NPSM121 Series

Instruction Manual

NPSM121 Series V4.0

www.nextys.com

Page 1/5

NPSM121 Series – Single phase / DC input switching power supply withintegratedPFC

Main Features:

High efficiency 90%

Extremely compact size

Active PFC for optimal efficiency

Overload 150%

Up to 60°C operating temperature with no derating

Constant current or Hiccup mode limitation, user settable

Wide range of output voltage

Easy parallelable for power increase

Only 35mm width aluminum enclosure

INDEX

Page

Installation Requirements

2

Declaration of Conformity

2

User Instructions

3

Connections

4

Dimensions

4

Distances

4

Mounting

4

Dismounting

5

Input Connections

5

Environment

5

Accessory Device

5

NPSM121 Series

Instruction Manual

NPSM121 Series V4.0

www.nextys.com

Page 2/5

READ THIS CAREFULLY BEFORE INSTALLATION!

LEGGERE ATTENTAMENTE PRIMA

DELL’INSTALLAZIONE!

A LIRE ATTENTIVEMENT AVANT L’INSTALLATION!

Before operating, read this document thoroughly and retain

it for future reference.

Non-respect of these instructions may reduce

performances and safety of the devices and cause danger

for people and property.

The products must be installed, operated, serviced and

maintained by qualified personnel in compliance with

applicable standards and regulations.

Don’t open the device, it does not contain replaceable

components, the tripping of the internal fuse (if included) is

caused by an internal failure.

Don’t repair or modify the device, if malfunction or failure

should occur during operation, send unit to the factory for

inspection. No responsibility is assumed by Nextys SA for

any consequences deriving from the use of this material.

Prima dell’installazione, leggere attentamente questo

documento istruzioni e conservarle per future consultazioni.

L’inosservanza delle presenti istruzioni può compromettere le

caratteristiche e la sicurezza dell’apparecchio e causare

pericolo per le personee le cose.

Il prodotto deve essere installato, utilizzato e riparato da

personale qualificato e nel rispetto delle normative vigenti.

Non aprire il prodotto, esso non contiene componenti sostituibili,

il guasto del fusibile interno (se previsto) è causato da un

guasto interno. Non tentare di riparare o modificare il prodotto,

se durante il funzionamento si verificano guasti o anomalie,

inviarlo al produttore per il controllo.

Nextys SA non si assume nessuna responsabilità per

qualunque conseguenza derivante dall’uso di questo materiale.

Lisez ces instructions avant l'installation, conservez ce

manuel pour référence future.

Défaut de se conformer à ces instructions peut affecter les

caractéristiques et la sécurité du dispositif de danger et de

causer aux personnes ou aux biens.

Les produits doivent être installés, exploité et entretenus par

personnel qualifié et en conformité avec les règlements.

N'ouvrez pas le produit, il ne contient aucune pièce réparable,

le déclenchement du fusible interne (le cas échéant) est

causé par un défaut interne. Ne pas essayer de réparer ou

modifier le produit; si des défaillances se produisent pendant

le fonctionnement ou les dysfonctionnements, le retourner au

fabricant pour inspection. Nextys SA n'assume aucune

responsabilité des conséquences éventuelles découlant de

l'utilisation des produits.

CAUTION

ATTENZIONE

AVVERTISSEMENT

RISK OF BURNS, EXPLOSION, FIRE, ELECTRICAL

SHOCK, PERSONAL INJURY.

Never carry out work on live parts! Danger of fatal injury!

The product’s enclosure may be hot, allow time for cooling

product before touching it. Do not allow liquids or foreign

objects to enter into the products.

To avoid sparks, do not connect or disconnect the device

before having previously turned-off input power and wait for

internal capacitors discharge (minimum 1 minute).

RISCHIO USTIONI, ESPLOSIONE, INCENDIO, SCOSSA,

LESIONI GRAVI.

Non effettuare mai operazioni sulle parti sotto tensione! Pericolo

di lesioni letali! Il contenitore può scottare, lasciar quindi

raffreddare il dispositivo prima di toccarlo. Non far entrare liquidi

o oggetti estranei nel dispositivo.

Per evitare scintille, non collegare o scollegare

l'apparecchiatura prima di avere tolto tensione di ingresso e

prima che sia avvenuta la scarica dei condensatori interni (min.

1 minuto).

RISQUE DE BRULURES, EXPLOSION, INCENDIE,

ELECTROCUTION, DOMMAGE AUX PERSONNES.

Ne jamais effectuer des opérations sur les parties sous

tension! Danger de mort! Le récipient peut produire des

brulures, le laisser refroidir avant de toucher l'appareil. Ne

faites pas pénétrer des liquides ou des corps étrangers dans

l'appareil. Pour éviter des étincelles, ne pas connecter ou

déconnecter l'équipement jusqu'à ce que vous avez supprimé

la tension d'entrée et avant qu'elle n'ait lieu de décharge des

condensateurs internes (minimum 1 minute).

