PSH150 user manual rev4

Page 1/15

PSH150

10kV Isolation Programmable Power

Supply

User Manual

POWERMASTER

PSH150 user manual rev4

Page 2/15

DISCLAIMER

NEXTYS

reserves the right to make changes without further notice to any products herein.

NEXTYS

makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does

NEXTYS

assume any liability arising out of the application or use of any

product, and specifically disclaims any and all liability, including without limitation consequential or

incidental damages. “Typical" parameters which may be provided in

NEXTYS

data sheets and/or

specifications can and do vary in different applications and actual performance may vary overtime. All

operating parameters, including “Typicals", must be validated for each customer application by

customer's technical experts.

NEXTYS

does not convey any license under its patent rights nor the

rights of others.

NEXTYS

products are not designed, intended, or authorized for use as components in

systems intended for surgical implant into the body, or other applications intended to support or

sustain life, or for any other application in which the failure of the

NEXTYS

product could create a

situation where personal injury or death may occur. Should Buyer purchase or use

NEXTYS

products

for any such unintended or unauthorized application, Buyer shall indemnity and hold

NEXTYS

and its

officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs,

damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim

of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that

NEXTYS

was negligent regarding the design or manufacture of the part.

The Customer should ensure that it has the most up to date version of the document by contacting its

local

NEXTYS

office. This document supersedes any earlier documentation relating to the products

referred to herein. The information contained in this document is current at the date of publication. It

may subsequently be updated, revised or withdrawn.

The Customer should ensure that

NEXTYS

product uses the most up to date Software and Firmware

provided on

NEXTYS

website to ensure reliable operation of the system.

All Trade Marks recognized. Specifications and information herein are Subject to change without

notice.

PSH150 user manual rev4

Page 3/15

TABLE OF CONTENTS

1 Product description ........................................................................................................................ 4

2 Features and benefits .................................................................................................................... 5

3 Functional description .................................................................................................................... 6

3.1 Main DC output ..................................................................................................................... 7

3.2 Auxiliary 12V output ............................................................................................................... 8

3.3 INHIBIT input ......................................................................................................................... 8

3.4 Display interface .................................................................................................................... 8

3.4.1 Normal operation ............................................................................................................. 8

3.4.2 Menu navigation .............................................................................................................. 9

3.4.3 Alarm codes ................................................................................................................... 10

3.5 Parallel connection .............................................................................................................. 10

3.6 Modbus Interface ................................................................................................................. 11

4 Installation ................................................................................................................................... 12

PSH150 user manual rev4

Page 4/15

1 Product description

Use latest device Documentation, Software and Firmware to ensure reliable operation of

the system (downloadable from www.nextys.com).

PSH150 is an advanced DIN rail 1-phase input, 150W SMPS (Switched Mode Power Supply) with a

distinctive feature: 10kV isolation between primary and secondary.

This allows it to be used in energy management, telecom, renewable energy and other demanding

applications.

Figure 1: Front panel view

1. AC input: 2 poles are provided for input connection. This must be connected to the AC or

DC line source. Voltage range is 90…277Vac or 110…400Vdc.

2. Modbus over USB: Used to connect a device running POWERMASTER or custom

application. Firmware update is also possible.

3. Modbus over RS-485: Used to connect a device running POWERMASTER or custom

application. Firmware update is also possible.

4. INHIBIT input: A voltage between 5Vdc and 30Vdc applied to this input activates the

inhibit function (§3.3).

5. Auxiliary 12Vdc output: This output provides a regulated 12Vdc output with 100mA

maximum output current. This output is short circuit protected (§3.2).

6. DC-OK dry contact: normally open and normally closed relay contacts are available; the

relay closes when the output voltage is >90% of the programmed output voltage value.

7. DC Output: 4 poles are provided for output connection; it must be connected to the load.

The output voltage is adjustable between 5…55Vdc. (§3.1)

8. Control keys: 3 push buttons are provided to navigate through menus and to select

various functions.

