Page 1

- ...

:.,

.

. .

·~.·i~~·;..

·-

..

. '

_.,.--·

;

..

....

:.

··

..

•\

. .

.r

i

1

.

:.

~'

·-·-

...

·,_··

4.

...

15

_,.

,.•

.•

1979.

Page 2

- 1

OPTIPHOT, LABOPHOT

BOOY

8,

F,

ER,

UW-TUBE

STAGE

WITH

VERTICAL

f

HANDLE

' (

Page 3

CONTENTS

CARE

TOOLS

MECHANISM

DISASSEMBL

REASSEMBL

FOR

ANO

1.

2.

3.

4.

5.

1.

1.

2.

3.

4.

1.

2.

3.

4.

Tools

Special

Lubricants

Adhesive

Others

Coaxial

Coaxial

Substage

Arm

Base

Coaxial

Substage

Arm

Base

STARTING REPAIR

PREPARATIONS

for

General

Tools

....................................................

.......................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

to

be

Repaired . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANO

PRINCIPLE

Coarse

Y PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coarse

Unit

Unit

Y PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coarse

Unit

Unit

and

and

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

and

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.............................................

Use

..............................................

...............................................

Fine Focus

Fine Focus

Fine Focus

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . l 9

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

.

.

.

6

18

19

21

21

23

26

29

32

32

34

36

37

ADJUSTMENT

1.

2.

3.

4.

5.

6.

7. Tube Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.

...........................................................

Torque of

Smooth Tuming

Smooth Tuming

Parallelism between the Tube Attaching

Centering the Tube Attaching

Centering

Adjustment

Coarse

of

Focus

Knob

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of

the Left

of

the Right Fine Focus

Optical System

of

Brightness Contrai Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fine

Focus

and

Stage

in

the Microscope

Knob

Knob

and

Stage

Attaching

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

............................

Attaching Surfaces . . . . . . . . . . . . .

Part

. . . . . . . . . . . . . . . . . . . . . . .

Base

. . . . . . . . . . . . . . . . . . . . . . . . . 4 l

38

38

38

39

39

40

4 l

42

Page 4

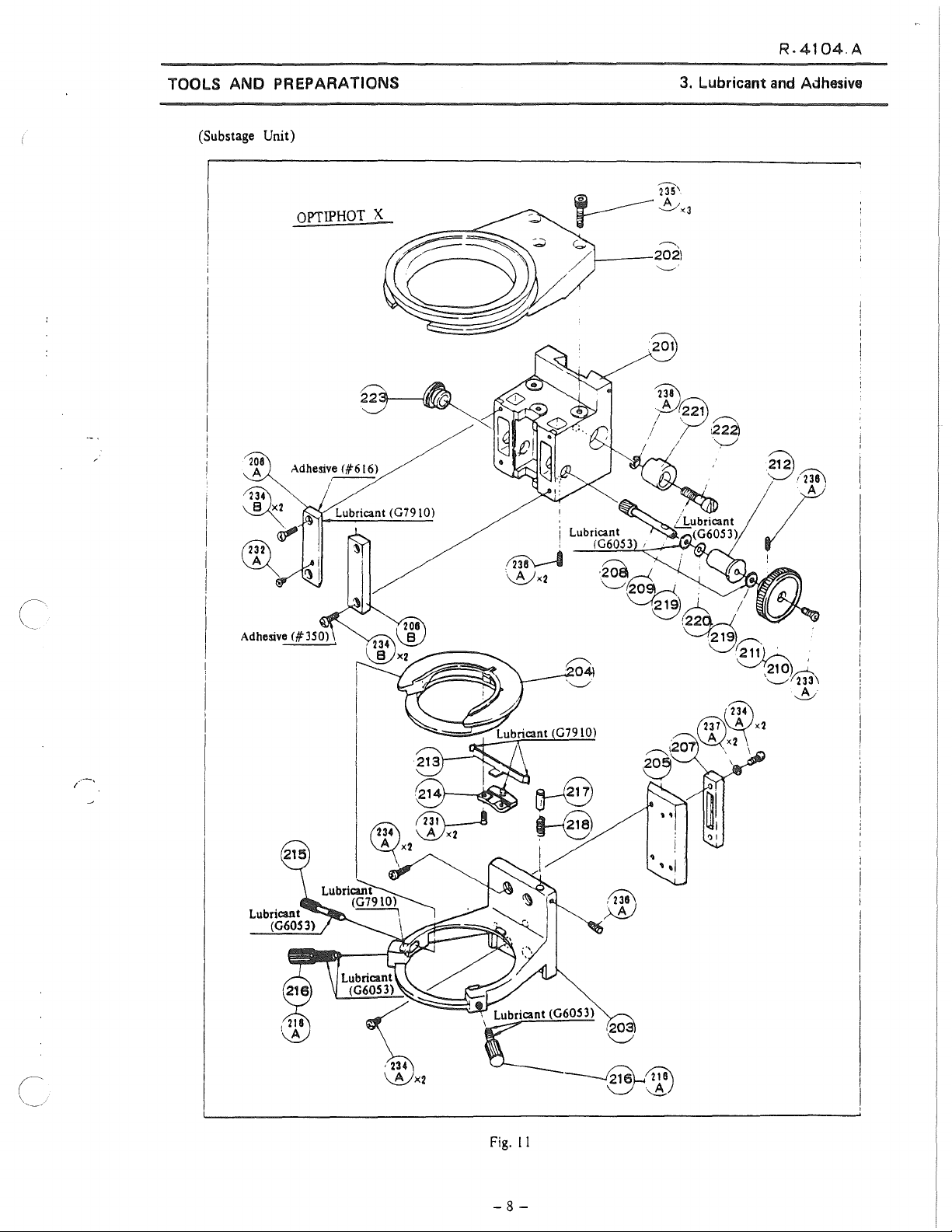

R-4104.A

CARE

FOR

STARTING REPAIR

CARE

•

e For replacement and others

e

• Take every caution

•

e

• Before replacing the

• For cleaning the

FOR

STARTING REPAI R

When

carrying the microscope, hold

with

the

directly

Wltlle

the

thinner, etc.

Be

careful not to

Make

sure

referring

using

to

a gauze.

lamp

fingers.

is

lighted, never bring

near

to

in

leave

of the power source

the

indication found

lens

the

fuse

surfaces, füst

its

arm

of

the lamp bulb,

any

inflammable substances

lamp housing.

handling against shock.

dust,

t1nger

marks, etc.

voltage

in

the transformer,

to

be

on

the transformer.

remove

dust,

with

one

hand.

do

not touch

on

the

used

(for example: UNE

pull

out

the

using

a sott

tenses,

plug

:rnd

1ts

base

with the other.

it.

aiter putting out the lamp,

such

as

alcohol, gasoline,

lamp

bulb, etc.

IOOV,

LAMP

of

the

power source cord.

haJr

brush, or

wipe

6V,

it

off lightly,

20W),

• Only

e For cleaning the parts painted or

e

• Apply only specified

for

removing

gauze, soaked with a bit of absolute alcohol (ethanol

alcohol, ether, thinner, etc.

Do

not

use

of

the instrument.

finger

marks or grease,

made

other tools other than the specified, except

oils

to

the parts, r"ferring

of

use

plastic,

a soft,

avoid

to

the

clean

cotton cloth, specified

or

methanol).

the

use

of such organic solvents

for

an

unavoidable

lubricant table, to keep

case.

up

lens

the

tissue

or

as

efficiency

-1-

Page 5

R-4104.A

TOOLS ANO PREPARATIONS

TOOLS ANO PREPARATIONS

1.

Toais

for

General Use

Name

- screwdriver

6

4 + screwdriver

set

set

Pair of tweezers (stainless)

Blower

Injector (2cc)

or

Plastic

wooden hammer

Handlap

Hexagonal wrench

Flat type thread dnver

For

screwing.

For

screwing.

For cleaning lenses, etc.

For injecting oil.

1

For

applying impact.

Cointainer

For

set

screws

For

HS

bolts

1. T ools for General Use 2. Special T ools

Use

for

alcohol

(3mm, 4mm).

(3mm,

4mm,

Smm,

6mm)

2. Special

i Substage condenser

i positioning tool

1 Tube receptacle/substage

1 centering tool

(

Toais

Name

Parallelism measuring

base

Centered condenser 125144 (Fig. 4)

4X

Objective "

Eyepiece

CFW

IOX

Rightangle/Centering tool

Base

axis collimator

"

Number

125141

125142 (Fig.

1

(Fig.!)

2)

125143 (Fig. 3)

125145 (Fig. 5)

125146 (Fig. 6)

125147 (Fig. 7) For

For

For

For

For positional adjustment of

For adjusting

nosepiece

For OPTIPHOT

Use

positioning substage

and

centering tube receptacle

rightangle

of

nosepiece

"

" "

rightang!e of substage to

LABOPHOT

condenser

and

substage

to

substage

base

and

ann

1

1

1

1

1

i

1

i

1

1

i

1

1

'

!

'

Standard vertical eyepiece

tube ( with Kellner eyepiece)

Diopter adjusting telescope

Checker pattem reticle

Tension

ga1Jge 1 Kg,

500g For measuring torque

Centered objectives

IOX,

40X

Tubelength adjusting tool

Collimator

plane

parallel

19008

128004

IOX

128018

40XJ28019

125148 (Fig. 8) For measunng tubelength

For

measuring tubelength and parfocality

For adjusting optical

axis

of

eyepiece tube

For checking travei accuracy of

and

parfocality

stage

1

1

1

1

1

1

Page 6

R-4104.A

TOOLS

ANO PREPARATIONS

• Substage/condenser positioning

too! (125141)

e Tube receptacle/substage

centering too! (125142)

55 -

Fig.

1.

?:

.___,/

33

~

A.

~'

~~

~

2. Special Tools

8;

--_./

1

o

-e.

"'

Fig.

2

e Parailelism measuring base

(125143)

-

: 1

10

Fig.

• Now-eccentric condenser

r

(125144)

-

ss

-P89

e

3

~

---!

1

1

@}])

Fig.

4

•

Substage

tool (125145)

rightangle/centering

-72

i 1

1

___;

-3-

Ftg.

5

Page 7

R-4104.A

TOOLS ANO PREPARATIONS

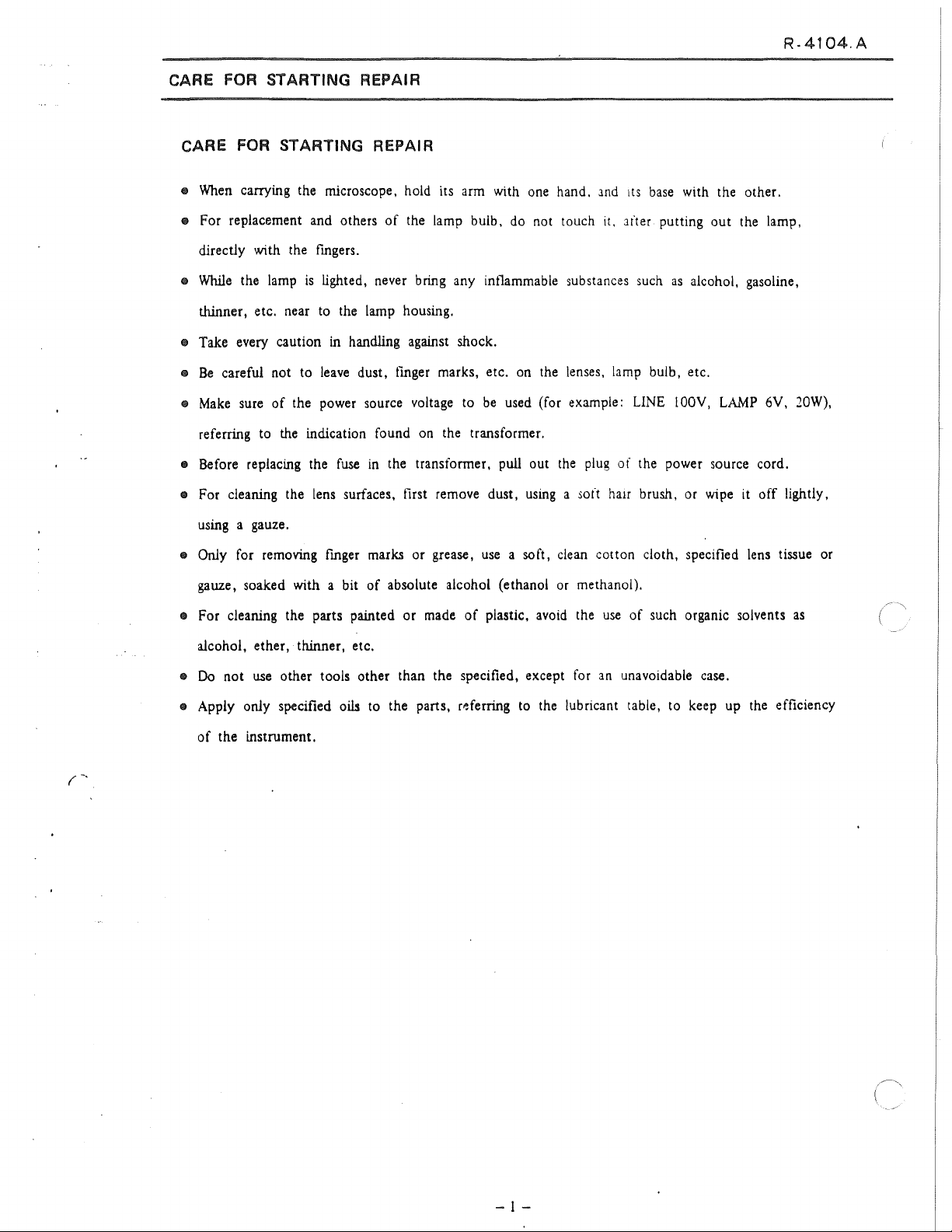

e

Base

ax.is

collimator

for

OPTIPHOT

(125146)

i

;

l 1

I '

1 1

' 1

1

'

'1

1

! '

2. Special Tools

e

Base

for

(125147)

ax.is

collimator

LABOPHOT

Fig.

