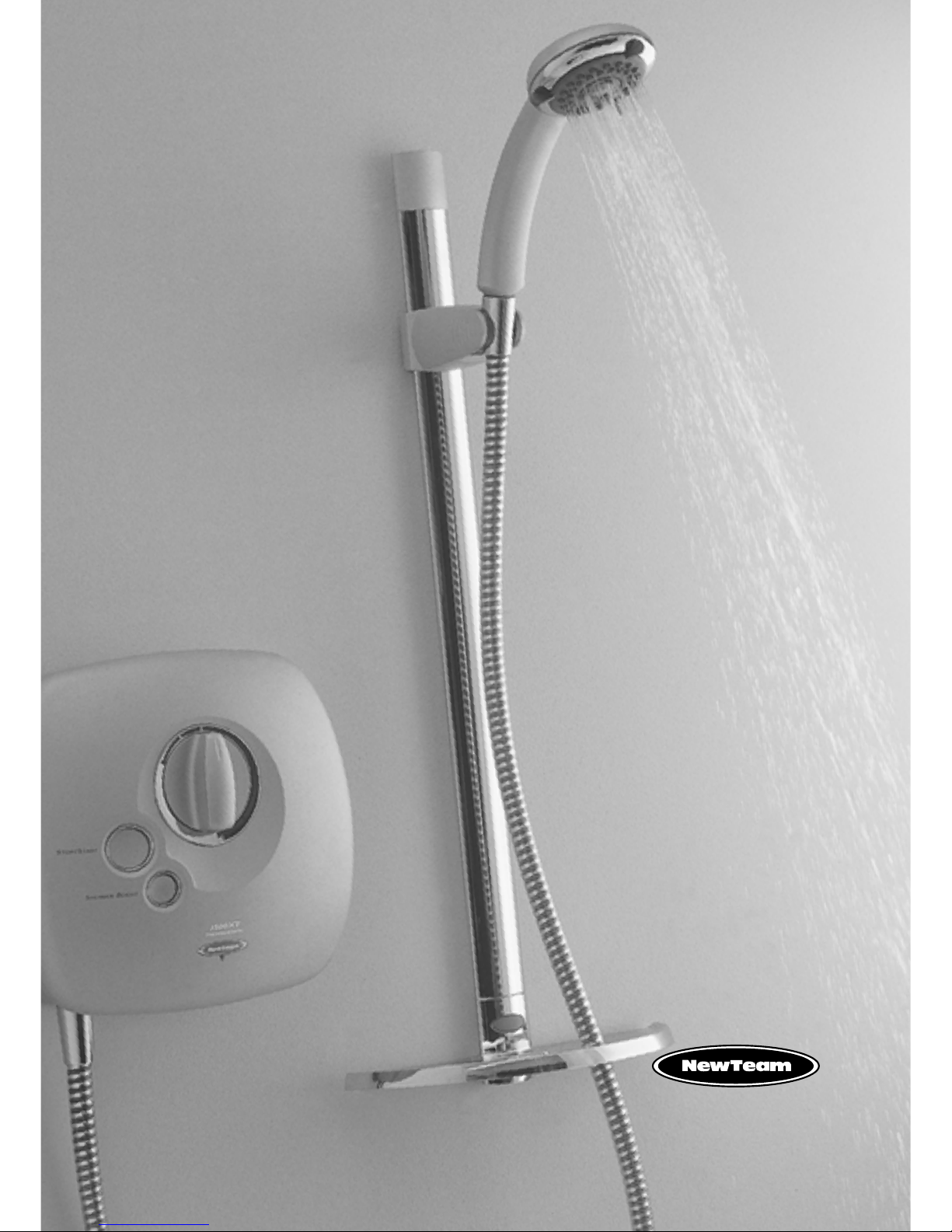

NewTeam 1500-XT Installation Instructions And User Manual

Installation Instructions

and User Guide

PLEASE KEEP THIS BOOKLET

FOR FUTURE REFERENCE

NEWTEAM 1500-XT

THERMOSTATIC POWER SHOWER

DEAR INSTALLER WHEN YOU HAVE READ THESE INSTRUCTIONS

PLEASE ENSURE YOU LEAVE THEM WITH THE USER

IN THE EVENT OF ANY QUERY PLEASE CONTACT

THE NEWTEAM CUSTOMER HELPLINE

Tel : 01536 264 012

Product Features

1

NEWTEAM 1500-XT

NewTeam 1500-XT

• Integral pump

• Push-fit fittings

• 3 spray massage handset

• Thermostatic control

• BEAB approval of safety

255mm

240mm

Contents

2

NEWTEAM 1500-XT

Please read this booklet carefully and ensure a competent person undertakes the

installation.

