Page 1

XPS-Q8

U

ser’s Manual,

Software Tools

and

Tutorial

V1.4

.x

Universal High-Performance

Motion Controller/Driver

Page 2

XPS-Q8 Universal High-Performance Motion Controller/Driver

Warranty

Newport Corporation warrants that this product will be free from defects in material and

workmanship and will comply with Newport’s published specifications at the time of

sale for a period of one year from date of shipment. If found to be defective during the

warranty period, the product will either be repaired or replaced at Newport's option.

To exercise this warranty, write or call your local Newport office or representative, or

contact Newport headquarters in Irvine, California. You will be given prompt assistance

and return instructions. Send the product, freight prepaid, to the indicated service

facility. Repairs will be made and the instrument returned freight prepaid. Repaired

products are warranted for the remainder of the original warranty period or 90 days,

whichever comes first.

Limitation of Warranty

The above warranties do not apply to products which have been repaired or modified

without Newport’s written approval, or products subjected to unusual physical, thermal

or electrical stress, improper installation, misuse, abuse, accident or negligence in use,

storage, transportation or handling. This warranty also does not apply to fuses, batteries,

or damage from battery leakage.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR USE. NEWPORT CORPORATION SHALL

NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, OR CONSEQUENTIAL

DAMAGES RESULTING FROM THE PURCHASE OR USE OF ITS PRODUCTS.

©2017 by Newport Corporation, Irvine, CA. All rights reserved.

Original instructions.

No part of this document may be reproduced or copied without the prior written

approval of Newport Corporation. This document is provided for information only, and

product specifications are subject to change without notice. Any change will be

reflected in future publishings.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) ii

Page 3

XPS-Q8 Universal High-Performance Motion Controller/Driver

Table of Contents

Waranty ............................................................................................................................ii

EU Declaration of Conformity ......................................................................................... x

Preface ............................................................................................................................. xi

User’s Manual

1.0 Introduction .................................................................................................. 1

1.1 Scope of the Manual ................................................................................................................ 1

1.2 Definitions and Symbols .......................................................................................................... 3

1.2.1 General Warning or Caution ................................................................................ 3

1.2.2 Electric Shock ...................................................................................................... 3

1.2.3 European Union CE Mark.................................................................................... 3

1.2.4 “ON” Symbol ....................................................................................................... 3

1.2.5 “OFF” Symbol ..................................................................................................... 3

1.3 Warnings and Cautions ............................................................................................................ 4

1.4 General Warnings and Cautions .............................................................................................. 4

2.0 System Overview........................................................................................... 6

2.1 Specifications ........................................................................................................................... 6

2.2 Drive Options .......................................................................................................................... 7

2.3 Compatible Newport Positioners and Drive Power Consumption ........................................... 8

2.4 XPS Hardware Overview......................................................................................................... 9

2.5 Front Panel Description ........................................................................................................... 9

2.6 Rear Panel Description .......................................................................................................... 10

2.6.1 Axis Connectors (AXIS 1 – AXIS 8) ................................................................. 10

2.7 Ethernet Configuration .......................................................................................................... 11

2.7.1 Communication Protocols .................................................................................. 11

2.7.2 Addressing ......................................................................................................... 12

2.8 Sockets, Multitasking and Multi-user Applications ............................................................... 12

2.9 Programming with TCL ......................................................................................................... 12

iii XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 4

XPS-Q8 Universal High-Performance Motion Controller/Driver

3.0 Getting Started ............................................................................................ 14

3.1 Unpacking and Handling ....................................................................................................... 14

3.2 Inspection for Damage ........................................................................................................... 14

3.3 Packing List ........................................................................................................................... 14

3.4 System Setup ......................................................................................................................... 14

3.4.1 Installing Driver cards ........................................................................................ 15

3.4.2 Power ON .......................................................................................................... 15

3.5 Connecting to the XPS ........................................................................................................... 16

3.5.1 Straight through cables (black) .......................................................................... 16

3.5.2 Cross-over cables (gray) .................................................................................... 16

3.5.3 Direct Connection to the XPS Controller ........................................................... 17

3.5.4 Connecting the XPS to a Corporate Network using Static IP Configuration ..... 19

3.5.5 Configuring the XPS for Connection to a Corporate Network Using Dynamic IP

Configuration ................................................................................................. 21

3.5.6 Recovering a lost IP configuration ..................................................................... 24

3.6 Testing your XPS-PC Connection and Communication ........................................................ 26

3.7 Connecting the Stages ............................................................................................................ 27

3.8 Configuring the Controller ..................................................................................................... 28

3.8.1 Auto Configuration ............................................................................................ 29

3.8.2 Manual Configuration for Newport Positioners ................................................. 31

3.8.3 Manual Configuration for non Newport stages .................................................. 35

3.9 System Shut-Down ................................................................................................................ 35

Software Tools

4.0 Software Tools............................................................................................. 36

4.1 Software Tools Overview ...................................................................................................... 36

4.2 CONTROLLER CONFIGURATION – Users Management................................................. 37

4.3 CONTROLLER CONFIGURATION – IP Management ...................................................... 38

4.4 CONTROLLER CONFIGURATION – General ................................................................... 38

4.5 SYSTEM – Error file display ................................................................................................ 39

4.6 SYSTEM – Last error file display ......................................................................................... 39

4.7 SYSTEM – Auto Configuration ............................................................................................ 40

4.8 SYSTEM – Manual Configuration ........................................................................................ 40

4.9 SYSTEM – Manual Configuration – Gantries (Secondary Positioners) ................................ 44

4.9.1 Home search of gantries ..................................................................................... 45

4.9.2 Gantries with linear motors ................................................................................ 46

4.9.3 Gantries with linear motors and variable force ratio .......................................... 47

4.10 STAGE – Add from Data Base ............................................................................................ 49

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) iv

Page 5

XPS-Q8 Universal High-Performance Motion Controller/Driver

4.11

STAGE – Modify ................................................................................................................ 50

4.12 FRONT PANEL – Move ..................................................................................................... 52

4.13 FRONT PANEL – Jog ......................................................................................................... 53

4.14 FRONT PANEL – Spindle .................................................................................................. 53

4.15 FRONT PANEL – I/O View................................................................................................ 54

4.16 FRONT PANEL – I/O Set ................................................................................................... 54

4.17 FRONT PANEL – Positioner Errors ................................................................................... 55

4.18 FRONT PANEL – Hardware Status .................................................................................... 55

4.19 FRONT PANEL – Driver Status ......................................................................................... 56

4.20 TERMINAL ......................................................................................................................... 56

4.21 TUNING – Auto-Scaling ..................................................................................................... 59

4.22 TUNING – Auto-Tuning ..................................................................................................... 60

4.23 FUNCTIONAL TESTS ....................................................................................................... 63

4.24 FTP (File Transfer Protocol) Connection ............................................................................ 63

5.0 Maintenance and Service ........................................................................... 65

5.1 Enclosure Cleaning ................................................................................................................ 65

5.2 Obtaining Service .................................................................................................................. 65

5.3 Troubleshooting ..................................................................................................................... 65

5.4 Updating the Firmware Version of Your XPS Controller ..................................................... 66

Motion Tutorial

6.0 XPS Architecture ........................................................................................ 67

6.1 Introduction ........................................................................................................................... 67

6.2 State Diagrams ....................................................................................................................... 68

6.3 Motion Groups ....................................................................................................................... 70

6.3.1 Specific SingleAxis Group Features .................................................................. 71

6.3.2 Specific Spindle Group Features ........................................................................ 71

6.3.3 Specific XY Group Features .............................................................................. 71

6.3.4 Specific XYZ Group Features ............................................................................ 71

6.3.5 Specific MultipleAxes Features ......................................................................... 71

6.4 Native Units ........................................................................................................................... 71

7.0 Motion .......................................................................................................... 73

7.1 Motion Profiles ...................................................................................................................... 73

7.2 Home Search .......................................................................................................................... 75

7.3 Referencing State ................................................................................................................... 78

7.3.1 Move on sensor events ....................................................................................... 79

v XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 6

XPS-Q8 Universal High-Performance Motion Controller/Driver

7.3.2 Moves of Certain Displacements ....................................................................... 80

7.3.3 Position Counter Resets ..................................................................................... 80

7.3.4 State Diagram .................................................................................................... 81

7.3.5 Example: MechanicalZeroAndIndexHomeSearch ............................................. 81

7.4 Move ...................................................................................................................................... 81

7.5 Motion Done .......................................................................................................................... 83

7.6 JOG ........................................................................................................................................ 85

7.7 Master Slave .......................................................................................................................... 86

7.8 Analog Tracking .................................................................................................................... 87

7.8.1 Analog Position Tracking .................................................................................. 88

7.8.2 Analog Velocity Tracking .................................................................................. 88

8.0 Trajectories ................................................................................................. 90

8.1 Line-Arc Trajectories ............................................................................................................. 90

8.1.1 Trajectory Terminology ..................................................................................... 90

8.1.2 Trajectory Conventions ...................................................................................... 91

8.1.3 Geometric Conventions ..................................................................................... 91

8.1.4 Defining Line-Arc Trajectory Elements ............................................................ 91

8.1.5 Define Lines ....................................................................................................... 92

8.1.6 Define Arcs ........................................................................................................ 93

8.1.7 Trajectory File Description ................................................................................ 93

8.1.8 Trajectory File Examples ................................................................................... 93

8.1.9 Trajectory Verification and Execution ............................................................... 94

8.1.10 Examples of the Use of the Functions.............................................................. 95

8.2 Splines ................................................................................................................................... 96

8.2.1 Trajectory Terminology ..................................................................................... 96

8.2.2 Trajectory Conventions ...................................................................................... 96

8.2.3 Geometric Conventions ..................................................................................... 96

8.2.4 Catmull-Rom Interpolating Splines ................................................................... 97

8.2.5 Trajectory Elements Arc Length Calculation..................................................... 97

8.2.6 Trajectory File Description ................................................................................ 98

8.2.7 Trajectory File Example .................................................................................... 98

8.2.8 Spline Trajectory Verification and Execution .................................................. 100

8.2.9 Examples .......................................................................................................... 101

8.3 PVT Trajectories .................................................................................................................. 101

8.3.1 Trajectory Terminology ................................................................................... 101

8.3.2 Trajectory Conventions .................................................................................... 101

8.3.3 Geometric Conventions ................................................................................... 102

8.3.4 PVT Interpolation ............................................................................................ 102

8.3.5 Influence of the Element Output Velocity to the Trajectory ............................ 103

8.3.6 Trajectory File Description .............................................................................. 104

8.3.7 Trajectory File Example .................................................................................. 105

8.3.8 PVT Trajectory Verification and Execution .................................................... 106

8.3.9 Examples of the Use of the functions .............................................................. 107

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) vi

Page 7

XPS-Q8 Universal High-Performance Motion Controller/Driver

9.0 Emergency Brake and Emergency Stop Cases ...................................... 108

10.0 Compensation.......................................................................................... 111

10.1 Backlash Compensation ..................................................................................................... 112

