MBar / LBar

EN - Instructions and warnings for installation and use

IT - Istruzioni ed avvertenze per l’installazione e manuale per l’uso

FR - Instructions et avertissements pour l’installation et l’utilisation

ES - Instrucciones y advertencias para la instalación y el uso

DE - Installierungs-und Gebrauchsanleitungen und Hinweise

PL - Instrukcje i ostrzeżenia do instalacji i użytkowania

NL - Aanwijzingen en aanbevelingen voor installatie en gebruik

Automatic barrier

0682

M3BAR

M5BAR

M7BAR

LBAR

ENGLISH

Original instructions

WARNINGS AND GENERAL PRECAUTIONS

1

English – 1

EN

Contents

Chapter 1 - WARNINGS AND GENERAL PRECAUTIONS

1.1 - Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 - Installation warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 - Special warnings related to European Directives applicable to the

product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.1 - Installation criteria and special warnings related to

essential requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 - PRODUCT DESCRIPTION AND INTENDED USE . . . . . . . . 3

Chapter 3 - INSTALLATION

3.1 - Preliminary checks for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2 - Product application limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.2.1 - Product durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 - Typical system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3.1 - Modifying the factory settings of the Closure manoeuvre . . . . . . . . 4

3.3.2 - Identification of the spring anchoring holes . . . . . . . . . . . . . . . . . . . 4

3.4 - Barrier lift fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4.1 - If the support surface already exists . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4.2 - If the support surface does not exist . . . . . . . . . . . . . . . . . . . . . . . 5

3.5 - Pole installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5.1 - Pole support assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5.2 - Pole assembly (3 metres / 5 metres) . . . . . . . . . . . . . . . . . . . . . . . . 5

3.5.3 - Pole assembly (6 metres / 9 metres) . . . . . . . . . . . . . . . . . . . . . . . . 6

3.6 - Manually releasing and locking the gearmotor . . . . . . . . . . . . . . . . . . . 6

3.6.1 - How to move the locking cylinder for manual release and lock . . . . 6

3.7 - Mechanical stop adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.8 - Pole balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.8.1 - M3BAR / M5BAR / M7BAR Pole balancing . . . . . . . . . . . . . . . . . . 6

3.8.2 - LBAR Pole balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 4 - ELECTRICAL CONNECTIONS

4.1 - Description of the electrical connections . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 - Initial start-up and electrical connections . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 - Pre-set functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 - Recognition of the connected devices . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 - Recognition of limit positions on opening and closing . . . . . . . . . . . . . . 7

4.6 - Pole movement check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.7 - Connecting a radio receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.8 - Connecting the pole lights (optional accessory) . . . . . . . . . . . . . . . . . . 8

4.9 - Connecting the LED flashing light mod. XBA7 or traffic light to

LED mod. XBA8 (optional accessories) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.10 - Connection of other devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.10.1 - Programming unit Oview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.10.2 - Buffer battery mod. PS224 (accessory) . . . . . . . . . . . . . . . . . . . . 8

4.10.3 - Solemyo System (photovoltaic supply) . . . . . . . . . . . . . . . . . . . . . 8

Chapter 5 - TESTING AND COMMISSIONING

5.1 - Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 - Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 6 - CONTROL UNIT PROGRAMMING

6.1 - Level one programming (ON-OFF functions) . . . . . . . . . . . . . . . . . . . . 10

6.2 - Level two programming (adjustable parameters) . . . . . . . . . . . . . . . . . 10

Chapter 7 - FURTHER INFORMATION

7.1 - Total deletion of control unit memory . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.2 - Other functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.3 - Adding or removing devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3.1 - Bluebus Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3.2 - Photocells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3.3 - MOTB digital selector and proximity reader for

MOMB transponder cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.3.4 - STOP Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.4 - Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.4.1 - Signals of control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.4.2 - Flashing light signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

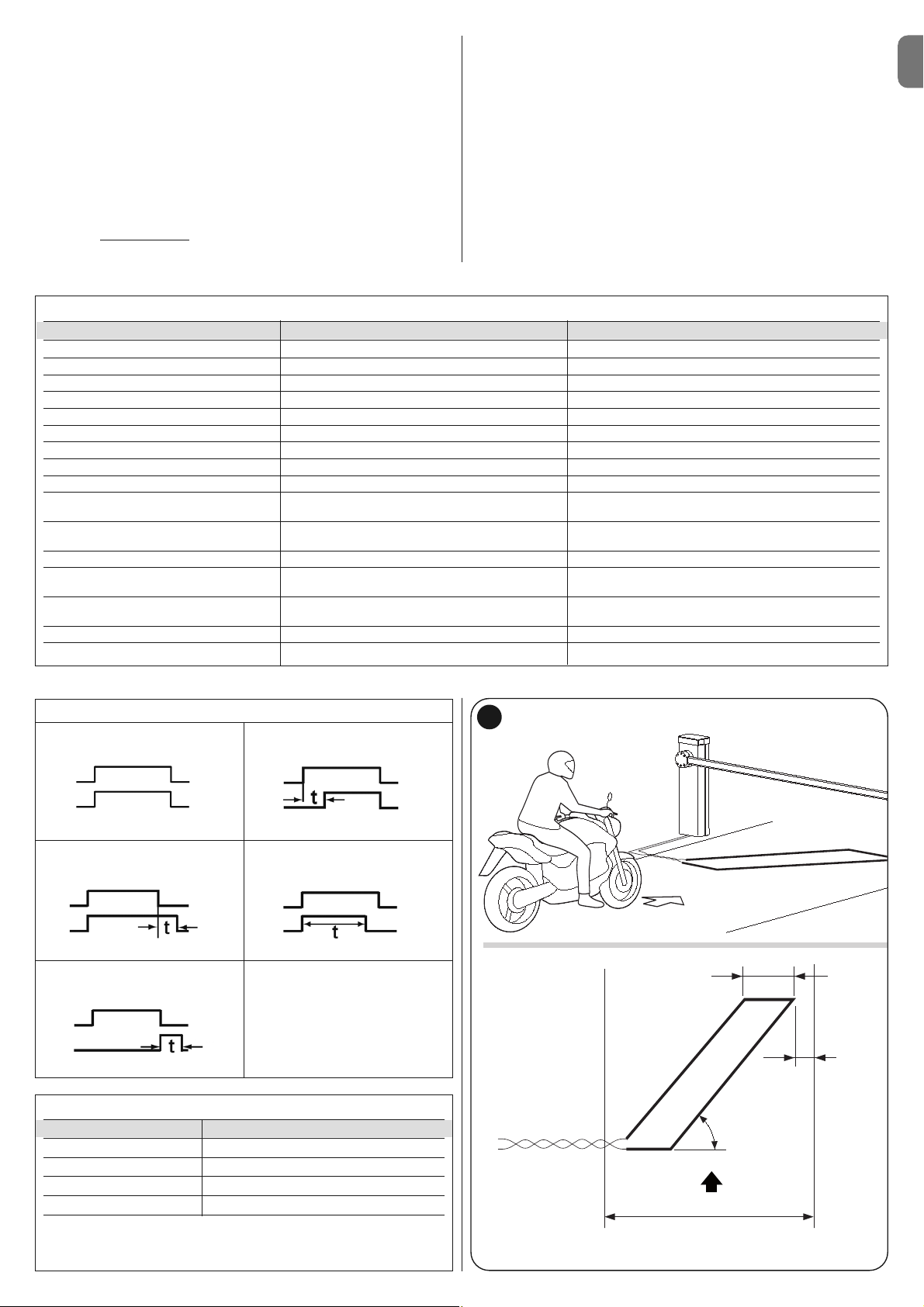

7.5 - Loop Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.5.1 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

