EN - Instructions and warnings for installation and use

IT - Istruzioni ed avvertenze per l’installazione e l’uso

FR - Instructions et avertissements pour l’installation et l’utilisation

ES - Instrucciones y advertencias para la instalación y el uso

DE - Installierungs-und Gebrauchsanleitungen und Hinweise

PL - Instrukcje i ostrzeżenia do instalacji i użytkowania

NL - Aanwijzingen en aanbevelingen voor installatie en gebruik

Moon

Control unit

MC424

EN

English – 1

ENGLISH

Safety warnings

• IMPORTANT! – This manual contains important instructions and warn-

ings for personal safety. Incorrect installation could cause serious physical

injury. Read all parts of the manual carefully before starting work. If in doubt,

interrupt installation and contact the Nice Service Centre for clarifications.

• IMPORTANT! – Important instructions: keep this manual in a safe place

to enable future product maintenance and disposal procedures.

Installation warnings

• Before commencing installation, check that the product is suitable for the

intended kind of use (see paragraph 2.2 “Limits of use” and chapter “Product

technical specifications”). If not suitable, do NOT proceed with installation.

• During installation, handle the product with care, avoiding the risk of crushing,

impact, dropping or contact with any type of liquid. Never place the product

near sources of heat or expose to naked flames. This may damage product

com ponents and cause malfunctions, fire or hazardous situations. If this oc curs, suspend installation immediately and contact the Nice Service Centre.

• Never make modifications to any part of the product. Operations other than

as specified can only cause malfunctions. The manufacturer declines all liability for damage caused by makeshift modifications to the product.

• The product should not be used by children or people with impaired physical,

sensorial or mental capacities or who have not received adequate training in

the safe use of the product.

• On the power line to the system, install a device for disconnection from the

power mains with a gap between contacts that assures complete disconnection in the conditions of overvoltage category III.

• Connect the control unit to an electric power line equipped with an earthing

system.

• The product’s packaging materials must be disposed of in full compliance

with local regulations.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

The MC424 control unit has been designed to control Wingo 24 V electromechanical actuators, for automated swing gates or doors. IMPORTANT! –

Any uses other than those specified herein or in environmental conditions

other than as stated in this manual are to be considered improper and are

strictly prohibited!

The MC424 control unit operates on the basis of a current sensitivity system

which checks the load of the motors connected to it. The system automatically

detects travel stops, memorises the running time of each motor and recognises obstacles during normal movement. This feature makes installation easier as

there is no need to adjust the working times nor the leaf delay.

The control unit is pre-programmed for the normal functions, while more spe cific functions can be chosen following a simple procedure (see chapter 5).

The control unit is designed to be powered by PS124 buffer batteries as emergency power supply in the event of a mains power failure (for further information

see chapter 6.2). It is also designed to be connected to the “Solemyo” solar

energy system (for further information see chapter 6.3).

PRODUCT DESCRIPTION

1

In order to explain certain terms and aspects of an automatic 2-leaf swing door

or gate system refer to the typical system shown in fig 1.

Key to fig. 1:

1.Wingo 24 V electromechanical actuator

2.Electromechanical actuator

3.Lucy24 flashing light

4.Key-operated selector switch

5.“PHOTO” pair of photocells

6.“FOTO1” pair of photocells

7.“PHOTO2” pair of photocells

8. Control unit

In particular, please note that:

• Refer to the product instructions for the characteristics and connection of the

photocells.

• Activation of the “PHOTO” pair of photocells have no effect on the gate during opening, while they reverse movement during closing.

INSTALLATION

2

Summary

GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . . . . . . 1

1 – PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 – INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 - PRELIMINARY CHECKS FOR INSTALLATION . . . . . . . . . . . . . 2

2.2 - PRODUCT APPLICATION LIMITS . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 - ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4.1 - Notes on connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4.2 - Type of ALT input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4.3 - Examples of photocell connections: with the STANDBY

function active and the Phototest function disabled . . . 3

2.4.4 - Examples of photocell connections: with the Phototest .

function active and the STANDBY function disabled . . . 3

2.5 - INITIAL START-UP AND ELECTRICAL CONNECTIONS . . . . . . 3

2.6 - AUTOMATIC LIMIT SWITCH SEARCH . . . . . . . . . . . . . . . . . . . . 3

3 – TESTING AND COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 - TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 - COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 – DIAGNOSTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5 – PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.1 - PRESET FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2 - PROGRAMMABLE FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2.1 - Direct programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5.2.2 - First level programming: first part . . . . . . . . . . . . . . . . . 4

5.2.3 - First level programming: second part . . . . . . . . . . . . . . 5

5.2.4 - Second level functions . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.3

- PROGRAMMING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.3.1 - First level programming: functions . . . . . . . . . . . . . . . . . 6

5.3.2 - Second level programming: parameters . . . . . . . . . . . . 6

5.3.3 - Deletion of memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.3.4 - Example of first level programming . . . . . . . . . . . . . . . . 7

5.3.5 - Example of second level programming . . . . . . . . . . . . . 7

5.3.6 - Programming diagrame . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 – FURTHER DETAILS: accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6.1 - CONNECTING A RADIO RECEIVER . . . . . . . . . . . . . . . . . . . . . . 9

6.2 - CONNECTING MODEL PS124 BUFFER BATTERY . . . . . . . . . . 9

6.3 - CONNECTING THE SOLEMYO SYSTEM . . . . . . . . . . . . . . . . . . 9

7 – TROUBLESHOOTING (troubleshooting guide) . . . . . . . . . . . . . . . 9

8 – PRODUCT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DISPOSAL OF THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TECHNICAL CHARACTERISTICS OF THE PRODUCT . . . . . . . . 10

EC DECLARATION OF CONFORMITY . . . . . . . . . . . . . . . . . . . . . 10

RADIO RECEIVER: SMXI - SMIXS . . . . . . . . . . . . . . . . . . . . . . . . 11

1 - PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 - AERIAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 - MEMORISING A REMOTE CONTROL . . . . . . . . . . . . . . . . . . . . 11

4 - DELETING ALL TRANSMITTERS . . . . . . . . . . . . . . . . . . . . . . . . 12

TECHNICAL CHARACTERISTICS OF THE PRODUCT . . . . . . . . . . 12

IMAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I - VII

EN

2 – English

Key to figs. 2 - 5a - 5b - 5c:

Terminals Function Description Type of cable

L - N - Power supply line Mains power supply 3 x 1,5 mm

2

1÷3 Motor 1 M1 motor connection 3 x 1,5 mm

2

1÷3 Motor 2 M2 motor connection (Note 1) 3 x 1,5 mm

2

4÷5 Flashing light Connection of flashing light 24 V max 25 W 2 x 1 mm

2

6÷7 Open Gate indicator / Connection for Open Gate Indicator 24 V max 5 W or Electric lock12 V SCA: 2 x 0,5 mm

2

Elect.Lock max 25 VA (“See chapter 5 - Programming”) Electric lock: 2 x 1 mm

2

8 Common 24 V Power Supply +24 V for TX photocells with phototest (max. 100 mA); “COMMON” 1 x 0,5 mm

2

(with standby / phototest) for all inputs, safety, with STAND BY function activated (Note 2)

9 0 V Power supply 0V for services 1 x 0,5 mm

2

10 24 V Power input for services, without “Standby” (24 V max 200 mA) 1 x 0,5 mm

2

11 Common 24 V Common for all inputs (+24 V ) without “Standby” 1 x 0,5 mm

2

12 STOP Input with STOP function (emergency, safety shutdown) (Note 3) 1 x 0,5 mm

2

13 PHOTO NC Input for safety devices (photocells, sensitive edges) 1 x 0,5 mm

2

14 PHOTO 1 NC Input for safety devices (photocells, sensitive edges) 1 x 0,5 mm

2

15 STEP BY STEP Input for cyclical functioning (OPEN-STOP-CLOSE-STOP) 1 x 0,5 mm

2

16 AUX Auxiliary input (Note 4) 1 x 0,5 mm

2

17÷18 Aerial Connection for the radio receiver aerial screened cable type RG58

Note 1 – This is not used for single leaf gates (the control unit automatically recognises if only one motor has been installed).

