New Yorker Boiler CL Installation Manual

INSTALLATION, OPERATING

Br

Be

AND SERVICE INSTRUCTIONS

CL™ SERIES

CAST IRON OIL-FIRED BOILER

As an

ENERGY

STAR® Partner,

New Yorker Boiler Co., Inc.

has determined that the

CL3-091, CL3-105, CL4-126

and CL5-168 water boilers

meet the ENERGY STAR

guidelines for Energy

efciency established by the

United States Environmental

Protection Agency (EPA).

®

9700609

nonoitamrofnignikeesnehW.rotcartnocgnitaehruoyllac,reliobotsriaperroecivresroF

.lebaLgnitaRnonwohssarebmuNlaireSdnarebmuNledoMrelioBedivorp,reliob

rebmuNledoMrelio

ebmuNlaireSrelio

taDnoitallatsnI

LC

rotcartnoCgnitaeH rebmuNenohP

sserddA

103876-03 - 11/13

Price - $5.00

IMPORTANT INFORMATION - READ CAREFULLY

All boilers must be installed in accordance with National, State and Local Plumbing, Heating

and Electrical Codes and the regulations of the serving utilities. These Codes and Regulations

may differ from this instruction manual. Authorities having jurisdiction should be consulted

before installations are made.

In all cases, reference should be made to the following Standards:

USA BOILERS

A. Current Edition of American National Standard ANSI/NFPA 31, “Installation of Oil

Burning Equipment”, for recommended installation practices.

B. Current Edition of American National Standard ANSI/NFPA 211, “Chimneys, Fireplaces,

Vents, and Solid Fuel Burning Appliances”, For Venting requirements.

C. Current Edition of American Society of Mechanical Engineers ASME CSD-1, “Controls and

Safety Devices for Automatically Fired Boilers”, for assembly and operations of controls

and safety devices.

D. All wiring on boilers installed in the USA shall be made in accordance with the National

Electrical Code and/or Local Regulations.

The following terms are used throughout this manual to bring attention to the presence of

hazards of various risk levels, or to important information concerning product life.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

Indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

CAUTION

NOTICE

NOTICE

This boiler has a limited warranty, a copy of which is printed on the back of this manual.

The warranty for this boiler is valid only if the boiler has been installed, maintained and operated in

accordance with these instructions.

Surface rust on cast iron sections may be attributed to the manufacturing process as well as condensation

during storage. Surface rust is normal and does not affect the performance or longevity of a boiler.

2

DANGER

DO NOT store or use gasoline or other ammable vapors or liquids in the vicinity of this or any other boiler.

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or loss of life. Failure to follow all instructions in the proper order can cause personal injury or

death. Read and understand all instructions, including all those contained in component manufacturers

manuals which are provided with the boiler before installing, starting-up, operating, maintaining or servicing

this boiler. Keep this manual and literature in legible condition and posted near boiler for reference by

owner and service technician.

This boiler requires regular maintenance and service to operate safely. Follow the instructions contained

in this manual.

Installation, maintenance, and service must be performed only by an experienced, skilled and knowledgeable

installer or service agency.

All heating systems should be designed by competent contractors and only persons knowledgeable in

the layout and installation of hydronic heating systems should attempt installation of any boiler.

Installation is not complete unless a pressure relief valve is installed into the tapping located on top left

corner of front section- Refer to Figures 1A thru 1D and Section III "Installation Instructions" for additional

details.

It is the responsibility of the installing contractor to see that all controls are correctly installed and are

operating properly when installation is complete including verifying that the limit sensor is fully installed

(seated in bottom of Well).

Failure to properly install Limit Sensor may result in property damage, personal injury or loss of life due

to elevated operating temperatures and/or pressures.

This boiler is suitable for installation on combustible ooring. DO NOT install boiler on carpeting.

DO NOT tamper with or alter the boiler or controls.

Inspect ueways at least once a year - preferably at the start of the heating season. The inside of

the combustion chamber, the vent system and boiler ueways should be cleaned if soot or scale has

accumulated.

When cleaning this boiler, DO NOT damage combustion chamber liner and/or rear target wall. If damaged,

combustion chamber insulation must be replaced immediately.

Oil Burner and Controls must be checked at least once a year or as may be necessitated.

DO NOT operate boiler with jumpered or absent controls or safety devices.

DO NOT operate boiler if any control, switch, component, or device has been subject to water.

Boiler materials of construction, products of combustion and the fuel contain alumina, silica, heavy metals,

carbon monoxide, nitrogen oxides, aldehydes and/or other toxic or harmful substances which can cause

death or serious injury and which are known to the state of California to cause cancer, birth defects and

other reproductive harm. Always use proper safety clothing, respirators and equipment when servicing

or working nearby the boiler.

3

WARNING

This boiler contains very hot water under 12 - 15 PSI pressure. DO NOT unscrew any pipe ttings nor

attempt to disconnect any components of this boiler without positively assuring the water is cool and has

no pressure. Always wear protective clothing and equipment when installing, starting up or servicing this

boiler to prevent scald injuries. DO NOT rely on the pressure and temperature gauges to determine the

temperature and pressure of the boiler. This boiler contains components which become very hot when

the boiler is operating. DO NOT touch any components unless they are cool.

High water temperatures increase the risk of scalding injury. If this boiler is equipped with a tankless

heater for domestic water supply, a ow regulator and automatic mixing valve must be installed properly

in tankless heater piping. Refer to Section III "Installation Instructions" for additional details.

