Nieco 1352, 1355, 1335 Service Manual

AUTOMATIC

FOODSERVICE

EQUIPMENT

AUTOMATIC ELECTRIC BROILER

MODEL 1352/1355, 1332/1335 ELECTRIC

OWNER’S MANUAL

IMPORTANT: RETAIN THIS MANUAL IN A SAFE PLACE FOR FUTURE REFERENCE.

Broiler area must be kept free of combustible materials, and the flow of combustion and ventilation air must not

be obstructed. Operating personnel must not perform any maintenance or repair functions. Contact your Nieco

Authorized Dealer.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

2

TABLE OF CONTENTS

A. Machine Installation.....................................................................................................................3

Pre-Installation

Mounting

Hood Requirements

Clearance

Electrical Connection

Pre-Operation Check

B. Operation......................................................................................................................................4

Controls and Indicators

Broil Temperature Stabilizer Control

Step-by-Step Starting Procedure

Shutdown Procedure

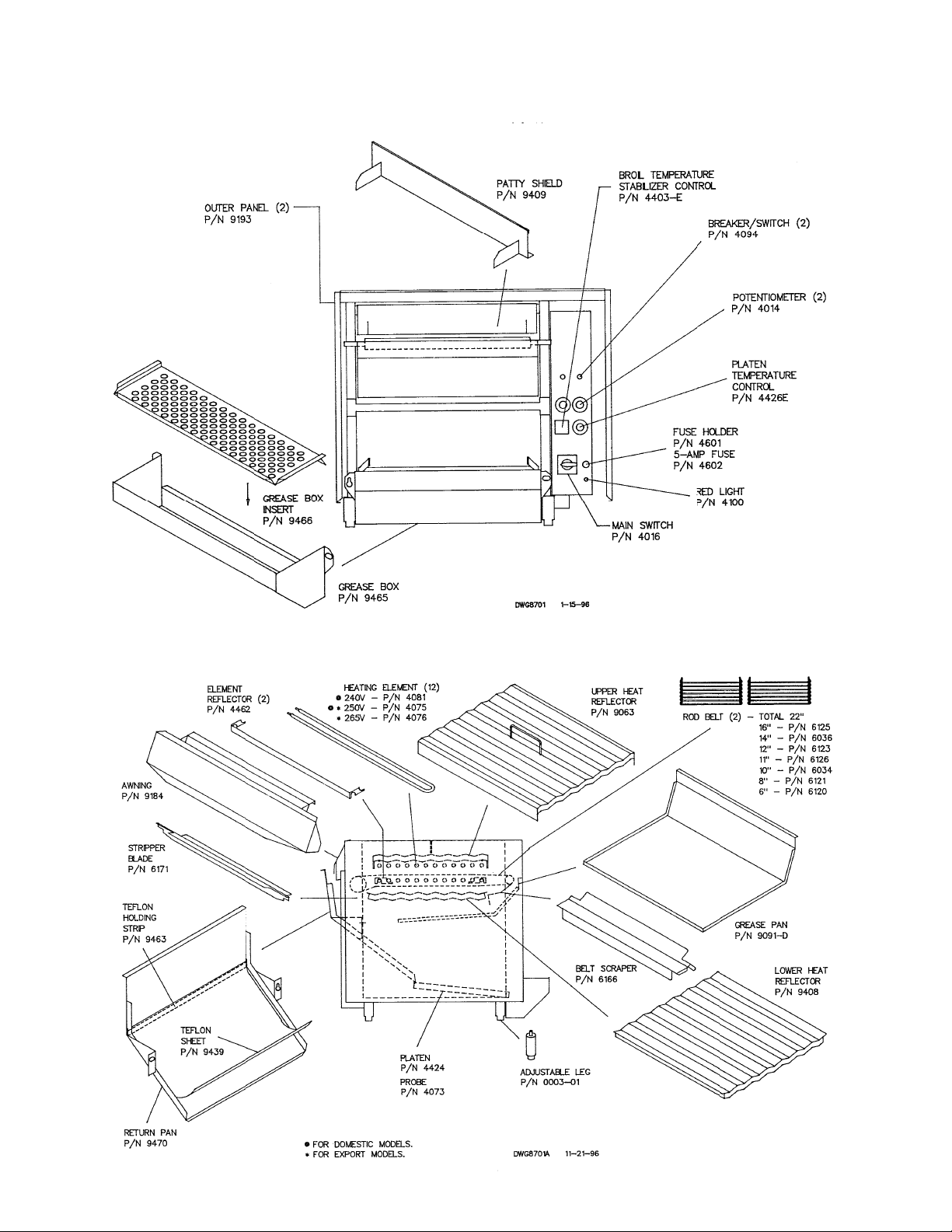

C. Parts and Location.......................................................................................................................7

