Version: 10.00, 13-04-2015

Software-version: 2.30

Installation instruction

CTS 602 by Nilan

Comfort 1200

Comfort 5000

Table of contents

Table of contents ............................................................................................................................ 2

Introduction ..................................................................................................................................... 3

Power supply .................................................................................................................................. 4

Assembly of Comfort ...................................................................................................................... 5

Condensation drain / water seal ..................................................................................................... 6

Heating surface, water .................................................................................................................... 7

Heating surface, electrical (retrofitting) ........................................................................................... 9

Activating the service menu ................................................................ ...................................... 10

Heating surface ......................................................................................................................... 11

Air quality .................................................................................................................................. 12

Air exchange ............................................................................................................................. 13

Defrost ...................................................................................................................................... 14

Temp. control ............................................................................................................................ 15

Inlet control ............................................................................................................................... 16

Room control ............................................................................................................................ 17

Re-start ..................................................................................................................................... 18

Preset ....................................................................................................................................... 19

Manual ...................................................................................................................................... 20

Modbus ..................................................................................................................................... 21

Datalog ..................................................................................................................................... 22

System dimensions ...................................................................................................................... 23

Accessories/spare parts ............................................................................................................... 25

Please control that the following documents have been delivered together with the unit:

- Directions for assembly & use (this document)

- CTS 600 directions

- Electrical chart

Introduction

Comfort is designed for heat recovery with air volumes up til1200m3 / h. The energy from the exhaust is recovered to the inlet via the counter flow heat exchanger, where the two air streams pass

each other without coming into direct contact.

The system is prepared for retrofitting of a post-heating element (electricity or water) for supply

heating of the inlet air. The post-heating element is controlled via CTS 602.

The system comes standard with filter class F5 on the extract air and F7 on the supply air.

Operating the unit is done with the CTS 602 control. The control has many functions such as menu

based attendance, week programme, time controlled filter guard and adjustment of the velocity of

the ventilator. (Directions for the CTS 602 control is described in another document delivered with

the unit.)

Comfort is delivered tested and ready for use. Installation and start-up must be carried out by an

authorized electrician.

Nilan reserves the right to alter these instructions without prior notice Page 3 af 25

Power supply including safety switch must be installed by an authorized electrician.

The Comfort-unit must be connected according to the attached electrical chart.

Power supply

The unit is delivered with 1m test cable for the CTS 602 panel. The panel should be connected to

the CTS 602 control in the unit with cable type 2x2x0.25mm2 twisted in pairs. (Maximum length

50m).

The CTS 602 panel must be placed dry and frost-proof. The panels’ integrated feeler prevents further cooling of the building if the primary heat-supply stops by stopping the ventilation if the panel

feeler gets below a specific value. (Factory setting is 10°C; the value can be set from 1-20°C.)

CTS 602 control

If a water heating element is installed in the system, the regulation vent must be connected electrically as described in the enclosed wiring diagrams.

Nilan reserves the right to alter these instructions without prior notice Page 4 af 25

When mounting the Comfort-unit future service and maintenance should be considered.

There is required a minimum of open space in front and behind of the unit of 60cm.

Comfort

1200/5000

4 x vibration absorbers

Assembly of Comfort

In order to ease the mounting each of the connection pieces is labeled. Please notice the labels.

The connection between the unit and the ducting should be a flexible transition.

The system must be level because of the condense outlet. The condense outlet requires a minimum clearance height of 125mm beneath the outlet connection.

The exchanger is low-noise and low-vibration. However, potential vibrations spreading from the

system to the individual building parts must be taken into account. To detach the system from the

floor, we recommend that the system is placed on vibration absorbers. The vibration absorbers

must be placed diagonally on each corner to ensure that the system does not “fall down” from

them. If a water heating element is installed in Comfort 300/450/600, a clearance distance of 60cm

is required behind the system.

It is not necessary to re-insulate the system as it is delivered with a 20mm standard insulation.

Mounting the Comfort unit

Nilan reserves the right to alter these instructions without prior notice Page 5 af 25

The condensation drain should be carried with an even inclination of at least 1cm per

metre, frost-proof to the nearest outlet. The overflow from the safety valve should also be

carried to the nearest outlet.