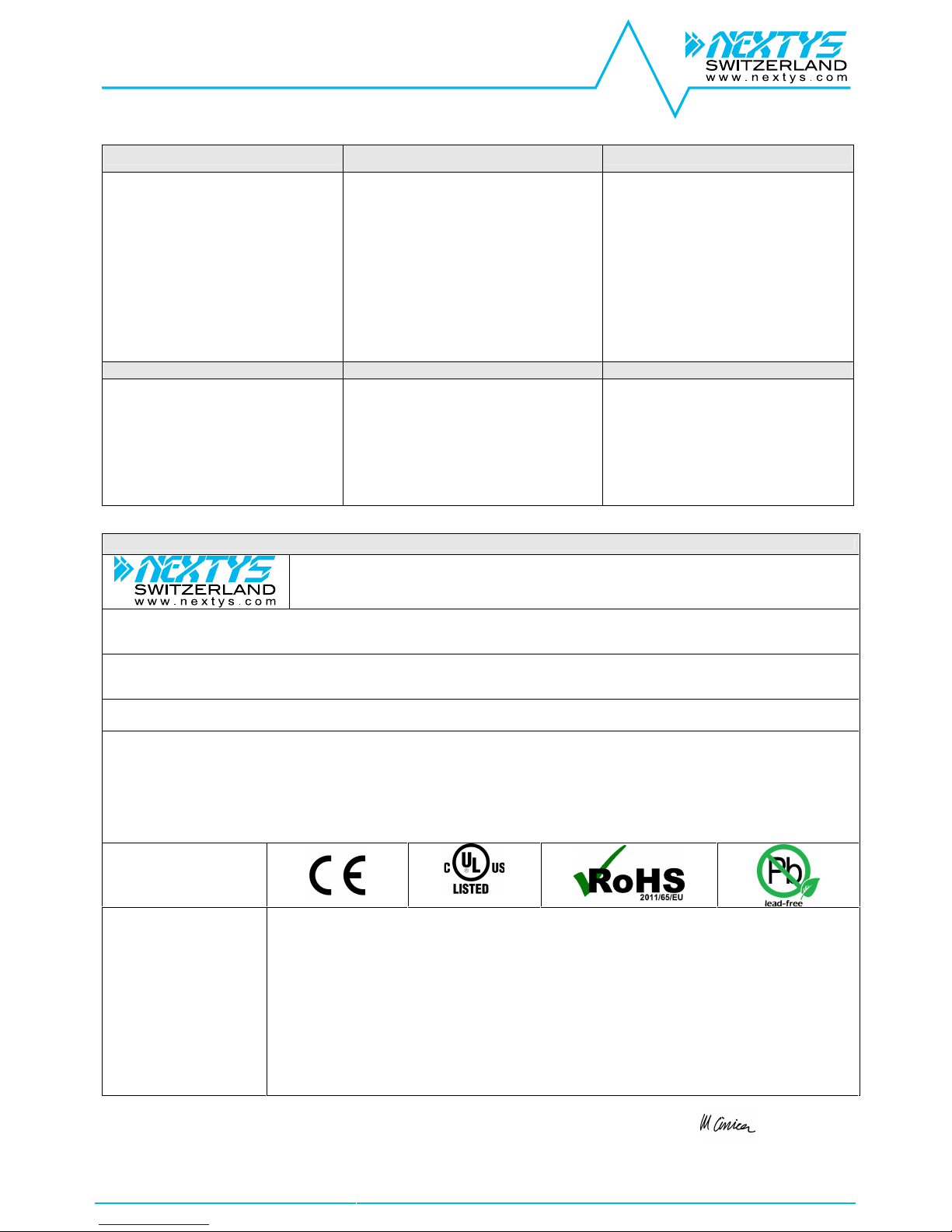

DECLARATION OF CONFORMITY

NEXTYS SA.

Via Luserte Sud 6, 6572 Quartino- Switzerland

Phone: +41-(0)91 840 14 46 / 840 14 48; Fax: +41-(0)91 840 14 47

E-mail: info@nextys.com

This Declaration of Conformity is suitable to the European Standard EN45014 "General criteria for supplier’s declaration of conformity".

We declare under our sole responsibility that the device included in this box, has passed all processing inspections and the final test and it is in conformity with the product

requirements, including all reference codes and supply specifications.

ROHS compliance: the product respects the EC requirements related to ROHS substances, according to “Restriction of Hazardous Substances” as per document 2011/65/UE

REACH compliance: the product respects the EC requirements related to REACH SVHC directive (2015)

Note: all the reported information comes from our suppliers, NEXTYS SA. has not run any test to evaluate if the specific elements are present.