1352/1355

1332/1335

D. Cleaning........................................................................................................................................10

E. Periodic Maintenance

..................................................................................................................10

F. Conveyor Belt Removal

...............................................................................................................11

G. Conveyor Belt Tension................................................................................................................12

Broil Belt Problems

H. Trouble Shooting Guide..............................................................................................................13

I. Wiring Diagrams

..........................................................................................................................15

J. Specifications...............................................................................................................................19

3

A. INSTALLATION

PRE-INSTALLATION

Uncrate the broiler, and inspect for shipping damage. Contact the factory if there is obvious damage. Remove

the tape securing the machine parts, and install the parts in their proper location. Refer to the Parts and

Location section of this manual. If you find concealed damage to any part of this unit, contact your freight carrier immediately. The factory warranty does not cover freight damage.

MOUNTING

If the broiler was shipped with a tubular stand, refer to separate tubular stand assembly instructions.

Note: The four legs of the broiler stand are equipped with casters. Always set the brakes on the casters to prevent the broiler from shifting during operation or cleaning.

HOOD REQUIREMENTS

This appliance must be installed under a ventilation hood of adequate size and capacity (approximately 600

CFM). The hood should be at least 6" larger in all dimensions than the appliance top, and be 12" to 18" above

the top. Do not obstruct the flow of combustion and ventilation air. An adequate air supply must be available

for safe and proper operation.

Note: See the National Fire Prevention Association booklet on ventilation of cooking equipment. Write

to: NFPA, 470 Atlantic Ave., Boston, MA 02210. Local codes on venting must also be complied with.

CLEARANCE

For proper installation, the minimum clearance from combustible and non-combustible construction is 6" from

the back and 6" from the front of the machine. Keep appliance area free from combustibles.

To facilitate disassembly and service of the unit a minimum of 24" should be allowed on the control panel

(right) side of the broiler, as well as in front of the broiler.

ELECTRICAL CONNECTION

Power requirements are stated on the unit nameplate and must be connected accordingly. Before starting

broiler, tighten all electrical connections in control box.

Note: This appliance must be electrically grounded in accordance with local codes or in the absence

of local codes, the National Electrical Code, ANSI/NFPA No. 70-1990. In Canada, in accordance with

the Canadian Electrical Code CSA 22.1 part 1, or local codes.

WARNING: This appliance should be connected with a five-pronged grounding plug for your

protection against shock hazard. Be sure to plug directly into a properly grounded five-prong

receptacle. Do not cut or remove grounding prong from plug.

Note:

This appliance cannot be safely operated in the event of a power failure. No attempt should be

made to operate during a power failure. Disconnect power supply before servicing.

PRE-OPERATION CHECK

Be sure that all parts are installed in the proper location. Refer to OPERATION section for lighting procedure.

Start broiler and test for proper operation.