Note 2 – The “Stand By” function serves to reduce consumptions. For further details on the electrical connections refer to paragraph 2.4.1 “Stand by/Phototest

connection” and for programming refer to chapter 5.2.3 “Stand by/Phototest function”.

Note 3 – The STOP input can be used for “NC” or constant resistance 8.2 k

Ω

contacts (please refer to the “Programming” chapter)

Note 4 – The AUX factory auxiliary input is programmed with the “Partial open type 1” function but can be programmed with any of the following functions:

Function Input type Description

PARTIAL OPEN TYPE 1 NO Fully opens the upper leaf

PARTIAL OPEN TYPE 2 NO Opens the two leaf half way

OPEN NO Only carries out the opening manoeuvre

CLOSE NO Only carries out the closing manoeuvre

• Activation of the “PHOTO 1” pair of photocells stops both the opening and

closing manoeuvres.

• Activation of the “PHOTO2” pair of photocells (connected to the suitably programmed AUX input) has no effect during closing while they invert movement

during opening.

To check the parts of the control unit see fig. 2.

Key to fig. 2:

A. 24V power supply connector

B. M1 motor connector

C. PS124 buffer battery connector / Solemyo solar energy supply

system (for further details see chapter 6.3)

D. 500mA F type services fuse

E. Selector switch for delaying the opening of motor M1 or M2

F. M2 motor terminal

G. Flashing light output terminal

H. Gate open indicator or electric lock output terminal

I. 24Vdc terminals for services and phototest

L. Input terminals

L1…L5. Input and programming LEDs

M. Terminal for radio aerial

N. “SM” radio receiver connector

O. Programming/diagnostics connector

P1, P2, P3. Programming buttons and LEDs

2.1 - Preliminary checks for installation

Before proceeding with installation, check the condition of the product components, suitability of the selected model and conditions of the intended installation environment:

• Ensure that all conditions of use remain within the limits of product application

and within the “Product technical specifications”.

• Ensure that the selected installation environment is compatible with the over-

all dimensions of the product (fig. 3).

• Ensure that the selected surfaces for product installation are solid and guar-

antee a stable fixture.

• Make sure that the fixing zone is not subject to flooding. If necessary, mount

the product raised from the ground.

• Ensure that the space around the product enables easy and safe completion

of manual manoeuvres.

• Make sure that the automation is provided with mechanical stops on both

closing and opening.

2.2 - Product application limits

The product may be used exclusively with Wingo 24 V gearmotors.

2.3 - Installation

To install the control unit, proceed as shown in fig. 4. Also observe the following warnings:

• The control unit is supplied in an enclosure that if correctly installed assures

an IP54 protection rating. The control unit is therefore suitable for installation

outdoors.

• Fix the control unit to a flat, vertical, non-removable surface that is adequately protected from potential impacts. Important! – The bottom of the control unit

must be at least 40 cm from the ground.

• Insert the dedicated cable clamps or pipe glands into the lower part of the

enclosure (fig. 4). Important! – If the cable protection tubes end in a pit, it is

likely that condensation will form inside the control unit, which will damage the

electronic board. In this case, protect the control unit adequately so as to prevent the formation of condensation.

• The cable clamps can be inserted on the long side of the enclosure only if the

control unit is installed in a protected indoor environment.

To install the other devices present in the automation, refer to the relevant

instruction manuals.

2.4 - Electrical connections

IMPORTANT!

– All electrical connections must be made with the unit disconnected from

the mains power supply and with the buffer battery disconnected, if present in the automation.

– Connections must be made exclusively by qualified personnel.

– Make sure that all the electric cables used are of a suitable type.

01. Loosen the screws of the cover.

02. Prepare the electrical cable routing holes.

03. Connect the cables as shown in the wiring diagram in fig. 5. To connect

the electric power cable, see fig. 6. Note – To facilitate cable connections,

the terminals can be removed from their seats.

• With the exception of the photocell inputs when the PHOTOTEST function is

activated, if the inputs of the NC (Normally Closed) contacts are not in use

they should be jumped with the “COMMON” terminal. Refer to paragraph

2.4.3 for further information.

• If there is more than one NC contact on the same input, they must be connected in SERIES.

• If the inputs of the NO (Normally Open) contacts are not used they should be

left free.

• If there is more than one NO contact on the same input, they must be connected in PARALLEL.

• The contacts must be electromechanical and potential-free. Stage connections, such as those defined as “PNP”, “NPN”, “Open Collector”, etc. are not

allowed.

• If the leafs overlap, use jumper E (Fig. 6) to select which motor starts up first

during opening.

EN

English – 3

PHOTO 2 NC PHOTO 2 function

DISABLED — No function

2.4.1 - Notes about connections

Most connections are extremely simple and many of them are direct connections to a single user point or contact. The following figures show examples of

how to connect external devices:

• Stand By / Phototest connection

The Stand-by function is active as standard. It is excluded automatically only

when the Phototest function is activated. Note - The Stand-by and Phototest

functions are alternatives as one excludes the other.

The Stand-by function allows consumptions to be reduced. Three types of con-

nections can be obtained:

- with “stand by” active (energy saving); see electrical diagram in fig. 5a

- standard connection: without “Stand by” and without “Phototest”; see electrical

diagram in fig. 5b

- without “Stand by” and with “Phototest”; see electrical diagram in fig. 5c

When the “Stand-by” function is active, 1 minute after the end of a manoeuvre

the control unit goes into Stand-by, turning off the Inputs and Outputs to

reduce consumptions. The status is indicated by the “OK” LED which begins to

flash more slowly. WARNING – If the control unit is powered from a photovolta-

ic panel (“Solemyo” system) or a buffer battery, the “Stand-by” function must be

activated as shown in the electrical diagram in fig. 5a.

When the “Stand-by” function is not required, the “Phototest” function may be

activated. This verifies at the beginning of a manoeuvre that the connected photocells operate correctly. To use this function, first connect the photocells appropriately (see electrical diagram in fig. 5c) and then activate the function.

Note – When the phototest is activated, the inputs subjected to the test procedure are PHOTO, PHOTO1 and PHOTO2. If one of these inputs is not used it

must be connected to terminal no. 8.

• Key switch connection

Example 1 (fig. 7a): How to connect the switch in order to perform the STEPBY-STEP and STOP functions

Example 2 (fig.7b): How to connect the switch in order to perform the STEPBY-STEP and one of the auxiliary input functions (PARTIAL OPENING, OPEN

ONLY, CLOSE ONLY …)

Note – For electrical connections with the “Stand By” function active, see

“Stand By/Phototest function” in this paragraph 2.4.1.

• Connection for Gate Open Indicator / Electric lock (fig. 8)

If the gate open indicator has been programmed, the output can be used as an

open gate indicator light. The light, flashes slowly during opening and quickly

during closing; If it is on but does not flash, this indicates that the gate is open.

If the light is off, the gate is closed. Se the output has been programmed as an

electric lock, it is activated for 3 seconds each time opening begins.

2.4.2 - STOP type input

The MC424 control unit can be programmed for two types of STOP input:

- NC type STOP for connecting up to NC type contacts.

- Constant resistance STOP. It enables the user to connect up to the control

unit of devices with 8.2kΩ constant resistance (e.g. sensitive edges). The

input measures the value of the resistance and disables the manoeuvre when

the resistance is outside the nominal value. Devices with normally open “NO”

or normally closed “NC” contacts, or multiple devices, even of different types,

can be connected to the constant resistance STOP input, provided that

appropriate adjustments are made; see Table 1.

WARNING! – If the constant resistance STOP input is used to connect

devices with safety functions, only the devices with 8.2 KΩ constant will

resistance output guarantee the fail-safe category 3.

Notes to Table 1:

Note 1 – Any number of NO devices can be connected to each other in paral-

lel, with an 8.2K

Ω

termination resistance (fig. 9a). For electrical connections

with the “Stand By” function active, see “Stand By/Phototest function” in this

paragraph 2.4.1.

Note 2 – The NO and NC combination can be obtained by placing the two contacts in parallel, and placing an 8.2K

Ω

resistance in series with the NC contact.

It is, therefore, possible to combine 3 devices: NO, NC and 8.2KΩ (fig. 9b).

Note 3 – Any number of NC devices can be connected in series to each other

and to an 8.2K

Ω

resistance (fig. 9c).