10.2 Linear Error Correction ..................................................................................................... 113

10.3 Positioner Mapping ............................................................................................................ 113

10.4 XY Mapping ...................................................................................................................... 116

10.5 XYZ Mapping .................................................................................................................... 118

10.6 “Yaw” Mapping (PP Firmware Version Only) .................................................................. 124

10.7 “Theta” Encoder and XY Correction ................................................................................. 127

11.0 Event Triggers......................................................................................... 128

11.1 Events ................................................................................................................................ 129

11.2 Actions ............................................................................................................................... 137

11.3 Functions ........................................................................................................................... 142

11.4 Examples ........................................................................................................................... 143

12.0 Data Gathering ....................................................................................... 147

12.1 Time-Based (Internal) Data Gathering .............................................................................. 148

12.2 Event-Based (Internal) Data Gathering .............................................................................. 150

12.3 Function-Based (Internal) Data Gathering ......................................................................... 153

12.4 Trigger-Based (External) Data Gathering .......................................................................... 153

13.0 Output Triggers ...................................................................................... 155

13.1 Triggers on Line-Arc Trajectories ..................................................................................... 155

13.2 Triggers on PVT Trajectories ............................................................................................ 157

13.3 Distance, Time Spaced Pulses or AquadB Position Compare ........................................... 158

13.3.1 Position compare settings and limits of use ................................................... 158

13.3.2 Even Distance Spaced Pulses Position Compare ........................................... 159

13.3.3 Compensated Position Compare .................................................................... 163

13.3.4 Time Spaced Pulses (Time Flasher) ............................................................... 166

13.3.5 AquadB Signals on PCO Connector .............................................................. 168

14.0 Control Loops ......................................................................................... 171

14.1 XPS Servo Loops ............................................................................................................... 171

14.1.1 Servo structure and Basics ............................................................................. 171

14.1.2 XPS PIDFF Architecture ............................................................................... 173

14.2 Filtering and Limitation ..................................................................................................... 177

14.3 Feed Forward Loops and Servo Tuning ............................................................................. 177

14.3.1 Corrector = PIDFFVelocity ........................................................................... 177

14.3.2 Corrector = PIDFFAcceleration ..................................................................... 179

14.3.3 Corrector = PIDDual FFVoltage .................................................................... 182

14.3.4 Corrector = PIPosition ................................................................................... 183

vii XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 8

XPS-Q8 Universal High-Performance Motion Controller/Driver

15.0 Analog Encoder Calibration .................................................................. 185

16.0 Excitation Signal ..................................................................................... 190

16.1 Introduction........................................................................................................................ 190

16.2 How to Use the Excitation-Signal Function ...................................................................... 190

16.3 Group State Diagram ......................................................................................................... 191

16.4 Function Description.......................................................................................................... 191

17.0 Pre-Corrector Excitation Signal ............................................................ 192

17.1 Description ......................................................................................................................... 192

17.2 Pre-corrector excitation signal wave forms ....................................................................... 192

17.3 Technical Implementation ................................................................................................. 194

17.3.1 Use case ......................................................................................................... 194

17.3.2 Implementation .............................................................................................. 195

17.3.3 Group capsule state diagram modification ..................................................... 196

18.0 Introduction to XPS Programming ....................................................... 197

18.1 TCL Generator ................................................................................................................... 198

18.2 LabVIEW ........................................................................................................................... 199

18.3 DLL Drivers....................................................................................................................... 200

18.4 Running Processes in Parallel ............................................................................................ 201

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) viii

Page 9

XPS-Q8 Universal High-Performance Motion Controller/Driver

ix XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Appendix

19.0 Appendix A: Hardware....................................................................... 204

19.1 Controller ........................................................................................................................... 204

19.2 Rear Panel Connectors ....................................................................................................... 205

19.3 Environmental Requirements............................................................................................. 205

20.0 Appendix B: General I/O Description .................................................. 206

20.1 Digital I/Os (All GPIO, Inhibit and Trigger In, and PCO Connectors) ............................... 206

20.1.1 Digital Inputs ................................................................................................. 206

20.1.2 Digital Outputs ............................................................................................... 207

20.2 Digital Encoder Inputs (Driver Boards & DRV00) ........................................................... 207

20.3 Digital Servitudes (Driver Boards, DRV00 & Analog Encoders Connectors) .................. 207

20.4 Analog Encoder Inputs (Analog Encoder Connectors) ...................................................... 207

20.5 Analog I/O (GPIO2 Connector) ......................................................................................... 208

20.5.1 Analog Inputs ................................................................................................. 208

20.5.2 Analog Outputs .............................................................................................. 208

21.0 Appendix C: Power Inhibit Connector ................................................. 209

22.0 Appendix D: GPIO Connectors ............................................................ 210

22.1 GPIO1 Connector .............................................................................................................. 2 1 0

22.2 GPIO2 Connector .............................................................................................................. 2 1 0

22.3 GPIO3 Connector .............................................................................................................. 2 1 1

22.4 GPIO4 Connector .............................................................................................................. 2 1 1

23.0 Appendix E: PCO Connector ................................................................ 212

24.0 Appendix F: Motor Driver Cards ......................................................... 213

24.1 DC and Stepper Motor Driver XPS-DRV01 ...................................................................... 213

24.2 Three phase AC brushless driver XPS-DRV02 ................................................................. 214

24.3 DC Motor Driver XPS-DRV03 ......................................................................................... 215

24.4 Pass-Through Board Connector (25-Pin D-Sub) XPS-DRV00 ......................................... 215

25.0 Appendix G: Analog Encoder Connector ............................................ 216

26.0 Appendix H: Trigger IN Connector ..................................................... 217

Service Form ...................................................................................................... 219

Page 10

XPS-Q8 Universal High-Performance Motion Controller/Driver

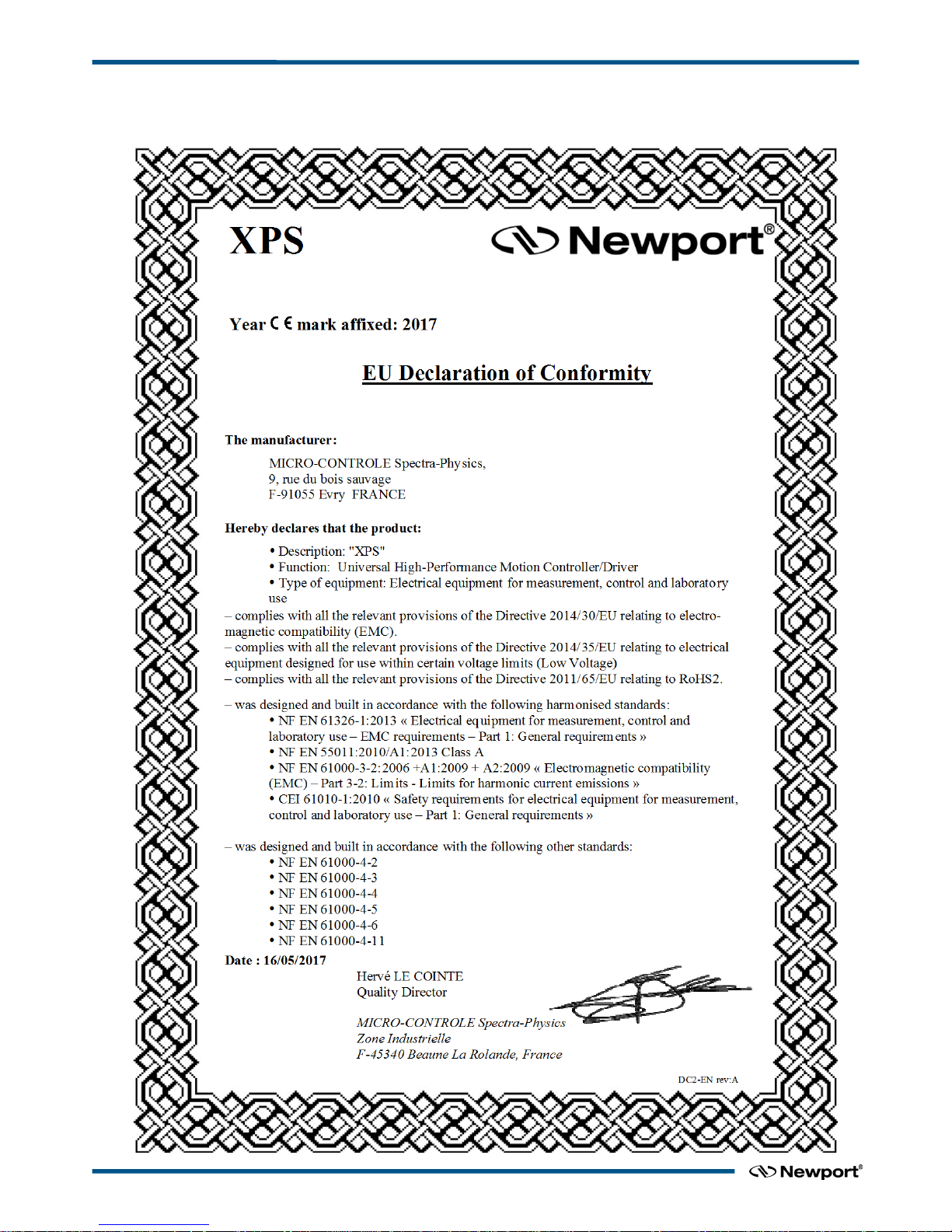

EU Declaration of Conformity

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) x

Page 11

XPS-Q8 Universal High-Performance Motion Controller/Driver

Preface

Confidentiality & Proprietary Rights

Reservation of Title

The Newport Programs and all materials furnished or produced in connection with them

(“Related Materials”) contain trade secrets of Newport and are for use only in the

manner expressly permitted. Newport claims and reserves all rights and benefits

afforded under law in the Programs provided by Newport Corporation.

Newport shall retain full ownership of Intellectual Property Rights in and to all

development, process, align or assembly technologies developed and other derivative

work that may be developed by Newport. Customer shall not challenge, or cause any

third party to challenge, the rights of Newport.

Preservation of Secrecy and Confidentiality and Restrictions to Access

Customer shall protect the Newport Programs and Related Materials as trade secrets of

Newport, and shall devote its best efforts to ensure that all its personnel protect the

Newport Programs as trade secrets of Newport Corporation. Customer shall not at any

time disclose Newport's trade secrets to any other person, firm, organization, or

employee that does not need (consistent with Customer's right of use hereunder) to

obtain access to the Newport Programs and Related Materials. These restrictions shall

not apply to information (1) generally known to the public or obtainable from public

sources; (2) readily apparent from the keyboard operations, visual display, or output

reports of the Programs; (3) previously in the possession of Customer or subsequently

developed or acquired without reliance on the Newport Programs; or (4) approved by

Newport for release without restriction.