This boiler needs fresh air for safe operation and must be installed so there are provisions for adequate

combustion and ventilation air.

This boiler must be connected to an approved chimney or vent system in good condition. Serious

property damage could result if the boiler is connected to a dirty or inadequate chimney or vent system.

The interior of the chimney ue must be inspected and cleaned before the start of the heating season for

any obstructions. A clean and unobstructed chimney ue is necessary to allow noxious fumes that could

cause injury or loss of life to vent safely and will contribute toward maintaining the boiler's efciency.

DO NOT operate boiler with the absence of an approved vent system.

This boiler is supplied with controls which may cause the boiler to shut down and not re-start without

service. If damage due to frozen pipes is a possibility, the heating system should not be left unattended in

cold weather; or appropriate safeguards and alarms should be installed on the heating system to prevent

damage if the boiler is inoperative.

This boiler is designed to burn No. 2 fuel oil only. DO NOT use gasoline, crankcase drainings, or any

oil containing gasoline. Never burn garbage or paper in this boiler. DO NOT convert to any solid fuel

(i.e. wood, coal). DO NOT convert to any gaseous fuel (i.e. natural gas, LP). All ammable debris, rags,

paper, wood scraps, etc., should be kept clear of the boiler at all times. Keep the boiler area clean and

free of re hazards.

All boilers equipped with burner swing door have a potential hazard which if ignored can cause severe

property damage, personal injury or loss of life. Before opening swing door, turn off service switch to

boiler to prevent accidental ring of burner outside the combustion chamber. Be sure to tighten swing

door fastener completely when service is completed.

TABLE OF CONTENTS

I. General Information ................................... 5

II. Pre-Installation .........................................10

III. Installation Instructions ........................... 12

IV. Electrical ................................................... 24

V. System Start-Up ....................................... 30

VI. Operating .................................................. 37

VII. Maintenance & Service Instructions. .... 42

4

VIII. Boiler Cleaning ........................................ 45

IX. Trouble Shooting .....................................48

X. Repair Parts .............................................51

XI. Burner Specications .............................58

Appendix A - Low Water Cut-Off ..........60

I: GENERAL INFORMATION

'B'

'C'

DIA.

