Page 1

NIBCO INC.

WORLD HEADQUARTERS

1516 MIDDLEBURY ST.

ELKHART, IN 46516-4740

USA

PHONE: 574.295.3000

FAX: 574.295.3307

WEB: www.nibco.com

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

Review Date: 06/14/2016

Original Date: 06/01/2009

Installation and Maintenance Guidelines for

NIBCO

®

Butterfly Valves with Rubber Seats

Fire Protection Valves

Commercial Series Valves *UL/ULC/FM Listed

CWP Rating WWP Rating

Figure Numbers

LD-1000/2000/7000/8000 Series

LD/WD-2000/3000/5000 Series

LC/WC-2000 Series

LD/WD-3500 Series* 250 psi/17.2 Bar CWP, 2” – 12”

GD-4700 Series* 300 psi/ 20.7 Bar CWP, 2-1/2” – 8”

175 psi/ 12.1 Bar CWP, 10”

GD-6700 Series** 350 psi / 24 Bar CWP, 2-1/2” – 10”

GD-4800 Series* 300 psi / 20.7 Bar CWP, 2-1/2”-10”

GD-6800 Series* 350 psi / 24 Bar CWP, 2-1/2” – 10”

FC/FD-2000 Series

FC/FD-5000 Series

N-200 Series

** UL Listed only

For any technical inquiries please call NIBCO Technical Services

CAUTION: Only qualified personnel should undertake the procedures outlined in this document. NIBCO

INC., its agents, representatives and employees assumes no liability for the use of these procedures. These

procedures are offered as suggestions only.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

1

Page 2

I. SHIPMENT & STORAGE

NIBCO butterfly valves are individually boxed thru the 12" size. The 14" through 60" butterfly

valves are shipped individually with the faces covered using cardboard or plywood to protect the

flange sealing surfaces.

The disc is shipped in the nearly closed position to protect the sealing edge and prevents the

liner from taking a temporary set. The stem bushings and disc edge have been coated with a

factory-applied lubricant to prolong storage and service life.

Valves may be shipped or stored in any position. Storage should be limited to 10 years indoors

with a temperature range of 40º F to 90º F (4°C to 32°C).

II. BUTTERFLY VALVE INSTALLATION GUIDELINES

NIBCO rubber-lined butterfly valves, depending on size and pressure rating, are designed to

mate with Class 125/150 flange patterns in conformance to ASME B16.1, ASME B16.5, or

ASME B16.47 (Series A) flanges. Cast iron and steel flat-face flanges can be used with all

NIBCO butterfly valves; however, steel raised-face flanges should not be used with cast grey

iron lug-style butterfly valves (NIBCO LC2000 and N200 series).

While flange standards specify flange OD, thickness, bolt size, bolt-circle diameter, and number

of bolts, they may not specify flange opening ID. Care must be used when selecting mating

components for use with NIBCO lug and wafer style butterfly valves. The internal diameter of

flanges, fittings, and pipe must be compatible with the butterfly valve for proper seal-face

integrity and disc operation.

When in the open position, the disc extends outward from the valve body. The internal diameter

of connecting components must be large enough to allow clearance for the disc to fully open.

The disc clearances specified in Table 1 (below) are in accordance with MSS Standard Practice

SP-67 Butterfly Valves, Table A1.

NIBCO 2” thru 48” size butterfly valves have an integral rubber face that seals to the attaching

flange; therefore, a separate gasket is not necessary and should never be used.

The flange inside diameter must not be too large or it will not mate properly with this integral

seal. See Table 1 (below) for minimum and maximum inside diameters of connecting

piping/flanges to assure proper seal-face integrity and full operation of NIBCO butterfly valves.

Verify the inside diameter and clearance dimensions of all components connecting directly to a

butterfly valve

.

NIBCO butterfly valves are bi-directional and may be installed with flow in either direction. These

valve can be installed in any horizontal or vertical position. If a choice of stem positions exists,

the valve should be installed with the stem in the horizontal position; this will minimize seat wear

by distributing the stem and disc weight evenly. Also, if the media is abrasive, the horizontal

stem position is highly preferred.

Butterfly valves should be installed a minimum of six (6) pipe diameters, upstream and

downstream, from other line components. This is not always practical but it is important to design

in as much distance as possible. Interference may occur when valves are installed directly to

the outlet flange of a swing check, silent check, or reducing flange. Check valve and butterfly

valve combinations are very popular; normally a short spool piece is required between the

valves.