To avoid frost problems it can be necessary to supply the condensation drain with a

heating cable. It is the plumbers’ responsibility to secure the drain. (See Accessories)

min. 112,5mm

min. 50mm.

min. 50mm.

Ø20mm drain

Comfort

The water seal should be tested as described below. (the unit must be connected to the

ducting and the front door should be closed):

Condensation drain / water seal

The Comfort unit is delivered with a 20mm condensation drain. (PVC, GF-fittings). The drain is

placed under the discharge.

When the system is running, there can be a vacuum of up to 500Pa (corresponding to 50mm water

column) in the outlet. For this reason, the difference in height in the water seal must be minimum

50mm.

The water seal can dry out and avoid the water from running out of the unit. Therefore the water

seal should be tested regularly and refilled with water if necessary. An elevated height of the water

seal will reduce the need for refilling with water.

Condensation drain / water seal

Nilan reserves the right to alter these instructions without prior notice Page 6 af 25

Connecting the heating surface must be done by an authorized plumber.

If the unit is placed outside or in a cold location the installation must frost secured.

To obtain a stable control of the heating surface, the distance between the mixing loop

and heating coil must not exceed 2 meters.

Avoid routing pipes in the system in such a way that the fan cannot be removed.

Air flow

Flow

Return

B3

T9

2

1

M

Heating surface

3

Note that the temperature sensor T9 and frost-protection B3 is placed at the heated side of the heating

surface close to the return connection. See electrical chart.

1:

Actuator and regulating valve:

Danfoss AME 140/24V, - 3-vejsventil VZ3 DN15 Kv0,63, (Nilan delivery)

2:

Circulation pump, eg. Grundfos UPS 25-40 or equivalent (not Nilan supply)

3:

Dirt-catcher (not Nilan delivery)

4:

Shutoff valve (not Nilan delivery)

5:

Exhaust (not Nilan delivery)

Connecting the heating surface, suggestion

Heating surface, water

The heating surface should be connected, scavenged and checked for any leakages before starting the unit.

The dirt-catcher should be checked and cleaned after a thoroughly flushing of the system.

Nilan reserves the right to alter these instructions without prior notice Page 7 af 25

Indicative performance data for the Comfort 1200 water heating element

Pipe connection: Ø15 (by factory-mounted water heating element)

Flow/return

temperatur

Airflow

Performan

ce

Air supply temperature (at temperature

of 5 °C immediately

prior to the heating

element)

Pressure

drop on

water side

Pressure

drop on

air side

Water

Quantity

Recommended

Kv value

for valve

[°C]

[m3/h]

[kW]

[°C]

[kPa]

[Pa]

[l/h]

40/30

400 3 26,1

5

4,3

259

0,63

600 4 23,7

8,4

8,4

344

800

4,8

22

11,8

13,5

416

1.000

5,6

20,7

15,3

19,5

480

1.200

6,2

19,6

18,7

26

537

60/40

400

4,5

36,8

2,9

4,3

196

600 6 33,1

4,8

8,4

260

800

7,2

30,5

6,7

13,5

314

1.000

8,3

28,4

8,6

19,5

361

1.200

9,3

26,8

10,5

26

403

70/40

400 5 39,9

1,6

4,3

144

600

6,5

35,6

2,7

8,4

189

800

7,9

32,7

3,7

13,5

228

1.000 9 30,4

4,7

19,5

261

1.200

10

28,6

5,8

26

291

IMPORTANT regarding Danfoss Actuator type AME 140:

Re-installing the actuator must be done as described below:

1. Disconnect the power supply and remove the cover of the actuator.

2. Liberate the gear by pressing down the button as the spindle is turned up (counter clockwise)

3. Re-install the actuator and turn on power.

4. DIP-switch nr. 1 should be moved to ON and then to OFF.

5. The actuator is automatically calibrating for up to 6 minutes.

(The LED is flashing when calibrating and is lit constantly when finished).

6. Re-install the cover of the actuator.

The actuator should be placed in an environment of 0°C to 55°C.

Nilan reserves the right to alter these instructions without prior notice Page 8 af 25

Power supply must be installed by an authorized electrician.