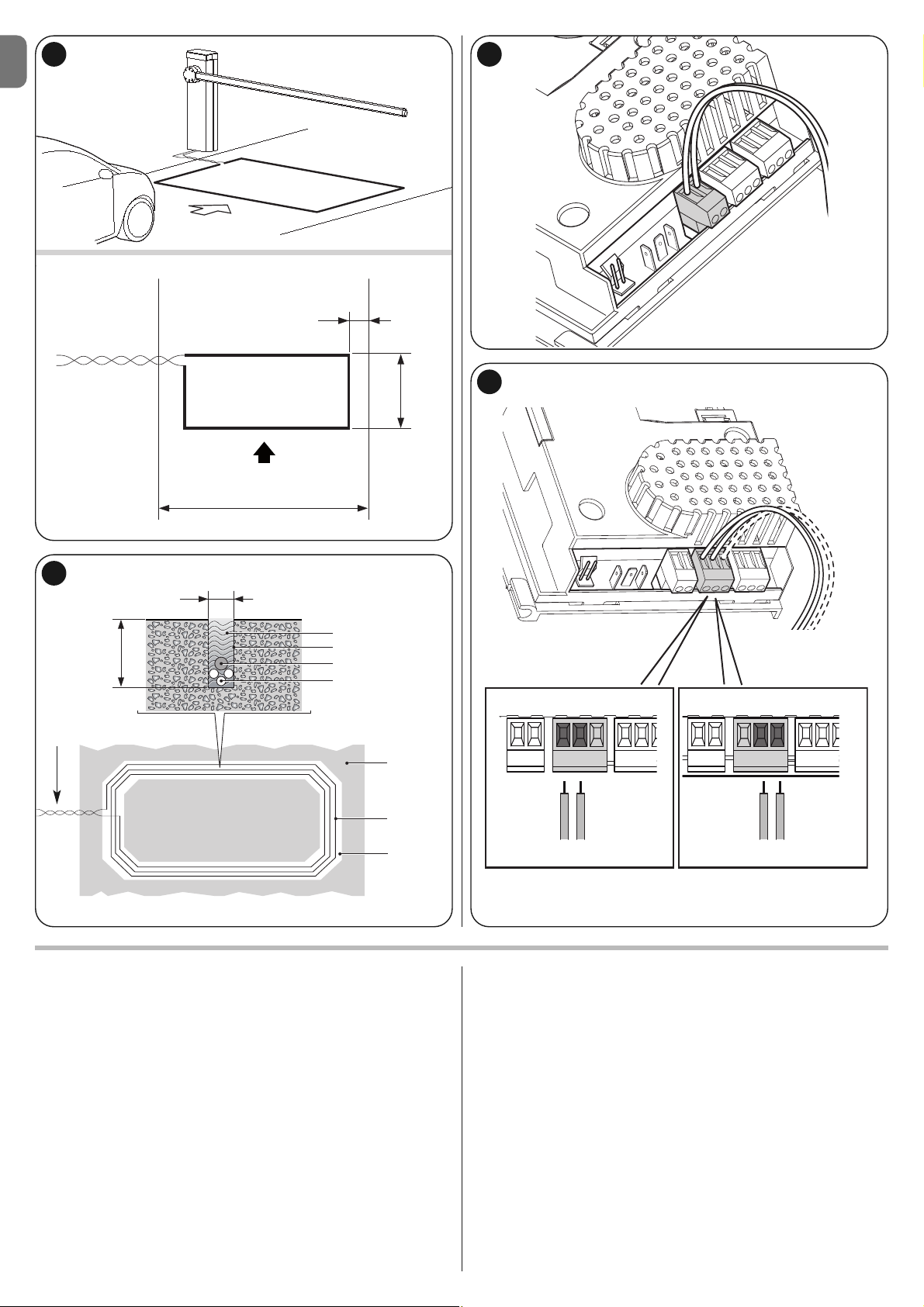

7.5.2 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.6 - Master - Slave mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.6.1 - Installation and electrical connections . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 8 - WHAT TO DO IF... (troubleshooting guide) . . . . . . . . . . . . .19

PRODUCT DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TECHNICAL CHARACTERISTICS OF THE PRODUCT . . . . . . . . . . . . . 20

Declaration of Conformity: appendix I (removable appendix) . . . . . . . . 21

Declaration of Conformity: appendix II (removable appendix) . . . . . . . . 22

Operation manual (removable appendix) . . . . . . . . . . . . . . . . . . . . . . . . . . A

Maintenance schedule (removable appendix) . . . . . . . . . . . . . . . . . . . . . . B

PICTURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I - XVIII

1.1 - Safety instructions

• CAUTION! – This manual contains important instructions and warnings for personal safety. Incorrect installation could cause serious physical

injury. We recommend that you read this entire manual with care before starting any work. If in doubt, do not install the product and contact the Nice technical assistance department.

• CAUTION! – Important instructions: keep this manual in a safe place

to enable future product maintenance and disposal operations.

1.2 - Installation warnings

• Before commencing installation, check that the product is suitable for the

intended kind of use (see paragraph 3.1 and 3.2).If not suitable, do NOT proceed with installation.

• The contents of this manual refer to a standard system such as that shown in

fig. 1.

Considering the risk situations that may arise during installation phases and

use of the product, the automation must be installed in observance of the following warnings.

- On the power line to the system, install a device for disconnection from the

power mains with a gap between contacts that assures complete disconnection in the conditions of overvoltage category III.

- All product installation and maintenance operations must be performed with

the automation disconnected from the power mains. If the power disconnect

device is not visible from the location of the automation, before starting working, a suitable notice must be affixed on the power disconnect device stating

“WARNING! MAINTENANCE IN PROGRESS”.

- Connect the product to an electric power line equipped with an earthing

system.

- During installation, handle the automation with care to avoid crushing, impact,

dropping or contact with liquids of any type. Never place the product near

sources of heat or expose to naked flames. This may damage product components and cause malfunctions, fire or hazardous situations. If this occurs, suspend installation immediately and contact the Nice Service Centre.

- Never make modifications to any part of the product. Operations other than

as specified can only cause malfunctions. The manufacturer declines all liability for damage caused by makeshift modifications to the product.

- This product is not designed to be used by persons (including children)

whose physical, sensorial or mental capacities are reduced, or with lack of

experience or skill, unless suitable instructions regarding use of the product

have been provided by a person responsible for safety.

- The product may not be considered an efficient system of protection

against intrusion. If an efficient protection system is required, the automation

must be integrated with other safety devices.

- Do not allow children to play with fixed control devices. Keep remote control

devices out of reach of children.

- The road barrier cannot be used before it has been commissioned as specified in chapter 5 “Testing and commissioning”.

- The product’s packaging materials must be disposed of in full compliance

with local regulations.

1.3 - Special warnings related to European Directives applica-

ble to the product

• “Construction Products” Directive:

Special warnings related to 89/106/EEC “Construction Products” Directive

and subsequent modification 98/38/EEC applicable to the product:

- Complete installation of this product, as described in this instruction manual and for certain types of use (for example excluding exclusive use for vehicles) may class it in the field of application of the Directive “Construction

Products” 89/106/EEC and relative harmonised standard EN 13241-1.

- Paragraph 1.3.1 specifies all installation criteria required to ensure that the

pro duct complies with the essential requirements of the directive 89/106/EEC;

the installer should check and ensure that all these criteria are strictly

observed.

- Failure to observe one or more of these criteria may mean that the road barrier may not meet all the essential requirements. Use of the product in

these situations is strictly prohibited until all the directive requirements are met; in this case, the label “ES13241-1.4870” applied on the

product must be removed and the “EC declaration of Conformity” in appendix I of this manual may not be used. As a consequence, the installer in turn

becomes the manufacturer of the “automatic barrier”, and must therefore

observe all the requirements of the Directive “Construction Products”

89/106/EEC and relative harmonised standard EN 13241-1. In this case the

road barrier must be considered as “any machine” and the “Declaration of

conformity” in appendix II may be used (for insertion in the technical documentation).

• “Machinery Directive”:

- Paragraph 1.3.1 specifies all installation criteria required to ensure that the

product complies with the essential requirements of the “Machinery directive”

2006/42/EC (ex 98/37/EC). The installer should check and ensure that all

these criteria are strictly observed.

- Failure to observe one or more of these criteria may mean that the road bar-

TABLE 1 - Essential requirements for CE marking (according to prospect ZA.1 of standard EN 13241-1)

Essential requirements Point of standard Result

Resistance to water 4.4.2 NPD*

Release of hazardous substances 4.2.9 Compliant

Resistance to wind load 4.4.3 Compliant

Heat resistance 4.4.5 NPD*

Permeability to air 4.4.6 NPD*

Safe opening for vertically moving doors 4.2.8 Compliant

Definition of the geometry of glass components 4.2.5 NPD*

Mechanical strength and stability 4.2.3 Compliant

Manoeuvring forces for power-operated doors/gates 4.3.3 Compliant

Durability of resistance to water, heat resistance and permeability to air 4.4.7 NPD*

* NPD = No Performance declared, when the product does not offer this performance, for example “Permeability to air”, or when the requirement is not applicable, such as “Definition

of the geometry of glass components”.

2 – English

EN

rier may not meet all the essential requirements. The use of the product is

prohibited in these situations until the correspondence to the requirements of the directive has been verified by those performing the

installation; in this case the “EC declaration of Conformity: appendix I” may

not be used. As a consequence, the installer in turn becomes the manufacturer of the “automatic barrier”, and must therefore observe all requirements

of the Machinery Directive 2006/42/EC. The manufacturer must complete a

risk assessment, which also includes the list of essential safety requirements

as stated in “appendix I of the Machinery Directive”, specifying the relative

solutions adopted. Note that the risk assessment is one of the documents

that constitutes the automation “technical documentation”. This must be

compiled by a professional installer with the possibility of using the “Declaration of Conformity” in appendix II to be compiled by the installer of the road

barrier.

Special warnings regarding suitability of this product in relation to the

“Machinery” Directive 2006/42/CE; to be taken into consideration when

the installer becomes the manufacturer of the product.

The road barrier is issued onto the market as a “quasi machine” and therefore

constructed for incorporation in a machine or to be assembled with other

machinery to produce a single “machine” in accordance with the Directive

2006/42/EC only in conjunction with the other components and in the ways as

described in this instruction manual. As established in directive 2006/42/EC,

this product may not be started up until the manufacturer of the machine, in

which this product is incorporated, has not identified and declared as compliant with the directive 2006/42/EC.

• “Low Voltage” Directive:

Particular warnings concerning the suitable use of this product in relation to

the 2006/95/EEC “Low Voltage” Directive:

This product meets the requirements of the “Low Voltage” Directive if used as

specified in the configurations as envisaged in this instruction manual and in

combination with the articles listed in the product catalogue of Nice S.p.a.

