version only)

12. LAN cable (for connection to router or PC)

13. Condensate drain with water trap

14. 180 l domestic hot water tank (DHW)

15. 1,5 kW electrical supply heating element (with

overheating cut-out, which has to be pressed

in again if activated)

16. Electronically monitored sacrificial anode

17. Supplement heating coils (SOL version only)

18. Plumbing connections

20. 2 kW electrical supplement heating

2

1. 2 x 8 l expansion tank for central heating and

brine circuit

22. Safety valve and manometer for the central

heating circuit

23. Inverter controlled DC compressor

24. Feed tab and particle filter for the central

heating circuit

25. Integrated circulation pump for the brine

circuit

8

Overview of temperature sensors

T11

T4

T6

T5

T3

T1/T20

T2

T12

T17/18

T16T13

T14

Temperature sensors in the unit Temperature sensors outside

t

he unit

Temperature sensors int the hot

water tank

T1: Outdoor air

T

2: Supply air

T3: Extract air

T4: Extract air after heat

exchanger

T5: Condenser

T6: Evaporator

T7: Supply air after heating

e

lement (accessory)

T8: Outdoor air before preheating element (accessory)

T9: On heating element

(accessory)

TExt: External temperature

sensor

(accessory)

T11: Top of water tank

T

12: Bottom of water tank

Temperature sensor Brine Temperature sensors GEO

T13: Brine supply flow

T

14: Brine return flow

T16: Before condenser

T17: After condenser

T18: Supply flow central heating

T20: Outdoor temperature

T23: Evaporator temperature

Compact P / Compact P Polar - GEO (English)

BY NILAN

9

Dimensional drawing

900

2065

120

179

399

141

337

160

160

119

97

328

160

610

1

2

3

4

Connections:

1. Outdoor air

2. Supply air

3. Extract air

4. Discharge air

Weight: 257 kg

All dimensions in mm

10

Pipe diagram

PTL PTH

1

2

8

9

10

~

11

11

3

4

5

7

25

19

18

17

16

PZAL

20

18

14

28

13

14

15

14

40

6

46

12

12

18

14

15

14

13

13

41

22

23

21

22

23

21

24

42

43

26

27

27

17

36

Coolin g module

Supply flow

Return flow

Centra l heatin g

Ground collect ors

GEO heat pump

Everything within the red box is Nilan delivery.

1. Evaporator

2

. Service valve for low pressure

3. Low-pressure pressostat

4. Compressor

5. High-pressure pressostat

6. Condensor

7. Expansion valve

8. Sight glass with humidity indicator

9. Service valve for high pressure

10. Combi filter

11. Connection 1"

12. Flexihose 1"

13. Feed tab

14. Shut-off valve

15. Dirt filter

16. Safety valve 3,5 bar

17. Manometer (for central heating, not mounted)

18. Ball valve

1

9. Circulation pump 130 mm

20. Pressure control 0,5/1,1 bar

21. Flexihose 10 mm

22. Expansion tank 8 L

23. Automatic control vent 3/8"

24. Electric cartridge 2 kW

25. Temperature sensor T18

26. Safety valve 2,5 bar (not mounted)

27. Connection 3/4"

28. Overcurrent valve

36. Circulation pump

40. Temperature sensor T13

41. Temperature sensor T14

42. Temperature sensor T16

43. Temperature sensor T17

46. Outdoor temperature sensor T20

ATTENTION

A

n overflow valve must be installed point 28 in the floor heating circuit, with a circulation pump

with fixed speed. Alternatively, remove the individual thermostats, to ensure sufficient flow.

Compact P / Compact P Polar - GEO (English)

BY NILAN

11

Accessories

E

lectrical preheating element for frost protection

In longer periods of sub-zero temperatures, the high-efficiency counterflow heat

e

xchanger will ice up. To avoid icing, it is recommended that an electrical

preheating element is mounted.

The preheating element uses very little energy, but ensures efficient heat

recovery without de-icing, thus achieving an overall saving in energy

consumption.

Adjustable water comfort heater

A water comfort heater can be used to increase supply air temperature to the

d

esired level. It is fitted in the supply air duct and must be connected to the

primary heat supply.

Supplied with a two-way regulating valve, temperature sensor and frost

thermostat.

Electric heating element

An electric heating element allows the supply air temperature to be raised to the

d

esired level. Electric heating elements are supplied for mounting in the supply

air duct, and are provided with the necessary sensors.

Pollen filter F7

The unit is supplied as standard with a G4 filter.

I

f persons in the dwelling suffer from a pollen allergy, there is an option for

mounting a F7 pollen filter in the outdoor air inlet to minimise the pollen in the

indoor air.

EM box

With an EM box it is possible to divide the extract air between the kitchen and

b

athroom.

If the cooker hood is operating via the unit and is switched on, air extraction from

the bathroom reduces slightly to allow sufficient air for the cooker hood to

extract kitchen fumes.

The EM box has a metal filter which efficiently separates grease particles from

the cooker hood air, thus protecting the unit.

CO2

sensor

Fitting a CO2

sensor means the ventilation speed can be pre-programmed to run

higher ventilation levels in the event of high CO2 level in the extracted air. CO

2

levels can be programmed.

12

Safety group

The safety group, which is made of brass, consists of a stop valve with an integral

n

on-return valve, a safety valve and drain cock. It can be installed directly

beneath the hot water tank.

Safety features

During periods with cooling ventilation, hot water in the tank can reach very high

t

emperatures - up to 80 ºC.

A maximum temperature of up to 60 ºC can be set in the control system to

prevent scalding, but active cooling is then limited.

To make full use of the cooling function, scalding protection should be fitted that

mixes hot water with cold to bring the temperature down.

If a solar panel is used to supplement hot water heating, scalding protection must

be fitted.

Flexible silencing

To facilitate later servicing of the unit, we recommend fitting a flexible

connection between the unit and the duct system.

Nilan's sound damping flexi-hose gives good sound damping both to the duct

system and to roof stacks.

Trolley

A trolley makes it possible to lift the unit of the pallet without physical strain.

T

he same trolley can be moved to wheel the unit around.

SHW hot water tank

If there is a large demand for hot water, a 250 litre hot water tank can be

c

onnected.

The hot water tank is heated by the central heating system’s heat pump and/or

via solar panels.

The water runs from the SHW tank, through the DHW tank in Compact P, before

running into the domestic hot water supply.

