ROX

ROX600

ROX1000

ROX1000/V1

For sliding gates

EN - Instructions and warnings for installation and use

CONTENTS

GENERAL WARNINGS

SAFETY - INSTALLATION - USE 2

1 - PRODUCT DESCRIPTION AND INTENDED USE 3

2 - OPERATING LIMITS 3

3 - INSTALLATION 4

4 - ELECTRICAL CONNECTIONS

4.1 - Types of electrical cables 9

4.2 - Electrical cable connections 9

5 - STARTING THE AUTOMATION AND CHECKING

THE CONNECTIONS

5.1 - Hooking the automation up to the mains 10

6 - TESTING AND COMMISSIONING

6.1 - Testing 11

6.2 - Commissioning 12

7 - PROGRAMMING

GLOSSARY 12

7.1 - Control unit: programming keys 13

7.1.1 - Trimmer 13

7.2 - Programmable functions 14

7.3 - Integrated radio receiver 15

7.3.1 - Memorisation of radio transmitters 15

7.3.2 - “Remote” memorisation 16

7.3.3 - Deleting radio transmitters 16

8 - DETAILED INFORMATION

8.1 - Adding or removing devices 17

8.2 - Power for external devices 17

8.3 - Total deletion of the receiver’s memory 17

8.4 - Diagnostics 17

8.4.1 - Control unit signals 17

9 - SCRAPPING 18

10 - BASIC TROUBLESHOOTING... 18

11 - MAINTENANCE 19

12 - TECHNICAL SPECIFICATIONS 19

CE DECLARATION OF CONFORMITY 20

User manual (end user version) 21

English – 1

GENERAL WARNINGS SAFETY - INSTALLATION - USE (instructions translated from Italian)

ATTENTION Important safety instructions. Follow all instructions as improper installation may cause serious damage

ATTENTION Important safety instructions. It is important for you to comply with these instructions for your own and other

people’s safety. Keep these instructions

• Before commencing the installation, check the “Technical characteristics” (in this manual), in particular whether this product is suitable for

automating your guided part. If it is not suitable, DO NOT continue with the installation

• The product cannot be used before it has been commissioned as specied in the chapter on “Testing and commissioning”

ATTENTION According to the most recent European legislation, the implementation of an automation system must comply

with the harmonised standards provided by the Machinery Directive in force, which enables declaration of the

presumed conformity of the automation. Taking this into account, all operations regarding connection to the

electricity grid, as well as product testing, commissioning and maintenance, must be performed exclusively by a

qualied and skilled technician!

• Before proceeding with the installation of the product, check that all the materials are in good working order and suited to the intended ap-

plications

• This product is not intended to be used by persons (including children) whose physical, sensory or mental capacities are reduced, or who

lack the necessary experience or skill

• Children must not play with the appliance

• Do not allow children to play with the xed control devices of the product. Keep the remote controls away from children.

ATTENTION In order to avoid any danger from inadvertent resetting of the thermal cut-off device, this appliance must not be powered

through an external switching device, such as a timer, or connected to a supply that is regularly powered or switched off by

the circuit

• Provide a disconnection device (not supplied) in the plant’s power supply grid, with a contact opening distance permitting complete discon-

nection under the conditions dictated by overvoltage category III

• Handle the product with care during installation, taking care to avoid crushing, denting or dropping it, or allowing contact with liquids of any

kind. Keep the product away from sources of heat and naked ames. Failure to observe the above can damage the product, and increase the

risk of danger or malfunction. Should this happen, stop installation immediately and contact Customer Service

• The manufacturer assumes no liability for damage to property, items or persons resulting from non-compliance with the assembly instructions.

In such cases the warranty for material defects is excluded

• The weighted sound pressure level of the emission A is lower than 70 dB(A)

• Cleaning and maintenance to be carried out by the user must not be carried out by unsupervised children

• Before working on the system (maintenance, cleaning), always disconnect the product from the mains power supply

• Check the system periodically, in particular all cables, springs and supports to detect possible imbalances, signs of wear or damage. Do not

use if repairs or adjustments are necessary, since installation failure or an incorrectly balanced door may cause injury

• The packing materials of the product must be disposed of in compliance with local regulations

• When operating a biased-off switch, make sure that other persons are kept away

• When operating the gate, keep an eye on the automated mechanism and keep all bystanders at a safe distance until the movement has been

completed

• Do not operate the product if anyone is working nearby; disconnect its power supply before permitting such work to be done

• If the power cable is damaged, it must be replaced by the manufacturer or by an appointed servicing company or similarly qualied person

in order to prevent any form of risk

INSTALLATION WARNINGS

• Prior to installing the drive motor, check that all mechanical components are in good working order and properly balanced, and that the gate

moves correctly

• If the gate or door being automated has a pedestrian gate, then the system must include a control device that will inhibit the operation of the

motor when the pedestrian gate is open

• Make sure that the control devices are kept far from moving parts but nonetheless in a visible position. Unless a selector is used, the control

devices must be installed at a height of at least 1.5 m and must not be accessible

• That windows, having a gap exceeding 200 mm when open, are to be closed using a biased-off switch if the opening movement is controlled

by a re-sensing system

• Ensure that entrapment between the driven part and the surrounding xed parts due to the opening movement of the driven part is avoided

• Permanently x the label concerning the manual release adjacent to its actuating member

• After installing the drive motor, make sure that the mechanism, protective system and all manual manoeuvres operate properly

2 – English

PRODUCT DESCRIPTION AND INTENDED USE

1

ROX is an electromechanical gearmotor intended for automating residential sliding gates: it is equipped with an electronic control unit with integral radio receiver (433.92 MHz with FLO, FLOR, OPERA, HCS SMILO, etc. coding)

CAUTION! – All uses other than the intended use described and use in environmental conditions other than those described in

this manual should be considered improper and forbidden!

APPLICATION LIMITS

2

Table 1: limits of application in everyday use.

Table 2: limits of application relating to the gate’s size and weight.

The effective suitability of ROX to automate a particular sliding gate depends on the friction as well as other correlated factors, such as ice, that

could interfere with the movement of the gate.

Measure the force required to move the gate through its entire stroke and check that this does not exceed 25% of the ‘maximum force’ (chapter

12 - technical specications): this leaves a suitable margin for unfavourable climatic conditions which can increase friction.

