Nice

MC424L

Control unit

EN - Instructions and warnings for installation and use

ENGLISH

Translation of the original instructions in full

CONTENTS

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS . . . . . 2

2 PRODUCT DESCRIPTION AND INTENDED USE. . . . . . . . . . 3

2.1 List of control unit parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Pre-installation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Product usage limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Product identification and overall dimensions . . . . . . . . . . . 4

3.4 Typical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.5 Installing the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Preliminary checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Wiring diagram and description of connections . . . . . . . . . 6

4.2.1 Wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2.2 Description of connections . . . . . . . . . . . . . . . . . . . . . . . 7

4.2.3 Operations for connection . . . . . . . . . . . . . . . . . . . . . . . 7

4.2.4 Notes on connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.5 ALT (STOP) input type . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3 Initial start-up and electrical connections test . . . . . . . . . . . 9

4.4 Motor selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Automatic limit switch search and “STOP” input

acquisition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 TESTING AND COMMISSIONING . . . . . . . . . . . . . . . . . . . . . 11

5.1 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.1 Using the programming buttons . . . . . . . . . . . . . . . . . . . . 11

6.2 Pre-set functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 Level 1 programming (ON-OFF) . . . . . . . . . . . . . . . . . . . . 12

6.3.1 Level 1 programming procedure . . . . . . . . . . . . . . . . . 12

6.4 Level 2 programming (adjustable parameters) . . . . . . . . . 13

6.4.1 Level 2 programming procedure . . . . . . . . . . . . . . . . . 13

6.5 Memory deletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.6 Memorising the transmitters . . . . . . . . . . . . . . . . . . . . . . . 15

6.6.1 Procedure for memorising transmitter buttons . . . . . . . 15

6.6.2 Number of transmitters that can be memorised . . . . . . 15

6.6.3 Transmitter memorisation and deletion procedures . . . 15

6.7 LOCKING AND UNLOCKING THE MEMORY . . . . . . . . . . 17

7 TROUBLESHOOTING... (troubleshooting guide) . . . . . . . . 17

7.1 Signalling through warning light . . . . . . . . . . . . . . . . . . . . 17

7.2 Signals on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Maintenance notification . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.4 Anomaly log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8 FURTHER INFORMATION (Accessories). . . . . . . . . . . . . . . 20

8.1 Connecting an SM-type radio receiver . . . . . . . . . . . . . . . 20

8.2 Connecting the IBT4N interface . . . . . . . . . . . . . . . . . . . . 20

8.3 Connecting the PS124 back-up battery . . . . . . . . . . . . . . 20

8.4 Connecting the Solemyo system . . . . . . . . . . . . . . . . . . . . 21

9 PRODUCT MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10 PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . 22

12 CONFORMITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

INSTRUCTIONS AND WARNINGS FOR THE USER . . . . . . 23

1

1 GENERAL SAFETY WARNINGS AND PRECAUTIONS

a

a

a

PRECAUTIONS

Prior to installing the appliance, carefully read and

observe these instructions, since incorrect installation can cause serious harm to people and damage

to the appliance. Store them with care.

According to the latest European legislation, an

automated device must be constructed in conform-

ity to the harmonised rules specied in the current

Machinery Directive, which allow for declaring the

presumed conformity of the automation. Consequently, all the operations for connecting the product to the mains electricity, its commissioning and

maintenance must be carried out exclusively by a

qualied and expert technician.

In order to avoid any danger from inadvertent resetting of the thermal cut-off device, this appliance

must not be powered through an external switching

device, such as a timer, or connected to a supply

that is regularly powered or switched off by the circuit.

WARNING! Please abide by the following warnings:

– Before commencing the installation, check the “Prod-

uct technical specications”, in particular whether this

product is suitable for automating your guided part.

Should it not be suitable, do NOT proceed with the installation.

– The product cannot be used before it has been com-

missioned as specied in the “Testing and commissioning” chapter.

– Before proceeding with the product’s installation,

check that all the materials are in good working order

and suited to the intended applications.

– The product is not intended for use by persons (includ-

ing children) with reduced physical, sensory or mental

capacities, nor by anyone lacking sufcient experience

or familiarity with the product.

– Children must not play with the appliance.

– Do not allow children to play with the product’s control

devices. Keep the remote controls out of reach of chil-

dren.

– The system’s power supply network must include a dis-

connection device (not supplied) with a contact open-

ing gap permitting complete disconnection under the

conditions envisaged by Overvoltage Category III.

– During the installation process, handle the product with

care by avoiding crushing, impacts, falls or contact

with liquids of any kind. Do not place the product near

sources of heat nor expose it to open ames. All these

actions can damage the product and cause it to mal-

function, or lead to dangerous situations. Should this

occur, immediately suspend the installation process

and contact the Technical Assistance Service.

– The manufacturer declines all liability for damages to

property, objects or people resulting from failure to

observe the assembly instructions. In such cases, the

warranty for material defects shall not apply.

– The weighted sound pressure level of the emission A is

lower than 70 dB(A).

– Cleaning and maintenance reserved for the user must

not be carried out by unsupervised children.

– Before working on the system (maintenance, cleaning),

always disconnect the product from the mains power

supply.

GENERAL SAFETY WARNINGS AND

2 – ENGLISH

– Inspect the system frequently, in particular the cables,

springs and supports to detect any imbalances and

signs of wear or damage. Do not use the product if it

needs to be repaired or adjusted, because defective

installation or incorrect balancing of the automation can

lead to injuries.

– The packing materials of the product must be disposed

of in compliance with local regulations.

2

2 PRODUCT DESCRIPTION AND INTENDED USE

MC424L is an electronic control unit for the automation of swing gates MC424L can command 24 V WINGO, TOO, SFAB elec-

tro-mechanical actuators. it incorporates an amperometric device that veries the force of the motors connected to it. This system

allows for automatically detecting the limit switches, memorising the work times of each motor and detecting any obstacles during

normal gate movement. These characteristics simplify the installation considerably, as the leaf offsets and work times do not require

any adjusting.

The control unit is programmed in advance for the most frequently used functions and incorporates a radio receiver for the remote

controls. In addition, a straightforward procedure can be implemented to select more specic functions (see the “PROGRAMMING” chapter).

MC424L is equipped with an SM-type connector for slot-in radio receivers (see the “Connecting an SM-type radio receiver“

paragraph) and an IBT4N-type connector which, through the IBT4N interface, can be used to connect BusT4 devices, such as the

Oview programmer (see the “Connecting the IBT4N interface” paragraph).

The control unit is congured for being powered with PS124 back-up batteries which, in case of a power outage, function as an

emergency power supply (see the “Connecting the PS124 back-up battery” paragraph). Moreover, the MC424L is congured for

being connected to a Solemyo solar power kit (see the “Connecting the Solemyo system” paragraph).

a

PRODUCT DESCRIPTION AND INTENDED USE

Any use of the product other than the intended use described is not allowed!

