Page 1

FAA23051– R. 3248. A

ASS13MBLING &

Contents

.—. ———-— —— __ _____ __ ._ ._.

[Ass:mbl

Camera back parts

Bottom cover and tripod parts

Film advance side cover, Film rewind side top cover

Back body parts

Sync contact, film detection switch --------FD, DBor DXFPC unit ------------------------------- -------- ----Shutter unit

\,

m

Film rewind motor

Film rewind unit - ----------------------- ----------------------------Upper film advance parts

Film advanw baseplate ---------------------------- ------------ --Film advance base plate unit, disassembly, assembling

ing, back body ]

--- -- -—______ -. ____ --- ___ _____ _ ____ __ _ ----- - .- __ _ - .

--

- -

-- - - -- . --- . . . . . . . .- -- . --

AD~USTM13NT

-- . _ - - ----- ----- . _ _. _ . . . __ _ . ____ . _ _____-_, _____

-------- .- .-. ------ . . . . . . . . . _.. _ _.. _ ---

..- -

. . . .

-- —-- - ---- ---- ---- -- ---- ___ . ___ . _ ..__

- --—— ---- __ ____ _ ___ . . _ __ . . - . __ . . . . . . _ __

-.

. ..-. -.

----- ----

-

_ _ ._

-

__ - _ .

M

A2

A3

A4

a?

A8

A9

A9

All

A12

A13

Al~

“

?q

Mounting film advance baseplate unit --------------------------- Shutter release fig, Lever under shutter release throught shaft ------- A25

DC-DC converter base plate

Power TrFPC unit ---------------------------------- ------------------- A26

Shutter speed dial base plate

Mounting Main FPC ----------------------------------------------------- A28

Checking camera’back

.——.——.—

l Assembling, front body]

Front body parts

AF baseplate unit, fo baseplate unit ----------------------- A32

Mirror box unit parts

Mirror box unit

Mounting mirror unit, I baseplate, L baseplate --------------------- A36

Mounting mirror box, front body

Filter driving base plate, filter unit, TTLSPD unit

Seesaw lever

------ ---- ---- ---- ----- ---- ----- ---- ---- ---- ---- --—- -—-.. -

-.

-------

--------— ------

---- ----- ------ ----- _____ ______ _-

--------- ----- ------ -- ------ ----- - ---- ----

---- . -

-

---- ---- . -- -- ------- ---- - . . . ---- ---- ---- ---- ---

..-

-----

..-

. . -— - - - . - ---- ------ - --- -- - . .

----. ---- —.

-

-- - ----- ..- - . . . .- - -- -- .-—-—---- ---- -----

------ ------- -.

---------- ----- ..-.

-------- ------ ----

------------ A26

----------------- A33

. . .

A:>

A27

A28

A29

A34

A36

A37

A37

AF rnodeselect.or lever unit --------------------------------- ---------- A37

Lens release button switch

Mirror operation base plate unit

f-fo base plate, f-fo pulley

Lock

Cable arrangement on the lower part of the L baseplate ------------- A41

enco&w

FPC unit ------------------------------- ------------------

- ---- --- --

---—-

-

---- - -. ------- ..- --—

---- . .

---- ---- ---- --------- ----- ---- ---- .

---- ---- ------ ----- -----

——

. — .

—-----

A37

A38

A38

A41,?-

Page 2

F’AA23051-R.3248. A

AF

base plate unit

Positioning adjustment of fmm switch ------------------------------- -- A42

Height adjustment of aperture lever ------------------------------- ---- -A43

Height adjustment of AF coupling ring shaft

Angle adjustment

—-...—.—. .-. .—— - . .

[Mounting of front body and back_ body]

.——

Mounting of front body and back body

Adjustment of film sprocket cogwheel positioning

Adjustment of body back

Adjustment of infinity

AE, AF Accuracy, inspection, and adjustment

.

. _ .-—- —

------ .

(4Y

) of main mirror (Gl)

.

-------------- ------- -------------- —----

- --- -- - . --- -- ----

sub-mirror

---- ----- . .

---- ---- -- ---- - ---- - -- ---- -- ---

(G2) ----------

-- . . . . ------ . . ..-— ------- --

-— -- ----- . . - . . .

----

--

_

---- -- . - --- —- . . . . .

.-—.

----- ----- ---

------

-

. --

---—

-. ----- ---

---- A49

.

A41

A43

~44

A45

A48

A49

A49

~’