Note 4 – Only one device with an 8.2K

Ω

constant resistance output can be

connected; multiple devices must be connected “in cascade” with a single

8.2K

Ω

termination resistance (fig. 9d).

2.5 - Initial start-up and electrical connections

IMPORTANT! – Connections must be made exclusively by qualified per-

sonnel.

After powering up the control unit, check that all the LEDs flash rapidly for a few

seconds, then perform the following checks:

1. Check that there is a voltage of approximately 30Vdc on terminals 9-10. If

not, unplug the unit immediately and carefully check the connections and

input voltage.

2. After initially flashing rapidly, the P1 LED will indicate the control unit is working correctly by flashing regularly at 1 second intervals. When there is a variation in the inputs, the “P1” led will rapidly flash twice to show that the input

has been recognised.

3. If the connections are correct, the LED for the “NC”-type inputs will be on,

while those for the “NO” type inputs must be off. See fig. A and Table 2.

TABLE 2

INPUT INPUT TYPE STATUS LED

STOP STOP NC L1 On

CONSTANT RESISTANCE L1 On

STOP 8.2 KΩ

PHOTO NC L2 On

FOTO1 NC L3 On

STEP-BY-STEP NO L4 Off

AUX OPEN PARTIALLY type 1 - NO L5 Off

OPEN PARTIALLY type 2 - NO L5 Off

OPEN ONLY - NO L5 Off

CLOSE ONLY - NO L5 Off

FOTO2 - NC L5 On

4.Check that the relative LEDs switch on and off when the devices connected

to the inputs are operated.

5.Check that by pressing P2 both motors perform a short opening manoeuvre,

and the motor of the upper leaf starts first. Block the manoeuvre by pressing P2 again. If the motors do not start up for opening, invert the polarities of

the motor cables. If, however, the first one to move is not the upper leaf,

operate jumper E (fig. 2).

2.6 - Automatic search system for the limit switches

On the successful completion of the various controls, start the automatic

search system phase for the limit switches. This work is necessary as the

MC424 control unit must “measure” how long the opening and closing

manoeuvres take This procedure is completely automatic and detects the

mechanical opening and closing stops by measuring the load on the motors.

Warning! – If this procedure has already been carried out, in order to

reactivate it, the user must first delete the memory (see the “Memory de letion” chapter). In order to check whether the memory contains any li mit

switch parameters, turn the power supply to the control unit on and then

off again. If all the LEDs flash rapidly for approximately 6 seconds, the

me mory is empty. If, however, they only flash for 3 seconds, the memory

already contains some limit switch parameters.

Before starting limit switch searching, make sure that all the safety devices are

enabled (STOP, PHOTO and PHOTO1). The procedure will be immediately

interrupted if a safety device triggers or a command arrives. Ideally the doors

should be half open, although they can be in any position.

Procedure – Press the P2 button (fig. 2) to start begin searching which

includes:

- Both motors open briefly.

- Motor closes the lower leaf until it reaches the mechanical closing stop.

- The upper leaf motor closes until it reaches the mechanical closing stop.

- The motor of the upper leaf begins to open.

- After the programmed delay, opening of the lower leaf begins. If the delay is

in sufficient, block the search by pressing P1 (fig. 2), then modify the time (see

chapter 5).

- The control unit measures the movement required for the motors to reach the

opening mechanical stops.

- Complete closing manoeuvre. The motors can start at different times, the aim

is to prevent the leafs from shearing by maintaining a suitable delay.

- End of the procedure with memorisation of all measurements.

A

1st device type:

NO NC 8,2 KΩ

In parallel (note 1)(note 2) In parallel

NC (note 2) In series (note 3) In series

8,2KΩ In parallel In series (note 4)

TABLE 1

second device type:

EN

4 – English

All these phases must take place one after the other without any interference

from the operator. If the procedure does not continue correctly, it must be interrup ted with the P1 button. Repeat the procedure, modifying some parameters if

necessary, for example the current sensitivity cut-in thresholds (see chapter 5).

These are the most important phases of automation set-up for ensuring maximum system safety. The test can also be performed as a periodic check of

automation devices. Testing and commissioning of the automation must be

performed by skilled and qualified personnel, who are responsible for the tests

required to verify the solutions adopted according to the risks present, and for

ensuring observance of all legal provisions, standards and regulations, and in

particular all requirements of the standard EN 12445, which establishes the test

methods for checking automations for doors and gates.

The additional or optional devices must undergo a specific test for functionality

and correct interaction with MC424. Refer to the instruction manuals of the

individual devices.

3.1 - Testing

The testing sequence refers to the control unit programmed with the preset

functions. See paragraph 5.1:

• Make sure that the activation of the STEP-BY-STEP input generates the following sequence of movements: “Open, Stop, Close, Stop”.

• Make sure that the activation of the AUX input (Type 1 partial opening function)

manages the “Open, Stop, Close, Stop” sequence of the motor of the upper

leaf only, while the motor of the lower leaf remains in the closed position.

• Perform an opening manoeuvre and check that:

- the gate continues the opening manoeuvre when PHOTO is engaged

- the opening manoeuvre stops when PHOTO1 is engaged and only continues

when PHOTO1 is disengaged

- The manoeuvre stops when PHOTO2 (if installed) is engaged and the closing

manoeuvre starts

• Make sure that the motor switches off when the door reaches the mechanical

stop.

• Perform an opening manoeuvre and check that:

- The manoeuvre stops when PHOTO is engaged and the opening manoeuvre

starts

- The manoeuvre stops when PHOTO1 is engaged and the opening manoeuvre starts again when PHOTO1 is disengaged

- the gate continues the closing manoeuvre when PHOTO 2 is engaged

• Check that the stopping devices connected to the STOP input immediately

stop all movement.

• Check that the level of the obstacle detection system is suitable for the application:

- During both the opening and the closing manoeuvres, prevent the leaf from

moving by placing an obstacle and check that the manoeuvre inverts before

exceeding the force set down by law

• Other checks may be required depending on which devices are connected to

the inputs.

Warning – If an obstacle is detected as moving in the same direction for 2

consecutive manoeuvres in the same direction, the control unit partially

inverts both motors for just 1 second. At the following command, the leafs

begin the opening manoeuvre and the first current sensitivity cut-in for

each motor is considered as a mechanical stop during the opening cycle.

The same happens when the mains power supply is switched on: the first

command is always an opening manoeuvre and the first obstacle is

always considered as a mechanical stop during the opening cycle.

3.2 - Commissioning

Commissioning can only be performed after positive results of all test

phases.

1 Prepare the automation technical documentation, which must contain the

following documents: overall drawing of the automation, electrical wiring

diagram, risk assessment and relative solutions adopted (refer to the relevant forms on our website www.niceforyou.com), manufacturer’s declara-

tion of conformity for all devices used and installer’s declaration of conformity.

2 Affix a dataplate on the gate, specifying at least the following data: type of

automation, name and address of manufacturer (responsible for commissioning), serial number, year of construction and CE mark.

3 Before commissioning the automation, ensure that the owner is adequately

informed of all associated risks and hazards.

TESTING AND COMMISSIONING

3

The diagnostics LED P2 (fig. 2) indicates any problems or malfunctions re vealed by the control unit during the manoeuvre.

A sequence with a certain number of flashes indicates the type of problem and

remains active until the following manoeuvre begins. The table below summarises this information:

Number Type of malfunction

Led P2 flashes

1 M1 current sensitivity device triggering

2 M2 current sensitivity device triggering

3 STOP input cut-in during the manoeuvre

4 Phototest error

5 Output overcurrent gate open indicator or electric lock

DIAGNOSTICS

4

The MC424 control unit features some programmable functions. These functions are pre-set in a typical configuration which satisfies most automatic systems. These functions can be changed at any time, both before and after

searching automatically for limit switches, by carrying out the relevant programming procedure; see paragraph 5.3.

5.1 - Preset functions

• Motor movement: fast

• Automatic closing: enabled

• Condominium function: disabled

• Pre-flashing disabled

• Close after photo: disabled

• Opening delay: level 2 (10%)

• STAND BY / Phototest: Stand by

• Gate open indicator/Electric Lock: Gate open indicator

• STOP input: NC type

• Heavy gates: disabled

• Proportional gate open indicator: disabled

• Pause time: 20 seconds

• Auxiliary input: type 1 partial opening (only the

upper leaf motor is activated)

• Current sensitivity: Level 2

5.2 - Programmable functions

To ensure the system is best suited to the user’s requirements, and safe in the

various different conditions of use, the MC424 control unit offers the possibility

to programme several functions or parameters, as well as the function of a

number of inputs and outputs.