1

6

-4-

Fig.

_,,

____

.,_J

1

7

Page 8

R.4104.A

TOOLS ANO PREPARATIONS

€1

Tubelength adjusting too!

(125148)

Eyepiece

2. Special Toais

20X

Fig. 8

o

l

o

"'

-5-

Page 9

R.

4104.A

TOOLS ANO PREPARATIONS

3. Lubricant and Adhesive

(Coaxial coarse-fine focus unit)

OPTIPHOT

Lubricant (G7920)

/

Â

~@

Lubricant (G7920

Adhesive

(#616

X.

XP

1251~

'-'

124•

3. Lubricant and Adhesive

Adhesive

(1616)

Lubricant (G

Adhesive

(#2002)

79

20)

(

I

/

,foi

'----'

Adhesive

\

/

,

(#2002)

Lubricant

(G7920)

,/'/

/

,r--'/

' '

1191__,t ' /

--.

..

JI

;'

21\;:--<'

/

j

~106)..-/

""~~

Adhesive

iAdhegve

1101

(rtJ50)

/

/

(#410

~'

12s1A

'--..__.;

127) ,

~

B/M)

.§

Lubricant

(G

201)

Fig. 9

-6-

8

Page 10

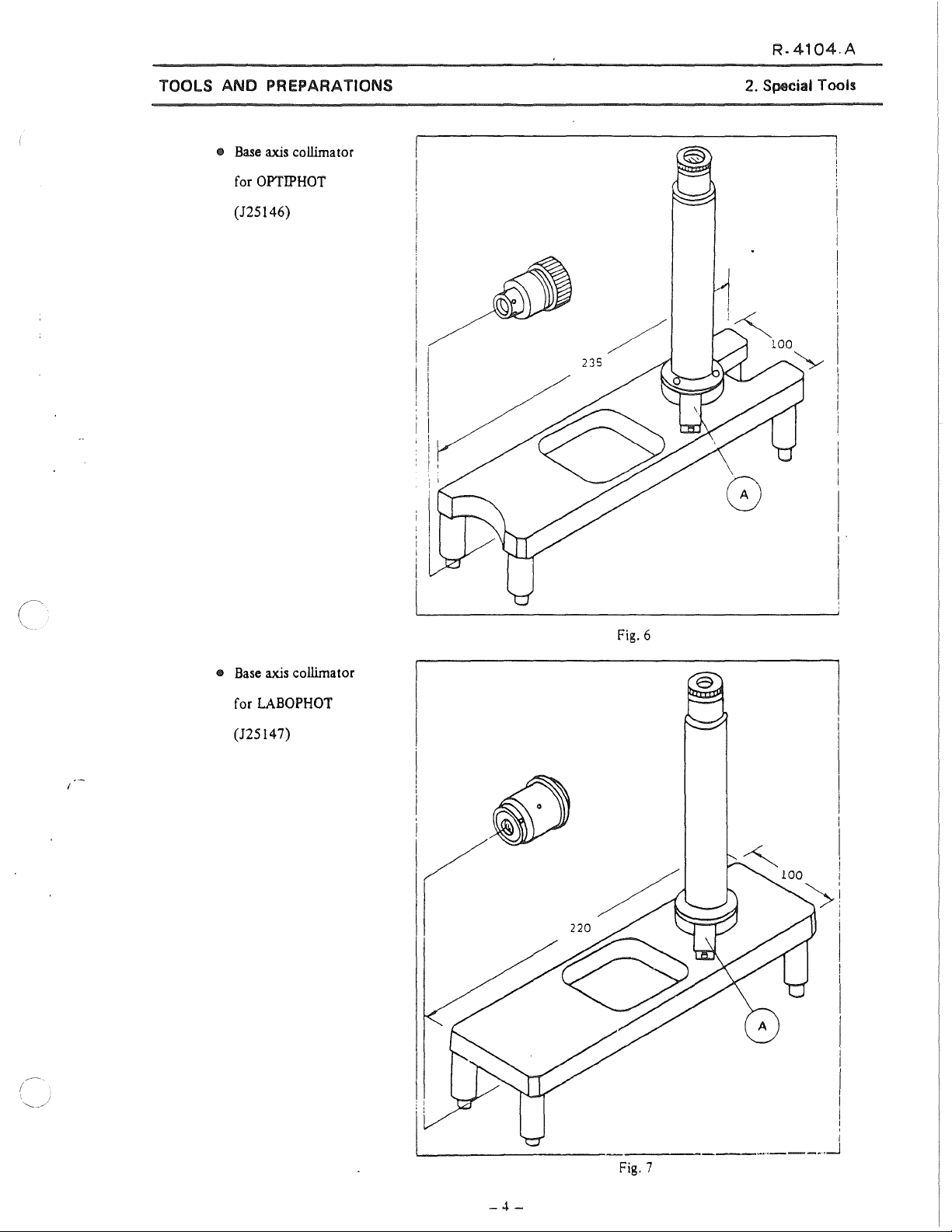

R-4104.A

TOOLS ANO PREPARATIONS

Lubricant (G7920)

I'

1

!

/

(~11

128

\

Lubricant (G7920)

Adhesive

LABOPHOT

(#616)

Y

129l~

'---' 1241

3.

Lubricant

and

Adhesive

Adhesive

(#2002)

Lubricant (G7920)

I

Lubricant (G201)

Fig. 10

-7-

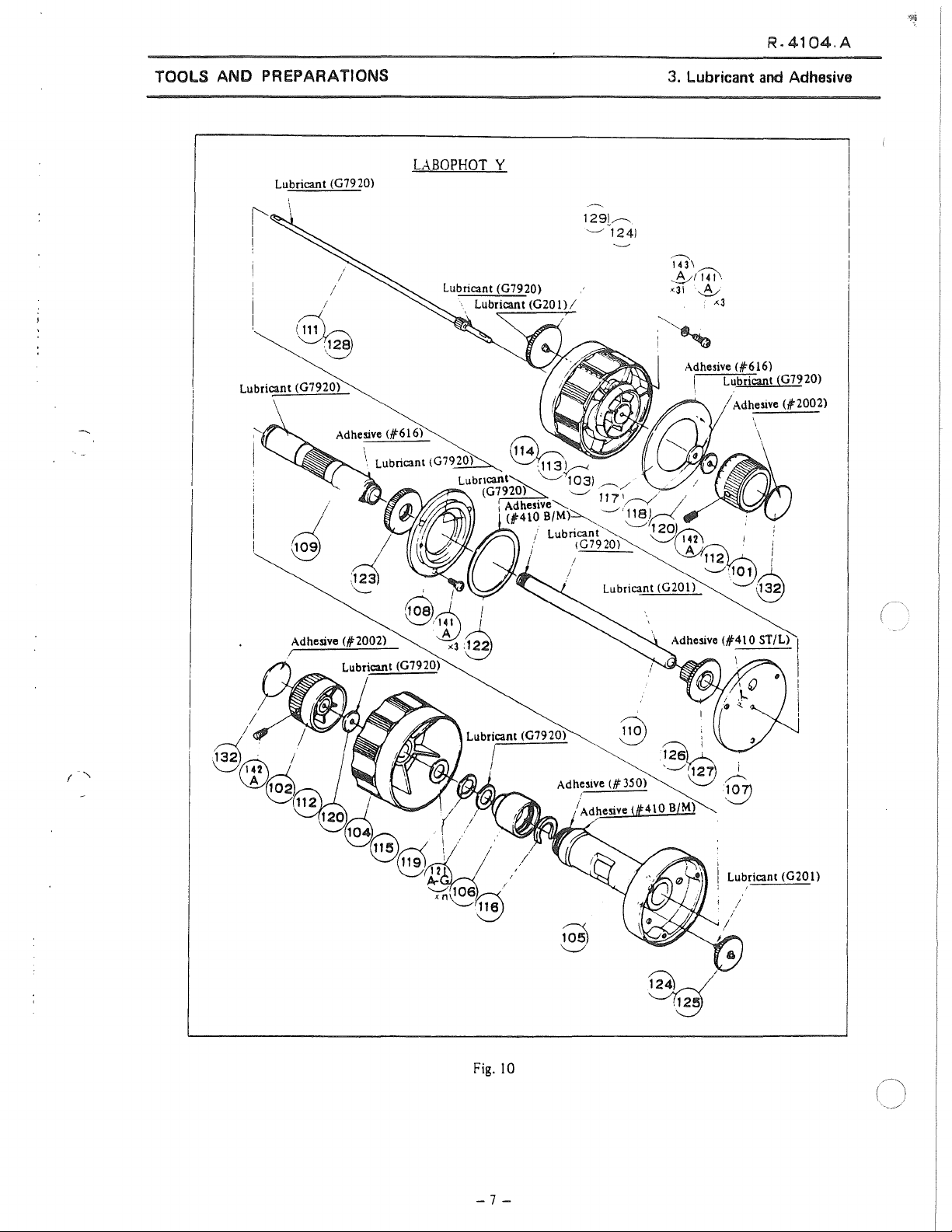

Page 11

TOOLS ANO PREPARATIONS

(Substage Unit)

R-4104.A

3.

Lubricant and Adhesive

e

208

A

OPTIPHOT

X

1----202)

,......__,

'--..__,-'

201

'@\

;M~221

Í @

/ I

'',--/'

Q

7

' , Lubricant (G60S 3)

ce,

---&~

Fig.

l l

-8-

')I

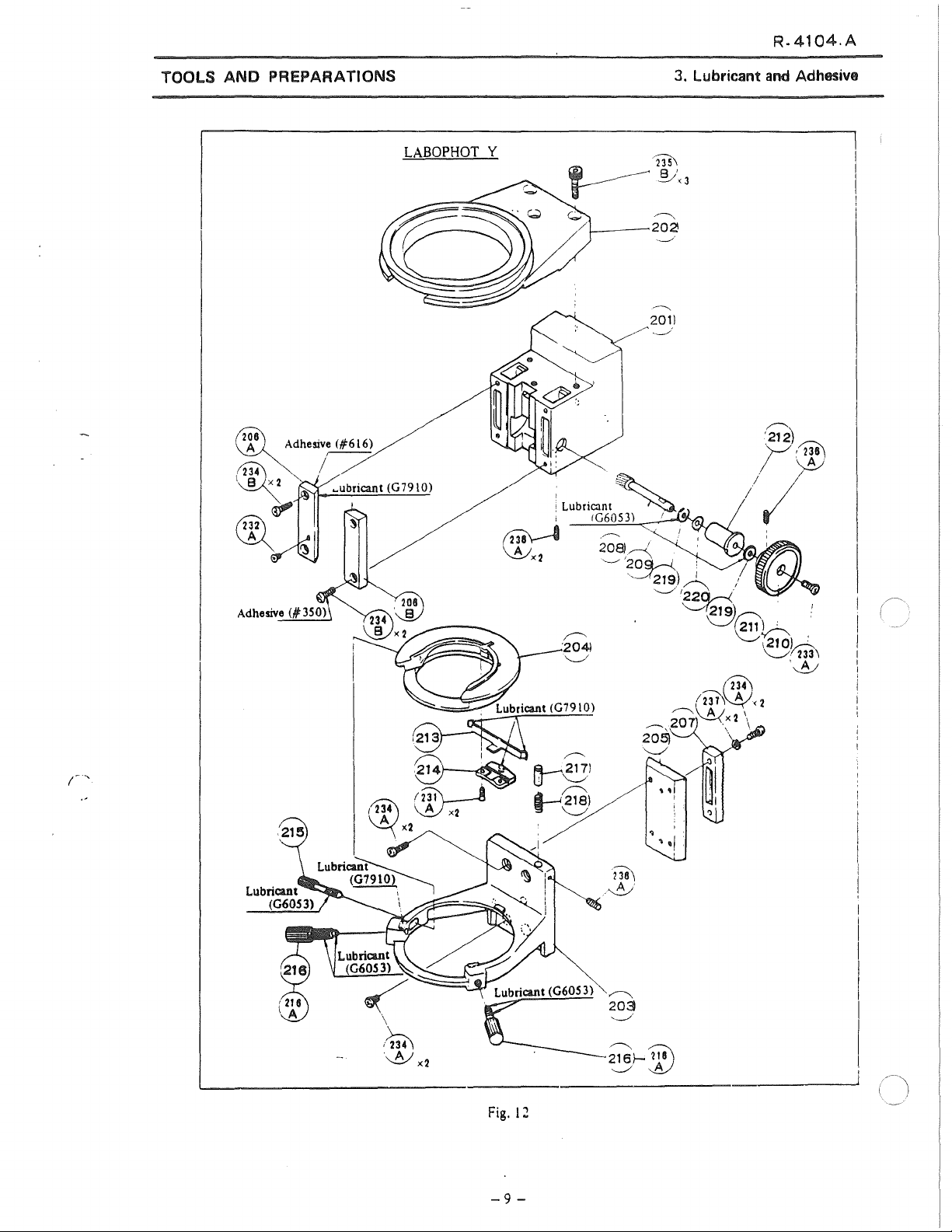

Page 12

R-4104.A

TOOLS ANO PREPAAATIONS

LABOPHOT

Y

~

r

ç;

/ 2021

1:

;

Lubricant'

1

~

\ A 1 208)

'-!Yx2

________.

'

IG6053)

-~

'-----'

235\

~

___

201)

----!

'2o~

~219)

'-//~

3. Lubricant

-ª.,;"3

/

/

.

1

-~

and

Adhesive

~

'212)

/C~

1;

/

1

(~

(1i4l

~

~x2

\

,{m

-~x2

~Q):

ç~):

,

__

),,@\

-~

(~

!231\~<2

.---- 2Q

205)

'---../

~\-Ã'

1

\~X2

\

1

\

_j

-

~m

~;,;f-íli\

.__,/

:_A)

Fig.