Page 3

FAA23051

\

- R.3248.A

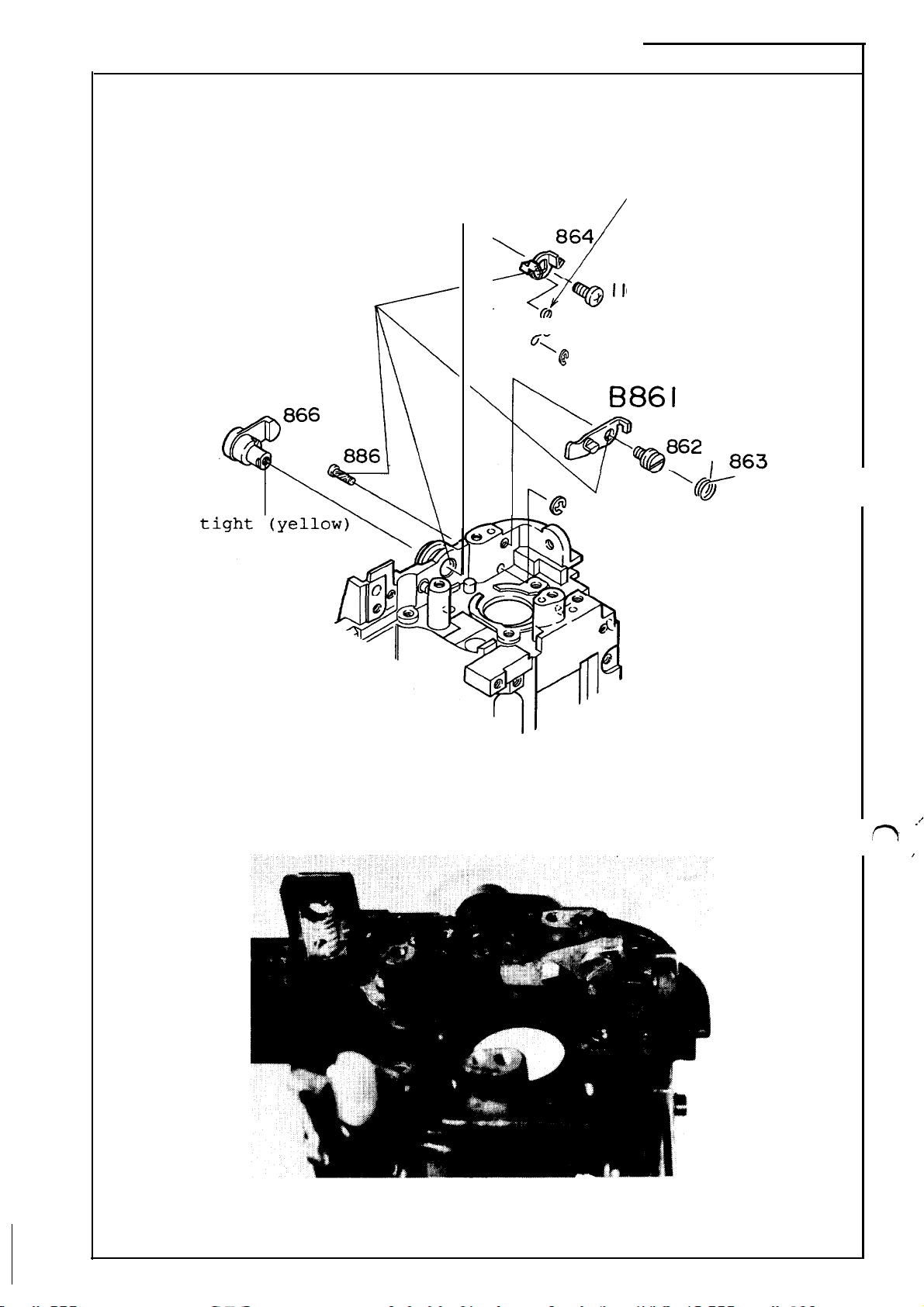

Camera back parts

_-—

/

——— ———. .—. ——— ——— ——— ——_—

—_____ _

1

I

I

I

I

‘n

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L

——

—————

B810

\

‘Al—

Page 4

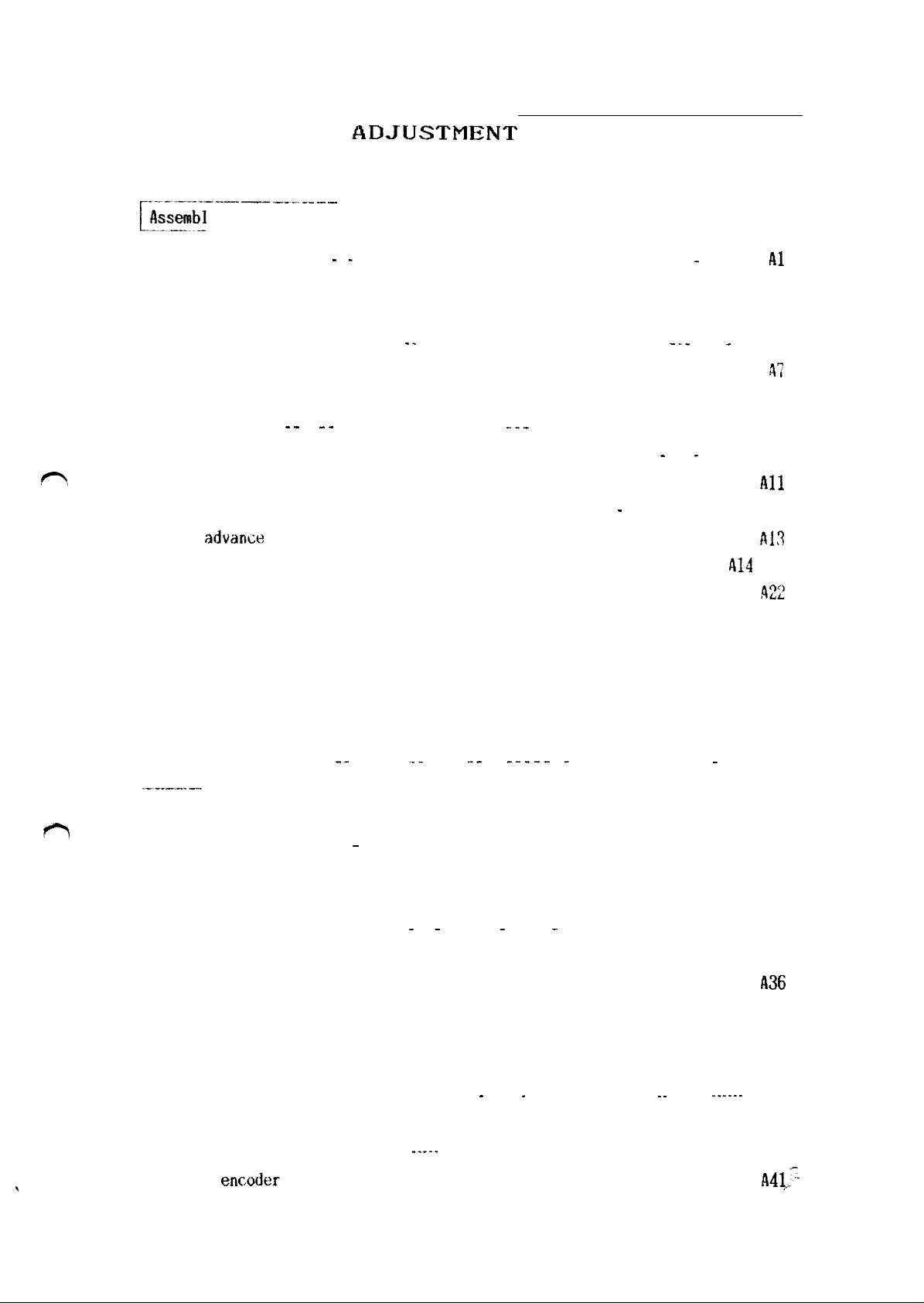

Bottom cover and tripod parts

/’”

-1

\

FAA23051

- R.3248.A

15

0

K

%1

W80

\ ////2’K

Lock

(yell

i

Screw

0935

lock (#350)

00007

n

lock

‘ ‘2%9

Lky+$

I 128x4

—A2—

Page 5

FAA23051

- R.3248.,

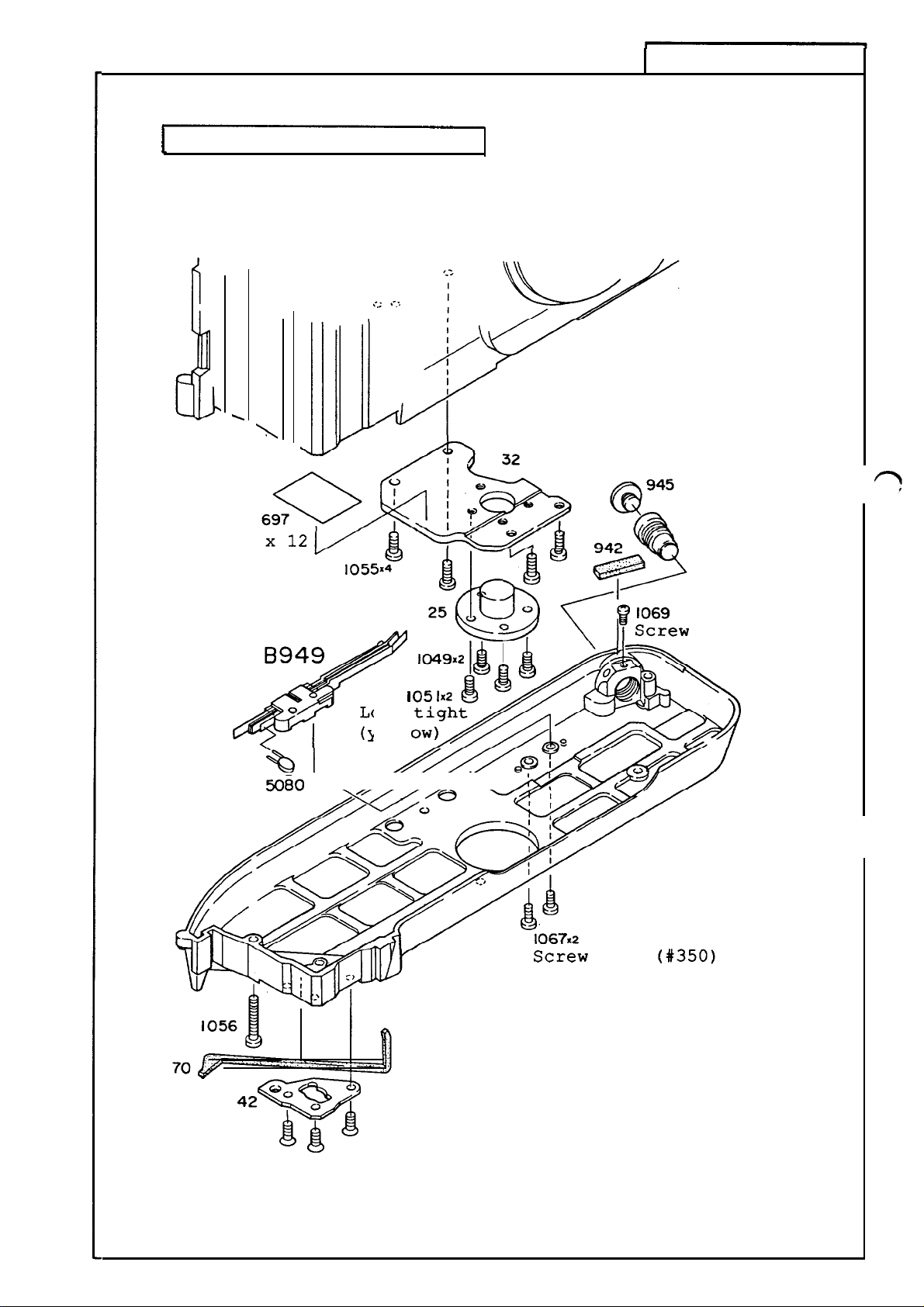

Film advance side top cover

Film rewind side top cover

.——. .—

~—— ———. —

Mult~ple

exposure

lever

— _________

786 “,

$?

~__——

I

—— — ___________

960

.

6?3

I

~

N

\

N.

i

I

~

&@&

/

I

105

4

%

i

/

/

I

I Turn

\

150°

I

--l l/

A’-----

\------w

\

v

I

I

l’~~z>$

1115

I

I

G __________________________________________________ J

Screw lock (#350)

