Page 1

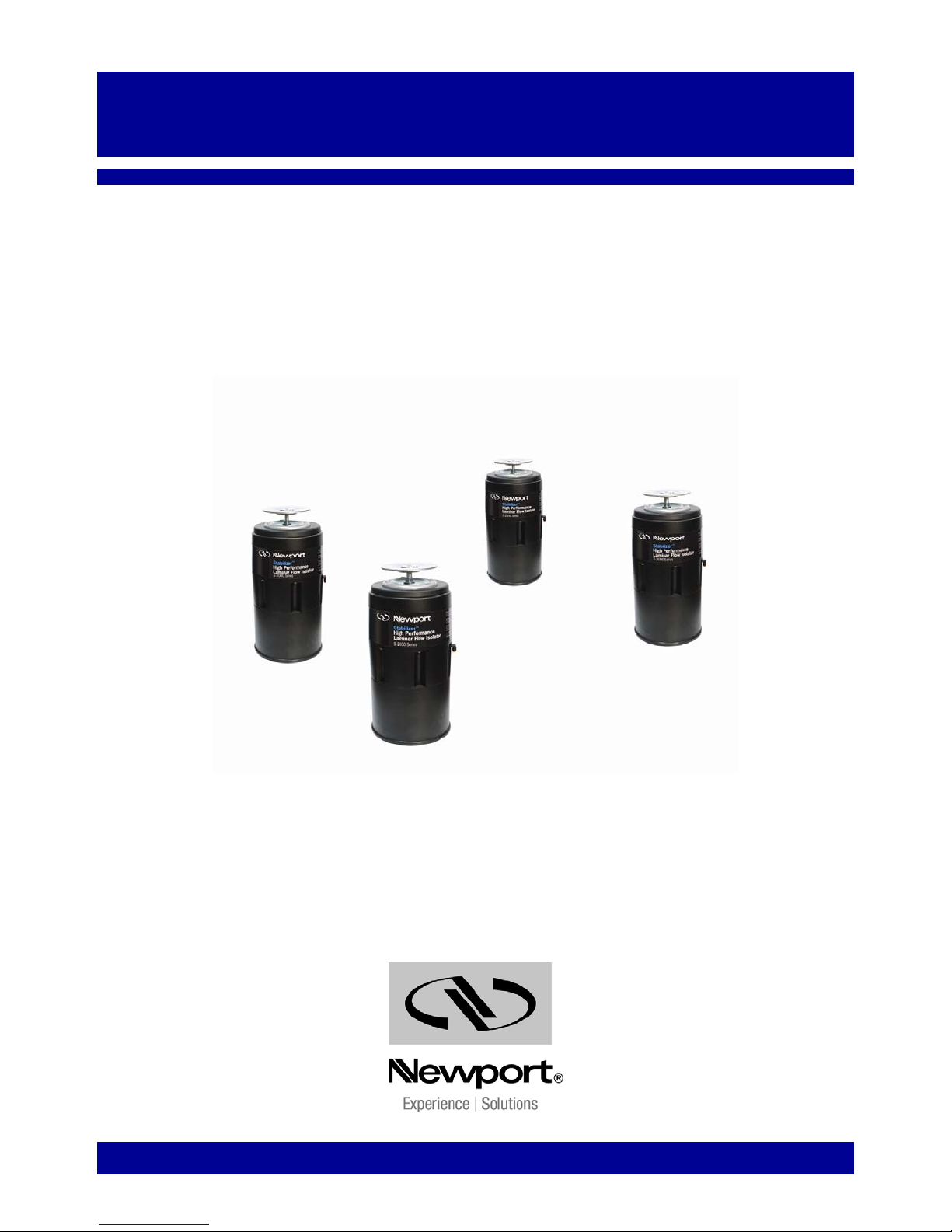

Vibration Control System

S-2000 StabilizerTM Vibration Isolators

and Optical Table Installation Manual

User’s Manual

Page 2

ii

Page 3

iii

Warranty

Newport Corporation warrants that this product will be free from defects in

material and workmanship and will comply with Newport’s published

specifications at the time of sale for a period of one year from date of

shipment. If found to be defective during the warranty period, the product

will either be repaired or replaced at Newport's option.

To exercise this warranty, write or call your local Newport office or

representative, or contact Newport headquarters in Irvine, California. You

will be given prompt assistance and return instructions. Send the product,

freight prepaid, to the indicated service facility. Repairs will be made and the

instrument returned freight prepaid. Repaired products are warranted for the

remainder of the original warranty period or 90 days, whichever first occurs.

Limitation of Warranty

The above warranties do not apply to products which have been repaired or

modified without Newport’s written approval, or products subjected to

unusual physical, thermal or electrical stress, improper installation, misuse,

abuse, accident or negligence in use, storage, transportation or handling. This

warranty also does not apply to fuses, batteries, or damage from battery

leakage.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

NEWPORT CORPORATION SHALL NOT BE LIABLE FOR ANY

INDIRECT, SPECIAL, OR CONSEQUENTIAL DAMAGES RESULTING

FROM THE PURCHASE OR USE OF ITS PRODUCTS.

First printing 2009

© 2009 by Newport Corporation, Irvine, CA. All rights reserved. No part of

this manual may be reproduced or copied without the prior written approval

of Newport Corporation.

This manual has been provided for information only and product

specifications are subject to change without notice. Any change will be

reflected in future printings.

Newport Corporation

1791 Deere Avenue

Irvine, CA, 92606 USA

Part No. 90030352 Rev. B

Page 4

iv

Table of Contents

Warranty................................................................................................iii

Table of Contents..................................................................................iv

List of Figures....................................................................................... vi

1 General Information 1

1.1 Introduction ...................................................................................1

1.2 Getting Started...............................................................................1

1.3 Unpacking and Inspecting .............................................................1

1.4 Safety Considerations....................................................................2

1.5 Table Placement ............................................................................2

1.6 Air Supply Requirements ..............................................................3

1.7 Warranty Information....................................................................4

2 Assembly 5

2.1 Assembling the System .................................................................5

2.1.1 Table Installation Assistance.............................................5

2.1.2 Positioning the Isolators....................................................5

2.1.3 Installing Table Top ..........................................................6

2.2 Leveling the Table.........................................................................7

2.3 Isolating the Table Top..................................................................8

2.3.1 Installing Leveling Valves.................................................8

2.3.2 Connecting Air Lines ......................................................10

2.3.3 Adjusting Leveling Valve Sensors..................................13

2.4 Installing tables with the Doubler Interface ................................14

3 Operation 17

3.1 Principles of Operation................................................................17

3.2 Performance Adjustments ...........................................................17

3.3 Maintenance ................................................................................18

3.3.1 Cleaning...........................................................................18

3.3.2 Air Quality.......................................................................19

4 Troubleshooting 20

4.1 Table Top Does Not Float...........................................................20

4.2 Poor Isolation Performance.........................................................20

Page 5

v

4.3 Table Top Oscillates....................................................................21

4.4 System Leaks Air Constantly......................................................21

4.5 Oil Leak From Isolator................................................................21

4.6 Adding Damping Oil...................................................................21

5 Factory Service 23

Page 6

vi

List of Figures

Figure 1 — Isolator Position......................................................................... 5

Figure 2 — Isolator Clamps and Mounting Holes........................................6

Figure 3 — Isolator Leveling Wrench .......................................................... 7

Figure 4 — Level Adjustment of Isolators.................................................... 7

Figure 5 — IPV Leveling Valve ................................................................... 9

Figure 6 — Valves attaching to isolator........................................................ 9

Figure 7 — Orientation of Control Arm ..................................................... 10

Figure 8 — Air Line Routing...................................................................... 11

Figure 9 — Detail of Valve Connections, Single Isolator .......................... 12

Figure 10 — Detail of Valve Connections, Two Isolators............................ 12

Figure 11 — Floating Height Adjustment and centering.............................. 14

Figure 12 — Typical Double Interface System............................................. 14

Figure 13 — Double Bolt Tightening Sequence........................................... 16

Figure 14 — System Stability ....................................................................... 18

Page 7

1 General Information

1.1 Introduction

The Newport Vibration Control System provides an ideal working platform

for vibration sensitive devices such as interferometers, microscopes, and

balances. The table surface is isolated from floor motion using the

Stabilizer™ pneumatic suspension system. The versatile Newport Vibration

Control System is available in a variety of sizes, working surfaces, and

options.

These systems integrate Newport’s rigid, laminated honeycomb panel

technology and pneumatic isolation systems to provide a mounting platform

which is rigid, yet thin and light weight.

1

It is possible to tailor the system to a wide variety of applications using the

entire range of sizes and working surfaces. A typical Newport Vibration

Control System consists of an optical table and vibration isolators.

The S-2000 Stabilizer™ isolation system is capable of supporting 2000

pounds per isolator. Caution must be observed to ensure that heavy payloads

are not located off center on the table surface. This could cause overloading

of one isolator even though the average load per isolator is below the 2000

pound limit.

1.2 Getting Started

Heavy payloads with very high centers of gravity (C-G) may cause the

isolation system to oscillate. Please consult Section 3.2 of this manual or

Newport Applications Engineering for high C-G applications.