Heating surface, electrical (retrofitting)

Electrical heating surface should be installed in the ducting Ø315mm, 400V, 3~.

Electric heating surfacel mounted in supply air duct for Comfort 1200.

There must be af safety distance of minimum 150 mm from the electrical heating element to flammable material. The heating element must be insulated with a fire-resistant insulating material,

however the connection box must not be insulated. (Important: The instructions from the manufacturer of the heating element MUST be followed).

• Electrical assembly must be performed by a qualified electrician.

• Power supply is installed with the ventilation system.

• T7, air supply sensors, installed in supply air duct approx. 1 meter after the electrical

heating el ement.

• 0-10V signal is connected to electrical heating element.

• Signal to overheating from the electrical heating element is connected to the CTS

602 print in the ventilation system.

The Nilan supplied heating element is installed in accordance with the enclosed chart

The heating element is now an option in the software via the control panel. See the instructions on

the following pages.

See electrical chart for the ventilation unit.

Nilan reserves the right to alter these instructions without prior notice Page 9 af 25

DEFROST

ENTER

SERVICE HOTWATER

AIR

EXCHANGE

TEMP.

CONTROL

INLET

CONTROL

ROOM

CONTROL

RESTART

OFF

PRESET

OFF

MANUAL

OFF

MODBUS

ADR

30

AIR

QUALITY

DATALOG

INTV 10

Activating the service menu

Press and ENTER at the same time for 10 seconds. The service menu is now available. Press

multiple times until the panel shows SERVICE. Press ENTER to enter the service menu. It is

now possible to move around in the menu by using . The headlines of the service menu are

shown below:

Headlines in the service menu

Nilan reserves the right to alter these instructions without prior notice Page 10 af 25

Use of the CTS 602 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

hotwater will be

HOTWATER

ENTER

EL SUP

ON

EL SUP

”ON”

LEGIONEL

”MON”

ENTER

ENTER

ENTER

ENTER

ENTER

EL SUP

”OFF”

LEGIONEL

OFF

LEGIONEL

”OFF”

A weekday can

be chosen,

where the

warmed up to

65°C between

01.00 and 06.00

o’clock.

Fuction is not

active.

SERVICE

ENTER

DEFROST

INLET

CONTROL

TEMP.

CONTROL

PRESET

OFF

RESTART

OFF

ROOM

CONTROL

AIR

EXCHANGE

MANUAL

OFF

MODBUS

ADR

30

AIR

QUALITY

DATALOG

INTV 10

Heating surface

The unit can be equipped with a heating surface.

It is possible to retrofit a heating surface. The surface must be activated in the CTS 602 control in

order to function together with the unit and for the frost-protection to be active.

When installing a heating surface T7 is the temperature sensor in the inlet.

The “Central heating” menu

Nilan reserves the right to alter these instructions without prior notice Page 11 af 25

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HOTWATER

DEFROST

FUNCTION

OFF

ENTERENTER

FUNCTION

”OFF”

AIR

EXCHANGE

INLET

CONTROL

SERVICE

ENTER

TEMP.

CONTROL

RESTART

OFF

MANUAL

OFF

PRESET

OFF

ROOM

CONTROL

AIR

QUALITY

Can be set to:

OFF, HUMIDITY or

HUM+CO2, when is

mounted.

MODBUS

ADR

30

DATALOG

INTV 10

Air quality

In the ”Air quality” menu it is possible to choose between 3 types of regulation: Humidity, Humidity

+ CO2 or OFF.

The “Air quality” menu

Nilan reserves the right to alter these instructions without prior notice Page 12 af 25

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

Möglichkeit zur Einstellung jeder

Der Wert gibt die kleinste

zulässige Lüfterstufe des

Zuluftgebläses an (0-2).

Der Wert gibt die kleinste

zulässige Lüfterstufe des

Abluftgebläses an (1-2).

LUFT

WECHSEL

ZULUFT

MIN 0

ABLUFT

MIN 1

ABLUFT

MAX 4

ENTER

SERVICE

ENTER

ABTAUEN

ZULUFT

STEUERNG

TEMP.