Table 1 – Application limits

ROX600 ROX1000 ROX1000/V1

Type of limit switch electromechanical electromechanical electromechanical

Optimal width of gate section

(recommended)

Max. gate weight 600 kg 1000 kg 1000 kg

Peak thrust 18 Nm 24 Nm 24 Nm

Corresponding to maximum force 600 N 800 N 800 N

5 m 5 m 5 m

Table 2 – Application limits

ROX600 ROX1000 ROX1000/V1

Leave width (m) Max. no. of

cycles/hour

Up to 4 40 20 40 20 60 30

4 ÷ 6 25 13 25 13 30 15

6 ÷ 8 20 10 20 10 24 12

8 ÷ 10 - - - - 16 8

10 ÷ 12 - - - - - -

Caution! Any other use or use with dimensions greater than specied is non-conforming. Nice declines all liability for damage

and injury resulting for non-conforming use.

Max. no. of

consecutive

cycles

Max. no. of

cycles/hour

Max. no. of

consecutive

cycles

Max. no. of

cycles/hour

Max. no. of

consecutive

cycles

English – 3

INSTALLATION

E

a

b

f

e

c c

d

F D D

B

C D

AD

3

Important! Before installing the product, refer to chapters 2 and 12 (technical specications).

Fig. 1 shows the contents of the package: check that everything is

present and correct.

1

Fig. 2 shows the location of the components of a typical installation

using Nice accessories:

a - ROX gearmotor

b - photocells

c - posts for photocells

d - Key switch / digital keypad

e - asher

f - rack

2

Before installing the system, check the gearmotor’s clearance (g. 3) and installation dimensions (g. 4):

3

4

303 mm

330 mm

0 ÷ 10

mm

192 mm

330 mm

0 ÷ 50 mm

210 mm

0 ÷ 50 mm

92 mm

0 ÷ 10

mm

192 mm

330 mm

4 – English

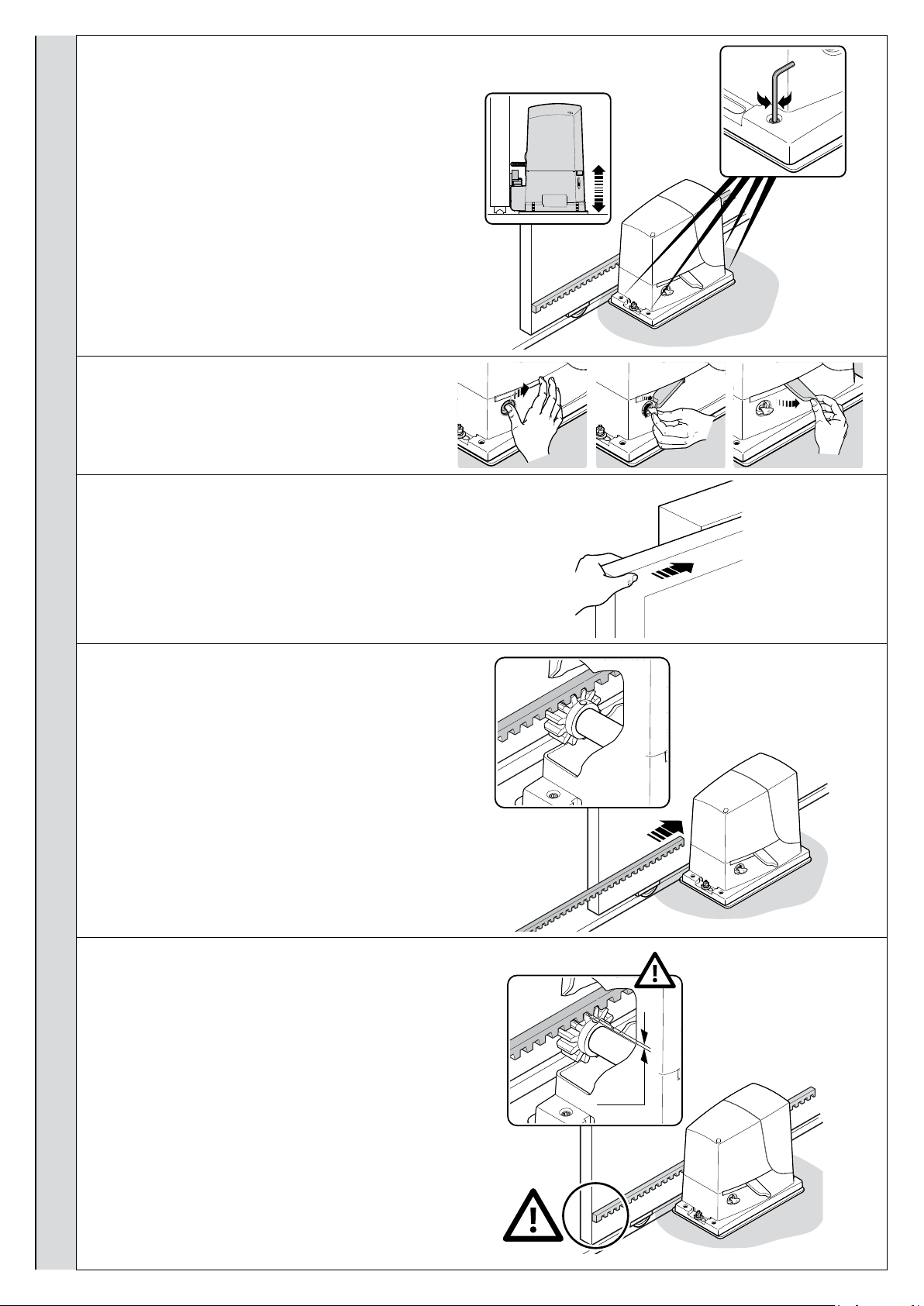

01. Dig the foundation and route the electric cable ducting

02. Secure the two anchors to the foundation plate with one

nut above and one below.

Tighten the lower nut in such a way that the

thread protrudes by 25/35 mm.

03. Now cast the concrete to secure the foundation plate.

Before the concrete hardens, make sure the

foundation plate is perfectly level and parallel to the

gate.