Sales, Tech Support & Service

North America & Asia

Newport Corporation

1791 Deere Ave.

Irvine, CA 92606, USA

Sales

Tel.: (877) 835-9620

e-mail: sales@newport.com

Technical Support

Tel.: (800) 222-6440

e-mail: tech@newport.com

Service, RMAs & Returns

Tel.: (800) 222-6440

e-mail: service@newport.com

Europe

MICRO-CONTROLE Spectra-Physics S.A.S

9, rue du Bois Sauvage

91055 Évry CEDEX

France

Sales France

Tel.: +33 (0)1.60.91.68.68

e-mail: france@newport.com

Sales Germany

Tel.: +49 (0) 61 51 / 708 – 0

e-mail: germany@newport.com

Sales UK

Tel.: +44 (0)1635.521757

e-mail: uk@newport.com

Technical Support

e-mail: tech_europe@newport.com

Service & Returns

Tel.: +33 (0)2.38.40.51.55

xi XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 12

XPS-Q8 Universal High-Performance Motion Controller/Driver

Service Information

The user should not attempt any maintenance or service of the XPS Series

Controller/Driver system beyond the procedures outlined in this manual. Any problem

that cannot be resolved should be referred to Newport Corporation. When calling

Newport regarding a problem, please provide the Tech Support representative with the

following information:

• Your contact information.

• System serial number or original order number.

• Description of problem.

• Environment in which the system is used.

• State of the system before the problem.

• Frequency and repeatability of problem.

• Can the product continue to operate with this problem?

• Can you identify anything that may have caused the problem?

Newport Corporation RMA Procedures

Any XPS Series Controller/Driver being returned to Newport must be assigned an RMA

number by Newport. Assignment of the RMA requires the item’s serial number.

Packaging

XPS Series Controller/Driver being returned under an RMA must be securely packaged

for shipment. If possible, re-use the original packaging.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) xii

Page 13

XPS-Q8 Controller User’s Manual

1.0 Introduction

1.1 Scope of the Manual

The XPS is an extremely high-performance, easy to use, integrated motion

controller/driver offering high-speed communication through 10/100 Base-T Ethernet,

outstanding trajectory accuracy and powerful programming functionality. It combines

user-friendly web interfaces with advanced trajectory and synchronization features to

precisely control from the most basic to the most complex motion sequences. Multiple

digital and analog I/O's, triggers and supplemental encoder inputs provide users with

additional data acquisition, synchronization and control features that can improve the

most demanding motion applications.

To maximize the value of the XPS Controller/Driver system, it is important that users

become thoroughly familiar with available documentation:

The XPS Quick Start and XPS User’s Manual are delivered as paper copies with the

controller.

The Programmer’s, TCL, Software Drivers and Stage Configuration manuals are PDF

files accessible from the XPS web site.

DLLs and corresponding sources are available from the controller disk in the folder

Public/Drivers/DLL. DLLs can also be downloaded through the FTP.

LabVIEW VIs with examples are also available from the controller disk in the folder

Public/Drivers/LabView. They can also be downloaded through FTP.

To connect through FTP, please see chapter 5: “FTP connection”.

The first part of this manual serves as an introduction and also as a reference. It

includes:

1. Introduction

2. System Overview

3. Getting Started Guide

User’s Manual

1 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 14

XPS-Q8 Controller User’s Manual

The second part provides a detailed description of all software tools of the XPS

controller. It also includes an introduction to FTP connections and some general

guidelines for troubleshooting, maintenance and service:

4. Software Tools

5. FTP connection

6. Maintenance and Service

The third part provides an exhaustive description of the XPS architecture, its features

and capabilities. Complementing the programmer’s guide, this part

is educational and is

organized by features starting with the basics and getting to the more advanced features.

It provides a complete list of descriptions of different features including:

7. XPS Architecture

8. Motion

9. Trajectories

10. Compensation

11. Event Triggers

12. Data Gathering

13. Triggers

14. Control Loops

15. Analog Encoder Calibration

16. Introduction to XPS programming

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 2

Page 15

XPS-Q8 Controller User’s Manual

1.2 Definitions and Symbols

The following terms and symbols are used in this documentation and also appear on the

XPS Series Controller/Driver where safety-related issues occur.

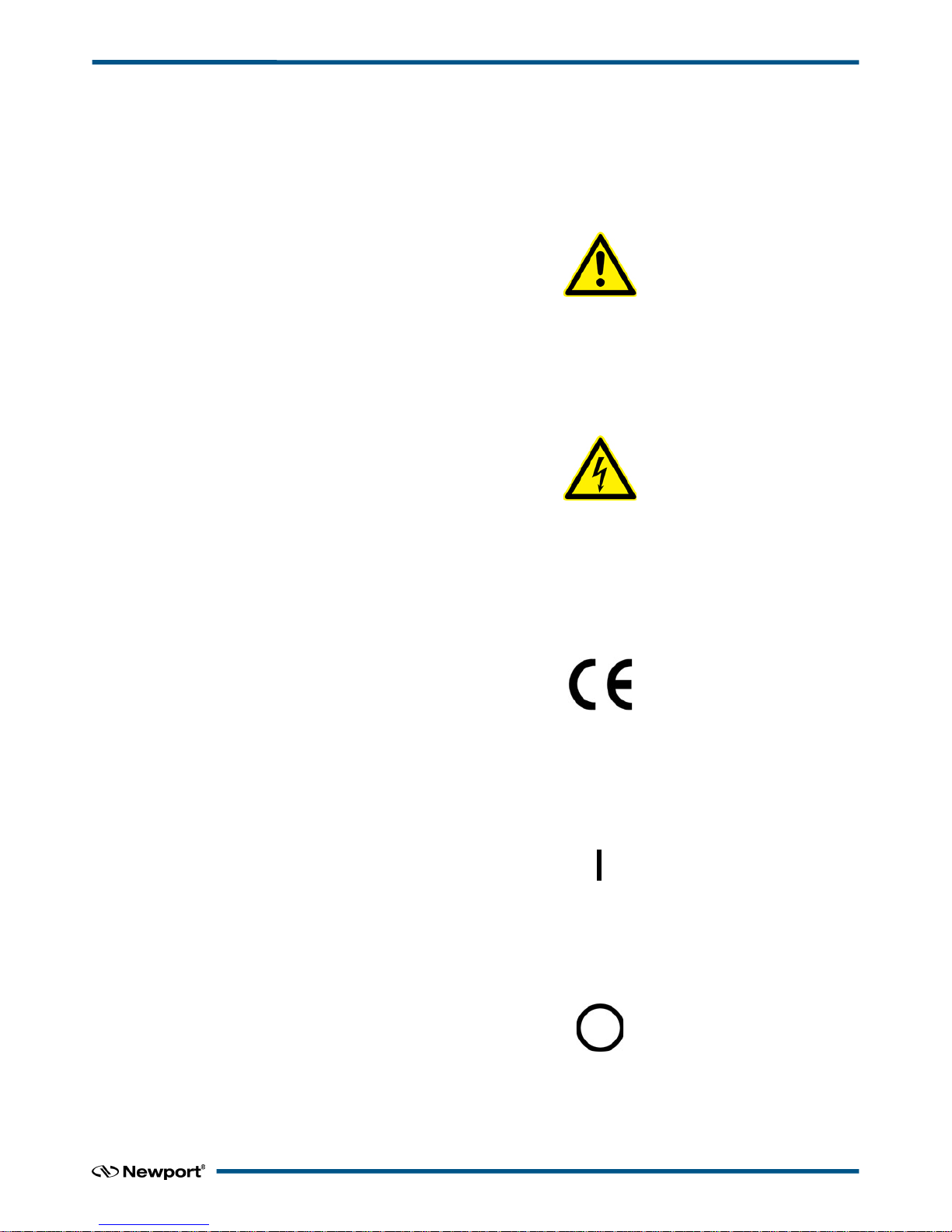

1.2.1 General Warning or Caution

Figure 1: General Warning or Caution Symbol.

The Exclamation Symbol in Figure 1 may appear in Warning and Caution tables in this

document. This symbol designates an area where personal injury or damage to the

equipment is possible.

1.2.2 Electric Shock

Figure 2: Electrical Shock Symbol.

The Electrical Shock Symbol in Figure 2 may appear on labels affixed to the XPS

Series Controller/Driver. This symbol indicates a hazard arising from dangerous

voltages. Any mishandling could result in damage to the equipment, personal injury, or

even death.

1.2.3 European Union CE Mark

Figure 3: CE Mark.

The presence of the CE Mark on Newport Corporation equipment means that it has

been designed, tested and certified to comply with all current and applicable European

Union (CE) regulations and recommendations.

1.2.4 “ON” Symbol

Figure 4: “ON” Symbol.

The “ON” Symbol in Figure 4 appears on the power switch of the XPS Series

Controller/Driver. This symbol represents the “Power On” condition.

1.2.5 “OFF” Symbol

Figure 5: “OFF” Symbol.

The “Off” Symbol in Figure 5 appears on the power switch of the XPS Series

Controller/Driver. This symbol represents the “Power Off” condition.