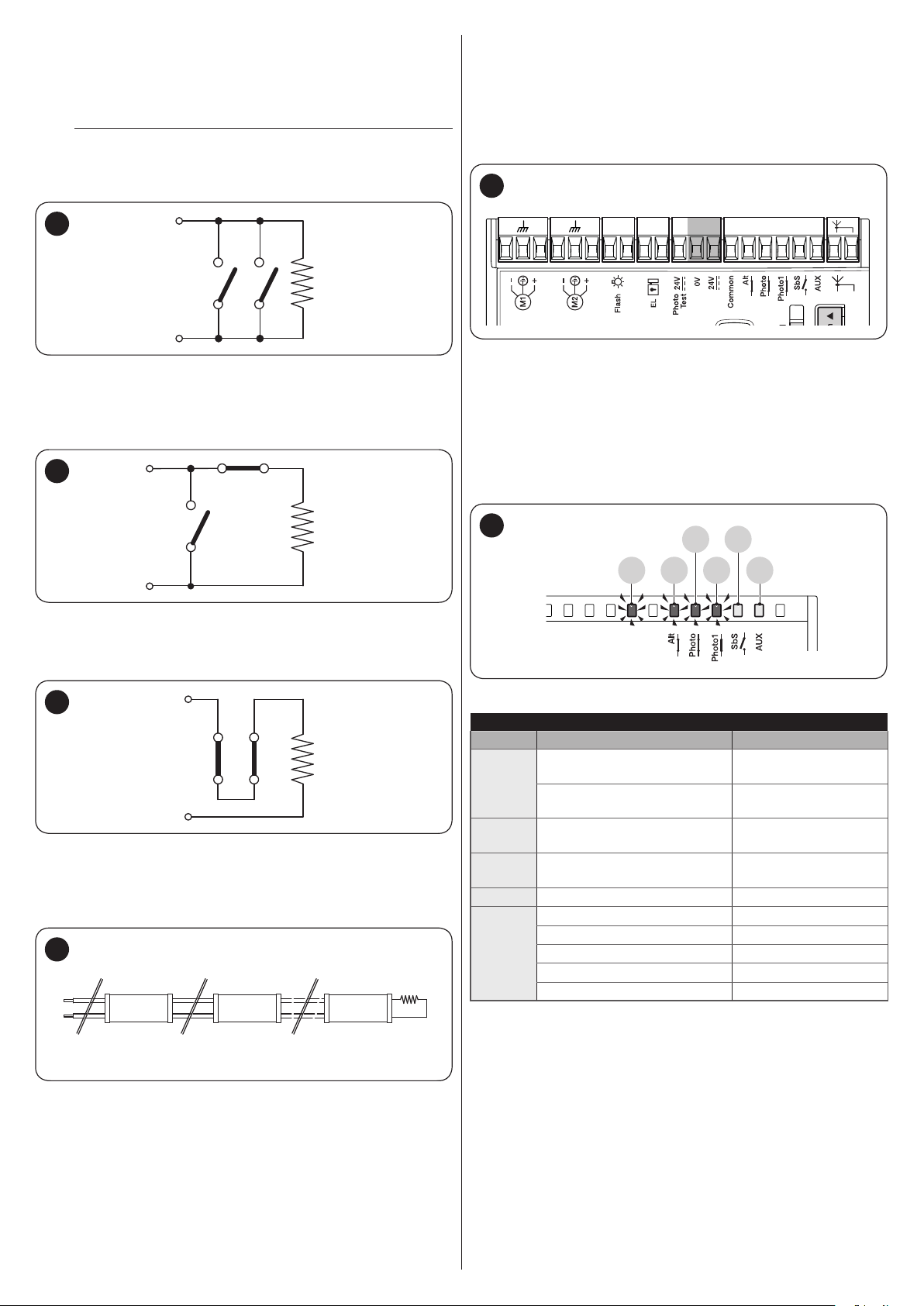

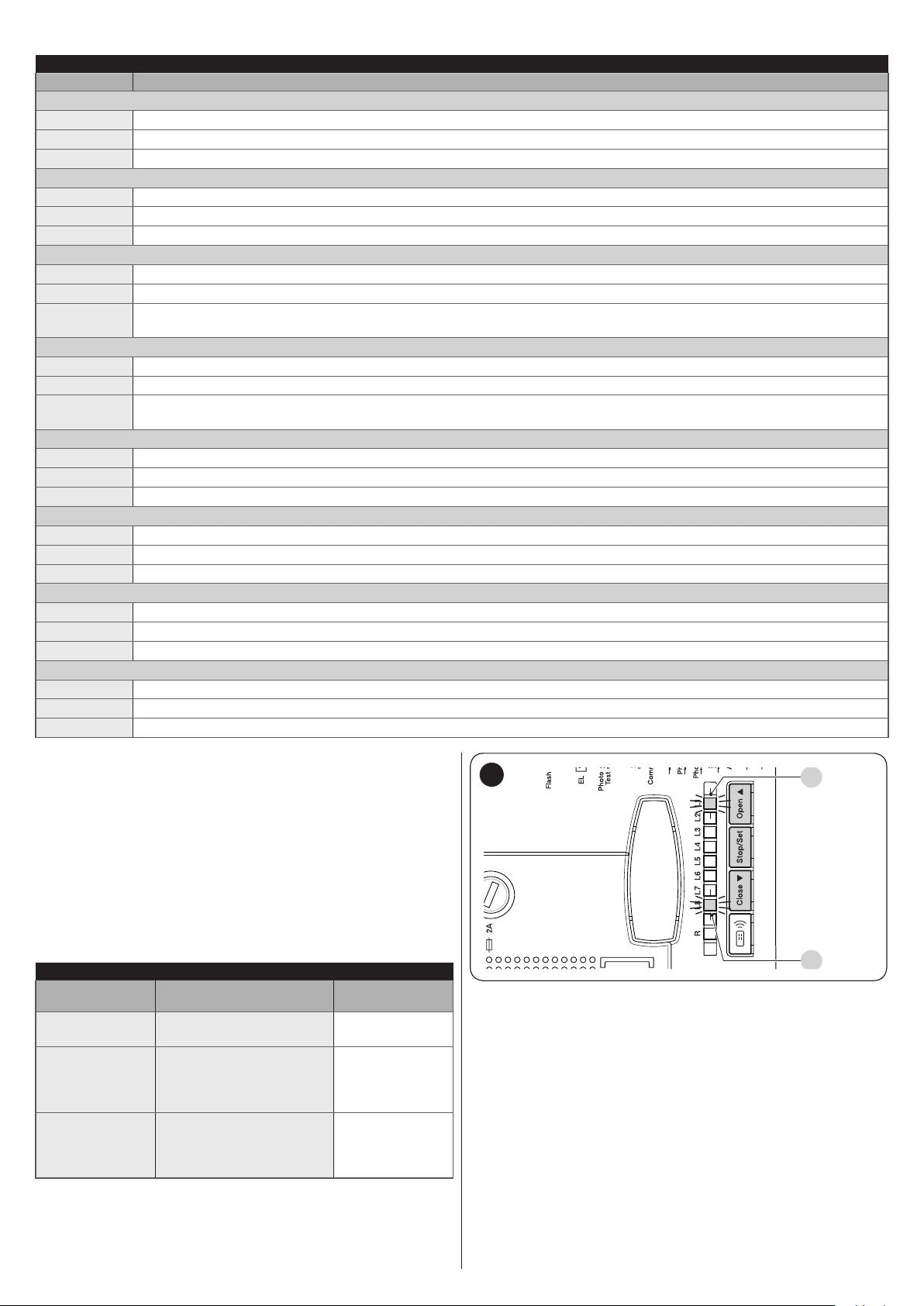

2.1 LIST OF CONTROL UNIT PARTS

The control unit is made up of an electronic command and control board housed and protected inside the box. “Figure 1” shows

the main parts making up the board.

1

L10

E F G H I M N

M M 5 6 7 8 9 10 11 12 131 2 3 4

M M

OK

L9

L11

L12

L13

R

S

L

U

N

D

T

C

B

A

A 24 V~ power supply connector

B Connector for PS124 back-up battery / Solemyo solar

power kit

C Service fuse (2 A, type F)

D “SM” connector for radio receiver

E M1 motor terminal (starts rst during the closing

phase)

F M2 motor terminal (starts rst during the opening

phase)

G Warning light terminal

H OGI output or electric lock terminal

I 24 VDC terminals for services and phototest

L9..L13 Input LEDs

OK “LED OK” status LED

L1

L8

..

P1

P2

P3

P4

LR

O

Q

L1..L8 Programming LED

LR Radio programming LED

M Input terminals

N Terminals for radio antenna

O Motor selector

Q Connector for IBT4N

R Mains fuse

S Mains power supply (L-Live; N-Neutral)

T Earth connection

U Cable clamp

P1..P3 Control unit programming buttons

P4 Radio programming button

ENGLISH – 3

3

310 mm

122 mm

3 INSTALLATION

INSTALLATION

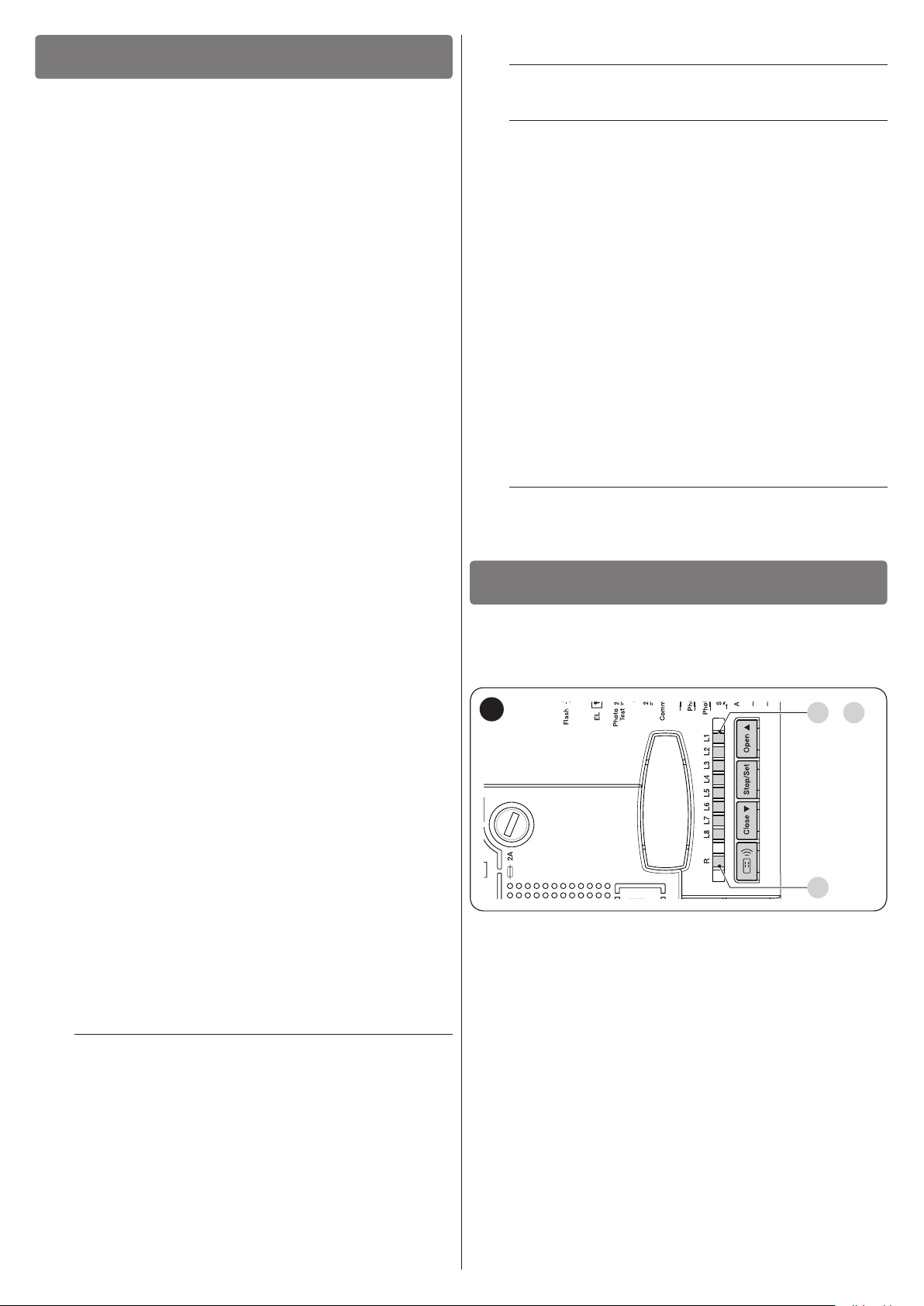

3.4 TYPICAL INSTALLATION

“Figure 3” shows an example of an automation system constructed using Nice components.

3.1 PRE-INSTALLATION CHECKS

Before proceeding with the product’s installation, it is necessary

to:

– check the integrity of the supply

– check that all the materials are in good working order and

suited to the intended use

– check that all operating conditions comply with that specied

in the “Product usage limits” paragraph and in the “TECHNI-

CAL SPECIFICATIONS” chapter

– check that the chosen installation location is compatible with

the product’s overall dimensions (see “Figure 2”)

– check that the surface chosen for installing the product is sol-

id and can ensure stable attachment

– make sure that the installation area is not subject to ooding; if

necessary, the product must be installed appropriately raised

above ground level

– check that the space around the product allows safe and easy

access

– check that all electrical cables to be used belong to the type

listed in “Table 1”

– check that the automation has mechanical stops in both the

opening and closing phases.

3.2 PRODUCT USAGE LIMITS

The product must be used exclusively with WG2024, WG3524,

WG4024, WG5024, TOO3024, TOO4524, XME2024 gearmotors

and in accordance with the corresponding usage limits.

3.3 PRODUCT IDENTIFICATION AND OVERALL DIMENSIONS

The overall dimensions and label (A) that allow for identifying the

product are shown in “Figure 2”.

2

3

G

A WINGO, TOO, SFAB 24 V electro-mechanical actuator

B WINGO, TOO, SFAB 24 V electro-mechanical actuator

C Warning light

D Key selector

E “PHOTO” pair of photocells

F “PHOTO1” pair of photocells

G “PHOTO2” pair of photocells

H Control unit

These above-mentioned components are positioned according

to a typical standard layout.

In particular, bear in mind that:

– for the characteristics and connection of the photocells, con-

sult the specic instructions of the product

– the intervention of the “PHOTO” pair of photocells during the

opening phase has no effect, while it triggers a reversal during

the closing phase

– the intervention of the “PHOTO1” pair of photocells stops the

manoeuvre during both the opening and closing phases

– the intervention of the “PHOTO2” pair of photocells during the

closing phase (connected to the suitably congured AUX input) has no effect, while it triggers a reversal during the opening phase.

l

C

H

G

F F

Bear in mind that motor M1 is the rst to start for

the closing movement, while motor M2 is the rst to

start for the opening movement (“Figure 4”).

E E

A

B

D

232 mm

4

A

M1 M2

Before proceeding with the installation, prepare the

a

electrical cables required for the system by referring to the “Wiring diagram and description of con-

nections” paragraph and to that specied in the “

TECHNICAL SPECIFICATIONS” chapter.

The cables used must be suited to the type of envi-

a

ronment of the installation site.

When laying the ducting for routing the electrical

a

cables and for the cable entry point into the control

unit housing, check that there are no water deposits in the junction wells nor condensate in the connection ducts, as water and damp conditions could

damage the product’s electronic circuits.