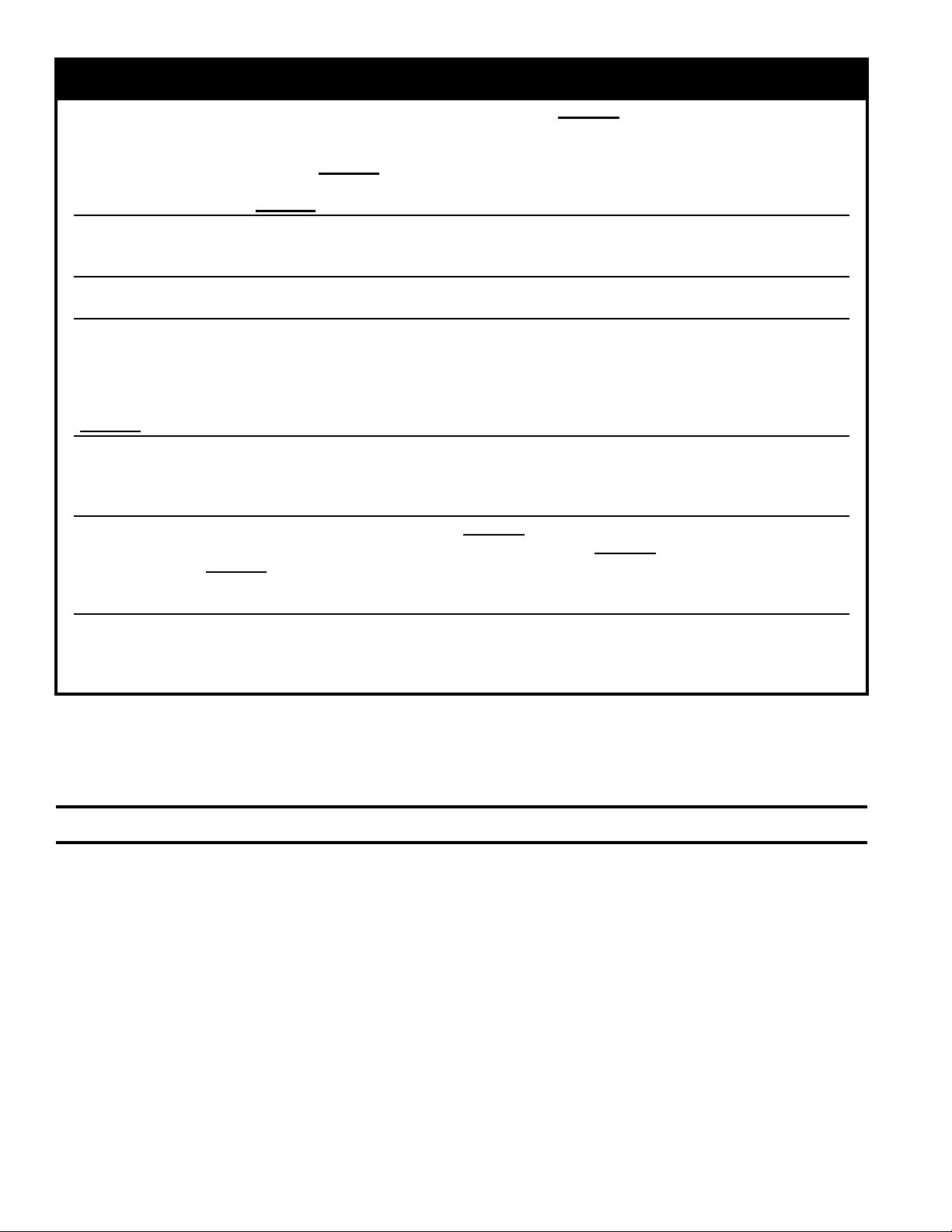

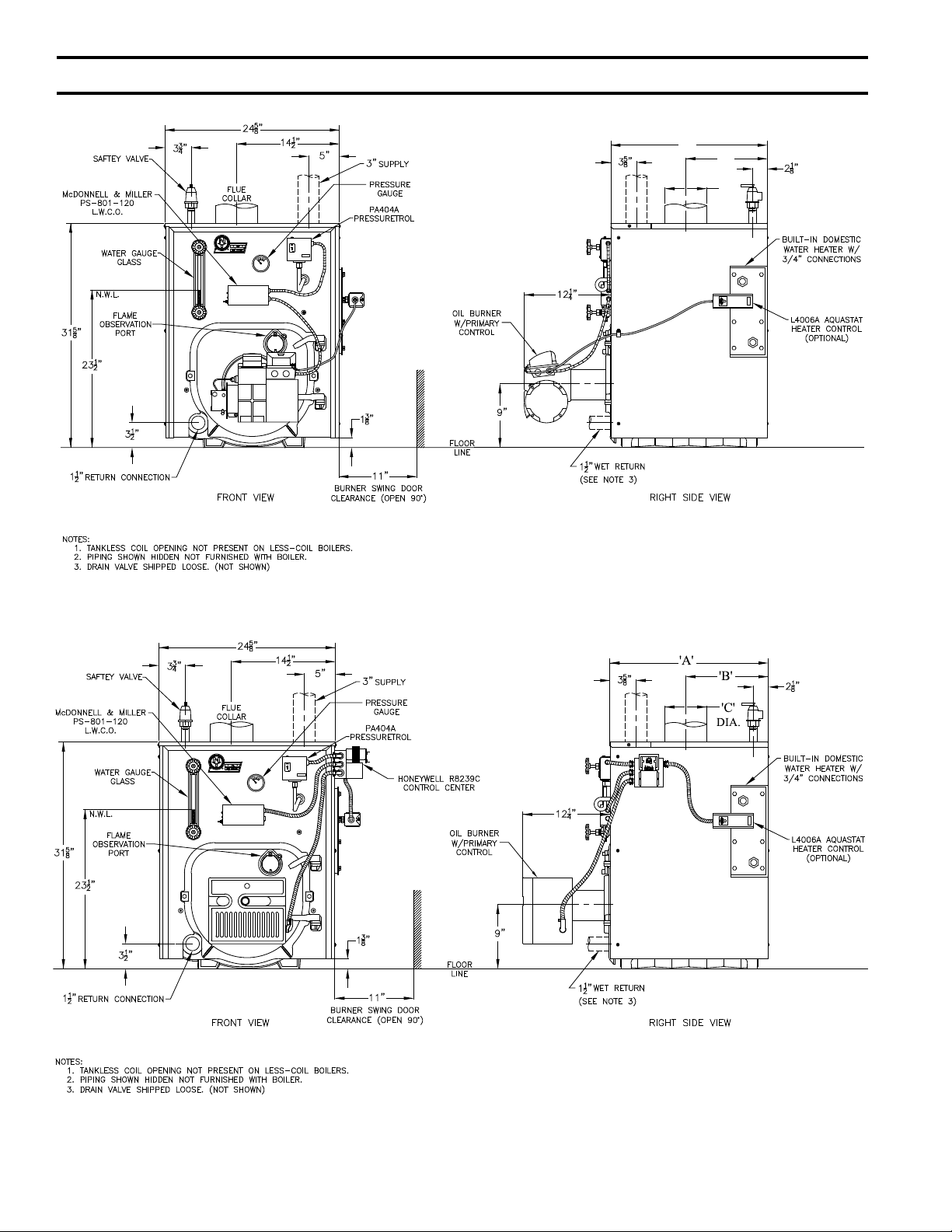

Figure 1A: CL3 Thru CL5 Water Boiler without Tankless Heater, All Burner Options

Figure 1B: CL3 Thru CL5 Water Boiler With Tankless Heater, All Burner Options

5

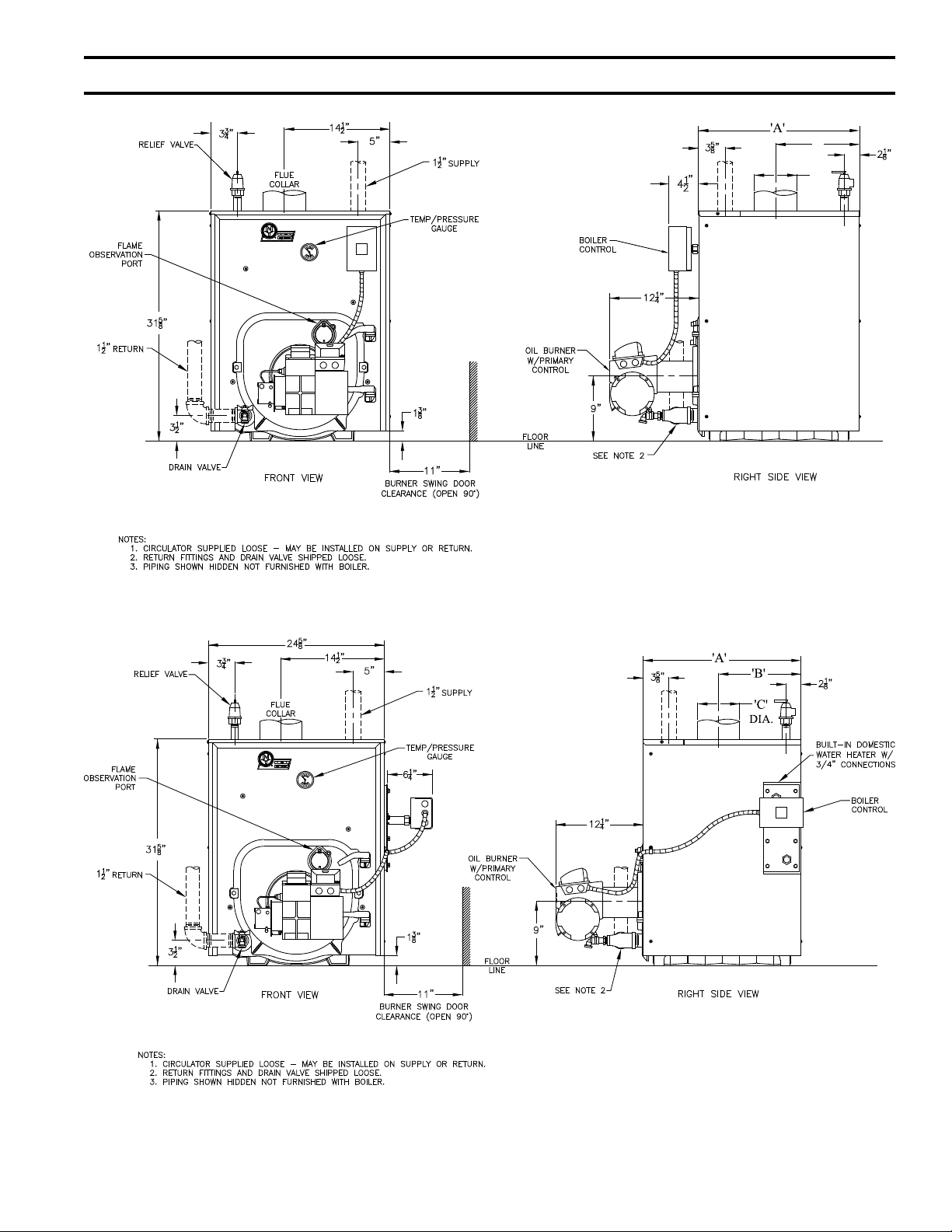

I: GENERAL INFORMATION (continued)

'A'

'B'

'C'

DIA.

Figure 1C: CL3 Thru CL5 Steam Boiler with or without Tankless Heater,

McDonnell & Miller PS-801, Beckett Burner

Figure 1D: CL3 thru CL5 Steam Boiler with or without Tankless Heater,

McDonnell & Miller PS-801, Riello Burner

6

I: GENERAL INFORMATION (continued)

TABLE 1: DIMENSIONAL DATA / GENERAL INFORMATION (SEE FIGURES 1A THRU 1D)

Boiler Model

CL3 17-3/8" 8-1/4" 5-7/8" 16 14.33

CL4 22-3/8" 10-7/8" 6-7/8" 20 20.90

CL5 27-3/8" 13-3/8" 7-7/8" 24 27.46

Maximum Working Pressure: Steam: 15 PSI; Water: 30 PSI Shipped Standard from Factory, 50 PSI Optional

"A" "B" "C"

Dimensions

Approx. Water Content

- Gallons

Heat Transfer Surface

Area - Sq. Ft.

