Page 1

SMC100CC & SMC100PP

Single-Axis Motion Controller/Driver

for DC or Stepper Motor

Controller GUI Manual

V2.0.x

Page 2

SMC100CC & SMC100PP Controller GUI Manual

EDH0310En1030 – 01/17 ii

Page 3

SMC100CC & SMC100PP Controller GUI Manual

Table of Contents

1.0 Introduction .................................................................................................. 1

1.1 Purpose ............................................................................................................................. 1

1.2 Overview .......................................................................................................................... 1

1.3 Controller State Diagram .................................................................................................. 2

1.4 Building the System.......................................................................................................... 3

2.0 Installation ..................................................................................................... 4

2.1 Install SMC100 Graphical User Interface ........................................................................ 4

2.2 Launch GUI ...................................................................................................................... 4

3.0 Getting Started .............................................................................................. 5

3.1 Discover Instruments ........................................................................................................ 5

4.0 User Interface ................................................................................................ 6

4.1 Configuration .................................................................................................................... 6

4.2 Main .................................................................................................................................. 8

4.3 Jog .................................................................................................................................. 10

4.4 GPIO ............................................................................................................................... 11

4.5 Parameters ...................................................................................................................... 12

4.6 Address ........................................................................................................................... 14

4.6.1 Controller pool setting ....................................................................................... 15

4.6.2 Controller address setting................................................................................... 17

4.7 Diagnostics ..................................................................................................................... 18

4.8 About .............................................................................................................................. 19

Service Form ........................................................................................................ 21

iii EDH0310En1030 – 01/17

Page 4

SMC100CC & SMC100PP Controller GUI Manual

EDH0310En1030 – 01/17 iv

Page 5

SMC100CC & SMC100PP Controller GUI Manual

SMC100

Single-Axis Motion Controller

1.0 Introduction

1.1 Purpose

The purpose of this document is to provide instructions on how to use the

SMC100 Controller

graphical user interface (GUI).

1.2 Overview

The SMC100 Controller GUI is a graphical user interface, that allows the user to

interact with the SMC100CC or SMC100PP controller that is connected to stages. The

user can initiate moves, change the state of the controller, adjust parameters, etc

.