-9-

12

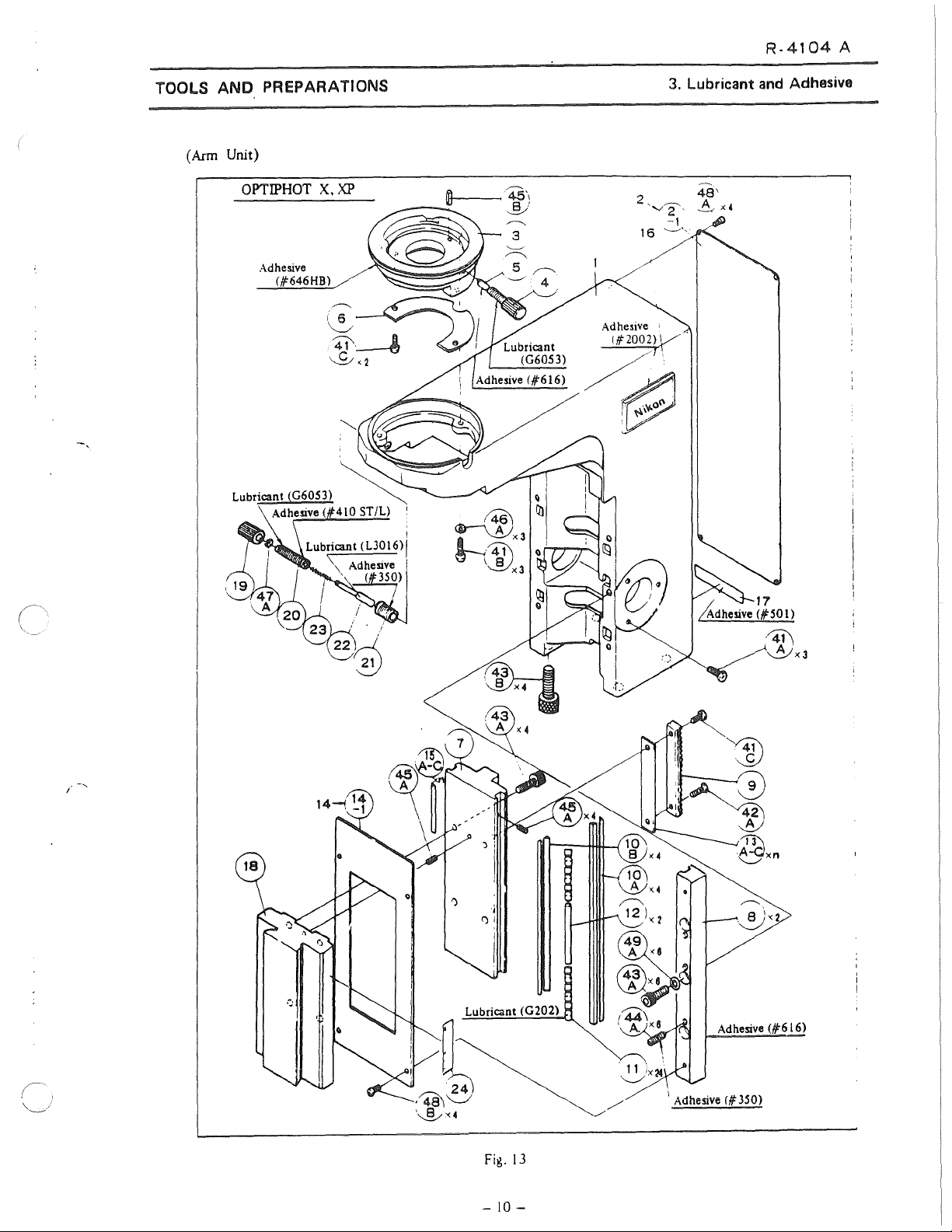

Page 13

R-4104

A

TOOLS

(Arm Unit)

ANO

PREPARATIONS

OPTIPHOT

X.

XP

1----45\

----

~)

3. Lubricant and Adhesive

48'

A

X4

'~

!X4

:43

ti

A

.

11

'-.___/

ix24

1

Adhesive

Adhesive

f#'

350)

(#616)

Fig.

-

13

10-

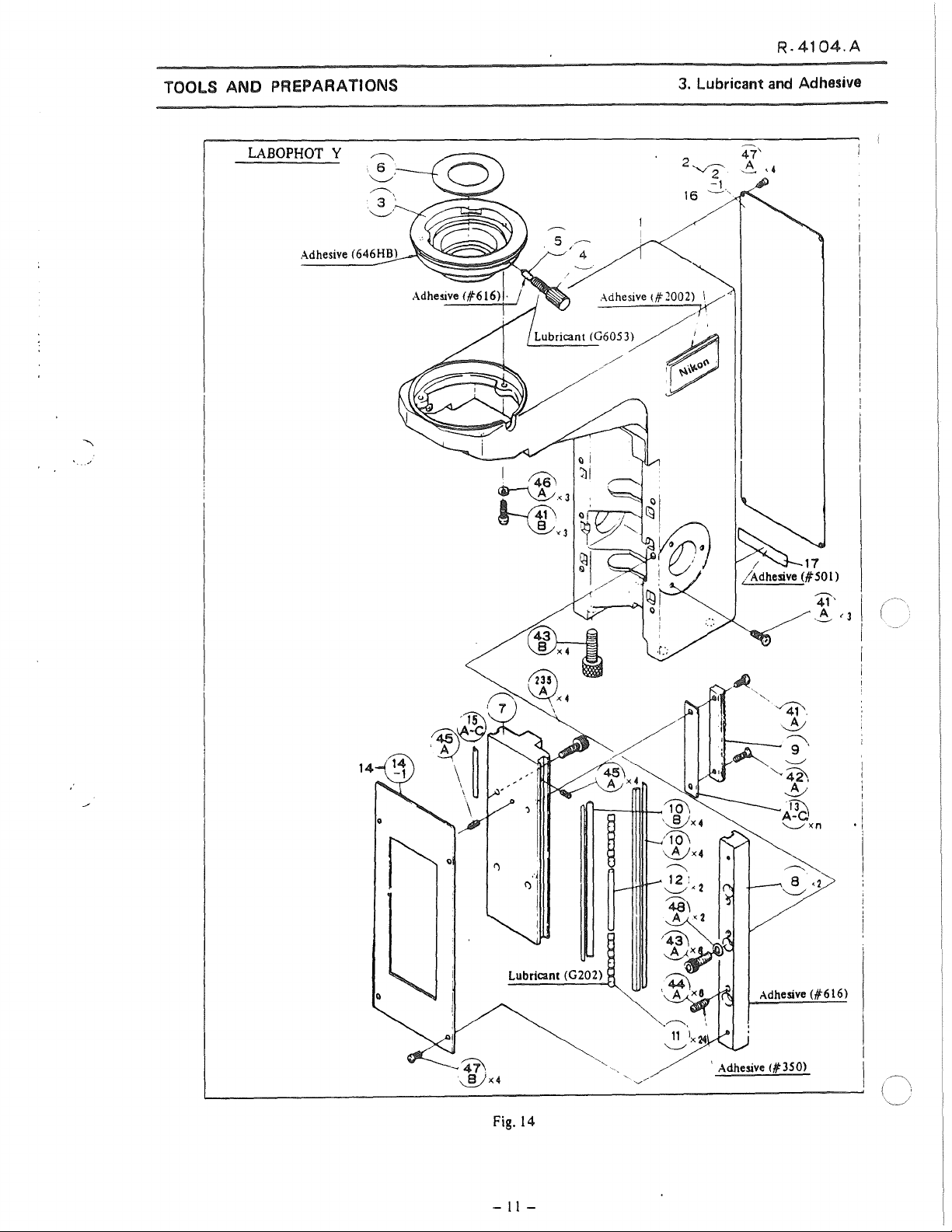

Page 14

R-4104.A

TOOLS ANO PREPAAATIONS

LABOPHOT

Y

Adhesive (646HB)

3. Lubricant and Adhesive

Lubricant (G202)

Fig.

14

-

11

-

Adhesive

' Adhesive <1350)

(#616)

Page 15

R-4104.A

TOOLS ANO PREPARATIONS

(Nosepiece)

OPTIPHOT

Adhesive

Adhesive

X

(#'350)

(#'616)

~,,.........___~<2

Lubricant

'fl

Adhesive1304l

.

(#'350)

'Jf:

-~

~~)

~

(G202)

~~)

1 .

!

Adhes1ve (# 350)

3. Lubricant and Adhesive

,..--.._

312:

__,,

Adhesive í,\'"2002)

'-__,/

(~

\__)

Fig.

15

r-----3011

~

'-J

-

12

-

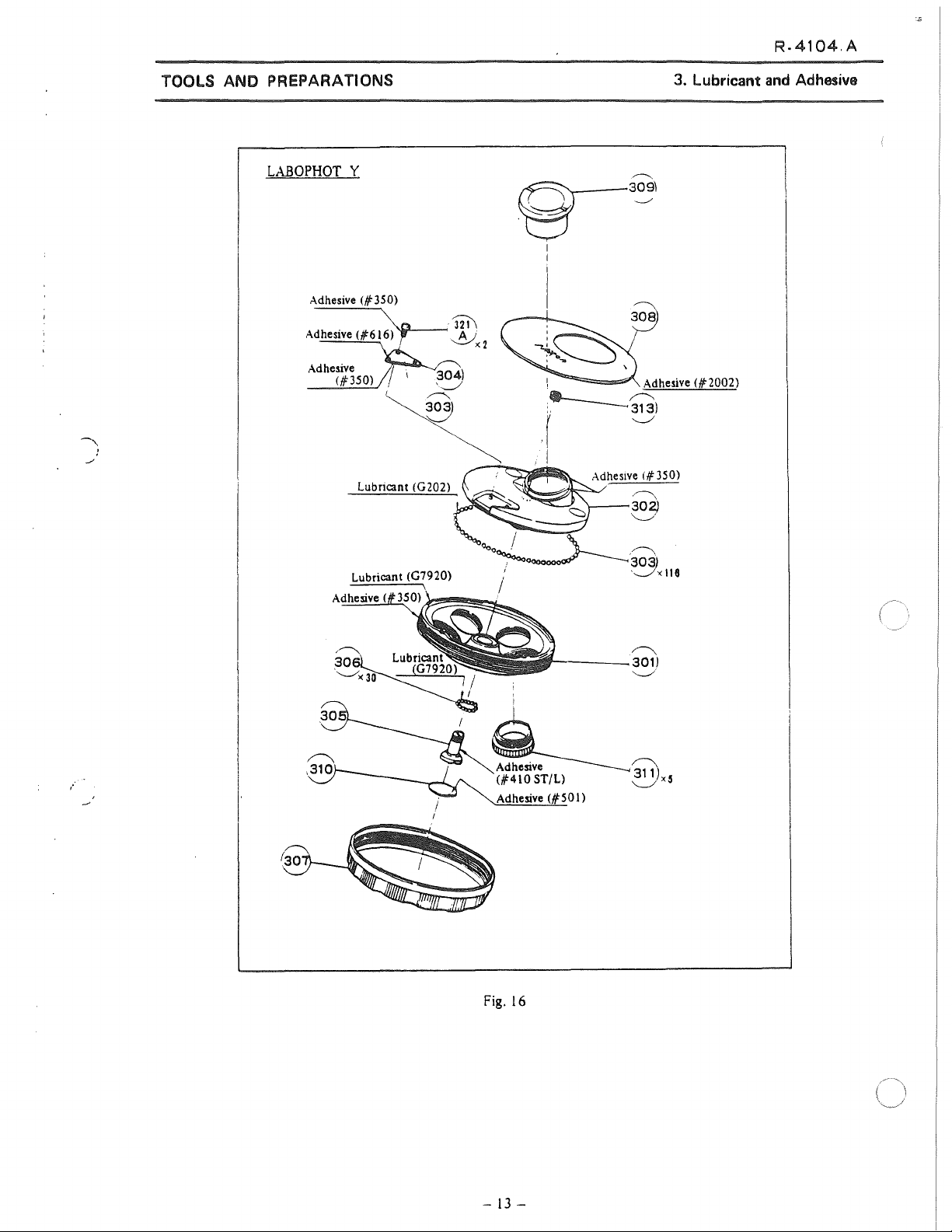

Page 16

R-4104.A

TOOLS ANO PREPARATIONS

LABOPHOT

Y

Adhesive (# 350)

Adhesive

Adhesive

(#616)\lopL-__,

(#350)

Lubricant (G202)

~

r

.J21\

A J

~"2

0--309\

''ô

1

1

......,.=~~

:._____Q)

.(

1

~

~

~

308

Adhesive (#"2002)

~

Adheslve <#350)

~

302)

~·

3. Lubricant and Adhesive

Ooo

/ '

~~·303)

1

~

'_____./X

li

8

/

11------

j

Adhesive

Fig. 16

(#501)

~

301)

'----"''