3 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 16

XPS-Q8 Controller User’s Manual

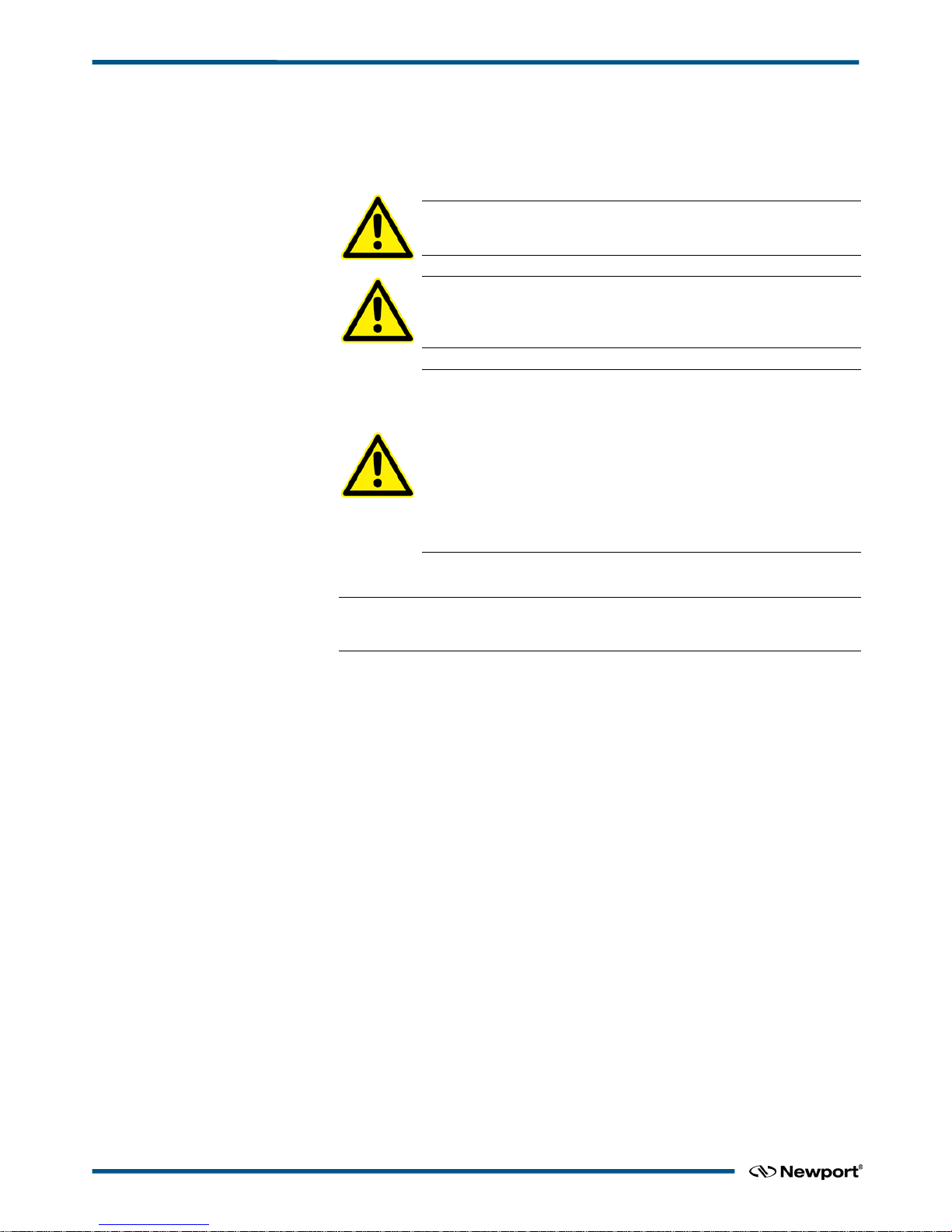

1.3 Warnings and Cautions

The following are definitions of the Warnings, Cautions and Notes that may be used in

this manual to call attention to important information regarding personal safety, safety

and preservation of the equipment, or important tips.

WARNING

Situation has the potential to cause bodily harm or death.

CAUTION

Situation has the potential to cause damage to property or

equipment.

WARNING

This product is equipped with a 3-wire grounding type plug. Any

interruption of the grounding connection can create an electric shock

hazard. If you are unable to insert the plug into your wall plug

receptacle, contact an electrician to perform the necessary alterations

to ensure that the green (green-yellow) wire is attached to earth

ground.

System earthing must be of type earthed neutral (TN-) as defined by

CEI60364.

NOTE

Additional information the user or operator should consider.

1.4 General Warnings and Cautions

The following general safety precautions must be observed during all phases of

operation of this equipment.

Failure to comply with these precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture, and the intended use of the

equipment.

• Heed all warnings on the unit and in the operating instructions.

• To prevent damage to the equipment, read the instructions in this manual for the

selection of the proper input voltage.

• Only plug the Controller/Driver unit into a grounded power outlet.

• Ensure that the equipment is properly grounded to earth ground through the

grounding lead of the AC power connector.

• Route power cords and cables where they are not likely to be damaged.

• Use Proper Power Cord

Use only the power cord specified for this product and certified for the country of

use.

• The system must be installed in such a way that the power switch and the power

connector remain accessible to the user.

• Disconnect or do not plug-in the AC power cord under the following conditions:

– If the AC power cord or any other attached cables are frayed or damaged.

– If the power plug or receptacle is damaged.

– If the unit is exposed to rain or excessive moisture, or liquids are spilled on it.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 4

Page 17

XPS-Q8 Controller User’s Manual

– If the unit has been dropped or the case is damaged.

– If the user suspects service or repair is required.

• Keep air vents free of dirt and dust and obstructions.

• Keep liquids away from unit.

• Do not expose equipment to excessive moisture (>85% humidity).

• Do not operate this equipment in an explosive atmosphere.

• Disconnect power before cleaning the Controller/Driver unit. Do not use liquid or

aerosol cleaners.

• Do not open the XPS Controller/Driver stand alone motion controller. There are no

user-serviceable parts inside the XPS Controller/Driver.

• Return equipment to Newport Corporation for service and repair.

• Dangerous voltages associated with the 100–240 VAC power supply are present

inside Controller/Driver unit. To avoid injury, do not touch exposed connections or

components while power is on.

• Follow precautions for static-sensitive devices when handling electronic circuits.

5 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 18

XPS-Q8 Controller User’s Manual

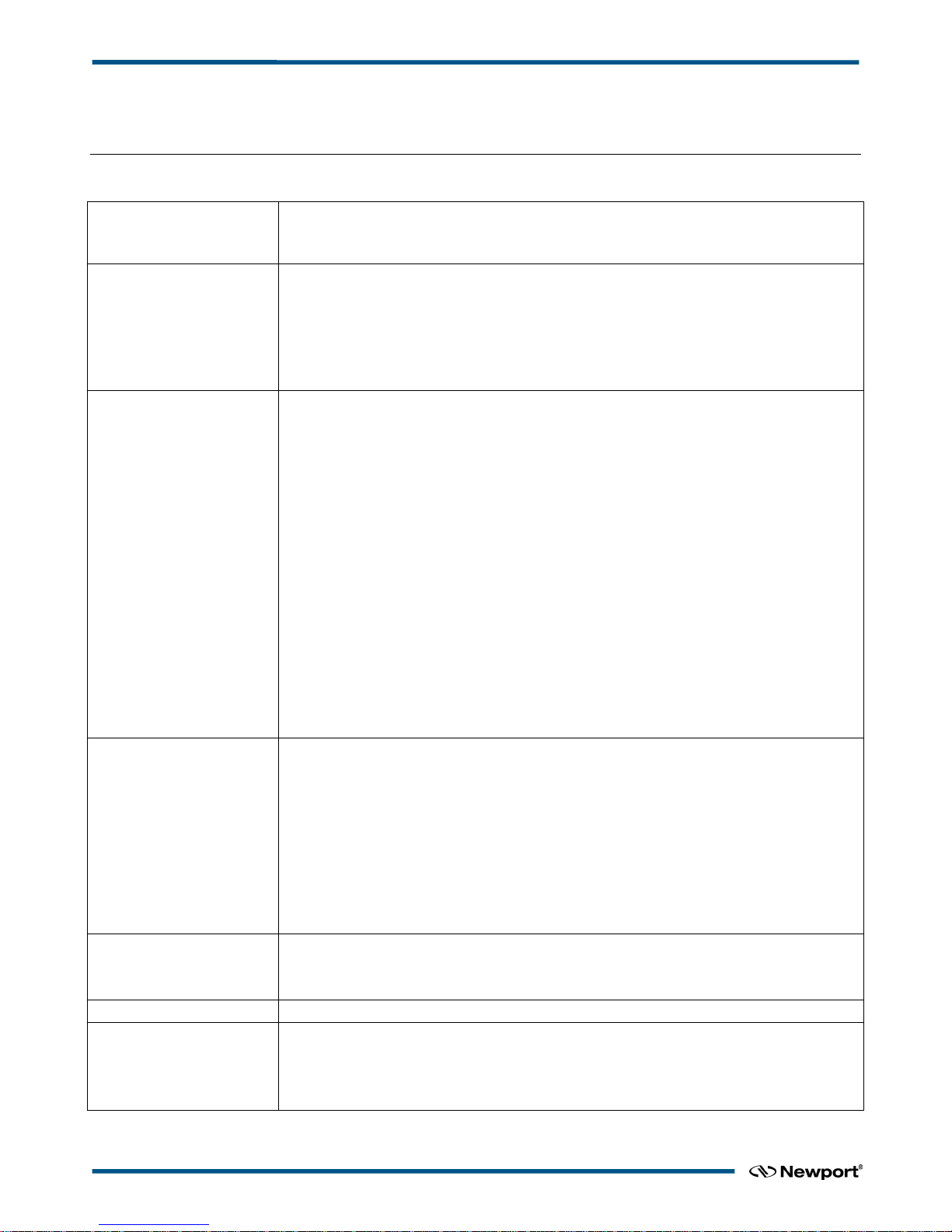

2.0 System Overview

2.1 Specifications

Number of Axes • 1 to 8 axes of stepper, DC brush, DC brushless motors or piezo-electric stacks using internal

drives

•

Other motion devices using external third-party drives

Communication Interfaces • Internet protocol TCP/IP

• One Ethernet 10/100 Base-T (RJ45 connector) with fixed IP address for local communication

• One Ethernet 10/100 Base-T (RJ45 connector) for networking, dynamic addressing with

DHCP and DNS

• Typically 0.3 ms from sending a tell position command to receiving the answer

• Optional XPS-RC remote control

Firmware Features

• Powerful and intuitive, object oriented command language

• Native user defined units (no need to program in encoder counts)

• Real time execution of custom tasks using TCL scripts

• Multi-user capability

• Concept of sockets for parallel processes

• Distance spaced trigger output pulses, max. 2.5 MHz rate, programmable filter

• Time spaced trigger output pulses, 0.02 Hz to 2.5 MHz rate, 50 ns accuracy

• Trigger output on trajectories with 100 µs resolution

• Data gathering at up to 8 kHz rate, up to 1,000,000 data entries

• User-defined “actions at events” monitored by the controller autonomously at a rate of 8 kHz

• User-definable system referencing with hardware position latch of reference signal transition

and “set current position to value” capability

• Axis position or speed controlled by analog input

• Axis position, speed or acceleration copied to analog output

• Trajectory precheck function replying with travel requirement and max. possible speed

• Auto-tuning and auto-scaling

Motion • Jogging mode including on-the fly changes of speed and acceleration

• Synchronized point-to-point

• Spindle motion (continuous motion with periodic position reset)

• Gantry mode including XY gantries with variable load ratio

• Line-arc mode (linear and circular interpolation incl. continuous path contouring)

• Splines (Catmull-Rom type)

• PVT (complex trajectory based on position, velocity and time coordinates)

• Analog tracking (using analog input as position or velocity command)

• Master-slave including single master-multiple slaves and custom gear ratio

Compensation • Linear error, Backlash, positioner error mapping

• XY and XYZ error mapping

• All corrections are taken into account on the servo loop

Servo Rate

• 8 kHz

Control Loop • Open loop, PI position, PIDFF velocity, PIDFF acceleration, PIDDualFF voltage

• Variable PID’s (PID values depending on distance to target position)

• Deadband threshold; Integration limit and integration time

• Derivative cut-off filter; 2 user-defined notch filters

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 6

Page 19

XPS-Q8 Controller User’s Manual

I/O • 30 TTL inputs and 30 TTL outputs (open-collector)

• 4 synch. analog inputs ±10 V, 14 Bit

• 4 synch. uncommitted analog outputs, 16 Bit

• Watchdog timer and remote interlock

Trigger In • Hardware latch of all positions and all analog I/O’s; 8 kHz max. frequency

• <50 ns latency on positions

• <100 µs time jitter on analog I/O’s

Trigger Out • One high-speed position compare output per axes that can be either configured for position

synchronized pulses or for time synchronized pulses : <50 ns accuracy/latency, 2.5 MHz max.

rate

Dedicated Inputs Per Axis • RS-422 differential inputs for A, B and I, Max. 25 MHz, over-velocity and quadrature error

detection

• 1 Vpp analog encoder input up to x32768 interpolation used for servo; amplitude, phase and

offset correction; additional 2nd hardware interpolator used for synchronization; up to x200

interpolation

• Forward and reverse limit, home, error input

Dedicated Outputs Per Axis

(when using external drives)

2 channel 16-bit, ±10 V D/A

Drive enable, error output

Drive Capability

• Analog voltage, analog velocity, and analog acceleration (used with XPS-DRV01 and

XPS-DRV03 for DC brush motor control).