EDH0310En1030 – 01/17 1

Page 6

SMC100CC & SMC100PP Controller GUI Manual

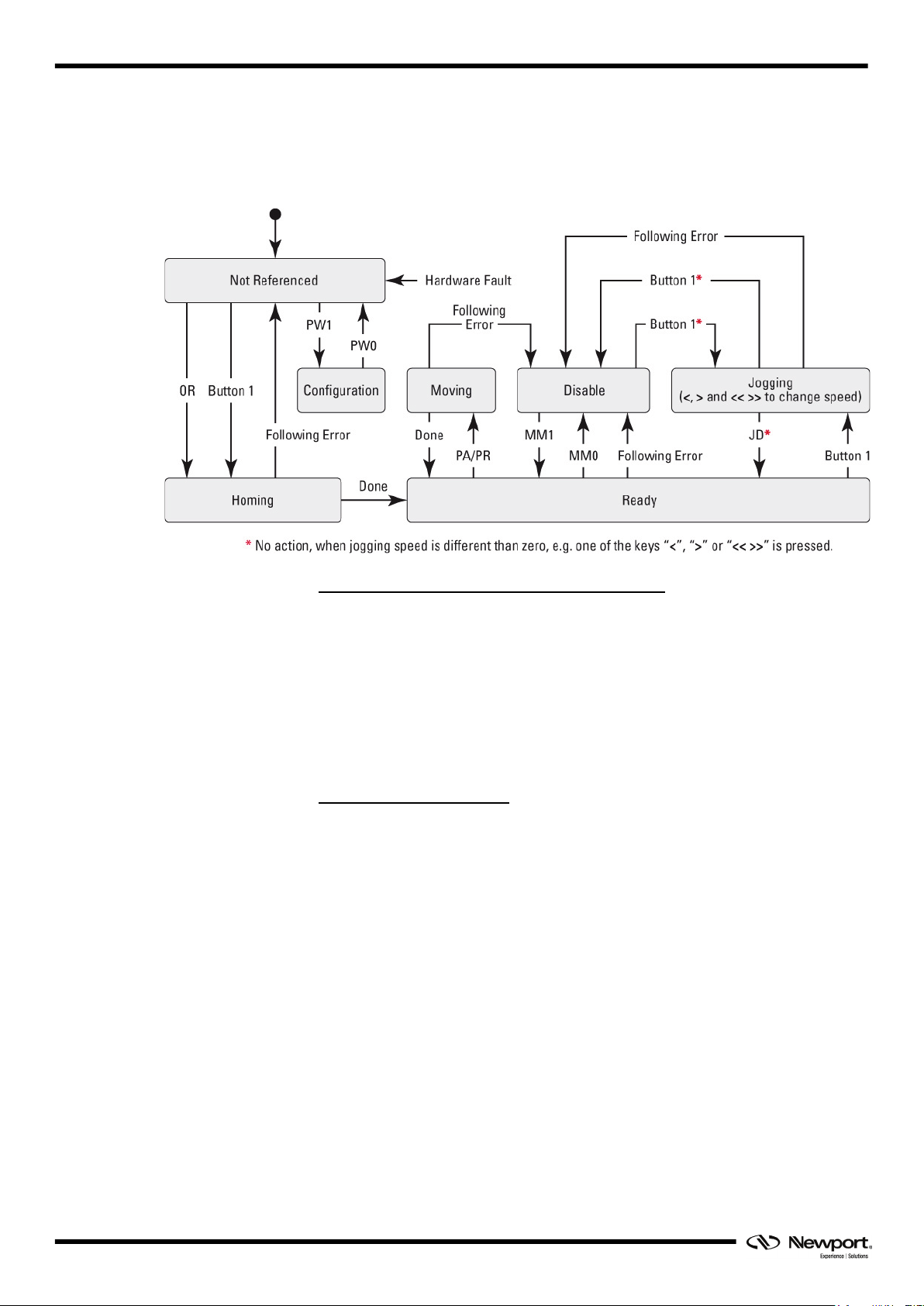

1.3 Controller State Diagram

The SMC100 controller is defined by the following state diagram.

End of Runs encountered in the following state:

NOT REFERENCED: No action.

CONFIGURATION: No action.

HOMING: Only check at end of HOMING and then change to NOT

REFERENCED state.

MOVING: Abort motion and then change to NOT REFERENCED state.

READY: Change to NOT REFERENCED state.

DISABLE: Change to NOT REFERENCED state.

Controller’s LED display:

NOT REFERENCED: If everything is OK then SOLID ORANGE.

NOT REFERENCED: If hardware faults or wrong parameters then SOLID RED.

NOT REFERENCED: If end of runs then SLOW BLINK ORANGE.

CONFIGURATION: SLOW BLINK RED.

READY: SOLID GREEN.

DISABLE: SLOW BLINK GREEN.

HOMING: FAST BLINK GREEN.

MOVING: FAST BLINK GREEN.

JOGGING: FAST BLINK GREEN.

EDH0310En1030 – 01/17 2

Page 7

SMC100CC & SMC100PP Controller GUI Manual

1.4 Building the System

Up to 31 controllers can be networked through the internal RS-485 communication

link. The first SMC100 is connected to the RS232 connector (address #1) which is

connected to the computer and the others are linked with the RS485 connectors (address

#2 to address #31).

When the addresses of all controllers are set, you can build your system.

Pull out all cables from all controllers. Set the dip switches of the controller with the

address number 1 as FIRST. Set the dip switches of the other controllers, except one, as

OTHERS, and set the dip switches of one controller as LAST. When you have only two

controllers, one has to be set as FIRST (the one with the address number 1), and the

other one as LAST. See below graphic for illustration.

Connect the SMC100CC/PP configured as FIRST to the RS-232-C port or to the USB

port of your PC. Connect a RS-485 network cable to the RS-485 OUT of the FIRST

controller and to the RS-485 IN of the next controller. Proceed the same with all other

controllers. When done, you can check your system:

• The controller configured as FIRST should have the RS-232-C cable connected to

the computer. It has the address #1.