-

13

-

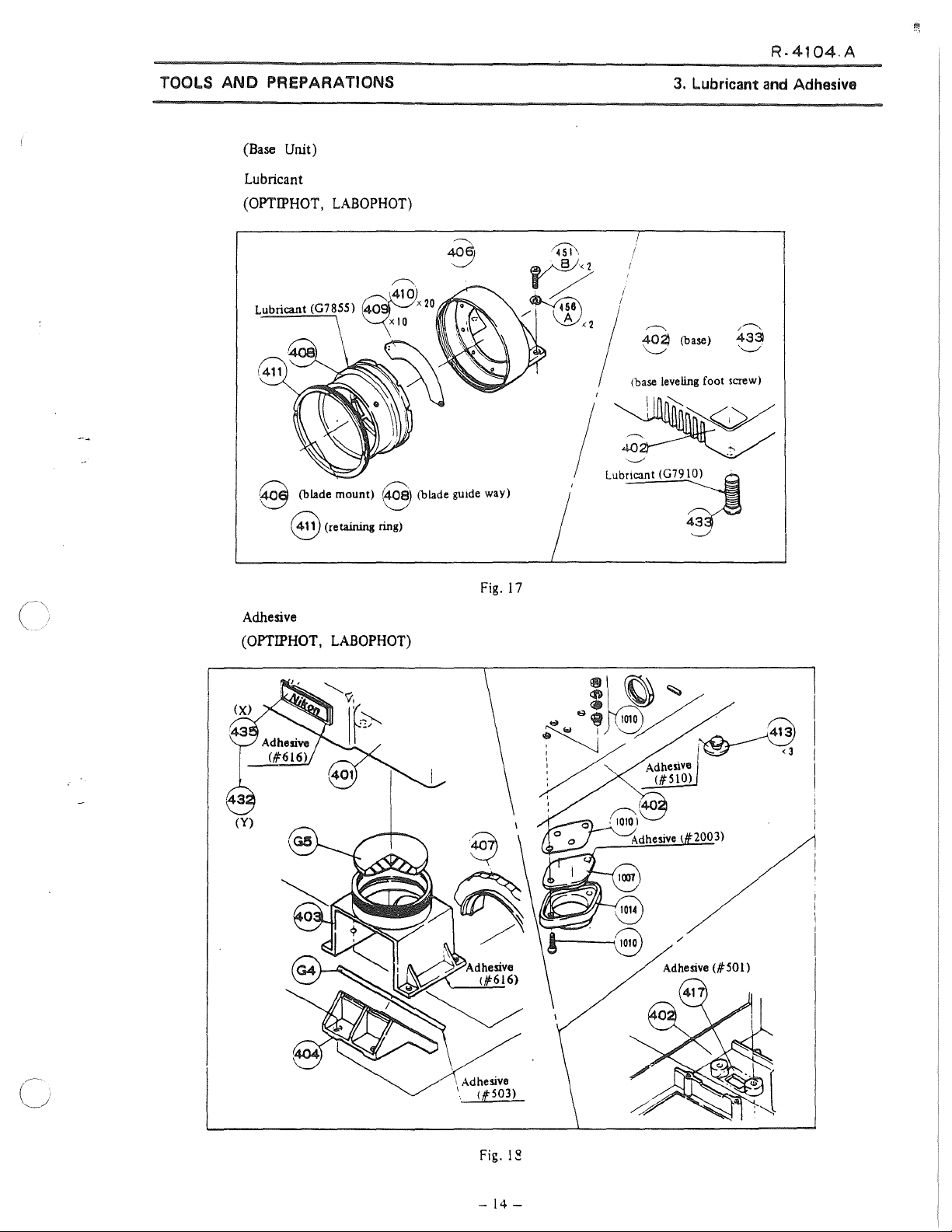

Page 17

R-4104.A

TOOLS

ANO

PREPARATIONS

(Base Unit)

Lubricant

(OPTIPHOT,

S (biade

8 (retai.ning ring)

LABOPHOT)

mount)

8 (biade gu1de way)

/

"--"'

Lub~

3.

Lubricant

r---..

~

(base)

1base

leveling foot screw)

~

~

and

Adhesive

Adhesive

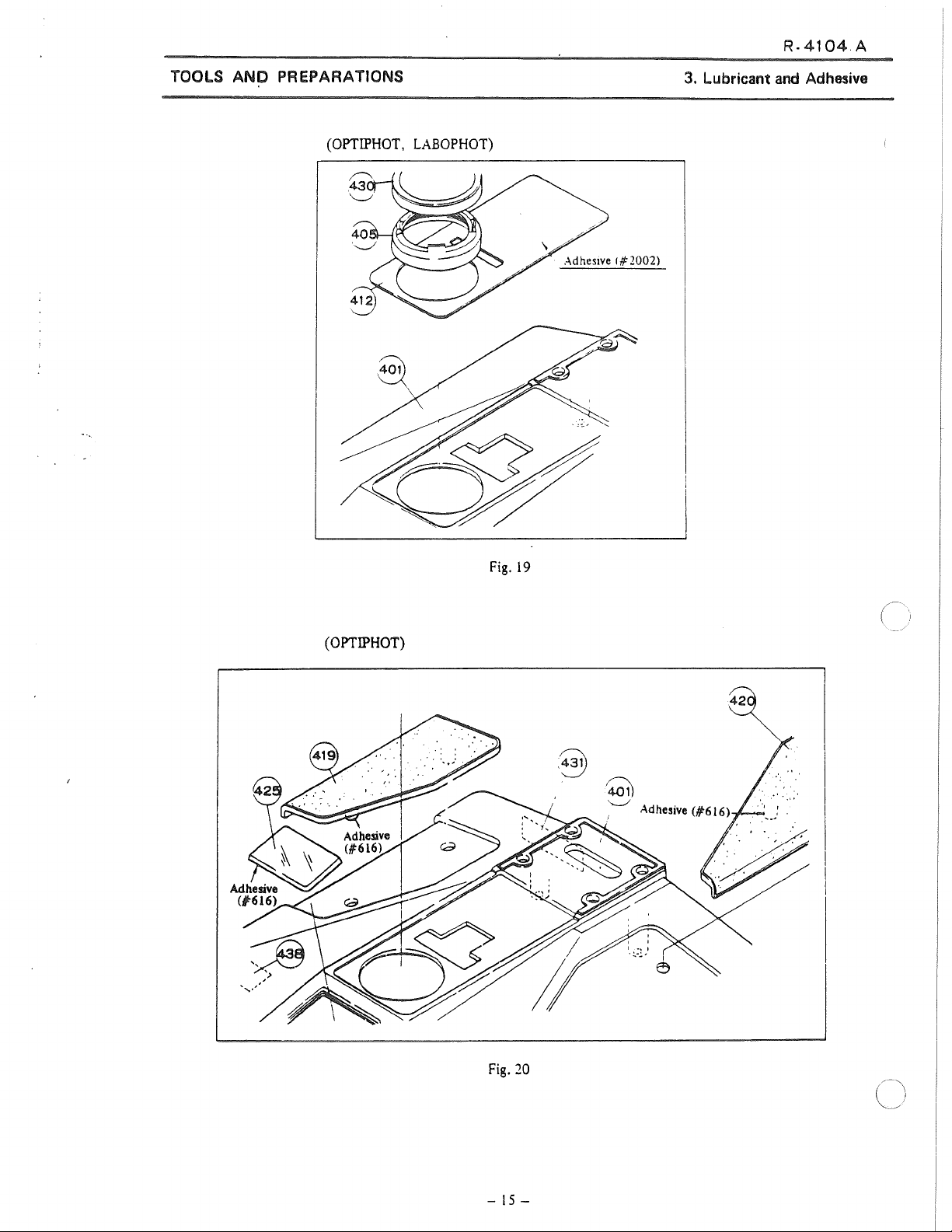

(OPTIPHOT,

LABOPHOT)

Fig.

17

2003)

/

1 Adhe:iive

1

(f503)

Fig. 1

-

14-

~

Page 18

R-4104

A

TOOLS ANO PREPARATIONS

(OPTIPHOT,

LABOPHOT)

3.

Lubricant

and

Adhesive

(OPTIPHOT)

Fig.

19

'~

'..___./

Adhesive (#"616)

'

42

Fig.

-

15

20

-

Page 19

R-41

.A

TOOLS ANO PREPARATIONS

(OPTIPHOT)

i.--

~~

UJ

~)

Adhesive 1

(#2003)

'

1

1

1

"4s1\

~\

\.__./

Fig.

3. Lubricant and Adhesive

21

e~\

(LABOPHOT)

1

I

Adhesive (/F2003)/ 1

Fig.

22

t=:~

~~

i

1 \

-16-

Page 20

TOOLS ANO PREPARATIONS

(Lamp Housing)

3.

Lubricant

and

Adhesive

Lubricant (G605 3)

OPTIPHOT

X

jfsPl

~x2

'50

Fig. 23

50

'--..-/

-

17

-

Page 21

TOOLS

ANO

PREPARATIONS

R-4104.A

4.

Others to be Repaired

4. Others

111

Absolute alcohol

• Lens tissue

to

be Repaired

-

18-

Page 22

R.4104.A

MECHANISM ANO PRINCIPLE

MECHANISM ANO PRINCIPLE

1.

Coaxial Coarse and Fine Focus Unit

1. Coaxial Coarse and Fine Focus

Unit

1)

Transmission of turning

e Tuming force

shaft (

(@)

of

to

@.@.

e ln this transmission with

stage

the

offered by spring

e Thus,

almost

virtue

the stage.

and substage,

even

though

no

slack will

of

the rotation

the

move

®·

(e[!]))

some

force

of

fine

focus

the rack

@,@,

such

which

to

backlash

be

seen

force

Fig.

24

fine

focus

knob

knob (

C@D

(®)

vertically through

@,

a reduction ratio

exerts

force

the

sliding surfaces of @

is

provided

in

the

rising

and lowering directions of

of the

gears

work.ing

or

@>

@),@).

as

from

to

rotate @ ,

for

each

in

one

is

transmitted

the

gear

@

to

is

overcome

and

@ .

gear

to

enable smooth gearing,

direction under

to

system

@ ,

by the friction

the

the

pinion

(@

the

stage,

the

wetght of

, @ ,

weight of

by

-

19

-

Page 23

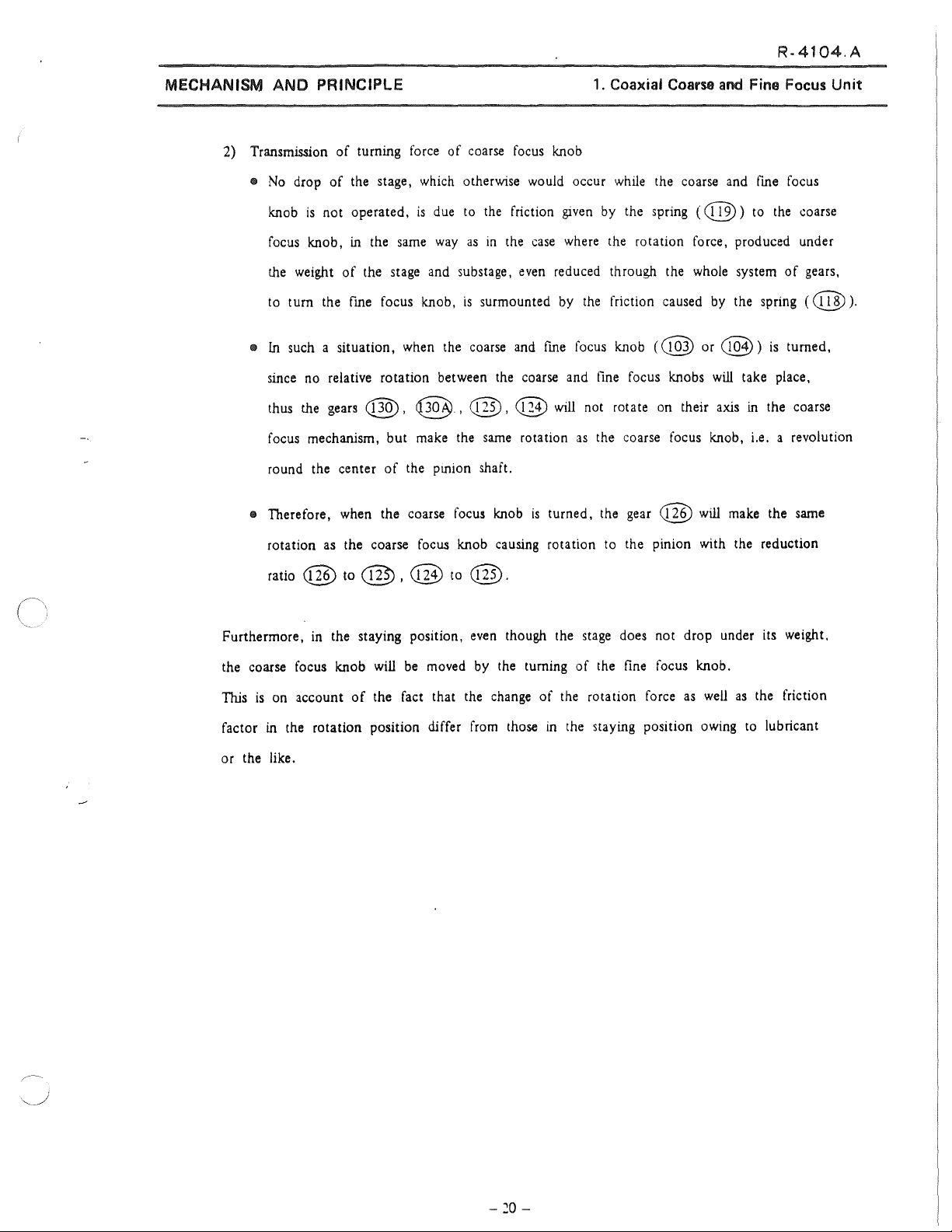

MECHANISM

ANO

PRINCIPLE

R-4104.A

1.

Coaxial Coarse and Fine Focus Unit

2) Transmission of turning

e

No

drop

of

the stage,

knob

is

not operated,

focus

knob, in the

the

weight

to tum the

• ln such a situation, when

since

thus

focus mechanism, but

round the center

• Therefore,

rotation

ratio @ to

of

the stage and substage,

fine

focus knob,

no

relative rotation between

the

gears

@.

of

when

the coarse

as

the coarse focus knob causing rotation to the pinion with the reduction

@,

force

of

coarse

which

otherwise

is

due

to

sarne

way

as

is

surmounted

the

coarse

@.

make

the pinion shaft.