‘A3

~

/

1087

I065xZ

—

,Opcoversidel

,

i

Page 6

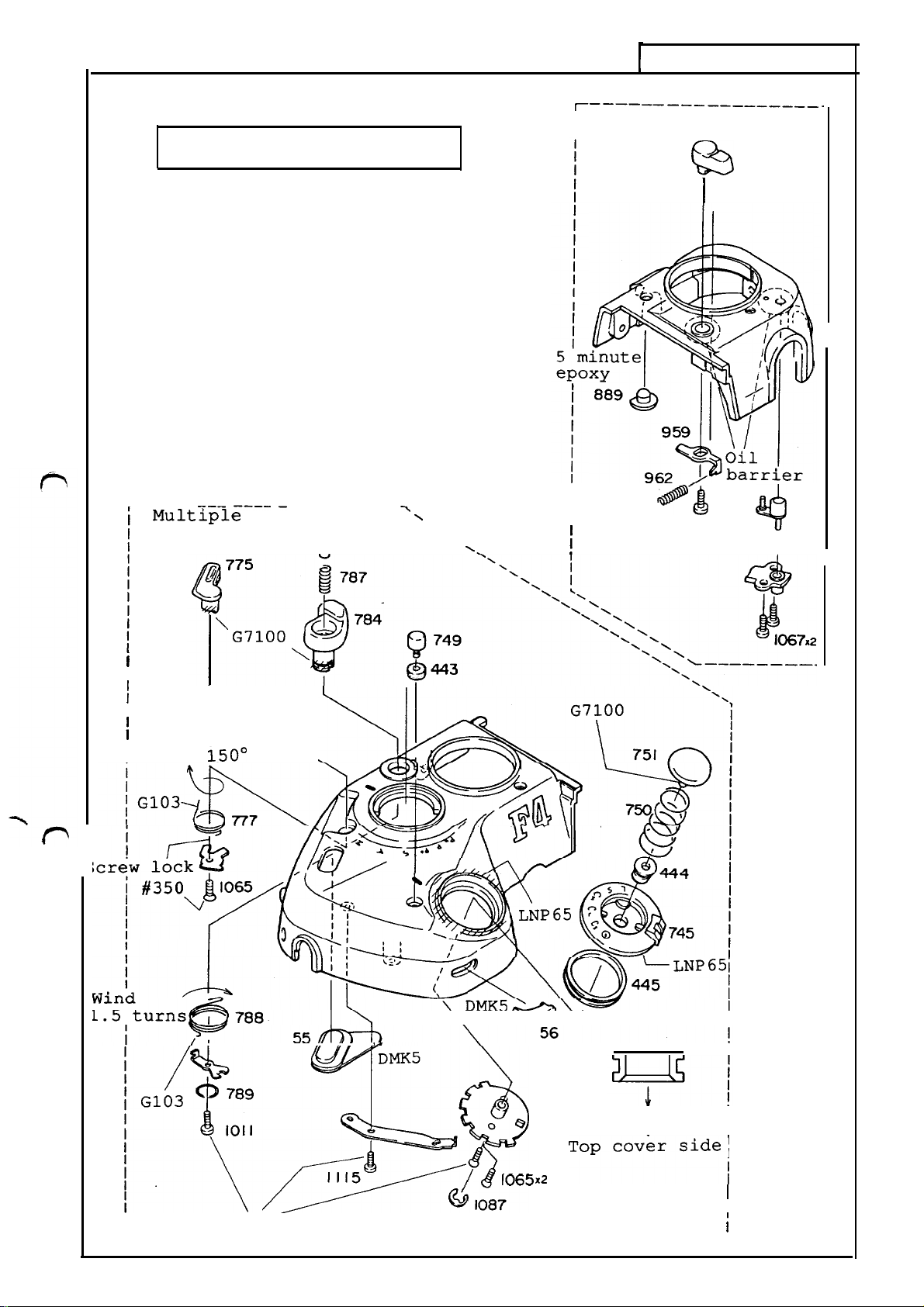

Back body parts

— Spread G103 on the body and paste,

—A4—

G92KA

Page 7

G71OO:

4

f)

28

FAA23051

1023

- R.3248. A

I 109

W

. 929

&

“ 930

&

\,

n

,./

I

554

m’

1074xZ

1076

@

@

433

1

29

G71OO:,

i

/*

1085

902

928

&

927

&

)

J

G103

\

59

(grey)

E

c

(white)

B

(purple)

—A5—

Page 8

FAA23051

Hook the spring end

(with more turns than the other end)

on the #864

- R.3248.A

864

Lock

G71OO

>

./

-&@

868

$

I 105

%

@

1087

n

p@?

v

1085

./

n

,

1

—A6—

Page 9

t

l17AA’_)2AC4

– D 90/.0

Sync contact,

film detection switch

— Sync contact

#llo9

lder this portion

(black) GND

(green) Sync contact

\

G103

n

— Film detection switch

Film detection switch

Lock

cable for base plate

g#lo40 SC;:;5;

I

Power supply base plate --

3

main FPC bottom unit

(orange) (black) L = 140mm

Power supply base plate --

+

power Tr. FPC

(orange) (black) L = llOmm

— junction cable

Film detection

switch pin

\

External film

guide rail

m

?&

/

Film detection switch (brown;

~[

PTr-E (grey)

PTr-C (purple)

PTr-B (white)

Check the ON-OFF position of the film

detection switch based on the external film

guide rail:

Height (or play); a = 1.13 f 0.15

1.00

ON–OFF switching position; b =

Total stroke;

More than 0.1 deeper from the

or more

external film guide rail.

—A7—

Page 10

FAA23051

.’

.

- R.3248.A

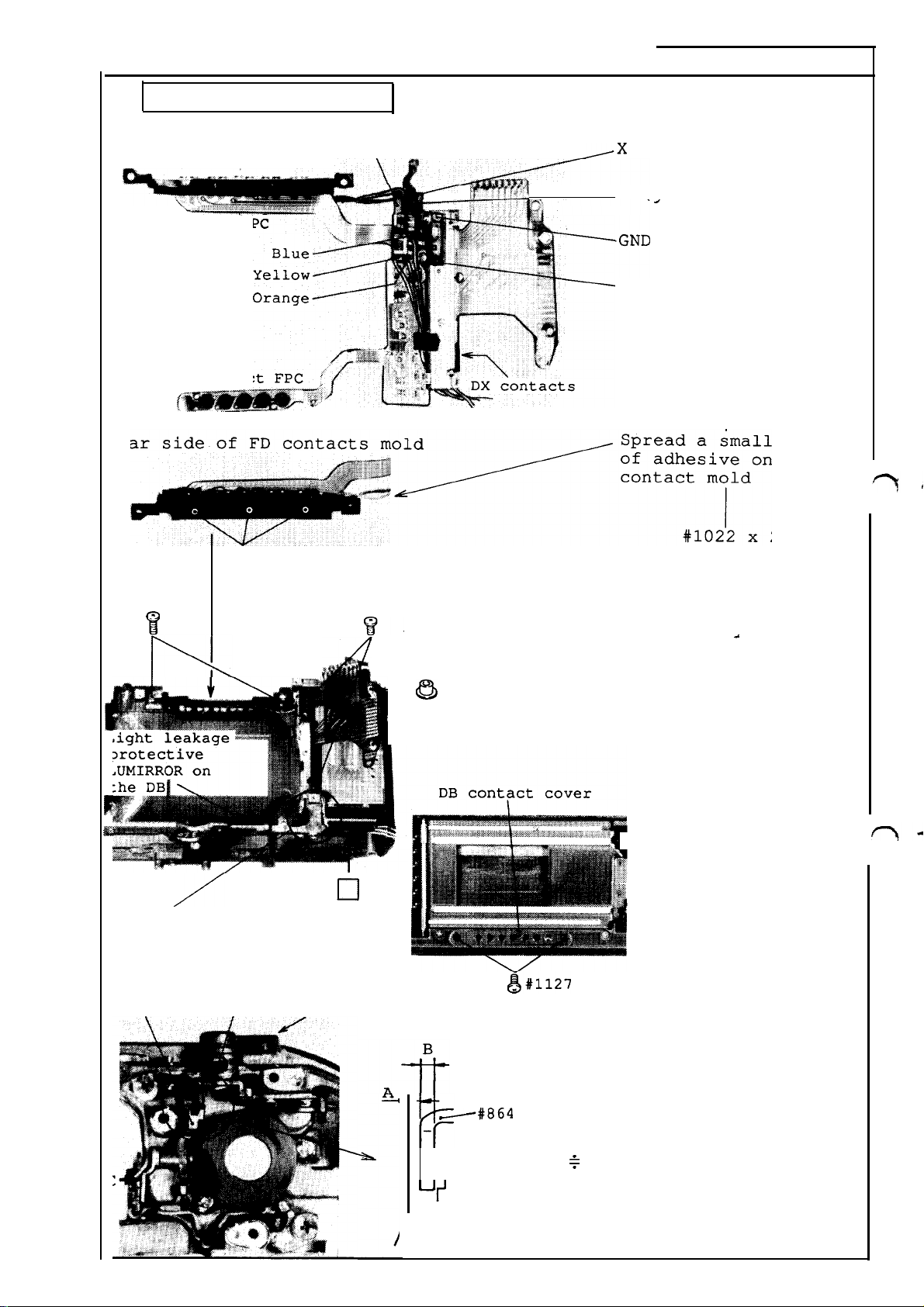

FD, DB,

Thyristor trigger base plate

FD contact FPC

DB contact FPC ‘“

{~

Lear side of FD contacts mold

*+’----+::::$’::

}1040 x 2

. .

II

or DX FPC unit

--

.,

~

i:E;2k>~

<. ~ ,’

i.

-.: ~ ‘,

,

:.+

. . . .

.

5 minute epoxy

,,

%!

fl;~

$. ,,~,

.

#lo22 x 2

\

,%;

%

‘.s:.:

l!?

“

,$ :.

$,: ?:, *2

9

%,

Kg

..’

~

rp-m

%$;<

~

F

7

DX contacts

.

~GND

, .,

,-

“.

t.

~X

(green) : from sync

contact

X (areen) : from FD

contact

(black): from sync

GND (black) : from

Mount FD, DB,

and DX FPCS

#lo22 x 2

#lo40 x 2

# 679 X 2

Place the DB contact

FPC through the hole

of the bodv

.

contact

FD

contact

““’

;

FL

1

/’”

Cable

arrangement

#869

#864

n

Tape for

arranging

cables

R2 lever

#678 X 2

&

P

DB contact cover

1~

*,. .,. .,>,.,.

. . .

~#864

P-

r

l-h

‘r’

—

#869

&

DB contact cover

I

#l127x2

I

Attach light leaka

protective plastic

sheet on the DB

..s

.

...+..:

>. . . . . .

~#1127

x2

Check the latching

condition of the R2 lever

The latching amount of the

#864 and #869 when the R2

lever is in locked state;

A + B (approx. 0.7)

Adjust by bending part C

indicated by the arrow in the

figure at left.