These requirements may not be guaranteed if the product is used in configurations or with other products that have not been foreseen; the use of the

product is prohibited in these situations until the correspondence to the

requirements foreseen by the directive have been verified by those performing the installation.

• “Electromagnetic compatibility” Directive:

Particular warnings concerning the suitable use of this product in relation to

the 2004/108/EEC “Electromagnetic Compatibility” 2004/10/EEC:

This product has been subjected to tests regarding the electromagnetic

compatibility in the most critical of use conditions, in the configurations foreseen in this instructions manual and in combination with articles present in

the Nice S.p.a. product catalogue..

The electromagnetic compatibility may not be guaranteed if the product is

used in configurations or with other products that have not been foreseen;

the use of the product is prohibited in these situations until the correspondence to the requirements foreseen by the directive have been verified by

those performing the installation.

1.3.1 - Installation criteria and special warnings related to essential

requirements

This product, if correctly installed, complies with the essential requirements as

envisaged by the European Directive on “Construction Products” 89/106/EEC

according to the provisions of harmonised standard EN 13241-1, as specified

in Table 1; and by the European Directive on “Machinery” 2006/42/EC.

Important! – If the road barrier is intended exclusively for vehicle transit, it

would be excluded from the field of application of EN 13241-1; in this case,

compliance with some of the requirements stated in Table 1 may not be compulsory. Transit may be considered “exclusively vehicle” when there is an

express prohibition for other types (for example pedestrians), such as by using

adequate signs and, if other types are required, there is adequate space in the

immediate vicinity.

• Release of hazardous substances:

The product does not contain and/or release hazardous substances in conformity with the provisions of the standard EN 13241-1, point 4.2.9 and ac cording to the list of substances stated in the web site of the European Community *: http:// europa.eu.int/comm/enterprise/construction/internal/dangsub/

dangmain_en.htm

(*) Last update: 17/03/2003

Special warning to guarantee compliance with the requirement –It is

essential that also all other materials used in installation, such as electric

cables, comply with this requirement

• Resistance to wind load:

Table 1a specifies resistance of the pole supplied to the differential pressure of

the wind. The tests were performed with the pole fitted with the impact protection profile; other accessories may increase the exposed surface and thus

reduce the resistance to wind load.

• Safe opening for vertically moving doors:

The product does not cause uncontrolled movements or dropping of the pole

in the event of a fault on a single component of the suspension or balancing

(spring) system.

Special warnings to guarantee compliance with the requirements:

- Perform installation in strict observance of all instructions in chapters “3 Installation“ and “5 - Testing and Commissioning”.

- Ensure that a maintenance schedule is drawn up (for example, by using a

“Maintenance indicator” connected to the FLASH output associated with the

relative function - see Table 10); in which, all instructions in the chapter “Maintenance Schedule” must be strictly followed.

• Mechanical strength and stability of the product:

The product is designed and constructed to ensure that, during normal use, all

forces applied, impact and normal wear will not damage or impair mechanical

performance.

Caution: See specifications for the requirement “Safe opening for vertically

moving doors”.

• Manoeuvring forces for power-operated doors/gates:

The operating forces applied by the pole in relation to the risks of crushing and

impact are protected by means of one of the three following methods:

1 For operation with “hold-to-run” controls: as specified in EN 12453:

2000, point 5.1.1.4. In this case the control button must be located in sight of

the automation, and if accessible by the public, the control must not be available to the latter, for example protected by means of a key-operated selector

switch.

2 For “semi-automatic” operating mode: by force limitation as specified in

EN 12453:2000, points 5.1.1.5 and 5.1.3.3.

TABLE 1a Barrier

M3BAR M5BAR M7BAR LBAR

Class 4422*

Wind load [Pa] ≤ 1000 ≤ 1000 ≤ 450 ≤ 450

Maximum wind speed [Km/h] 155 155 104 104

Descriptive term Hurricane Hurricane Violent storm Violent storm

Squall Squall

* Class 2 is achieved using accessory model WA11

200.000

0

400.000

600.000

800.000

1.000.000

INSTALLATION

3

PRODUCT DESCRIPTION

AND INTENDED USE

2

English – 3

EN

GRAPH 1

Severity index (%)

Manouvre cycles

3.1 - Preliminary checks for installation

Before proceeding with installation, check the condition of the product components, suitability of the selected model and conditions of the intended installation environment.

• Ensure that all material used is in perfect condition and suitable for use.

• Ensure that all product application limits can be observed (see paragraph

3.2).

• Ensure that the selected installation environment is compatible with the overall dimensions of the product (fig. 2).

• Ensure that the selected surfaces for barrier installation are solid and guarantee a stable fixture.

• Make sure that the fixing zone is not subject to flooding. If necessary, mount

the barrier raised from the ground.

• Ensure that the space around the barrier enables easy and safe completion

of manual manoeuvres.

• Ensure that there are no obstacles along the pole trajectory which prevent the

opening and closing manoeuvres.

• Ensure that each device to be installed is in a sheltered location and protected against the risk of accidental impact.

3.2 - Product application limit

Before installing the product, ensure that all values specified in the chapter

“Technical product specifications” are compatible with the intended use.

– Ensure that the estimated durability (see paragraph 3.2.1) is compatible with

the intended use.

– Ensure that all limits, conditions and warnings in this manual can be

observed.

3.2.1 - Product durability

The lifetime is the average economic duration of the product. The value of lifetime is strongly influenced by the intensity of the manoeuvres, i.e. the sum of all

factors that contribute to product wear (see Table 2).

To estimate the lifetime of your automation, proceed as follows:

01. Add the values of the items in Table 2 regarding the system conditions;

02. In Graph 1 from the value obtained above, trace vertical line until it inter-

sects the curve; from this point trace a horizontal line until it intersects the

line of the “manoeuvre cycles”. The obtained value is the estimated lifetime

of your product.

The lifetime values specified in the graph are only obtainable if the maintenance

schedule is strictly observed (see chapter “Maintenance schedule”). The estimation of lifetime is made on the basis of design calculations and the results of

tests performed on prototypes. As it is only an estimation, it does not represent

any form of guarantee on the effective lifetime of the product.

Example of calculating the durability of the road barrier (refer to Table 2 and

Graph 1): M5BAR with mobile support (severity index of 10%) - Speed level 3

(severity index of 10%) - Braking (severity index of 10%):

Total severity index = 30%

The estimated durability is approx. 550,000 manoeuvre cycles.

MBAR and LBAR are electromechanical road barriers for residential and industrial use; they control the opening and closing of a road transit point with widths

from 3 to 8 metres.

IMPORTANT! – All uses other than the intended use described and use

in environmental conditions other than those described in this manual

should be considered improper and forbidden!

These barriers are fitted with an electromechanical gearmotor with a 24 V

motor, with incorporated Loop Detector for 2 magnetic loops, with electric limit switch system and a flashing light signal which can be incorporated in the lid

(optional accessory). These two models may be installed as counterposed barriers in “Master-Slave” mode to cover a surface of a road transit point exceeding 8 metres (see paragraph 7.5).

The control unit is set up for connection to devices belonging to the Nice Opera

system and to the “Solemyo” solar power system (see paragraph 4.10.3).

The barriers run on electric energy and in the event of a power failure the pole

can be released and moved manually. Alternatively the buffer battery model

PS224 can be used (optional accessory - see paragraph 4.10.2), which guarantees a number of automation manoeuvres in the first few hours of power failure. Should you desire to prolong this period or extend the number of manoeuvres, the Stand by function should be enabled (see table 6).

Important points on consulting the manual

- In this manual, the words “road barrier” refer to the two products “MBAR” and

“LBAR”.

- The accessories mentioned in the manual are optional.

Available accessory list:

XBA4 - M3BAR and M5BAR pole lights

XBA5 - Aluminium pole painted white, L. 5150 mm

XBA6 - M7BAR pole lights

XBA7 - LED flashing lights that can be installed inside the lid

XBA8 - LED traffic lights that can be installed inside the lid

XBA9 - Universal joint

XBA10 - pivottante connection

XBA11 - Pivot for pole

WA11 - Adjustable pole support (compulsory for LBAR)

WA12 - Mobile support

XBA13 - Impact protection rubber kit

XBA14 - Aluminium pole painted white, L. 4150 mm

XBA15 - Aluminium pole painted white, L. 3150 mm

XBA16 - MBAR foundation plate

XBA17 - LBAR foundation plate

XBA18 - LBAR pole lights

3 For “automatic” operating mode: by force limitation as specified in EN

12453:2000, points 5.1.1.5 and 5.1.3; in this case installation is compulsory

of at least one pair of photocells as shown in fig. 1.

Specific warnings for “semi-automatic” and “automatic” operating mo des: the type tests to check the efficiency of force limitation were performed

with the Force setting at the factory level and Speed setting at the factory value; with the pole assembled as per the instructions and fitted with the “impact

protection profile” above and below the pole and with the accessory “indicator

lights” XBA4 inserted on the upper impact protection profile.

Special warning to guarantee compliance with the requirement: See

speci fications for the requirement “Safe opening for vertically moving doors”.