9. Display: 3-digits LED display providing information about the device status (§3.4).

10. Units LEDs: 2 green LEDs are used to indicate the actual measurement indicated on the

display (§3.4.1).

11. Alarm LED: blinking when there is an alarm; the relevant alarm code is indicated on the

display (§3.4.3).

PSH150 user manual rev4

Page 5/15

2 Features and benefits

Class II wiring (PE connection not required)

10kVac primary to secondary isolation (suitable for energy management applications)

Wide output voltage range 5…55Vdc, user settable

Auxiliary 12V/100mA power supply

High efficiency and compact size

Remote ON/OFF or other remote control functions possible through INHIBIT input

Modbus over RS-485 or USB interfaces for control and monitoring

Multiple protections

Can be paralleled for power or redundancy (integrated ORing circuitry)

Up to 50°C operating temperature with no derating

Wall mount fixing possible

Suitable for POWERMASTER software (available for Windows and Android)

Embedded user interface:

3 keys and 3 digits 7-segments LED display

Allows online device configuration

Displays the PSH150 status and alarms

Free PC and Android application POWERMASTER used for:

Connection through Modbus

Remote monitoring and configuration

Firmware upgrade

Same functionalities of the embedded used interface with the ease of the PC benefits

PSH150 user manual rev4

Page 6/15

3 Functional description

PSH150 includes a 1 phase SMPS module with PFC and class II wiring. A converter located on the

secondary side allows the supply of a programmable voltage (5 to 55V), with user settable current

limitation. The output is provided with an active ORing circuit that allows the parallel connection for

redundancy of several units without the need of an external redundancy module.

An auxiliary power supply of 12V/100mA is available.

An external INHIBIT signal can be applied for controlling the output status.

A multifunctional display shows the output parameters and 3 keys can be used for programming the

unit. A dry contact (relay) is related to “DC-OK” status.

RS485 and USB ports are available for remote monitoring and setup.

Power path

Monitoring and control

EMI

f ilter

PFC

Input

Isolation

10kV

DC

DC

DC

DC

I

U

Output voltage

and current

measurement

Digital

fuse

U

Voltage

measurement

Output

Aux

supply

uController

Modbus/RTU

USB

RS485

I/O

Relay

Inhibit

HMI

Digital control

DC/DC

converter

Figure 2: PSH150 simplified block diagram

PSH150 user manual rev4

Page 7/15

3.1 Main DC output

PSH150 provides a DC output programmable from 5Vdc to 55Vdc with up to 12A output current and a

maximum output power of 150W. The maximum output current varies according to the programmed

output voltage and to the ambient temperature; in Figure 3 and Figure 4 the current and power

derating curves are reported.

Current Derating Curve

0

2

4

6

8

10

12

14

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Temperature [°C]

Current [A]

5V 12V 24V 48V

Figure 3: PSH150 current derating curves

Power Derating Curve

0

40

80

120

160

-40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Tem perature [°C]

Power [W]

5V 12V 24V and 48V

Figure 4: PSH150 power derating curves

The output is short circuit protected; in case of an output short circuit the output is switched off and an

hiccup cycle is started. A “short circuit” alarm code is reported on the display (§3.4.3).

PSH150 user manual rev4

Page 8/15

3.2 Auxiliary 12V output

PSH150 is provided with an auxiliary regulated 12V output with up to 100mA current capacity. This

output is short circuit protected. The auxiliary output shares the same ground (negative terminal) with

the main DC output.

3.3 INHIBIT input

An opto-isolated input allows switching off the main DC output. The polarity of the input can be

defined using the “inhibit polarity” (POL) field (§3.4.2). The controlling signal must have a voltage

between 5Vdc and 30Vdc. The auxiliary 12V output is always active and can not been switched off.