5.2.1 - Direct programming

• Slow/rapid movement: The user can choose the speed of movement of the

gate, at any time (with the motor arrested) simply by operating the P3 key (fig.

2) at any time the control unit is not being programmed. If LED L3 is off, this

shows that the slow movement has been set, if on the fast one has.

5.2.2 - Level one programming: part one

• Automatic closing: This function features an automatic closing cycle after

the programmed pause time; the pause time is factory set to 20 seconds but

it can be modified to 5, 10, 20, 40 or 80 seconds.

If the function is not activated, the system will run “semi-automatically”.

• “Condominium” function: This function is useful when the automatic sys-

tem is radio-commanded by many different people. If this function is active,

each command received triggers an opening manoeuvre that cannot be interrupted by further commands. If the function has been deactivated, a command causes: OPEN-STOP-CLOSE-STOP.

• Pre-flashing: This function activates the flashing light before the manoeuvre

begins for a time that can be programmed to 3 seconds.

If the function is disabled, the light will start flashing when the manoeuvre

starts.

• Close after photo: During the automatic closing cycle, this function reduces

the pause time to 4 seconds after the PHOTO photocell has disengaged, i.e.

the gate closes 4 seconds after the user has passed through it. If the function

is disabled, the whole programmed pause time will pass.

• Opening delay: During opening, this function causes a delay in the activation

PROGRAMMING

5

EN

English – 5

of the lower leaf motor compared with the upper one This is necessary in

order to prevent the leafs from getting stuck. There is always a standard delay

during closing, calculated automatically by the control unit in order to ensure

the same delay as the one programmed for opening.

5.2.3 - Level one programming: part two

• Stand By / Phototest function: The control unit has the “Stand-by” function

preset. If this function is active, 1 minute after the end of a manoeuvre the

control unit turns off the “Stand-by” output (terminal no. 8) and all the Inputs

and other Outputs to reduce consumptions (see electrical diagram in fig. 5a).

This function is obligatory if the control unit is powered exclusively with Solemyo photovoltaic panels. It is also recommended if the control panel is powered from the electric mains and if you wish to extend emergency operation

with the buffer battery PS124. As an alternative to the “Stand-by” function,

the “Phototest” function may be activated. This verifies at the beginning of a

manoeuvre that the connected photocells operate correctly. To use this function, connect the photocells correctly (see electrical diagram in fig. 5c) and

then activate the function.

• Open gate indicator light / electric lock: If the function is activated, termi-

nals 6-7 can be used to connect up the electric lock. If the function is deactivated, terminals 6-7 can be used to connect up a 24V gate open indicator.

• NC Type or Constant Resistance STOP Input: If the function is activated,

the STOP input is set to “8.2KΩ Constant Resistance”. In this case, there

must be a 8.2KΩ +/-25% resistance between the common and the input to

enable the operation. If the function is not set, the configuration of the STOP

input will enable it to function with NC type contacts.

• Light/heavy gates : If the function is activated, the control unit enables the

user to manage heavy gates, setting the acceleration ramps and slowdown

speeds during closing differently. If the function is deactivated, the control unit

will be set to manage light gates.

• Proportional gate open indicator: If the function is activated, the gate open

in dicator output will be set with the proportional flashing light. This means that

during opening, the flashing becomes more intense as the leafs come nearer

to the opening stops; vice-versa, for closing, the flashing becomes less

intense as the leafs come nearer to the closing stops. If the function is deactivated, the light will flash slowly during opening and rapidly during closing.

5.2.4 - Level two functions

• Pause time: The pause time, namely the time which lapses between opening

and closing during automatic functioning, can be programmed to 5, 10, 20,

40, and 80 seconds.

• Auxiliary input AUX: The control unit offers an auxiliary input which can be

set to carry out one of the following 6 functions:

- Partial opening type 1: this carries out the same function as the STEP-BYSTEP input. It causes only the upper leaf to open. It only works if the gate is

closed completely, otherwise the command is interpreted as if it were a

STEP-BY-STEP comman.

- Partial opening type 2: this carries out the same function as the STEP-BYSTEP input. It causes the two leafs to open for half the time it would take

them to open completely. It only works if the gate is closed completely, otherwise the command is interpreted as if it were a STEP-BY-STEP command.

- Open only: this input only causes opening in the Open-Stop-Open-Stop

sequence.

- Close only: this input only causes closing in the Open-Stop-Open-Stop

sequence.

- Photo 2: this carries out the function of the “PHOTO 2” safety device.

- Disabled: the input will not carry out any function

• Discharge time: At the end of the Closing manoeuvre, after the leafs have

reached the totally closed position, the motor continues to “push” the leaf for

a brief interval, to ensure perfect closure. Immediately afterwards, this function activates a very brief inversion of movement to reduce excessive pressure exerted by the motor on the leafs.

• Current sensitivity: The control unit is equipped with a system which meas-

ures the current absorbed by the two motors used to detect the mechanical

stops and any obstacles when the gate is moving. Since the current ab sorbed depends on a number of conditions, including the weight of the gate,

friction, wind and variations in voltage, the cut-in threshold can be changed.

There are 6 levels: 1 is the most sensitive (minimum force), 6 is the least sensitive (maximum force).

WARNING! – If the “current sensitivity” function (together with other

vital features) is adjusted correctly, the system will comply with European standards, EN 12453 and EN 12445, which require techniques or

devices to be used to limit force and danger during the functioning of

automatic gates and doors are moved.

• Leaf delay: The delay in starting up the motor of the lower leaf can be pro-

grammed to 5, 10, 20, 30 or 40% of the working time.

5.3 - Programming

All the functions described in paragraph 5.2 “Programmable functions” chapter

can be selected by means of a programming phase which terminates by memorising the choices made. The control unit therefore has a memory which stores

the functions and parameters relative to the automation process.

The P1, P2 and P3 buttons are used for all the programming phases, while the

5 LEDs (L1, L2…L5) indicate the selected parameter.

There are two different programming levels:

• At level 1, the functions can be enabled or disabled. Each Led (L1, L2…L5)

corresponds to a function: if the Led is on, the function is active; if it is off, it is

deactivated.

Level one consists in 2 parts which can be selected using the P3 button. The

cor responding LED P3 indicates which of the 2 parts has been selected.

Level one (P1 Led lit): part two (P3 Led lit)

L1 Led L2 Led L3 Led L4 Led L5 Led

Stand By / Electric lock Resistance Heavy gates Gate open

Phototest stop proportional

Level one (P1 Led lit): part one ( P3 Led off)

L1 Led L2 Led L3 Led L4 Led L5 Led

Closing Function Pre-flash Close after Delay in

Automatic Condominium photo opening

• It is possible to pass to the second level from level one of part one. At this

second level the user can choose the parameter relating to the function. A

different value corresponds to each LED which must be associated to the

parameter.

Level one (P1 Led lit): part two (P3 Led lit)

L1 Led L2 Led L3 Led L4 Led L5 Led

Stand By / Electric lock Resistance Heavy gates Gate open

Phototest stop proportional

Level one (P1 Led lit): part one (led P3 off)

L1 Led L2 Led L3 Led L4 Led L5 Led

Closing Function Pre-flashing Close after Delay in

automatic condominium photo opening

Level two:

Parameter: Parameter: Parameter: Parameter: Parameter:

Time AUX input Time Current Leaf delay

pause discharge sensitivity

L1: 5s L1: Open L1: no L1: Level 1 L1: 5%s

partial TYPE 1 discharge (more sensitive)

L2: 10s L2: Open L2: 0.3s L2: Level 2 L2: 10%

partial TYPE 2

L3: 20s L3: Open Only L3: 0.7s L3: Level 3 L3: 20%

L4: 40s L4: Close Only L4: 1.3s L4: Level 4 L4: 30%

L5: 80s L5: Photo 2 L5: 2s L5: Level 5 L5: 40%

(less sensitive)

All LEDs off: All LEDs off:

input Level 6

not used (max current

sensitività )

EN

6 – English

TABLE A1 - Entering level one programming

01. Press and hold down buttons P1 and P2 for at least 3 seconds

The programming mode has been entered if all the Leds start flashing quickly

TABLE A2 - Activating or deactivating a function

01. Press P1 repeatedly until the flashing Led reaches the function required

02. Press P1 repeatedly until the flashing Led reaches the function required

TABLE A3 - To pass from part one to part two of level one (and vice-versa)

01. Press P3. button

TABLE A4 - To exit level one and save the modifications

01. Press P1 and then immediately P2, holding them both down for at least 3 seconds

TABLE A5 - Exiting level one and delete the modifications

01. Either press P1 for at least 3 seconds, or wait for 1 minute, or disconnect the power supply

5.3.1 - Level one programming: functions

At level 1, the functions can be enabled or disabled. At level one, LED P1 is

always on; if LEDs L1, L2…L5 are on, the functions are activated; if the LEDs

are off, the functions are deactivated. A flashing LED indicates which function

has been selected, short flashes indicate the function has been deactivated;

long flashes indicate the function has been activated. Press P3 to pass from

part one programming to part two programming, and vice-versa.