Cabinet

M3BAR

M5BAR

M7BAR

LBAR

Pole

3 m

4 m

5 m

5 m

3+3 m

3+4 m

3+4 m

4+4 m

4+5 m

Rubber

x

x

x

x

x

x

x

x

x

Lights

x

x

x

x

x

x

x

x

x

Rack

x

x

x

x

x

Mobile

support

x

x

x

x

x

Installable accessories

4 – English

EN

3.3 - Typical system

Fig. 3 shows the components in the product pack:

[a] - road barrier with built-in control unit

[b] - pole support and cover

[c] - 2 boxes for photocells

[d] - 4 half-shells for pole insertion

[e] - Fixed pole plug; 2 insertions per impact protection rubber; 2 insertions

without impact protection rubber

[f] - keys for manual locking and release of the pole; keys for locking the

cover; metal hardware (screws, washers, etc.)

[g] - foundation plate

[h] - 4 fixing bolts

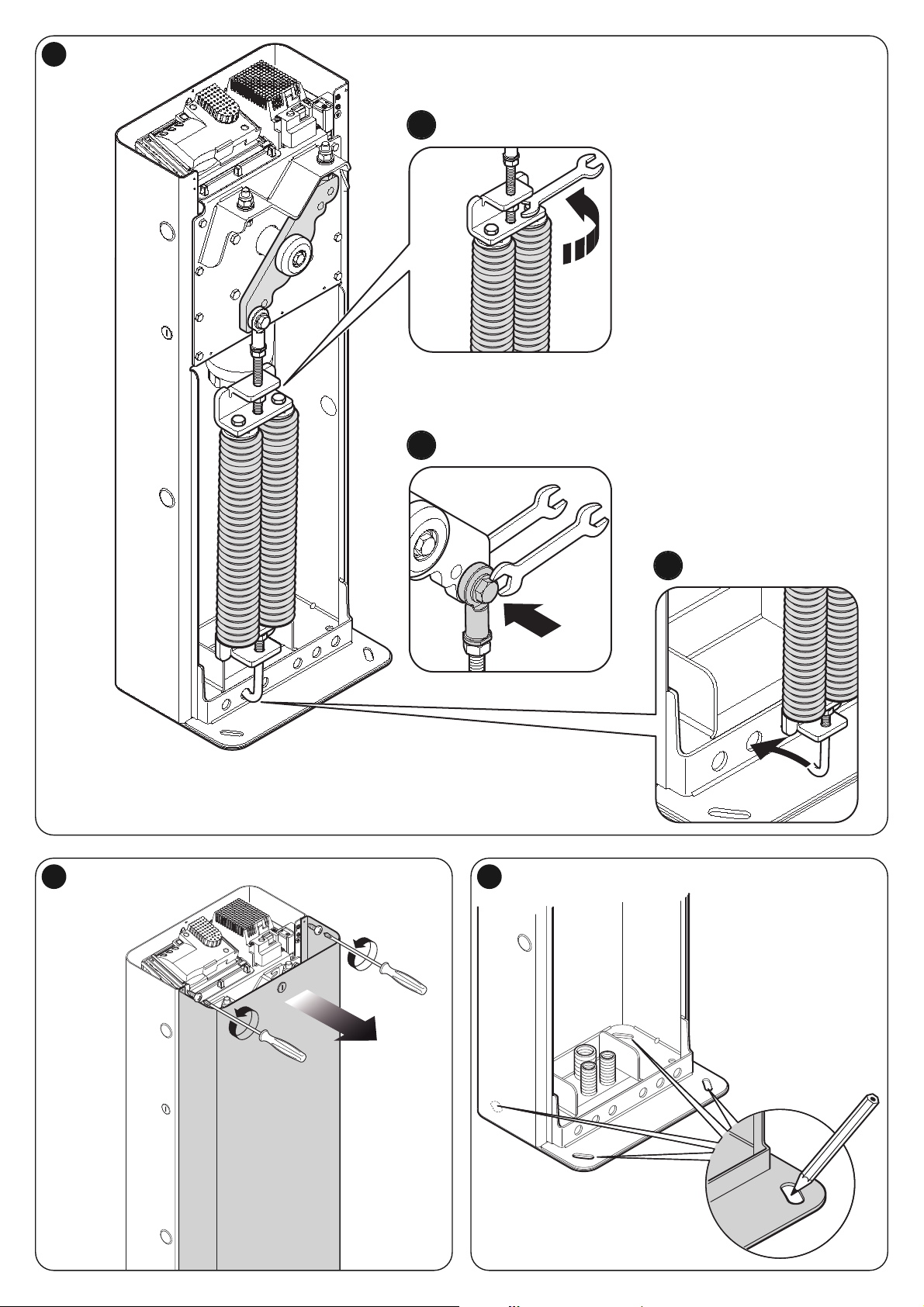

04. Loosen the bolt that fixes the rod end to the balancing lever (fig. 11 phase b);

05. Detach the bolt from the lower connection plate of the spring (fig. 11 phase c);

06. Release the gearmotor (fig. 7): refer to paragraph 3.6;

07. Turn the balancing lever by 90° (fig. 8);

08. Identify the hole where to fix the spring on both the balancing lever and the

lower plate: see table 4;

09. Hook the bolt to the lower plate and then lock the rod end on the balanc-

ing lever through close tightening (fig. 12);

10. Lock the gearmotor (fig. 10): refer to paragraph 3.6.

3.3.2 - Identification of the spring anchoring holes

To identify the holes to be used to anchor the spring, in correspondence to the

accessories to be used in the system, we recommend using Table 4 to quick-

ly find the correct hole.

In Table 4, in correspondence to the “pole length” of your barrier, find the

accessories to be used, add them and check the result in item “position of the

spring anchoring hole”. The key explains, based on the length of the barrier, the

meaning of the letters (A, B, C) and the numbers (1, 2, 3)

NOTE – For single use of the following accessories: Rubber, Lights with pole

long up to 3 m and for the Pivot Pole long up to 4 m, check the result directly in

the item of the same accessory.

TABLE 3 - Technical specifications of electrical cables (Fig. 1)

Fig. 1, shows an example of an automation system set up with Nice compo-

nents. With reference to the typical standard layout fig. 1, locate the approximate position for installation of each component envisaged in the system.

IMPORTANT! – In general, position the ends of the ducting used for

electrical cables in the vicinity of the points envisaged for fixture of the

various components. Note: The ducting serves to protect electric cables

and prevent accidental damage, such as in the case of impact.

The barrier is factory set for the closing manoeuvre to the left; in this

phase, it is important to decide whether the opening direction of the pole is to

be inverted. If Closure to the right is required, see paragraph 3.3.1.

Prepare the electrical cables needed for your system, referring to fig. 1 and

“Table 3 - Technical characteristics of electrical cables”.

3.3.1 - Modifying the factory settings of the Closure manoeuvre

If Closure to the right

is required, proceed as follows:

• MBAR Version:

01. Remove the cover (fig. 4);

02. Loosen the 2 screws fixing the cabinet door (fig. 5);

03. Manually turn the balancing screw (fig. 6 - phase a and b) so that there is

no power;

04. Loosen the spring lock bolt and manually turn the balancing screw (fig. 6 phase a and b) so that there is no power;

05. Detach the bolt from the lower connection plate of the spring (fig. 6 phase d);

06. Release the gearmotor (fig. 7): refer to paragraph 3.6;

07. Turn the balancing lever by 90° (fig. 8);

08. Identify the hole where to fix the spring on both the balancing lever and the

lower plate: see paragraph 3.3.2, table 4 and figure;

09. Hook the bolt to the lower plate and then lock the rod end on the balanc-

ing lever through close tightening (fig. 9);

10. Lock the gearmotor (fig. 10): refer to paragraph 3.6.

LBAR Version:

01. Remove the cover (fig. 4);

02. Loosen the 2 screws fixing the cabinet door (fig. 5);

03. Turn the tensioning nut of the springs (fig. 11 - phase a);

Connection Cable type Maximum admissible length

A: mains power supply cable 3 x 1,5 mm

2

30 m (note 1)

B: BlueBus cable 2 x 0,5 mm

2

20 m (note 2)

C: key-operated selector switch cable 2 cables 2 x 0,25 mm2(note 3) 30 m

Input cable Open 2 x 0,25 mm

2

30 m

Input cable Close 2 x 0,25 mm

2

30 m

Flashing light cable (note 4) 2 x 0,5 mm

2

30 m

with aerial RG58 shielded type 15 m (less than 5 m recommended)

Pole indicator cable Open (note 4) 2 x 0,5 mm

2

30 m

Pole lights (note 4) --

Loop Detector Cable 1 x 1,5 mm2twisted (note 5) 20 m twisted (note 5)

Master/Slave Cable 3 x 0,5 mm

2

20 m

IMPORTANT! – The cables used must be suited to the installation environment.

Note 1 – If the power cable is longer than 30 m, a cable with a larger cross-section is required (3x2.5 mm

2

) and safety earthing is necessary in the vicinity of

the automation.

Note 2 – If the BlueBus cable is longer than 20 m, up to a maximum of 40 m, a cable with a larger cross-section is required (2x1 mm

2

).

Note 3 – These 2 cables may be replaced by a single cable 4x0.5 mm

2

.

Note 4 – Before making the connection, check that the output is programmed for the device to be connected (see paragraph 6.2 - Table 8).

Note 5 – Shorten the two ends coming out of the loop, with at least 20 turns per metre.

