Programmable functions

using the Oview programmer

Robus

600/1000

STF ROBUS 600-1000 – Rev00

Firmware: RF02

2 – Robus 600-1000

This parameter enables the user to assign the automation with a name other than the original, to facilitate identification (e.g.

northern gate”).

A name comprising maximum 24 characters, including spaces, is admitted.

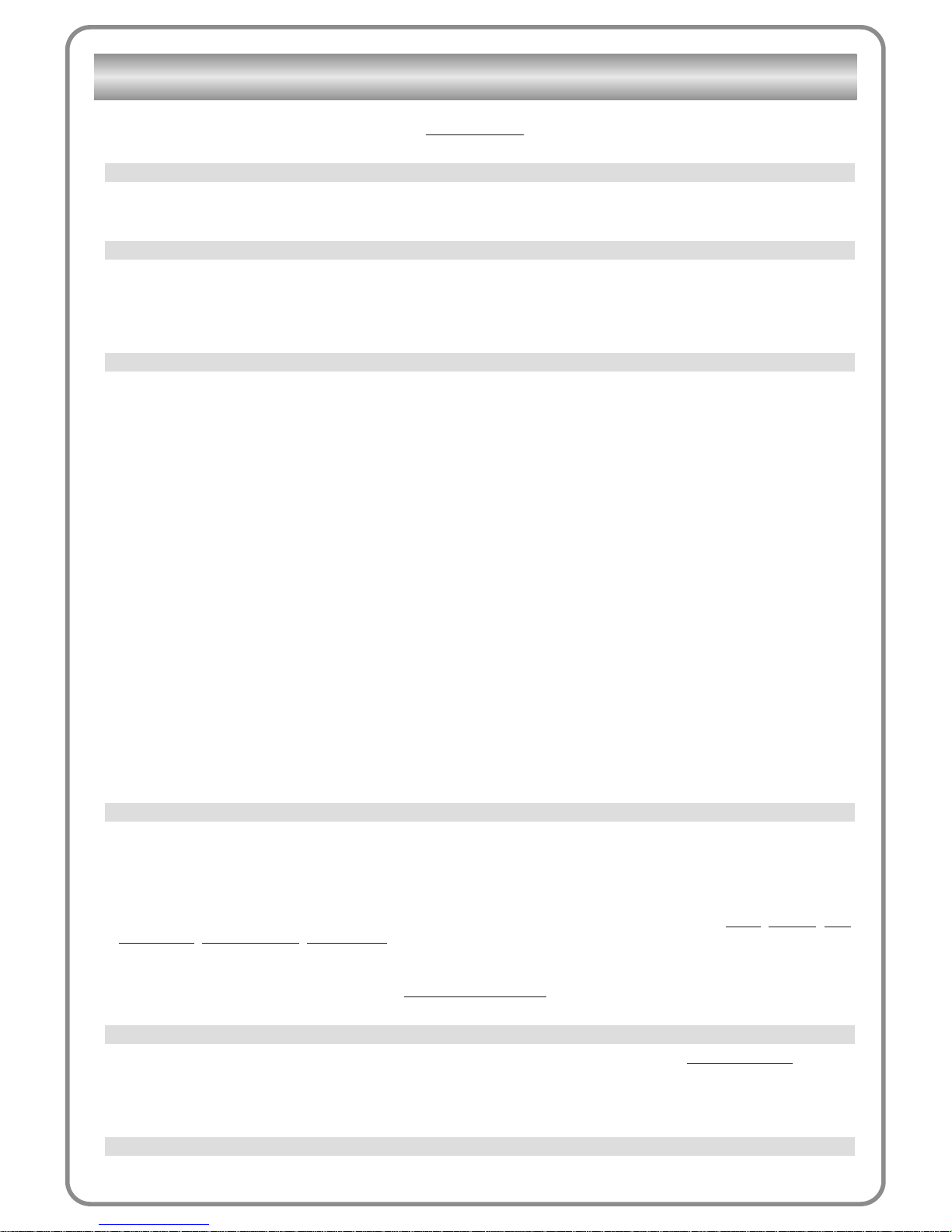

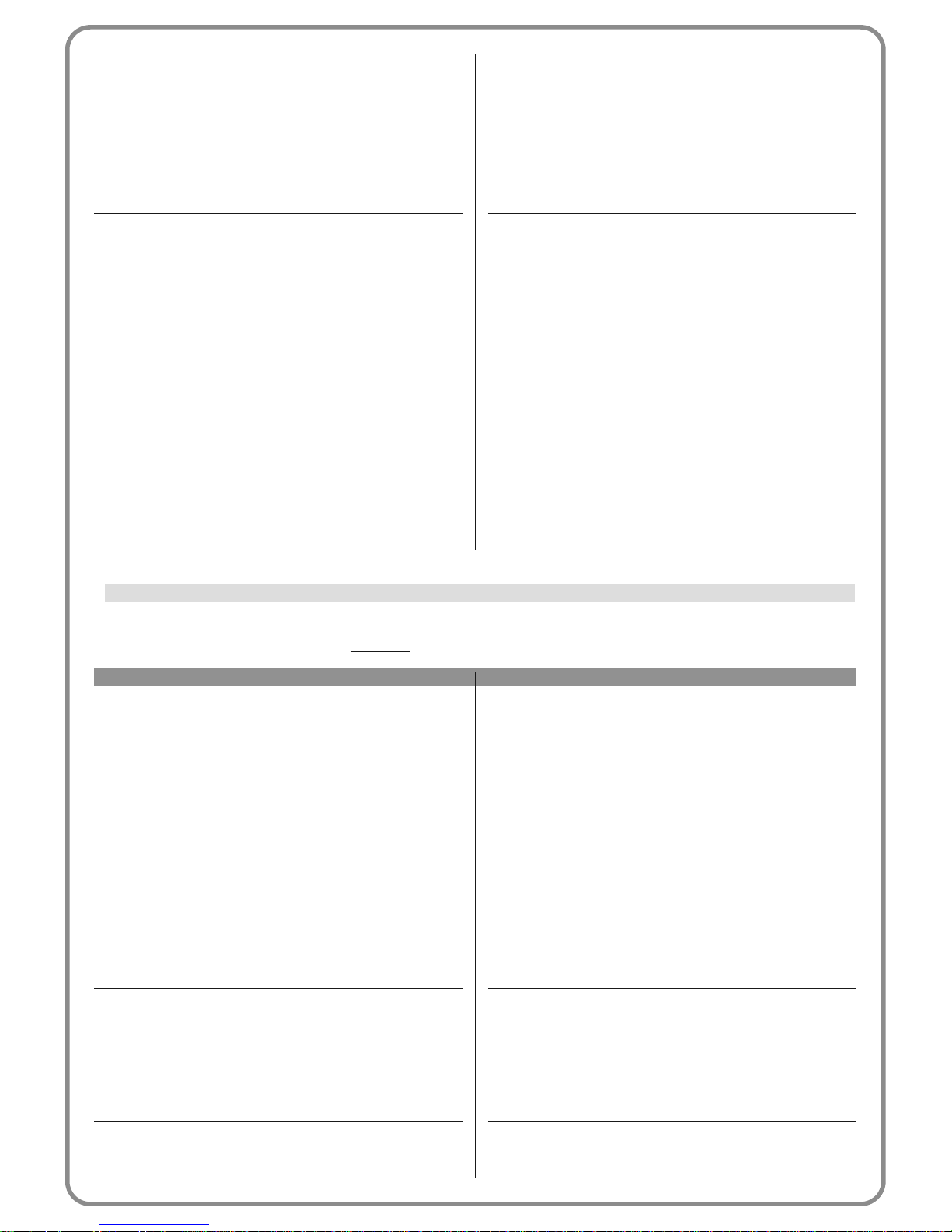

This parameter can be set with a value from 0 to 63; the factory setting is “0”.

The series is a number that has to be assigned to each gearmotor, receiver or other device potentially connectable on a BusT4

network, to define its “classification area”. Subsequently, when using automations in a complex system, all devices with the

same series number can be controlled simultaneously.

This parameter can be set with a value from 1 to 128; the factory setting is “2” for Receivers and 3 for Control Units.

The address is a number that has to be assigned to each gearmotor, receiver or other device potentially connectable on a

BusT4 network, to distinguish it from other devices in a series. Therefore all devices within a series must have a different

address from one another.

This parameter can be set with a value from 1 to 14, or “None”; the factory setting is “None”.

The function enables the user to assign a number to a device to be controlled (for example a gearmotor or other device potentially connectable to a BusT4 network), which enables this device to belong to a specific “command group”.

Several devices, also if belonging to different series, can form part of the same group. Up to 14 groups of devices can be created and, in particular, the same device may be inserted in 4 different groups.

In a device network, use of this function enables:

- simultaneous control of different devices inserted in a group, even if some of these belong to different series;

- use of a single receiver, installed in one of the devices belonging to the group, to control all the devices belonging to this group.

This function enables the display of the version of the firmware present in a device.

This function enables the display of the version of the hardware present in a device.

This function enables the display of the serial number identifying a specific device. This number is different for each device, even

if of the same model.

