New Yorker Boiler FR-HGS User Manual

X: MAINTENANCE AND SERVICE INSTRUCTIONS

A. WATER BOILERS:

1. Filling of boiler and system.

GENERAL — In a hot water heating system, the

boiler and entire system (other than the expansion

tank) must be full of water for satisfactory

operation. Water should be added to the system until

the boiler pressure gauge registers 12 psi. To insure

that the system is full, water should come out of all

air vents when opened.

2. BOILING OUT OF BOILER AND SYSTEM. The

oil and grease which accumulate in a new hot water

boiler can be washed out in the following manner:

a. Remove relief valve using extreme care to avoid

damaging it.

b. Add an appropriate amount of recommended boil

out compound.

c. Replace relief valve.

d. Fill the entire system with water.

e. Start ring the boiler.

f. Circulate the water through the entire system.

g. Vent the system, including the radiation.

h. Allow boiler water to reach operating

temperature, if possible.

i. Continue to circulate the water for a few hours.

j. Stop ring the boiler.

k. Drain the system in a manner and to a location

that hot water can be discharged with safety.

l. Remove plugs from all available returns and

wash the water side of the boiler as thoroughly as

possible, using a high-pressure water stream.

m. Rell the system with fresh water.

3. Add appropriate boiler water treatment compounds

as recommended by your qualied water treatment

company.

4. Make pH or Alkalinity Test.

After boiler and system have been cleaned and

relled as previously described, test the pH of

the water in the system. This can easily be done

by drawing a small sample of boiler water and

testing with hydrion paper which is used in the

same manner as litmus paper, except it gives

specic readings. A color chart on the side of the

small hydrion dispenser gives the reading pH.

Hydrion paper is inexpensive and obtainable from

any chemical supply house or through your local

druggist. The pH should be higher than 7 but lower

than 11. Add some of the washout chemical (caustic

soda), if necessary, to bring the PH within the

specied range.

5. Boiler is now ready to be put into service.

38

B. EXCESSIVE MAKE-UP WATER

A leaky system will increase the volume of make-up

water supplied to the boiler, which can signicantly

shorten the life of the boiler. Entrained in make-up

water are dissolved minerals, salts and oxygen. When

the fresh, cool make-up water is heated in the boiler, the

minerals fall out as sediment, the salts coat the inside

of the boiler, and the oxygen escapes as a gas. The

accumulation of sediment eventually isolates the water

from contacting the cast iron. When this happens the

cast iron in that area gets extremely hot and eventually

cracks. The presence of free oxygen or chloride salts

in the boiler corrodes the cast iron from the inside.

More make-up water and higher concentrations of

contaminants damage the boiler sooner. Our warranty

does not cover corrosion and sediment-related

damage. Clearly it is in everyone’s best interest to

prevent this type of failure. You can do your part by

ensuring that your system is leak-free, keeping leakage

to less than 2 percent of the boiler water volume each

month. Refer to Chart below.

IMPORTANT

IF, DURING NORMAL OPERATION, IT IS NECESSARY

TO ADD MORE WATER THAN INDICATED BELOW,

CONSULT A QUALIFIED SERVICE TECHNICIAN

TO CHECK YOUR SYSTEM FOR LEAKS.