Note: Following the headings in sequence will guide you through the installation

and operation of your NewTeam 1500-XT Power Shower.

PLANNING YOUR INSTALLATION

• Plumbing

• Electrics

FITTING YOUR SHOWER

• General

• The Unit

• Water/Electrical Connections

• Surface Mounting

• Recessed Fitting Pipework

• Riser Rail

USER INSTRUCTIONS

COMMISSIONING

Refer to back cover for Guarantee, Customer Service and Replacement Parts Policy.

In the event of any query regarding installation please contact the NewTeam Customer

Service Department

Tel: 01536 264 012 • Fax: 01536 409 201

E-mail: service@newteam.co.uk • E-mail: spares@newteam.co.uk

In line with our policy of continual product development the specifications may be

varied and product design altered. We reserve the right to depart from the details

given in this manual without prior notice.

3

Pages

4 - 7

8

9

Installation and Operating Instructions

for NewTeam Power Shower

• 1500-XT

SPARE PARTS LISTING

10

INSTALLER NOTES

11-12

GUARANTEE

13

Planning your Installation

3

NEWTEAM 1500-XT

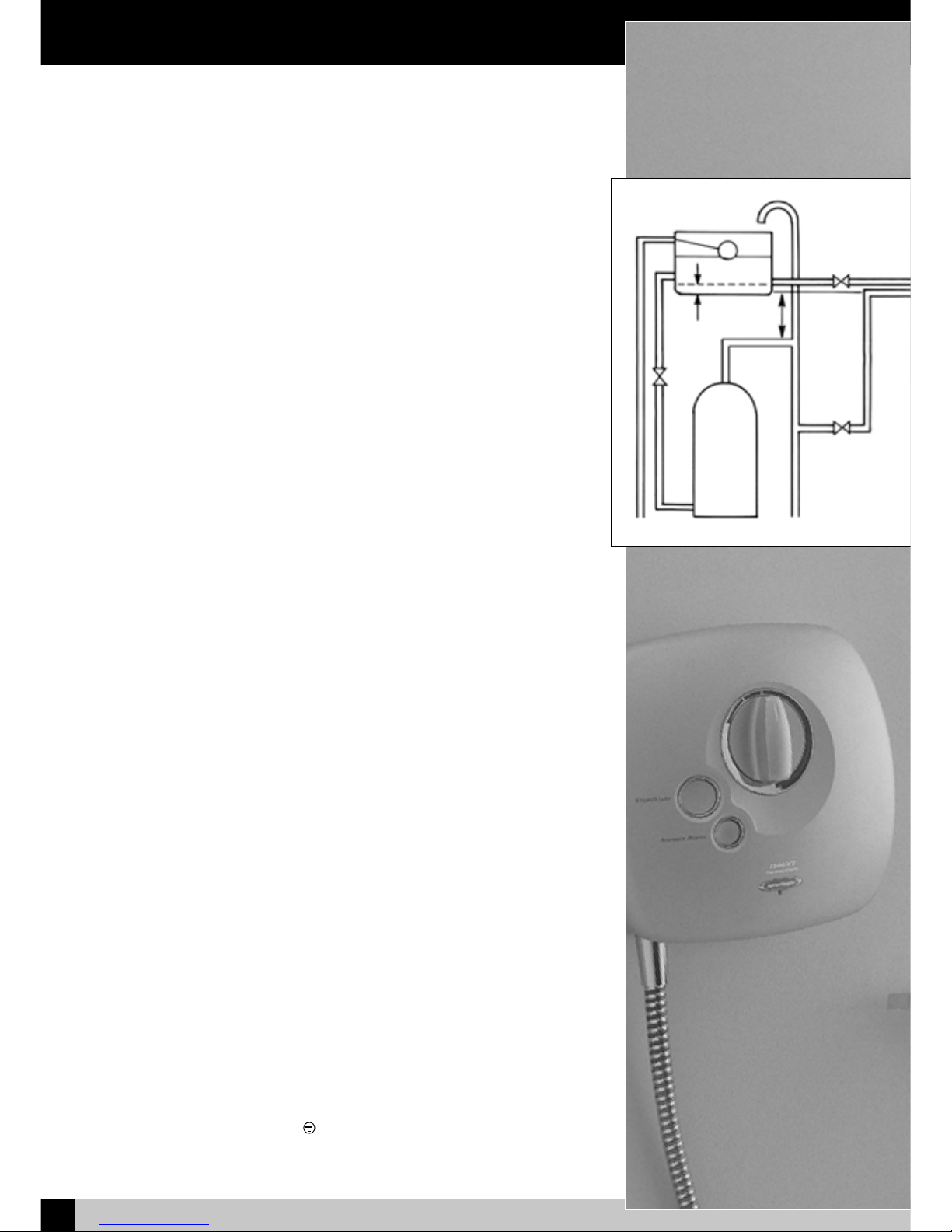

Plumbing

Under no circumstances should the unit be connected directly to the mains

cold water supply, or to a combination boiler, or pressurised hot water system.