This function is useful to restrict access by unauthorised personnel to all or some of the programming functions of a device. If a

device is password protected, the user must perform the “log in” procedure to proceed with a programming session, followed

by the “log out” procedure on completion of the programming procedure. Note – the “log out” procedure enables the user to

prevent access by unauthorised personnel, by re-activating the existing password. Caution! – When programming the password on several devices (for example in Oview, the Control unit, Receiver etc.), we recommend using the same password for

all devices including Oview. This will avoid the need to repeat the login procedure each time the device is changed during use

of Oview and the connected Software.

Two types of password can be programmed on the devices (including Oview).

- the user password

, comprising maximum 6 alphanumeric characters. Caution! – Do not use uppercase letters.

- the installer password

, comprising maximum 6 alphanumeric characters. Caution! – Do not use uppercase letters.

password management

serial number (not modifiable)

hardware version (not modifiable)

firmware version (not modifiable)

group

address

series

name

COMMON FUNCTIONS

Robus 600-1000 – 3

Installation

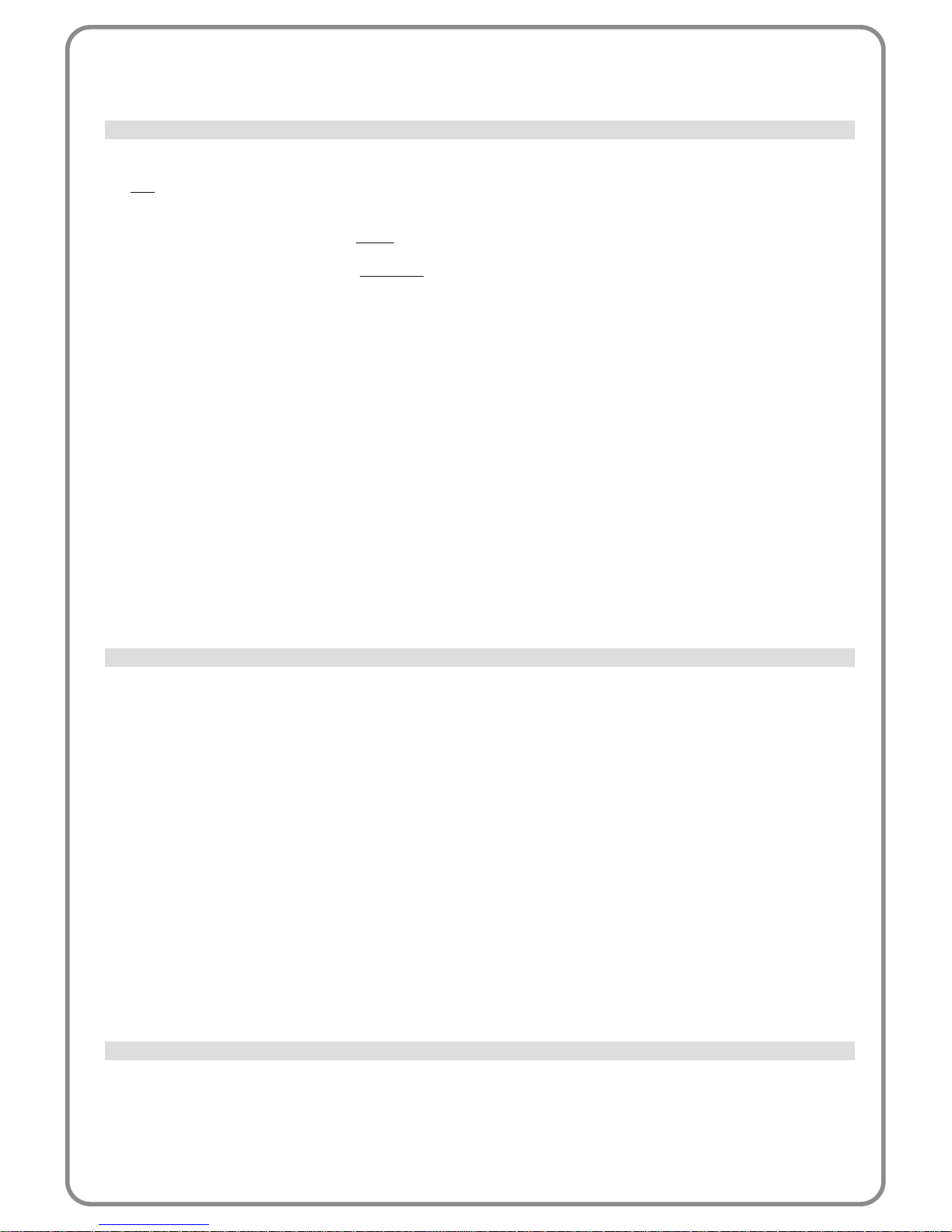

This function enables start-up of the procedure for learning the devices connected to the Bluebus input and the HALT input of

the control unit of an automation. Important – To activate the device search, press “Start”.

This function enables the measurement of the distance between the Closing limit position and Opening limit position (length of

the gate leaf). This measurement is used by the control unit to censure the precise calculation of the points (positions) at which

the gate leaf must start to decelerate during a manoeuvre and to determine the partial opening positions. To activate the position search, press “Start”.

• maximum opening

This function enables the display of the Opening limit position, after the relative learning procedure has been completed.

• deceleration on opening

This function is expressed in metres. This enables programming of the precise point (position) at which the gate should start

decelerating before reaching the limit switch at the end of the Opening manoeuvre. After programming the required point, press

“OK” to save the value.

• partial open 1

This function is expressed in metres. During the opening manoeuvre this enables programming of the precise point (position) at

which the gate stops travel (partial open). After programming the required point, press “OK” to save the value.

• partial open 2

This function is expressed in metres. During the opening manoeuvre this enables programming of the precise point (position) at

which the gate stops travel (partial open). After programming the required point, press “OK” to save the value.

• partial open 3

This function is expressed in metres. During the opening manoeuvre this enables programming of the precise point (position) at

which the gate stops travel (partial open). After programming the required point, press “OK” to save the value.

• deceleration on closing

This function is expressed in metres. This enables programming of the precise point (position) at which the gate should start

decelerating before reaching the limit switch at the end of the Closing manoeuvre. After programming the required point, press

“OK” to save the value.

This function enables the user to delete the configuration of a control unit and the relative stored data, selecting items from a

series. These items are:

positions – enables deletion of all memorised positions;

bluebus devices – enables deletion of the configuration of the Bluebus devices and the HALT input;

function values – enables deletion of all values and settings of functions envisaged on the control unit;

all – enables the deletion of all data in the Control unit memory excluding the reserved parameters: series

, address, hard-

ware version

, software version, serial number.

Basic parameters

This parameter type is ON/OFF; the factory setting is “OFF”. This function enables the activation of automatic closure at the end

of an opening manoeuvre in the control unit of the automation. If the function is active (ON) the automatic closure manoeuvre

starts at the end of the wait time programmed in the function “pause time”.

If the function is not active (OFF) the Control unit operation mode is “semiautomatic”.

This parameter is expressed in seconds and can be set with a value from 0 to 250 sec.; the factory setting is 30 sec. This func-

pause time

automatic closure

data deletion

bluebus search

positions

position search

CONTROL UNIT FUNCTIONS

4 – Robus 600-1000

tion enables programming on the Control unit of the required wait time which must pass between the end of an Opening

manoeuvre and the start of a Closing manoeuvre. IMPORTANT – This function is only enabled if the “automatic closure” func-

tion is active.

• active

This parameter type is ON/OFF; the factory setting is “OFF”. The function enables the automation to remain in the Opening position only

for the time required for vehicle or person transit. When this interval elapses the Automatic Closure manoeuvre is acti-

vated automatically, which in turn is started after a time as set in the function “wait time”. Important – When the function is

active (ON), operation varies according to the parameter set in the function “Automatic closure”:

with the function “Automatic closure” active

(ON), the Opening manoeuvre is stopped immediately after disengagement of

the photocells and, after the wait time set in “wait time”, the automation starts up the Closure manoeuvre.

with the function “Automatic closure” not active (OFF), the automation completes the entire Opening manoeuvre (even if

the photocells are disengaged beforehand) and, after the wait time set in “wait time”, the automation starts up the Closure

manoeuvre.

Caution! – The function “reclose after photo” is disabled automatically if Stop command is sent during the manoeuvre in

progress, to stop the manoeuvre.

• mode

This parameter is factory set on the mode “open until disengage” The function has 2 operating modes:

open all – when this mode is enabled, if the safety devices (photocells) are activated during a Closure manoeuvre, the

automation starts to perform a complete Opening manoeuvre. On the other hand, if the safety devices are disengaged, the

automation starts up the automatic closure manoeuvre after the wait time as programmed in the function “closure delay time”

has elapsed.

open until disengage – when this mode is enabled, if the safety devices (photocells) are activated during a Closure

manoeuvre, the automation starts to perform an Opening manoeuvre, which proceeds until the photocells are disengaged. At

this point the manoeuvre is shut down and the automation starts the closure manoeuvre after the wait time as programmed

in the function “closure delay time” has elapsed. Note – If the “Automatic closure” function is not active, the Control unit

switches to “open all” mode.