P1

3s

or

60s

or

5.3.2 - Level two programming: parameters

The function parameter can be chosen at level two. Level two can only be

reached from level one. At level 2 the P1 Led flashes quickly while the 5 Leds

(L1, L2…L5) indicate the selected parameter.

TABLE B1 - Entering level two programming

01. Enter level one programming by pressing P1 and P2 for at least 3 seconds

02. Select the function by pressing P1 until the flashing Led reaches the point required

03. Enter level two by pressing the P2 button for at least 3 seconds

TABLE B2 - Selecting the parameter

01. Press P2 repeatedly until the Led reaches the desired parameter

TABLE B3 - Returning to level one

01. Press P1

TABLE B4 - Exiting level one and saving modifications

01. Press P1 and then immediately P2, holding them both down for at least 3 seconds

TABLE B5 - Exiting level one and cancelling modifications

01. Either press P1 for at least 3 seconds, or wait for 1 minute, or disconnect the power supply

3 s

3s

or

60s

or

P1

3 s

5.3.3 - Memory deletion

Each new programme replaces the previous settings. It is usually unnecessary

to “delete all” the parameters”. If required, the memory can be totally deleted by

performing this simple operation: WARNING – As all the functions return to

their pre-set values after the memory is deleted, a new search for the limit switches must be carried out.

3 s

P1 P2

P1

P1 P2

P2

P3

P1 P2

P2

P1

P2

P1

P1 P2

EN

English – 7

TABLE C1 - Delete memory

01. Switch the power supply to the control box off, and wait until all the LEDs have gone off (remove fuse F1 if necessary)

02. Press P1 and P2 on the board down and keep them pressed down

03. Switch the power supply on again

04. Wait at least 3 seconds before releasing the two keys

If the memory was deleted correctly, all the Leds will switch off for 1 second

3s

5.3.4 - Example of level one programming

The following examples show how to activate or deactivate a level one function,

the “Condominium” function, for example, and prepare the “Gate Open Indicator” output in order to activate the electric lock.

Example of level one programming:

activate the “Condominium” function and “Electric lock” output

01. Access the level one programming mode by pressing P1 and P2, and keeping them pressed down for at least 3 seconds

02. Press P1 once to move the flashing Led to the Led 2 (the flashes will be short)

03. Activate the “Condominium” function by pressing P2 (the flashes will be longer)

04. Press P3 once in order to activate part two (the P3 LED will switch on)

05. Press P1 once to move the flashing Led to the Led 2 (the flashes will be short)

06. Activate the “Electric lock” output by pressing P2 (the flashes will be longer)

07. Exit programming (with memorisation) by pressing P1 and then immediately P2, holding them both down

for at least 3 seconds

3s

3s

x1

Example of level two programming: modifying “current sensitivity”

01. Access the level one programming mode by pressing P1 and P2 for at least 3 seconds

02. Press P1 three times to move the flashing Led to the Led 4

03. Access level two by pressing P2 for at least 3 seconds

04. Press P2 three times until Led 5 switches on

05. Return to level one by pressing P1

06. Exit programming (with memorisation) by pressing P1 and then immediately P2, holding them both down

for at least 3 seconds

3s

3s

3s

x3

x3

5.3.5 - Example of level two programming

This example shows how to modify a level two parameter, for example, how to

modify current sensitivity intil “level 5”.

P1

P1

P1 P2

P1 P2

P1 P2

2

P2

P3

2

P2

P1

P2

P1 P2

P1 P2

P2

P1

P1 P2

4

5

EN

8 – English

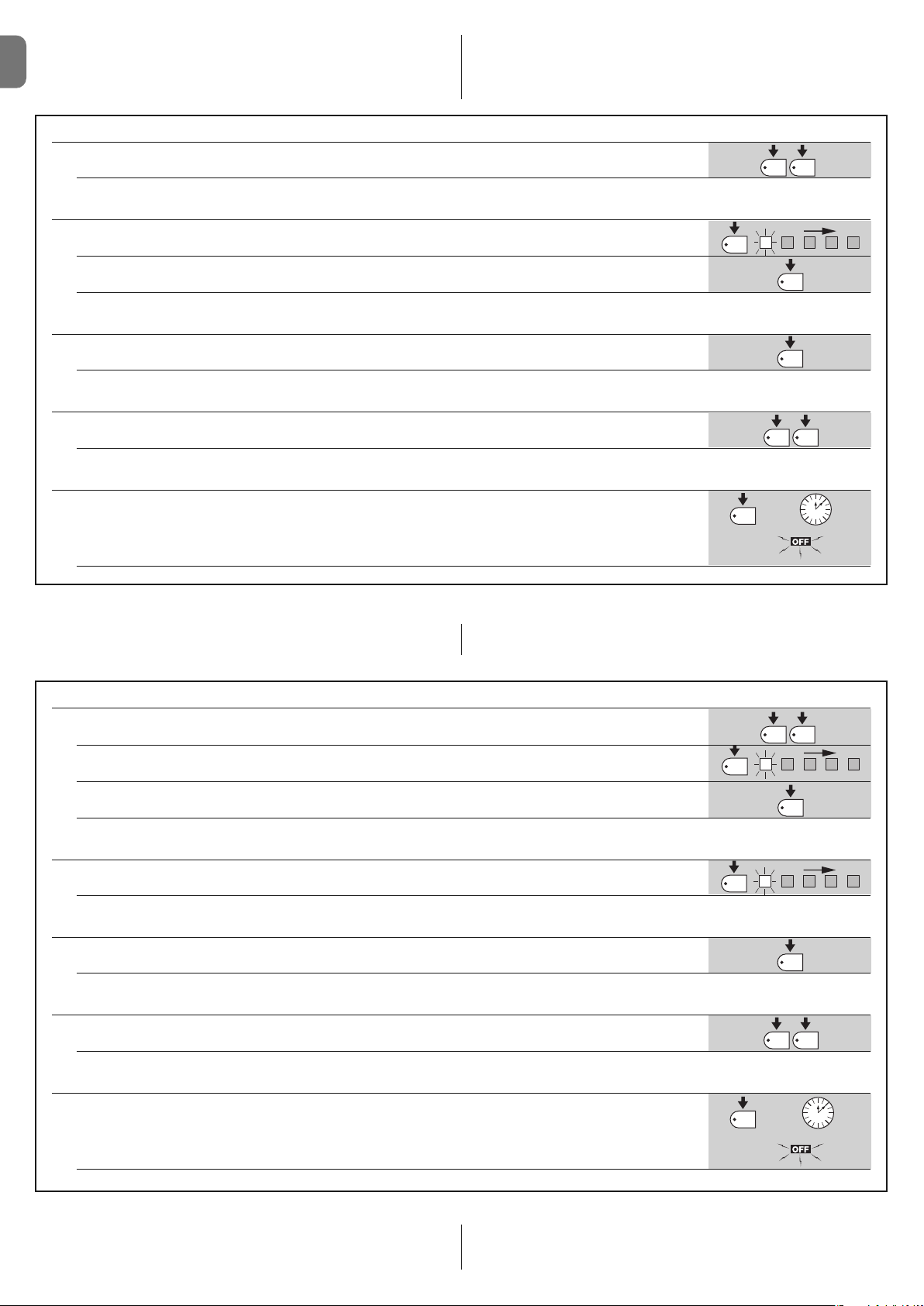

5.3.6 - Programming diagram

The following figure shows the complete programming diagram of the functions

and relative parameters.