4

B. OPERATION

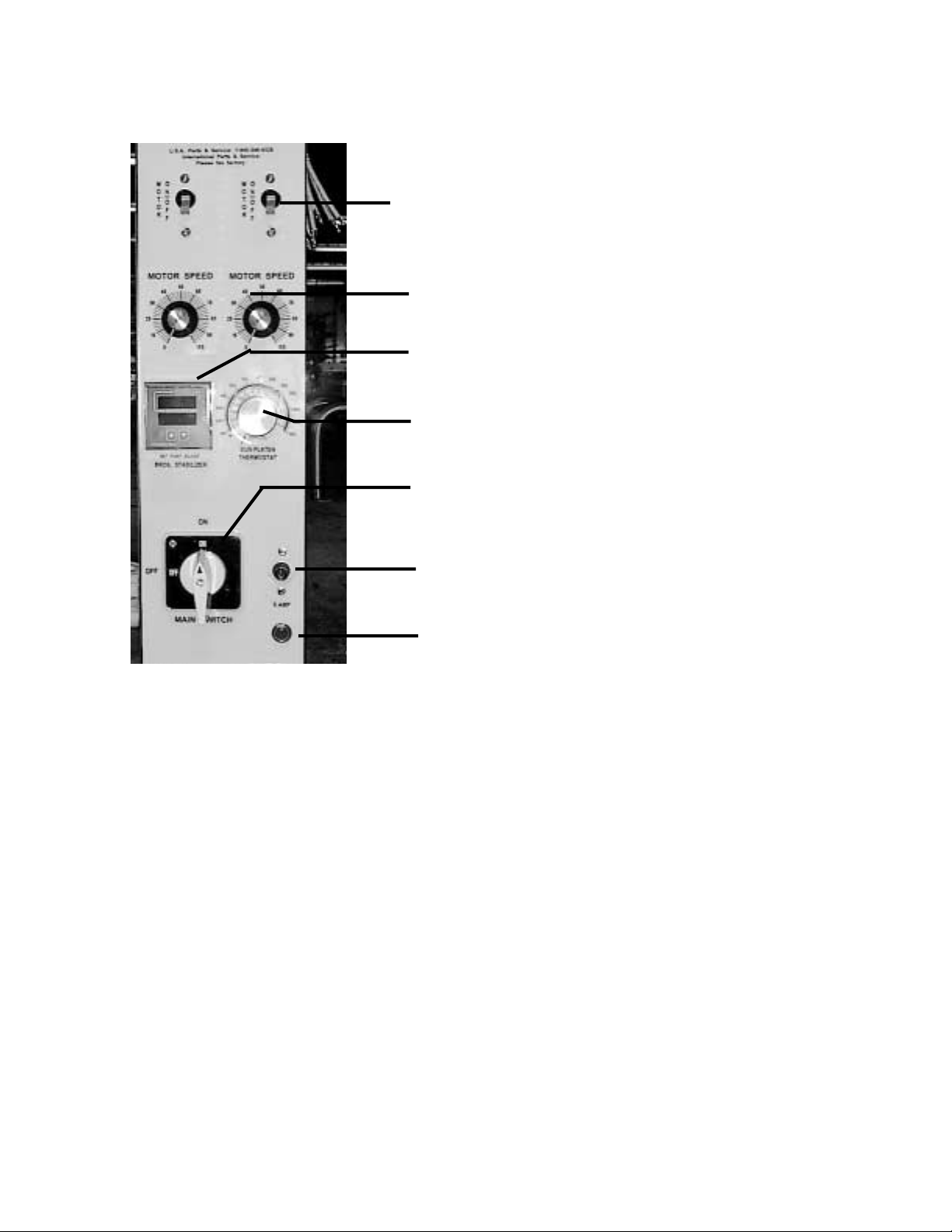

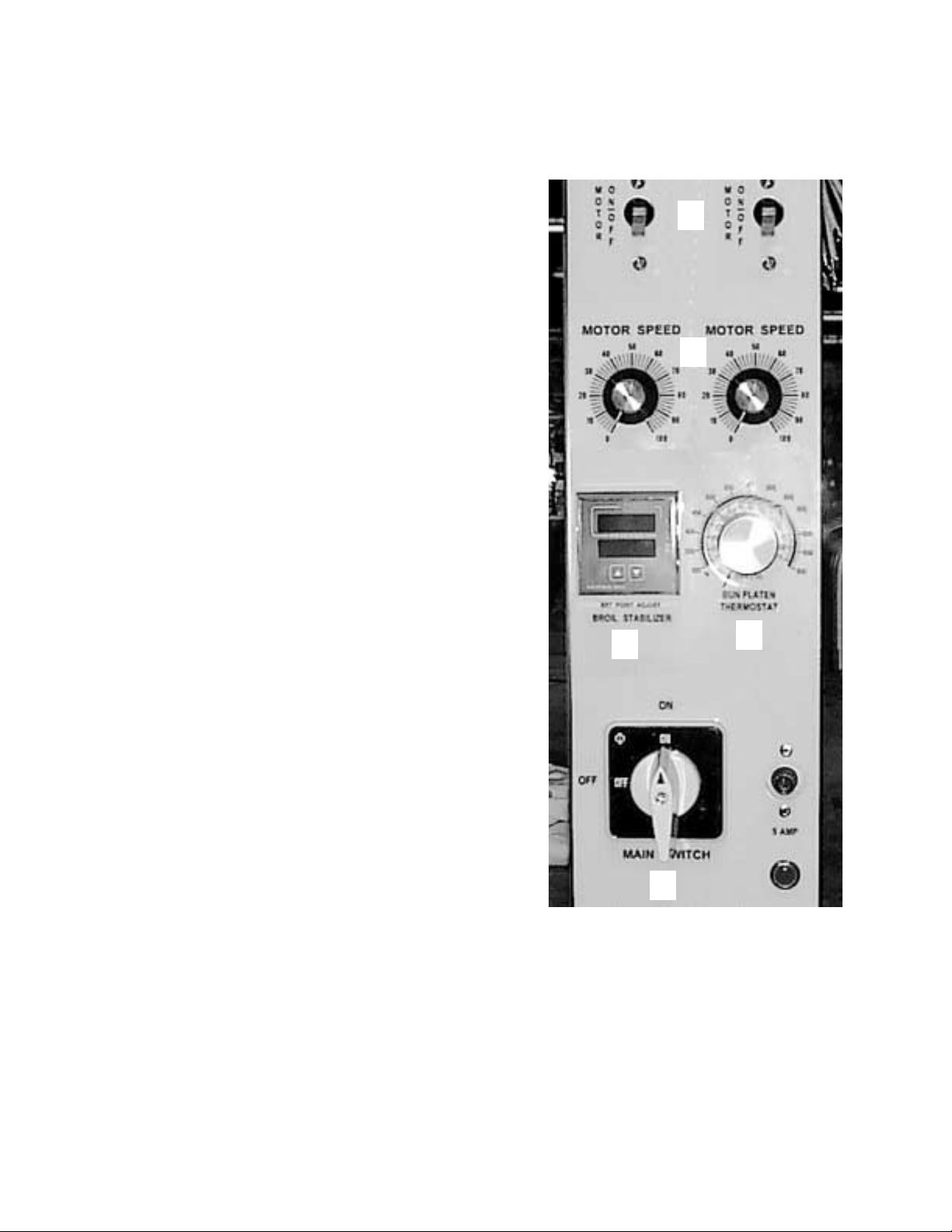

CONTROLS AND INDICATORS

Motor Breaker Switches

Motor Speed Controls - adjusts the speed of the conveyor belt.

Broil Temperature Stabilizer Control:

Top Number = Actual Temperature

Bottom Number = Set Temperature

Meat Holding Unit Temperature Control. (Use a setting of 200°

F to start)

Main Power Switch

Fuse - 5 amp

Power on indicator light.

After the hamburgers are cooked, they drop into the Holding Unit, which uses an electrically heated base to

maintain a set temperature for holding the hamburgers or chicken.

5

BROIL TEMPERATURE STABILIZER CONTROL

The Models 1332/1335/1352/1355 are equipped with a Broil Temperature Stabilizer Control

that senses when the broiler is being used, and adjusts the temperature to keep the broiler hot

during heavy use. The control consists of two parts - a temperature probe to sense the internal

temperature of the broiler, and the control itself.

CALIBRATING THE BROIL STABILIZER CONTROL

In order to assure proper operation, the Broil Stabilizer Control must be calibrated for operation

in the restaurant. Every broiler will calibrate slightly differently, depending on supply voltage,

ventilation, etc. Follow these step by step instructions when the broiler is new, and once per

month after.

Step 1: Be sure all pieces of the broiler are in place. Make sure the broiler is plugged in and

the exhaust hood is turned on. Turn the broiler on by turning the main power switch to

the right. Turn on the conveyor belts using the motor breaker switch.

Step 2: Set the temperature (bottom number) to 200° F. Use the up or down arrows on the con-

trol to set the temperature. The bottom number is the set temperature and the top number is the actual temperature.

Step 3: Allow the broiler to heat up for 40 minutes. During this time, the actual temperature will

climb. Wait until the actual temperature stabilizes before proceeding.