STEUERNG

RAUM

STEUERNG

HEIZUNG

W-HEIZRG

Der Wert gibt die höchste

zulässige Lüfterstufe des

Abluftgebläses an (3-4).

ZULUFT

>1< 20%

ZULUFT

>2< 45%

ZULUFT

>3< 65%

ABLUFT

>1< 25%

ABLUFT

>3< 70%

ABLUFT

>4< 100%

ZULUFT

>4< 100%

ABLUFT

>2< 45%

Lüfterstufe ausgedrückt in % der

maximale Lüfterleistung.

LUFT

QUALITÄT

VERSöG

2 MIN

PRESET

AUS

RESTART

AUS

MANUELL

AUS

MODBUS

ADR

30

DATALOG

INTV 10

BYPASS

150 SEK

Air exchange

In the ”Air exchange” menu it is possible to adjust 4 steps of ventilation speed (air volume). Inlet

and exhaust is to be adjusted individually at each level.

The inlet speed can be adjusted to a minimum and the exhaust can be adjusted to both a maximum and a minimum.

It is possible to delay the starting of the fan in order to give time to the register to open.

Nilan reserves the right to alter these instructions without prior notice Page 13 af 25

The "Air exchange" menu

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

ENTER

.

AIR

USER

ENTER

BYPASS

”OPEN”

ENTER

BYPASS

”CLOSE”

BYPASS

OPEN

EXCH.

PERIODE

90 MIN

TERMINAT

T4/6 °C4

AIR

”USER”

EXCH.

”OFF”

AIR

”LOW”

EXCH.

AIR EXCH.

Fixed off-period in

minutes between two

defrost modes. Can

be set to anything

from 15 to 720

minutes.

Adjustable temperature

for discontinuing

defrosting measured on

T4, discharge censor

Low-level

injection during

defrosting

Custom injection

during defrosting.

Discontinued

injection during

defrosting

DEFROST

HOTWATER

AIR

EXCHANGE

INLET

CONTROL

SERVICE

ENTER

TEMP.

CONTROL

RESTART

OFF

MANUAL

OFF

PRESET

OFF

ROOM

CONTROL

MODBUS

ADR

30

AIR

QUALITY

DATALOG

INTV 10

Defrost

In the ”Defrost” menu it is possible to chose how the unit should perform during defrosting of the

evaporator in the exhaust.

” ” indicates that the menu point flashes and can be set to another value

The "Defrost" menu

Nilan reserves the right to alter these instructions without prior notice Page 14 af 25

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HEATING

SURFACE

TEMP.

CONTROL

AIR

EXCHANGE

DEFROST

INLET

CONTROL

SERVICE

ENTER

ROOM

CONTROL

The unit stops at this

room temperature (120°C) - - means that the

function is unactive.

- - should be chosen if

the panel is placed in a

cold environment.

SENSOR

”EXTERNAL”

SENSOR

PANEL

SENSOR

”PANEL”

PRIORITY

”HP + EXT”

PRIORITY

”HF”

ENTER ENTER

ENTER

SENSOR

”EXHAUST”

ROOM

LOW 10°C

PRIORITY

HP + EXT

EXTERNAL

-1 °C

PRIORITY

”OFF”

Indicates which sensor

that needs to be the

controlling one.

PANEL T15 (Panel

sensor).

ROOM EXT: T10 (to be

installed in representative

extraction fitting).

EXHAUST: T3 (Exhaust)

AIR

QUALITY

Option for an extra heating

element via relay output,

R8. R8 is an accessory and

the option is only possible

via accessory pcb.

The temperature is added

or subtracted to/from the

set point shown in the main

menu.

OFF: ventilation

without heating surface

HP: ventilation only

with heatrecovery

HP+EXT:ventilation with

heatpump and heating

surface activ

RESTART

OFF

MANUAL

OFF

PRESET

OFF

MODBUS

ADR

30

DATALOG

INTV 10

Temp. control

In the ”Temp. control” menu it is possible to chose a room temperature where the unit stops in

order to avoid further cooling of the building if the primary heating shuts down.

Nilan reserves the right to alter these instructions without prior notice Page 15 af 25

The "Temp. control" menu

The ”Inlet control” menu should only be adjusted by persons with knowledge of control

engineering.

