INSTALLATION MANUAL

7/10

T5-ETL

T7-ETL

12 VOLT DC Swing Gate Operator

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ............................................................. 3

Applications ........................................................................................................ 4

Pre-Installation Checklist .................................................................................. 5

Operator Components ....................................................................................... 6

Pivot Arm Installation……………………………………………………………..…. 7

Gate Bracket and Actuator Installation ............................................................ 8

Limit Adjustments .............................................................................................. 9

Electrical Connections ……………………………………………………………… 11

Battery Connections ………………………………………………………………… 12

Encoder Board Connections ………………………………………………………. 13

Dimensions and Options ………………………………………………...………… 14

Programming Current Sensing ……………………………………………………. 15

Control Board .................................................................................................... 16

Siren Connection ………………………………………………………………….…. 21

Push to Open Installation…………………………………………………………… 22

Unblocking and Blocking Gear Motor Manually………………………………… 23

Radio Receiver Options ………………………………………………………….…. 24

Specifications …………………………………………………………………………. 25

Warranty .............................................................................................................. 26

33

WARNING- To reduce the risk of injury or death:

READ AND FOLLOW ALL INSTRUCTIONS.

Installation should be performed by a professional installer.

Should electricity be required, use a certified electrician only.

Any device that requires 120 Volts AC should be U.L. approved.

Install control devices such as keypads far enough away (5 feet or further) from any

moving parts of the operator and gate to prevent possible injury.

A secondary entrapment device such as loop detectors, edge switches, and beam

detectors are highly recommended and required to meet the UL325 standard.

Review with the owner all safety concerns including:

Do not operate the gate unless area around gate is in full view.

Never let children operate or play with operator controls. Keep the remote con-

trol away from children.

Always keep people and objects away from the gate. NO ONE SHOULD CROSS

THE PATH OF THE MOVING GATE/ARM.

Test the operator monthly (see STEP 7 Programming the current sensitivity).

The gate MUST reverse on contact with a rigid object or stop when an object

activates the non-contact sensors. After adjusting the force or limit of travel, retest the operator. Failure to adjust and retest the gate operator properly can increase the risk of injury or death.

Arrange with local fire and law enforcement for emergency access.

Always disconnect the battery or power source when making adjustments or

repairs to any part of the operator.

The entrance is for vehicles only. Pedestrians must use separate entrance.

Auto Close feature not recommended without a safety device such as a loop

detector or photo eye.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

The Toona Swing Gate Operator is designed to handle a swing gate up to 14 feet

(T5-ETL) and 20 feet (T7-ETL) in total length. Apollo Operators are available only

through qualified dealers with an outstanding reputation in the fence and gate

industry. These dealers will be able to recommend the proper equipment for

particular applications. Apollo Operators are 12 Volt DC (Direct Current) powered.

If a electrical battery charger is used a 12 Volt sealed battery (33 ampere hour minimum) is recommended . If solar charging is used a 12 volt 105 ampere hour battery

is recommended. There are several advantages with 12 Volt DC systems:

Low voltage virtually eliminates risk of electrical shock.

Battery powered operators can provide up to 500 operations in the event of

power outages.

The battery may be recharged with a trickle charger or by solar energy

(eliminating the need for costly trenching to remote entrances).

If a trickle charger is used and a standard electrical outlet is not readily available, a

licensed electrician will be required for proper electrical hook up.