TABLE 2 Severity Index

M3BAR M5BAR M7BAR LBAR

Pivot Pole (XBA12) 20 15 - Speed level 3 15 10 15 15

Speed level 2 0 0 10 10

Interruption of manoeuvre via Foto > 10% 15 10 15 15

Interruption of manoeuvre via Alt > 10% 10 10 15 15

Mobile support (XBA11) - 101010

Braking 10 10 10 10

Force equal to 7 or 8 10 10 10 10

Force equal to 5 or 6 5 555

Presence of saline mist 10 10 10 10

Presence of dust or sand 5 555

Rack - 555

Room temperature higher than 40° and lower than 0° C 5 5 5 5

English – 5

EN

3.4 - Barrier lift fixture

3.4.1 - If the support surface already exists

01. Open the cabinet of the barrier (fig. 13);

02. Place the barrier on the fixing surface and trace the points where the slots

are to be fixed (fig. 14);

03. Move the barrier and drill the traced surface points; then insert 4 expansion

bolts, not supplied (fig. 15);

04. Position the barrier correctly and secure by means of the relative nuts and

washers not supplied (fig. 16).

3.4.2 - If the support surface does not exist

01. Dig the foundation pit (*) to house the foundation plate;

02. Prepare ducting for connection cables (fig. 17);

03. On the foundation plate, fix the 4 bolts, placing a nut on the upper side of

each and one on the lower side of the plate (fig. 17). Caution – The lower

nut must be tightened down to the threaded section;

04. Now cast the concrete, and before it sets, embed the foundation plate,

which must be positioned flush with the surface, parallel to the pole and

perfectly level (fig. 17). Wait for the concrete to set completely; in general,

at least 2 weeks;

05. Remove the 4 upper nuts of the bolts;

06. Open the cabinet of the barrier (fig. 18);

07. Position the barrier correctly and secure it by means of the relative nuts

and washers supplied with the foundation plate and removed in point 04

(fig. 19).

(*) Note - The fixing surface must be perfectly smooth and flat. If the surface is

in concrete, it must be at least 0.15 m thick, and must be adequately reinforced

with steel cages. The concrete volume must be greater than 0.2 m

3

(a thick-

ness of 0.25 m corresponds to 0.8 m

2

; in other words equal to a square base

of approx. 0.9 m per side). Anchoring to the concrete can be by means of 4

expansion bolts, fitted with 12 MA screws, which resist to a traction load of at

least 400 Kg. If the fixing surface is in another material, the consistency must be

checked and ensure that the 4 anchoring points can resist a load of at least

1000 Kg. For fixture, use 12 MA screws.

3.5 - Pole installation

3.5.1 - Pole support assembly

01. Insert the two plugs in the relative seats on the output motor shaft (fig. 20);

02. Position the support on the output motor shaft, placing it in the “vertical

pole” position and tighten the relative screws and washers fully down to

secure (fig. 21);

03. Position the pole cover and partially secure

by means of the 6 screws sup-

plied (fig. 22).

3.5.2 - Pole assembly (3 metres / 5 metres)

01. Assemble the two pole insertions (fig. 23);

02. Insert, from the same end of the pole, the insertions just assembled. Use a

rubber mallet (fig. 24);

03. Lightly grease the aluminium guide on both sides (fig. 25);

08. Perform this operation on both ends of the pole: insert the first part of impact

protection rubber in the slot, through to the end of the pole; then insert the

joint for the impact protection rubber (fig. 26) and repeat with all parts;

09. The impact protection rubber may protrude by about 1 cm from the end of

the profile (fig. 27):

A) position the pole plug and lock it with the two screws (fig. 28);

B) position and block the two rubber cover plugs (fig. 28);

10. Insert the pole assembly in the pole support shell, pushing it up to the end

and then tighten the 6 previously inserted support screws fully down (fig. 29).

TABLE 4

LENGTH OF THE POLE

M3BAR M5BAR M7BAR LBAR

2,65 m 3,15 m 3,5 m 4,15 m 5,15 m 5,15 m 5 m, 6,33 m 7,33 m 7,33 m 8,33 m 9,33 m

entire entire with joint

ACCESSORIES

XBA13 - Rubber A1 A3 0 0 C2 0 0 0 B2 0 0 B1

XBA4/XBA6/XBA18 - Lights A1 A3 1 1 C2 1 1 1 B2 1 1 B1

WA13 - Rack - - 1 1 - 2 1 1 - 2 2 WA12 - Mobile support - - 5 4 - 4 3 3 - 3 3 XBA11 - Pivot Pole B3 B3 C1 C3 - - - - - - - -

POSITION OF THE SPRING ANCHORING HOLE

0÷1 = B2 0÷1 = B3 0÷2 = A2 0÷2 = B1 0÷2 = A1 0÷2 = A3

2÷7 = B3 2÷4 = C1 3÷5 = A2 3÷5 = B2 3÷4 = A2 3÷6 = B1

5÷6 = C2 6÷7 = A3 5÷6 = A3

Example:

M5BAR with 4m pole + Rack

(1piece) (value:1) + Pole lights

(value:1) = Sum of values: 2

Risult = POSITION C1

A

M3BAR / M5BAR M7BAR / LBAR

123

B

C

123

A

B

6 – English

EN

ELECTRICAL CONNECTIONS

4

CAUTION! – All electrical connections must be made with the unit disconnected from the mains power supply.

01. Remove the cover by loosening the screws and turning the key clockwise

(fig. 39);

02. Route the electric cables inside the barrier, starting from the base towards

the control unit and routing them to the left. Instead, the cables of the Loop

detectors and for the “Master-Slave” mode must be made by routing them

to the right;

03. Route the power supply cable through the cable gland and connect them

to the 3-contact terminal with fuse. Tighten the cable gland by tightening

the screws (fig. 40);

04. Connect the other cables as shown in the wiring diagram in fig. 41. Note –

To facilitate cable connections, the terminals can be removed from their

seats.

4.1 - Description of the electrical connections

• LIGHT = this output is programmable (see Chapter 6, paragraph 6.2 - Level

2 programming - adjustable parameters) to connect one of the following

devices:

– Flashing light: if programmed as “flashing light” on the “LIGHT” output,

a NICE flashing light model “LUCY B, MLB or MLBT” with a 12 V 21 W car

type lamp can be connected. During the manoeuvre it flashes at intervals of

0.5 s lit and 0.5 s off. Factory setting: configuration for operation as “Flashing light for pole lights” 24 V/10 W.

– “pole open indicator” - “activated if the pole is closed” - “activated

if pole is open” - “flashing light for pole lights” and “maintenance

indicator”: if programmed with one of these 5 functions on the “LIGHT”

output, a 24 V indicator (max. 10 W) can be connected for the following signals:

“Pole open indicator” function

Pole closed: Off

Pole opening: slow flashing light

Pole closing: quick flash light

Pole open (not closed): on

“Active if pole closed” function

Pole closed: on

All other cases: Off

“Active if pole open” function

Pole open: on

All other cases: Off

Function “flashing light for pole lights”

The indicator light or pole lights indicate execution of the manoeuvre

in progress by flashing constantly at regular intervals (0.5 sec on; 0.5

seconds off)

Function “Maintenance indicator”

- indicator lit on for 2 seconds at the start of the opening manoeuvre

= number of manoeuvres less than 80%

- flashing light indicator during execution of the entire manoeuvre =

number of manoeuvres between 80 and 100%

- indicator constantly flashing = number of manoeuvres greater than

100%.

– Suction cup: a 24V max 10W suction cup can be connected (versions

with electromagnet only, without electronic devices). When the pole is

closed, the suction cup is activated to lock the pole in place. During the

opening and closing manoeuvre it is deactivated.

– Electric block: a 24 V max 10 W electric block with latch can be connected (versions with electromagnet only, without electronic devices). During the opening manoeuvre, the electric lock is activated and remains

active to free the pole and perform the manoeuvre. In the closing manoeuvre ensure that the electric block re-engages mechanically.

– Electric lock: a 24 V max 10 W electric lock with latch can be connected (versions with electromagnet only, without electronic devices). At the

start of the opening manoeuvre, the electric lock is activated for a short

period to release the pole and complete the manoeuvre. In the closing

manoeuvre ensure that the electric lock re-engages mechanically.

• FLASH = this output is programmable by using the Oview programmer. It is

possible to connect the same devices of the LIGHT output. In the factory it is

configured for operation with flashing light 12 V 21 W.

3.5.3 - Pole assembly (6 metres / 9 metres)

01. Assemble the two plastic pole insertions (fig. 23);

Important: to compose the required pole, use the pole accessory as

described below:

6 m pole = 2 pieces XBA15 mod.

7 m pole = 1 piece XBA15 mod + 1 piece XBA14 mod.; IMPORTANT! Position the XBA15 mod. pole first (3150 mm)

8 m pole = 2 pieces XBA14 mod.

9 m pole = 1 piece XBA14 mod + 1 piece XBA5 mod.; IMPORTANT! Position the XBA14 mod. pole first (4150 mm)

02. Insert, from the same end of the pole, the insertions just assembled. Use a

rubber mallet (fig. 24);

03. Insert the universal joint in the free ends of the two poles. Take care in cor-

rectly directing the joint since the heads of the screws must be on the

same part of the holes on the poles (fig. 30);

04. Act to the same degree on the three screws of the joint by loosening them

in a way to “expand” the joint inside the poles (fig. 31);

05. Lightly grease the aluminium guide on both sides (fig. 25);

06. Perform this operation on both ends of the pole: insert the first part of impact

protection rubber in the slot, through to the end of the pole; then insert the

joint for the impact protection rubber (fig. 26) and repeat with all parts;

07. The impact protection rubber may protrude by about 1 cm from the end of

the profile (fig. 27):

A) position the pole plug and lock it with the two screws (fig. 28);

B) position and block the two rubber cover plugs (fig. 28);

08. Insert the pole assembly in the pole support shell, pushing it up to the end

and then tighten the 6 previously inserted support screws fully down (fig. 29).