Please read this instruction manual thoroughly before assembling the table

system. The individual components have been assembled at the factory and

require only final system assembly and performance adjustment.

1.3 Unpacking and Inspecting

The components of your Newport Vibration Control System are packed in

individual, labeled boxes. Be sure the number of boxes you received is equal

to the total number listed on the label (for example, if a box is labeled 1 of 4,

there should be 4 boxes).

Page 8

2

1.4 Safety Considerations

Carefully inspect all components for shipping damage. Report any shipping

damage immediately to the shipping company and Newport.

The following terms are used in this manual that relate to your safety.

Warning is used to indicate dangers that could result in personal

injury.

Caution is used to indicate situations that may result in damage

to components of your Newport Vibration Control System.

1.5 Table Placement

WARNING

CAUTION

To ensure optimal performance from your Vibration Control System, it

should be located on a level surface. Uneven floors may cause difficulty

during the leveling of the table top if their irregularity is outside of the

adjustment range of the isolators.

The S-2000 Stabilizer™ isolator must be mounted so that its axis is not more

than 0.5 degrees from vertical. This is necessary for the isolator to function

properly in the horizontal mode. Note: 0.5 degrees is equal to 0.09 (2.2 mm)

inches in 10.0 inches which is the isolator base diameter. A typical spirit

level will easily measure 0.5 degrees and can be used to check the vertical

alignment of each isolator.

If the floor where the isolators are being mounted has a depression of more

than 0.09 inches under one side of the base, then the floor should be grouted

or shimmed level at this location.

If the system is not located on the ground floor of the building, it should be

located near primary vertical structures such as exterior walls or support

columns. By locating the table near these structures, the effects of low

frequency floor motion will be minimized, thus increasing the performance of

the table. It is also advisable to avoid locations adjacent to major sources of

vibration from operating machinery such as elevators, air conditioning plants,

or factory equipment.

Page 9

WARNING

The table top is attached to the isolators with clamps and hex

head bolts. In the event of an earthquake, the table may

collapse. For areas susceptible to earthquakes, we recommend

that Newport Earthquake Restraints be installed on each

Vibration Control System.

WARNING

The table top is a metallic electrical conductor. For installations

where electrical shock is a possibility, the table top should be

grounded to prevent personal injury.

1.6 Air Supply Requirements

A constant supply of air must be connected to the Vibration Control System

during operation. After initial setup and filling, the isolators consume air

only when the leveling valves adjust the pressure to compensate for changes

in the load on the table.

3

Bottled nitrogen or mechanically compressed air may be used. The required

pressure is determined by dividing the total load, including table weight, by

the total isolator diaphragm area (25.9 in2 per isolator) plus

5-10 psig.

For example, if the table plus load is 2850 pounds and will be mounted on 4

isolators, the required pressure is:

Note that the maximum operating pressure for the system is 95 psig

2

(6.7 kg/cm

).

The Newport Model ACGP air compressor is an extremely quiet source of

clean, pressure regulated air. If another compressor or plant air is used, the

Newport model ARF Air Regulator Filter should be used to ensure

maintenance free operation. These filters prevent water and dirt from getting

into the leveling valves and causing the valves to fail due to clogging.

The supply should include a valve so that the air may be shut off during

maintenance or extensive setup when the load is changed drastically.

CAUTION

Bottled carbon dioxide (CO2) is not recommended since “icing”

can occur during rapid filling of the isolators.

Page 10

4

1.7 Warranty Information

Warranty information may be found on the page preceding the Table of

Contents in this manual. Should it become necessary to exercise the

warranty, contact your Newport representative to determine the proper course

of action. Newport Corporation maintains offices throughout the United

States and other locations worldwide.

Page 11

2 Assembly

2.1 Assembling the System

2.1.1 Table Installation Assistance

Optical tables are heavy. Even a small table top weighs over 500 pounds

(227 Kg). Contact Newport or your local sales representative for help in

preparing your facility.

2.1.2 Positioning the Isolators

Figure 1 shows the correct isolator positions for standard table sizes. Table 1

shows the correct dimensions (A, B, & C) for each table size.

5

TableWidth

ft(mm)

3(900) 6(1800)

3(900) 8(2400)

3(900) 10(3000)

4(1200) 6(1800)

4(1200) 8(2400)

4(1200) 10(3000)

4(1200) 12(3600)

4(1200) 14(4200)

4(1200) 16(4800)

5(1500) 6(1800)

5(1500) 8(2400)

5(1500) 10(3000)

5(1500) 12(3600)

5(1500) 14(4200)

5(1500) 16(4800)

TableLength

Figure 1 — Isolator Position

ft(mm)

A

in(mm)

14(341) 30(733) 35.5(899)

14(341) 42(1028) 47.25(1159)

14(341) 56(1374) 60.25(1479)

14(341) 30(733) 43.75(1079)

26(641) 42(1028) 52.25(1310)

26(641) 56(1374) 65.25(1604)

26(641) 70(1720) 77.75(1914)

26(641) 84(2166) 90.75(2326)

26(641) 94(2311) 100(2463)

38(941) 30(733) 51.75(1296)

38(941) 42(1028) 60(1499)

38(941) 56(1374) 71(1766)

38(941) 70(1720) 82.75(2054)

38(941) 84(2166) 95(2445)

38(941) 94(2311) 104.25(2576)

Table 1 — Isolator Positions

B

in(mm)

C

in(mm)

Page 12

6

2.1.3 Installing Table Top

If your table is equipped with a Doubler Interface be sure to follow the

instructions in Section 2.4 for assembling the table sections prior to installing

them on the isolators.

Table tops are heavy! Use a forklift or other appropriate

equipment. Be sure to use proper lifting procedures to avoid

severe personal injury.

1. With the isolators located as described in Section 2.1.2, raise the table

top and position it above the isolators. Be sure each isolator is centered

within the tapped three-hole patterns on the lower surface of the table

(Figure 2).

WARNING

Figure 2 — Isolator Clamps and Mounting Holes

2. Gently lower the table so that is just above the top of isolators.

3. Install three isolator clamps in the corners where each isolator is located

(Figure 2). Loosely secure the clamps with the bolts. Do not tighten

the clamps at this time.

4. Lower the table top until it rests on the isolator support plates.

Page 13

When lowering the table on to the supports, do not allow the

table to shift sideways. Doing so could damage the isolators

and cause degradation in performance.

2.2 Leveling the Table

Use the following procedure to level the table. The special wrench (Figure 3)

is for all adjustments.

7

CAUTION

Figure 3 — Isolator Leveling Wrench

1. Refer to Figure 4. As shown, use one of the special wrenches to hold

the hex nut stationary. Insert the prongs of the second wrench into the

holes on the bottom of the support plate. Rotate the plate using the top

wrench to adjust the height.

2. Place a level on the table top, approximately in the center.

3. For each isolator, adjust the support plates as required to bring the table

to a level condition. Be sure to check the level using both the length and

width axes of the table. Verify that the centering disks are centered in

and resting on their respective guides (Figure 4).

Figure 4 — Level Adjustment of Isolators

Page 14

8

4. When the table is completely level, ensure by eye that every isolator

support plate is snug against the table bottom and that each centering

disk is centered in its guide (Figure 4).

5. Use the level to confirm that the tabl e top is still level and equally

supported by all isolator support plates. Tighten all isolator clamp bolts

snugly to secure the table to the isolators.

6. Loosen the two screws securing each leveling valve to its bracket. Slide

the valve body until it is approximately 0.060 inches (1.5mm) below the

bottom of the table. Be sure the valve is not tilted, then tighten the

screws (Figure 6).

2.3 Isolating the Table Top

2.3.1 Installing Leveling Valves

The IPV leveling valve is shown in Figure 5. Three valves are used in all

systems, regardless of the number of isolators, as only three points are

required to determine a plane. The leveling valve locations are selected such

that they form the largest triangle possible under the table. The larg er the

triangle, the more stable the system will be. When two or more isolators are

controlled by the same valve, they act as a single large isolator supporting the

table at the center of force of the several isolators. The floating height of the