4 – ENGLISH

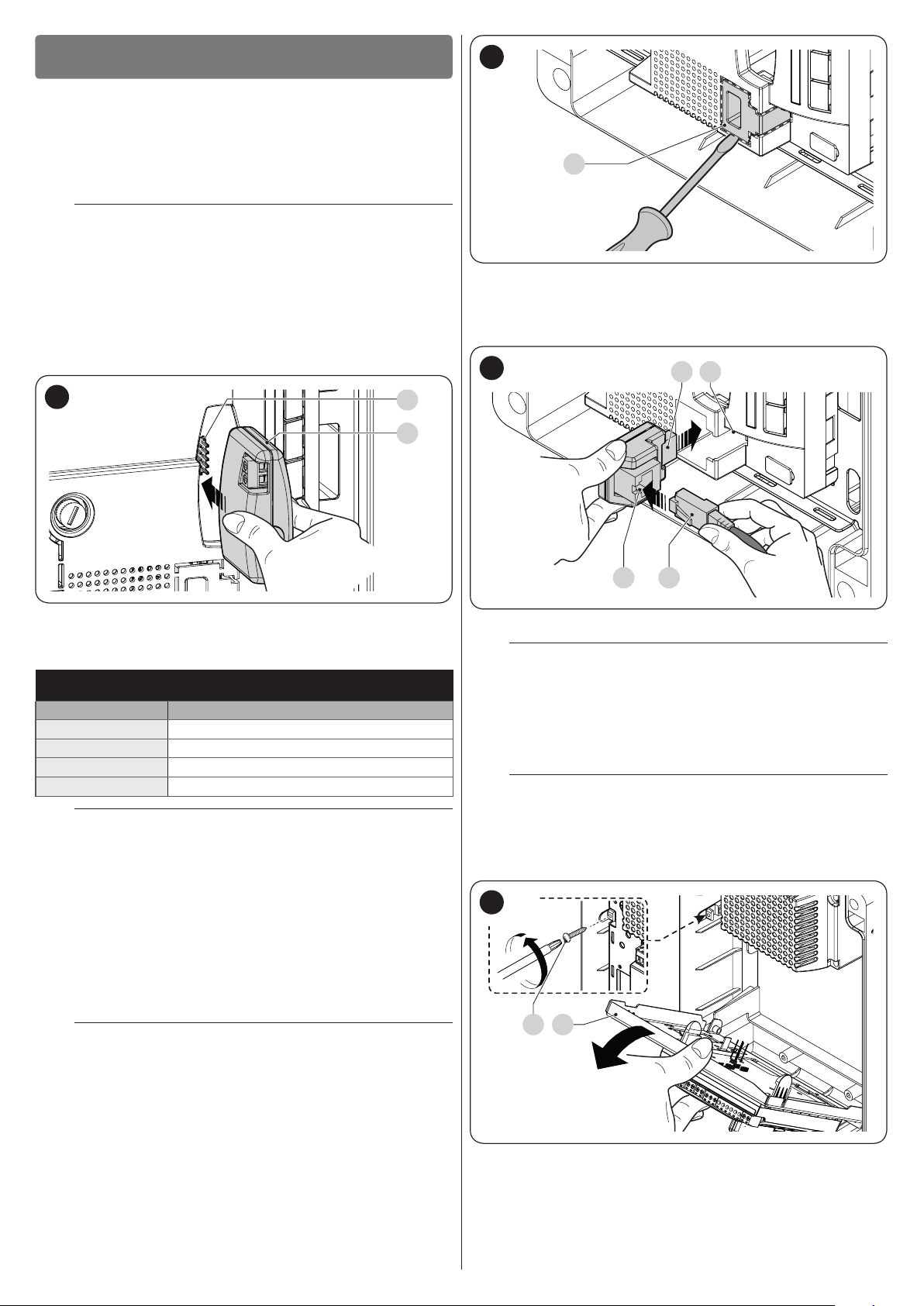

3.5 INSTALLING THE CONTROL UNIT

Secure the control unit to an unmovable, vertical,

a

at surface adequately protected against possible

impacts. The lower part of the control unit must be

at least 40 cm above the ground.

The control unit is also suitable for being installed

l

outdoors, as it is supplied in a container that, if adequately installed, guarantees an IP54 protection

rating.

To secure the control unit (“Figure 5” and “Figure 6”):

1. loosen the screws (A) and remove the cover (B) of the

control unit

2. identify the pre-cut holes (C) located along the lower side

of the box and perforate the ones used to pass the electrical cables

The side cable entry (D) can only be used if the con-

l

trol unit is installed indoors, in a protected environment.

5

B

A

6

205 mm

G

F

237 mm

E

D

C

3. drill the wall (E) by observing the measurements shown in

the gure and arrange suitable wall plugs (not supplied)

4. position the box (F) and fasten it with the screws (G) (not

supplied)

5. arrange cable glands for passing the connecting cables

6. make the electrical connections by operating as de-

scribed in the “ELECTRICAL CONNECTIONS” chapter.

To install any other devices used on the automated

l

system, refer to the respective instruction manuals.

7. after making the electrical connections, put the cover (B)

back on and tighten the screws (A).

4

4 ELECTRICAL CONNECTIONS

ELECTRICAL CONNECTIONS

4.1 PRELIMINARY CHECKS

All electrical connections must be made with the

f

system disconnected from the mains electricity and

with the back-up battery (if present) disconnected.

The connection operations must only be carried out

a

by qualied personnel.

Check that all electrical cables to be used are of the

f

suitable type

ENGLISH – 5

4.2 WIRING DIAGRAM AND DESCRIPTION OF CONNECTIONS

4.2.1 Wiring diagram

7

Connection with “Stand-by all” active

A

(energy saving)

TX RX

OGI

M M 5 6 7 8 9 10 11 12 131 2 3 4M M

5 - 10 RX = PHOTO

5 - 11 RX = PHOTO1

5 - 13 RX = PHOTO2

PHOTO2

Standard connection: without using the

B

“Stand-by all” and without the “Phototest”

TX RX

OGI

M M 5 6 7 8 9 10 11 12 131 2 3 4M M

8-10 RX = PHOTO

8-11 RX = PHOTO1

8-13 RX = PHOTO2 (AUX)

Connection without the “Stand-by all”

C

and with the “Phototest”

TX RX

OGI

M M 5 6 7 8 9 10 11 12 131 2 3 4M M

8-10 RX = PHOTO

8-11 RX = PHOTO1

8-13 RX = PHOTO2 (AUX)

Connection without the “Stand-by all”, with the

D

“Phototest” and without the “Photo1”

TX RX

OGI

M M 5 6 7 8 9 10 11 12 131 2 3 4M M

8-10 RX = PHOTO

6 – ENGLISH

4.2.2 Description of connections

L

N

T

A

C

B

The meaning of the codes/wording stamped on the electronic board near the relative terminals is described below.

ELECTRICAL CONNECTIONS

Terminals Function Description Cable type

120/230/250 V ~ 50/60

Hz POWER SUPPLY

Motor 1

Mains power supply 3 x 1.5 mm

Connection of motor M1 [note 1]

3 x 1.5 mm

Motor 2 Connection of motor M2 3 x 1.5 mm

1÷2

3÷4

5

Warning light

OGI / Electric lock

24 V c common

input (with Stand-by

all / phototest)

Connection of the 24 V c max 25 W warning light

Connection of the 24 V c max 5 W Open Gate Indicator or 12 V c max 15

VA Electric Lock (see the “PROGRAMMING” chapter)

+24 V c power supply for TX photocells with phototest (max 100 mA);

“COMMON” for all safety inputs, with “Stand-by all” function active [note 2]

6 0 V c 0 V power supply c for services

7 24 V c Services power supply, without “Stand-by all” (24 V c max 200 mA)

8 Common 24 V c Common for all inputs (+24 V c) without “Stand-by all”

9

10

11

12

13

ALT (STOP)

Input with STOP function (emergency, safety lock) [note 3]

FOTO (PHOTO) NC input for safety devices (photocells, sensitive edges) 1 x 0.5 mm

FOTO1 (PHOTO1) NC input for safety devices (photocells, sensitive edges) 1 x 0.5 mm

PASSO-PASSO

(STEP-BY-STEP)

AUX

Input for cyclic operation (OPEN-STOP-CLOSE-STOP) 1 x 0.5 mm

Auxiliary input [note 4]

Antenna Radio receiver antenna connection

2 x 1 mm

OGI: 2 x 0.5 mm

Electric lock: 2 x 1

2

mm

1 x 0.5 mm

1 x 0.5 mm

1 x 0.5 mm

1 x 0.5 mm

1 x 0.5 mm

1 x 0.5 mm

RG58-type shielded

cable

Table 1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Note 1 Not used for single-leaf gates (the control unit automatically recognises whether there is only one motor installed).

Note 2 The “Stand-by all” is used to limit consumption; for further details on the electrical connections, refer to the “Stand-by all /

Phototest connection” paragraph, and consult the “PROGRAMMING” chapter for information on programming.

Note 3 The ALT (STOP) input can be used for NC contacts or 8.2 kΩ xed resistor contacts in self-recognition mode (see the “

PROGRAMMING” chapter).

Note 4 The AUX auxiliary input is programmed by default with the “Type 1 partial open” function, but can be programmed with one

of the functions shown in “Table 2”.