When using a valve with gear operator attached, it may be desirable to have the hand wheel

positioned to allow easy access, or for use of an optional adjustable sprocket rim (chain wheel)

for remote operation. Before valve installation, please review Gear Operator Installation and

Hand Wheel Positioning section of this booklet. These instructions illustrate how to orient the

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

2

Page 3

gear operator hand wheel position in relation to the valve body and piping system. Pre-planning

may save from having to remove a newly installed valve and reinstalling in another orientation.

TABLE 1

Piping/Flange Inside Diameter Requirements - Flange, Lug, & Wafer BFVs Only

Valve

Series

Valve Size

2” 2.00 2.49 1.31 2.43 1.38 2.24

2½” 2.37 2.86 1.89 3.06 1.95 2.74

3” 2.67 3.43 2.64 3.65 2.66 3.33

4” 3.69 4.55 3.67 4.75 3.67 4.55

5” 4.76 5.62 4.44 5.54 4.48 5.50

6” 5.84 6.62 5.96 6.84 5.96 6.66

8” 8.01 8.62 7.85 8.89 7.85 8.61

10” 10.00 10.80 9.73 10.70 9.76 10.75

12” 11.99 13.12 11.71 12.74 11.72 12.79

14” 13.02 14.01 13.02 15.50 — —

16” 15.20 16.30 15.20 17.90 — —

18” 17.09 18.31 17.16 19.67 — —

20” 18.90 20.08 19.10 21.05 — —

24” 23.05 24.71 23.04 25.57 — —

28” — — 27.10 29.31 — —

30” 29.06 30.29 29.08 31.28 — —

32” — — 30.91 33.93 — —

36” 33.59 35.78 33.60 36.77 — —

42” 39.83 42.77 39.87 44.96 — —

48” 44.85 48.27 44.86 51.57 — —

54” — — 50.67 54.25 — —

60” — — 54.93 60.25 — —

1000/2000/3000/5000 Series

Pipe/Flange

LD/WD/LC/WC

Minimum

ID for Disc

Clearance

Maximum

Pipe/Flange

ID for

Proper Seal

LD7000/8000 Series N200 Series

Minimum

Pipe/Flange

ID for Disc

Clearance

Maximum

Pipe/Flange

ID for

Proper Seal

Minimum

Pipe/Flange

ID for Disc

Clearance

Pipe/Flange

Proper Seal

III. GEAR OPERATOR INSTALLATION AND HANDWHEEL POSITIONING

Maximum

ID for

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

3

Page 4

TABLE 2

Tools Required

2” – 8” 9/16” Hex Wrench and 1/8” Hex Allen Wrench

Fire Protection

(UL/FM)