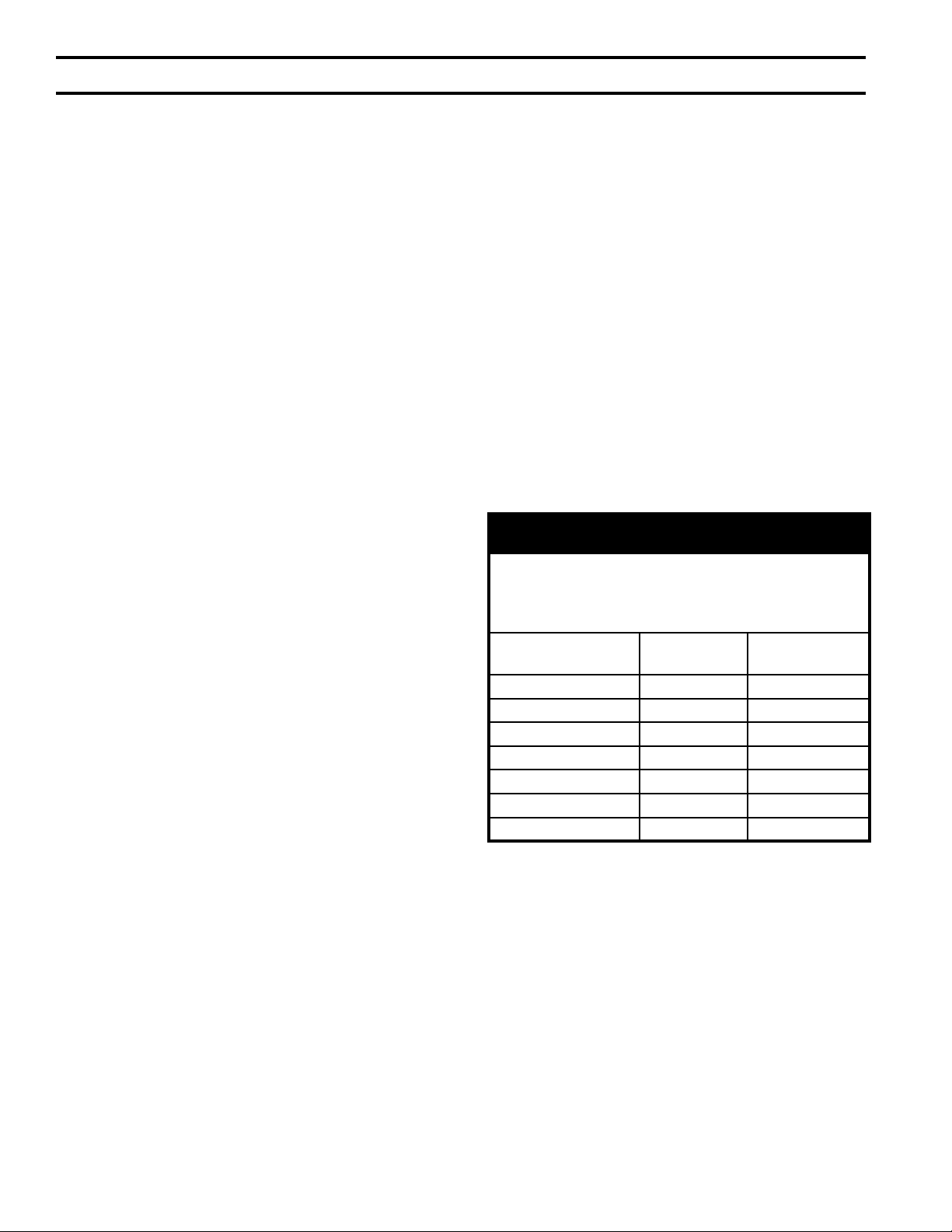

Boiler Series

FR-HGS/FR-HGSII 0.2 2.4

FR-98/122 0.4 4.8

FR-147/173 0.8 9.6

FR-205/232 0.9 10.8

FR-265/305 1.0 12.0

FR-350/400 1.4 16.8

FR-462 1.6 19.2

Gallons Per

Month

C. ATTENTION TO BOILER WHILE NOT IN

OPERATION

1. IMPORTANT

IF BOILER IS NOT USED DURING WINTER

TIME, IT MUST BE FULLY DRAINED TO

PREVENT FREEZE DAMAGE.

2. Spray inside surfaces with light lubricating or

crankcase oil using gun with extended stem so as to

reach all corners.

3. With steam boilers, at end of season add sufcient

water to ll boiler to top of water column and leave

it that way until fall when water should be drained

again to proper level. If, at this time, boiler water

is dirty, drain water, ush out boiler, and rell with

clean water to prescribed water level.

Gallons Per

Year

X: MAINTENANCE AND Service INSTRUCTIONS (continued)

4. Always keep the manual fuel supply valve shut off

if the burner is shut down for an extended period of

time.