• wait time

This parameter is expressed in seconds and can be set with a value from 0 to 250 sec.; the factory setting is 5 sec. This function enables programming on the Control unit of the required wait time to pass between the end of an Opening manoeuvre and

the start of a Closing manoeuvre.

• active

This parameter type is ON/OFF; the factory setting is “OFF”. This function is useful in the event of a power failure, even brief. In

fact, during an Opening manoeuvre if the automation shuts down due to a power failure and the function is active (ON), the Closure manoeuvre is performed normally when the electrical power is restored. On the contrary, if the function is not active (OFF),

the automation remains stationary when the power is restored. Note – For reasons of safety, when the function is active, the

Closure manoeuvre is preceded by a wait time as programmed in the function “pre-flash time”.

• mode

This parameter is factory set on the mode “always close” The function has 2 operating modes:

standard – For this mode, refer to the function “active” under the item “always close”;

save automatic closure – When this mode is activated, there are two possible results after a power failure: a) execution

of automatic closure, observing the time as programmed in the function “pre-flash time”, if the timeout interval of this time

was in progress at the time of the power failure; b) execution of closure manoeuvre if automatic closure was in progress at

the time of the power failure and the manoeuvre had not been completed. Note – If the automatic closure manoeuvre was

cancelled before the power failure (for example, by sending the Halt command), the Closure manoeuvre is not performed

when the power is restored.

• wait time

This parameter is expressed in seconds and can be set with a value from 0 to 20 sec.; the factory setting is 5 sec. This function

enables programming on the Control unit of the required wait time to pass between the end of an Opening manoeuvre and the

start of a Closing manoeuvre.

• manual force level

This parameter can be set with a value from 10% to 100%; the factory setting is 100%. The function enables control of the force

absorbed by the motor during execution of a manoeuvre.

force management

always close

reclose after photo

Robus 600-1000 – 5

• open speed

This parameter can be set with a value from 0% to 100%; the factory setting is 60%. The function enables programming of the

required motor speed during an Opening manoeuvre. Important – When this parameter is modified, the control unit updates

the “force” and “obstacle sensitivity” values during the subsequent manoeuvres.

• open deceleration speed

This parameter can be set with a value from 0% to 100%; the factory setting is 15%. The function enables programming of the

required motor speed during the deceleration phase of an opening manoeuvre. Important – When this parameter is modified,

the control unit updates the “force” and “obstacle sensitivity” values during the subsequent manoeuvres.

• close speed

This parameter can be set with a value from 0% to 100%; the factory setting is 60%. The function enables programming of the

required motor speed during a Closing manoeuvre. Important – When this parameter is modified, the control unit updates the

“force” and “obstacle sensitivity” values during the subsequent manoeuvres.

• close deceleration speed

This parameter can be set with a value from 0% to 100%; the factory setting is 15%. The function enables programming of the

required motor speed during the deceleration phase of a closing manoeuvre. Important – When this parameter is modified, the

control unit updates the “force” and “obstacle sensitivity” values during the subsequent manoeuvres.

• active

This parameter type is ON/OFF; the factory setting is “OFF”. When this function is set to “ON”, the values attributed to the functions associated with motor force and speed give the motor more power during the initial phase of a manoeuvre. This function

is useful in the presence of static friction (for example, snow or ice which obstruct the automation). Note – If the function is not

active (OFF) the Opening or Closing manoeuvre starts with a gradual acceleration.

• start-up time

This parameter is expressed in seconds and can be set with a value from 0.5 to 5 seconds; the factory setting is 2 seconds. The

function enables programming of the duration of initial motor start-up. Important – The function is only effective if the “start-up”

function is enabled (ON).

• active

This parameter type is ON/OFF; the factory setting is “OFF”. When this function is set to “ON” it enables the activation of a flashing time, which passes between activation of the flashing light and the start of an Opening or Closing manoeuvre. This time is

adjustable and useful to for an advance indication of a hazardous situation. Important – When this function is not active (OFF),

the flashing light is switched on at the same time as the start of the manoeuvre.

• time in opening

This parameter is expressed in seconds and can be set with a value from 0 to 10 seconds; the factory setting is 3 seconds. The

function enables programming of the flashing time which indicates the imminent start of an Opening manoeuvre and is associated with the “preflash” function.

• time in closing

This parameter is expressed in seconds and can be set with a value from 0 to 10 seconds; the factory setting is 3 seconds. The

function enables programming of the flashing time which indicates the imminent start of a Closing manoeuvre and is associated with the “preflash” function.

• active

This parameter type is ON/OFF; the factory setting is “OFF”. When this function is set to “ON”, automation power consumption

can be reduced.

• mode

The function has 3 operating modes:

safety – when this mode is set, at the end of a manoeuvre and when the standby time has elapsed (parameter program-

mable in the function “wait time”), the control unit switches off the transmitters of the Bluebus photocells and all leds

, with the

exception of the Bluebus led, which flashes at a slower interval. Note – When the control unit receives a command, it automatically restores normal operation of the automation, and no longer in energy saving mode.

bluebus – when this mode is set, at the end of a manoeuvre and when the standby time has elapsed, the control unit

switches off the Bluebus output (devices) and all leds

, with the exception of the Bluebus led, which flashes at a slower inter-

val. Note – When the control unit receives a command, it automatically restores normal operation of the automation, and no

longer in energy saving mode.