Commercial

10” – 12” 3/4” Hex Wrench and 1/8” Hex Allen Wrench

All Sizes 5/16” Socket Wrench for Stamped Flag

2” – 8” 9/16” Hex Wrench

10” – 14” 3/4” Hex Wrench

16” – 18” 1-1/8” Hex Wrench

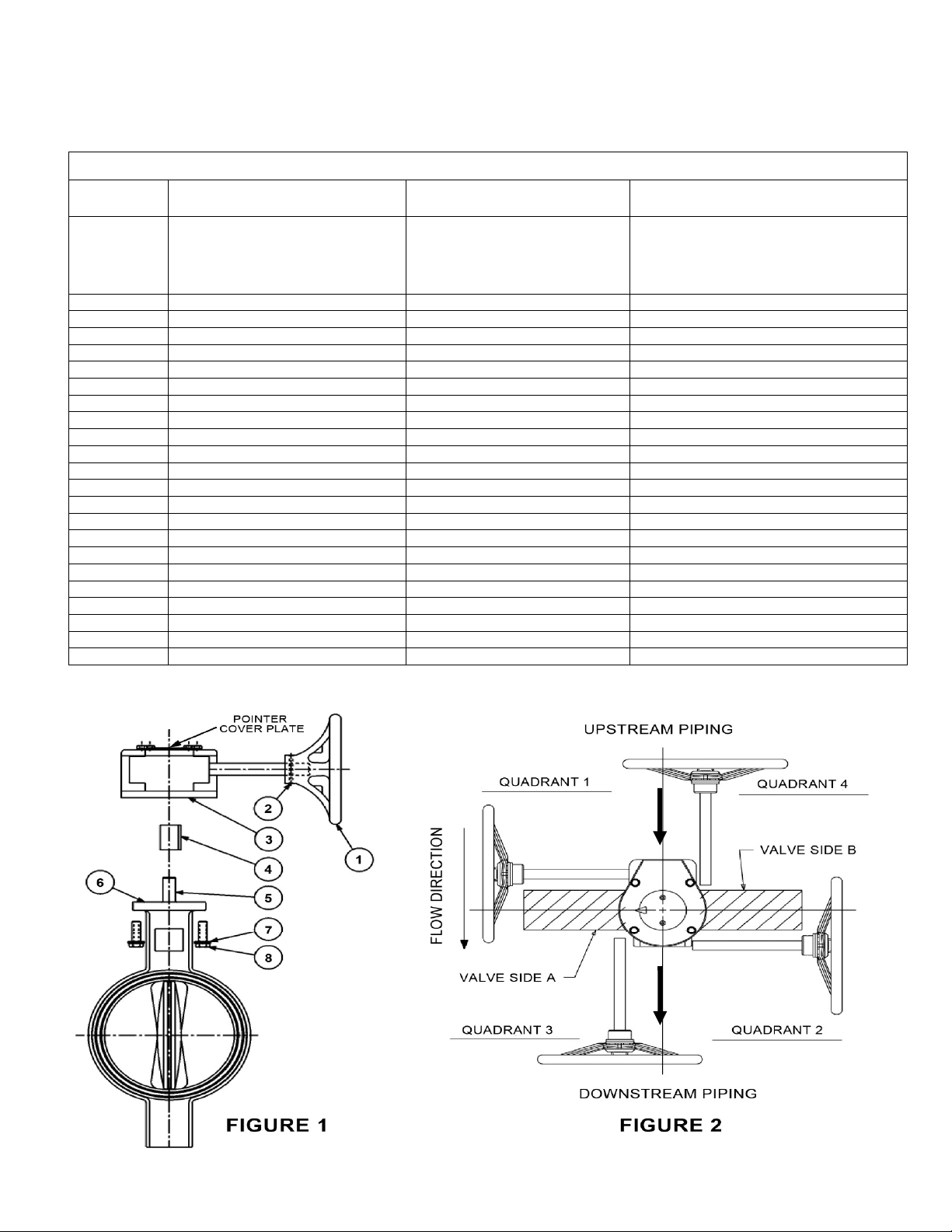

1. Install hand wheel (1) onto gear operator shaft and secure with pin (2). (If not already attached)

See Figure 1.

2. Turn the hand wheel (1) clockwise until in full SHUT position.

3. Remove 2 screws holding pointer cover plate to center of gear operator to expose bore. Retain

pointer cover plate and screws for reinstallation later.