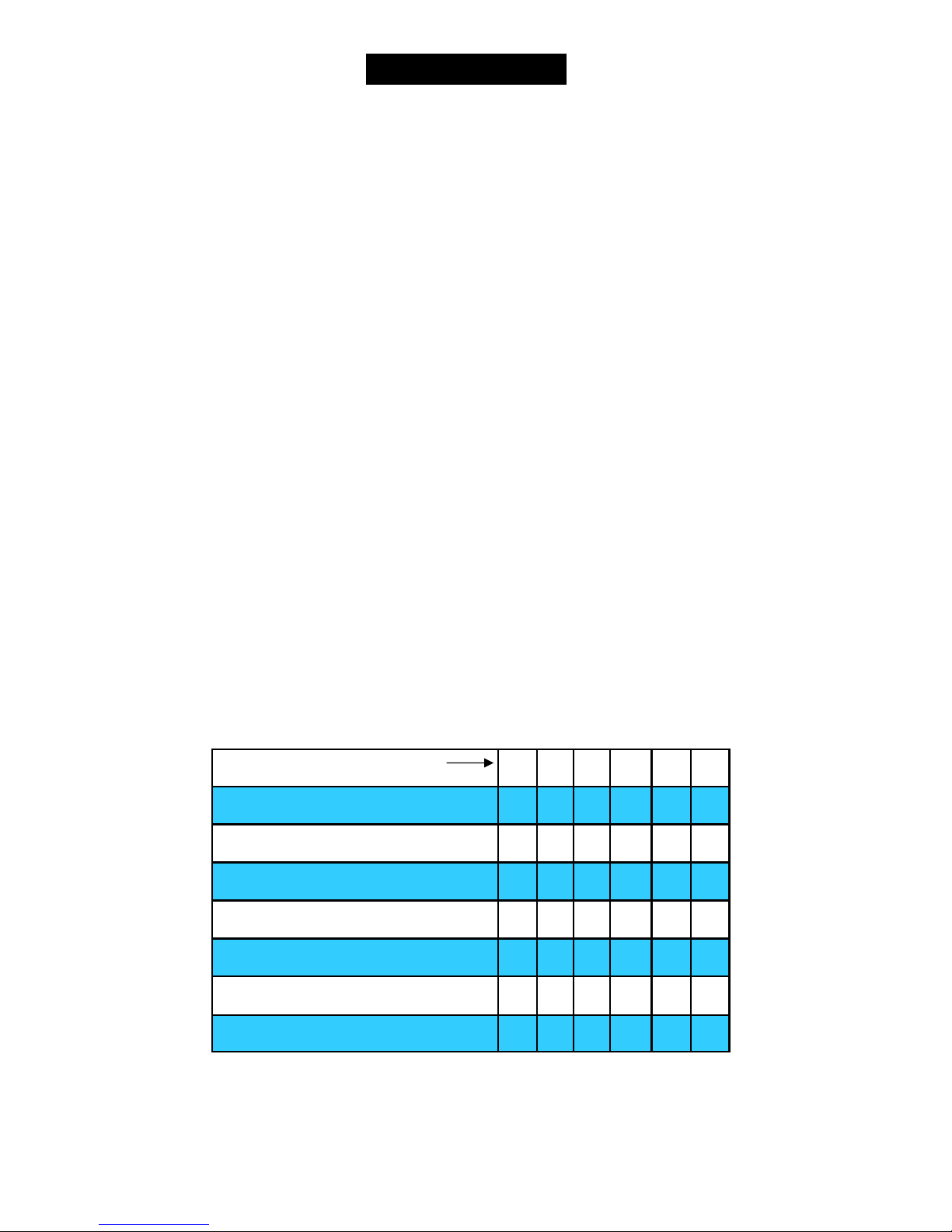

The following table should be used as a guide for capacity of operation of operators

only, additional options may reduce the the daily usage. Please note that the charge

capability of solar panels will vary with different geographical locations. All solar

panels and battery chargers are designed for use with a 12 volt battery.

Daily Cycles 1-10 1-20 1-40 1-60 1-80 80+

5 watt solar panel

*

10 watt solar panel

*

20 watt solar panel (requires 5310 regulator)

*

30 watt solar panel (requires 5310 regulator)

*

40 watt solar panel (requires 5310 regulator)

*

1.5 amp battery charger

*

10 amp battery charger

*

Note: Double the amount of solar panels for Dual Operators.

APPLICATIONS

55

The following checklist should be used before beginning installation:

Verify that the proper operator has been selected for this application.

Determine the general location of the operator, access controls, and solar

panel (if used).

1. Is there a suitable location for the operator?

2.Can the solar panel (if used) be mounted in an unobstructed area facing

south?

3. Will additional solar panel cable be required? If additional cable is required,

do not cut out the blocking diode when adding the cable.

4. Is electricity available (if required)?

Consider safety and access options. Recommend if needed.

