Page 1

Nice

SO2000

Garage door opener

EN - Instructions and warnings for installation and use

Page 2

ENGLISH

Translation of the original instructions in full

CONTENTS

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . .2

1.1 IMPORTANT INSTALLATION INSTRUCTIONS . . . . . . . . . . . 2

1.2 IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . 3

2 PRODUCT DESCRIPTION AND INTENDED USE . . . . . . . . . 4

2.1 List of constituent parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Pre-installation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Product usage limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2.1 Product durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Product identification and overall dimensions . . . . . . . . . . . . 6

3.4 RECEIPT OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Pre-installation works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Installing the gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Manually unlocking and locking the gearmotor . . . . . . . . . . . 9

4 ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Preliminary checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Wiring diagram and description of connections . . . . . . . . . . 10

4.2.1 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.2 Description of connections . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Addressing of devices connected with the BlueBUS system 11

4.3.1 FT210B photosensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 FINAL CHECKS AND START-UP. . . . . . . . . . . . . . . . . . . . . . 12

5.1 Power supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Device learning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.3 Learning of the door opening and closing positions. . . . . . . 12

5.4 Checking the door movement . . . . . . . . . . . . . . . . . . . . . . . 14

5.5 Connecting other devices . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 TESTING AND COMMISSIONING. . . . . . . . . . . . . . . . . . . . . 14

6.1 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.1 Using the programming buttons . . . . . . . . . . . . . . . . . . . . . 16

7.2 Level 1 programming (ON-OFF) . . . . . . . . . . . . . . . . . . . . . 17

7.2.1 Level 1 programming procedure . . . . . . . . . . . . . . . . . . . 17

7.3 Level 2 programming (adjustable parameters) . . . . . . . . . . . 18

7.3.1 Level 2 programming procedure . . . . . . . . . . . . . . . . . . . 18

7.4 Programming the direction . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.5 Resetting the encoder position . . . . . . . . . . . . . . . . . . . . . . 20

7.6 Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.6.1 “Always open” function . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.6.2 “Move anyway” function . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.6.3 “Maintenance notice” function . . . . . . . . . . . . . . . . . . . . 20

7.7 Verifying the number of manoeuvres completed . . . . . . . . . 21

7.8 Manoeuvre counter resetting . . . . . . . . . . . . . . . . . . . . . . . . 21

7.9 Memory deletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2 Anomaly log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.3 Signalling through warning light . . . . . . . . . . . . . . . . . . . . . . 23

8.4 Signals on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 FURTHER DETAILS (Accessories) . . . . . . . . . . . . . . . . . . . . 26

9.1 Modifying the STOP input configuration . . . . . . . . . . . . . . . 26

9.2 Alarm system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.3 Connecting an SM-type radio receiver . . . . . . . . . . . . . . . . 26

9.4 Connecting and installing the back-up battery . . . . . . . . . . . 27

9.5 Connecting the Oview programmer . . . . . . . . . . . . . . . . . . . 28

9.6 Connecting the Solemyo solar energy system . . . . . . . . . . . 29

10 PRODUCT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

12 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . 31

INSTRUCTIONS AND WARNINGS FOR THE USER. . . . . . 33

1

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS

1.1 IMPORTANT INSTALLATION INSTRUCTIONS

a

PRECAUTIONS

WARNING – To reduce the risk of severe

injury or death:

• READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

• Install only on a properly operating and balanced

garage door. An improperly balanced door has the

potential to inict severe injury.

– For vertically sliding doors: have a qualied service

person make repairs to cables, spring assemblies,

and other hardware before installing the opener.

– For horizontally sliding doors: have a qualied

service person make repairs and hardware adjustments before installing the opener.

• Remove all pull ropes and remove, or make inoperative, all locks connected to the garage door before installing the operator.

• For “Commercial/industrial door operators (or

systems)”: moving parts capable of causing injury

to persons or employs a motor deemed indirectly

accessible by virtue of its location above the oor

shall include:

– a) Install the door operator at least 2.44 m (8 ft) or

more above the oor; or

– b) If the operator must be installed less than 2.44

m (8 ft) above the oor, then exposed moving parts

must be protected by covers or guarding, provided

by the operator manufacturer; or

– b) If the operator must be installed less than 2.44

m (8 ft) above the oor, then exposed moving parts

must be protected by covers or guarding, provided

by the operator manufacturer; or

• Where possible, install the door operator 2.14 m (7

ft) or more above the oor. For products having an

emergency release, mount the emergency release

within reach, but at least 1.83 m (6 ft) above the

oor and avoiding contact with vehicles to avoid

accidental release.

• Do not connect the door operator to source of

power until instructed to do so.

• Locate the control button: (a) within sight of the

door, (b) at a minimum height of 1.53 m (5 ft) above

oors, landings, steps or any other adjacent walking surface so small children are not able to reach

it, and (c) away from all moving parts of the door.

• Install the Entrapment Warning Label next to the

control button in a prominent location. Install the

Emergency Release Marking. Attach the marking

on or next to the emergency release.

GENERAL SAFETY WARNINGS AND

2 – ENGLISH

Page 3

• After installing the opener, the door must reverse

when it contacts a 38-mm (1-1/2-inch) high object

(or a 2 by 4 board laid at) on the oor.

• For products having a manual release, instruct the

end user on the operation of the manual release.

• Only enable [+] feature when installed with a sectional door.”, where + is the unattended operation

function.

• This operator not equipped for permanent wiring.

Contact licensed electrician to install a suitable receptacle if one is not available.

• Before commencing the installation, check the “Product

technical specications”, in particular whether this product is suitable for automating your guided part. Should

it not be suitable, do NOT proceed with the installation.

• The product cannot be used before it has been commissioned as specied in the “Testing and commissioning” chapter.

• Before proceeding with the product’s installation, check

that all the materials are in good working order and suited to the intended applications.

• ATTENTION! In order to avoid any danger from

inadvertent resetting of the thermal cut-off device, this appliance must not be powered through

an external switching device, such as a timer, or

connected to a supply that is regularly powered or

switched off by the circuit.

• The system’s power supply network must include a disconnection device (not supplied) with a contact opening

gap permitting complete disconnection under the conditions envisaged by Overvoltage Category III.

• Handle the product with care during installation, taking

care to avoid crushing, denting or dropping it, or allowing contact with liquids of any kind. Keep the product

away from sources of heat and naked ames. Failure

to observe the above can damage the product, and

increase the risk of danger or malfunction. Should this

happen, stop installation immediately and contact Customer Service.

• The manufacturer declines all liability for damages to

property, objects or people resulting from failure to observe the assembly instructions. In such cases, the warranty for material defects shall not apply.

• The weighted sound pressure level of the emission A is

lower than 70 dB(A).

• Before working on the system (maintenance, cleaning),

always disconnect the product from the mains power

supply.

• Inspect the system frequently, in particular the cables,

springs and supports to detect any imbalances and

signs of wear or damage. Do not use the product if it

needs to be repaired or adjusted, because defective installation or incorrect balancing of the automation can

lead to injuries.

• The packing materials of the product must be disposed

of in compliance with local regulations.

• The product must not be installed outdoors.

• Prior to installing the drive motor, check that the door

is in good working order, correctly balanced and that it

opens and closes properly.

• Prior to installing the motor, remove all unnecessary cables or chains and deactivate any equipment – such as

locking devices – not required for motorised operation.

• Check that there are no points where people could get

trapped or crushed against xed parts when the door

is fully open or closed; if there are, arrange adequate

protective measures for these parts.

• After installation, make sure that the motor prevents or

stops opening of the door when the latter is loaded with

a 20-kg weight secured to the centre of its bottom edge

(for drive motors that can be used with doors having

opening widths exceeding 50 mm).

• After installation, make sure that the mechanism is properly adjusted and that the motor reverses when the door

collides with a 38mm (1inch 1/2) -tall object placed on

the ground (for drive motors incorporating a trapping

safety system that intervenes when the bottom edge of

the door encounters an obstacle).

• Following installation, check and ensure that no door

parts obstruct public roadways or pavements.

1.2 IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce the risk of severe

a

injury or death:

• READ AND FOLLOW ALL INSTRUCTIONS.

• Never let children operate or play with door controls. Keep the remote control away from children.

• Always keep the moving door in sight and away

from people and objects until it is completely

closed. NO ONE SHOULD CROSS THE PATH OF

THE MOVING DOOR.

• For vertically moving doors: NEVER GO UNDER A

STOPPED, PARTIALLY OPEN DOOR.

• For horizontally moving doors: NEVER GO

THROUGH A STOPPED, PARTIALLY OPEN DOOR.

• Test door opener monthly. The garage door MUST

reverse on contact with a 38-mm (1-1/2-inch) high

object (or a 2 by 4 board laid at) on the oor. After adjusting either the force or thelimit of travel,

retest the door opener. Failure to adjust the opener properly increases the risk ofsevere injury or

death.