system is determined at the valve position. Therefore, ideally, the valves

should be located at the center of force of the isolators they control. In

practice, however, simply grouping the isolators and their control valves is

sufficient. The groups of isolators and their valves act as three legs for the

system. The center of gravity of the combined table and payload must be

within the triangle formed by the centers of force of the isolator groups for

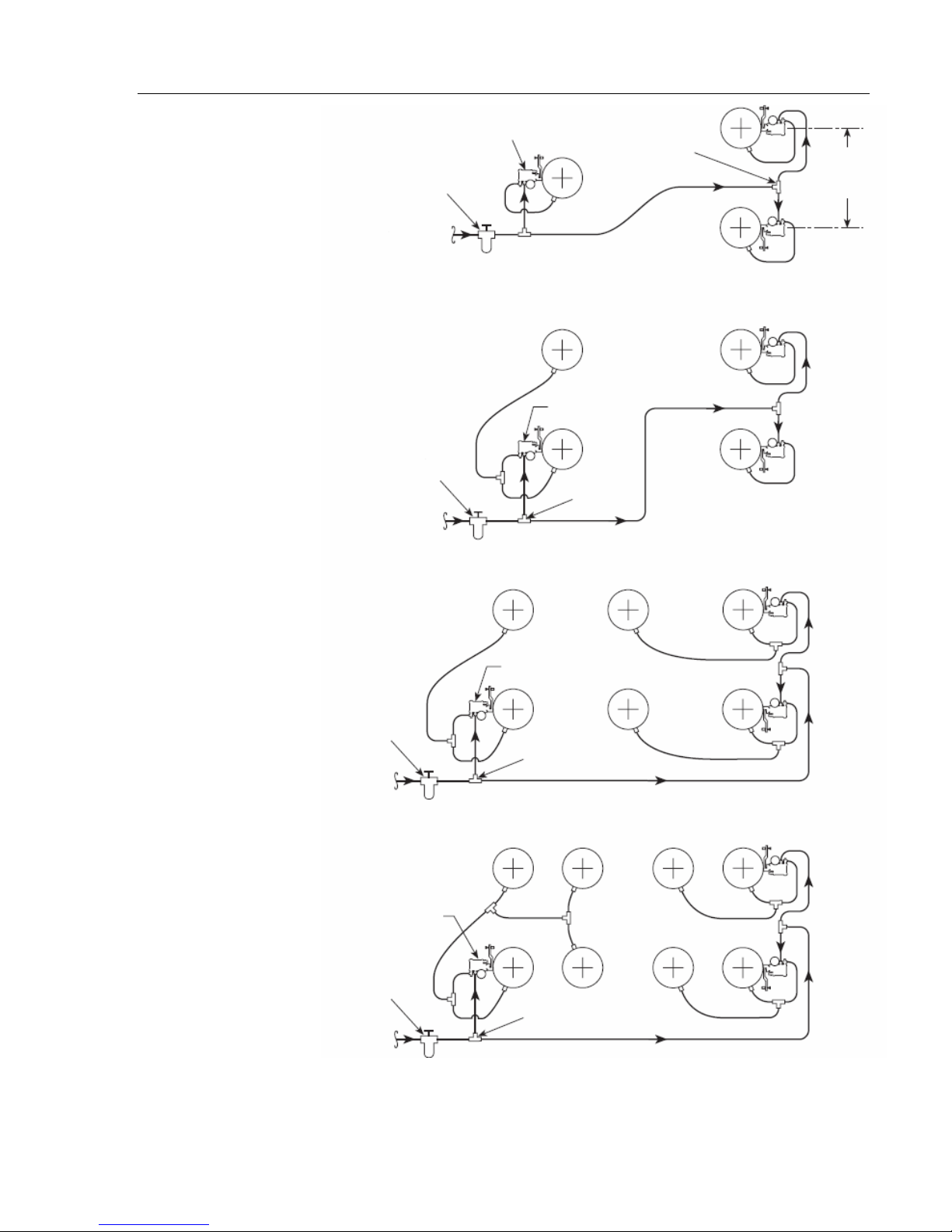

the system to float. Figure 8 shows valve and isolator arrangements for

rectangular tables. Complex table shapes require isolator and valve layouts

designed specifically for each application.

Page 15

9

j

j

Table height sensor

Control arm

Isolator pressure

gauge

Table height

ad

ustment screw

Air supply

Metering

needle valve

Air line to isolator

Over-pressure relief valve

Figure 5 — IPV Leveling Valve

Mounting screw holes

Table height

ad

ustment screw

The valves should be attached to the isolators as shown in Figure 6 after

installing the table top.

1. Set the table height adjustment screw on each valve to the center of its

travel (Figure 6).

2. Attach the leveling valve to the isolators as shown in Figure 6. Secure

the valve to the bracket using the two mounting screws and the nutplate.

Figure 6 — Valves attaching to isolator

Page 16

10

Position the valve at the bottom of the bracket slots until after the table is

installed and leveled.

3. Rotate the control arm on valves “A” in Figure 7 so that they point

towards the nearest corner of the table.

4. Rotate the control arm on valve “B” in the figure so that it points toward

the table’s center, midway between the isolators that it controls.

5. For systems with more than four isolators, use the same basic setup just

described: Two valves control the height of the two end corners (A & A)

while the third valve (B) controls the height of the opposite end (Figure

8).

Figure 7 — Orientation of Control Arm

2.3.2 Connecting Air Lines

1. Connect air lines to the isolators as shown in Figure 8. When cutting

tubing, be sure the ends are round and cut squarely. This is best done

with a single edge razor blade (scissors will deform the tubing, causing

leaks). The connections are detailed in Figures 8, 9 and 10.

a. Use translucent tubing to connect the air supply to each of the

leveling valves. Use “Tee” connectors as required. Press the free

end of the tubing into the yellow collar of the valve’s “IN”

connector. Be sure the connection is firm by tugging on the tube.

b. Connect a length of grey tubing (supplied with the valves for use on

the valve barb fitting) between the hose barb on the valve and the

inlet connector on the isolator (Figure 9). If more than one isolator

is supplied by a valve, use “Tee” connectors as required (Figure 10).

Connect the grey tube from the valve to the “Tee” and use

translucent tubing between the “Tee” and each isolator.

Page 17

11

3 Isolator Schematic

Air

Regulator

Filter

Air Supply

4 Isolator Schematic

Air

Regulator

Filter

Air Supply

Leveling Valves

3 Reqd

Leveling Valves

3 Reqd

Tee

3 Reqd

Tee

2 Reqd

Table Width

Less 12”

Typ All Tables

6 Isolator Schematic

Air

Regulator

Filter

Air Supply

8 Isolator Schematic

Leveling Valves

3 Reqd

Air

Regulator

Filter

Air Supply

Leveling Valves

3 Reqd

Tee

5 Reqd

Tee

7 Reqd

Figure 8 — Air Line Routing

Page 18

12

Metering needle

valve

Figure 9 — Detail of Valve Connections, Single Isolator

2. Close the metering needle valve (Figure 9) on each valve and then open

it 1⁄2 turn for each isolator that is connected to it. For example, if the

valve controls two isolators, the needle valve is opened 1 full turn.

[Please note: If you have a minimum load on your optical table top, open

the metering valve about 1⁄8 – 1⁄4 of a turn.]

3. Turn on the air supply and adjust the regulator for the pressure calculated

using the formula given in Section 1.6. This pressure must not exceed

95psig (6.7 kg/cm2).

Figure 10 — Detail of Valve Connections, Two Isolators

4. Check all connections for leaks. Correct or repair any leaks before

proceeding.

5. If the table does not float within several minutes, increase the air

pressure until the table floats or adjust the value height sensors to hold

Page 19

pp

g

k

r

the control arms further down. Confirm that the needle valves are open

1

⁄2 turn per isolator supplied.

NOTE: If the table oscillates after it floats, decrease the air pressure or

close the needle valves slightly.

6. In clean room applications the “EXH” (exhaust) port on the valves may

be connected to the clean room vacuum system to capture the valve

exhaust.

NOTE: Exhaust must be routed to a vacuum system. Backpressure in

the tubing will cause the exhaust air to leak from the valve.

2.3.3 Adjusting Leveling Valve Sensors

1. After the table floats, check the position of the centering guide and

flange of all isolators (Figure 11). The gap between the guide and flange

1

should be

disk should be aligned with the float height indicator tabs (Figure 11).

2. Adjust the Table Height sensor screw of each isolator (Figure 5) as

required to obtain this gap. When all isolators are adjusted, re-check the

level of the table. NOTE: this step should require only minor

adjustments. Do not move the small set screw near the pivot of the valve

control arm.

⁄4" ± 1⁄16" (6mm ±1.5mm). The center of the isolator centering

13

3. If the table is no longer level, you may have to remove the air pressure

and re-adjust the height of the isolator support plates as described in

Section 2.

4. Verify that the table is freely floating on the isolators. Move the table

gently from side-to-side about

1

⁄8". You should not encounter any

resistance. Re-check by moving the table up and down the same amount.

Again, there should be no restriction of movement.

5. Push one corner of the table down approximately 1⁄8" and release it. The

table should return to the original position within less than 4 seconds.

Response time may be adjusted as described in Section 3.2.

Su

ort Plate

1/4” ± 1/16”

Centerin

Float height

indicato

dis

Page 20

14

Above alignment tabs

Even with alignment tabs Below alignment tabs

Too high Correct height Too low

Notice

gap

Incorrect centering Correct centering

Figure 11 — Floating Height Adjustment and centering

2.4 Installing tables with the Doubler Interface

The following instructions are applicable only to those tables equipped with

the Doubler Interface. Figure 12 shows a typical Doubler Interface System.

No gap

1. Use the procedures in Section 2.1.2 and 2.3.1 to assemble the isolators

for both table sections.

2. Carefully uncrate each table top, noting the correct orientation indicated

on the crates. Carefully check the doubler faces for any damage that

might prevent them from fitting tightly together.

Figure 12 — Typical Double Interface System

3. Position the isolators for one table section as described in Section 2.1.2.

Install valves on the appropriate isolators as shown in Figure 8.

4. Install the first table section on the isolators as described in

Section 2.1.3.

Page 21

15

NOTE: It may be necessary to use jack stands to support the first table

section if fewer than four isolators are located under the section.

5. Position the second table section on three jack stands mounted on dollies.

Adjust the position of the table so that it is at the same height as, and

adjacent to, the first table section.

