Ray Sub Series

RS18 Subwoofer

User Manual

RS18 Subwoofer User Manual V1.02

Date: 31/08/2010

Page 2/54 PLEASE READ CAREFULLY BEFORE PROCEEDING

GOING ONE STEP FURTHER IN LOW FREQUENCY CONTROL: RAY SUB TECHNOLOGY

Radiation control of low frequencies is hard to achieve due to wavelength being larger

than cabinet size. Consequently, most of current subwoofers available on the audioprofessional market are omnidirectional.

Drawbacks in using omnidirectional subwoofers are known by experienced engineers:

- Low Frequency sound pressure level is typically higher on stage than over the

audience; high-pass filters are mandatory in almost all microphones inputs to avoid

feedback from the microphones to the subwoof ers. Moreover, gain fr om microphone

to speakers is highly limited due to that feedback (reinforcing a double-bass can be

an enormous challenge);

- Indoor environments typically have much higher reverberation time in the Low

Frequency range than in the mid and high Frequencies. This characteristic is

emphasized by the omnidirectional pattern of conventional subwoofers (all sound

engineers experienced kick drum lasting forever);

- Many outdoor shows occur nearby residential areas where noise constraints are very

restrictive; in such cases, low frequencies levels over the audience have to be

limited so that environment criterias are fulfilled (possibly leading to unacceptable

wideband limitations).

Gradient subwoofers provide an elegant solution to the above issues, based on a

technology that is a simple transposition to sound sources of what has been applied for

decades in microphones: radiated field derives from pressure differences generated

from two (or more) sources:

- Rear radiation is lowered by more than 12 dB, which benefits to stage as well as to

neighbours;

- Direct to r everberant ratio is increased by nearly 6 dB in the low frequency range

(which potentially gives back a kick drum its original “punch”).

However, there are efficiency limitations: gain in lower bandwidth is reduced when

sources become too close in relation to wavelength, and pattern control is limited in

upper bandwidth when both sources interfere destructively in the radiation axis.

Operating bandwidth were efficiency combines with pattern control is around 2 octaves.

Poor correlation between ca binet design and targeted specifications leads to two (and

eventually more) driv ers in directional mode pr oducing less energy than one driver in

omnidirectional mode, which is not acceptable for simple practical aspects such as

weight and volume.

NEXO released its first gradient subwoofer – the CD12 – in 2002, which has been

complemented since then by CD18, GEO SUB and RS15. These have been quickly

adopted worldwide as standards, and are considered today as state of the art

subwoofers. This success is a consequence of proper cabinet design and optimized

definition of phase relations through sophisticated DSP algorithms leading to high

directional control and SPL output.

PLEASE READ CAREFULLY BEFORE PROCEEDING Page 3/54

With RAY SUB patented technology, NEXO is again moving one step forward. RAY SUB

technology is about optimizing positioning and phase relat ionship of radiatin g surfac es in

vented enclosures, so that acoustic distance from rear to front sections always increases

as frequency decreases; consequently, rear and front section always sum up efficiently –

typically 5 dB gain from rear section in the forward direction – and cancel in the

rearward direction.

Used as a single cabinet, RAY SUB Technology allows the same cabinet to be configured

for any polar pattern, omnidirectional as a standard direct radiating subwoofer when

speakers are facing the audience, or highly directional when cabinet is rotat ed speakers

sideways or upwards.

Used in arrays, RAY SUB subwoofers can be set back to back, front to front, in vertical

columns, and beam-steered upwards or downwards provided column length is sufficient.

NEXO RAY SUB technology brings a never achieved low frequency directional control to

the sound reinforcement industry, raising one more time NEXO standards.

Page 4/54 PLEASE READ CAREFULLY BEFORE PROCEEDING

PLEASE READ CAREFULLY BEFORE PROCEEDING

BASIC PRECAUTIONS

Do not open the speaker system or attempt to disassemble the internal parts or modify them in any

way. The speaker system contains no user-serviceable parts. If it should appear to be malfunctioning

or damaged, discontinue use immediately and have it inspected by qualified NEXO service personnel.

Water exposure: Do not expose the speaker system to direct rain, do not use it near water or in wet

conditions. Do not place containers with liquid on speaker system as they might spill into openings. If

any liquid such as water seeps into the speaker system, have it inspected by qualified NEXO

personnel.

SYSTEM DEPLOYMENT SAFETY RULES

Read User Manual before deployment. Before use of enclosed speaker system,

please ensure that anyone involved in system deployment understands the rigging –

stacking – pole mounting safety rules as described in the speaker system User Manual.

Failure to do this exposes people to potential injury or death.

Always consult qualified NEXO personnel if the device installation requires construction work and make

sure to observe the following precautions:

Mounting precautions

- choose mounting hardware and an installation location that can support the weight of the speaker

system;

- do not use speaker system handles for suspended installation;

- do not expose speaker system to excessive dust or vibration, or extreme cold or heat to prevent

possibility of component damage;

- do not place the speaker system in an unstable position from which it might fall accidentally;

- if speaker systems uses a stand, ensure that stand specifications are adapted, and that stand

height does not exceed 1.40m/55”; never move the stand while the speaker is in position.

Connection and powering precautions

- remove all connected cables before moving the speaker system;

- turn off AC power of all power amplifier units before connecting the speaker system;

- when turning on the AC power to the audio system, always turn on the power amplifier last; when

turning the AC power off, always turn off the power amplifier first;

- when used in cold conditions, a gradual power ramp up should applied to the system on an 5 mn

period to allow the loudspeaker components to stabilize during the very first minutes of usage.

Inspect the speaker system periodically.

PLEASE READ CAREFULLY BEFORE PROCEEDING Page 5/54

SAFETY INSTRUCTIONS FOR NEXO TD CONTROLLERS

NEXO ANALOGUE TDCONTROLLERS, NX242 DIGITAL CONTROLLER, NXAMP4x1

AND NXAMP4x4 POWERED CONTROLLERS ARE CLASS 1 APPARATUS AND

MUST BE EARTHED.

THE GREEN AND YELLOW WIRE OF THE MAINS CORD MUST ALWAYS BE CONNECTED TO AN

INSTALLATION SAFETY EARTH OR GROUND. THE EARTH IS ESSENTIAL FOR PERSONAL

SAFETY AS WELL AS THE CORRECT OPERATION OF THE SYSTEM, AND IS INTERNALLY

CONNECTED TO ALL EXPOSED METAL SURFACES.

- Read these instructions.

- Keep these instructions.

- Heed all warnings.

- Follow all instructions.

- Do not use this apparatus near water.

- Clean only with dry cloth.

- Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

- Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

- Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades and a third grounding

prong. The wide blade or the third prong are provided for your safety. If the provided plug does not

fit into your outlet, consult an electrician for replacement of the obsolete outlet. (US market)

- Protect the power cord from being walked on or pinched particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

- Only use attachments/accessories specified by the manufacturer.

- Unplug this apparatus during lightning storms or when unused for long periods of time.

- Refer all servicing to qualified service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled

or objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does

not operate normally, or has been dropped.

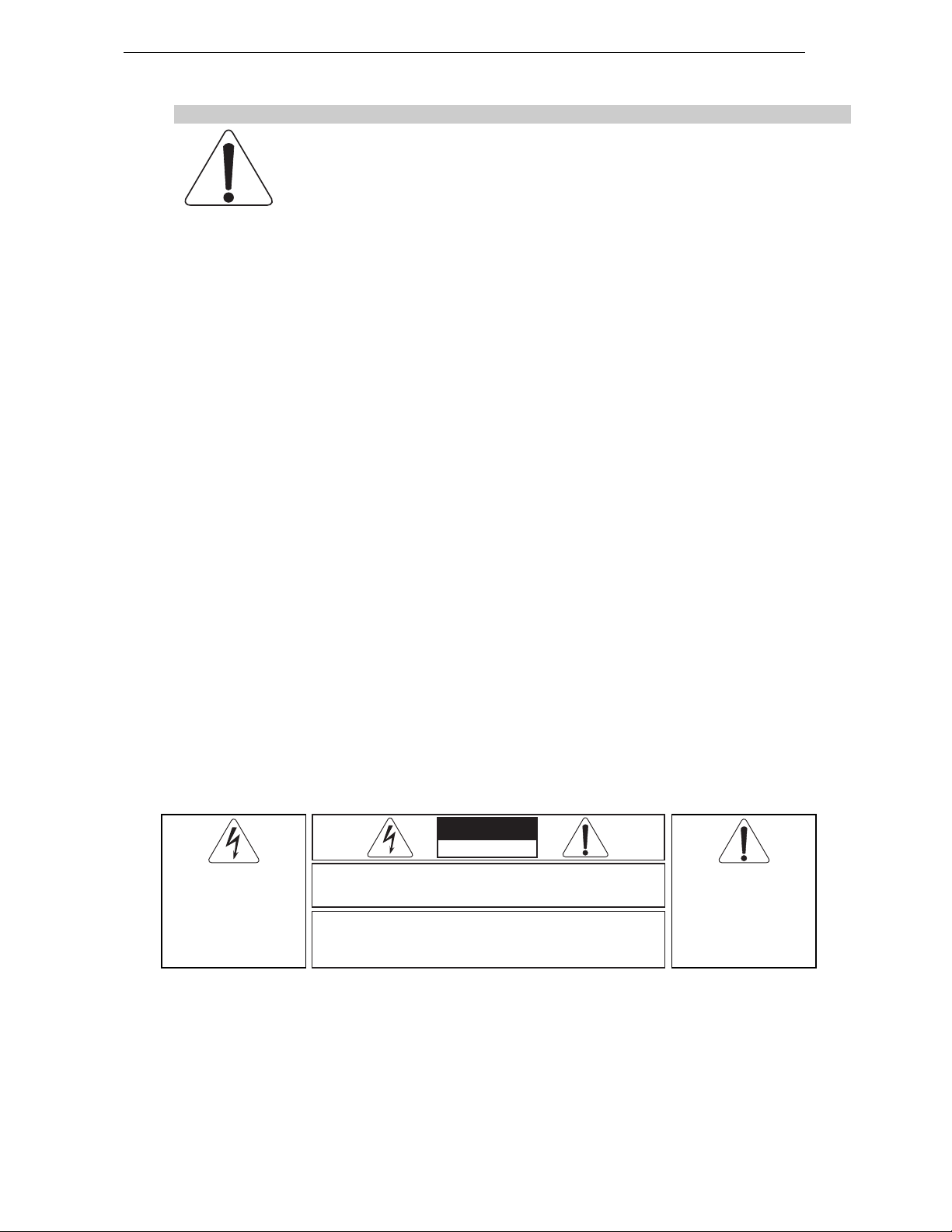

The lightning flash with arrowhead

symbol, within an equilateral triangle

is intended to alert the user to the

presence of uninsulated “dangerous

voltage” within the product's

enclosure that may be of sufficient

magnitude to constitute a risk of

electric shock to persons.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

WARNING: To reduce the risk of fire or electric shock,

do not expose this apparatus to rain or moisture.

To avoid electrical shock, do not remove covers.

Dangerous voltages exist inside.

Refer all servicing to qualified personnel only.

The exclamation point within an

equilateral triangle is intended to

alert the user to the presence of

important operating and

maintenance (servicing) instructions

in the literature accompanying

the appliance.

Page 6/54 PLEASE READ CAREFULLY BEFORE PROCEEDING

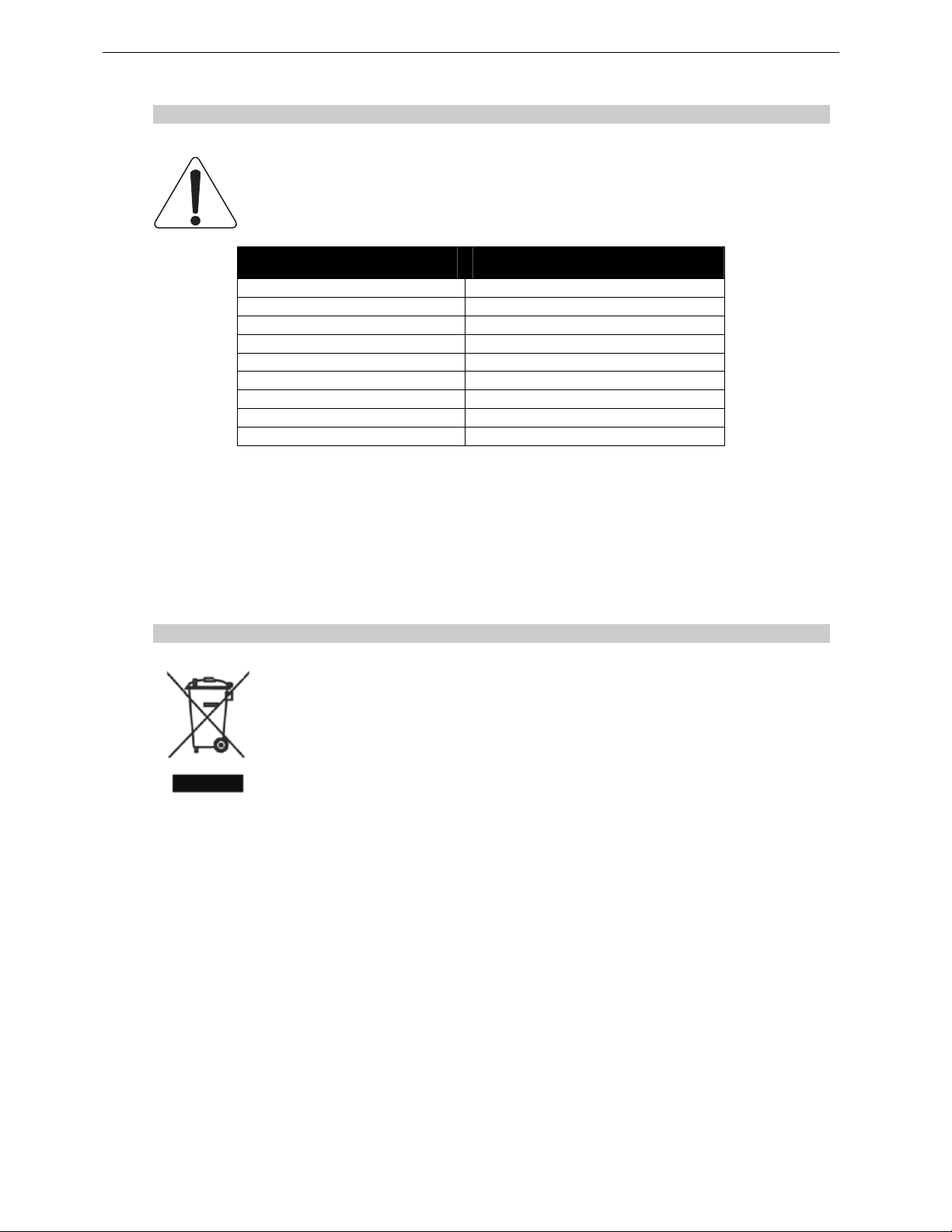

HIGH SOUND PRESSURE LEVELS

Exposure to extremely high noise levels may cause permanent hearing loss.