1. Will there be chidren or animals in the area?

2. Are safety loops, edge switches, or photo eye detectors required? The auto

close feature is not recommended unless one or more of these devices are

used.

3. How can the gate be opened in emergencies?

4. How will visitors enter and exit?

5. Will vehicles (and trailers) have sufficient room off roadway to operate

access control devices such as keypads?

PRE-INSTALLATION CHECKLIST

OPERATOR COMPONENTS

f

5

h

2 pieces

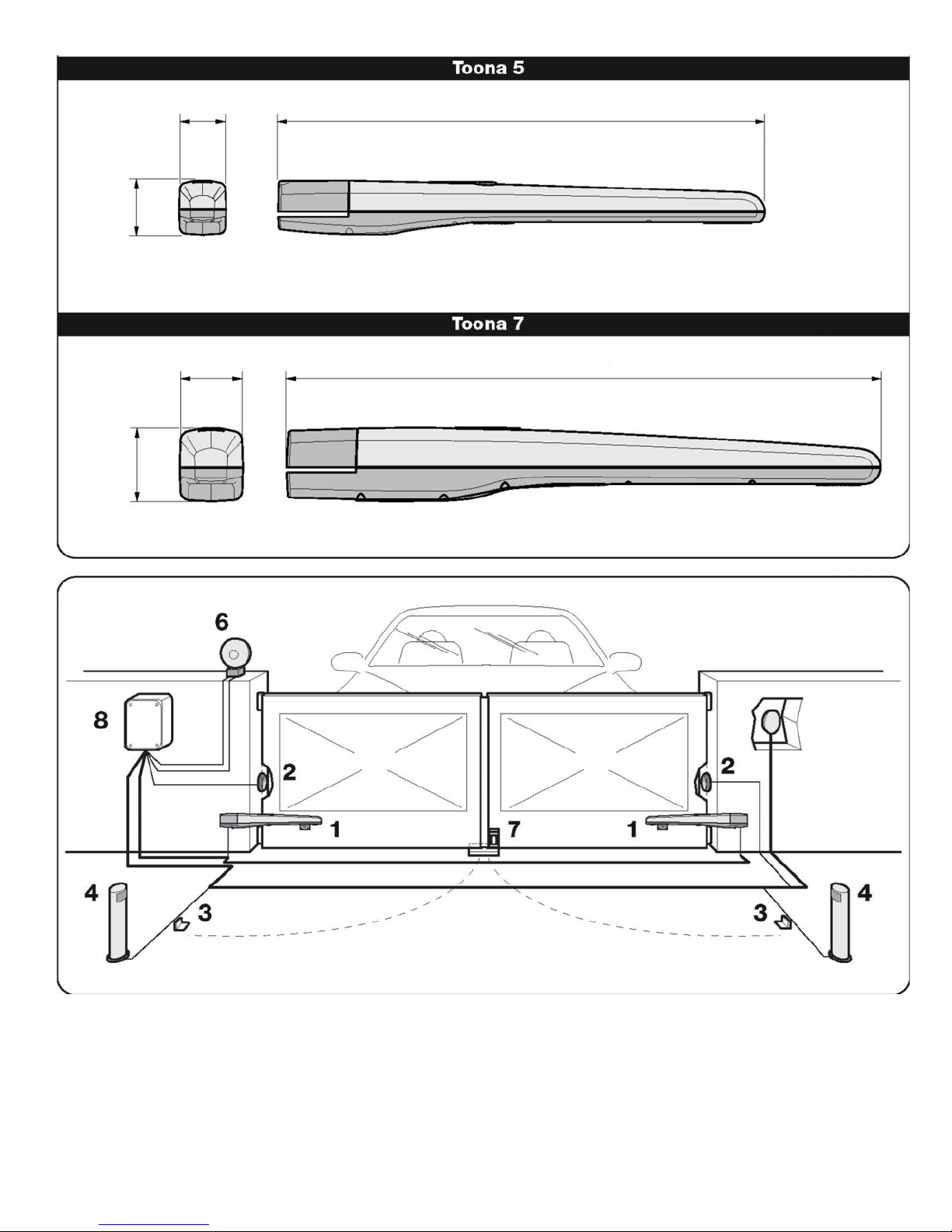

Toona 5

TO5012

Toona 7

TO7012

i

a Actuator

b Gate attach bracket (two pieces)

c Pivot bracket

d Mounting Hardware

e Release lock keys

f Control Box

g Cable Harness

h Caution signs (2)

i Battery Charger (optional)

j Solar Panel (optional)

j

g

77

Pivot Arm position is measured

from the center of the gate

TOONA 5/7

A B

Toona 5 7-1/16” 7-1/16”

Toona 7 7-3/4” 7-3/4”

These dimensions are for 4” post

with hinge in center. Adjust accordingly if post size or hinge location varies. A & B should always

be same value.