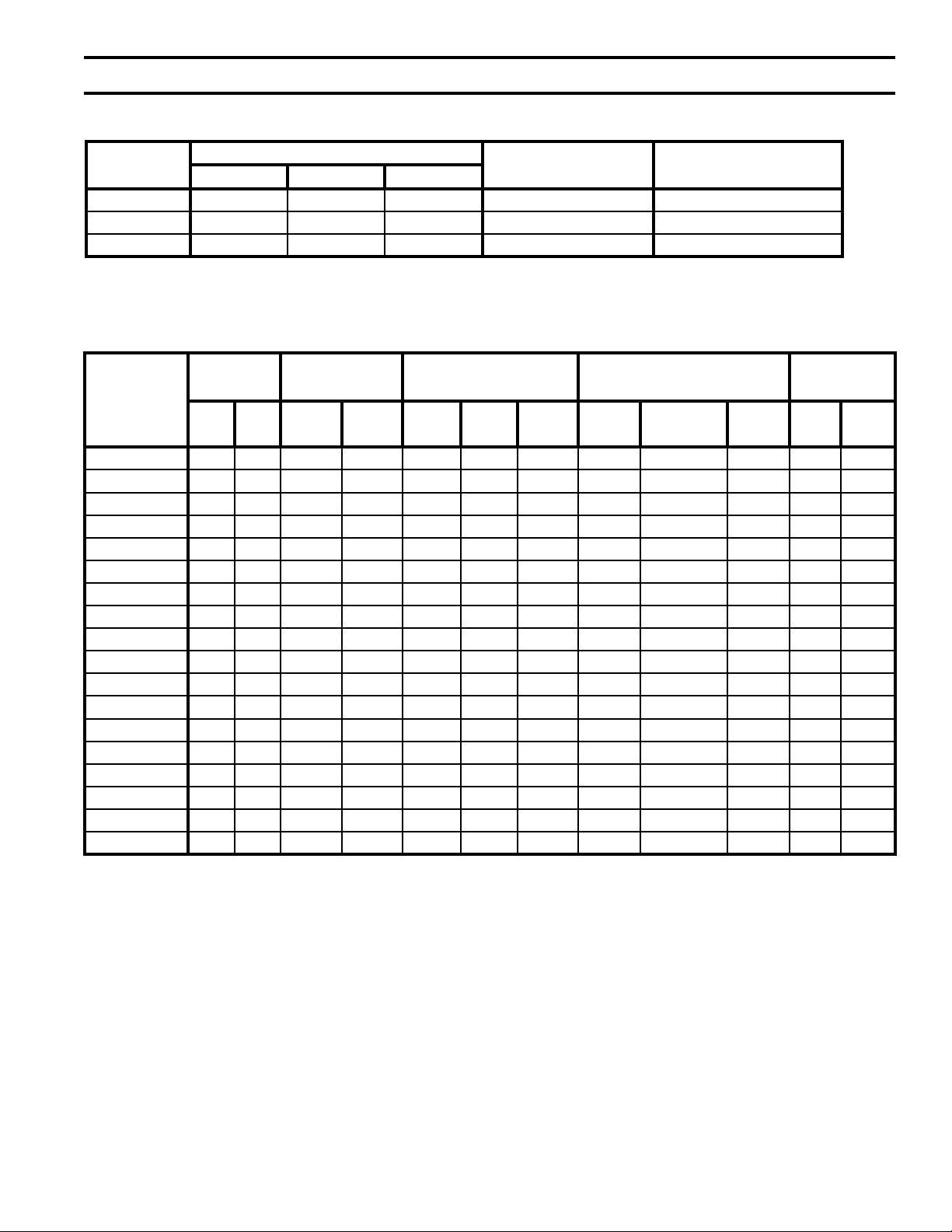

TABLE 2: RATING DATA

Burner

Boiler Model

Capacity

No. *

GPH MBH

CL3-091(W) 0.65 91 80 --- 70 --- --- 6 8 x 8 15 86.1 ---

CL3-091(S) 0.65 91 --- 78 --- 56 233 6 8 x 8 15 --- 84.1

CL3-105(W) 0.75 105 91 --- 79 --- --- 6 8 x 8 15 86.0 ---

CL3-105(S) 0.75 105 --- 90 --- 68 283 6 8 x 8 15 --- 83.8

CL3-140(W) 1.00 140 120 --- 104 --- --- 6 8 x 8 15 84.3 ---

CL3-140(S) 1.00 140 --- 119 --- 89 370 6 8 x 8 15 --- 82.7

CL4-126(W) 0.90 126 111 --- 97 --- --- 7 8 x 8 15 86.0 ---

CL4-126(S) 0.90 126 --- 108 --- 81 338 7 8 x 8 15 --- 84.1

CL4-175(W) 1.25 175 152 --- 132 --- --- 7 8 x 8 15 85.1 ---

CL4-175(S) 1.25 175 --- 149 --- 112 467 7 8 x 8 15 --- 83.5

CL4-210(W) 1.50 210 179 --- 156 --- --- 7 8 x 8 15 84.0 ---

CL4-210(S) 1.50 210 --- 177 --- 133 554 7 8 x 8 15 --- 82.6

CL5-168(W) 1.20 168 147 --- 128 --- --- 8 8 x 8 15 85.9 ---

CL5-168(S) 1.20 168 --- 144 --- 108 450 8 8 x 8 15 --- 83.7

CL5-245(W) 1.75 245 210 --- 183 --- --- 8 8 x 8 15 85.1 ---

CL5-245(S) 1.75 245 --- 207 --- 155 646 8 8 x 8 15 --- 82.5

CL5-280(W) 2.00 280 238 --- 207 --- --- 8 8 x 8 15 84.7 ---

CL5-280(S) 2.00 280 --- 235 --- 176 733 8 8 x 8 15 --- 82.3

* Boiler Model Sufx: (W) = Water, (S) = Steam

DOE Heating

Capacity

Water

MBH

Steam

MBH

AHRI NET Ratings

Water

MBH

Steam

MBH

Steam

Sq. Ft.

Minimum Chimney

Requirements

Round

In. Dia.

Rectangle

In. x In.

Height

Ft.

AFUE %

Water Steam

7

I: GENERAL INFORMATION (continued)