speed management

stand-by

preflash

start-up

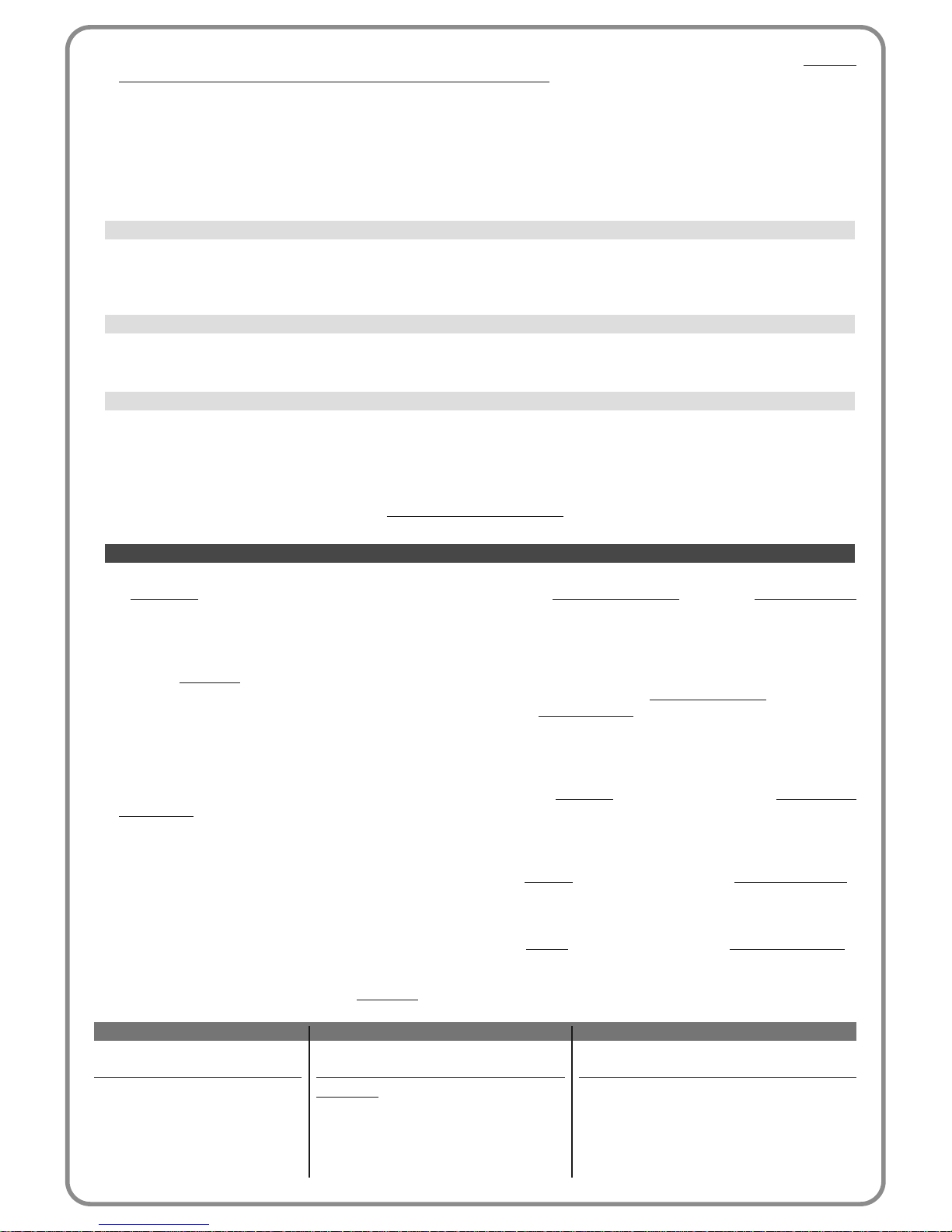

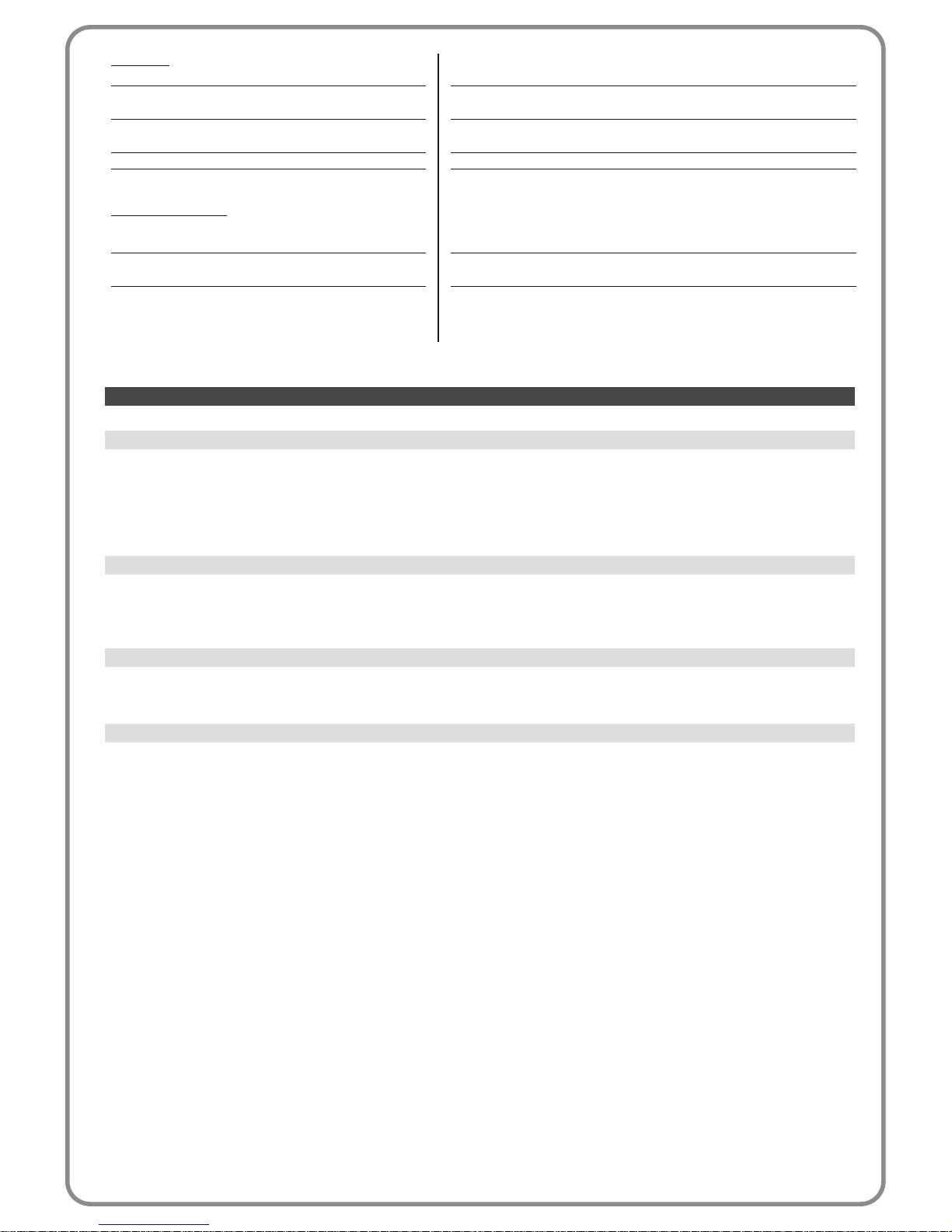

DESCRIPTION

Does not perform any command

This command is factory set to Input 1,

with operating mode “step step” and operating sequence “open- stop - close - open”.

When this command is sent, the control unit

activates the application to complete the next

COMMAND

No command

Step step

COMMAND CATEGORY

Step step

program the required operating mode,

selecting in Table 1-A (“command con-

figuration” > “step step” > operating

mode...)

6 – Robus 600-1000

all – when this mode is set, at the end of a manoeuvre and when the standby time has elapsed, the control unit switches

off the Bluebus output (devices), some of the internal circuits and all leds, with the exception of the Bluebus led, which flashes at a slower interval. Note – When the control unit receives a command, it automatically restores normal operation of the

automation, and no longer in energy saving mode.

• wait time

This parameter is expressed in seconds and can be set with a value from 0 to 250 seconds; the factory setting is 60 seconds.

The function enables programming of the time which must pass between the end of a manoeuvre and the start of the “standby” function, if the latter is active (ON).

This parameter type is ON/OFF; the factory setting is “OFF”. This function enables automation operation to be disabled, by setting the value to “ON”. In this case no type of command is acknowledged or performed, with the exception of “High priority

step-step”, “Release”, “Release and close” and “Release and open”.

This parameter type is ON/OFF; the factory setting is “OFF”. This function disables operation of the keys present on the control

unit.

This parameter type is ON/OFF; the factory setting is “OFF”. In the case of two gearmotors which must operate in synchronised

mode, each installed on one of the two leafs of a gate or door, one must operate as a Master and the other as a Slave. To use

this configuration, set the Master motor to “OFF” and the Slave motor to “ON”.

Advanced parameters

This item covers the commands available and associable with inputs 1-2-3 present on the control unit of an automation.

The commands available for each input are described in Table 1; while the command categories and relative operating modes

are described in Tables 1a, 1b, 1c etc. Important – For correct operation of the control unit, the command programmed

on an input must be associated with the corresponding command category and lastly the required operating mode.

For configure an input, proceed as follows:

01. In the section “Advanced parameters” select the item “input configuration” and then the input to be programmed. Select

the required command

and press “OK” to confirm the selection.

02. Then, again in “Advanced parameters”, select “command configuration” and select the command category corresponding

to the command selected previously in step 01. Then select the required operating mode.

There are three available inputs:

• Input 1

This function enables the programming of Input 1, assigning a command as required, from those listed in Table 1. Input 1 is

factory set with the “step-step” command, with the command category “step-step

” and the operating mode “open - stop -

close - open”.

• Input 2

This function enables the programming of Input 2, assigning a command as required, from those listed in Table 1. Input 2 is

factory set with the “open” command, with the command category “opening

” and the operating mode “open - stop - open”.

• Input 3

This function enables the programming of Input 3, assigning a command as required, from those listed in Table 1. Input 3 is

factory set with the “close” command, with the command category “closing” and the operating mode “close - stop - close”.

TABLE 1: INPUT CONFIGURATION

INPUT configuration

slave mode

key lock

automation block

Robus 600-1000 – 7

manoeuvre following the previous one (or still in

progress) according to the sequence of

manoeuvres as envisaged in the programmed

sequence.

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the

Opening manoeuvre until the position is

reached as set in the function “partial open

1”(Control unit functions > installation > positions > partial open 1).

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the

Opening manoeuvre until the opening limit

switch is reached.

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the Closing manoeuvre until the closing limit switch is

reached.

Input configured as normally open.

When this command is sent, the control unit

stops the manoeuvre in progress gradually and

in a short time (not instantly).

Input configured as normally open.

When this command is sent, the control unit

activates the application to complete the next

manoeuvre following the previous one (or still in

progress) according to the sequence of ma noeuvres as envisaged in the programmed se quence.

Important – This command is performed even

if the control unit is set with the command

“block” (see Table 1).

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the Ope ning manoeuvre until the position is rea ched as

set in the function “partial open 2” (Control unit

functions > installation > positions > partial

open 2).

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the Ope ning manoeuvre until the position is reached as

set in the function “partial open 3” (Control unit

functions > installation > positions > partial

open 3).

Input configured as normally open.

When this command is sent the control unit

activates the application to complete the Ope ning manoeuvre until the position is reached as

set in the function “partial open 3”(Control unit

functions > installation > positions > partial

open 3).

Input configured as normally open.

Partial open 1

Open

Close

Stop

High priority step step

Partial open 2

Partial open 3

Open and block

Partial open

program the required operating mode,

selecting in Table 1-B (“command con-

figuration” > “partial open” > operating

mode...)

Opening

program the required operating mode,

selecting in Table 1-C (“command config-

uration” > “opening” > operating mo de...)

Closing

program the required operating mode,

selecting in Table 1-B (“command config-

uration” > “closing” > operating mo de...)

Stop

program the required operating mode,

selecting in Table 1-E (“command con-

figuration” > “stop” > operating mode...)

Step step

program the required operating mode,

selecting in Table 1-A (“command con-

figuration” > “step step” > operating

mo de...)

Partial open

program the required operating mode,

selecting in Table 1-B (“command con-

figuration” > “partial open” > operating

mo de...)

Partial open

program the required operating mode,

selecting in Table 1-B (“command con-

figuration” > “partial open” > operating

mo de...)

Opening

program the required operating mode, se lecting in Table 1-C (“command configu-

ration” > “opening” > operating mo de...)