3.4 Display interface

The PSH150 is provided with a 3-digits 7-segments LED display used to indicate the status and to

navigate through the configuration menus. During normal operation, the output parameters are

reported (§3.4.1). Alarms and error codes are also reported on the display (§3.4.3)

3.4.1 Normal operation

During normal operation the output voltage, current and power are reported on the display. 2 green

LEDs indicate which measurement is currently shown. Every parameter is visible for 3 seconds, then

the next measurement is shown.

V

A

!

W

Output voltage measurement:

The display is indicating 24.0V. Note that the “V”

green LED is on, indicating voltage

measurement.

V

A

!

W

Output current measurement:

The display is indicating 6.0A. Note that the “A”

green LED is on, indicating current

measurement.

V

A

!

W

Output power measurement:

The display is indicating 144W. Note that both

the “V” and “A” green LEDs are on, indicating

power measurement.

.

PSH150 user manual rev4

Page 9/15

3.4.2 Menu navigation

The layout of the menu is shown in Figure 5. The various options are selected with the 3 keys.

2s

2s

Set

Set

(Stor e)

Set

5s 5s

Output

Volta ge

(No st ore)

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Output

measures

Output

voltage

Inhibit

polarity

5s

(No st ore)

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Operating

mode

5s

(No st ore)

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Modbus

addess

5s

(No st ore)

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Modbus

baudrate

5s

(No st ore)

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Modbus

stop bits

5s

2s

Set

Set

(Stor e)

Set

5s

Output

Volta ge

Modbus

parity

5s

(No st ore)

Allowed values: 5..55V

Default value: 5V

Allowed values: Low (LO), High (Hi)

Default value: High

Allowed values: Single (SI), Parallel (PA)

Default value: Single

Allowed values: 1..247

Default value: 1

Allowed values: 4.8, 9.6, 19.2, 38.4Kb/S

Default value: 38.4

Allowed values: 1, 2

Default value: 1

Allowed values: None (No), Even (Ev), Odd (Od)

Default value: Even

Over temperature

Output short circuit Internal error

u

Figure 5: HMI

PSH150 user manual rev4

Page 10/15

3.4.3 Alarm codes

In case of internal or external faults an error code is reported on the display. When an error code is

reported the “Alarm” red LED blinks at 1Hz rate.