~

E’

i

Solder cables

Arrange cables

I

I

ge

‘—A8 —

Page 11

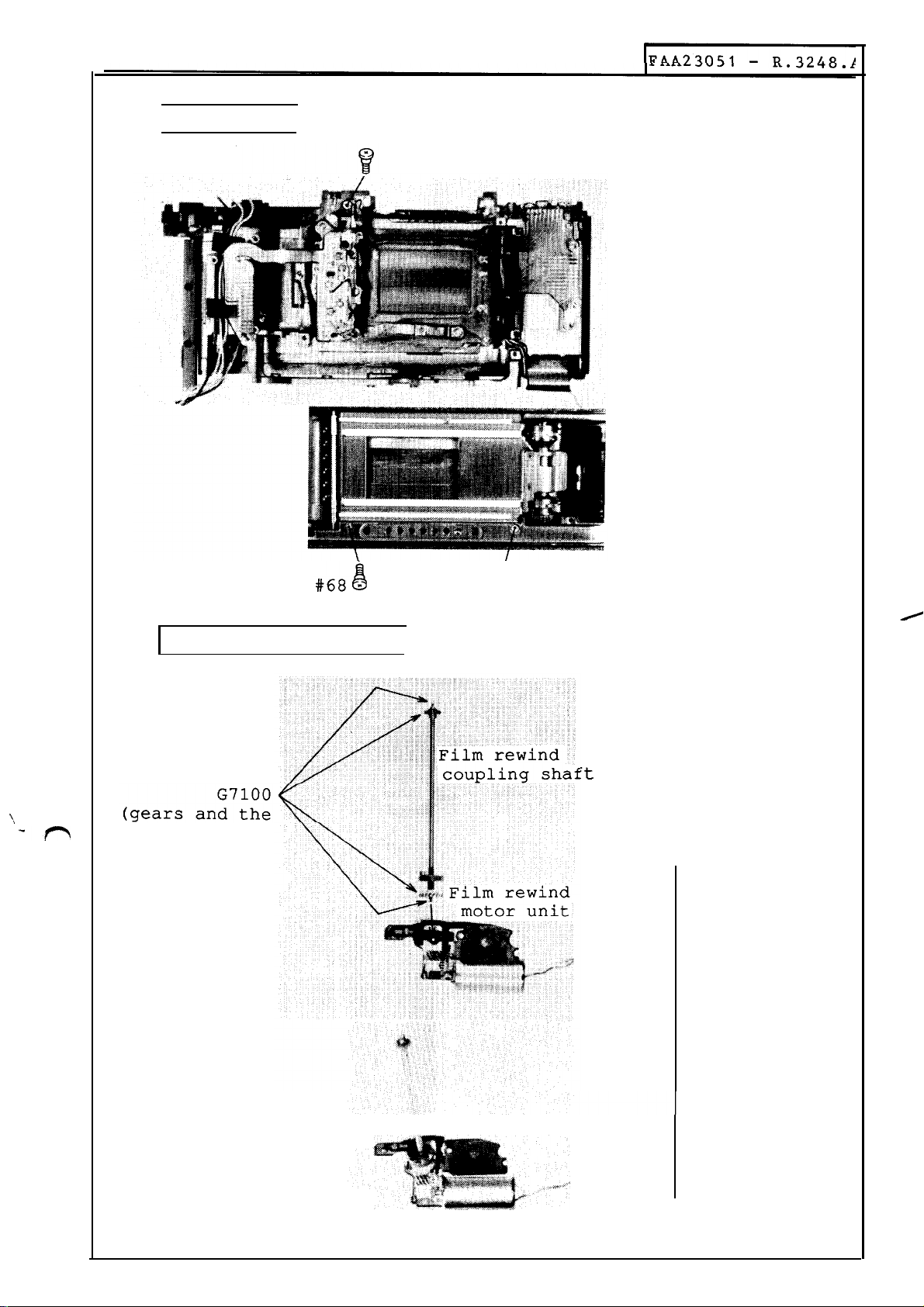

Shutter unit

1

J

#66

Shutter unit

#66

#68

#1135

\\

-?’-$

Film rewind motor unit

tips of the

shaft)

8#1135

‘t

Mount a film rewind

coupling shaft in the

film rewind motor unit.

—A9—

Page 12

Film rewind

motor unit

Au

‘&&&+. .’

Lock tight

(Purple)

. .

‘~.,~

k“

‘“ ‘“o

&

~#1019

#40

x 2

FAA23051

Mount a film rewind

motor unit

#39

#40

#lo19 x 2

- R.3248.A

Approx.

0.4

&

Check the position of

the filter selection

lever

The tip of the filter

selection lever (as

shown in the figure)

should be located

within the range of

approx.

lower end of the

shutter.

Adjust by bending the

part B as shown in the

figure .

Arrange film rewind

motor cables.

#964 X 3

0.4 from the

*

#964 X 3

—AlO—

.

Page 13

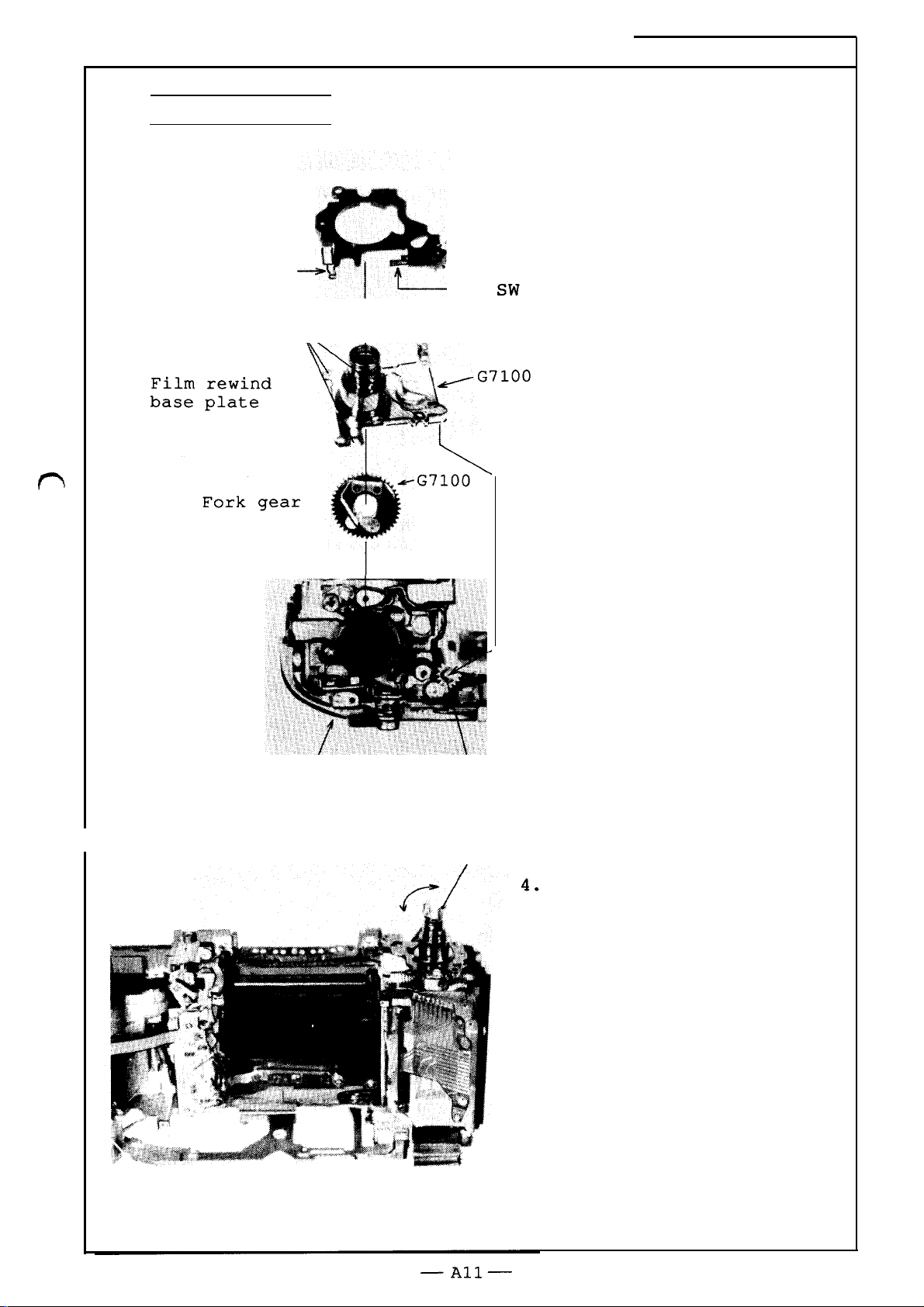

Film rewind unit

Film rewind mold

base plate

FAA23051

- R.3248.A

I-J

Camera back

switch

#1113 x 3%’

~

p

CR, ~~

I

I

Check following items:

1.

Gaps (up and down) of the

film rewind shaft;

0.1 –– 0.3

2.

ON–OFF operation of the

camera back switch.

3.

ON-OFF operation of the

R2 SW.

-m

Camera back

switch pin

Insert the film rewind

shaft from the other end.

Film rewind shaft

Lock the R2 lever (move

the lever up) . Check to

see if there is irregular

rotation and strange

sound when rotating the

film rewind shaft.

Page 14

Upper film advance parts

82563

“~

~––—–.

I

I

I

I

I

~

—_ ———. ——__— ——— — _______________

@l

1

1

I

I

I

I

I

I

I

I

614

!

u

[

j

663

;%”

86! ‘.7 , I

#

K

\

i

I

I

I

I

I

I

I

-s

W

585

t?

