Nice RONDO, RONDO RN2040, RONDO RN2040/V1 Instructions And Warnings For Installation And Use

Nice

RONDO

Balanced rolling door opener

EN - Instructions and warnings for installation and use

ENGLISH

Translation of the original instructions in full

CONTENTS

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . . 2

1.1 General warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Installation warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 PRODUCT DESCRIPTION AND INTENDED USE . . . . . . . . . 3

2.1 List of constituent parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Pre-installation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Product usage limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Product identification and overall dimensions . . . . . . . . . . . . 4

3.4 RECEIPT OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . 4

3.5 Pre-installation works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.6 Installing the gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Preliminary checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Wiring diagram and description of connections . . . . . . . . . . . 8

5 FINAL CHECKS AND START-UP. . . . . . . . . . . . . . . . . . . . . . . 9

5.1 Adjusting the mechanical limit switches . . . . . . . . . . . . . . . . . 9

5.2 Manually unlocking and locking the gearmotor . . . . . . . . . . . 9

6 TESTING AND COMMISSIONING. . . . . . . . . . . . . . . . . . . . . . 9

6.1 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 10

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 PRODUCT MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . 11

9 PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . 12

11 CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INSTRUCTIONS AND WARNINGS FOR THE USER. . . . . . 15

1

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS

1.1 GENERAL WARNINGS

a

a

a

PRECAUTIONS

Prior to installing the appliance, carefully read and

observe these instructions, since incorrect installation can cause serious harm to people and damage

to the appliance. Store them with care.

According to the latest European legislation, an automated device must be constructed in conformity

to the harmonised rules specied in the current

Machinery Directive, which allow for declaring the

presumed conformity of the automation. Consequently, all the operations for connecting the product to the mains electricity, its commissioning and

maintenance must be carried out exclusively by a

qualied and expert technician.

In order to avoid any danger from inadvertent resetting of the thermal cut-off device, this appliance

must not be powered through an external switching

device, such as a timer, or connected to a supply

that is regularly powered or switched off by the circuit.

WARNING! Please abide by the following warnings:

– Before commencing the installation, check the “Product

technical specications”, in particular whether this product is suitable for automating your guided part. Should it

not be suitable, do NOT proceed with the installation.

– The product cannot be used before it has been commis-

sioned as specied in the “Testing and commissioning”

chapter.

– Before proceeding with the product’s installation, check

that all the materials are in good working order and suited

to the intended applications.

– The product is not intended for use by persons (including

children) with reduced physical, sensory or mental capacities, nor by anyone lacking sufcient experience or famil-

iarity with the product.

– Children must not play with the appliance.

– Do not allow children to play with the product’s control

devices. Keep the remote controls out of reach of chil-

dren.

– The system’s power supply network must include a dis-

connection device (not supplied) with a contact opening

gap permitting complete disconnection under the condi-

tions envisaged by Overvoltage Category III.

– During the installation process, handle the product with

care by avoiding crushing, impacts, falls or contact with

liquids of any kind. Do not place the product near sources

of heat nor expose it to open ames. All these actions can

damage the product and cause it to malfunction, or lead

to dangerous situations. Should this occur, immediately

suspend the installation process and contact the Techni-

cal Assistance Service.

– The manufacturer declines all liability for damages to

property, objects or people resulting from failure to ob-

serve the assembly instructions. In such cases, the war-

ranty for material defects shall not apply.

– The weighted sound pressure level of the emission A is

lower than 70 dB(A).

GENERAL SAFETY WARNINGS AND

2 – ENGLISH

– Cleaning and maintenance reserved for the user must not

C

F

A

be carried out by unsupervised children.

– Before intervening on the system (maintenance, cleaning),

always disconnect the product from the mains power

supply and from any batteries.

– Inspect the system frequently, in particular the cables,

springs and supports to detect any imbalances and signs

of wear or damage. Do not use the product if it needs to

be repaired or adjusted, because defective installation or

incorrect balancing of the automation can lead to injuries.

– The packing materials of the product must be disposed of

in compliance with local regulations.