6. Align the two table sections using a straight edge. Carefully roll the

second table section toward the first so that the alignment dowel pins

engage in their mating holes. Be sure the bolts are aligned with their

corresponding holes.

7. Draw the two table sections together approximately 1⁄8 inch (5mm) using

the two outermost top bolts.

CAUTION

Do not force the bolts. The second table section should be

easily pulled up to the first. Figure 2.13 shows correct bolt head

position during assembly.

Do not cause the first table section to shift sideways on its

isolators. Doing so could damage the isolators.

8. Tighten all of the bolts until they are finger-tight or until they just begin

to move the table sections together. Do not force or over-tighten the

bolts.

9. Repeat steps G and H until the two table sections are completely drawn

together.

10. When all bolts are snug, apply a final torque of 60 pound-feet (80 N-M)

to all bolts using the sequence shown in Figure 13.

11. Jack up the assembled table as required to install the remaining isolators

and leveling valves. Install the isolators and valves as described in

Section 2.1.

12. Remove the jack stands and level the table as described in

Section 2.3.

13. Install the air lines and float the table as described in Section 2.3.

Page 22

16

Figure 13 — Double Bolt Tightening Sequence

Page 23

3 Operation

3.1 Principles of Operation

The S-2000 Stabilizer™ Isolators provide one of the best methods of

vibration isolation for critical applications. The system operates on the

principle of air pistons, which are equivalent of soft springs. The main

advantage of the Newport system over other designs are low vertical resonant

frequency with low amplification at resonance (Q) and a Pendulum

horizontal decoupling system for effective isolation from low amplitude

vibration.

Newport optical tables provide a working surface that is statically rigid with

high internal tuned damping for high dynamic rigidity and minimal response

to environmental disturbances.

17

TM

The leveling valves provided with the system control the height of the table

to within ±0.01" (0.3mm) accuracy. This tolerance is adequate for most

applications. More accurate valves are available for specialized

applications.

3.2 Performance Adjustments

Once the system is assembled and the table floating, it is possible to make

minor adjustments to suit your individual needs. These adjustments involve

the system air pressure, the control arms, and needle valves.

WARNING

Once the table is floating, keep fingers away from the area

between the centering guide and outer clamp of the isolators.

Any object between these points may be caught if the table load

or air supply changes, causing personal injury.

1. Stabilizing high center-of-mass loads: If your load has a high center of

mass or if the load is particularly heavy, the table may oscillate. In this

case, lower the system pressure or close the needle valves slightly. This

may improve stability and reduce the oscillation or “hunting”.

2. A rule of thumb for determining high center of gravity (C-G) system

stability is shown in Figure 14. If the combined center of gravity of the

payload and table top is within the “stable region”, the system will be

stable. If the combined C-G is inside the “may be stable region”, the

Page 24

18

system may be stable. If the combined C-G is outside both regions, the

system will probably be unstable.

Figure 14 — System Stability

3. Improving leveling response times: If the system is stable, the re-

leveling response time may be decreased by increasing the system

pressure. In addition, the needle valves may be opened until the system

oscillates and then closed slightly. This is desirable if components are

moving over the surface of the table.

For systems where the loads are seldom changed, slower re-leveling may

be beneficial. This is accomplished by closing the needle valves slightly

and/or decreasing the system pressure.

All needle valves should be opened the same amount for each isolator

that they supply.

4. Table loads and/or load positions change: If the loads are moving or

changing significantly, the control arms may require adjustment. Each

time the load is changed, check the relationship of the centering guide to

the flange on each isolator. If the desired 1⁄4 inch is not maintained,

adjust the overall system pressure and/or the sensor positions.

Newport Vibration Control Systems require little maintenance. No periodic

maintenance is required.

3.3 Maintenance

3.3.1 Cleaning

Newport optical table tops are made of 400 series stainless steel. This

material is relatively corrosion resistant. It may be cleaned by applying nonabrasive liquid household cleaner to a rag and wiping the table top. Avoid

abrasive cleaners as they will foul the mounting holes.

All other surfaces on the table top or isolator system may be cleaned in the

same manner.

Page 25

3.3.2 Air Quality

Oil, water, or debris in the air supply may contaminate the leveling valves or

isolator damping system and degrade performance. Use of the Newport

model ARF Air Regulator and Filter in the air supply will prevent this

occurrence. The filter does require occasional cleaning.

19

Page 26

20

4 Troubleshooting

4.1 Table Top Does Not Float

Use the following procedure if the table top does not float, or lift up, when

pressure is applied to the isolators.

1. Ensure that the supply pressure is 5–10 psig (0.4–0.7kg/cm

pressure reading of any of the leveling valves. If the load is increased,

the pressure should be increased to maintain the difference between

supply and valve pressure. Refer to Section 1.6.

2. Check to see if all air lines are connected properly and the supply

pressure is adequate (see step 1). Refer to Figures 8, 9, and 10.

2

) above the

3. Be sure that the needle valves are not closed completely.

4. Check each leveling valve for clogging. To do this, press the control

arm down. Air should flow into the isolator, accompanied by the

familiar sound of moving air. Repair or replace any clogged valve. Use

the ARF filter/regulator to prevent this situation.

4.2 Poor Isolation Performance

The following may lead to poor isolation performance of your system.

1. Vibration may be transmitted to the table through direct physical contact

of equipment with external sources of vibration.

2. Isolators that float too high, too low, or are not centered may conduct

floor vibration to the table top. Refer to Section 2.3.2. (Figure 11)

Centered isolators will remain centered unless the table and isolators are

moved relative to each other.

3. Equipment on the table may be vibrating at a resonant frequency of other

components. Improve the rigidity of the mounting for that equipment or

remove that item from the table.

4. Non-level floor may prevent the horizontal isolation system from

functioning properly (see Section 1.5).

Page 27

4.3 Table Top Oscillates

If the table top oscillates or “hunts”, you may have a set up with a high center

of mass. Refer to the information in Section 3.2 or consult your Newport

representative or Newport Corporation for further assistance.

4.4 System Leaks Air Constantly

All Newport isolators and valves are pressure leak tested prior to shipment.

Check all tubing connections for leaks with soapy water. Tubing that is

crushed out of round or that is not cut squarely may not seal in the push-in

fittings. Use a single edge razor blade to cut the tubing cleanly (refer to

Section 2.3.2). If testing with soapy water indicates that either the isolator or

valve are leaking contact Newport Customer Service.

4.5 Oil Leak From Isolator

Damping oil may leak from the isolator if it is inverted or tilted more than 45

degrees. If more than 1⁄8 cup (30ml) of oil is lost, add additional oil (available

from Newport Corporation) as directed in Section 4.6. Losses of less than

1

⁄8 cup will not affect the isolator performance. Total volume of damping oil

per isolator is approximately 1⁄2 cup (125ml).

21

4.6 Adding Damping Oil

If the isolator loses damping oil, additional oil may be added as follows:

1. Remove the air pressure from the isolator and allow the piston to retract.

Ensure that the remaining isolators will support the table or use a jack

stand to replace the isolator to be serviced. Loosen the three bolts

securing the support plate to the bottom of the table, and slide the

isolator from under the system.

The table top is heavy and may cause severe personal injury if it

falls! Be sure it is properly supported before getting underneath

the table top or removing the isolator.

2. Measure the height of the support plate relative to the centering disk

(Figure 2.4). Record this distance so that the isolator may be returned to

its normal position.

3. Unscrew the isolator support screw (right-hand thread) and remove the

plate and jack screw from the piston assembly.

4. Use a funnel to add damping oil through the support shaft hole until the

oil level is approximately

Allow time for the viscous oil to settle before measuring the oil level.

WARNING

1

⁄4" (6.4mm) from the bottom of the piston.

Page 28

22

5. Use a clean, small diameter rod to check the level. When checking the

level, be sure the rod sits on the bottom of the piston and not on the

narrow ledge at the bottom of the support shaft.

6. Reverse Steps 2 and 3 to re-assemble the isolator. Return the support

plate to the position noted in Step 2.

7. Reinstall the isolator and apply air pressure. Make any required

adjustments to return the system to operation.

Page 29

5 Factory Service

To obtain information concerning factory service, contact Newport

Corporation or your Newport representative. Please have the following

information available.

1. Model number.

2. Purchase order number.

3. Complete description of the problem.

If components are to be returned to Newport Corporation, you will be given a

Return Number, which you should reference in your shipping documents.

23

Please fill out the service form located on the next page, and have the

information ready when contacting Newport Corporation. Include the

completed service form with any parts or components that are returned.

Page 30

Lead

<0.1% (1000 PPM)

Mercury

<0.1% (1000 PPM)

Cadmium

<0.01% (100 PPM)

Hexavalent Chromium

<0.1% (1000 PPM)

Polybrominated Biphenyls (PBB)

<0.1% (1000 PPM)

Polybrominated Diphenyl Ethers (PBDE)

<0.1% (1000 PPM)

Product

RoHS Compliant Part Number

SUPPORT SYSTEM,TIE BAR,S-2000

S-2000A-428-TC

_____________6/6/18_________________

Date

RoHS

(Restriction of Hazardous Substances)

Certificate of Compliance

MKS Instruments, Inc. hereby certifies that the products listed in the table below are compliant

with the European Union’s RoHS directive 2011/65/EU (effective 22 July 2017) regarding the

restriction of the use of certain hazardous substances in electrical and electronic equipment. The

products listed below are compliant to RoHS requirements for concentration limitations, by weight

of homogeneous material, of the following six substances:

The above thresholds are not in place for any legally allowable exemptions per Annex III of the

aforementioned directive. If such exemptions are in use, they are noted on the attached table. If no

exemptions are in use, then no further information is provided.