04. Allow the concrete to harden.

05. Secure the gearmotor:

a - Remove the top anchor nuts

25 ÷ 35 mm

b - rest the gearmotor on the anchor dowels: make sure

that it is parallel with the gate section

c - t the provided washers and nuts and hand tighten

them

English – 5

d - screw down the adjuster screws so that the gearmotor

g

1÷2 mm

g

1÷2 mm

g

g

is at the proper height, leaving a gap of 1-2 mm between

the pinion and the rack (this is to prevent the gate loading

the gearmotor shaft)

e / f / g - release the gearmotor

h - open the gate fully by hand

i - rest the rst section of rack on the gearmotor’s pinion:

make sure that it corresponds to the start of the gate section and that there is a gap of 1-2 mm between the rack

and the pinion itself (this is to prevent the gate loading the

gearmotor shaft

l - secure the rack section

1÷2 mm

6 – English

m - slide the gate by hand and, using the pinion as a ref-

1÷2 mm

g

h

1÷2 mm

g

erence, install the other sections of rack

n - cut any excess rack off the end

06. Slide the gate open and closed by hand to check that the rack is properly aligned with the pinion.

N.B.: make sure that there is a gap of 1-2 mm between the rack and pinion for the entire length of the gate

1÷2 mm

07. Tighten the nuts securing the gearmotor to the foundation

plate fully down and cover the nuts with their caps

08. Install the OPEN and CLOSE limit switch brackets: proceed in the same way for each limit switch

OPEN:

a - slide the gate open by hand, stopping it 2/3 cm before the mechanical stop

b - slide the limit switch bracket along the rack in the open direction until the limit switch trips (you will hear it click)

c - after you hear the ‘click’, move the bracket further forwards by 2 cm (minimum)

d - secure the bracket to the rack with the provided grub screws

English – 7

+2 cm

+2 cm

LIMIT SWITCH

click!

2-3 cm

CLOSE:

a - slide the gate closed by hand, stopping it 2/3 cm before the mechanical stop

b - slide the limit switch bracket along the rack in the close direction until the limit switch trips (you will hear it click)

c - after you hear the ‘click’, move the bracket further forwards by 2 cm (minimum)

d - secure the bracket to the rack with the provided grub screws

2-3 cm

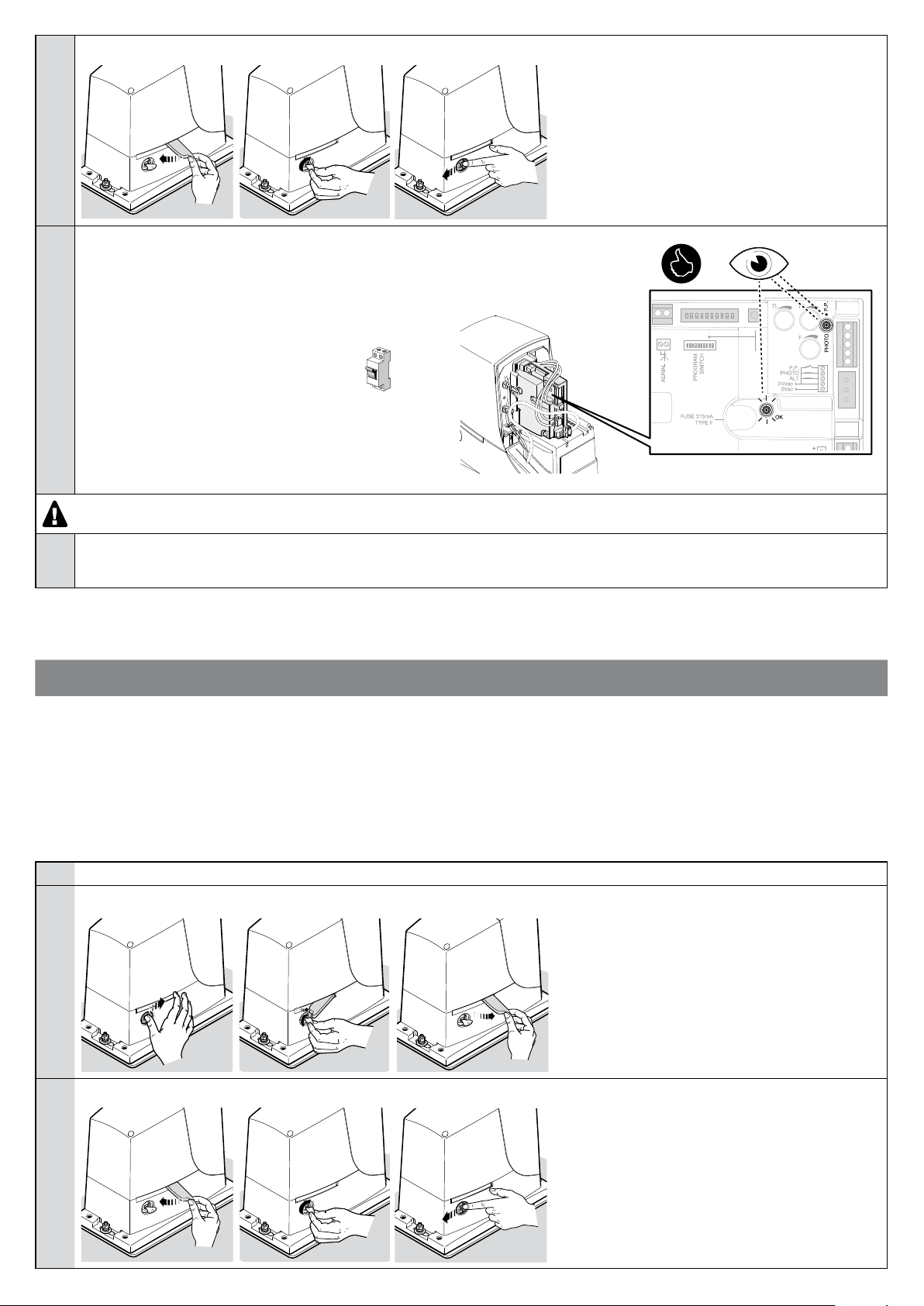

09. Manually lock the gearmotor

Manually lock the gearmotor.

IMPORTANT! – The gearmotor is set up (at the factory) for installation on the right (g. 5); if it must be installed on the left, pro-

ceed as shown in g. 6 (a - b).

click!

5

6

8 – English

a

MOTOR

b

180°

180°

ELECTRICAL CONNECTIONS

4

CAUTION! - All electrical connections must be made with the system powered off Incorrect connections can result in damage

and injury.