• Analog position (used with XPS-DRV01 for stepper motor control or with the XPS-DRVP1

for piezo control)

• Analog position (used with external drives for example 3rd party motors)

• Analog acceleration, sine acceleration and dual sine acceleration (used with XPS-DRV02 for

brushless motors control)

• Step and direction and +/- pulse mode for stepper motors (requires XPS-DRV00P and external

stepper motor driver)

• 500 W @ 230 VAC and 425 W @ 115 VAC total available power

AC Power Requirements • 100–240 VAC 60/50 Hz 10 A–5.5 A The controller should be connected to a power

installation that incorporates appropriate protection devices. Refer to the installation

requirements of your facility and local applicable Standards concerning the use of RCDs

(residual current device).

Dimensions (W x D x H)

•

19” – 4U, L: 508 mm

Weight

• 15 kg max

2.2 Drive Options

The XPS controller is capable of driving up to 8 axes of most Newport positioners using

driver cards that slide through the back of the chassis. These factory-tested drives are

powered by an internal 500 W power supply, which is independent of the controller

power supply. When used with Newport ESP stages, the configuration of the driver

cards is easy using the auto-configuration utility software. Advanced users can also

manually develop their own configuration files optimized for specific applications.

The XPS-DRV01 is a software configurable PWM amplifier that is compatible with

most of Newport’s and other companies’ DC brush and stepper motor positioners.

The XPS-DRV01 motor driver supplies a maximum current of 3 Amps and 48 Volts. It

has the capability to drive bipolar stepper motors in microstep mode (sine/cosine

commutation) and DC brush motors in velocity mode, for motors with tachometer, or

voltage mode, for motors without tachometer. Programmable gains and a programmable

PWM switching frequency up to 300 kHz allow a very fine adjustment of the driver to

the motor. For added safety, a programmable over-current protection setting is also

available.

7 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 20

XPS-Q8 Controller User’s Manual

The XPS-DRV02 is a software configurable PWM amplifier for 3-phase brushless

motors. It has been optimized for performance with XM, ILS-LM, IMS-LM linear

motor stages and RGV direct drive rotation stages. The XPS-DRV02 supplies a 100

kHz PWM output with a maximum output current of 5 A per phase and 44 Vpp. The

XPS-DRV02 requires 1 Vpp analog encoder input signals used also for motor

commutation. Motor initialization is done by a special routine measures the magnetic

position without the need for Hall or other sensors.

The XPS-DRV03 is a fully digital, programmable PWM-amplifier that has been

optimized for use with high-performance DC motors. The high switching frequency of

100 kHz and appropriate filter technologies minimize noise to enable ultra-precision

positioning in the nm-range. The XPS-DRV03 supplies a maximum current of 5 Amps

and 48 Volts. It is capable of driving DC motors in velocity mode (for motors with

tachometer), in voltage mode (for motors without tachometer), and in current mode (for

torque motors). All parameters are programmable in physical units (for instance the

bandwidth of the velocity loop). Furthermore, the XPS-DRV03 features individual

limits for the rms current and the peak current.

The XPS-DRVP1 is a programmable driver card for Newport's NanoPositioning line of

piezoelectric stack stages. This driver card has a range of -10 to 150 VDC with 30 mA

continuous. The drive features a 4 kHz update rate and resolution of 16 bits ADC and

DAC. It also accepts strain gage position feedback.

The XPS-DRV00 and XPS-DRV00P pass-through module can be used to pass control

signals to other external third-party amplifiers (drivers). By setting the controller’s dual

DAC output to either analog position, analog stepper position, analog velocity, analog

voltage or analog acceleration (including sine commutation), the XPS is capable of

controlling almost any motion device including 3

rd

party brushless motors and voice

coils.

In addition to conventional digital AquadB feedback encoder interface, the XPS

controller also features a high-performance analog encoder input (1 Vpp Heidenhain

standard) on each axis. An ultra-high resolution, very low noise, encoder signal

interpolator converts the sine-wave input to an exact position value with a signal

subdivision up to 32,768-fold. For example, when used with a scale with 4 µm signal

period the resolution can be as fine as 0.122 nm. This interpolator can be used for

accurate position feedback on the servo corrector of the system. An additional hardware

interpolator with 40 MHz clock frequency and programmable signal subdivision up to

200-fold is used for synchronization purposes. This fast interpolator latches the position

directly with less than 50 ns latency and provides a much higher level of precision for

synchronization than alternative time based systems. Unlike most high-resolution

multiplication devices, the XPS interpolators do not compromise positioning speed.

With a maximum input frequency ranging from 180 kHz to 400 kHz (depending on the

interpolation factor), the maximum speed of a stage with a 20 µm signal period scale

can be up to 3.6 m/s.

2.3 Compatible Newport Positioners and Drive Power Consumption

The list of all compatible Newport positioners and the corresponding drive module

needed is available from the Newport catalog or at www.newport.com

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 8

Page 21

XPS-Q8 Controller User’s Manual

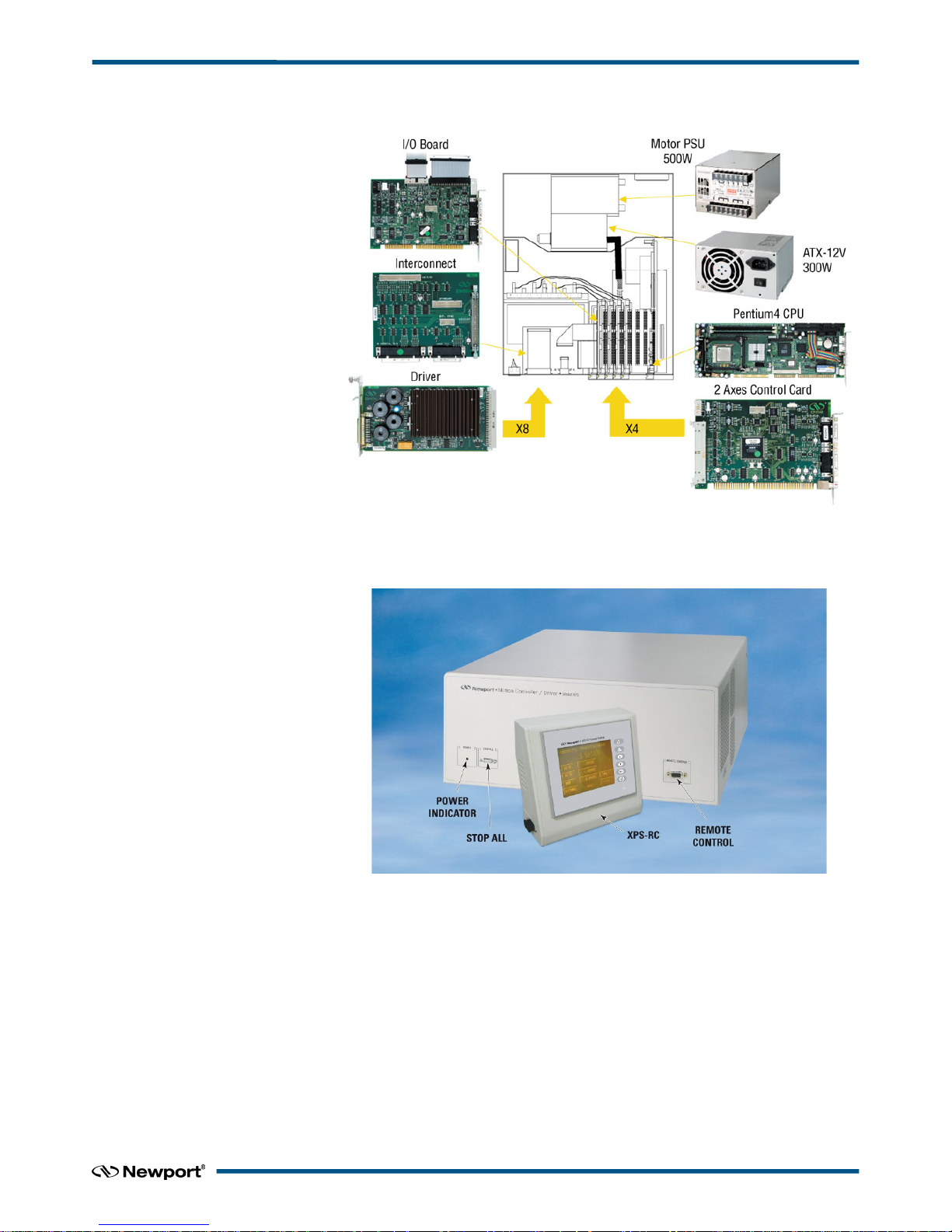

2.4 XPS Hardware Overview

Figure 6: XPS Hardware Overview.