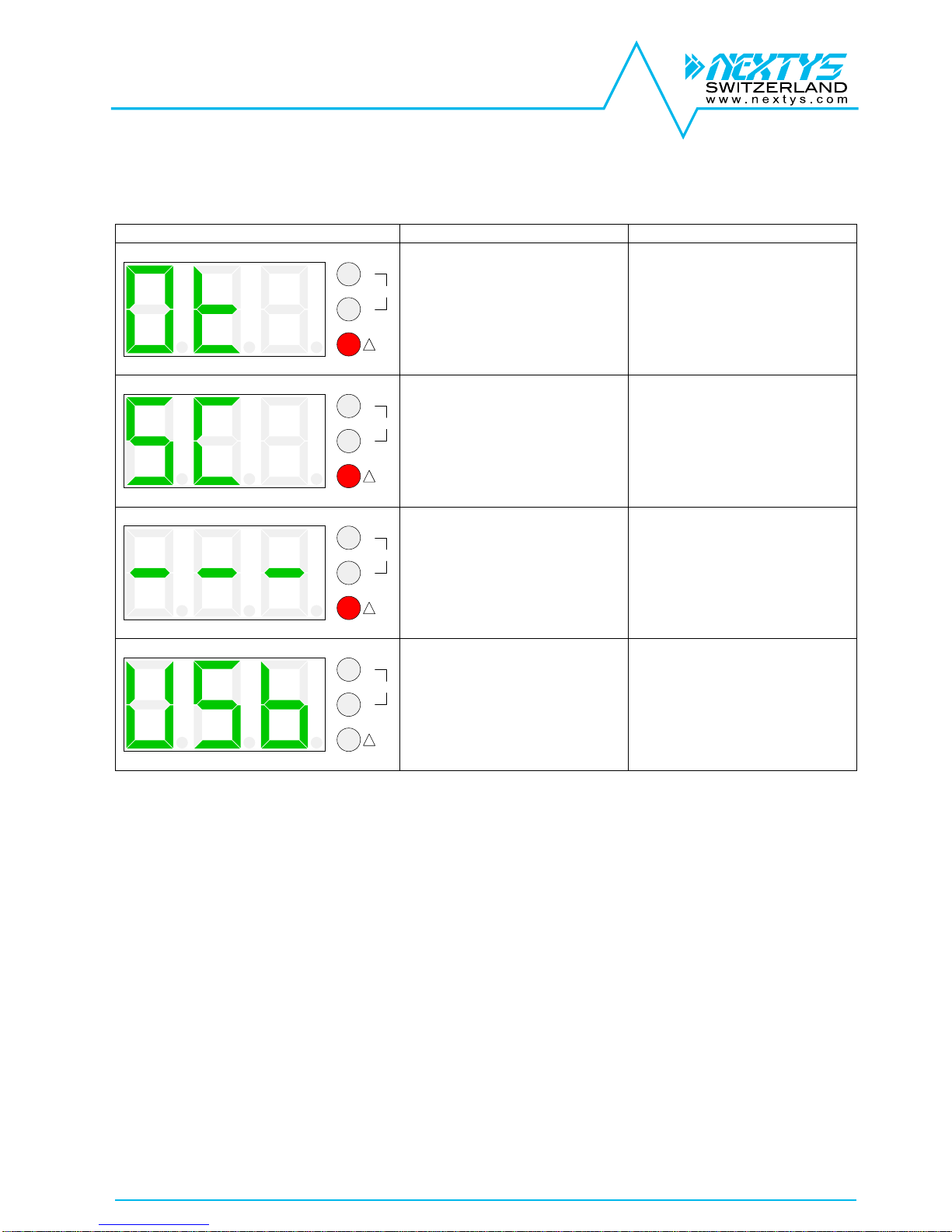

Display code

Description

Behaviour

V

A

!

W

Over-temperature protection

The red LED blinks

The output is switched off

until the internal temperature

decreases to safe values

V

A

!

W

Short circuit protection

The red LED blinks

The output current is limited

at the programmed value for

5 seconds, then the product

switches off for 10 seconds.

The cycle is repeated until

the short circuit is removed

V

A

!

W

Internal error, non

recoverable

The red LED blinks

The output is switched off.

This error is caused by an

unrecoverable internal fault

V

A

!

W

USB power, no mains

available

The product is powered

through USB and the input

mains is not present. The

user can navigate through

the menus. It can be used for

firmware upgrade without the

need of the input mains.

3.5 Parallel connection

Multiple PSH150 can be connected with the output in parallel for power increase and / or redundancy.

In this mode of operation, the field “operating mode” (OP) shall be set to “Parallel” (PA).

The unit integrates an internal ORing circuit allowing paralleling several units for redundancy.

For proper operation the cable length connecting the PSH150 outputs to the load must have the same

length and cross-section. For optimal current sharing it may be necessary to slightly adjust one of the

two devices output voltage until the same current is delivered by the two units. It is recommended to

limit the load power to 80% of the sum of the individual output power of the paralleled units.