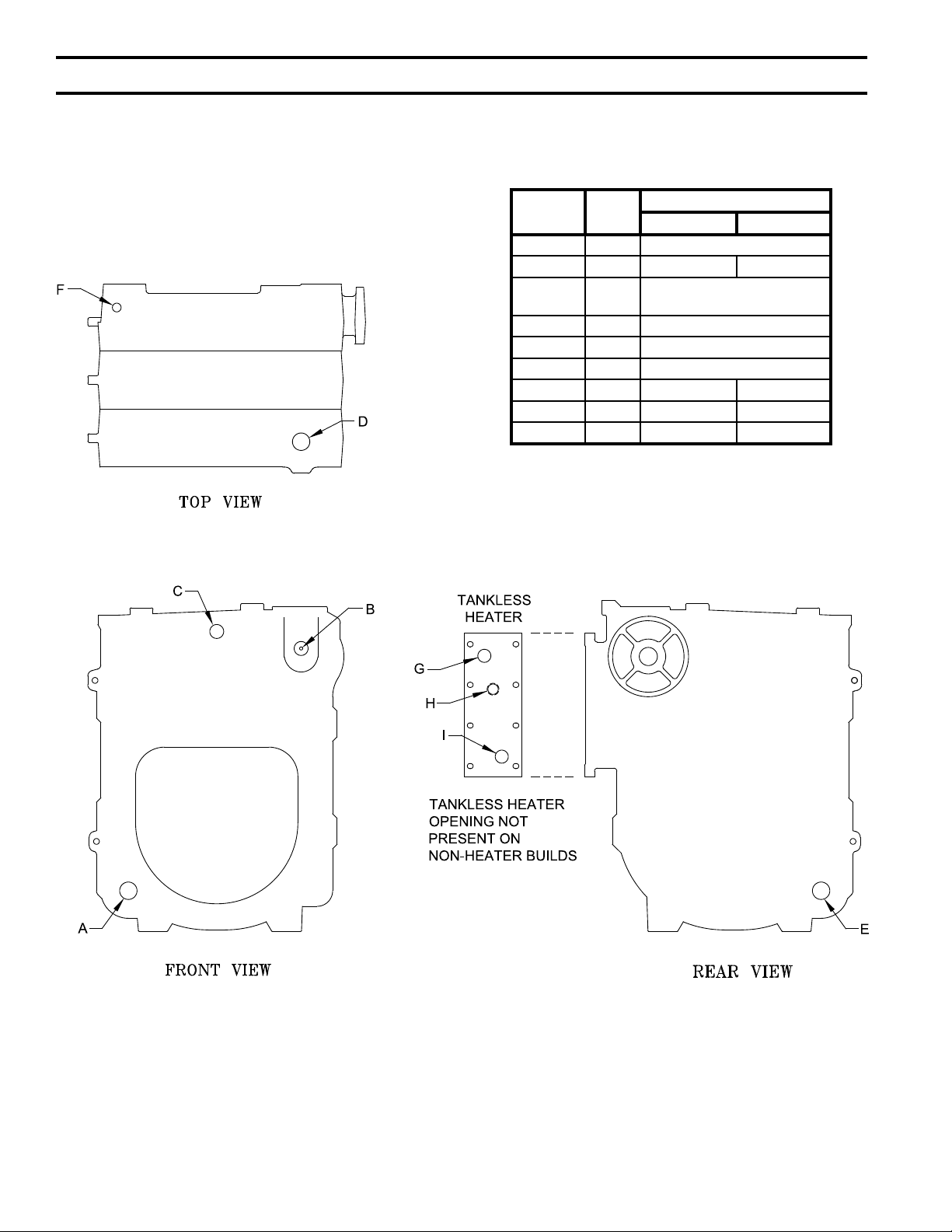

TABLE 3A: PURPOSE OF TAPPINGS (WATER)

Tapping

Location

A 1½” Return

B ½” Limit Well Plug

C ¼”

D 1½” Supply

E 1½” Optional Return

F ¾” Relief Valve

G ¾” N/A DHW Outlet

H ¾” N/A Limit Well

I ¾” N/A DHW Inlet

Size,

NPT

Less Heater With Heater

Purpose

Temperature/Pressure

Gauge

Figure 2A: Purpose of Tappings (Water)

8

I: GENERAL INFORMATION (continued)