Pull to open installation shown here.

For push to open installation see page 22.

TOONA 5 F= 1.75”

TOONA 7 F= 2”

99

Toona 5/7

3.9” max

Limit Switch Adjustment

Loosen nuts and adjust limits.

Retighten nuts.

(Nuts may be hex or socket.)

1111

T5-ETL Actuator Wiring

T7-ETL Limit Wires

The limit wires (orange and white) are reversed on the T7-ETL

from the picture shown.

BATTERY CONNECTIONS

If a electrical battery charger will be used, a 12 volt

sealed lead acid battery rated for 33 ampere hour or

more is recommended for the Toona 5 & 7.

A 1.5 amp automatic battery charger is sufficient for

most applications

The battery may also be recharged with a solar panel. If

solar charging is a requirement refer to page 4 or contact

our customer service department at 800 226-0178 to

help determine the solar panel size needed. A 12 volt

105 ampere hour battery is recommended with solar

charging.

G-CELL

12 Volt 34aH Sealed Battery

Connect the two ring terminals on the connector end of the cable to the battery. The battery

charger or solar panel should be installed at

this time.

(RED is positive(+) and Black is negative(-)

Plug the Toona actuator

connector into the Master

connector on the circuit

board.

The operator is now active. Limits must be set and tested. The current sense must now be programmed as shown on page 10.

If the operator does not work, check the battery connections for proper polarity. If the connections

are reversed, the “REVERSE BATTERY POLARITY” LED will be illuminated at the bottom center of

the circuit board.