This figure also shows the functions and parameters either as they were initially

or following total memory deletion.

ALT Photo Photo1Step

by

step

AUX

Normal

operation

Led P1 Slow flashing

Level one

Led P1 On permanently

Level two

Led P1 Rapid flashing

type 1

p.o

type 2

p.o

only

opening

only

closing

Photo 2

All Leds off · max. current sensitivity

P1+P2

for 3 secs

P1

for 3 secs

(NO SAVE)

P1+P2

for 3 secs

(SAVE)

Autom.

closing

Cond. Pre-

flashing

Close

after

Photo

Opening

delay

On

Off

On

Off

AUXILIARY INPUT (*)

DISCHARGE

CURRENT SENSITIVITY

123

Level

45

OPENING DELAY

51020%30 40

51020

seconds

40 80

PAU SE TIME

P1

P2

for 3 secs

P1

P1

P2

P3

P1

P2

P3

P1

P2

P3

P1

P2

P3

P1

P2

P3

P1

P2

P3

P2

P3

Stand

by /

Phototest

Electric

Lock

Resist.

STOP.

Heavy

gates

Proportional

Gate

Open

P3

P1

P2

P3

0 0,3 0,7

seconds

1,3 2

(*)

a.p. type 1 type 1 partial open, upper leaf

moves [N.O.]

a.p. type 2 type 2 partial opening, both

motors move for 1/2 the working

time set [N.O.]

Only open open stop open stop…

[N.O.]

Only closed close stop close stop…

[N.O.]

Photo 2 used as photo 2 [N.C.]

EN

English – 9

6.1 - Connecting a radio receiver

The control unit has a connector for fitting a 4 channel radio card complete with

SM slot. This remote control device functions by means of transmitters which

act on the inputs as per the following table:

Output Receiver Control unit input

N° 1 Step by step

N° 2 AUX (reset value: Partially Open 1)

N° 3 “Open only”

N° 4 “Close only”

6.2 - Connecting model PS124 buffer battery

PS124 buffer batteries can be used to supply the control unit in case of network blackouts. To install and connect the battery, proceed as shown in fig. 10.

6.3 - Connecting the Solemyo system

The control unit is designed to be powered with the “Solemyo” photovoltaic

system (photovoltaic panel and 24 V battery). To connect the Solemyo battery

to the control unit, use the socket on the control unit that is normally used for

the buffer battery (see paragraph 6.2).

IMPORTANT!

- When the automation is powered by the “Solemyo” system, it MUST

NOT BE POWERED at the same time from the electrical mains.

- The Solemyo system can be used only if the Standby function on the con trol unit is ON and the connections are as shown in the diagram in fig. 5a.

FURTHER DETAILS: accessories

6

No LEDs are on:

• Check whether the control unit is powered (measure a voltage of about

30Vdc at terminals 9-10 (or 24 Vdc with battery power).

• Check the 2 fuses, if not even the P1 Led is on or flashing a serious fault has

probably occurred and the control unit must therefore be replaced.

The P1 LED flashes regularly but the input LED’s L1, L2...L5 do not reflect

the state of the respective inputs

• Switch the unit off for the moment in order to exit a possible programming

phase.

• Carefully check the connections on terminals 11 to 16.

LED P1 flashes every 4 seconds

• The control unit is in Stand by status.

The “Automatic search” procedure does not start up

• The “Automatic search” procedure only starts if it has never been performed

before or if the memory has been deleted. To check whether the memory is

empty switch off the unit for a moment. When it is switched on again, all the

Leds should flash rapidly for about 6 seconds. If they only flash for 3 seconds, the memory already contains valid values. If a new “Automatic search”

is required, the memory must be completely deleted.

The “Automatic search” procedure has never been performed but it either

does not start or it behaves incorrectly

• The system and all the safety devices must be operative in order to activate

the “Automatic search” procedure.

• Make sure that no device connected to the inputs cuts in during the “Automatic search” procedure.

• In order for the “Automatic search” procedure to start correctly, the input

Leds must be on as shown in fig. 11, the P1 Led must flash once a second.

The “Automatic search” procedure was performed correctly but the

manoeuvre does not start

• Check that the safety device (STOP, PHOTO, PHOTO1 and, if installed,

PHOTO2) Leds are on and that the relative command Led (STEP-BY-STEP

or AUX) remains on for the entire duration of the command.

• If the “Phototest” function is activated but the photocells do not function correctly, the DIAGNOSTICS LED indicates the fault by flashing four times.

The gate inverts the direction while moving

An inversion is caused by:

• The photocells triggering (PHOTO2 during the opening manoeuvre, PHOTO

or PHOTO1 during the closing manoeuvre). In this case, check the photocell

connections and input LEDs.

• The current sensitivity device triggers while the motors are moving (not near

TROUBLESHOOTING

(troubleshooting guide)

7

the mechanical stops, therefore). This is considered as an obstacle and

causes an inversion. To find out if the current sensitivity device has triggered,

count how many times the Diagnostics LED flashes: 1 flash indicates that the

current sensitivity device triggered on account of motor 1, 2 flashes indicate

that this was caused by motor 2.

PRODUCT MAINTENANCE

8

As the MC424 control unit is electronic it requires no particular maintenance.

However, at least every six months the efficiency of the entire system must be

checked according to the information described in chapter 3.

DISPOSAL OF THE PRODUCT

This product is an integral part of the automation, and therefore, they

must be disposed of together.

As for the installation operations, at the end of the life of this product, the dismantling operations must be performed by qualified personnel.

This product is made from different types of materials: some can be recycled,

others must be disposed of. Please inform yourselves on the recycling or disposal systems provided for by the laws in force in your area, for this category of

product.

CAUTION! – some parts of the product can contain polluting or dangerous

substances which, if dispersed in the environment, may cause serious harm to

the environment and human health.

As indicated by the symbol at the side, it is forbidden to

throw this product into domestic refuse. Therefore, follow the

“separated collection” instructions for disposal, according to

the methods provided for by local regulations in force, or

redeliver the product to the retailer at the moment of purchase of a new, equivalent product.

CAUTION! – the regulations in force at local level may envisage heavy sanctions in case of abusive disposal of this product.

EN

10 – English

EC DECLARATION OF CONFORMITY

Note - The contents of this declaration correspond to declarations in the last revision of the official document deposited at the registered offices of Nice Spa available before this

manual was printed. The text herein has been re-edited for editorial purposes.

Number: 296/MC424 Revision: 0

The undersigned, Lauro Buoro, in the role of Managing Director, declares under his sole responsibility, that the product:

Manufacturer’s Name: NICE s.p.a.

Address: Via Pezza Alta 13, Z.I. Rustignè, 31046 Oderzo (TV) Italy

Type: Two 24 Vdc motor control unit

Models: MC424

Accessories: SMXI, SMXIS radio receiver

conform with the requirements of the following EC directives:

• 98/37/EC (89/392/EEC amended); DIRECTIVE 98/37/EC OF THE EUROPEAN PARLIAMENT AND COUNCIL of 22 June 1998 regarding the approximation of member state legislation relating to machinery.

As established in directive 98/37/EC, the above-mentioned product may not be started up unless the machine in which the product is incorporated has

been identified and declared as conforming to directive 98/37/EC.

The product also complies with the requirements of the following EC directives:

• 2006/95/EEC (ex directive 73/23/EEC); DIRECTIVE 2006/95/EEC OF THE EUROPEAN PARLIAMENT AND COUNCIL of 12 December 2006 regarding

the approximation of member state legislation relating to electrical material intended for use within specific voltage limits

According to the following harmonised standards: EN 60335-1:1994+A11:1995+A1:1996+A12:1996+A13:1998+A14:1998+A15:2000+A2:2000+

A16:2001

• 2004/108/EEC (ex directive 89/336/EEC); DIRECTIVE 2004/108/EEC OF THE EUROPEAN PARLIAMENT AND COUNCIL of 15 December 2004 regarding the approximation of member state legislation relating to electromagnetic compatibility, repealing directive 89/336/EEC

According to the following harmonised standards: EN 61000-6-2:2001; EN 61000-6-3:2001+A11:2004

The product also complies, within the constraints of applicable parts, with the following standards:

EN 60335-1:2002+A1:2004+A11:2004+A12:2006+ A2:2006, EN 60335-2-103:2003, EN 13241-1:2003; EN 12453:2002; EN 12445:2002;

EN 12978:2003

Oderzo, 25 September 2008 Lauro Buoro (Managing Director)

WARNINGS: • All technical characteristics stated refer to an ambient temperature of 20°C (±5°C). • Nice S.p.a reserves the right to modify the product at any

timee, while maintaining the same functionalities and intended use.