Table 2

PROGRAMMABLE FUNCTIONS FOR THE AUX INPUT

Function Type of input Description

TYPE 1 PARTIAL OPEN

TYPE 2 PARTIAL OPEN

OPEN

CLOSE

PHOTO 2

STOP

EXCLUDED

NO (normally open) Opens the upper leaf completely

NO (normally open) Opens the two leaves halfway

NO (normally open) Performs the open manoeuvre only

NO (normally open) Performs the close manoeuvre only

NC (normally closed) PHOTO 2 function

NO (normally open) Stops the manoeuvre

-- No function

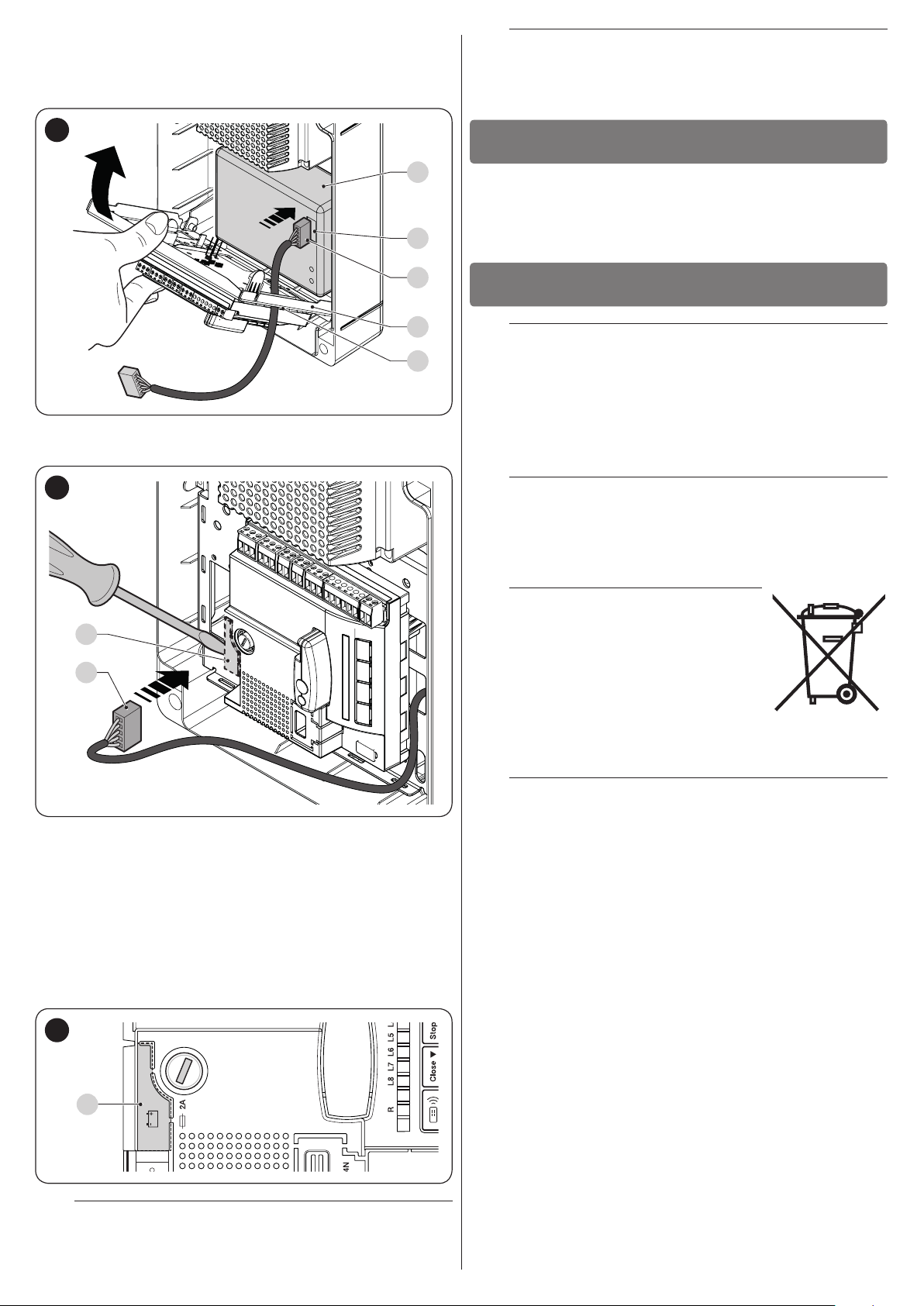

4.2.3 Operations for connection

To make the electrical connections (“Figure 7”):

8

1. remove the terminals from their housings

2. connect the various devices to the relevant terminals ac-

cording to the diagram shown in “Figure 7”

3. put the terminals back into their housings.

4. connect the power supply cable to points (A) and (B) and

secure it with the cable clamp (C) (“Figure 8”).

ENGLISH – 7

4.2.4 Notes on connections

STEP BY STEP

12 8 8 13

AUX

NC NCNO NOC C

Most of the connections are extremely easy to make, as they are

largely connections directed at a single user or contact. Below

are some examples on how to connect external devices.

Connection of the selector to carry out the “STEP-BY-STEP”

functions and one of those relevant to the AUX auxiliary input

(PARTIAL OPENING, OPEN ONLY, CLOSE ONLY, etc.) (“Figure 10”).

4.2.4.1 Stand-by all / Phototest connection

The “Stand-by all” function allows for reducing consumption and

is active as a standard feature. It is automatically excluded only

when the “Phototest” function activates.

Note The “Stand-by all” and “Phototest” functions are alterna-

tive, as one excludes the other.

The possible connection options are listed below:

– with “Stand-by all” active (energy saving) (“Figure 7 A”)

– without “Stand-by all” and without “Phototest” (standard con-

nection) (“Figure 7 B”)

– without “Stand-by all” and with “Phototest” (“Figure 7 C”).

With the “Stand-by all” function active, 1 minute after the end of

the manoeuvre the control unit enters the “Stand-by all” mode

by switching off all the inputs and outputs to limit consumption.

The relevant status is signalled by the “OK” LED, which starts

ashing more slowly.

If the control unit is powered with a photovoltaic

m

panel (“Solemyo” system) or with a back-up battery, the “Stand-by all” function must be activated

as shown in the “energy saving” diagram (“Figure

7 A”).

When the “Stand-by all” function is not required, the “Phototest”

function can be activated, which can be used to verify – at the

start of each manoeuvre – whether the connected photocells are

working properly. To use this function, it is necessary to connect

the photocells appropriately (“Figure 7 C”) and then activate

the function.

Note By activating the “Phototest” function, the inputs sub-

ject to the testing procedure are PHOTO, PHOTO1 and

PHOTO2. If one of these inputs is not used, it must be

connected to the “PHOTOTEST” terminal (number 5)

("Figure 7 D").

10

4.2.4.3 Connecting the Open Gate Indicator / Electric

Lock

The OGI (Open Gate Indicator) output, if suitably programmed,

can be used as a “Open Gate Indicator”. The indicator light

will ash slowly during the opening phase and quickly during

the closing phase. It will remain steady lit with the gate open

(stopped) and off with the gate closed. If the output is programmed as an electric lock, it activates for 3 seconds whenever an opening manoeuvre starts (“Figure 11”).

11

3 4

4.2.4.2 Key selector connection

Connection of the key selector to perform the “STEP-BY-STEP”

and “STOP” functions (“Figure 9”).

9

STEP BY STEP

NC NCNO NOC C

12 8 8 9

To connect ALT (STOP) with the “Stand-by all” func-

m

tion active, use terminal no. 5 and not no. 8 (see the

“Stand-by all / Phototest connection” paragraph).

ALT

3

4

OGI

33Vc

max 5 W

EL

12Va

max 15 VA

4.2.5 ALT (STOP) input type

The MC424L control unit can be programmed to congure two

types of ALT (STOP) inputs:

– NC-type STOP for NC contacts

– Fixed resistor STOP type for connecting devices with 8.2 kΩ

xed resistor output (e.g. sensitive edges) to the control unit.

The input measures the resistor’s value and removes the manoeuvre consent when the resistor exceeds the nominal value. With suitable arrangements, normally open (NO), normally

closed (NC) and even multiple devices of a different type can

be connected to the ALT input, congured as a xed resistor

(see “Table 3”).

Table 3

FIXED RESISTOR STOP INPUT

FIRST device type

NO NC 8.2 kΩ

NO

type

NC [Note 2]

SECOND device

8.2 kΩ

In parallel

[Note 1]

In parallel In series

[Note 2]

In series

[Note 3]

In parallel

In series

[Note 4]

8 – ENGLISH

Note 1 One or more NO devices can be connected in parallel

8

9

NO NO

8,2KΩ

8

9

NO

NC

8,2KΩ

8

9

NC NC

8,2KΩ

to one another without any quantity limitation with an 8.2

kΩ termination resistor (“Figure 12”). For electrical connections with the “Stand-by all” function active, refer to

the “Stand-by all / Phototest connection” paragraph.

To connect ALT (STOP) with the “Stand-by all” func-

m

tion active, use terminal no. 5 and not no. 8 (see the

“Stand-by all / Phototest connection” paragraph).

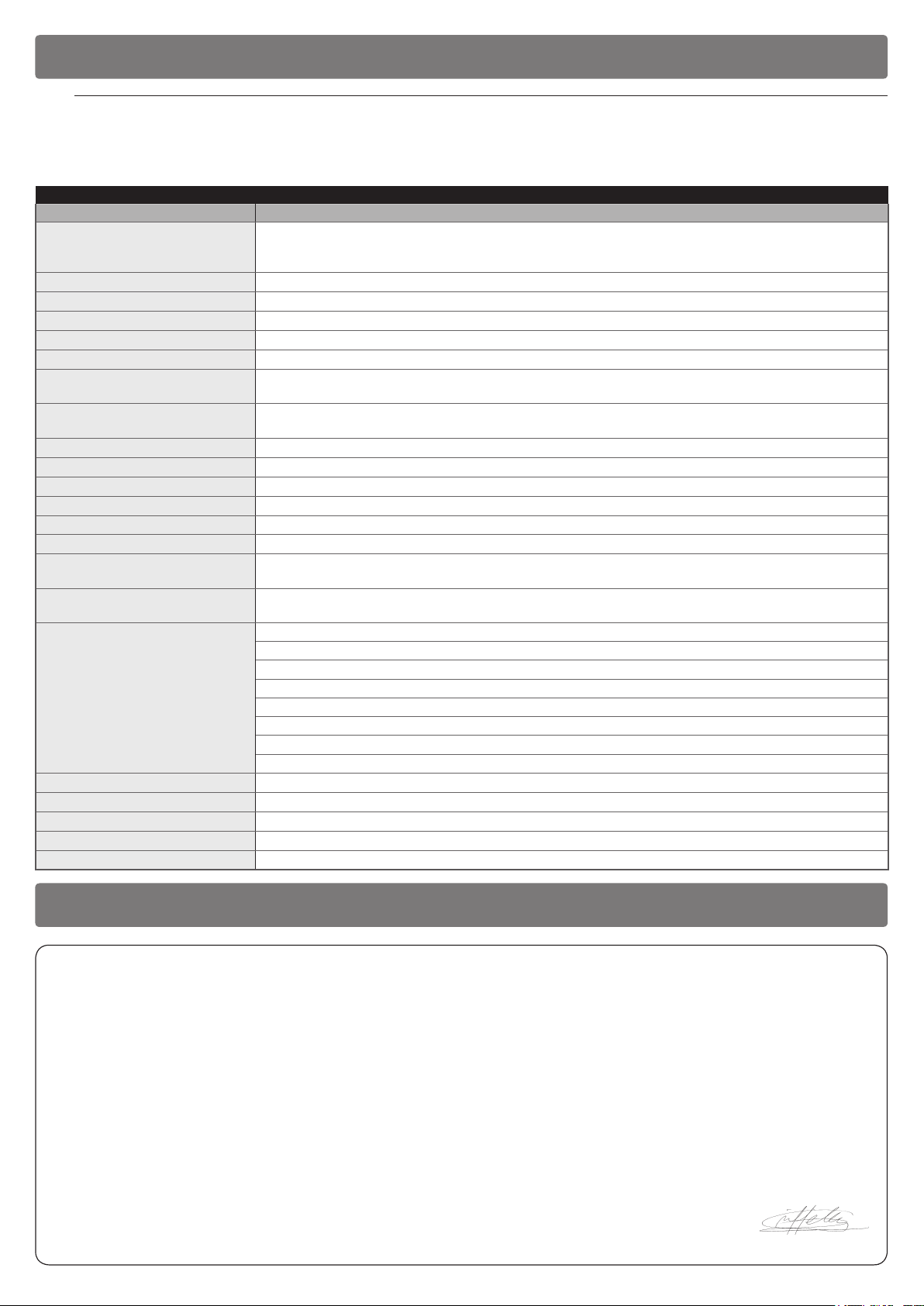

4.3 INITIAL START-UP AND ELECTRICAL

CONNECTIONS TEST

After powering the control unit, carry out the following checks:

1. check that terminals “6-7” have roughly 30 VDC voltage

(“Figure 16”). If the values do not match up, immediately

disconnect the power supply and carefully check the connections and supply voltage.

16

12

Note 2 Multiple devices can be connected as NO and NC con-

tacts in parallel, taking care to place a 8.2 kΩ resistor in

series with the NC contact (this also allows for combining 3 devices: NO, NC and 8.2 kΩ (“Figure 13”).

13

Note 3 One or more NC-type devices can be connected in se-

ries to one another and to an 8.2 kΩ resistor without any

quantity limitation (“Figure 14”).