ENGLISH – 3

Page 4

• For vertically moving doors for products having

an emergency release, when possible, use the

emergency release only when the door is closed.

Use caution when using this release with the door

open. Weak or broken springs are capable of increasing the rate of door closure and increasing

the risk of severe injury or death.

• KEEP GARAGE DOORS PROPERLY BALANCED.

See user’s manual. An improperly balanced door

increases the risk of severe injury or death.

– For vertically moving doors: have a qualied ser-

vice person make repairs to cables, spring assemblies, and other hardware.

– For horizontally moving doors: have a qualied

service person make repairs and hardware adjustments before installing the opener.

• For operator systems equipped with an unattended operation feature, the following statement shall

be included: “This operator system is equipped

with an unattended operation feature. The door

could move unexpectedly. NO ONE SHOULD

CROSS THE PATH OF THE MOVING DOOR.”

• SAVE THESE INSTRUCTIONS.

• Be careful when activating the manual unlocking device

(manual manoeuvre), as an open door may fall suddenly

due to weak or broken springs, or if it is unbalanced.

• If the power cable is damaged, it must be replaced by

the manufacturer or by an appointed servicing company

or similarly qualied person in order to prevent any form

of risk.

2

2 PRODUCT DESCRIPTION AND INTENDED USE

SO2000 is an electromechanical actuator for automating sectional

doors up to 215ft2 40in2 1/16 (20mq). Thanks to the cable outlet

shaft, it ensures easy connection with the spring support shaft of

most sectional doors available on the market. !da duplicazione!

The control unit supplied with the product, besides powering the

DC motor, ensures optimal adjustment of the gearmotor torque

and speed, precise measurement of the positions, gradual starting and closing, and obstacle detection. It is also equipped with

a maintenance indicator to enable recording of the manoeuvres

performed by the gearmotor during its lifetime.

The unlocking mechanism, activated from the ground, disengages

the motor from the gearmotor body.

a

2.1 LIST OF CONSTITUENT PARTS

“Figure 1” shows the main parts making up the Soon.

INTENDED USE

Any use of the product other than the intended use

described is not allowed!

1

A

B

PRODUCT DESCRIPTION AND

RECEIVER

FUSE

FUSE

LED

Light

Flash Alarm

Bluebus

StopSbSOpenLight

C D E

A Cover

B Electronic control and command unit

C Gearmotor body

D Locking/unlocking system

E Transmission shaft housing

4 – ENGLISH

Page 5

3

3 INSTALLATION

INSTALLATION

3.1 PRE-INSTALLATION CHECKS

The installation must be carried out by qualied

a

personnel in compliance with the current legislation, standards and regulations, and with the instructions provided in this manual.

Before proceeding with the product’s installation, it is necessary to:

– check the integrity of the supply

– check that all the materials are in good working order and suited

to the intended use

– make sure that the structure of the door is suitable for being

automated

– make sure that the characteristics of the door fall within the op-

erating limits specied in the “Product usage limits” paragraph

– verify that there are no points of greater friction during the open-

ing and closing movements along the entire door path

– verify that the area where the gearmotor is installed allows for

unlocking the latter and manoeuvring easily and safely

– verify that the mounting positions of the various devices are pro-

tected against impacts and that the mounting surfaces are suf-

ciently sturdy

– prevent any parts of the automation from being immersed in wa-

ter or other liquids

– keep the product away from heat sources and open ames and

acid, saline or potentially explosive atmospheres; these may

damage the product and cause malfunctions or dangerous situations

– connect the control unit to an electricity supply line equipped

with a safety earthing system

– include a device on the electric power line ensuring complete

disconnection of the automation from the grid. The disconnec-

tion device must have contacts with a sufcient gap to ensure

complete disconnection, under the Category III overvoltage conditions, in accordance with the installation instructions. Should it

be necessary, this device guarantees fast and safe disconnection

from the power supply; it must therefore be positioned in view of

the automation. If placed in a non-visible location, it must have a

system that blocks any accidental on unauthorised reconnection

of the power supply, in order to prevent dangerous situations.

The disconnection device is not supplied with the product.

3.2 PRODUCT USAGE LIMITS

The data relative to the product’s performances is included in the

“TECHNICAL SPECIFICATIONS” chapter and is the only data

that allows for properly assessing whether the product is suitable

for its intended use.

Check the application limits of SO2000 and of the accessories to

be installed, assessing whether their characteristics are capable of

meeting the requirements of the environment and the limitations

specied below:

– the door dimensions must be below 215ft2 40in2 1/16 (20mq)

– the drive shaft must be compatible with the SO2000 output and

the relative keys supplied with the package

– the wall-mounting bracket must be sufciently long.

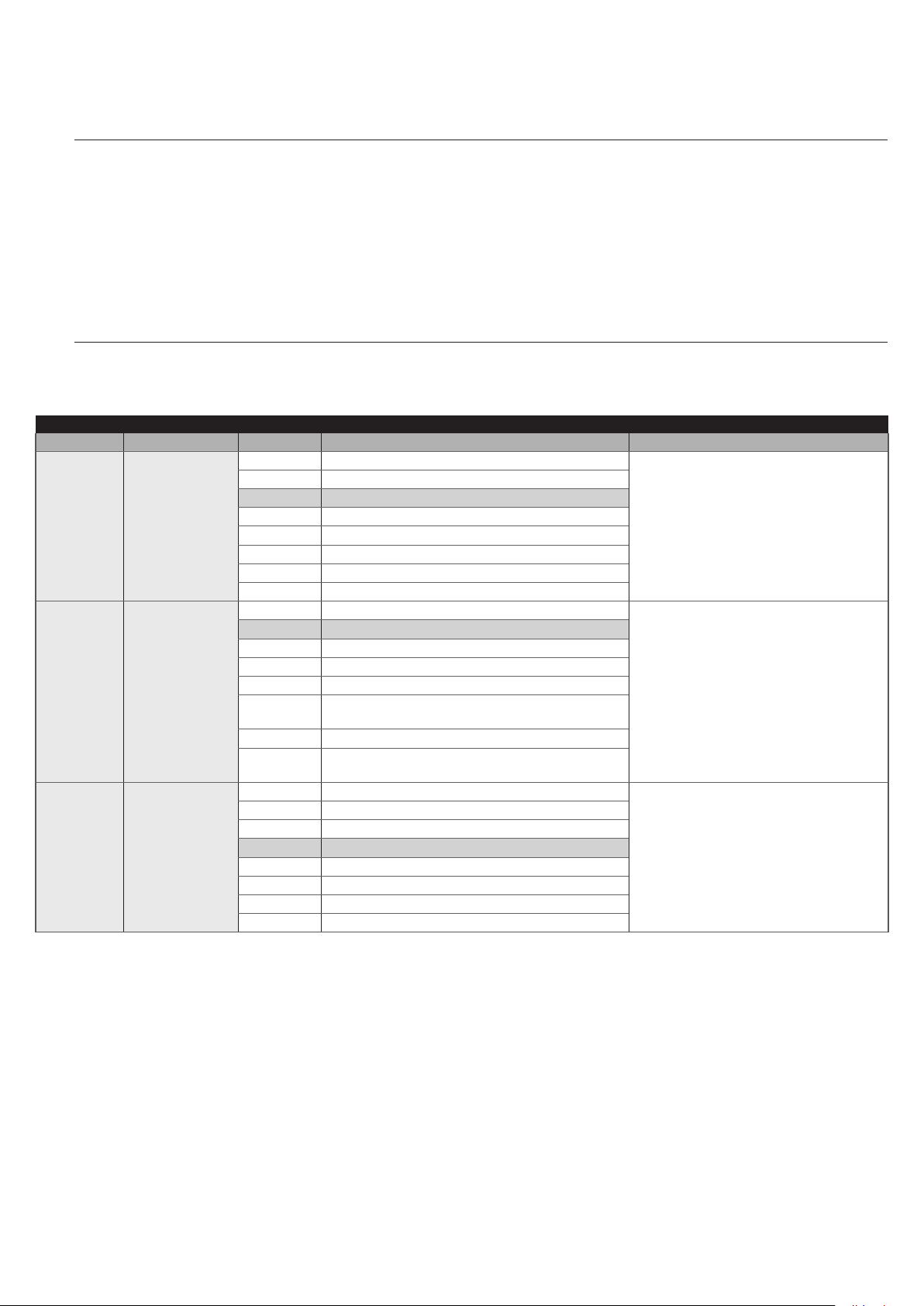

Table 1

SO2000 - LIMITATIONS OF USE IN RELATION TO THE TYPE OF

DOOR

Type of door Operating limits (m)

Door

Max height 16ft 4in

55/64 (5m)

Max width 13ft 1in

31/64 (5m)

The measurements shown in “Table 1” are purely indicative and

are only needed for making a rough estimate. The actual suitability

of SO2000 for automating a specic door depends on the degree

of leaf balancing, guide friction and other aspects, including occasional events such as wind pressure or the presence of frost, which

could obstruct the leaf’s movement.