– The product must not be installed outdoors.

– Keep an eye on moving doors and do not let anyone go

near them until they have opened or closed fully.

– Be careful when activating the manual unlocking device

(manual manoeuvre), as an open door may fall suddenly

due to weak or broken springs, or if it is unbalanced.

– Every month, check that the drive motor reverses when

the door encounters a 50 mm-high object placed on the

ground. If necessary, readjust the door and check it again,

as incorrect adjustment is potentially dangerous (for drive

motors incorporating a trapping safety system that inter-

venes when the door's lower edge encounters an obsta-

cle).

– Motor with xed power cable: the power cable cannot

be replaced. If the cable is damaged, the appliance must

be scrapped.

– Motor with removable power supply cable with dedicat-

ed connector: if the power supply cable is damaged, it

must be replaced by the manufacturer or by the latter’s

technical assistance service, or nonetheless by a similarly

qualied person, so as to prevent any risk.

1.2 INSTALLATION WARNINGS

– Prior to installing the drive motor, check that the door is in

good working order, correctly balanced and that it opens

and closes properly.

– Prior to installing the drive motor, remove all unnecessary

cables or chains and deactivate any equipment, such as

the locking devices,

– Check that there are no points where people could get

trapped or crushed against xed parts when the door is

fully open or closed; if there are, arrange adequate pro-

tective measures for these parts.

– Install the manoeuvre device for manual unlocking at less

than 1.8 m above the ground. NOTE - If removable, the

manoeuvre device must be kept next to the door when

removed.

– Make sure that the control elements are kept far from

moving parts but nonetheless directly within sight. Unless

a selector is used, the control elements must be installed

at least 1.5 m above the ground and must not be acces-

sible.

– Permanently attach the trapping hazard warning labels in

a highly visible location or near the xed control devices

(if present).

– Permanently attach the manual unlock (manual manoeu-

vre) label close to the manoeuvring element.

– After installation, make sure that the motor prevents or

stops opening of the door when the latter is loaded with a

20-kg weight secured to the centre of its bottom edge (for

drive motors that can be used with doors having opening

widths exceeding 50 mm).

– After installation, make sure that the mechanism is prop-

erly adjusted and that the motor reverses when the door

collides with a 50 mm-tall object placed on the ground (for

drive motors incorporating a trapping safety system that

intervenes when the bottom edge of the door encounters

an obstacle). Following installation, check and ensure that

no door parts obstruct public roadways or pavements.

PRODUCT DESCRIPTION AND

2

2 PRODUCT DESCRIPTION AND INTENDED USE

RONDO is a gearmotor for spring-balanced rolling shutters. It

allows for automating shutters with a maximum height 6 m and

weight up to 170 kg.

The gearmotor can be mounted on shutters with spring support

shaft having a 42 mm, 48 mm or 60 mm diameter.

The spring support boxes can have a 200 mm or 220 mm diameter. The two collars are made of die-cast aluminium.

It has a limit switch with micrometer screw and mechanical position

memory.

The unlocking device, operated from the ground, disengages the

motor from the gearmotor body and is only available for models

with electric brake.