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HEATING

SURFACE

TEMP.

CONTROL

AIR

EXCHANGE

DEFROST

SERVICE

ENTER

ROOM

CONTROL

INLET

CONTROL

ENTER

GAIN

7.0%/°

INTEGRAL

120 s

N-ZONE

0.5°C

TMP-RAMP

0.10°/s

CAP-RAMP

0.5%/s

AIR

QUALITY

RESTART

OFF

MANUAL

OFF

PRESET

OFF

MODBUS

ADR

30

DATALOG

INTV 10

Inlet control

In the ”Inlet control” menu it is possible to adjust the regulation of the inlet. The menu is only accessible when the unit has a heating surface installed.

” ” indicates that the menu point flashes and can be set to another value.

Nilan reserves the right to alter these instructions without prior notice Page 16 af 25

The "Inlet control" menu

The ”Room control” menu should only be adjusted by persons with knowledge of control

engineering.

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HEATING

SURFACE

ROOM

CONTROL

TEMP.

CONTROL

AIR

EXCHANGE

DEFROST

INLET

CONTROL

SERVICE

ENTER

ENTER

RESPONSE

NORMAL

RESPONSE

”USER”

RESPONSE

”FAST”

RESPONSE

”NORMAL”

GAIN

6.0°/°

INTERGRAL

6m

RESPONSE

”SLOW”

ENTER

N-ZONE

2.0°C

ENTER

RESPONSE

USER

N-ZONE

2.0°C

The RESPONSE

menu is only

accessible when the

CTS 600 control is

set up to heating

surface

Rum control parametres:

Response Gain Integral

Slow 4.0 12

Normal 6.0 6

Fast 8.0 4

User 6.0 6

AIR

QUALITY

RESTART

OFF

MANUAL

OFF

PRESET

OFF

MODBUS

ADR

30

DATALOG

INTV 10

Room control

In the ”Room control” menu it is possible to adjust the regulator for controlling the room temperature.

” ” indicates that the menu point flashes and can be set to another value.

Nilan reserves the right to alter these instructions without prior notice Page 17 af 25

The "Room control" menu

HEATING

SURFACE

TEMP.

CONTROL

AIR

EXCHANGE

DEFROST

INLET

CONTROL

SERVICE

ENTER

AIR

QUALITY

MANUAL

OFF

PRESET

OFF

MODBUS

ADR

30

DATALOG

INTV 10

ENTER

RESTART

”OFF”

ROOM

CONTROL

RESTART

OFF

”FIRE”

FIRE: Auto restart

when fire input is back

to normal

RESTART

Re-start

Fire alarms can be acknowledged automatically in connection with fire drills/testing. A condition for

acknowledgement is that the fire thermostat input has returned to normal state.

The "Restart"

Nilan reserves the right to alter these instructions without prior notice Page 18 af 25

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HEATING

SURFACE

AIR

EXCHANGE

DEFROST

INLET

CONTROL

SERVICE

ENTER

TEMP.

CONTROL

MANUAL

OFF

ROOM

CONTROL

PRESET

OFF

ENTER

PRESET

”OFF”

PRESET

”STANDARD”

Factory settings are

chosen when pressing

ENTER at

”STANDARD”. If a

heating element is

installed, it must be

activated in the service

menu again.

AIR

EXCHANGE

”BACKUP”

”RESTORE”

PRESET

PRESET

The backup will be

saved.

The backup is restored.

Subsequently, the

system must be

restarted.

MODBUS

ADD 30

DATALOG

INTV 10

RESTART

OFF

Preset

” ” indicates that the menu point flashes and can be set to another value.

RESTORE menu allows you to reload a copy of the installation setup.

By keeping the ESC + key pressed for 5 seconds a new menu item RESTORE appear, this is

then acceptable / activated by pressing the ENTER

Nilan reserves the right to alter these instructions without prior notice Page 19 af 25

The "Preset" menu

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

Test der

Abtaufunktion.

Manueller Test

deaktiviert

(normaler

Betriebsmodus).

HEIZUNG

W-HEIZRG

LUFT

WECHSEL

ABTAUEN

ZULUFT

STEUERNG

SERVICE

ENTER

TEMP.