Fig. 2 shows the hookup of a typical installation; g. 7 shows the connections to be made on the control unit.

4.1 - Types of electrical cables

Table 3 - Types of electrical cable (see g. 2)

Connection Type of cable Maximum length

A POWER 3 x 1,5 mm

B

C

FLASHER WITH AERIAL 1 cable: 2 x 1,5 mm

1 shielded RG58 cable

D PHOTOCELLS 1 cable: 2 x 0,25 mm

1 cable: 4 x 0,25 mm

E - F KEY SWITCH 1 cable: 2 x 0,5 mm

2

2

2

(TX)

2

(RX)

2

** 20 m

* A power supply cable longer than 30 m may be used provided it has a larger gauge, e.g. 3x2.5mm

provided near the automation unit.

** The two 2 x 0.5 mm

2

cables can be replaced by a single 4 x 0.5 mm2 cable.

30 m *

10 m

10 m (< 5 m recommended)

30 m

30 m

2

, and that a safety grounding system is

4.2 - Electrical cable connections: g. 7

Table 4 - Description of electrical connections

Terminals Function Description

1 - 2 Aerial - radio receiver aerial input

9 - 12 Step-by-step input for devices which control movement. NO (Normally Open) contacts can be connected

9 - 10 Stop - input for devices which lock or stop a movement: NC (Normally Closed) contacts may be connected

9 - 11 Photo - input for safety devices which when tripped reverse the gate's direction of movement: NC (Normally Closed)

5 - 4 Flashing light - asher output (230 V auto-intermittent)

Warnings

• NC (Normally Closed) input: these must be shorted if not used; if more than one contact is to be connected to the stop input, they must be

connected IN SERIES;

• NO (Normally Open) input: these must be left unconnected if not used; if more than one contact is to be connected to the input, they must

be connected IN PARALLEL.

• Contacts must be mechanical and disconnected from any voltage.

Sensitive

edges

No specic input; use Nice equipment:

- xed sensitive edges: use the TCE interface

- mobile sensitive edges: use the FT210 unit or IRW interface

Refer to the product’s instruction manual for details

- aerial integrated into asher; an external aerial can be used if desired

- for further details, refer to par. 8.1

contacts may be used

- for further details, refer to par. 8.1.

- ashes at regular intervals while the gate is moving: 0.5s on, 0.5s off

To make the electrical hookup, proceed as described below with reference to g. 7:

01. Open the cover: undo the screw and raise the cover

02. Run the power cable through the hole (leave 20/30 cm of free cable) and connect it to its terminal clamp

03. Run the cables of the equipment to be installed or already present through the provided hole (leave 20/30 cm of free cable) and connect

them to their terminal clamps (see g. 14)

04. Before closing the cover, program the system: chapter 7

05. Close the cover and tighten down its bolt

English – 9

7

AERIAL = AERIAL LIMIT SWITCH = LIMIT SWITCH

PROGRAM

SWITCH

LED RADIO = RADIO LED

LED PHOTO = PHOTOCELL LEDS

LED P.P. = STEP-BY-STEP LED MOTOR = MOTOR

LED OK = OK LED FUSE = FUSE

RADIO = RADIO KEY

= MICRO SWITCHES FLASH = FLASHER

BOOST

CAPACITOR

RUN

CAPACITOR

STARTCONDEN-

=

SATOR

= CAPACITOR RUN

2

1

PROGRAM SWITCH

1234

5678910

LED

LED:

LED FCC

LED FCA

LED

TX

RX FLASH

230 V

1

2

12

11

10

9

8

54

(ROX1000)

21 543

NC NO CC NO NC

21

STARTING THE AUTOMATION AND CHECKING THE CONNECTIONS

5

5.1 - Hooking the automation up to the mains

CAUTION! – The automation must be hooked up to the mains by an expert electrician, in observance of established local

regulations.

Proceed as follows

01. Manually release the gearmotor so that the gate can be opened and closed

02. Move the gate to the halfway position

10 – English

03. Manually lock the gearmotor

04. Power the automation up and check:

- that the OK led is ashing regularly: 1 ash

per second

- that the gate does not move and that the

asher is off

ON

if any of these conditions are not satised, proceed as follows (step 05)

05. Shut off mains power to the automation and check the electrical connections, photocell alignment, and fuses. If necessary, check the

limit switch connections: move the limit switch levers and check that the switch trips and turns off the FCA / FCC led on the control

unit respectively

TESTING AND COMMISSIONING

6

These are the most important phases of automation set-up to ensure maximum system safety.

They must be done by a qualied technician who agrees to run the tests and check the solutions to any risks present, as well as checking compliance with regulations, standards and the law: in particular, the requirements of EN 13241-1, EN 12445 and EN 12453.

Any supplementary equipment must be tested separately for operation and interaction with the ROX: refer to the respective user manuals.

6.1 - Testing

The testing procedure can also be performed as a periodic check of the automation devices. Each component of the system (sensitive edges,

photocells, emergency stop, etc.) requires a specic testing phase. To do so, follow the procedures given in the instruction manuals.

Run the test as follows:

01. Ensure that all specications in chapter 1 “WARNINGS” have been observed in full

02. Check that the gate can be moved by hand in both directions with a force no greater than the value given in the application limits (Table 1)

03. Lock the gearmotor

English – 11

OFF

ON

04. Using the key switch, control key or radio transmitter, test the opening and closing of the gate and make sure that it moves in the in-

tended direction

05. The test should be carried out a number of times to make sure that the gate moves smoothly, that there are no points of excessive

friction and that there are no defects in the assembly or adjustments

06. Check the operation of the safety equipment, one by one (photocells, sensitive edges, etc.)

07. Check the operation of the photocells and any interference with other equipment:

1 - pass a dia. 5 cm length 30 cm cylinder along the optical axis, rst close to the TX, then close to the RX

2 - check that the photocells trip in any condition, switching from active to alarm and back

3 - check that tripping the photocell results in the intended response of the control unit: e.g., when tripped during a closing stroke, the

gate changes direction.

08. If the dangerous situations caused by the movement of the door have been safeguarded by limiting the force impact, the user must

measure the impact force according to the EN 12445 standard.