Individuals vary considerably in susceptibility to noise-induced hearing loss but nearly

everyone will lose some hearing if exposed to sufficiently intense noise for a sufficient

period of time. The U.S. Government’s Occupational and Health Administration (OSHA)

has specified the following permissible noise level exposures: Sound Duration Per

Day In Hours Sound Level dBA, Slow Response

8 90

6 92

4 65

3 97

2 100

1 ½ 102

1 105

½ 110

¼ or less 115

According to OSHA, any exposure in excess of the above permissible limits could result in some

hearing loss. Ear plugs or protectors to the ear canals or over the ears must be worn when operating

this amplification system in order to prevent permanent hearing loss, if exposure is in excess of the

limits as set forth above. To ensure against potentially dangerous exposure to high sound pressure

levels, it is recommended that all persons exposed to equipment capable of producing high sound

pressure levels such as this amplification system be protected by hearing protectors while this unit is in

operation.

DISPOSAL OF OLD ELECTRICAL & ELECTRONIC EQUIPMENT

This symbol on the product or on its packaging indicates that it shall not be treated

as household waste. Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic equipment. By ensuring this

product is disposed of correctly, you will help prevent potential negative

consequence for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. The recycling of materials

will help to conserve natural resources. For more detailed information about

recycling of this product, please contact your local city office, your household waste

disposal service or the shop where you purchased the product.

TABLE OF CONTENTS Page 7/54

TABLE OF CONTENTS

PLEASE READ CAREFULLY BEFORE PROCEEDING..................................................... ............................... 4

Table of contents..................................................................................... .......................................................... 7

1 Introduction............................................................................................................................................... 9

2 RS18 General Instructions ........................................................................................ ............................. 11

2.1 Mounting Rigging Plate..................................................................................................................... 11

2.1.1 RS18 Painted........................................................................................................................... 11

2.1.2 RS18 Carpeted ........................................................................................................................ 13

2.1.3 RS18 Dolly ............................................................................................................................... 15

2.1.4 RS18 Wheel Board .................................................................................................................. 16

2.2 Speaker connection............................. ............................................................................................. 17

2.2.1 Configuring Connector and Owner plates................................................................................. 17

2.2.2 RS18 connectors...................................................................................................................... 17

2.2.3 Cabling..................................................................................................................................... 18

2.2.4 Example ................................................................................................................................... 18

3 Amplifier selection for use with RS18................................................................................................... 19

3.1 RS18 recommended amplification.................................................................................................... 19

3.2 Current rating....................................... ............................................................................................. 19

3.3 Amplifier settings........................ ..... .... ..... ......... ..... .... ......... ..... ..... ......... .... ..... ......... .... .................... 19

4 NEXO TD Controllers and RS18 Setups................................................................................................ 21

4.1 RS18 and NXAMP TDControllers..................................................................................................... 21

4.1.1 NXAMP connectors.................................................................................................................. 21

4.1.2 RS18 and NXAMP recommended configurations..................................................................... 21

4.2 RS18 setups on NXAMP TDControllers...................... ...................................................................... 21

5 Connection diagrams.............................................................................................................................. 22

5.1 RS18 with NX242-ES4 TD Controller (Stereo Omni or Directional Mode)........... ............................. 22

5.2 RS18 with NXAMP4x4 (Stereo Omni or Directional Mode)............................................................... 23

6 RS18 Rigging Instructions ..................................................................................................................... 24

6.1

SAFETY FIRST................................................................................................................................ 24

6.1.1 Flown Systems Safety.............................................................................................................. 24

6.1.2 Ground Stacking Safety ........................................................................................................... 25

6.1.3 Contacts................................................................................................................................... 26

6.2 Flying RS18 arrays... ..... ......... .... ..... ......... .... ..... ..... ......... .... ..... ......... ..... .... ..... ......... .... ..... ............... 27

6.2.1 Hoist Rating ............................................................................................................................. 27

6.2.2 Connecting first RS18 to bumper ............................................................................................. 27

6.2.3 Adjusting rigging point for horizontality..................................................................................... 28

6.2.4 Flying subsequent RS18s ........................................................................................................ 28

6.3 Testing and Maintenance of the RS18 flying system........................................... ..... .... ......... ..... ..... . 31

7 General guidelines for subwoofer design............................................................................................. 32

7.1 Low Frequency Issues...................................................................................................................... 32

7.2 Gradient Subwoofers benefits....................................................... .................................................... 33

7.3 Monophonic Design.......................................................................................................................... 33

7.4

Stereo Design ...........................................................................................................................34

Page 8/54 TABLE OF CONTENTS

8 RAY SUBs implementation..................................................................................................................... 35

8.1 Omnidirectional Mode......................................... .... ..... ......... .... ..... ......... ..... .... ..... ......... .... ............... 35

8.1.1 Single RS18 ............................................................................................................................. 35

8.1.2 RS18 arrays ............................................................................................................................. 35

8.2 Directional Mode............................................................................................................................... 35

8.2.1 Single RS18 ............................................................................................................................. 35

8.2.2 RS18s pair ............................................................................................................................... 36

8.2.3 RS18s arrays ........................................................................................................................... 37

8.3 Steered RS18s arrays.................................................................................. ......... .... ..... ................... 37

8.3.1 Steering technique ................................................................................................................... 37

8.3.2 Delay values implementation.................................................................................................... 38

8.3.3 Coverage result........................................................................................................................ 39

8.4 Aligning RS18s with main system ..................................................................................................... 39

8.4.1 NEXO systems acoustic reference point .................................................................................. 39

8.4.2 Precautions .............................................................................................................................. 40

8.4.3 Alignment with distance measurement..................................................................................... 40

8.4.4 Alignment with phase measurement......................................................................................... 41

8.5 Recommended installation tools and equipment. .............................................................................. 41

9 RS18 System Check List......................................................................................................................... 43

9.1 Are the NX Digital TDcontrollers properly configured?...................................................................... 43

9.2 Are the amplifiers properly configured?.............................................................................. ............... 43

9.3 Are the amps and the NX properly connected? ........................................................ ........................ 43

9.4 Are the speakers properly connected? ............................................................................................. 43

9.5 Final Pre-Sound Check Check..... ..................................................................................................... 44

10 RS18 Technical Specifications ......... ................................................................................................. 45

10.1 System specifications.................. ..................................................................................................... 45

10.2 Dimensions....................................................................................................................................... 46

10.3 RS18 Accessories ....................................................... ...................................................... ..

............. 47

10.3.1 RS18-BUMPER........................................................................................................................ 47

10.3.2 RS18 Push-Pins....................................................................................................................... 47

10.3.3 RS18-FPLATES ....................................................................................................................... 48

10.3.4 RS18-FRONT WHEELBOARD ................................................................................................ 49

10.3.5 RS18-DOLLY ........................................................................................................................... 49

10.4 NX242-ES4 Digital TDController....................................................................................................... 50

10.4.1 Specifications........................................................................................................................... 50

10.4.2 Front and Rear Panel view....................................................................................................... 50

10.5 NXAMP4x1 & NXAMP4x4 Powered Digital TDCo ntrollers................................................................ 51

10.5.1 Specifications........................................................................................................................... 51

10.5.2 Front and Rear Panel view....................................................................................................... 52

11 RS18 Parts & Accessories List................................ .......................................................................... 53

11.1 Modules & Control Electronics List ................................................................................................... 53

11.2 Accessories List.................................................................... ............................................................ 53

12 USER NOTES.................................................... ................................................................................... 54

INTRODUCTION Page 9/54

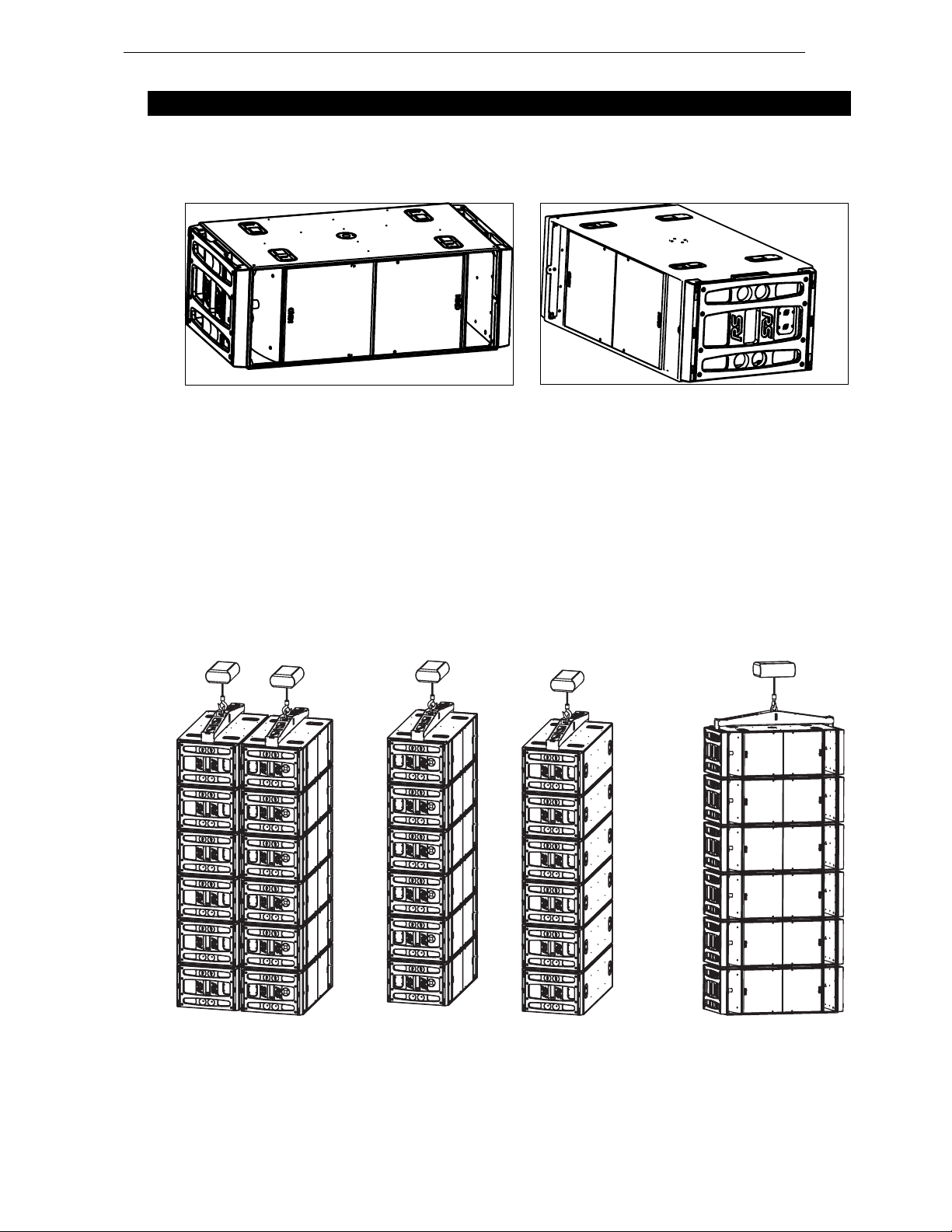

1 INTRODUCTION

Thank you for selecting a NEXO RS18 Subwoofer System. This manual is intended to provide you with

necessary and useful information about your RS System, which includes the following products:

• RS18 is a Directivity Configurable Subwoofer, which comprises two 18” (46cm) long

excursion Neodynium direct radiating drivers mounted in a dual volume vented enclosure

with aerodynamic profiled vents; its coverage ranges from omnidirectional to highly

directional and its frequency response extends from VLF to LF ranges. Two versions are

available (Touring and Fix installations), with two finishing for both versions (carpeted or

painted).

• a full range of accessories that provides safe, flexible and simple means of transporting and

installing RS18 subwoofers in fixed installation as well as in touring applications. These

include flying hardware, dolly and wheelboard.