@ to

@,

the

focus

@.

sarne

the

in

the

knob

focus

would

friction

the

case

even

and

fine

coarse and

@

rotation

is

knob

occur

while

the coarse

giVen

by

the spring

where

the rotation force, produced under

reduced through the

by

the

friction caused

focus knob

fine

will

not rotate

as

the coarse focus knob, i.e. a revolution

turned, the

(@

focus knobs

on

gear

@

(@)

whole

their

will

and

fine

to

the

system

by

the spring ( (@).

or

C@3)

will

axis

make

of

)

is

take place,

in the coarse

the

focus

coarse

gears,

turned,

sarne

Furthermore,

the coarse focus knob

This

is

factor

or the like.

in

the staying position,

on

account

in the rotation position differ

of

even

will

be

moved

the fact that the

from

though the

by

the tuming of

change

those

stage

does not drop under

the

fine

focus knob.

of the rotation force

in

the staying position

as

well

owing

its

as

the friction

to

lubricant

weight.

-

20

-

Page 24

DISASSEMBLY PROCEDURE

DISASSEMBLY PROCEDURE

1.

Coaxial

Coarse

R.4104.A

and

Fine Focus Unit

1. Coaxial

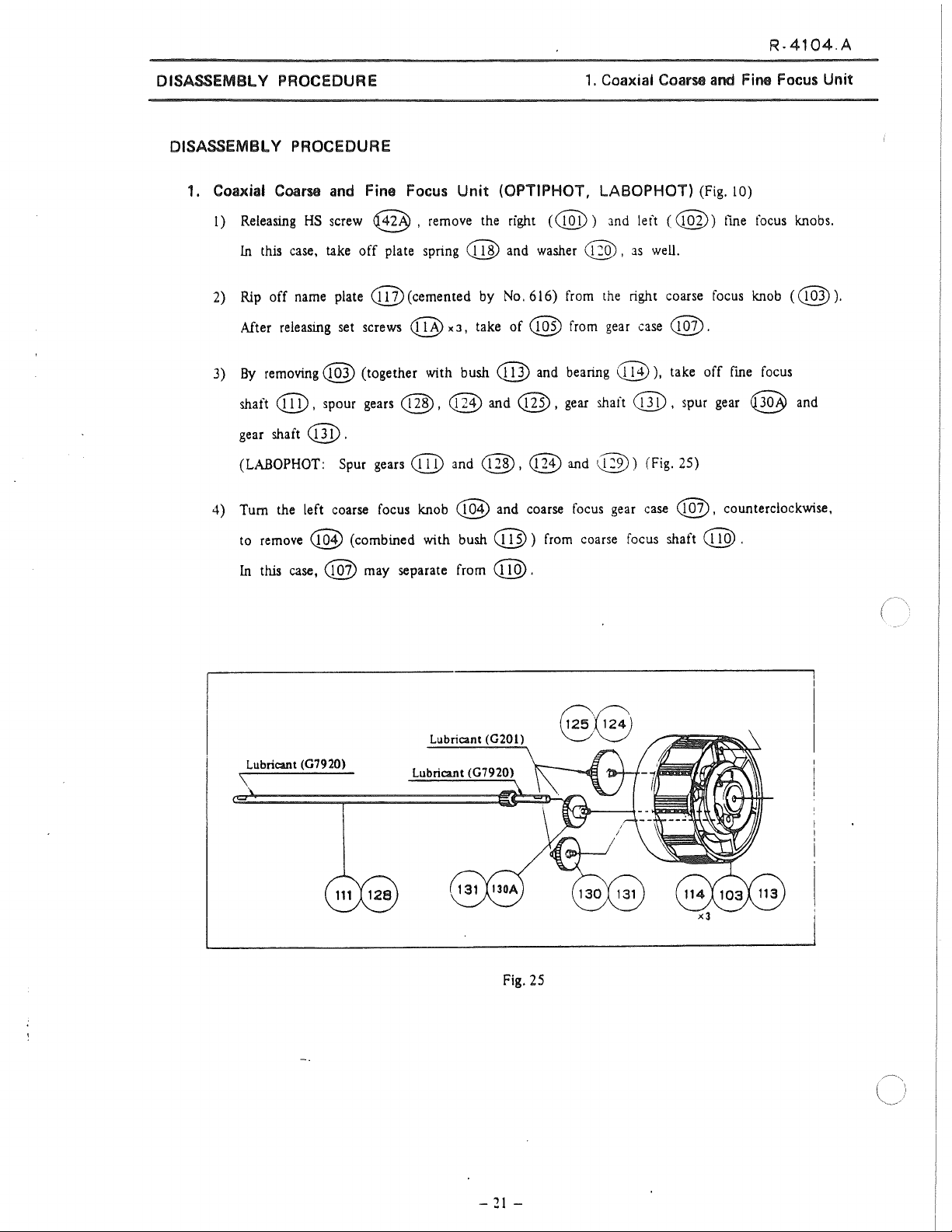

1)

Releasing

ln this case, take

2) Rip

After releasing set screws <@ x

3)

By

shaft

gear shaft

(LABOPHOT: Spur gears e@ and

4)

Tum

to remove @ (combined with

ln this case, @ may separate from e@.

Coam

off

removing@

e@

and

Fine Focus

HS

screw @ , remove the right

off

plate spring e@ and washer @ ,

name plate

(@(cemented

(together with bush @ and bearing

, spour gears @ , @ and @ , gear shaft @ , spur gear @ and

@ .

the left coarse focus knob

Unit

(OPTIPHOT, LABOPHOT) (Fig. 10)

(e@))

by

No.616)

J,

take

of

@ from gear case

and left

as

well.

from the right coarse focus knob

@),

@,

(@1)

bush@)

@ and

and coarse focus gear case

from coarse focus shaft

@)

(Fig. 25)

C@))

@.

take

off

@,

@.

fine focus knobs.

((@).

fine focus

counterc!ockwise,

Lubricant (07920)

Lubricant

(0201)

Fig. 25

-21-

Page 25

R-4104.A

DISASSEMBL Y PROCEDURE

5)

Draw

out

coarse

focus

6)

Remove

coarse

focus

shaft e@ . (Gears @ and @

bearing @

Adhesive <#350)

\ Adhesive

\

\

as

Adhesive (#

\

(#410

well

) Lubricant

616

B/M)

as

gears

e@

1. Coaxial Coami and Fine Focus Unit

will

come

in

sight.)

and

@.

(G7920)

(Fig.

26).

7)

Releasing

8)

Releasing

9) lmmersing the subassembly consisting of

alcohol, separate

Furthermore, take off thrust

@ can

(@

Note: Pinion

and

HS

bolts

PM

screw

be

taken out.

@

case

@x4,

@

coarse

are

cemented

<@ can

separate the

and

CM

focus

bearing @ .

loose

be

screw @ ,

stoppet' @ ,

wHh

e:ich

left attached on the

Fig.

arm

unit

remove

@, @,

and

oth.;r

uy

26

from

the

base.

rack

0 .

@,

[-íu.

main

@

and

@ into

then pinion @ and spur

ói ó) (Fig. 2ó).

body.

gear

-

21-

Page 26

R-4104.A

DISASSEMBL Y PROCEDURE

2. Subrtage Unit (OPTIPHOT, LABOPHOT) (Fig. 11. 12)

l)

To

remove the substage

(LABOPHOT:

First.

as

a unit, release clamp screw @ .

remove

rear

e o

ver

0 and substage body @

(j)).

2) After releasing

@.(Fig.

3) Pinion

4) After unscrewing

ª

(combined with

subassembly.

Condenser centering mount @ and dovetail @ having been attached

two

set

screws

28).

and

pinion shait @ can

bush

@)

PM

screw

(Fig.

28).

@ on

has

been removed. (Fig. 28).

'®

the

be

taken off, after condenser focus knob @

on the @ , remove the condenser carrier

bottom

of

@,

from

remove

2.

Subrtage Unit

rotler

race

pinion bearing

in

the correct

(mal e)

position,

arises. (Fig. 28).

using

the

tool,

it

is

not recommended

to

detach them,

so

far

as

no

problem

-

23-

Page 27

R-4104

A

DISASSEMBLY PROCEDURE

/~

204)

2. Substage Unit

2

38

A

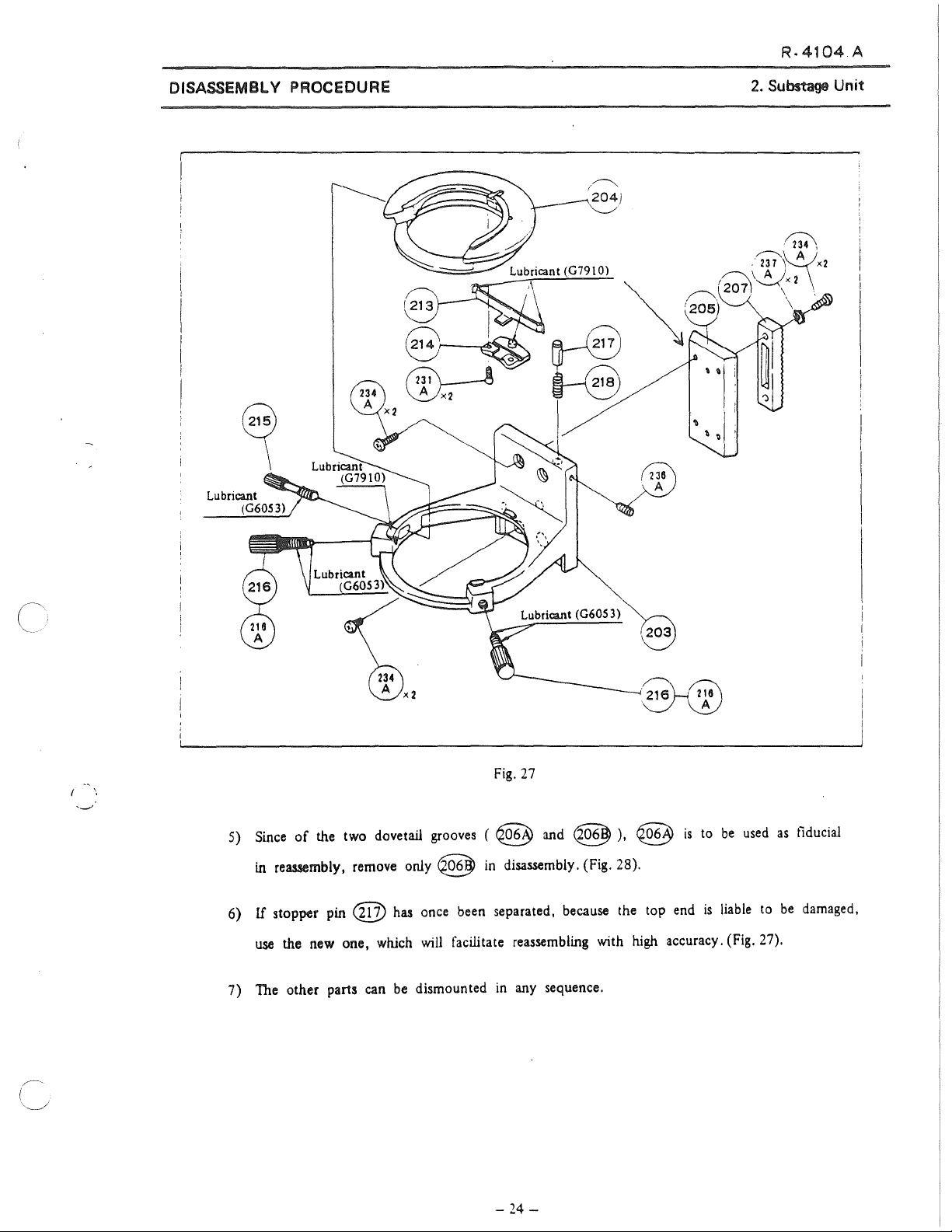

5)

Since

of

the two dovetail grooves ( @ and @

in

reassembly, remove only @

6)

If

stopper pin @

use

the new one, whlch

7) The other parts can

Lubricant (G6053)

Fig.

27

in

disassembly. (Fig. 28).

has

once been separated, because the top

will

facilitate reassembling with

be

dismounted

in

any sequence.

,203

~/~

·~

),

@

high

is

to

be

used

end

is

liable

to

accuracy. (Fig. 27).

as

be

fiducial

damaged,

-

24

-

Page 28

DISASSEMBLY PROCEDURE

Adhesive

(#"616)

i

---------

r

1----~202i

~

2 3 5 \

'~<3

~

' \

'---../

R-4104

2.

Substage Unit

A

~

\.Vx2

Fig.

1

28

-

25

-

Page 29

DISASSEMBL Y PROCEDURE

3.

Arm

Unit (OPTIPHOT, LABOPHOT)

!)

2)

3)

Releasing

Releasing

dovetail

Releasing

HS

set

HS

set

Q§j))

HS

screws

screws

screws

(Fig.

29).

@x4

@§3>

x4 (LABOPHOT:

@x4,

(LABOPHOT:

take

oif

dovetail @

@x4),

~

x4),

take

(LABOPHOT:

take off cover plate

oif

R-4104.A

3.

rear

coverQ.

Screw @ and

@.(Fig.

Arm

29).

Unit

Lubricant (G202)

Fig.

29

- 26 -

Adhesive

(#'616

Page 30

R-4104.A

DISASSEMBL Y PROCEDURE

4) After removing bottom plate @

CD

from

base

body @ . (Fig. 29).

5) Releasing screws @ and @ (LABOPHOT: @B

together with

6) Forcibly draw out roller

7) Releasing

(This@

In

this case,

reassembling,

re

tainer @

<

The

washers

screws

being cemented

<@ x

the

lefthand

remove

will

separa te.

disassembly described below should

from

@ - @ toward

race

(male) toward

J,

only

remove

to

(viewed

the

roller

main

body

from

righthand one.

CD

the user)

the base,

the

the

race

(female)

by

e@,

At

be

3.

and

base.

base.

releasing

and

(Fig.

(Fig.

@

29).

31).