If the adjustment of the “force” is used to assist the system for the reduction of the impact force, try to nd the adjustment that gives

the best results.

6.2 - Commissioning

Commissioning can take place only after all testing phases have been terminated successfully (par. 6.1).

Partial or “makeshift” commissioning is strictly prohibited.

01. Prepare and store the technical documentation for the automation for at least 10 years. This must include at least: an assembly drawing

of the automation, a wiring diagram, an analysis of hazards and solutions adopted, a manufacturer’s declaration of conformity of all

the devices installed (for ROX use the annexed CE declaration of conformity); a copy of the automation system instruction manual and

maintenance schedule.

02. Afx a label or plate permanently to the gate, bearing instructions on how to manually release the gearmotor: use the gures included

at the end of the User Manual (tearout insert)

03. Post a permanent label or sign near the gate containing this

picture (min. height 60 mm):

04. Using the key switch or radio transmitter, test the opening and closing of the gate and make sure that it moves in the intended direction

05. Prepare the declaration of conformity of the automation system and deliver it to the owner.

06. Give the owner the user manual (tearout insert)

07. Prepare and give the owner the maintenance schedule

08. The force adjustment is an important safety aspect and must be done with care by an expert technician. Important! - Adjust the force

to enable the gate to move as intended; higher forces than this can cause injury to animals and persons or damage to property if the

gate collides with an obstacle.

09. Before commissioning the gate, inform the owner in writing about the attendant residual risks.

PROGRAMMING

7

In this manual the programming procedures are explained with the use of icons and their meanings are given in the following glossary:

GLOSSARY

Symbol Description Symbol Description

RADIO led on

RADIO led off

wait ...

observe / check

12 – English

RADIO led ashing

shut off mains power

turn on mains power

press and release the RADIO key

hold down RADIO key

release RADIO key

press and release the desired key on the radio

transmitter to be memorized

release the RADIO key exactly when the led behaves

↕

in the specied manner (on, ashing, off)

hold down the desired key on the radio transmitter

to be memorized

release the transmitter key INCORRECT procedure

correct procedure

7.1 - Control unit: programming keys

The control unit has a variety of factory settings which can be reprogrammed: this chapter describes the available functions and how to program

them.

The control unit is equipped with microswitches and trimmers (g.7):

Name Symbol Description

PROGRAM SWITCH

Trimmer TL

Trimmer TP

Trimmer F

Activates a function

Sets the Operating Time parameters (see paragraph 7.1.1)

Sets the Pause Time parameters’ (see paragraph 7.1.1)

Sets the Force parameters (see paragraph 7.1.1)

RADIO key

Factory settings (default)

MICRO SWITCHES:

Semiautomatic (1 = ON)

Trimmer TL (Operating Time) Trimmer TP (Pause Time) Trimmer F (Force)

7.1.1 - Trimmer (TL - TP - F)

The control unit’s parameters can be adjusted with three trimmers (g. 7)

TL (Operating Time)

Operating mode Adjustment

sets the maximum duration of an

Open or Close movement

Slow down function: to use this function, activate the programmable function “slow down” and set trimmer TL so that the slow down phase

starts 50/70 cm before the gate trips the limit switch.

N.B.: the result of an adjustment to this parameter is visible during the rst Open movement run after the modication has been made.

01. select ‘

02. set trimmer TL to the mid position

03. run a full Open and Close cycle:

check that the maximum duration setting (Open / Close) is high enough and that a margin of 2 or 3

seconds remains.

Adjust trimmer TL to its maximum setting if necessary.

N.B.: if this time is not sufcient, cut the TLM jumper next to trimmer TL (g. 7) to obtain a ‘Long

Operating Time’ (TLM)

Programs the radio receiver

1

ON

2 3 4 5 6 7 8 9 10

OFF

Semiautomatic’ or ‘Automatic’ and set micro switch 1 to ‘ON’

English – 13

TP (Pause Time)

Operating mode Adjustment

sets the time between the end of

an Open movement and the start

of the next Close movement

F (Force)

CAUTION! – Adjustments to this parameter are safety critical: take great care when making this adjustment.

To adjust the parameter, try various settings: you must measure the force applied by the gate when moving and compare it with local regulations.

01. select ‘Automatic’ and set micro switch 2 to ‘ON’

02. set trimmer TP to the desired value;

03. to check the time setting, run a full Open movements and see how long it takes before the Close

movement starts.

7.2 - Programmable functions

The control unit has a set of micro switches (PROGRAM SWITCH - g. 7) which activate functions to adapt the automation to the user’s needs

as well as making it safer to use.

The micro switches select the operating modes and program the functions, as described in Table 5.

To activate/deactivate a function:

Micro switches (1 ... 10) ACTIVATE DEACTIVATE

ON OFF

IMPORTANT! - some functions are safety critical; make sure to check which function is safest.

Table 5

Switches 1-2 Operation

Off-Off Manual (hold-to-run)

On-Off Semiautomatic

Off-On Automatic (automatic closing)

On-On Automatic + Always Closes

Switch 3 Operation

On Condominium (not available in manual mode)

Switch 4 Operation

On Pre-ashing

Switch 5 Operation

On Closes 5 seconds after ‘Photo’ if set to ‘Automatic’ or ‘Close after Photo’ if set to ‘Semiau-

Switch 6 Operation

On Safety “Photo” also when Opening

Switch 7 Operation

On Gradual Start-up

Switch 8 Operation

On Slow down

Switch 9 Operation

On Brake

Switch 10 Operation

Off Not used

tomatic’

Switches 1-2:

Manual operation the movement is only executed while the control is active (transmitter key held to run).

Semiautomatic

operation

Automatic

operation

Always Closes

operation

Switch 3:

Condominium

function

Switch 4:

When a command is sent, the asher starts ashing and, after 5 seconds (2 seconds in Manual mode), the movement starts.

14 – English

sending a command executes the entire movement until the operating time expires or the gate trips the limit switch.

after an Open, the system pauses and then automatically Closes the gate.

follows a power failure: if, when power is restored, the control unit determines that the gate is open, it automatically

ashes the asher for ve seconds and then runs a Close cycle.

when a “Step-by-Step” command is sent and the gate starts to Open, it cannot be stopped by any other “Step-byStep” or Open command sent by radio until it has completed.

When closing, on the other hand, sending a new Step-by-Step command will stop and reverse the movement.