STEUERNG

PRESET

AUS

RAUM

STEUERNG

MANUELL

AUS

MANUELL

”AUS”

MANUELL

”ABTAUEN”

MANUELL

”ZULUFT”

MANUELL

”ABLUFT”

MANUELL

”VENT+HEI”

ENTER

Test der Zuluft

Test der Abluft

Test der Lüftung

und des

Heizbetriebs.

Während des

Tests wird 50%

Heizsignal

gegeben.

LUFT

QUALITÄT

MANUELL

”KLAPPE”

Test der Klappe

MODBUS

ADD 30

DATALOG

INTV 10

RESTART

AUS

Manual

In the ”Manual” menu it is possible to test the functions of the unit manually.

” ” indicates that the menu point flashes and can be set to another value.

The "Manual" menu

Nilan reserves the right to alter these instructions without prior notice Page 20 af 25

Use of the CTS600 panel:

- press ESC to go one step back in the menu

- press to move up or down in a menu or to adjust an

activated menu

- press ENTER to activate a menu

- press ENTER to confirm a menu

- press OFF to turn off the unit

- press ON to turn the unit on

HEATING

SURFACE

AIR

EXCHANGE

DEFROST

INLET

CONTROL

SERVICE

ENTER

TEMP.

CONTROL

ROOM

CONTROL

PRESET

OFF

AIR

QUALITY

MANUEL

OFF

MODBUS

ADD 30

Modbus Communication

[1..247]

DATALOG

INTV 10

RESTART

OFF

Modbus

” ” indicates that the menu point flashes and can be set to another value.

The "Modbus" menu

Nilan reserves the right to alter these instructions without prior notice Page 21 af 25

På CTS602 Panelet tryk:

- ESC for at gå et trin tilbage i menuen

- for at gå hhv. ned og op i menuen eller for at justere et

aktiveret menupunkt

- ENTER for at aktivere et menupunkt

- ENTER for at bekræfte et menupunkt

- OFF for at slukke anlægget

- ON for at tænde anlægget

INDBLÆS

VARME

LUFT

SKIFTE

AFRIMER

INDBLÆS

KONTROL

SERVICE

ENTER

TEMP.

KONTROL

NULSTIL

OFF

RUM

KONTROL

MANUEL

OFF

LUFT

KVALITET

MODBUS

ADR 30

DATALOG

INTV 10

Datalog inteval

[1..120] minutter

GENSTART

OFF

Datalog

Data log intervallet indstilles via menuen SERVICE - DATALOG INTV mellem 1 og 120 minutter.

Hvis der vælges 0 / OFF, logges der ikke periodisk, men kun ved events og alarmer.

Det er valgt at logge temperaturer i hele grader celsius, for at minimere log fil størrelsen.

Status for digitale ind- og udgange er slået sammen i to fælles log variable, ”Din” og ”Dout”.

Menuen ”Manuel” giver mulighed for en manuel test af anlæggets funktioner.

Nilan reserves the right to alter these instructions without prior notice Page 22 af 25

The "Datalog"

System dimensions

System dimensions for Comfort 1200

Nilan reserves the right to alter these instructions without prior notice Page 23 af 25

System dimensions for Comfort 5000

Nilan reserves the right to alter these instructions without prior notice Page 24 af 25