1010

----

[

dAA52nKi–D29ACI

[

H,J+Ldwdl

1

1

I

I

I

I

.!

1106

I

I

A-

m

Inn-r

-

Ii.dc’-tu.

J-I

t+

6

:nr@ad m+

r----

--- -------

r———-———

35

i

/

I

I

I

i

L____

1

haw~la~

. .

-

-N

\ “.

.fi --

%–-–---––––––––––----–––––––––––--J portions

69

a

\

@

B47

v

I

Igo2

except

specified portions

d

1

I

1

-— —— _____

Spread

I

the~f~KA ~

n.

~

BBO08

Pi

u-w

UC U.L.L

61

CU.

—

I

I

L—— —— — _______________________

J

Page 15

Film advance base plate

—Al 3—

1

0

2

o

IFAA23051

-

R.3248.A

)

-4

c

Page 16

Film advance base plate unit,

disassetiling, assembling

~

Disassembling

IFAA23051

- R.3248.A

Pulse blade

#1087

Pulse driving

gear

#1106

“106

Multiple

exposure

lever wire

~,;,:wd’+_:pp’eexpO

Pulse PI

(@ ~ ~ ‘“

\%

6

relay lever

shaft

‘\’

hY

t? #llo7

\l

*,

#1106

I

exposure

~

relay

.

lever

1) Upper film advance unit

(frame counter unit)

Pulse PI #1107

Pulse blade

1?

E

clip #1087

@a

not remove

driving gear)

Multiple exposure relay

lever shaft

s”rere’ay

Multiple exposure lever wire

I

pu-lse

Frame counter sw

t

I

#l106x3

2) Film take-up spool motor

(FM) #1019x2

—

)= #476

>

~Film

;

spool motor (FM)

#476

take-up

lever wire

~v

~#1019x2

—A14 —

.,

%

+

Page 17

FAA23051

3) Inside film advance unit

Ge,ar S7

Ge~r

S2

- R.3248.A

-p

~

#llo2

\,

illl@

Gear Cll

I

Gear S9

Gear S2

Gear S7

#l106x3

w

\

h

$*’

“4

k

/

~~

: %

*

~

I

Gear

Film take–up spool

clutch spring

Film take-up

clutch lever

Gear S9

Gear S1O

Cll

#lIo2

I

I

spool

#1087

I

I

\,

-n

Gear

#1087

Film take–up spool spring

Inside film advance unit

~

Film take-up

~

spool clutch lever

i

~

/.....@:

— A15—

Page 18

#1019x2

Screw lock

(#350)

I?AA23051

Lever on the

shutter release

through shaft

S

/

Gear S11

4) Shutter charge motor

(MM) #1019x2

— Assembling

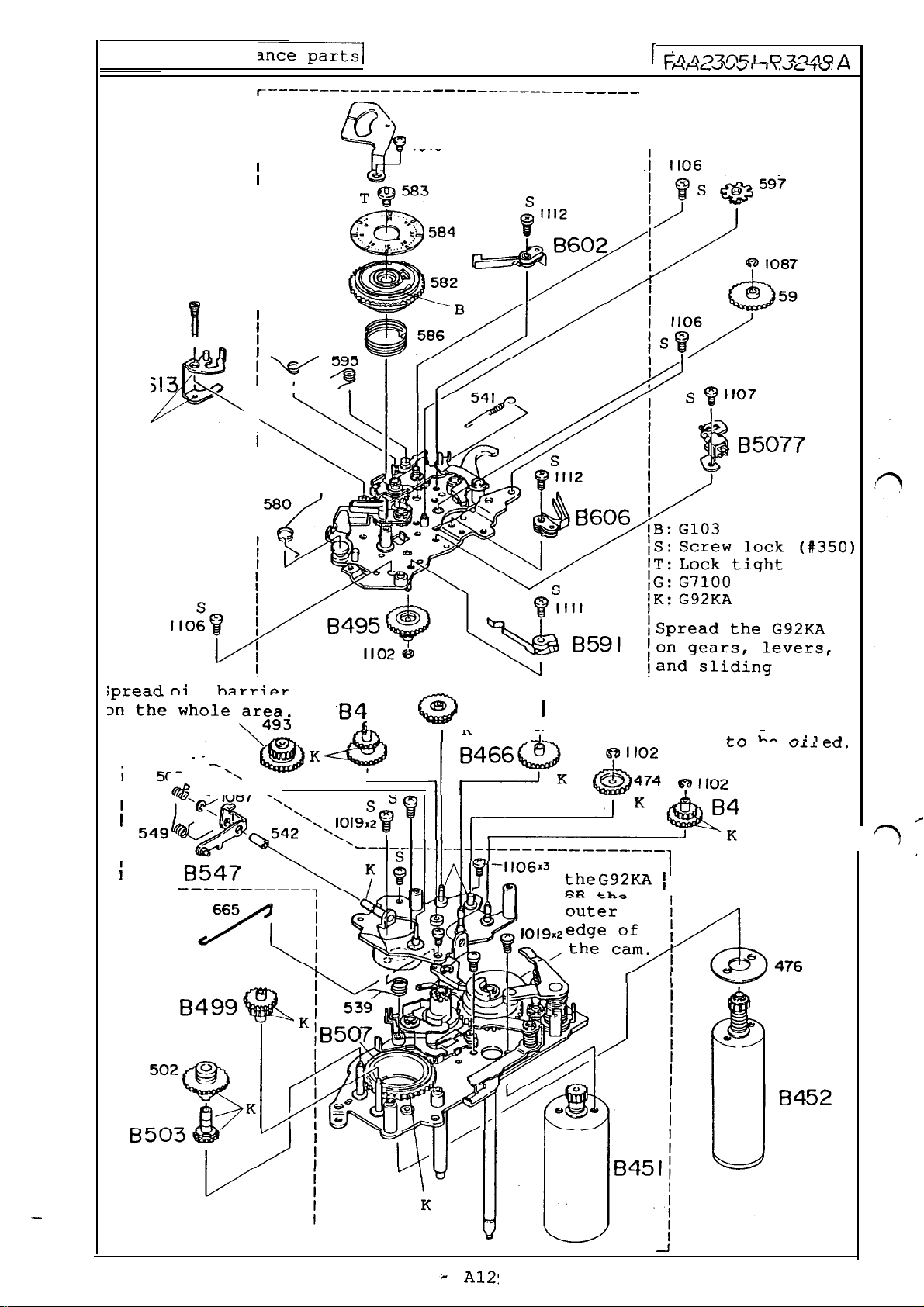

(See page A12 for applying

oil and attaching)

1) Shutter charge motor

(MM)

#1019x2

- R.3248.A

Multiple

lever spring (#539)

Charge motor(MM)

Fig.

Film sprocket advance completion state.

below:

/

Film sprocket

shaft

Overcharge amount

is more than 0.2.

Film”advance

stopper

l-H-

‘ilm advance

topper click

14

Film advance

stopper

~latch lever

&xposure

(1) Portions b and c (as shown in

the figure) of the film advance

stopper will be disengaged from

the film advance stopper latch

lever when the shutter charge cam

is rotated in the direction

indicated by arrow a.

(2) Portions b and c will be

engaged when the film advance

stopper click moves toward

the portion e by rotating the

Film Sprocket shaft

the direction indicated by

arrow d (as shown in the figure) .

Check to see if the overcharged

amount of

lever and the stopper is more than

0.2 by rotating the film sprocket

shaft in the direction indicated

by arrow d. (See left figure)

-

Mount the motor by moving

aside in the direction

indicated by arrow.

Check the condition of the

Film Sprocket shaft

advance completion.

Set the Film Sprocket

shaft to the film advance

completion state

theFilm

advance stopper

Film

in

latc~

e?

Film advance stopper

Film’sprocket advance

completion lever

—A16—

Page 19

lFAA23051

1

2) Inside film advance unit

- R.3248.J

“

,,

p

Gear S11

\

Multiple exposure

lever spring (#539

.ng

latching

location (#539)

Mount this by rotating

the inside film advance

unit in the direction

indicated .by arrow b

while pulling the spring

(#539) in the direction

indicated by arrow a.

Note :

not to pinch the spring

(#539) between the lower

film advance unit and the

inside film advance unit.

Care should be taken

I

&#l106 x 3

Screw lock (#350)

3) Film take-up spool

motor (FM)

#476

#1019x2

\

{

/

‘1

/

Multiple exposure

lever wire

~#1019x2

Screw lock (#350)

—

A17—

Page 20

#llo2

9\

Dipping in oil barrier

Gear S2

.#l106x3

Gear S7

Gear

S9

4 ) Mounting gears

Gear S1O

I

Gear S9

I

Film take–up

clutch lever

spool

#1087

I

Film take–up

clutch spring

spool

~pply

oil (G92KA)

to each gear.

Dip the gear S2

in

oil barrier

*

Slo

Film take-up

spool clutch spring

View

A

Gear Cll #11

Gear C9

02

I

Gear S2

I

Gear S7

Check the film take-up

spool clutch lever

latching amount

n

—A18—

Film

cl

take-up spool

.utch lever

Gear S9

,>~

Length b should be more

than half of length a.

View A

,

Page 21

.

Frame counter

scale plate mask

Frame

scale plate

counter gear

Stopper

Shutter charge

completion sw

al

\

Screw lock

counter

G103~

/

&ll!l$

#583 ‘

*

l’”

. .