Page 10/54 INTRODUCTION

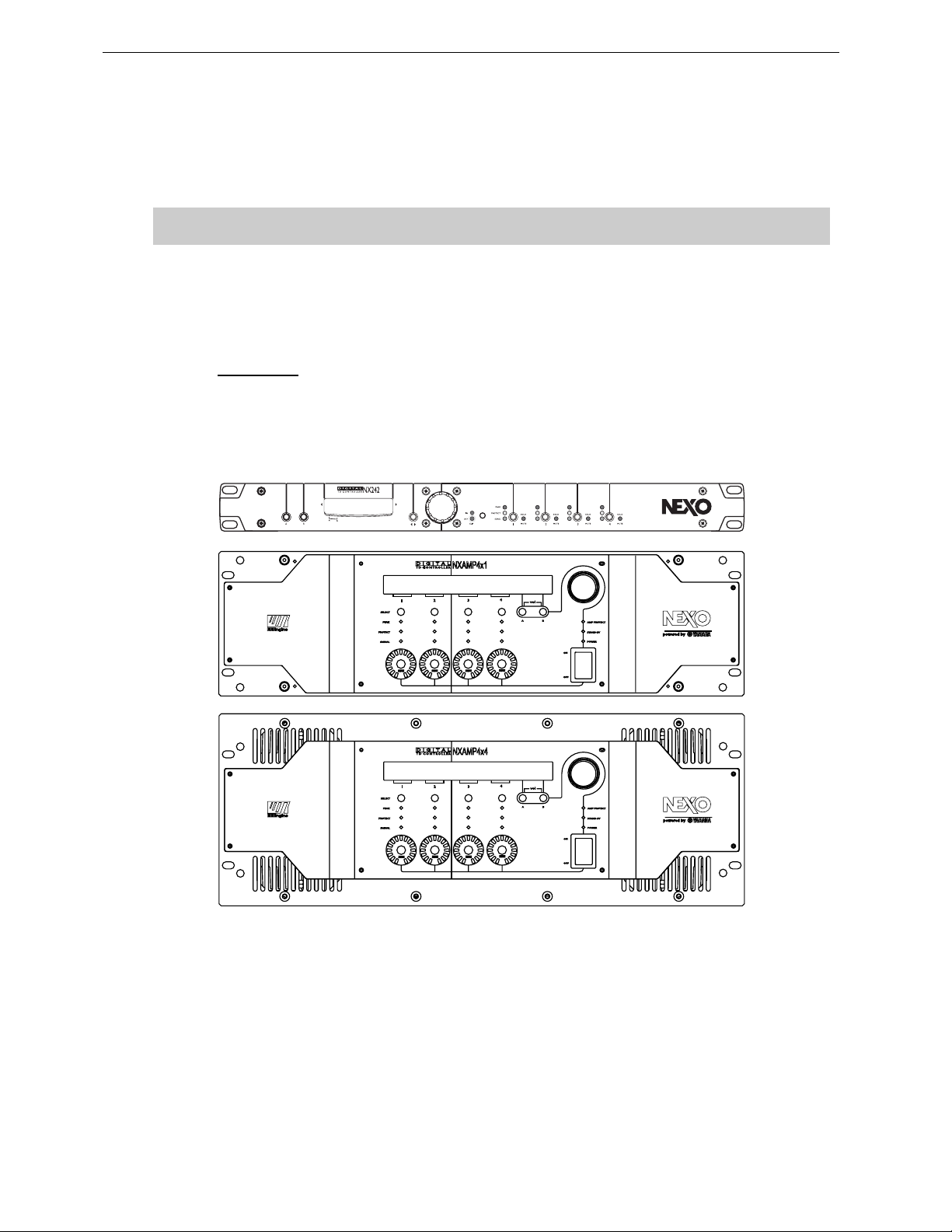

As for all NEXO systems, the RS18 is controlled, powered and monitored by dedicated NEXO

TDControllers:

• NX242-ES4 Digital TDController provides comprehensive control of RS18 loudspeakers in multiple

configurations. It allows Ethersound

TM

digital audio networking, as well as remote control for all units

in the network. It has 2 analogue / 4 digital inputs and 4 analogue / 4 digital outputs;

IMPORTANT : NX242 must be equipped with NX-Tension Card to access RS18 directional

mode setups

• NXAMP4x1 and NXAMP 4x4 are Powered Digital Controllers, providing full control and amplification

for RS18 in multiple configurations. Both devices feature 4 analogue inputs and 4 speaker

outputs.When equipped with optional card, 4 digital inputs in Ethersound

format as well as remote control for all units in the network become available.

For a complete description of these controllers, please refer to User Manuals. The NX242 and NXAMP

DSP algorithms and parameters are fixed in software and updated regularly: Please consult the NEXO

web site (www.nexo.fr

) for the latest software releases.

Please devote your time and attention to reading this manual. A comprehensive understanding of RS18

specific features will help you to operate your system at its full potential.

GeoD Passive mode

Crossover 80Hz

TM

digital audio network

RS18 GENERAL INSTRUCTIONS Page 11/54

1 RS18 GENERAL INSTRUCTIONS

1.1 Mounting Rigging Plate

IN ORDER TO PREVENT SCREWS FROM GETTING LOOSE, USE BLOCKING LIQUID LOCTITETM

243 OR EQUIVALENT FOR ALL SCREWS USED WITH RS18 ACCESSORIES.

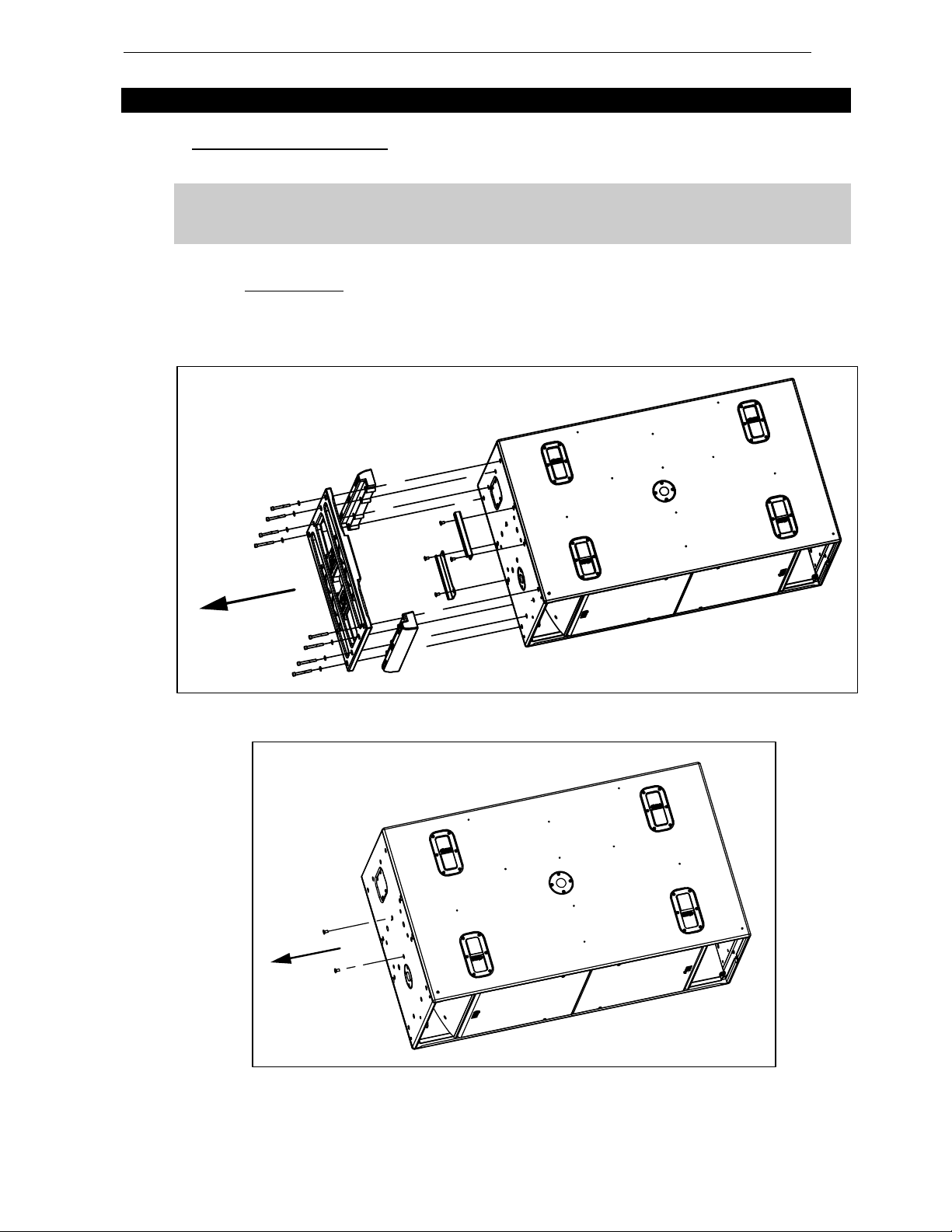

1.1.1 RS18 Painted

• Tools: Allen Key 6mm.

• Remove the twelve screws on each side of RS18.

IMPORTANT

•

• Remove the four screws on each side of RS18.

Page 12/54 RS18 GENERAL INSTRUCTIONS

• Insert Spacer between cabinet and Rigging plates.

• Fill each screw hole with Loctite 243 or equivalent.

• Tighten the 6 screws alternately, at the rate of 4 revolutions per screw.

• Fill each screw hole with Loctite 243 or equivalent.

• Insert the 8 handles washers and screws and tight them.

INSTALLING PAINTED RS18 RIGGING PLATES

IMPORTANT

RS18 handles must not be used to fly RS18’s (through illegal use of straps for example)

RS18 GENERAL INSTRUCTIONS Page 13/54

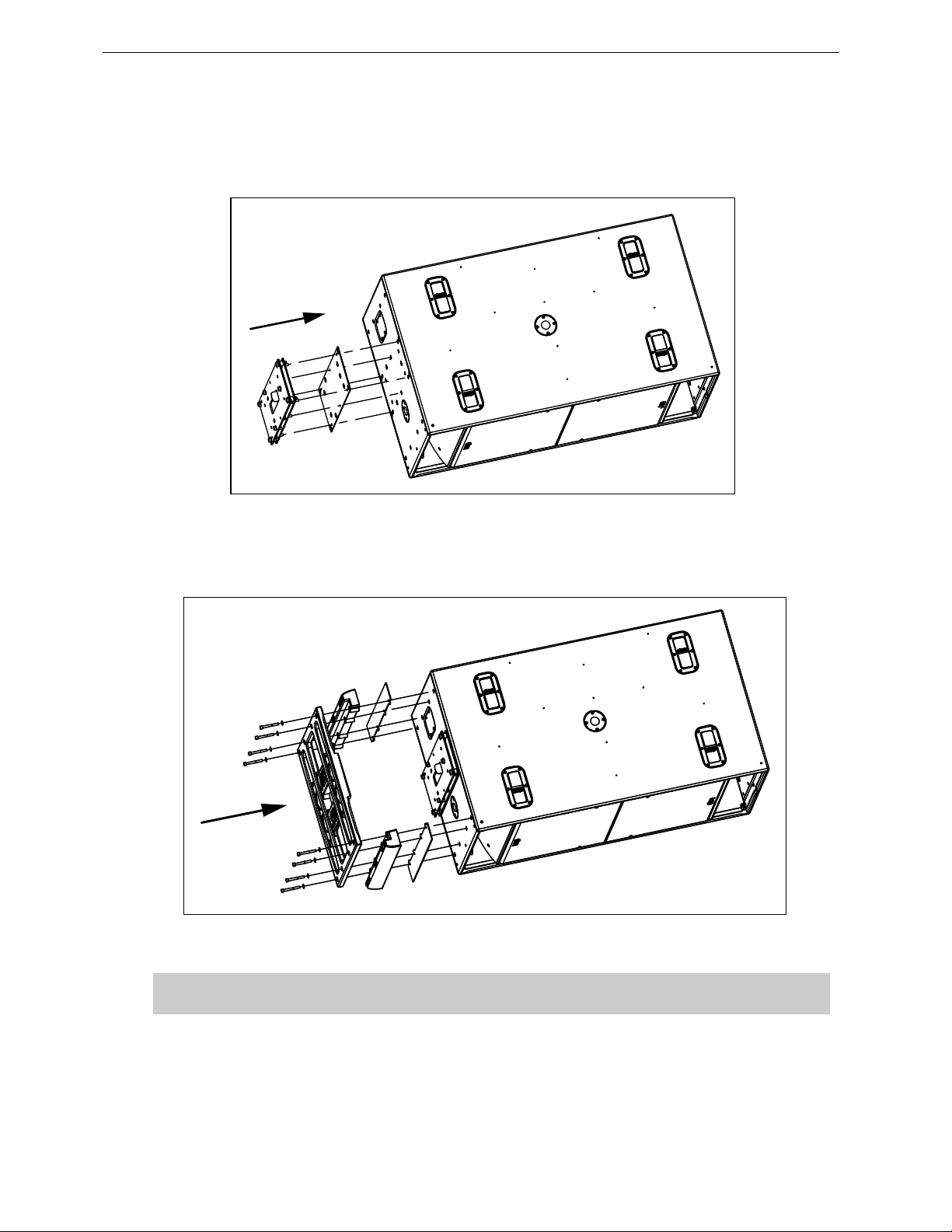

1.1.2 RS18 Carpeted

• Tools: Allen Key 6mm.

• Remove the twelve screws on each side of RS18.

• Remove the four screws on each side of RS18.

Page 14/54 RS18 GENERAL INSTRUCTIONS

• Fill each screw hole with Loctite 243 or equivalent.

• Tighten the 6 screws alternately, at the rate of 4 revolutions per screw.

• Fill each screw hole with Loctite 243

TM

or equivalent.

• Insert the 8 Handles washers and screws and tight them.