a

2.1 LIST OF CONSTITUENT PARTS

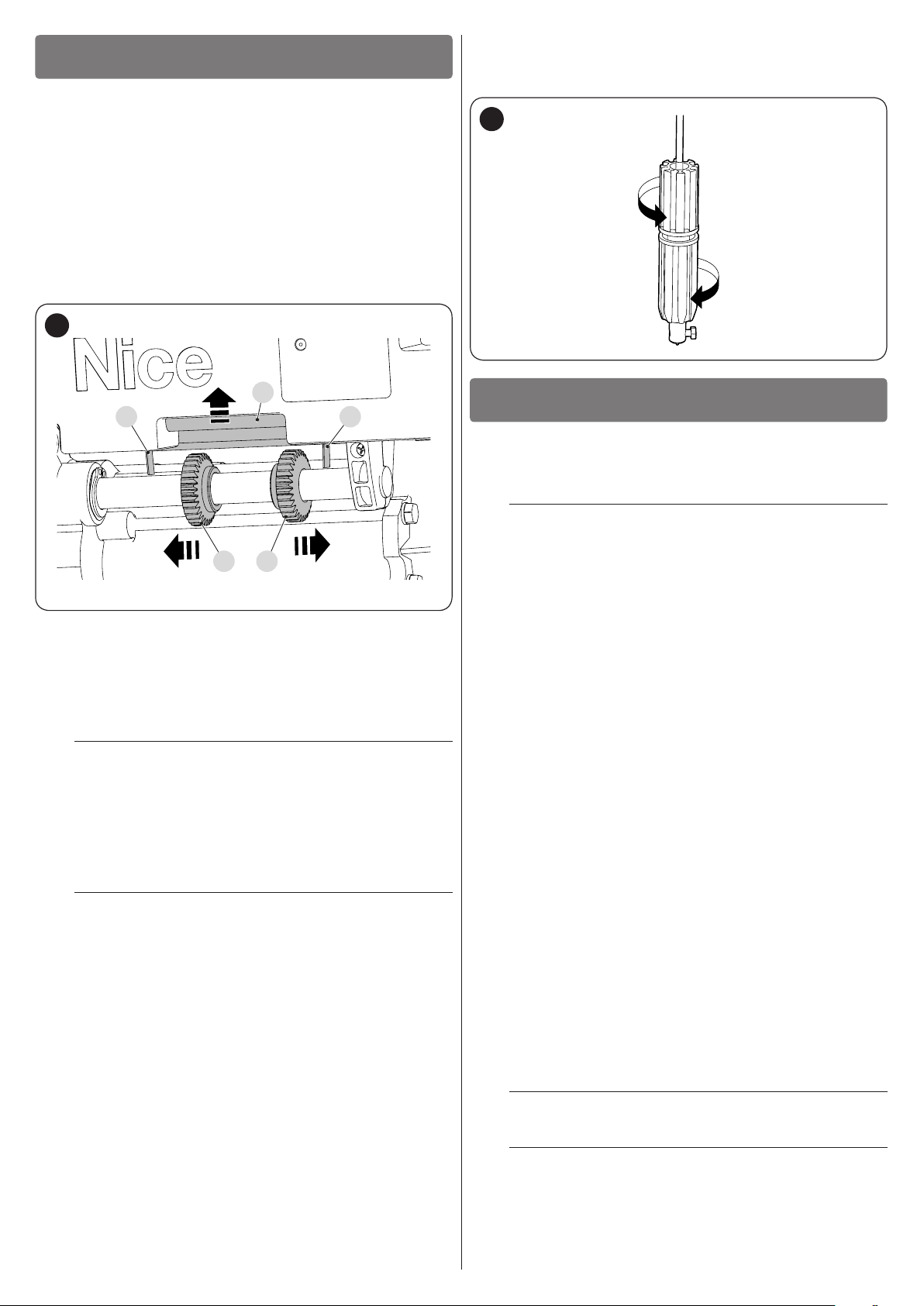

"Figure 1" shows the main parts making up the RONDO.

A Half-collar

B Transmission shaft housing

C Adaptor for collar

D Gearmotor body

E Limit switch position regulators

F Locking/unlocking system (where congured)

G Electric brake (where congured)

INTENDED USE

Any use of the product other than the intended use

described is not allowed!

1

G

B

E

D

ENGLISH – 3

3

Ø 220 mm

A

DC E F

3 INSTALLATION

INSTALLATION

3.1 PRE-INSTALLATION CHECKS

The installation must be carried out by qualied

a

personnel in compliance with the current legislation, standards and regulations, and with the instructions provided in this manual.

Before proceeding with the product’s installation, it is necessary to:

– check the integrity of the supply

– check that all the materials are in good working order and suited

to the intended use

– check that the shutter is properly balanced, in other words, it

must not start moving again when stopped in any position

– verify that there are no points of greater friction during the open-

ing and closing movements along the entire shutter path

– verify that the shutter moves silently and smoothly along its path

– verify that the xing zone is compatible with the product’s size

(see paragraph “Product identication and overall dimen-

sions“).