Switch 5:

OFF

ON

This function, when set in Automatic mode, holds the gate open only for the time required for vehicles or pedestrians to pass through it; when

the Photo device is cleared, the movement stops and a Close movement starts after a 5 second delay.

If the functions is set in Semiautomatic mode, when the photocells are tripped while the gate is closing, automatic Close is activated with the

programmed Pause Time.

Switch 6:

The Foto function is usually active only during Close movements; if micro switch 6 is set to “ON”, tripping the photocell interrupts Open

movements too. On the other hand, in Semiautomatic or Automatic modes, the Open movement starts again as soon as the photocell

clears.

Switch 7

This function activates a soft start to gate movements to prevent them moving jerkily.

Switch 8:

Slow down, which reduces the speed to 30% of its nominal value, reduces the impact force of the gate at the end of a movement.

When this function is active, yo must adjust the operating Time (TL) since the start of the slow down phase is linked to this setting. Set the

TL so that the slow down starts 50-70 cm before the limit switch is tripped. The slow down function not only reduces the speed of the gate

but also the torque exerted by the motor ( by 70%). CAUTION – In automations which demand a high motor torque, setting this function can

stop the motor.

Switch 9:

This function brakes the motor at the end of a movement; the effect is moderate at rst, but increases to quickly and smoothly stop the

gate.

Switch 10:

Not used.

7.3 - Integrated radio receiver

For remote control operation, the control unit has an integral radio receiver (433.92 MHz compatible with FLO, FLOR, OPERA, and HCS SMILO

coding)

Since the coding systems are different, the rst transmitter to be memorised determines the type of transmitter memorised thereafter.

• To modify the coding family, proceed as indicated in ‘Total deletion of the receiver’s memory’ - par. 8.3.

• To check whether the receiver has already memorised any transmitters, and to determine the type of coding, proceed as follows:

01.

02.

03.

7.3.1 - Memorisation of radio transmitters

Each radio transmitter is recognised by the radio receiver by means of a “code” which is different from that of any other transmitter.

There are two types of memorisation: Mode 1 and Mode 2.

• Mode 1:

automatically assigns the commands indicated in table 8 to the

transmitter’s keys.

Each transmitter is memorised in a single step, with all keys programmed: it does not matter which key is pressed. (One memory location is occupied for each key).

N.B.: when memorised in Mode 1, a transmitter can control only one

automation.

to control unit

to control unit

count the number of green ashes emitted by the receiver and

refer to table 7

Flash Coding

1 Flo

2 O-Code / FloR / TTS

3 Smilo

4 no transmitter memorised

Transmitter key Command

1 Step-by-step

2 STOP

3 Open

4 Close

N.B.: single-channel transmitters have only key 1; two-channel

transmitters have keys 1 and 2

Table 7

Table 8

Mode 1 memorisation

01. 02. 03. 04.

x 4s

RADIO KEY RADIO KEY AND LED TRANSMITTER DESIRED BUTTON RADIO LED

↕

within 10s

x 3s

English – 15

• Mode 2:

freely assigns a command among those listed in table 9.

For each phase, only one key is memorised (the one pressed during

memorisation).

(One memory location is occupied for each key).

Mode 2 memorisation

01. 02. 03. 04.

Table 9

Transmitter key Command

1 Step-by-step

2 STOP

3 Open

4 Close

Step-bystep

STOP

Open

Close

RADIO KEY RADIO LED

N.B.: if you wish to memorise other transmitters, repeat step 03 within 10 sec. The memorisation procedure terminates after 10 sec if no other operations

are run

7.3.2 - “Remote” memorisation

You can memorise a new transmitter without having to operate the receiver key (10-20 m from the receiver).

You must have a previously memorised transmitter (old). The new transmitter will be memorised with the same characteristics as the old one.

Important! Remote memorisation may be done on all receivers within the range of the transmitter; therefore, only the one in-

volved in the operation should be kept switched on.

Standard procedure Alternative procedure

x 1

x 2

x 3

x 4

within 10s

within 10s

within 10s

within 10s

KEY IN QUESTION

TRANSMITTER

x 3s

x 3s

x 3s

x 3s

RADIO LED

During the procedure, if the old transmitter was memorised in: During the procedure, if the old transmitter was memorised in

- Mode 1 ¨ press any key

- Mode 2 ¨ press the key you wish to memorise

01. With the motor stopped, stand close to the control unit

NEW

02.

transmitter

OLD

transmitter

03.

already

memorised

NEW

04.

transmitter

If the procedure terminated successfully the new transmitter is memorised

* same key as NEW transmitter

Deleting radio transmitters

01. 02. 03. 04.

x 5s

*

x 1s

x 1s

*

x 1s

x 1s

- Mode 1 ¨ press any key

- Mode 2 ¨ press the key you wish to memorise

01. With the motor stopped, stand close to the control unit

NEW

02.

transmitter

OLD previously

03.

memorised

transmitter

NEW

04.

transmitter

OLD previously

05.

memorised

transmitter

If the procedure terminated successfully the new transmitter is

memorised

* same key as NEW transmitter

** same key as OLD transmitter

*

**

*

**

x 3s

x 3s

x 3s

x 3s

RADIO LED

not visible

remote

:

RADIO KEY RADIO LED RADIO LED RADIO KEY AND LED RADIO KEY AND LED

16 – English

↕

FURTHER DETAILS

STOP

8910 11 12

TX

1 2

RX

21 543

8910 11 12

8

8.1 - Adding or removing devices

You can add or remove devices at any timee.

STOP input

Input that stops movement immediately, followed by a brief reverse of the manoeuvre.

You may connect devices with NC contacts to this input; multiple devices can be connected in series.

N.B.: when the NC contact opens, the automation stops and reverses its direction briey.

STOP

8910 11 128910 11 12

8910 11 12

Photocells

To add a pair of photocells, proceed as follows:

01. Power up the receivers (RX) via terminals 8 - 9

02. Connect the receiver’s NC contact in series with the NC contact already connected to control unit terminals 9 - 11.

If using two pairs of photocells, to prevent them interfering with each other, activate the synchronisation function described in the respective

user manual.

TX

1 2

8910 11 12

RX

8910 11 128910 11 12

21 543

8.2 - Power for external devices

To power external devices (transponder badge reader, or backlighting for a keyswitch) connect the device

to the control unit as shown in the gure.