Compact P / Compact P Polar - GEO (English)

BY NILAN

13

Installation

Installing the unit

Transport into the dwelling

C

ompact P is supplied in one piece on a pallet, packed in cardboard.

It is fitted at the factory with 4 lifting straps, one for each top corner. This makes it possible to lift in the

unit with a crane. When lifting the units with the supplied straps, these must be at an angle of max. 45°

from the vertical.

Nilan also offers a lifting trolley, with which the unit can be lifted directly off the pallet and into the

building. If the filter box is removed, the unit can be manoeuvred through an ordinary door.

Positioning of unit

ATTENTION

W

hen setting up the unit, consideration must always be given to future servicing and

maintenance.

It must be easy to replace filters, and it must be possible to perform tasks such as removing the

heat exchanger, replacing fans and other components.

ATTENTION

A

minimum free space in front of the unit of 60 cm is recommended.

It is important that the unit is level in order to achieve proper run-off from the condensate tray.

The unit should be positioned on a level and vibration-free substrate. In itself, the unit is low-noise and

l

ow-vibration, but even so, account must be taken of possible vibrations which could be transferred to

building parts. We recommend maintaining a minimum 10 mm gap from building parts and other fixed

equipment.

ATTENTION

F

or noise reasons, it is recommended that the unit is positioned with its rear panel against an

outer wall.

At the lower rear and sides there are punched

areas which can be clipped out.

This avoids the necessity of cutting holes

yourself.

The rear angle iron on the base frame can be

removed, allowing the unit to be pushed up

against the wall, thereby concealing the water

connections.

ATTENTION

I

f a screen is mounted over the Compact P, it must be easy to dismantle this.

14

Ground collector circuit

E

xamples of the laying

By laying the geothermal circuit there are some range distances, which need to be observed to get a

unit which will have an effective and smooth operation. Further local authorities may make

requirements for installation and acceptance of the facility before entry into use.

In some cases where there is less space vertically holes is drilled for hoses, but most lay the hoses

horizontally. Below are some examples of laying the ground collectors.

ATTENTION

I

s is important to pressure test the pipes for tightness one by one immediately before covering

with soil, as during handling.

Example of layout of ground tubes collecting in a well.

Min.

1,5 m

Min. 0,6 m

Min. 0,4 m

Min.

1 m

Example of layout of ground tubes collected within the foundation.

Min.

1,5 m

Min. 0,6 m

Min.

1 m

Compact P / Compact P Polar - GEO (English)

BY NILAN

15

16

Electrical installation

Safety

ATTENTION

A

ll work must be carried out by qualified personnel and in accordance with applicable legislation

and regulations.

ATTENTION

I

t is important that power is disconnected when working with the unit's electrical components.

It is important to check that cables have not been damaged or trapped during connection and use.

C

onnections lists

1

3

2

4

5

1. Connection for the Touch control panel (RJ45 plug)

2

. Connection for ventilation and domestic hot water via Schuko plug, 230V (do not forget the earth

connection)

3. Connection for PC or router via LAN cable

4. Connection of the heat pump (cable mounted)

5. Connection of the circulation pump for central heating (cable mounted)

Compact P / Compact P Polar - GEO (English)

BY NILAN

17

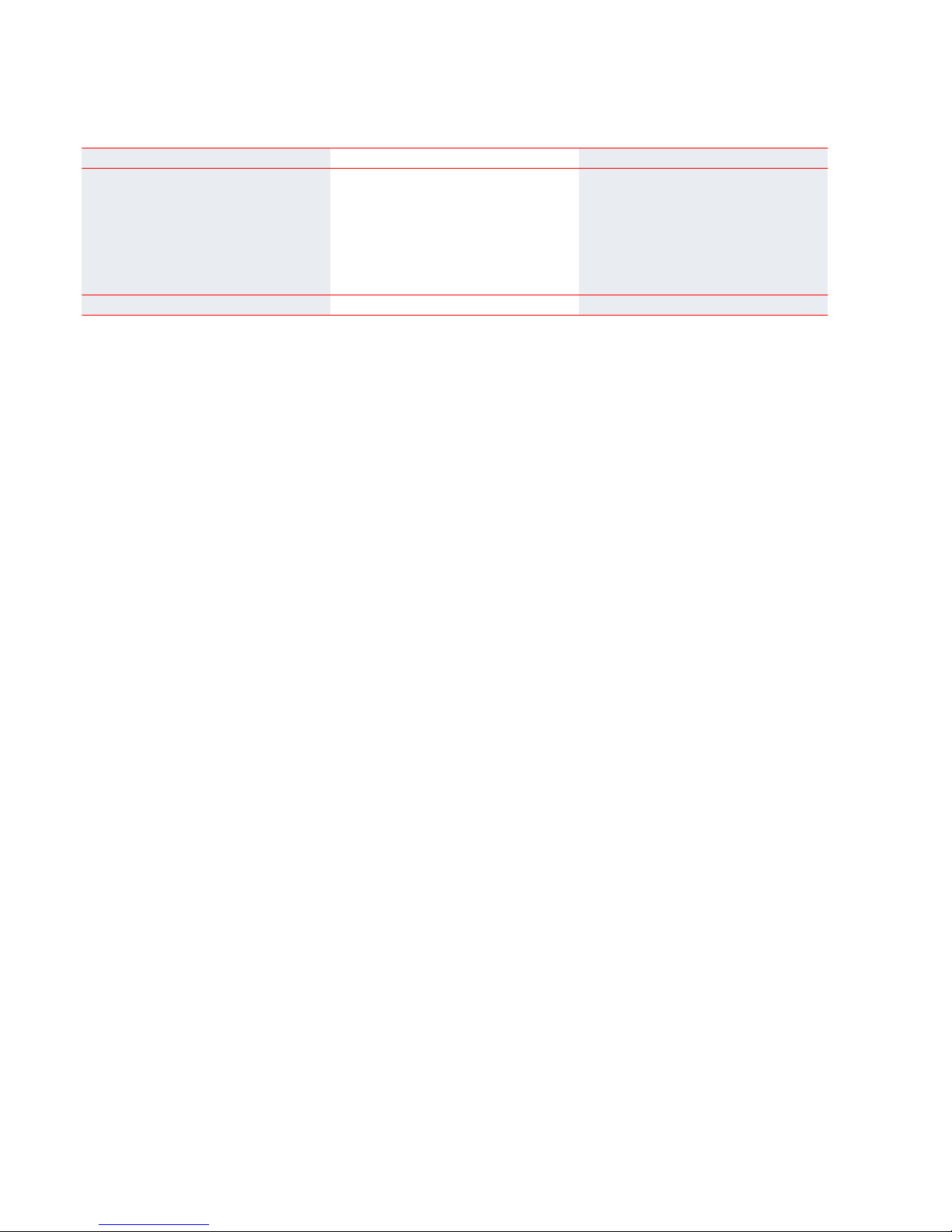

Control panel

T

ouch panel

The unit is supplied with a 3 m cable with RJ45 plug mounted on the touch panel for connection to the

unit. The cable may be extended to a maximum length of 50 m.