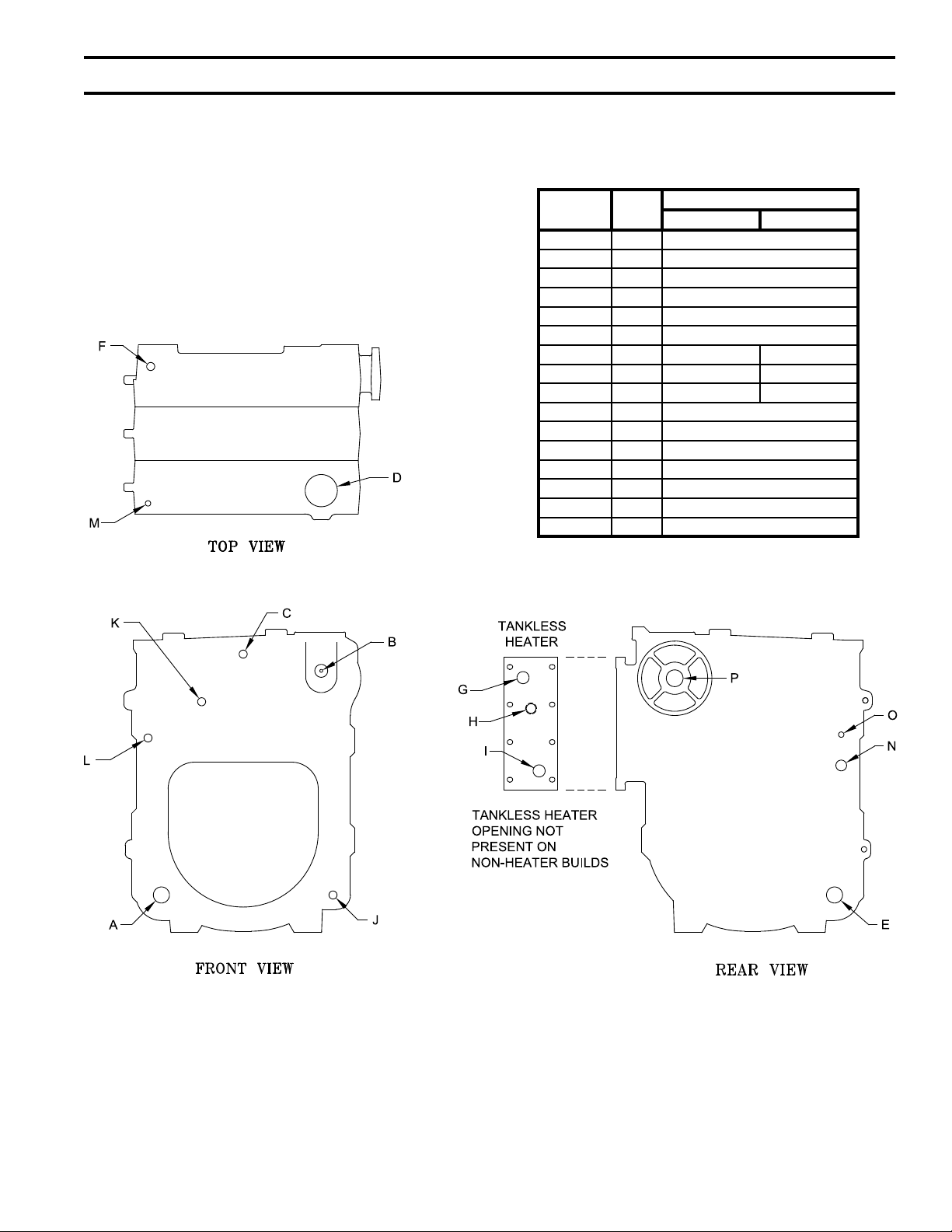

TABLE 3B: PURPOSE OF TAPPINGS (STEAM)

Tapping

Location

A 1½” Return

B ½” Pressure Limit

C ¼” Pressure Gauge

D 3” Supply

E 1½” Optional Return

F ¾” Relief Valve

G ¾” N/A DHW Outlet

H ¾” N/A Limit Well

J ¾” Drain

K ¾” LWCO

L ½” Water Gauge Glass

M ½” Water Gauge Glass

N 1” Indirect Water Heater Supply

O ½” Indirect Water Heater Limit

P 1½” Surface Blowoff

Size,

NPT

Less Heater With Heater

I ¾” N/A DHW Inlet

Purpose

Figure 2B: Purpose of Tappings (Steam)

9

II: PRE-INSTALLATION

A. INSPECT SHIPMENT carefully for any signs of

damage.

1. All equipment is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery

of crated boiler to the carrier in good condition.

2. Any claims for damage or shortage in shipment

must be led immediately against the carrier by

the consignee. No claims for variances from,

or shortage in orders, will be allowed by the

manufacturer unless presented within sixty (60)

days after receipt of goods.

B. LOCATE BOILER near nal position before removing

crate. See Figures 1A thru 1D. Using hand truck or

pipe rollers under skid, move boiler into position along

side installation site.

1. LOCATE so that vent pipe connection to chimney

will be short and direct.

2. BOILER IS SUITABLE FOR INSTALLATION

ON COMBUSTIBLE FLOOR. Boiler cannot be

installed on carpeting.

3. FOR BASEMENT INSTALLATION, provide

a solid elevated base, such as concrete, if oor is

not level, or if water may be encountered on oor

around boiler.

4. PROVIDE SERVICE CLEARANCE of at least

24” clearance from front jacket panel for servicing

and removal of front tankless heater. If boiler is

equipped with a rear tankless heater, provide at

least 24" service clearance on the right side of the

boiler. Boiler ueways may be cleaned either from

the top or from the right side. Provide at least 24"

clearance from either the right side of the boiler or

the top of the boiler for cleaning ueways.

5. For minimum clearances to combustible materials.

See Figure 3.

NOTICE

Clearance to venting is for single wall vent

pipe. If Type L vent is used, clearance may be

reduced to the minimum required by the vent pipe

manufacturer.

C. PROVIDE COMBUSTION AND VENTILATION

AIR. Local and National Codes may apply and should

be referenced.