All indicated devices are designed according to the latest Reference standards, if not expressly indicated through the official documents or files, they have been tested through

our internal pre-compliance testing. Consult directly on www.nextys.com the reference standards applied to each model.

Code Description

NPSM121-24 Single phase with integrated PFC switching power supply IN 120 - 240Vac (110 - 345Vdc)/ OUT 24Vdc - 5A

NPSM121-24P Single phase with integrated PFC switching power supply IN 120 - 240Vac (110 - 345Vdc)/ OUT 24Vdc - 5A + ORing circuit

NPSM121-48 Single phase with integrated PFC switching power supply IN 120 - 240Vac (110 - 345Vdc)/ OUT 48Vdc - 2.5A

NPSM121-48P Single phase with integrated PFC switching power supply IN 120 - 240Vac (110 - 345Vdc)/ OUT 48Vdc - 2.5A + ORing circuit

Certifications and approvals

IND.CONT.EQ. 4WX9

Reference standards

2014/35/EU (2014) (Low Voltage Directive)

2014/30/EU (2014) (EMC directive)

EN60950-1:2006 /A2:2013 (Safety Standards)

UL508 (Certified - IND. CONT. EQ. 4WX9 file no. E356563)

EN61000-6-2:2005 (Generic immunity standard for industrial environments)

- EN61000-4-2:2008 (Electrostatic discharge immunity test)

- EN61000-4-3:2006 /A2:2010 (Radiated, radio-frequency, electromagneticfield immunity test)

- EN61000-4-4:2012 (Electrical fast transient/burst immunity test)

- EN61000-4-5:2014 (Surge immunity test)

- EN61000-4-11:2004 /A1:2010 (Voltage dips, short interruptions and voltage immunity test)

EN61000-6-3:2007 /A1:2011 (Generic emission standard for residential environments)

- EN55022:2010 (CISPR22 - EMC)

- EN55011:2009 /A1:2010 (CISPR11 - EMC)

- EN61000-3-2:2014 (Limits for harmonics current emissions)

Date: 25.02.2016

Place: Quartino, Switzerland

The product manager

Marius Ciorica

NPSM121 Series

Instruction Manual

NPSM121 Series V4.0

www.nextys.com

Page 3/5

USER INSTRUCTIONS

1) Description: DIN rail mountable primary switched-mode power supply with 90...264Vac (110…345Vdc) input, suitable for Single phase main line and DC line.

2) Installation: use DIN-rails according to EN60715. Installation should be made vertically (see Fig.4). For better device stability fix the rail to the wall close to the point where

the device is to be mounted. In order to guarantee sufficient convection, we recommend observing a minimum distance to other modules (see Fig.3).

The device is provided with a thermal protection; a limited air flow can cause the thermal protection tripping.

The SMPS automatically restarts after cooling. To get normal operation reduce the temperature of the air surrounding the power supply, increase the ventilation or reduce the

load (see Fig.8)

3) Connections: the device is equipped with pluggable screw terminals. To avoid sparks, do not connect or disconnect the connectors before having previously turned-off input

power and waited for internal capacitors discharge (minimum 1 minute)

In order to comply with UL certification, use appropriate copper cables of indicated cross section, designed for an operating temperatures of:

60°C for ambient up to 45°C

75°C for ambient up to 60°C

90°C for ambient up to 70°C

Strip the connecting ends of the wires according to the indication and ensure that all strands of a stranded wire enter the terminal connection (see Fig.5)

4) Input protection: the device input is provided with varistors against overvoltage. Input is providedwith internal fuses 3.15AT/250Vac, thus an external short

circuit/overcurrent protection must be provided by the end user (see Fig.6).

For operation on a single-phase system, a protection fuse on the phase must be provided.

Surge protection: it is strongly recommended to provide external surge arresters (SPD) according to local regulations.

5) AC input connection: the device can be connected to single-phase AC lines with Uin 120…240Vac (see Fig.7). Please connect first the PE.

6) DC input connection: connect L terminal to (+) positive pole, N terminal to (-) negative pole andI terminal to GND. Rated voltage 110...345Vdc.

The device is also suitable for photovoltaic or wind turbine applications (see Fig.7).

7) Output connection: The device is suitable forSELV and PELV circuitry.

Uout can be adjusted with a potentiometer to a wide range (see Fig.1)

Check Uout before connecting the power supply to the load. With output voltage set to the max. value, the continuous[current x voltage] must not exceed the nominal power.

8) Parallel connection and redundancy:power supplies can be connected in parallel to increase power. For paralleling for power set the Ilim jumper toC.C. algorithm.

Uout must be set uniformly (±100mV) on each power supply and the wiring must be symmetrical to ensure an equal current distribution.

Models with “P” suffix have an integrated ORing circuit.

For redundant connection, use the Models“P” or an external isolating device must be used (see accessory device).