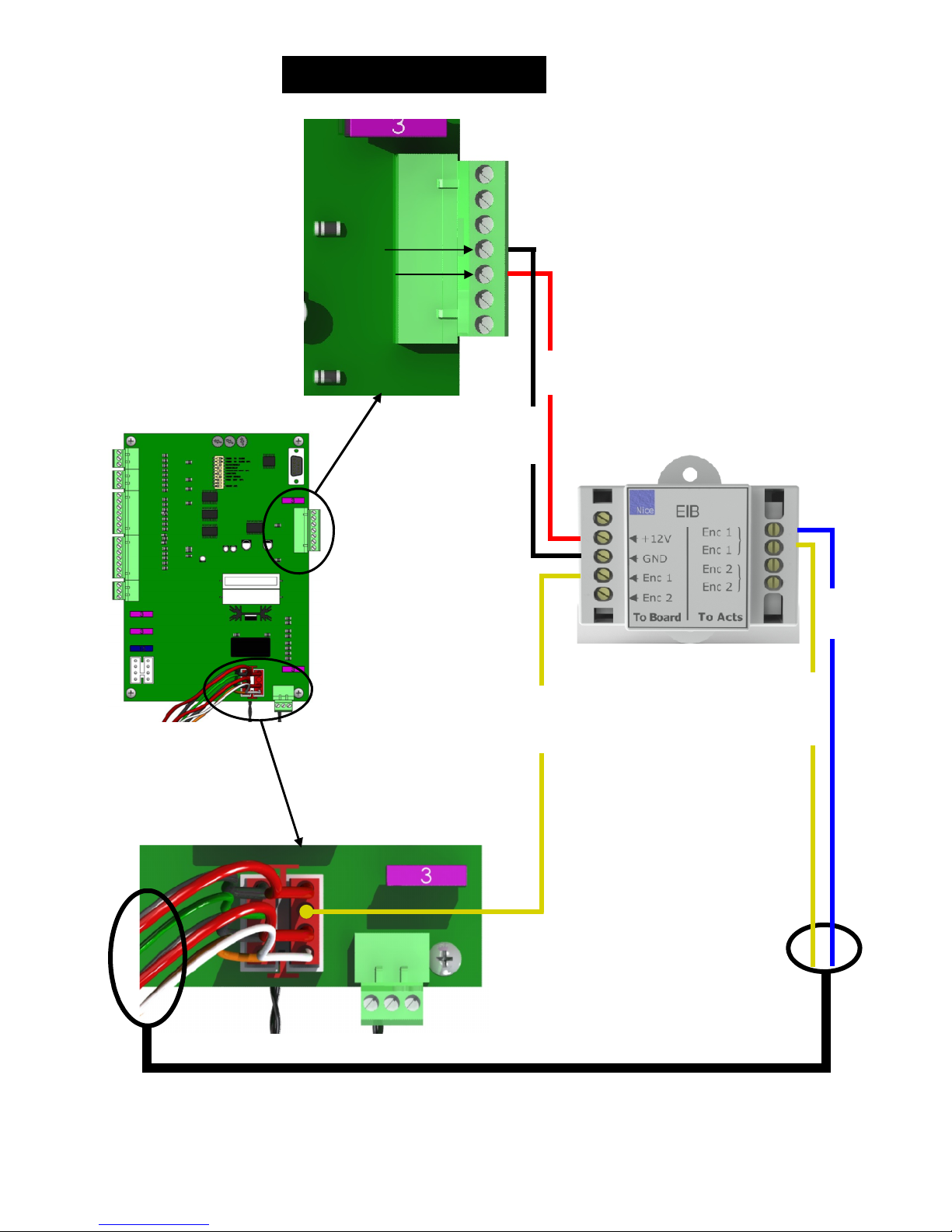

1313

SIREN

GND

ACTUATOR CABLE

BLUE

TOONA Wiring Diagram

YELLOW

YELLOW

RED

BLACK

4.5”

4.125”

38”

5”

5.9”

47.25”

Description

1 Actuator 5 Keypad*

2 Photo Beam * 6 Siren

3 External Stop* 7 Solenoid Lock*

4 Photo Beam* 8 Control Box

* Optional

5

1515

PROGRAMMING CURRENT SENSING

The 835/836 control boards incorporate a safety feature that will put the operator into a hard shutdown mode if the control board detects a current sense

two consecutive times during a cycle. This hard shutdown condition may be

reset by shorting the FIREBOX or UL inputs on the left side of the control

board to ground. This condition may also be reset by pressing the HARD

SHUTDOWN RESET button located toward the upper right hand corner of the

control board. If a firebox is used in the installation, The firebox door (optional)

can be opened and closed to reset the control board.

The following instructions must be followed at installation for proper safety assurance.

All limits must be set before beginning this procedure.

1. Press and hold the LED ENABLE button for five seconds and release. The STOP LED

will blink indicating that the board is in learn mode.

3. Cycle gate/arm for 3-4 full cycles. The STOP LED will stop blinking indicating that the

operator is now ready for normal operation

4. Test the auto reverse sensitivity by obstructing the gate to ensure maximum safety

protection. The current sensitivity adjustment pot may be adjusted to decrease or

increase sensitivity.

Perform this test procedure on a monthly basis to assure proper and safe operation.

8. Refer to the page 17 to set other options such as

program switch options and close timer adjustments.

Installation is now complete.

Note: Once the board has learned the operator, the current sense may be readjusted at any

time without re-learning the board..

CLOCKWISE

Less sensitivity

Operator is harder to

current sense

COUNTER CLOCKWISE

More sensitivity

Operator is easy to

current sense

LED Enable & Learn

Mode Push Button

Optional Device Inputs

Stop Circuit Jumper

Fire & ETL Inputs

Emergency Bypass

Reverse Battery Polarity

Indicators

Optional Device Input

Remote Monitor Outputs

Microprocessor

Timer To Close -

Dual Gate Delay -

Current Sensitivity -

Adjustments

Program Switches

835/836 Control Board Parts Identification

Operator Connector

(Master)

Operator Connector

(Slave)

