New Yorker Boiler CG-E Installation Manual

INSTALLATION, OPERATING

AND

SERVICE INSTRUCTIONS

CG-E™ SERIES

GAS BOILER

9700609

BEFORE INSTALLATION: READ THIS MANUAL

SAVE THESE INSTRUCTIONS

Installing contractor and homeowner should read and be informed as to the proper installation and operation of this boiler.

The manufacturer will not be responsible for improper installation or operation. This manual and all associated instruction

material should be conspicuously posted near the boiler.

For service or repairs to boiler, call your heating contractor. When seeking information on boiler,

provide Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number

CG _ _ E

Heating Contractor Phone Number

Address

Boiler Serial Number Installation Date

106213-01- 11/15

Price - $5.00

The City of New York requires a Licensed Master Plumber supervise the installation of this product.

The Massachusetts Board of Plumbers and Gas Fitters has approved the CG-E™ Series Boiler. See the Massachusetts Board of

Plumbers and Gas Fitters website, http://license.reg.state.ma.us/pubLic/pl_products/pb_pre_form.asp for the latest Approval

Code or ask your local Sales Representative.

The Commonwealth of Massachusetts requires this product to be installed by a licensed Plumber or Gas tter.

The following terms are used throughout this manual to bring attention to the presence of hazards of various

risk levels, or to important information concerning product life.

DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death, serious

injury or substantial property damage.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death, serious injury

or substantial property damage.

Table of Contents

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in moderate or minor

injury or property damage.

NOTICE

Indicates special instructions on installation,

operation, or maintenance which are important

but not related to personal injury hazards.