– verify that the mounting positions of the various devices are pro-

tected against impacts and that the mounting surfaces are suf-

ciently sturdy

– prevent any parts of the automation from being immersed in wa-

ter or other liquids

– keep the product away from heat sources and open ames and

acid, saline or potentially explosive atmospheres; these may

damage the product and cause malfunctions or dangerous sit-

uations

– connect the control unit to an electricity supply line equipped

with a safety earthing system

– include a device on the electric power line ensuring complete

disconnection of the automation from the grid. The disconnec-

tion device must have contacts with a sufcient gap to ensure

complete disconnection, under the Category III overvoltage con-

ditions, in accordance with the installation instructions. Should it

be necessary, this device guarantees fast and safe disconnection

from the power supply; it must therefore be positioned in view of

the automation. If placed in a non-visible location, it must have a

system that blocks any accidental on unauthorised reconnection

of the power supply, in order to prevent dangerous situations.

The disconnection device is not supplied with the product.

3.2 PRODUCT USAGE LIMITS

The data relative to the product’s performances is included in the

“TECHNICAL SPECIFICATIONS” chapter and is the only data

that allows for properly assessing whether the product is suitable

for its intended use.

Check the application limits of RONDO and of the accessories to

be installed, assessing whether their characteristics are capable of

meeting the requirements of the environment and the limitations

specied below:

– verify that the weight of the shutter does not exceed the value

stated in the "TECHNICAL SPECIFICATIONS" chapter

– the door dimensions must be below 20 m2

– the drive shaft must be compatible with the RONDO output and

the relative keys supplied with the package.

The gearmotor is equipped with a thermal cut-off which, in case

of overheating caused by overuse of the automation (beyond the

specied limits), automatically cuts off the electricity supply, restoring it as soon as the temperature returns to its normal value.

The control unit is equipped with a manoeuvre lim-

a

iting device that prevents possible overheating; it is

based on the motor load and duration of the cycles,

and intervenes when the maximum limit is exceeded.

3.3 PRODUCT IDENTIFICATION AND OVERALL DIMENSIONS

The overall dimensions and the label (A), which allows for identifying the product, are shown in "Figure 2".

2

320 mm

A

350 mm (230V)

370 mm (120V)

3.4 RECEIPT OF THE PRODUCT

All the components contained in the product’s packaging are illustrated and listed below.

3

A

B

A Gearmotor

B Electric brake (where congured)

C Adaptor for collar

D Adaptor for spring support shaft size 48 mm

E User manual

F Power cable

4 – ENGLISH

3.5 PRE-INSTALLATION WORKS

The gure shows an example of an automation system, constructed using Nice components.

4

D

3

1

C

2

B

A

A Spring support box

B Spring support shaft

C Gearmotor

D Junction box

E Locking/unlocking knob

F Command inverter

The above-mentioned components are positioned according to a

typical standard layout. Using the layout shown in "Figure 4" for

reference, dene the approximate position in which each component of the system will be installed.

Table 1

TECHNICAL SPECIFICATIONS OF ELECTRICAL CABLES

Identication

no.

1

2

Cable characteristics

GEARMOTOR POWER SUPPLY cable

1 cable 4 x 0.75 mm

Maximum length 30 m [note 1]

PUSHBUTTON PANEL cable

1 cable 3 x 0.75 mm

2

2

minimum

E

Note 1 If the power supply cable is longer than 30 m, a cable with

larger cross-sectional area (3 x 2.5 mm

F

2

) must be used

and a safety earthing system must be installed near the

automation.

The cables used must be suited to the type of envi-

a

ronment of the installation site.

ENGLISH – 5

3.6 INSTALLING THE GEARMOTOR

12 mm

Incorrect installation may cause serious physical

a

injury to the person working on the system or to its

future users.

Before starting to assemble the automation, complete the preliminary checks described in the “Pre-

installation checks” and “Product usage limits”

paragraphs.