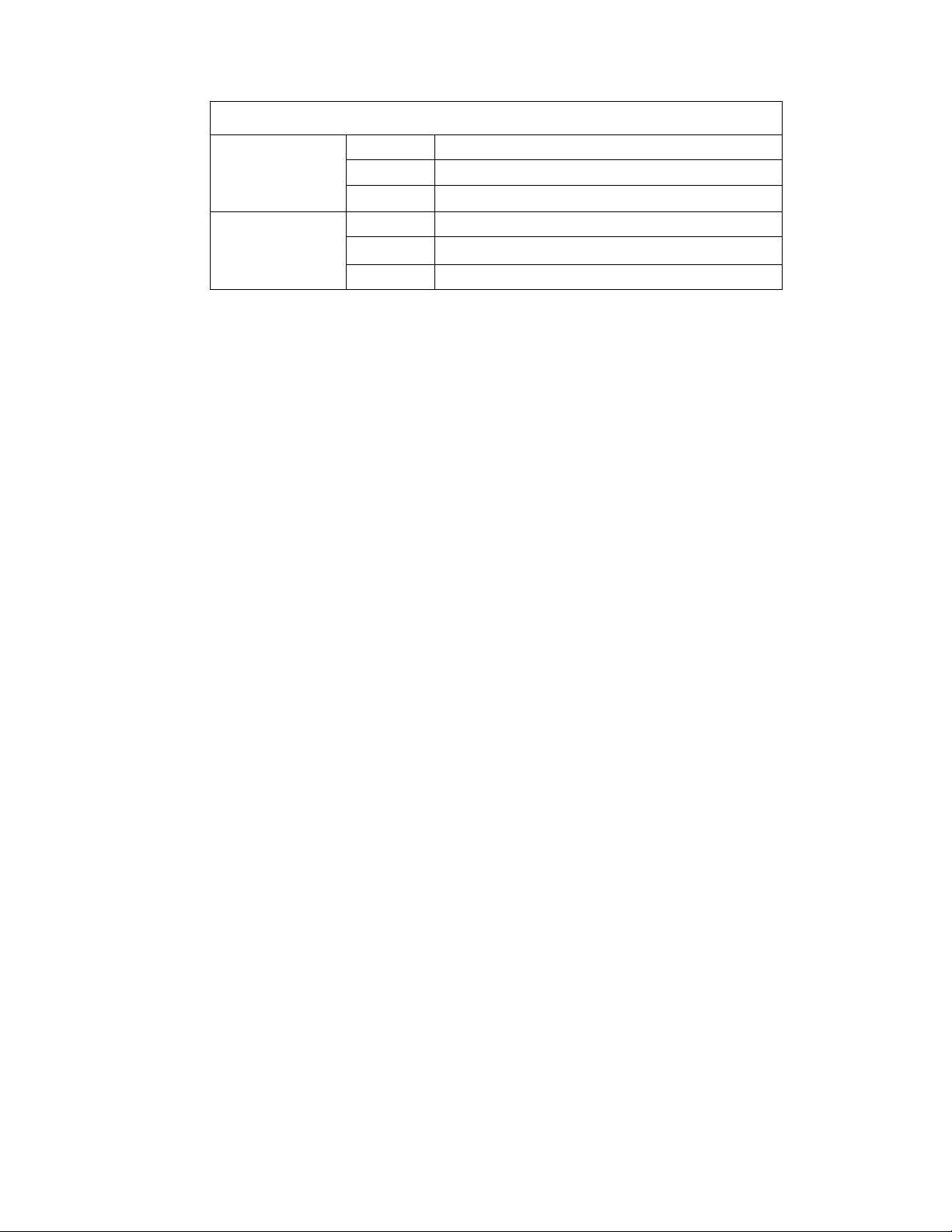

4. Assure valve is in full SHUT position, turn valve stem (5) to close disc if necessary.

5. Assure mounting base of gear operator (3) and the valve top flange (6) are both clean and dry.

6. Determine desired hand wheel position in reference to the piping system and compare with Fig.

2. There are 2 mounting positions for the gear operator onto the valve and the valve can be

mounted in either direction into the piping system. This will allow hand wheel to be positioned in

any of the 4 quadrants as shown in Fig. 2. Note that all Fire Protection and 10” and 12” size

commercial valves allow for hand wheel positioning in quadrants 1 and 2 only.

7a. Gear operators with adapter bushing:

Insert adapter bushing (4) into gear operator (3) bore aligning bushing key with desired

keyway. Keyway selection will determine hand wheel orientation position. (Note that Fire

Protection model adapter bushings differ from illustration and only have 1 keyway position).

Align adapter bushing (4) bore with valve stem (5) and slide gear operator assembly onto valve

stem (5) until seated with valve top flange.

7b. Gear operators without adapter bushing:

Align gear operator (3) bore with valve stem (5) and align with desired keyway. Keyway

selection will determine hand wheel orientation position.

Slide gear operator assembly onto the valve stem (5) until seated with valve top flange.

8. Tightly secure gear operator (3) to valve top flange (6) using supplied* fasteners (7 & 8).

9. Reinstall pointer cover plate onto gear operator removed in Step 3 above. Arrow should be aligned

to indicate SHUT position.

10. Install flag and secure with Allen Screw. (Fire Protection gear operators only).

11. Rotate hand wheel from SHUT to Full OPEN positions several times to assure proper orientation.

See Stop Adjustment Procedure Section of this instruction booklet if stop alignment adjustment is

necessary.

12. Proceed with valve installation into piping system.

* A minimum of two fasteners is required, installed in opposite diagonal corners.

NOTES:

For Fire Protection gear operators, it is critical to use only the key supplied with gear operator

in order to conform to UL, FM and ULC specifications.

Connection of gear operator to valve stem varies depending on gear operator model, size and

style. The adapter bushing and key may be different from Figure 1 illustration shown.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

4

Page 5

IV. VALVE INSTALLATION PROCEDURE – FLANGE, LUG & WAFER STYLE ONLY

Always position the connecting pipe flanges accurately in the line, allowing sufficient space between

the flanges for the valve. Make sure the pipe flange faces are clean of any foreign material such as

scale, metal shavings or welding slag. Valves should be installed with the disc in the closed position

to prevent damage to sealing surfaces.

NOTE: Fully open and fully shut any butterfly valve before attempting to install it into a system, to

ensure and confirm the valve is operational across its travel range and seating properly in the opened

and shut positions.

1. Carefully ins ert the valve between the pipe flanges. Do not apply any lubricants to the seat faces

as this may damage them.