To determine the actual conditions, the force required to move the

leaf throughout its path must be measured, to ensure that this value

does not exceed the “rated torque” specied in the “TECHNICAL

SPECIFICATIONS” chapter; moreover, to calculate the number of

cycles/hour and consecutive cycles, it is important to consider the

data shown in “Table 2”.

Table 2

SO2000 - LIMITS RELATING TO THE FORCE REQUIRED TO MOVE

THE DOOR LEAF

Force required to move the

leaf (N)

Up to 120

120 ÷ 180

180 ÷ 220

The control unit is equipped with a manoeuvre lim-

a

Maximum no. of cycles/hour

Maximum no. of consecutive cycles

20

35

18

33

15

30

iting device that prevents possible overheating; it is

based on the motor load and duration of the cycles,

and intervenes when the maximum limit is exceeded.

3.2.1 Product durability

The product’s durability is its average economic life value and is

strongly inuenced by the degree of severity of the manoeuvres: in

other words, the sum of all factors that contribute to product wear.

To estimate the durability of your automated device, proceed as

follows:

1. add the values of the items in “Table 3” relative to the sys-

tem’s conditions

2. in the graph shown in “Figure 2”, from the value obtained

above, trace a vertical line until it intersects the curve; from

this point trace a horizontal line until it intersects the line of

the “manoeuvre cycles”. The value obtained is the estimated

lifetime of your product.

The durability values shown in the graph can only be obtained if the

maintenance schedule is strictly observed – see the “PRODUCT

MAINTENANCE” chapter. The durability is estimated on the basis

of the design calculations and the results of tests effected on pro-

totypes. Being an estimate, therefore, it offers no explicit guarantee

of the product’s actual useful life.

Example of durability calculation: automation of a door

weighing 286lb 9oz (130 Kg)

“Table 3” shows the “severity indices” for this type of installation:

30% (“Weight of the door”), 20% (“Force required to move the

door”) and 10% (“Ambient temperature above 40°C or below 0°C

or humidity above 80%”).

These indicators must be added together to obtain the overall se-

verity index, which in this case is 60%. With the value identied

(60%), look at the horizontal axis of the graph (“severity index”) and

identify the value corresponding to the number of “manoeuvre cycles” that the product can perform throughout its lifetime – roughly

18,000 cycles.

ENGLISH – 5

Page 6

Table 3

100

140.000

Durability in cycles (No.)

Severity index (%)

B

PRODUCT DURABILITY

Severity

index

Weight of the

door

Force

required to

move the

door

Ambient temperature greater than 104°F (40°C) or

below 32°F (0°C), or humidity greater than 80%

Presence of dust, sand or salinity 15%

Manoeuvre interrupted by photocell 10%

Manoeuvre interrupted by Stop 20%

Speed greater than “L4 fast” 15%

< 200lb 7oz

200lb 7oz - 396lb 13oz

396lb 13oz - 507lb 1oz

> 507lb 1oz

< 352lb 12oz

352lb 12oz - 529lb 2oz

529lb 2oz - 639lb 5oz

< 100 kg

100 - 180 kg

180 - 230 kg

> 230 kg

< 160 kg

160 - 240 kg

240 - 290 kg

20%

30%

40%

60%

10%

20%

40%

10%

2

120.000

3.3 PRODUCT IDENTIFICATION AND OVERALL DIMENSIONS

The overall dimensions and label (A) that allow for identifying the

product are shown in “Figure 3”.

3

2” 41/64

(67 mm)

2” 31/64

27/64

(10,8 mm)

A

14” 49/64 (375 mm)

4” 63/64

(126,5 mm)

(63 mm)

4” 17/32

(115 mm)

61/64”

(24,3 mm)

11” 3/4 (298 mm)

100.000

80.000

60.000

40.000

20.000

0

10 20 30 40 50 60 70 80 90

3.4 RECEIPT OF THE PRODUCT

All the components contained in the product’s packaging are illustrated and listed below.

4

C

A

A Gearmotor

B Release mechanism

C 3 black self-tapping screws

D M8x130 screw

E M8 locknut

F D8 washer

G Mounting bracket

H User manual

I 2 keys

D

E

F

G

H

I

6 – ENGLISH

Page 7

3.5 PRE-INSTALLATION WORKS

The gure shows an example of an automation system, constructed using Nice components.

5

A4

6

F

B

A Gearmotor

B Photocells

C Wall-mounted push-button panel

D Photocells on column

E Warning light with incorporated antenna

F Transmitter

G Main edge

These above-mentioned components are positioned according to

a typical standard layout. Using the layout in “Figure 5” as a refer-

ence, dene the approximate position in which each component of

the system will be installed.

Table 4

TECHNICAL SPECIFICATIONS OF ELECTRICAL CABLES

Identication

no.

1

2

3

4

5

6

Cable characteristics

GEARMOTOR POWER SUPPLY cable

1 cable 3 x 15 AWG (3 x 1,5 mm2)

Maximum length 98ft 5in 7/64 (30 m) [note 1]

WARNING LIGHT cable

1 cable 2 x 17 AWG (2 x 1 mm

Maximum length 65ft 7in 13/32 (20 m)

ANTENNA cable

1 x RG58-type shielded cable

Maximum length 65ft 7in 13/32 (20 m);

recommended < 16ft 4in 55/64 (5 m)

PHOTOCELL cable

1 cable 2 x 20 AWG (2 x 0,5 mm

Maximum length 98ft 5in 7/64 (30 m) [note 2]

WALL-MOUNTED PUSH-BUTTON PANEL cable

2 cables 2 x 20 AWG (2 x 0,5 mm

Maximum length 164ft 1/2in (50 m)

MAIN EDGE cable

1 cable 2 x 20 AWG (2 x 0,5 mm

Maximum length 65ft 7in 13/32 (20 m)

2

)

2

)

2

2

)

) [note 3]

1

E

2 3

C

D

D

4

5

B

G

Note 1 If the power supply cable is longer than 98ft 5in 7/64 (30

m), a cable with larger cross-sectional area (3 x 13 AWG

(3 x 2,5 mm

2

)) must be used and a safety earthing system

must be installed near the automation.

Note 2 If the BlueBus cable is longer then 98ft 5in 7/64 (30 m),

up to maximum 164ft 1/2in (50 m), it is necessary to use a

cable with a greater cross-sectional area (2 x 17 AWG (2 x

2

1 mm

)).

Note 3 These two cables can be replaced by a single 4 x 20 AWG

(4 x 0,5 mm

Before proceeding with the installation, prepare the

a

2

) cable.

required electrical cables by referring to “Figure 5”

and to that stated in the “TECHNICAL SPECIFICA-

TIONS” chapter.

The cables used must be suited to the type of envi-

a

ronment of the installation site.

When laying the pipes for routing the electrical ca-

a

bles, take into account that any water deposits in

the junction boxes may cause the connection pipes

to form condensate inside the control unit, thus

damaging the electronic circuits.

ENGLISH – 7

Page 8

3.6 INSTALLING THE GEARMOTOR

Incorrect installation may cause serious physical

a

injury to the person working on the system or to its

future users.

Before starting to assemble the automation, complete the preliminary checks described in the “Pre-

installation checks” and “Product usage limits”

paragraphs.

The automation must be installed EXCLUSIVELY

a

WITH THE DOOR CLOSED.

To install SO2000:

1. insert the output shaft (A) into the transmission shaft (B) of

the door, coupling them with the aid of the key (C) provided

6

A

3. fasten the bracket (E) to the wall using wall plugs (not sup-

plied) suited to the wall’s material

8

E

B

C

2. fasten the bracket (E) to the gearmotor (D) using the screw,

nut and washer provided

7

D

E

4. SO2000 can be installed in the horizontal position using the

release mechanism (F), supplied with the kit, which must be

fastened with the three screws in the position shown, while

making sure that the unlocking cables (G) are fed through.

9

D

F

G

8 – ENGLISH

Page 9

3.7 MANUALLY UNLOCKING AND LOCKING THE GEARMOTOR

The gearmotor is equipped with a mechanical unlocking device

that can be used to open and close the door manually.

These manual operations should only be performed in case of a

power outage, malfunctions or during the installation phases.

To unlock the device:

1. pull the ball (A)

2. the door can now be moved manually to the desired posi-

tion.

2. insert all the connecting cables into the various devices,

leaving them 8÷12 in (20÷30 cm) longer than necessary. Refer to “Table 4” for the type of cables and to “Figure Table

4” for the connections.