To install RONDO:

1. close the shutter completely

2. cut the three holes specied in the image on the spring sup-

port shaft

5

=

50 mm

Ø 10 mm

=

500 mm

Ø 12 mm

4. dismantle the two half-collars (B) by loosening the screws

(C)

7

C

B

B

C

550 mm

Ø

3. loosen the screw (A) and remove the washer

6

A

5. gently remove the roller band (D) without bending it, as the

rollers could fall off

8

D

6 – ENGLISH

6. separate the item (E) by loosening the four screws (F)

The sleeves (G) on the gearmotor are suitable for

m

a spring support shaft with 48 mm diameter. If the

shutter shaft has a smaller diameter, replace the

sleeves with other sleeves having a 33 or 42 mm

diameter (not supplied) and place them against the

10 mm hole cut previously (see “Figure 5“).

9

F

E

G

9. tighten the M10 screw (J) with the nut supplied (K) to lock

the gearmotor on the spring support shaft; tighten the nut to

lock the screw in position

11

J

K

10. mount the roller band back on without bending it, as the

rollers could fall off

11. mount the two half-collars back on with the appropriate

screws

12. if there are any spring support boxes with a 220 mm diam-

eter, mount the adaptor supplied (L) using the appropriate

at-head screw (M)

7. draw the gearmotor against the spring support shaft and

couple it with item (E) using the four screws (F) removed

previously

8. completely tighten the M10 screw supplied (H) without the

hexagonal nut, until it penetrates into the spring support

shaft through the 10 mm hole

10

H

F

E

H

12

L

M

13. cut a 12 mm hole on the last item of the shutter near the hole

on the half-collar (B)

14. fasten the last item of the shutter to the gearmotor using

screw (A) and the appropriate washer

Ø10 mm

ENGLISH – 7

13

12 mm

Ø 12 mm

50 Hz

Ø 12 mm

15

Ø

A

B

4

4 ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

4.1 PRELIMINARY CHECKS

All electrical connections must be made with the

f

system disconnected from the mains electricity and

with the back-up battery (if present) disconnected.

The connection operations must only be carried out

a

by qualied personnel.

To make the electrical connections:

1. remove the screws and the protective cover (A)

4. make the connections by following the scheme shown in

"Figure 16"

5. after making the connections, lock the power cable by

screwing the protective cover (A) in place.

4.2 WIRING DIAGRAM AND DESCRIPTION OF CONNECTIONS

16

B

A

NL

C

230 Vac

14

A

2. pass the power cable through the hole cut previously on the

spring support shaft

3. if the gearmotor is equipped with an electric brake, t the

brake sheath through the second hole on the spring support

shaft

A Mains power inputs terminal

B Manual command buttons

C Omnipolar device

8 – ENGLISH

5

5 FINAL CHECKS AND START-UP

FINAL CHECKS AND START-UP

6 TESTING AND COMMISSIONING

2. at this point, the shutter can be moved manually to the desired position.

To lock the device, turn the knob clockwise all the way.

5.1 ADJUSTING THE MECHANICAL LIMIT SWITCHES

To adjust the limit switches, proceed as follows:

1. close the shutter completely

2. press and hold the presser (A) upwards so as to allow the

limit switch adjusters to move freely

3. turn the adjuster (B) until the lowering switch (C) clicks (lowering limit switch adjustment completed)

4. turn the adjuster (D) by moving it towards the lifting switch

(E)

5. release the presser (A)

17

A

EC

DB

6. power the gearmotor

7. control the lowering of the shutter through the key selector

or button

8. verify whether the shutter stops in the desired position

9. to allow the shutter to stop in a different position during the

opening movement, change the position of the adjuster (D)

as shown previously

If the gearmotor is installed in the opposite direc-

m

tion, switch (C) will allow the shutter to stop while it

is lifted, while switch (E) will allow it to stop while it

is lowered. Adjust the cursors accordingly.

5.2 MANUALLY UNLOCKING AND LOCKING THE GEARMOTOR

If the shutter is lifted before the limit switches are

a

adjusted, the gearmotor could get seriously damaged. Carry out the procedure set forth in the "Ad-

justing the mechanical limit switches" paragraph.