5. To recondition the heating system in the fall season

after a prolonged shut down, follow the instructions

outlined in Section IV, Paragraphs A through K.

This boiler contains controls which may cause

the boiler to shut down and not restart without

service. If damage due to frozen pipes is a

possibility, the heating system should not be

left unattended in cold weather; or appropriate

safeguards and alarms should be installed on the

heating system to prevent damage if the boiler is

inoperative.

WARNING

39

XI: BOILER CLEANING

NOTICE

BURNER SHUTDOWN: Open Service Switch

to turn off burner.

Manual Oil Supply Valve should be closed and

Electric Service to boiler turned off if boiler will

not be operated for an extended period of time.

A. GENERAL

Inspection service and cleaning should be conducted

annually. Turn off electric power and close oil supply

valve while conducting service or maintenance.

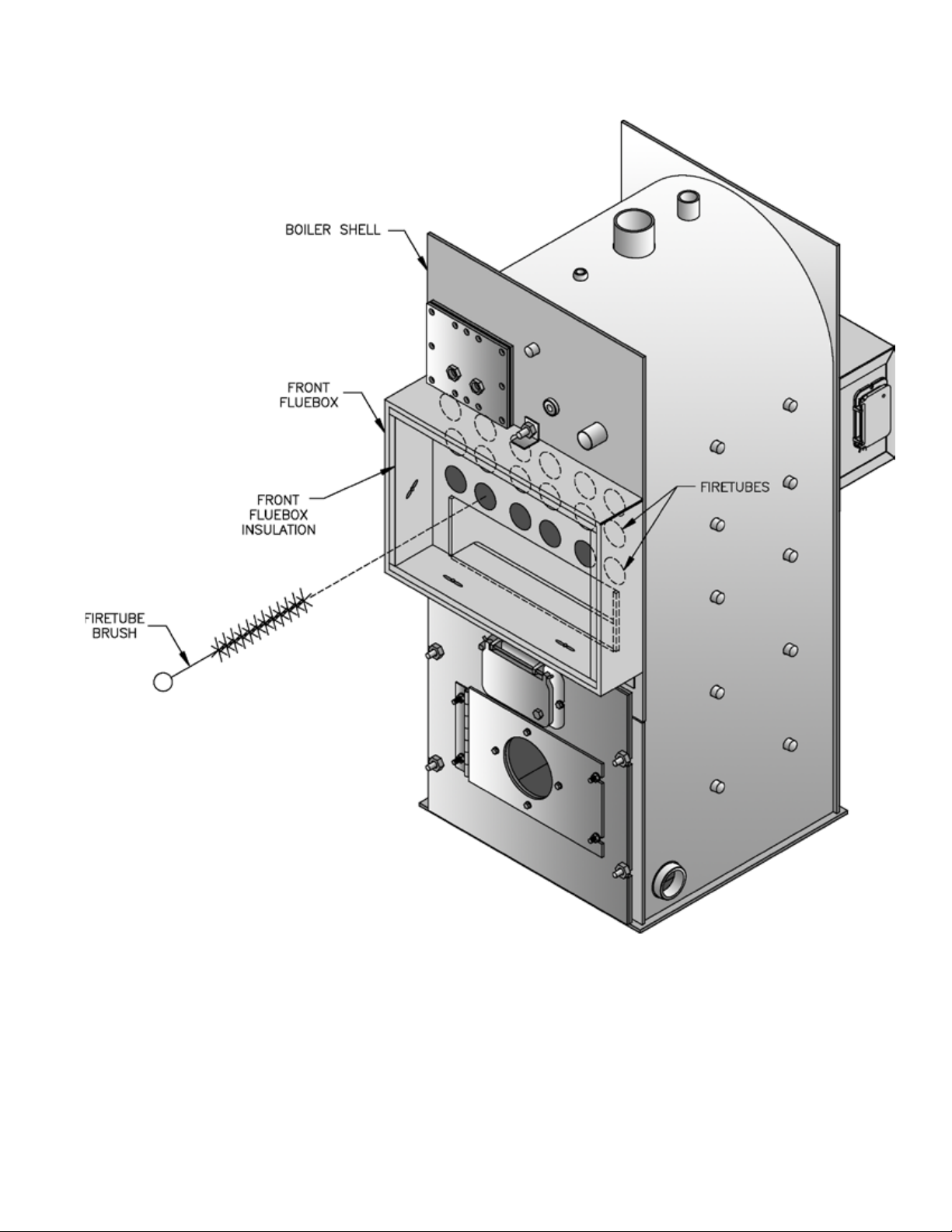

B. FIRETUBES AND COMBUSTION CHAMBER

(See Figure 22)

1. CLEAN THE FIRETUBES

a. Disconnect electric service to burner.

b. To gain access to the retubes, remove the front

ue box door. For boilers equipped with ue

box swingdoor, remove two (2) nuts at top of

ue box door and swing door down. For boilers

not equipped with swingdoor, remove fasteners

around the perimeter of ue box frame and

remove door.

c. Remove turbulators.

d. Using a retube brush clean retubes. Using

a wire or bre bristle brush, clean front tube

sheet. Use care not to damage the insulation on

the inside of the ue box. Remove debris and

vacuum as necessary.

e. Replace turbulators and ue box door.

f. Disconnect vent pipe from rear smokebox

collar. Through collar opening, brush surfaces

and vacuum as necessary to remove debris

from cleaning retubes in Step d above. Inspect

base of chimney for accumulation of debris.

Remove debris, clean and vacuum as necessary.

Reconnect vent pipe to smokebox collar and

secure. Seal joint at chimney collar, if necessary.

Units should be cleaned at least once a year, preferably

at the end of each heating season.

It is not necessary to remove burner to clean boiler.

40

XI: BOILER CLEANING (continued)

Figure 22: Cleaning of FR Boiler

41

Important Product Safety Information

Refractory Ceramic Fiber Product

Warning:

The Repair Parts list designates parts that contain refractory ceramic fibers