I. Pre-Installation ....................................5

II. Unpack Boiler .....................................5

III. Water Piping and Trim ........................6

IV. Venting .............................................. 10

V. Gas Piping .........................................12

VI. Electrical ............................................13

2

VII. System Start-up and Checkout ..................... 17

VIII. Operation ..........................................20

IX. Service and Maintenance ...................22

X. Troubleshooting ................................24

XI. Repair Parts .......................................29

Warranty .............................Back Cover

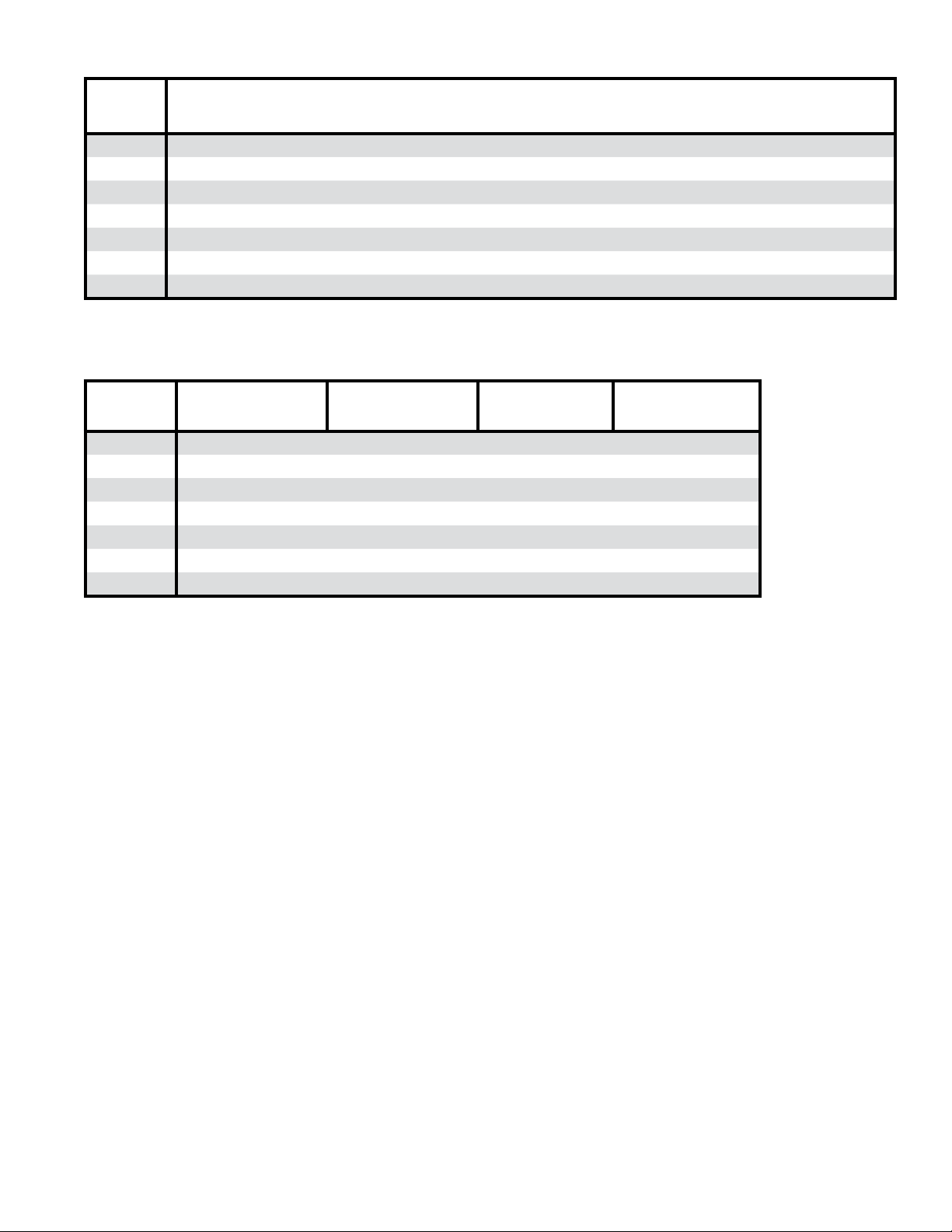

Table 1A: Dimensions and Connections

Boiler

Model

CG30E 32 14 40 1¼ 1¼ 4 ½ ¾ ¾

CG40E 32 16 40 1¼ 1¼ 5 ½ ¾ ¾

CG50E 32 19 40 1¼ 1¼ 6 ½ ¾ ¾

CG60E 32 22 40 1¼ 1¼ 6 ½ ¾ ¾

CG70E 32 25 40 1¼ 1¼ 7 ¾ ¾ ¾

CG80E 32 28 40 1¼ 1¼ 7 ¾ ¾ ¾

CG90E 32 31 40 1¼ 1¼ 8 ¾ ¾ ¾

Depth Width Height

Supply NPT

(inch)

Return NPT

(inch)

Vent

(inch)

Gas NPT

(inch)

Relief Valve

NPT (inch)

Drain

NPT (inch)

Table 1B: Inputs, Weights and Volumes

Boiler

Model

CG30E 70 254 180 2

CG40E 105 304 231 3

CG50E 140 357 284 4

CG60E 175 405 332 5

CG70E 210 462 382 6

CG80E 245 518 438 7

CG90E 280 564 484 8

(1)

Input ratings can be used for elevations up to 2000 ft. Refer to System Start-up and Checkout Sections for elevations 2000 ft.

or higher.

Input (MBH)

(1)

Shipping Weight

(lbs)

Empty Weight

(lbs)

Water Content

(gal)

Electrical Requirements: 120VAC, 60 Hz, 1-ph, Less than 12A

Maximum Allowable Working Pressure - 50 psi. Boiler shipped from factory with a 30 psi relief valve.