Gearmotors equipped with an electric brake have a mechanical

unlocking system that allows for opening and closing the shutter

manually.

These manual operations should only be performed in case of a

power outage, malfunctions or during the installation phases.

To unlock the device:

1. loosen the lower part of the knob anti-clockwise until you

can

18

6

These are the most important phases of the automation’s con-

struction, as they ensure maximum safety of the system. The test

can also be used to periodically verify the devices making up the

automation.

m

The additional devices must undergo specic testing, both in terms

of their functions and their proper interaction with the control unit.

Refer to the instruction manuals of the individual devices.

TESTING AND COMMISSIONING

Testing and commissioning of the automation must

be performed by skilled and qualied personnel,

who are responsible for the tests required to verify the solutions adopted according to the risks

present, and for ensuring that all legal provisions,

standards and regulations are met, in particular all

the requirements of the EN 12445 standard, which

denes the test methods for checking door automations.

6.1 TESTING

To run the test:

1. verify that all the instructions stated in the “GENERAL

SAFETY WARNINGS AND PRECAUTIONS” chapter have

been strictly observed

2. check that the die-cast items are in good condition and are

not broken

3. check that the gearmotor is properly secured to the spring

support shaft

4. check that the electrical contacts are in good condition

5. check that the collar does not have any excessive axial

clearance

6. verify the adjustment of the limit switches by performing a

complete manoeuvre (up-down)

7. check that the gearmotor – when locked in any position –

does not move

8. check that the unlocking manoeuvre easily disengages the

gearmotor from the shutter (only for versions with brake).

6.2 COMMISSIONING

Commissioning can only be performed after all

a

testing phases have been successfully completed.

Before commissioning the automation, ensure that

a

the owner is properly informed of all residual risks

and hazards.

ENGLISH – 9

The gate cannot be commissioned partially or un-

a

der “temporary” conditions.

To commission the automation:

1. compile the automation’s technical le, which must include

the following documents: overall drawing of the automation, wiring diagram, risk assessment and relative solutions

adopted, the manufacturer’s declaration of conformity for all

devices used and the declaration of conformity compiled by

the installer

2. permanently afx a label or plate near the manual manoeu-

vre knob, indicating the operations for unlocking the shutter

“Figure 19“

19

3. permanently afx a label or sign to the door with the follow-

ing image (minimum height 60 mm) “Figure 20“

20

4. afx a label to the door containing at least the following data:

type of automation, name and address of manufacturer (person responsible for commissioning), serial number, year of

manufacture and the CE mark

5. compile the declaration of conformity of the automation and

hand it to the owner of the automation

6. compile the User Manual of the automation and hand it to

the owner of the automation

7. compile and provide the owner with the automation’s “Main-

tenance schedule”, containing the maintenance instructions

for all the automation’s devices.

For all the above-mentioned documentation, Nice –

l

through its technical assistance service – provides

the following: pre-completed forms.

TROUBLESHOOTING...

7

7 TROUBLESHOOTING GUIDE

7.1 TROUBLESHOOTING

The table below contains useful instructions to resolve any malfunctions or errors that may occur during installation or in case of a fault.

TROUBLESHOOTING

Problems Recommended checks

The motor does not start

The shutter does not stop in the pre-dened

positions

The manual manoeuvre knob is unlocked, but the

shutter cannot be lifted

The thermal cut-off was activated The motor has overheated: wait until its normal temperature is restored.

The motor struggles to lift the shutter

(troubleshooting guide)

Table 2

Verify that the connections shown in the electrical diagram are correct.

If the motor is equipped with an electric brake, verify that it is properly connected to

the limit switch casing.

On the version without brake, a jumper must be connected between the two

terminals.

Verify that the limit switch is properly adjusted as set forth in the "Adjusting the

mechanical limit switches" paragraph.

Verify that the cord of the electric brake was suitably tensioned during the

installation phase.

Verify that the spring support boxes are not damaged.

Verify that the size and weight of the shutter are compatible with the gearmotor’s

installation.

Verify the correct operation of the spring support boxes.