3.6 - Manually releasing and locking the barrier

This operation is required in the event of a power failure or malfunction.

IMPORTANT!

– The release and locking operations must be performed only when the

pole is horizontal and stationary.

– It is possible to carry out the manual release and lock on both sides of

the barrier by moving the locking cylinder (see paragraph 3.6.1).

To manually lock and release the barrier, insert the key supplied and turn it by

180° (fig. 32); the key can be turned to the left or to the right.

3.6.1 - How to move the locking cylinder for manual release and lock

01. Insert the key supplied and turn through 180° clockwise (fig. 33-a);

02. Remove the locking cylinder by using a wrench (fig. 33-b and 33-c)

03. From the other side of the caisson, remove the rubber plug (fig. 33-a);

04. Position the ring nut and insert the locking cylinder inside the pre-drilled

hole and lock it as shown in fig. 34-b and 34-c.

3.7 - Mechanical stop adjustment

01. Manually release the gearmotor: see paragraph 3.6;

02. Manually move the pole through a complete Opening and Closing manoeuvre;

03. Then adjust the mechanical stop screws (fig. 33 and 34) to align the pole

vertically and horizontally;

04. Tighten down the nuts.

3.8 - Pole balancing

The pole needs to be balanced to establish the best balance between two factors: the weight of the pole and any accessories and the counterposed force

of the balancing spring. The latter individually guarantees the balancing of the

pole; if this rises or lowers, proceed as described in the paragraphs below.

3.8.1 - M3BAR / M5BAR / M7BAR Pole balancing

01. Manually release the gearmotor: see paragraph 3.6;

02. Manually move the pole to mid-travel (45°) and leave stationary. If the pole

tends to lift, reduce the tension of the spring by manually turning it clockwise

(fig. 37-a). If the pole tends to lower, reduce the tension of the spring by

manually turning it anti-clockwise (fig. 37-b). Note - the off-balance value is

only acceptable when the force required to move the pole* when open,

closed and in all the other positions, is lower than or equal to half of the

nominal value (equal to about 1.5 kg for M3; 3.5 kg for M5 and 4.5 kg for

M7, about 5 kg at 1 m). [(*) force measured at right angles to the pole and at

1 m from the rotation axis].

03. Repeat point 02 positioning the pole also at approx. 20° and approx. 70°. If

the pole remains still in position, this means that balancing is correct; a slight

off balance is admissible, but the pole must never move significantly.

04. Tighten the nut to lock the balancing spring (fig. 37-c);

05. Manually lock the gearmotor: see paragraph 3.6.

3.8.2 - LBAR Pole balancing

01. Manually release the gearmotor: see paragraph 3.6;

02. Manually move the pole to mid-travel (45°) and leave stationary. If the pole

tends to rise or lower, it is necessary to use the nut (fig. 38) to increase or

decrease the tension of the spring. Note - the off-balance value is only

acceptable when the force required to move the pole* when open, closed

and in all the other positions, is lower than or equal to half of the value of

the nominal torque (for this product, about 6.5 kg at 1 m). [(*) force meas-

ured at right angles to the pole and at 1 m from the rotation axis].

03. Manually lock the gearmotor: see paragraph 3.6.

English – 7

EN

4.4 - Recognition of the connected devices

After the initial power-up, the control unit must be able to recognise the devices

connected on the inputs “Bluebus” and “Stop”.

CAUTION! – The learning phase must be performed even if no device is

connected to the control unit.

To indicate whether this operation is necessary, leds “L1” and “L2” on the control unit emit a number of flashes.

01. Press and hold down “Open” and “Set” keys at the same time;

02. Release the keys when LEDs L1 and L2 start flashing quickly (after approx.

3 seconds).

03. Wait a few seconds for the control unit to complete the device learning

phase. At the end of this phase, the “Stop” led must be lit and leds “L1”

and “L2” must turn off (leds “L3” and “L4” may start flashing to indicate

that the positions have not be learnt).

This procedure must be repeated in the case of modifications to the devices

connected to the terminals BlueBus and Stop; for example, after connecting a

new device to the control unit.

4.5 - Recognition of limit positions on opening and closing

After learning the connected devices, the control unit also has to learn the positions of the mechanical stops. In this phase, the pole travel distance is read,

measured from the closing mechanical stop to the opening mechanical stop.

01. Manually release the gearmotor (see chapter 3.6) and manually position

the pole at approx. 45° (mid-travel);

02. Lock the gear motor (see paragraph 3.6);

03. Press and hold down “Close” and “Set” keys at the same time;

04. Release the keys when the manoeuvre starts (after approx. 3 seconds);

05. Wait a few seconds for the control unit to complete the position learning

phase: close, open and close of the pole or with intervals with a 3 second

pause.

06. Press “Open” for the pole to run a complete Opening manoeuvre.

07. Press “Close” for the pole to run a complete Closing manoeuvre.

During these manoeuvres, the control unit memorises the force required to

complete these manoeuvres.

CAUTION! – The learning phases must never be interrupted

. If this

occurs, the entire learning procedure must be repeated.

At the end of the learning phase, if leds “L3” and “L4” flash, this means that

there is an error. The phase for learning the mechanical stops can be repeated

at any time, also after installation (for example, if the position of a mechanical

stop is moved).

IMPORTANT! – The parameters concerning the deceleration positions

and the

braking intensity, are functions preset by the unit. In any case it is possible to

modify them by directly acting on the unit, modifying the parameters “L5

Long/short deceleration (see Table 6 - paragraph 6.1)” and “L8 Braking

(see Table 6 - paragraph 6.2)” or by using the Oview programmer.

4.6 - Pole movement check

After learning about the devices, a number of Opening and Closing manoeuvres should be performed to ensure correct pole movement.

01. Press “Open” to activate an Opening manoeuvre; ensure that the pole

starts to decelerate before reaching the opening position;

02. Press “Close” to activate a Closing manoeuvre; ensure that the pole starts

to decelerate before reaching the closing position;

03. Make sure that the LED flashing light, if present, flashes at regular intervals

(0.5 sec on, 0.5 sec off) during a manoeuvre;

04. Run a number of Opening and Closing manoeuvres to ensure that there

are no points of increased friction or malfunctions.

• SCA = this output is programmable by using the Oview programmer. It is

possible to connect the same devices of the LIGHT output. In the factory it is

configured for operation with Pole Open Indicator 24 V 10 W.

• BLUEBUS = this terminal enables the connection of compatible devices; all

are connected in parallel with just two wires conveying the electric power and

communication signals. For further details see Chapter 8.

• STOP = input for devices that block or shut down the manoeuvre in

progress; by setting the input accordingly, it is possible to connect Normally

Closed type contacts, Normally Open contacts, constant resistance or optical devices. For further details see chapter 8.

• PP = input for devices control movement in Step-Step mode, enabling the

connection of Normally Open contacts.

• OPEN = input for devices which control only opening manoeuvre. NO con-

tacts can be connected to this input.

• CLOSE = input for devices which control only closing manoeuvre. NO con-

tacts can be connected to this input.

• AERIAL = input for connection of the aerial for the radio receiver (the aerial is

incorporated on LUCY B, MBL, MLBT).

• LED BOARD OUTPUT = this output is programmable (see Chapter 6, para-

graph 6.2 - Level 2 programming - adjustable parameters) and is used to

connect the LED flashing light board (XBA7) or the LED traffic lights board

(XBA8). With the factory setting, it performs the flashing light function, flashing at intervals of 0.5 s lit and 0.5 s off. In addition, diagnostic flashing is performed.

• LOOP1 = Loop Detector input to connect a loop detector, for the detention

of metal masses. The operating modes associated to this input may be modified with the Oview programmer (see paragraph 7.5 – Loop Detector). Factory setting: configuration for the opening manoeuvre

• LOOP2 = Loop Detector input to connect a loop detector, for the detention

of metal masses. The operating modes associated to this input may be modified with the Oview programmer (see paragraph 7.5 – Loop Detector). Factory setting: configuration for the opening manoeuvre

• MASTER-SLAVE = connector for the connection of 2 barriers in MasterSlave mode (see paragraph 7.6 – Master-Slave)

IMPORTANT! – NEVER CONNECT DEVICES OTHER THAN THOSE SPE CIFIED.

4.2 - Initial start-up and electrical connections

CAUTION! – The final connection of the automation to the electrical

mains must be made exclusively by a qualified skilled technician, in

observance of current local standards.

Connect the control unit to an electric power line equipped with an earthing

system. Envisage a mains disconnect device, with a contact opening distance

that ensures complete disconnection in the conditions of overvoltage category

III, or envisage a plug and socket system.

After powering up the control unit, perform the following checks:

• Make sure that the “Bluebus” LED flashes quickly for a few seconds and then

regularly with a frequency of about one flash per second.

• If photocells are present, check that the leds on the latter also flash (both on

TX and RX elements); the type of flash is not significant as this depends on

other factors.