M M 5 6 7 8 9 10 11 12 131 2 3 4M M

2. after the quick initial ash, the “OK” LED will signal the

correct operation of the control unit by ashing regularly

every second. When there is a variation on the control unit

inputs, the “OK” LED will emit a quick double ash to sig-

nal that the input has been recognised

3. if the connections have been made correctly the “NC”-

type inputs must have the corresponding LED lit, while the

“NO”-type inputs must have the corresponding LED off

(refer to “Figure 17“ and to “Table 4”).

17

L10

L12

L9

OK

L11

L13

14

Note 4 Only one device with 8.2 kΩ xed resistor output can

be connected; if needed, multiple devices must be connected “in cascade” mode with a single 8.2 kΩ termination resistor (“Figure 15”).

15

1 2

8

9

Sensitive

edge

Sensitive

edge

n

Sensitive

edge

8,2kΩ

INPUT-LED MATCHES

Input Type of input LED status

L9 lit

(Only after point 5)

L9 lit

(Only after point 5)

ALT

(STOP)

FOTO

(PHOTO)

FOTO1

(PHOTO1)

Sbs

AUX

ALT (STOP) NC

8.2 kΩ FIXED RESISTOR

STOP

NC L10 lit

NC L11 lit

NO L12 off

PARTIAL OPEN type 1 - NO L13 off

PARTIAL OPEN type 2 - NO L13 off

OPEN ONLY - NO L13 off

CLOSE ONLY - NO L13 off

PHOTO2 - NC L13 lit

Table 4

ENGLISH – 9

4. verify that, when intervening on the devices connected to

1

2 3 4

1

2 3 4

1

O

2 3 4

1

O

2 3 4

1

2 3 4

1

O

2 3 4

1

2 3 4

1

2 3 4

the inputs, the corresponding LEDs switch off or on

5. verify that, when pressing the “[Stop/Set]” button and

[Close

] (“Figure 18”) for over 3 seconds, both the mo-

q

tors complete a brief opening manoeuvre with the upper

leaf motor starting rst. Stop the manoeuvre by pressing

the [Stop/Set] button. LED “L9” (“Figure 17”) must switch

on to signal the correct self-recognition.

SELECTING THE MOTOR TYPE

Motor type Motor selector

O

TOO4524

XME2024

N

O

N

18

If the motors do not start for the opening manoeu-

l

vre, invert the polarity of the motor cables. If the

rst motor to move is not the one associated with

the upper leaf, invert M1 with M2.

If any one of these tests fails, disconnect the pow-

a

er supply to the control unit and check the various

electrical connections made previously.

4.4 MOTOR SELECTOR

The control unit is equipped with a selector (A - “Figure 19”) that

allows for specifying which type of motor to use (see “Table 5”).

4.5 AUTOMATIC LIMIT SWITCH SEARCH AND “STOP” INPUT ACQUISITION

Once the checks have been completed, the automatic search

for mechanical stop devices connected to the control unit can

start. This operation is necessary, as the control unit must detect

the duration of the opening and closing manoeuvres. The procedure is entirely automatic and consists in measuring the motor

effort to detect the mechanical stop devices during the opening

and closing phases.

Before starting the limit switch search, check that

m

all the safety devices give their consent (STOP,

PHOTO and PHOTO1 enabled). The intervention of

a safety device or the arrival of a command during

the procedure causes its immediate interruption.

The leaves MUST be positioned roughly halfway

along their path.

20

19

Any conguration not appearing in “Table 5” is not

m

allowed.

SELECTING THE MOTOR TYPE

Motor type Motor selector

O

Generic

WG2024

WG3524

WG4024

WG5024

TOO3024

N

O

N

N

N

O

N

N

A

Table 5

Press [Stop/Set] and [Close q] (“Figure 20”) for over 3 sec-

onds to start the automatic search phase.

The procedure entails:

– control and memorisation of the motor selector

– control and memorisation of the ALT input (NC / 8.2 kΩ)

– brief opening of both motors

– closing of the lower leaf motor up to the mechanical stop for

the closing phase

– closing of the upper leaf motor up to the mechanical stop for

the closing phase

– start of upper leaf motor opening

– after the programmed offset, start of the lower leaf opening

movement

– the control unit will measure the movement required so that

the motors can reach the mechanical stops for the opening

phase

– the control unit runs the complete closing manoeuvre. The

motors can start at different times. The aim is to have a stag-

gered closing of the leaves so as to avoid potential shearing

between the leaves

– end of the procedure with memorisation of all the measure-

ments recorded.

All these phases occur one after the other, without

m

any intervention by the operator.

If, for any reason, the procedure fails to advance

m

correctly, it must be interrupted by pressing the

[Stop/Set] button. The procedure must then be repeated (if necessary, by modifying the parameters,

for example the amperometric device thresholds

and the leaf delay – consult the “PROGRAMMING”

chapter).

10 – ENGLISH

This procedure can be repeated without having to

l

delete the memory.

5

5 TESTING AND COMMISSIONING

These are the most important phases of the automation’s con-

struction, as they ensure maximum safety of the system. The

test can also be used to periodically verify the devices making

up the automation.

Testing and commissioning of the automation must be per-

formed by skilled and qualied personnel, who are responsible

for the tests required to verify the solutions adopted according

to the risks present, and for ensuring that all legal provisions,

standards and regulations are met, in particular all the requirements of the EN 12445 standard, which denes the test methods for checking gate automations.

The additional devices must undergo specic testing, both in

terms of their functions and their proper interaction with the control unit. Refer to the instruction manuals of the individual devices.

TESTING AND COMMISSIONING

5.1 TESTING

The sequence of steps to be performed when running the testing phase, as described below, refers to a typical system (“Fig-

ure 3”).

To run the test:

1. check that the activation of the STEP-BY-STEP (Sbs) input

triggers the “Open, Stop, Close, Stop” sequence

2. check that the activation of the AUX input (Type 1 partial

opening function) manages the “Open, Stop, Close, Stop”

sequence only for the upper leaf motor. The lower leaf motor must remain still during the closing phase

3. start an opening manoeuvre and verify that:

– when engaging FOTO (PHOTO) the gate continues the

opening manoeuvre

– when engaging FOTO1 (PHOTO1) the manoeuvre

stops until FOTO1 is disengaged. Subsequently, the

manoeuvre will resume the opening movement

– with FOTO2 (PHOTO2), after engaging this device, the

manoeuvre must stop and restart during the closing

phase

4. verify that when the leaf reaches the mechanical stop for

the opening phase, the motors switch off

5. start a closing manoeuvre and verify that:

– when engaging FOTO, the manoeuvre stops and re-

starts during the opening phase

– when engaging FOTO1 (PHOTO1) the manoeuvre

stops until FOTO1 is disengaged. Subsequently, the

manoeuvre will resume the opening movement

– when engaging FOTO2, the gate continues the closing

manoeuvre

6. verify that the stoppage devices connected to the STOP

input cause the immediate stoppage of any movement under way and a brief reversal

7. check that the level of the obstacle detection system is

suited to the application: during the manoeuvre, during

both the opening and closing phases, prevent the leaf’s

movement by simulating an obstacle and verify that the

manoeuvre reverses before exceeding the force specied

in the regulations

8. other checks can be necessary depending on the devices

connected to the inputs.

If an obstacle is detected for two consecutive ma-

a

noeuvres in the same direction, the control unit will

perform a partial reversal of both motors for one

second only. After the next command is given, the

leaves will start opening and the rst intervention of

the amperometric device for each motor will be regarded as a mechanical stop for the opening phase.

The same behaviour occurs when the mains power

supply is restored: the rst command is always an

opening command and the rst obstacle is always

regarded as a mechanical stop for the opening

phase.

5.2 COMMISSIONING

Commissioning can only be performed after all test-

a

ing phases have been successfully completed.

Before commissioning the automation, ensure that

a

the owner is properly informed of all residual risks

and hazards.

To commission the automation:

1. compile the automation’s technical le, which must in-

clude the following documents: overall drawing of the

automation, wiring diagram, risk assessment and relative

solutions adopted, the manufacturer’s declaration of conformity for all devices used and the declaration of conformity compiled by the installer

2. afx a data plate on the gate specifying at least the fol-

lowing data: type of automation, name and address of

the manufacturer (responsible for commissioning), serial

number, year of manufacture and CE mark

3. compile the declaration of conformity of the automation

and hand it to the owner of the automation

4. compile the User Manual of the automation and hand it to

the owner of the automation

5. compile and provide the owner with the automation’s

“Maintenance schedule”, containing the maintenance instructions for all the automation’s devices.

For all the above-mentioned documentation, Nice –

l

through its technical assistance service – provides

the following: pre-completed forms.

6

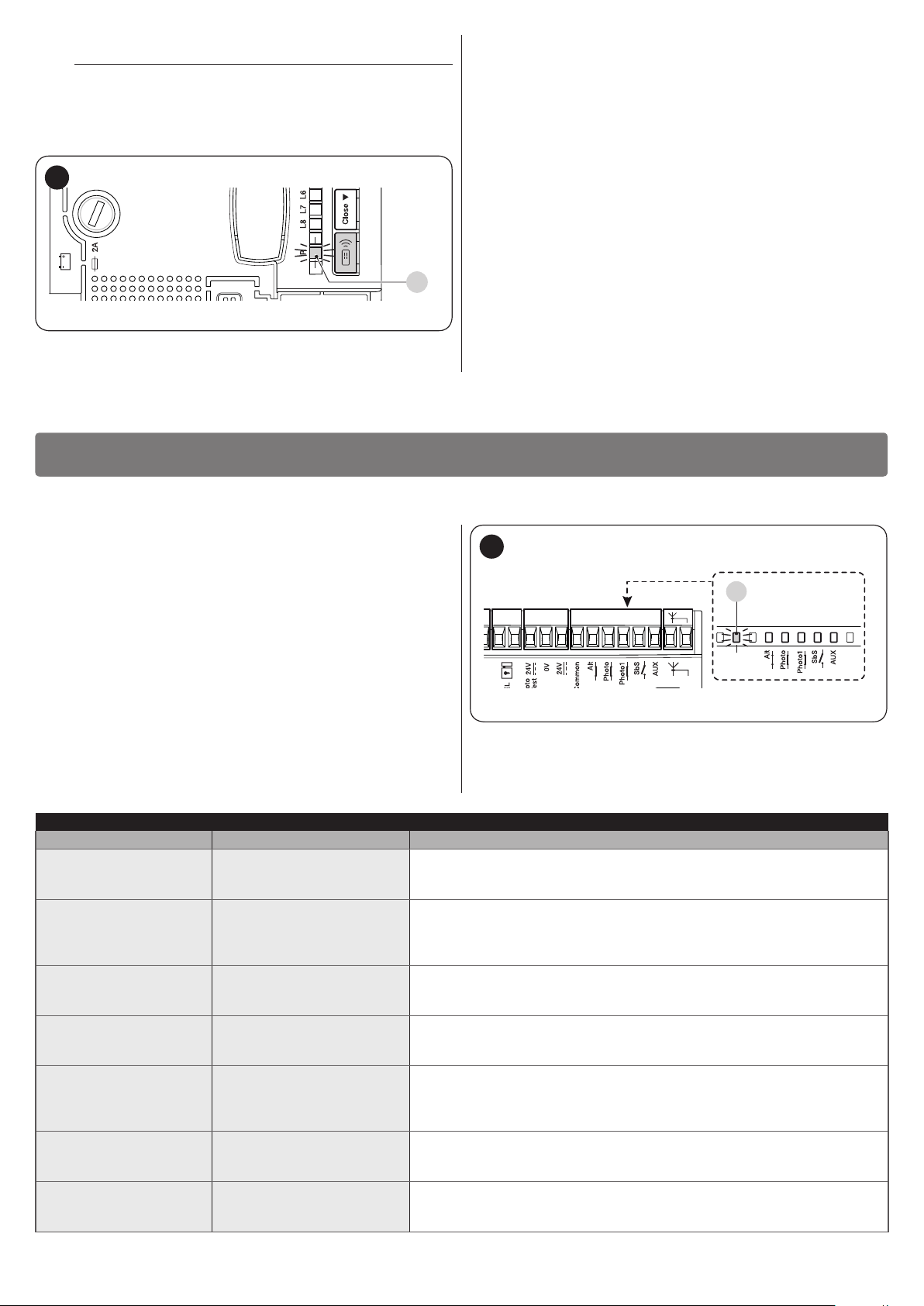

6 PROGRAMMING

There are 4 buttons on the control unit: [Open p], [Stop/Set],

[Close

both for commanding the control unit during the testing phases

and for programming the available functions.