2. Line up, center and secure the valve between flanges using desired bolts or studs as listed in Table

4. Do not tighten bolts at this time.

3. Carefully open the valve to assure free unobstructed disc movement. Disc interference may result

when valves are installed in pipelines having smaller than normal inside diameters, such as heavy

wall pipe, plastic-lined pipe, as-cast flanges, or reducing flanges. Interference can also occur when

connecting directly to a swing check or silent check. Suitable corrective measures must be taken

to remove these obstructions, such as taper boring the pipe or installing a spacer or spool piece.

4. After proper operation is verified, tighten the bolts to the minimum recommended bolt torques listed

in Table 3, below, using a cross-over pattern as shown in Figure 3. NOTE: When installing any

cartridge liner butterfly valve, i.e. N200 valves or LD 1000/2000 valves NPS 14” and larger,

between two flanges, it is critical that the cartridge liner be evenly compressed from both

sides of the mating flanges (REFER to NIBCO Technical Bulletin NTB-1012-03 for more

details). NIBCO recommends a multi-stepped process utilizing the cross-over pattern be used to

draw the flanges against the liner from both side of the valve at the same rate, ensuring the liner

is compressed evenly. This method differs from the practice used on smaller valves, wherein one

flange side is completely tightened before moving to the opposite side.

5. Pressurize piping to valve and inspect for leakage. If leakage is observed, tighten bolts using

cross-over pattern, increasing torque until leak stops.

DO NOT EXCEED MAXIMUM TORQUES LISTED IN TABLE 3 BELOW.

6. Recommended torques are made without warranty. Installer must verify proper strength bolts for

application. Bolts shall be clean and un-lubricated.

NOTES:

LUG STYLE VALVES – Extra care should be used when installing with raised faced flanges.

Over tightening of bolts can result in broken valve lugs.

Class 250 cast iron and Class 300 steel flanges cannot be used on these valves.

Rubber faced or mechanical flanges are not recommended.

These valves are not recommended for steam service.

Valves should not be assembled to the flanges & then welded into the piping system.

Lever-lock handles are not recommended for use on 8” and larger valves.

Do not install valves with EPDM liner in compressed air lines.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

5

Page 6

TABLE 3

Recommended Bolt Tightening Torques

Flange Size Bolt Size

2” – 4” 5/8” 20 70

5” – 8” 3/4” 30 120

10” and 12” 7/8” 50 200

14” and 16” 1” 70 240

18” and 20” 1-1/8” 100 380

24” – 30” 1-1/4” 140 520

32” – 48” 1-1/2” 200 800

54” – 60” 1-3/4” 350 1800

Minimum Bolt

Torque (ft./lbs.)

Maximum Bolt

Torque (ft./lbs.)

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

6

Page 7

)

TABLE 4

Recommended Bolt Lengths

A)