+

:$.

I

-’

#lolo

(#350)~

i

Lock tight

Frame counter

&reset

spring

lFAA23051

5) Upper film advance

unit

Frame counter reset

spring

I

Frame counter gear

Fix with a stopper after

rotation the gear two

turns in the direction

indicated by arrow a

(clockwise)

- R.3248.A

I

#583

Frame counter scale

Use G103 to stick the

projected portion of

the frame counter gear

and the caved portion of

the frame counter scale.

Frame counter scale

plate mask

,

#lolo

Cut-outW’s”

-,*.

W*,

W

““P

n

,/

/

Film advance completion switch

Adhere each screw with screw lock (#350) .

Apply oil (G92KA’

m

:..: .

1

l=+

n

Index

Frame counter

scale

I

““’

on each gear and lever.

%

b

Inspection (ON–OFF)

“ Shutter charge completion switch

● Film advance completion switch

“

Frame counter switch

Frame counter scale goes off between

frame counter O and 1 when the frame

counter gear is rotated clockwise.

● Check the location of the frame counter

scale mask

Frame counter scale is within the range of

more than 2/3 of the width of the counter

index (counter scale plate mask) . See the

figure at left.

Adjustment :

counter scale plate mask after unfastening

#lolo.

Cut-out of #576

should be faced with #577.

Adjust by moving the frame

—A19—

Page 22

6)-Mounting upper film advance unit

*Small parts (see page A14)

~wer

film advance unit assembly

lFAJk2305i

Upper film advance unit

-

~#l106x3

R.sN+&Al

Screw lock

(#350)

Fil”m rewind

coupling

slide lever

Lower film advance unit assembly

Set the film sprocket shaft and the shutter charge cam

to, the film advance completion state.

I

I

Upper film advance unit

#576

Set the cut-out of #576 to the proper place as shown in

the figure at left.

Mount the unit so that the contacts

of the film advance

completion switch comes to the location indicated by a

in the lower film advance unit assembly, and the film

%

#577

rewind coupling slide lever comes to the location

indicated by b in the lower film advance unit assembly.

(See above figure)

#l106x3

I

—A20—

Page 23

FAA23051

On–off inspection of film advance completion switch

Film sprocket shaft is in the film advance completion state.

k

- R.3248.A

B51

Film sprocket sha’ft

Ipper

film

.dvance plate

‘ilm advance

!ompletion

witch #602

Thermal contraction tube

lpper film

Ldvance

plate

B531

#603

(#564)

I

Fi’lm advance

Film advance stopper

(B531)

/

c,

/

Film sprocket

advance completion

lever (B533)

1

B533

ilm advance

Film sprocket advance

completion lever (B533)

stopper

(l

Film advance completion

I

switch is off in

film sprocket shaft

advance completion state.

{L)

The gap between the lower

part of the thermal

contraction tube (#564)

and the upper side of

#B531 and #B533 is more

than 0.2 when rotating

the film sprocket shaft

while depressing #B519 in

the direction indicated

by arrow a.

St

.oppe

r (B531)

-

the

(3

Depress #519 in the

-More than 0.2

II

#602

#603

$4iii==0”2

#602

*

~

#603

~B531

B533

direction indicated by

arrow a while film

sprocket shaft is in film

advance completion state.

(Set to the film advance

stopper release state.)

Make sure that film

advance completion switch

goes on by #B531 and

the gap between the

thermal contraction tube

(#564) and #602 is more

than 0,2.

(4)

Rotate the film sprocket

shaft in the above state.

Make sure that the film

advance completion switch

goes on by B533

instead of #531. And the

gap between the thermal

contraction tube (#564)

and #602 is more than

0.2.

—A21—

Page 24

Mounting film advance base plate unit

“

FAA23051

- R.3248.A

~utter

?ve

r

Figure below:

Shutter charge cam

charge

\

Film advance completion

Lever on shutter relase

through

haft

Shutter charge

completion switch

(grey)

(white)

Film advance

completion switch

state

.,

E (blue)

I

P

K (green)

+ 3.3V

(Pink)

‘n

;hutter charge:

Iotor

(MM)

g

1+

R

,’-”

AWIW&

~Film

spool

/“

r

,. .,-

//”

/

take–up spool spring as

ar S11

take-up

spool

motor (FM)

.

//”

“P

1) Mounting film take-up

spool

Install a film take–up

spool after mounting a f

shown in the figure.

Film take-up

spool spring

a

/“

‘. . .

-

. J

—

Film take-up

spool

17

i lm

0,

Page 25

Film advance base plate

positioning pin

G71OO

FAA23051

Z)Latched portion

of film advance base

plate and shutter.

“:

Indicating

latched portion

- R.3248.

-r

N

:amera

:losing coupling pin

back opening/

#1049x2

\

Shutter

T lever

Shutter

release

lever

3)

(1)

(2)

How to install film

advance base plate unit.

Reset the shutter Mg set

lever by depressing the

lever on the shutter

release through shaft

after setting to the film

advance completion state

by rotating the shutter

charge cam

counterclockwise .

Set to the film sprocket

shaft advance completion

state by rotating the

film sprocket shaft

counterclockwise .

Resetting method

Reset the shutter Mg

set lever by

depressing the lever

on the shutter

release through

shaft (see page A22)

while settinq it to

the film

completion state by

rotating the shutter

charge cam

counterclockwise .

I

adv~nce

:ft

side

film sprocket

:rew

(#1074)

Pull the EL roller forward

mount a film take-up spool

on the film advance base plate unit.

and

—A23 —

Mount the film advance

(3)

ba:

e Plate

EL

roller forward.

Note:

“

Film advance base plate

should be surely fixed

in the film advance base

plate positioning pin.

● Film advance base plate

and shutter are surely

latched.

“

Film take-up spool

motor (FM) cables should

not be pinched.

by

pulling the

Page 26

I

(4) (See page A21)

Mount film advance base plate

mounting screws (#1049x2

#774) after resetting the film

advance stopper by depressing

B519 in the direction

indicated by arrow a.

Temporarily fasten the film

sprocket screw (#1074xl)

(the left side sprocket screw)

Inspection

- R.3248.A

r

a.

b.

Shutter charge

Rotate the shutter charge

cam counterclockwise.

Shutter

Depress

shutter

shaft

l-~ &..-...-

LL LULIIS

release

the lever on the

release through

to T (time)

I

Reset the T by moving the

T lever in film rewind

direction.

(5) Cable arrangement

(a:

Junction cables)

Adhesive

arranging

t

:ape

for

cables

,

I

Power supply base plate

–– main FPC bottom unit

(orange)(black) L =

—

Power supply base plate

–– power Tr. FPC

(orange)(black)L = llOmm

PTr-E (grey)

PTr-C (white)

PTr-B (purple)

140r

T?

n

!/

PTr (3V)

lo~—(yellow)

Film rewind motor (RM)

(pink) (blue)

—A24—

@

G103

Shutter charge motor

F~lm detection switch (brown

,black)

Film film–take-up

SDOO1

motor (FM)

{red) (black)

(MM)

Page 27

Shutter release Mg,

Lever under shutter release through shaft

Shutter release

throuqh shaft

K

@llol

d

616

Shutter release Mg

FAA23051 - R.3248.,

B453 “

#G2KA

;ever under

shutter rele

through shaf

and its bear

(release Mg)

Shutter

&

~

<2

i

%!

‘1

~

—.

00

o

1052

hQ

i.”

@

615

“a

~

1090

““

1052

_ lever under shutter

release through shaft

/

Inspection

a. Thrut play of shutter

release through shaft:

0.1 -- 0.3

b. charge amount of the

lever under the shutter

release through shaft:

More than 0.2

Check the charge amount

by rotating the shutter

charge cam

counterclockwise.

““ Adhesive tape

for arranging cables

Spring latching

lL&ver under shutter

I

#616

release throuqh shaft

— A25—

Page 28

DC-DC converter base plate

GND (

Vccl

+5 . 5V

l?AA23051

- R.3248.A

+12V

CONTR

*Be

sure not to pinch cables.

!Power

Tr FPC

unitl

Q

#685 X

Q

#lo19

2

—A26—

Page 29

Shutter speed dial base plate

i

FAA23051

1)

T (time) lever

RI set lever

Latched position

- R.3248.A

r

Insulating tape

: ,,

\

\

106

.1

.catec

by a in the figure.

● RI set lever

See the portion indicatec

by b in the figure.

R1 set lever on the film

advance base plate

(uppe;

film advance unit-) and R

sw lever on the shutter speed

dial base plate should

bf

latched.

2) Mounting shutter speed

dial base plate

\

.

1-

Adhesive tape

Solder

(frame counter switch)

3) Soldering cables

I

#lo50

#lo54

#1106

B

A#A ~.

Shutter charge

~completion

b

~Pulse

PI (pink)

switch (grey)

<Film advance

-

completion switch (white)

\

\

\

‘k

‘\

‘se’PI (blue)

b

— A27—

Page 30

FAA23051

,/’

/

- R.3248.A

amounting

a

Main

FPCI

Shutter release tool

T

Refer to pages D1O to

Dll when mounting main

FPC .

a.

Insulating tape

b.

Adhesive tape for

arranging cables.

Adhere cables on the

rear side of the

main FPC.

#&.

I

F

4

?—Press contact

I

.