10 – ENGLISH

8

8 PRODUCT MAINTENANCE

a

To service the gearmotor, repeat the testing procedure from beginning to end.

PRODUCT MAINTENANCE

Maintenance must be carried out strictly in compliance with the safety provisions provided in this

manual and in accordance with the laws and regulations in force.

9

9 PRODUCT DISPOSAL

l

As with the installation, only qualied personnel must dismantle the

product at the end of its life.

This product is composed of different types of materials. Some

of these materials can be recycled; others must be disposed of.

Please enquire about the recycling or disposal systems in place in

your local area for this type of product.

a

l

PRODUCT DISPOSAL

This product is an integral part of the operator and

must therefore be disposed of with it.

WARNING

Some parts of the product may contain polluting or

dangerous substances. If not disposed of correctly,

these substances may have a damaging effect on

the environment and human health.

As indicated by the symbol shown

here, this product must not been

disposed of with household

waste. Separate the waste for disposal and recycling, following the

methods stipulated by local regulations, or return the product to

the seller when purchasing a new

product.

WARNING

a

Local regulations may impose heavy penalties if

this product is not disposed of in compliance with

the law.

ENGLISH – 11

10

10 TECHNICAL SPECIFICATIONS

l

TECHNICAL SPECIFICATIONS

All technical specications stated in this section refer to an ambient temperature of 20°C (± 5°C). Nice S.p.A.

reserves the right to apply modications to the product at any time when deemed necessary, without altering

its functions and intended use.

TECHNICAL SPECIFICATIONS

Description Technical specication

RN2040 RN2040/V1

Product type Gearmotor for spring-balanced rolling shutters

Power supply

Maximum current draw (A) 2,7 5,2

Maximum torque (Nm) 170

Maximum power consumption (W) 630 610

Maximum speed (rpm) 10

Protection rating (IP) 20

Operating temperature (min/max °C) -20°C ÷ 50°C

Maximum shutter height (m) 7

Lifting capacity (kg) 170

Cycles per hour at the rated torque – for shutters

with 3 m height (cycles/hour)

Dimensions (mm) Ø220 x 350 Ø220 x 370

Weight (kg) 7 8

Emergency power supply No

Use in highly acid, saline or potentially explosive

atmosphere

230Va (+10% -15%) 50 Hz 120Va (+10% -15%) 60 Hz

1

No

Table 3

12 – ENGLISH

11

EU Declaration of Conformity

Note - The contents of this declaration correspond to declarations in the ofcial document deposited at the registered ofces of Nice S.p.a. and in particular to the last revision available before

printing this manual. The text herein has been re-edited for ed

Number:

Manufacturer’s Name:

Address:

Authorized Person to constitute

technical documentation:

Type of product:

Model/Type:

Accessories:

The undersigned Roberto Griffa, in the role of Chief Executive Ofcer, declares under his sole responsibility that the product described above complies with the provisions

laid down in the following directives:

•

The product also complies with the following directives according to the requireme

•

It is hereby stated that the relevant technical documentation has been compiled in accordance with annex VII B of Directive 2006/42/EC and that the following essential

requirements have been fullled: 1.1.1 - 1.1.2 - 1.1.3 - 1.2.1 - 1.2.6 - 1.5.1 - 1.5.2 The manufacturer undertakes to transmit to the national authorities, in response to a reasoned request, the relevant information on the “ partly completed machinery “, while

maintaining full rights to the related intellectual property.

Should the “ partly completed machinery” be put into service in a European country with an ofcial language other than that used in this declaration, the importer is obliged

to arrange for the relative translation to accompany this declaration.

The “partly completed machinery” must not be used until the nal machine in which it is incorporated is in turn declared as compliant, if applicable, with the provisions of

directive 2006/42/EC.

The product also complies with the following standards:

EN 60335-1:2012+A11:2014, EN 62233:2008, EN 60335-2-103:2015

Oderzo,

Ing. Roberto Griffa

(Chief Executive Ofcer)

11 CONFORMITY

CONFORMITY

and declaration of incorporation of “partly completed machinery”

itorial purposes. A copy of the original declaration can be requested from Nice S.p.a. (TV) I.