INSTALLING CARPETED RS18 RIGGING PLATES

IMPORTANT

RS18 handles must not be used to fly RS18’s (through illegal use of straps for example)

RS18 GENERAL INSTRUCTIONS Page 15/54

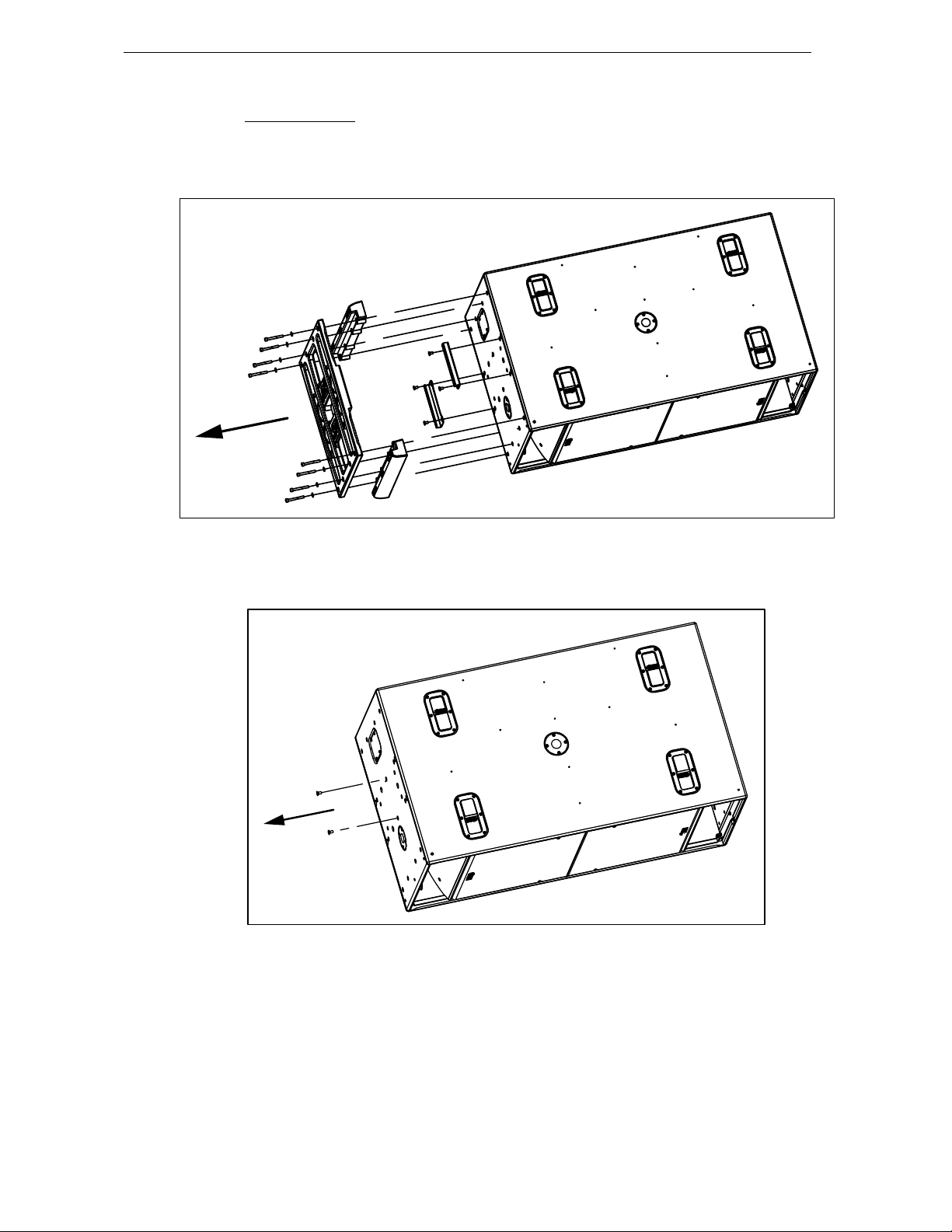

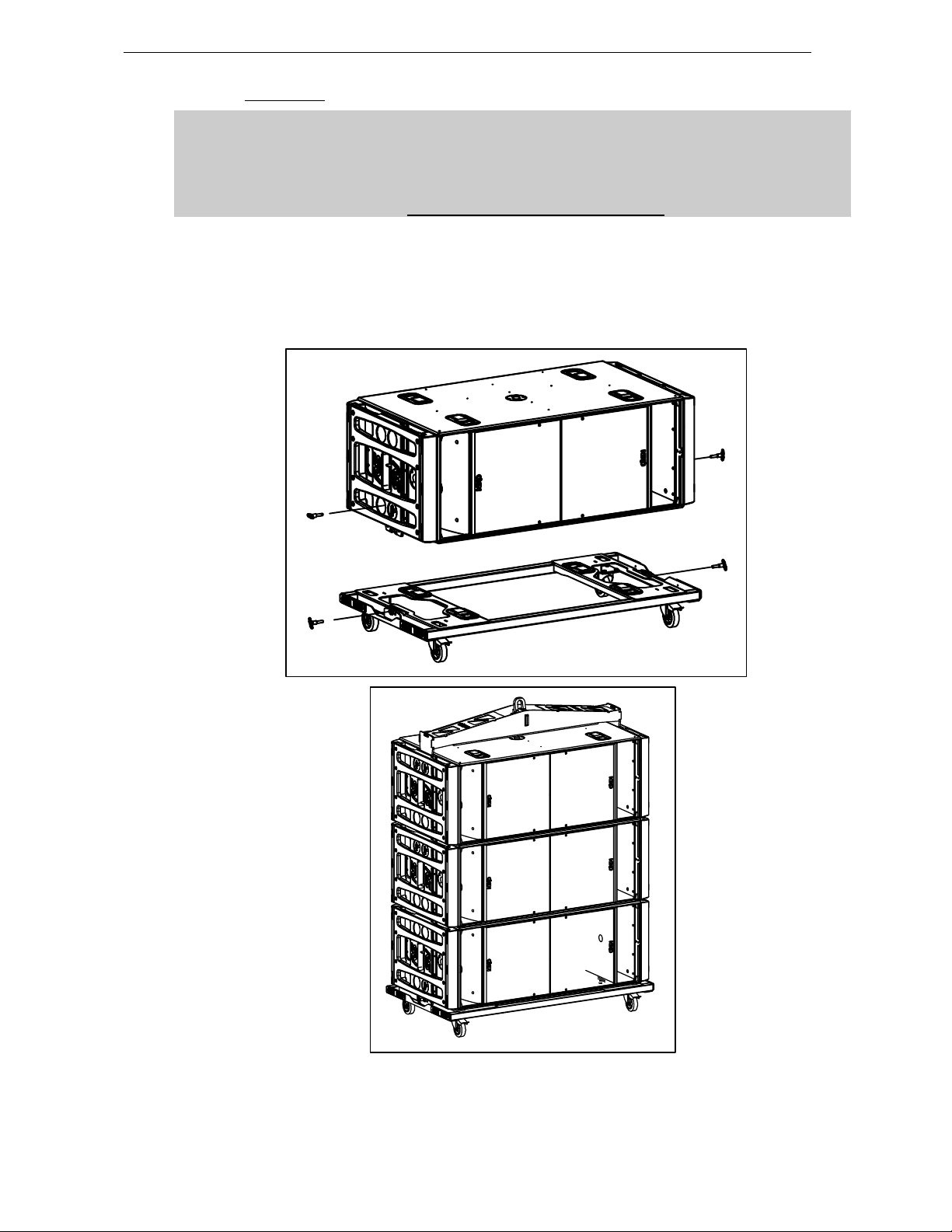

1.1.3 RS18 Dolly

IMPORTANT

1- TRANSPORTING RS18 ON DOLLY REQUIRES THAT FLYING PLATES ARE INSTALLED

ON ALL CABINETS SO THAT RS18’S CAN BE SECURED TOGETHER:

2- RS18 DOLLY IS DESIGNED FOR UP TO 3 RS18’S AND BUMPER;

NEVER EXCEED THESE QUANTITIES.

• The first RS18 must be locked to the RS18 dolly using 4 push-pins according to below drawing;

• Subsequent RS18s are stacked on top using four push-pins per additional cabinet to secure the

assembly.

• Bumper is to be attached to the top cabinet.

Page 16/54 RS18 GENERAL INSTRUCTIONS

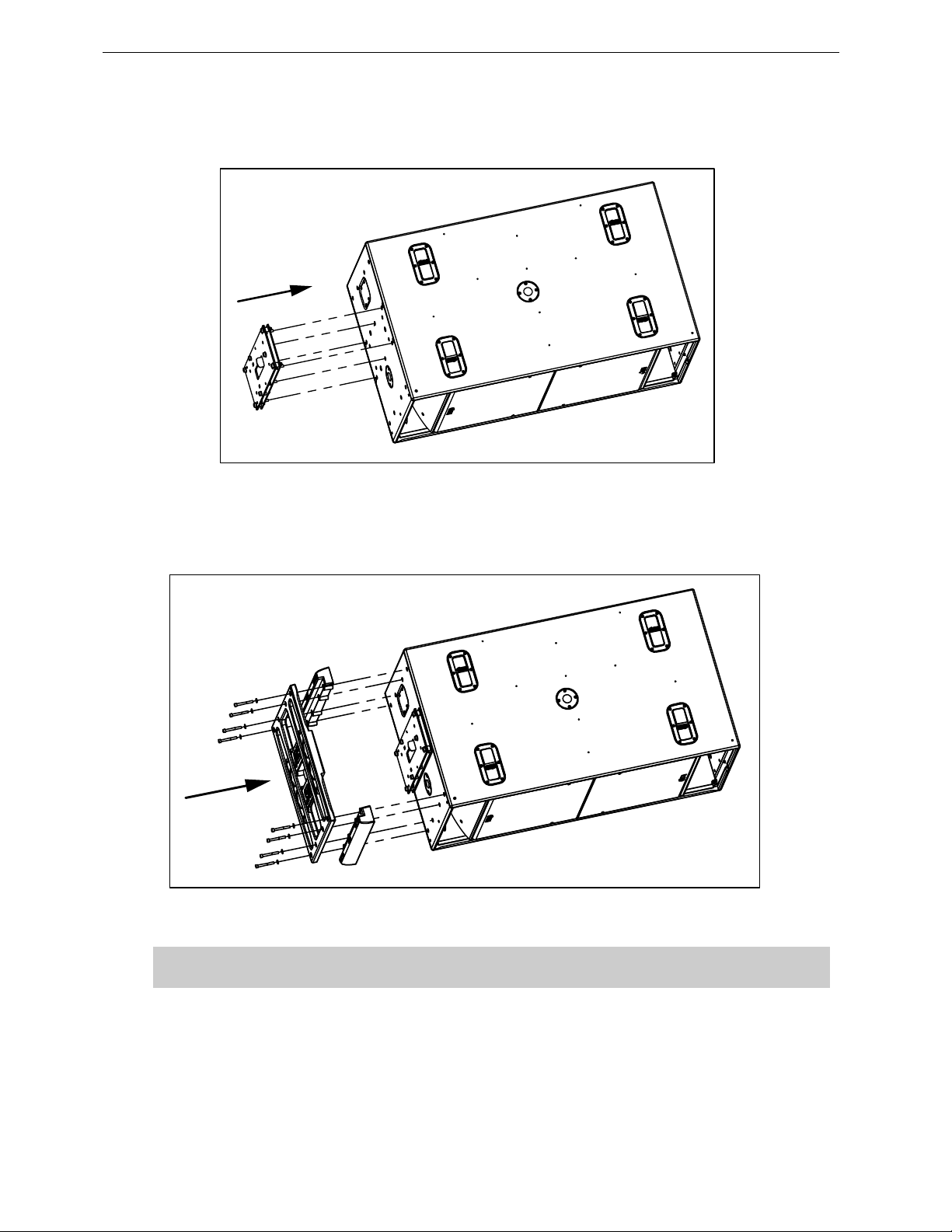

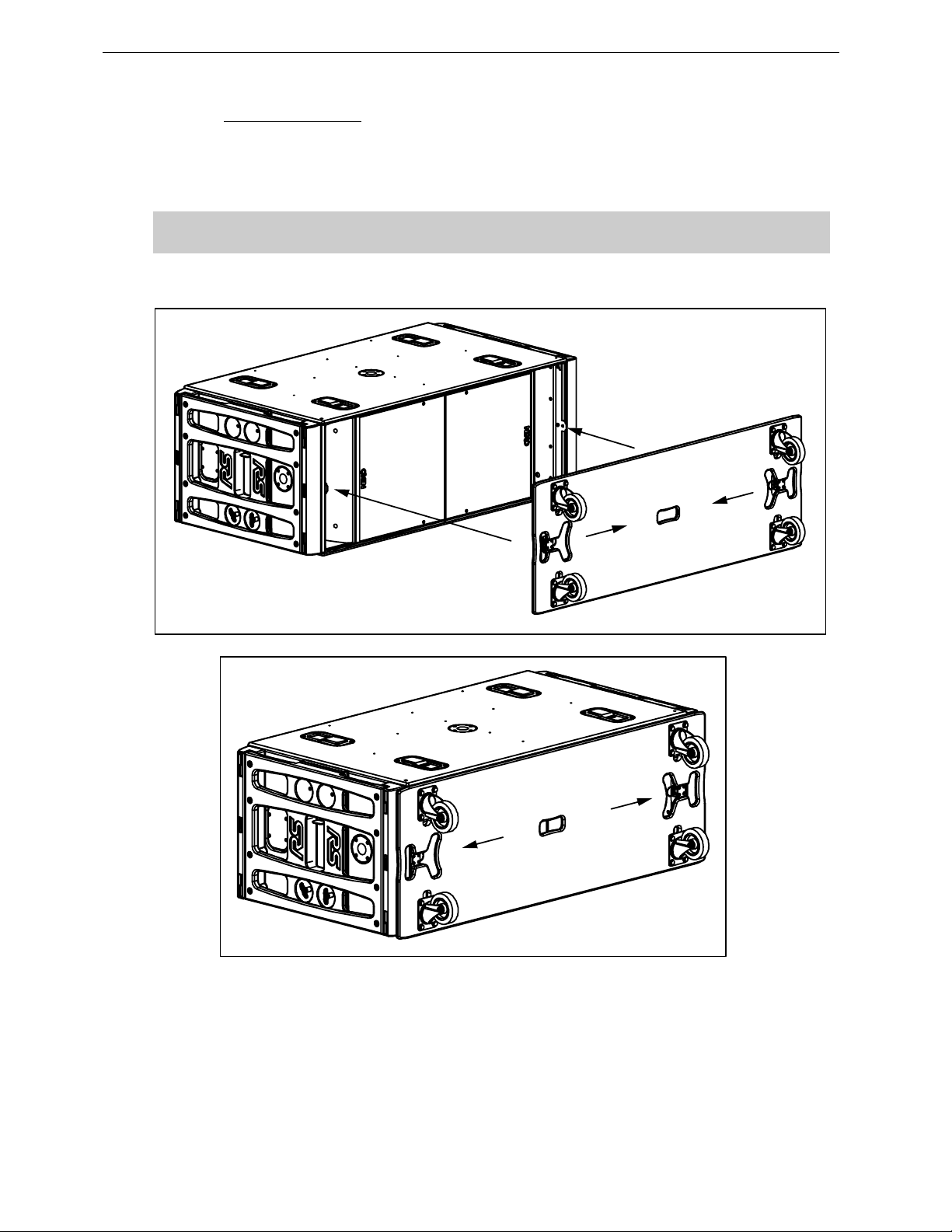

1.1.4 RS18 Wheel Board

• Pull wheel board lockers inwards;

• Maintain lockers while positioning wheel board on RS18 front panel ;

• Release lockers.

IMPORTANT

ENSURE WHEEL BOARD IS PROPERLY LOCKED TO RS18

RS18 GENERAL INSTRUCTIONS Page 17/54

r

1.2 Speaker connection

1.2.1 Configuring Connector and Owner plates

Owner and connector plates can be exchanged depending on chosen directional configuration.

Please note that connector plates can pass through the holes, it is therefore not required to unsolder the

connectors.