PSH150 user manual rev4

Page 11/15

3.6 Modbus Interface

PSH150 supports Modbus RTU over RS-485 line or USB (Virtual com port). The following Modbus

table is implemented:

Name

Address

Hex (dec)

Modbus type

Function

code

Description

Modbus settings (loaded on next startup)

Address

0x1000 (4096)

Hold register

3,4,6,16

Range 1..247

Baudrate

0x1001 (4097)

Hold register

3,4,6,16

1: 4800

2: 9600

3: 19200

4: 38400

Parity

0x1002 (4098)

Hold register

3,4,6,16

1: None

2: Even

3: Odd

Stop bits

0x1003 (4099)

Hold register

3,4,6,16

1: 1 stop bits

2: 2 stop bits

Device settings

Output voltage

0x1010 (4112)

Hold register

3,4,6,16

Inhibit polarity

0x1011 (4113)

Hold register

3,4,6,16

Operating mode

0x1012 (4114)

Hold register

3,4,6,16

Display mode

0x1013 (4115)

Hold register

3,4,6,16

1: Automatic

2: Voltage

3: Current

4: Power

Output enable

0x1014 (4116)

Hold register

3,4,6,16

0: Disabled

1: Enabled

Auxiliary output

enable

0x1015 (4117)

Hold register

3,4,6,16

0: Disabled

1: Enabled

Metering

Output voltage

0x2000 (8192)

Input register

3,4

Measured output voltage

Output current

0x2001 (8193)

Input register

3,4

Measured output current

Output power

0x2002 (8194)

Input register

3,4

Measured output power

Auxiliary voltage

0x2003 (8195)

Input register

3,4

Measured auxiliary voltage

Internal

temperature

0x2004 (8196)

Input register

3,4

Measured internal temperature

State

DC OK

0x4000 (16384)

Discrete input

1,2

Measured output voltage is >90% of the

set point

Output short

circuit

0x4001 (16385)

Discrete input

1,2

A short circuit is present on the output

Auxiliary overload

0x4002 (16386)

Discrete input

1,2

Auxiliary output is overloaded

Inhibit signal

0x4003 (16387)

Discrete input

1,2

Status of the inhibit signal

USB powered

0x4004 (16388)

Discrete input

1,2

Device is powered by USB only

Over temperature

warning

0x4005 (16389)

Discrete input

1,2

Device internal temperature is high

Over temperature

error

0x4006 (16390)

Discrete input

1,2

Device internal temperature is too high,

the output is disabled

Internal error

0x4007 (16391)

Discrete input

1,2

An internal error occurred, the output is

disabled

Output disabled

0x4008 (16392)

Discrete input

1,2

Output is disabled in settings.

Auxiliary output

disabled

0x4009 (16393)

Discrete input

1,2

Auxiliary is disabled in settings.

PSH150 user manual rev4

Page 12/15

4 Installation

READ THIS CAREFULLY BEFORE INSTALLATION!

LEGGERE ATTENTAMENTE PRIMA

DELL’INSTALLAZIONE!

A LIRE ATTENTIVEMENT AVANT L’INSTALLATION!

Before operating, read this document thoroughly and

retain it for future reference.

Non-respect of these instructions may reduce

performances and safety of the devices and cause danger

for people and property.

The products must be installed, operated, serviced and

maintained by qualified personnel in compliance with

applicable standards and regulations.

Don’t open the device, it does not contain replaceable

components, the tripping of the internal fuse (if included) is

caused by an internal failure.

Don’t repair or modify the device, if malfunction or failure

should occur during operation, send unit to the factory for

inspection. No responsibility is assumed by Nextys SA for

any consequences deriving from the use of this material.

Prima dell’installazione, leggere attentamente questo

documento istruzioni e conservarle per future consultazioni.

L’inosservanza delle presenti istruzioni può compromettere le

caratteristiche e la sicurezza dell’apparecchio e causare

pericolo per le persone e le cose.

Il prodotto deve essere installato, utilizzato e riparato da

personale qualificato e nel rispetto delle normative vigenti.

Non aprire il prodotto, esso non contiene componenti

sostituibili, il guasto del fusibile interno (se previsto) è causato

da un guasto interno. Non tentare di riparare o modificare il

prodotto, se durante il funzionamento si verificano guasti o

anomalie, inviarlo al produttore per il controllo.

Nextys SA non si assume nessuna responsabilità per

qualunque conseguenza derivante dall’uso di questo materiale.