168/RN

Rev: 8 Language: EN

Via Callalta 1, 31046 Oderzo (TV) Italy

Nice s.p.a.

“RONDO” electromechanical gearmotor for balanced shutters

Nice s.p.a.

RN2040

Refer to the catalog

Directive 2014/30/EU (EMC), according to the following harmonized standards: EN 61000-6-2:2005, EN 61000-6-3:2007+A1:2011

Directive 2006/42/EC of the EUROPEAN PARLIAMENT AND COUNCIL of 17 May 2006 related to machinery and amending the Directive 95/16/EC (recast).

07/05/2019

nts envisaged for “partly completed machinery” (Annex II, part 1, section B):

1.5.5 - 1.5.6 - 1.5.7- 1.5.8 - 1.5.10 - 1.5.11

ENGLISH – 13

NOTES

14 – ENGLISH

&

INSTRUCTIONS AND WARNINGS FOR THE USER

Before using the automation for the rst time, ask the installer to

explain the origin of any residual risks and take a few minutes to

read this instruction manual and warnings for the user given to you

by the installer. Store the manual for future reference and hand it to

the new owner when transferring the automation.

WARNING!

a

Your automation is a machine that faithfully executes commands imparted by the user. Negligence

and improper use may lead to dangerous situations:

– do not manoeuvre the gate if there are people, animals or

objects within its range of operation

– it is strictly forbidden to touch parts of the automation

while it is moving.

IT IS STRICTLY FORBIDDEN to transit while the au-

a

tomation is closing! Transit is allowed only if the automation is fully open and stationary.

CHILDREN

a

An automation system guarantees a high degree

of safety. With its detection systems, it can control

and guarantee the gate’s movement in the presence

of people or objects. It is nonetheless advisable to

forbid children from playing near the automation

and not to leave remote controls near them to prevent any unwanted activation of the system. The

automation is not a toy!

The product is not intended for use by persons, including children, with limited physical, sensory or

mental capacities, or who lack experience or knowledge, unless supervised or trained in the use of the

product by a person responsible for their safety.

Anomalies: if the automation shows any signs of anomalous be-

haviour, disconnect the power supply to the system and manually

unlock the motor (see instructions at the end of the chapter) to

manoeuvre the automation manually. Do not attempt any repairs

personally, but contact your trusted installer.

Failure or lack of power supply: while waiting for the installer

to intervene or the electricity to be restored, if the system is not

equipped with back-up batteries, the automation can nonetheless

be used by manually unlocking the motor (see the instructions at

the end of the chapter) and moving the automation manually.

Do not modify the system: the responsibility lies on

l

your installer.

Testing, periodic maintenance and any repairs must be documented by the person performing the operations and the relative documents must be kept by the owner of the installation.

Before carrying out any maintenance operations,

m

the user of the automation must manually unlock

the motor to prevent anyone from accidentally triggering the automation’s movement (see the instructions at the end of the chapter).

Maintenance: in order to ensure constant levels of safety and the

longest useful life for the automation, routine maintenance must be

carried out (at least every 6 months).

Only qualied personnel is authorised to carry out

l

checks, maintenance operations and repairs.

Disposal: at the end of its useful life, the automation must be dis-

mantled by qualied personnel and the materials must be recycled

or disposed of in compliance with the local regulations in force.

Unlocking and manual movement

The device can only be unlocked once the automa-

a

tion is stationary.

Gearmotors equipped with an electric brake have a mechanical

unlocking system that allows for opening and closing the shutter

manually.

These manual operations should only be performed in case of a

power outage, malfunctions or during the installation phases.

To unlock the device:

1. loosen the lower part of the knob anti-clockwise until you

can

2. at this point, the shutter can be moved manually to the de-

sired position.

21

&

To lock the device, turn the knob clockwise all the way.

ENGLISH – 15

Nice SpA

Via Callalta, 1

31046 Oderzo TV Italy

info@niceforyou.com

IDV0726A00EN_31-05-2019

www.niceforyou.com

Loading...

Loading...