3

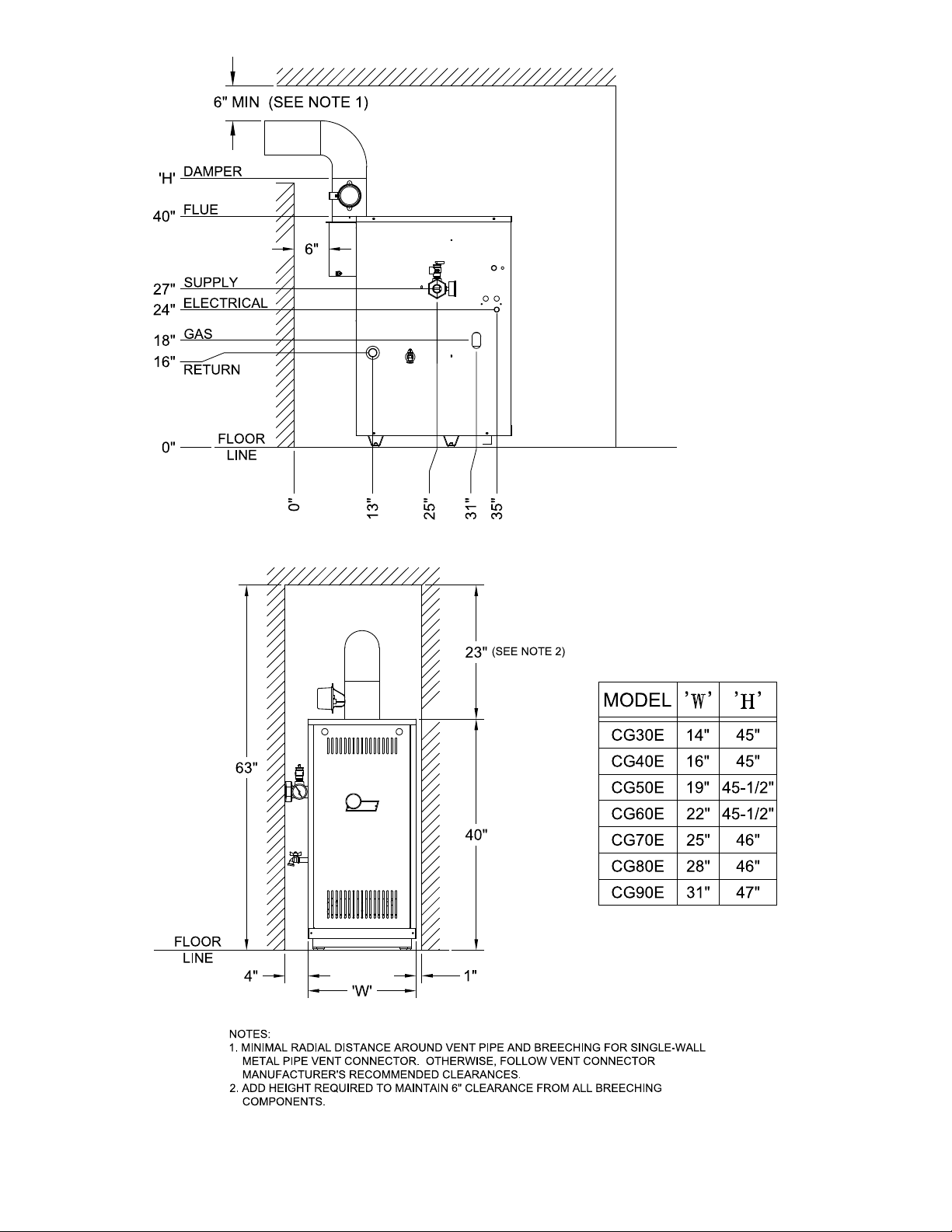

Figure 1: Minimum Clearance to Combustible Materials and Alcove Dimensions

4

I. Pre-Installation

WARNING

Carefully read all instructions before installing

boiler. Failure to follow all instructions in proper

order can cause personal injury or death.

A. Inspect shipment carefully for any signs of damage.

All equipment is carefully manufactured, inspected

and packed. Our responsibility ceases upon delivery

of boiler to carrier in good condition. Any claim

for damage or shortage in shipment must be led

immediately against carrier by consignee. No claims

for variances or shortages will be allowed by Boiler

Manufacturer, unless presented within sixty (60) days

after receipt of equipment.

B. Installation must conform to the requirements of the

authority having jurisdiction. In the absence of such

requirements, installation must conform to National

Fuel Gas Code, ANSI Z223.1/NFPA 54.

C. Appliance is design certied for installation on

combustible ooring. The boiler must not be installed

on carpeting.

D. Provide clearance between boiler jacket and

combustible material in accordance with local re

ordinance. Refer to Figure 1 for minimum clearance

from combustible material for alcove installation.

Provide 1/2" clearance from water piping to

combustible materials.

F. Install on level oor. For basement installation provide

concrete base if oor is not level or if water may be

encountered on oor around boiler.

CAUTION

ASSURE THAT THE FRONT AIR DAM is in place

and undamaged. A damaged front air dam will

negatively affect the performance of this boiler,

which can cause serious property damage,

personal injury or death.

G. Protect gas ignition system components from water

(dripping, spraying, rain, etc.) during boiler operation

and service (circulator replacement, condensate trap,

control replacement, etc.).

H. Provide combustion and ventilation air in accordance

with the section "Air for Combustion and Ventilation,"

of the National Fuel Gas Code, ANSI Z223.1/NFPA 54,

or applicable provisions of local building codes.

WARNING

Adequate combustion and ventilation air must be

provided to assure proper combustion.

I. Do not install boiler where gasoline or other

ammable vapors or liquids, or sources of

hydrocarbons (i.e. bleaches, cleaners, chemicals, sprays,

paint removers, fabric softeners, etc.) are used or stored.

E. Provide practical service clearances. A minimum

of 24" from the left side and front jacket panels is

recommended for servicing but may be reduced to

minimums shown in Figure 1.

II. Unpack Boiler

CAUTION

Do not drop boiler. Do not bump boiler jacket

against oor.

A. Move boiler to approximate installed position.

B. Remove all crate fasteners.

C. Lift outside container and remove with all other

inside protective spacers and bracing. Save two of the

wooden slats from the container sleeve for use in Steps

E and F.

D. Remove all boiler hold-down fasteners.

E. Tilt the boiler to one side and slide a wooden slat under

the two raised feet.

F. Tilt the boiler to the other side and slide another

wooden slat under the two raised feet.

G. Slide the boiler forward or backward off the skid using

the two wooden slats as runners.

H. Move boiler to its permanent location.

5

Loading...

Loading...