'@

),

draw

x4,

take off ann

out

rack

@.

strike

it

with

a wooden hammer).

race

being

to

serve

as

fiducial in

this time, cylindrical roller @ and

attempted only

by

an

expert >

Arm

®

Unit

8) Nosepiece subassembly (only

Follow the sequence

i)

Remove

knob

ii)

Take off clamp screw

receptacle

main

ili)

Remove

to dismount clamp

nosepiece clamp

@.

body

E-ring

@

(D.

as

from

@

follows

pin

@ and spring @ .

iv)

Nosepiece clamp screw

@ and screw receptacle

@, though cemented

No.

by

unscrewed,

410 St/L, can

using

be

an

for

OPTIPHOT)

(Fig. 32 and 33):

Lubricant (G605

Adhesive

3)

(#410 ST/L)

ordinary tool.

Fig. 30

-

27

-

Page 31

DISASSEMBL Y PROCEDURE

9)

Release screws

off

the receptac!e 0 from main body. (Fig.

Cf!]>

x

J,

and by striking tube

Adhesive

(#646HB

receptade

31

).

6

R-4104.A

3.

Arm Unit

0 with a wooden hammer, take

Fig.

31

1

1

146\

~x3

h'40.

~1x3

-

28

-

Page 32

R-4104.A

DISASSEMBL Y PROCEDURE

4.

Base

Unit

(OPTIPHOT, LABOPHOT)

1)

Remove

2)

Releasing

take off

3) Releasing

4)

Remove

5)

Remove

@will

lens cap @ .

HS

screws

@ and @ (only @

PM

screws @ x

field

diaphragrn controlling

retaining

separate.

ring

@x4,

remove

for

base

@ and bottom plate

LABOPHOT).

< Field diaphragm (Fig. 36 and 37) >

2,

remove biade mount @ from bottom plate

ring

@.

@ , and then biade guide

way

4. Base Unit

@.

Beforehand,

@.

@ , biades @ and dowel

6) Take out lens

bottom plate

7) Remove retaining

@ and @

@(LABOPHOT:

@>

),

).

ring@

and spacer

@)

(LABOPHOT:

ring

@ (LABOPHOT:

G810

V.

Fig. 32

from filter receptacle

-@).

'<20 y

.<10

and then @ and @ (LABOPHOT:

@)

will

·~

/

e@

(LABOPHOT: From

separate.

-

29

-

Page 33

DISASSEMBL Y PROCEDURE

Fig. 33

R-4104.A

Base

4.

Unit

8) Take

9)

By

< Removing variable resistor

off

brightness contrai

removing the nut, variable resistor e® (LABOPHOT:

dial

e@

e§

and bush

(LABOPHOT:

@.

@)

@)

(Fig. 34) >

can

be

separated.

-30-

Fig.

34

Page 34

R-4104

A

DISASSEMBL Y PROCEDURE

< Removing mirrar @ and mirrar holder @ >

l

O)

After removing brightness indicator holder ( only for OPTIPHOT), take

@.(Fig.

35).

off

retaining ring

4. Base Unit

Fig.

_./

11)

Other

Note:

Washers

main

parts can

(@

body,

be

disassembled

-

@>

should be returned

xn,

in

any sequence.

used for adjusting slack, when attaching the base to the

to

their original positions.

-31-

35

Page 35

R-4104.A

REASSEMBL Y PROCEDURE

REASSEMBLY PROCEDURE

1.

Coaxial

1)

2)

3)

Coarse

Beforehand,

Applying

Apply

G7920

consisting

receptacle

and

clean@,

No.

616

of@

e@

to

to

@ at

and @ into pinion

to

@.

@.

4)

Clean

the thread of pinion

After drying, apply

Fine Focus Knob Unit

e@)

,

the

No.

@,

thread

the

position indicated

[n

this case,

case

350, and

of

pinion

@,

screw

@ -

shaft@,

case

make

using

in

coarse

1.

Coaxial

@,

in

@.

sure

gasoline.

focus

Coarse

@.

@

screw

it

into spur

Fig.

16,

and

Furthermore, attach pinion thrust

of smooth rotation of @

beanng

@.(Fig.

and

Fine Focus Knob Unit

usmg

tridane.

gear@.

insert

the

subassembly

and

36).

(

) Lubricant

--------'""--'-~~

5)

Insert the above subassembly into the arm. (Fig. 37).

616

Fig.

(G7920)

1

~

36

6) Inserting

screw @

arm

~ote:

e@ might

case, replace it.

by

rack

(V from undemeath

and

CM

screw

means

of

screws

be

scratched or deformed

@>.(Fig.

~

xJ.

the

arm, attach

38). After attaching,

(Fig. 37).

by

the

use

-

32

-

it

to the

of

a wrench,

bali

fi.x

race

pinion

when

by

means

case

@ to

detached,

in

of

PM

the

this

Page 36

REASSEMBL Y PROCEDURE

e~~~

'123f109 f 105 i 106)

. '--.__/

"-._/'

\.___./

1 •

; I \

1.

Coaxial

Coarse

and

Fine Focus Knob

R-4104.A

Unit

7) Attach

(this should

e@

8) lnsert the subassembly consisting of

shaft) and @ and @ (gears),

Fig.

9) Thereafter, following

fine

and @ should

Cover

washer

gears

are

10).

focus

plate @

@.

e@

and @

be

cleaned, beforehand)

to

be

oiled

as

4)-l ),

shaft @ ,

be

oiled

is

to

shown

gears

as

be

to

pinion

in

reverse

@ and

shown

cemented

Fig.

37

case

@ ,

to

e@

Fig.

36, after cleaned

e@])

(coarse

as

shown

the disassembly procedure. (After cleaned and dried,

@,

in

Fig.

24.

by

No.

by

in

@,

616.

means

focus

Fig.

and

37

e@

Apply

coarse

of

screws

and

case)

(apply

and @

G7920

focus

@x3.

dried.)

and

@ (coarse

oil

to

to

knob bearing @

e@

focus

@

as

shown

and

gears

@

plate spring e@ and

and

in

-

33

-

Page 37

REASSEMBLY PROCEDURE

2.

Substage Unit

R.4104.A

2.

Substage Unit

For reassembly,

1)

The

positions

only

2)

Rotation torque of

when

turning the pinion bearing @ .

(Measuring procedure:

After adjustment, fix the knob with

3)

If

in

have

reason,

position to

4) Check

reverse

the

specified lubricant

the knob

Disassembly

been

removed

it

will

use

for

smooth movement of the sliding parts

the

disassembly procedure, taking the cautions

to

be

oiled

the

condenser focus knob @

is

turned with pinion @ held by

Fig.

Process

(D

simultaneousty

be

necessary

the

specified positioning too!.

or

cemented should

:md

adhesive.

38)

set

(P.

24) both

for

for

finding the fiducial

screw

the

an

unavoidable

be

cleaned

is

the

@ .

dovetails

of

the

to

as

and

dried, beforehand.

be

adjusted

hand.

\1ake

below:

to

450g - 500g,

the adjustment

Tension gauge

Use

by

dovetails, without slack, unevenness or the like.

5)

Proceed to fitting of the rack

i)

Insert

set

screws

@x2

ii)

Attach the knob

üi) Attach

iv)

After releasing @ x 2 and inserting the dovetail, tum pinion bearing @ ,

lhe gearing of rack @

(utilizíng lhe eccentricity

v)

Make

slack, unevenness or the like.

rack@

sure of

to

to dovetail

no

clearance between @ and @ and smooth operation without

as

into the

@ with

is

achieved,

of

@

below:

@x

(male)@

main

body of substage.

2,

transitorily.

with

and

fix

).

@x2.

it

in

this position with @ x 2

Fig.

38

so

that

- 34 -

Page 38

REASSEMBLY PROCEOURE

R-4104

2.

Substage Unit

A

6) To attach the condenser mount follow the procedure

i) Attach spring retainer

ii) Insert plate spring @ between @ and

the arrow

ili)

Apply G79 I O

centering mount

in

Fig.

to

e@

to

condenser receptacle

Q8)

39.

the sliding surface

of

condenser

@ , and condenser receptacle

@.

iv)

Insert @ into

v)

Screw condenser clamp screw @ into @ through the opening

vi)

See

that

no

left condenser centering screws

operates smoo thly.

@.

seizure occurs between @ and @ ,

@

to

bring @

as

below (Fig. 27):

@)

with

.

Bend

the

when

to

the

screws

@ .

spnng

as

shown

Fig.

of@

manipulating right and

center, and @

2.

by

39

.

-

35

-

Page 39

REASSEMBL V PROCEDURE

3.

Arm Unit (OPTIPHOT, LABOPHOT)

R-4104

3.

Arm Unit

A

For reassembly,

l)

Clean

the

specified lubricant and adhesive.

2)

If

in

dismounted

the right and left races

3) Proceed to adjustment

i)

Fix

surfaces

ii)

Attach

attaching surfaces

using lubricant G202. (Fig. 40).

Apply lubricant G202

ili)

of

reverse

and dry the parts to

Disassembly Procedure 7

for

@x4

of

the disassembly procedure, taking the cautions

an

unavoidable reason,

to

@,

@x4

<@ , @ and cylindrical rollers @ .

be

oiled

(P.

22)

have

not been dismounted).

of

the

roiler

the

guide

rails

@ attaching

using

lubricant G202. (Fig. 40).

to both the guide

of

roller

race

to

the sliding surfaces

or

cemented

the

use

races

rail

(male)

as

lefthand

the right one

as

race@

below:

@

G),

as

below:

shown

in

Fig.

29, 30, and then apply

on

the fiducial

as

fiducial (Assuming that both

G202

Fig.

40

side

has

G202

8

been

'

'-·

Place cylindrical rollers @ and retainer @ onto the surfaces of e@ .

iv)

time, insert @ one after another

Assemble

v)

As

vi)

in

Set it with <@

vii)

cementing agent No.

~

(j) and

shown

this position with <@

at

six

@,

in

Fig. 21, pushing

x6,

350 into

points.

transitorily.

and

xJ.

inject

in

tum. (Fig. 29).

@,

adjust the torque of (j)

to

IOOg

Fig.

At

- l 20g. Fix

(Iorque mearuring)

fiducial

ooe

41

this

it

- 36 -

Page 40

R-4104

A

REASSEMBLY

4.

Base

Unit

For reassembly,

cemented (Fig.

or adhesive should

PROCEDURE

reverse

32

- 35)

be

applied.

the disassembly procedure, remembering that the parts

are

to

be

cleaned and dried, beforehand,

and

the specified lubricant

to

be

4.

oiled

Base

or

Unit

- 37 -

Page 41

ADJUSTMENT

ADJUSTMENT

1.

Torque

1)

Referring to Reassembly Procedure

washer e@ and adjusting washer e@

as

After screwing coarse focus knob @ and bush

of

Coarse Focus Knob

shown

in

Fig.

42, into coarse focus shaft

(P.

32), insert

in

sequence,

(@.

2. Smooth

wave

1.

Torque

of

R-4104.A

of

Coane Focus

the

Left

Fine Focus Knob

iº.

01121

Knob

(

__

@ into

400g -

2)

When

focus knob

Applying adhesive

to let the adhesive enter

2.

Smooth Turning of

1)

Referring to Reassembly Procedure

and insert the washer into

into

@

,

that the thrust slack

@,

SOOg,

a correct torque

e@

),

and set it with @ in such a position

make

adjustment of the torque

by

means of washers @ , @ .

is

obtained, disassemble coarse

(®

and bush e@.

No.

410

to

the thread, tlx @ and @

the

internal surface of @ .

the

Laft Fine Focus Knob

(P.

fine

focus shaft e@. Then, insert left

(beforehand, place set screw

of

the knob

is

not felt by

32), attach G7920 onto both sides

~

into

to

in

position.

Fig.

42

Be

of

washer

fme

focus knob @

careful not

@,

touching with the

li

2)

Make

sure

C@1)

and @ , and their smooth tuming.

fmger.

of

seizurc between coarse focus knobs

- 38 -

Fig.

43

Page 42

AD.JUSTMENT

3.

Smooth

!)

Referring

4.

Parallelism between the Tube Attaching and Stage Attaching Surfaces

3.

Turning of the Right Fine Focus Knob

to

Reassernbly

Procedure

(P.

32), insert right

Smooth

fine

R-4104.A

Turning of the Right Fine Focus Knob

focus

knob

C@D

into

fine

focus shaft

right

torque of

2)

Make

@

and

fine

sure

and

coarse

e@

(beforehand,

focus

knobs inwards,

30g - 40g

of

no

thrust slack felt

right

coarse

focus

knobs.

place

set screw @ into

fix

thern

in

such positions

is

obtained. (Measuring procedure:

by

touching with t

focus

knob

@.

Also, check

C@D

).

by

rneans

Fig.