Mains power supply MC424 Control units: 230 V~ ±10% 50 ÷ 60 Hz

MC424/V1 Control units: 120 V~ ±10% 50 ÷ 60 Hz

Max absorbed power 170 W

Emergency power supply for PS124 buffer batteries and for Solemyo solar kit

Maximum motor current: 3A (with a “level 6” current sensitivity cut in)

Service power output 24 V 200 mA maximum current (the voltage can vary from 16 to 33 V )

Phototest Output 24 V 100 mA maximum current (the voltage can vary from 16 to 33 V )

Flashing lamp output for flashing lamp 24 V , maximum power 25 W (the voltage can vary from 16 to 33 V )

Gate open indicator output for indicator lamps at 24 V maximum power 5 W (the voltage can vary from 16 to 33V )

or electric locks 12 V~ 25 W

STOP Input for NC contacts or constant resistance 8,2 KΩ +/- 25%

Working time automatic detection

Pause time programmable at 5, 10, 20, 40, 80 seconds

Discharge time programmable to 0, 0.3, 0.7, 1.3, 2 seconds

Leaf delay in open cycle programmable at 5, 10, 20, 30 and 40 % of working time

Leaf delay in close cycle automatic detection

1st motor output for Wingo WG4024 - WG5024

2nd motor output for Wingo WG4024 - WG5024

Max. cable length 230 V power supply 30 m

Solemyo solar power kit 3 m

motors 10 m

other inputs/outputs 30 m

flashing light 10 m

SCA 30 m

electric lock 10 m

aerial 20 m (recommended less than 3 m)

Radio receiver “SM” type coupling for receivers SMXI, SMXIS, OXI (Mode I and Mode II)

Temperatura di esercizio from - 20 to 50 °C

Protection rating IP 54 with enclosure intact

Dimensions (mm) 310 x 232 x H 122

Weight (kg) 4,1

TECHNICAL CHARACTERISTICS OF THE PRODUCT

EN

English – 11

smxi - smixs radio receiver

0682

SMXI and SMXIS are 4-channel radio receivers for control units equipped with

SM-type connector. The peculiarity of compatible transmitters is that the identification code is different for each transmitter. Therefore, in order to allow the

receiver to recognise a determined transmitter, the recognition code must be

memorised. This operation must repeated for each transmitter required to communicate with the control unit.

Notes:

– Up to a maximum of 256 transmitters can be memorised in the receiver. No

one transmitter can be cancelled; all the codes must be deleted

– For more advanced functions use the appropriate programming unit.

PRODUCT DESCRIPTION

1

The receiver features 4 outputs, all available on the underlying connector. To

find out which function is performed by each output, see chapter 6.1.

During the transmitter code memorisation phase, one of these two options may

be chosen:

Mode I - Table B1: Each transmitter button activates the corresponding output in the receiver, that is, button 1 activates output 1, button 2 activates output

2, and so on. In this case there is a single memorisation phase for each transmitter; during this phase, it doesn’t matter which button is pressed and just one

memory sector is occupied.

Mode II - Table B2: Each transmitter button can be associated with a particular output in the receiver, e.g., button 1 activates output 2, button 2 activates

output 1, and so on. In this case, the transmitter must be memorised, pressing

the required button, for each output to activate. Naturally, each button can activate just one output while the same output can be activated by more than one

button. One memory section is occupied for each button.

TABLE B1 - Mode I memorising (All buttons are memorised on the related receiver output)

01. Press and hold down the receiver button for at least 3 seconds

02. Release the button when the Led lights up

03. Push, for at least 2 seconds, any of the buttons of the transmitter to be memorised within 10 seconds

Note – If the procedure was memorised correctly, the Led on the receiver will flash 3 times. If there are other transmitters

to memorise, repeat step 3 within another 10 seconds. The memorisation phase finishes if no new codes are received

for 10 seconds.

3s

2s

x3

INSTALLING THE AERIAL

2

The receiver requires an ABF or ABFKIT type aerial to work properly; without an

aerial the range is limited to just a few metres. The aerial must be installed as

high as possible; if there are metal or reinforced concrete structures nearby you

can install the aerial on top. If the cable supplied with the aerial is too short, use

a coaxial cable with 50-Ohm impedance (e.g. low dispersion RG58), the cable

must be no longer than 10 m.

If the aerial is installed in a place that is not connected to earth (masonry structures), the braid’s terminal can be earthed to provide a larger range of action.

The earth point must, of course, be local and of good quality. If an ABF or

ABFKIT aerial cannot be installed, you can get quite good results using the

length of wire supplied with the receiver as the aerial, laying it flat.

WARNING – When the memorisation phase is activated, any tran smitter correctly recognised within the reception range of the radio

is memorised. Consider this aspect with care and remove the aerial if necessary to reduce the capacity of the receiver.

MEMORISING A REMOTE CONTROL

3

The procedures for memorising the remote controls must be performed within

a certain time limit; please read and understand the whole procedure before

starting.

In order to carry out the following procedure, it is necessary to use the button

located on the box of the radio receiver (reference A, Fig. 1a), and the corresponding LED (reference B, Fig. 1a) to the left of the button.

1a

TABLE B2 - Mode II memorising (A specific receiver output can be associated to each button)

01. Press and release the receiver button as many times as the number of the desired output (Once for output No. 1,

twice for output No. 2)

02. Check that the LED emits the same number of flashes as the desired output, repeated over 10 seconds in regular

intervals (1 flash if output No. 1, 2 flashes if output No. 2)

03. Within 10 seconds press the desired button on the transmitter to be memorised, holding it down for at least 2 seconds.

Note – If the procedure was memorised correctly, the Led on the receiver will flash 3 times. If there are other transmitters

to memorise, repeat step 3 within another 10 seconds. The memorisation phase finishes if no new codes are received

for 10 seconds.

2s

x3

RX

RX

RX

TX

TX

I

EN

IT

FR

ESDEPL

NL

EN - Images

IT - Immagini

FR - Images

ES - Imágenes

DE - Bilder

PL - Zdjęcia

NL - Afbeeldingen

II

M2

M1

L

N

D

C

A

FEGHILM

45 6 8910 111213 14 15 167123

123

B

P1

L1...L5

P2

P3

O

N

2

1

2

3

4

55

7

7

8

6 6

1

EN - E = Electric jumper

IT - E = Ponticello elettrico

FR - E = Cavalier électrique

ES - E = Conexión eléctrico

DE - E = Brücke

PL - E = Mostek elektryczny

NL - E = Elektrische

geleidingsbrug

III

3

205

237

4

232 mm

310 mm

122 mm

TX RX

PHOTO2

5a

EN- Connection with “Stand by” active (energy saving)

IT - Collegamento con “Stand by” attivo (risparmio energetico)

FR- Connexion avec « stand-by » actif (économie d’énergie)

ES- Conexión con “Stand by” activo (ahorro energético)

DE- Anschluss mit aktivem “Standby” (Energieeinsparung)”

PL - Połączenie z aktywną funkcją “Stand by” (oszczędność energii)

NL- Aansluiting met “Stand by” actief (energiebesparing)

IV

6

TX RX

5c

EN- Connection without “Stand by” with “Phototest”

IT - Collegamento senza “Stand by” con “Fototest”

FR- Connexion sans « stand-by » et avec « phototest »

ES- Conexión sin “Stand by” con “Fototest”

DE- Ohne “Standby” und ohne “Phototest”

PL - Połączenie bez funkcji “Stand by” i z funkcją “Fototest”

NL- Aansluiting zonder “Stand by” met “Fototest”

TX RX

5b

EN- Standard connection: without using Standby or Phototest

IT - Collegamento standard: senza utilizzare “Stand by” e senza “Fototest”