ATTENTION

A

n ordinary LAN cable must be used, not a crowwover bacle max 50 m.

Do you want to crimp a RJ45 plug on to a cable, you must notice the following:

1. Green/white

2

. Green

3. Orange/white

4. Empty

5. Empty

6. Orange

7. Brown/white

8. Brown

Use RJ45 T568 type A plug and RJ45 crimping tool.

The touch user panel should be located in a prominent place to allow changes to be made to settings

a

nd for observing operational warnings or alarms.

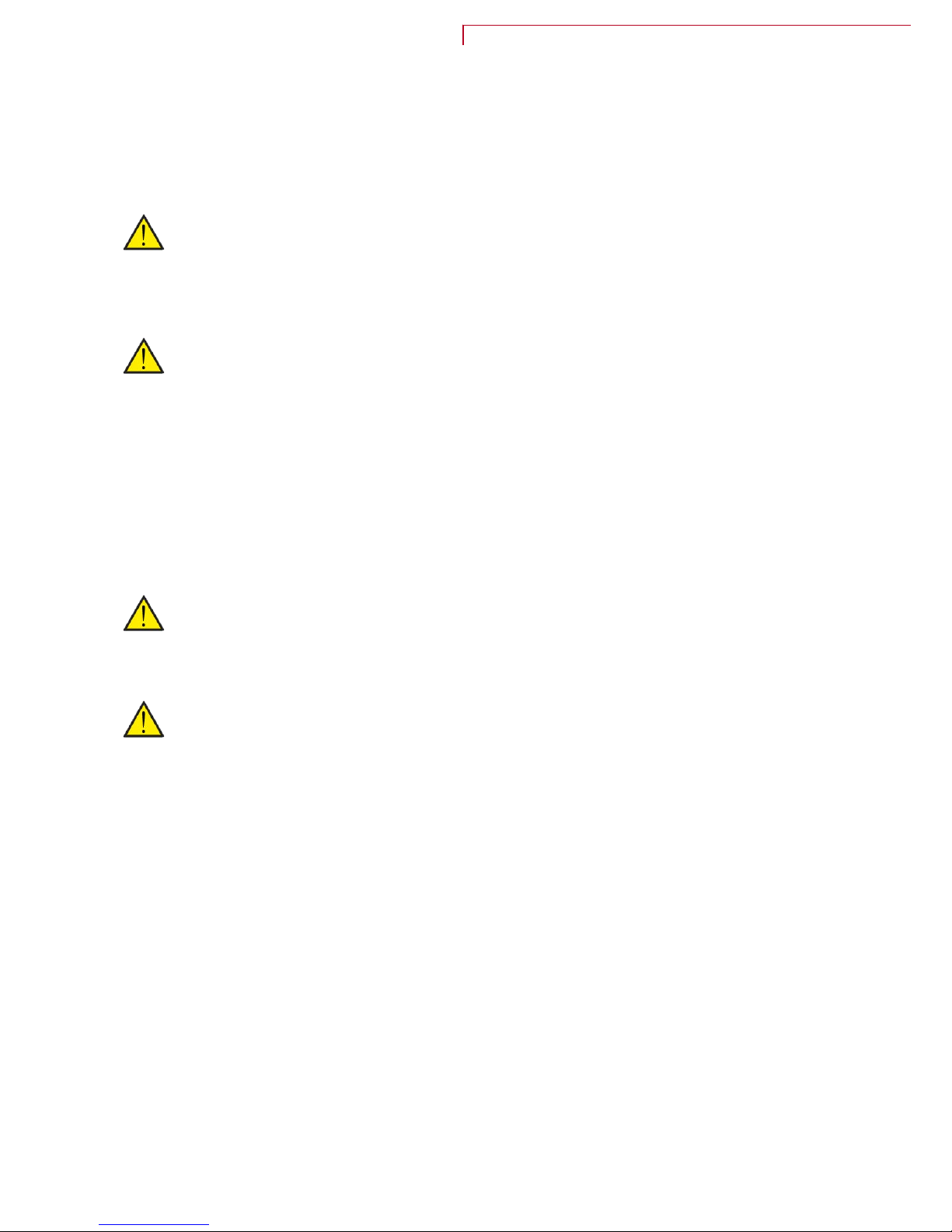

Touch panel seen from below:

1. Locking clip

2

. Power connection

3. USB stick

Control panel connection

18

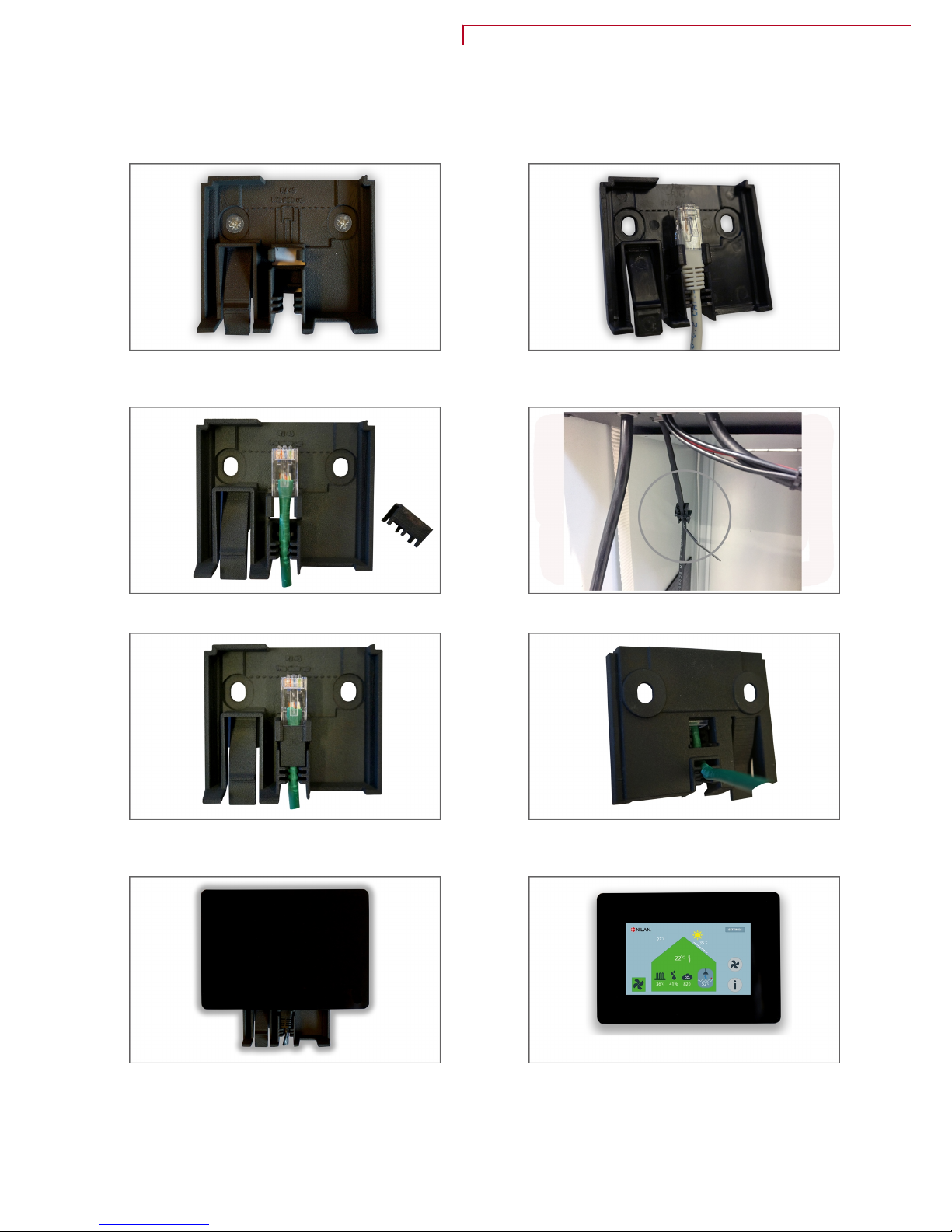

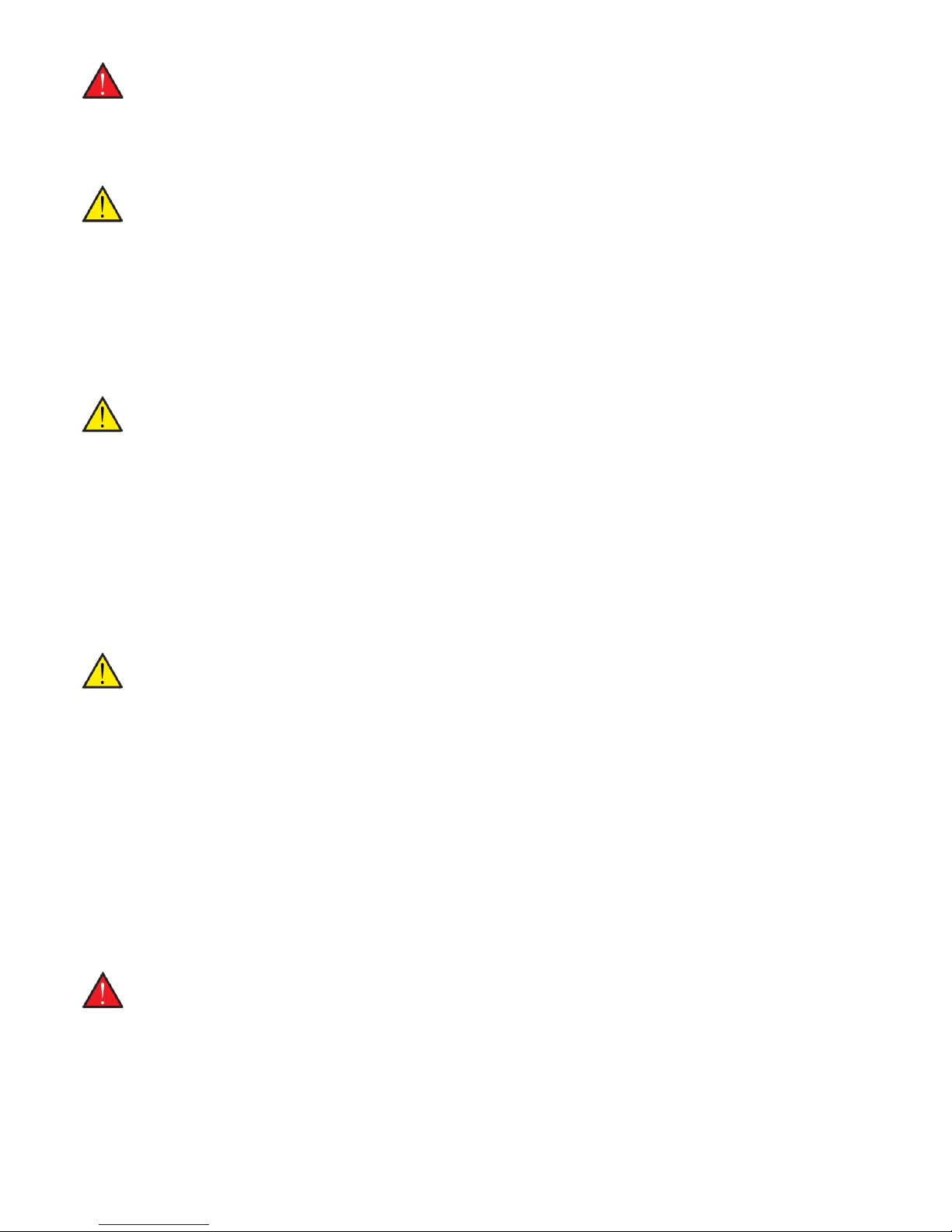

Wall fittings

T

he touch panel should be mounted on the wall with the integral wall fittings, and the cable form the

unit is mounted here too.

1. The wall bracket is fixed to the wall with two screws. 2.a. The RJ45 plug is mounted in the wall fitting with the

the top of the plug flush with the dotted line in the wall

fitting, and with the RJ45 trigger pin away from the wall.