All information provided in this Certificate of Compliance is accurate to MKS’ knowledge as of the

date of this certification. This confirmation is made based our internal engineering risk analysis of

the individual items possibly being present along with the best technical information made available

to MKS from its material suppliers.

MKS Instruments, Inc. Page 1 of 2 Document Number: MKS-CD-1138

MKS CONFIDENTIAL Revision: B

Page 31

MKS Product

Number

MKS Product

Description

Annex III

Exemption #

Annex III

Exemption Description

MKS RoHS2 PRODUCT EXEMPTION LISTING

MKS Instruments, Inc. Page 2 of 2 Document Number: MKS-CD-1138

MKS CONFIDENTIAL Revision: B

Page 32

Vibration Control

System

I

NSTRUCTION

M

ANUAL

Page 33

Warranty

Newport Corporation warrants isolator products to be free of defects in

material and workmanship for a period of two years from the date of

shipment. In addition, the laminated honeycomb tops have an extended

lifetime warranty against delamination of the skins under normal use and

proper handling. If found to be defective during the warranty period, the

product will either be repaired or replaced at Newport’s option.

To exercise this warranty, write or call your local Newport representative

or contact Newport headquarters in Irvine, California. You will be given

prompt assistance and return instructions.

Repaired or replaced products are warranted for the balance of the original

warranty period or 90 days, whichever is longer.

This warranty does not apply to defects resulting from modifications or

improper use of the system or its component parts.

This warranty is in lieu of all other warranties, expressed or implies,

including any implied warranty of merchantability or fitness for a particular use. Newport Corporation shall not be liable for any indirect, special,

or consequential damages.

©1991, Newport Corporation

Irvine, California, U.S.A.

P/N 18615-01 Rev. H4

IN-04913 (08-00)

ii

Page 34

Table of Contents

Warranty ............................................................................................................... ii

List of Figures ..................................................................................................... iv

Specifications ....................................................................................................... v

Section 1 — General Information .....................................................................1

1.1 Introduction ............................................................................................ 1

1.2 Getting Started ........................................................................................1

1.3 Unpacking and Inspection .....................................................................1

1.4 Safety Considerations ............................................................................1

1.5 Table Placement .....................................................................................3

1.6 Air Supply Requirements ...................................................................... 3

1.7 Warranty Information ............................................................................ 4

1.8 Options and Accessories .......................................................................5

Section 2 — Assembly .........................................................................................6

2.1 Assembling the System..........................................................................6

2.1.1 Table Installation Assistance .................................................... 6

2.1.2 Positioning the Isolators ............................................................ 6

2.1.3 Installing Table Top .................................................................... 7

2.2 Leveling the Table ................................................................................. 8

2.3 Isolating the Table Top ..........................................................................9

2.3.1 Installing Leveling Valves .......................................................... 9

2.3.2 Connecting Air Lines ................................................................ 11

2.3.3 Adjusting Leveling Valve Sensors........................................... 14

2.4 Installing Tables with the Doubler Interface ................................... 15

Section 3 — Operation ..................................................................................... 17

3.1 Principles of Operation ...................................................................... 17

3.2 Performance Adjustments ................................................................. 17

3.3 Maintenance ......................................................................................... 18

3.3.1 Cleaning ...................................................................................... 18

3.3.2 Air Quality .................................................................................. 18

3.3.3 Spare Parts ................................................................................. 19

Section 4 — Troubleshooting ......................................................................... 20

4.1 Table Top Does Not Float ................................................................... 20

4.2 Poor Isolation Performance ............................................................... 20

4.3 Table Top Oscillates............................................................................ 20

4.4 System Leaks Air Constantly ............................................................. 20

4.5 Oil Leaking From Isolator ................................................................... 21

4.6 Adding Damping Oil ............................................................................ 21

Section 5 — Factory Service ........................................................................... 22

5.1 Obtaining Factory Service.................................................................. 22

5.2 Service Form ........................................................................................ 23

iii

Page 35

List of Figures

Figure Title Page

1.1 Vibration Control System Assembly ..................................................... 2

2.1 Isolator Position .......................................................................................6

2.2 Isolator Clamps and Mounting Holes ....................................................7

2.3 Isolator Leveling Wrench ........................................................................8

2.4 Level Adjustment of Isolators ................................................................8

2.5 IPV Leveling Valve ................................................................................... 9

2.6 Leveling Valve Mounting ...................................................................... 10

2.7 Orientation of Control Arm .................................................................. 11

2.8 Air Line Routing ..................................................................................... 12

2.9 Detail of Valve Connections, Single Isolator...................................... 13

2.10 Detail of Valve Connections, Two Isolators ....................................... 13

2.11 Floating Height Adjustment ................................................................. 14

2.12 Typical Doubler Interface System....................................................... 15

2.13 Doubler Bolt Tightening Sequence ..................................................... 16

3.1 System Stability ..................................................................................... 18

3.2 Stabilizer™ Spare Parts ........................................................................ 19

iv

Page 36

Specifications

Table Tops:

Flatness: ±0.005in. (0.13mm)*

Compliance: Consult your Newport Catalog or Newport

directly for the specific compliance and

other pertinent table top specifications of

your particular table top model.

Isolators: Stabilizer™ I-2000

Vertical Resonant

Frequency: <1.1 Hz at 80 psi

Horizontal Resonant

Frequency: <1.5 Hz

Recommended Load

Range:

(per 4 isolators) 660 to 8,000 lb (300 to 3,600 kg)

Automatic Leveling

Accuracy: ±0.010 inch (0.25 mm) standard,

higher accuracy available on

special order

Vertical Adjustment

Range: 1.3 inches (33 mm)

Settling Time:

(after 5-lb. weight removal) <1.5 sec.

Typical Air Pressure

Range: 10 to 85 psi (0.7 to 6.0 kg/cm

2

)

* Flatness value provided for a typical 4' × 8' × 12" table. Request Newport

“Table Quality Specification” for complete specifications.

v

Page 37

Isolation System Transmissibility

10

1

0.1

TRANSMISSIBILITY (T)

0.01

0.001

0.8 1 10 30

Vertical Transmissibility (at maximum recommended load)

5

1

FREQUENCY (Hz)

0.1

TRANSMISSIBILITY (T)

0.01

0.5 1 10 25

FREQUENCY (Hz)

Horizontal Transmissibility

vi

Page 38

Valve: Model IPV

Leveling Accuracy: ±0.010 in (.25 mm) standard**

Materials: Glass fiber reinforced polycarbonate

brass

Available in non-magnetic version

Exhaust may be captured by clean room

vacuum system

** Higher accuracies are available by special order.

Table Height Sensor

Exhaust Port

1⁄8 NPT

Isolator

Pressure Gauge

Air Supply Line

Metering

Needle Valve

Over-pressure

Relief Valve

Mounting

Screw

Holes

Control Arm

Air Line to Isolators

Model IPV Leveling Valve

vii

Page 39

viii

Page 40

Section 1

General Information

Introduction

1.1

Getting Started

1.2

The Newport Vibration Control System provides an ideal working platform for

vibration sensitive devices such as interferometers, microscopes, and balances.

The table surface is isolated from floor motion using the Stabilizer™ pneumatic

suspension system. The versatile Newport Vibration Control System is available

in a variety of sizes, working surfaces, and options.

These systems integrate Newport’s rigid, laminated honeycomb panel technology and pneumatic isolation systems to provide a mounting platform which is

rigid, yet thin and light weight.

It is possible to tailor the system to a wide variety of applications using the

entire range of sizes and working surfaces. A typical Newport Vibration

Control System is shown in Figure 1.1

The Stabilizer™ isolation system is capable of supporting 2000 pounds

per isolator. Caution must be observed to ensure that heavy payloads are

not located off center on the table surface. This could cause overloading

of one isolator even though the average load per isolator is below the

2000 pound limit.

Heavy payloads with very high centers of gravity (C-G) may cause the

isolation system to oscillate. Please consult Section 3.2 of this manual or

Newport Applications Engineering for high C-G applications.

Please read this instruction manual thoroughly before assembling the table

system. The individual components have been assembled at the factory

and require only final system assembly and performance adjustment.

Unpacking and

1.3

Inspection

Safety Considerations

1.4

The components of your Newport Vibration Control System are packed in

individual, labeled boxes. Be sure the number of boxes you received is

equal to the total number listed on the label (for example, if a box is labeled

1 of 4, there should be 4 boxes).