• Directional Mode : it is recommended to install the connector panel on the side which supports the

rigging plates;

• Connection side is always opposite to FOH (main lobe direction)

SP4

Connector

REAR

Speaker

Top View

FRONT

Speaker

FOH

FOH

FRONT

Speaker

Top View

REAR

Speaker

SP4

Connecto

CONNECTOR PLATE IN DIRECTIONAL MODE

• Omni Mode: it is recommended to install the connector panel on the side opposite to the drivers

(factory default configuration)

SP4

Or

SP4

CONNECTOR PLATE IN OMNI MOD E

FOH

1.2.2 RS18 connectors

RS18 is connected through Speakon NL4FC plugs (not supplied).

Either connector can be used to connect an amplifier or to link to an additional RS18 cabinet.

Connectors are wired as follows:

Speakon NL4F

Connectors

1(-)

1(+)

2(-)

2(+)

Omni Mode Directional Mode Comment

⇒

⇒

⇒

⇒

18’’ driver Right (-) 18’’ driver Rear (-)

18’’ driver Right (+) 18’’ driver Rear (+)

18’’ driver Left (-) 18’’ driver Front (-)

18’’ driver Left (+) 18’’ driver Front (+)

Driver Next to Connector

Panel

Driver Opposite to

Connector Panel

Page 18/54 RS18 GENERAL INSTRUCTIONS

DIRECTIONAL

MODE

OMNI

MODE

1.2.3 Cabling

• NEXO recommends the exclusive use of multi-conductor cables to connect the system: the cable kit

is compatible with all the cabinets, and there is no possible confusion between Front and Rear

drivers.

• Cable choice consists mainly of selecting cables of the correct sectional dimension (size) in relation to

the load resistance and the cable length. Too small a cable section will increase both its serial

resistance and its capacitance; this reduces the electrical power delivered to the loudspeaker and can

also induce response (damping factor) variations.

• For a serial resistance less or equal to 4% of the load impedance (damping factor = 25), the

maximum cable length is given by:

L

= Z x S S in mm2, Z in Ohm, L

max

in meters

max

• The table below indicates these values, for 3 common sizes.

Load Impedance (Ω)

Cable section Maximum Length (meters)

2,5 mm² (AWG #12) 5 10 20

4 mm² (AWG #10) 8 16 32

2 4 8

1.2.4 Example

• Each RS18 driver has a 8 Ohms nominal impedance; in omni mode, both loudspeakers can be

driven in parallel on one amplifier channel, presenting therefore a 8/2 = 4 Ohms load impedance. The

maximum acceptable 2x2.5 mm

2

(AWG #12) cable length L

for RS18 with its 2 drivers in parallel is

max

10 meters.

• When driven in directional mode, RS18 requires 2 amplifier channels, presenting therefore two

independent 8 Ohm load impedances. The maximum acceptable 4x1.5 mm

length L

for RS18 with its 2 drivers driven independently is 32 meters.

max

2

(AWG #110) cable

IMPORTANT

Long speaker cables induce capacitive effects – up to hundreds of pF depending on the

quality of the cable - with a low-pass-pass effect on high frequencies. If long speaker

cables must be used, ensure that they do not remain coiled while in use.

AMPLIFIER SELECTION FOR USE WITH RS18 Page 19/54

2 AMPLIFIE R SELECTION FOR USE WITH RS18

NEXO recommends high power amplifiers in all cases. Budget constraints are the only reason to select

lower power amplifiers. A lower power amplifier will not reduce the chances of driver damage due to

over-excursion, and may actually increase the risk of thermal damage due to sustained clipping. If an

incident occurs on an installation without protection, the fact that amplifiers only generating half their

rated output power (-3dB) are used will not change anything in respect of possible damage. This is due

to the fact that the RMS power handling of the weakest component in the system is always 6 to 10 dB

lower than the amplifier rating.

2.1 RS18 recommended amplification

RS18 is rated for very high power handling and has a 2x8 Ohms nominal impedance.

Nexo recommends amplifiers in agreement with table below:

Recommende d

Amplifier#

1 x RS18 2 x 1000 Watts to 2000 Watts / 8 Ohms or

1 x 2000 Watts to 4000 Watts / 4 Ohms (*)

OMNI MODE DIRECTIONAL MODE

2 x 1000 to 2000 Watts / 8 Ohms

(*) driving both drivers in parallel requires dedicated speaker cable

2.2 Current rating

It is very important that the amplifier behaves correctly under low load conditions. A speaker system is

reactive by nature: on transient signals like music it will require four to ten times more instantaneous

current than its nominal impedance would indicate. Amplifiers are generally specified by continuous

RMS power into resistive loads; however the only useful information about current capacity is the

specification into a 2 Ohm load. It is possible to perform an amplifier listening test by loading the amps

with twice the number of cabinets considered for the application (2 speakers per channel instead of one,

4 instead of 2) and running the amps up to the onset of clipping. If the signal does not noticeably

deteriorate, the amplifier is well adapted (overheating after approximately ten minutes is normal but

thermal protection must not operate too quickly after starting this test).

2.3 Amplifier settings

Gain value

Gain is the key to correct alignment of the system. It is especially important to know the gain of all

amplifiers used in your set-up. The tolerance should be about ±0.5 dB. In practice this can be difficult to

achieve because:

• Some amplifier brands have an identical input sensitivity for models of different power rating (this

infers a different voltage gain for each model). For example, a range of amplifiers with different power

outputs, all having a published input sensitivity of 775mV/0dBm or 1.55V/+6dBm, will have a wide

range of actual gains – the higher the power, the greater the gain.

• Various other brands may offer constant gain but only within a given product range, for example they

may fit fixed input sensitivity only on their semi-professional amps.

• Even if a manufacturer applies the constant gain rule to all models, the value selected will not

necessarily be the same as that chosen by other manufacturers.

• Some products can exhibit manufacturing tolerances for the same model of ±1dB or more. Some

amplifiers may have been modified, possibly without any label indicating the new values. Others may

have gain switches fitted internally where it is impossible for the user to verify the actual setting

without opening the amplifier casing.

• In cases where you don't know the gain of your amplifier (or want to check it) please follow this

procedure:

1) Unplug any loudspeakers from the amplifier outputs

Page 20/54 AMPLIFIER SELECTION FOR USE WITH RS18

2) With a signal generator, feed a sine wave at 1000Hz at a known voltage (say 0.5V) to

the input of the amplifier under test

3) Measure the voltage at the output of the amplifier

4) Calculate the gain using the formula Gain = 20 * LOG

(Vout/Vin).

10

Some examples:

Vin / Gain 20dB 26dB 32dB 37dB (1.4V sensitivity / 1350Wrms)

0.1 V 1 V 2 V 4 V 7.1 V

0.5 V 5 V 10 V 20 V 35.4 V

1 V 10 V 20 V 40 V 70.8 V

Remember that constant sensitivity settings will give a different gain value when the amplifier power is

different.

NEXO recommends low gain amplifiers: +26dB is recommended, as it is at the same time adequately

low and quite common amongst amplifier manufacturers. This gain setting improves signal to noise ratio

and allows all preceding electronic equipment, including the NX242-ES4 TDcontroller, to operate at

optimum level. Remember that using a high gain amplifier will raise the noise floor proportionally.

Operating Mode

Most two channel amplifiers available on the pro-audio market have the following operating modes:

• Stereo:

• Bridge-Mono:

two fully independent channels deliver identical power into identical loads

the second signal channel processes the same input as the first channel, but with

reversed phase. The (single) load is connected between the two positive channel outputs using a

suitable connection. While the total output of the amplifier remains the same, the available output

voltage, the minimum impedance that can be connected and the voltage gain are doubled as

compared with stereo operation. Typically, only channel 1 input is active. Positive and negative output

connections vary depending on amplifier manufacturers.

• NEXO does not recommend Bridge Mono Mode unless amplifier power is clearly not sufficient.

IMPORTANT

When in Bridge-Mono mode, check your amplifier user manual for proper connection of

outputs 1(+) and (2+) in relation to input phase.

• Parallel-mono: the output terminals of the two channels are configured in parallel using an internal

relay. The (single) load is connected either to the output of channel 1 or to that of channel 2 (as if in

stereo). While the total output of the amplifier remains the same the output voltage level is also the

same as in stereo mode. The minimum impedance that can be connected is reduced by half due to

the fact that current capability is doubled. Typically, only channel 1 input is active.

• NEXO does not recommend Parallel-Mono Mode for RS18 amplification.

Warning on amplifiers signal processing features

Some high-end amplifiers may include signal processing functions similar to those found in the NX242ES4 TDcontroller ("loudspeaker offset integration", "limiter", "compressor," etc.). Moreover, when this

processing is digital, computation latency time can introduce a few milliseconds delay from input to

output. These functions are not adapted to specific system requirements and may interfere with the

complex protection algorithms used in the NX242-ES4.

NEXO do not advise using other protection systems in conjunction with the NX242-ES4 and they should

be disabled.

IMPORTANT

For proper system protection, no latency time or non-linear devices should be inserted

between the output of NX242-ES4 TDController and the input of loudspeakers through

use of DSP modules such as internal amplifier signal processing.

NEXO TD CONTROLLERS AND RS18 SETUPS Page 21/54

3 NEXO TD CONTROLLERS AND RS18 SETUPS

3.1 RS18 and NXAMP TDControllers

NEXO Powered TDControllers NXAMP 4X1 & 4X4 are integrated solutions for Control and amplification

for all NEXO speaker ranges.

NXAMP4x1 and NXAMP4x4 power capability is listed in the table below:

Mode 4 Channels Bridge Stereo

NXAMP4x1 4 x 600 Watts / 8 Ohms

NXAMP4x4 4 x 1900 Watts / 8 Ohms

3.1.1 NXAMP connectors

NXAMP4x1 and NXAMP4x4 rear panels feature:

• 4 analog inputs / outputs (links) on XLR3 connectors;

• 4 digital inputs / outputs on RJ45 connectors with optional card;

• 4 speaker level outputs on NL4FC connectors.

Figure below shows connectors implementation on the rear panel.

4 x 900 Watts / 4 Ohms

4 x 1300 Watts / 2 Ohms

4 x 3300 Watts / 4 Ohms

4 x 4000 Watts / 2 Ohms

2 x 1800 Watts / 8 Ohms

2 x 2600 Watts / 4 Ohms

2 x 6600 Watts / 8 Ohms

2 x 8000 Watts / 4 Ohms

3.1.2 RS18 and NXAMP recommended configurations

OMNI MODE DIRECTIONAL MODE

1 x RS18 1 channel of NXAMP4x1 in Bridge Stereo Mode

1 channel of NXAMP4x4 in 4 channels mode

2 x RS18 2 channels of NXAMP4x1 in Bridge Stereo Mode

2 channels of NXAMP4x4 in 4 channels mode

3 x RS18 2 channels of NXAMP4x4 in 4 channels mode

2 channels of NXAMP4x1 in Bridge Stereo Mode

2 channels of NXAMP4x4 in 4 channels mode

2 channels of NXAMP4x1 in Bridge Stereo Mode

2 channels of NXAMP4x4 in 4 channels mode

2 channels of NXAMP4x4 in 4 channels mode

3.2 RS18 setups on NXAMP TDControllers

At RS18 release time (February 2010), 60 setups combining RS18 with NEXO speakers are available in

NX242-ES4 / NXAMP load 2.52.

Please consult www.nexo-sa.com

periodically for upgrade releases.

Page 22/54 CONNECTION DIAGRAMS

4 CONNECTION DIAGRAMS

4.1 RS18 with NX242-ES4 TD Controller (Stereo Omni or Directional Mode)

FROM AMPLIFIERS

TO AMPLIFIERS

OUT

OUT

OUT

+ 4 -

RIGHT

FRONT

+ 3 -

RIGHT

+ 2 - + 1 -

LEFT

REAR

LEFT

FRONT

REAR

RIGHT

FRONT

RIGHT

REAR

LEFT

FRONT

OUT

LEFT

REAR

IN RIGHT IN LEFT

SP4

SP4

SP4

LEFT

RIGHT

STEREO

STEREO

SP4

SP4

SP4

CONNECTION DIA GRAMS Page 23/54

4.2 RS18 with NXAMP4x4 (Stereo Omni or Directional Mode)

OUT C

SP4 SP4

OUT A

IN B

IN A

SP4

SP4

SP4

SP4

SP4

SP4

SP4

SP4

Page 24/54 RS18 RIGGING INSTRUCTIONS

5 RS18 RIGGING INSTRUCTIONS

Before proceeding with assembly of RS18 arrays, please ensure that the components are present and

undamaged. A component list is appended to this manual. In the event of any shortage, please contact

your supplier.

For maximum efficiency the RS18 rigging system requires three experienced persons for set-up:

typically one motor hoist operator, and one RS18 operator per side of the array. Good synchronisation

and crosscheck between the operators are key elements for a reliable and safe set-up.

5.1 SAFETY FIRST

RS18 Rigging System structural computations and related documents are available in Geosoft2 or at

Nexo (info@nexo.fr

We include this section to remind you of safe practice when flying the RS18 system. Please read it

carefully. However, user must always apply his or her knowledge, experience and common sense. If in

any doubt, seek advice from your supplier or NEXO agent.

This manual offers guidance only for RS18 RAYSUB systems. References in this manual to other

rigging equipment such as motor hoists, steels, shackles etc. are made to clarify the description of

RS18 procedures. The user must ensure that operators are properly trained by other agencies in the

use of these items.

The RS18 Rigging System has been optimised for the deployment of vertical arrays of RS18

loudspeakers. No angle adjustment is allowed between cabinets.

The RS18 Rigging System is a professional precision tool set, and should be handled with extreme

care. Only persons who are fully conversant with the operation of the RS18 Rigging System and

provided with suitable safety equipment should deploy RAYSUB Arrays. Misuse of the RS18 Rigging

System could lead to dangerous consequences.

Used and maintained correctly, the RS18 Rigging System will give many years of reliable service in

portable systems. Please take the time to read and understand this manual.

) upon request.

5.1.1 Flown Systems Safety

• Always inspect all the rigging components and cabinets for damage before assembly. Pay special

attention to the lifting points, and safety clips. If you suspect that any of the components are damaged

or defective, DO NOT USE THE AFFECTED PARTS. Contact your supplier for replacements.

• Read this manual carefully. Also be familiar with the manuals and safe working procedures for any

ancillary equipment that will be used with the RS18 Rigging System.

• Ensure that all local and National regulations regarding the safety and operation of flying equipment

are understood and adhered to. Information on these regulations can usually be obtained from Local

Government Offices.