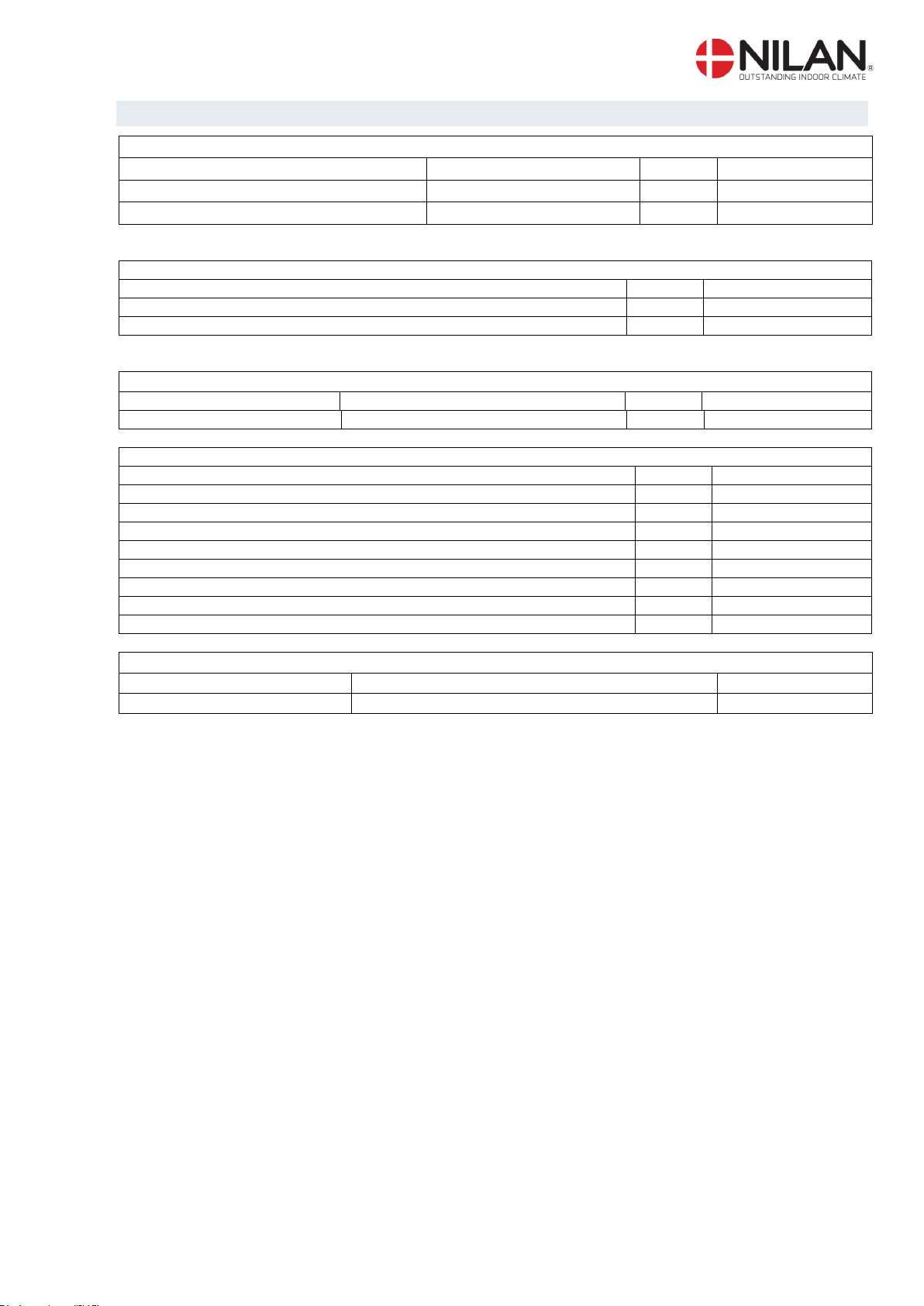

Filters

Type

System type

Qty

Nilan item no.

F7

Comfort 1200

1

3949

F5

Comfort 1200

1

3948

Heating surface for water incl. regulation

System

Qty

Nilan item no.

Comfort 1200 (right)

1

76792

Comfort 1200 (left)

1

76793

Electrical heating surface (for fitting in inlet duct)

System

Output

Qty

Nilan item no.

Comfort 1200

6kW, 400V, 3~

1

7644

Spare parts/accessories

Type

Qty

Nilan item no.

Hygrostat 1 3637

CTS 602, control PCB

1

239932

CTS 602, control panel, complete

1

2398

CTS 602, white control panel enclosure

1

2398HX

Filterguard excl. hose (3m item nr. 3049)

1

3635

Vibration absorber

1

7722401

Humidity sensor

1

23997

CO2-Sensor

1

7134B13

Heating cable for condensation outlet (frost protection)

System

Type

Nilan item no.

Comfort

Heating cable

2172

Accessories/spare parts

Nilan reserves the right to alter these instructions without prior notice Page 25 af 25

Loading...

Loading...