—.

Checking camera back

(Refer to above figures)

,SC base plate

5.W

c1

+–

-D

#672

#B670

#1023x2

1

Vcc

L = 105mm

(n:

— A28—

(grey)

junction ca

1)

shown in

figure.

2)

advance side press

contact.

3)

power supply base plate.

4)

tool (self–made tool)

I

,ble)

Set the

Press contact the film

Supply 5.5V power to the

Mount a shutter release

SC base plate as

the above

./

Page 31

lFAA23051

‘“,

/

- R.3248.1

r

Note :

A. Check the back body (as shown on page A28) .

B. Personal computer and back body inspection

Set the shutter speed dial to 1/4000 sec. or

slower until AE adjustment is completed.

“

Set the exposure selector mode to M

● Turn off the camera back switch (push the camera back

switch pin)

(1) Shutter release

(2) Shutter speed

(3) Mechanical shutter charge sequence

(4) S-C mode (L,

(Hook up personal computer and communication tool

[J15279])

(1) Inspection of operation

Film take-up spool

Film rewind motor

Shutter release

Mechanical shutter

(2) Inspection of switches

(3) Inspection of dials

(4) Inspection of LCD display

S, CH, CL, Cs,

Self–timer)

motor

charge sequence

-f’-

\

‘\

—A28-l—

Page 32

Front body parts

Lens release

,019.FC:F.

I

1138 T

IO18X2

m

lFAA23051

- R.3248.

J

?’

172

B161

1034

%

lo19@a@

/

\s

@@

s

k

196

o

J

199B

\

199A

\

T

@@

0,

353 ‘

G

19

@

354

I

%

s

EE recognition switch

5

/-’

/

1072

B43

I 057

Oil barrier

G103

Screw lock (#350)

Lock tight

;:

G71OO

::

G92KA

:: LEN317A

%’

T

B46

~————___

I

,

I

/

I

I

/

“+

I

I—_

—— ——__

—A29—

-1

Double lock knob

\

0--’

1

\

9$

v)

o

AF lock button

t-

Page 33

/’

FAA23051

-

R.3248.i

r+

B688

@

a

0

0

@’

695

.

98mm ,

//AF lens contact

/

-

B

FPC

22

—A30 —

Page 34

EE recognition switch (orange)

I

FAA23051

- R.3248. A

Insulating tape

1)

Checking double lock switch

The switch turns on when the double lock knob is set

to the double lock side.

Double lock . . . .

2)

Checking EE recognition switch

The switch turns off at the height of 0.3 to 0.85mm

from the bayonet ring surface.

Aperture coupling ring

AF PTr-E (orange)

AF PTr-C (white)

AF PTr-B (purple)

.

\*.~

(~

--

owe

ase

+

b

P

Tr

latg

‘n

EE recognition pin

//////////1

Bayonet ring

— A31

i

I

—

0.3 to 0.85mm

Page 35

AF base plate unit, fo base plate unit

AF motor

B313

lFAA23051

- R.3248.A

fo base plate .

s:

Screw lock (#350)

K: G92KA

I

b’:

fo lever

AF coupling

ever hole

Spread L21

on each sh

13

aft .

5075

\

~

AF.PI

— .

Checking fo base plate

Adjustment of btush position on

fo base plate

. . . . . . .

.

‘b:

.:?!

.< 1

!

_

*C

brush positioning

1~

I

{

AF

coupling

ring lever

: Note:

Do not bend

I

II

1.24~0.2

Mount the fo lever on the

base plate unit,

Mount the AF base plate unit

on the front body by adjusting

levers and pin indicated by

arrows in

b–b’:

~–cl:

Hook the AF lever spring

(#410) on

There should be a

contact portion

and end of fo pattern when lens

attached.

the figures:

fo lever

AF coupling lever

AF base plate

positioning pin

#1048x2

the hook.

space between

Al

brush

is not

— A32 —

Page 36

I

i

I

I

/

/

:

I

I

I

I

I

i

i

L––_–––_–_– _______

Z7A--+j/

/

KE347B

.A

—

990 ,

6

N

@’ e

T~

[015

1032

B 207 I

——— — — _________ ,

I base plate unit

r

.1.

11085

I

I

1085G~

/’

I

I

J

9

i 44

149

\

\

:4

i

I

I

I

Lti

__________

‘“’”

‘

---------------

i

S:

:

G:

T: LOckt’ght

I

I

i .\\

Screw lock (#350)

G7100°

Filter driving

base plate unit

]

-1

I

3

1012

I

1

L

—————_————— ._——_—____ _ _______.___l

tr-

Sprea’d L2113 on each gear shaft

— A33 —

1

I050X2

I

I

Page 37

Mirror box unit

L

base plate unit

fmm

sl

~itch

TC switch

(white)

(brown)

L_”l._J

lFAA23051

fmm base plate

I

.-

~

- R.3248.A

Mirror

Sub-mir

‘stopper

fmm signal

i

I

base plate

lever

G8181

Ma

in mirror brake

coupling lever

,Sub-mir

stopper

Shutter

{

~own

ror

spring

ror

lever

charae

spring

lever

.-

Mirror up stopper

G71OO

Aperture lever

“Aperture photointerruptor

(with positioning pin,

attach with adhesive like Alon

up sprin

re lever

spring

re lever

re Mg

lever

Al fa )

—A34—

Page 38

lWAA92n<l

- D ‘1’_)/,

Q

I

— Aperture Mg

Aperture Mg click — Adjust the gap between the

click and the ratchet gear.

Shutter charge lever

(See page D23)

I

n

0.2 to 0.3

f~y

;L

u

,/

Aperture driving lever

-

-1

—

Ratchet

gear (#81)

crew lock (#350)

\

#lo12

resetl

#149

I

,atchet

reset gear (#81)

Aperture Mg

Push the shutter charge

lever in the direction

indicated by an arrow b

to be shutter charged

I

I

I

state.

Mount on the I base

plate by hooking #149 in

the hole of #81.

(Arrow a indicates the

hooking position on

which one end of the

spring (#149) is hooked)

I

#lo5

erture PI

Spread KE347w

—A35 —

I

Mount #105 by rotating

#81 around 270°

clockwise .

#lo12

Page 39

FAA23051 - R.3248.

IMountin

g mirror unit, I base plate,

See page

Mounting mirror box, front body

See page

Adjust thrust play of

Rated value: O

Adjustment washer

L base

D23

D22

1K050-334

1K050-335

1K050-336

platel

-

.1 ~o 0.3

0.1

0.05

0.15

mirror

I

unit

Cable arrangement

:ab

le,

FPC, adhesive tape

foz

. cable arrangement

AF lens contact FPC

TC switch (white)

fmm switch (brown)

EE switch (orange)

1K050-337

1K050-338

‘J

0.2

0.3

,

FPC positioning pin

~

\

y

~

!4

—A36—

Page 40

AA23051

-*

R.3248.

A

Filter driving base plate, filter unit, TTL SPD

See

pages D20 to D21

— Filter unit

Check:

Filter mirror holder moves by its own weight

when the front body is declined after

assembly.

— Filter driving base plate unit

Check:

Check to see if the filters are switchable

after assembly.

See

page D19.

AF mode selector lever unit

unitl

,nl

lLens

Check AF switch 1, AF switch

Check continuity of each switch

AF switch 1 (blue), and GND and

tester.

;

mode

;

mode

d

mode I

(2)

See

page D19.

release button

switchl

See

page D18.

2,

lens release button switch

by”connecting GND (body) and

AF switch 2 (white) using a

(1) AF switch inspection

AF switch 1 (blue) AF switch (white)

I

off

on

off

I

on

off

off

Lens release button switch inspection

AF switch 1 and AF switch 2 turn off when the lens

release pin is within the range of 0.45 to 0.85 from

the bayonet ring.

~—c

,––__

I

~

~_

Al? SW

Release SW

“1

c1

j

AF SW2 (white)

~AF

_>_M_

J

GND(body)

SWI

(blue)

Bayonet

— A37 —

Page 41

Mirror operation base plate unit

See page D17.

Check preview bottom and mirror up operations

f–fo base plate, f–fo pulley

)

FAA23051 - R.3248.,

— f–fo base plate

— f–fo pulley

f–fo pulley stopper

See page D18.

Mount by rotating the

pulley once clockwise

while aligning the f–fo

pulley spring (#402) with

the f–fo pulley shaft

groove .

#1087

Note :

the plastic mold

shaft of the f–fo

pulley.

Reel aperture

coupling ring thread

in the #403 groove.

(See figure a)

Do not damage

Aperture co

I

ring thread

*

— A38—

087

Note :

(1) Thread knot

should not be pushed

out from the surface

of the f–fo base

plate.

(2) Aperture

coupling ring thread

should be hooked in

the roller on the AF

mode selector base

plate.

(3) Aperture

coupling ring thread

should not be bent.

.

a

Page 42

1) Adjustment of f–fo pulley stop position

Aperture coupling ring is attached to the stopper.

/

2) Adjustment of the f–fo base plate position.

~–fo

base plate

\

The f–fo pulley

is being attached

to the stopper.

Use adhesive

(Alon Alfa) to-

attach.

c-

#403

Adjust by rotating #403 so that the aperture coupling

ring and the f–fo pulley come into contact with the

stopper simultaneously.

Screw lock

(1)

(2)

10X2

(3)

Mount the f–fo tool lens

(J18202)

Set the digital voltmeter (at

the resistance measuring

range) as shown in Fig. a.