• When deploying a RS18 system always wear protective headwear, footwear and eye protection.

• Do not allow inexperienced persons to handle a RS18 system. Installation personnel should be

trained in loudspeaker flying techniques and should be fully conversant with this manual.

• Ensure that motor hoists, hoist control systems and ancillary rigging components are currently

certified as safe and that they pass a visual inspection prior to use.

• Ensure that the public and personnel are not allowed to pass beneath the system during the

installation process. The work area should be isolated from public access.

• Never leave the system unattended during the installation process.

• Do not place any object, no matter how small or light, on top of the system during the installation

procedure. The object may fall when the system is flown and is likely to cause injury.

• Secondary safety steels must be installed once the system has been flown to the operating height.

Secondary steels must be fitted irrespective of requirements of the local safety standards applicable

to the territory.

RS18 RIGGING INSTRUCTIONS Page 25/54

• Ensure that the system is secure and prevented from pivoting around the motor hoist.

• Avoid any form of excessive dynamic loading to the assembly (structural computations on RS18

Rigging System are based on a 1/1.2 factor for hoist or motor acceleration).

• NEVER attach any item to the RS18 system other than the RS18 accessories.

• When flying outdoor systems ensure that the system is not exposed to excessive wind or snow loads

and is protected from rainfall.

• The RS18 Rigging System requires regular inspection and testing by a competent test centre. NEXO

recommend that the system is load tested and certified annually or more frequently if local regulations

require.

• When de-rigging the system ensure that the same duty of care is given to the procedure as for the

installation. Pack RS18 components carefully to prevent damage in transit.

5.1.2 Ground Stacking Safety

Statistically, many more injuries occur due to unstable ground stacked PA systems than those

associated with flown systems. There are several reasons for this fact, however the message is clear:

• Always survey the supporting structure upon which a ground stack is to be built. Always look beneath

PA wings to inspect the deck support and if necessary ask for the stage scrims and dressings be

removed to allow access.

• If the stage surface slopes, as it does in some theatres, ensure that the system is prevented from

sliding forwards due to vibration. This may require the fitting of timber battens to the stage floor.

• For outdoor systems ensure that that the system is protected from wind forces which might cause the

ground stack to become unstable. Wind forces can be huge, especially upon large systems, and

should never be underestimated. Observe meteorological forecasts, calculate the “worst case” effect

upon the system prior to erection and ensure that the system is secured appropriately.

• Take care when stacking cabinets. Always employ safe lifting procedures and never attempt to build

stacks without sufficient personnel and equipment.

• Never allow anyone, whether operators, artists or members of the public to climb onto a ground

stacked PA system. Anyone who needs to climb over 2m (6 ft) high should be fitted with suitable

safely equipment including a clip-on harness. Please refer to local Health and Safety legislation in

your territory. Your dealer can help with advice on access to this information.

• Apply the same attention to all safety matters when de-stacking systems.

• Be aware that safety procedures are as important in the truck and in the warehouse as they are at the

venue.

Page 26/54 RS18 RIGGING INSTRUCTIONS

IMPORTANT

- All RS18 Accessories are specifically rated in agreement with structural

computations.

- Never use other accessories – including push-pins - when as sembling RS18 cabinets

than the ones provided by NEXO: NEXO will decline responsibility over the entire

RS18 accessory range if any component is purchased from a different supplier.

5.1.3 Contacts

Correct training is fundamental to safe practise when working with loudspeaker flying systems. NEXO

recommend that users contact local industry associations for information on specialist courses.

Information for International training agencies can be obtained by contacting either:

The Production Services Association

(PSA),

School Passage,

Kingston-upon-Thames,

KT1 SDU Surrey,

ENGLAND

Telephone: +44 (0) 181 392 0180

ESTA

Rigstar Training and Testing Center

82 Industrial Dr. Unit 4

Northampton, Massachusetts 01060 U.S.A.

Phone: 413-585-9869 -- Fax: 413-585-9872

school@rigstar.com

Entertainment Services & Technology Association

875 Sixth Avenue, Suite 1005

NEW YORK, NY 10001 USA

Phone: 212-244-1505 – Fax: 212-244-1502

info@esta.org

RS18 RIGGING INSTRUCTIONS Page 27/54

5.2 Flying RS18 arrays

IMPORTANT

- Maximum allowed RS18 quantity to be flown is 12;

- RS18 bumper rigging point must be adjusted so that bumper always remains

horizontal;

- RS18 flying system forbids angles between adjacent cabinets.

IMPORTANT

RS18 bumper is designed to be flown from one rigging point only.

Motor hoist must be rated to support entire cluster weight.

Required items

• 1 x Bumper (RST-BUMPER18) , 4 Quick release pins 10x25mm included;

• N Pair of RS18 Rigging Plates (RST-FPLATES18) for N cabinets, 4xN quick release pins 10x25mm

(included).

5.2.1 Hoist Rating

N being RS18 quantity within a cluster, cluster weight is given by:

W

= (30kg/66lbs) + Nx(131kg/289lbs)

cluster

including cable weight up to 5kg/11lbs per RS18

Hoist rating is:

• Up to 3 RS18 cluster = ½ ton hoist;

• 4 to 6 RS18 cluster = 1 ton hoist;

• 7 to 12 RS18 cluster = 2 ton hoist.

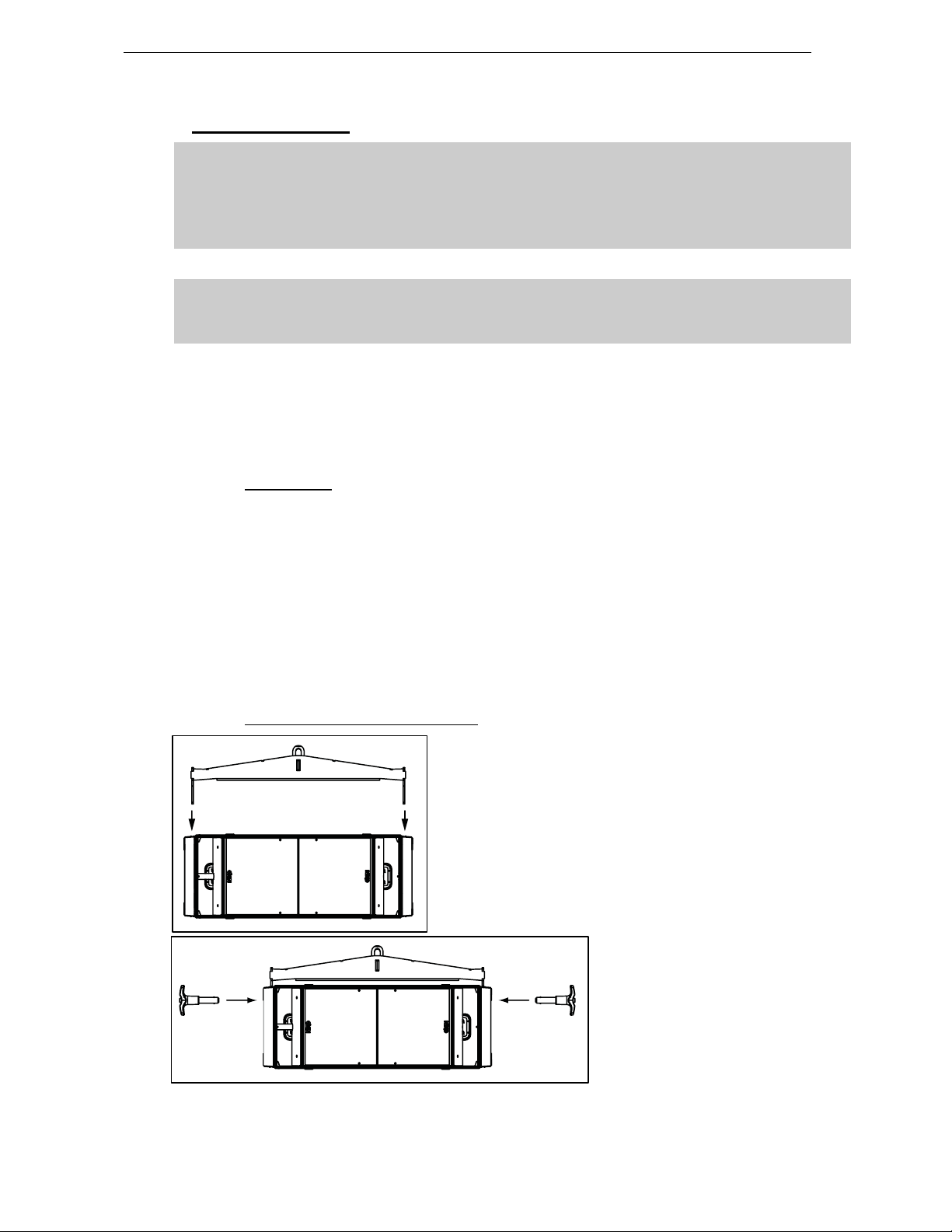

5.2.2 Connecting first RS18 to bumper

• Connect bumper to first RS18 flying system link

plates by using 4 10x25mm quick release pins;

• ensure the 4 quick release pins are properly

locked;

• Connect hoist hook to bumper axis (see below)

Page 28/54 RS18 RIGGING INSTRUCTIONS

5.2.3 Adjusting rigging point for horizontality

Before connecting a second cabinet, bumper angle has to be adjusted for perfect horizontality.

This requires that the rigging point is adjusted in the two horizontal directions so that the bumper

remains horizontal within +/-1°. Adding cabinets will improve this tolerance.

Adjusting 0° along the cabinet depth

Adjusting horizontality along cabinet depth is done by properly selecting bumper hole:

GRIDS SAME SIDE

5.2.4 Flying subsequent RS18s

• Lift assembly to sufficient height in

order to connect a second RS18;

• Position and align second RS18

below assembly;

• Remove the 4 quick release pins from

the PARKING position so that sliding

connector plate can be moved;

RS18 RIGGING INSTRUCTIONS Page 29/54

• On both sides, push the top RS18

sliding connecting plate all the way

downwards into the second RS18

rigging system

• Insert the 4 quick release pins into

the FLOWN position of second RS18

ensure quick release pins are

•

properly locked;

• Repeat above steps for subsequent

RS18’s;

• Lift cluster up to defined rigging

height, and secure it horizontally to

prevent rotation.

Page 30/54 RS18 RIGGING INSTRUCTIONS

• Secure bumper with secondary safety

steel.

IMPORTANT

Do not attempt to make any change to the bumper rigging point once the cluster is lifted

IMPORTANT

The requirements for secondary safety systems vary with territories. However, the

secondary safety steel MUST have a SWL equivalent or greater than that of the rigging

system

RS18 RIGGING INSTRUCTIONS Page 31/54

5.3 Testing and Maintenance of the RS18 flying system

• General: please keep regular maintenance attention to the RS18 flying system in order to provide

long and reliable service. NEXO recommends regular testing of loudspeaker rigging components,

preferably using a suitable test rig coupled with a visual inspection.

• Fasteners: there are several critical points in the RS18 cabinets; primary concerns are:

- the grid screws attaching the grid to the cabinet;

- the screws attaching the connecting plates to the cabinet.

• These fasteners should be regularly checked and tightened as necessary.

• Cleaning: The exterior of the cabinet and the rigging system can be cleaned with a damp cloth

soaked in mild soapy water. On no account use solvent based cleaners , which may damage the

finishing of the cabinet

• After cleaning, the rigging system must be treated with a suitable lubricant to prevent rusting. NEXO

recommends the use of Scottoil FS365 or equivalent which is a water-based lubricant with a mixture

of machine oil, surfactant and anti-rust treatment.

Page 32/54 GENERAL GUIDELINES FOR SUBWOOFER DESIGN

6 GENERAL GUIDELINES FOR SUBWOOFER DESIGN

6.1 Low Frequency Issues

Even low frequency coverage is amongst the toughest issues in sound system design. Common issues

that are faced in design are as follow:

• Low frequency radiation is hard to control

efficiently because of wavelength

becoming large (10m / 30ft at 34 Hz) in

relation to sources; and most of available

subwoofers are omnidirectional; this

results in important low frequency

feedback on stage, environmental

problems in outdoor venues and

increased reverberation time in indoor

venues;

• Stereophonic implementation of

subwoofers introduces very strong

interference patterns; these are related to

Left and Right path length difference to

listener location while pressure levels are

comparable for Left and Right arrays;

while always maximum at the center –

where distance to Left and Right arrays

are equal -, pressure level can severely

drop at locations where path length

equals half the wavelength of frequency

of interest. This effect is well-known from

audio-engineers, and often referred to as

“Power Alley”;

L(m)

L(m)

(nulls and max) are dominant over source

location; because these modes depend

on accurate characterization of boundary

surfaces (walls, ceiling, floor), audience

• In closed venues, room eigen modes

f1=C/2L

f1=C/2L

coverage is very hard to predict.

To overcome these difficulties, some common sense

rules can help.

GENERAL GUIDELINES FOR SUBWOOFER DESIGN Page 33/54

6.2 Gradient Subwoofers benefits

Gradient subwoofers can provide up to 15 dB front to rear average

attenuation (Please refer to Ray Sub technical note for in-detail explanation

on gradient subwoofers).

Low frequency level on stage is therefore significantly reduced on stage, and

in the neighbouring environment in open air venues.

Because of their directional pattern, Gradient subwoofer are also less

sensitive to room eigen modes.

6.3 Monophonic Design

Left and Right subwoofer arrays can be merged into a monophonic system so that interferences no

longer exist.

When using few cabinets, this can be done by installing these cabinets at the centre front stage. If

cabinets are set on the ground in front of the stage, level discrepancy from first to last rows will be

important. Flying cabinets above centre stage will reduce first to last rows discrepancies significantly.