CLASS 125

VALVE SIZE

SERIES ONLY

1000 / 2000 / 3000

5000 / 7000 / 8000

2” 1.69

2-1/2” 1.81

3” 1.81

4” 2.06 0.94 0.94 — 1.75 5.00 16 5/8 – 11 UNC

5” 2.19 0.94 0.94 — 1.75 5.00 16 3/4 – 10 UNC

6” 2.19 1.00 1.00 — 2.00 6.00 16 3/4 – 10 UNC

8” 2.38 1.12 1.12 — 2.25 6.00 16 3/4 – 10 UNC

10” 2.69 1.19 1.19 — 2.25 7.00 24 7/8 – 9 UNC

12” 3.00 1.25 1.25 — 2.50 7.00 24 7/8 – 9 UNC

14” 3.01 1.38 1.38 — 2.50 7.00 24 1 – 8 UNC

16” 3.38 1.44 1.44 — 3.00 8.00 32 1 – 8 UNC

18” 4.12 1.56 1.56 — 3.00 9.00 32 1-1/8 – 7 UNC

20” 5.14 1.69 1.69 — 3.50 10.00 40 1-1/8 – 7 UNC

24” 5.98 1.88 1.88 — 4.00 11.00 40 1-1/4 – 7 UNC

28” 6.42

30” 6.57

32” 7.40

36” 8.00

42” 9.88

48” 10.87

54” 15.00

60” 15.00

BODY WIDTH

TOTAL VALVE

CAST IRON

ASME B16.1

0.63 — — 1.25 4.00 8

— 0.75 — 1.50 4.00 8

0.69 — — 1.50 5.00 8

— 0.88 — 1.75 5.00 8

0.75 — — 1.50 5.00 8

— 0.94 — 1.75 5.00 8

— — — — — 56

— — — 4.00 — 56

— — — 4.00 — 56

— — 2.81 5.00 — 56

2.12 — — 3.50 — 56

— — — 3.00 — 56

— — — 3.50 — 56

— — 2.94 4.25 — 56

— — — — — 56

— — — 4.00 — 56

— — — 4.00 — 56

— — 3.91 5.00 — 56

2.38 — — 4.00 — 64

— — — 3.50 — 64

— — — 4.00 — 64

— — 3.56 5.00 — 64

2.62 — — 4.50 — 72

— — — 4.00 — 72

— — — 4.50 — 72

— — 3.81 5.50 — 72

2.75 — — 4.50 — 88

— — — 4.50 — 88

— — — 5.00 — 88

— — 4.25 6.00 — 88

3.00 — — 7.00 — 88

— — — 7.00 — 88

— — — 7.50 — 88

— — 4.75 8.50 — 88

3.12 — — 7.00 — 104

— — — 7.00 — 104

— — — 8.00 — 104

— — 5.19 9.00 — 104

FLANGE THICKNESS

ASME B16.5

CLASS 150 STEEL

FLANGE THICKNESS

MSS SP-44

CLASS 150 STEEL

ASME B16.47 (SERIES

RECOMMENDED

FLANGE THICKNESS

LENGTH

CAP SCREW

(LUG & FLANGE

STYLE VALVES

BOLT LENGTH

RECOMMENDED

(WAFER VALVES)

TOTAL QUANTITY

(TO MOUNT VALVE

BETWEEN 2 FLANGES)

CAP SCREWS / BOLTS

CAP SCREW SIZE

5/8 – 11 UNC

5/8 – 11 UNC

5/8 – 11 UNC

1-1/4 – 7 UNC

1-1/4 – 7 UNC

1-1/2 – 6 UNC

1-1/2 – 6 UNC

1-1/2 – 6 UNC

1-1/2 – 6 UNC

1-3/4 – 5 UNC

1-3/4 – 5 UNC

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

7

Page 8

GEAR OPERATOR PART NUMBERS

2” – 12”

UL/FM VALVE GEAR OPERATOR

2” – 24”

COMMERCIAL VALVE GEAR OPERATOR

Part

Number

T117166 PP

T117167 PP

T117890 PP

T117168 PP

UL/FM VALVE GEAR OPERATOR

Part

Number

T118775 PP 2-1/2” – 4” GD-4865/6865

T118776 PP 6” – 8” GD-4865/6865

T117168 PP 10” GD-4865/6865

Valve

Size

2” – 4”

2-1/2” – 3”

5” – 6”

4” – 6”

8”

8”

10” – 12”

10”

2-1/2” – 10”

Valve

Size

Valve

Series

WD/LD-3510

GD-4765

WD/LD-3510

GD-4765

WD/LD-3510

GD-4765

WD/LD-3510

GD-4765

Valve

Series

Part

Number

T117118 PP

T117119 PP

T117120 PP

T117121 PP

T116697 PP

T026150 PP

T026151 PP

T026211 PP

T026212 PP

Valve

Size

2” – 6”

2” – 5”

8”

6” – 8”

10”

12”

10” – 12”

14”

16”

18”

20”

24”

Valve

Series

WD/LD-2000/3000

FC/FD/GD-

2000/5000/4000

WD/LD-2000/3000

FC/FD/GD-

2000/5000/4000

WD/LD-2000/3000

WD/LD-2000/3000

FC/FD/GD-

2000/5000/4000

LD-1000/2000

TABLE 5

2” – 8” valves 4mm or 5mm Hex Allen Wrench

10” – 18” valves 6mm Hex Allen Wrench

20” – 24” valves 8mm Hex Allen Wrench

Tools Required

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

8

Page 9

V. STOP ADJUSTMENT PROCEDURE

NOTE: It is best to visually check the valve disc OPEN and SHUT positions before the valve is

installed in the system piping to assure proper valve operation.

1. Attach gear operator to the top of the valve and securely tighten bolts, or verify bolts are

securely tight if you received a valve with the gear operator already attached.

2. Rotate the hand wheel clockwise until it stops. Visually check to see that the valve disc is

centered in the valve seat for proper seal. Note that the indicator flag (Fire Protection) or

pointer (Commercial) on top of gear operator represents the disc position. If the stop location

is not correct, proceed to step 5.

3. Rotate the hand wheel counter-clockwise until it stops. Visually check to see that the valve

disc is centered in the valve opening. Note that the indicator flag (Fire Protection) or pointer

(Commercial) on top of gear operator represents the disc position. If the stop location is not

correct, proceed to step 5.