Control Board Reset

Hard Shutdown Reset

Operate Push Button

1717

Board Harness Function

Pin 1 Orange Open Limit

Pin 2 White Close Limit

Pin 3 Black Motor (positive on open, negative on close)

Pin 4 Red Motor (negative on open, positive on close)

Pin 5 Green Common for both limit switches

Pin 6 Yellow Encoder Input from EIB module

Pin 7 Black Battery Negative

Pin 8 Red Battery Positive

1

3

5

7

2

4

6

8

Master/Slave Connector

Applies battery voltage directly to motor to open gate (will not close gate) if

control board fails. User must unplug before gate opens to maximum travel or

the 15 amp fuse will open. Fuse should be checked before returning gate to

service.

EMERGENCY BYPASS

12V Supplied battery voltage

SLV Slave Operator Indicator (indicates slave side of gate is closed)

+12V when on closed limit. Ground when off of closed limit.

MAS Master Operator Indicator (indicates master side of gate is closed)

+12V when on closed limit. Ground when off of closed limit.

GND Battery supplied ground (connects to GND on EIB module)

SIREN Connect to siren + (also connects to +12V on EIB module)

applies +12V when gate(s) are running, or in hard shutdown

GND Battery supplied ground

LOCK Connect to lock + (optional) Magnetic or Solenoid type locks (Dip Switch #6 Selectable)

Remote Outputs

Adjustments

Push Buttons

TIMER TO CLOSE Adjusts time before gate automatically

closes Adjustable 5 to 70 seconds.

DUAL GATE DELAY Adjusts delay between master and slave

(Dual board only) operation 0-4 seconds (836 only with

magnetic, solenoid, and other locking

devices)

CURRENT SENSITIVITY Increases or decreases the Auto Reverse

sensitivity.

LED ENABLE When depressed, activates LEDs for 15

minutes to assist in installation and troubleshooting.

Hold the push button down for five seconds to put

the board in program mode.

RESET Resets the microprocessor. Returns processor to

last known state.

Jumpers

STOP CIRCUIT JUMPER When the STOP CIRCUIT

JUMPER is connected, the gate

will operate normally.

STOP CIRCUIT JUMPER When a 3-button station is connected

to the board, the STOP CIRCUIT

JUMPER must be removed.

OPERATE When depressed, activates the gate. Used for initial

installation and testing.

Hard Shutdown Reset Resets the operator when the gate current

senses twice before fully opening or closing.

1919

Program Switches

OFF ON

1 TIMER TO CLOSE Gate does not automatically close. Gate automatically closes.

2 TIMER TO CLOSE OPT. Gate automatically closes from Gate automatically closes only when completely

any position after opening. open (open limit engaged).

3 SLAVE DISABLE Enables slave side (dual gate use). Disables slave side. (single gate use)

4 SIREN DELAY Siren (optional) active when gate is Siren (optional) starts 5 seconds before gate moves.

moving.

5 OPEN/CLOSE INPUT OPT. Must hold down open or close Normal operation

buttons to move gate. Gate stops Momentary open or close input runs gate to limit.

when button released.

6 LOCK TYPE For 12V mechanical (solenoid) locks. For 12V magnetic locks.

(+12V for 4 seconds on open cycle) (+12V when on close limit)

7 COAST ENABLE Gate will stop immediately when at Gate will coast (minimally) when it reaches limits.

Open or Close limit Not recommended for slide gates using chain

magnets.

8 FREE EXIT OPT. A free exit input will open gate from A free exit input will open gate from any

closed position or after a close cycle position after an open or close cycle.

only.

9 DUAL GATE SYNC Both gates operate at normal This feature will control the master gate to open

Speed (slave slower than or close at the same speed as the slave gate.

Master).

10 SMART ACT. Off for all slide gate operators On for 1550/1650/Toona 5&7/Metro/Hyppo

and 1500/1600/3500/3600 swing Enables soft start & soft stop.

Gate operators.

GND Supplied Battery Ground

INP Activate Gate (Push button activation when momentarily shorted to ground)

12V Supplied Battery Voltage (Protected with 3 Amp fuse)

GND Supplied Battery Ground

INP Activate Gate (Push button activation when momentarily shorted to ground)

12V Supplied Battery Voltage (Protected with 3 Amp fuse)

EDGE Reverse edge input. When grounded, will stop and reverse gate if closing, resets close timer if gate is open.