3. use a clamp to hold together all the cables entering the gear-

motor then place the clamp slightly below the cable entry

hole

4. connect the other cables according to the diagram shown

in “Figure 12”. For greater convenience, the terminals are

removable.

10

A

To lock the mechanism, pull the ball (B).

4

4 ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

4.1 PRELIMINARY CHECKS

12

B

5. Connect the power cable (B) to the relevant socket, then use

another clamp to fasten the cable onto the rst cable ring.

All electrical connections must be made with the

f

system disconnected from the mains electricity and

with the back-up battery (if present) disconnected.

The connection operations must only be carried out

a

by qualied personnel.

To make the electrical connections:

1. take out the screw and remove the protective cover (A) by

lifting it up

11

A

13

B

ENGLISH – 9

Page 10

4.2 WIRING DIAGRAM AND DESCRIPTION OF CONNECTIONS

4.2.1 Wiring diagram

14

NO

NC

8K2

OSE

STOP

DOOR

CONTROL

OPEN

NO

KEYS

Light

LED

RECEIVER

FUSE

Bluebus

StopSbSOpenLight

FUSE

Flash Alarm

FLASH

AERIAL

BUZZER

TX

1 2

RX

1 2

4.2.2 Description of connections

ELECTRICAL CONNECTIONS

Terminals Description

ALARM This (programmable) output is congured as default for alarm system notications.

This output is programmable (refer to the “PROGRAMMING” chapter) to connect one of the following devices:

Warning light, “Door open indicator” output, Suction cup [note 1], Electric latch [note 1], Electric lock

[note 1].

If programmed as “warning light”, on the “FLASH” output it is possible to connect a “LUCYB” warning light

or similar with a single 12 V maximum 21 W car-type lamp. During the manoeuvre, check that the warning light

ashes at intervals of 0.5 seconds on and 0.5 seconds off.

If programmed as “door open indicator”, on the “FLASH” output it is possible to connect a 24 V max 5 W

indicator light to signal the door open status. It can also be programmed for other functions (refer to the “PRO

GRAMMING” chapter).

FLASH

If programmed as “suction cup”, on the “FLASH” output it is possible to connect a 24 V max 10 W suction

cup (versions with electromagnet only, without electronic devices). When the door is closed, the suction cup is

activated to lock the door in place. During the opening and closing manoeuvre, it is deactivated.

If programmed as “electric latch”, on the “FLASH” it is possible to connect a 24 V max 10 W electric device

with latch (versions with electromagnet only, without electronic devices).

During the opening manoeuvre, the electric latch is activated and remains active to free the door and perform

the manoeuvre.

During the closing manoeuvre, ensure that the electric latch re-engages mechanically.

If programmed as “electric lock”, on the “FLASH” output it is possible to connect a 24 V max 10 W electric

lock with latch (versions with electromagnet only, without electronic devices).

During the opening manoeuvre, the electric lock is activated for a brief interval to free the door and perform the

manoeuvre. During the closing manoeuvre, ensure that the electric lock re-engages mechanically.

Table 5

Note 1 Only devices containing the electromagnet only can be connected.

10 – ENGLISH

Page 11

ELECTRICAL CONNECTIONS

Terminals Description

This terminal can be used to connect compatible devices, which are all connected in parallel with only two

BLUEBUS

STOP

SbS

OPEN Input for devices that control the opening movement only; it is possible to connect “Normally Open” contacts.

LIGHT Input dedicated to the control of the Courtesy light; it is possible to connect “Normally Open” contacts.

ANTENNA

wires carrying both the electric power and communication signals.

For further information on the BlueBUS, refer to the “Addressing of devices connected with the BlueBUS

system” paragraph.

Input for the devices that block or, if necessary, stop the manoeuvre under way. With suitable arrangements,

“Normally Closed” or “Normally Open” contacts, or xed resistor or optical devices can be connected to the

input.

For further information on the STOP function, refer to the “Modifying the STOP input conguration”

paragraph.

Input for devices that control the movement in Step-by-Step mode; it is possible to connect “Normally Open”

contacts.

With the motor stopped, the movement lock status imposed by the Alarm system can be reset.

Antenna connection input for radio receiver; the antenna is incorporated in the warning light; alternatively, an

external antenna can be used.

4.3 ADDRESSING OF DEVICES CONNECTED WITH THE BLUEBUS SYSTEM

By means of addressing using special jumpers, the “BlueBUS”

system enables the user to make the control unit recognise the

photocells and assign the correct detection function.

The addressing operation must be done on both the TX and RX

photocells (setting the jumpers in the same way), while making

sure there are no other pairs of photocells with the same address.

In systems for automated overhead doors, the photocells can be

connected as shown in the gure below.

15

FOTO 2

FOTO 2 II

FOTO 1 II

FOTO 1

At the end of the installation procedure, or after

m

photocells or other devices have been removed, it

is necessary to complete the learning procedure

(see the “Device learning” paragraph).

FOTO II

FOTO

PHOTOCELL ADDRESSES

Photocell

FOTO (PHOTO)

External photocell h = 50 activated during

the closing phase (stops and reverses the

gate’s movement)

FOTO II (PHOTO II)

External photocell h = 100 activated

during the closing phase (stops and

reverses the gate’s movement)

FOTO 1 (PHOTO 1)

Internal photocell h = 50 activated during

the closing and opening phases (stops

and reverses the door’s movement)

FOTO 1 II (PHOTO 1 II)

Internal photocell h = 100 activated during

the closing and opening phases (stops

and reverses the door’s movement)

FOTO 2 (PHOTO 2)

External photocell activated during the

opening phase

FOTO 2 II (PHOTO 2 II)

Internal photocell activated during the

opening phase

FOTO 3 (PHOTO 3)

Single photocell covering the entire

automation

FA1

Photocell for opening command

(cut jumper A on the back of the TX and

RX boards)

FA2

Photocell for opening command

(cut jumper A on the back of the TX and

RX boards)

Table 6

Position of the

jumpers

ENGLISH – 11

Page 12

4.3.1 FT210B photosensor

RECEIVER

RECEIVER

The FT210B photosensor combines in a single device a force limiting system (type C, in accordance with the EN12453 standard)

and a presence sensor that detects obstacles on the line of sight

between the TX transmitter and RX receiver (type D, in accordance

with the EN12453 standard). In the FT210B photosensor, the signals regarding the status of the sensitive edge are sent through the

photocell range, integrating the 2 systems in a single device. The

transmitting element located on the moving leaf is battery-powered, which eliminates visually unpleasant connection systems;

special circuits reduce battery consumption, ensuring up to 15

years’ life (see estimation details in the product’s instructions).

A single FT210B device combined with a sensitive edge (TCB65,

for example) allows for attaining the level of safety of the “primary

edge” required by the EN12453 standard for all “types of use” and

“types of activation”.

The FT210B photosensor combined with the “resistive” sensitive

edges (8.2 kΩ) is safe against faults (category 3 pursuant to the

EN 13849-1 standard). It is equipped with a special anti-collision

circuit to prevent interference with other detectors, even not syn-

chronised, and allows for adding other photocells; for example,

in case of transit of heavy vehicles, where a second photocell is

normally positioned 1 m above the ground.

Consult the FT210B instruction manual for further

l

information on the connection and addressing

methods.

5.2 DEVICE LEARNING

Once the power supply has been connected, the control unit must

recognise the devices connected to the “BlueBUS” and “STOP”

inputs. Prior to this phase, LEDs “L1” and “L2” will ash to signal

that the device learning procedure must be performed.

The learning phase must be carried out even if no

m

device is connected to the control unit.

To do this:

1. simultaneously press and hold the

2. release the buttons when LEDs “L1” and “L2” start ashing

quickly (after roughly 3 seconds)

3. wait a few seconds until the control unit has completed the

device learning phase

4. once this phase terminates, the “Stop” LED must be lit and

LEDs “L1” and “L2” must switch off (LEDs “L3” and “L4”

could start ashing).

16

LED

L1

L2

Light

and o buttons

p

FUSE

FUSE

5

5 FINAL CHECKS AND START-UP

It is advisable to position the leaf approximately halfway along its

path before starting the automation check and start-up phases, so

that the leaf is free to open and close.

FINAL CHECKS AND START-UP

5.1 POWER SUPPLY CONNECTION

The power supply connections must only be made

a

by qualied and experienced personnel possessing

the necessary requirements and in full conformity

to the laws, regulations and standards in force.

As soon as the product is powered, a few simple checks should

be carried out:

1. check that the BlueBus LED ashes regularly with one ash

per second.

2. make sure that the LEDs on the photocells (both the TX and

RX) also ash; the type of ashing is irrelevant, since it depends on other factors.

3. check that the warning light connected to the FLASH output

is off.