Adjust by rotating the f-fo

base plate so that each

resistance value can be

measured when the f–fo tool

lens (J18202) is moved aside

as shown in Fig. b.

on the body.

\f

[

Q

&

v

>,

W

$

\

o

.

+

]urple)

ig

a-

.

J

‘iq.

(yellow)

Resistance value is 624 to

936f2

moved in the direction

indicated by arrow c.

Resistance value is OQ when

moved in the direction

indicated by arrow d.

(4)

—A39—

Fasten screws (#1010x2) and

spread screw lock (#350) on

them.

when the tool lens

is

Page 43

\

— Soldering cables

- R.3248.A

Solder

plate.

f–fo base plate

Vref

(purple)

AGND (blue) and Vref (purple) on the f–fo

F’-

+

70

AGND (blue)

base p

late

base

— When f–fo pulley shaft is damaged.

(1)

(2

(3

(4

Remove the f–fo pulley and the f–fo base plate.

Remove the damaged f–fo pulley shaft.

Note:Check to see if there are any broken

pieces left in the L base plate.

Mount the f–fo pulley shaft (1K371-359) .

Spread adhesive (Alon Alfa) at the portion where

the f–fo pulley shaft is mounted.

‘A40

—

Page 44

lFAA23051

- R.3248.A

Lock encoder FPC unit

See page D17.

Cable arrangement on the lower part of the L base plate

Hook AF motor cables on the holder.

--’4

,

[se

adhesive

:103)

to atta

ref (purple) ,

-fo (yellow)

SND

(blue).

~F

switch 1 (blue) _/’

w

switch 2 (white)

AF motor (red),

Vref (purple)

AGND (blue)

(black)

IAF

base plate unit

See pages D15 to D16.

—

A41—

Page 45

I

FAA

230 51

-

R.3248.

I

lPositioning

fmm base plate

rC

switch

white)

(

Emm

lbrown)

I

H-

o

w

adjustment of fmm

Screw lock

(#350)

\

\/l

o

fmm signal lever

#1037x2

switchl

(1) Connect a tester between

the TC switch (white) and

the body (GND) .

(2) Mount the 50mm (f/1.4) AI

lens on the body. Do not

move

the protection ring of

the 50mm f/1.4 AI lens

(indicated by arrow a)

pushes the fmm signal

lever.

(3) Fasten the fmm base plate

at the point when

switch is changed from ON

to OFF by moving the fmm

base plate.

signal lever brush should

be positioned at the

center of the TC switch

and the fmm switch

patterns.

any further once

th=

TC

Then the fmm

I

Protection ring

\

(4

Noi_e :

a

The fmm switch should be

off when the 50mm f/1.4

AI lens is removed.

Correct lens:

50mm f/1.4 AI

(Do not use 50mm

AI-S and AF 50mm f/1.4.)

f/1.4

—A42—

Page 46

Height adjustment of aperture lever

IFAA23051

- R.3248.,

Rated

value :

n

Eccentric

adjusting

lever

screw for

aperture

Screw lock

(#350)

o

Aperture lever

Height adjustment of AF coupling ring shaft

Adjust the height by turning the screw (#1078) so that the

&

AF coupling shaft is higher by 1.6

surface when the lens release button is free in AF-C or AF–S

mode .

0.1 than the bayonet

-’l

Lens release pin

Lens relea

button

se

Bayonet surface

u

w

#1~78

Screw lock

i

Q

AF coupling

ring shaft

3

o

.

—A43—

Page 47

L....-<”

1

<,

. ..4-T”.

Angle adjustment (45°) of main mirror (Gl), sub–mirror (G2)

— Angle adjustment (45°) of main mirror (Gl)

Tool: . J18037 (Optical flat)

Screw lock (#350)

1037x2

● J18038

● Vertical collimator

● Hex key

Rated value:

Horizontal discrepancy;

()+18 g

B204

Adjustment of hor

i

.zontal

Vertical discrepancy;

+0 )

o

–lo ‘

discrepancy

&

,

Adjust

by moving

B204 vertically.

#239

Adjustment

Adjust

vertical discrepancy

of

by

rotating #239.

— Angle ad-justment (45°) of sub-mirror (G2)

To01:oJ18196

(determines the

angle (45°) of the subrnirror)

●

Vertical collimator

Rated value:

Vertical discrepancy;

5*5’

#253

+

o

@

%

n

f–fo pulley

T

Sub-mirror stopper lever

Adjustment of vertical discrepancy

~

o

Adjust by rotating #253.

— A44—

Page 48

- R.3248.A

lMounting

— Preparation for mounting on front body side

~ilter

d

oupling

.riv

le’

on front body and back

bodyl

Shutter

Start 1

cha~

ever

“ge

lever

1)

2)

Move the mirror down

Move aside the filter driving coupling lever to film

Note :

● Move the mirror down

lever to the bayonet

“

Spread G71OO on the tip of the shutter charge

by pressing the shutter charge

ring.

lever, and start lever.

rewind side or in the direction indicated by arrow a.

Eliminate foreign matter in the filter and AF sensor

units by using a blower.

‘A45

—

?,

Page 49

— Preparation for mounting on back of body

- R.3248.,

1)

The body should be set in the film advance completion

state.

Shutter charge lever

/

Shutter release lever

Shutter release

levez

should be set to the

back position.

‘Mirror down lever

Note:

Check that the T (time) lever is correctly

latched.

(See page A27)

far

2)

3)

Set the shutter speed dial to the T (time) position,

Move the filter driving coupling lever to the film

rewind side.

/

Filter driving lever

* Set the clutch pin at this position and fix the

filter driving coupling lever.

0

Film rewind side

Clutch pin

—A46—

Page 50

— Mounting

FAA23051

Back of body

-

R.3248.A

of body

Assembling: See pages D3 to D5.

—A47

—

Page 51

FAA23051

Adjustment of film sprocket cogwheel positioning

- R.3248.}

1)

2)

3)

4)

Set the body to the film advance completion state.

Unfasten the film sprocket screw (#1074xl) .

Set the film sprocket cogwheel positioning tool

(J18064-1) on the aperture surface.

Fasten the film sprocket screw (#1074) temporarily

after aligning the right end of the film sprocket

cogwheel to the position 31.8.

Ad-just it further so

that the right end of the film sprocket cogwheel will

+

be within the range of 31.8

0.2 when moving the film

sprocket in the direction indicated by arrow a.

I>Lock tight (purple)

\

#lo74

Reference length:

#

t-

32.4

5)

Mount the film sprocket screw (#1074) with lock tight

1111I4J-

I

a

0.4’

I

(purple) in the left film sprocket screw hole

(indicated by arrow b).

6)

Check to see the film sprocket cogwheel position by

repeating film advance operation several times.

—A48—

Page 52

Adjustment of body back

Same as for F3 and other models.

Adjustment of infini,ty

Same as for F3 and other models.

IFAA23051

R.3248.A

-

E, AF Accuracy,

inspection, and adjustment

AE accuracy inspection and adjustment items (followina

instructions by personal computer)

1. AE accuracy inspection, adjustment

I

f

Sub–menu

1. F4 + AMP.FD

Inspection, adjustment items

I

~Spot

~AMP

exposure metering ad-justment->

exposure metering

I

2. F4

3. AMP.FD

4. F4 +

Action

FD

5.

Action FD

(1) —> Adjust M 1/8000 (M 1/4000)

~Spot

I

lAMP

~

I

I

lSpot

lCenter-weighted

I

I

exposure metering adjustment—>(l)

exposure metering adjustment

(adjust by mounting on the tool body)

exposure metering —>

exposure metering—>(1)

:Center-weighted exposure metering

~

(adjust by mounting on the tool body)

—> TTL adjustment

>(1)

(Adjust by mounting

AMP.FD or

Action

FD )

.

-’l

2) When main FPC on the F4 body or EEPROM is replaced:

1) Make following adjustment (write AF compensation

value into EEPROM) after the inspection of item 1.

—> X BER P adjustment —> AZ adjustment —> Hard AGC

adjustment

—A49

—

Page 53

lFAA23051

-

R.3248.4

— AF accuracy inspection,

instructions by personal computer)

Note :

1) When making adjustment of AF accuracy, remove bottom

cover,

#1026, #1038) (see page D6), and set up the bottom FPC unit.

2) When making adjustment,

shutter or cover the body with black cloth.

3) When viewfinder is not attached,

aligning the AF inspection chart and target zone on the

focusing screen.

4) It is not required to attach AF sensor adjustment screws

(x 3) with screw lock.

1) AF accuracy

inspection

(adjustment when

disassembling AF

sensor unit)

tripod socket (see page D2), bottom FPC screw (#685,

2) AF Sensor

(when displacing)

adjustment items (following

close the viewfinder eyepiece

adjust

the AZ by

3) Main FPC of F’4

body (when

displacing main FPC

or EEPROM)

X BER P

inspection and

adjustment

I

YAW inspection

and adjustment

I

PITCH inspection

and adjustment

I

AZ inspection

and adjustment

X BER P After AE adjustment,

adjutment

djustment

YAW

write following

compensation value

into EEPROM

I

PITCH adjustment

I

AZ adjustment

I

Hard AGC Hard AGC

adjustment

X BER P adjustment

I

AZ adjustment

I

adjustment

— A50—

Loading...

Loading...