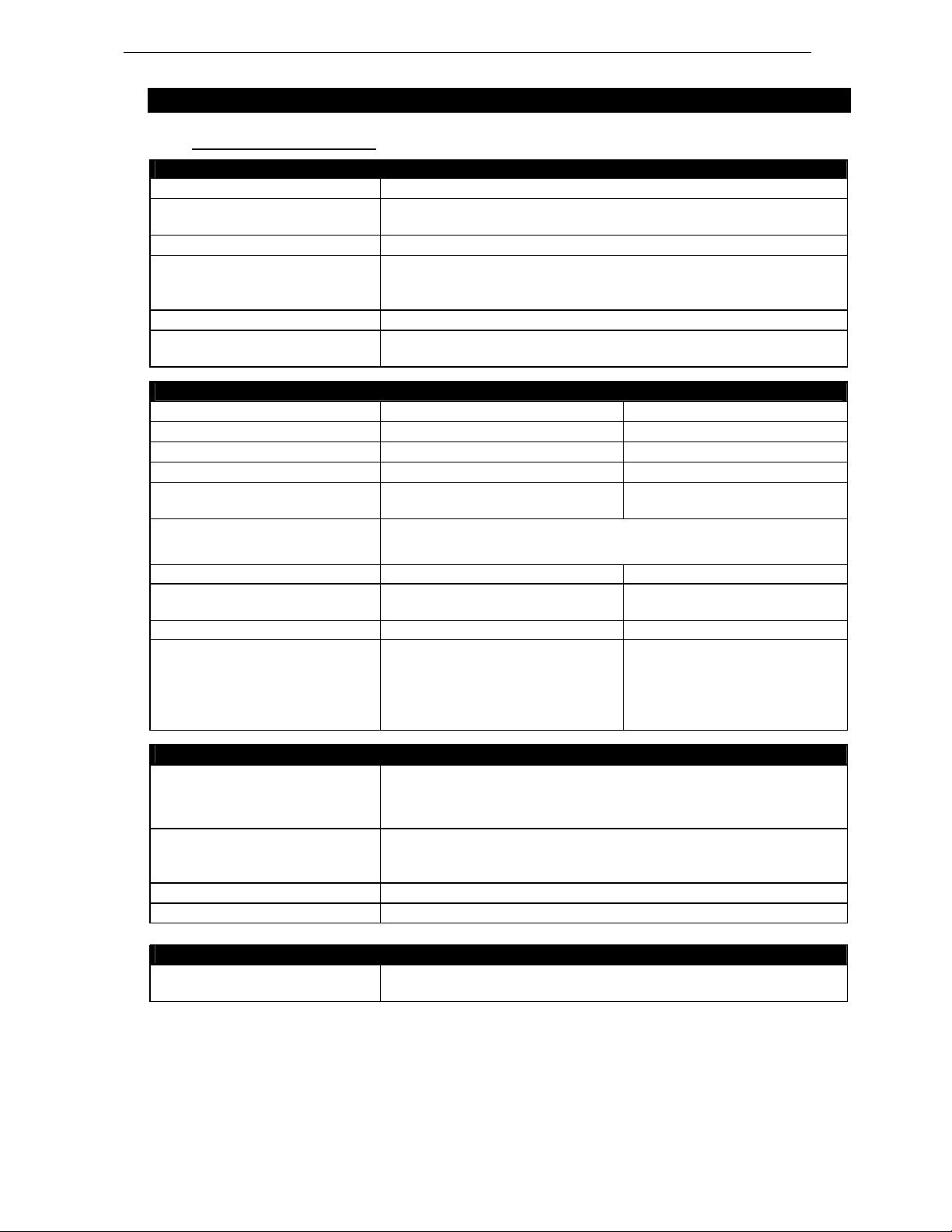

CENTRE STACKED DIRECTIONAL SUBWOOFER CENTRE FLOWN DIRECTIONAL SUBWOOFER

When using a larger amount of cabinets, these can then be installed all across the stage provided

distance between units does not exceed half the wavelength of the upper frequency limit (1.7m/5.6ft at

100 Hz). Array coverage can then be adjusted geometrically (by curving the array horizontally so that it

matches the audience area, which creates an asymmetrical front stage to rear stage pattern with a “hot”

point on stage) or electronically (by implementing a delay that increase from the centre to the sides,

which creates a symmetrical pattern front to rear). In both cases, omnidirectional subwoofers should be

avoided so low frequency that level on stage does not exceed level in the audience.

CURVED SUBWOOFER ARRAY ACR O S S STA G E STR AIG HT DELA Y ED SUBWOOFER ARRAY ACROSS STAGE

Page 34/54 GENERAL GUIDELINES FOR SUBWOOFER DESIGN

Main drawback of monophonic designs as the ones described above is inconsistent phase relationship

between subwoofer arrays and main systems over the audience area (lack of impact in the 80Hz-125Hz

bandwidth).

6.4 Stereo Design

If stereophonic implementation has to be maintained, then Left and Right array coverage patterns have

to be as independent as possible – ie coverage overlap from Left to Right has to be minimized.

When using few cabinets, minimizing overlap can

only be achieved with directional devices by

rotating the subwoofers 30° to 45° outwards

(rotating an omnidirectional subwoofer makes no

difference in the coverage pattern).

When using a larger amount of cabinets, Left and Right subwoofers arrays must be designed so that

level drops as much as possible inwards, and is maintained as going outwards. Therefore, main axis

efficiency must be orientated outwards (through use of delays or curving the array outward as in below

figure). Such arrays must be experimented playing one side only to check if above condition is fulfilled,

and then summed left and right for interference evaluation (see below drawings). Although pressure

level will still drop in the centre vicinity, overall level in the audience area is comparable to what occurs

at the centre.

Curved Sub Array

Steered Sub Array

LEFT IMPLEMENTATION MI NIMIZING RIGHT COVERAGE LEFT AND RIGHT SUM

Advantage of stereo design as oppose to mono design is much improved phase relationship between

subwoofer arrays and main systems since distance between them is greatly reduced.

However, it is essential to keep in mind that stereo subwoofer array design always leads to strong

interferences in the centre alley vicinity (a couple of steps left and right of mixing position).

A successful design requires minimizing the audience area over which these interferences occur, and

therefore lots of on-site experimentation.

RAY SUBS IMPLEMENTATION Page 35/54

7 RAY SUBS IMPLEMENTATION

7.1 Omnidirectional Mode

7.1.1 Single RS18

Omnidirectional Mode implementation should be favoured in configurations where:

- sufficient depth is not available for directional implementation (proscenium, front stage

etc…);

- strong rear radiation is not critical.

Although wide in both cases, coverage is slightly narrower along RS18’s width than height (see

drawings below).

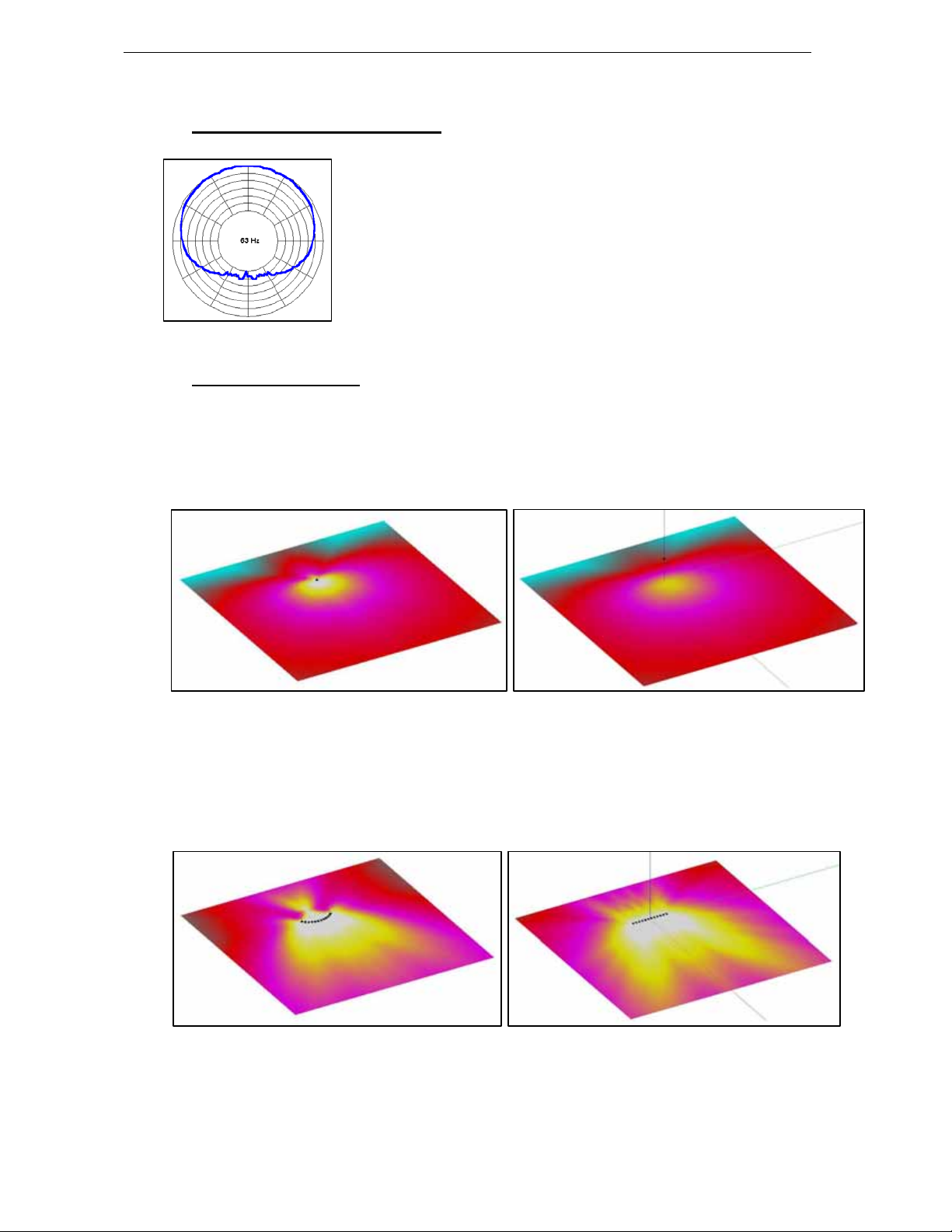

HORIZONTAL COVERAGE IN OMNI MODE VERTICAL COVERAGE IN OMNI MODE

7.1.2 RS18 arrays

IMPORTANT

RS18s arrays must be installed with bumper set horizontally and all cabinets at 0°.

Design procedure should be in agreement with what has been described in the preceding section.

See following section on Steered Arrays

7.2 Directional Mode

7.2.1 Single RS18

Single RS18 have an asymmetrical pattern in the horizontal plane (ie speakers on the side), which is

tilted 30° off-axis towards speakers direction; vertical pattern (ie speakers facing up or down) is

symmetrical).

HORIZONTAL COVERAGE IN DIRECTIONAL MODE VERTICAL COVERAGE IN DIRECTIONAL MODE

Page 36/54 RAY SUBS IMPLEMENTATION

IMPORTANT

So that directional behaviour and acoustic load are not altered, no reflecting surface

should be at less than 50cm (20”) from the RS18 side walls and drivers.

In case of stereo configurations, NEXO recommends that speaker side is set outwards to minimize

interference region in stereo designs.

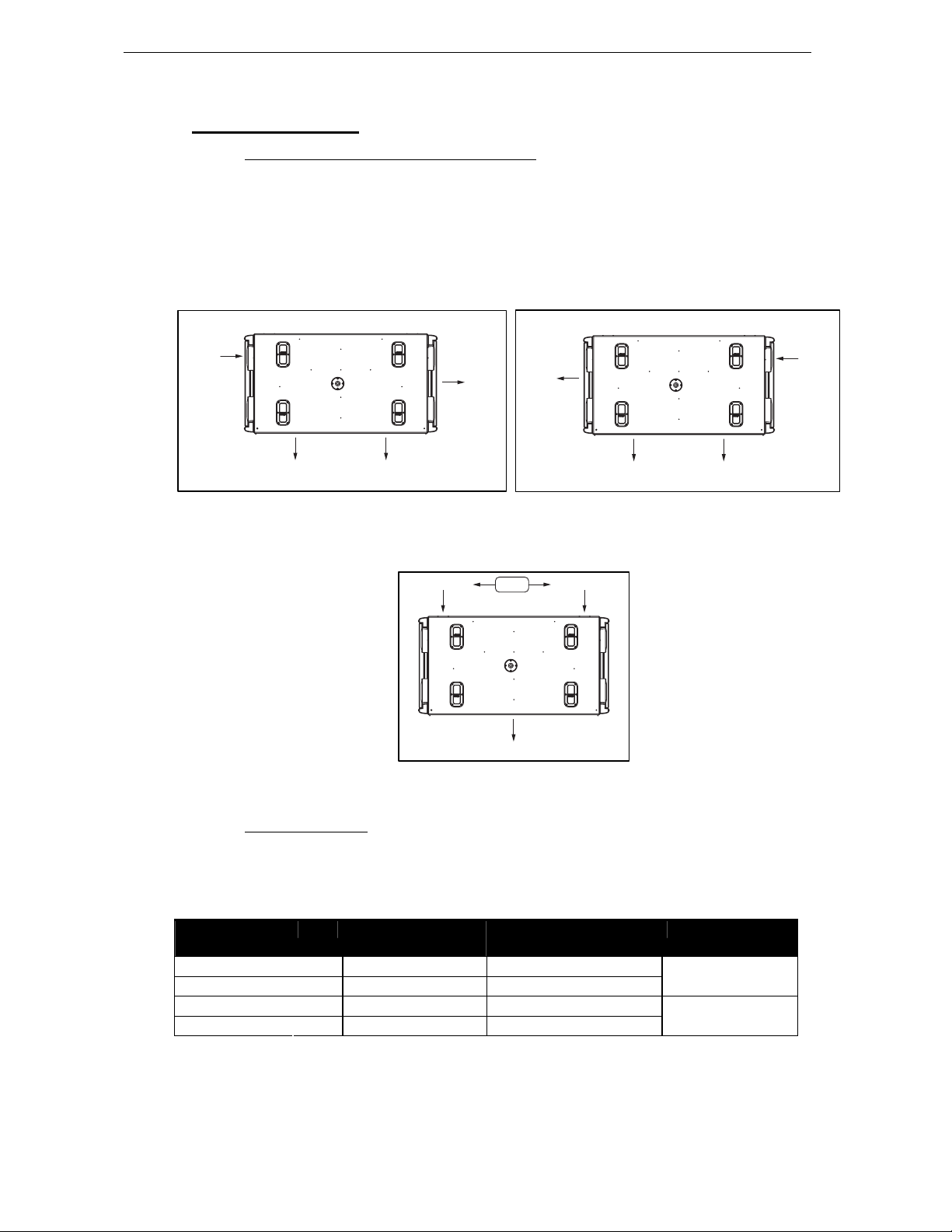

7.2.2 RS18s pair

There are three ways of using pairs of RS18s in directional mode: “one side”, “back to back” and “face

to face” (50cm / 20” between grids)

All of these configurations have symmetrical patterns with a smooth 15dB attenuation at the rear over

the entire RS18 bandwidth, but significantly different horizontal coverage.