FR- Connexion standard : sans utiliser « Stand by » et sans « Phototest »

ES- Conexión estándar: sin utilizar “Stand by” y sin “Fototest”

DE- Standardanschluss: ohne Nutzung des “Stand by” und ohne “Fototest”

PL - Połączenie standard: bez wykorzystywania funkcji “Stand by”

i bez “Fototestu”

NL- Standaard aansluiting: zonder gebruik van “Stand by”

en zonder "Fototest”

V

6

6

7

7

8

33 V

max 5 W

12 V~

max 25 VA

11

12

8,2KΩ

NC

NC

NA

NC

11

12

8,2KΩ

NA

NA

11

12

8,2KΩ

9a

7a

ALT

NC NO C C NO NC

15

11

11

12

STEP BY STEP

7b

AUX

NC NO C C NO NC

15

11

11

16

STEP BY STEP

11

12

1

2

n

8,2KΩ

9d

EN- With Stand by active connect terminal no. 8 and not no. 11

IT - Con Stand by attiva collegare il morsetto n° 8 e non il n° 11

FR- Avec Stand-by actif connecter la borne n° 8 et pas la n° 11

ES- Con “Stand by” activo, conecte el borne n° 8 y no el n° 11

DE- Bei aktivem Standby, die Klemme Nr. 8 und und nicht 11 anschließen

PL - Z aktywną funkcją Stand by należy połączyć zacisk nr 8 a nie nr 11

NL- Met actieve Stand by sluit u klem 8 aan en niet klem 11

EN- For the ALT connection with “Stand by” active, connect terminal

no. 8 and not no. 11

IT - Per il collegamento ALT, con “stand by” attiva, collegare il

morsetto n° 8 e non il n° 11

FR- Pour la connexion HALTE, avec « stand-by » actif, connecter la

borne n° 8 et pas la n° 11

ES- Para la conexión ALT, con “stand by” activo, conecte el borne n°

8 y no el n° 11

DE- Für den Anschluss STOPP, bei aktivem Standby, die Klemme Nr.

8 und nicht 11 anschließen

PL - Aby wykonać połączenie STOP z aktywną funkcją “stand by”

należy połączyć zacisk nr 8 a nie nr 11

NL- Voor de aansluiting ALT, met actieve “stand by”, sluit u de klem

8 aan en niet de klem 11

IT - Bordo sensibile

FR - Bord sensible

ES - Banda sensible

DE - Schaltleiste

PL - Listwa optyczna

NL - Contactlijst

Sensitive edge

IT - Bordo sensibile

FR - Bord sensible

ES - Banda sensible

DE - Schaltleiste

PL - Listwa optyczna

NL - Contactlijst

Sensitive edge

IT - Bordo sensibile

FR - Bord sensible

ES - Banda sensible

DE - Schaltleiste

PL - Listwa optyczna

NL - Contactlijst

Sensitive edge

9b 9c

VI

1110

Codice: IST280.4858 – Rev. 01 del 15 – 12 – 2008

Nice Turkey

Kadikoy Istanbul Turkey

Ph. +90.216.456.34.97

Fax +90.216.455.78.29

info@tr.niceforyou.com

Nice UK

Sutton in Ashfield

United Kingdom

Ph. +44.16.23.55.80.86

Fax +44.16.23.55.05.49

info@uk.niceforyou.com

Nice Australia

Wetherill Park Australia

Ph. +61.(0)2.96.04.25.70

Fax +61.(0)2.96.04.25.73

info@au.niceforyou.com

Nice China

Shanghai P. R. China

Ph. +86.21.575.701.46/45

Fax +86.21.575.701.44

info@cn.niceforyou.com

Nice USA

Jacksonville Florida USA

Ph. +1.904.786.7133

Fax +1.904.786.7640

info@us.niceforyou.com

www.niceforyou.com

Headquarters

Nice SpA

Oderzo TV Italia

Ph. +39.0422.85.38.38

Fax +39.0422.85.35.85

info@niceforyou.com

Nice in Italy

Nice Padova

Sarmeola di Rubano PD Italia

Ph. +39.049.89.78.93.2

Fax +39.049.89.73.85.2

infopd@niceforyou.com

Nice Roma

Roma RM Italia

Ph. +39.06.72.67.17.61

Fax +39.06.72.67.55.20

inforoma@niceforyou.com

Nice Worldwide

Nice France

Buchelay France

Ph. +33.(0)1.30.33.95.95

Fax +33.(0)1.30.33.95.96

info@fr.niceforyou.com

Nice France Sud

Aubagne France

Ph. +33.(0)4.42.62.42.52

Fax. +33.(0)4.42.62.42.50

infomarseille@fr.niceforyou.com

Nice France Rhône Alpes

Decines Charpieu France

Ph. +33.(0)4.78.26.56.53

Fax +33.(0)4.78.26.57.53

infolyon@fr.niceforyou.com

Nice Belgium

Leuven (Heverlee) Belgium

Ph. +32.(0)16.38.69.00

Fax +32.(0)16.38.69.01

info@be.niceforyou.com

Nice Deutschland

Gelnhausen Deutschland

Ph. +49.(0)6051.91.520

Fax +49.(0)6051.91.52.119

info@de.niceforyou.com

Nice España Madrid

Mostoles Madrid España

Ph. +34.(0)9.16.16.33.00

Fax +34.(0)9.16.16.30.10

info@es.niceforyou.com

Nice España Barcelona

Sant Quirze del Valles

Barcelona España

Ph. +34.(0)9.37.84.77.75

Fax +34.(0)9.37.84.77.72

info@es.niceforyou.com

Nice Polska

Pruszków Polska

Ph. +48.(022).759.40.00

Fax +48.(022).759.40.22

info@pl.niceforyou.com

Nice Portugal

Mem Martins Portugal

Ph. +351.21.922.82.10

Fax +351.21.922.82.19

info@pt.niceforyou.com

Nice Romania

Cluj Napoca Romania

Ph./Fax +40.(0)264.453.127

info@ro.niceforyou.com

TABLEAU C1 - Pour effacer la mémoire

01. Éteindre l’alimentation de la logique de commande et attendre que toutes les leds soient éteintes

(éventuellement enlever le fusible F1)

02. Presser et maintenir enfoncées les deux touches P1 et P2 sur la carte électronique

03. Remettre la logique sous tension

04. Maintenir les deux touches enfoncées pendant 3 secondes et les relâcher dès que ce temps se sera écoulé

Si l’effacement de la mémoire a été effectué correctement, toutes les leds s’éteignent pendant 1 seconde ; si les leds continuent à clignoter, il faut répéter

toute la procédure d’effacement de la mémoire.

TABLE C1 - Delete memory

01. Switch the power supply to the control box off, and wait until all the LEDs have gone off (remove fuse F1 if necessary)

02. Press P1 and P2 on the board down and keep them pressed down

03. Switch the power supply on again

04. Press and hold the two keys for 3 seconds and release as soon as this interval elapses

If the memory was deleted correctly, all the Leds will switch off for 1 second; if the leds continue to flash, the entire memory deletion procedure must be

repeated.

3s and

P1 P2

EN

Paragraph 5.3.3 – Deleting the memory: replace Table C1 with the following

TABELLA C1 - Per cancellare la memoria

01. Spegnere l’alimentazione alla centrale ed aspettare che tutti i LED siano spenti (eventualmente togliere il fusibile F1)

02. Premere e tenere premuti i due tasti P1 e P2 sulla scheda

03. Ridare alimentazione alla centrale

04. Tenere premuti i due tasti per 3 secondi e rilasciarli appena scaduto questo tempo

Se la cancellazione della memoria è andata a buon fine, tutti il led si spengono per 1 secondo; se i led continuano a lampeggiare, occorre ripetere tutta la

procedura di cancellazione della memoria.

3s e

IT

Paragrafo 5.3.3 - Cancellazione memoria: sostituire la Tabella C1 con la seguente

3s et

P1 P2

FR

Paragraphe 5.3.3 - Effacement mémoire : remplacer le Tableau C1 par le suivant

Errata corrige

MC424

IST280B.4858 Rev. 00 15-04-2010

P1 P2

P1 P2

P1 P2

P1 P2

P1 P2

P1 P2

P1 P2

Loading...

Loading...