For correct operation of the NewTeam 1500-XT power shower, both hot and cold

water supplies must be gravity fed, at nominally equal pressures, from a cold water

storage tank, and a hot water storage cylinder.

We recommend a minimum of 115 litres (25 gallon actual) of cold water

supplied by a storage tank. Please ensure compliance with all Water

Regulations.

Under no circumstances must the Power Shower be connected to the

mains cold water supply.

Please ensure maximum supply head of 10 metres, minimum 1 metre.

It is recommended that the hot water supply is at a temperature of 60ºC, in line with

British Standard 6700, British Water Regulations, and Plumbing Code of Practice.

Do not use jointing compounds when connecting, and do not solder within 300mm

of the unit.

Before proceeding with the installation of this unit, check that your site requirements

allow the handset to be a minimum of 1 metre below the bottom of the cold water

storage tank to allow the 1500-XT to also operate on gravity.

WARNING: THIS APPLIANCE MUST BE EARTHED.

All electrical wiring for the shower must comply with the current

I.E.E Regulations which includes earth-cross bonding to all metal pipework.

IMPORTANT:

All plumbing should be completed before final electrical connections are made.

The shower must be connected to a 230/240 volt A.C electrical supply from a

13-amp ring main, via a fused double pole switch with at least 3mm contact

separation. The switch is to be clearly identifiable, a minimum distance of 2.5m from

a fixed tap or shower, i.e. mounted in an adjacent room or via a ceiling-type pull cord

switch. The unit should be fused at no more than 3 amps.

This appliance must be earthed, and all associated metal pipework earth

crossbonded in line with current I.E.E regulations.

As the colours of the wires in the cable (not supplied) used to connect to this

appliance may not correspond with the coloured markings identifying the terminals

in your switch, please follow the procedure below:

Please use the cable entry point provided. Failure to comply will eliminate any

BEAB approval.

Procedure:

• The wire, which is coloured Blue or Black, must be connected to the terminal that

is marked with the letter N.

• The wire, which is coloured Brown or Red, must be connected to the terminal that

is marked with the letter L.

• The wire which is coloured Yellow/Green must be connected to the terminal which

is marked with the earth symbol .

• The installation and wiring must comply with I.E.E regulations.

Electrics

Fig. 1 – Gravity Power Shower Installation

1m

Minimum

60mm

Fitting your Shower

4

NEWTEAM 1500-XT

In addition to the recommendation on `Planning your Installation’ please take note of

the following:

• All plumbing should be completed before any electrical connections are undertaken.

• The unit can be connected to a combination cylinder system providing it

has a cold water storage capacity of 115 litres (25 gallons actual).

• When connecting pipework avoid using elbows: sweep or formed bends will

ensure optimum performance.

• Do not solder within 300mm of the unit.

• Do not run pump dry this will damage the internal seal and invalidate the warranty.

• All pipework to and from the unit should be a minimum of 15mm. Non-restrictive

isolating valves must be fitted on hot and cold supply pipes.

• Do not position unit in areas subjected to freezing conditions.

• The temperature of your stored water must not

exceed 65ºC. A stored water

temperature of 60ºC is considered sufficient to meet all normal requirements

in line with the British Standard 6700.

WARNING – ALL CONNECTING PIPEWORK SHOULD BE EARTHED

Procedure - Plumbing Connections: Fig 1.

1. Isolate mains water and electrical supplies.

2. To empty the pipework open the hot and cold water taps.

3. Make your connection into the hot water supply pipe from the cylinder, ensuring

that it is the first draw-off (below the expansion pipe tee) to minimise the effects

of water draw offs elsewhere in the house, and a minimum of 1 metre from the

base of the cold storage tank and the expansion tee.