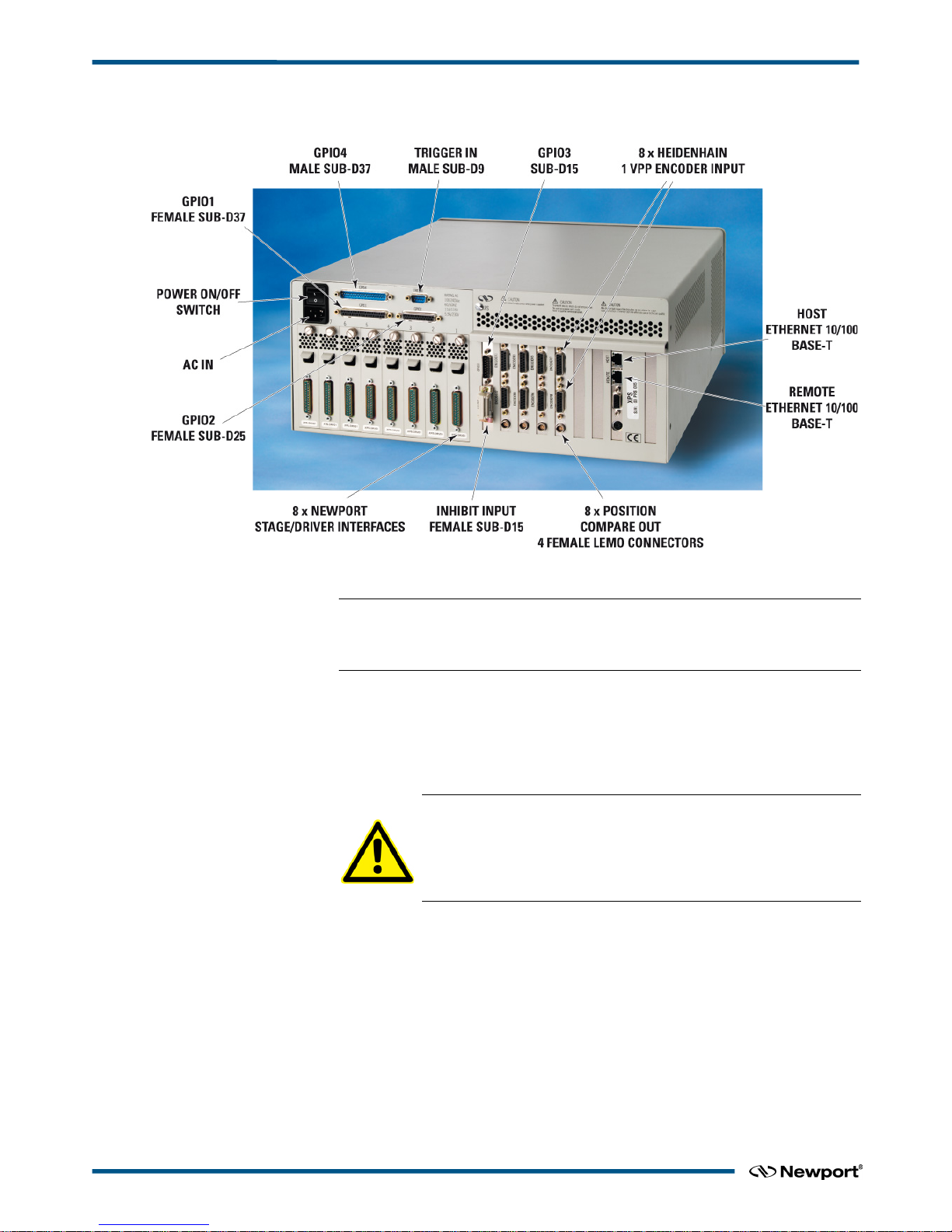

2.5 Front Panel Description

Figure 7: Front Panel of XPS Controller/Driver.

The XPS-RC Remote Control plugs into the front panel of the XPS controller to enable

computer-independent motion and basic system diagnostics. For more information, refer

to the XPS data sheet and the XPS-RC manual.

9 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 22

XPS-Q8 Controller User’s Manual

2.6 Rear Panel Description

Figure 8: Rear Panel of XPS Controller/Driver.

NOTE

The Main Power ON/OFF Switch is located above the inlet for the power cord. The

switch and the inlet must be accessible to the user.

2.6.1 Axis Connectors (AXIS 1 – AXIS 8)

Each installed axis driver card features a connector to attach a cable (supplied with

every Newport stage) between the controller and a motion device.

CAUTION

Carefully read the labels on the driver cards and make sure the

specifications (motor type, voltage, current, etc.) match those of the

motion devices you intend to connect. Severe damage could occur if a

stage is connected to the wrong driver card.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 10

Page 23

XPS-Q8 Controller User’s Manual

Figure 9: Axis Driver Card.

Please see the next section for installation instructions.

NOTE

Power Input: 100–240 V, 50–60 Hz, 11 A–5.5 A.

2.7 Ethernet Configuration

Figure 10: Ethernet Configuration.

2.7.1 Communication Protocols

The Ethernet connection provides a local area network through which information is

transferred in units known as packets. Communication protocols are necessary to dictate

how these packets are sent and received. The XPS Controller/Driver supports the

industry standard protocol TCP/IP.

TCP/IP is a “connection” protocol and in this protocol, the master must be connected to

the slave in order to begin communication. Each packet sent is acknowledged when

received. If no acknowledgment is received, the information is assumed lost and is

resent.

11 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 24

XPS-Q8 Controller User’s Manual

2.7.2 Addressing

There are two levels of addresses that define Ethernet devices. The first is the MAC

address. This is a unique and permanent 6 byte number. No other device will have the

same MAC address. The second level of addressing is the IP address. This is a 32-bit

(or 4 byte) number. The IP address is constrained by each local network and must be

assigned locally. Assigning an IP address to the controller can be done in a number of

ways (see section 3.5: “Connecting to the XPS“).

2.8 Sockets, Multitasking and Multi-user Applications

Based on the TCP/IP Internet communication protocol, the XPS controller has a high

number of virtual communication ports, known as sockets. To establish communication,

the user must first request a socket ID from the XPS controller server (listening at a

defined IP number and port number). When sending a function to a socket, the

controller will always reply with a completion or error message to the socket that has

requested the action.

The concept and application of sockets has many advantages. First, users can split their

application into different segments that run independently on different threads or even

on different computers. To illustrate this, see below:

In this example, a thread on socket 1 commands an XY stage to move to certain

positions to take pictures while another thread on socket 2 independent of socket 1,

concurrently manages an auto-focusing system. The second task could even be run on a

different PC than the first task yet be simultaneously executed within the XPS.

Alternatively, if the auto-focusing system is providing an analog feedback, this task

could have been also implemented as a TCL script within the XPS (see the next topic).

Second, the concept of sockets has another practical advantage for many laboratory

users since the use of threads allows them to share the same controller for different

applications at the same time. With the XPS, it is possible that one group uses one axis

of the XPS controller for an optical delay line, while another group simultaneously uses

other axes for a totally different application. Both applications could run completely

independent from different workstations without any delays or cross-talk.

The XPS controller uses TCP/IP blocking sockets, which means that the commands to

the same socket are “blocked” until the XPS returns feedback about the completion of

the currently executed command (either '0' if the command has been completed

successfully, or an error code in case of an error). If customers want to run several

processes in parallel, users should open as many 84 parallel sockets. Please refer to

section 18.4: “Running Processes in Parallel“ for further information about sockets and

parallel processing.

2.9 Programming with TCL

TCL documentation is in a PDF file accessible from the XPS controller web site.

TCL stands for Tool Command Language and is an open-source string based command

language. With only a few fundamental constructs and relatively little syntax, it is very

easy to learn, yet it can be as powerful and functional as traditional C language. TCL

includes many different math expressions, control structures (if, for, foreach, switch,

etc.), events, lists, arrays, time and date manipulation, subroutines, string manipulation,

file management and much more. TCL is used worldwide with a user base approaching

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 12

Page 25

XPS-Q8 Controller User’s Manual

one million users. It is quickly becoming a standard and critical component in thousands

of corporations. Consequently TCL is field proven, very well documented and has many

tutorials, applications, tools and books publicly available (www.tcl.tk).

XPS users can use TCL to write complete application code and the XPS allows them to

include any function in a TCL script. When developed, the TCL script can be executed

in real time in the background of the motion controller processor and does not impact

any processing requirements for servo updates or communication. The QNX hardware

real time multiprocessing operating system used on the XPS controller assures precise

management of the multiple processes with the highest reliability. Multiple TCL

programs run in a time-sharing mode with the same priority and will get interrupted

only by the servo, or communication tasks or when the maximum available time of 20

ms for each TCL program is over.

The advantage of executing application code within the controller over host run code is

faster execution and better synchronization, in many cases without any time taken from

the communication link. The complete communication link can be reserved for time

critical process interaction from or to the process or host controller.

NOTE

It is important to note that the XPS gives communication requests priority over

TCL script execution. When using TCL scripts for machine security or other time

critical tasks, it is therefore important to limit the frequency of continuous

communication requests from a host computer, which includes the XPS website,

and to verify the execution speed of repetitive TCL scripts.

13 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 26

XPS-Q8 Controller User’s Manual

3.0 Getting Started

3.1 Unpacking and Handling

It is recommended that the XPS Controller/Driver be unpacked in your lab or work site

rather than at the receiving dock. Unpack the system carefully; small parts and cables

are included with the equipment. Inspect the box carefully for loose parts before

disposing of the packaging. You are urged to save the packaging material in case you

need to ship your equipment.

3.2 Inspection for Damage

XPS Controller/Driver has been carefully packaged at the factory to minimize the

possibility of damage during shipping. Inspect the box for external signs of damage or

mishandling. Inspect the contents for damage. If there is visible damage to the

equipment upon receipt, inform the shipping company and Newport Corporation

immediately.

WARNING

Do not attempt to operate this equipment if there is evidence of

shipping damage or you suspect the unit is damaged. Damaged

equipment may present additional personnel hazard. Contact

Newport technical support for advice before attempting to plug in

and operate damaged equipment.

3.3 Packing List

Included with each XPS controller are the following items:

• User’s Manual and Motion Tutorial.

• XPS controller.

• Cross-over cable, gray, 3 meters.

• Straight-through cable, black, 5 meters.

• Power cord.

• Rack mount ears and handles.

If there are missing hardware or have questions about the hardware that were received,

please contact Newport.

CAUTION

Before operating the XPS controller, please read chapter 1.0 very

carefully.

3.4 System Setup

This section guides the user through the proper set-up of the motion control system. If

not already done, carefully unpack and visually inspect the controller and stages for any

damage. Place all components on a flat and clean surface.

CAUTION

No cables should be connected to the controller at this point!

First, the controller must be configured properly before stages can be connected.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 14

Page 27

XPS-Q8 Controller User’s Manual

3.4.1 Installing Driver cards

Figure 11: Installing Driver cards.

Due to the high power of the XPS controller (300 W for the CPU and 500 W for the

drives), ventilation is very important.

To ensure a good level of heat dissipation, the following rules must be followed:

1. It is strictly forbidden to use the XPS controller without the cover properly mounted

on the chassis.

2. Driver boards must be inserted from right (driver 1) to left (driver 8) when looking

at the rear of the controller.

3. If less than eight are used, the remaining slots must be disabled with the appropriate

slot covers that were delivered with the controller.

4. The surrounding ventilation holes at the sides and back of the XPS rack must be free

from obstructions that prevent the free flow of air.