2.b. You can fit the RJ45 plug to the cable you make

y

ourself. A spacer is supplied for this purpose.

The specer is fastened to the LAN-cable which is located

behind the large door.

2.c. The top of the plug must be flush with the dotted line

i

n the wall fitting. The spacer fits between the plug and

cable relief bracket.

3. The cable may be led down from the wall fitting or into

a

hole in the wall behind it.

4. Push the touch panel down over the wall bracket until a

c

lick is heard.

The panel may be removed from the wall by pressing the

locking clip.

5. The touch panel is ready for use.

Compact P / Compact P Polar - GEO (English)

BY NILAN

19

Electrical connections unit

S

afety

ATTENTION

A

ll work must be carried out by qualified personnel and in accordance with applicable legislation

and regulations.

ATTENTION

I

t is important that power is disconnected when working with the unit's electrical components.

It is important to check that cables have not been damaged or trapped during connection and use.

Compact P

Ventil ation an d domesti c hot wa ter

230V H z max 13 A (Schuko plug)

(Polar version 16A)

Safety switch

20

GEO3

Heat p ump for central h eating

Standa rd:

2 x 40 0V, 2L+N +PE, 13A, 50 Hz

Option 1:

Safety switch

3 x 23 0V, 3L+P E, 13A, 5 0 Hz

Option 2:

1 x 23 0V, L+N+ PE, 20A, 50 Hz

GEO6

Heat p ump for central h eating

400/23 0V, 2L+N +PE, 16A, 50 Hz

Safety switch

Compact P / Compact P Polar - GEO (English)

BY NILAN

21

Electrical connections accessories

E

xternal electrical preheating element

If Compact P has not been purchased in the Polar version with integral preheating element, there is an

option for purchasing an external electrical preheating element for subsequent installation.

The electric preheating element is mounted in the outdoor air duct before the unit with the necessary

temperature sensor, and connected to an external power supply.

1x230V ~ 50 Hz max. 16A

7 8

Min. 32 cm

T8

ATTENTION

I

t is important that the temperature sensor for the heating element is positioned at least 32 cm

after the preheating element in order to achieve correct regulation.

The T8 outdoor air temperature sensor is positioned before the external preheating element and

c

onnected to the Compact P control system, to allow it to perform regulation via the outdoor air

temperature. If it is not wished to regulate the functions via the outdoor air temperature, T8 may be

deactivated in the software under the frost protection section:

The preheating element has a three-stage safety system against overheating.

1

. There is a operating thermostat which regulates the heat and ensures that the supply air

temperature does not fall below -1 °C

2. There is a max. thermostat, which shuts down the preheating element if the temperature rises

above 50 °C

3. There is a manual safety thermostat, which shuts down the preheating element if the

temperature rises above 100 °C

ATTENTION

When mounting the electric preheating element, there must be a safety gap of minimum 15 cm

from any flammable material. The heating element must be insulated with a fire retardant

insulation material, but the cover on the connection box must not be insulated.

A dimensional drawing is available under the section on the electric heating element.

22

Electric heating element

I

f it is wished to control the supply air temperature, it will be necessary to fit a heating element.

An electric heating element can be purchased for fitting in the supply air duct (inlet air), and comes with

the necessary sensor and connection to the unit.

0-10V

GND

1x230V ~ 50 Hz max. 16A

Min. 50 cm

T7

0-10V

GND

T7

Wiring diagrams are supplied with the products. The heating element is set on the display under menu

o

ption: Ventilation/Heating element.

The wires are led alongside the duct and drawn through the bushing on top of the Compact P, led down

to the circuit board and mounted in accordance with the wiring diagram.

ATTENTION

W

hen mounting the electric heating element, there must be a safety gap of minimum 15 cm

from any flammable material. The heating element must be insulated with a fire retardant

insulation material, but the lid on the connection box must not be insulated.

Dimensional drawing:

Ø160

Positi oning opt ions:

Water comfort heater

I

f it is wished to control the supply air temperature, it will be necessary to fit a heating element.

Compact P / Compact P Polar - GEO (English)

BY NILAN

23

A water heating element can be purchased for fitting in the supply air duct, and comes with the

n

ecessary sensor and connection to the unit.

Connecting the sensors

Min. 50 cm

T7

T7

T9

T9

B44

B44

21 24

T7: Temperature sensor - T9: Temperature sensor heating element - B44: Frost protection

ATTENTION

W

hen B44 frost protection is mounted, the jumper in the same connections is removed.

The wires are led alongside the duct and drawn through the bushing on the top of the Compact P, led

d

own to the circuit board and mounted in accordance with the wiring diagram. The heating element

settings can be found on the display under menu option: Ventilation / Heating element.

24

Electrical connection for 2-way valve

1

1.

A 24V autotransformer is supplied and should be installed in a suitable position in the unit.

ATTENTION

T

he valve must not be connected to a 230V power supply

The wires are led alongside the duct and drawn through the bushing on the top of the Compact P, led

down to the circuit board and mounted in accordance with the wiring diagram.

Dimensional drawing:

83

310

440

Ø 125/160

238

22

32

31

300

3/4" RG

3/4" RG

Compact P / Compact P Polar - GEO (English)

BY NILAN

25

CO2

sensor

It is possible to purchase a CO2 sensor as an accessory if it is wished to control the ventilation level via

the CO2level in the dwelling.

The CO2 sensor is positioned in the extract air from the dwelling, and mounted on the beam with the

screws supplied:

The wire from the CO2sensor is led to the circuit board and connected as shown below:

The three wires are connected as follows:

G

ND: Blue

Out: Black

24V Brown

26

Cooker hood and EM box

T

here are several benefits from connecting the cooker hood to the dwelling's ventilation system.

Firstly, there is full heat recovery of heat from cooking.

Secondly, the unit is able to provide balance in the ventilation. If the cooker hood does not run via the

ventilation system and if the house is new and airtight, use of the cooker hood will create a

underpressure in the dwelling, minimising the suction effect from the cooker hood and also creating

smoke problems, for instance if a wood-burning stove or open fire is installed and in use. By running the

cooker hood via the ventilation system, the unit can increase the supply air as the volume of extract air

from cooker hood operation goes up. In this way, a balance can be maintained in the dwelling, and the

cooker hood will retain its full suction power.