9) Output protection: the device is protected against overload (OL) / short circuit (SC) / overvoltage (OV) / overtemperature (OT).

OL and SC: are controlled by a hiccup mode or a constant current (C.C.) mode protection with the following behaviour.

The Hiccup mode or C.C. mode are selectable with Jumper (see Fig.1)

OL behaviour in hiccup mode: Max. OL= 1.5 x In the output voltage remains constant at nominal voltage for 5s and after that time the device starts an ON/OFF cycle.

OL behaviour in C.C. mode: the maximum output current is limited at 1.5 x In if the load resistance is further decreased the output voltage starts to drop.

SC behaviour in hiccup mode: the device supplies 1.5 x In for 5s, afterthat time it switches off for 10s. The ON/OFF cycle is repeated continuously.

SC behaviour in C.C. mode: the device supplies 1.5 x In the output voltage drops to a value depending on the impedance of the failed load circuit. After 5s the current is

limited to In. The device never switches off.

Output OV circuit protection: the output is protected against potential OV due to internal malfunction or coming from the load for Uout Unom x 1.2 – 1.3, depending on the

model.

OT protection: turns off the device if the internal temperature exceeds a safe limit.

The device restarts automatically after cooling down. To recover to normal operation reduce air temperature surrounding the power supply, increase cooling or reduce load

(see Fig.8).

10) Feeding DC motors:it is possible to feed DC motors considering that when a motor starts-up under effort its consumption is much higher than the nominal current and it

can trigger overcurrent protection (see accessory device). For these applications theC.C. (Constant Current) mode of current limitation is recommended.

NOTE: motors can generate high conducted noise on the DC line. Therefore it is not recommended to feed on the same line motors and equipment sensitive to noise.

11) Operation with Battery: when a battery is connected in parallel to the Output for backup purposes; the NPSM121 must be set onC.C. mode to avoid battery over-charging

(see accessory device).

NPSM121 Series

Instruction Manual

NPSM121 Series V4.0

www.nextys.com

Page 4/5

Fig.1

Connections

Fig.2

Dimensions

Fig.3

Distances

Just for reference

(1) AC/DC input

(2) DC output (load)

(3) Diagnostic Output

(dry contact, NC output OK)

(4) Green LED: Output OK

(5) Red LED: Overload

(6) Output voltage adjustment

(7) Selectable limitation mode

(Hiccup mode, C.C. mode)

Input AC Line:

L = Line

N = Neutral

I = earth ground

Input DC Line:

L = + Positive DC

N = - Negative DC

I = earth ground

Output:

+ = Positive DC

- = Negative DC

Dry contact = NC

Dimension

W

D

H

mm (inch)

35 (1.37)

104 (4.09)

103 (4.05)

Distance

A

B

mm (inch)

20 (0.8)

50 (2.0)

Fig.4

Mounting / Dismounting Instructions

For DIN rail fastening according to IEC 60715 TH35-7.5(-15)

Mounting as shown in figure, with input terminals on lower side, with suitable cooling and maintaining a proper distance between adjacent devicesas specified inthe I.S.

manual of each family.

Mounting:

1

2

1.Tilt the unit slightly backwards.

2.Fit the unit over thetop edge of therail.

3.Slide it downward until it hits the stop.

4.Press against the bottom for locking.

3

4

NPSM121 Series

Instruction Manual

NPSM121 Series V4.0

www.nextys.com

Page 5/5

Dismounting:

1.Pull down the slide clamp lever

2.Tilt the unit upward

3.Unhook the unit from the rail

1 & 2

3

Fig.5

Recommended connecting cable

Recommended Tightening torque

0.5-0.6 Nm

4.42-5.30 lbf in

Solid: 2.5mm² / 12AWG

Stranded:1.5mm² / 12AWG

L: 6.0-7.5mm / 0.24-0.30 in

Fig.6

Input protection

Fuse MCB 4A C curve.

For USA and Canada, use the fuse type closest to the European equivalent type.

Surge protection: it is strongly recommended to provide external surge arresters(SPD) according to local regulations.

Fig.7

Input connections

AC Line

DC Line

Fig.8

Environment

Operating temperature

Derating

- 35°C…70°C

5…95% r.H. non condensing

UL Certified up to 60°C

Overtemperature protection

- 1.2W/°C over 60°C

Note:

Data may change without prior notice in order to improve the product.

Please refer to the latest version of the "Instruction Manual" for each product by visitingwww.nextys.com

See also the products below that can be used in conjunction with NPSM121 units: (accessory device)

OR20 20A Active ORing controller

OR50 50A Active ORing controller

DCU20 20A High performance DC UPS

BU150U 150J Buffer Module

NUPS12/24 Battery charger and DC UPS Module

MBC2K 2000W Motor brake controller

NBP30 Sealed Lead acid Battery pack

Loading...

Loading...