4. check that the courtesy light is off.

If the above conditions are not satised, immediately switch off the

power supply to the control unit and carefully check the electrical

connections.

Further useful information on searching and diagnosing faults is

included in the “Troubleshooting” paragraph.

Flash Alarm

Bluebus

StopSbSOpenLight

The self-learning phase of the connected devices can be repeated

at any time also after the installation, for example whenever a device must be added.

5.3 LEARNING OF THE DOOR OPENING AND CLOSING POSITIONS

Once the devices have been learned, the control unit must recognise the door opening and closing positions, in addition to a few

optional positions.

There are 6 positions in total:

Before this phase, LEDs “L3” and “L4” ash (“Figure 17”) to signal that the positions must be learned.

17

FUSE

LED

L3

L4

Light

FUSE

12 – ENGLISH

StopSbSOpenLight

Bluebus

Flash Alarm

Page 13

The position memorisation procedures are described below.

Two procedures are available:

– FULL: enables the user to manually set multiple positions

(FCA-opening limit switch, RA-opening slowdown, RI-intermediate slowdown, AP-partial opening, etc.)

– REDUCED: allows for setting only the opening and closing limit

switches (respectively FCA and FCC; the other positions will be

calculated autonomously by the control unit). If necessary, they

can be modied at a later stage through the full procedure.

Table 7

PROGRAMMING POSITIONS

Position

A1 L1

RA1 L2

RINT L4

AP L5

RA0 L7

A0 L8

m

LED Description

Maximum desired opening position. When the

door reaches this position it stops.

Slowdown start position during opening

manoeuvre. When the door reaches this position,

the motor slows down to the minimum speed.

Intermediate slowdown position during closing

manoeuvre. When this point is programmed, the

door starts to slow down roughly 50 cm before

the point so that it passes the intermediate

slowdown position at minimum speed. On

passing the intermediate slowdown position, the

motor returns to the set speed.

Partial opening position. This is the position at

which the door stops after receiving a partial

opening command.

Slowdown start position during closing

manoeuvre. When the door reaches this position,

the motor slows down to the minimum speed.

Maximum closing position. When the door

reaches this position it stops.

The automation can only be moved between the 5%

and 95% values of the nominal range. If the automation’s position falls out of this range, the control

unit will signal an overrun error (refer to the control unit signals chapter): it is necessary to manu-

ally turn the motor axis or impart any manoeuvre

command to bring the automation back to a valid

position. If this is not done, the automation cannot

be moved in any way.

FULL PROCEDURE

1. Press the

sition memorisation mode

Position A1 programming, LED “L1” ashes:

2. use the

mum opening position

3. press the

LED “L1” will remain lit

Position RA1 programming, LED “L2” ashes:

4. if the opening slowdown position does not have to be pro-

grammed, press the

next programming; LED “L2” will remain off. Otherwise, pro-

ceed with the sequence

5. use the

slowdown position

6. press the

LED “L2” will remain lit

and q buttons for 3 seconds to enter the po-

o

and q buttons to move the door to the maxi-

p

button for 2 seconds to conrm position “A1”.

o

button twice rapidly to skip to the

o

and q buttons to move the door to the opening

p

button for 2 seconds to conrm position “RA1”.

o

Position RINT programming, LED “L4” ashes:

7. If the intermediate slowdown position does not have to be

programmed, press the

the next programming; LED “L4” will remain off. Otherwise,

proceed with the sequence

8. use the

diate slowdown position

9. press the

“RINT”. LED “L4” will remain lit

Position RAP programming, LED “L5” ashes:

10. if the partial opening position does not have to be pro-

grammed, press the

next programming; LED “L5” will remain off. Otherwise, pro-

ceed with the sequence

11. use the

opening position

12. press the

“RAP”. LED “L5” will remain lit

Position RA0 programming, LED “L7” ashes:

13. if the closing slowdown position does not have to be pro-

grammed, press the

next programming; LED “L7” will remain off. Otherwise, pro-

ceed with the sequence

14. use the

slowdown position

15. press the

LED “L7” will remain lit

Position A0 programming, LED “L8” ashes:

16. use the

mum closing position

17. press the

LED “L8” will remain lit

18. when the

19. the courtesy light will start ashing once every second (1

Hz) to signal the need to run the MANDATORY “Automatic

Force Search” procedure. During the “Automatic Force

Search” procedure, check that there are no assembly and

adjustment defects, or other anomalies, for example points

of excessive friction

20. impart a movement command (for example: through the

“SbS”, “OPEN” inputs) to start the” Automatic Force

Search” procedure: 3 complete cycles will be performed.

If the above-mentioned procedure is interrupted, it can be

restarted by selecting the “SbS”, “Open”, “Close” commands.

REDUCED PROCEDURE

1. Press the

sition memorisation mode

Position A1 programming, LED “L1” ashes:

2. use the

mum opening position

3. press the

LED “L1” will remain lit

Position A0 programming, LED “L8” ashes:

4. use the

mum closing position

5. press the

LED “L8” will remain lit

6. when the

and q buttons to move the door to the interme-

p

button for 2 seconds to conrm position

o

and q buttons to move the door to the partial

p

button for 2 seconds to conrm position

o

and q buttons to move the door to the closing

p

button for 2 seconds to conrm position “RA0”.

o

and q buttons to move the door to the maxi-

p

button for 2 seconds to conrm position “A0”.

o

button is released, all the LEDs will switch off

o

and q buttons for 3 seconds to enter the po-

o

and q buttons to move the door to the maxi-

p

button for 5 seconds to conrm position “A1”.

o

and q buttons to move the door to the maxi-

p

button for 2 seconds to conrm position “A0”.

o

button is released, all the LEDs will switch off

o

button twice rapidly to skip to

o

button twice rapidly to skip to the

o

button twice rapidly to skip to the

o

ENGLISH – 13

Page 14

7. the courtesy light will start ashing once every second (1

RECEIVER

L8

RECEIVER

Hz) to signal the need to run the MANDATORY “Automatic

Force Search” procedure. During the “Automatic Force

Search” procedure, check that there are no assembly and

adjustment defects, or other anomalies, for example points

of excessive friction

8. impart a movement command (for example: through the

“SbS”, “OPEN” inputs) to start the” Automatic Force

Search” procedure: 3 complete cycles will be performed.

If the above-mentioned procedure is interrupted, it can be

restarted by selecting the “SbS”, “Open”, “Close” commands.

During these manoeuvres, the control unit memorises the force

required for the opening and closing movements.

18

L7

L2

L1

L5

L4

FUSE

LED

FUSE

To do this:

1. press the

check that the door opens properly without any speed variations; only when the leaf reaches the “RA1” position, it must

reach the minimum speed and stop at the “A1” maximum

opening position

2. press the

check that the door closes properly without any speed variations; only when the leaf reaches the “RA0” position, it must

reach the minimum speed and stop at the “A0” maximum

closing position

3. during the manoeuvre, check that the warning light ashes

at intervals of 0.5 seconds on and 0.5 seconds off

4. open and close the gate several times to make sure that

there are no points of excessive friction and that there are no

defects in the assembly or adjustments

5. check that the gearmotor is fastened in a solid, stable and

suitably resistant manner even during sudden door acceleration or slowdown movements.

button to command an “Open” manoeuvre;

p

button to command a “Close” manoeuvre;

q

5.5 CONNECTING OTHER DEVICES

If the user needs to power external devices, such as a proximity

reader for transponder cards or the light of the key selector switch,

power can be tapped as shown in the gure.

The power supply voltage is 24Vc -30% ÷ +50% with a maximum

available current of 100mA.

The position learning procedure can be redone at any time, even

after installation; simply repeat it from the beginning. If only a single

position must be modied, repeat the reduced procedure only.

It is important that the “Automatic Force Search”

m

procedure is not interrupted, e.g. by a STOP command. If the “positions”, “motor opening speed”,

“motor closing speed” and “motor rotation direction” parameters are modied, the “Automatic Force Search” procedure will be automatically re-proposed by the control unit. The procedure

must terminate correctly and autonomously, that is,

without any interruptions: the procedure will remain

pending even after a blackout.

5.4 CHECKING THE DOOR MOVEMENT

Once the leaf length has been learned, it is advisable to carry out

a few manoeuvres in order to verify that the door moves properly.

19

FUSE

FUSE

LED

20

(-)(+)

SBS

6

6 TESTING AND COMMISSIONING

These are the most important phases of the automation’s con-

struction, as they ensure maximum safety of the system. The test

can also be used to periodically verify the devices making up the

automation.

m

TESTING AND COMMISSIONING

Testing and commissioning of the automation must

be performed by skilled and qualied personnel,

who are responsible for the tests required to verify the solutions adopted according to the risks

present, and for ensuring that all legal provisions,

standards and regulations are met, in particular all

the requirements of the EN 12445 standard, which

denes the test methods for checking door automations.