The power supply voltage is 24Vac -20% ÷ +30% with a maximum available current of 100mA.

24 Vac (30 Vac max)

8910 11 12

0

8.3 - Total deletion of the receiver’s memory

To cancel all memorised transmitters or all data in the receiver’s memory, proceed as follows:

01. 02. 03. 04.

↕

RADIO KEY RADIO LED RADIO LED RADIO KEY AND LED RADIO KEY AND LED

8.4 - Diagnostics

Some devices are display messages to identify their status and faults.

8.4.1 - Control unit signals

The leds on the control unit issue signals to indicate their normal/faulty operation.

Table 10 lists the signals:

English – 17

Table 10

OK LED Cause Solution

Off Malfunction Make sure there is power supply; check to see if the fuses are blown; if necessary,

On Serious

One ash every

second

2 quick ashes The status of the inputs has

PHOTO led Cause Solution

Off Photocell input activated At the start of the manoeuvre, one or more photocells are preventing movement; check

On All OK The photocell is aligned and the movement is permitted

FCA and FCC

leds

Off Activation of the STOP input Check the devices connected to the STOP input

On All OK STOP Input active

DISPOSAL OF THE PRODUCT

9

This product constitutes an integral part of the automation system, therefore it must be disposed of together with the former.

As in installation, also at the end of product lifetime, the disassembly and scrapping operations must be performed by qualied personnel.

This product is made up of different types of material, some of which can be recycled while others must be disposed of. Seek information on the

recycling and disposal systems envisaged by the local regulations in your area for this product category.

malfunction

All OK Normal operation of control unit

changed

Cause Solution

identify the reason for the failure and then replace them with others of the same type

There is a serious malfunction; try switching off the control unit for a few seconds; if the

condition persists, it means there is a malfunction and the circuit board has to be replaced

This is normal when there is a change in one of the inputs: Step-by-Step, STOP, triggering of photocells or the radio transmitter is used

to see if there are any obstacles, also check the NC connection for faults.

CAUTION! – Some parts of the product may contain polluting or hazardous substances which, if disposed of into the environ-

ment, constitute serious environmental and health risks.

As indicated by the symbol, the product may not be disposed of as domestic waste. Sort the materials for disposal, according

to the methods envisaged by current legislation in your area, or return the product to the retailer when purchasing an equivalent

product.

CAUTION! - Local legislation may include the application of serious nes in the event of improper disposal of this

product.

10

In case of malfunction due to problems during installation of failure of parts, refer to table 11:

WHAT TO DO IF...

Table 11

Problem Solution

The radio transmitter does not control the

gate and the led on the transmitter does not

light up

The radio transmitter does not control the

gate but the led on the transmitter lights up

No manoeuvre starts and the OK LED fails

to ash.

No manoeuvre starts and the asher is off Check that the command is actually received: if the command reaches the Step-by-Step input,

Check to see if the transmitter batteries are exhausted, if necessary replace them

Check to see if the transmitter has been memorised correctly in the radio receiver.

Check that the emission of the transmitter radio signal is correct by means of this empirical test:

push a key and rest the LED on the aerial of a normal radio (ideally an economical one) that

is switched on and tuned in, as close as possible, to 108.5Mhz FM; a slight crackling sound

should be heard

Check that the product is being supplied 230 V mains power

Check to see if fuses F1 and F2 (g. 7) have blown; if necessary, identify the reason for the

failure and then replace the fuses with others that have the same current rating and specs

the OK led ashes twice to indicate that the command has been received

18 – English

11

OFF

ON

To keep the system safe and ensure a long service life, it must be serviced regularly: at most every 6 months or after 20,000 movements since

the last service.

manual and according to applicable legislation and standards.

MAINTENANCE

CAUTION! – The maintenance operations must be performed in strict compliance with the safety directions provided in this

01.

Check for any deterioration in automation system components, paying special attention to erosion or oxidation of

the structural parts. Replace any parts which are below the required standard.

02.

Check the wear and tear on the moving parts: pinion, rack and the gate components; if necessary replace them.

03.

12

All technical specications stated herein refer to an ambient temperature of 20° C (± 5° C). • Nice S.p.a. reserves the right to apply modica-

tions to products at any time when deemed necessary, maintaining the same intended use and functionality.

Type Electromechanical gear motor for the automatic movement of sliding gates for residential use, complete

Pinion Z 15; Modulus: 4; Pitch: 12.5 mm; Primitive diameter: 60 mm

Peak thrust 18 Nm 24 Nm 24 Nm

Nominal torque 9 Nm 9 Nm 12 Nm

Speed (no load) 11 m/min 11 m/min 13 m/min

Nominal torque speed 8.5 m/min 8.5 m/min 8.5 m/min

Operating cycles 20 cycles/hour 20 cycles/hour 25 cycles/hour

Maximum continuous operating

time

Nominal power supply 230 V - 50/60 Hz 230 V - 50/60 Hz 120 V - 60 Hz

Nominal power 300 W 350 W 350 W

Electrical isolation class 1 (a safety grounding system is required)

Flasher output For 1 ashing light 230 V auto-intermittent

STOP input For NC contacts (a variation with respect to the closed state causes the command “STOP”).

Step-by-step Input For NO contacts (closing of the contact causes the “STEP-BY-STEP” command)

PHOTO input For NC contacts (a variation with respect to the closed state causes a change of direction during closing

Radio AERIAL Input 52 Ω for RG58 or similar type of cable

Radio receiver Incorporated

Operating temperature -20°C - 50°C

Protection class IP 44

Dimensions (mm) and weight 330 x 210 x 303 h; 11 kg

Dimensioni (mm) e peso 330 x 210 x 303 h; 11 kg

Integrated radio receiver

Type 4 channel receiver for incorporated radio command

Frequency 433.92MHz

Transmitter compatibility FLO, FLOR, OPERA, HCS SMILO... coding

Transmitters memorized Up to 1024 if memorized in mode 1

Input impedance 52Ω

Sensitivity better than 0.5 µV

Range of the transmitters From 100 to 150 m. The range can vary if there are obstacles or electromagnetic disturbances, and is

Outputs For the controls listed in tables 8 and 9

Operating temperature -20°C - 50°C

Run all the tests and checks indicated in par. 6.1 - Testing.