Lisez ces instructions avant l'installation, conservez ce

manuel pour référence future.

Défaut de se conformer à ces instructions peut affecter les

caractéristiques et la sécurité du dispositif de danger et de

causer aux personnes ou aux biens.

Les produits doivent être installés, exploité et entretenus par

personnel qualifié et en conformité avec les règlements.

N'ouvrez pas le produit, il ne contient aucune pièce

réparable, le déclenchement du fusible interne (le cas

échéant) est causé par un défaut interne. Ne pas essayer de

réparer ou modifier le produit ; si des défaillances se

produisent pendant le fonctionnement ou les

dysfonctionnements, le retourner au fabricant pour

inspection. Nextys SA n'assume aucune responsabilité des

conséquences éventuelles découlant de l'utilisation des

produits.

CAUTION

ATTENZIONE

AVVERTISSEMENT

RISK OF BURNS, EXPLOSION, FIRE, ELECTRICAL

SHOCK, PERSONAL INJURY.

Never carry out work on live parts! Danger of fatal injury!

The product’s enclosure may be hot, allow time for cooling

product before touching it. Do not allow liquids or foreign

objects to enter into the products.

To avoid sparks, do not connect or disconnect the device

before having previously turned-off input power and wait

for internal capacitors discharge (minimum 1 minute).

RISCHIO USTIONI, ESPLOSIONE, INCENDIO, SCOSSA,

LESIONI GRAVI.

Non effettuare mai operazioni sulle parti sotto tensione!

Pericolo di lesioni letali! Il contenitore può scottare, lasciar

quindi raffreddare il dispositivo prima di toccarlo. Non far

entrare liquidi o oggetti estranei nel dispositivo.

Per evitare scintille, non collegare o scollegare

l'apparecchiatura prima di avere tolto tensione di ingresso e

prima che sia avvenuta la scarica dei condensatori interni (min.

1 minuto).

RISQUE DE BRULURES, EXPLOSION, INCENDIE,

ELECTROCUTION, DOMMAGE AUX PERSONNES.

Ne jamais effectuer des opérations sur les parties sous

tension! Danger de mort! Le récipient peut produire des

brulures, le laisser refroidir avant de toucher l'appareil. Ne

faites pas pénétrer des liquides ou des corps étrangers dans

l'appareil. Pour éviter des étincelles, ne pas connecter ou

déconnecter l'équipement jusqu'à ce que vous avez

supprimé la tension d'entrée et avant qu'elle n'ait lieu de

décharge des condensateurs internes (minimum 1 minute).

Connections

1. AC input

2. USB-B Type

communication port

3. RS-485 communication

port

4. DC output (load)

5. INHIBIT

6. Auxiliary 12Vdc

7. DC OK dry contact

8. UP button menu

9. SET button menu

10. DOWN button menu

11. Display

Input Connection:

Single Phase

L = Line

N = Neutral

Input DC

L = Positive DC

N = Negative DC

Output Connection:

+ = Positive DC

- = Negative DC

Signaling:

INHIBIT

(5…30Vdc)

+ = Positive DC

- = Negative DC

12V AUX

(12Vdc / 100mA)

12V+ = Positive DC

12V- = Negative DC

Dry contact:

COM

NO

NC

RS-485

PIN4 = TX/RX D1

PIN5 = TX/RX D0

PIN8 = GND

USB-B Type

1 = VBUS (+5V)

2 = Data (D-)

3 = Data (D+)