The additional devices must undergo specic testing, both in terms

of their functions and their proper interaction with the control unit.

Refer to the instruction manuals of the individual devices.

STOP

14 – ENGLISH

Page 15

6.1 TESTING

To run the test:

1. verify that all the instructions stated in the “GENERAL

SAFETY WARNINGS AND PRECAUTIONS” chapter have

been strictly observed

2. unlock the gearmotor as indicated in the “Manually un-

locking and locking the gearmotor” paragraph

3. make sure that the leaf can be moved manually during both

the opening and closing phases with a force not exceeding

225N (roughly 51 lb (23 Kg))

4. lock the gearmotor

5. using the control devices (selector, radio transmitter, etc.),

test the door opening, closing and stoppage phases, en-

suring that the movement matches the specications. Run

several tests to check that the door moves smoothly and

check for any defects in the assembly or adjustment and any

possible points of friction

6. To check the operation of the photocells and ensure that

there is no interference with other devices, pass a cylinder

(2in (5 cm) diameter, 12in (30 cm) length) on the optical axis,

rst near the “TX” photocell then near “RX” photocell and,

lastly, at the mid-point between the two and verify that in

all these cases the device is triggered, switching from the

active to the alarm status and vice-versa; make sure that it

triggers the intended action in the control unit; for example,

that it triggers the reversal of movement during the closing

manoeuvre.

7. check, one-by-one, that all safety devices mounted on the

system (photocells, sensitive edges, etc.) work properly.

Each time a device intervenes, the “Bluebus” LED on the

control unit will emit two faster ashes to conrm the recognition

8. if potentially dangerous situations due to the movement of

the leaves have been prevented by limiting the impact force,

the latter must be measured according to the EN 12445

standard and, if the “motor force” control is used to aid the

system in reducing the impact force, it is necessary to test

various adjustments to nd the one that gives the best results.

6.2 COMMISSIONING

Commissioning can only be performed after all

a

testing phases have been successfully completed.

Before commissioning the automation, ensure that

a

the owner is properly informed of all residual risks

and hazards.

21

3. permanently afx a label or sign to the door with the follow-

ing image (minimum height 2in 3/8 (60 mm)) “Figure 22“

22

4. afx a label to the door containing at least the following data:

type of automation, name and address of manufacturer (person responsible for commissioning), serial number, year of

manufacture and the CE mark

5. compile the declaration of conformity of the automation and

hand it to the owner of the automation

6. compile the User Manual of the automation and hand it to

the owner of the automation

7. compile and provide the owner with the automation’s “Main-

tenance schedule”, containing the maintenance instructions

for all the automation’s devices.

For all the above-mentioned documentation, Nice –

l

through its technical assistance service – provides

the following: pre-completed forms.

The gate cannot be commissioned partially or un-

a

der “temporary” conditions.

To commission the automation:

1. compile the automation’s technical le, which must include

the following documents: overall drawing of the automation, wiring diagram, risk assessment and relative solutions

adopted, the manufacturer’s declaration of conformity for all

devices used and the declaration of conformity compiled by

the installer

2. permanently afx a label or plate in the vicinity of the door,

indicating the operations for the door unlocking and manual

manoeuvres “Figure 21“

ENGLISH – 15

Page 16

7

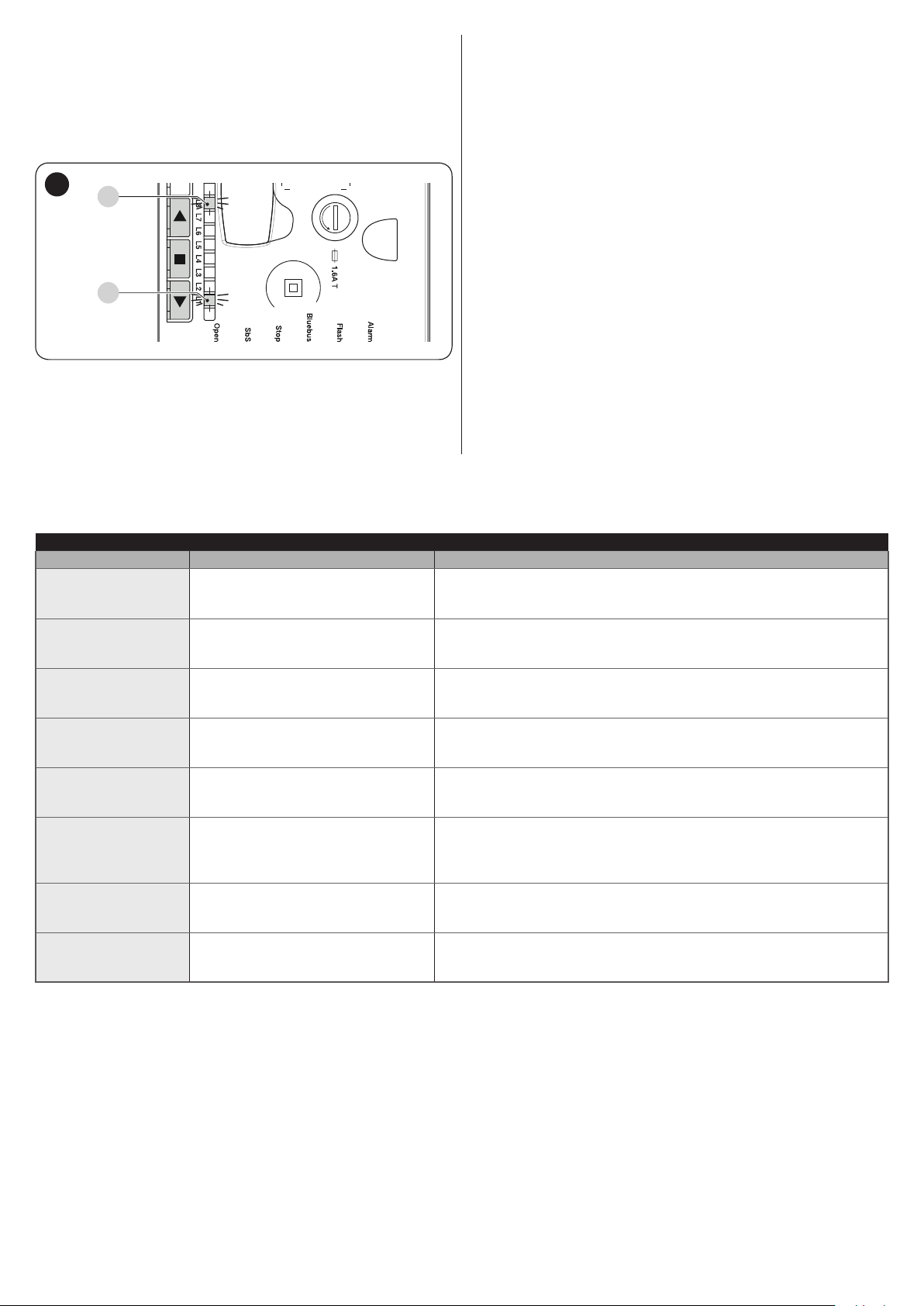

RECEIVER

7 PROGRAMMING

There are 3 buttons on the control unit: p, o and q (“Figure

23”) which can be used both to command the control unit during

the testing phase and to programme the available functions.

PROGRAMMING

23

FUSE

FUSE

LED

L1 ... L8

The available programmable functions are grouped into two levels

and their operating status is signalled by eight LEDs “L1 ... L8”

located on the control unit (LED lit = function enabled; LED off =

function disabled).

7.1 USING THE PROGRAMMING BUTTONS

The button allows for commanding the door opening move-

p

ment, or shifting the programming point upwards.

Button used to stop a manoeuvre

o

If pressed for more than 3 seconds, it allows for entering the

programming mode.

The button enables the user to close the door or shift the

q

programming point downwards.

During the manoeuvre, whether opening or closing is irrelevant, all the buttons perform the STOP function and stop the

motor’s movement.

16 – ENGLISH

Page 17

7.2 LEVEL 1 PROGRAMMING (ON-OFF)

All the Level 1 functions are factory-set to “OFF” and can be modied at any time. To check the various functions, refer to “Table 8”.

7.2.1 Level 1 programming procedure

The user has maximum 10 seconds to press the buttons consecutively during the programming procedure, af-

m

ter which time the procedure terminates automatically and memorises the changes made up to then.

To perform Level 1 programming:

1. press and hold the

2. release the

3. press the

4. press the

– short ash = OFF

– long ash = ON

5. wait 10 seconds (maximum time) to exit the programming mode.

To set other functions to “ON” or “OFF”, while the procedure is running, repeat points 2 and 3 during the phase

l

button when LED “L1” starts ashing

o

or q button to move the ashing LED to the LED associated with the function to be modied

p

button to change the status of the function:

o

itself.