4. If both stops are set correctly, valve is ready for installation.

5. Stop adjustment – Using a proper size hex Allen wrench, remove both locking set screws (A)

as shown in Figures 5 and 6.

SHUT stop adjustment - Using proper size hex Allen wrench, turn set screw (B) counter-

clockwise 2 turns. Rotate hand wheel until disc is centered in valve seat. Turn set screw

(B) clockwise until it stops. Secure set screw “B” by replacing only one locking set screw

(A) in same hole and tightening it until it stops.

OPEN stop adjustment – Using proper size hex Allen wrench, turn set screw (C) counter-

clockwise 2 turns. Rotate hand wheel until disc is centered in valve opening. Turn set

screw (C) clockwise until it stops. Secure set screw (C) by replacing second locking set

screw (A) in same hole and tightening it until it stops.

6. Again visually verify both OPEN and SHUT stops are correctly set. Repeat step 5 if

necessary.

7. If the valve is installed in the system piping and cannot be removed, it is possible to adjust

the stops, but is a little more difficult. The only difference is that instead of visually checking

the actual disc in the valve; you have to visually check the flag (Fire Protection) or pointer

(Commercial) position. Because the exact flag or pointer position is more difficult to

determine, it may take a couple tries to set the SHUT stop. OPEN stop adjustment is not

critical; ±5° travel is adequate.

NOTE: The gear operator’s OPEN and SHUT positions have been set at time of shipping.

These instructions should be used for slight adjustment as needed.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

9

Page 10

VI. SWITCH DETAILS– UL/FM FIRE PROTECTION GEAR OPERATORS

Rating:

11 amps @ 125 VAC 60 Hz, or 1 amp @ 28 VDC non-inductive.

Wiring:

All lead wires are 18 AWG, 18 inches long and exit the operator housing through a single threaded

hole designed for use with a ½ inch conduit fitting.

Valve Series

GD4765-8N

WD/LD3510-8*

GD4765C-8N

WD/LD3510C-8*

GD4865-8N

GD6865-8N

GD4865C-8N

GD6865C-8N

*2002 or Newer Model Wafer & Lug UL/FM Butterfly Valves

Supervision Position Switch Kit Number

Valve Open

Valve Closed

T117774 PP

(TS-4)

T1447531 PP

Valve Open

Valve Closed

T1446762 PP

T1447532 PP

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

10

Page 11

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

11

Page 12

VII. TS-4 SWITCH T-117774 PP & T-1446762 PP SWITCH REPLACEMENT

INSTRUCTIONS FOR FACTORY INSTALLED SWITCHES FOR NIBCO GD4765-8N,

GD4765C-8N, WD/LD3510-8, WD/LD3510C-8 (2002 or Newer Model Wafer & Lug

UL/FM Butterfly Valves)

TABLE 6

Tools Required

1/8” Hex Allen Wrench

All valves

2” – 8” valves

10” – 12” valves

Standard Flat Blade Screwdriver

Continuity Tester

5/32” Pin Head Wrench

9/16” Socket Wrench

3/16” Pin Head Wrench

3/4” Socket Wrench

FIGURE 8

1. Remove flag (A) by backing out (approx. 2 turns) screw (B). See Figure 8.

2. Remove one tamper-proof pin head screw (C), three hex head screws (D), and gear operator

cover (E).

3. Remove the two screws holding the switch assembly into the housing, and one screw holding

the green ground wire to housing, and remove complete switch assembly.

4. Feed electrical wires of new switch assembly through the conduit hole in rear of housing.

5. Place two screws (with lock washers) thru the switch mounting holes, then thru the mounting

holes of the insulation paper. Place switch assembly (F) into gear housing with switch actuating

arms against quadrant gear. Tighten two screws to secure switches, and one screw to secure

green ground wire to housing.

6. Conduct switch continuity test to make sure they are functioning properly. Refer to Figure 7.

7. Reinstall cover plate, screws, and flag. Tighten all screws.

8. Auxiliary switch end connection to be reviewed and accepted by local authority having

jurisdiction.

NOTE: Instructions are the same regardless of valve end connections.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

12

Page 13

VIII. T-1446762 PP AND T1447532 PP SWITCH REPLACEMENT INSTRUCTIONS

FACTORY INSTALLED SWITCHES FOR NIBCO GD4865-8N, GD4865-C-8N,

GD6865-8N, GD6865-C-8N UL/FM Butterfly Valves

NOTE: Grooved end valve shown

For illustration purposes only.