• All controllers configured as OTHERS should have one RS-485 network cable

connected to the RS-485 IN and another one to the RS-485 OUT.

• The controller connected as LAST should have one RS-485 network cable

connected to the RS-485 IN.

Connect your stages to the SMC100CC/PP’s (MOTOR connector). Connect your

SMC100CC/PP’s to power.

The SMC100CC/PP allows chaining power from one SMC100CC/PP to another one

using the SMC-PSC0.2 cable supplied with the controller. But the total power

consumption of all stages connected to the same power supply should not exceed 80 W.

The maximum power consumption of each Newport stage is listed in the Newport

catalog and on the Newport web site. In case of questions, contact Newport. Once

controllers have been networked the GUI can be used to switch between stages using

the selected stage box.

3 EDH0310En1030 – 01/17

Page 8

SMC100CC & SMC100PP Controller GUI Manual

2.0 Installation

2.1 Install SMC100 Graphical User Interface

Following are steps to install SMC100 GUI:

• For 32 bit, Select and launch “SMC100 Utility Installer Win32.exe”. For 64 bit,

Select and launch “ SMC100 Utility Installer Win64.exe”.

• A window opens up showing Install welcome page.

• Click on “Next”.

• A window opens up allowing destination folder selection. By default it is showing

C:\.

• Click on “Next”.

• Ready to install window opens up. Click “Install”.

• Then installation starts, wait for completion. Click on “Finish” to finalize the

installation.

32 bit installer will be installed “Newport.SMC100.CommandInterface.dll” in GAC_32

folder and 64 bit installer will be installed the dll in GAC_64 folder.

NOTE

LabVIEW user can add reference of command interface dll from GAC during VI

creation.

2.2 Launch GUI

From Windows “START” menu , select “All Programs\Newport\Motion

Control\SMC100\SMC100 Utility”.

EDH0310En1030 – 01/17 4

Page 9

SMC100CC & SMC100PP Controller GUI Manual

3.0 Getting Started

3.1 Discover Instruments

Start the Controller GUI from Newport\MotionControl\SMC100.

Next, click on “Discover” button and the number of instruments discovered will appear.

This window allows the user to select a com port where the desired instrument is

connected.

Next, click “Launch Applet” button.

5 EDH0310En1030 – 01/17

Page 10

SMC100CC & SMC100PP Controller GUI Manual

4.0 User Interface

4.1 Configuration

The Configuration tab allows the user to view and/or change information related to the

logging configuration and the instrument settings.

In LoggingConfiguration, read only values are displayed for the log file name and the

log file path. The logging level may be changed to any of the settings in the drop-down

list on the right hand side.

Trace is the most detailed option of the settings. When this setting is selected, the

Controller GUI logs all the information.

Critical Error is the least detailed option of the settings. When this setting is selected,

the Controller GUI will log errors that are defined to be critical only.

The polling interval defines the number of milliseconds between each time the

Controller GUI polls the SMC100 for the latest information. The user may change the

polling interval by entering a value. Diagnostics Delay defines the time delay in

milliseconds between each command sent from a text file. InstrumentType and

NoOfInstruments display the type of controller and number of the connected

instrument.

The Save button allows to save the current settings to the configuration file.

EDH0310En1030 – 01/17 6

Page 11

SMC100CC & SMC100PP Controller GUI Manual

Parameter

Description

Values / Type

Default

LoggingConfiguration

Level

Logging level. Trace is the most detailed

critical.

Trace Detail

Equipment Message

Trace

InstrumentInformation

PollingInterval

The polling interval defines the number

instrument for the latest information.

An Integer

200

NbDigits

Number of fractional digits after the

decimal point.

An Integer

6

Models\InstrumentInfo

CommunicationChannel

The communication channel

RS232

RS232

Diagnostics

Delay

The delay defines the number of

command from a text file

1000

MemorizedPosition

BufferDepth

MaxItem defines the maximum number

buffer.

An Integer

5

RollingBuffer

The list of the memorized position in the

address

A String

ControllerAddress

List of the selected controller address.