EDGE Reverse edge input. When grounded, will stop and reverse gate if closing, resets close timer if gate is open.

GND Supplied Battery Ground

GND Supplied Battery Ground

STOP Stop input from a 3 button station (must remove STOP CIRCUIT JUMPER) Normally closed

CLOSE Close input from a 3 button station (see program switch #5 for options)

OPEN Open input from a 3 button station (see program switch #5 for options)

GND Supplied Battery Ground

GND Supplied Battery Ground

FREE EXIT Opens gate if closed, stops and reverses gate if closing, resets close timer if gate is open.

GND Supplied Battery Ground

SHADOW Resets close timer when gate is open (also referred to as under gate loop)

GND Supplied Battery Ground

SAFETY Resets close timer if gate is open, stops and reverses if gate is closing. (Does not open a closed gate)

GND Supplied Battery Ground

FIRE When grounded, opens gate and holds gate open until released.

Clears “Hard Shutdown” mode of software.

UL When grounded, opens gate and holds gate open until released.

Clears “Hard Shutdown” mode of software.

Optional Device Inputs

GND Supplied Battery Ground

INP Activate Gate (Push button activation when momentarily shorted to ground)

12V Supplied Battery Voltage (Protected with 3 Amp fuse)

2121

APOLLO Gate Operators, Inc.

911 Siren

Mount siren in an area that will produce maximum performance (additional wire may be required).

Connect the red wire to the SIREN connector on the Remote Monitor Output Connector block.

Connect the black wire to the GND connector on the Remote Monitor Output Connector block.

Red

Black

Set Program Switch # 4 as preferred:

ON - Upon activation, Siren will start for 5 seconds before gate(s) begin moving.

OFF - Siren and gate(s) start immediately upon activation.

The 911 Siren is included with all Apollo ETL Gate Operators.

PUSH TO OPEN APPLICATION

2323

APOLLO Gate Operators RECEIVER OPTIONS

Do not confuse the receiver code switches with the red program switches on the gate control board.

Never set all code switches to the same position. Transmitters must match code switches for proper operation.

If power is taken directly from battery or connected as shown below, receiver should be configured for 12VDC

Multi-Code/Digi-Code

Allstar

Lift-Master

black

gray

gray

red

white

black

red

4

3

2

1

Heddolf

black

yellow

red

white

Jumpers must be

set for 12V &

constant relay

option

2525

Supply Voltage ……………………………………………….. 12VDC

Recommended Battery (electrically charged) .………..….. 12 V, 33aH (or larger) Sealed Lead Acid

Recommended Battery (solar charged) …………………… 12 V, 105 aH

Battery Charger ………………………………………………. 1.5 or 6 amp Automatic

Recommended Solar Panel ………………………………… 5 watt minimum

Duty Cycle …………………………………………………….. Continuous

Operating Temperature ……………………………………… –400F - +1500F

Current Draw Standby (with no accessories).……………. 10mA

Current Draw Operating …………………………………….. 2A

SPECIFICATIONS

LIMITED TWO-YEAR WARRANTY

Apollo Gate Operators are warranted against defects for a period of

24 months from the date of purchase, providing recommended installation

procedures are followed. This warranty is in lieu of all other warranties

expressed or implied (some states do not allow limitations on how long an

implied warranty lasts, so this limitation may not apply to you) and shall be

considered void if damage was due to improper installation or use,

connection to improper power source, or if damage was caused by fire,

flood, or lightning. The manufacturer will not be responsible for any labor

charges incurred in the removal or replacement of defective parts.

In case of failure due to defective material or workmanship during the

warranty period, the defective part will be repaired or replaced at the

manufacturer’s option at no charge if returned freight prepaid. New or factory

rebuilt replacements may be used. Replacement parts are warranted for the

remaining portion of the original warranty period. The manufacturer will pay

standard ground freight back to the customer on the return of repaired or

replaced items in warranty.

Lighting or electrical power surges may cause damage beyond repair and

are not covered in this warranty.

APOLLO Gate Operators, Inc.

Loading...

Loading...