21

PROGRAMMING

] and [Radio R] (“Figure 21”), which can be used

q

L1 L8

..

LR

The programmable functions available are arranged on two levels and their operating status is signalled by the eight LEDs “L1

... L8” and by the “LR” LED present on the control unit (LED lit =

function active; LED off = function not active).

6.1 USING THE PROGRAMMING BUTTONS

[Open p]:

– Button for commanding the gate opening

– Selection button during the programming phase.

[Stop/Set]:

– Button used to stop a manoeuvre

– If pressed for more than 5 seconds, it allows for entering the

programming mode.

[Close

– Button for commanding the gate’s closure

– Selection button during the programming phase.

q

]

ENGLISH – 11

6.2 PRE-SET FUNCTIONS

The control unit has a few programmable functions, which are

pre-set in a typical conguration that suits most automations (see

“Table 6”). The functions can be modied at any time, both be-

fore and after the automatic limit switch search phase, through

appropriate programming procedures described below.

PRE-SET FUNCTIONS

Function Pre-set value

Automatic closing

Condominium

Pre-ashing

Close after photo

Opening delay

Stand-by all / Phototest

Electric lock / OGI

ALT (STOP) input

Heavy gates

Pause time

Auxiliary input

Amperometric sensitivity

active

disabled

disabled

disabled

level 5 (20%)

Stand-by all

Electric lock

self-recognition NC / 8.2 kΩ

disabled

30 seconds

Type 1 partial opening (activates

upper leaf motor only)

level 3

Table 6

6.3 LEVEL 1 PROGRAMMING (ON-OFF)

All the Level 1 functions are set by default to “OFF” and can be modied at any time. Refer to “Table 7” to check the various func-

tions.

6.3.1 Level 1 programming procedure

The user has maximum 10 seconds to press the buttons consecutively during the programming procedure,

m

after which time the procedure terminates automatically and memorises the changes made up to then.

To perform Level 1 programming:

1. press and hold the [Stop/Set] button until LED “L1” starts ashing

2. press the [Open

] or [Close q] button to move the ashing LED to the LED associated with the function to be modied

p

3. press the [Stop/Set] button to change the status of the function:

– short ash = OFF

– long ash = ON

4. wait 10 seconds (maximum time) to exit the programming mode.

To set other functions to “ON” or “OFF”, while the procedure is running, repeat points 2 and 3 during the phase

l

itself.

LEVEL 1 FUNCTIONS (ON-OFF)

LED Function Description

Function ENABLED: after an opening manoeuvre there is a pause (equal to the set pause time), after

L1 Automatic closing

L2 Close after photo

L3 Always Close

Stand-by /

L4

Phototest

which the control unit automatically starts a closing manoeuvre. The pause time is set by default to 30

seconds. Pressing the [Stop/Set] button or the intervention of the “STOP” input stop the cycle.

Function NOT ENABLED: the system works in “semi-automatic” mode.

Function ENABLED: if the photocells intervene during the opening or closing manoeuvre, the pause

time drops to 4 seconds regardless of the set “pause time”. With “automatic closing” deactivated, if the

photocells intervene during the opening or closing manoeuvre, the “automatic closing” activates with a

4-second “pause time”.

Function ENABLED: in the event of a blackout, even of short duration, 10 seconds after the electricity

is restored the control unit detects that the gate is open and automatically starts a closing manoeuvre,

preceded by 5 seconds of pre-ashing.

Function ENABLED: phototest.

Instead of the “Stand-by all” function, the user can activate the “Phototest” function, which veries

whether the photocells function properly at the start of a manoeuvre. To use this function, the connect the

photocells correctly (see “Figure 7 C”) then activate the function.

Function NOT ENABLED: stand-by.

The control unit has the “Stand-by all” function set by default; if it is active, 1 minute after the end of the

manoeuvre the control unit switches off the “Stand-by all” function (terminal 5), all the inputs and the other

outputs to limit consumption (see “Figure 7 A”). This function is mandatory if the control unit is powered

exclusively through Solemyo photovoltaic panels. It is recommended even if the control unit is powered

from the mains and the user wishes to increase the emergency mode operation with the PS124 back-up

battery.

Table 7

12 – ENGLISH

LEVEL 1 FUNCTIONS (ON-OFF)

LED Function Description

Electric lock /

L5

OGI (Open Gate

Indicator)

L6 Pre-ashing

Condominium

L7

function

L8 Light/Heavy Gates

Function ENABLED: OGI (Open Gate Indicator).

If the function is enabled, terminals 3-4 can be used to connect an open gate indicator light (24 V).

Function NOT ENABLED: electric lock.

If the function is not enabled, terminals 3-4 can be used to connect the electric lock.

Function ENABLED: the warning light starts ashing 3 seconds before the start of the manoeuvre to

signal in advance a dangerous situation.

Function NOT ENABLED: the warning light starts ashing when the manoeuvre starts.

Function ENABLED: each command received triggers an opening manoeuvre that cannot be interrupted

by subsequent command impulses.

Function NOT ENABLED: each command received triggers an OPEN-STOP-CLOSE-STOP sequence,

which is useful when many people use the automation with radio commands.

Function ENABLED: if the function is enabled, the control unit can be congured to control heavy gates

by setting the acceleration ramp and closing slowdown speeds differently.

Function NOT ENABLED: if the function has not been enabled, the control unit is set for controlling light

gates.

6.4 LEVEL 2 PROGRAMMING (ADJUSTABLE PARAMETERS)

All Level 2 parameters are set by default as shown under “GREY” in “Table 8” and can be modied at any time. The parameters

can be adjusted to a value between 1 and 8. To check the value corresponding to each LED, refer to “Table 8”.

6.4.1 Level 2 programming procedure

The user has maximum 10 seconds to press the buttons consecutively during the programming procedure,

m

after which time the procedure terminates automatically and memorises the changes made up to then.

To perform Level 2 programming:

1. press and hold the [Stop/Set] button until LED “L1” starts ashing

2. press the [Open

modied

3. press and hold the [Stop/Set] button. With the [Stop/Set] button pressed:

– wait roughly 3 seconds, until the LED representing the current level of the parameter to be modied lights up

– press the [Open

4. release the [Stop/Set] button

5. wait 10 seconds (maximum time) to exit the programming mode.

] or [Close q] button to move the ashing LED to the “entry LED” associated with the parameter to be

p

] or [Close q] button to shift the LED associated with the parameter’s value

p

To set multiple parameters during the procedure's execution, repeat the operations from point 2 to point 4 dur-

l

ing the phase itself.

The set value highlighted in grey (“Table 8”) indicates that is the default value.

l

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry

LED

L1 Pause Time

Parameter

LED

(level)

L1 5 seconds

L2 15 seconds

L3 30 seconds

L4 45 seconds

L5 60 seconds

L6 80 seconds

L7 120 seconds

L8 180 seconds

Set value Description

Adjusts the pause time, in other words, the time that elapses before

automatic re-closure. It is only effective if the Close function is

enabled.

Table 8

ENGLISH – 13

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry

LED

Parameter

LED

(level)

Set value Description

L1 Type 1 partial open

L2 Type 2 partial open

L3 Open only

L4 Close only

L5 Photo 2

L6 Stop (stops the manoeuvre)

L2 AUX input

L7 Excluded

L8 Excluded

L1 Open: 40%; Close: 40%

L2 Open: 60%; Close: 40%

L3 Open: 80%; Close: 40%

L3 Motor speed

L4 Open: 80%; Close: 60%

L5 Open: 80%; Close: 80%

L6 Open: 100%; Close: 60%

L7 Open: 100%; Close: 80%

L8 Open: 100%; Close: 100%

L1 No discharge

L2 0.2 seconds

L3 0.4 seconds

L4

Motor

discharge after

closing

L4 0.6 seconds

L5 0.8 seconds

L6 1.0 seconds

L7 1.2 seconds

L8 1.4 seconds

L1 Level 1 - Minimum force Adjusts the force of both motors.

L2 Level 2 - ...

L3 Level 3 - ...

L4 Level 4 - ...

L5 Level 5 - ...

L6 Level 6 - ...

L5

Motor force

(amperometric

L7 Level 7 - ...

sensitivity)

L8 Level 8 - Maximum force

L1 0%

L2 5%

L3 10%

L6 Leaf delay

L4 15%

L5 20%

L6 30%

L7 40%

L8 50%

The control unit has an auxiliary input that can be congured with

one of the following 6 functions.

Type 1 partial opening: performs the same function as the STEPBY-STEP input, triggering the opening of the upper leaf only. It

only works with the gate fully closed, otherwise the command is

interpreted as if it were a STEP-BY-STEP command.

Type 2 partial opening: performs the same function as the STEPBY-STEP input, triggering the opening of the two leaves for half the

time it takes for full opening. It only works with the gate fully closed,

otherwise the command is interpreted as if it were a STEP-BY-STEP

command.

Open Only: this input performs opening only with the Open-StopOpen-Stop sequence.

Close Only: this input performs closing only with the Close-StopClose-Stop sequence.

Photo 2: performs the function of the “PHOTO 2” safety device.

Excluded: this input does not manage any function.

Adjusts the motor speed during normal travel.

Adjusts the duration of the “brief reversal” of both motors, after

completing the closing manoeuvre, to reduce the residual nal

thrust.

The control unit features a system that measures the current

absorbed by the two motors and used to detect the mechanical

limit switches and any obstacles during the gate’s movement. As

the absorbed current depends on variable conditions (weight of the

gate, sources of friction, wind gusts, voltage uctuations, etc.), the

intervention threshold can be modied. There are 8 levels: level 1

is the most sensitive level (minimum force), while level 8 is the least

sensitive (maximum force).

Increasing the degree of amperometric sensitivity increases the

slowdown speed during the gate closing manoeuvre.

WARNING! – The suitably adjusted “amperometric” function

(together with other indispensable arrangements) can be

useful to ensure compliance with the EN 12453 and EN 12445

standards, which require the use of techniques or devices that

limit the force and dangerousness associated with automatic

door and gate movements.

Adjust the closing delay for the upper leaf motor.