A String

Selected stage

This box allows the user to switch between stages connected to networked S.

of the settings and when this setting is

selected the Controller GUI logs

everything. Critical Error is the least

detailed of the settings and when this

setting is selected the Controller GUI

will only log errors that are defined to be

of milliseconds (delay) between each

time the Controller GUI polls the

Info Warning Error

Critical Error

milliseconds between each sent

of memorized positions in each rolling

rolling buffer for a selected controller

7 EDH0310En1030 – 01/17

Page 12

SMC100CC & SMC100PP Controller GUI Manual

4.2 Main

The Main tab displays the main controls in the Controller GUI like a virtual front panel.

It is updated each time the polling interval timer expires.

“Initialization and Configuration”

In the “Initialization and Configuration” area, the first button changes the controller

status to “Enabled” or “Disabled”. To see the different controller states, refer to the

controller state diagram. The second button “Save Pos.” memorizes the current

positions in the combo box. As soon as a new position is memorized, this is displayed in

the trace.

“Current Position”

In the “Current Position” area, the current position is displayed in a text box and

visualized in a slider. The slider limits are defined with the ends of run. An LED icon

shows the current controller state. When the mouse hovers over the LED icon, the

controller state is displayed in an information balloon.

EDH0310En1030 – 01/17 8

Page 13

SMC100CC & SMC100PP Controller GUI Manual

Loop #1

Loop #2

Tempo (Dwell)

Target #2

Target #1

Tempo (Dwell)

Tempo (Dwell)

Tempo (Dwell)

Loop #N

“Incremental Motion / PR-Move Relative”

In the “Incremental Motion / PR-Move Relative” area, two increment values can be

defined. For each defined increment, a relative move is preformed in either the negative

direction or positive direction.

“Cyclic Motion” and “Target position / PA-Move Absolute”

In the “Cyclic Motion” area, a motion cycle is configured with a number of cycles

(Cycle) and a dwell time in milliseconds. The motion cycle gets the defined target

positions from the “Target position / PA-Move Absolute’ area to perform the cycle.

In the “Target position / PA-Move Absolute” area, two target positions can be defined.

The “Go to” button executes the absolute move to the specified target position.

“Motion Configuration Values”

In the “Motion Configuration Values”, the current ends of run and the velocity are

displayed in a disabled text box: “Minimum end of run”, “Maximum end of run” and

“Velocity”. These ends of run and the velocity can be modified and saved with the

“Set” button.

Memorized positions

The combo box allows memorizing the positions by the “Save Pos.” button. Each of

these positions can be renamed or deleted. To execute an absolute move to one of these

memorized positions, select one item of the combo box and click on the “Go to” button.

When the mouse hovers over the combo box, the selected memorized position is shown

in an information balloon.

Rename a memorized position: Select an item from the combo box, edit the position

name and click on the “Rename” button to save the new position name.

Delete a memorized position: Select an item from the combo box, right-click on the

mouse and select the “Delete” to delete the selected memorized position.

9 EDH0310En1030 – 01/17

Page 14

SMC100CC & SMC100PP Controller GUI Manual

4.3 Jog

Under this tab, the controller allows the jog mode with use of two arrow buttons.

EDH0310En1030 – 01/17 10

Page 15

SMC100CC & SMC100PP Controller GUI Manual

4.4 GPIO

The GPIO tab allows the user to modify digital outputs and to view digital and analog

inputs.

Digital IO

TTL outputs

The four TTL outputs can be modified with a radio button (ON/OFF) and are updated

each time the polling interval expires.

TTL inputs

The four TTL inputs are updated each time the polling interval expires.

Analog Inputs

Analog input #1

The analog input is updated each time the polling interval expires.

11 EDH0310En1030 – 01/17

Page 16

SMC100CC & SMC100PP Controller GUI Manual

4.5 Parameters

The Parameters tab allows the user to view or modify stage parameters for the selected

controller. A warning message is displayed as below.

Parameters page for a CC stage

EDH0310En1030 – 01/17 12

Page 17

SMC100CC & SMC100PP Controller GUI Manual

Parameters page for a PP stage

“Download parameters from SmartStage” button

The “Download parameters from SmartStage” button downloads parameters from the

SmartStage and saves them in its flash memory (configuration parameters). After the

parameters have been downloaded the configuration parameters are read and updated.