• Check that the device connected to the FLASH output or XBA7 LED flashing

light is off (with factory setting).

If the above conditions are not satisfied, switch off the power supply to the control unit and check the electrical connections previously made.

For more useful information see also chapter “8 Troubleshooting” (troubleshooting guide).

4.3 - Pre-set functions

The control unit is equipped with a series of programmable functions, which

are factory set with the most commonly used values. These values can be

modified at any time: See chapter 6.

Open

Stop

Set

Close

L1

Close

Open

PP

Stop

L2

L3

L4

L5

L6

L7

L8

BusT4

Open

Stop

Set

Close

L1

Close

Open

PP

Stop

L2

L3

L4

L5

L6

L7

L8

BusT4

8 – English

EN

4.10.1 - Programming unit Oview

The use of the programming unit Oview enables complete and rapid management of installation, maintenance and troubleshooting of any malfunctions of

the whole automation system. Oview can be connected to the road barrier by

means of the BusT4 connector on the control unit.

To access the BusT4 connector, open the cover of the road barrier and insert

the connector in its seat (fig. 50).

In general, Oview can be positioned at a maximum distance of 100 m of cable

from the control unit; it can be connected to multiple control units simultaneously (max. 16) and can also remain connected during normal operation of the

automation; to exceed these limits, observe the warnings in the Oview instruction manual and the Oview System Book system manual. If a OXI type radio

receiver is present in the control unit, Oview enables access to the parameters

of the transmitters memorised in this receiver. For detailed information, refer to

the instruction manual of the Oview programmer or the barrier function

datasheet also available on the website www.niceforyou.com.

4.10.2 - Buffer battery mod. PS224 (accessory)

In the event of a mains power failure, the road barrier can also be powered by a

buffer battery model PS224. To install and connect the battery, proceed as follows:

Important! – The electric connection of the battery to the control unit

must only be made after completing all installation and programming

phases, as the battery constitutes an emergency power supply.

01. Position the buffer battery as shown in fig. 51-a;

02. Disconnect the mains power and then connect the relative cable of the

buffer battery (fig. 51);

03. Connect the mains power.

4.10.3 - Solemyo System (photovoltaic supply)

The barrier is designed to be powered with the “Solemyo SYKCE” photovoltaic

system. For connection to the control unit, use the 2 pole plug shown in fig. 52.

IMPORTANT!

- When the barrier is powered by the “Solemyo” system IT MUST NOT

BE POWERED by the electricity grid at the same time.

- Due to the limited solar power available, depending on the installa-

tion location and time of year, the barrier can perform a maximum

number of manoeuvres per day. Before installing the Solemyo system, check in the relative instruction manual whether the maximum

number of possible manoeuvres is compatible with the intended use.

- The Solemyo system can only be used efficiently if the control unit is

active and set with the Standby function set to “All” mode (only possible using the Oview programmer).

CAUTION – If the manoeuvre starts from a position different from that of one

of the mechanical stops (opening or closing), it is performed at low speed.

4.7 - Connecting a radio receiver

The control unit is fitted with a SM type connector for connection of a radio

receiver (optional accessory) model SMXI, SMXIS, OXI or OXIT and similar.

To insert the radio receiver, disconnect the control unit from the power mains

and insert the receiver as shown in fig. 42.

Table 5 shows the actions performed by the control unit according to the outputs activated or the commands sent from the radio receiver.

4.8 - Connecting the pole lights (optional accessory)

01. Move the pole to the vertical position;

02. Unscrew the 6 screws that hold the pole cover (Fig. 43);

03. Remove the pole temporarily;

04. Insert the grommet in the pre-drilled hole for cable routing (Fig. 44);

05. Route the lights cable through the impact protection rubber profile, using a

guide to facilitate attachment if necessary (Fig. 45);

06. If necessary, shorten the length of the lights cable: cuts may only be made

at the points bearing the relative mark. After cutting, the plug at the cut end

must be moved to seal off the new end;

07. Insert the cable first through the hole on the pole support and then through

the hole on the cabinet (Fig. 46); Caution – Leave a little extra cable in the

pole support, to enable pole rotation through 90° without tensioning the

cable;

08. Connect the lights cable to the LIGHT terminal on the control unit: see diagram in Fig. 47. Note – The LIGHT output features polarity: if the lights do

not illuminate, as planned, it is necessary to invert the cables connected to

the terminal.

09. Position and secure the connector in the slot on the pole (Fig. 48);

10. Insert the pole and secure with its cover, tightening the 6 screws (fig. 49)

fully down and taking care not to pinch the wiring cable.

4.9 - Connecting the LED flashing light mod. XBA7 or LED traf-

fic light mod. XBA8 (optional accessories)

On the cover of the barrier a LED flashing light mod. XBA7 or red and green

LED traffic light mod. XBA8 may be fitted. The operating modes of these flashing lights may be modified through the Oview programmer or with suitable programmes of the control unit. For further information, refer to the instruction

manual for the two products.

4.10 - Connection of other devices

The built-in unit enables the power supply to the external devices (a radio

receiver or the key-operated selector switch lighting) by receiving power from

the control unit: for the type of connection, see fig. 41.

The power supply voltage is 24 Vdc, -30%/+50%, with maximum available current 100 mA.

SMXI, SMXIS, OIX, OXIT receiver in mode I or II

output description

Output no. 1 Step by step

Output no. 2 Partial Open (opens to approx. 45%;

value programmable with Oview, see paragraph 4.10.1)

Output no. 3 Open

Output no. 4 Close

OXI receiver, OXIT programmed in “Extended Mode II”

Command description

Command no. 1 Step by step

Command no. 2 Partial Open (opens to approx. 45%;

value programmable with Oview, see paragraph 4.10.1)

Command no. 3 Open

Command no. 4 Close

Command no. 5 Stop

Command no. 6 Apartment block Step by Step

Command no. 7 Step-Step High priority

(controls also if automation is blocked)

Command no. 8 Unblock + Open

Command no. 9 Unblock + Close

Command no. 10 Open and block automation

Command no. 11 Close and block automation

Command no. 12 Block automation

Command no. 13 Release automation

Command no. 14 Master door Step by Step

Command no. 15 Slave door Step by Step

TABLE 5

EN

English – 9English – 9

These are the most important phases of automation set-up for ensuring maximum system safety. The test can also be performed as a periodic check of

automation devices. Testing and commissioning of the automation must be

performed by skilled and qualified personnel, who are responsible for the tests

required to verify the solutions adopted according to the risks present, and for

ensuring observance of all legal provisions, standards and regulations, and in

particular all requirements of the standard EN 12445, which establishes the test

methods for checking automations for doors and barriers. All these operations

must be performed under the direct supervision of the head installer, i.e. the

person who enters his/her name and signature in box N°1 of the declaration of

conformity (see appendix I).

The additional or optional devices must undergo a specific test for functionality

and correct interaction with the barrier.

5.1 - Testing

The sequence of operations to be performed for testing refers to a standard

system (Fig. 1) classed for “untrained users” and the automation activation set

to “automatic control” which envisages, as a minimum protection level of the

primary edge, device types C (force limitation - see standard EN 12445) combined with device types D (presence detectors, e.g. photocells). Bearing in

mind that this type of use is among the most intensive, the same testing

sequence can be effectively implemented in less intensive conditions.

1 Ensure that all specifications in this manual have been observed, with spe-

cial reference to the chapter “1 Safety Instructions”.

2 Check correct balancing of the pole, see paragraph 3.8.

3 Check correct operation of the manual release, see paragraph 3.6.

4 Using the transmitter or key-operated selector switch, perform tests of

opening, closing and stopping the barrier, and ensure that pole movement

corresponds to specifications. Test several times to check for pole movement and any defects in assembly or adjustment and any possible points of

friction.

5 Check operation of all system safety devices one at a time (photocells, sen-

sitive edges, etc.). Each time a device is activated the “Bluebus” LED on the

control unit must flash rapidly twice to confirm acknowledgement of the

event.

6 Check correct operation of the photocells as follows: depending on

whether one or two pairs of photocells have been installed, one or two parallelepipeds in rigid material are required (e.g. wooden panels) with the

measurements 70 x 30 x 20 cm. Each parallelepiped must have three

sides, one for each size, in reflective material (e.g. mirror or white gloss

paint) and three sides in opaque material (e.g. black matt paint). To test the

photocells positioned at 50 cm from the ground, the parallelepiped must be

placed on the ground or raised at 50 cm in the case of photocells placed at

1 m from the ground.

When testing one pair of photocells

, the test specimen must be positioned

exactly at the centre of the pole with the 20 cm sides facing the photocells

and moved along the entire length of the pole (Fig. A).

When testing two pairs of photocells

, the test must first be performed individually for each pair of photocells, using one test specimen, and then

repeated using two test specimens.

Each test specimen must be positioned laterally with respect to the centre

of the pole, at a distance of 15 cm sides and then moved along the entire

length of the pole (Fig. B).

During these tests, the test specimen must be read by the photocells in any

position along the entire length of the pole.

7 Ensure there is no interference between the photocells and other devices,

by intercepting the optic axis joining the two photocells by means of a cylinder (diameter 5 cm, length 30 cm, Fig. C): pass the cylinder first close to

the TX photocell, then close to the RX and lastly at the centre between the

two. Ensure that in all cases the device engages, changing from the active

status to alarm status and vice versa, and that the envisaged action is generated in the control unit (for example movement inversion in the Closing

manoeuvre).