4 = GND

Dimensions

Distances

Dimension

W

D

H

mm

179.5

100.3

64.5

Distance

A

B

mm

20

50

PSH150 user manual rev4

Page 13/15

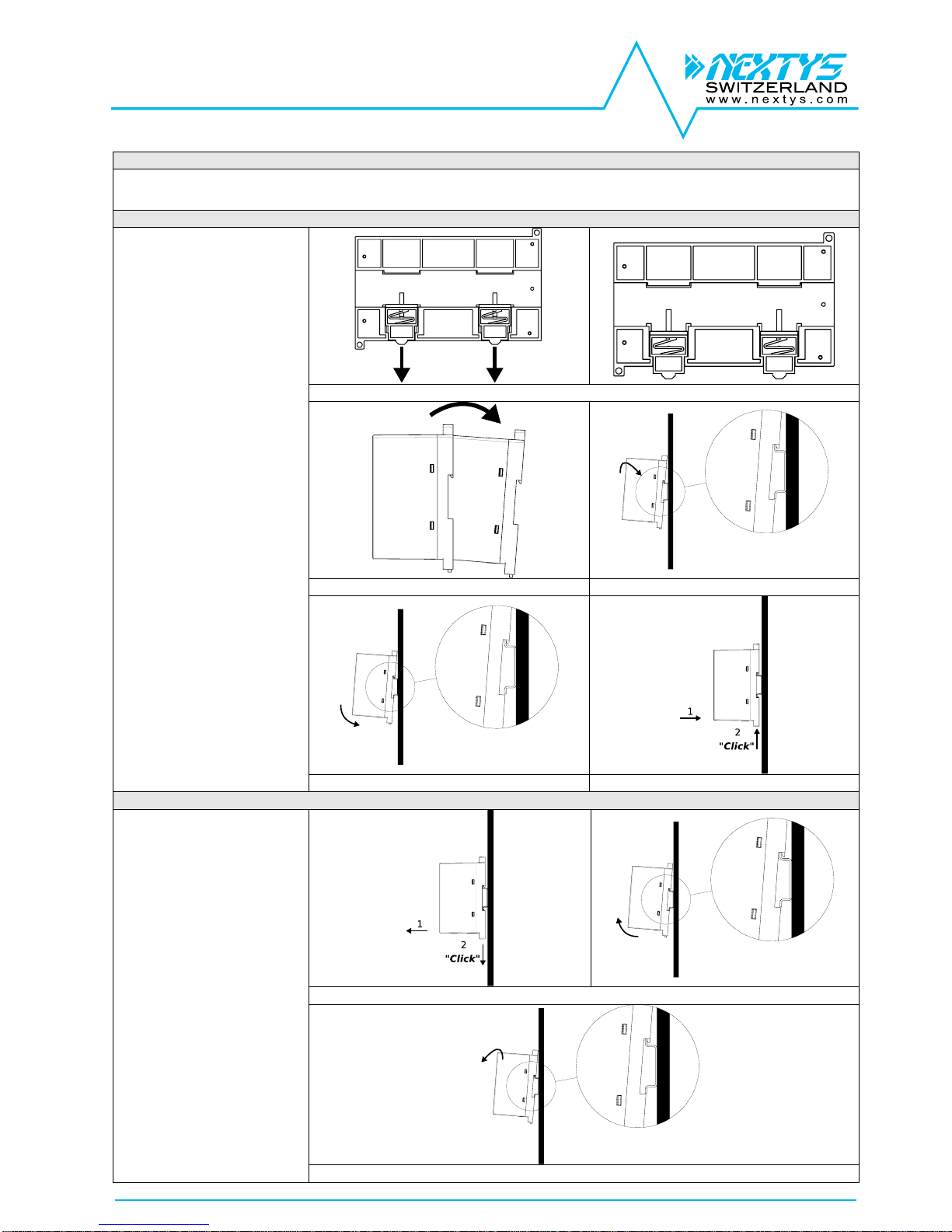

Mounting / Dismounting Instructions

For DIN rail fastening according to IEC 60715 TH35-7.5(-15)

Mounting as shown in figure, with input terminals on lower side, with suitable cooling and maintaining a proper distance between adjacent devices as specified in the I.S.

manual of each family.

DIN rail mounting:

1. Pull down to release and unlock the

slide clamps.