Step 4: Set the ATC (bottom number) to 200° F higher than the actual temperature. For exam-

ple, if the broiler stabilizes at 700° F, then the proper setting should be 900° F. The

temperature control light will come on and the actual temperature (top number) will

climb to 900° F. As the temperature approaches 900 F the control light will pulsate

rapidly.

WARNING

The broiler can be damaged if this control is not set according to instructions.

TROUBLE SHOOTING ERROR MESSAGES

Message Action

ER 4 Turn power on and off several times. If the message remains, replace control. If

the message disappears, the control may need to be reprogrammed. Call Nieco

or your local distributor for instructions.

ER 6 Cycle power on and off several times. If message remains, replace temperature

probe (P/N 4073).

6

Before starting broiler, ensure that all parts are installed in the proper location, and the ventilation hood is turned on.

STEP-BY-STEP STARTING PROCEDURE

1. Turn on Main Power by turning the Main

Power Switch (A) to the right.

2. Turn on Motor Power Switch (B) and set

Motor Speed Control (C) to desired setting. (Use a setting of “50” to start.)

3. Check the Broil Temperature Stabilizer

(D). Daily setting should not be necessary.

Top Number = Actual Temperature

Bottom Number = Set Temperature

4. Set the temperature on the holding section (E). Use a setting of 200° F to start.

Recommended maximum holding time is 10

minutes.

SHUTDOWN PROCEDURE

For EMERGENCY Shutdown, turn the Main Power Switch off. Rotate the switch to the left.

For planned shutdowns, perform the following procedure:

1. Clear machine of all food products.

2. Turn Main Power Switch off.

3. Turn Motor Switch off.

CAUTION: Always turn machine completely off before unplugging power cord.

CAUTION: Allow machine to cool before removing any parts.

A.

B.

C.

D.

E.

7

C. PARTS AND LOCATION

Model 1352/1355 Electric - Feed End View

Model 1352/1355 Electric - Left Side View