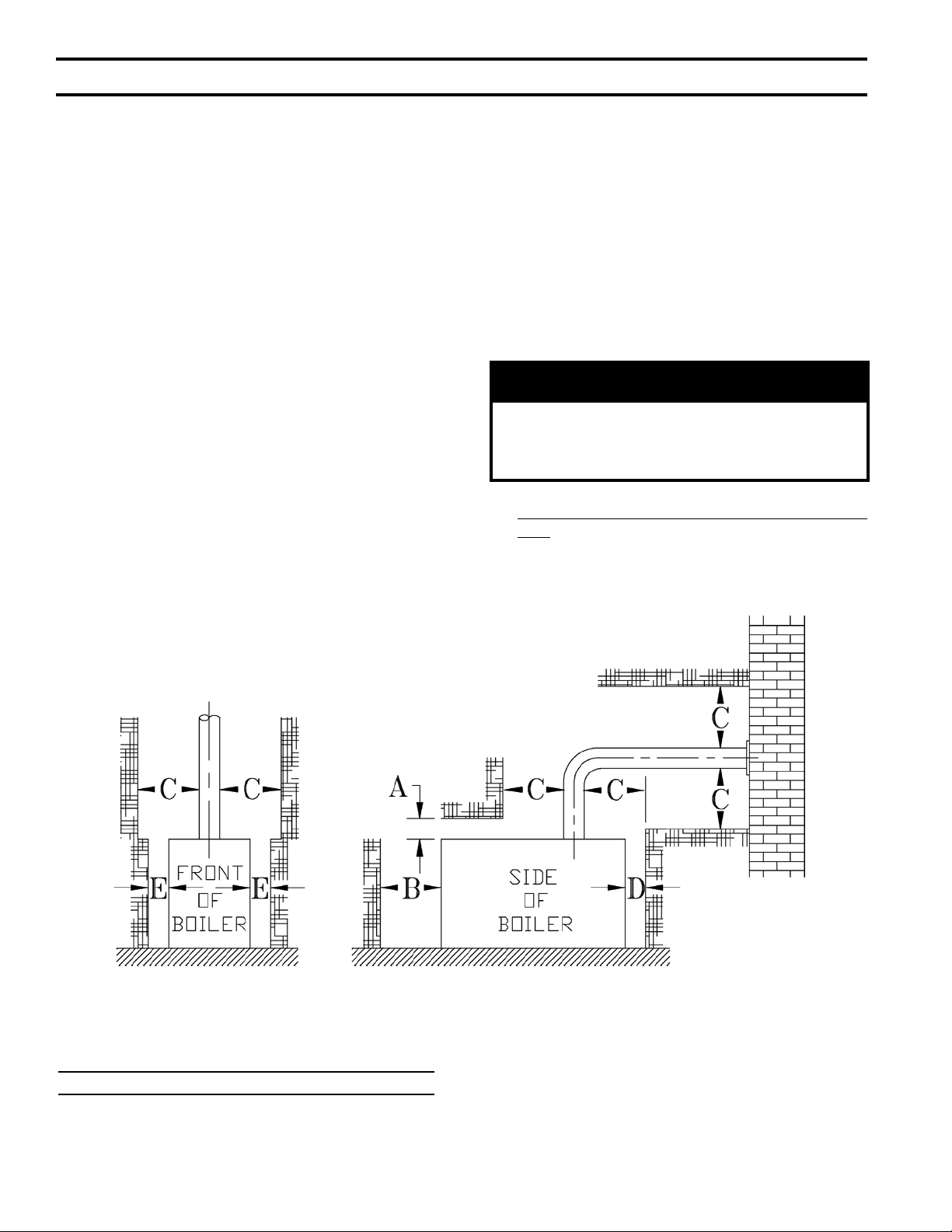

Figure 3: Minimum Installation Clearances To Combustible Materials (Inches)

C

A

Above

6 24 18 6 6

NOTE 1: Listed clearances comply with American National

Standard NFPA 31, Standard for the Installation of Oil

Burning Equipment.

B

Front

Chimney

Connector

D

Rear

E

Sides

10

NOTE 2: CL Series boilers can be installed in rooms with

clearances from combustible material as listed above.

Listed clearances cannot be reduced for alcove or closet

installations.

NOTE 3: For reduced clearances to combustible material,

protection must be provided as described in the ANSI/NFPA

31 standard.

II: PRE-INSTALLATION (continued)

WARNING

Adequate combustion and ventilation air must

be provided to assure proper combustion and

to maintain safe ambient air temperatures.

DO NOT install boiler where gasoline or other

ammable vapors or liquids, or sources of

hydrocarbons (i.e. bleaches, fabric softeners,

etc.) are used or stored.

1. Determine volume of space (boiler room). Rooms

communicating directly with the space in which

the appliances are installed, through openings not

furnished with doors, are considered a part of the

space.

3

Volume(ft

2. Determine total input of all appliances in the space.

Add inputs of all appliances in the space and round

the result to the nearest 1000 BTU per hour.

3. Determine type of space. Divide Volume by total

input of all appliances in space. If the result is

greater than or equal to 50 ft3/1000 BTU per hour,

then it is considered an unconned space. If the

result is less than 50 ft3/1000 BTU per hour then the

space is considered a conned space.

4. For boiler located in an unconned space of a

conventionally constructed building, the fresh

air inltration through cracks around windows

and doors normally provides adequate air for

combustion and ventilation.

5. For boiler located in a conned space or an

unconned space in a building of unusually tight

construction, provide outdoor air.

Outdoor air may be provided with the use of two

permanent openings which communicate directly or

by duct with the outdoors or spaces (crawl or attic)

freely communicating with the outdoors. Locate one

opening within 12 inches of top of space.

) = Length(ft) x Width(ft) x Height(ft)

Locate remaining opening within 12 inches of

bottom of space. Minimum dimension of air opening

is 3 inches. Size each opening per following:

a. Direct communication with outdoors.

Minimum free area of 1 square inch per 4,000

BTU per hour input of all equipment in space.

b. Vertical ducts. Minimum free area of 1 square

inch per 4,000 BTU per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

c. Horizontal ducts. Minimum free area of 1

square inch per 2,000 BTU per hour input of all

equipment in space. Duct cross-sectional area

shall be same as opening free area.

Alternate method for boiler located within

conned space. Use indoor air if two permanent

openings communicate directly with additional

space(s) of sufcient volume such that combined

volume of all spaces meet criteria for unconned

space. Size each opening for minimum free area

of 1 square inch per 1,000 BTU per hour input

of all equipment in spaces, but not less than 100

square inches.

6. Louvers and Grilles of Ventilation Ducts

a. All outside openings should be screened and

louvered. Screens used should not be smaller

than 1/4 inch mesh. Louvers will prevent the

entrance of rain and snow.

b. Free area requirements need to consider the

blocking effect of louvers, grilles, or screens

protecting the openings. If the free area of the

louver or grille is not known, assume wood

louvers have 20-25 percent free area and metal

louvers and grilles have 60-75 percent free area.

c. Louvers and grilles must be xed in the open

position, or interlocked with the equipment to

open automatically during equipment operation.

11

Loading...

Loading...