3.4.2 Power ON

• Plug the AC line cord supplied with the XPS into the AC power receptacle on the

rear panel.

• Plug the AC line cord into the AC wall-outlet. Turn the Main Power Switch to ON

(located on the Rear Panel).

• The system must be installed in such a way that power switch and power connector

are accessible by the user.

• After the main power is switched on, the LED on the front panel of the XPS will

turn green.

• There is an initial beep after power on and a second beep when the controller has

finished booting. If the controller boots properly, the second beep is happysounding, otherwise the sad-sounding beep is emitted. The time between the first

and the second beeps can be 12–18 seconds.

• There is also a STOP ALL button on the front panel that is used to stop any motion

in progress and then activate the inhibit input of all motor drivers. This is a software

function triggered by the inhibit input located on the rear panel or the STOP ALL

front panel button.

15 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 28

XPS-Q8 Controller User’s Manual

3.5 Connecting to the XPS

The Newport’s XPS Controller/Driver is a multi-axis motion controller system that is

based on a high performance 10/100 Base-T Ethernet connection using a CAT5 cable.

The controller can be connected in 2 different ways:

1. Direct connection-PC to XPS through a cross over cable (gray cable supplied).

2. Corporate Network connection – requires input from a Network Administrator

(black).

Two cables are provided with the motion controller:

• Cross-over cable – used when connecting the XPS directly to a PC.

• Straight Ethernet cable – used when connecting the XPS through an intranet.

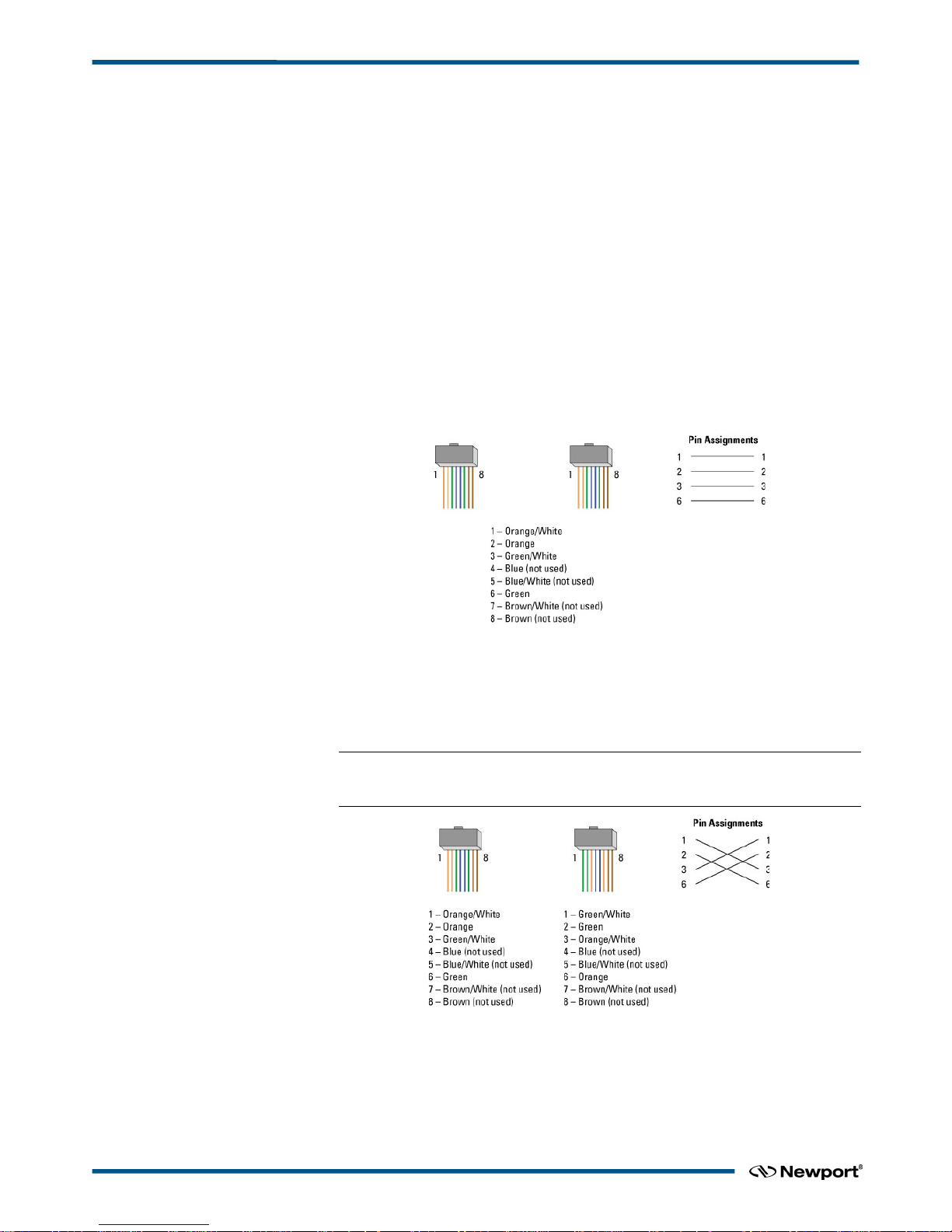

3.5.1 Straight through cables (black)

Standard Ethernet straight through cables are required when connecting the device to a

standard network hub or switch.

Figure 12: Straight through cables.

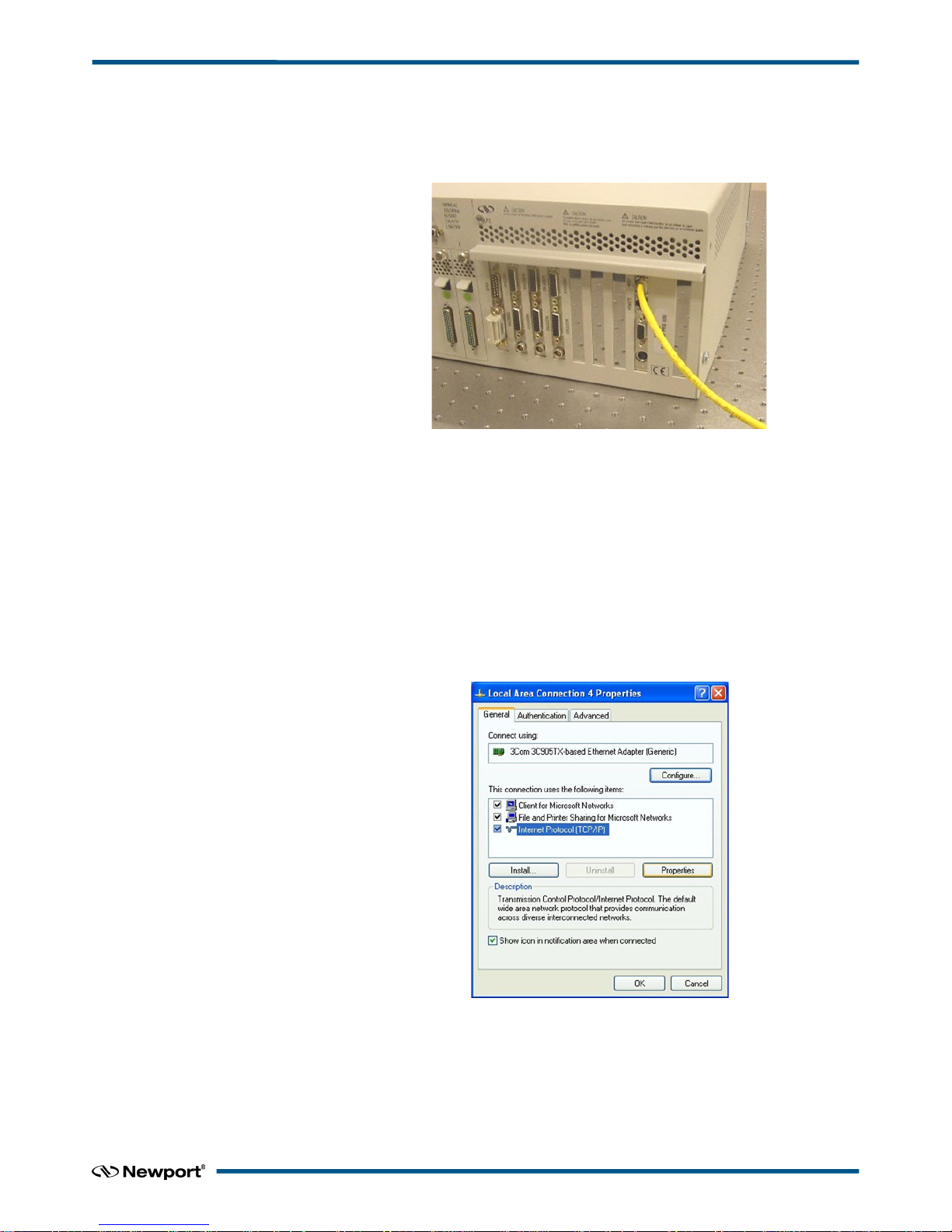

3.5.2 Cross-over cables (gray)

Standard Ethernet cross over cables are required when connecting the device directly to

the Ethernet port of a PC.

NOTE

Cross over cables are typically labeled (cross over or XO) at one or both ends.