(RCF). RCF has been classified as a possible human carcinogen. When

exposed to temperatures above 1805°F, such as during direct flame contact,

RCF changes into crystalline silica, a known carcinogen. When disturbed as a

result of servicing or repair, these substances become airborne and, if inhaled,

may be hazardous to your health.

AVOID Breathing Fiber Particulates and Dust

Precautionary Measures:

Do not remove or replace RCF parts or attempt any service or repair work

involving RCF without wearing the following protective gear:

1. A National Institute for Occupational Safety and Health (NIOSH)

approved respirator

2. Long sleeved, loose fitting clothing

3. Gloves

4. Eye Protection

• Take steps to assure adequate ventilation.

• Wash all exposed body areas gently with soap and water after contact.

• Wash work clothes separately from other laundry and rinse washing

machine after use to avoid contaminating other clothes.

• Discard used RCF components by sealing in an airtight plastic bag. RCF

and crystalline silica are not classified as hazardous wastes in the United

States and Canada.

42

First Aid Procedures:

• If contact with eyes: Flush with water for at least 15 minutes. Seek

immediate medical attention if irritation persists.

• If contact with skin: Wash affected area gently with soap and water.

Seek immediate medical attention if irritation persists.

• If breathing difficulty develops: Leave the area and move to a location

with clean fresh air. Seek immediate medical attention if breathing

difficulties persist.

• Ingestion: Do not induce vomiting. Drink plenty of water. Seek

immediate medical attention.

XII: TROUBLESHOOTING

A. COMBUSTION

1. NOZZLES — Although the nozzle is a relatively

inexpensive device, its function is critical to the

successful operation of the oil burner. The selection

of the nozzle supplied with the FR boiler is the

result of extensive testing to obtain the best ame

shape and efcient combustion. Other brands of the

same spray angle and spray pattern may be used but

may not perform at the expected level of CO

smoke. Nozzles are delicate and should be protected

from dirt and abuse. Nozzles are mass-produced

and can vary from sample to sample. For all of

those reasons a spare nozzle is a desirable item for a

serviceman to have.