TECHNICAL SPECIFICATIONS

ROX600 ROX1000 ROX1000/V1

with electronic control unit

4 minutes

when the photocell is occluded)

affected by the position of the receiving aerial

English – 19

CE Declaration of Conformity

Declaration in accordance with the following Directives:

2004/108/EC (EMC); 2006/42/EC (MD) Annex II, part B

Note: The contents of this declaration correspond to declarations in the ofcial document led in the ofces of Nice S.p.a. and, in particular, the latest version thereof available prior to the printing of this manual. The text herein has been re-edited for editorial purposes. A copy

of the original declaration can be requested from Nice S.p.A. (TV) I..

Declaration number: 532/ROX Revision: 0 Language: EN

Manufacturer’s Name: NICE S.p.A.

Address: Via Pezza Alta 13, 31046 Rustignè di Oderzo (TV) Italy

Person authorized to compile the technical documentation: NICE S.p.A.

Type of product: Electromechanical gearmotor with incorporated control unit

Model / Type: ROX600, ROX1000

Accessories:

The undersigned Mauro Sordini, as Chief Executive Ofcer, hereby declares under his own responsibility that the product identied above

complies with the provisions of the following directives:

• The model conforms to Directive 1999/5/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 9 March 1999 on radio

equipment and telecommunications terminal equipment and the mutual recognition of their conformity, in accordance with the following

harmonised standards:

· Health and safety (Art. 3(1)(a)): EN 62479:2010

· Electrical safety (Art. 3(1)(a)): EN 60950-1:2006+A1:2010+A12:2011+A1:2010+A2:2013

· Electromagnetic compatibility (Art. 3(1)(b)): EN 301 489-1 V1.9.2:2011, EN 301 489-3 V1.6.1:2013

· Radio spectrum (Art. 3(2)): EN 300 220-2 V2.4.1:2012

Pursuant to Directive 1999/5/EC (Annex V), the product is rated Class 1

• The model conforms to DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 15 December 2004

on the approximation of the laws of the Member States relating to electromagnetic compatibility and repealing Directive 89/336/EEC, in

accordance with following harmonised standards:

EN 61000-6-2:2005, EN 61000-6-3:2007 + A1:2011

In addition, the product conforms to the following directive in accordance with the provisions applicable to partly completed machinery:

Directive 2006/42/EC OF THE EUROPEAN PARLIAMENT AND COUNCIL of May 17 2006 regarding machines and amending directive

95/16/EC (consolidated text)

– It is hereby declared that the relevant technical documentation has been compiled in accordance with Annex VII Part B of Directive

2006/42/CE and that the following essential requirements have been applied and fullled: 1.1- 1.1.2- 1.1.3- 1.2.1-1.2.6- 1.5.1-1.5.2-

1.5.5- 1.5.6- 1.5.7- 1.5.8- 1.5.10- 1.5.11

– The manufacturer undertakes to transmit, in response to a reasoned request by the national authorities, relevant information on the

partly completed machinery. This shall be without prejudice to the intellectual property rights of the manufacturer of the partly completed

machinery.

– Should the partly completed machinery be put into service in a European country with an ofcial language different to the one used in

this declaration, a translation into that language must be provided by the person bringing the machinery into the language area in question

– The partly completed machinery may not be put into service until the nal machinery into which it is to be incorporated has been declared in conformity with the provisions of Directive 2006/42/EC, where appropriate.

The product also complies with the following standards:

EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006 + A2:2006 + A13:2008+A14:2010+A15:2011, EN 60335-2-103:2003+A11:2009

All parts of the product subject to the following standards comply with them:

EN 13241-1:2003+A1:2011, EN 12445:2002, EN 12453:2002, EN 12978:2003+A1:2009

Oderzo, 28 april 2015

Ing.Mauro Sordini

(Chief Executive Ofcer)

20 – English

Operation manual

(to be given to the nal user)

• When you rst use the automation, the installation

technician must inform you about the origin of the

residual risks and you must take time to read this user

manual.

• Make sure to keep this user manual (delivered by the

installation technician) for future reference and for handover to any further owner of the automation.

• Your automation system is a machine that will faithfully execute your commands; unreasonable or improper

use may generate dangers: do not operate the system

if there are people, animals or objects within its range of

operation.

• Children: automation systems are designed to guarantee high levels of safety and security.They are equipped

with detection devices that prevent movement if people or

objects are in the way, guaranteeing safe and reliable activation. However, it is advisable to ensure that children do

not play in the vicinity of the automation; remote controls

should always be kept out of reach. It is not a toy!

• Checking the system: in particular all cables, springs

and supports to detect possible imbalance, signs of

wear or damage.

• Manually locking the gearmotor

• Manually locking the gearmotor

– Check that the system is safe every month using the

safety equipment with sensitive edges.

– Do not use the automation if repairs or adjustments are

required; any fault or an incorrectly balanced gate may

lead to physical injury.

• Malfunctions: if the automation is malfunctioning, shut

off its power supply. Never attempt any repairs; contact

your local installer for assistance.

– The system can be operated manually: release the

gearmotor, as described in “Manual release and lock”.

– Do not modify the system or its programming and ad-

justment parameters in any way, even if you feel capable

of doing it: your installation technician is responsible for

the system.

– The nal test, the periodic maintenance operations and

any repairs must be documented by the person who has

performed them; these documents must remain under

the custody of the owner of the system.

Important: have the system repaired as soon as possible

if the safety equipment is malfunctioning. Transit is admitted only if the gate is completely open and stationary.

• Disposal: At the end of the automation’s lifetime, ensure

that it is disposed by qualied personnel and that the

materials are recycled or scrapped according to current

local regulations for this category of product.

• Maintenance: As with all machinery, the automation

requires periodic maintenance to ensure optimal operation, extended lifetime and complete safety. Arrange

a periodic maintenance schedule with your installation

technician. Nice recommends that maintenance checks

be carried out every six months for normal domestic use,

but this interval may very depending on the intensity of

use. Only qualied personnel are authorised to carry out

checks, maintenance operations and repairs.

English – 21

Nice SpA

Oderzo TV Italia

info@niceforyou.com

IDV0378A03EN_18-12-2015_DIGITAL VERSION

www.niceforyou.com

Loading...

Loading...