8 Check protection against the risk of lifting: on automations with verti-

cal movement, it must be ensured that there is no risk of lifting. This test can

be performed as follows: hang a weight of 20 kg mid-way along the pole

(for example, a sack of gravel), activate an Opening manoeuvre and ensure

that during operation the pole does not exceed the height of 50 cm from

the closing position. If the pole exceeds this height, reduce the motor force

(see chapter 6 - Table 7).

9 If hazardous situations generated by the moving poles are protected by

means of impact force limitation, measure the force as specified in the standard EN 12445. If motor force control is used as auxiliary function with the

system for reduction of impact force, test and identify the setting that

obtains the best results.

10 Check efficiency of the release system: place the pole in the Closing

position and manually release the gearmotor (see paragraph 3.6) ensuring

that there is no difficulty with this procedure. Ensure that the manual force

required to move the pole on opening is no greater than 200 N (approx. 20

Kg); the force is measured perpendicular to the pole and at 1 m from the

rotation axis. Lastly, ensure that the key required for manual release is available in the vicinity of the automation.

11 Power supply disconnection system check: by using the power dis-

connect device, and disconnecting any buffer batteries, ensure that all leds

on the control unit are off and that the pole remains stationary when any

commands are sent. Check efficiency of the locking device to prevent inadvertent and/or unauthorised reconnection.

5.2 - Commissioning

Commissioning can only be performed after positive results of all test

phases. Partial or “makeshift” commissioning is strictly prohibited.

1 Compile and provide the automation owner with the “CE Declaration of

conformity - Appendix I”, at the end of this manual, in the removable section.

2 Compile and provide the automation owner with the form “Operation

Manual” at the end of this manual, in the removable section.

3 Compile the form “Maintenance schedule”, containing all maintenance

instructions for all devices in the automation and forward it to the owner. In

the case of the barrier, this form is present at the end of this manual, in the

removable section.

4 Before commissioning the automation, ensure that the owner is adequately

informed of all associated risks and hazards.

5 Permanently affix on the barrier, the label in the pack regarding the gearmo-

tor manual release and locking operations.

6 ONLY for installations NOT IN CONFORMITY with the criteria stated in

chapter 1.3.1 of this manual: produce the technical documentation of the

automation, which must include the following documents: an overall drawing of the automation, the wiring diagram of all connections made, an

assessment of all risks present and relative solutions adopted (see forms to

be compiled on the website www.niceforyou.com), declarations of conformity of the manufacturer of all devices used (for the barrier see appendix

II) and the declaration of conformity compiled by the installer.

Affix a dataplate on the barrier, specifying at least the following data: type of

automation, name and address of manufacturer (responsible for commissioning), serial number, year of construction and CE mark.

TESTING AND COMMISSIONING

5

300

200

700

500

A

300

200

700

300

200

700

500

150

150

B

C

TABLE 6 - First level functions

LED Description Example

L1 Automatic closure This function performs automatic closure of the pole after the programmed pause time. Factory setting:

20 seconds. Value programmable from 3 to 60 seconds.

L2 Reclose after photo This function enables the pole to remain in Opening position for the time required for transit. When the function is

active, operation depends on the parameter set in the function “Automatic closure”:

• with “Automatic closure” active, the Opening manoeuvre stops immediately after the photocells are disengaged

and the Closure manoeuvre starts after 5 seconds.

• with “Automatic closure” not active, the pole always reaches the maximum Opening position (even if the

photocells are disengaged beforehand) and Closure starts after 5 seconds.

L3 Always close This function is useful in the event of a power failure, even brief. In fact if this function is active (ON), when power

is restored, the control unit detects the pole as open and starts Closure. For reasons of safety the Closure manoeuvre

is preceded by a 3-second pre-flashing interval.

L4 Stand by This function allows consumptions to be reduced. If active, 1 minute after the end of the manoeuvre, the control

unit turns off the TX of the Bluebus photocells and all the LEDS, excluding the Bluebus LED which flashes more

slowly. When the control unit receives a command normal operation is restored. For the use of the barrier with

the Solemyo system it is necessary to activate an even deeper “Stand by” mode, the “Stand by all”.

This operation is performed using the Oview programmer.

L5 Long/short deceleration This function enables the user to double the space for starting deceleration, both in Opening and Closing. If the

function is deactivated, deceleration is short.

L6 Automatic start-up This parameter, if active (ON), lets you activate the start-up (starting at maximum speed) until the pole is made to

move. The default value is “OFF”.

L7 Modo Slave By activating this function the barrier becomes “Slave”: it is possible to synchronize the operation of 2

counterposed barriers where one works as Master and the other as Slave; for more information see

paragraph 7.6 - Master-Slave Mode.

L8 Direction of motor rotation This parameter enables inversion of the direction of motor rotation to enable barrier installation on the right; the

factory setting is “OFF” (standard motor rotation – pole closure on left).

Important – If the function is activated, the Opening and Closing positions must be memorised again

(Paragraph 4.5).

EN

10 – English

The control unit has 3 keys OPEN (▲), STOP (Set), CLOSE (▼) (Fig. 49) that

can be used both for controlling the unit during testing and for programming

the available functions.

The programmable functions available are divided into 2 levels and their relative

operating status is displayed by

means of the 8 LEDs (L1 ... L8)

on the control unit.

LED SIGNALS:

• Led lit = function active;

• Led off = function not active.

PROGRAMMING KEYS:

• OPEN (▲): the “OPEN” key

enables control of pole opening

or can be used, during programming, to move the programming

point up.

• STOP (Set): the “STOP” key enables the user to stop the manoeuvre; if

pressed for more than 5 seconds, it enables entry to programming mode.

• CLOSE (▼): the “CLOSE” key enables control of pole closing or can be used,

during programming, to move the programming point down.

IMPORTANT! – During a manoeuvre (open or close) all 3 keys (▲, Set,

▼) work as STOP; causing the maneuver underway to stop or the

reverse of the maneuver.

6.1 - Level one programming (ON-OFF functions)

All the level 1 functions (Table 6) are set by default to “OFF” and may be mod-

ified at any time as explained in Table 7. The parameters can be set on a scale

from 1 to 8. To check the value corresponding to each LED see Table 6.

IMPORTANT – In the programming procedure, the maximum time interval that

can elapse between activation of one key and the next is 10 seconds. When

this time elapses, the procedure terminates automatically, memorising the

modifications made up until then.

CONTROL UNIT PROGRAMMING

6

IMPORTANT – In the programming procedure, the maximum time interval that

can elapse between activation of one key and the next is 10 seconds. When

this time elapses, the procedure terminates automatically, memorising the

modifications made up until then.

6.2 - Level two programming (adjustable parameters)

All level 2 parameters are set by default (Table 8) and may be modified at any

time as explained in Table 9.

The parameters can be set on a scale from 1 to 8. To check the value corresponding to each LED see Table 8.

Open

Stop

Set

Close

L1

Close

Open

PP

Stop

Bluebus

Light

2

L2

L3

L4

L5

L6

L7

L8

BusT4

Open

Stop

Set

Close

TABLE 7 - Programming procedure (first level functions)

01. Press and hold down the “Set” key for approx. 3 seconds;

02. Release the key when LED L1 starts flashing;

03. Press keys “▲” or “▼” to move from the flashing led to the led associated with the function to be modified;

04. Press “Set” to change the status of the function:

(short flash = OFF; long flash = ON)

05. Wait 10 seconds (maximum time) to exit the programming mode.

Note – During this procedure, points 03 and 04 need to be repeated when programming other functions to “ON” or “OFF” during the phase itself.

SET

SET

SET

L1

or

3 s

10 s

TABLE 8 - Second level functions

Input LED Parameter LED (level) Value Description

EN

English – 11

L1 L1

L2

L3

L4

L5

L6

L7

L8

3 seconds

5 seconds

7 seconds

10 seconds

15 seconds

20 seconds

40 seconds

60 seconds

Sets the pause time, i.e. the time that

passes between the end of an opening manoeuvre and the start of an

automatic closing manoeuvre

This parameter is only effective if the

“automatic Closure” is active.

Time

Pause

L2 L1

L2

L3

L4

L5

L6

L7

L8

Open – stop – close - stop

Open – stop – close - open

Open – close – open - close

Apartment block 1

Apartment block 2

Step by step 2

Hold-to-run

Opening in semi-automatic mode, closing in dead man mode

Sets the sequence of commands associated with the input or the radio

control: “Step by step”.

Function

Step by

step

L3 L1

L2

L3

L4

L5

L6

L7

L8

Speed 1 (50%)

Speed 2 (80%)

Speed 3 (100%)

Open V3, Close V1

Open V1, Close V2

Open V2, Close V3

Open V3, Close V2

Open V2, Close V1

Sets the motor speed during normal

travel.

Speed

Motor

L4 L1

L2

L3

L4

L5

L6

L7

L8

Pole Open Indicator (24 V - 10 W)

Pole closed (24 V - 10 W)

Pole open (24 V - 10 W)

Flashing light(12 V - 21 W)

Flashing light 1 (24 V - 10 W) (for pole lights)

Electric lock(24 V - 10 W)

Suction cup(24 V - 10 W)