In the case of ventilation of a large dwelling/building, with more than one bathroom, there may be

problems creating sufficient air capacity for the cooker hood. In these cases, an EM box will be an ideal

addition, as it minimises the extract air from the other high-humidity rooms for the short period that

the cooker hood is in use, and in this way ensures sufficient air for extraction via the cooker hood.

ATTENTION

I

f the cooker hood is connected to the ventilation system, it is important that it is fitted with a

good grease filter and that this can be regularly cleaned.

User selection 1

User selection 2

EM box

The potential free contact for the cooker hood is connected to User selection 1 or 2, which are

p

rogrammed in the unit's software under the section General settings. User selection 2 is chosen if an

EM box is to be installed.

Compact P / Compact P Polar - GEO (English)

BY NILAN

27

Other electrical connections

U

ser selection 1

It is possible to override the unit's functions via an external signal from a potential free contact.

The User selection function can be used for many purposes, e.g. in the case of a wood burning stove or

open fire. Initial settings of the ventilation system set up a small underpressure, so that humidity in the

air is not forced into building parts. This is naturally a disadvantage when lighting a wood burning stove,

as smoke will enter the room. By means of an potential free contact, one of the fan speeds, e.g. fan

speed 4, can be set to run with a slight overpressure instead, so the smoke goes up the chimney as it

should.

Connection to CTS700 control system:

Potential free contact

User selection 1 is programmed in the unit's software under General settings. See the options in the

S

oftware instructions.

28

User selection 2

A

s with User selection 1, it is also possible with User selection 2 to override the unit's functions via an

external signal from a potential free contact. The difference is that by activating User selection 2, the

control system also transmits an output signal.

User selection 2 has the higher priority and is therefore used for cooker hood operation if a cooker

hood is connected to the ventilation system. Normally fan speeds 3 or 4 are set for cooker hood

operation. The output signal can be used for connecting an EM box or external damper which is to

assume a particular setting during cooker hood operation.

There are many other uses for User selection 2 which we shall not discuss further in these instructions.

Connections:

Potent ial free contact

Output signal

Compact P / Compact P Polar - GEO (English)

BY NILAN

29

External room temperature sensor

D

o you not want to control the unit according to a room temperature measured through the T3 extract

air, an external room temperature sensor can be connected..

The room temperature sensor is placed in the room, which should be the reference for the house.

Fire protection

A

fire thermostat or external fire automatic can be connected. It must be a joined signal, when it is

broken the Compact P register it as a fire and stop the unit.

Note! If the unit is connected to external fire automatic, you set the software: General Settings/

S

ervice/Auto reset for external fire alarm to "On".

30

Common alarm

I

f the unit is located in a place where access is poor or infrequent, and if the control panel is also located

here, it may be hard to observe any alarms.

An external alarm in the form of a light or acoustic signal, etc., can be connected to the unit.

External heat supply

C

ompact P is able to control an external room heating such as electric radiators or a floor heating

system.

The room temperature is monitored by the Compact P, which block the external heating supply when

there is no need for heating. If Compact P cannot achieve the desired room temperature through the

ventilation, the external heating supply is released until the room temperature is in the desired level.

The external heat supply is connected via relay 8, and set in the touch-display under the menu:

Ventilation-/Temperature regulation

A maximum effect of 500W can be connected (Compact P Polar need to have a transfer relay mounted).

Compact P / Compact P Polar - GEO (English)

BY NILAN

31

Connecting EHD damper

T

o conduct outdoor air down through a geothermal pipe in the ground makes good sense. The air is

heated during the winter and cooled in the summer by the ground.

But passing outdoor air through such a geothermal system may not be the best idea in the spring and

autumn, but taking it directly through a roof vent is recommended.

The CTS700 control system has a built-in function that measures whether the geothermal pipe or roof

vent provides the best option for air intake.

It measures the outdoor temperature during a stabilising period from the geothermal pipe and roof

vent respectively. The measurement indicates where it is best to direct the outdoor air. CTS700 sets

the EHD damper to the best option, and continues ventilation for a set period, referred to in the

program as holding time.

The EHD damper is connected via relay 7 and set on the display menu item: Ventilation / Frost

protection or de-icing / Frost protection.

EHD

ATTENTION

D

amper, geothermal pipe and roof vent are not supplied by Nilan.

ATTENTION

W

hen using a geothermal pipe, the "Low ventilation a low outdoor temperature" feature cannot

be used.

32

BAH Geothermal heater

A

geometric preheater has two functions:

1. It acts as frost protection in the winter, heating up the outdoor air and protecting the unit against

icing up

2. It can then be used to cool down outdoor air in the summer, supplying cooled air to the home

The heater is set on the display under: Ventilation/frost-protection or de-icing

11

12

14

14

13

12

12

19

1517

18

16

T8

Pdiff.

19

18

T8

11. Condensation drain

1

2. Shut-off valves

13. Particle filter

14. Filling and drain cocks

15. Safety valve

16. Bleed screw

17. Expansion tank

18. Pressostat

19. Circulation pump

T8. Outdoor temperature sensor

ATTENTION

C

irculation pump, heater and brine circuit are not supplied by Nilan.

Compact P / Compact P Polar - GEO (English)

BY NILAN

33

Passive cooling function

G

EO has a passive cooling function. It works by the soil which cools the temperature of the brine, the

cold brine water used to cool the water in the central heating floor system or led to a fan coil.

Passive cooling by the floor heating system

An external temperature sensor is connected to digital input 10. When the contact is switched on GEO

goes into passive cooling, where the circulation pump for the brine circuit and the circulation pump for

the central heating are running. The relay output 10 is activated and turns a tree-way-valve, so the

brine water is led to the passive heat exchanger (not a Nilan delivery). When the contact is switched off

again, GEO will go back to normal operation.

The external temperature sensor is often equipped with an infrared sensor, which measures the floor

temperature and stop the cooling before, dew is formed on the floor.

+

+

+

+

+

T18

T17T13

T14

T16

T21

T22

If there is a need that GEO must produce domestic hot water, the passive cooling is stopped.

+

+

+

+

+

T18

T17T13

T14

T16

T21

T22

34

Passive cooling by fan coils

A

n external temperature sensor is connected to digital input 10. When the contact is switched on GEO

goes into passive cooling, where the circulation pump for the brine circuit are running. The relay output

10 is activated and turns a tree-way-valve, so the brine water is led tod the fan coil (the fan coil is not a

Nilan delivery). When the contact is switched off again, GEO will go back to normal operation.