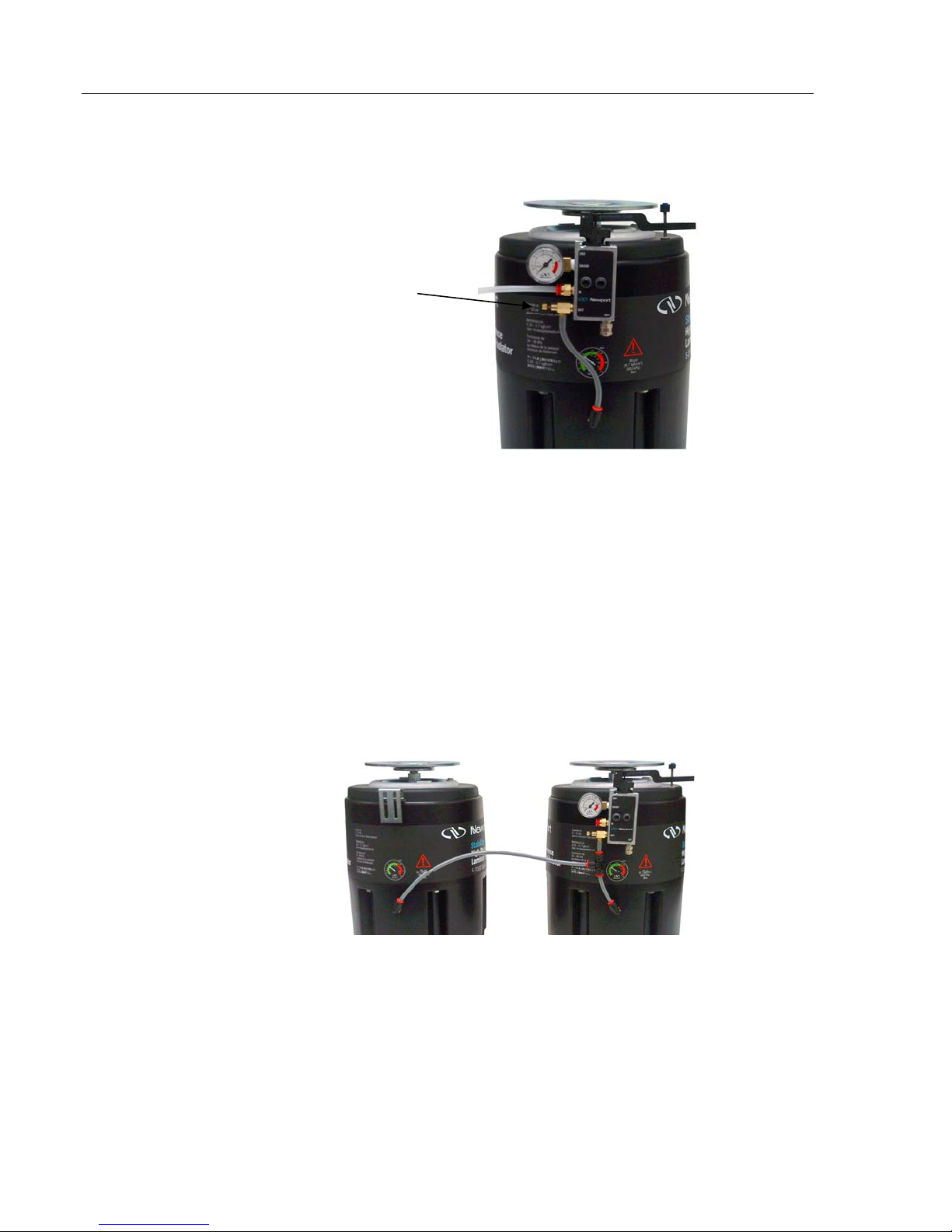

Use the photographs in Figure 1.1 to locate and identify each component as

you remove it from the box. Carefully inspect all components for shipping

damage. Report any shipping damage immediately to Newport and the

shipping company.

The following terms are used in this manual that relate to your safety.

Warning is used to indicate dangers that could result in personal injury.

Caution is used to indicate situations that may result in damage to compo-

nents of your Newport Vibration Control System.

1

Page 41

Clamp

(3 per Isolator)

Wrench Holes

Level

Adjustment

Screw

Stabilizer™

Isolator

Leveling Valve

(3 per system)

Figure 1.1 — Vibration Control System Assembly

Leveling Valve

(3 per system)

2

Page 42

Table Placement

1.5

To ensure optimal performance from your Vibration Control System, it

should be located on a level surface. Uneven floors may cause difficulty

during the leveling of the table top if their irregularity is outside of the

adjustment range of the isolators.

The Stabilizer™ isolator must be mounted so that its axis is not more than

0.5 degrees from vertical. This is necessary for the isolator to function

properly in the horizontal mode. Note: 0.5 degrees is equal to 0.09 (2.2 mm)

inches in 10.0 inches which is the isolator base diameter. A typical spirit

level will easily measure 0.5 degrees and can be used to check the vertical

alignment of each isolator.

If the floor where the isolators are being mounted has a depression of more

than 0.09 inches under one side of the base, then the floor should be

grouted or shimmed level at this location.

If the system is not located on the ground floor of the building, it should be

located near primary vertical structures such as exterior walls or support

columns. By locating the table near these structures, the effects of low

frequency floor motion will be minimized, thus increasing the performance

of the table. It is also advisable to avoid locations adjacent to major

sources of vibration from operating machinery such as elevators, air

conditioning plants, or factory equipment.

Warning

The table top is attached to the isolators with clamps and hex head

bolts. In the event of an earthquake, the table may collapse. For

areas susceptible to earthquakes, we recommend that Newport

Earthquake Restraints be installed on each Vibration Control

System.

Air Supply

1.6

Requirements

The table top is a metallic electrical conductor. For installations

where electrical shock is a possibility, the table top should be

grounded to prevent personal injury.

A constant supply of air must be connected to the Vibration Control System

during operation. After initial setup and filling, the isolators consume air

only when the leveling valves adjust the pressure to compensate for

changes in the load on the table.

Bottled nitrogen or mechanically compressed air may be used. The

required pressure is determined by dividing the total load, including table

weight, by the total isolator diaphragm area (25.9 in2 per isolator) plus

5-10 psig.

For example, if the table plus load is 2850 pounds and will be mounted on 4

isolators, the required pressure is:

2850

lbs

4259

×

.

Note that the maximum operating pressure for the system is 100 psig

(7.0 kg/cm2).

The Newport Model ACMP air compressor is an extremely quiet source of

clean, pressure regulated air. If another compressor or plant air is used,

10 33 8

psig psig

+=

2

in

.

3

Page 43

the Newport model ARF Air Regulator/Filter should be used to ensure

maintenance free operation. These filters prevent water and dirt from

getting into the leveling valves and causing the valves to fail due to

clogging.

The supply should include a valve so that the air may be shut off during

maintenance or extensive setup when the load is changed drastically.

Caution

Bottled carbon dioxide (CO2) is not recommended since “icing”

can occur during rapid filling of the isolators.

War ranty Information

1.7

Warranty information may be found on the page preceding the Table of

Contents in this manual. Should it become necessary to exercise the

warranty, contact your Newport representative to determine the proper

course of action. Newport Corporation maintains offices throughout the

United States and other locations worldwide. Refer to the back cover of

this manual for the addresses and telephone numbers of these offices.

4

Page 44

1.8

Options and

Accessories

Your Vibration Control System may include one or more of the following

options.

Options Model No.

Air Compressor .............................................................................ACMP

Retractable Casters ......................................................................XLC

Tie Bar & Caster Set ......................................................................XLTC-XXX

Doubler Interface .......................................................................... RSD, RSW

Laser Access Hole .........................................................................AH

Clean Room Valve Exhaust System .............................................CE-1

Earthquake Restraint System ...................................................... ER

Accessories Model No.

Overhead Shelf Systems

6' long .................................................................................... ATS-6

8' long .................................................................................... ATS-8

10' long .................................................................................. ATS-10

Accessory Shelf ............................................................................. AS-1568

Beam Steering Instruments

Damped .................................................................................675TS

Standard ................................................................................ 670TS

Table Enclosures - 32" (81.3 cm) high

4' × 6' ......................................................................................TE1406

4' × 8' ......................................................................................TE1408

4' × 10' ....................................................................................TE1410

4' × 12' ....................................................................................TE1412

4' × 14' ....................................................................................TE1414

4' × 16' ....................................................................................TE1416

4' × 18' ....................................................................................TE1418

4' × 20' ....................................................................................TE1420

5' × 8' ......................................................................................TE1508

5' × 10' ....................................................................................TE1510

5' × 12' ....................................................................................TE1512

5' × 14' ....................................................................................TE1514

5' × 16' ....................................................................................TE1516

5

Page 45

Section 2

Assembly

2.1

Assembling

the System

2.1.1 Table Installation Assistance

Optical tables are heavy. Even a small table top weighs over 500 pounds

(227 Kg). Contact Newport or your local sales representative for help in

preparing your facility.

2.1.2 Positioning the Isolators

Figure 2.1 shows the correct isolator positions for standard table sizes.

Table 2.1 shows the correct dimensions (A, B, & C) for each table size. If

your table is not listed, the isolator positions for your table will be included

in the data package provided with the system.

C

B Typ.