- “one side” configuration has a constant -3 dB coverage of 120° from 31.5 Hz to 80 Hz;

- “back to back” configuration has a -3dB coverage which decreases from 90° at 31.5 Hz to

60° at 80Hz;

- “face to face” configuration has a -3 dB coverage which increases from 90° at 31.5 Hz to

120° at 800 Hz.

“ONE SIDE CONFIGURATION“

“BACK TO BACK“ CONFIGURATION

RAY SUBS IMPLEMENTATION Page 37/54

“FACE TO FACE“ CONFIGURATION

7.2.3 RS18s arrays

IMPORTANT

RS18s arrays must be installed with bumper set horizontally and all cabinets at 0°.

Flying RS18s columns can significantly improve low frequency coverage in the vertical plane, and

therefore over audience depth provided height is sufficient.

A 10 RS18 cluster flown at 10m/30ft will provide a +/- 3dB pressure level deviation at 100Hz over an

audience area 75m/200ft deep while maintaining 15 to 20dB attenuation on stage (see figure below).

10 RS18 CLUSTER OVER 75M/200FT

7.3 Steered RS18s arrays

7.3.1 Steering technique

RS18s arrays must be flown vertically with bumper set horizontally and all cabinets at 0°.

Coverage adjustments can be efficiently implemented through the “steering” technique, which consists

in implementing delays in cabinets to tilt coverage up or down.

Page 38/54 RAY SUBS IMPLEMENTATION

IMPORTANT

- “Steering” techniques should not be applied to clusters of less than 3 RS18;

- Coverage control through steering technique increases with cluster height.

Steering can be applied by unit, group of 2 or group of 3 in Omni Mode as well as in Directional Mode

GROUP OF 2 RS18S STEERING GROUP OF 3 RS18S STEERING

“Steering” delays values for the pairs can easily be computed according to following formula:

θ

t

t

θ

.

τ = h*sin(θ)/C (metric)

τ is the value to be applied to the second pair

h is the height of tilted elements ( 1.04m for 2 RS18s, 1.56m for 3 RS18s)

C is the speed of sound ( = 343m/s )

7.3.2 Delay values implementation

• If the coverage is to be tilted down, then top group delay should be set at 0ms and delay should

progressively increase on lower groups.

• If the coverage is to be tilted up, then lower group delay should be set at 0ms and delay should

progressively increase on upper pairs.

• Delay value for first group is always 0ms.

• Delay value for second unit or group is τ

• Delay values for subsequent units or groups are 2τ, 3τ etc…

RAY SUBS IMPLEMENTATION Page 39/54

Table below lists these values for typic al angle values:

TILT ANGLE 0° 5° 10° 15° 20° 25° 30° 35° 40° 45°

1 RS18

GROUP

2 RS18s

GROUP

3 RS18s

DELAY τ (ms)

DISTANCE (cm)

DELAY τ (ms)

DISTANCE (cm)

DELAY τ (ms)

DISTANCE (cm)

0.0 0.1 0.3 0.4 0.5 0.6 0.8 0.9 1.0 1.1

0 5 9 13 18 22 26 30 33 37

0.0 0.3 0.5 0.8 1.0 1.3 1.5 1.7 1.9 2.1

0 9 18 27 36 44 52 60 67 74

0.0 0.4 0.8 1.2 1.6 1.9 2.3 2.6 2.9 3.2

0 14 27 40 53 66 78 89 100 110

7.3.3 Coverage result

Below figure shows coverage control over distance with a “steering” delay sequence corresponding to a

15° tilt down.

10 RS18 CLUSTER OVER 75M/200FT, STEERED 15° DOWN

7.4 Aligning RS18s with main system

7.4.1 NEXO systems acoustic reference point

The NX TDControllers factory presets are optimised to provide the best possible crossover bet ween the

RS18s and the Main NEXO system. These crossover algorithms are defined for speaker acoustic

reference points being aligned.

The acoustic reference point on all NEXO products is the front of each cabinet, therefore:

• RS18’s reference point in Omni Mode is center of the front grid

• RS18’s reference point in Directional Mode is center of the face opposite to connector panel.

Page 40/54 RAY SUBS IMPLEMENTATION

RS18 REFERENCE POINT IN OMNI MODE RS18 REFERENCE POINT IN DIRECTIONA L MODE

7.4.2 Precautions

It is common to use the AUX send of a mixing desk to drive the Sub section of a PA system. This gives

the mixing engineer more flexibility to set the level of the subbass relative to the main PA, apply special

effects, or to use a different EQ on the Sub. However, it also raises some serious issues for the

performance & safety of the system (mostly time alignment).

At NEXO, great care is taken to design optimum phase alignment from one octave above to one octave

below the crossover frequency point. By doing so, drivers are working perfectly together and providing

the best efficiency possible. It is then up to the user to adjust the delay on the NX TDControllers to

match the physical path difference of the different systems. It is thus possible to get a well adjusted

system, even without measuring instruments.

If RS18s are driven form an AUX output, NX TDController is fed with two signals coming from different

sources. If those two sources (MAIN output & AUX send) are not exactly in phase, delay is introduced

into the crossover between main system and RS18s. It is then mandatory to use prop er measurement

tool to optimize phase response.

IMPORTANT

- Before using different outputs of a mixing des k, ensure that MAIN and SUB outputs are

in phase;

- Never add additional low pass filtering on the SUB output or high pass filt ering on the

MAIN output;

- Always apply identical processing (EQ etc…) on both outputs, so that the phase

relationship between MAIN and SUB is not altered;

7.4.3 Alignment with distance measurement

The fastest way to align RS18 arrays to a main system is simply to measure distance difference from

listening point to RS18 and main system reference points.

r

being the distance from main array to listener position, and r2 being the distance from RS18 to

1

listener position, the distance difference is then r

• r

> r2, the delay should be set on the RS18 TDcontroller channel.

1

< r2, the delay should be set on the main system TDcontroller channel

• r

1

• ∆t = (r

)/C gives conversion from distance to delay r1, r2 in meters, C = 343 m/s.

1-r2

(specified meters or feet).

1–r2

RAY SUBS IMPLEMENTATION Page 41/54

NEXO recommends that main system and subwoofer systems are adjust ed so that arrivals from RS18

and Main System are coincident at a fairly distant listening position (mixing position or further).

Because of proper acoustic reference point definition in NEXO TDControllers DSP setups, this method

is highly reliable.

r1

r2

Mixing position

or further

7.4.4 Alignment with phase measurement

Phase measurement with real time FFT analyzer can also provide reliable measurements, provided:

• measurement microphone is set on the ground to avoid floor interference in the reading;

• floor is perfectly rigid (concrete);

• measurement microphone is set far from any walls / ceiling, or inside angles / corners;

• coherence values are high (typically above 75%).

If one of above conditions is not respected, then distance measurement should be preferred.

7.5 Recommended installation tools and equipment

• Tape measure – should be 30m/100ft in length and be of durable fibre material. Have one per array

available to speed up the installation process.

• Laser Inclinometer – For measuring vertical and horizontal angles in the v enue. An ideal product is

the Calpac ‘Laser projecting a dot’ version which costs approximately 60 €.

• Spirit level – used to ascertain the trueness of the surface from which the angle measurements

originate.

• Rangefinder measuring device – either a Disto type laser measure or an optical laser rangefinder can

be used. Devices such as the Bushnell ‘Yardage Pro’ sports rangefinders provide sufficiently

accuracy and are easy to use. They have the additional advantage of working very well in bright

sunlight.

• Electronic calculator with trigonometric functions to calc ulate the height from ground level t o points in

the room. The formula to calculate height of a point from measured angle and distance is:

• Height of point = Sin(vertical angle in degrees) x distance to point

• NB: Take care when using spreadsheets as they calculate using radians by default. To convert

degrees to radians use the formula:

• Angle (in radians)=3.142 x Angle (in degrees)/180

• Computer – Laptop or Desk top PC running Windows 2000 or XP with the current version of NEXO

GeoSoft2 installed. It is not possible to configure a Geo tangent array properly without using

GeoSoft2. Note that, when GeoSoft2 designs are prepared prior to arrival at the venue, it is often

Page 42/54 RAY SUBS IMPLEMENTATION

necessary to modify or update the design to accommodate special circumstances. A PC is absolutely

essential to make such changes.

• Audio Analysis Software – recommended but not absolutely essential, programs such as Easera

Systune

TM

, SmaartTM or WinMLSTM enable rapid and detailed analysis of the installation. Consider

taking a training course in using one of these tools if you are not already competent with them – it will

pay dividends in increased performance of the system.

RS18 SYSTEM CHECK LIST Page 43/54

8 RS18 SYSTEM CHECK LIST

It is essential to execute all these check steps prior to a sound check on the “front end” to the system.

Following this checklist step by step will prevent many troubles and will save time in the end.

8.1 Are the NX Digital TDcontrollers properly configured?

IMPORTANT

If you must change any of the parameters listed below, make sure that you use the same

values on all NX’s.

Output Assignment

NX Setup / NXChannel 1 2 3 4

RS18 4 Channels Omni Mode RS18-1 RS18-2 RS18-3 RS18-4

RS18 Stereo Directional Mode RS18 Rear Left RS18 Front Left RS18 Rear Right RS18 Front Right

Output parameters

Output

Label

All channels 26 dB refer to amp 0 dB 0 ms 0 dB 0 5 bars

(1) Local gain and delay values are inter-locked on channel 1&2 and 3&4 in Directional Mode

(2) values for recommended amplifier gain and power : should be set in agreement with selected

amplifiers specifications

(3) Should be in agreement with implemented cluster; acts on a shelving filter designed to compensate

for LF coupling.

(4) Disabled when using digital inputs.

Amp

Gain (2)

Amp

Power (2)

Global

Gain

Global

Delay

Sense

Gain

Array EQ

(3)

Headrom

(4)

8.2 Are the amplifiers properly configured?

Freq. Band Mode Gain Switch Limiter High Pass

All channels

Stereo 26 dB None None

8.3 Are the amps and the NX properly connected?

Check that the sense lines on the NX’s are properly connected by applying a signal to the

corresponding output and verify that the correct Sense LED illuminates.

8.4 Are the speakers properly connected?

• Attach the first serie of modules to the bumper

• Before flying, verify that all drivers of all modules are functioning properly.

• Make sure that each RS18 driver is producing proper summation in omni mode:

• The two RS18 individual 18” driver should sum up by 6 dB;

• Doubling RS18 quantity (2, 4 and so on) should also produce 6 dB gain.

• Make sure that each RS18 is producing the proper front/rear summation in directional mode:

Page 44/54 RS18 SYSTEM CHECK LIST

• when listening from behind the system, switch the front drivers in and out. You should hear a

reduction in the LF range when the both front and rear drivers are on as compared to when the rear

drivers only are on;

• When listening from the front, you should hear a strong increase in the LF range when connecting the

rear drivers.

• Raise the bumper, attach the next series of modules and repeat the above checks.

• Make sure that these series of modules sum properly with the modules above them.

8.5 Final Pre-Sound Check Check

• Play a CD track (preferably generous and periodic in the LF content) on the SUB output, mono left,

mono right and then both sides:

• both sides must sound strictly identical when listening at the center;

• level must not decrease at the center when playing left and right simultaneously as opposed to one

side only.

• Play the same CD track on the MAIN system, on the SUB system, then on both:

• Inverting polarity on one of these outputs – MAIN or SUB - should always result in a massive

difference near the crossover point.

RS18 TECHNICAL SPECIFICATIONS Page 45/54

9 RS18 TECHNICAL SPECIFICATIONS

9.1 System specifications

RS18 PRODUCT FEATURES

Components 2 x 18” (46cm) long excursion neodymium 8Ω drivers

Height x Width x Depth 520 x 1403 x 732mm (20.46” x 55.24” x 28.81”) with handles

Shape Rectangular

Weight Net Weight with handles 105Kg (231.5 lbs)

Connectors 4 x NL4MP SPEAKON 4 pole on two connection plates (In & Through)

Construction Baltic Birch ply finish with structured black coating

RS18 with NX242-ES4 TDcontroller or NXAMP SYSTEM SPECIFICATION

Omni Directional

Frequency Response @ -3db [a] 32Hz–100Hz 32Hz-100Hz

Usable Range @ -6db [a] 29Hz–250Hz 29Hz–150Hz

Sensitivity 1W @ 1m [b] 105dB SPL Nominal 103dB SPL Nominal

Peak SPL @ 1m [b] 143–146dBPeak

Dispersion Omni & Directional pattern over the entire useable bandwidth depending on the NX242

Directivity Index [c] 1.5<Q<2 1.7dB<DI<3dB Q=4.3 DI=5.3dB

Crossover Frequency:

NX242 or NXAMP preset dependent

Nominal Impedance 2 x 8Ω 2 x 8Ω

Recommended Amplifiers 2 amplifier channels for directional mode

SYSTEM OPERATION

Electronic Controller NX242ES4 Digital TDcontroller & NXAMP Powered Digital TDcontroller presets are

Speaker Cables 1-/1+ = Right or Rear

Accessories Bumper – Flying Plates – Dolly - Front Wheel Board

Rigging system [d] Please refer to the user manual before any operation

520 x 1238 x 732mm (20.46” x 49.92” x 28.81”) without handles

Net Weight with rigging system 126Kg (278 lbs)

Net Weight without accessories 90Kg (199 lbs)

Dark grey carpet finish also available

140–143dBPeak

(2x1000 to 2x2000W/8Ω)

or NXAMP TDcontrollers setup. (two channels of the NX242ES4 or NXAMP are

required to process directional setups)

From 75Hz to 100Hz From 75Hz to 100Hz

operation, each rated at 1000 to 2000 Watts

into 8Ω per channel

or 1 amplifier channel for omni mode

operation, rated at 2000 to 4000 Watts into

4Ω

precisely matched to RS18 and include sophisticated protection systems.

Using RS18 without a properly connected TDController will result in poor sound quality

and can damage components.

2-/2+ = Left or Front