8 – Robus 600-1000

When this command is sent the control unit

activates the application to complete the Closing manoeuvre until the position is reached as

set in the function “closing”(Control unit functions > installation > positions > closing) and

the automation is then blocked.

Input configured as normally open.

When this command is sent, the control unit is

blocked and does not perform any type of

command, with the exception of “High priority

step-step”, “Release”, “Release and close” and

“Release and open”.

Input configured as normally open.

When this command is sent, the control unit is

released restoring normal operating status (all

commands sent can be performed)

Input configured as normally open.

This command enables activation of the courtesy light on the control unit and that programmable on Output 1 and Output 2.

The courtesy light remains active for the time

as programmed in the function “courtesy light

ti me” (Control unit functions > advanced pa rame ters > output configuration > courtesy li ght ti me).

For the courtesy light connected to Output 1,

the command is only enabled when this output

is programmed in “courtesy light” mode (Control unit functions > advanced parameters >

out put configuration > output 1 (flash) > courtesy light).

Note – When the courtesy light is already

active and the command “timed courtesy light”

is sent again, the time programmed in the function “courtesy light time” is reloaded.

Input configured as normally open.

This command enables activation and deactivation of the courtesy light on the control unit and

that programmable on Output 1 and Output 2.

For the courtesy light connected to Output 1,

the command is only enabled when this output

is programmed in “courtesy light” mode (Control unit functions > advanced parameters >

output configuration > output 1 (flash) > courtesy light).

CAUTION! – The courtesy light is switched off

automatically if the relative time interval elapses, as programmed in the function “courtesy

light time” (Control unit functions > advanced

parameters > output configuration > courtesy

light time).

Input configured as normally open.

This command is factory set to Input 1,

with operating mode “ss apartment block

1” and operating sequence “open- stop close - open”.

When this command is sent, the control unit

activates the application to complete the next

manoeuvre following the previous one (or still in

progress) according to the sequence of ma noeuvres as envisaged in the programmed

sequence.

Note – This apartment block step step command is used for apartment blocks and in general envisages programming of all apartment

block transmitters with a single “apartment

block step step” key.

Input configured as normally open.

Close and block

Block

Release

Timed Courtesy light

Courtesy light: on/off

Apartment block

Closing

program the required operating mode,

selecting in Table 1-D (“command config-

uration” > “closing” > operating mo de...)

Step step

program the required operating mode, ss

apartment block 1 (“command config-

uration” > “step step” > operating mo -

de: ss apartment block 1

)

Robus 600-1000 – 9

When this command is sent, the control unit sto ps the manoeuvre in progress and activates the

application to execute the set operating mode.

Input configured as normally closed.

When this command is sent, the control unit

ac tivates the application to perform the opening

manoeuvre only until the limit switch is reached.

Note – This command is useful when using

control photocells or a magnetic detector loop.

Input configured as normally open.

When this command is sent, the control unit

activates the application according to the se lected manoeuvre type.

Input configured as normally closed.

When this command is sent, the control unit

activates the application according to the

selected manoeuvre type.

Input configured as normally closed.

When this command is sent, the control unit

activates the application according to the se lected manoeuvre type.

Input configured as normally closed.

When this command is sent, the control unit

activates the master (primary) leaf of the application to complete the next manoeuvre following the previous one (or still in progress) ac cording to the sequence of manoeuvres as en visaged in the programmed sequence.

Input configured as normally open.

When this command is sent, the control unit

activates the master (primary) leaf of the application to complete an Opening manoeuvre.

Input configured as normally open.

When this command is sent, the control unit

activates the master (primary) leaf of the application to complete a Closing manoeuvre.

Input configured as normally open.

When this command is sent, the control unit

activates the slave (secondary) leaf of the application to complete the next manoeuvre following the previous one (or still in progress)

according to the sequence of manoeuvres as

envisaged in the programmed sequence.

Input configured as normally open.

When this command is sent, the control unit

activates the slave (secondary) leaf of the application to complete an Opening manoeuvre.

Input configured as normally open.

When this command is sent, the control unit

activates the slave (secondary) leaf of the application to complete a Closing manoeuvre.

Input configured as normally open.

Alt

Apartment block open

Photo

Safety function

Photo 2

Safety function

Photo 3

Safety function

Master Step Step

Master open

Master close

Slave Step Step

Slave open

Slave close

Alt

on closing

program the required operating mode,

selecting in Table 1-L (“command con-

figuration” > “alt on closing” > operating mode...)

Opening

program the required operating mode,

apartment block 1 open

(“command

configuration” > “opening” > operating

mode apartment block 1 open)

Photo

program the required operating mode,

selecting in Table 1-F (“command config-

uration” > “photo” > operating mo de...)

Photo 2

program the required operating mode,

selecting in Table 1-H (“command con-

figuration” > “photo 2” > operating

mo de...)

Photo 3

program the required operating mode,

selecting in Table 1-I (“command config-

uration” > “photo 3” > operating mo de...)

Step step

program the required operating mode,

open - stop - close - open

(“command

configuration” > “step step” > operating

mode: open - stop - close - open

)

Opening

program the required operating mode,

selecting in Table 1-C (“command con-

figuration” > “opening” > operating

mo de...)

Closing

program the required operating mode,

selecting in Table 1-D (“command

con figuration” > “closing” > operating

mo de...)

Step step

program the required operating mode,

open - stop - close - open

(“command

configuration” > “closing” > operating

mo de: open - stop - close - open

)

Opening

program the required operating mode,

selecting in Table 1-C (“command con-

figuration” > “opening” > operating

mo de...)

Closing

program the required operating mode,

selecting in Table 1-D (“command con fig-

uration” > “closing” > operating mo de...)

10 – Robus 600-1000

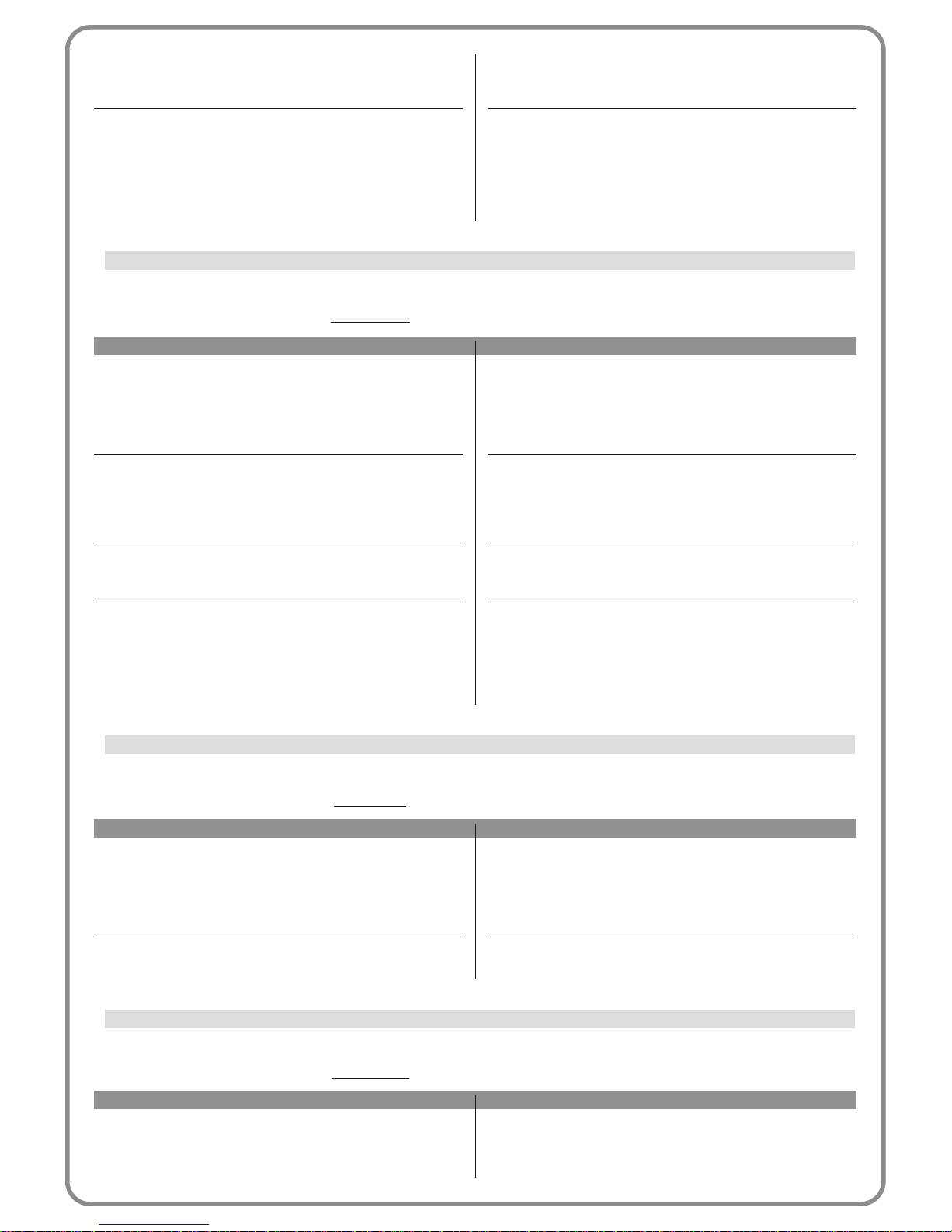

OPERATING MODE

Industrial mode

Open - Stop - Close - Stop

Open - Stop - Close - Open

Open - Close - Open - Close

Apartment block 1 step step

Apartment block 2 step step

Step Step 2

Hold-to-run

DESCRIPTION

This executes the sequence “open in semi-automatic - close in

hold-to-run”.