Figure 2.1 — Isolator Position

Table 2.1 — Isolator Positions

Table Length Distance A Distance B Distance C

6' 40" 987mm 16" 406mm 6" (152mm)

8' 52" 1282mm 22" 559mm from edge of

10' 66" 1628mm 27" 686mm table

12' 80" 1974mm 32" 813mm

14' 94" 2420mm 37" 940mm

16' 104" 2565mm 42" 1087mm

18' 120" 2962mm 47" 1194mm

20' 134" 3308mm 53" 1346mm

A

6" (152 mm)

4 PL

6

Page 46

2.1.3 Installing Table Top

If your table is equipped with the Doubler Interface be sure to follow the

instructions in Section 2.4 for assembling the table sections prior to installing

them on the isolators.

Warning

Table tops are heavy! As described in Section 2.1.1, use a forklift

or other appropriate equipment. Be sure to use proper lifting

procedures to avoid severe personal injury.

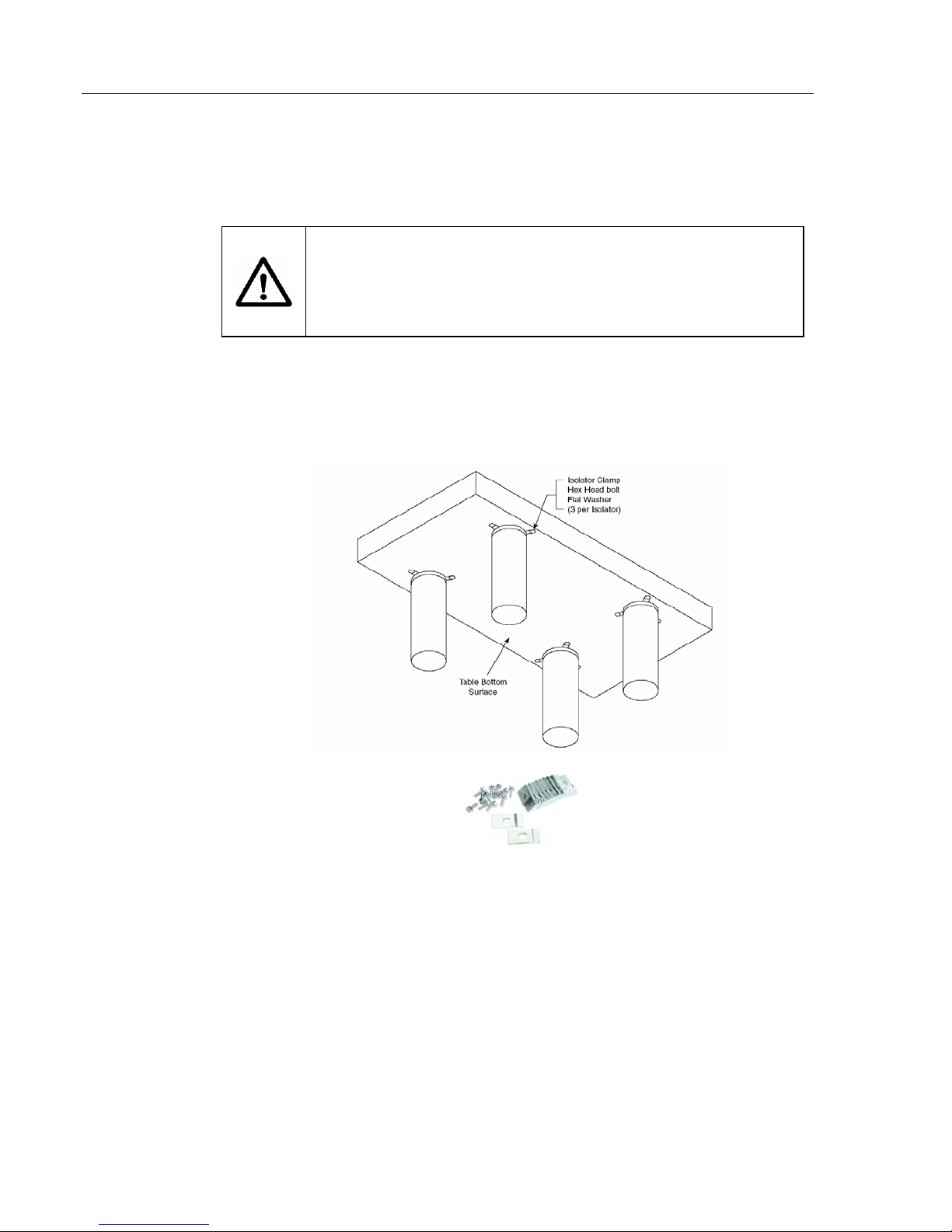

A. With the isolators located as described in Section 2.1.2, raise the table

top and position it above the isolators. Be sure each isolator is

centered within the tapped three-hole patterns on the lower surface

of the table (Figure 2.2).

Isolator Clamp

Hex Head bolt

Flat Washer

(3 per Isolator)

Table Bottom

Surface

Figure 2.2 — Isolator Clamps and Mounting Holes

B. Gently lower the table so that is just above the top of isolators.

C. Install three isolator clamps in the corners where each isolator is

located (Figures 1.1 & 2.2). Loosely secure the clamps with the bolts.

Do not tighten the clamps at this time.

D. Lower the table top until it rests on the isolator support plates.

Caution

When lowering the table on to the supports, do not allow the table

to shift sideways. Doing so could damage the isolators.

7

Page 47

Leveling the Table

2.2

Use the following procedure to level the table. The special wrench (Figure

2.3) is for all adjustments.

Support

Clamp

Bolts

Level Adjustment

Support Plate

Spanner Wrench

Hex Nut

Figure 2.3 — Isolator Leveling Wrench

A. Refer to Figure 2.4. As shown, use one of the special wrenches to hold

the hex nut stationary. Insert the prongs of the second wrench into

the holes on the bottom of the support plate. Rotate the plate using

the top wrench to adjust the height.

B. Place a level on the table top, approximately in the center.

C. For each isolator, adjust the support plates as required to bring the

table to a level condition. Be sure to check the level using both the

length and width axes of the table. Verify that the centering disks are

centered in and resting on their respective guides (Figure 2.4).

2.55 in. (65 mm)

Nominal

Isolator fully down

on stops – no air

applied

Bolt & Clamp

Support Plate

Hex Nut

Centering Disk

Centering Guide

Figure 2.4 — Level Adjustment of Isolators

D. When the table is completely level, ensure by eye that every isolator

support plate is snug against the table bottom and that each centering disk is centered in its guide (Figure 2.4).

E. Use the level to confirm that the table top is still level and equally

supported by all isolator support plates. Tighten all isolator clamp

bolts snugly to secure the table to the isolators.

F. Loosen the two screws securing each leveling valve to its bracket.

Slide the valve body until it is approximately 0.060 inches (1.5mm)

below the bottom of the table. Be sure the valve is not tilted, then

tighten the screws.

Wrenches

8

Page 48

2.3

Isolating the

Table Top

2.3.1 Installing Leveling Valves

The IPV leveling valve is shown in Figure 2.5. Three valves are used in all

systems, regardless of the number of isolators, as only three points are

required to determine a plane. The leveling valve locations are selected

such that they form the largest triangle possible under the table. The larger

the triangle, the more stable the system will be. When two or more isolators

are controlled by the same valve, they act as a single large isolator supporting the table at the center of force of the several isolators. The floating

height of the system is determined at the valve position. Therefore, ideally,

the valves should be located at the center of force of the isolators they

control. In practice, however, simply grouping the isolators and their

control valves is sufficient. The groups of isolators and their valves act as

three legs for the system. The center of gravity of the combined table and

payload must be within the triangle formed by the centers of force of the

isolator groups for the system to float. Figure 2.8 shows valve and isolator

arrangements for rectangular tables. Complex table shapes require isolator

and valve layouts designed specifically for each application.

Control Arm

Assy

Table Height Sensor

Adjustment Screw

Pivot Clamp

Screw

Exhaust

Metering

Needle Valve

Mounting Screws (2)

Washers (2)

Barb Fitting

Air

Supply

Control Arm

Adjustment Screw

(Preset at Factory)

EXH

GAGE

OUT

OUT

Mounting Bracket

Pressure

Relief Valve

Nut Plate

Factory Sealed —

Do Not Remove

Figure 2.5 — IPV Leveling Valve

9

Page 49

Control Arm

EXH

GAGE

Valve

Mounting

Bracket

Nut &

Washer

Mounting Screws (2)

Washers (2)

10-32 Screws (2)

OUT

Leveling Valve

Nut Plate

OUT

Figure 2.6 — Leveling Valve Mounting

The valves should be attached to the isolators as shown in Figure 2.6 after

installing the table top.

A. Set the table height adjustment screw on each valve to the center of

its travel.

B. Attach the leveling valve to the isolators as shown in Figure 2.6.

Secure the valve to the bracket using the two mounting screws and

the nutplate. Position the valve at the bottom of the bracket slots

until after the table is installed and leveled.

C. Rotate the control arm on valves “A” in Figure 2.7 so that they point

towards the nearest corner of the table.

D. Rotate the control arm on valve “B” in the figure so that it points

toward the table’s center, midway between the isolators that it

controls.

10

Page 50

E. Gently tighten the clamping screw on the control arm pivot.

(Figure 2.5)

F. For systems with more than four isolators, use the same basic setup

just described: Two valves control the height of the two end corners

(A & A) while the third valve (B) controls the height of the opposite

end. See Figure 2.8.