LEVEL 1 FUNCTIONS (ON-OFF)

LED Function Description

L1 Automatic closing

L2 Close after photo

L3 Always Close

L4 Stand-by

L5 Long reversal

L6 Pre-ashing

L7 Sensitivity

L8 Type of door

button until LED “L1” starts ashing

o

Function ENABLED: after an opening manoeuvre there is a pause (equal to the set pause time), after which

the control unit automatically starts a closing manoeuvre. The pause time is set by default to 30 seconds.

Function NOT ENABLED: the system works in “semi-automatic” mode.

Function ENABLED: the behaviour changes depending on whether the “Automatic Closing” function is

enabled or not.

When “Automatic closing” is not active: The door always reaches the fully open position (even if Photo is

disengaged beforehand). When Photo disengages, automatic closing is triggered with a 5-second pause.

When “Automatic Closing” is enabled: the opening manoeuvre stops immediately after the photocells have

disengaged. After 5 seconds, the gate will start closing automatically.

The “Close After Photo” function is always disabled in manoeuvres interrupted by a Stop command.

Function DISABLED: the pause time is that which has been programmed or automatic re-closing will not take

place if the function is disabled.

Function ENABLED: in the event of a blackout, even of short duration, if the control unit detects that the door

is open once the electricity is restored, it automatically starts a closing manoeuvre, preceded by a 3-second

pre-ashing sequence.

Function DISABLED: when the electricity is restored, the gate remains in the same position.

Function ENABLED: 1 minute after the completion of the manoeuvre, the control unit switches off the

BlueBUS output (and, therefore, the devices) and all LEDs, with the exception of the BlueBUS LED, which

ashes more slowly. When the control unit receives a command, it restores full operation.

Function DISABLED: there will be no reduction in consumption.

This function is useful, in particular, during operation with the back-up battery.

Function ENABLED: once the STOP device or the force limiter intervenes, the movement is reversed up to the

maximum opening or closing position

Function DISABLED: the reversal is short (roughly 6in (15cm)).

Function ENABLED: a 3-second pause can be added between the switching on of the warning light and the

start of the manoeuvre, to warn the user in advance of a potentially dangerous situation.

Function DISABLED: the signalling of the warning light coincides with the start of the manoeuvre.

Function ENABLED: allows for considerably increasing the motor’s sensitivity in detecting obstacles. If used

to aid impact force detection, the “Speed” and “Motor force” parameters in the Level 2 menu must also be

adjusted.

Function DISABLED: the motor’s obstacle detection sensitivity is unchanged.

Function ENABLED: allows for selecting the type of door to be moved: Light or Heavy. If enabled, the control

unit is optimised to move Heavy doors.

Function DISABLED: the control unit is optimised to move smaller-size doors.

Table 8

During normal operation, in other words when no manoeuvre is under way, LEDs “L1 ... L8“” are on or off de-

l

pending on the status of the respective function; for example, “L1” is lit when the “Automatic Closing” function

is enabled. During the manoeuvre, LEDs “L1 ... L8” ash to signal the force required to move the door at that

time. If “L1” ashes, the force required is low and so forth, until LED “L8” ashes to signal the maximum force.

There is no relation between the force level indicated by the LEDs during the movement (which is an absolute

value) and the level indicated by the LEDs during the force (which is a relative value) programming phase. See

“L5” and “L6” in “Table 9”.

ENGLISH – 17

Page 18

7.3 LEVEL 2 PROGRAMMING (ADJUSTABLE PARAMETERS)

All the Level 2 parameters are factory-set as highlighted in “GREY” in “Table 9” and can be modied at any time. The parameters can

be set to a scale of 1 to 8. The check the value corresponding to each LED, refer to “Table 9”.

7.3.1 Level 2 programming procedure

The user has maximum 10 seconds to press the buttons consecutively during the programming procedure, af-

m

ter which time the procedure terminates automatically and memorises the changes made up to then.

To perform Level 2 programming:

1. press and hold the

2. release the

3. press the

4. press and hold the

– wait roughly 3 seconds, until the LED representing the current level of the parameter to be modied lights up

– press the

5. release the

6. wait 10 seconds (maximum time) to exit the programming mode.

To set multiple parameters during the procedure's execution, repeat the operations from point 2 to point 4 dur-

l

button when LED “L1” starts ashing

o

or q button to move the ashing LED to the “entry LED” associated with the parameter to be modied

p

p

button

o

ing the phase itself.

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry LED Parameter LED (level) Set value Description

L1* Pause Time

L2**

L3* Motor speed

Step-by-Step

function

button until LED “L1” starts ashing

o

button. With the o button pressed:

o

or q button to shift the LED associated with the parameter’s value

L1 10 seconds

L2 20 seconds

L3 40 seconds

L4 60 seconds

L5 80 seconds

L6 120 seconds

L7 160 seconds

L8 200 seconds

L1 Open - Stop - Close - Stop

L2 Open - Stop - Close - Open

L3 Open - Close - Open - Close

L4 Condominium

L5 Condominium 2 (more than 2 sec triggers “Stop”)

L6

L7 Hold-to-run

L8

L1 Speed 1 (30% - slow)

L2 Speed 2 (44%)

L3 Speed 3 (58%)

L4 Speed 4 (72%)

L5 Speed 5 (86%)

L6 Speed 6 (100% - fast)

L7 Open V4, close V2

L8 Open V6, close V4

Step-by-Step 2 (more than 2 sec triggers “Partial

Open”)

Opening in “semi-automatic” mode, closing in

“hold-to-run” mode

Table 9

Adjusts the pause time, in other words,

the time before automatic re-closure. It is

only effective if the “Automatic Closing”

function is enabled.

Controls the sequence of controls

associated with the Sbs input or the 1st

radio command.

Adjusts the motor speed during normal

manoeuvres.

18 – ENGLISH

Page 19

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry LED Parameter LED (level) Set value Description

L1 Door Open Indicator

L2 Enabled if door closed

L3 Enabled if door open

L4** FLASH output

L5*

L6*

L7*

L8

Motor force on

opening

Motor force on

closing

Maintenance

notice

List of

malfunctions

L4 Warning light

L5 Electric latch

L6 Electric lock

L7 Suction cup

L8 Maintenance indicator

L1 Force 1 (low)

L2 Force 2

L3 Force 3

L4 Force 4

L5 Force 5

L6 Force 6

L7 Force 7

L8 Force 8 (high)

L1 Force 1 (low)

L2 Force 2

L3 Force 3

L4 Force 4

L5 Force 5

L6 Force 6

L7 Force 7

L8 Force 8 (high)

L1

L2 1000

L3 2000

L4 4000

L5 6000

L6 8000

L7 10000

L8 12000

L1 Result of 1st manoeuvre (most recent)

L2 Result of 2nd manoeuvre

L3 Result of 3rd manoeuvre

L4 Result of 4th manoeuvre

L5 Result of 5th manoeuvre

L6 Result of 6th manoeuvre

L7 Result of 7th manoeuvre

L8 Result of 8th manoeuvre

Automatic (depending on the severity of the

manoeuvres)

Selects the device connected to the

FLASH output.

Adjusts the motor force control system to

adapt it to the weight of the door during

the opening manoeuvre.

Adjusts the motor force control system to

adapt it to the weight of the door during

the closing manoeuvre.

Adjusts the number of manoeuvres after

which the automation maintenance

request is triggered (see the “

“Maintenance notice” function”

paragraph).

Allows for viewing the type of anomalies

that occurred in the last 8 manoeuvres

(refer to the “Anomaly log” paragraph).

This is a read-only parameter, which

means that its values cannot be modied.

All parameters can be adjusted as desired without any problems; only the “Motor force on opening” and “Motor force on closing” settings

require special attention:

– high force values should not be used to compensate for points of abnormal friction on the leaf. Excessive force can jeopardise the

operation of the safety system or damage the leaf

– if the “Motor Force” control is used to aid the impact force reduction system, measure the force again after each adjustment in ac-

cordance with the EN 12445 standard

– wear and atmospheric conditions inuence the door’s movement, so the force settings should be checked periodically.

(*) If the value of a parameter falls between two adjacent values, the control unit will switch on intermittently the two LEDs identifying

the value itself. If necessary, the values can be rounded off by pressing the

or q button to round off respectively to the higher

p

or lower value among the two values highlighted by the control unit.

Example: Maintenance warning = 7000 manoeuvres - LEDs L5 and L6 ash. Pressing the

(6000), while pressing the

button rounds off to value L6 (8000).

p

button rounds off to value L5

q

If the value of a parameter is below the minimum value or above the maximum value among those listed in the table, the control

unit will switch on intermittently LED L1 or L8 respectively. If necessary, the values can be rounded off by pressing the

p

or q

button to round off to the nearest value.