2. Tilt the unit slightly backwards.

3. Fit the unit over the top edge of the rail.

4. Slide it downward until it hits the stop.

5. Press toward top the two slide clamps

for locking

1

2

3

3

4 & 5

DIN rail dismounting:

1. Pull down to release and unlock the

slide clamps.

2. Tilt the unit upward

3. Unhook the unit from the rail

1 & 2

3

PSH150 user manual rev4

Page 14/15

Wall / Panel mounting

It is possible install directly on panel or wall using the appropriate fixing points according the above image.

Recommended connecting cable

Recommended Tightening torque

Input / output connections

0.5-0.6Nm

4.42-5.30 lbf in

Auxiliary connections

Insertion force per pole

Max 3N or 0.674 lbf

Withdrawal force per pole

Min 1.5N or 0.337 lbf

Input / output connections

Solid: 2.5mm² / 12AWG

Stranded:1.5mm² / 12AWG

L: 6.0-7.5mm / 0.24-0.30in

Auxiliary connections

Solid: 0.5mm² / 20AWG

Stranded: 0.5mm² / 20AWG

L: 7.0-8.0mm / 0.27-0.315in

Input connection

AC Line

DC Line

Input protection

Fuses MCB 6A C curve

For USA and Canada, use the fuse type closest to the European equivalent type.

Surge protection: it is strongly recommended to provide external surge arresters (SPD) according to local regulations.

Environment

Operating temperature

Derating

- 40°C…70°C

5…95% r.H. non condensing

Overtemperature protection

See Figure 3 and Figure 4

PSH150 user manual rev4

Page 15/15

DECLARATION OF CONFORMITY

NEXTYS SA.

Via Luserte Sud 6, 6572 Quartino - Switzerland

Phone: +41-(0)91 840 14 46 / 840 14 48; Fax: +41-(0)91 840 14 47

E-mail: info@nextys.com

This Declaration of Conformity is suitable to the European Standard EN45014 "General criteria for supplier’s declaration of conformity".

We declare under our sole responsibility that the device included in this box, has passed all processing inspections and the final test and it is in conformity with the product

requirements, including all reference codes and supply specifications.

ROHS compliance: the product respects the EC requirements related to ROHS substances, according to “Restriction of Hazardous Substances” as per document

2011/65/UE

REACH compliance: the product respects the EC requirements related to REACH SVHC directive (2015)

Note: all the reported information comes from our suppliers, NEXTYS SA. has not run any test to evaluate if the specific elements are present.

All indicated devices are designed according to the latest Reference standards, if not expressly indicated through the official documents or files, they have been tested

through our internal pre-compliance testing. Consult directly on www.nextys.com the reference standards applied to each model.

Code Description

PSH150 10kV Isolation Programmable Power Supply IN 120…240Vac (110…400Vdc) / OUT 5…55Vdc – 12A Max (150W Max)

Certifications and approvals

Reference standards

2014/35/EU (2014) (Low Voltage Directive)

2014/30/EU (2014) (EMC directive)

UL508 (Safety Standards)

EN60255-27 (Safety Standards)

IEC60664-1 (Safety Standards)

EN50178 (Safety Standards)

EN61000-6-2 (Generic immunity standard for industrial environments)

- EN61000-4-2 (Electrostatic discharge immunity test)

- EN61000-4-3 (Radiated, radio-frequency, electromagnetic field immunity test)

- EN61000-4-4 (Electrical fast transient/burst immunity test)

- EN61000-4-5 (Surge immunity test)

- EN61000-4-11 (Voltage dips, short interruptions and voltage immunity test)

EN61000-6-4 (Generic emission standard for industrial environments)

- EN55022 (CISPR22 - EMC)

- EN55011 (CISPR11 - EMC)

- EN61000-3-2 (Limits for harmonics current emissions)

Date: 10.10.2016

Place: Quartino, Switzerland

The product manager

Marius Ciorica

Loading...

Loading...