See SECTION VII. SWITCH REPLACEMENT INSTRUCTIONS

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

13

Page 14

IX. KEY DRIVE REPLACEMENT INSTRUCTIONS – 2” THRU 12” UL / FM BUTTERFLY

VALVES

NOTES:

All replacement parts must be obtained from your NIBCO distributor. Key drive material and

size is specifically designed to meet performance requirements of UL and FM. Failure to use

the properly sized replacement parts may void the UL and FM ratings.

Drive Key (s ection of weakness) will shear if excessive torque is applied to the input of the

gear operator while the disc is blocked partially open.

TABLE 7

Tools Required

All valves 1/8” Hex Allen Wrench

2” – 8” valves 9/16” Socket Wrench

10” – 12” valves 3/4” Socket Wrench

FIGURE 9

1. Loosen the set screw (B) that secures the flag (A) to the stem. Remove the flag. See Fig. 9.

2. Remove the four (4) hex head cap screws (C) that fasten the gear operator (D) to the valve.

3. Lift the gear operator straight up from the valve. In most cases the adapter bushing (F) will stay

in the segment quadrant gear because the broken key causes interference between the gear

and adapter bushing.

4. Pull the adapter bushing from the gear. Some force may be required.

5. After removing the adapter bushing, remove the broken key.

6. Place the new key in keyway of adapter bushing (F).

7. With drive adapter bushing and key in place within gear operator, carefully slide the gear

operator over stem until it rests flush on the valve operator mounting flange. The hand wheel

may need to be turned in order to align bolt holes and the orientation pin.

8. Secure gear operator with four (4) hex head screws (securely tighten), replace flag on stem

and then tighten set screw on flag.

9. Check operation of valve by turning hand wheel from fully OPEN to fully SHUT position.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

14

Page 15

X. MEMORY STOP INSTALLATION INSTRUCTIONS –

2” THRU 24” SIZE COMMERCIAL GEAR OPERATORS ONLY

TABLE 8

Tools Required

All valves

2” – 8” valves 10mm Wrench

10” – 24” valves 13mm Wrench

2.5mm Hex Allen

Wrench

FIGURE 10

1. Remove the two screws holding the top cover (Indicator Pointer) onto segment gear. Discard

cover and screws. See Figure 10.

2. Place indicator (5), supplied with kit, around bottom hub (4). Align key (6) on bottom hub with

slot in segment gear and slide into place.

3. Attach with two supplied M4 x 12 flat head screws (3).

4. Remove one cap screw (1) holding cover onto gear operator housing and replace with stop

pin (7).

5. Use cap screw (1) you just removed to secure the top hub (2) to the bottom hub (4). Top hub

can be moved 360 degrees in 5 degree increments.

6. Tighten cap screw (1) once top hub is appropriately set.

NOTE: The gear operator provides a large mechanical advantage. Be careful to stop turning

the handwheel when the pointer of top hub (2) contacts stop pin (7) to prevent damage.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

15

Page 16

XI. MAINTENANCE AND REPAIR – ALL SERIES & SIZES - VALVES ONLY

Due to the many unique features in the NIBCO butterfly valve design, there is no regular

maintenance or lubrication required.

XII. GEAR OPERATOR SERVICE & MAINTENANCE

During installation, customer should carefully adjust gear operator stops for proper valve OPEN and

SHUT positioning.

NIBCO gear operators are suitable for both indoor and outdoor service. However, outdoor service

can be harsh depending upon the conditions that the unit is exposed to. For example; constant

exposure to high heat, humidity, rain, snow, salt spray, or other corrosive media may lead to corrosion

of the iron castings, steel hand wheel shaft, or other components.

NIBCO recommends that gear operators exposed to these extreme conditions be checked and

serviced on a regular basis. This can be accomplished during normal exercising or operation of the

valve (Butterfly Valves should be operated at least once per year or depending upon conditions, as

often as quarterly).

NIBCO tries to balance the needs of our customers and provide a gear operator that fits most service

conditions. It is the responsibility of the ultimate installer / owner to specify the valve and gear operator

based upon the application and conditions that it will be exposed to.

For general gear operator maintenance, refer to NIBCO Technical Bulletin NTB-1012-01

.

For harsh outdoor service refer to NIBCO Technical Bulletin NTB-0208-02 to address maintenance

that can be performed in the field for units installed outdoors in extreme conditions.

For installations where spare parts are held on site, it is suggested that a spare gear operator be held

as an interchangeable item.

NIBCO Technical Services • Phone: 1.888.446.4226 • Fax: 1.888.336.4226

16

Loading...

Loading...