38).

he

finger

and

for

smooth tuming of the

Pushing

of @ , that a

no

seizure

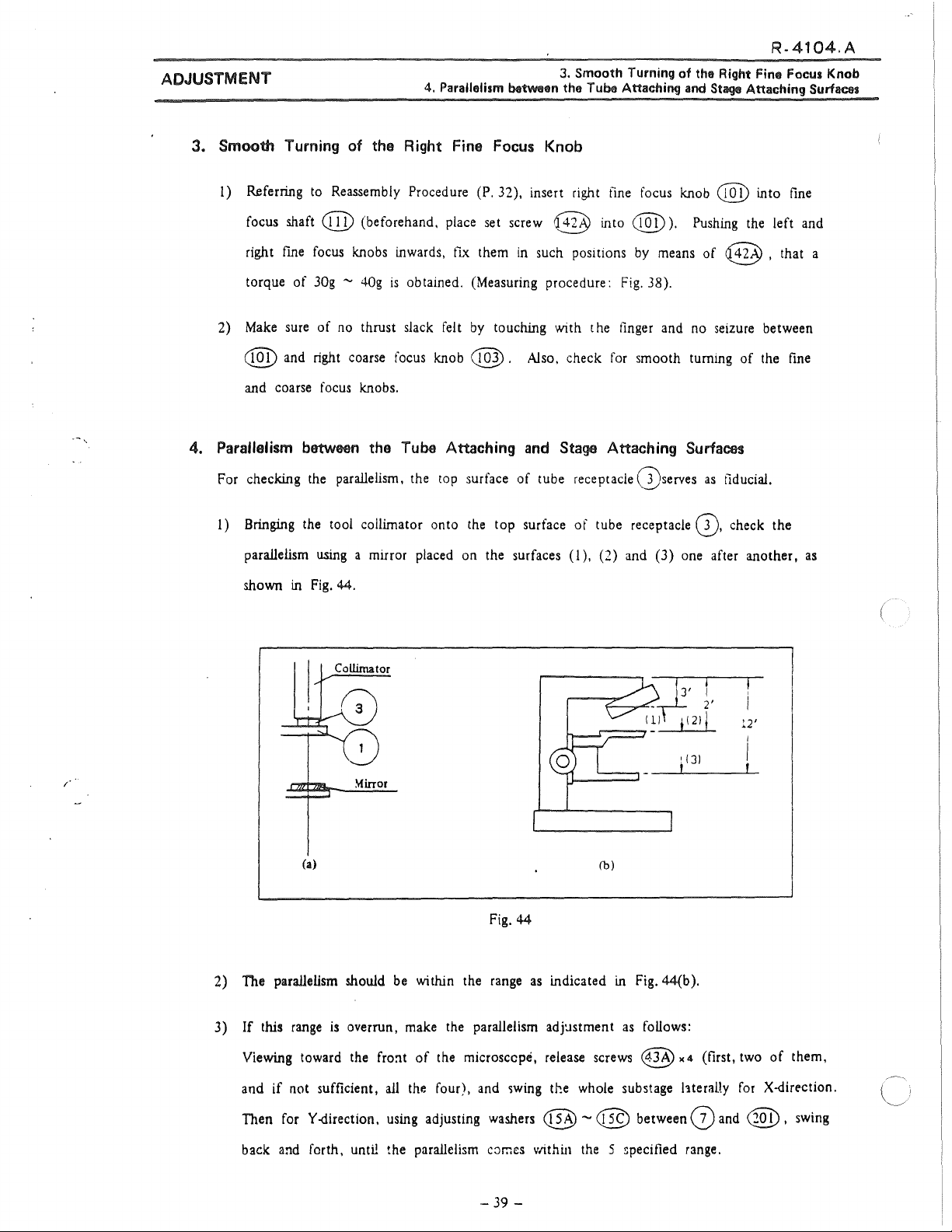

4. Parallelism between the Tube Attaching and Stage Attaching Surfaces

For checking the parallelism, the

1)

Bringing

parallelism

shown

in

the

using

Fig.

too!

44.

collimator onto

a mirror placed

top

surface of tube receptacle (})serves

the

top surface of tube receptacle 0. check the

on

the surfaces

(!

),

(2)

and

as

fiducial.

(3) one after another,

the

between

left

and

fine

as

12'

/

(a)

2) The parallelism should

3)

lf

this

range

Viewing toward

and if not sufficient,

Then

for

Y-direction.

back

and

forth, until the parallelism

~irror

is

overrun,

the

be

fro=it

ali

using

Fig.

44

within the

make

of

the microsccpé, release screws

the

four),

adjusting

range

as

indicated

the

parallelism adjcistment

and

~wing

the whole substage

was.hers

c::imes

@ - @ between (j)

vtithin

(b)

in

Fig.

as

foUows:

<@K4

the

5 >pecified range.

44(b).

l1teraHy

(flrst,

and

two

of

for

X-direction.

@ ,

them,

swing

- 39 -

Page 43

R-4104A

ADJUSTMENT

5. Centering

To

perform the centering,

5-1.

Using

1)

Place

Fig.

the part @ onto the stage attaching mrface

of the substage. (Fig.

2)

Push

above.

proves correct centering.

3)

If

upper screws

so

5. Centering

the

Tube

Attaching and Stage Attaching Parts

use

the three

the tube receptacle substage centering tool 125142.

the part ®

2 (P. 3) on the tube receptacle 0·

the part

If

the former enters

not, make adjustment,

that the

of

the tool,

45)

@)

against the part @ from

the

using

of

~

•4

behind the arm,

part@

enters the part

as

latter,

the

to

shown

two

@.

ois,

it

in

Set

the

as

Tube

foilows:

Attaching and Stage Attaching Parts

Thereafter, make parallelism adjustment,

using

the lower two screws.

(

(

4) Smooth insertion

range

as

shown

5-2.

Using

substage rightangle/centering too! 125145 and 125143,

between the objective attaching and stage attaching surfaces.

1) Set tool 125145 onto the objective attach·

ing

surface to

the stage attaching surface.

Raise

2)

3)

the substage to

of

125145

and

Y directions).

If

it

is

found over l/IOOmm, make the

sarne adjustment

(P.

39), until it comes within the specified

of

in

be

checked.

is

smaller than

as

the part @ into the part @ ensures the parailelism within the

Fig. 44(b ).

Place

125143 on

see

that the clearance

1/1

OOmm

(in X

mentioned above

in

4.3)

to

Fig.

45

check the parallelism

range.

-40-

Fig.

46

Page 44

ADJUSTMENT

5-3.

Using positioning tool 125141,

As

1)

of

to

check the position

shown

in

Fig. 1 (P. 3), bring the

the tool onto the condenser attaching

part@,

5. Cantllring

6. Cantering

of

the

Tube

Attmching and Stago Attaching

of

OptiCllll

substage and condenser mount

System in

the

R-4104.A

Paru

Microscope Base

surface, and the

attaching surface.

2) Raise the condenser attaching surface to

make sure that the part

part

@.

3)

If

it

does not, make adjustment by

means

of

6. Cantering

6-l.

Using tools 125146 (for OPTIPHOT)

1) Take

125146. (Fig. 48).

2)

Set the above cited collimators on the specified

positions on the

of

off

the lamp housing, and set the too!

part@

@ enters the

@

x4.

Optical System

base.

onto the stage

in

the Microscope Base

Fig. 47

,.·

Elimina te any slack, if takes place, by means of

washers.

3) Bringing the part

without the lens, make sure

positions

collima

4)

If

@

5)

P1ace

Viewing the position

to the center by means

of

tor. (Fig. 49 ).

the positions are

x:i,

provided for attaching mirror mount

the part

@CFig.

the filament

not

@onto

of

6) onto the position

of

the correct

(G))

and mirrar

found coincided, make adjustment by means

the positfon with the lens.

the field diaphragm through the eyepiece, bring the diaphragm

of

screws @ x 2 provided for attaching biade mount

125146

(@),

viewing through the eyepiece

@.(Fig.

32).

Fig.

of

48

screws

of

@.

~.

;

-41

-

Page 45

R.

4104.A

"

ADJUSTMENT

6)

If

or

ln

7)

Check

the

6. Centering

the

field

díaphragm does not come to the center, incorrect positioning

filament

this

field

is

conceivable.

case, correct their positions, and proceed to 3)

the minimum

diaphragm.

(less

than lmm4') and maximum (more than 35.9mm4') díameters of

J 25146

~)'~

~

'-;/

of

Optical System in

and

6)

again.

~

4221

.___/

125146

the

Microscope Base

of

the mirrar

11

@,

(P.

_1j

Fig.

@,

and set

41

).

49

the

tool 125147. (Fig. 49).

(

6-2.

Using

tools 125147 (for LABOPHOT)

!)

Take

off

@.

@,

2)

Refer

to

2)

- 7)

of

6-1.

0

\ '

~/

Fig.

-42

125147

50

-

Page 46

.A

ADJUSTMENT

7. Tube Length

1)

Attach the part @ of tool 125148 (Fig. 8) (P.

®

2)

Attach the trinocular eyepiece tube to the part

Using

3)

In

lf

until the

to

the nosepiece, and the part @ to the

the

20X

eyepiece,

this case, the colors should

not, rotate cover

sarne

colors

see

the interference colors

be

the

ring

e@])

(beforehand, dissolve

are

attained. Cement @ agam,

sarne

as

5)

to

the

tube attaching part, the part

stage

a ttaching surface, respectively.

@.

in

the

grating of

those

viewed

No.

through the vertical tube.

350

by

alcohol)

using

No.350.

7. Tube Length

the

part

of

the tube,

@.

-43

-

Page 47

.4

04.A

ADJUSTMENT

8.

Adjustment

!)

Tum

2) Fully tum (

of

Brightness Control Circuit (Fig.

off

the power switch 5

~

) the shait of variable resistor

(

~

1

).

8.

Adjustment

51,

52)

VR

in

3

of Brightness Control Circuit

the

DC

ammeter M

(

1

@),

counterclockwise.

3) Fully tum (

~

) the shait of variable resistor

VR

(e@

1

)

in

the printed circuit

counterclockwise.

4)

Change

5)

Set the power voltage to

'

..

6) Connect the thermostat·type voltmeter (

the terminal

over the power change-over switch Sl (

of

the lamp.

AC 1 OOV

± 1

%,

over

5

Hz.

l

.5

~

class)

)

to

AC 1 OOV.

for

measuring the

lamp

voltage

to

7)

Plug

the power source cord into the socket.

lamp

After connecting the halogen

of l 2V,

SOW

with the lamp socket.

(

8) Tum on the power switch S

Do

not tum the power switch

ON

(at a maxirnum voltage

ln

this position the brightest illumination will

9) Slowly

tum

thP.

shaft of

and then the illumination

Stop this tuming at the position where the lamp filament looks dim.

Do

not

tum

the shaft beyond this limit, because the lamp

10) Tum the

variable

dial

resistor

of

power switch S

(

VR

@ ) becomes lower, until the thermostat-type voltmeter

2

indicates 9.0V.

(

~

1

dial

of

variable resistor

variabie

oi

the

1

).

beyond the position where the swttch

VR

(

~

).

)

in

the printed circuit, clockwise,

will

glow

in

which the voltage

res1stor

lamp

(

~)

will

1

be

obtained .

...--...

VR

(

~

1

be

slowly darkened.

in

the direction

is

just turned

suddenly.

of

11) Tum the shaft

so

that the

DC

of

variable resistor

ammeter M

(@

1

(

VR

~)

3

) indicates 9

-44

-

for sensitivity adjustment, clockwise,

.OV.

Page 48

AOJUSTMENT

12)

Tum the

M

1

In

13)

If

dia!

of power switch S

@ ) minimum.

(

this case, the voltage

the

DC

ammeter M

of

variable resistor

C@)

1

(@)

1

indicates a

8. Adjustment

to

make

the indication

VR

( @ )

2

value

not higher than 1.8, tum

will

of

Brightness Contrai Circuit

of

DC

ammeter

be

maximum.

the

shaft of

variable resistor

a higher

value

value

within the

14) Fully tum the

the lamp and

over 11.5.

VR

(@

)

in

the printed circuit, counterclockwise,

than 2.5, slowly tum

range

1.8

- 2.5V.

dia!

of

power switch S

swing

of

the needle in

and

if

the

shaft clockwise, until the meter indicates a

1

the

(e)

DC

to

make

ammeter M

sure that the brightness

(

@ ) changes smoothly

1

it

indicates

of

- 45 -

Page 49

UIMB

111MB2(

(

125

250V-

·,

l>

E

e

~

s:

m

z

V-

4A)

2Al

~

.&:.

°'

1

,... L

J\

1

\

l

{

1 ;,<

o

'"O

-1

='3

:e

o

-1

1004

)

CIO

l>

Q.

e

~

3

<111

::J

....

o

-

CD

:=!

.

<C

::T

....

:::s

<111

~

n

o

e:.~

IOOl

111MB

(

~

)

_"'

( ª:f)

(-{(~')(<

~~t(llrown)

(

1002)

1

-.

Whuc

\

1.

(

·n

'-

N ,

F 1 Brown

Grccn

J)

11~--y+.

"Jl

ciQº

Vo

( 1018)

(i~)

(IA)

MB2(0

l5~J

...

)(~)

('"') / -

IOOG

/ 8

111MB (

Jll

MB2!2" / 2<0VJ

I / / - \

s

1

fl

D

I\

1

'

C A

. s

Whnc

IOOV

l20V

2

or

220V

tlllack)

\

\

or

\_

_____

240V

(Wlutc)

llluc

4V

70mA

(

1012

\ _

r Y'\: D

(Whllc)

Ul20

(

---

100/i20V)

~oo0 _ ~OKl

)

~---------

~

e;.:)-

0o·0

\

Rcd 1 IGrccnl l 1

1

A M, -

(~

_.;;,

nluc

•"

/·--

'~)

(•~20)

P11n1cJ l.JíLUll l>u.uú \ ---

--

----

(·~~)

(·~9)--

(

·~·)

F)

---

\

l:Uuc

liluc

(um\

.

8)

(•~_-)

(~~

(

wm)

( 1014)

lµ

l_

. -

----~--

(1100)

- -

-\------

(1~6)

~

(

'ºt1)

-

I

íay

--i

~

1~

o

.$:>.

- .

Q

..

o

....

=·

l

l>

Page 50

ADJUSTMENT

112MB ( 100V) LABOPHOT Y

~

A1

'-..__/

'~

'

1013

1

','---/

QI

\'-...__,,/

.~

~(

r~,

~}

1002

)

\

\.~

'-..__/

F1

BrownlS1 Brown

Cf/!

D

l20V i

White

lOOV

~

I,~

T1

9V

\ i

,~

/

'------

'

C A

ov

Black

Black

~

112M81 C120Yl

3.3A

Red

Red

8.

Adjustment

'~

1005

,1

'----._/

D1

- t

of Brightness

'~

·~·

~)

Red

/

~

Contrai

®

; Brown

®

Circuit

~

,..~

_,

CV

8~6

\..

112MB2

\ 1

\ \ 1

\ 1

\ J 1 White J

W1\ i '

(220 /

24-0Y

IOIMI

White

2

,

L_

>

~1

\ 1

\ \

__

----

Black

!'·

0)

C!)

8

®

t

3.3A

Red

i

1

®/

(

--

--

_____

_/

1015

8

Brown

/ C A

L_

______________

Black

- 47 -

---·

,~/

\JU;

,

1

1

__

_/

Brown

®

Fig.