This executes the above sequence.

Operating mode set in factory (Input 1 - “step step” command). This executes the above sequence.

This executes the above sequence.

This executes the sequence “close - stop - open - open” un til the maximum opening position is reached. Note – If another

command is sent after this one, the application executes the

Closing manoeuvre with the same sequence.

This executes the sequence “close - stop - open - open”

until the maximum opening position is reached. Note – If

another command is sent after this one, the application executes the Closing manoeuvre with the same sequence.

Important – When sending a command, if the transmitter key

is held down for more than 2 seconds, the control unit activates a Stop.

This executes the sequence “open - stop - close - open”.

Important – When sending a command, if the transmitter key

is held down for more than 2 seconds, the control unit activates

a “partial open 1” command (input configuration > Table 1).

The Opening or Closing manoeuvre is executed exclusively if

the transmitter key is held down (hold-to-run).

This item covers the command categories associable with inputs 1 - 2 - 3 (refer to the section “input configuration - Table 1”

to check the commands available). Each command category features various operating modes as described in a table (1-A, 1B, etc.):

In this command category the user can select one of the operating modes specified in Table 1-A.

TABLE 1-A: COMMAND CONFIGURATION

step step

COMMAND configuration

When this command is sent, the control unit is

released (restoring normal operating status)

and activates the application to execute an

Opening manoeuvre.

Input configured as normally open.

When this command is sent, the control unit is

released (restoring normal operating status)

and activates the application to execute a

Closing manoeuvre.

Input configured as normally open.

This command enables the activation or deactivation of the function for bluebus control photocells and inputs configured in “apartment

block open” mode. Note – the factory setting

of this function is “active”.

For example, if this function is active, when the

control photocells are engaged, the control unit

activates the application to execute an Opening manoeuvre.

Input configured as normally open.

This command enables deactivation of the “au to matic opening active” mode described above.

Input configured as normally open.

Release and open

Release and close

Automatic opening active

Automatic opening

deactivated

Robus 600-1000 – 11

OPERATING MODE

Open - Stop - Close - Stop

Open - Stop - Close - Open

Open - Close - Open - Close

Apartment block 1 step step

Apartment block 2 step step

Hold-to-run

Industrial mode

DESCRIPTION

Operating mode set in factory. This executes the above

sequence.

This executes the above sequence.

This executes the above sequence.

This executes the sequence “close - stop - partial open 1-

partial open 1” until the maximum position is reached as programmed in the function “Partial Open 1”. Note – If another

command is sent after this one, the application executes the

Closing manoeuvre with the same sequence.

This executes the sequence “close - stop - partial open 1 partial open 1” until the position is reached as programmed in

the function »Partial Open 1”. Note – If another command is

sent after this one, the application executes the Closing ma noeuvre with the same sequence.

Important – When sending a command, if the transmitter key

is held down for more than 2 seconds, the control unit activates a Stop.

The Partial open 1 or Closing manoeuvre is executed exclusively if the transmitter key is held down (hold-to-run)..

This executes the sequence “open in semi-automatic – close

in hold-to-run”.

In this command category the user can select one of the operating modes specified in Table 1-B.

TABLE 1-B: COMMAND CONFIGURATION

partial open

OPERATING MODE

Open - Stop - Open

Apartment block 1

Apartment block 2

Open 2

Hold-to-run Open

DESCRIPTION

Operating mode set in factory (Input 2 - “open” command). This executes the above sequence.

This executes the sequence “open - open”.

Important – When sending a command, if the transmitter key

is held down for more than 2 seconds, the control unit activates a Stop.

This executes the Opening sequence. Important – When

sending a command, if the transmitter key is held down for

more than 2 seconds, the control unit activates a “partial open

1” command (input configuration > Table 1).

The Opening manoeuvre is executed exclusively if the transmitter key is held down (hold-to-run).

In this command category the user can select one of the operating modes specified in Table 1-C.

TABLE 1-C: COMMAND CONFIGURATION

open

OPERATING MODE

Close - stop - close

DESCRIPTION

Operating mode set in factory (Input 3 - “close” comma nd). This executes the above sequence.

In this command category the user can select one of the operating modes specified in Table 1-D.

TABLE 1-D: COMMAND CONFIGURATION

close

12 – Robus 600-1000

OPERATING MODE

stop and brief inversion

DESCRIPTION

When the control unit receives the command, it stops the

Closing manoeuvre in progress and activates the application

to perform a brief inversion in the opposite direction (Opening).

Caution! – During execution of the Opening manoeuvre,

this command is ignored.

In this command category the user can select one of the operating modes specified in Table 1-G.

TABLE 1-G: COMMAND CONFIGURATION

photo 1

OPERATING MODE

stop

stop and brief inversion

DESCRIPTION

Operating mode set in factory. When the control unit re ceives the command, it stops the manoeuvre in progress

gradually and in a short time (not instantly).

When the control unit receives the “stop” command, it stops

the manoeuvre in progress and activates the application to

perform a brief inversion in the opposite direction.

In this command category the user can select one of the operating modes specified in Table 1-E.

TABLE 1-E: COMMAND CONFIGURATION

stop

OPERATING MODE

stop and inversion

stop and brief inversion

stop

temporary stop

DESCRIPTION

Operating mode set in factory. When the control unit

receives the command, it stops the Closing manoeuvre in

progress and activates a total inversion (Opening). Caution! –

During execution of the Opening manoeuvre, this command is ignored.

When the control unit receives the command, it stops the

Closing manoeuvre in progress and activates the application

to perform a brief inversion in the opposite direction (Opening).

Caution! – During execution of the Opening manoeuvre,

this command is ignored.

When the control unit receives the command, it stops the

Closing manoeuvre in progress. Caution! – During execu-

tion of the Opening manoeuvre, this command is ignored.

When the control unit receives the command, it stops the

Closing manoeuvre for the entire time that the command

remains active. Otherwise, when the command is no longer

active, the control unit activates the application to perform an

Opening manoeuvre. Caution! – During execution of the

Opening manoeuvre, this command is ignored.

In this command category the user can select one of the operating modes specified in Table 1-F.

TABLE 1-F: COMMAND CONFIGURATION

photo

Apartment block 1 close

Apartment block 2 close

Hold-to-run close

This executes the sequence “close - close”.

This executes the sequence “close - close”. Important –

When sending a command, if the transmitter key is held down

for more than 2 seconds, the control unit activates a Stop.

The Closing manoeuvre is executed exclusively if the hold-torun command is used.

Robus 600-1000 – 13

OPERATING MODE

stop and inversion

stop and brief inversion

stop

temporary stop

DESCRIPTION

Operating mode set in factory. When the control unit re ceives the command, it stops the Opening manoeuvre in

progress and activates a total inversion (Closing). Caution! –

During execution of the Opening manoeuvre, this command is ignored.

When the control unit receives the command, it stops the

Opening manoeuvre in progress and activates the application

to perform a brief inversion in the opposite direction (Closing).

Caution! – During execution of the Opening manoeuvre,

this command is ignored.

When the control unit receives the command, it stops the

Opening manoeuvre in progress. Caution! – During execu-

tion of the Opening manoeuvre, this command is ignored.

When the control unit receives the command, it stops the

Opening manoeuvre for the entire time that the command

remains active. Otherwise, when the command is no longer

active, the control unit activates the application to perform a

Closing manoeuvre. Caution! – During execution of the

Opening manoeuvre, this command is ignored.

In this command category the user can select one of the operating modes specified in Table 1-H.

TABLE 1-H: COMMAND CONFIGURATION

photo 2

OPERATING MODE

temporary stop

stop

DESCRIPTION

Operating mode set in factory. When the control unit re ceives the command, it stops the Closing manoeuvre for the

entire time that the command remains active. Otherwise, when

the command is no longer active, the control unit activates the

application to perform an Opening manoeuvre.

When the control unit receives the command, it stops the

manoeuvre in progress.

In this command category the user can select one of the operating modes specified in Table 1-I.

TABLE 1-I: COMMAND CONFIGURATION

photo 3

stop

temporary stop

When the control unit receives the command, it stops the

Closing manoeuvre in progress. Caution! – During execu-

tion of the Opening manoeuvre, this command is ignored.

When the control unit receives the command, it stops the

Closing manoeuvre for the entire time that the command

remains active. Otherwise, when the command is no longer

active, the control unit activates the application to perform an

Opening manoeuvre. Caution! – During execution of the

Opening manoeuvre, this command is ignored.

OPERATING MODE

alt

DESCRIPTION

When this type of function is set, when the control unit re ceives the command, it stops the Opening manoeuvre in

progress immediately.