13 EDH0310En1030 – 01/17

Page 18

SMC100CC & SMC100PP Controller GUI Manual

“Set parameters” button

The “Set parameters” button modifies the configuration parameters.

4.6 Address

The Address tab allows two things:

1) To scan and select connected SMC100 controllers.

2) To configure an RS485 address

EDH0310En1030 – 01/17 14

Page 19

SMC100CC & SMC100PP Controller GUI Manual

4.6.1 Controller pool setting

“Discover” button

The Discover button scans to find connected SMC100 controllers (address #1 to address

#31).

After a Discover action, the list of detected controllers is filled.

15 EDH0310En1030 – 01/17

Page 20

SMC100CC & SMC100PP Controller GUI Manual

“Add” button

The Add button allows the user to add a connected SMC100 controller to the list of

“Selected controllers”.

After adding a detected controller, the list of selected controllers is updated.

“Delete” button

The Delete button deletes an SMC100 controller from the list of selected controllers.

EDH0310En1030 – 01/17 16

Page 21

SMC100CC & SMC100PP Controller GUI Manual

4.6.2 Controller address setting

This part allows the user to configure the RS485 address of the FIRST controller.

“Set” button

Select a controller address from the list and press the “Set” button. A progress bar is

displayed during the address configuration.

It is recommended to note the address of the controller somewhere. For example, use

the stickers supplied with the SMC100CC/PP.

Now disconnect this controller from your PC and connect the next one instead. Select a

new, not yet allocated address and press the “Set” button again (proceed the same with

all other controllers).

17 EDH0310En1030 – 01/17

Page 22

SMC100CC & SMC100PP Controller GUI Manual

4.7 Diagnostics

The Diagnostics tab allows the user to enter instrument commands and to view the

history of commands that were sent and the responses that were received. This list of

commands and the syntax of each command can be found in the Command Interface

User Manual.

A file of commands can be sent line by line to the controller with the “Send

Command file” button.

EDH0310En1030 – 01/17 18

Page 23

SMC100CC & SMC100PP Controller GUI Manual

4.8 About

The About tab displays the information about the Controller GUI and the connected

instruments. It displays the Controller GUI name, version, and copyright information.

It also displays the instrument model, the instrument key (serial number or COM port),

the firmware version for the selected axis and the list of the selected axes.

.

19 EDH0310En1030 – 01/17

Page 24

Page 25

SMC100CC & SMC100PP Controller GUI Manual

Service Form

Your Local Representative

Tel.: __________________

Fax: ___________________

Name: _________________________________________________ Return authorization #: ____________________________________

Company:_______________________________________________

Address: ________________________________________________ Date: __________________________________________________

Country: ________________________________________________ Phone Number: __________________________________________

P.O. Number: ____________________________________________ Fax Number: ____________________________________________

Item(s) Being Returned: ____________________________________

Model#: ________________________________________________ Serial #: ________________________________________________

Description: ________________________________________________________________________________________________________

Reasons of return of goods (please list any specific problems): ________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

__________________________________________________________________________________________________________________

(Please obtain prior to return of item)

EDH0310En1030 – 01/17 21

Page 26

e-mail: service@newport.com

Visit Newport Online at:

North America & Asia

Newport Corporation

1791 Deere Ave.

Irvine, CA 92606, USA

Sales

Tel.: (800) 222-6440

e-mail: sales@newport.com

Technical Support

Tel.: (800) 222-6440

e-mail: tech@newport.com

Service, RMAs & Returns

Tel.: (800) 222-6440

www.newport.com

Europe

MICRO-CONTROLE Spectra-Physics S.A.S

9, rue du Bois Sauvage

91055 Évry CEDEX

France

Sales

Tel.: +33 (0)1.60.91.68.68

e-mail: france@newport.com

Technical Support

e-mail: tech_europe@newport.com

Service & Returns

Tel.: +33 (0)2.38.40.51.55

Loading...

Loading...