Example: Pause Time = 5 seconds - LED L1 will ash. Pressing the

button rounds off to value L1 (10 s) and L1 will no longer

p

ash because the parameter will have been rounded off to a known value.

(**) If the conguration has not been learned, when LEVEL 2 of the MENU opens up, the control unit will propose the default cong-

uration.

ENGLISH – 19

Page 20

7.4 PROGRAMMING THE DIRECTION

This procedure allows for reversing the motor’s rotation direction.

To do this:

1. press and hold the

2. release the

3. simultaneously press the

motor’s direction

4. release the

– the lit courtesy light signals that the reversal of the motor

direction has been programmed

– if the courtesy light is off, the standard motor rotation di-

rection has been programmed.

5. wait 10 seconds to exit the programming mode due to the

expiry of the maximum time limit.

Note Points 3 and 4 can be repeated during the same program-

ming phase to change the direction of motor rotation.

When the direction of motor rotation is changed,

m

button when LED “L1” starts ashing

o

and q buttons:

p

button for roughly 3 seconds

o

and q buttons to change the

p

the “Position memorisation” procedure must be repeated (refer to the “Learning of the door opening

and closing positions” paragraph).

At the end of the programming procedure, it is necessary to verify

the direction of motor rotation.

To do this:

1. disconnect the power supply (by removing the plug or fuse)

2. power the device

3. after the initial ashing of LEDs “L1 … L8”, a single LED light

up to signal the encoder position

4. on the signal indicating the encoder position, check the

courtesy light:

– if the courtesy light switches on, the reversed direction of

motor rotation has been programmed

– if the courtesy light is off, the standard motor rotation di-

rection has been programmed.

7.5 RESETTING THE ENCODER POSITION

This procedure allows for restoring the encoder to the factory-set

position to enable the assembly of Soon with the door closed. At

the same time, it will reset the factory settings in the memory: all the

parameters and the settings chosen by the user will be restored.

If the motor’s direction of rotation must be modied, rst run the

“Programming the direction” procedure then the “Resetting

the encoder position” procedure.

The procedure described below must be performed

m

exclusively on a workbench. Do not perform the

procedure with the motor installed.

To do this:

1. press and hold the

“L1” to “L8” light up.

2. release the buttons when only one lights up again (from “L1”

to “L8”) to signal the current position of the encoder

3. press and release the

The control unit commands the motor’s movement to bring

the encoder position to LED “L7”

4. once the motor has stopped, all LEDs switch on and then

off; at this point, check that the LED that lights up again is

“L7”. If this does not occur, repeat the procedure

5. at the end of the sequence, LEDs “L1” and “L2” continue

to ash.

and q buttons until all LEDs from

p

button when the motor restarts.

o

7.6 SPECIAL FUNCTIONS

7.6.1 “Always open” function

The “Always open” function is a control unit feature that enables the

user to always command an opening manoeuvre when the “Step-

by-Step” command lasts longer than 2 seconds; this is useful,

for example, for connecting a timer contact to the SbS terminal in

order to keep the gate open for a certain time frame.

This feature is valid regardless of how the “SbS” input is programmed, unless it is programmed to perform the “Condominium 2” function. Refer to the “Step-by-Step function” under the “

Level 2 programming (adjustable parameters)” paragraph.

7.6.2 “Move anyway” function

This function can be used to operate the automation even one or

more some safety devices fail to work properly or are out of order.

The automation can be controlled in “hold-to-run” mode by proceeding as follows:

1. send a command to operate the gate, using a transmitter or

key selector, etc. If everything functions properly, the gate

will move normally, otherwise proceed with point 2

2. within 3 seconds, press the control again and hold it down

3. after roughly 2 seconds, the gate will complete the request-

ed manoeuvre in “hold-to-run” mode, in other words, it will

continue to move so long as the control is held down.

When the safety devices fail to work, the warning

l

light will emit a few ashes to signal the type of

problem. To verify the type of anomaly, consult the “

TROUBLESHOOTING GUIDE” chapter.

7.6.3 “Maintenance notice” function

This function noties the user when the automation needs a maintenance check. The number of manoeuvres after which the signal

is triggered can be selected among 8 levels, through the “Main-

tenance notice” adjustable parameter (see paragraph “Level 2

programming (adjustable parameters)“).

Level 1 adjustment is “automatic” and takes into account the severity of the manoeuvres, in other words, their force and duration,

while the other adjustments are dened on the basis of the number

of manoeuvres.

The maintenance signal is sent through the Flash warning light or

the maintenance indicator, depending on the relative settings (see

paragraph “Level 2 programming (adjustable parameters)“).

The “Flash” warning light and the maintenance indi-

l

cator give the signals indicated in “Table 10” based

on the number of manoeuvres completed with respect to the set limit.

20 – ENGLISH

Page 21

Table 10

RECEIVER

RECEIVER

RECEIVER

MAINTENANCE NOTICE THROUGH FLASH AND MAINTENANCE

INDICATOR

Number of

manoeuvres

Below 80% of the

limit

Between 81% and

100% of the limit

Exceeding 100% of

the limit

Signal on “Flash”

Normal (0.5 sec on,

0.5 sec off)

Remains lit for 2

seconds at the start

of the manoeuvre

Remains lit for 2

seconds at the

start and end of the

manoeuvre then

carries on normally

Maintenance

indicator signal

Lit for 2 seconds

at the start of the

opening manoeuvre

Flashes for the

entire duration of the

manoeuvre

Flashes always

7.7 VERIFYING THE NUMBER OF MANOEUVRES COMPLETED

The “Maintenance notice” function can be used to verify the

number of manoeuvres completed as a percentage of the set limit.

24

L7

FUSE

LED

FUSE

25

L7

FUSE

LED

L1

To do this:

1. press and hold the

2. release the

3. press the

that is, the “entry LED” for the “Maintenance notice” parameter

4. press and hold the

– wait roughly 3 seconds until the LED representing the cur-

rent level of the “Maintenance notice” parameter lights

up

– press and hold for at least 5 seconds the

tons then release them. The LED corresponding to the

selected level will emit a series of fast ashes to signal that

the manoeuvre counter has been reset

5. release the

button when LED “L1” starts ashing

o

or q button to shift the ashing LED to “L7”,

p

button

o

button until LED “L1” starts ashing

o

button. With the o button pressed:

o

FUSE

p

7.9 MEMORY DELETION

and q but-

L1

To do this:

1. press and hold the

2. release the

3. press the

that is, the “entry LED” for the “Maintenance notice” parameter

4. press and hold the

– wait roughly 3 seconds until the LED representing the cur-

rent level of the “Maintenance notice” parameter lights

up

– press and immediately release the

– the LED corresponding to the selected level will ash a

few times; the number of ashes indicates the percentage

of manoeuvres performed (in multiples of 10%) with re-

spect to the set limit. For example: with the maintenance

notice set to L7 namely 10000, 10% corresponds to 1000

manoeuvres; if the visualisation LED ashes 4 times, it

means that 40% of the manoeuvres has been reached

(being between 4000 and 4999 manoeuvres). If 10% of

the manoeuvres has not yet been reached, the LED does

not ash at all.

5. release the

button when LED “L1” starts ashing

o

or q button to shift the ashing LED to “L7”,

p

button.

o

button until LED “L1” starts ashing

o

button. With the o button pressed:

o

and q buttons

p

7.8 MANOEUVRE COUNTER RESETTING

Once maintenance has been performed on the system, the manoeuvre counter must be reset.

The procedure described below restores the con-

m

trol unit’s default settings. All the custom settings

will be lost.

26

FUSE

FUSE

LED

L1 ... L8

To delete the control unit’s memory and restore all the default settings, proceed as described below:

1. press and hold the

LEDs “L1-L8” light up (after roughly 3 seconds)

2. release the buttons

3. if the operation was successful, the programming LEDs “L2”

and “L8” will ash rapidly for 3 seconds.

With this procedure it is possible to also delete any

l

errors left in the memory.

This procedure does not cancel the parameter rel-

l

ative to the motor’s rotation direction and the num-

ber of manoeuvres executed.

and q buttons until the programming

p

ENGLISH – 21

Page 22

8

8 TROUBLESHOOTING GUIDE

8.1 TROUBLESHOOTING

The table below contains useful instructions to resolve any malfunctions or errors that may occur during installation or in case of a fault.

TROUBLESHOOTING

Problems Recommended checks

The radio transmitter does not control the

automation and the LED on the transmitter

fails to light up

The radio transmitter does not control the

automation but the LED on the transmitter

lights up

No manoeuvre starts and the “BlueBUS”

LED does not ash

No manoeuvre starts and the warning light

is off

No manoeuvre starts and the warning light