Isolator

A

Control

Arm

Leveling

Valves

AB

Table Top

Figure 2.7 — Orientation of Control Arm

2.3.2 Connecting Air Lines

A. Connect air lines to the isolators as shown in Figure 2.8. When

cutting tubing, be sure the ends are round and cut squarely. This is

best done with a single edge razor blade (scissors will deform the

tubing, causing leaks). The connections are detailed in Figures 2.9

and 2.10.

1. Use translucent tubing to connect the air supply to each of the

leveling valves. Use “Tee” connectors as required. Press the free

end of the tubing into the yellow collar of the valve’s “IN” connector. Be sure the connection is firm by tugging on the tube.

11

Page 51

3 Isolator Schematic

4 Isolator Schematic

Table Width

Less 12"

Typ All Tables

Te e

2 Reqd

Leveling Valves

3 Reqd

Te e

3 Reqd

Leveling Valves

3 Reqd

Air

Regulator

Filter

Air Supply

Air

Regulator

Filter

Air Supply

6 Isolator Schematic

8 Isolator Schematic

Leveling Valves

3 Reqd

Te e

5 Reqd

Te e

7 Reqd

Air

Regulator

Filter

Air Supply

Leveling Valves

3 Reqd

Air

Regulator

Filter

Air Supply

Figure 2.8 — Air Line Routing

12

Page 52

2. Connect a length of grey tubing (supplied with the valves for use on

the valve barb fitting) between the hose barb on the valve and the

inlet connector on the isolator (Figure 2.9). If more than one isolator

is supplied by a valve, use “Tee” connectors as required (Figure 2.10).

Connect the grey tube from the valve to the “Tee” and use translucent

tubing between the “Tee” and each isolator.

Table Bottom

Sensor

Control

Arm

Air

Suppl

yy

Metering Needle

EXH

GAGE

IN

OUT OUT

Attachment

Screws

Leveling Valve

Valve

Barb Fitting

Grey Tubing

Figure 2.9 — Detail of Valve Connections, Single Isolator

B. Close the metering needle valve (Fig. 2.9) on each valve and then open it

1

⁄2 turn for each isolator that is connected to it. For example, if the valve

controls two isolators, the needle valve is opened 1 full turn. [Please note:

If you have a minimum load on your optical table top, open the metering

valve about 1⁄8 – 1⁄4 of a turn.]

C. Turn on the air supply and adjust the regulator for the pressure calculated

using the formula given in Section 1. This pressure must not exceed 100

psig (7.0 kg/cm2).

Figure 2.10 — Detail of Valve Connections, Two Isolators

Sensor

Control

Arm

Translucent

Tubing

Air

Suppl

yy

Barb Fitting

13

Table Bottom

EXH

GAGE

IN

OUT OUT

Attachment

Screws

Leveling Valve

Grey Tubing

Te e

Page 53

D. Check all connections for leaks. Correct or repair any leaks before

proceeding.

E. If the table does not float within several minutes, increase the air

pressure until the table floats or adjust the value height sensors to

hold the control arms further down. Confirm that the needle valves

are open 1⁄2 turn per isolator supplied.

NOTE: If the table oscillates after it floats, decrease the air pressure

or close the needle valves slightly.

F. In clean room applications the “EXH” (exhaust) port on the valves

may be connected to the clean room vacuum system to capture the

valve exhaust. Order Newport kit #CE-1.

NOTE: Exhaust must be routed to a vacuum system. Backpressure in

the tubing will cause the exhaust air to leak from the valve.

2.3.3 Adjusting Leveling Valve Sensors

A. After the table floats, check the position of the centering guide and

flange of all isolators (Figure 2.11). The gap between the guide and

flange should be 1⁄4" ± 1⁄16" (6mm ±1.5mm).

B. Adjust the Table Height sensor screw of each isolator (Figure 2.5) as

required to obtain this gap. When all isolators are adjusted, re-check

the level of the table. NOTE: this step should require only minor

adjustments. Do not move the small set screw near the pivot of the

valve control arm.

C. If the table is no longer level, you may have to remove the air pressure

and re-adjust the height of the isolator support plates as described in

Section 2.2.

D. Verify that the table is freely floating on the isolators. Move the table

gently from side-to-side about 1⁄8". You should not encounter any

resistance. Re-check by moving the table up and down the same

amount. Again, there should be no restriction of movement.

E. Push one corner of the table down approximately 1⁄8" and release it.

The table should return to the original position within less than 4

seconds. Response time may be adjusted as described in Section 3.2.

Support Plate

Centering Disk

Centering

Guide

1/4" ± 1/16"

Figure 2.11 — Floating Height Adjustment

14

Page 54

Installing Tables with

2.4

the Doubler Interface

The following instructions are applicable only to those tables equipped with

the Doubler Interface. Figure 2.12 shows a typical Doubler Interface System.

A. Use the procedures in Section 2.1.2 and 2.3.1 to assemble the isolators

for both table sections.

B. Carefully uncrate each table top, noting the correct orientation

indicated on the crates. Carefully check the doubler faces for any

damage that might prevent them from fitting tightly together.

Doubler Faces

Table

Section

Alignment Dowel

Pins

Doubler Bolts

Table

Section

Figure 2.12 — Typical Double Interface System

C. Position the isolators for one table section as described in Section

2.1.2. Install valves on the appropriate isolators as shown in

Figure 2.7.

D. Install the first table section on the isolators as described in

Section 2.1.3.

NOTE: It may be necessary to use jack stands to support the first

table section if fewer than four isolators are located under

the section.

E. Position the second table section on three jack stands mounted on

dollies. Adjust the position of the table so that it is at the same height

as, and adjacent to, the first table section.

F. Align the two table sections using a straight edge. Carefully roll the

second table section toward the first so that the alignment dowel pins

engage in their mating holes. Be sure the bolts are aligned with their

corresponding holes.

G. Draw the two table sections together approximately 1⁄8 inch (5mm)

using the two outermost top bolts.

Caution

Do not force the bolts. The second table section should be easily

pulled up to the first. Figure 2.13 shows correct bolt head position

during assembly.

Do not cause the first table section to shift sideways on its isolators.

Doing so could damage the isolators.

15

Page 55

H. Tighten all of the bolts until they are finger-tight or until they just

begin to move the table sections together. Do not force or overtighten the bolts.

I. Repeat steps G and H until the two table sections are completely

drawn together.

J. When all bolts are snug, apply a final torque of 60 pound-feet (80 N-M)

to all bolts using the sequence shown in Figure 2.13.

K. Jack up the assembled table as required to install the remaining

isolators and leveling valves. Install the isolators and valves as

described in Section 2.1.

L. Remove the jack stands and level the table as described in

Section 2.2.

M. Install the air lines and float the table as described in Section 2.4.

19 17 13 11 159 5 1 3 7

20 16 12 10 14 188 4 2 6

(Correct)

Female Table Male Table

(Incorrect)

See CAUTION

Figure 2.13 — Double Bolt Tightening Sequence

16

Page 56

Section 3

Operation

Principles of

3.1

Operation

Performance

3.2

Adjustments

The Stabilizer™ Isolators provide one of the best methods of vibration

isolation for critical applications. The system operates on the principle of

air pistons, which are equivalent of soft springs. The main advantage of the

Newport system over other designs are low vertical resonant frequency

with low amplification at resonance (Q) and a Pendulum

decoupling system for effective isolation from low amplitude vibration.

Newport optical tables provide a working surface that is statically rigid

with high internal tuned damping for high dynamic rigidity and minimal

response to environmental disturbances.

The leveling valves provided with the system control the height of the table

to within ±0.01" (0.3mm) accuracy. This tolerance is adequate for most

applications. More accurate valves are available for specialized

applications.

Once the system is assembled and the table floating, it is possible to make

minor adjustments to suit your individual needs. These adjustments

involve the system air pressure, the control arms, and needle valves.

TM

horizontal

Warning

Once the table is floating, keep fingers away from the area between

the centering guide and outer clamp of the isolators. Any object

between these points may be caught if the table load or air supply

changes, causing personal injury.

A. Stabilizing high center-of-mass loads: If your load has a high center of

mass or if the load is particularly heavy, the table may oscillate. In

this case, lower the system pressure or close the needle valves

slightly. This may improve stability and reduce the oscillation or

“hunting”.

A rule of thumb for determining high center of gravity (C-G) system

stability is shown in Figure 3.1. If the combined center of gravity of

the payload and table top is within the “stable region”, the system will

be stable. If the combined C-G is inside the “may be stable region”,

the system may be stable. If the combined C-G is outside both

regions, the system will probably be unstable.

17

Page 57

May Be Stable Region

Stable Region

B

3B

B

⁄

2

Figure 3.1 — System Stability

B. Improving leveling response times: If the system is stable, the re-leveling

response time may be decreased by increasing the system pressure. In

addition, the needle valves may be opened until the system oscillates and

then closed slightly. This is desirable if components are moving over the

surface of the table.

For systems where the loads are seldom changed, slower re-leveling

may be beneficial. This is accomplished by closing the needle valves

slightly and/or decreasing the system pressure.