+

+

+

+

+

T18

T17T13

T14

T16

T21

T22

If there is a need that GEO must produce domestic hot water, the passive cooling will still be running,

e

ven with higher effect, because the brine water will be cooled by the heat pump, when it is producing

domestic hot water.

+

+

+

+

+

T18

T17T13

T14

T16

T21

T22

Compact P / Compact P Polar - GEO (English)

BY NILAN

35

Plumbing installation

Condensate drain

Important information

C

ompact P is supplied with a reinforced 20 mm condensation drain pipe with built-in water lock.

ATTENTION

I

nstall the condensation drain with an even slope of minimum 1 cm per metre to the nearest

drain. The overflow from the safety valve to the cold water supply must be piped to a visible

drain.

ATTENTION

I

f the unit is placed outside the building, the condensation drain must be protected against icing

up. The fitter is responsible for ensuring that the unit is protected from freezing.

The connection of the water lock must be airtight to prevent air being sucked into the unit, trapping

c

ondensation in the unit. Ehen the condensation overflows the tray and runs out of the unit, damages

must be expected.

After fitting the water trap, you must test the function in the following way: Fill the condensate tray

with water. Start up the unit at highest fans speed, and allow it to run for several minutes. After that

control that no water is left in the condensation tray (the unit must be connected to the duct system,

and the lid must be on during the test).

The water trap can dry out, preventing water to run out from the unit condensation tray. Control the

water trap in regular intervals, especially after the summer and top up with water if needed.

The water trap is integrated in the pipe running from the condensation tray to the drain.

36

Domestic hot water tank

C

onnection overview

Compact P front

310

110 248

200

240

1

2

3

5

4

Compact P back

C

onnections:

1. Connection for 3/4” circulation pipe

2. Hot water outlet 3/4"

3. Cold water intake 3/4"

4. Return supplementary coil 3/4"

5. Supply supplementary coil 3/4"

Supplementary coil is only standard on Compact P SOL models.

The coil is located in the bottom, and has an external diameter of 22 mm and is 8,500 mm long,

equivalent to 0.6 m 2 .

Connection

ATTENTION

A

ll work must be performed by qualified personnel and in accordance with relevant legislation

and provisions.

Nilan's hot water tanks are double-enamelled, ensuring long life. The efficient foam insulation protects

a

gainst unnecessary heat loss.

All connection nozzles for water have 3/4" thread and are located in the tank bottom.

The tank is also fitted with an electronically-monitored sacrificial anode that automatically displays a

warning on the display when it needs changing.

Compact P / Compact P Polar - GEO (English)

BY NILAN

37

CAUTION

C

hanging the anode when notified on the display is important. Failure to do so can cancel the

guarantee on the hot water tank.

The tank is fitted with a 1.5 kW supplementary electrical heater deactivated by default and activated

v

ia the control panel if required.

ATTENTION

T

he supplementary heating must not be activated before the water tank is full of water.

Hot water circulation

I

f wished, hot water circulation can be established by fitting a non-return valve and a circulation pump

for domestic water to the tank's circulation connector (1).

If hot water circulation is not established, the connector must remain closed with the factory-mounted

shut-off plug.

ATTENTION

H

ot water circulation can lead to a significant heat loss in the pipes, diverting a good proportion

of the heat pump's output. To avoid this, circulation pipes and the hot water loop must be

insulated with at least 30 mm mineral wool.

It is advisable to set a timer so that the circulation pump is not running constantly.

Solar coil

A

ll Compact P SOL models have integral supplementary coil, see connections list.

The solar coil with a surface area of 0.6 m2 is intended for solar heating systems, though it can also be

connected to other heat sources.

ATTENTION

I

f a solar collector or other heat source is connected to a Compact P model, it is recommended

that a safety group is connected to the hot water outlet to secure against scalding.

Softened water

I

f it is wished to soften water with salt in a Nilan hot water tank, the following must be observed:

• The hardness of the water must be at least -2° dh (proportion of alkaline earths 0,4 mmol/l)

• The conductivity must be between 13 mS/m og 150 mS/m (millisiemens per m)

• The pH value must be between 6.5 and 9.5

• The chlorine content must be under 250 mg Cl/l

If the above criteria are exceeded, the anode current will be too high, the anode will break down too

quickly and the water will begin to smell bad.

CAUTION

D

emineralised water (double ion exchange) must not be used as the tank will corrode very

rapidly. Demineralised water is also called totally desalinated water and deionised water.

38

Central heating

W

ater connection list

4

3

21

1. Supply flow central heating

2. Return flow central heating

3. Supply flow brine (from ground hose)

4. Return flow brine (to ground hose)

Compact P / Compact P Polar - GEO (English)

BY NILAN

39

Brine circuit

A

fter completed and demonstrated leak testing, brine can be filled. Filling the brine should be

performed by a qualified installer.

It is recommended to buy ready-mixed brine with corrosion inhibitors. If you mix the brine by yourself,

the water quality must be suitable for brine.

CAUTION

E

nsure that the brine hoses are deflated and without dirt, befor the brine is connected to the

heat pump.

Isolation of the brine tubes

A

ll pipes to and from the ground collectors / geothermal circuit must be isolated completely into the

heat pump, to prevent condensation on the cold tubes.

A collection tray must be established for condensation water from the heat pump and water from the

safety valve.

Safety for the brine system

The brine hoses is equipped with a pressure control which make an alarm by falling pressure in the

ground hoses. The alarm is triggered, if the pressure falls below 0,6 bar. The unit is turned of and

cannot start up again automatically.

The ground hose system must be designed as a closed system with a pressure at rest of 1,5 - 2,5 bar.

40

Check list for the central heating system prior to start-up

T

he check list is used when starting and delivering the system, and it should always be filled in. See the

other sections in the manual for further information.

Electrical connection and controls Checked - date Notes

The power supply is connected and secured in

a

ccordance with the wiring diagram and manual

The control panel is installed in a place that can

e

asilybe seen by the user

Central heating circuit Checked - date Notes

The central heating circuit is sealed

The central heating circuit has been vented after filling

Central heating circuit pressure, overpressure Bar

The opening pressure for the central heating circuit´s

s

afety valve is correct

The circulation pump is rated correctly for the

i

nstallation

The circulation pump is in constant operation or is

c

ontrolled by the heating pump

Brine circuit Checked - date Notes

Brine circuit / ground hoses is sealed

Brine type

Brine concentration % %

Freezing point (recommended -20 °C to -18 °C) °C

The brine is mixed thoroughly before filling

The brine circuit is vented after filling

Pressure of brine circuit bar

Fluid from the safety valve for the brine circuit cannot

r

un into the sewer

The brine circuit is connected correctly to the heat

p

ump (the heat pump can be damaged by wrong

connection)

Design flow brine circuit m3/h

Adjusted flow brine circuit m3/

h

There is a risk of low pressure and frost damage of evaporator in the heat pump, if the conditions for

t

he brine circuit is not met.