In this command category the user can select one of the operating modes specified in Table 1-L.

TABLE 1-L: COMMAND CONFIGURATION

alt in opening

14 – Robus 600-1000

OPERATING MODE

alt

alt and brief inversion

alt and inversion

DESCRIPTION

When the control unit receives the command, it stops the

Opening manoeuvre in progress.

Operating mode set in factory. When the control unit

receives the command, it stops the Opening manoeuvre in

progress immediately and activates the application to perform

a brief inversion in the opposite direction (Closing).

When the control unit receives the command, it stops the

Opening manoeuvre in progress immediately and activates the

application to perform a total inversion in the opposite direction (Closing).

In this command category the user can select one of the operating modes specified in Table 1-N.

TABLE 1-N: COMMAND CONFIGURATION

obstacle detection in opening

OPERATING MODE

alt

alt and brief inversion

alt and inversion

DESCRIPTION

When the control unit receives the command, it stops the

Closing manoeuvre in progress.

When the control unit receives the command, it stops the

Closing manoeuvre in progress immediately and activates the

application to perform a brief inversion in the opposite direction (Opening).

Operating mode set in factory. When this type of function is

set, when the control unit receives the command, it stops the

Closing manoeuvre in progress immediately and activates the

application to perform a total inversion in the opposite direction (Opening).

In this command category the user can select one of the operating modes specified in Table 1-O.

TABLE 1-O: COMMAND CONFIGURATION

obstacle detection in closing

OPERATING MODE

alt

alt and brief inversion

alt and inversion

DESCRIPTION

When the control unit receives the command, it stops the

Closing manoeuvre in progress.

Operating mode set in factory. When the control unit

receives the command, it stops the Closing manoeuvre in

progress immediately and activates the application to perform

a brief inversion in the opposite direction (Opening).

When the control unit receives the command, it stops the

Closing manoeuvre in progress immediately and activates the

application to perform a total inversion in the opposite direction (Opening).

In this command category the user can select one of the operating modes specified in Table 1-M.

TABLE 1-M: COMMAND CONFIGURATION

alt in closing

alt and brief inversion

alt and inversion

Operating mode set in factory. When the control unit

receives the command, it stops the Opening manoeuvre in

progress immediately and activates the application to perform

a brief inversion in the opposite direction (Closing).

When the control unit receives the command, it stops the

Opening manoeuvre in progress immediately and activates the

application to perform a total inversion in the opposite direction (Closing).

Robus 600-1000 – 15

FUNCTION

sca (= gate open indicator)

gate open

gate closed

maintenance indicator light

flashing light

courtesy light

electric lock 1

suction cup 1

radio channel no.1

DESCRIPTION

The programmed light indicates the operating status of the

control unit.

light off = application in maximum Closing position;

slow flashing = application Opening manoeuvre execution

phase;

quick flashing = application Closing manoeuvre execution

phase;

light permanently on = application in maximum Opening

position.

The programmed light indicates the operating status of the

control unit.

light on = application in maximum Opening position;

light off = application in other positions.

The programmed light indicates the operating status of the

control unit.

light on = application in maximum Closing position;

light off = application in other positions.

The programmed light indicates the count of manoeuvres

completed and therefore the need (or not) for system maintenance operations.

light on for 2 sec at start of Opening manoeuvre = number

of manoeuvres less than 80%;

light flashing during execution of entire manoeuvre = number of manoeuvres between 80 and 100%;

light always flashing = number of manoeuvres over 100%.

This function enables the flashing light to indicate execution of

a manoeuvre in progress with flashes at regular intervals (0.5

sec ON, 0.5 sec OFF).

This function type is ON/OFF. Important – For safety reasons,

as the light is not controlled by a timer, use of an adequate light,

able to withstand the heat of the light emitted, is recommended.

With this function programmed, when an Opening manoeuvre

is performed the electric lock is activated for a time as set in

the function “electric lock time – output configuration”.

With this function programmed, the suction cup is activated

when the application is in the maximum Closing position. Note

– The suction cup is disabled in all other situations.

When the suction cup is disabled, before an Opening manoeuvre is started, the time interval as programmed in the function

“suction cup time – output configuration” is activated, which

delays the start of the manoeuvre.

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. It is useful if installing external devices (for

example, an auxiliary light) in the same system to be controlled

with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

This item covers the functions available and associable with Outputs 1 (flash) - 2 - 3 present on the control unit of an automation. Each output has various functions as described in a table (Table 2, Table 3 etc):

In this output the user can select one of the functions specified in Table 2.

TABLE 2: OUTPUT CONFIGURATION

output 1 (flash)

OUTPUT configuration

16 – Robus 600-1000

FUNCTION

sca (= gate open indicator)

gate open

gate closed

maintenance indicator light

flashing light

DESCRIPTION

The programmed light indicates the operating status of the

control unit.

light off = application in maximum Closing position;

slow flashing = application Opening manoeuvre execution

phase;

quick flashing = application Closing manoeuvre execution

phase;

light permanently on = application in maximum Opening

position.

The programmed light indicates the operating status of the

control unit.

light on = application in maximum Opening position;

light off = application in other positions.

The programmed light indicates the operating status of the

control unit.

light on = application in maximum Closing position;

light off = application in other positions

The programmed light indicates the count of manoeuvres

completed and therefore the need (or not) for system maintenance operations.

light on for 2 sec at start of Opening manoeuvre = number

of manoeuvres less than 80%;

light flashing during execution of entire manoeuvre = number of manoeuvres between 80 and 100%;

light always flashing = number of manoeuvres over 100%.

This function enables the flashing light to indicate execution of

a manoeuvre in progress with flashes at regular intervals (o.5

sec ON, 0.5 sec OFF).

In this output the user can select one of the functions specified in Table 3.

TABLE 3

: OUTPUT CONFIGURATION

output 2

radio channel no.2

radio channel no.3

radio channel no.4

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. This mode is useful if installing external devices

(for example, an auxiliary light) in the same system to be controlled with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. This mode is useful if installing external devices

(for example, an auxiliary light) in the same system to be controlled with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. This mode is useful if installing external devices

(for example, an auxiliary light) in the same system to be controlled with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

Robus 600-1000 – 17

courtesy light

electric lock 1

suction cup 1

radio channel no.1

radio channel no.2

radio channel no.3

radio channel no.4

This function type is ON/OFF. Important – For safety reasons,

as the light is not controlled by a timer, use of an adequate light,

able to withstand the heat of the light emitted, is recommended.

With this function programmed, when an Opening manoeuvre

is performed the electric lock is activated for a time as set in

the function “electric lock time – output configuration”.

Output active 24 Vdc / max 4 W

With this function programmed, the suction cup is activated

when the application is in the maximum Closing position. Note

– The suction cup is disabled in all other situations.

When the suction cup is disabled, before an Opening manoeuvre is started, the time interval as programmed in the function

“suction cup time – output configuration” is activated, which

delays the start of the manoeuvre.

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. It is useful if installing external devices (for

example, an auxiliary light) in the same system to be controlled

with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

Output active 24Vdc / max 4 W

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. It is useful if installing external devices (for

example, an auxiliary light) in the same system to be controlled

with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

Output active 24Vdc / max 4 W

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. It is useful if installing external devices (for

example, an auxiliary light) in the same system to be controlled

with a single transmitter.

WARNING – If this channel is not free on the control unit

receiver, as previously memorised with a command, the control unit activates exclusively the programmed output when the

channel is activated with the transmitter, ignoring the command to the motor.

Output active 24Vdc / max 4 W

If this radio channel is set for the configuration of output 1

(flash), this channel is activated when a command is set with

the transmitter. It is useful if installing external devices (for

example, an auxiliary light) in the same system to be controlled

with a single transmitter.

WARNING – If this channel is not free on the control unit receiver, as previously memorised with a command, the control unit

activates exclusively the programmed output when the channel

is activated with the transmitter, ignoring the command to the

motor.

Output active 24Vdc / max 4 W

18 – Robus 600-1000

FUNCTION

Diagnosis 1 - IN

RADIO INPUTS (On / Off)

:

Channel 1

Channel 2

Channel 3

Channel 4

SERIAL RADIO INPUTS

BOARD KEYS:

no. 1

no. 2

no. 3

DIRECTION SELECTOR

INPUT STATUS

inp 1

inp 2

inp 3

inp alt

ALT CONFIGURATION

MOTOR 1 (On / Off):

Limit switch on opening

Limit switch on closing

MANOEUVRE THRESHOLD

:

DESCRIPTION

Indicates when radio receiver channel 1 is active.

Indicates when radio receiver channel 2 is active.

Indicates when radio receiver channel 3 is active.

Indicates when radio receiver channel 4 is active.

Indicates when the control unit receives a serial command via BusT4

from a radio receiver; these commands range from minimum 1 to

maximum 15.

Indicates when key 1 is pressed (= OPEN) on the control unit.

Indicates when key 2 is pressed (= STOP) on the control unit.

Indicates when key 3 is pressed (= CLOSE) on the control unit.

Indicates the operating status of the selector for the direction of a

manoeuvre performed by the application.

Indicates when input 1 is active.