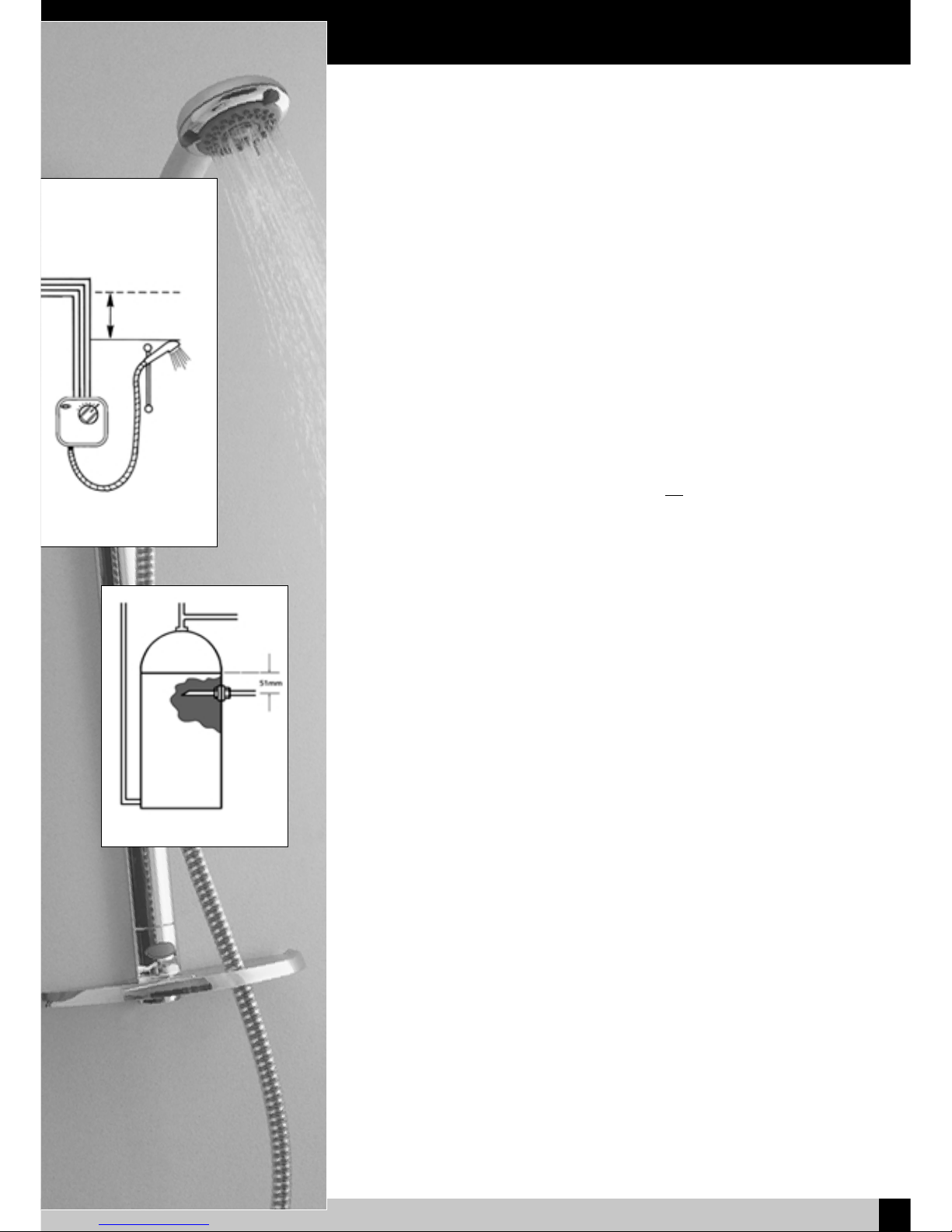

4. If this is not possible, a direct connection must be made from the hot water

cylinder with a cylinder flange, Fig 2.

5. The cold water supply should be taken directly from the cold storage tank,

and must be positioned 60mm below the cold feed connection to the hot

water cylinder. This should not be directly beneath the ball valve as aeration of the

water going to the shower could cause pump damage.

6. Run hot and cold pipework to the unit position.

We recommend that the unit is fitted at chest height, and set to one side of the

intended riser rail position, ensuring that the top of the unit is at least 75mm below

the base of the cold water tank.

IMPORTANT:

• The unit must be fitted on the finished tiled surface.

•

Do not seal the edge of the unit to the tiled surface with any sealant, as the

gap below the back of the unit and the tiles is needed for ventilation.

• The outlet connection must be positioned at the bottom of the unit.

General

The Unit

Fig 2 - Cylinder Flange

1m

Minimum

Loading...

Loading...