Compact P / Compact P Polar - GEO (English)

BY NILAN

41

Plumbing connections for accessories

S

afety group

CAUTION

A

safety device must be connected to the hot water tank.

When water is heated to 60 °C, it expands by 2%. A pressure tank could burst without a safety valve

k

eeping excess water out. The safety valve should therefore drip during warming up.

Installation:

The following should be remembered during installation:

a

.

The double nut is attached to the water heater’s cold water

pipe so that the arrows are pointing in towards the water

heater (in the direction of the flow). The joint with the water

heater is sealed using a threaded washer.

b.

The joint between the double nut and the system is sealed

using fibre packing.

c.

The rubber ring seal (the O-ring) is fitted to the unit so that it

can function as a seal between the safety valve and the unit in

such a way that the valve is locked.

The end of the overflow pipe must be visible, and it must be able to run out safely via the drain.

ATTENTION

A

s water expands as it heats up, the safety valve will drip.

ATTENTION

It is up to the installation engineer to tell the customer where the safety valve is and how it

works, and also that it must be regularly checked at least twice a year in order to prevent

incrustation.

42

Safety group with anti-scald protection

T

he control system contains as standard a temperature limit for domestic hot water of 65 ºC. This

setting prevents users from scalding themselves when the hot tap is turned on.

It also means that when Compact P is in cooling mode, cooling will stop when the domestic hot water

reaches a temperature of 65 ºC.

If the cooling requirement is higher than this, the temperature limit may be raised to 80 ºC, but in this

case an anti-scald device must be mounted under the hot water tank, to prevent users from scalding

themselves when turning on the hot tap.

The anti-scald device mixes hot water with cold water, thus bringing down the temperature and

avoiding scalding. This will extend the period for which Compact P can perform cooling.

CAUTION

I

f a solar panel is connected to the hot water tank, an anti-scald device must be mounted.

1

2

3

4

5

6

7

8

1. Hot water from the hot water tank

2

. Cold water to the hot water tank

3. Stop cock cold water

4. Pressure relief valve (6 bar or 10 bar)

5. The overflows from the safety valve are led to a prominent drain

6. Cold water supply

7. Domestic hot water for the dwelling

8. Mixing valve for domestic hot water for the dwelling (can be set between 35 - 60 ºC)

Compact P / Compact P Polar - GEO (English)

BY NILAN

43

Hot water heater (accessory)

CAUTION

Connection of the hot water heating element must be carried out by an authorised plumber.

CAUTION

I

f the control unit is installed outdoors or external to the building, it must be protected against

frost.

The heater is for duct connection, and cannot be integrated into the control unit.

T

he heater is supplied as an accessory and consists of: Heating element with temperature sensor T9

and frost thermostat B3, actuator, regulator valve and autotransformer.

Must be activated via the control system.

The system should be connected, bled and checked for leaks. The system can then be started. Check

and clean the sediment trap after flushing the system appropriately.

4

2

3

1

Supply

Return

1. Water heater

2

. Actuator and regulation valve: Danfoss AME 140/24V 0-10V signal, 2-way valve VZ2 Kv0,4

(supplied by Nilan) Kvs-value MUST be checked compared to the supply.

Differential pressure: 0.1-0.6 bar

At a supply temperature of 60°C, a cooling effect of 20°C over the heater is calculated at maximum

heat output.

3. Bleed valve (not supplied by Nilan)

4. Snavsopsamler (ikke Nilan leverance)

44

IMPORTANT, concerning Danfoss Actuator type AME 140:

M

andatory procedure for refitting the actuator:

1. Disconnect from mains electricity. Remove actuator cover.

2. Disengage the gear by holding the button under the housing in while screwing the spindle upwards

as far as it will go (counter-clockwise)

3. Fit actuator and reconnect mains electricity.

4. Switch DIP switch no. 1 to ON and then OFF.

5. Automatic calibration will run for up to 6 minutes.

(The diode will flash during calibration before becoming constant).

6. Fit actuator cover.

Output chart, hot water heater

Water side Air si de

[°C] [m3/h] [kPa] [kW] [m3/h] [°C] [°C] [Pa]

40/30

0,04 0,85 0,52 100 16 31,1 2

0,06 1,25 0,64 135 16 29,8 3

0,08 2,18 0,87 210 16 28,1 6

0,11 4,65 1,32 400 16 25,7 17

0,17 9,62 1,98 800 16 23,2 53

0,19 11,9 2,23 1000 16 22,5 77

60/40

0,04 0,69 0,94 100 16 43,5 2

0,05 1,00 1,16 135 16 41,1 3

0,07 1,75 1,58 210 16 38,0 6

0,10 3,70 2,40 400 16 33,5 17

0,16 7,66 3,58 800 16 29,1 53

0,18 9,48 4,03 1000 16 27,8 77

70/40

0,03 0,40 1,06 100 16 47,0 2

0,04 0,58 1,30 135 16 44,2 3

0,05 1,00 1,76 210 16 40,5 6

0,08 2,09 2,64 400 16 35,3 17

0,11 4,25 3,9 800 16 30,3 53

0,13 5,24 4,38 1000 16 28,8 77

Temper ature

supply /return

Flow Pressu re loss Output Air v olume Temper ature

before HWH*

Temper ature

after HWH*

Pressu re loss

over H WH*

*(HWH) hot water heater

Compact P / Compact P Polar - GEO (English)

BY NILAN

45

Domestic hot water tank

T

he GEO unit can be connected to an external hot water tank (SHW) and to the hot water tank in the

Compact P (DHW). A three-way valve, which can be purchased as an accessory, is required.

PTL PTH

1

2

8

9

10

~

11

11

3

4

5

7

25

19

18

17

16

PZAL

20

18

44

14

28

13

14

15

14

40

35

6

B

AB

35

B

A

46

12

12

18

14

15

14

13

13

41

22

23

21

22

23

21

24

42

43

45

26

27

27

17

36