Figure 13: Ethernet Cross Over Cables.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 16

Page 29

XPS-Q8 Controller User’s Manual

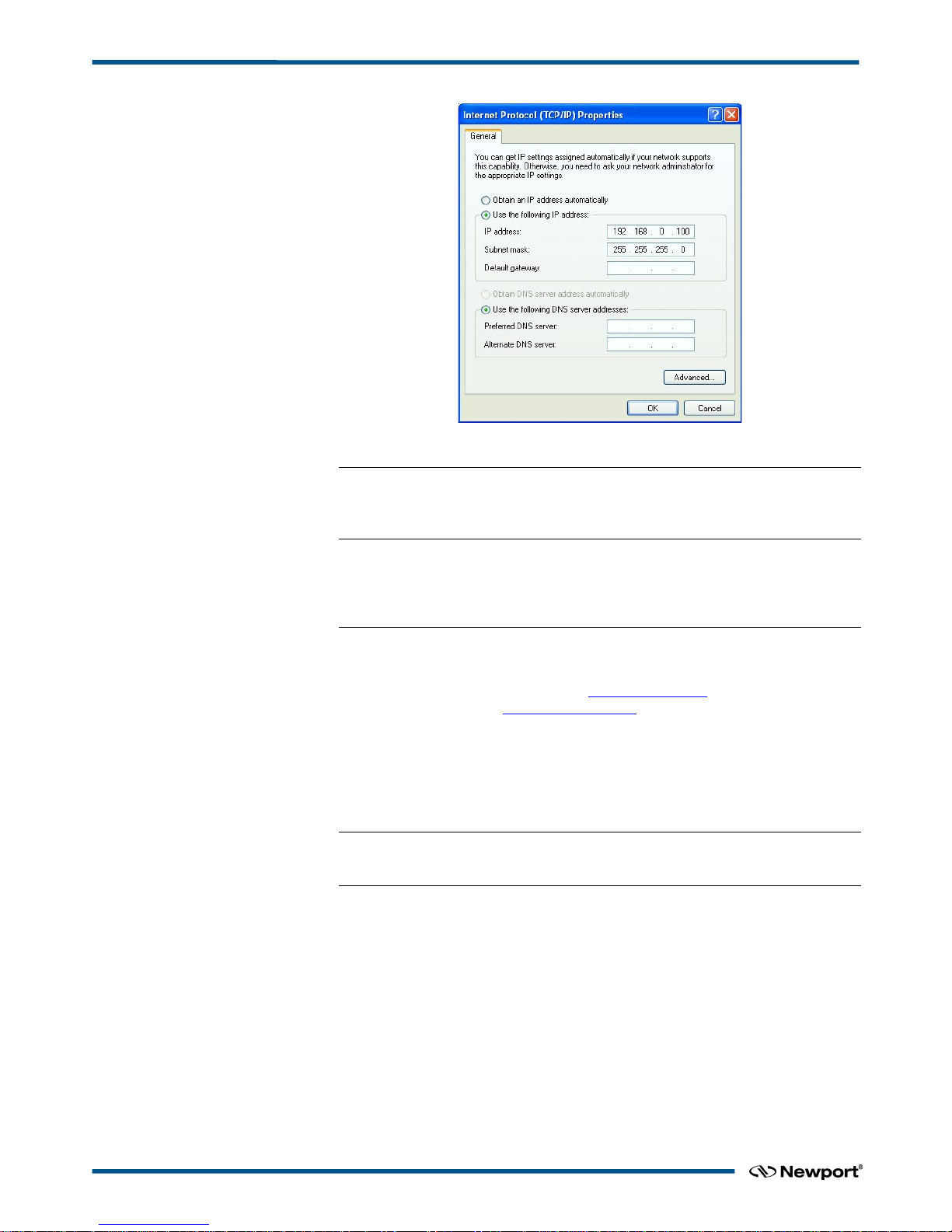

3.5.3 Direct Connection to the XPS Controller

For a direct connection between a PC and the XPS controller you need to use the

crossover cable and the HOST or REMOTE connector at the back of the XPS.

Figure 14: Direct Connection to the XPS using cross-over cable.

First, the IP address on the PC’s Ethernet card has to be set to match the default factory

XPS’s IP address 192.168.0.254 for the HOST connector or 192.168.254.254 for the

REMOTE connector.

Following is the procedure to set the Ethernet card address.

This procedure is for the Windows XP operating system (almost similar process

forWindow 7):

1. Start Button > Control Panel > Network Connections (Network and Sharing Center

=> Change adapter settings).

2. Right Click on Local Area Connection Icon and select Properties.

3. Highlight Internet Protocol (TCP/IP, TCP/IP4) and click on Properties.

4. In case using HOST connector type the IP address: 192.168.0.100 and Subnet Mask:

255.255.255.0.

In case using REMOTE connector type the IP address: 192.168.254.100 and Subnet

Mask: 255.255.255.0

17 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 30

XPS-Q8 Controller User’s Manual

5. Click “OK”.

NOTE

The The Last number of the IP address must be set to any number between 2 to

253: 100 for example.

NOTE

When configuring the controller to be on the network, the settings for the PC’s

Ethernet card will have to be set back to default under “Obtain an IP address

automatically”.

Once the Ethernet card address is set, you are ready to connect to the XPS controller.

Following is the procedure for connecting to the controller:

6. Open Internet Browser and connect to http://192.168.0.254

in case using HOST

connector or connect to http://192.168.254.254 in case using REMOTE connector

Login:

Name: Administrator

Password: Administrator (Please see the picture below).

Rights: Administrator

NOTE

Please note that the login text is case sensitive.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 18

Page 31

XPS-Q8 Controller User’s Manual

Once logged in, the XPS has established a direct connection to the local computer.

If you don’t want to connect the XPS controller through a Corporate Network you may

skip to section 3.7: “Connecting the Stages“.

NOTE

If you want to change the IP address of the XPS controller, follow the explanation

in the next section. It is necessary to keep using the gray cross-over Ethernet cable

to connect the XPS controller directly to the PC.

3.5.4 Connecting the XPS to a Corporate Network using Static IP Configuration

Once you are logged in using the previously described steps for direct connection, you

can change the IP configuration of the controller in order to connect the XPS over a

Network. Select “CONTROLLER CONFIGURATION” of the web-site and select the

sub-menu “IP Management”.

The static IP address, the subnet mask and the Gateway IP address must be provided by

your Network Administrator to avoid network conflicts. Once you have these addresses,

you can input them in the IP configuration window as shown above. The above shown

addresses are only examples.

19 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 32

XPS-Q8 Controller User’s Manual

NOTE

To avoid conflict with the REMOTE Ethernet plug, the IP address must be

different from 192.168.254…

NOTE

For the majority of Networks, the setting above for the Subnet Mask will work.

However, for larger networks (200 computers or more), the Subnet Mask address

must be verified with the IT department. In most cases and for larger networks,

the Subnet Mask is set to 255.255.0.0.

Once the appropriate addresses for the Static IP configuration are set, click on SET and

the following screen appears:

Go to the TERMINAL window, and double click on Reboot function, then press the

Execute button:

Wait for the end of the boot sequence. There is an initial beep a few seconds after power

on and a second beep when the controller has finished booting. The time between the

first beep and the second beep is approx. 12-18 seconds.

Connect the CAT-5 network cable (black) to the HOST connector of the XPS controller

and to your network.

After restarting the controller and restoring your PC’s Ethernet card default

configuration, open the Internet browser and connect using your given Static IP address.

If you don’t want to connect directly to the Corporate Network using the Dynamic IP

Configuration, skip to section 3.7: “Connecting the Stages“.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 20

Page 33

XPS-Q8 Controller User’s Manual

3.5.5 Configuring the XPS for Connection to a Corporate Network Using Dynamic IP

Configuration

It is recommended to ask your IT department to configure the XPS to your network to

avoid any issue with your network policies and rules.

• Configure your connection as described in §3.5.3 for REMOTE connection

• Connect the host plug to your network using a direct cable.

• Get to CONTROLLER CONFIGURATION=> IP management web page

• Select dynamic IP as shown below:

Click the SET button and the following screen appears:

Go to the TERMINAL window, double click on the Reboot function, then press the

Execute button:

21 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 34

XPS-Q8 Controller User’s Manual

Wait for controller to reboot, open the internet browser and connect to REMOTE

You can see the dynamic IP address in CONTROLLER CONFIGURATION =>

General

The IP address delivered by your DHCP is displayed above.

In case the XPS cannot negotiate an IP address from the DHCP the displayed address

will be 0.0.0.0. In that case contact your IT department.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 22

Page 35

XPS-Q8 Controller User’s Manual

Remove the REMOTE cable and, if needed, configure your PC back to its original

Ethernet configuration, you have saved before modification.

Make sure that the standard CAT-5 network cable (black) is connected to the HOST

connector of the XPS controller and to your network.

Open your internet browser and use the dynamic IP address.

Check with your IT department that the lease time set at the DHCP is longer than the

time you plan to leave the XPS switched off otherwise you will lose your dynamic

address and will need to connect to the REMOTE to know the new assigned one by the

DHCP.

NOTE

Do not use Dynamic IP configuration if your DHCP server uses Windows NT 4.0

23 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 36

XPS-Q8 Controller User’s Manual

3.5.6 Recovering a lost IP configuration

If you want to recover a lost IP configuration, you need to connect the PC directly to the

REMOTE connector at the back of the XPS with the gray cross-over cable.

Figure 15: Direct connection to the XPS

using a cross-over cable and the REMOTE connector.

First, the IP address on the PC’s Ethernet card must be set to match the fixed IP address

of the XPS in the REMOTE plug (192.168.254.254). Following is the procedure to set

the Ethernet card address.

This procedure is for the Windows XP operating system (almost similar process to

Windows 7):

1. Start Button > Control Panel > Network Connections (Network and Sharing).

2. Right Click on Local Area Connection Icon and select Properties.

3. Highlight Internet Protocol (TCP/IP, TCP/IP4) and click on Properties.

4. Type the following IP address and Subnet Mask as shown in the next figure.

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 24

Page 37

XPS-Q8 Controller User’s Manual

5. Click “OK”.

NOTE

The last number of the IP address must be set to any number between 2 to 253:

100 in this example.

NOTE

When configuring the controller to be on the network, the settings for the PC’s

Ethernet card must be set back to default which is “Obtain an IP address

automatically”.

Once the Ethernet card address is set, you are ready to connect to the XPS controller.

Following is the procedure for connecting to the controller:

6. Open Internet Browser and connect to http://192.168.254.254

Login:

Name: Administrator

Password: Administrator (Please see the picture below).

Rights: Administrator

NOTE

Please note that the login text is case sensitive.

25 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Page 38

XPS-Q8 Controller User’s Manual

Once you are logged in, you can change the IP configuration by following the steps

described in section 3.5.4 or 3.5.5 depending on your configuration.

NOTE

If you want to reset the IP address to the default factory setting, follow the section

3.5.4

to set the IP address back to 192.168.0.254.

3.6 Testing your XPS-PC Connection and Communication

To check if the XPS communicates with to the host computer, send a ping message

from the computer to the XPS. This is done through the Windows menu: Start->Run->,

then type: ping + IP address of the XPS. See the example below for the IP address

192.168.33.236:

If the XPS is connected and communicates properly, it replies in the terminal window

that appears after clicking on the OK button:

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 26

Page 39

XPS-Q8 Controller User’s Manual

If the XPS controller is not communicating, the window displays that the time delay of

the request is exceeded. Ensure that the correct cable and IP addresses are set properly.

3.7 Connecting the Stages

CAUTION

Never connect/disconnect stages while the XPS controller is powered

on.

CAUTION

Mount the stage(s) on a flat, stable surface before connecting to the

XPS controller.

With the power off, carefully connect the supplied cables to the stage and to the

appropriate axis connector at the rear of the controller. Secure both connections with the

locking thumbscrews.

When using stages with an analog encoder interface, a separate encoder cable must be

connected to the corresponding axis connector of the control board labeled “Encoder 1”

to “Encoder 8”.

Please note that the XPS controller will not detect cross-connection errors between the

motor of one stage and the encoder of another stage. Make sure that motor, encoder and

other cables are plugged to the appropriate axis driver card and encoder connectors.

CAUTION

It is strongly recommended that the user read section 3.4: “System

Setup