52

Page 51

R-4108.A

TOOLS ANO PREPARATIONS

TOOLS ANO PREPARATIONS

1. Tools for General

Use

Item

4 + screwdriver

- screwdriver set

6

set

Tweezers (Stainless steel)

Blower

Handlap

Hexagonal spanner

+ Screwdriver with

wood handle

Plastic hammer

1. Toais for General

Used

Screwing

1

Oeaning

Containing absolute alcohol.

Hexagonal socket head bolts (

Set screws

3 and 2.6mm screws ( conical

potnt)

Giving sharp knock

in

general

"

(3, 4mm)

for

3,

4,

5,

pomt and

Use

6mm),

oval

2. Exclusive Toais

2. Exclusive Tools

Item Tool No.

l

Smm

grating micrometer

Microscopes stand with

IOX

40X

objectives

Kellner eyepiece

Tension

Box screwdriver

Torque adjusting too!

• Torque adjusting tool

gage

Used

for

128004 Checking perpendicularity, straightness

of

movement

Adjustment

in

general

128006

Measuring torque

121060

121061

Hexagonal nuts

Round nuts (

(4mm)@

15) \ 16)

(Fig. 1)

Fig.

1

Page 52

R-4108.A

TOOLS ANO PREPARATIONS

3. Lubricant

1

4. Adhesive

Item

G6053

G7910

G7866

Item

#'410

N/L

Stage

base

Pinion

bearing

pinion

@.

@ .

Wave

Spiral spring @

Stage

upper plate

@,

Pinion

Y pinion @ and Y axle (screw).

plate(

~

Wave

washer

cover@

for

üsed

2)

and clamp

and

was.her

@

Used

Q,

stopper @

screw

@inion

17

and

and

Delrin

for

and pinion bearing @,

3. Lubricant 4. Adhesive 5. Others

( 42).

@.

Y

Delrin

washer

was.her

and

@ .

screw

5. Others

• Absolute alcohol (ethanol or methanol)

•

Lens

tissue

Page 53

DISASSEMBLING PROCEDURE

DISASSEMBLING PAOCEOURE

1)

2)

3)

Detach the

Releasing

Removing

the

slide

holder assembly

the

screws

the

screws

spiral spring @

@x

@separate

from

the holder

2

remove

from

the

stage

the

holder metal @

the

slide

glass

metal

@. (Fig. 2)

releasing

the

flxmg

screws

from

the

retainer @ together with

39

holder

x

2.

(E).

the

washer

R-4108.A

@

and

4)

5)

6)

7)

8)

9)

10)

11)

Releasing

Removing

Remove

Remove

Remove

Remove

Remove

Remove

Fig.

2

the screws @

the

screws@><2

the nut @

the X knob @.

the

wave

washer @. the

the round nuts

the

wave

washer@

the Y pinion @ and Y knob @ assembly.

..

2.

of

the

X (right

@@

remove

of

the

of

and

the

the

pinion

and

Delrin

the

Delrin

rack@

cover(V

left)

washer@

Y (to

and

washer

knob

fro) knob

(Fig. 4).

separate

@.

and

the tlat washer

@.

the

@.

handle assembly

@.

from

the

stage.

-4-

Page 54

R-4108.A

DISASSEMBLING

12) Remove the beirin washer @ .

13) Remove the X

PROCEDURE

pinion@@

together with the Delrin

washer@

. (Fig. 3)

14)

Releasing the

(Fig.

4)

15) Releasing the screws

At

the sarne time the X block

also separated.

16) Remove the X

17) Separa te the guide block either @ or

plate

0 the

screws@x2,

@x4

rack@

rollers@,

separate the vernier scale

separate the X guide

(D.

the

from the X

the

retainers(Z)

block(D.

Fig. 3

seat@

block@

rollers@

@.

the

retainers(V

from the stage upper pia te

and the guide rails @ becomes free. (Fig. 5)

from the stage base

from the Y guide blocks @ ,

and the guide rails

G).

Then the stage base

plate(3).

@@

@.

are

-5-

Page 55

DISASSEMBLING PROCEDURE

Fig.

R-4108.A

4

Lubricant (G60S 3)

Fig.

-6-

5

Page 56

DISASSEMBLING PROCEDURE

R-4108.A

Fig.

-7-

6

Page 57

REASSEMBLING PROCEDURE

REASSEMBLING PROCEDURE

R-4108.A

< Reassembling

1)

Put

@ inserting its inner

2) Insert the outer

3) Keeping the spiral spring, the inner end

the

Slide Holder >

the axle supporter @ on the slide holder metal @ .

and

into the

and

of the spiral spring @ through the

C A)

pin

hole of the metal @.

Fig.

7

in

the

pin

hoie, tum the washer @

Place

pin

hole of the

the spiral

(

8)

spring

washer

in

@

on

@.

the

arrow direction

the

metal

(A) and to

Then, place the slide

into the pin hole

4)

Fix

the above slide

be

positioned

as

shown

glass

retainer @

of

the retainer @

glass

retainer assembly

by

(B)

over

and

in

Fig.

7.

the washer @ inserting the spiral spring outer end

fasten the screw

Fig.

8

on

the holder @. The latter

@.

(Fig. 8)

is

to

be

attached

to

the stage.

-8-

Page 58

REASSEMLBING PROCEDURE

R-4108.A

< Reassembling the Handle > (Fig.

J) 1nsert the X pinion with the axle

pinion bearing

Placing the washer @

Lubrica.~

2)

Fit the assembly

washer@.

3) Put the Delrin washer @ x

in following order: @ -+ @

4)

Screw on the

bearing. The turning torque

5) Put the tlat washer

the following order: @ -+ @ - @.

6) Screw on the X

7) Put the

@ .

in

@CD]) with the

of

the Y pinion @ and the Y knob @ to the bearing @ inserting the

round

nut

@ and the lock nut @ to the bearing @ to hold the Y knob

@,

knob

@ to the axle (@.

washer@

and screw on the

between.

oi!

1,

the

of

the Y knob

the wave washer @ and the Delrin washer @

9)

(§>@

G7910 and @ wtth the oil G7920.

wave

...,.

@ .

into the assembly

washer @ and the tlat washer @ x 1 on the bearing @

is

to

be

adjusted by means

nut

@ to the axle

of

the pinion

@.

of

these nuts.

cover(V

on

the axle

and the

on

e@

the

in

The tuming

torque

of

the X·knob

is

to

be

adjusted by means

of

the

nut

@.

r;~·.

Fig. 9

-9-

Page 59

REASSEMBLING PROCEDURE

R-4108.A

< Reassembling

1)

Place the stage upper

whichever that has been left fixed on (j) makes the basis

Place the rails @

on the groove

2)

P1ace

rollers and retainer

oil.

Place the guide block @

guide block

3)

Make

plate(D

If

any slack

that has been just reassembled by the procedure 2).

me

X

the stage

and Y Movement

pia

te

Q upside down tilting on a table. The guide block @ ( or @ )

x2

-+

the

rollers@x4

of

the guide block @ .

baseplate@

@

on (D facing its rail groove to the

x2

-@x4

e@)

-(})x

on

CD

> (Fig.

@ to the upper plate Q by screwing the screws @ x

sure that no slack

on the base plate

is

found, release slightly the

in

the X direction

{]).

screws@

s.

6)

.

of

the reassembling.

.....

the

retainer(Dx

1 on the other rail groove

facing its rail groove to the rail groove

is

found at the both end of the moving range

xJ

1 lubricating with lubricant G202

rail

groove

of

@ . Put the rails,

ofG)

applying G202

J.

to adjust the guide block @ (or

of(D.

Fix the

of

the upper

@)

4)

P1ace

the whole stage assembly tilting on the work table

upperside.

@x2

Put

5) Apply

one rail groove

Put@x

6) Put @

Then,

7) Fix the vemier scale @ and its

8) Fix the handle assembly to the guide block @ or @ and adjust the meshing

the X rack

-•{V•4

G202

oi!

ofÜ

4 -(V. 1 on the other rail groove

x2

on 8 rail groove applying G202 oil and place the latter to

fix@to@,@

@ releasing the screws

-(2),.

to

the both rail grooves

faces to the groove

1 on the above groove applying G202 oi!.

screwing the

seat@

@x

ofG)

on which put @

of(D.

of@.

screws@x4.

to the stage

2 slightly.

soas

the X rail groove

base(D

x4,

then place 0 on

face

by the

screws@

of(D

the groove

is

on the

G)so

ofO.

x2.

of

the pinion and

as

1

J

-10-

Page 60

REASSEMBLING PROCEDURE

9)

Pl.ace

10)

the Y rack @

ing

the

screws

@x

Attach

the slide holder assembly to the stage.

on

the stage base (D and adjust the meshrng with the handle assembly releas-

2 .

R-4108.A

-

ll

-

Page 61

REPAIR ANO AOJUSTMENT

1. Failure of the Slide Glass Retainer 2. Slack

3. Wobbling

of

the

Slide Glass Retainer and

of

the

Slide Glass Carrier

the

Slide Glass Carrier

R-4108.A

'··

REPAIR

1.

ANO

Failure

Cause: (1)

AOJUSTMENT

of

the

Slide Glass Retainer

The

yielded

(2) Looseness of the

or

disengaged

small

t1at

sp1ral

head

spring @.

screw@.

< Repair and Adjustment >

(!)

Exchange

Procedure j

,,

i)

Disassemble the retamer assembly following the procedure

ü)

If

it

ili)

Check the function of repaired retainer.

the

the spring

correctly

yielded spiral spring @

is

yielded replace

foilowing

the reassembling proced.ure (P.

it

with a spare, and if

or

hook the disengaged spring

2),

the

spring

7).

to

the

pin

hole.

3)

(P.

5).

is

disengaged, reposition

(2)

If

the small ílat

function.

2.

Slack

of

the

Slide

Cause: Looseness

< Repair

3. Wobbling

Wobbling in X direction: Refer

Wobbling

and

Fasten

of

in

Y direction:

Adjustment >

firm

the

the

Slide Glass Retainer and

Gim

of

screws

head

screw

@

Carrier

the

screws

@

@ .

Make

to

the

following chapter 4.

Refer

to the following chapter

is

loosened fasten

sure

that

the

no

slack

Slide

5.

is

Gim

it

firm

found.

Carrier.

and check the retainer

·~)

-

12

-

Page 62

R-4108.A

REPAIR ANO AOJUSTMENT

4.

Wobbling in X (right

Cause:

(!)

Slack, sticking, squeezing in the X

a) Inferior meshing

b) Dent on the X guide rails @ , @ , the

and

(j).

e) Dust, soil, scratch on teeth

(2) Looseness

< .Repair

Procedure

and

(!)-a)

Adjustment >

If

the rack @ and pinion @ rneshing

and

pirúon.

4. Wobbling in X {right

left) Movement

gu1de

rail assembly.

of

the rack @ and the pinion

of

the rack @

of

the screws @ or inferior adjustment

is

and

left) Movement

@.

rollers@

or

inferior adjust the position

or deformed retainers

the pinion

of

@.

the X guide

block@.

of

the rack

i) Detach the slide holder assembly from the stage.

ü) Releasing the

bloclcs @ , @ .

Then,

rails

@ , @ will be rnade free simultaneously.

üi) The rack

iv) The pinion @ position

v)

Follow

vi) Check

screws@x4

the X movement

block(D,

@ position

the

reassembling procedure.

the

rack

and

pinion rneshing and the wobbling in the X rnovement.

separate the X guide

the

rollers@,

is

to be adjusted slightly releasing the screws

is

to

be adjusted slightly releasing the

block@from

the

retainers(Z)

the Y guide

and the guide

@x

screws@

2 .

•

2.

-

13

-

Page 63

R-4108.A

REPAIR

ANO

ADJUSTMENT

(1

)-b)

Procadure

i)

ii)

ili) Follow the reassembling procedure.

iv)

(i)-c)

If

a~y

dent

is

found on the

(})

is

deformed, replace them with spares.

Foilow the procedure i),

Replace

Check wobbling

Dust

brush

lf they

dented or deformed parts with spares.

in

the X movement.

or

soil

on teeth

or

cleaned by gasoline.

are

ínjured, replace them with spares.

of

the rack @

guide

ii)

of

4.

rails

@ , @ ,

(1)-a).

and

Wobbling in X (right

the

rollers@

pinion

e@

are

to

be

and

left) Movement

or if the retainer

removed

by

a

Procedure

í)

ii)

iii)

iv)

v)

vi)

vii)

viii)

Follow the procedure

Remove

Remove

the rack @ releasing the

the handle assembly releasing

i)

of

( 1

)-a).

®·

Follow

the

procedure

Follow the disassembling procedure

Remove

spares.

Follow the reassembling procedure.

Check wobbling in the X movement.

dust and

soil

ii)

by

of

the

a brush

above

or

screws

the

( 1

6)-13)

clean

@ x

screws

)-a).

by

2.

c@x

(P.

4).

gasoline. Replace injured parts with

2

of

the pinion cover

-

14-

Page 64

REPAIR ANO ADJUSTMENT

4.

Wobbling in X (right

5.

Wobbling in Y (to and fro)

R-4108.A

and

left)

Movement

Mov11m11nt

5.

Wobbling

(2) Loosened screws @

readjusted.

Procedure /

Slightly releasing the screws

X movement.

in

Y (to

and

Cause: (

l)

Slack, sticking, squeezing

a)

Inferior meshing

b)

Dent

G).

e) Dust,

are

to

be

tightened

@x

2 adjust the G position and check wobbling

fro) Movement

in

the Y guide

of

the rack @ and the pinion @ .

on the Y guide rails @ , the

soil

or scratch on teeth

of

the rack @ or the pinion @.

firm

and inferior position of

rai!

assembly.

rollers@or

deformed retainers

(D

is

to

be

in

the

< Rapar

(1

Procedure

(2) Looseness