It is programmed as a percentage of the work time.

The opening delay is half the time of the closing delay.

14 – ENGLISH

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry

LED

L7

L8

Parameter

Maintenance

notication

List of

malfunctions

LED

(level)

L1 500

L2 1000

L3 1500

L4 2500

L5 5000

L6 10000

L7 15000

L8 20000

L1 Result of 1

L2 Result of 2

L3 Result of 3

L4 Result of 4

L5 Result of 5

L6 Result of 6

L7 Result of 7

L8 Result of 8

Set value Description

st

nd

rd

manoeuvre

th

manoeuvre

th

manoeuvre

th

manoeuvre

th

manoeuvre

th

manoeuvre

Adjusts the number of manoeuvres after which

the automation maintenance request is triggered

(see the “Maintenance notication” paragraph).

manoeuvre (most recent)

manoeuvre

Allows for verifying the type of anomaly that

occurred in the last 8 manoeuvres (see “Anomaly

log” paragraph).

6.5 MEMORY DELETION

The procedure described below restores the con-

m

trol unit’s default settings. All the custom settings

will be lost.

22

L1 L8

..

To delete the control unit’s memory and restore all the default

settings, proceed as described below:

1. press and hold the [Open

the programming LEDs “L1-L8” light up (after roughly 3

seconds)

2. release the buttons

3. if the operation was successful, the programming LEDs

“L1-L8” ash quickly for 3 seconds.

The following features will be deleted: STOP cong-

l

uration, limit switch positions, Level 1 and Level 2

programming, number of manoeuvres. The memorised transmitters will not be deleted.

] and [Close q] buttons until

p

6.6.1.1 STANDARD memorisation (Mode 1: all buttons)

Procedures of this kind allow for simultaneously memorising,

during their execution, all the buttons on the transmitter. The

system automatically associates each button with a pre-dened

command, according to the following scheme:

Table 9

TRANSMITTER FUNCTION PAIRINGS

Command Button

1 - Step-by-Step

2 - AUX

3 - OPEN

4 - CLOSE

Will be paired with button 1

Will be paired with button 2

Will be paired with button 3

will be paired with button 4 (if

present on the transmitter).

6.6.1.2 CUSTOM memorisation (Mode 2: one button

only)

Procedures of this kind allow for memorising, during their execution, a single button among those present on the transmitter.

The following commands can be paired with the buttons: Step-

by-Step, AUX, OPEN, CLOSE.

The installer decides which button to associate with the command on the basis of the automation’s needs.

6.6.2 Number of transmitters that can be memorised

The control unit’s receiver has 100 memory locations. A location

can memorise either a single transmitter (i.e. the combination of

its buttons and commands) or a single button with the relative

command.

6.6 MEMORISING THE TRANSMITTERS

The control unit incorporates a radio receiver compatible with all

transmitters that adopt the following NICE radio encoding protocols: FLO, FLOR, O-CODE and SMILO.

6.6.1 Procedure for memorising transmitter buttons

Among the available procedures for memorising transmitters,

some allow for memorising in “standard” mode (or Mode 1) and

others in “custom” mode (or Mode 2).

6.6.3 Transmitter memorisation and deletion procedures

To perform the procedures A, B, C and D described

a

below, the control unit’s memory must be unlocked.

If the memory is locked, perform the unlocking procedure described in the “LOCKING AND UNLOCK-

ING THE MEMORY” paragraph

ENGLISH – 15

23

LR

6.6.3.1 PROCEDURE A - Memorising ALL buttons of a

single transmitter (STANDARD mode or Mode 1)

To perform this procedure:

1. on the control unit: press and hold the [Radio

ton until the “LR” LED lights up

2. release the button [Radio

3. (within 10 seconds) on the transmitter to be memorised:

press and hold any button and wait until the “LR” LED

emits 3 long ashes (= memorisation completed correctly)

4. release the transmitter button.

After the 3 long ashes a further 10 seconds remain

l

to memorise an additional transmitter (if desired),

starting from step 3.

The “LR” LED can also emit the following signals: 1

l

fast ash, if the transmitter is already memorised, 6

ashes, if the transmitter’s radio encoding system

is not compatible with that of the control unit’s receiver, or 8 ashes, if the memory is full.

6.6.3.2 PROCEDURE B - Memorising a SINGLE BUTTON

of a transmitter (CUSTOM mode or Mode 2)

To perform this procedure:

1. choose the command to be paired with the relevant button

to be memorised:

– for no. 1 - “Step-by-Step” press the [Radio

once

– for no. 2 - “AUX” press the [Radio

– for no. 3 - “OPEN” press the [Radio

times

– for no. 4 - “CLOSE” press the [Radio

times

2. on the control unit: press and release the [Radio

button for a number of times corresponding to the desired

command, as shown near the command selected beforehand at step 1.

3. (within 10 seconds) on the transmitter: press and hold

the button to be memorised and wait for the “LR” LED to

emit 3 long ashes (= memorisation completed correctly)

4. release the transmitter button.

After the 3 long ashes a further 10 seconds remain

l

to memorise an additional button (if desired), starting from step 1.

The “LR” LED can also emit the following signals: 1

l

fast ash, if the transmitter is already memorised, 6

ashes, if the transmitter’s radio encoding system

is not compatible with that of the control unit’s receiver, or 8 ashes, if the memory is full.

R

]

] button twice

R

R

R

] but-

R

] button

R

] button 3

] button 4

R

6.6.3.3 PROCEDURE C - Memorising a transmitter by

means of another transmitter already memorised

(memorisation far from the control unit)

This procedure can be used to memorise a new transmitter by

means of a second transmitter, already memorised in the same

control unit. In this way, the new transmitter can receive the

same settings as those of the memorised transmitter. The user

does not have to intervene directly on the control unit’s [Radio

] button, as the procedure is simply carried out within the

R

control unit’s radius of reception.

To perform this procedure:

1. on the transmitter to be memorised: press and hold the

button to be memorised

2. on the control unit: after a few seconds (roughly 5) the

“LR” LED lights up

3. release the transmitter button

4. on the transmitter already memorised: press and slowly

release 3 times the memorised button to be copied

5. on the transmitter to be memorised: press and hold the

same button pressed at point 1 and wait for the “LR” LED

to emit 3 long ashes (= memorisation completed correctly)

6. release the transmitter button.

The “LR” LED can also emit the following signals: 1

l

fast ash, if the transmitter is already memorised, 6

ashes, if the transmitter’s radio encoding system

is not compatible with that of the control unit’s receiver, or 8 ashes, if the memory is full.

6.6.3.4 PROCEDURE D - Deleting a single transmitter

(if memorised in Mode 1) or a single transmitter

button (if memorised in Mode 2)

To perform this procedure:

1. on the control unit: press and hold the [Radio

ton

2. after roughly 4 seconds, the “LR” LED will light up steady

(continue holding down the [Radio

3. on the transmitter to be deleted from the memory:

press and hold a button (*) until the “LR” LED (on the con-

trol unit) emits 5 fast ashes (or 1 ash if the transmitter or

button is not memorised).

4. release the [Radio

(*) If the transmitter is memorised in Mode 1, any button

]

6.6.3.5 PROCEDURE E - Deleting ALL memorised

To perform this procedure:

1. on the control unit: press and hold the [Radio

2. after roughly 4 seconds, the “LR” LED will light up steady

3. after roughly 4 seconds, the “LR” LED will turn off (contin-

4. when the “LR“ LED starts ashing, count 2 ashes and

5. during the deletion process, the “LR” LED will ash rapidly

6. the “LR” LED will emit 5 long ashes to signal that the

can be pressed and the control unit will delete the entire transmitter. If the transmitter is memorised in Mode

2, it is necessary to press the memorised button to be

deleted. To delete further buttons memorised in Mode 2,

repeat the entire procedure for every button to be deleted.

transmitters

ton

(continue holding down the [Radio

ue holding down the [Radio

prepare to release the button precisely during the 3rd

ash that follows

deletion has been completed correctly.

R

] button.

R

R

R

] button

] button

] button

R

R

] but-

] but-

16 – ENGLISH

6.7 LOCKING AND UNLOCKING THE MEMORY

2

WARNING! - This procedure locks the memory, pre-

a

venting the execution of Procedures A, B, C and D

described in the “Transmitter memorisation and de-

letion procedures“ paragraph

24

LR

Procedure for locking/unlocking the memory:

1. disconnect the control unit from the power supply

2. press and hold the [Radio

R

] button

3. power the control unit again (by pressing down the [Radio

] button)

R

4. after 5 seconds the “LR” LED will emit 2 slow ashes

5. release the button [Radio

6. (within 5 seconds) repeatedly press the [Radio

R

]

] but-

R

ton to select one of the following options:

– disabling of the memory lock function = LED off

– enabling of the memory lock function = LED on

7. ve seconds after last pressing the button, the “LR” LED

will emit 2 slow ashes to signal the end of the procedure.

7

7 TROUBLESHOOTING... (troubleshooting guide)

Some devices are congured for signalling the operating status or the presence of any anomalies.

7.1 SIGNALLING THROUGH WARNING LIGHT

If a warning light is connected to the FLASH output on the control unit, the light will ash once every 1 second while the manoeuvre is being performed.

If any anomalies occur, the warning light will emit slow ashes

repeated twice with a 1-second interval. “Table 10” describes

the cause and possible solutions for each type of anomaly signalled by the warning light.

In case of anomaly, the “OK” LED will also emit signals. “Table

10” describes the cause and possible solutions for each type of

anomaly signalled by the “OK” LED.

SIGNALS EMITTED BY THE OK LED (“FIGURE 25”) AND WARNING LIGHT

Flashes Anomaly Possible solution

2 short red ashes

1-second pause

2 short red ashes

3 short red ashes

1-second pause

3 short red ashes

4 short red ashes

1-second pause

4 short red ashes

5 short red ashes

1-second pause

5 short red ashes

6 short red ashes

1-second pause

6 short red ashes

7 short red ashes

1-second pause

7 short red ashes

8 short red ashes

1-second pause

8 short red ashes

(troubleshooting guide)

Intervention of a photocell

Intervention of the

“Obstacle Detection”

function through the force

limiter

Intervention of the ALT

(STOP) input

Error in the internal

parameters of the control

unit

The maximum limit for

consecutive manoeuvres or

manoeuvres per hour has

been exceeded

Electric circuit anomaly

A command that prevents

other commands from being

executed is already present

25

5 6 7 8 9 10 11 12 13

3 4

One or more photocells do not consent to the movement or have caused

the latter to reverse. Check for any obstacles.

During the gate’s movement, the motors encountered more resistance.

Verify the cause and increase the motor force if necessary.

At the start of the manoeuvre or during the movement itself, the ALT (STOP)

input intervened. Identify the cause.

Wait at least 30 seconds then try giving a command and disconnect the

power supply if necessary. If the condition persists, there may be a serious

malfunction and the electronic board needs to be replaced.

Wait for a few minutes until the manoeuvre limiting device drops to under

the maximum limit.

Wait at least 30 seconds then try giving a command and disconnect the

power supply if necessary. If the condition persists, there may be a serious

malfunction and the electronic board needs to be replaced.

Check the type of the “always present” command (for example, it could be

a command from a clock on the AUX input).

TROUBLESHOOTING...