2. FUEL LEAKS — Any fuel leak between the

pump and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the air

tube, under the ignitor, and around the air inlet. Any

such leaks should be repaired as they may cause

erratic burning of the fuel and in the extreme case

may become a re hazard.

3. SUCTION LINE LEAKS — Any such leaks should

be repaired, as they may cause erratic burning of

the fuel and in extreme cases may become a re

hazard. Whatever it takes, The Oil Must Be Free

of Air. This can be a tough problem, but it must be

resolved. Try bleeding the pump through a clear

tube. There must be no froth visible. There are

various test kits available to enable you to look at

the oil through clear tubing adapted to the supply

line at the pump tting. Air eliminators are on the

market that have potential. Also, electronic sight

glasses are being used with good success. At times,

new tubing must be run to the tank or new ttings

put on. Just make sure you get the air out before

you leave.

Any air leaks in the fuel line will cause an unstable

ame and may cause delayed ignition noises. Use

only are ttings in the fuel lines.

4. GASKET LEAKS — If 11.5 to 12.5% CO

#1 smoke cannot be obtained in the breeching, look

for air leaks around the burner mounting gasket,

observation door, and canopy gasket. Such air leaks

will cause a lower CO2 reading in the breeching. The

smaller the ring rate the greater effect an air leak

can have on CO2 readings.

5. DIRT — A fuel lter is a good investment.

Accidental accumulation of dirt in the fuel system

can clog the nozzle or nozzle strainer and produce a

poor spray pattern from the nozzle. The smaller the

ring rate, the smaller the slots become in the nozzle

and the more prone to plugging it becomes with the

same amount of dirt.

and

2

with a

2

6. WATER — Water in the fuel in large amounts will

stall the fuel pump. Water in the fuel in smaller

amounts will cause excessive wear on the pump,

but more importantly water doesn’t burn. It chills

the ame and causes smoke and unburned fuel to

pass out of the combustion chamber and clog the

ueways of the boiler.

7. COLD OIL — If the oil temperature approaching

the fuel pump is 40°F or lower, poor combustion or

delayed ignition may result. Cold oil is harder to

atomize at the nozzle. Thus, the spray droplets get

larger and the ame shape gets longer. An outside

fuel tank that is above grade or has fuel lines in a

shallow bury is a good candidate for cold oil. The

best solution is to locate the tank near the boiler in

the basement utility room or bury the tank and lines

deep enough to keep the oil above 40°F. Check

environmental issues with local authorities having

jurisdiction.

8. FLAME SHAPE — Looking into the combustion

chamber through the observation port, the ame

should appear straight with no sparklers rolling up

toward the crown of the chamber. If the ame drags

to the right or left, sends sparklers upward or makes

wet spots on the target wall, the nozzle should be

replaced. If the condition persists look for fuel leaks,

air leaks, water or dirt in the fuel as described above.

9. HIGH ALTITUDE INSTALLATIONS — Air

openings must be increased at higher altitudes. Use

instruments and set for 11.5 to 12.5% CO

.

2

10. START-UP NOISE — Late ignition is the cause

of start-up noises. If it occurs recheck for electrode

settings, ame shape, air or water in the fuel lines.

11. SHUT DOWN NOISE — If the ame runs out of

air before it runs out of fuel, an after burn with noise

may occur. That may be the result of a faulty cut-off

valve in the fuel pump, or it may be air trapped in the

nozzle line. It may take several ring cycles for that

air to be fully vented through the nozzle. Water in the

fuel or poor ame shape can also cause shut down

noises.

NOTICE

CHECK TEST PROCEDURE. A very good test for

isolating fuel side problems is to disconnect the

fuel system and with a 24" length of tubing, re

out of an auxiliary ve gallon pail of clean, fresh,

warm #2 oil from another source. If the burner runs

successfully when drawing out of the auxiliary

pail then the problem is isolated to the fuel or fuel

lines being used on the job site.

43

Loading...

Loading...