Indicates when input 2 is active.

Indicates when input 3 is active.

Indicates when the alt input is active.

Indicates the type of connection on the alt terminal. Connection

types are: not configured; NC; NO; 1 8K2 resistive edge; 2 8K2 resistive edges; 1 OSE optical edge; out of range.

Indicates when motor 1 reaches the maximum opening position.

Indicates when motor 1 reaches the maximum closing position.

Indicates the operating status of the manoeuvre limiter, expressed in

levels:

Level 1: OK;

This function enables the display of the operating status of all inputs and outputs present on the control unit. The functions of

the inputs and outputs are described in Table 4.

TABLE 4: input/output DIAGNOSTICS

inputs / outputs

DIAGNOSTICS

This parameter is expressed in seconds and can be set with a value from 0.1 to 10 sec.; the factory setting is 2 sec. This function enables programming on the Control unit of the required time interval to pass between the end of a Closing manoeuvre and

the start of an Opening manoeuvre.

This parameter is expressed in seconds and can be set with a value from 0.1 to 10 sec.; the factory setting is 2 sec. This function enables programming on the Control unit of the required time interval to pass between the end of a Closing manoeuvre and

the start of an Opening manoeuvre, when the suction cup is detached.

This parameter is expressed in seconds and can be set with a value from 0 to 250 seconds; the factory setting is 60 seconds.

This function enables programming of the required time for which the courtesy light remains lit both on the control unit and on

output 1 (flash).

courtesy light time

suction cup time

electric lock time

Robus 600-1000 – 19

LAST 8 MANOEUVRES

AUTOMATIC OPENING

Diagnosis 1 - OUT

GENERAL DATA:

Stand-by

POWER SUPPLY

:

MEMORY ERROR

:

Rego

Functions

Alt

Bluebus

Positions

ENCODER STATUS

:

Abs M1

OUTPUTS

:

Suction cup Out

Out 1

Out 2

Out M1

ALARMS

:

Out 1 overload

Out 2 overload

M1 high overtravel

Level 2: THRESHOLD 1; the manoeuvre is started with a 2 second

delay;

Level 3: THRESHOLD 2; the manoeuvre is started with a 5 second

delay;

Level 4: MOTOR ALARM; the manoeuvre is only enabled with the

hold-to-run control.

Indicates any malfunctions occurring during normal operation of the

application, showing the last 8 manoeuvres completed.

Indicates if this function is active.

Indicates when the automation is in the standby status.

Indicates the type of electrical mains used by the automation: electric

mains (120/230 Vac) or buffer battery (24 Vdc)

Indicates whether there is an error in the memorised data on the control unit regarding settable parameters.

Indicates whether there is an error in the memorised data regarding

the functions programmable with Oview.

Indicates whether there is an error in the memorised data regarding

the configuration of the alt input.

Indicates whether there is an error in the memorised data regarding

the configuration of the devices connected to the bluebus input.

Indicates whether there is an error in the memorised data regarding

positions.

Indicates whether there is a reading error or operating malfunction on

the absolute encoder of motor 1.

Indicates when the suction cup is active.

Indicates when output 1 is active. Caution – 12/24 Vdc voltage present.

Indicates when output 2 is active. Caution – 24 Vdc voltage present.

Indicates when motor 1 is in operation.

Indicates an electrical overload or short circuit on output 1 or on the

courtesy light of the control unit.

Indicates an electrical overload or short circuit on output 2.

Indicates that the absolute encoder of motor 1 is in a position close to

the maximum limit (100%), over which the motor does not function.

PARAMETER

Diagnostics 2

VARIOUS PARAMETERS

:

Courtesy light

Pause time

Temperature

DESCRIPTION

Indicates the timer for shutoff of the courtesy light.

Indicates the timer for counting the pause time between one

manoeuvre and the next.

Indicates the temperature of the motor, measured by the control unit.

This function enables display of the operating status of some parameters measured by the control unit. These parameters are

described in Table 5.

TABLE 5: DIAGNOSTICS of other parameters

other parameters

20 – Robus 600-1000

PARAMETER

Bluebus

PHOTOCELLS

:

PHOTO

PHOTO II

PHOTO 1

PHOTO 1 II

PHOTO 2

PHOTO 2 II

PHOTO 3

FT A

FT B

FT C

OPEN PHOTO

OPEN PHOTO II

COMMANDS

:

CMD 1

CMD 2

CMD 3

CMD 4

DESCRIPTION

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the sensitive edge is present, the relative operating

status and the correct memorisation in the control unit.

Indicates whether the sensitive edge is present, the relative operating

status and the correct memorisation in the control unit.

Indicates whether the sensitive edge is present, the relative operating

status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

Indicates whether the control photocell is present, the relative operating status and the correct memorisation in the control unit.

This function enables the display of the device type, operating status, and configuration of the devices connected to the Bluebus output. These parameters are described in Table 6.

TABLE 6: DIAGNOSTICS of bluebus devices

bluebus device diagnostics

Service voltage

Bus medium current

MOTOR 1

:

To rq ue

Speed

Voltage

Position

Indicates the voltage supplied to external devices.

Indicates the current absorption of the devices connected to the

bluebus output, calculated as a percentage.

Indicates the torque generated by motor 1 during the manoeuvre,

calculated as a percentage.

Indicates the speed of motor 1 during the manoeuvre, calculated as

a percentage.

Indicates the mean voltage to be supplied to motor 1 during the

manoeuvre, calculated as a percentage.

Indicates the physical position of the gate leaf, calculated as a percentage: the values concerned are the minimum limit of the leaf

when it reaches the closing limit switch (equal to 0%) and the maximum limit of the leaf when it reaches the opening limit switch (equal

to 100%).

Robus 600-1000 – 21

OTHERS:

GATE

BLOCK AUTOMATION

MEMORY

BUS

STAND-BY

OTHER DEVICES:

COURTESY LIGHT

SUCTION CUP

LOCK

Indicates the operating status of the application.

Indicates when the automation is blocked following a “Block” command.

Indicates a problem regarding the data related to bluebus devices,

memorised in the control unit.

Indicates whether there is a short circuit on the bluebus output.

Indicates when the control unit is in standby status.

Indicates whether the control device is present, the relative operating

status and whether it is memorised correctly in the control unit.

Indicates whether the control device is present, the relative operating

status and whether it is memorised correctly in the control unit.

Indicates whether the control device is present, the relative operating

status and whether it is memorised correctly in the control unit.

This function enables programming of the type, and method of managing the control unit maintenance phase. There are two

application modes:

automatic – When this mode is set, the “partial counter” (number of manoeuvres completed after maintenance) is updat-

ed automatically according to the duration of the manoeuvres performed and the force applied on the motor;

manual – When this mode is set, the “partial count” is updated according to the number of manoeuvres performed.

A value from 0 to 16777215 (manoeuvres) can be assigned to this parameter; if the mode is set to manual, the factory setting

of the parameter is 10000 (manoeuvres).

This function enables programming of a reference limit, over which automation maintenance is required.

This function enables the user to check the number of manoeuvres performed by an automation since the last maintenance procedure on the latter.

This parameter type is ON / OFF; the factory setting is “OFF”. This function enables deletion of the “partial count” value; this is

required after performing maintenance on the automation.

delete maintenance

partial count

manual alarm threshold

MAINTENANCE

mode

22 – Robus 600-1000

This function enables the display of the events generated or received by the control unit. “Event” refers to a condition that

changes the operating status of the control unit, for example: activation of an input, end of a manoeuvre, activation of a photocell or the alt input, etc. In this section the date and type of event can be displayed.

This function enables the firmware of a control unit to be updated with another compatible version, without the obligation to

change the board. To update, proceed as follows:

01. Download the firmware update file (the software update is available at the site internet www.nice-service.com);

02. In “Advanced Functions” select “Update firmware”;

03. In the window displayed, select “Select file” and then select the update file previously downloaded. The data related to the

software of the device to be updated are displayed on the left of the window, while the data related to the update software and

compatible hardware versions are displayed on the right;

04. If the file is compatible, the text “Update firmware” appears on the button, and when this is clicked, the update procedure

is started. At the end of the procedure, if the message “Update completed successfully” is displayed, this means that the procedure has bee completed. Otherwise, the message “Retry” appears on the button; in this case press the button again to

repeat the update process.

If the update process is not completed, the user can retry a number of times, or return to the window “Device List”, selecting

“Back” and then decide on how to proceed. In this window, the device previously selected will no longer be visible; to display

the latter select the down arrow on the right of the window and select the function “Devices in boot phase”. This enables a

search for devices ready for the firmware update phase.

At this point the user can retry the update process, repeating the procedure described above.

If the update is still not completed successfully, contact the Nice Assistance Service.

This function enables the installer to decide which functions and parameters are to be selected for display and modifications by

the user. For example, for safety reasons, the installer can decide to prevent the user from modifying the parameters related to

automation motor force and speed.

User permits can be managed exclusively by using the “installer password” (password management, common functions).

Note – All parameters of the various functions of a control unit or receiver are factory set as disabled.

user permits

firmware updates

event log

ADVANCED FUNCTIONS

Loading...

Loading...