OK

Table 10

ENGLISH – 17

7.2 SIGNALS ON THE CONTROL UNIT

The control unit has LEDs “L1-L8” on the buttons and LEDs “L9-

L13” and the “OK” LED on the control unit terminals (“Figure

26”).

Each of these LEDs can emit special signals, both during normal operation and in case of anomalies. “Table 11” and “Table

12” describe the cause and possible solution for every type of

anomaly.

SIGNALS OF THE LED ON THE CONTROL UNIT TERMINALS

Status Meaning Possible solution

All LEDs

Check whether the control unit is powered: measure on terminals 6-7 a

No LED is lit No power to the control unit

voltage of roughly 30 VDC (or 24 VDC if battery-powered).

Check the 2 fuses; if the OK LED is also not lit nor ashes, there may be a

serious fault, therefore the control unit must be replaced.

OK LED

Make sure there is power supply; verify whether the fuses are blown; if

OFF Anomaly

necessary, identify the reason for the failure then replace the fuses with

others of the same type

There is a serious anomaly; try switching off the control unit for a few

On Serious anomaly

seconds; if the condition persists, it means there is a fault and the circuit

board needs to be replaced

1 ash per second All OK

1 ash every 5 seconds All OK

2 quick ashes

The status of the inputs has

changed

The control unit works normally

Control unit in stand-by mode

This is normal when there is a change affecting one of the inputs: OPEN,

STOP, intervention of the photocells, or when the radio transmitter is used

Series of ashes

separated by a one-

Various This is the same signal as the one on the warning light (see “Table 10”)

second pause

STOP LED

OFF

Intervention of the ALT

(STOP) input

On All OK

Check the devices connected to the STOP input

STOP Input active

PHOTO LED

OFF

Intervention of the PHOTO

input

On All OK

Check the devices connected to the PHOTO input

PHOTO input active

PHOTO1 LED

OFF

Intervention of the PHOTO1

input

On All OK

Check the devices connected to the PHOTO1 input

PHOTO1 input active

Sbs LED

OFF All OK

On Intervention of the Sbs input

Sbs input not active

Normal if the device connected to the Sbs input is active

AUX LED

OFF All OK

On

Intervention of the AUX

input

AUX input not active

Normal if the device connected to the AUX input is active

26

6 7 8 9 10 11 12 13

L1 L8

..

OK

L9

L10

L11

L12

L13

Table 11

18 – ENGLISH

SIGNALS OF THE LED ON THE CONTROL UNIT BUTTONS

Status Meaning

L1 LED

OFF

On

Flashes

L2 LED

OFF

On

Flashes

L3 LED

OFF

On

Flashes

LED L4

OFF

On

Flashes

LED L5

OFF

On

Flashes

LED L6

OFF

On

Flashes

LED L7

OFF

On

Flashes

LED L8

OFF

On

Flashes

During normal operation, it signals that the “Automatic closing” mode is not active

During normal operation, it signals that the “Automatic closing” mode is active

Function programming in progress

During normal operation, it signals that the “Close after photo” mode is not active

During normal operation, it signals that the “Close after photo” mode is active

Function programming in progress

During normal operation, it signals that the “Always Close” mode is not active

During normal operation, it signals that the “Always Close” mode is active

Function programming in progress. If it ashes together with LED L4, the position recognition phase must be carried out

(see the “Automatic limit switch search and “STOP” input acquisition” paragraph)

During normal operation, it signals that the “Stand-by” mode is active

During normal operation, it signals that the “Phototest” mode is active

Function programming in progress. If it ashes together with LED L3, the position recognition phase must be carried out

(see the “Automatic limit switch search and “STOP” input acquisition” paragraph)

During normal operation, it signals the OGI output as OGI (open gate indicator)

During normal operation, it signals the OGI output as ELS (electric lock)

Function programming in progress

During normal operation it signals that the “Pre-ashing” mode is not active

During normal operation it signals that the “Pre-ashing” mode is active

Function programming in progress

During normal operation, it signals that the “Condominium” mode is not active

During normal operation, it signals that the “Condominium” mode is active

Function programming in progress

During normal operation, it signals that the “Light gates” mode is active

During normal operation, it signals that the “Heavy gates” mode is active

Function programming in progress

Table 12

7.3 MAINTENANCE NOTIFICATION

The control unit allows for notifying the user when to perform

maintenance on the automation. The signal is emitted once the

number of manoeuvres completed equals the value set for the

“Maintenance warning” adjustable parameter (see the “Table 8”

paragraph).

The maintenance request signal is emitted through the FLASH

warning light.

The FLASH warning light and the maintenance indicator emit the

signals indicated in “Table 13” based on the number of manoeu-

vres completed with respect to the set limit.

Table 13

MAINTENANCE SIGNALS

Number of manoeuvres

Below 80% of

the limit

Between 81%

and 100% of the

limit

Over 100% of

the limit

Signal on “Flash”

Normal (0.5 s on, 0.5 s

off)

At the start of the

manoeuvre, it remains

lit for 2 s then continues

normally

At the start and end of

the manoeuvre, remains

lit for 2 s then continues

normally

Signal on maintenance indicator

On for 2 s at the

start of opening

Flashes

throughout the

manoeuvre

Flashes always

7.4 ANOMALY LOG

The control unit can display any anomalies that have occurred

in the last 8 manoeuvres (for example, the interruption of a manoeuvre due to the intervention of a photocell or sensitive edge).

27

L1

L8

To check the list of anomalies:

1. press and hold the [Stop/Set] button for roughly 3 sec-

onds

2. release the [Stop/Set] button when the “L1” LED starts

ashing

3. press and release the [Open

] or [Close q] button to

p

shift ashing of the LED to “L8” (“Anomaly list” parameter)

4. keep the [Stop/Set] button pressed down (it must be kept

pressed throughout phases 5 and 6)

5. wait roughly 3 seconds, after which LED “L1” – corre-

sponding to the outcome of the last manoeuvre – will light

up

6. press and hold the [Open

] or [Close q] button to se-

p

lect the desired manoeuvre: the corresponding LED will

emit the same number of ashes as those normally emitted by the warning light after an anomaly (see “Table 10”)

7. release the [Stop/Set] button.

ENGLISH – 19

8

A

8 FURTHER INFORMATION (Accessories)

8.1 CONNECTING AN SM-TYPE RADIO RECEIVER

The control unit has a slot for mounting radio receivers with SM

connector (optional accessories) belonging to the SMXI and

OXI families, which can be used to remotely control the control

unit through transmitters that intervene on the unit’s inputs.

f

To install a receiver (“Figure 28”):

1. remove the cover of the control unit’s containment box

2. insert the receiver (A) in the appropriate slot (B) on the

3. put the cover of the control unit’s containment box back

At this stage, the control unit can be powered again.

28

(Accessories)

Before installing a receiver, disconnect the power

supply to the control unit.

control unit’s electronic board

on.

B

A

FURTHER INFORMATION

29

3. place the interface (B) in the appropriate slot (C) on the

control unit’s electronic board

4. insert the cable (D) in the appropriate slot (E) on the in-

terface.

30

B C

“Table 14” shows the receiver outputs and the control unit inputs

associated with each.

Table 14

SMXI / SMXIS OR OXI / OXIFM / OXIT / OXITFM IN MODE 1 OR MODE

2

Receiver output Control unit input

Output No. 1

Output No. 2

Output No. 3

Output No. 4

For further information, consult the specic manual

l

of the receiver.

Step-by-Step

AUX (pre-set value: Partial open 1)

“Open Only”

“Close Only”

8.2 CONNECTING THE IBT4N INTERFACE

The control unit is equipped with a “IBT4N”-type connector for

the IBT4N interface, which allows for connecting all devices

equipped with BusT4 interface, such as, for example, Oview

programmers and the IT4WIFI Wi-Fi interface.

The Oview programmer allows for comprehensively and rapidly

managing the installation, maintenance and diagnosis of the entire automated system.

Before connecting the interface, disconnect the

f

power supply to the control unit.

To install the interface (“Figure 29” and “Figure 30”):

1. remove the cover of the control unit’s containment box

2. remove the plastic pre-cut element (A) and check that

there are no burrs

DE

At this stage, the control unit can be powered again.

For further information, consult the specic manu-

l

als of the connected devices.

8.3 CONNECTING THE PS124 BACK-UP BATTERY

The control unit is congured for being powered with PS124

back-up batteries that intervene in case of a power outage.

Before installing a back-up battery, disconnect the

f

power supply to the control unit.

Before installing and connecting the back-up battery:

1. remove the cover of the control unit’s containment box

2. loosen the screw (A) and turn the panel (B)

31

A B

20 – ENGLISH

3. position the battery (C)

4. insert the connector (D) through the opening (E) and con-

nect it to the slot (F)

5. close the panel (B)

The “Solemyo” system can only be used if the

a

“Stand-by all” function is enabled (ON) on the control unit and if the connections are made as shown

in the diagram (A) in “Figure 7”.

32

C

F

D

B

E

6. remove the pre-cut element (G) and insert the connector

(H) into the slot located under the pre-cut element

33

9

9 PRODUCT MAINTENANCE

Being an electronic part, the control unit does not require any

special maintenance. Nonetheless, the system should be reg-

ularly checked to ensure that it works efciently at least every

6 months according to the instructions in the “TESTING AND

COMMISSIONING” chapter.

10

10 PRODUCT DISPOSAL

l

As with the installation, only qualied personnel must dismantle

the product at the end of its life.

This product is composed of different types of materials. Some

of these materials can be recycled; others must be disposed of.

Please enquire about the recycling or disposal systems in place

in your local area for this type of product.

a

PRODUCT MAINTENANCE

PRODUCT DISPOSAL

This product is an integral part of the operator and

must therefore be disposed of with it.

WARNING

Some parts of the product may contain polluting or

dangerous substances. If not disposed of correctly,

these substances may have a damaging effect on

the environment and human health.

G

H

7. put the cover of the control unit’s containment box back

on.

At this stage, the control unit can be powered again.

8.4 CONNECTING THE SOLEMYO SYSTEM

The control unit is congured for being powered with the “Solemyo” photovoltaic system (photovoltaic panel and 24 V battery).

To connect the Solemyo battery to the control unit, remove the

pre-cut element (A) and use the same connector normally used

for the back-up battery.

34

As indicated by the symbol shown

l

here, this product must not been

disposed of with household

waste. Separate the waste for disposal and recycling, following the

methods stipulated by local regulations, or return the product to

the seller when purchasing a new

product.

WARNING

a

Local regulations may impose heavy penalties if

this product is not disposed of in compliance with

the law.

A

When the automation is powered through the “Sole-

a

myo” system, IT MUST NOT BE POWERED through

the mains electricity at the same time.

ENGLISH – 21

11

EU Declaration of Conformity

Note - The contents of this declaration correspond to declarations in the ofcial document deposited at the registered ofces of Nice S.p.a. and in particular to the last revision available before

printing this manual. The text herein has been re-edited for ed

Number:

Manufacturer’s Name:

Address:

Authorized Person to constitute

technical documentation:

Type of product:

Model/Type:

Accessories:

The

provisions

laid

•Directive

The

•

It

essential

requirements

The

while

maintaining full rights to the related intellectual property.

Should

obliged

to arrange for the relative translation to accompany this declaration.

The

of

directive 2006/42/EC.

The

EN 60335-1:2012+A11:2014, EN 62233:2008, EN 60335-2-103:2015

Oderzo, 05/09/2017